Patents

Literature

199results about How to "Improve anti-cavitation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

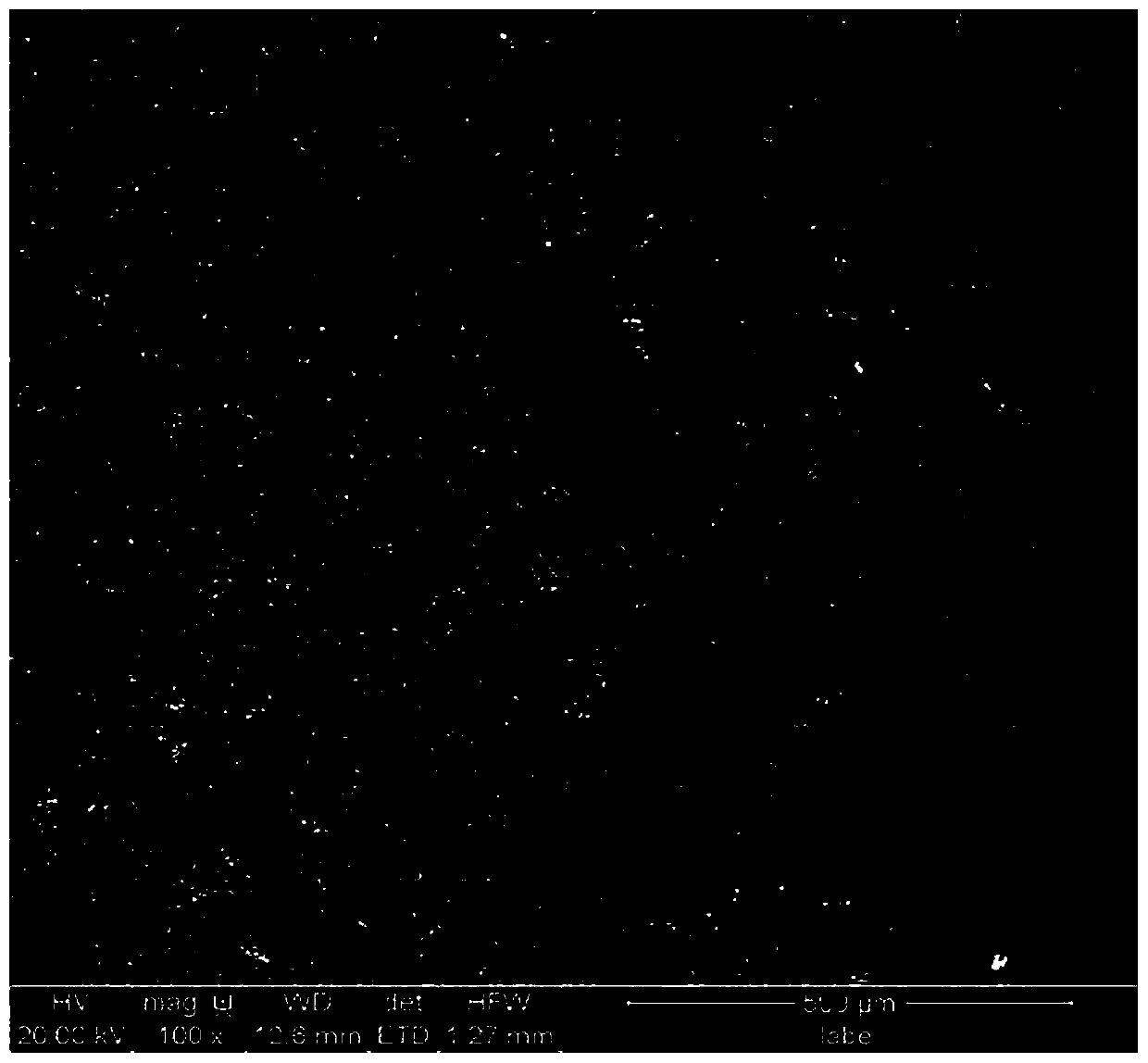

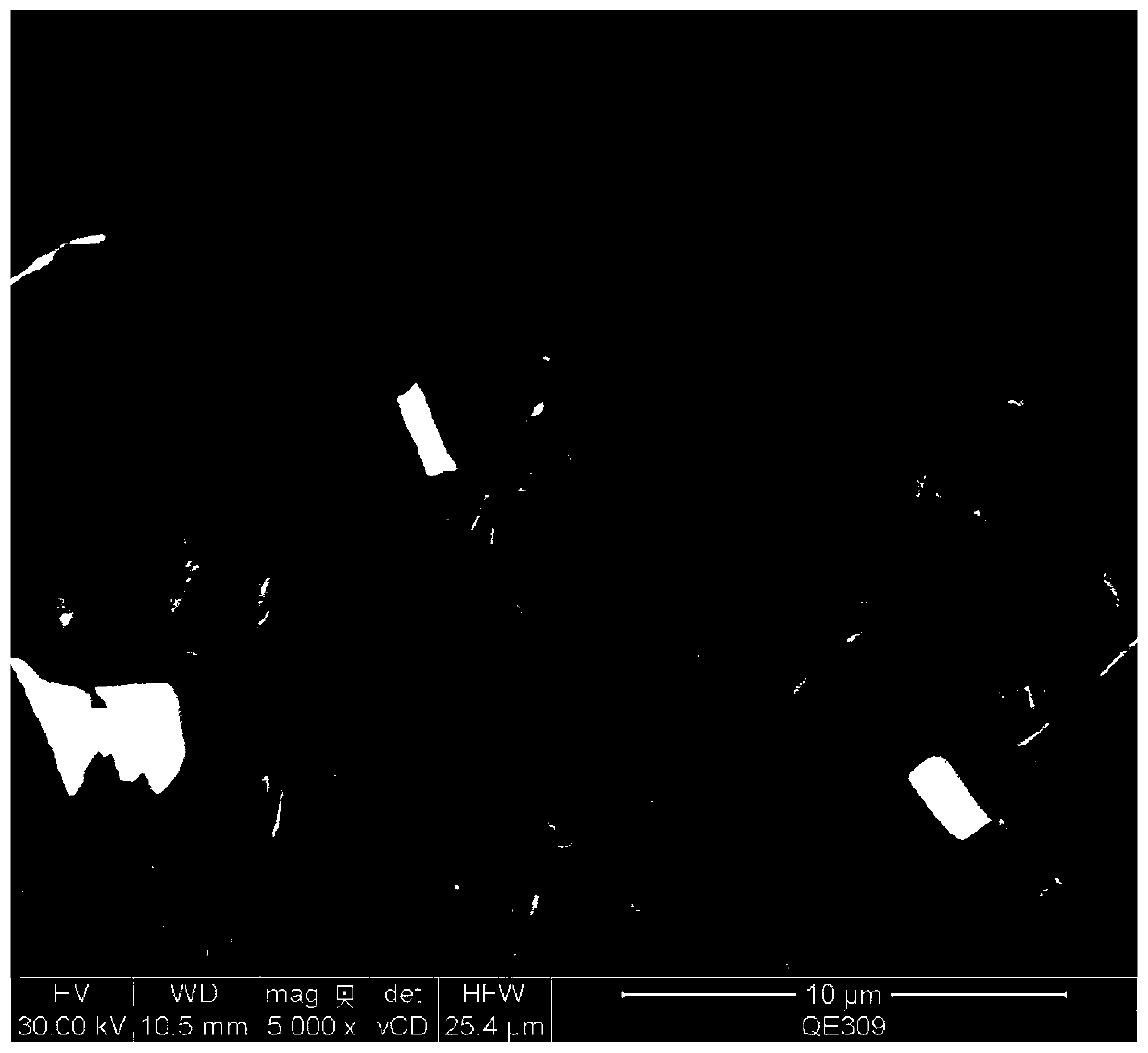

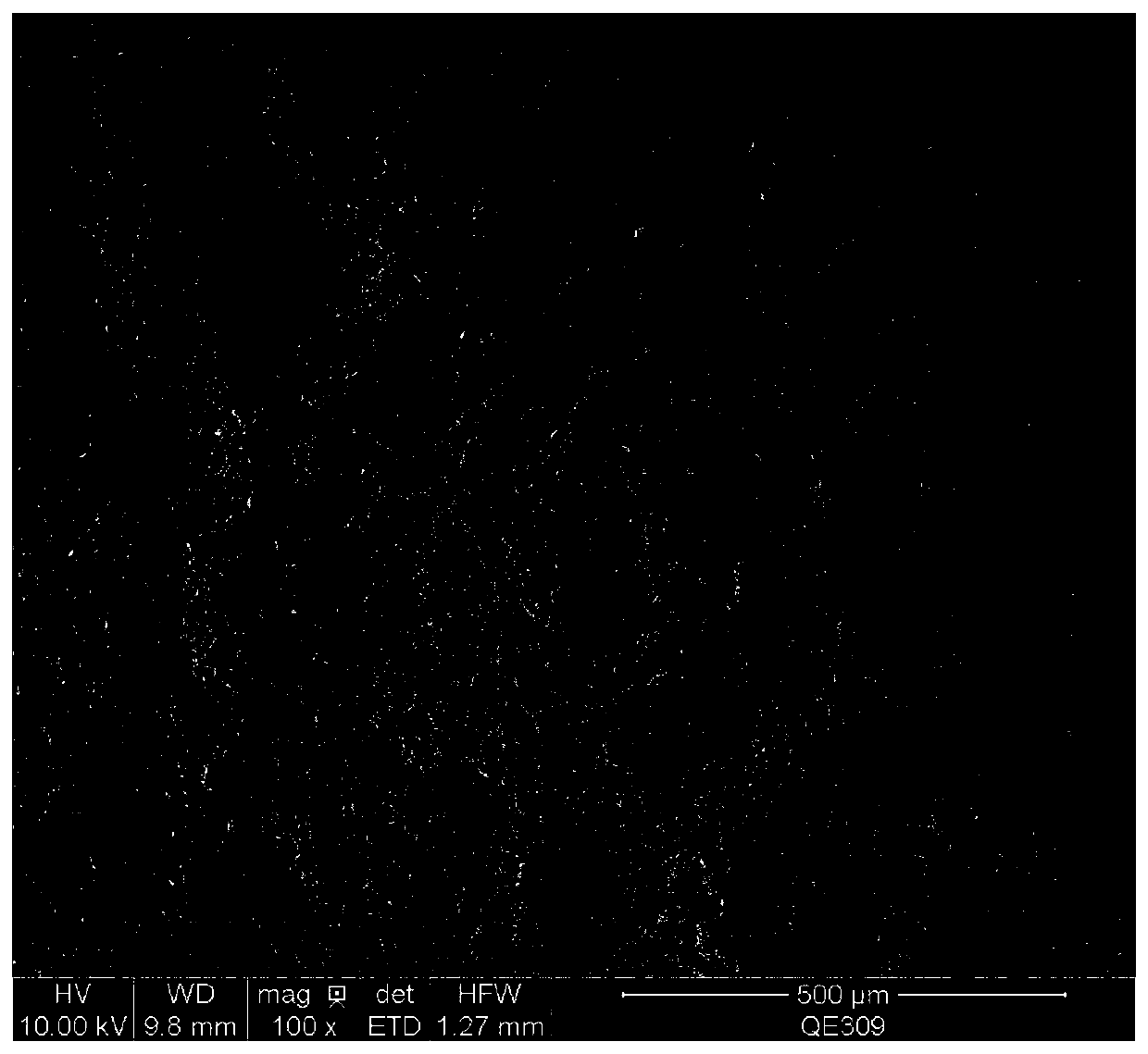

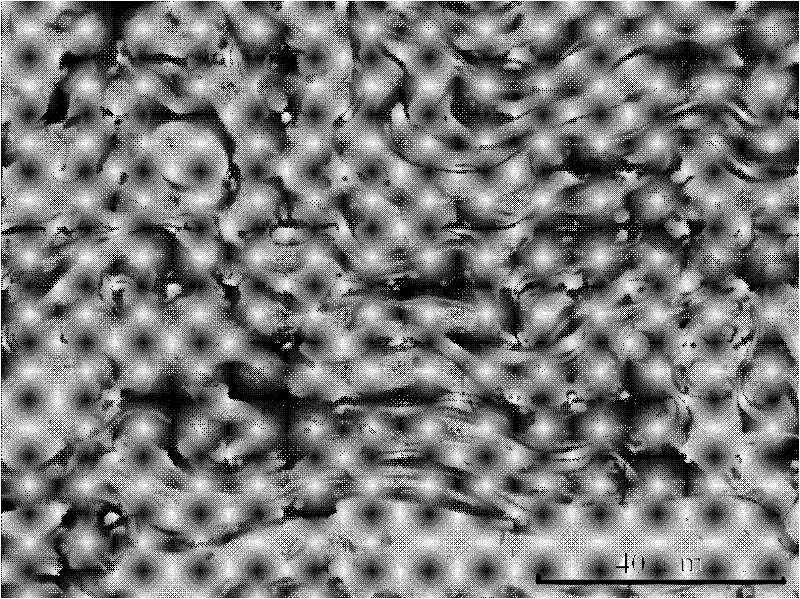

Iron-based amorphous powder and preparation method and application thereof

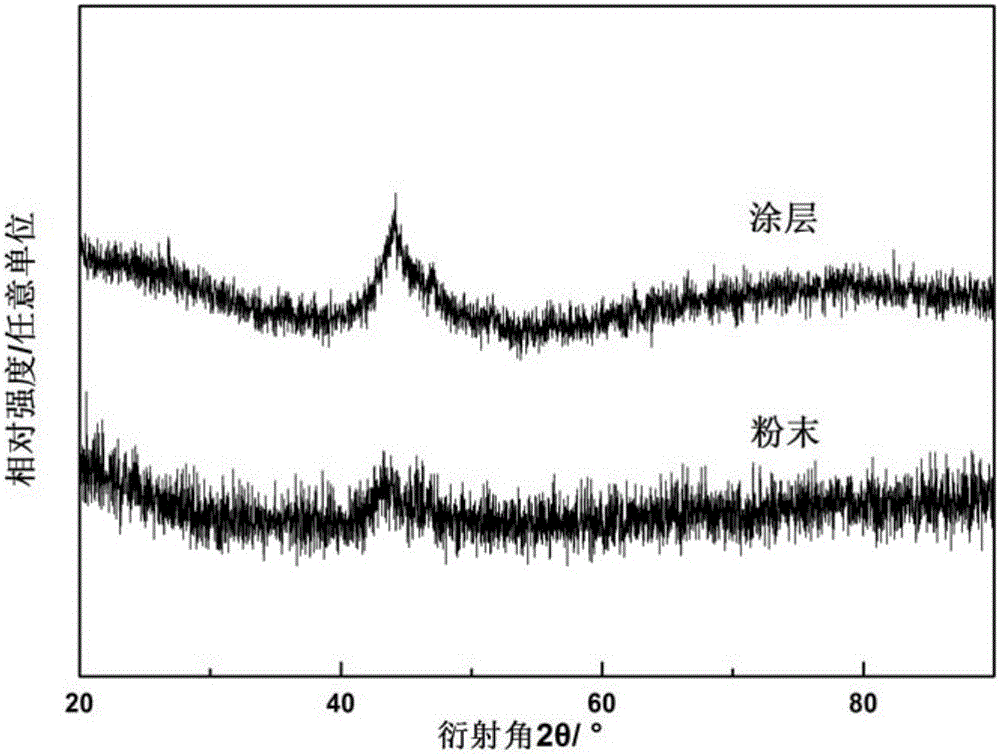

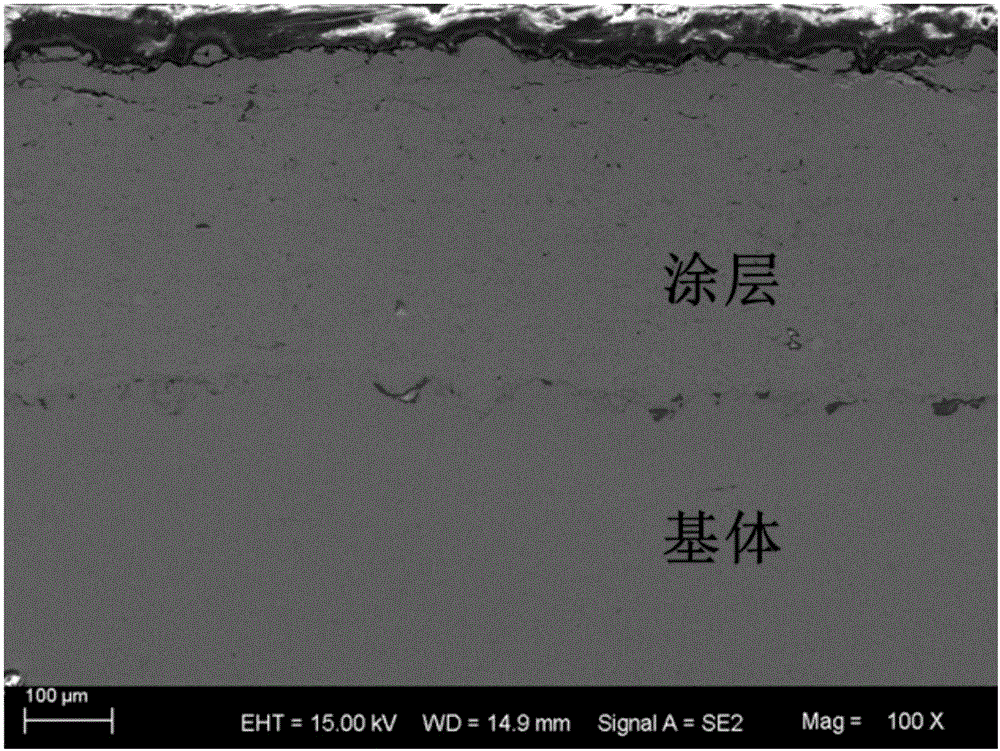

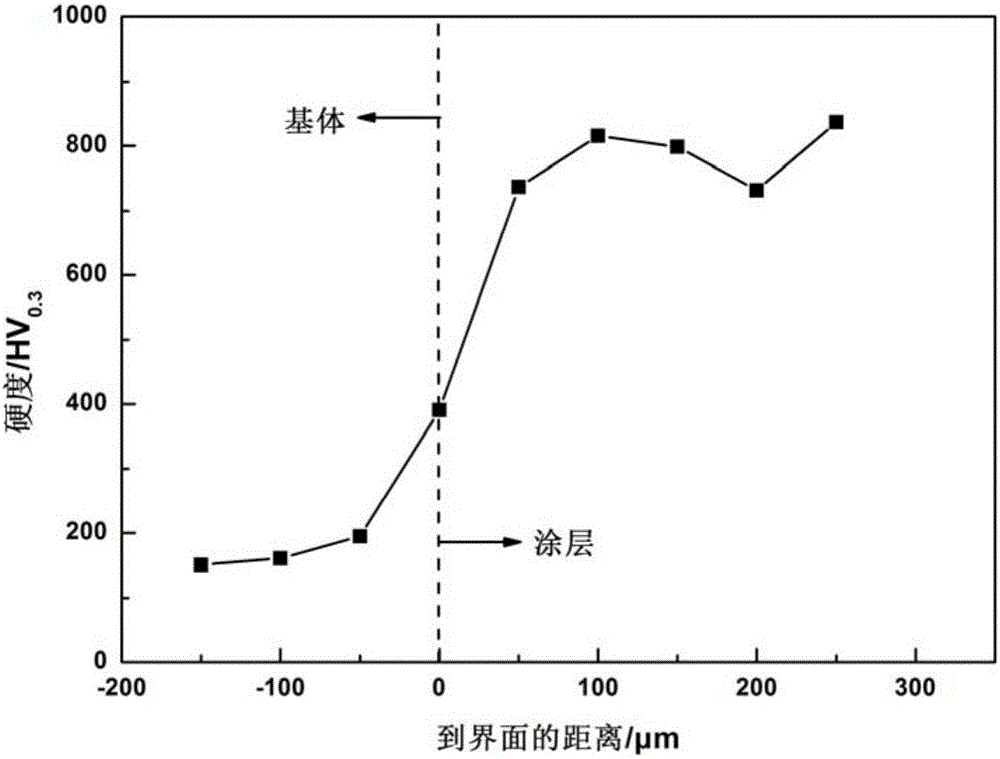

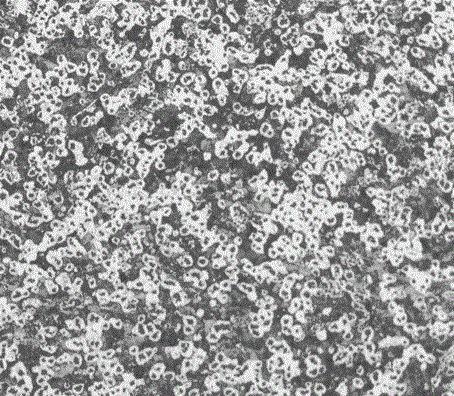

The invention discloses iron-based amorphous powder and a preparation method and application thereof. The powder comprises the following elements in percentages by weight: 17-23wt% of Cr, 2.7-4.5wt% of B, 0.3-1wt% of C, 0.5-2.5wt% of Si, 2-3wt% of Cu, 3-8wt% of Ni, 12-18wt% of Mo, 2-4wt% of Co and the balance of Fe. The preparation method comprises the following steps: adding raw materials in an induction electromagnetic furnace, heating and melting; and carrying out water atomization on molten metal, then drying, and screening powder. According to the application of the iron-based amorphous powder in preparation of an anti-cavitation and corrosion-resistant iron-based amorphous powder coating, the coating is prepared by a supersonic flame spraying technology, and the surface of a matrix is subjected to oil removal and rust removal treatment, and then is subjected to pretreatment such as sand blasting. The coating which is low in porosity, high in hardness, excellent in anti-cavitation property and excellent in corrosion resistance can be obtained. The iron-based amorphous powder is suitable for demanding components such as marine hydraulic machinery, key components of nuclear submarines, parts of engines of airplanes, and bosses of blades of aviation engines, particularly has advantages in a severe marine environment, facilitates industrialization, and is wide in application prospect.

Owner:HOHAI UNIV

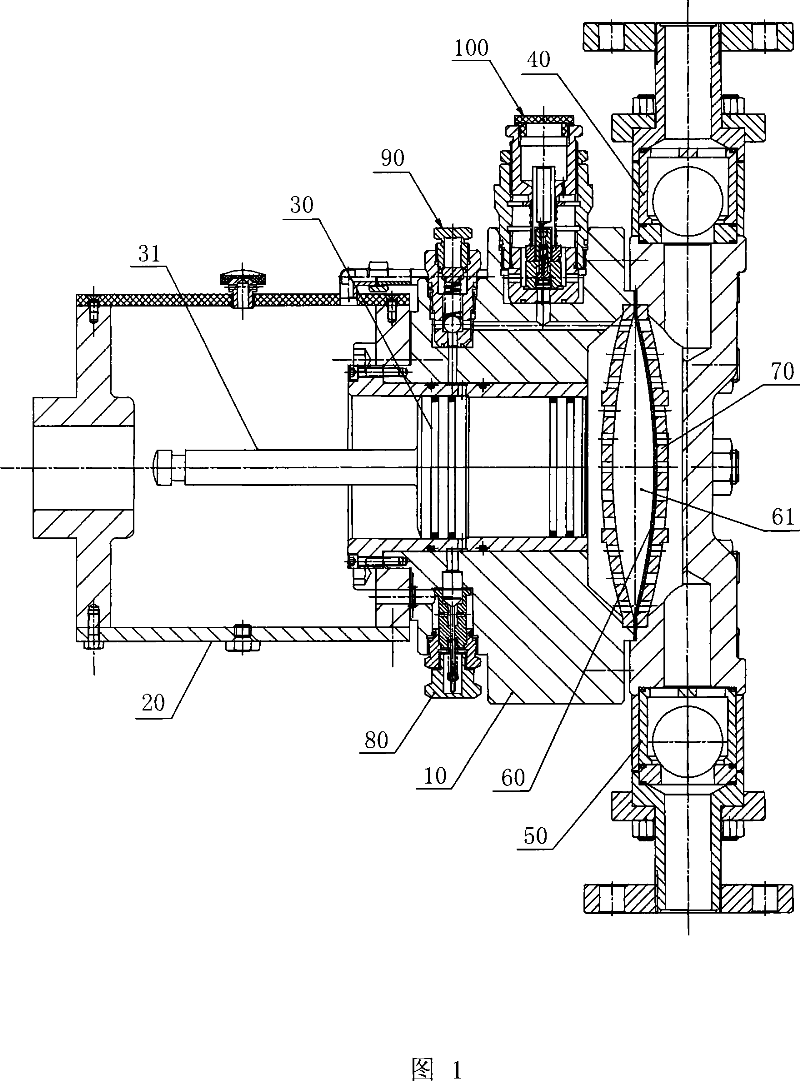

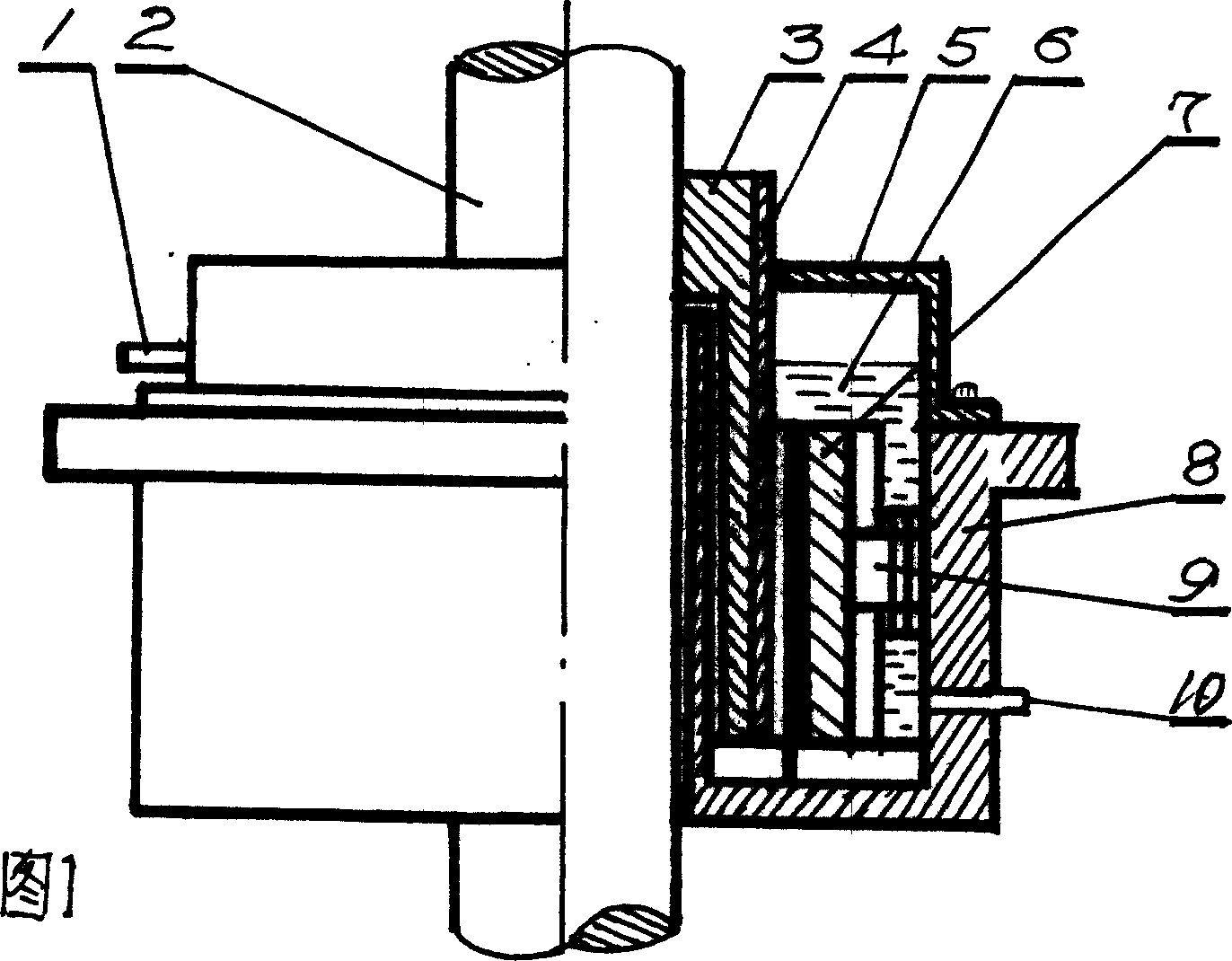

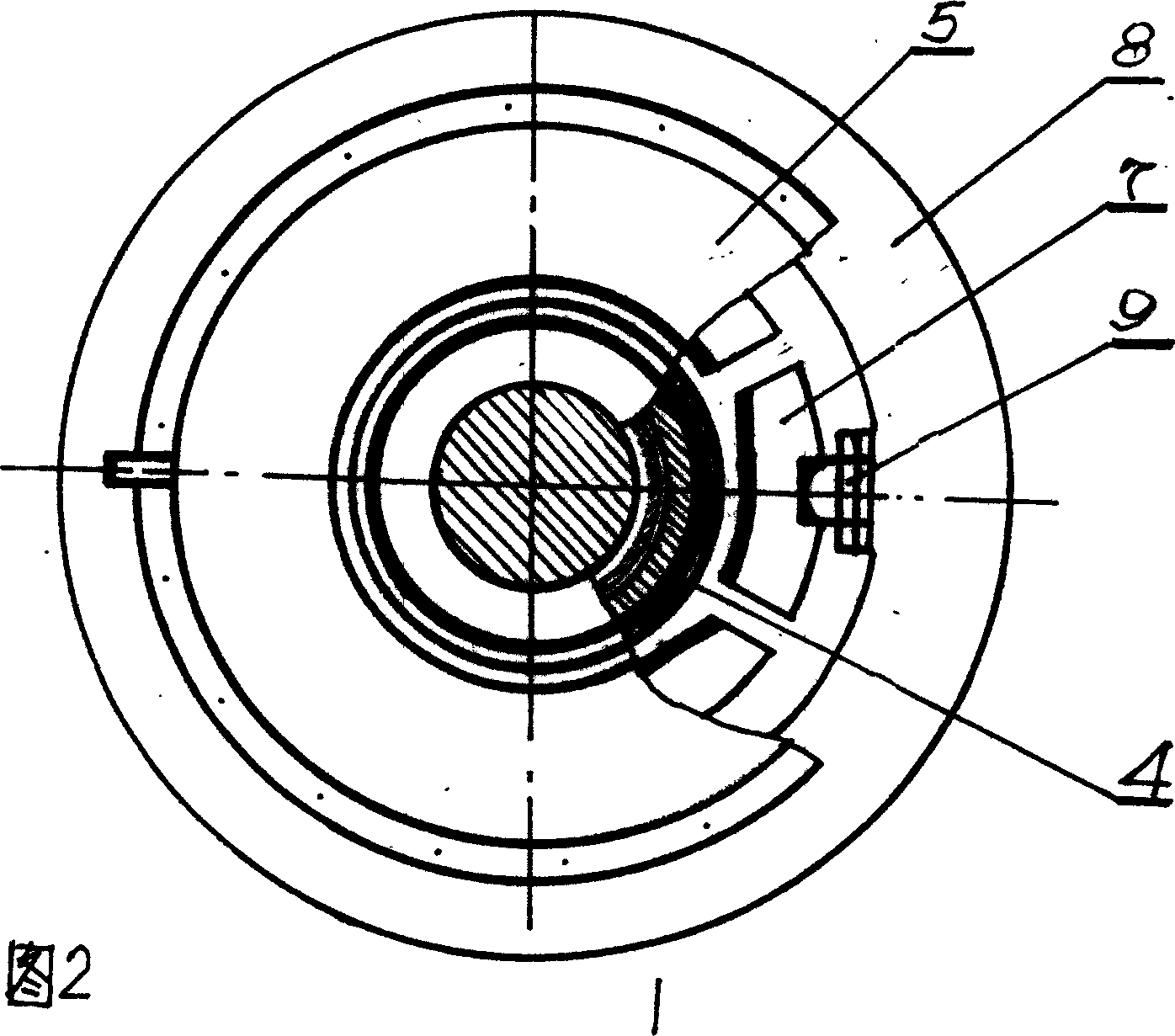

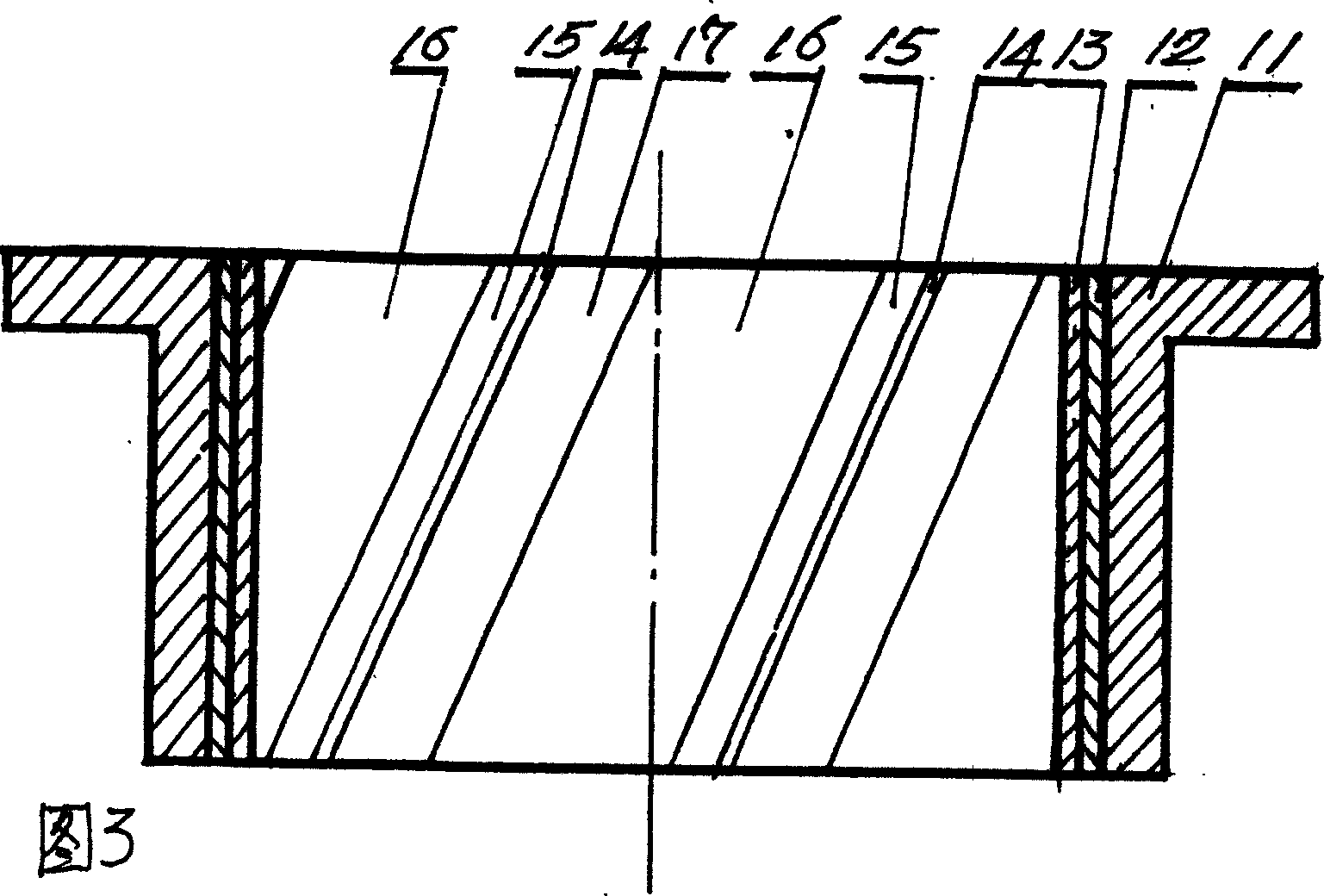

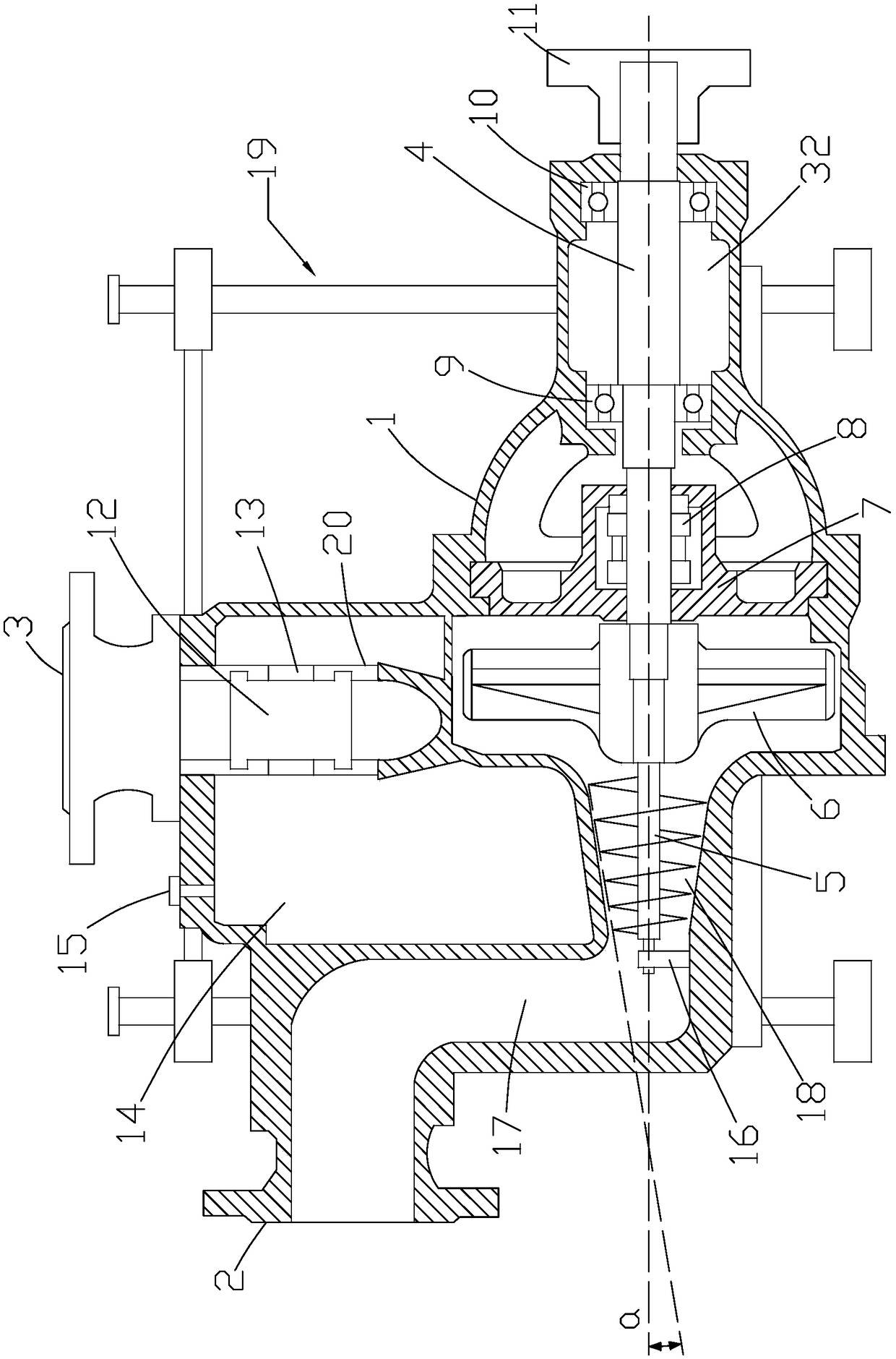

Fine vacuum diaphragm pump

ActiveCN101037992AImprove reliabilityImprove anti-cavitation performanceFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpInlet valve

The invention relates to a high-vacuum diaphragm pump, stabilizing vacuum environment when the diaphragm pump is sucking hydraulic fluid and supplying pressure requirement when discharging hydraulic fluid, which comprises a cylinder body and a oil pool cylinder. The cylinder body is provided with a pressure-fluid inlet valve and an outlet valve, the diaphragm and a support bracket are provided between them, the said piston presents a echelonment shape, the oil pool cylinder communicates with a cavum between the piston and the piston cavity via a compensator valve, the cavum between the piston and the piston cavity communicates with the diaphragm oil pressure cavity via a pressure control valve. The invention can ensure reliability service of the pump while state of stable fine vacuum suction ability is maintained.

Owner:合肥华升泵阀股份有限公司

High-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and coating and preparing method of coating

ActiveCN105463359AImprove solid solution strengtheningPlay a reinforcing roleMolten spray coatingChromium carbideTurbine blade

The invention discloses high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide composite powder and a high-temperature resisting, abrasion resisting, corrosion resisting and cavitation resisting nickel-chromium-chromium carbide coating prepared through the composite powder. The composite powder comprises, by weight percentage, 65-85% of Cr3C2, 10-25% of NiCr, 1-5% of Nb and 1-5% of Ta. The coating is prepared in the manner that the composite powder is subjected to hypersonic flame spraying or high-enthalpy plasma spraying or is subjected to hypersonic flame spraying or high-enthalpy plasma spraying, and then the high-enthalpy plasma remelting technology is combined. The coating is greatly improved in the aspects of microhardness, combing strength, corrosion resistance and cavitation resistance. Meanwhile, the production cost is low, the preparing method is reliable in technology, performance is stable, and the coating is suitable for being applied to the fields such as hydraulic machine flow passage components, compressor screws and turbine blades on a large scale.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

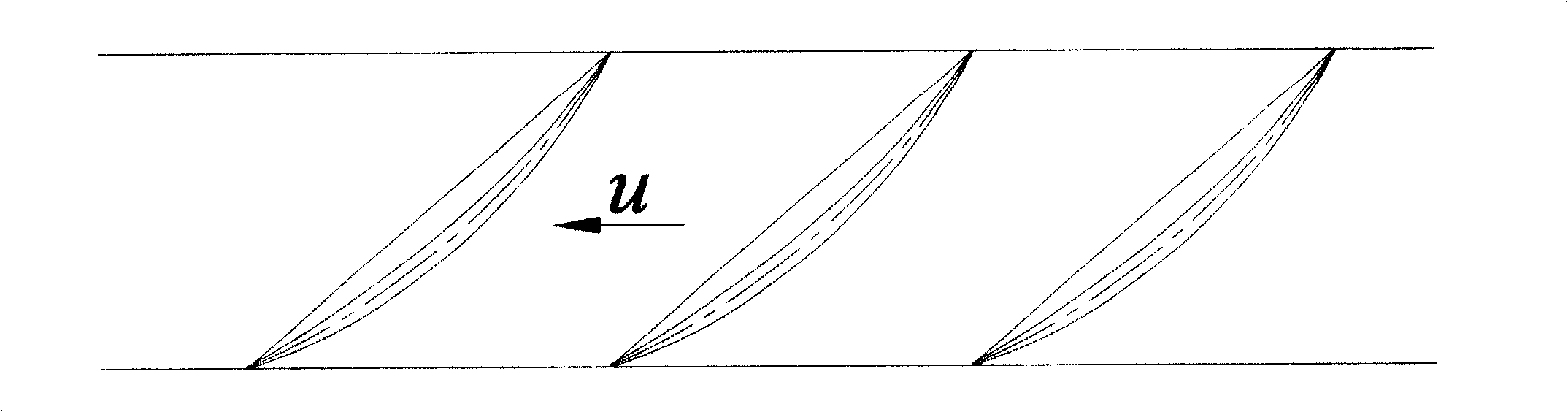

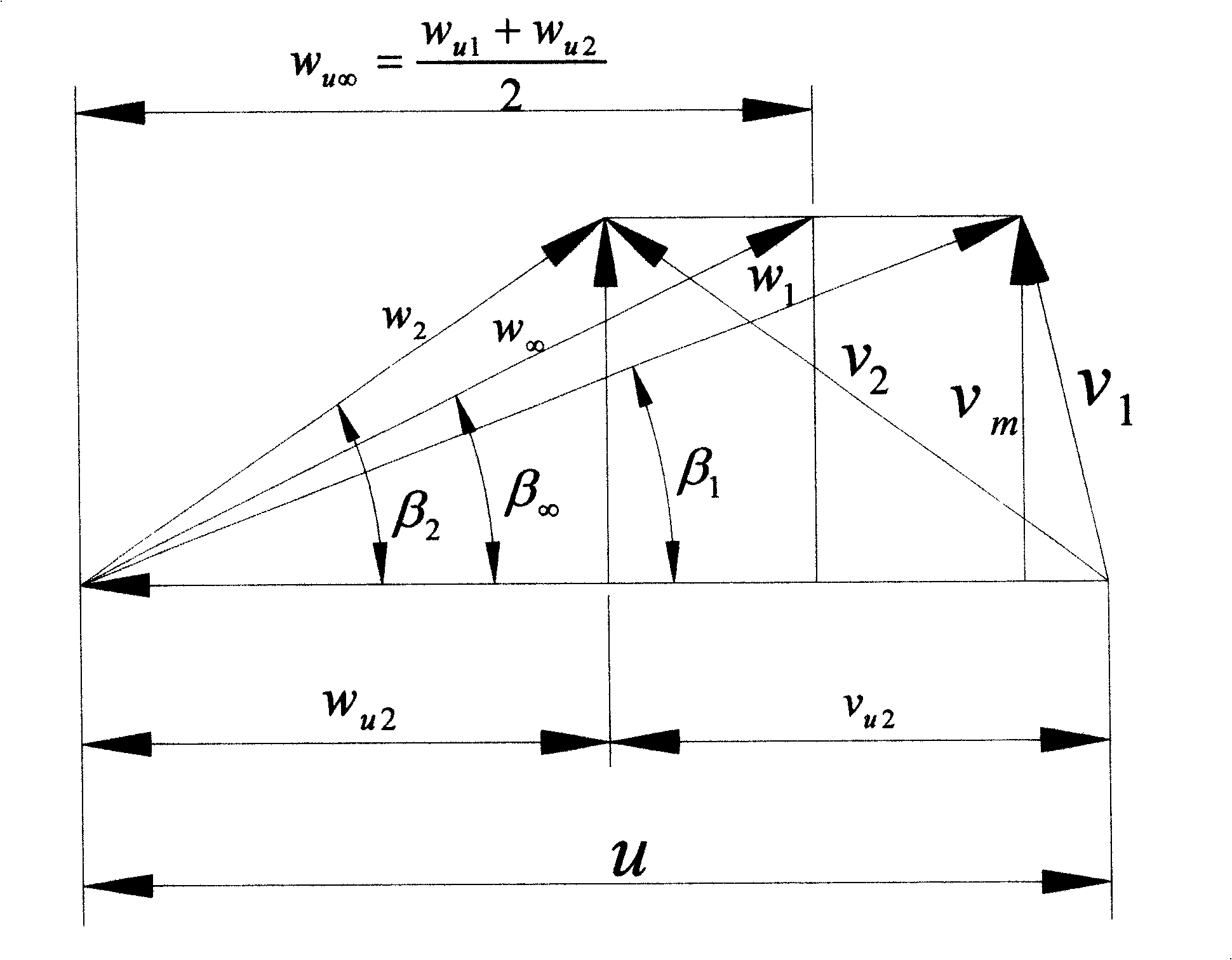

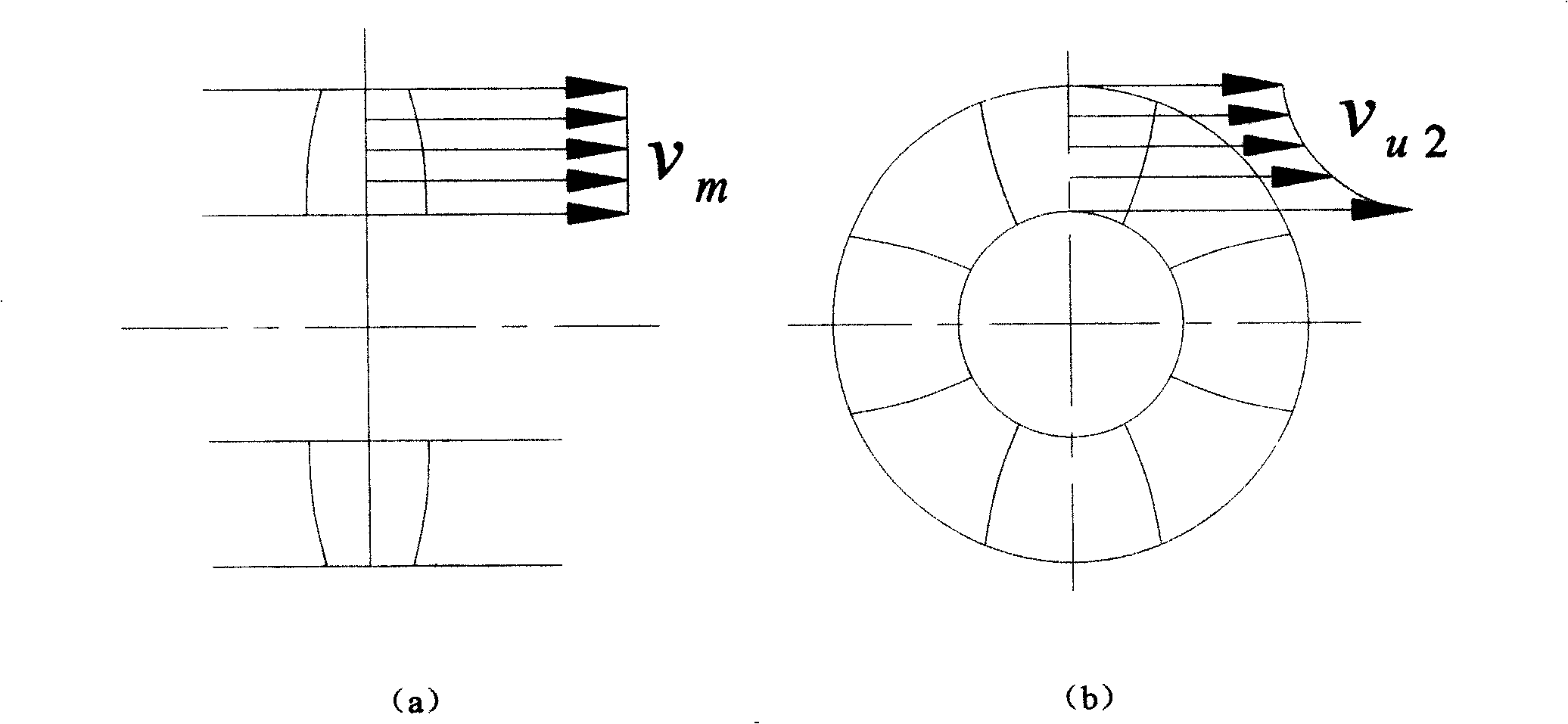

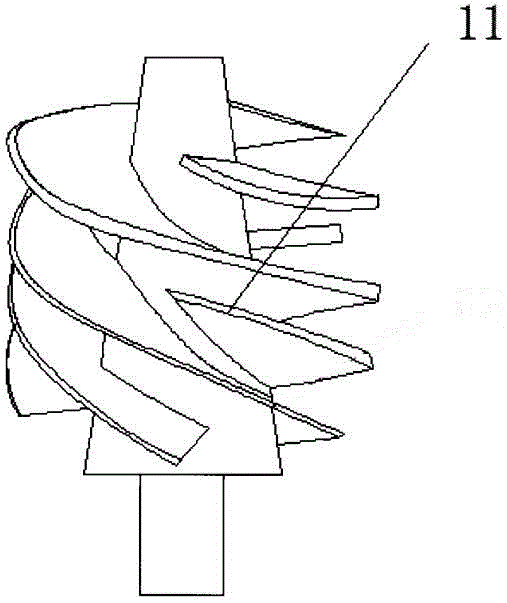

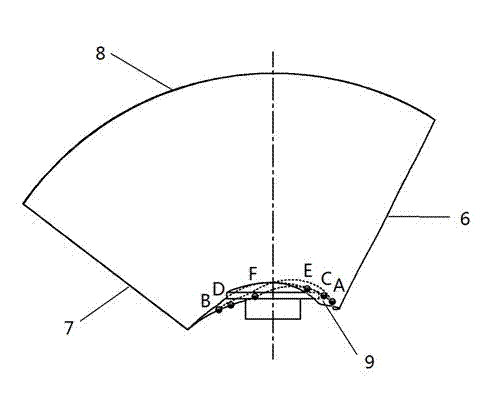

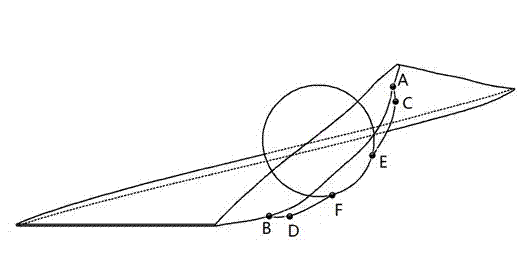

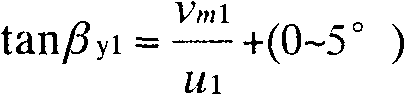

Axial flow impeller machine design method and blade

InactiveCN101245711AImprove efficiencyIncrease pressurePump componentsBlade accessoriesImpellerEngineering

The invention provides a design method for an axial flow impeller machine for confirming the flow model of the axial flow impeller machine. The method at least includes the circle component of vu2 and axial plane speed of vm2 which are at the exit of a vane and are distributed in a way of linearity along the radius of the vane, and the circle component and axial plane at the hub side is small while the circle component and axial plane at the wheel edge side is larger; the distribution functions of the circle component vu2 and axial plane speed vm2 at the exit of the vane are confirmed according to the external characteristic parameters and structure parameters as well as the flow model of the axial flow impeller machine; the axial flow impeller machine is designed according to the confirmed distribution functions of the circle component vu2 and axial plane speed vm2 at the exit of the vane. The invention also provides the vane of the designed axial flow impeller machine; wherein, the difference of the mounting angles for the wing models of the hub side and wheel edge side of the vane Delta Beta is equal to Beta h minus Beta s and is between minus 3 degrees to 10 degrees. The equipressure area at the back of the vane is distributed along the radial direction of the vane in strip. The invention can improve the efficiency of the impeller machine to reach 91 percent and improve the anti-cavitation erosion capacity.

Owner:任明琪

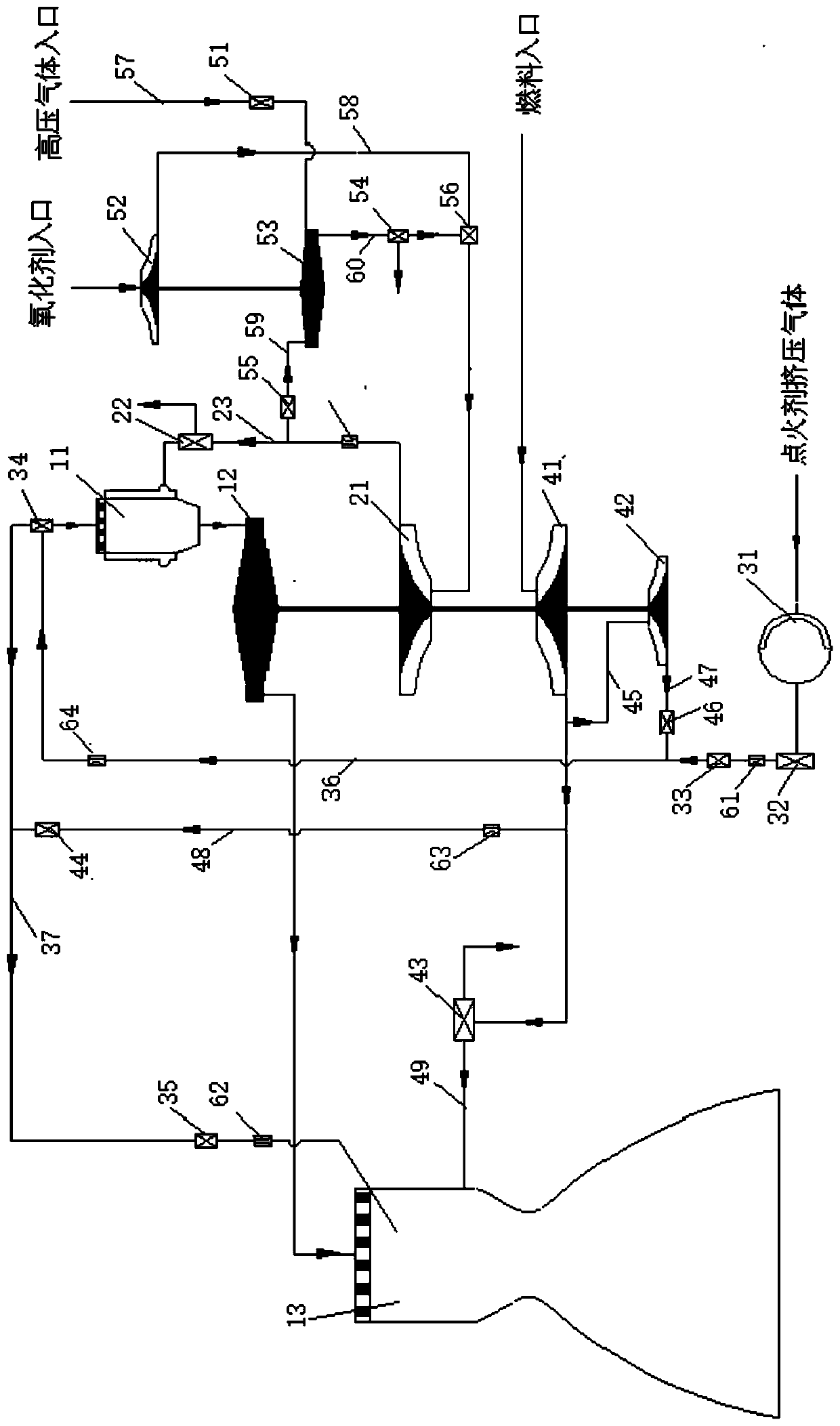

Multiple-starting liquid oxygen kerosene engine of gas driven preloading turbine and starting method

ActiveCN109736953AEnough starting energyImprove anti-cavitation performanceTurbine/propulsion engine ignitionTurbine/propulsion engine startersKeroseneThrust chamber

The invention relates to a multiple-starting liquid oxygen kerosene engine of a gas driven preloading turbine. The multiple-starting liquid oxygen kerosene engine solves the problems that an oxygen-rich afterburning circulating liquid oxygen kerosene engine has no capacity of being started under low inlet pressure and can not being started for multiple times. The liquid oxygen kerosene engine comprises a gas system, a liquid oxygen system, a fuel supply system, an ignition agent supply system and a starting system. The ignition agent supply system comprises an ignition agent starting box, an ignition agent supply valve, a third one-way valve, a generator fuel valve and a fourth one-way valve. The generator fuel valve is a two-position three-way valve and comprises an inlet, an outlet A andan outlet B. The starting system comprises a high-pressure gas supply device, a high-pressure gas one-way valve, an oxygen preloading pump, an oxygen preloading turbine, a switching valve, a liquid oxygen one-way valve and a mixer. The ignition agent starting box of the liquid oxygen kerosene engine is relatively independent, an ignition agent is supplied to fuel gas generator and the thrust chamber for multiple times, and therefore the engine has the capacity of being started for multiple times.

Owner:XIAN AEROSPACE PROPULSION INST

Cavitation-erosion-resistant laser re-melting method of metal ceramic coating through thermal spraying

InactiveCN110699626ASurface texture improvementRegular coating structureMolten spray coatingCeramic coatingCermet

The invention relates to the technical field of cavitation-erosion-resistant coatings, and discloses a method for preparing a cavitation-erosion-resistant coating through a thermal spraying and laserre-melting compound technology. The method comprises the following steps that (1) a metal ceramic composite coating is prepared on a matrix through thermal spraying; and (2), laser re-melting treatment is carried out on the metal ceramic composite coating obtained in the step (1), the surface of the metal ceramic coating is re-melted to form a new structure under high-density energy of lasers, thestructure property of the coating is enhanced after cooling, and the cavitation erosion resistance of the coating can be greatly improved. The method effectively eliminates the problem that ceramic powder deposits on the surface of the matrix through direct laser cladding, the obtained coating is low in porosity, the surface is compact and smooth, the cavitation erosion resistance is excellent, the coating can be widely applied to propellers, water turbine blades and other equipment prone to cavitation damage, the service life of the equipment can be prolonged, the frequency of maintaining the equipment due to cavitation damage is greatly reduced, and the using efficiency of the equipment is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

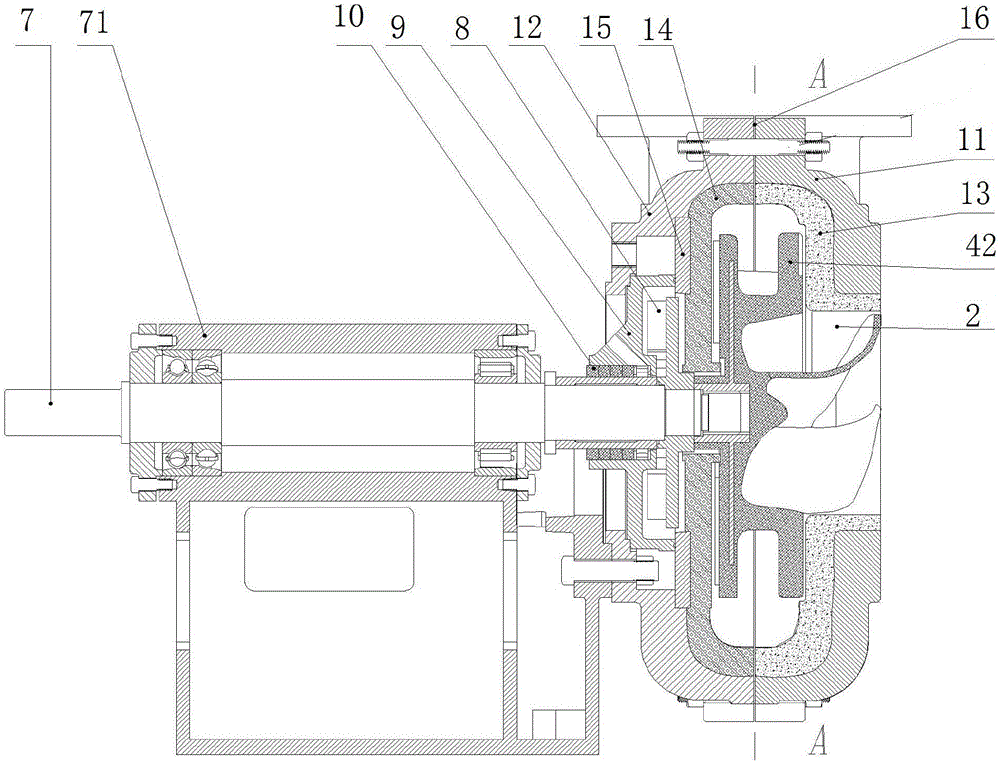

Air turbine pump with pre-pressing pump

InactiveCN108386366AImprove cavitation resistanceImprove anti-cavitation performancePump componentsPump installationsImpellerLow speed

The invention relates to an air turbine pump with a pre-pressing pump. The problems that an existing air turbine pump cannot work at low inlet pressure and is low in system efficiency, is complex in system structure, and is difficult to use in a small-size space are solved. The air turbine pump comprises the pre-pressing pump, a speed reducer and a main pump; the pre-pressing pump comprises a front shell, a pre-pressing impeller and a pre-pressing pump shaft, and the pre-pressing impeller is arranged on the pre-pressing pump shaft and is arranged in the front shell; the main pump comprises a middle shell, a rear shell, an induction wheel, a centrifugal wheel, a turbine and a main pump shaft, the induction wheel and the centrifugal wheel are both arranged in the middle shell, the turbine isarranged in the rear shell, the middle shell is correspondingly and fixedly connected with the front shell and the rear shell, the induction wheel and the turbine are arranged on the two sides of themain pump shaft correspondingly, the centrifugal wheel is arranged between the induction wheel and the turbine, the main pump shaft penetrates through the induction wheel and is connected with the speed reducer; and the speed reducer comprises a high-speed gear and a low-speed gear train, the main pump shaft is connected with the high-speed gear of the speed reducer, and the pre-pressing pump shaft is connected with the low-speed gear system of the speed reducer.

Owner:XIAN AEROSPACE PROPULSION INST

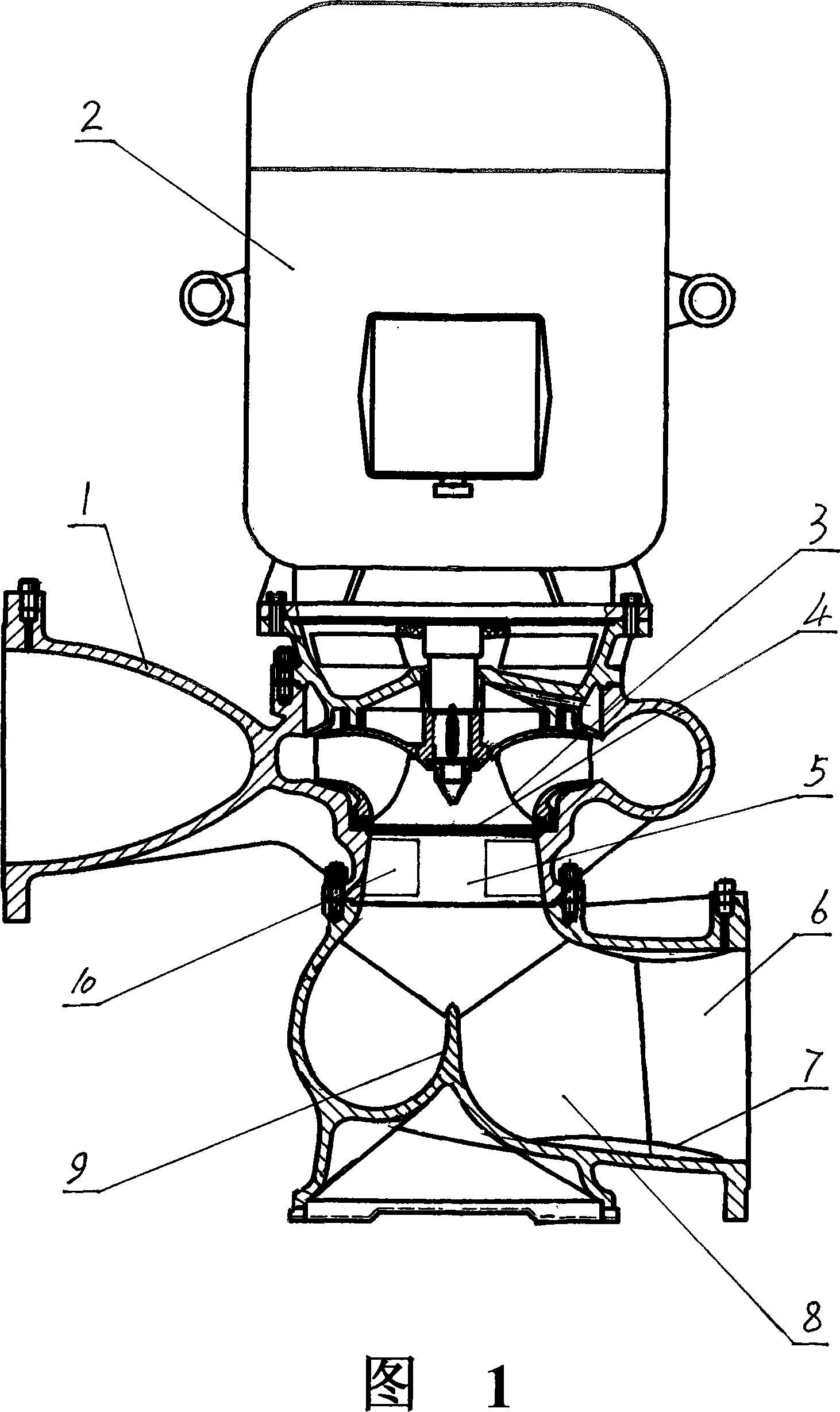

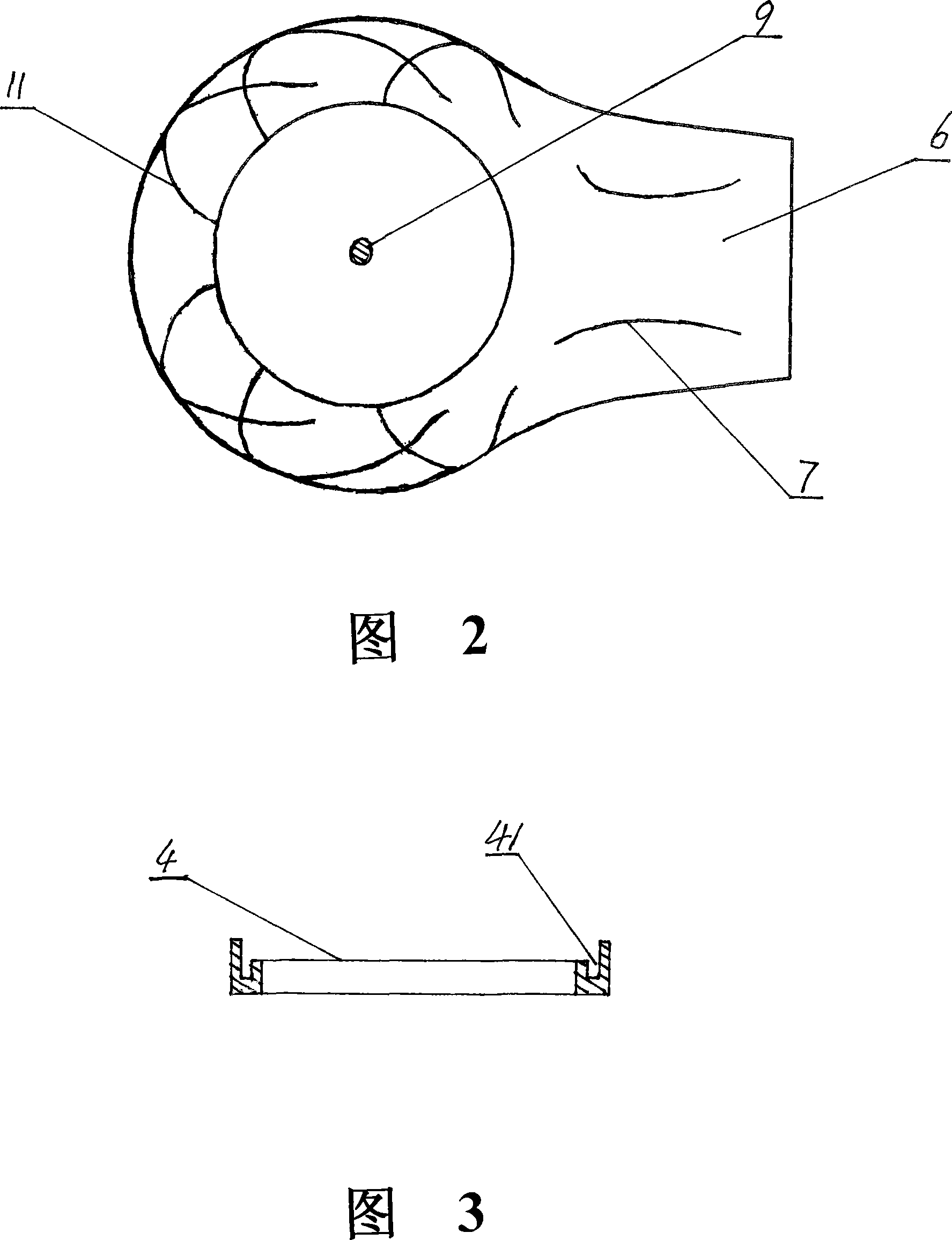

BJL multi-channel modified line special air conditioner energy-saving centrifugal pump

InactiveCN101089403AImprove hydraulic efficiencyImprove performancePump componentsPumpsCircular discWater discharge

The present invention discloses a BJL multichannel modified line special-purpose air-conditioning energy-saving centrifugal pump. Said centrifugal pump includes the following several portions: motor, blade wheel, water-discharging chamber, water-entering chamber, straight taper tube flow channel, conical water-dividing cone, curved flow-guiding rib and flow deflector, etc. said invention can raise cavitation resistance of vertical centrifugal pump, and can raise hydraulic efficiency of pump and its volume efficiency.

Owner:海南南方特能泵业有限公司

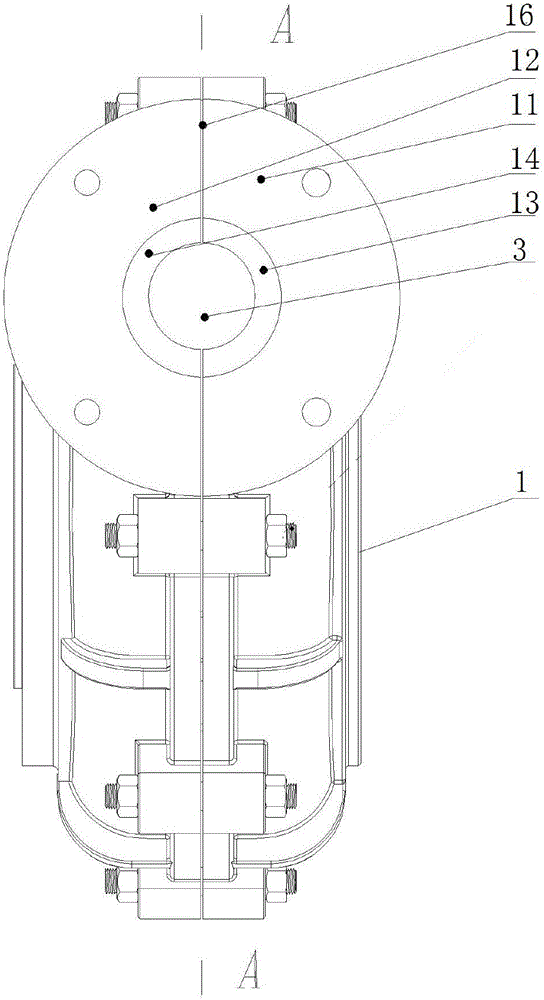

Nuclear main pump maximum flow hydraulic design method

ActiveCN103742445AImprove efficiencyImprove anti-cavitation performancePump componentsPumpsImpellerNuclear engineering

The invention provides a nuclear main pump maximum flow hydraulic design method and particularly relates to a maximum efficiency design method for the nuclear main pump under the accident of loss of coolant. Main geometrical parameters of an impeller are confirmed according to the following relational expressions which mainly comprise an impeller outlet placing angle, the impeller outlet width, the impeller outlet diameter, an eighth section and the like. The impeller designed through the nuclear main pump maximum flow hydraulic design method not only improves the flow condition inside the impeller and meanwhile improves the nuclear main pump performance and the operational reliability.

Owner:JIANGSU UNIV

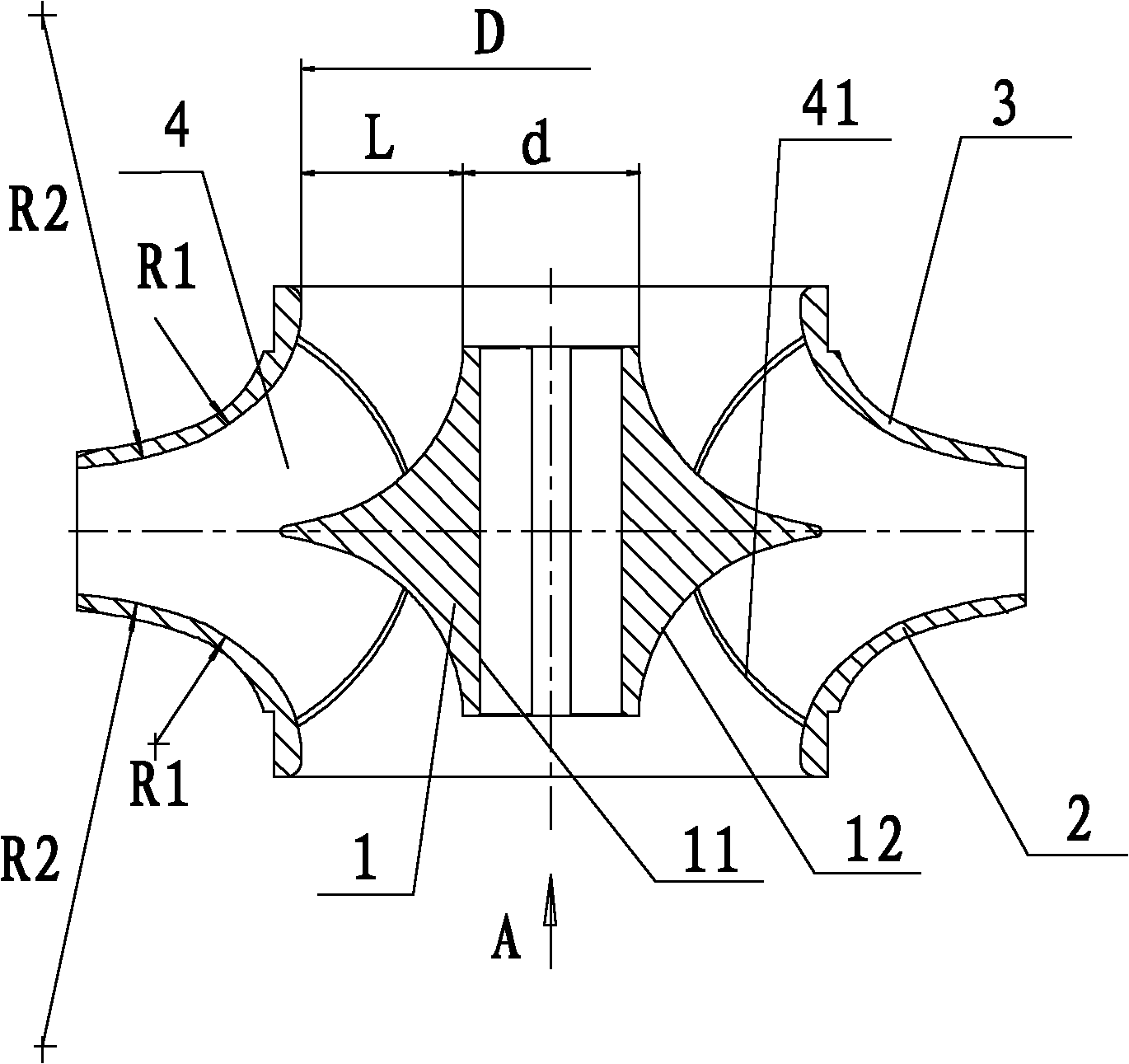

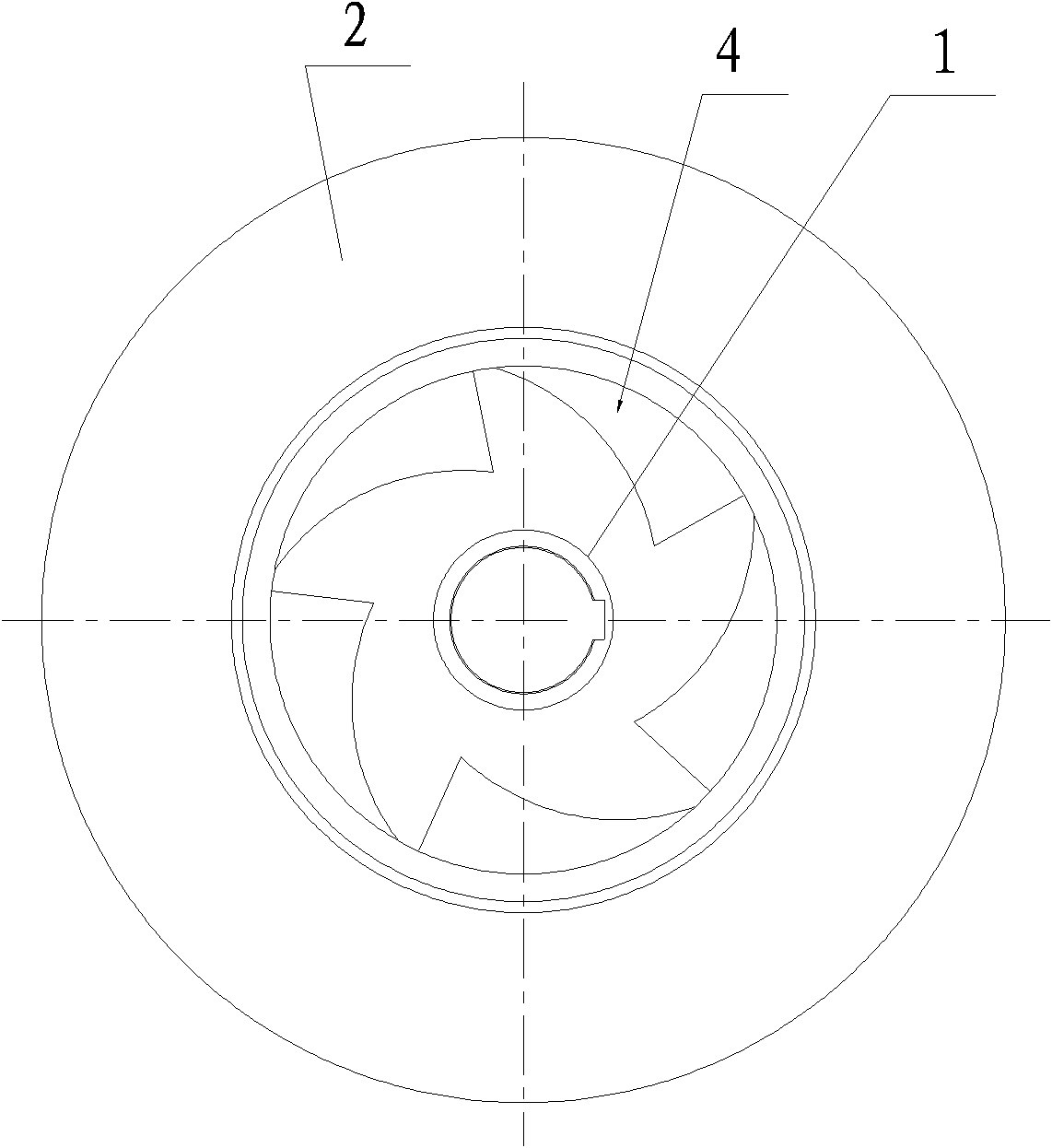

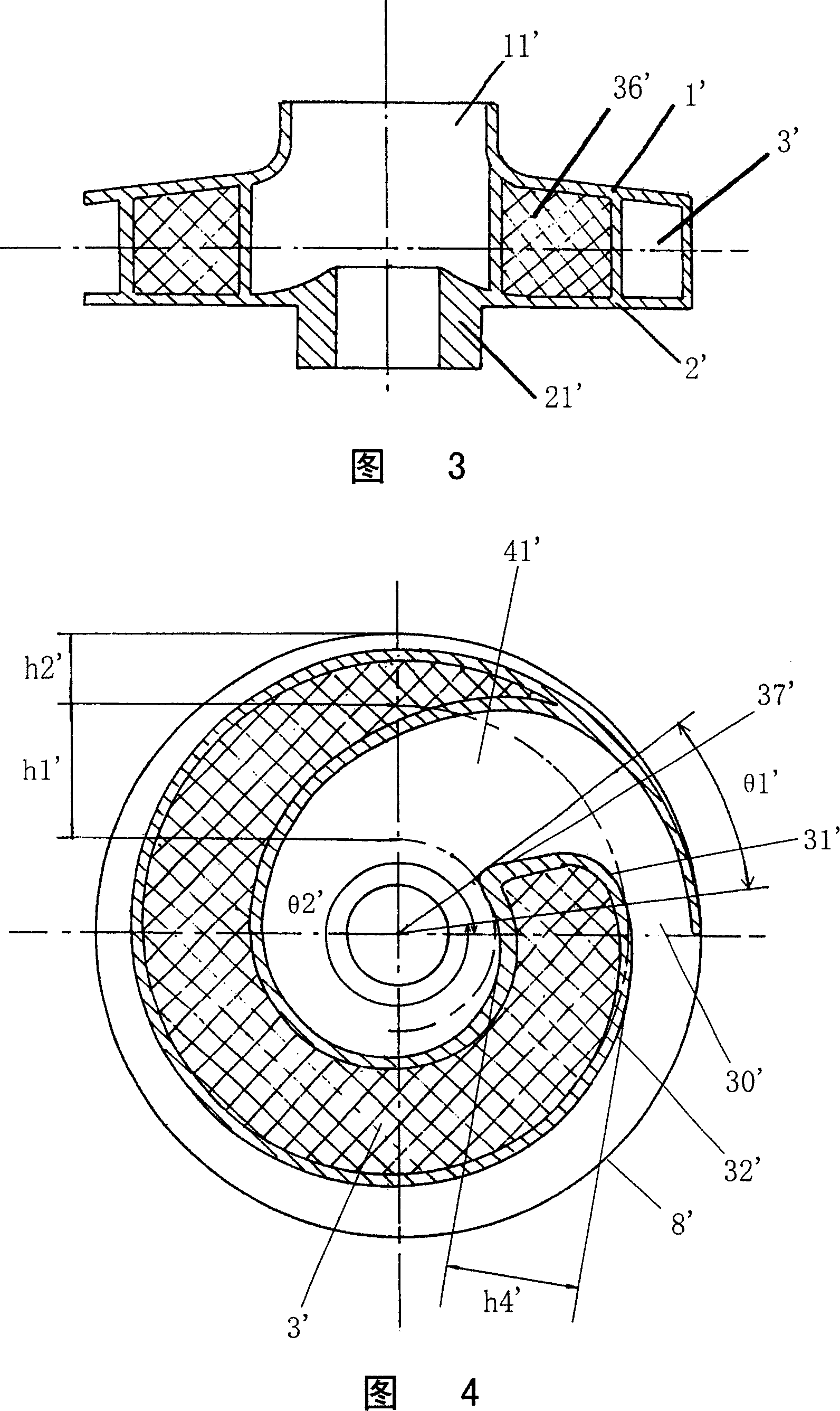

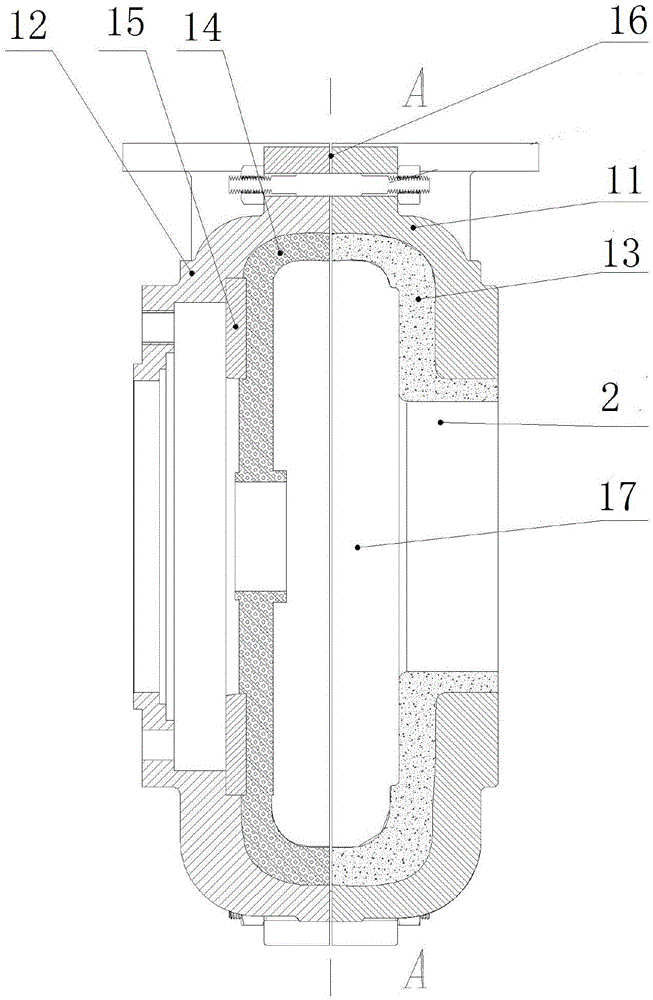

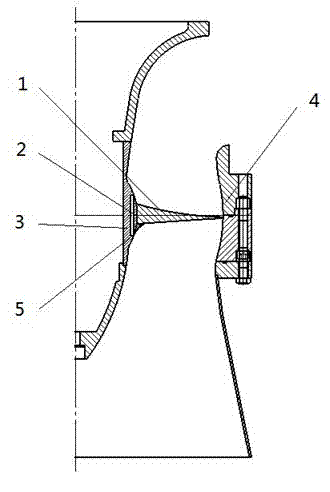

Top-level impeller on condensate extraction pump for nuclear power station

InactiveCN102116311AReduce NPSHImprove anti-cavitation performancePump componentsPumpsImpellerCavitation

The invention discloses a top-level impeller on a condensate extraction pump for a nuclear power station, which comprises a hub, a front cover plate, a rear cover plate and a plurality of blades, wherein the inner end surface of the hub is a cylindrical surface, and the outer end surface of the hub is formed by connecting two sections of trumpet-shaped curved surfaces which are in the same shape and have the same size back to back; the front cover plate and the rear cover plate are trumpet-shaped curved plates which are in the same shape and have the same size; the inner end surface of the front cover plate and the rear cover plate are formed by sequentially connecting a small section of straight surface, a section of first curved surface of which the curvature radius is R1 and a second curved surface of which the curvature radius is R2; the R2 is more than R1; the front cover plate and the rear cover plate are coaxially arranged at the periphery of the hub back to back to ensure that the inlet diameter and the outlet diameter of the top-level impeller are the same as each other; the front edge and the rear edge of each blade are connected on the inner end surfaces of the front cover plate and the rear cover plate respectively; and a V-shaped inner edge formed in the middle of each blade is connected on the outer end surface of the hub to form a double-suction impeller. The top-level impeller can reduce necessary net positive suction head of a small pump and has higher cavitation resistance.

Owner:SHANGHAI APOLLO MACHINERY

High-damping and high-performance alloy cylinder sleeve and preparation technology thereof

ActiveCN105821294AHigh damping characteristicsReduce vibrationCylinder headsCylindersCavitationAlloy coating

The invention discloses a high-damping and high-performance alloy cylinder sleeve and a preparation technology thereof. The high-damping and high-performance alloy cylinder sleeve comprises a cylinder sleeve body and a zinc-aluminum high-damping alloy coating sprayed to the outer wall of a cylinder sleeve body. The thickness of the zinc-aluminum alloy coating is 0.3-1 mm. The cylinder sleeve body comprises, by weight, 3.2-3.5% of C, 2.8-3.3% of Si, 0-0.02% of P, 0-0.01% of S, 3.0-4.0% of Cu, 1.5-2.0% of Mn, 0.4-0.6% of Ni, 0.04-0.08% of Mg, 0.02-0.05% of Ce, and the balance Fe. The nodular cast iron cylinder sleeve obtained through the formula and preparation technology has high damping characteristics, vibration and noise of the engine cylinder sleeve can be effectively reduced, and a wearing surface on the inner wall of the cylinder sleeve has good wear resistance and anti-attrition performance, and the outer wall of the cylinder sleeves has the advantages of being high in strength, good in plasticity, good in corrosion resistance and anti-cavitation ability, short in run-in period with pistons and the like.

Owner:ZYNP GRP

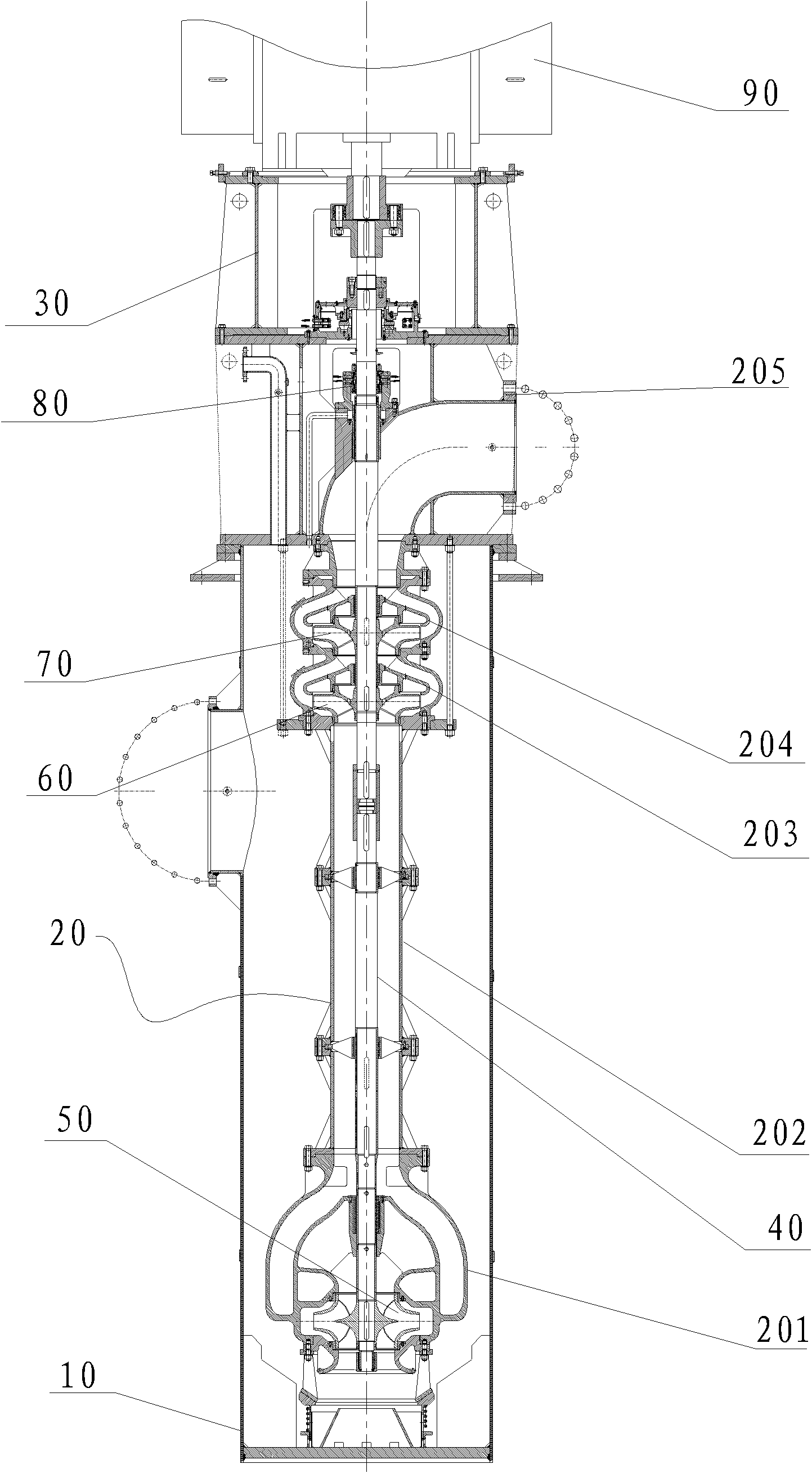

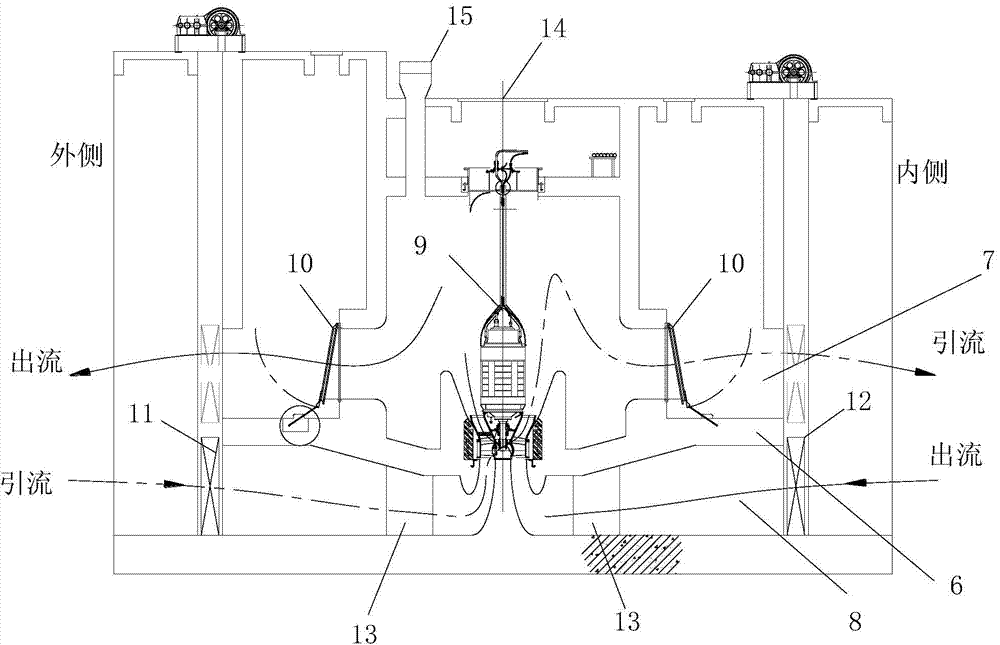

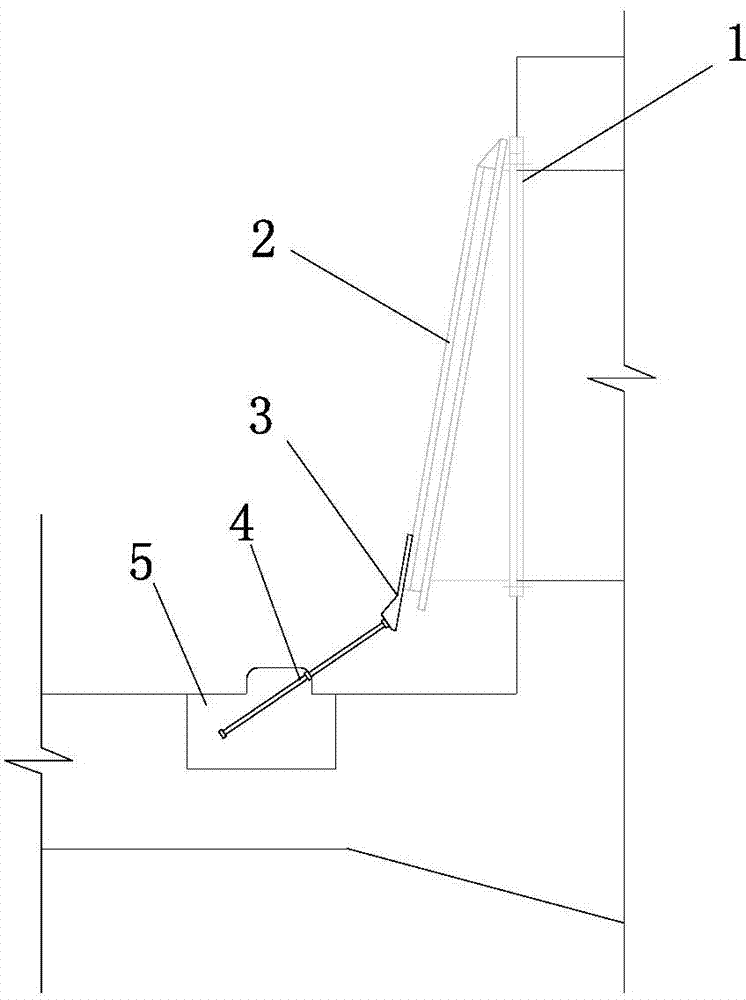

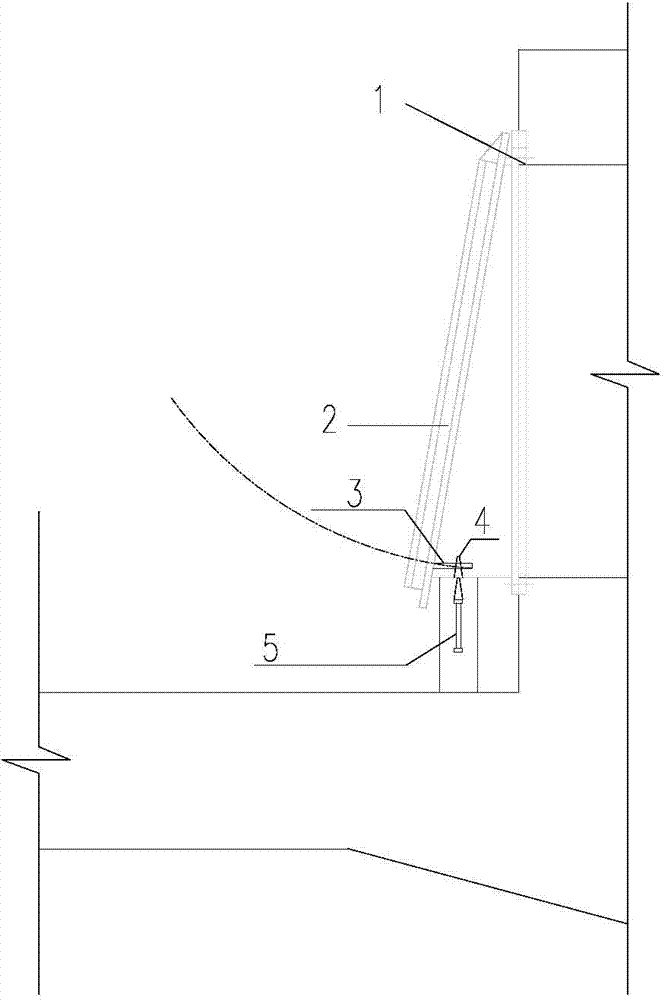

Double-layer bidirectional flow passage system of vertical submersible axial-flow pump

ActiveCN104500455ASubmerged wellImprove pumping efficiencyPump componentsPump controlAxial-flow pumpEngineering

The invention discloses a double-layer bidirectional flow passage system of a vertical submersible axial-flow pump. The double-layer bidirectional flow passage system comprises a support, an upper layer flow passage and a lower layer flow passage; the upper layer flow passage is located above the support; the lower layer flow passage is located below the support; the upper layer flow passage comprises an upper outflow passage and an upper drainage passage; the lower layer flow passage comprises a lower outflow passage and a lower drainage passage; the upper outflow passage and the lower outflow passage are oppositely arranged left and right as well as the upper drainage passage and the lower drainage passage; the middle part of the support is provided with the vertical submersible axial-flow pump; the water inlet side of the vertical submersible axial-flow pump is communicated with the lower layer flow passage; the water outlet side of the vertical submersible axial-flow pump is communicated with the upper layer flow passage; valves are respectively arranged in the upper outflow passage and the upper drainage passage. The invention provides the double-layer bidirectional flow passage system of the vertical submersible axial-flow pump, which is high in reliability, lower in construction cost, high in applicability and high in synchronicity.

Owner:浙江省钱塘江管理局勘测设计院

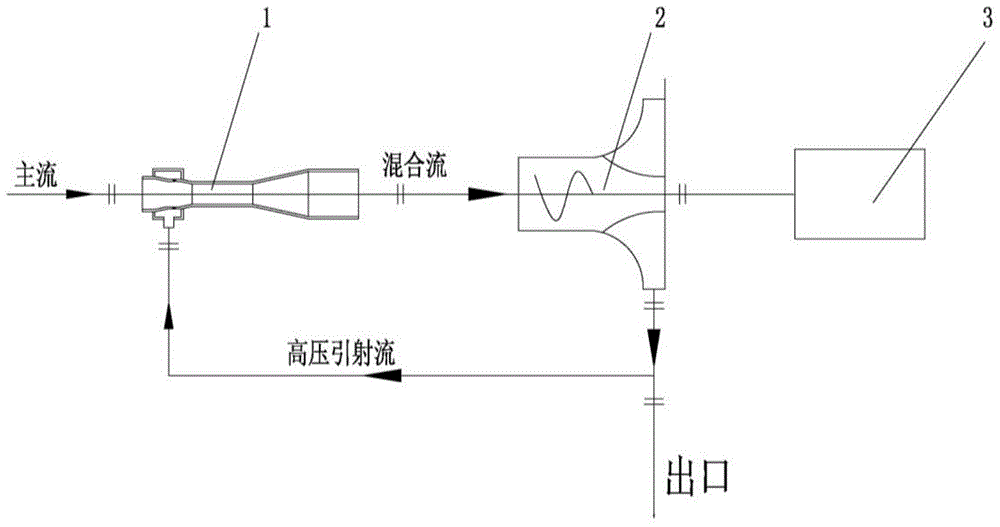

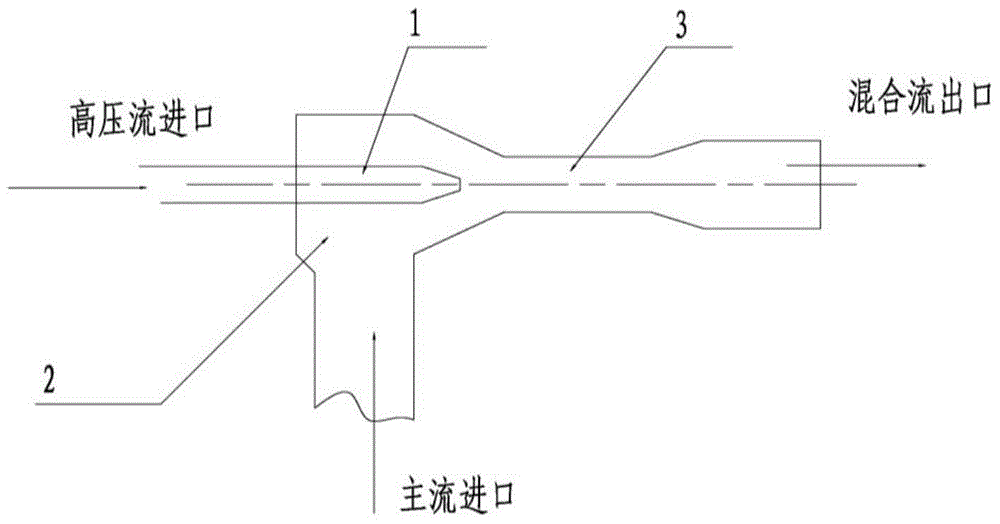

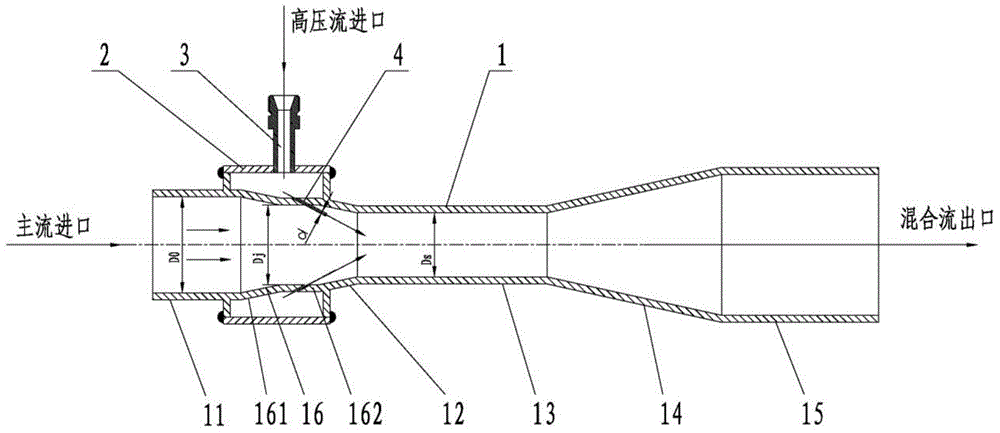

High pressure annular jet pump suitable for pumping pressure type supply system

The invention belongs to the technical field of aviation and space, and particularly relates to a high pressure annular jet pump suitable for a pumping pressure type supply system. The high pressure annular jet pump comprises an inlet section pipe, a mixing section pipe, a throat pipe, a diffusion section pipe and an outlet section pipe which are sequentially arranged in the flowing direction of main fluid. The high pressure annular jet pump is characterized by further comprising step section pipes which are sequentially arranged between the inlet section pipe and the mixing section pipe; each step section pipe comprises a convergence section pipe and a straight section pipe; each straight section pipe is provided with a spraying nozzle for providing high pressure fluid. The high pressure annular jet pump is compact in structure, light in weight, good in anti-cavitation performance and capable of meeting the requirement for normal work under the working conditions of high rotating speed and low inlet pressure.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

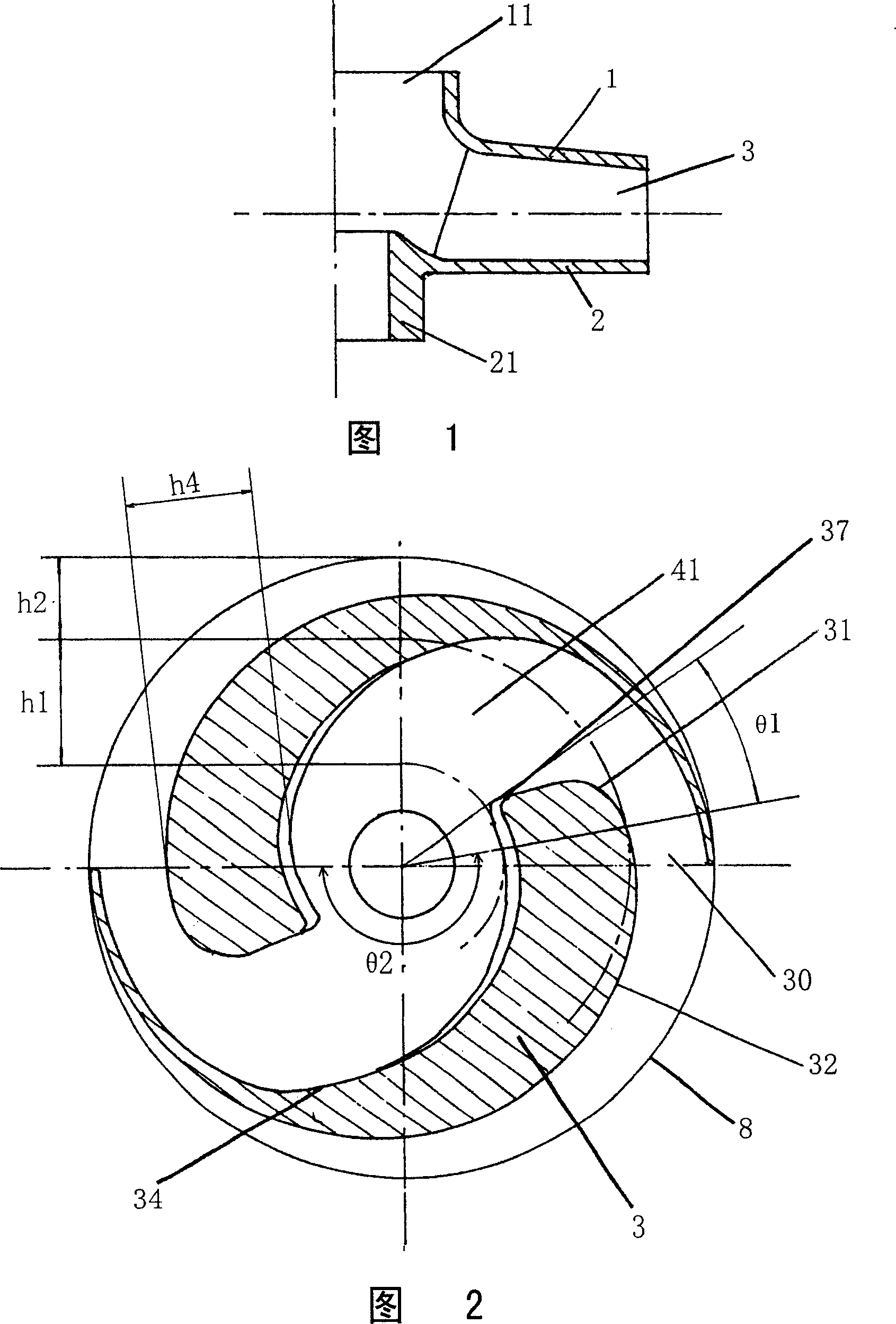

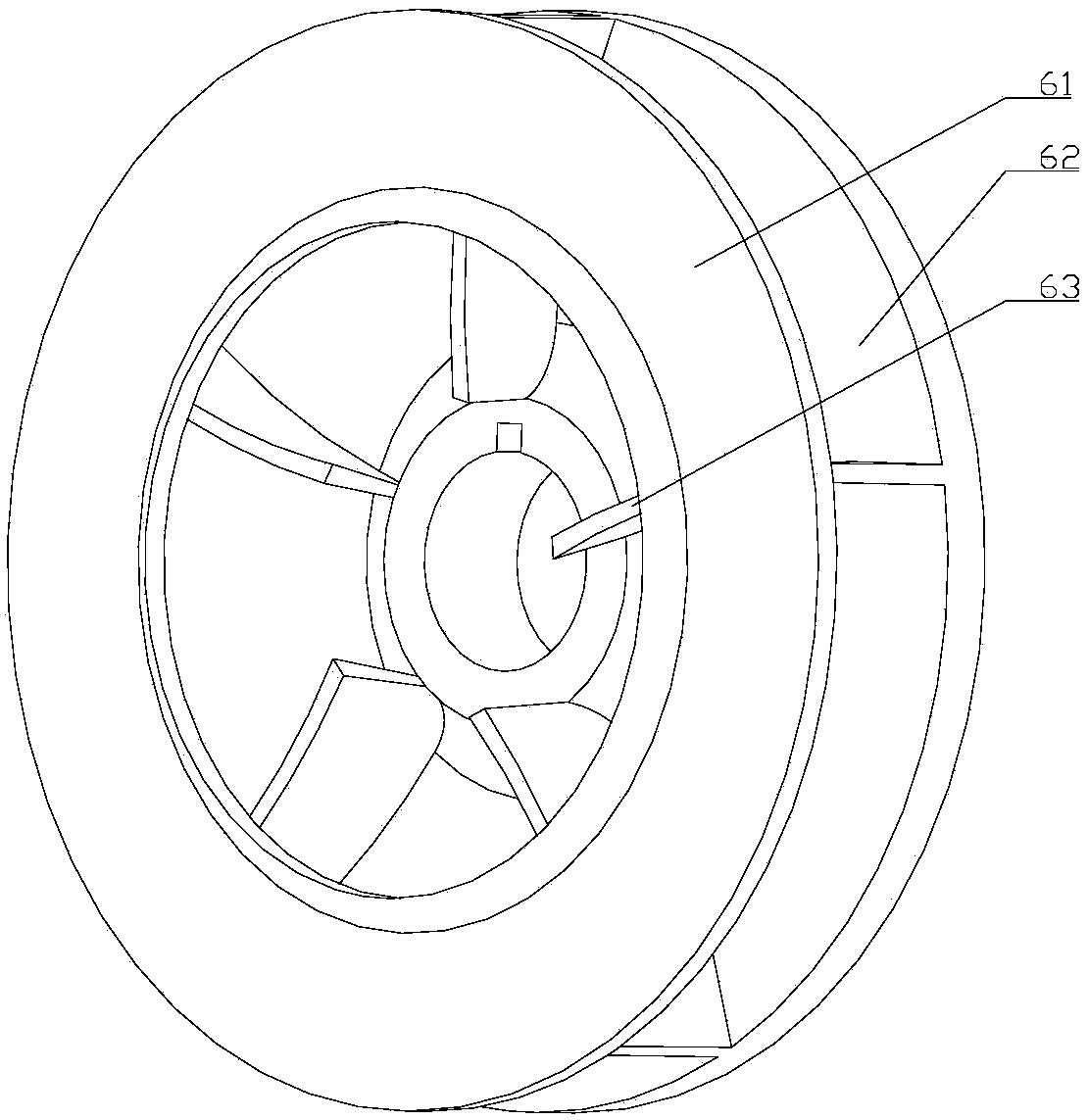

Centrifugal type fluid machine blade wheel

InactiveCN101096964AImprove efficiencyReduce squeeze frictionPump componentsPumpsImpellerEngineering

The invention discloses a centrifugal type fluid mechanical blade wheel, which is characterized by the following: comprising blade wheel inlet, boss, front shroud, back shroud and blade; possessing bigger curvature radius in the front of the face front segment of the blade; forming fore of flow passage between blade; bending the rear segment of the face front segment toward back; connecting to one integral with the face front segment of the blade; making the rear section of the flow passage between blade; possessing outlet along tangent direction near the blade wheel; displaying circumferential arc state near the blade wheel; forming a transition space from the outlet of the blade wheel to the rear end of the blade. This invention can increase the efficiency of the blade wheel.

Owner:高其海

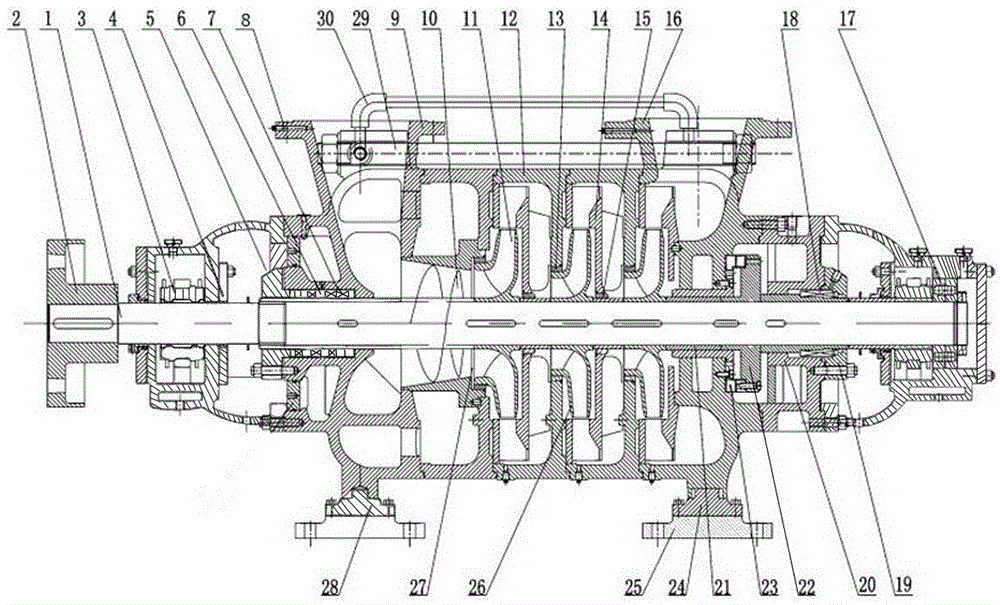

Horizontal multi-stage centrifugal pump

InactiveCN106089728AImprove working conditionsImprove sealingPump componentsRadial flow pumpsCouplingEngineering

The invention discloses a horizontal multi-stage centrifugal pump. The horizontal multi-stage centrifugal pump comprises a pump body; a pump shaft is mounted in the pump body, and is connected with a prime mover through a coupling; the pump body includes a sucking section, a pumping section and a pumping-out section which communicate with one another in sequence; the pump shaft is inserted in the sucking section, the pumping section and the pumping-out section; a sucking port is formed in the sucking section; a discharge port is formed in the pumping-out section; the sucking port and the discharge port are both upwards arranged; an impeller is mounted on the pump shaft in the pumping section, and includes a first-grade impeller mounted on the pump shaft near the sucking section and multiple secondary-grade impellers behind the first-stage impeller; an induction wheel is mounted on the pump shaft, near the first-stage impeller, in the sucking section; guide blades are mounted on one sides, near the pumping-out section, of the secondary-grade impellers; the guide blades are fixed on the pump shaft; and the outer diameters of the later-grade guide blades are 1.1-1.15 times of the outer diameters of the previous-stage guide blades. The horizontal multi-stage centrifugal pump is the same in designed flow of all stages of impellers and different in designed lift; and the lifts of the later-stage impellers are 1.05-1.15 times of the lifts of the previous-stage impellers, so that all stages of impellers can be synchronously kept in optimal working conditions, and the efficiency is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Polyvinyl alcohol fiber-fluorine polyurethane anti-cavitation paint and preparation method thereof

The invention belongs to the technical field of paints, and relates to a polyvinyl alcohol fiber-fluorine polyurethane anti-cavitation paint and a preparation method thereof. The film forming material of the paint is fluorine-containing polyurethane, and has the advantages of high adhesive force, high toughness, weather resistance, chemical mediator resistance, temperature resistance, low surface energy, low friction property and the like. By adding the high-strength high-modulus polyvinyl alcohol fiber as the filler, the paint has the advantages of very high tensile strength and modulus, acid / alkali resistance, aging resistance, corrosion resistance, weather resistance and the like; and the effective combination of the filler and the paint film forming material can further enhance the properties of the coating. The isocyanate-grafted high-strength high-modulus polyvinyl alcohol fiber, which is prepared by carrying out grafting reaction on the hydroxyls on the surface of the high-strength high-modulus polyvinyl alcohol fiber and isocyanates, is used as the filler. The anti-cavitation coating prepared by applying the paint at normal temperature has the characteristics of easy production, simple application, light weight, erosion resistance, corrosion resistance and the like, and is mainly used for protecting propellers, pumps, valves, pipelines and the like in a cavitation environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

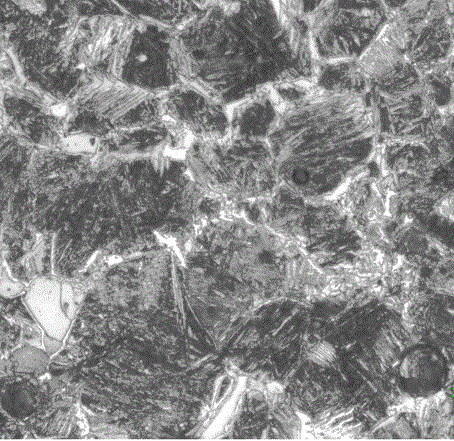

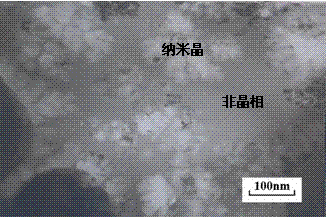

Cavitation corrosion gradient reparation coating of water pump blade and producing method thereof

ActiveCN102211428ALow costImprove anti-cavitation performanceMolten spray coatingPump componentsTotal thicknessCorrosion resistant

The invention discloses a cavitation corrosion gradient reparation coating of a water pump blade and a producing method thereof. The gradient reparation coating is produced by high-energy arc spraying, and is formed by alternatively and sequentially arranging an adhering layer and a work layer from a substrate of the water pump blade to the surface of the coating; the outmost layer is the work layer which contains amorphous and nanocrystalline; the material of the adhering layer is NiAl alloy, wherein Ni accounts for 20-80wt%; the material of the work layer is ferrous alloy; and the total thickness of the gradient reparation coating is 0.1-15mm. The method comprises the following steps of: spraying the adhering layer on the surface of the substrate of the water pump blade which is subjected to normal spraying treatment by the high-energy arc method; then continuously spraying the work layer on the surface of the adhering layer, and spraying the adhering layer on the surface of the work layer by the high-energy arc method, alternatively carrying out the step until achieving the thickness required for reparation, and finally spraying the work layer; and sealing holes on the surface of the work layer. The gradient reparation coating has excellent cavitation corrosion resistant performance.

Owner:HOHAI UNIV

Cavitation prevention slurry pump

InactiveCN105927595AExtend your lifeEasy to demouldSpecific fluid pumpsPump componentsHigh concentrationImpeller

The invention discloses a cavitation prevention slurry pump. The cavitation prevention slurry pump comprises a pump body. The pump body is provided with a suck-in opening and a discharge opening. An impeller is arranged in the pump body and provided with main blades and induction blades. The induction blades extend into the suck-in opening. The main blades and the induction blades are connected. The cross section area of the suck-in opening is 3 to 10 times of the cross section area of the discharge opening. The invention aims at providing the slurry pump which can prevent cavitation and can convey high-concentration two-phase flow or high-vapor-content three-phase flow.

Owner:GUANGZHOU TOTALL MATERIAL TECH CO LTD

Multistage deep sea mixture pump with axial force transmission structure

ActiveCN108468645AImprove performance dropImprove cavitation resistanceSpecific fluid pumpsPump componentsImpellerAxial force

The invention discloses a multistage deep sea mixture pump with an axial force transmission structure. The pump comprises a pump case. Two ends of the pump case are fixedly provided with an inlet pumpcover and an outlet pump cover. The other end of the outlet pump cover is fixedly connected with an outlet connecting pipe. The outlet pump cover is coaxially provided with an outlet bearing pedestal. The other end of the inlet pump cover is fixedly connected with an inlet connecting pipe, a bearing box, and a motor. The inlet pump cover is coaxially provided with an inlet bearing pedestal. The bearing box is internally provided with a bearing box shaft. One end of the bearing box, far away from a motor, extends into the inlet connecting pipe. The pump case is internally provided with a pumpshaft. One end of the pump shaft extends into the inlet connecting pipe and is connected with the bearing box by a shaft, and the other end of the pump shaft is in the outlet bearing pedestal. A plurality of stages of static pressure expanders are uniformly sleeved on the pump shaft along an axial direction in sequence. Ends of the pressure expanders, close to the inlet pump cover, are provided with closed impellers which are fixedly coupled with the pump shaft in a cooperated manner. A thrust collar is arranged between a first stage impeller and the inlet bearing pedestal. The pump is high inoperation efficiency under a working condition of high gas content, and the pump is easy to process and install.

Owner:XIAN UNIV OF TECH

Axial-flow type water turbine inner skirt blade rotary wheel

InactiveCN103114952AImprove anti-cavitation performanceReduce cavitation wearHydro energy generationReaction enginesAerospace engineeringCavitation

The invention relates to an axial-flow type water turbine inner skirt blade rotary wheel. The axial-flow type water turbine inner skirt blade rotary wheel comprises a curved blade and a ball-shaped pivot which connects the curved blade and the hub body, and a small gap is arranged between the hub body and the curved blade. A backpressure face of the curved blade is closed to the hub body, and a skirt with a small gap exists between the curved blade and the hub body. An effect of inhibiting gap cavitation from appearing on the surface of the blade can be achieved by increasing the skirt of one side of the blade backpressure face hub body. The axial-flow type water turbine inner skirt blade rotary wheel can prevent the blade from being damaged by gap caviation on the portion of the blade, and the portion of the blade is close to the hub body. The axial-flow type water turbine inner skirt blade rotary wheel can reduce cavitation abrasion of the blade surface, improves anti-cavitation ability of the blade and improves security and stability of operation.

Owner:HARBIN ELECTRIC MASCH CO LTD +2

Centrifugal pump impeller and LNG (Liquefied Natural Gas) immersed pump comprising same

InactiveCN108361205AEasy to be cavitatedSolve efficiency problemsSpecific fluid pumpsPump componentsEngineeringCavitation erosion

The invention belongs to the field of centrifugal pump type mechanical devices, and specifically relates to a centrifugal pump impeller. The centrifugal pump impeller comprises a front cover plate, arear cover plate, main blades and splitter blades, wherein the main blades and the splitter blades are obliquely arranged between the front cover plate and the rear cover plate; the main blades and the splitter blades are centrifugally uniformly distributed and alternatively arranged; the main blades are longer than the splitter blades; a spiral passageway is formed between every two adjacent blades; the main blades and the splitter blades gradually narrow from an inlet to an outlet. The invention also discloses an LNG (Liquefied Natural Gas) immersed pump comprising the abovementioned centrifugal pump impeller. With the adoption of the centrifugal pump impeller and the LNG immersed pump, the efficiency and the cavitation erosion performance can be improved under the condition that the flow rate and the lift of the LNG immersed pump is ensured; and meanwhile, the centrifugal pump impeller and the LNG immersed pump have the advantages of being simple in structure, convenient to process,and low in cost.

Owner:HUAZHONG UNIV OF SCI & TECH

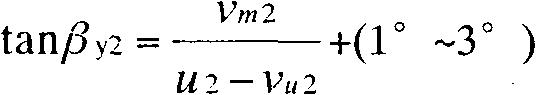

Designing method of cylindrical blade with controllable inlet setting angle

InactiveCN105134646AReduce impact hydraulic lossBoost Energy IndexPump componentsPumpsImpellerCavitation

The invention discloses a designing method of a cylindrical blade with the controllable inlet setting angle. A designing and shape drawing process of a novel cylindrical blade is given. The inlet edge of the novel blade and the blade inlet attack angle at the intersection of a front cover plate and a rear cover plate can both be given. The impact hydraulic loss at the positions of the blade inlet can be reduced through the controllable inlet setting angle, the major reason for the large hydraulic loss of a traditional cylindrical blade is eliminated, and the purpose of increasing the blade energy index is achieved. The anti-cavitation capability of the blade can be improved through the blade structure, and the application range of the cylindrical blade is enlarged. After the blade is used in an impeller with the specific speed reaching 120, a pump can still have high hydraulic efficiency.

Owner:XIHUA UNIV

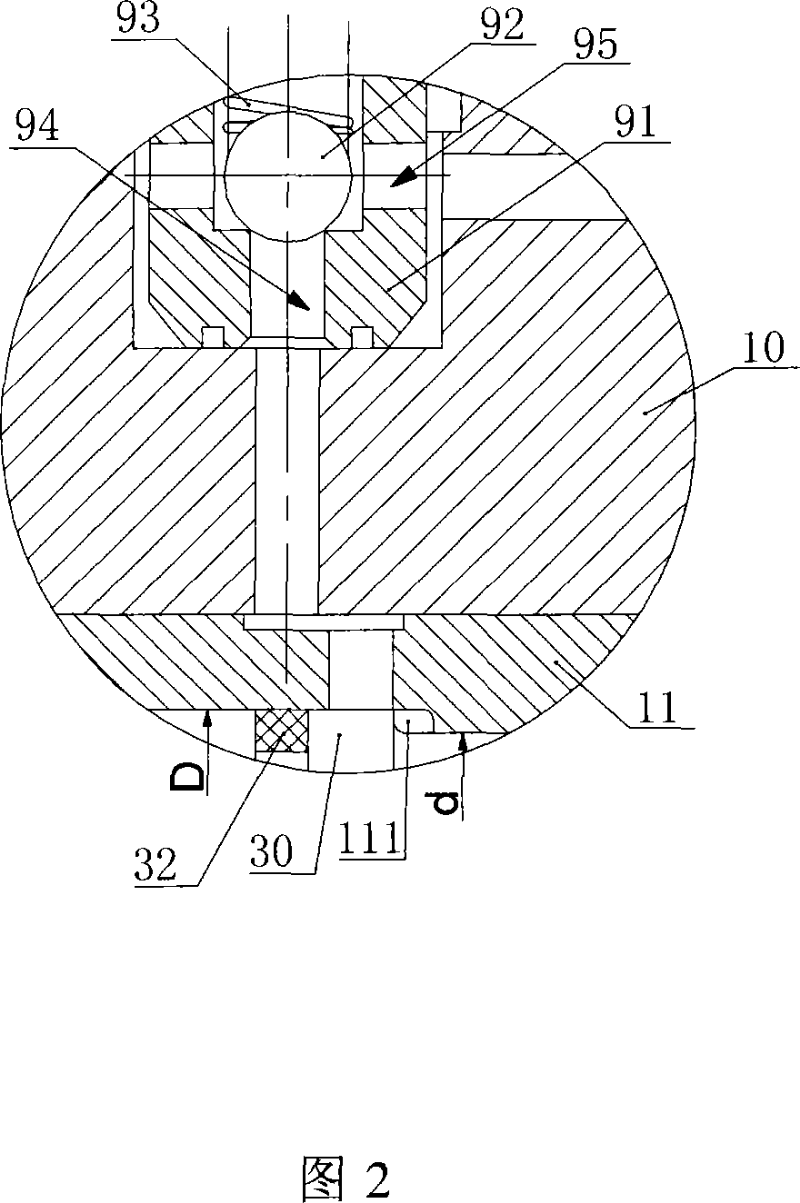

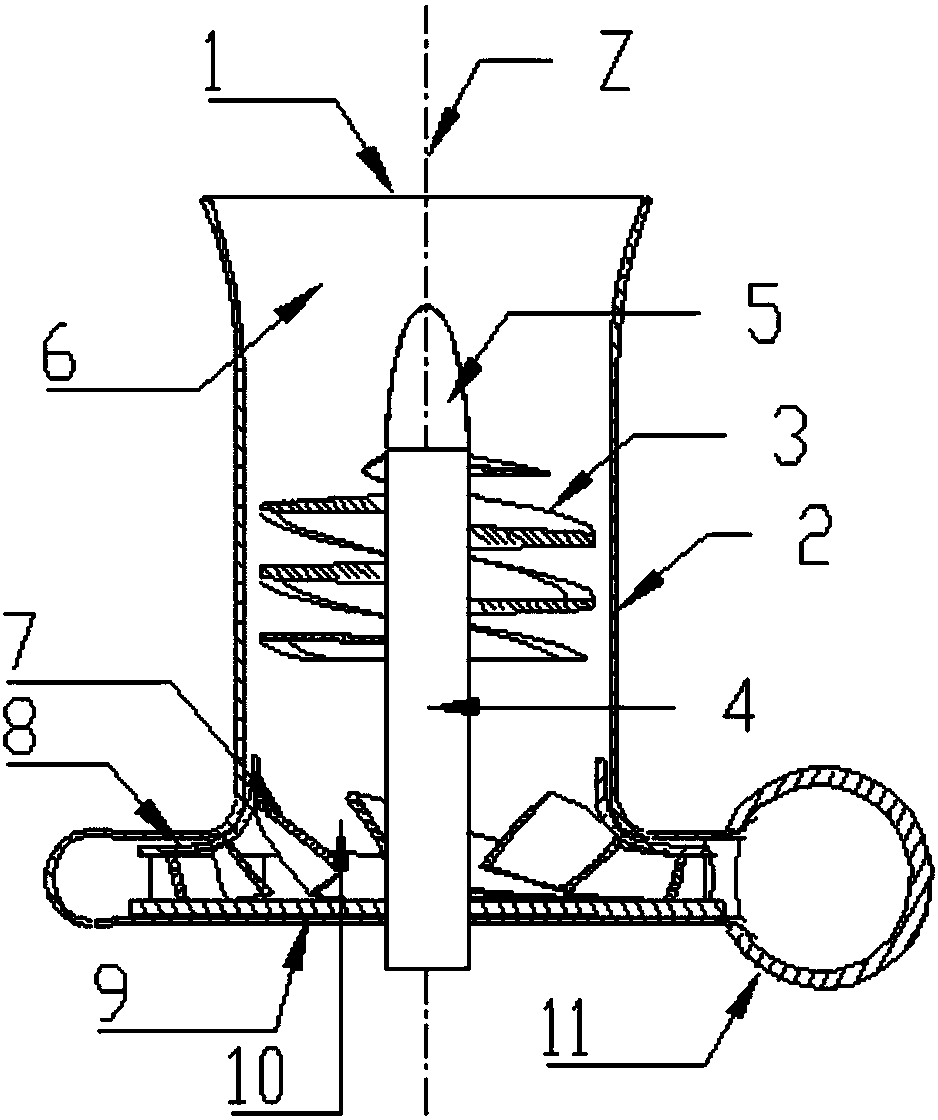

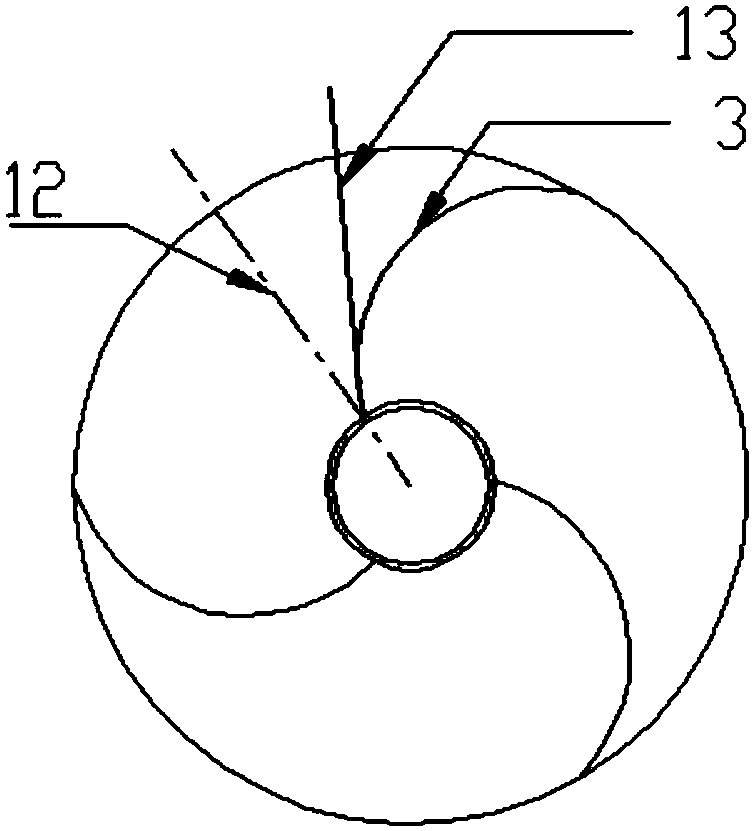

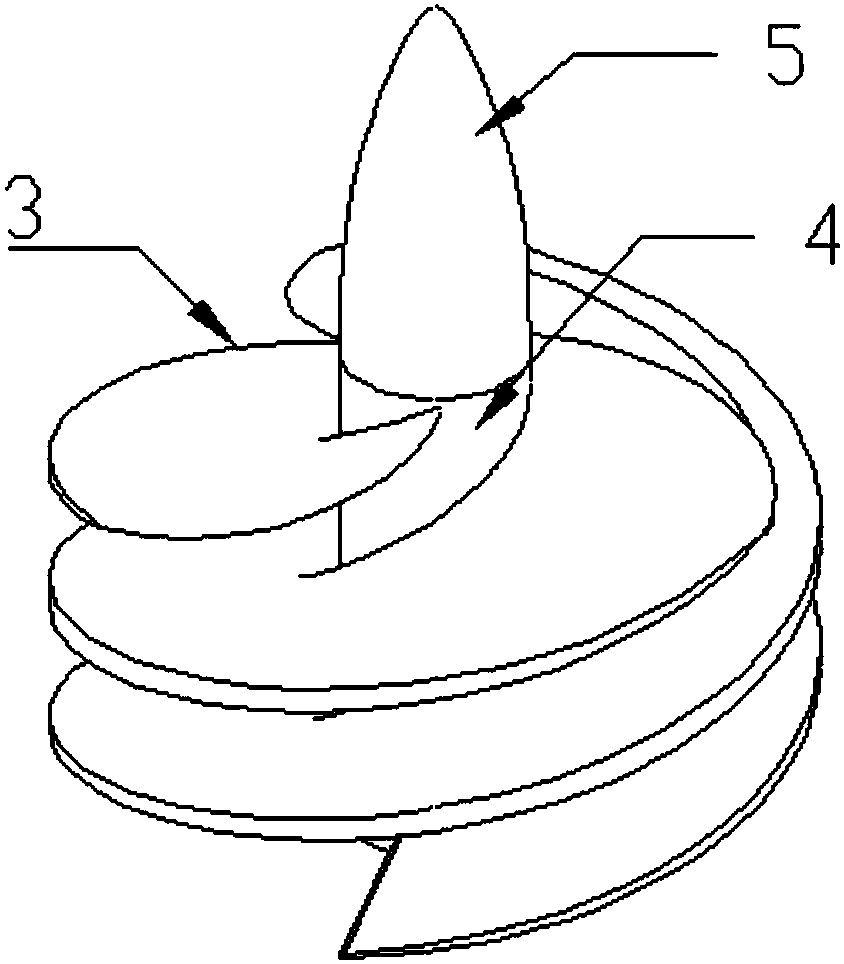

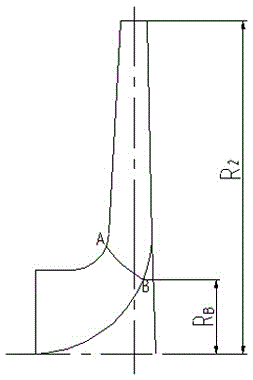

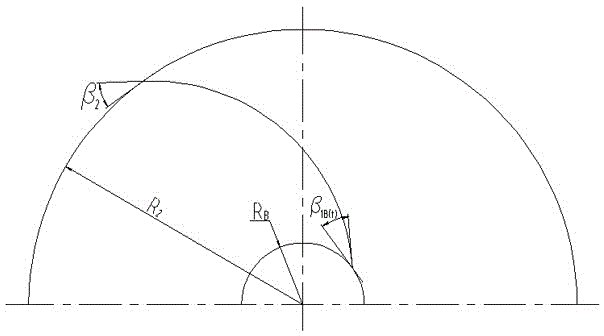

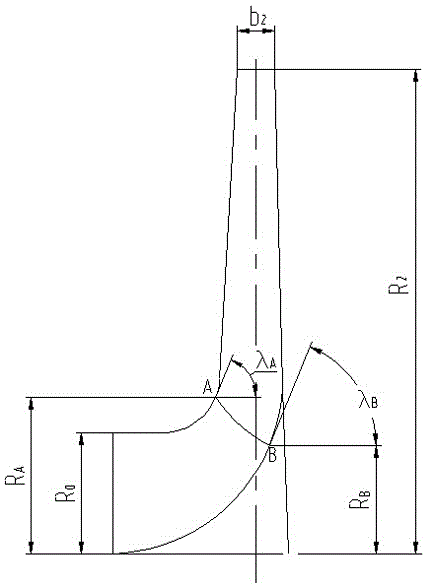

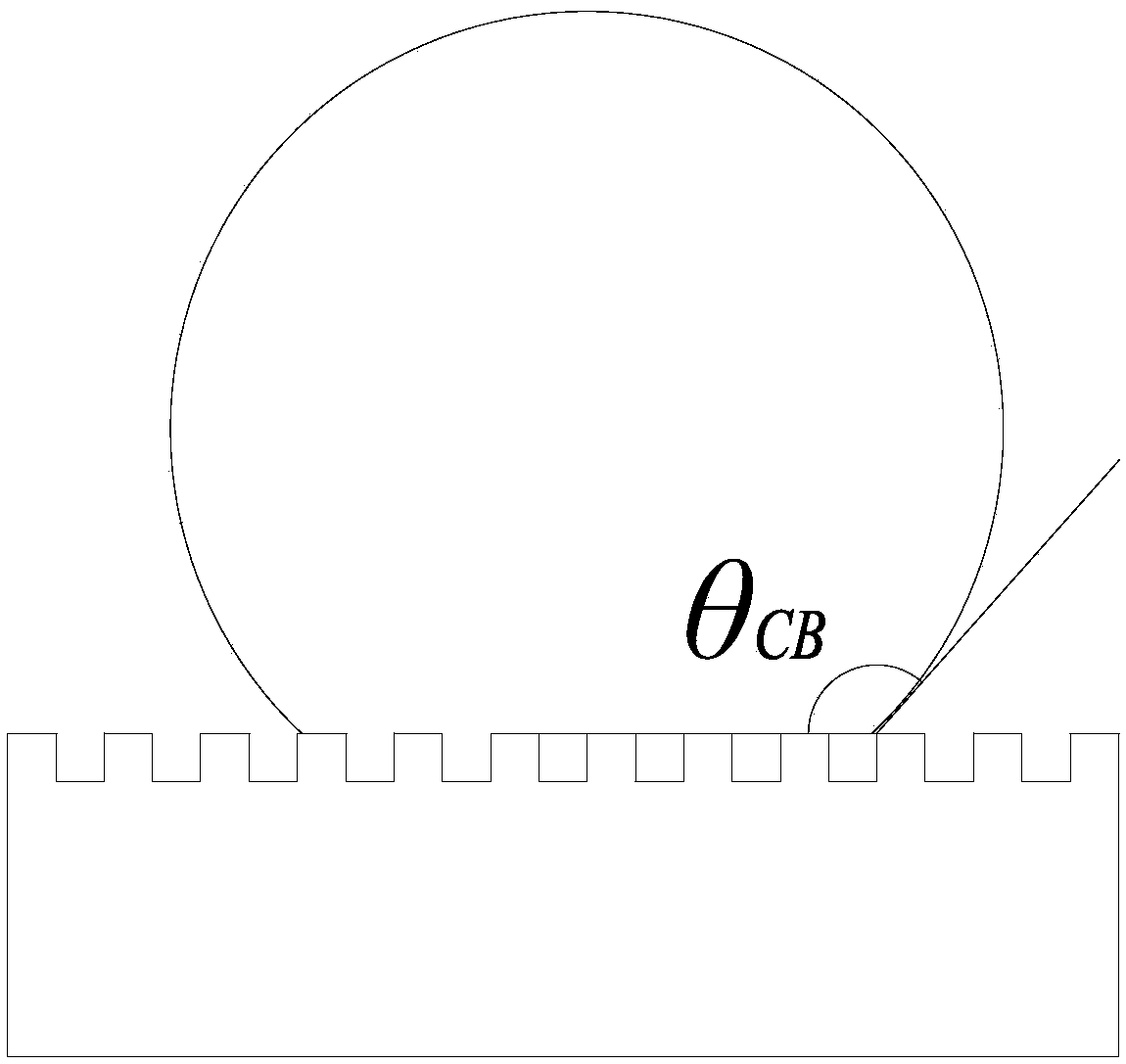

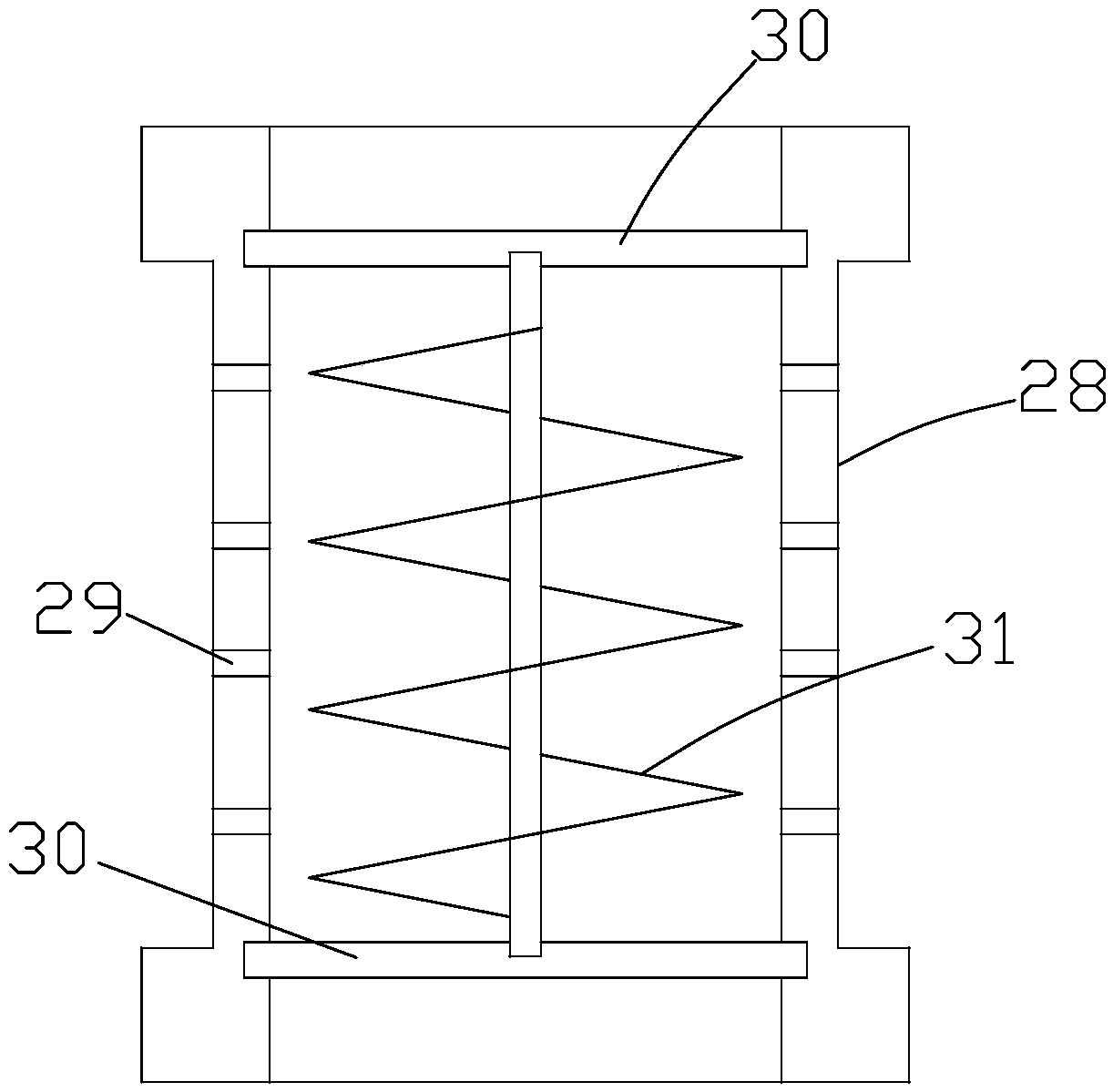

Design method for inducer with long and short blades of nuclear main pump

InactiveCN103307008AImprove anti-cavitation performanceCavitation does not occurPump componentsPumpsEngineeringBiochemistry

The invention relates to a design method for an inducer with long and short blades of a nuclear main pump. According to the design method, blades of the inducer are improved as a mode that the long and short blades are spaced on the basis of a common inducer, and the outlets of the long and short blades are positioned in the same interface, so that the characteristics of the long and short blades and the inducer are combined, and a novel inducer capable of improving the speed distribution of a liquid and improving the anti-cavitation capability of the pump can be designed.

Owner:JIANGSU UNIV

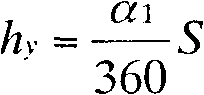

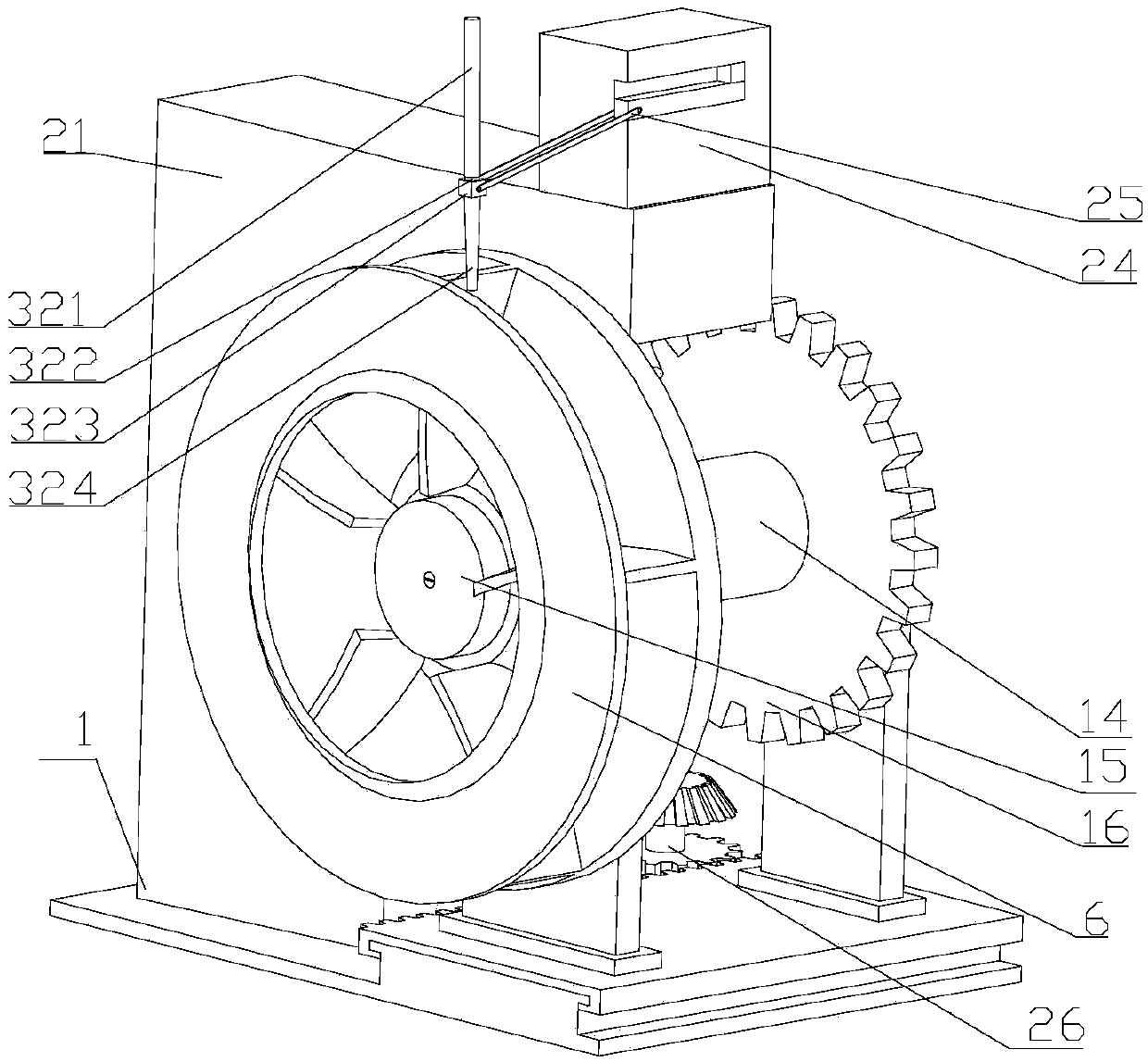

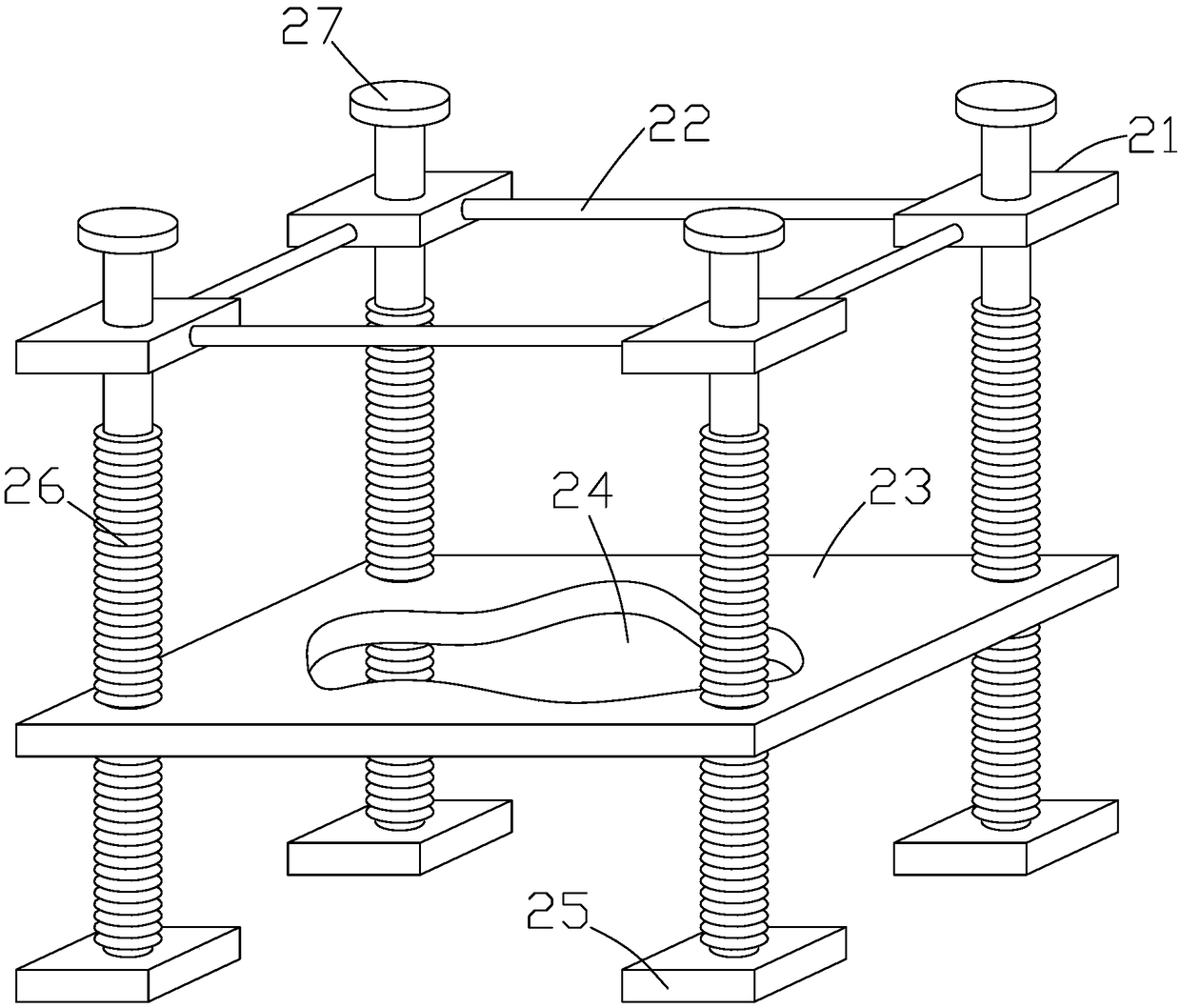

Machining equipment used for impeller with super-hydrophobic surface and impeller manufactured by machining equipment

PendingCN107617822AImprove corrosion resistanceImprove anti-icing performancePump componentsPumpsLaser etchingImpeller

The invention discloses machining equipment used for an impeller with the super-hydrophobic surface and the impeller manufactured by the machining equipment. The machining equipment comprises a fixingsupport used for clamping the impeller, driving equipment used for driving the impeller to rotate, laser etching equipment used for machining the super-hydrophobic surface on the surface of the impeller, a dust suction device used for sucking dust particles, and a controller used for controlling the whole machining process. The driving equipment is mounted on the fixing support; the laser etchingequipment is mounted on the driving equipment; a dust suction opening of the dust suction device is aligned with a working area of the fixing support; and the control end of the driving equipment, the control end of the laser etching equipment and the control end of the dust suction device are electrically connected with corresponding pins of the controller. The impeller comprises an impeller body. The impeller body comprises an impeller front cover plate, an impeller rear cover plate and a plurality of impeller blades. A plurality of grooves used for improving the surface lubricating characteristic of the impeller blades are etched in the surfaces of the impeller blades. The machining equipment has the beneficial effects that manual disturbance is avoided, detaching is convenient, and the viscous resistance and hydraulic loss of the impeller are reduced.

Owner:ZHEJIANG UNIV OF TECH

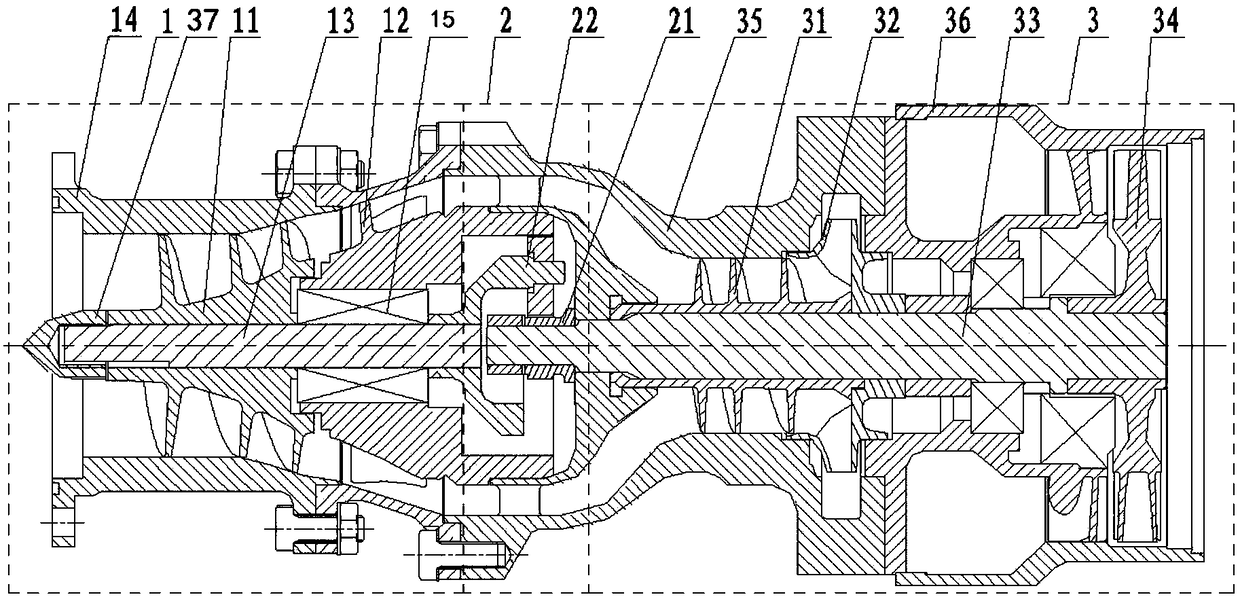

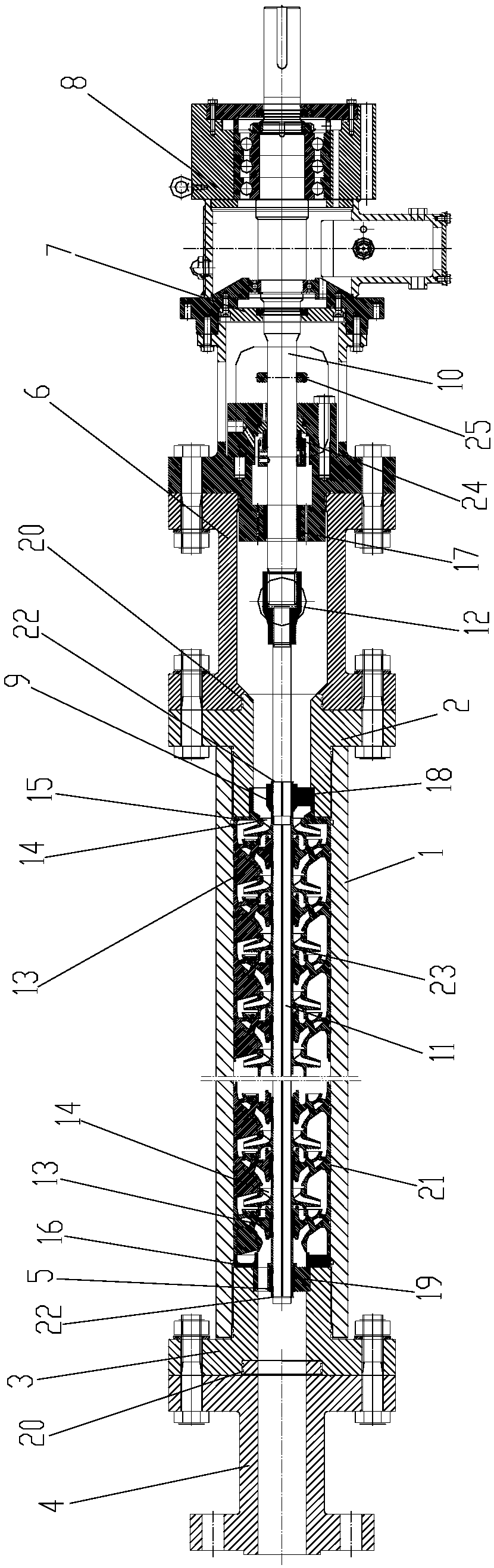

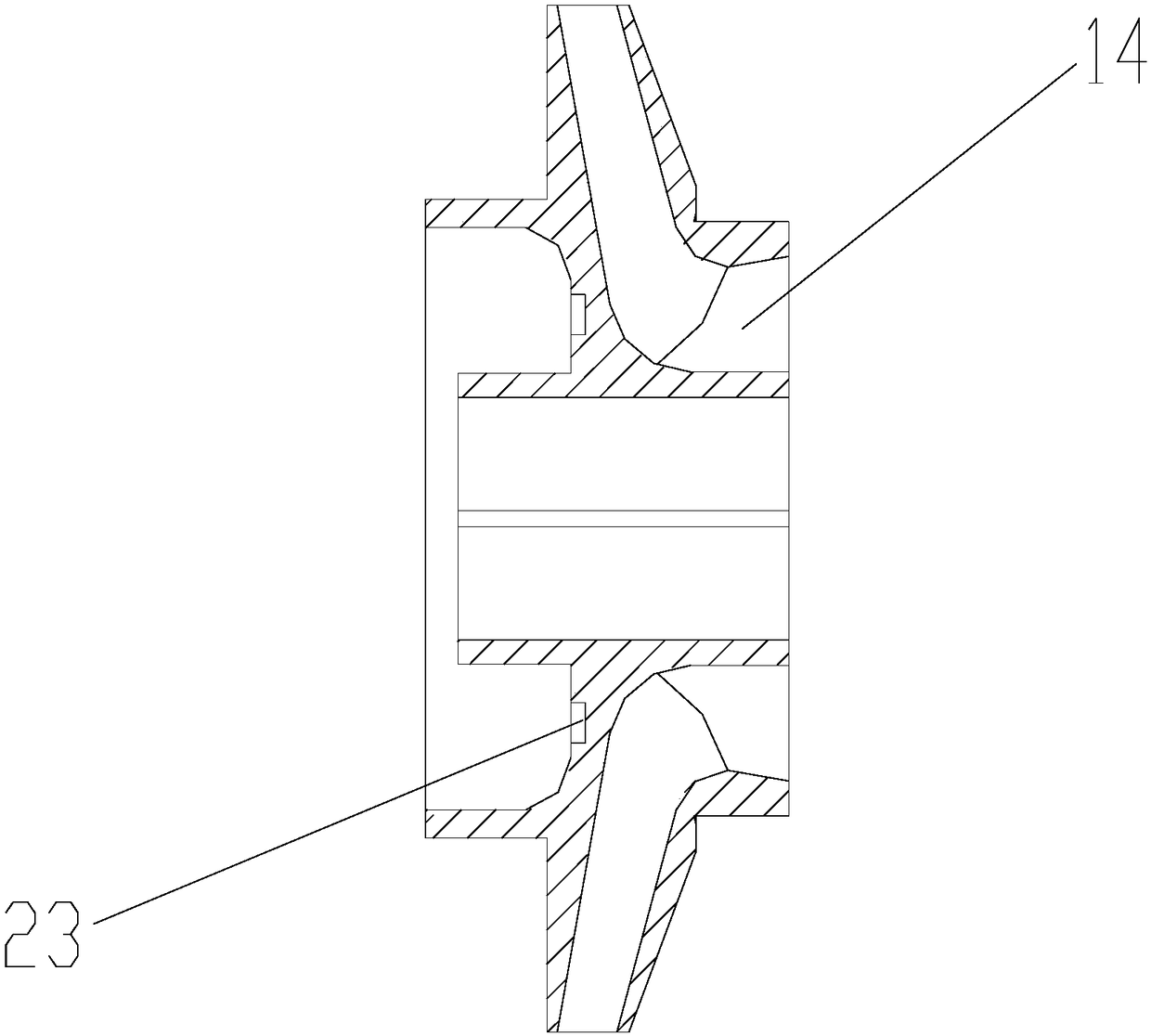

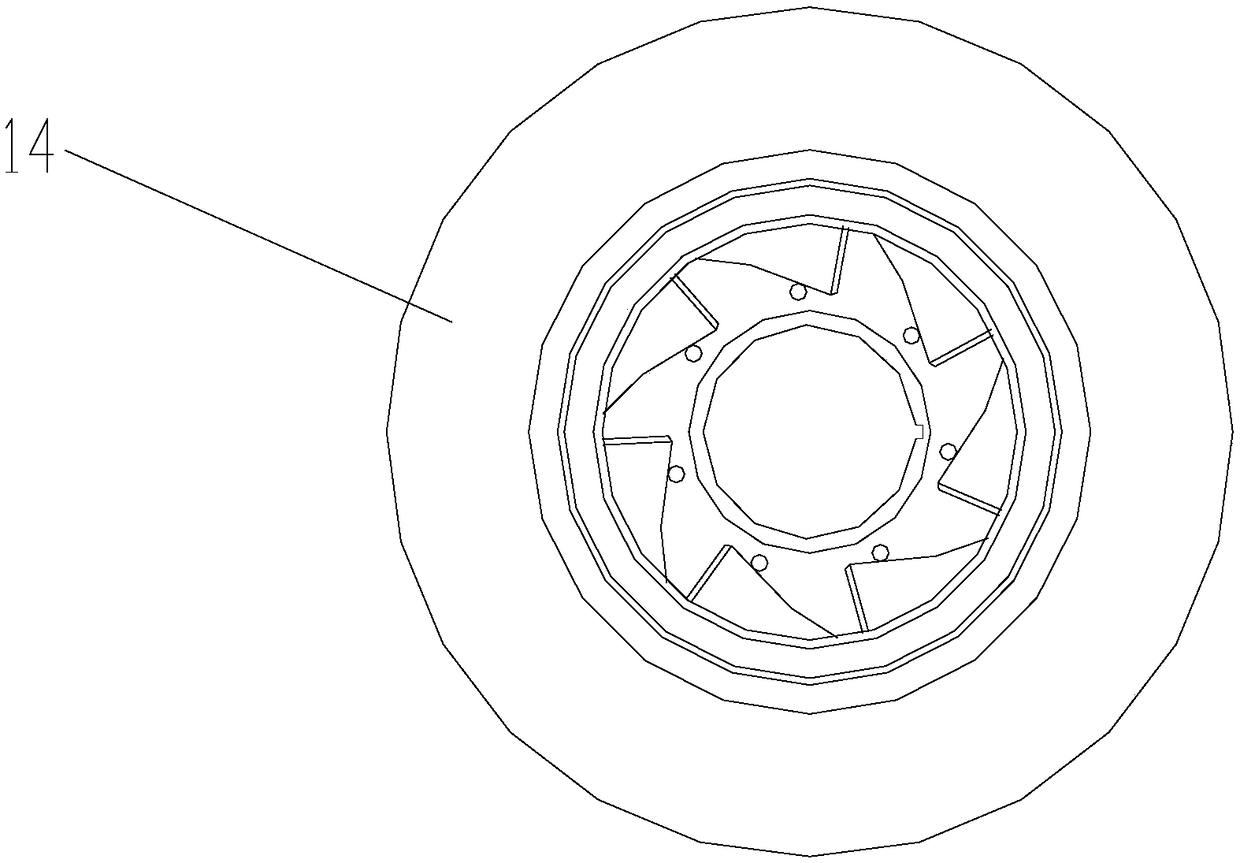

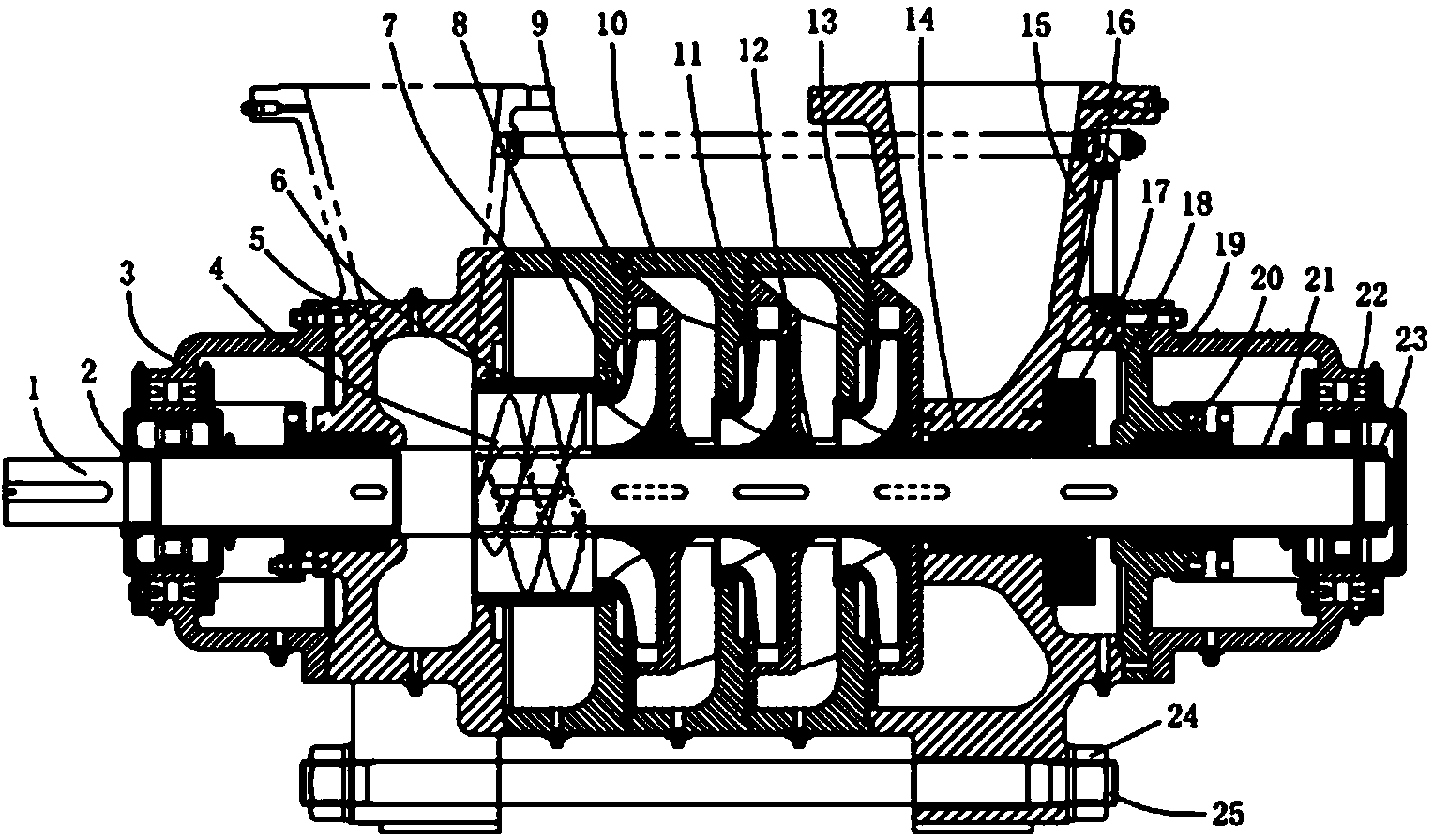

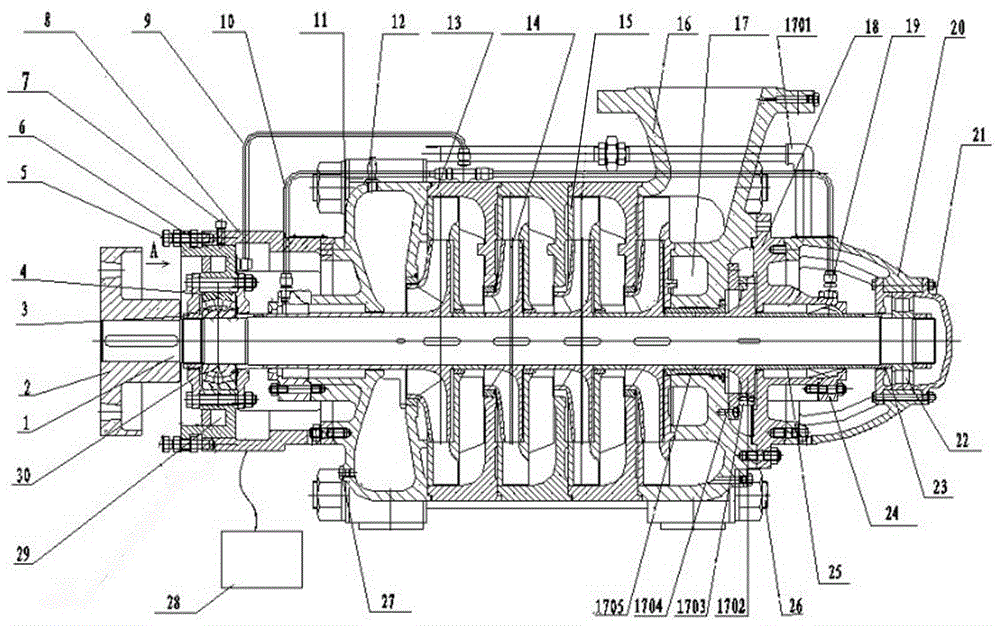

Horizontal multi-stage centrifugal pump with high cavitation resistance

InactiveCN103352876AImprove anti-cavitation performanceAvoid damagePump componentsRadial flow pumpsCavitationEngineering

A horizontal multi-stage centrifugal pump with high cavitation resistance comprises a stator component and a rotor component, wherein the stator component comprises a water inlet section, an inducer middle section, a middle section, a guide vane, a final-stage guide vane, a flow guide sealing ring, a water outlet section, a stuffing box, an equilibrium ring, a left bearing component and a right bearing component; the rotor component comprises a shaft, a first bearing locking nut, an inducer, a first-stage impeller, an impeller, an impeller spacer sleeve, a balance disc spacer sleeve, a balance disc, a shaft sleeve, a bearing spacer sleeve, a bearing and a second bearing locking nut; the rotor component is fixed through the bearing locking nuts at the two ends; the inducer matched with the first-stage impeller is equipped in front of the first-stage impeller; the inducer and the first-stage impeller are fixed on the shaft and is connected with the shaft through keys for transmission; the first bearing locking nut and the second bearing locking nut close to two ends are fixed in the axial direction; the flow guide sealing ring has a function of a first-stage sealing ring and is arranged on the outer side of the inducer; and the two ends of the flow guide sealing ring are fixed at the inducer middle section and the water inlet section respectively.

Owner:SHANGHAI FIRST PUMP WORKS

Hydrogenorator with water lubricated bearing structuve

InactiveCN1483945AReduce friction lossImprove bindingBearing componentsMachines/enginesWater flowLubrication

The present invention relates to a hydro generator with water-lubricated bearing structure, and is characterized by that the partial or all the bearings are water-bubricated elastic metal plastic tile structure, the stainless steel or copper alloy wire is coiled and laminated into the wire cake layer with a certain elastic modulus, its one surface is inlaid into 0.5-1.5 mm of plastic layer, and another surface is soldered on the tile base of the steel, and the length of water inlet wedge surface of the plastic surface is 1 / 5-1 / 3 of the circumferential length of the tile surface, the water stream can be fed into the bearing, and passed through the friction surface and flowed out so as to form lubrication.

Owner:孙晶 +1

Horizontal multi-stage pump with variable lifts

InactiveCN106122030ASame design flowImprove sealingPump componentsPump controlImpellerWater discharge

The invention discloses a horizontal multi-stage pump with variable lifts. The horizontal multi-stage pump with the variable lifts comprises a pump body. The pump body comprises a water feeding section, a water discharging section, a plurality of middle sections arranged between the water feeding section and the water discharging section, and a tail cover, wherein the water feeding section, the water discharging section, the multiple middle sections and the tail cover communicate with one another sequentially. A sucking section is provided with a sucking opening. A pumping-out section is provided with an output opening. The sucking opening and the output opening are both arranged upwards. A plurality of impellers are arranged on a pump shaft in an inner cavity of the multi-section pump body and include the first-stage impeller installed on the part, near the water feeding section, of the pump shaft, and the multiple second-stage impellers arranged at the back of the first-stage impeller. A balancing device is arranged on one side of the water discharging section of the pump body. Each middle section is internally provided with one impeller, and the number of the middle sections of the pump body is variable. A plurality of impeller installation positions are reserved on the pump shaft. The outer diameter of the later-stage impeller is larger than that of the former-stage impeller. The hub diameter of the later-stage impeller is equal to that of the former-stage impeller. The designed flow amounts of all the stages of impellers are the same, the lifts are different, it is guaranteed that all the stages of impellers can be in the best work condition at the same time, and efficiency is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

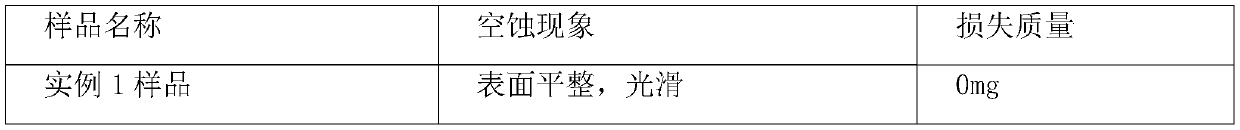

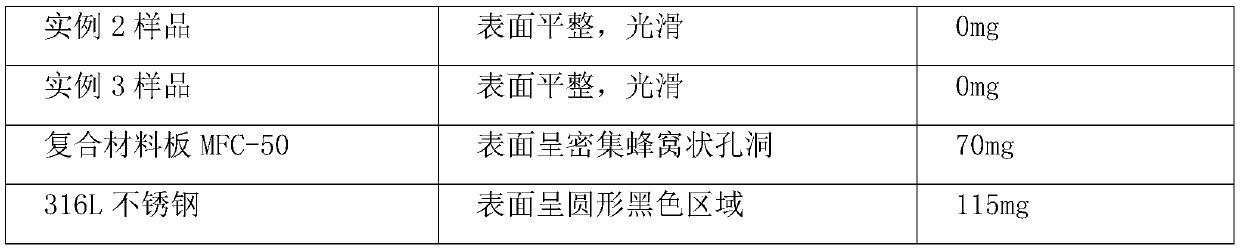

Anti-cavitation erosion polyurethane elastic layer and preparation method thereof

The invention discloses an anti-cavitation erosion polyurethane elastic layer and a preparation method thereof. Raw materials comprise the following components in parts by mass: 100 parts of isocyanate, 150-400 parts of polyether polyol, 4-50 parts of a cross-linking agent, 3-8 parts of a chain extender and 1-5 parts of a defoaming agent; the isocyanate has two isocyanate functional groups; the main chain of the polyether polyol has two hydroxyl functional groups; the cross-linking agent is a monomer or polymer with three hydroxyl functional groups; the isocyanate is diphenylmethane diisocyanate, toluene diisocynate or isophorone diisocyanate; and the polyether polyol is polytetrahydrofuran glycol, polypropylene glycol or polypropylene glycol. The anti-cavitation erosion polyurethane elastic layer has the characteristics of adjustable hardness, impact resistance, good tensile property, good environmental resistance and the like, and cavitation erosion resistance is superior to cavitation erosion resistance of composite material plate MFC-50 and 316L stainless steel according to a cavitation vibration test.

Owner:HARBIN ENG UNIV

High-speed pump with tapered inducing wheel arranged forward

InactiveCN109236677AImprove stability and reliabilityImprove securityPump componentsPump installationsImpellerEngineering

The invention discloses a high-speed pump with a tapered inducing wheel arranged forward. The high-speed pump comprises a pump body, a liquid inlet passage and a liquid outlet pipe are arranged in thepump body, and an inlet flange is communicated with the liquid inlet passage; an outlet flange is communicated with the liquid outlet pipe, a pump shaft is horizontally arranged in the pump body, andan impeller is fixedly connected with the pump shaft; a tapered passage is arranged between the liquid inlet passage and the liquid outlet pipe, the tapered inducing wheel is arranged on the pump shaft, and a gas storage cavity is formed in the tapered passage; a gas-liquid separation device is arranged in the liquid outlet pipe, and a height adjusting mechanism is arranged on the outer side of the pump body. Through the design of the tapered inducing wheel, the inlet area can be increased, cavitation can be conveniently compressed in the local area of the wheel edge, and therefore the anti-cavitation performance of the tapered inducing wheel is improved; in order to achieve the purpose that the impeller is higher in work efficiency, low in noises and stable in running, bubbles can be separated from liquid, the separated bubbles can enter into the gas storing cavity for storage through a vent groove, it is ensured that pressure exists in the pump body, and the running stability of thehigh-speed pump is improved.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

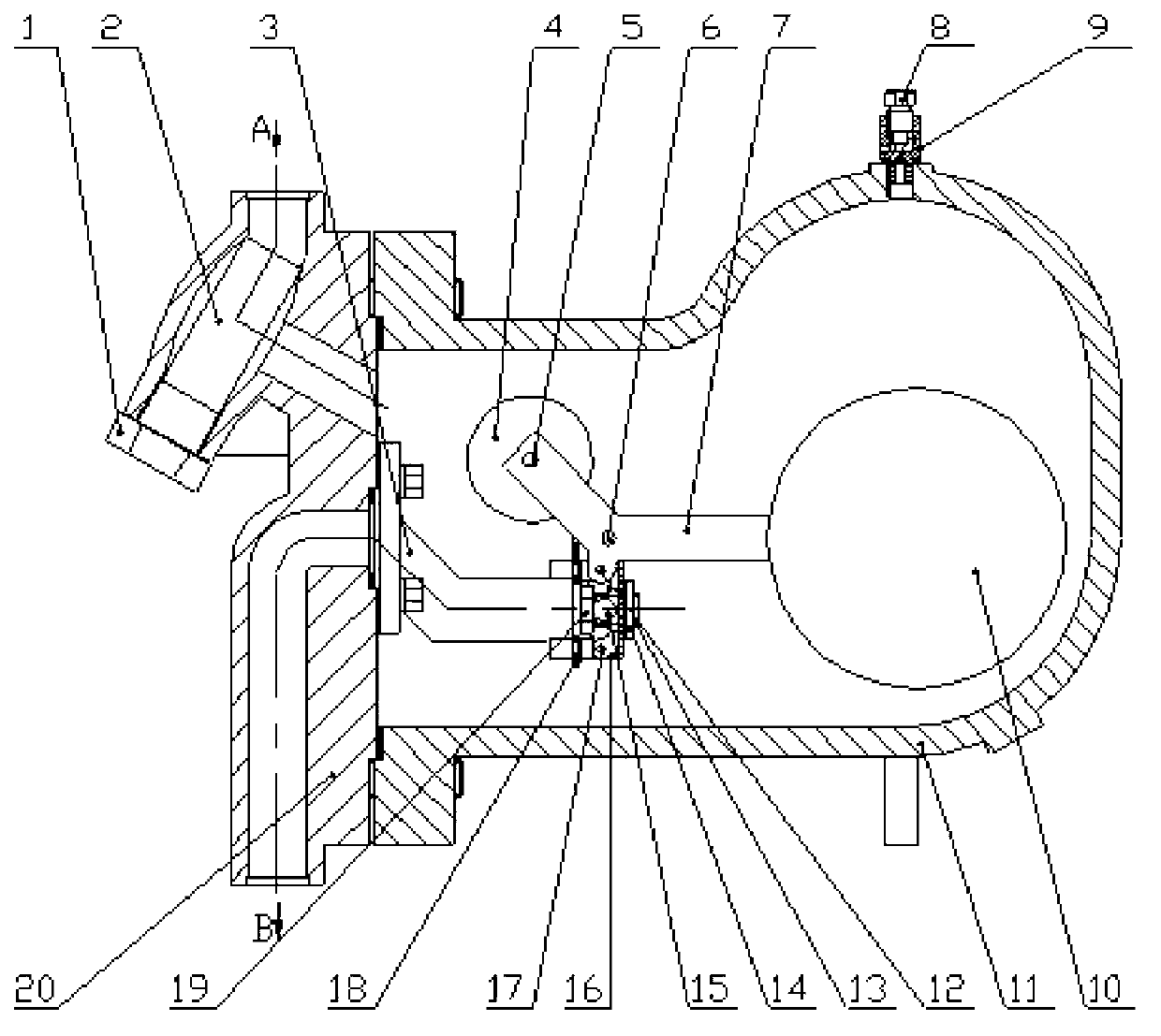

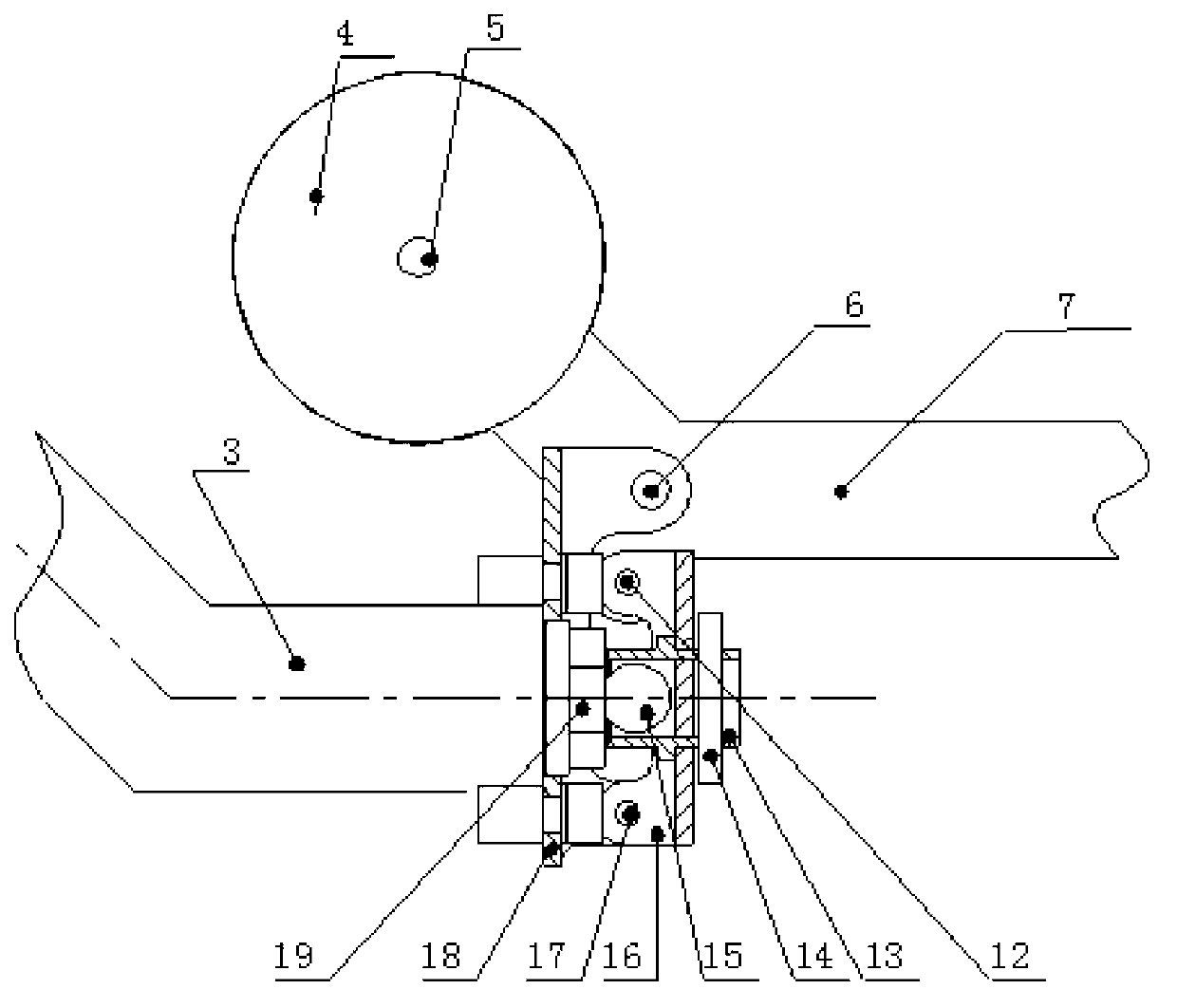

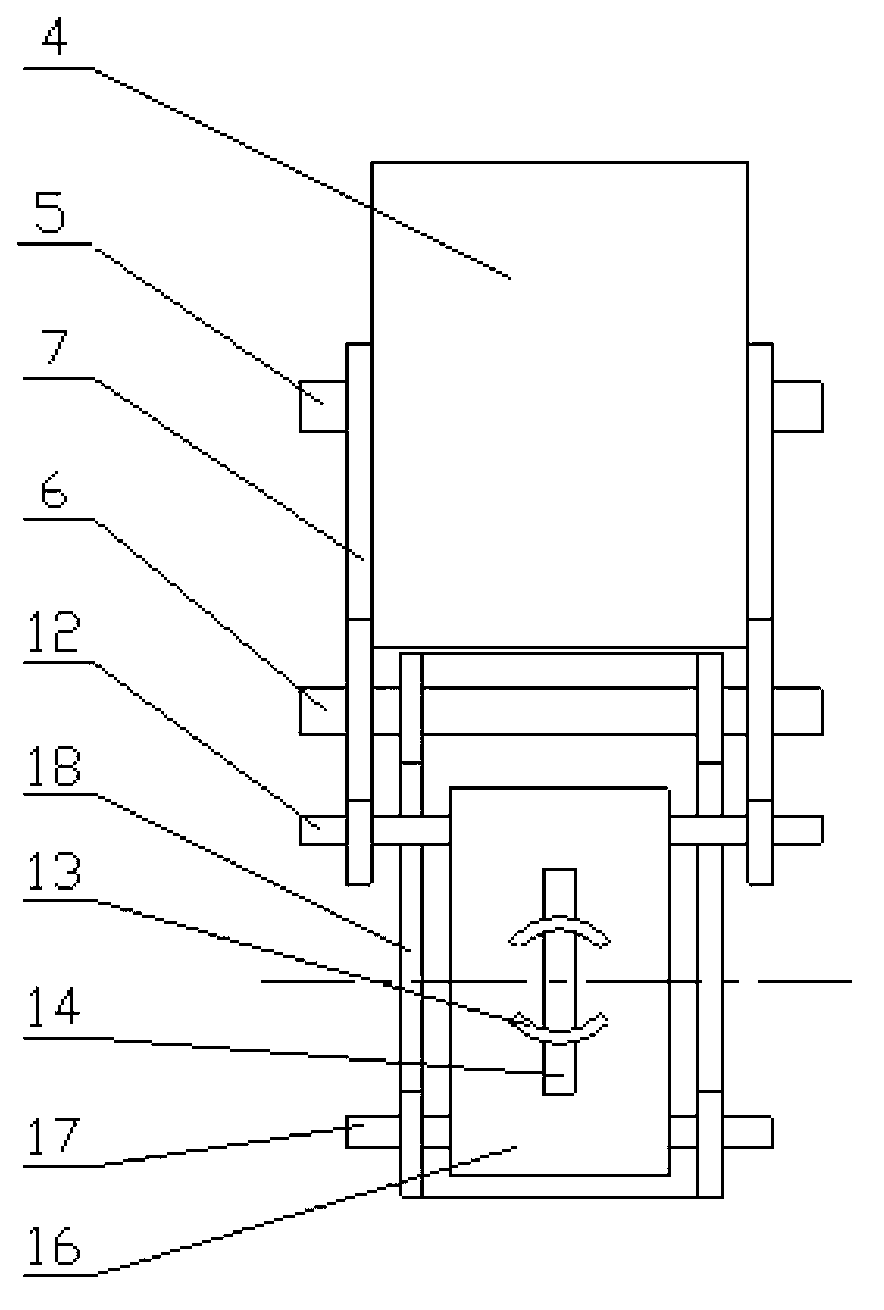

High-pressure lever ball float type steam trap

The invention discloses a high-pressure lever ball float type steam trap and aims at providing the steam trap which is free of shock motion, not limited by structure in terms of working pressure and capable of meeting vertical installation and horizontal installation and improving loading capacity of a floating ball. According to the technical scheme, a valve cover (20) is fixedly connected at an inlet end of a valve body (11) in a detachable mode, a support seat (3) is arranged on an inner side end face of the valve cover and stretches toward a valve cavity, a support (18) is fixedly connected at a free end of the support seat, an upper end shaft hole and a lower end shaft hole of the support are connected with two levels of leverages and a hollow valve ball (15) which is positioned in a ball sleeve in the middle of the support and serves as a sealing valve. The two levels of leverages take shaft holes at two ends of the support as supporting points and compose a two-level leverage collectively, and first levers (7) are connected together through a support upper end rotating shaft (6) and rotate around the rotating shaft with the rotating shaft as a fulcrum. A counter weight (4) and a floating ball (10) are respectively positioned at the two ends of a fulcrum crank support arm, and part of the gravity of the floating ball is overcome through the counter weight of the first levers.

Owner:CHENGDU KAITIAN ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com