High-speed pump with tapered inducing wheel arranged forward

A technology of inducer and high-speed pump, which is applied to the components, pump, pump device, etc. of the pumping device for elastic fluid, can solve the problem of affecting the operation stability of high-speed pump, the decline of pump suction performance, and the low anti-cavitation performance, etc. problems, to achieve the effect of increasing the scope of use, reducing cavitation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

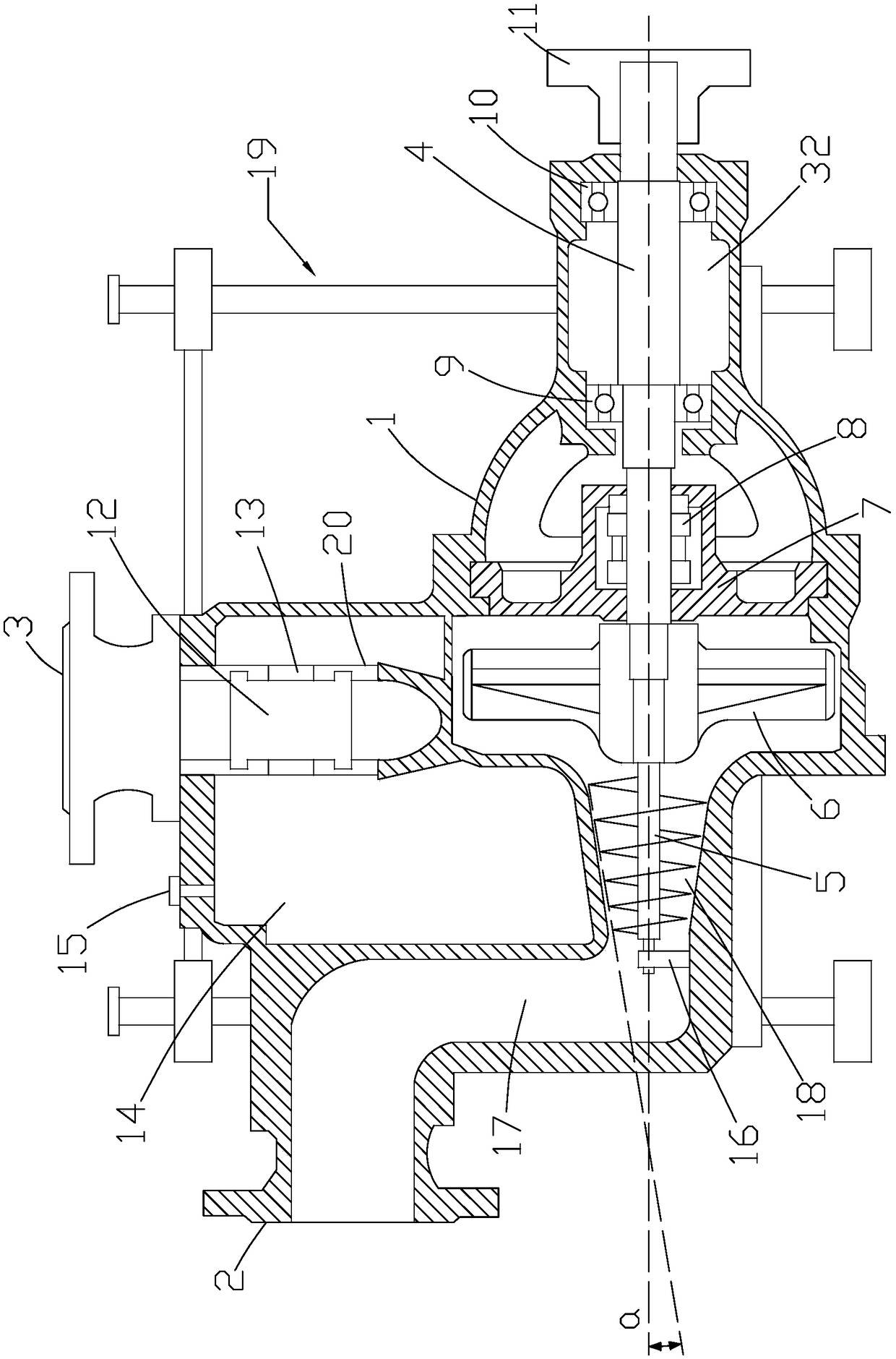

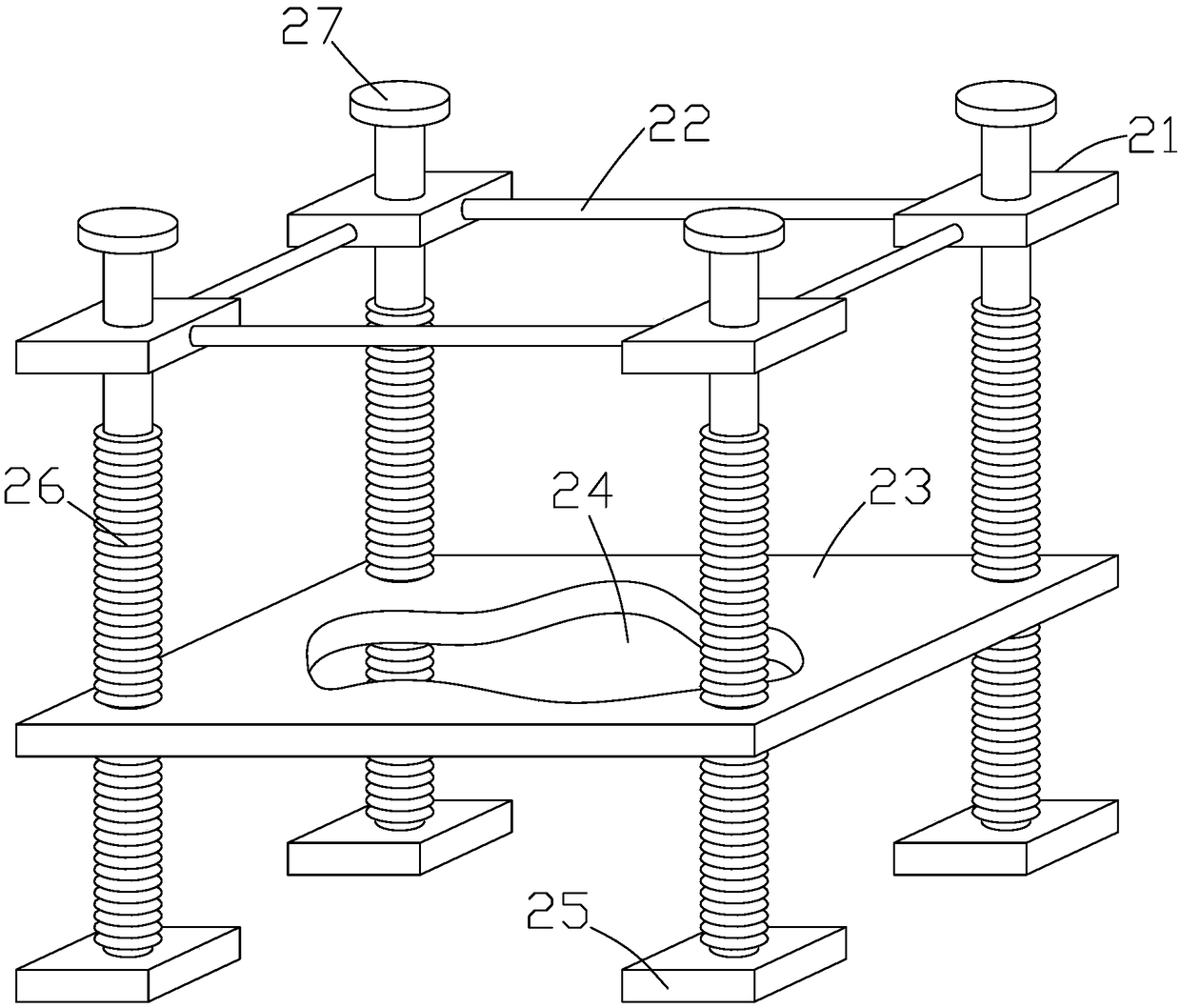

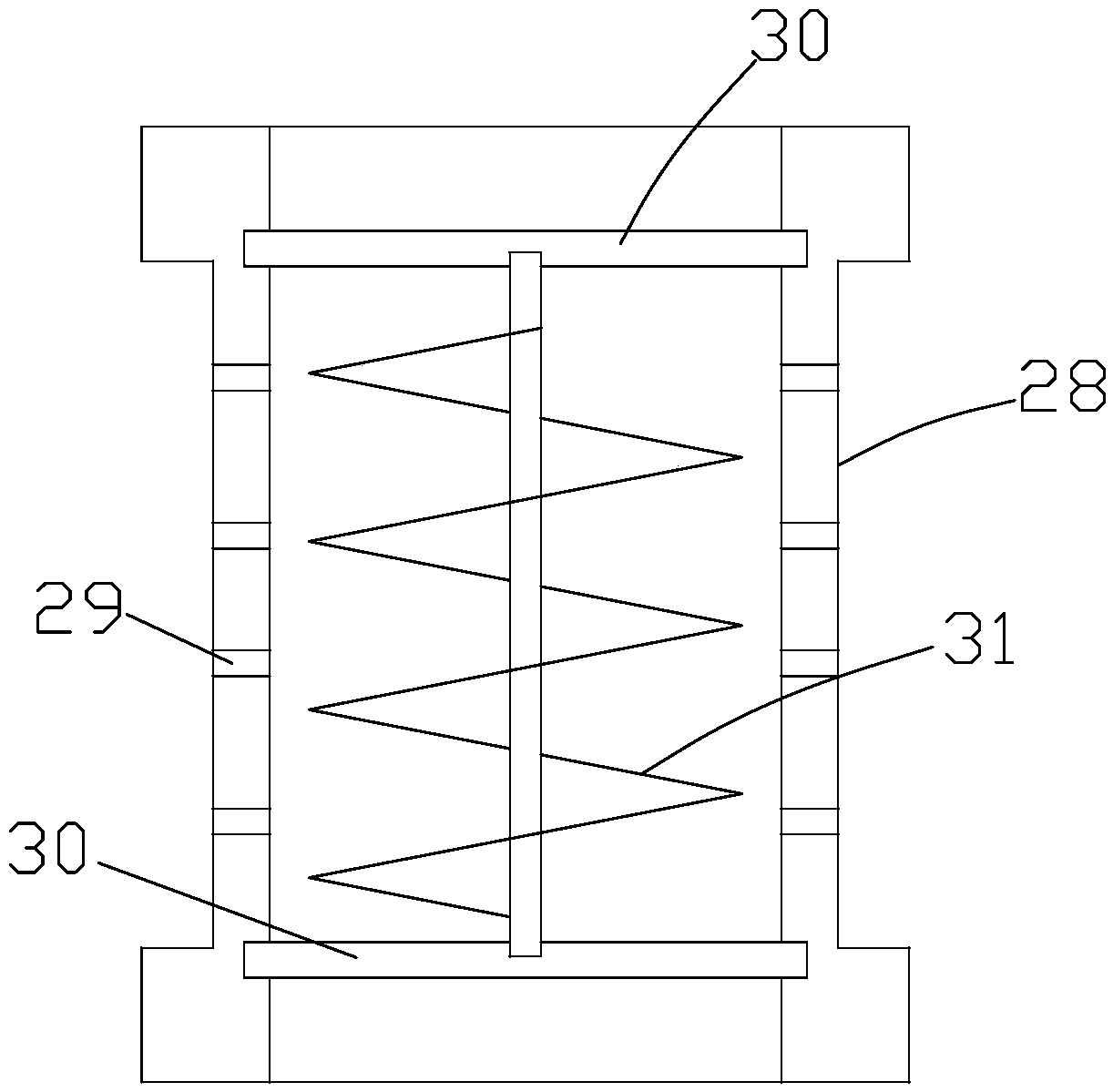

[0025] Such as Figure 1 to Figure 3 As shown, it is a high-speed pump with a front conical inducer according to the present invention, which includes a pump body 1, an inlet flange 2 and an outlet flange 3 are arranged on the pump body 1, and a liquid inlet channel 17 is arranged in the pump body 1 and the liquid outlet pipe 20, the inlet flange 2 is connected to the liquid inlet channel 17, the outlet flange 3 is connected to the liquid outlet pipe 20, the pump shaft 4 is horizontally arranged inside the pump body 1, and the impeller 6 is fixedly connected to the pump shaft 4, and the liquid inlet A tapered passage 18 is provided between the passage 17 and the liquid outlet pipe 20, and a tapered inducer 5 is arranged on the pump shaft 4. On the left side, the conical inducer 5 matches the conical channel 18, the pump shaft 4 is connected in the pump body 1 through the bracket 16, the rear cover 7 and the bearing body 32, the bracket 16 is located at the front end of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com