Fully formulated coolant for heavy-duty engine

An engine coolant, heavy-duty technology, used in chemical instruments and methods, heat exchange materials, etc., can solve problems such as high reliability and durability requirements, poor working conditions, engine component corrosion, etc., and achieve excellent corrosion resistance. Rust resistance, outstanding cooling effect, and enhanced protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The following components are blended according to mass percentage:

[0016] components

[0017] The sum of the above components is 100%.

Embodiment 2

[0019] The following components are blended according to mass percentage:

[0020] components

[0021] The sum of the above components is 100%.

Embodiment 3

[0023] The following components are blended according to mass percentage:

[0024] components

Content (mass percentage)

Mass ratio of 50% propylene glycol and 50% ethylene glycol

55.0%

4.0%

Mass ratio of 50% sodium benzoate and 50% benzotriazole

1.6%

Sebacic acid produced from 50% castor oil and 50% diethylacetic acid by mass ratio

0.8%

Heptadecenyl imidazolinium succinate

0.52%

Deionized water

38.0%

0.08%

[0025] The sum of the above components is 100%.

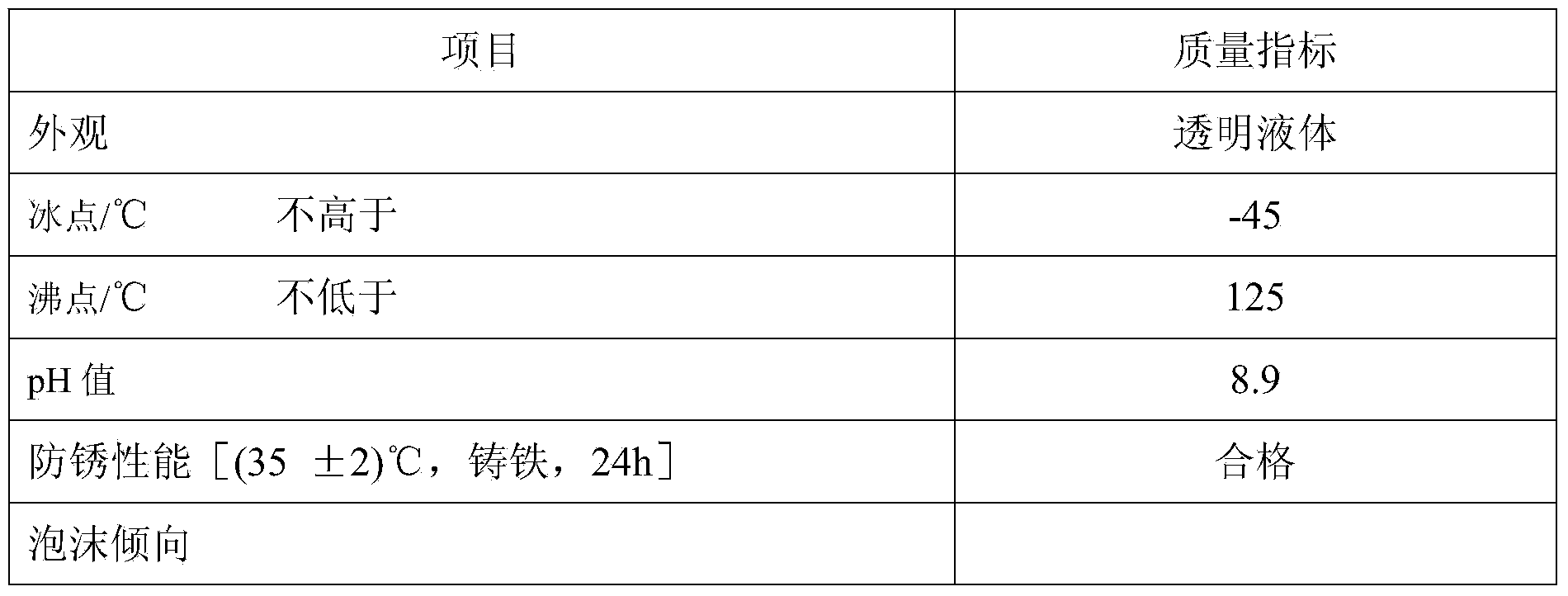

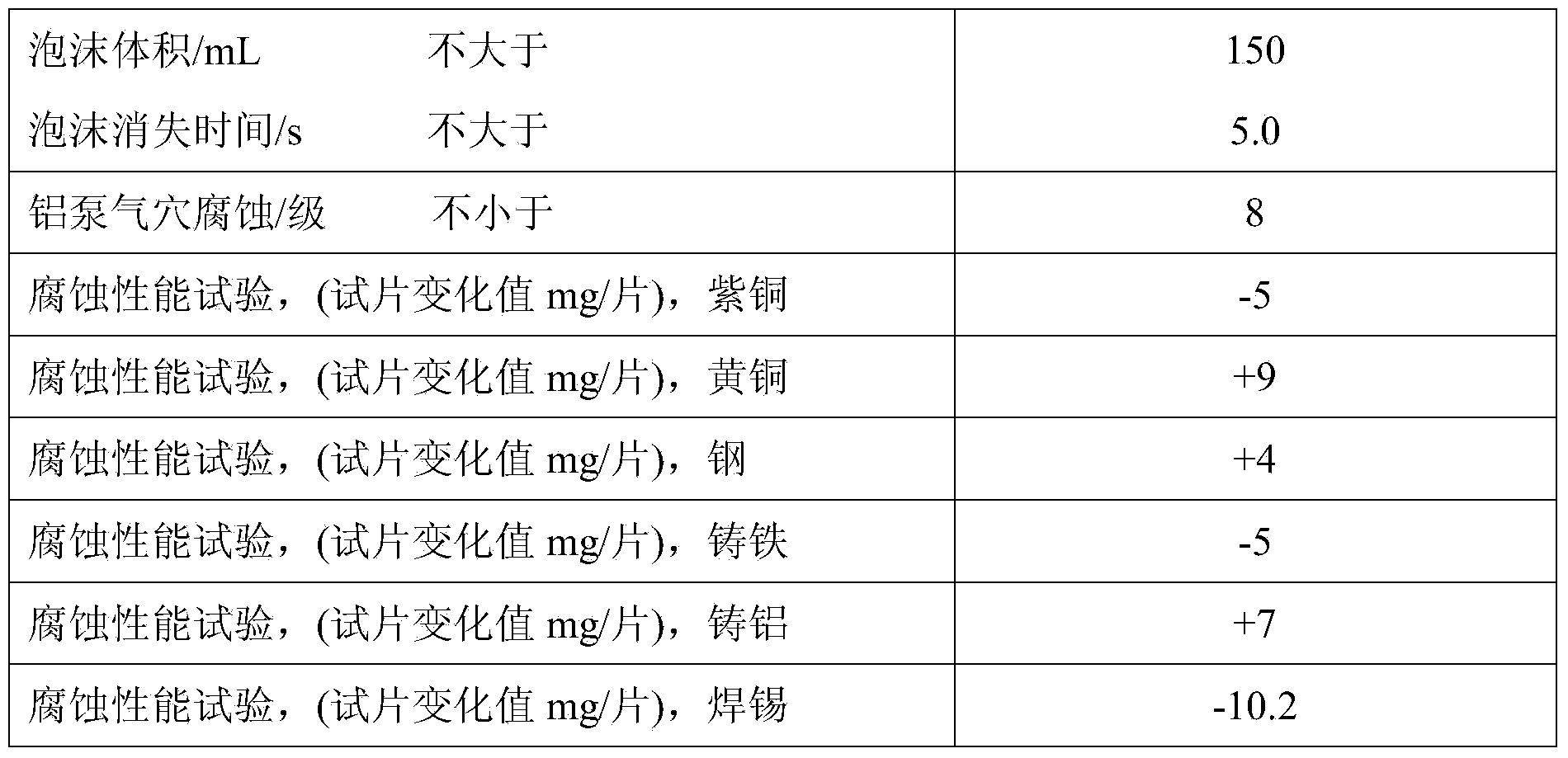

[0026] The main physical and chemical index of embodiment 2 product is

[0027]

[0028]

[0029] A fully formulated heavy-duty engine coolant, using propylene glycol and ethylene glycol as the base fluid, with a variety of compound additives; including ethanol additives, corrosion inhibitors, corrosion inhibitors, rust inhibitors, deionized water, defoaming agent. The full formula heavy-duty engine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com