Horizontal multi-stage pump with variable lifts

A multi-stage pump, variable technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problems that the impellers of all stages cannot be positioned at the same time, the flow loss is different, and the suction performance is poor, so as to achieve simple structure , increase the service life, easy to manufacture and maintain the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

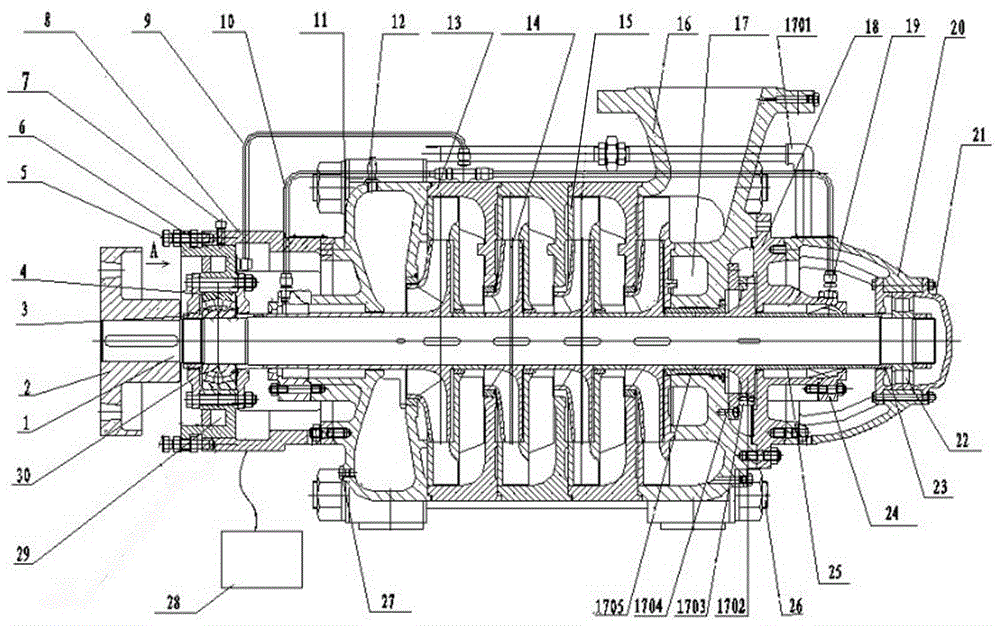

[0017] as attached figure 1 As shown, a horizontal multistage pump with a variable head design includes a pump body, a pump shaft 1 is installed in the pump body, and the two ends of the pump shaft 1 are respectively installed on the water inlet end bearing 4 and the water outlet end bearing 22, the pump A shaft coupling 2 is installed at the connecting end of the shaft 1 and the output shaft of the motor, and the pump body includes a water inlet section 11, a water outlet section 16 connected in sequence, a plurality of middle sections 13 and a tail section arranged between the water inlet section 11 and the water outlet section 16. Composed of cover 18, the pump shaft 1 is installed in the water inlet section 11, the middle section 13, the water outlet section 16 and the tail cover 18, the water inlet section 11 is provided with a suction port, and the water outlet section 16 is provided with a discharge port, the suction port and the discharge port are both Set upwards, mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com