Horizontal type self-balancing multistage centrifugal pump with high cavitation resistance

A self-balancing, centrifugal pump technology, applied in the direction of non-variable pumps, non-displacement pumps, components of pumping devices for elastic fluids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

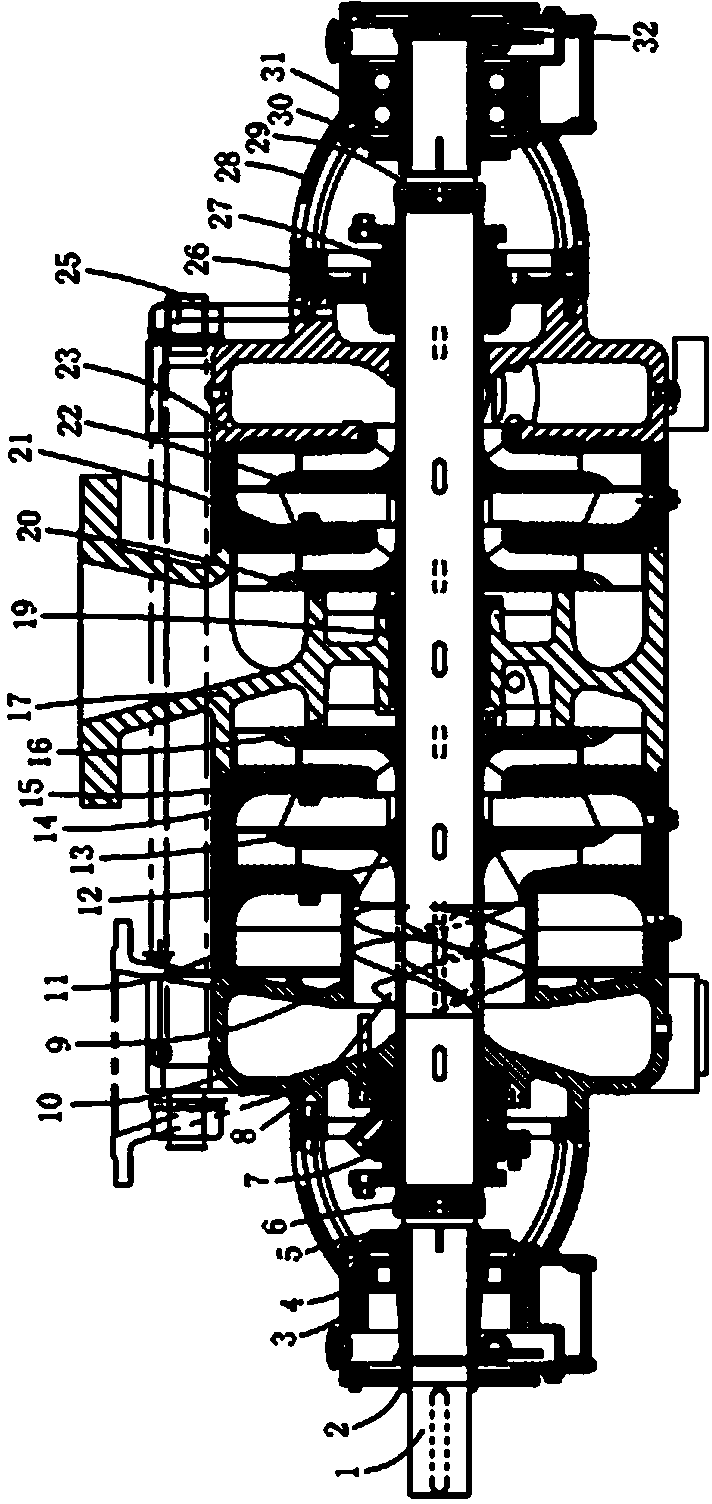

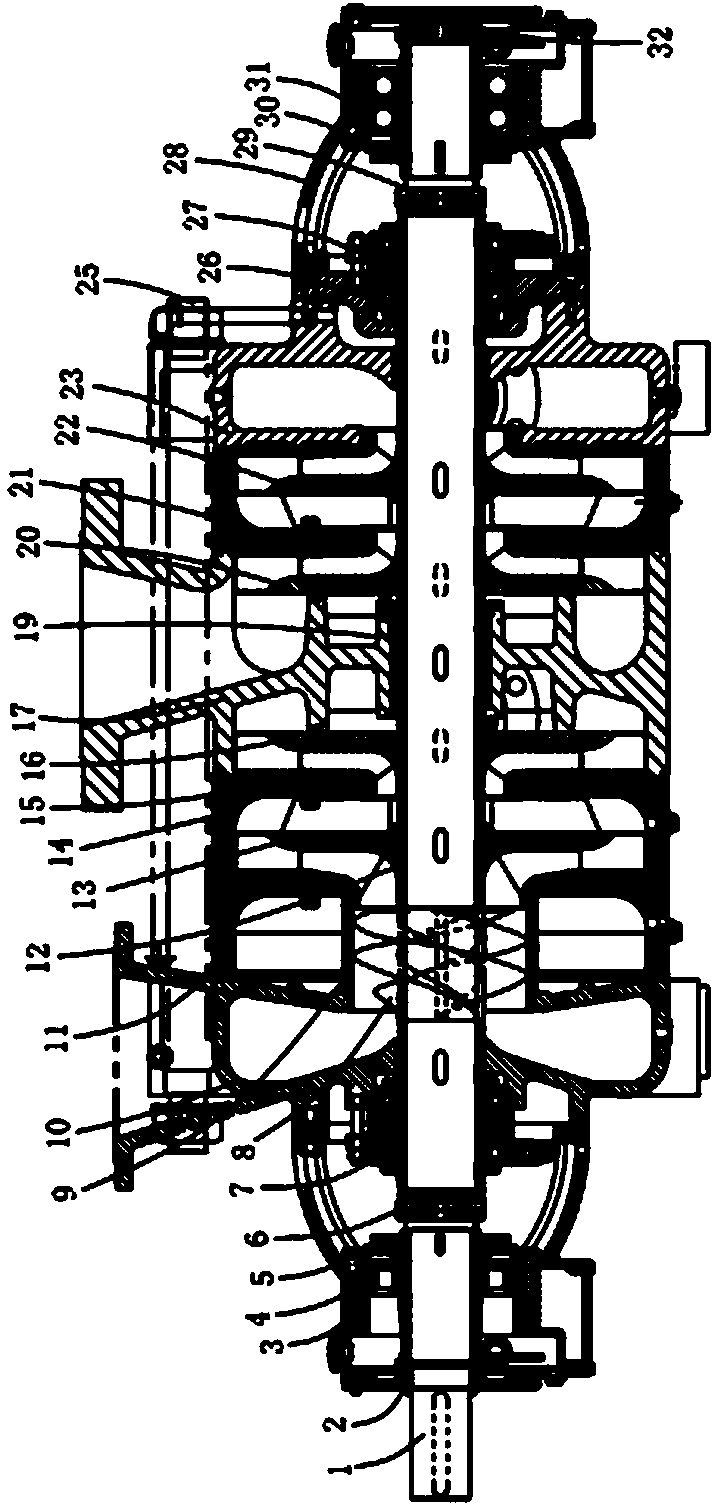

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0033] figure 1 It is a sectional view of the packing-sealed high cavitation resistance horizontal self-balancing multistage centrifugal pump of the present invention, figure 1 The high anti-cavitation performance horizontal multistage centrifugal pump includes stator parts and rotor parts. The stator component consists of water inlet section 10, middle section of inducer 11, guide seal ring 9, middle section 14, leading guide vane 13, front final guide vane 16, water outlet section 17, rear final guide vane 20, rear guide vane 22, two Secondary suction section 23, stuffing box 26, drive end bearing component 3, non-drive end bearing component 28 and other components.

[0034] Water inlet section 10, inducer middle section 11, guide seal ring 9, middle section 14, front guide vane 13, front final guide vane 16, water outlet section 17, rear final guide vane 20, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com