Axial-flow type water turbine inner skirt blade rotary wheel

A hydraulic turbine and axial flow technology, applied in the field of skirt blade runners, can solve problems such as deterioration of hydraulic performance parameters of hydraulic turbines, affecting safe operation of hydraulic turbines, mechanical vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

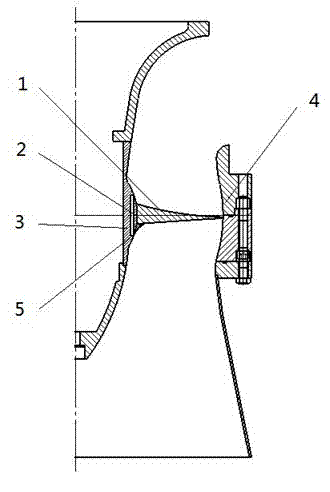

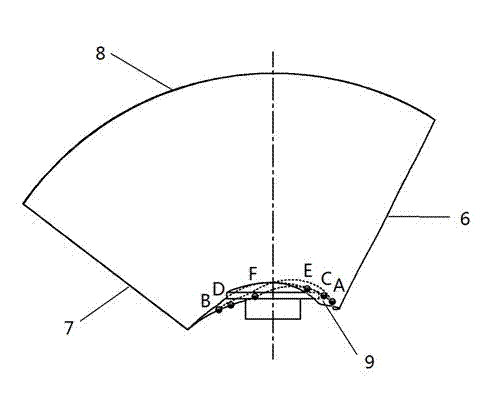

[0015] Such as figure 1 , figure 2 As shown, an axial flow turbine blade that minimizes the cavitation wear of the axial flow turbine blade due to cavitation in the gap, prolongs the service life of the blade, and improves the operation stability, including a connecting curved surface blade 1, a spherical pivot 2, The hub 3, the rim 4, the skirt 5, the blade 1 has 4 peripheral parts, namely the water inlet edge 6, the water outlet edge 7, the outer side 8 of the blade near the rim 4 and the inner side 9 of the blade near the hub 3, connecting curved surfaces There is a small gap between the blade 1 and the hub 3 , and the back pressure surface of the curved blade 1 is close to the hub 3 and has a small gap with the hub 3 .

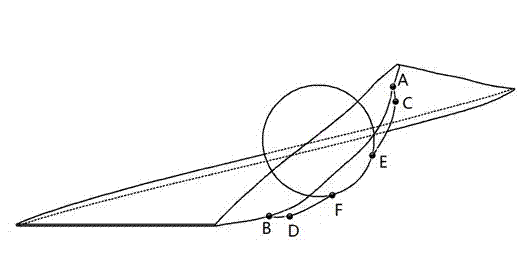

[0016] The definition of blade-related points and their characteristics are as follows: figure 2 , image 3 Shown: Point A is the connection point between skirt 5 and blade 1 near the water inlet side 6 of the blade, point B is the connection point be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com