Condenser steam jet vacuum system

A vacuum system and condenser technology, applied in jet pumps, machines/engines, non-displacement pumps, etc., can solve problems such as maintenance cost reduction in unit efficiency, and achieve long-term stable operation, improved safety, and improved stability. Effect

Inactive Publication Date: 2013-09-25

上海赛迩福电力技术有限公司

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to overcome the deficiencies of the above-mentioned prior art, and provide a condenser steam injection vacuum system with simple structure, low maintenance cost, which can completely solve the problem of unit efficiency reduction caused by vacuum pump cavitation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

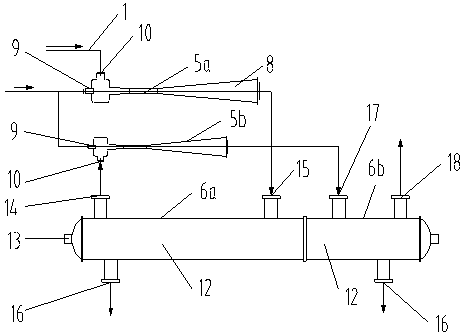

[0027] The vapor-gas mixture discharged from the condenser II6b enters the cold water separator after passing through the tubular heat exchanger.

Embodiment 2

[0029] The outlet pressure of the steam ejector II5b is 101.5Kpa, and there is no need to use moving parts and power-consuming parts.

Embodiment 3

[0031] The control system of the present invention can be controlled by a DCS system connected to the central control room of the power plant.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

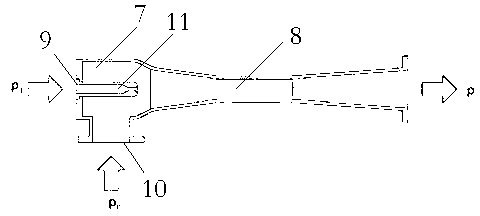

The invention discloses a condenser steam jet vacuum system which comprises a condenser pipeline connected with a condenser, a steam ejector set formed by at least a steam ejector I and a steam ejector II, and a condenser set formed by at least a condenser I and a condenser II. Power steam inlets of the steam ejector I and the steam ejector II are connected into power steam. Steam is used as media of the steam ejector I, and supersonic jet is produced through a power nozzle, so a head cavity is vaccumized to extract steam-gas mixtures in the condensers, the steam-gas mixtures exported from the condensers are mixed with the power steam and then are ejected into the condenser I through the steam ejector I to be processed in a condensed mode and finally are sucked in by the steam ejector II to be reprocessed. The condenser steam jet vacuum system is simple in structure and low in transformation cost, and can thoroughly solve the problem of unit efficiency reduction brought by vacuum pump cavitation.

Description

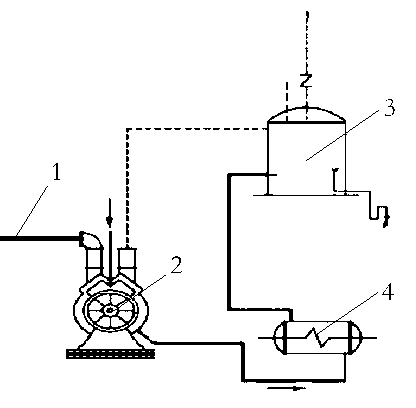

technical field [0001] The invention relates to an improvement to a condenser vacuum system, in particular to a condenser steam injection vacuum system. Background technique [0002] In a thermal power plant, a water ring vacuum pump is usually used to extract the non-condensable gas in the condenser to ensure the vacuum of the condenser. The specific plan is: see figure 1 , the condenser vacuum system in the prior art includes a condenser pipeline 1 connected to the condenser (not shown in the figure), and the condenser pipeline 1 is connected to the inlet end of the water ring vacuum pump 2 , the water ring vacuum pump 2, the steam-water separator 3 and the working fluid heat exchanger 4 are connected in pipelines to realize vacuum treatment. [0003] Its shortcoming is that the working fluid of the water ring vacuum pump is water, and its design temperature is generally 15°C, and the working fluid is cooled by circulating cooling water. However, the temperature of the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04F5/22F04F5/52

Inventor 程晋瑞

Owner 上海赛迩福电力技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com