Patents

Literature

77results about How to "Continuous and stable feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

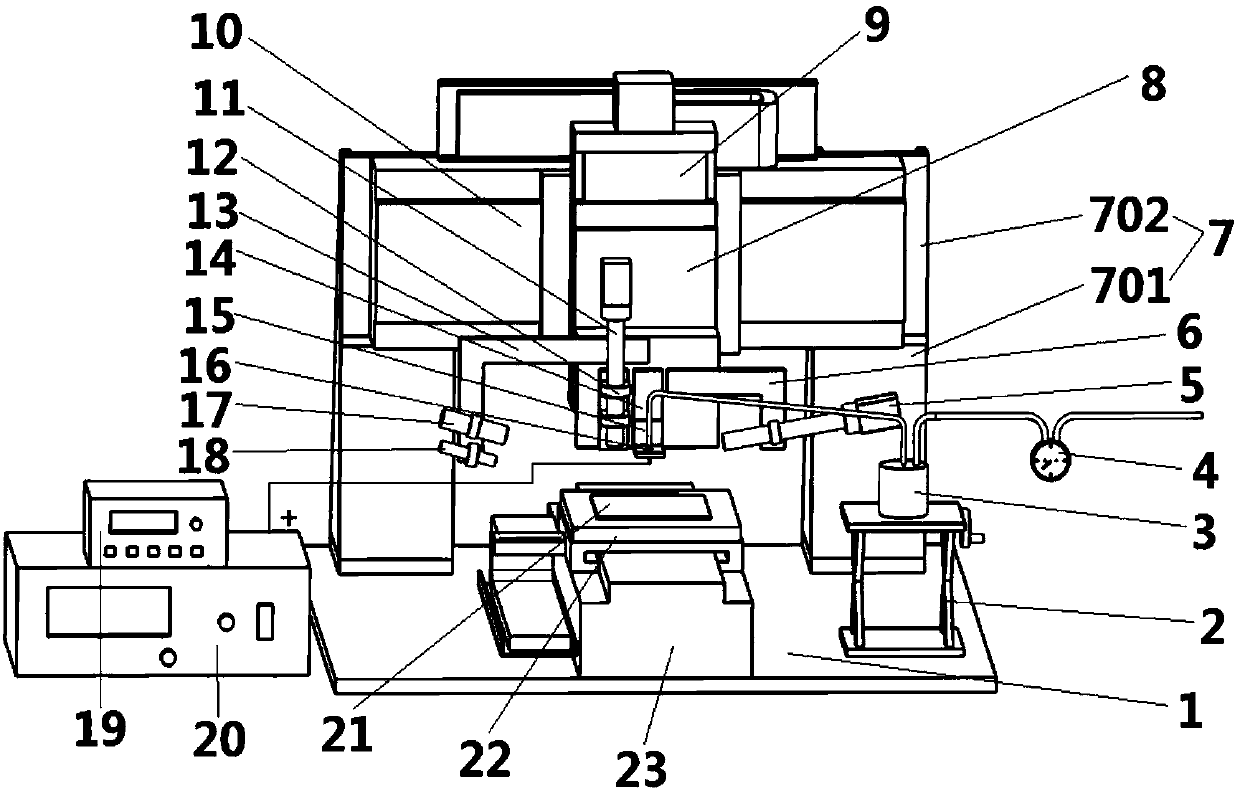

High-precision electric field driven spray deposition 3D printer and working method thereof

PendingCN107932894AHigh frequencyContinuous and stable feedingAdditive manufacturing apparatus3D object support structuresComputer printingImage resolution

The invention discloses a high-precision electric field driven spray deposition 3D printer and a working method thereof, and solves the problems of a traditional 3D printer on multiple aspects of resolution, stability and controllability; high-precision printing of multilayer structures can be realized; the printing process is observed and monitored in real time; and high-precision pattern printing is performed on insulation substrates through electric conducting materials. The high-precision electric field driven spray deposition 3D printer comprises a mounting baseplate; a Y-axle worktable is arranged on the mounting baseplate; a vacuum absorption platform is fixed on the Y-axle worktable; a printing substrate is absorbed on the vacuum absorption platform; a printing nozzle and a vertical observation camera are correspondingly arranged above the printing substrate, and are connected to a Z-axle worktable; the Z-axle worktable is fixed on an X-axle worktable; a squint observation camera is correspondingly arranged on one side of the printing nozzle; an LED light source and a far infrared curing light source are correspondingly arranged on the other side of the printing nozzle; theprinting nozzle communicates with a storage bottle; and the storage bottle is arranged on a lifting table.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

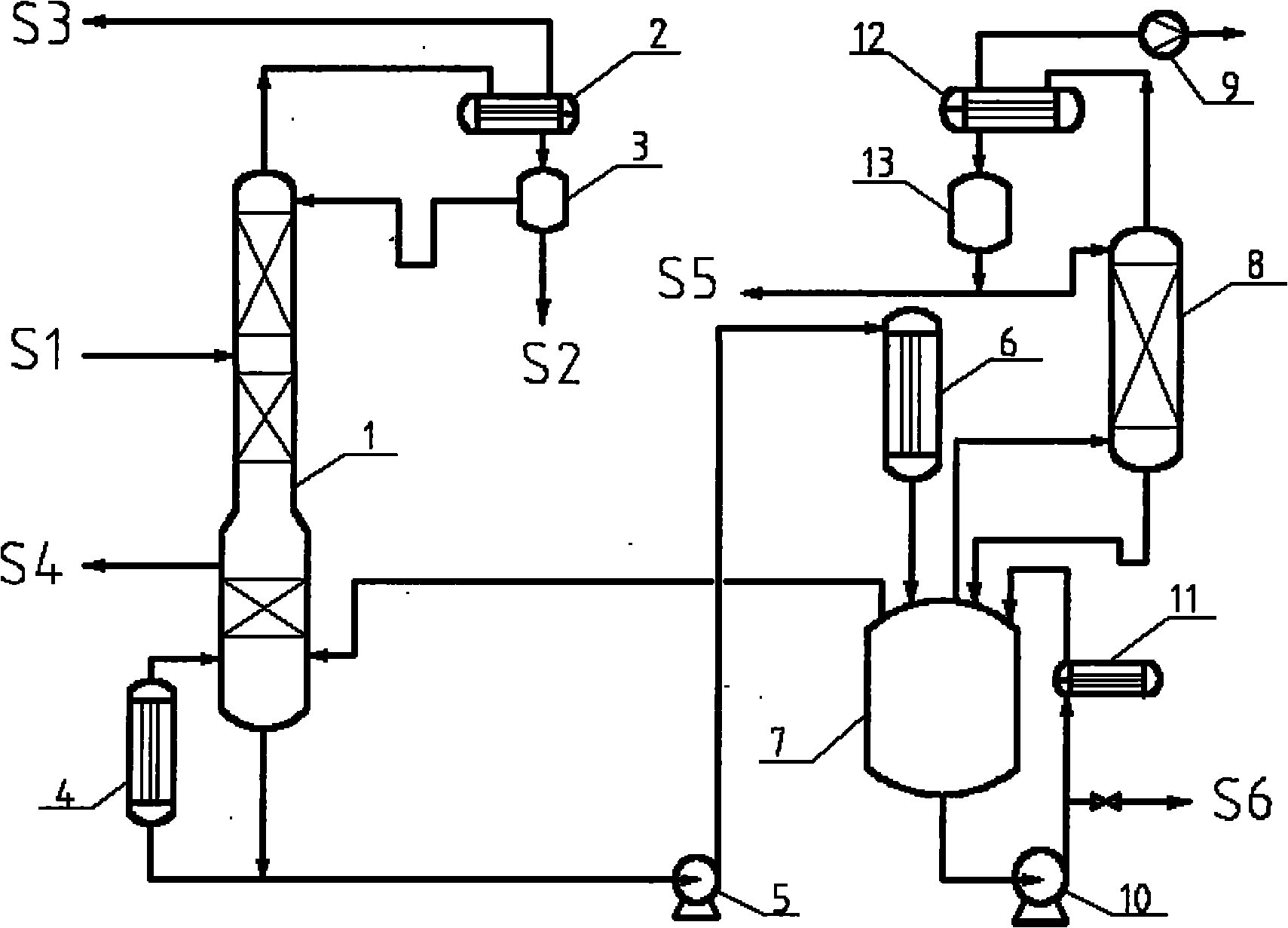

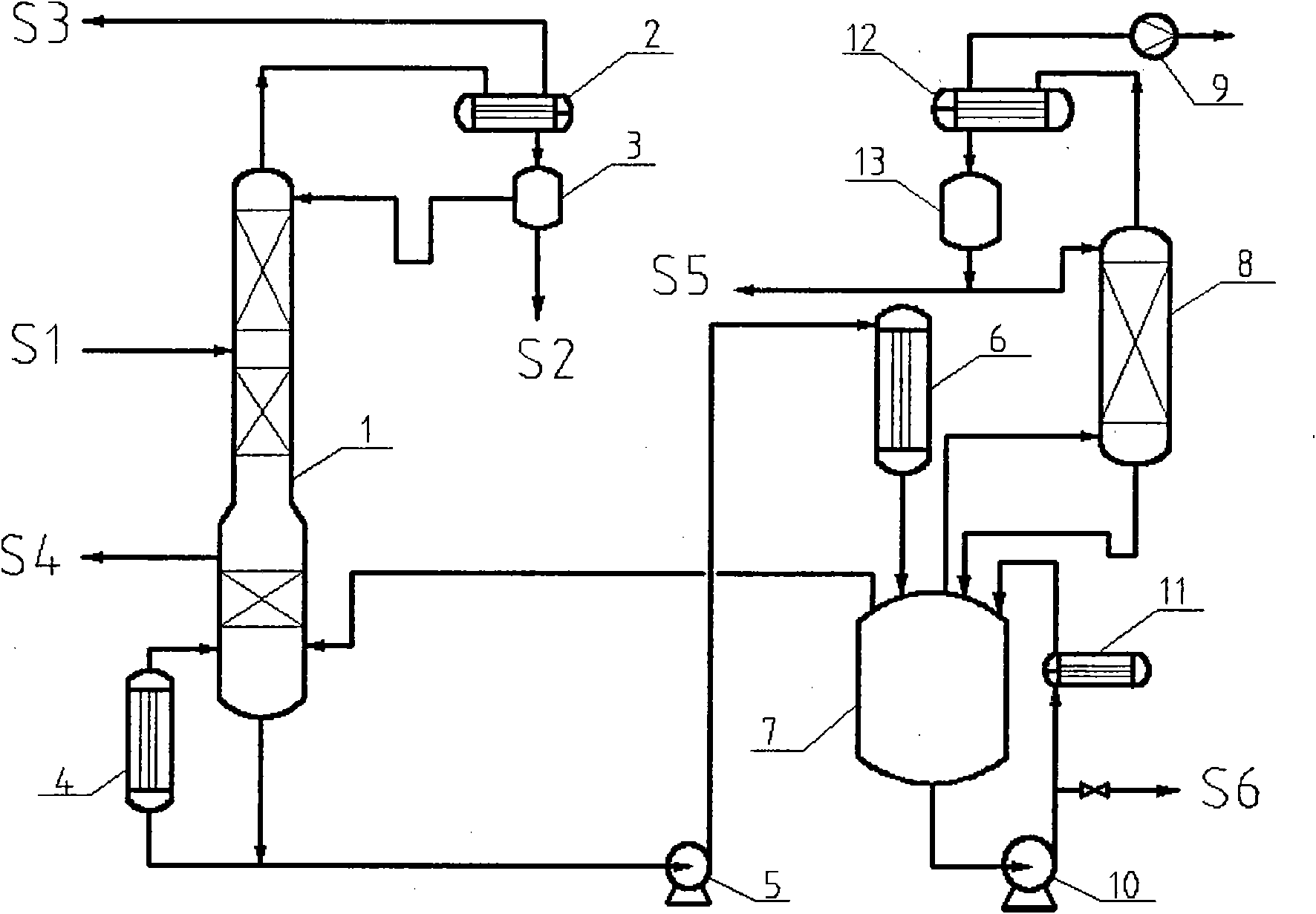

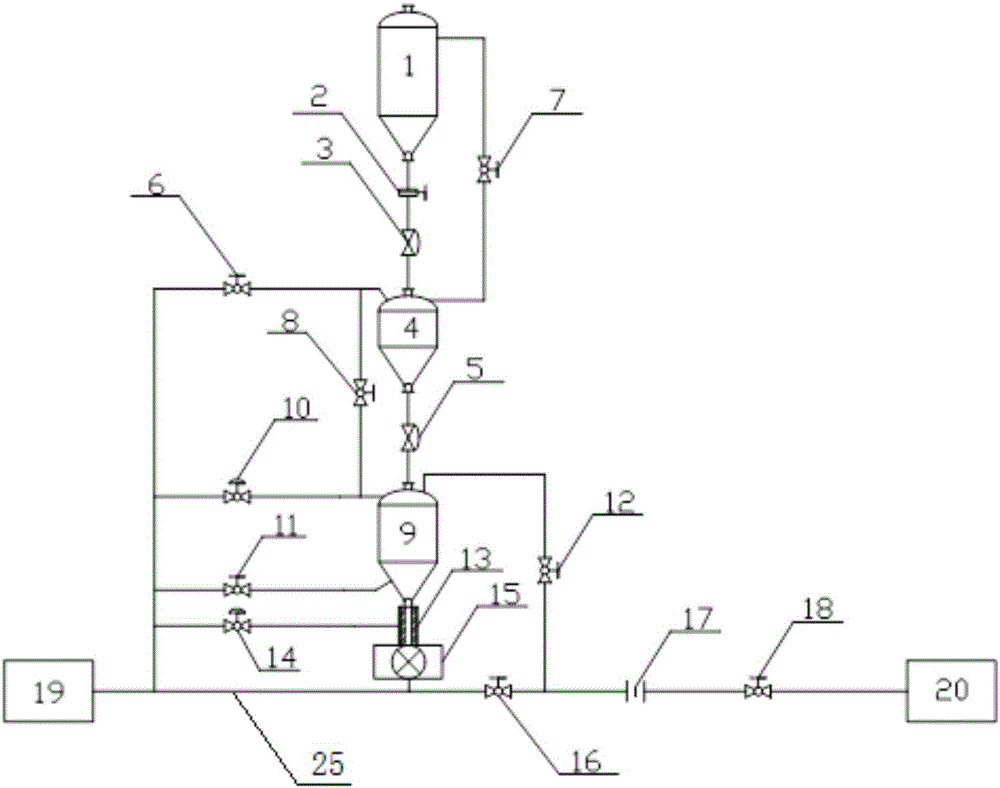

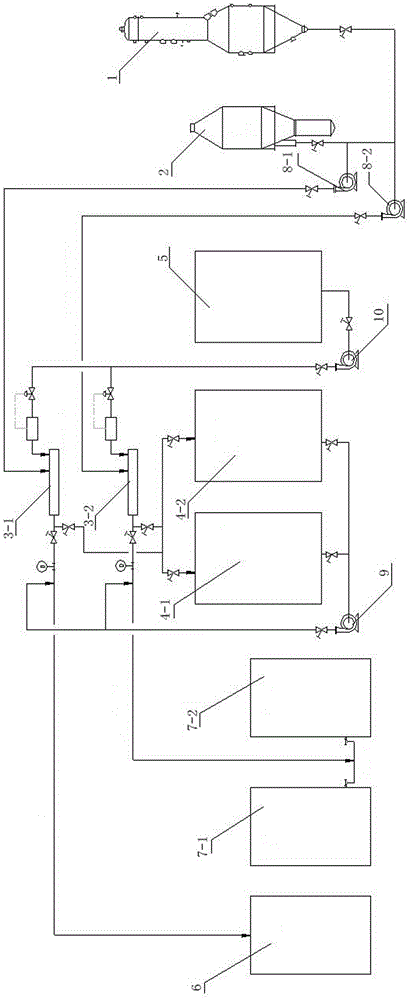

Refining and reclaiming technology of tail gas absorption solvent in production of toluene diisocyanate

InactiveCN101870666AContinuous and stable feedingContinuous and stable dischargeDispersed particle separationDistillation purification/separationToluene diisocyanateGas phase

The invention relates to a refining and reclaiming technology of a tail gas absorption solvent in the production of toluene diisocyanate (TDI). The solvent containing little phosgene, toluene diisocyanate and di-Et-1,3-benzenedicarboxylate (DEIP) performs two-stage refinement in an atmospheric refining tower and a vacuum refining tower, and a falling-film evaporator and a storage tank are arranged between the two towers. The overhead non-condensable gas phase of the atmospheric refining tower is returned to a phosgene absorption tower to recycle phosgene, the refined solvent is drawn from theside of the atmospheric refining tower, the temperature of the tower bottom is controlled to be 3-8 DEG C higher than the boiling point of the solvent, the discharged material of the tower bottom enters the falling-film evaporator, the evaporating temperature is 20-30 DEG C higher than the boiling point of the solvent, the unevaporated material enters the storage tank for storage, the material inthe storage tank performs batch vacuum rectification under the absolute pressure of 0.1-0.25bar, and the unevaporated residual material enters the residue evaporator of a TDI device to recycle TDI and DEIP. By using the solvent refining technology provided by the invention, the useful components in the solvent can be completely recycled, and the technology has the advantages of simple and stable operation and lower cost and energy consumption.

Owner:QINGDAO UNIV OF SCI & TECH +1

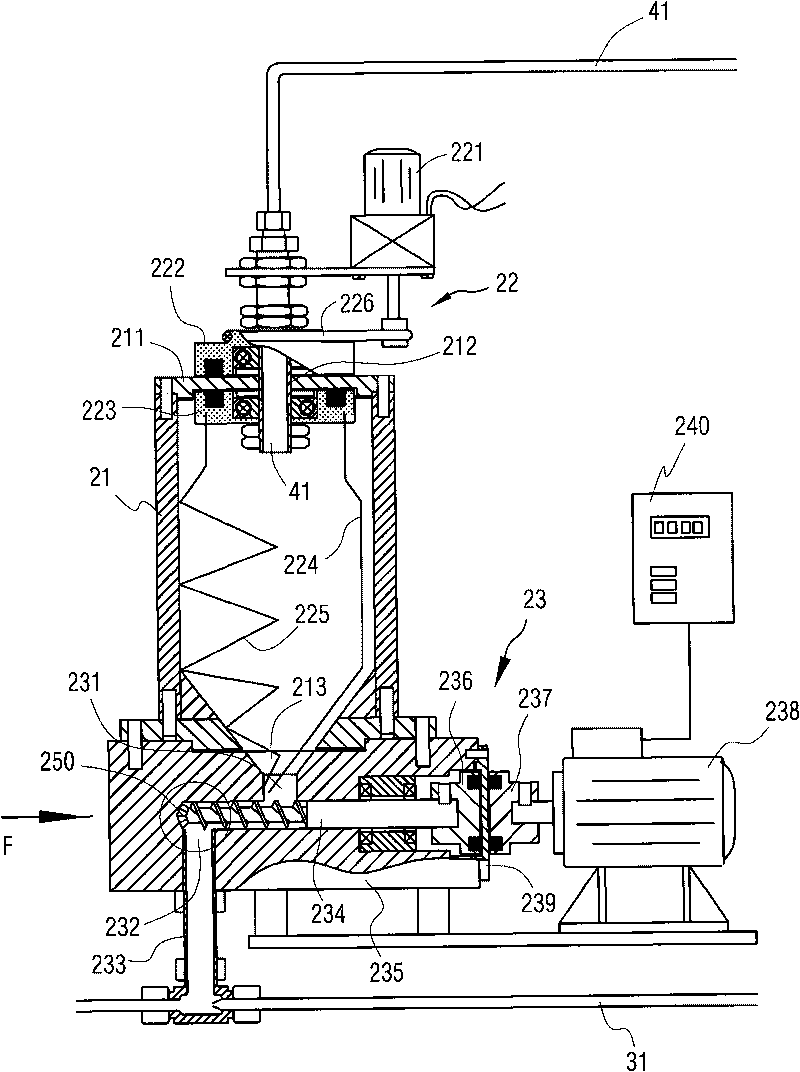

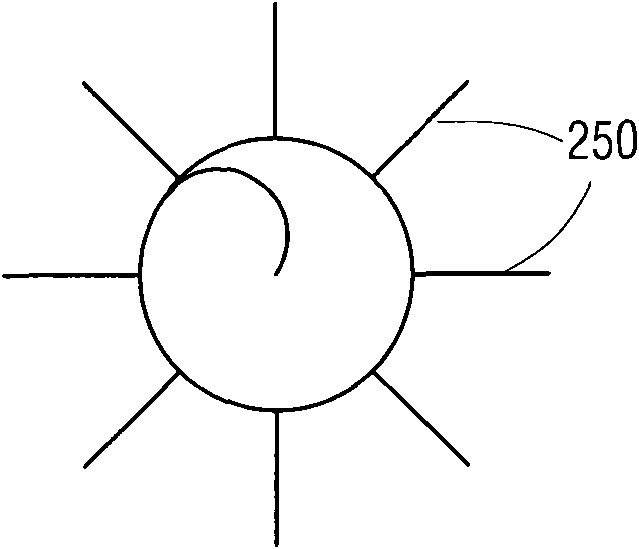

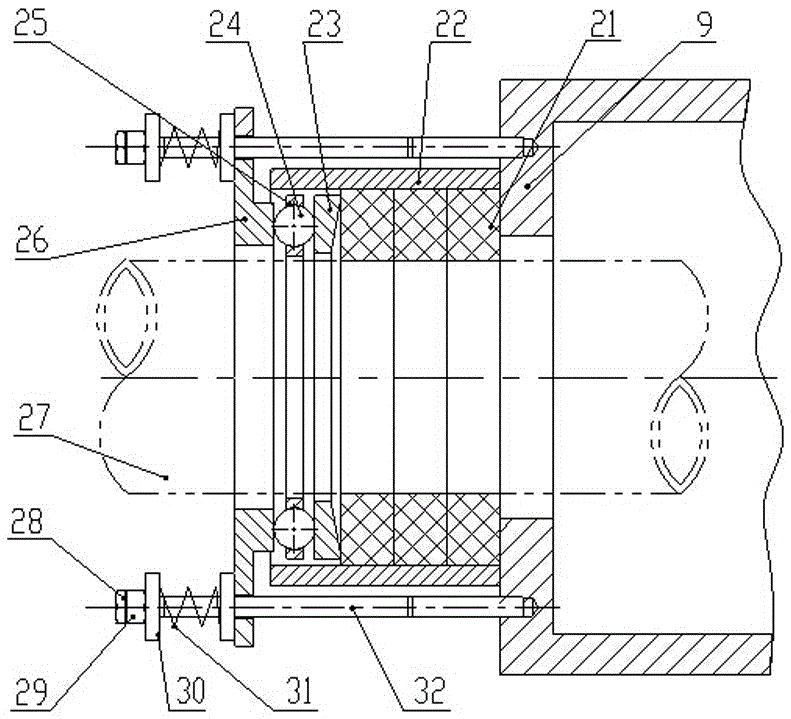

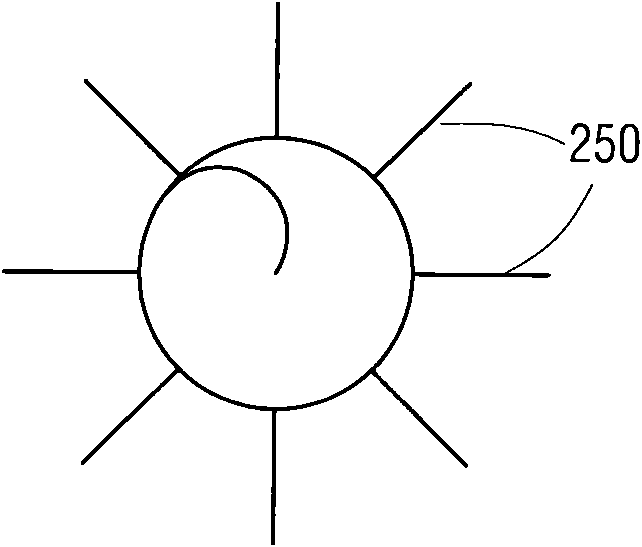

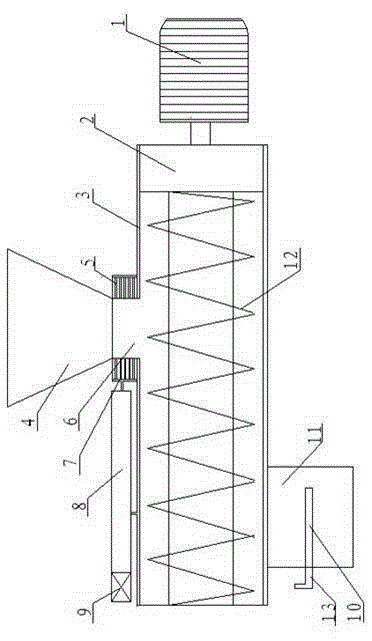

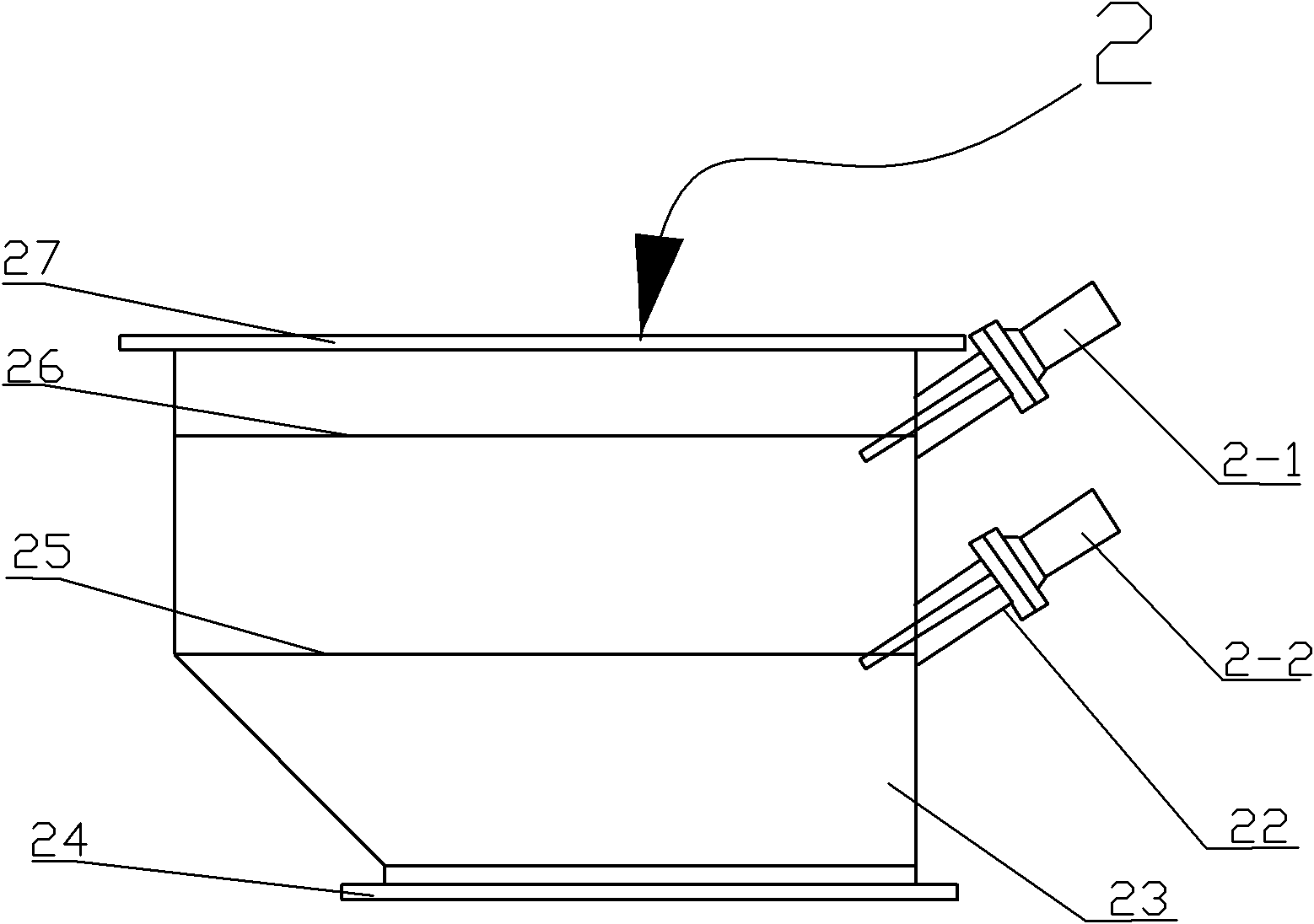

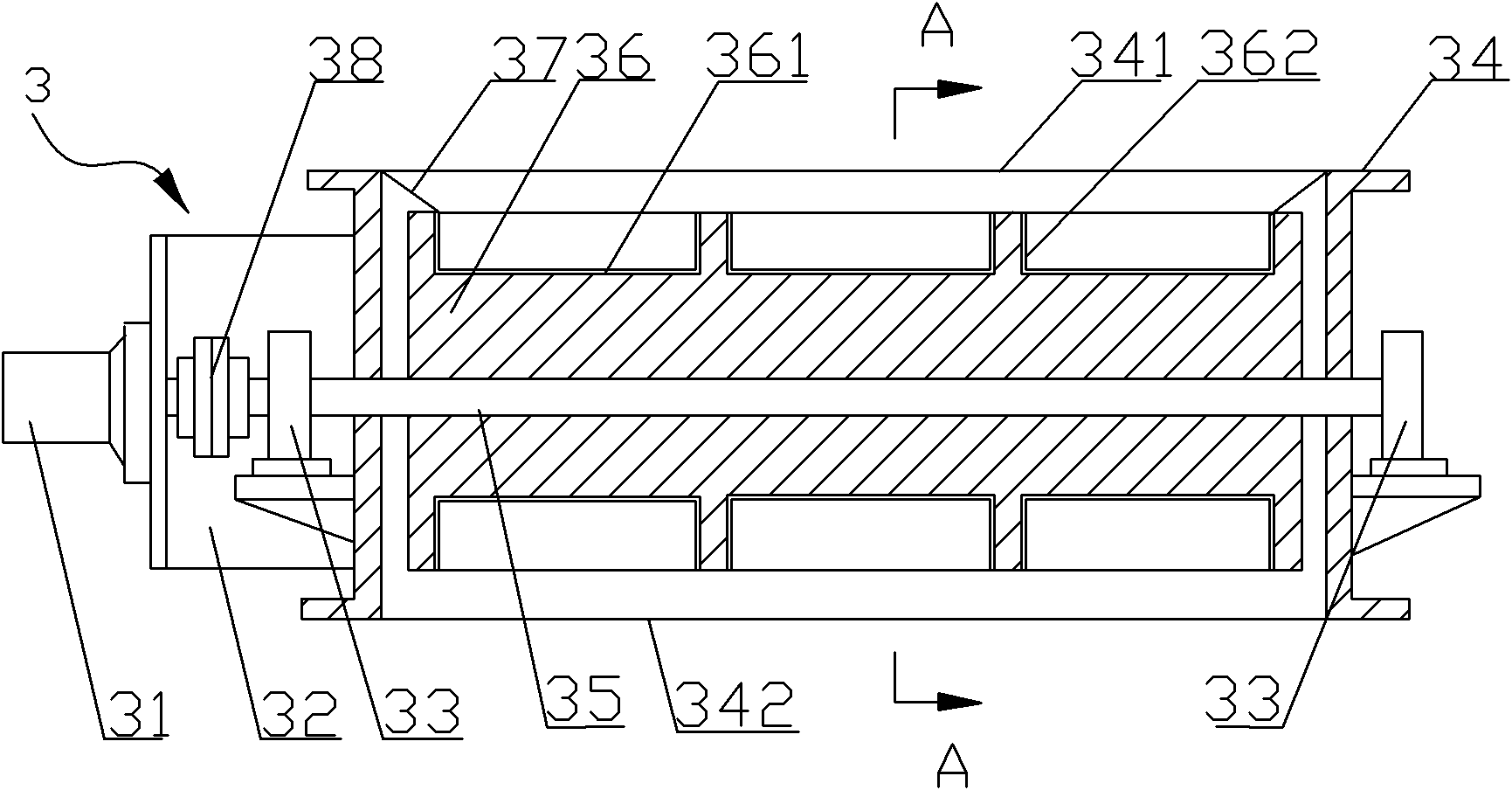

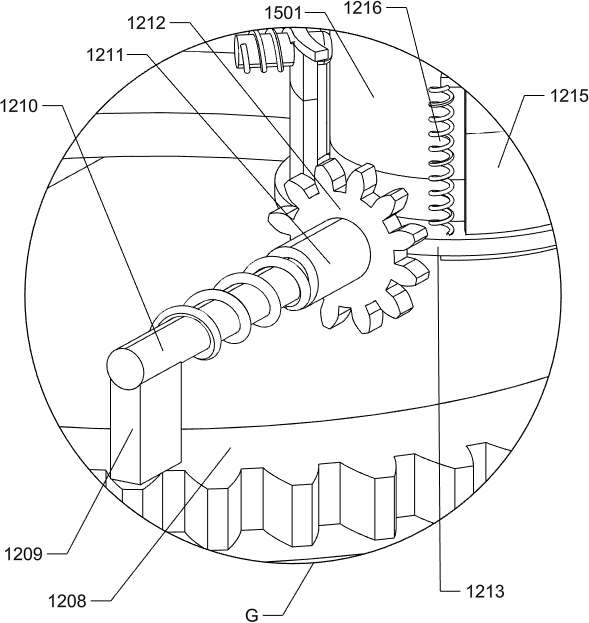

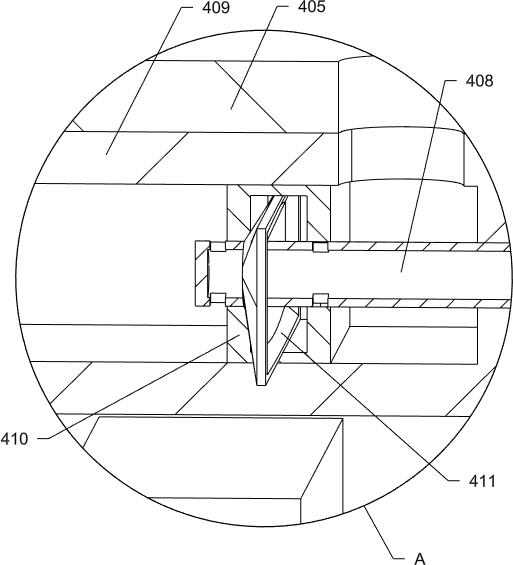

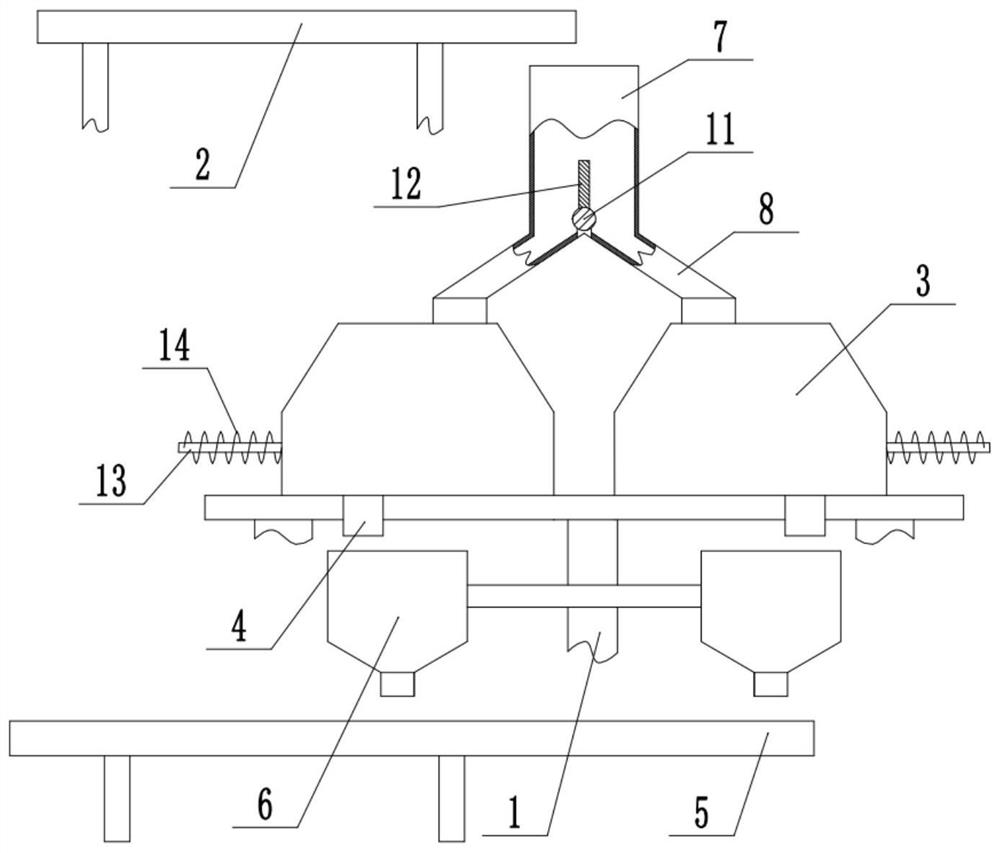

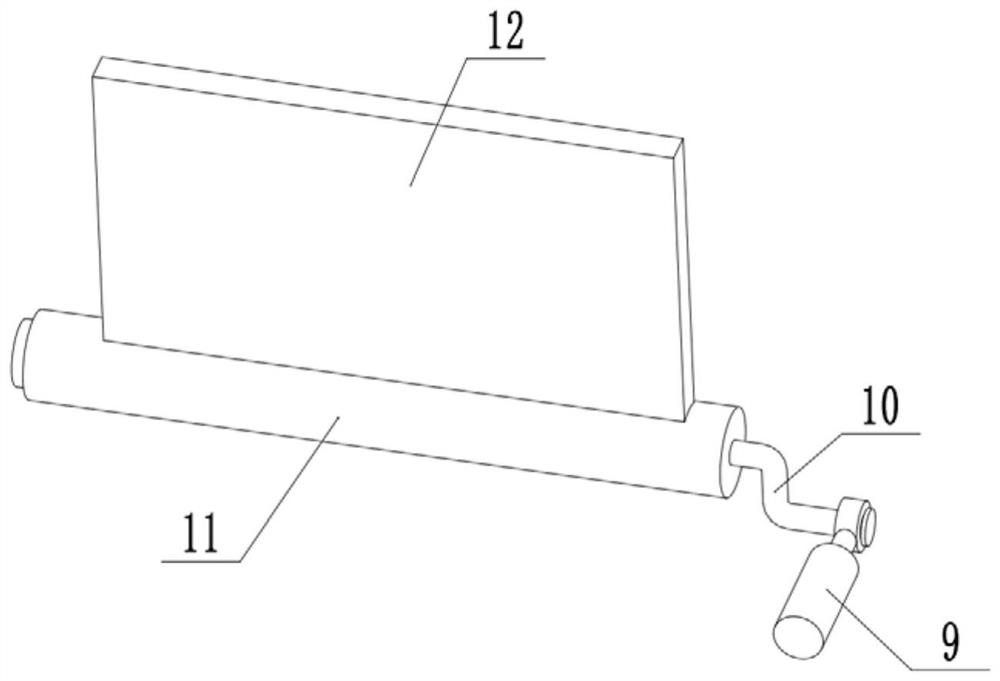

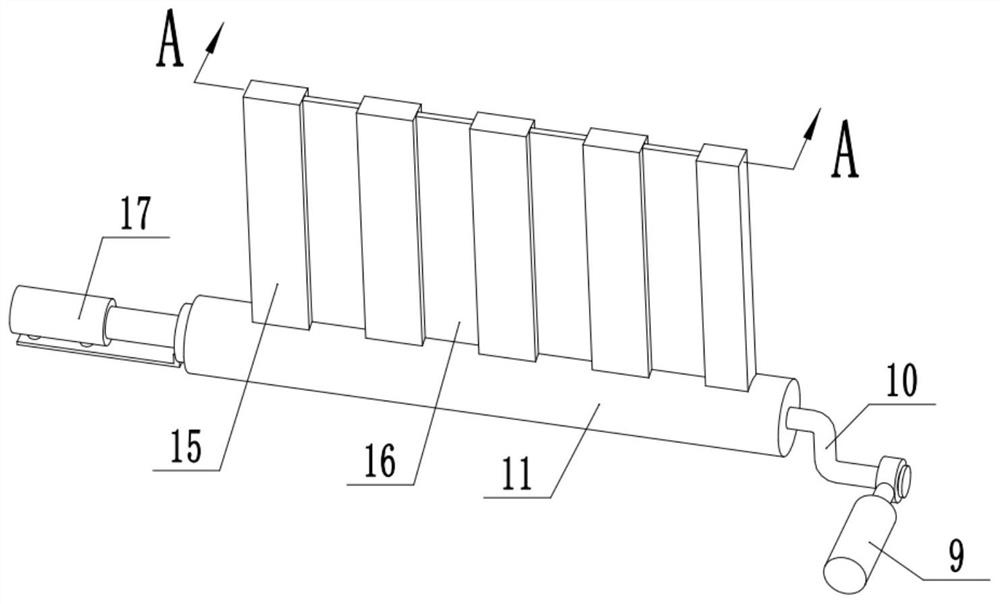

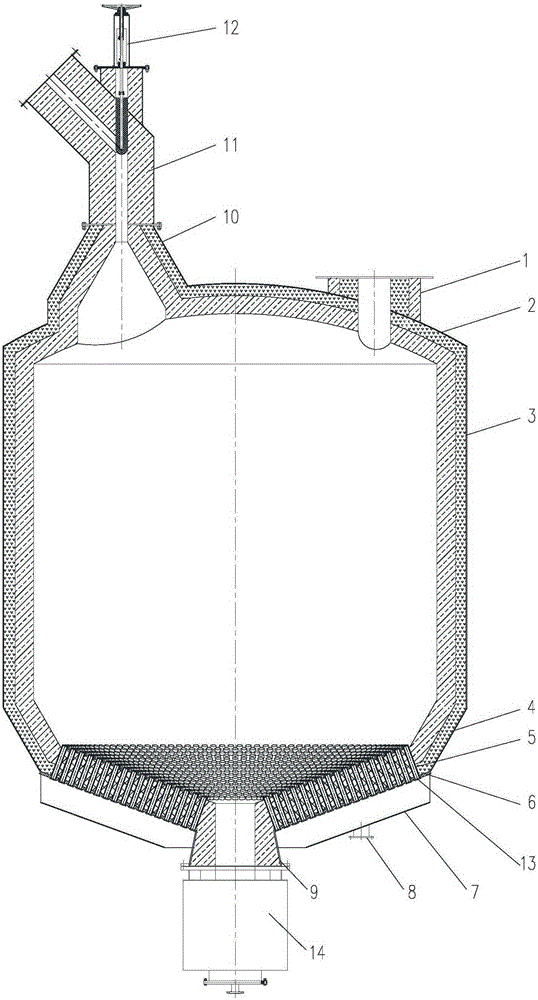

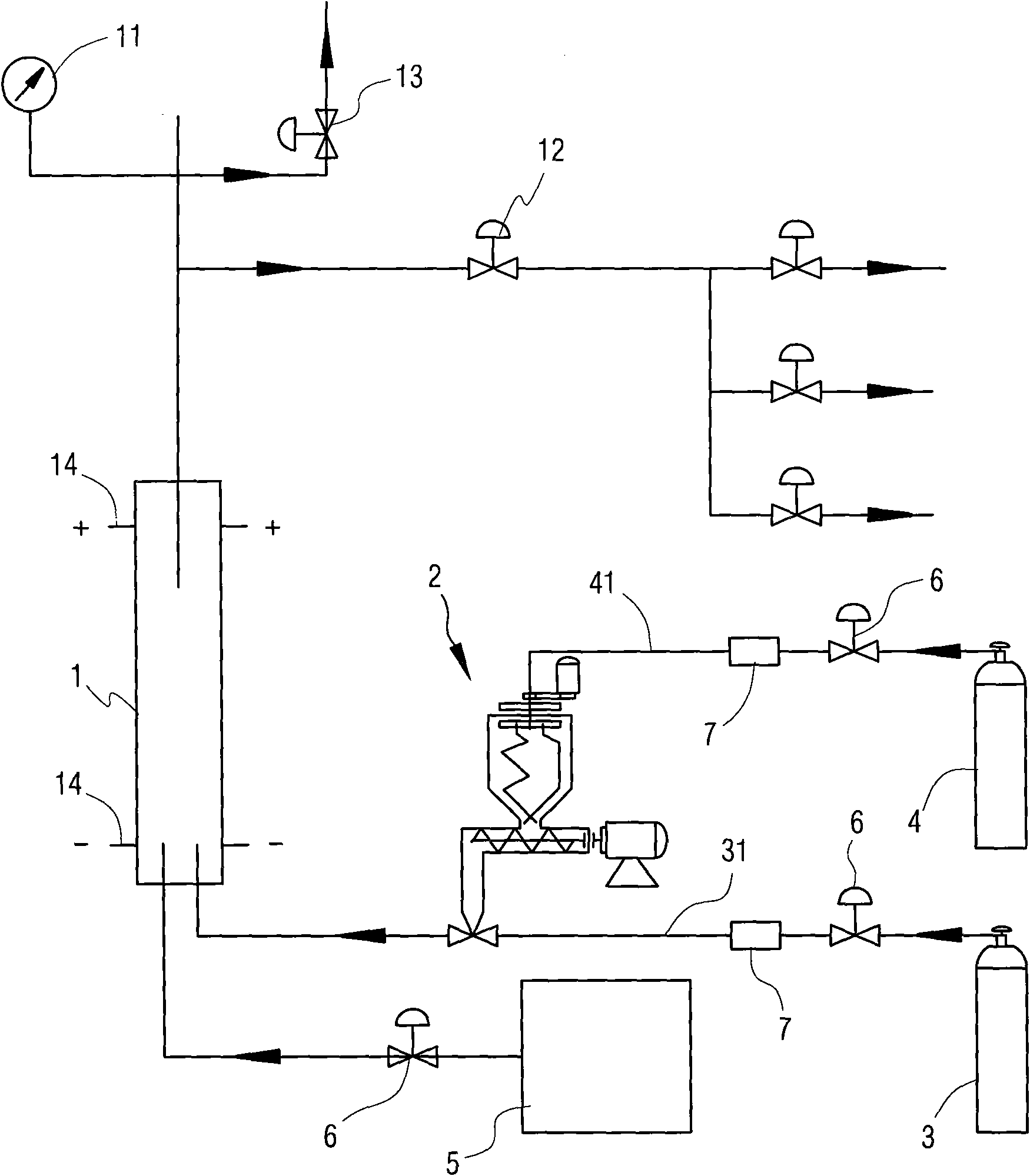

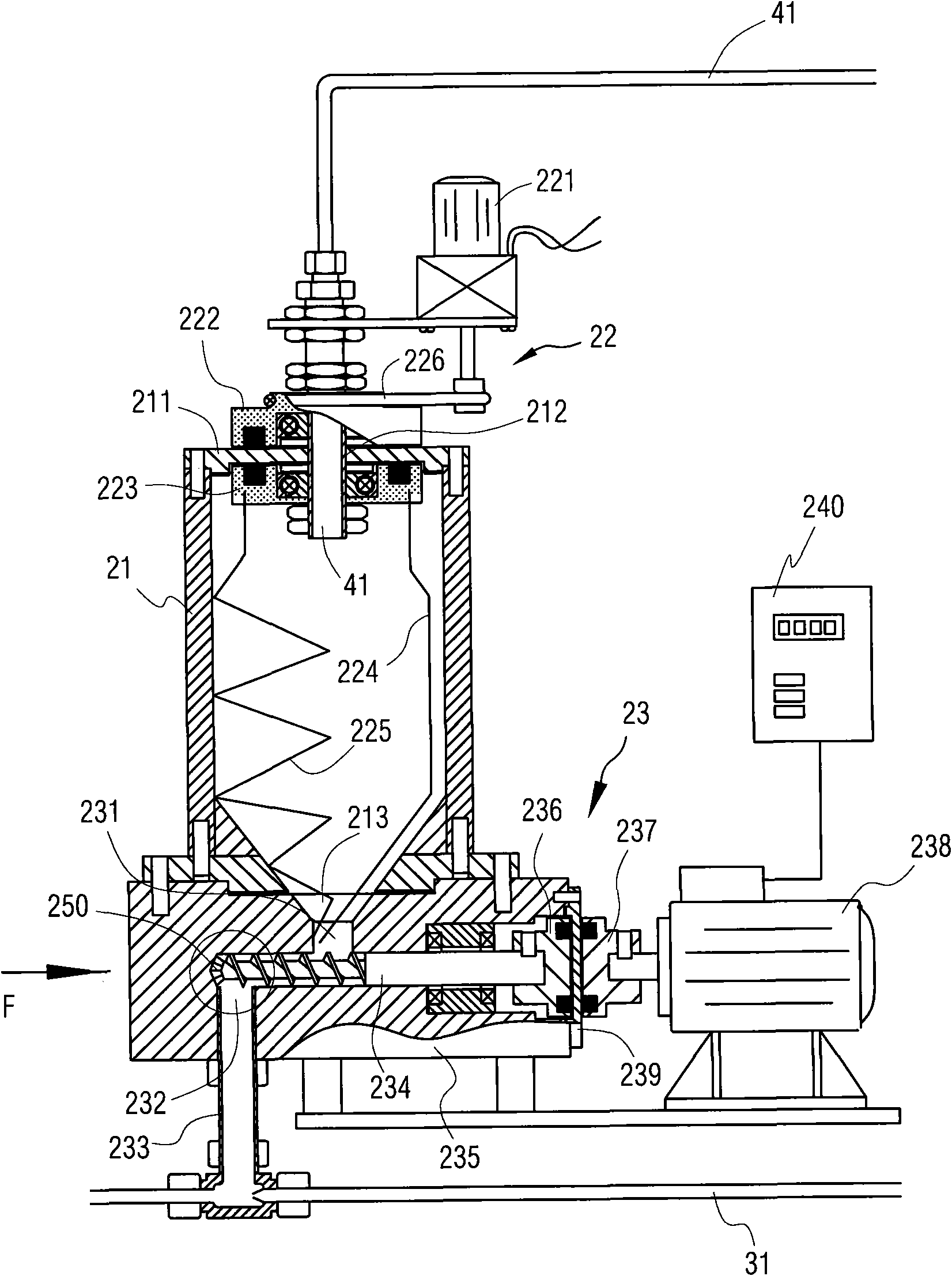

Biomass feeder for pressurized fluidized bed gasifier

InactiveCN101760246AInto continuous stabilityContinuous and stable feedingProductsReagentsFluidized bed gasifierEngineering

The invention provides a biomass feeder for a pressurized fluidized bed gasifier, which comprises a sealed hopper with a non-magnetic conductive top cover, a stirring device and a spiral feeding device. The invention draws lessons from the basic working principle of magnetic transmission, respectively improves the stirring device and the spiral feeding device, so as to achieve the purpose of sealed transmission. The biomass feeder for the pressurized fluidized bed gasifier of the invention is applicable in the feeding of biomass powder under high-pressure condition and gasification in the gasifier, particularly improves the stirring device and the sealed transmission of the spiral feeding device so that the spiral device and the spiral feeding device are applicable in the feeding of biomass powder in high-pressure environment, thereby solving the problems that the low-density fine powder is easy to be lapped, bridged, channeled and cohered into a group, and is not easy to enter the next stage of reactor, so as to disclose a technical scheme which can realize continuous and stable feeding at high pressure and lead the material to enter the reactor continuously and stably.

Owner:TAIYUAN UNIV OF TECH

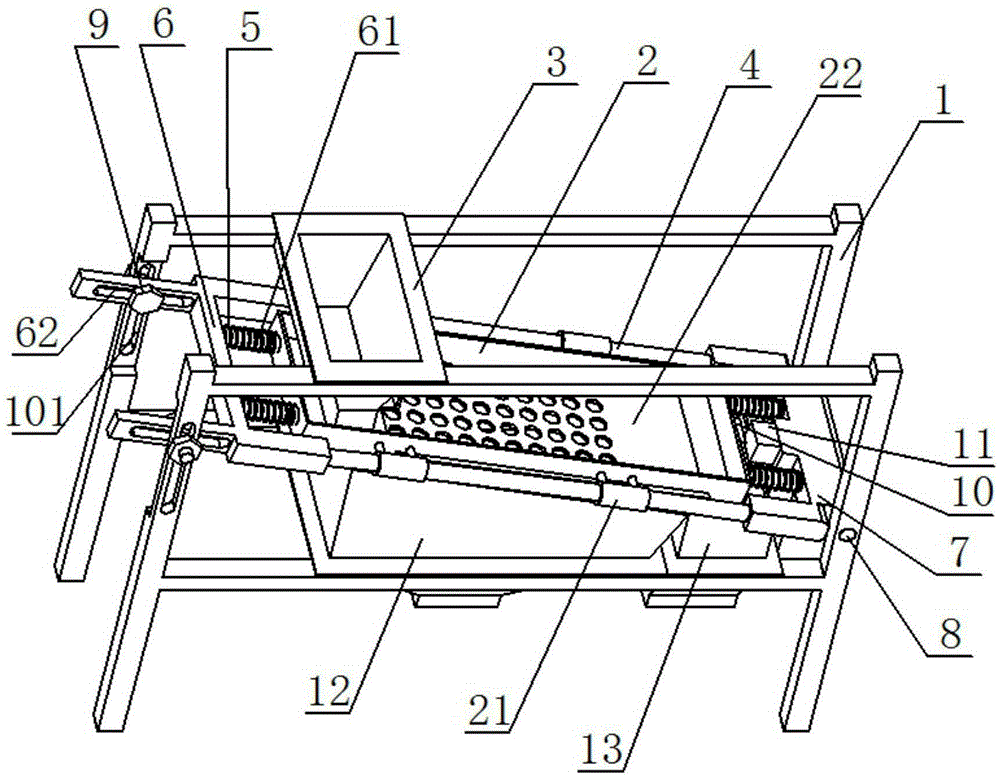

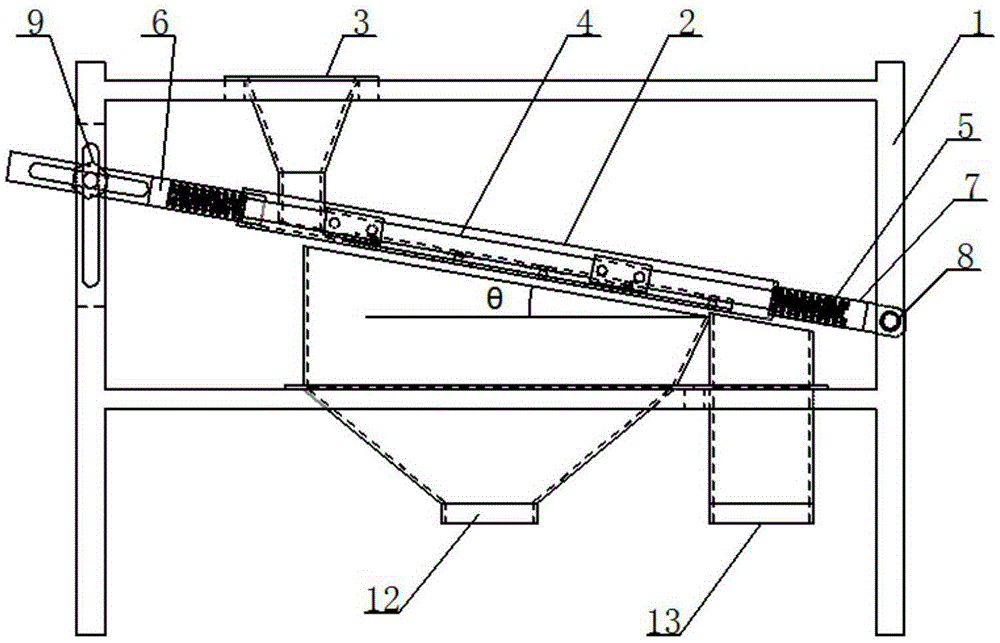

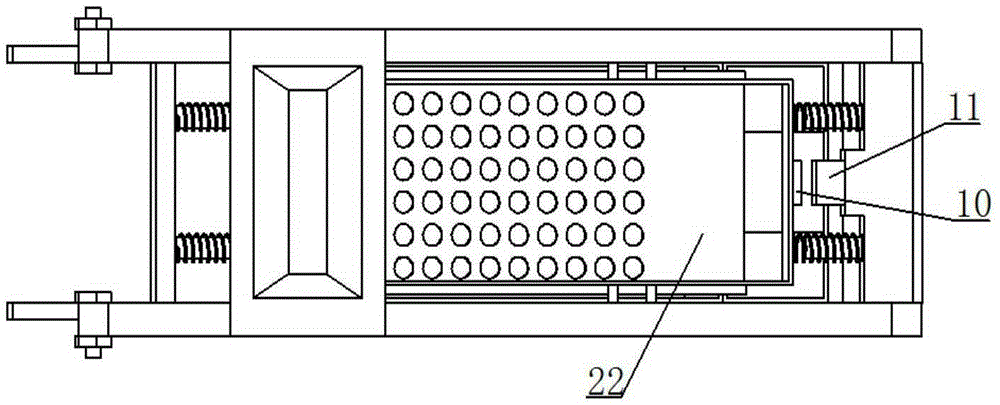

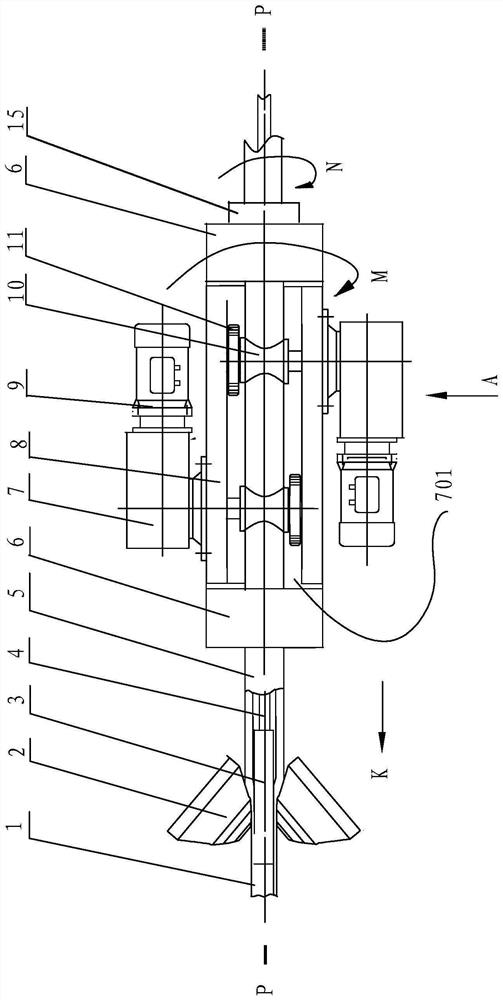

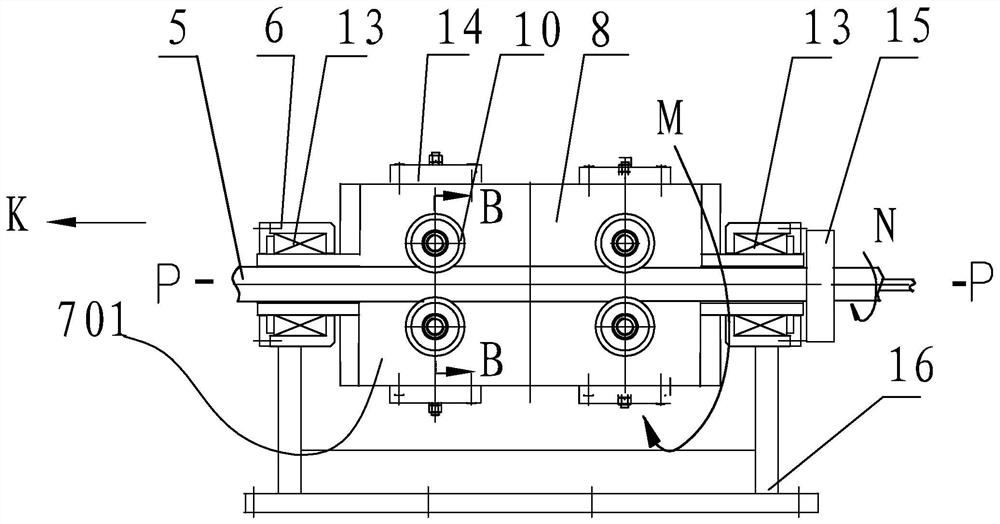

Screening device capable of vibrating parallel to screen plate and efficient screening method

ActiveCN105396775ASolve the high false screening rateSolve the difficulty of screeningSievingScreeningScreening methodEngineering

The invention discloses a screening device capable of vibrating parallel to a screen plate and an efficient screening method, and relates to the field of screening machines. The screening device is mainly composed of a main support, a screen box, a first movable frame, a second movable frame, a guide rod, an electromagnet, an exciting coil, a spring, a positioning bolt, a long pin, a feeding hopper, a screened object receiving hopper and an oversize product receiving hopper. According to the efficient screening method, the screen box is driven by the exciting coil and the electromagnet to vibrate along the screen plate face under the guide effect of the guide rod; the inclination angle theta, the screen hole diameter and screen hole distribution of the screen box are adjusted, and through control over the amplitude and the frequency of the electromagnet and the exciting coil, rapid slippage of particles on the screen plate can be achieved, and efficient screening is achieved. Accurate vibration in the direction parallel to the screen face can be achieved, the method is particularly suitable for selecting and grading of long-strip-shaped particles such as medlar, rice grains, melon seeds and long and short straw, and the problems that the error-sifting rate is high, and screening is difficult are solved.

Owner:JIANGSU UNIV

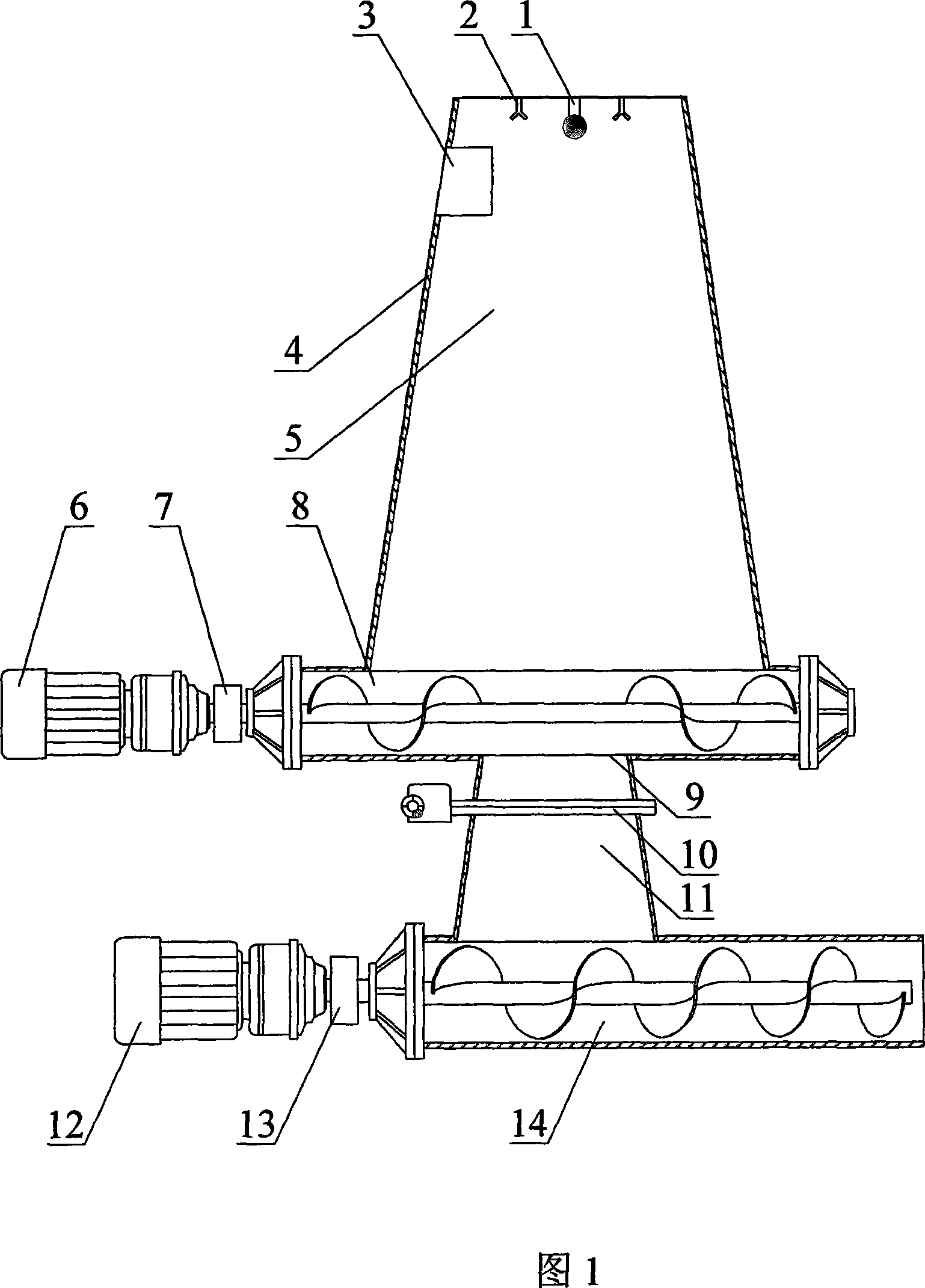

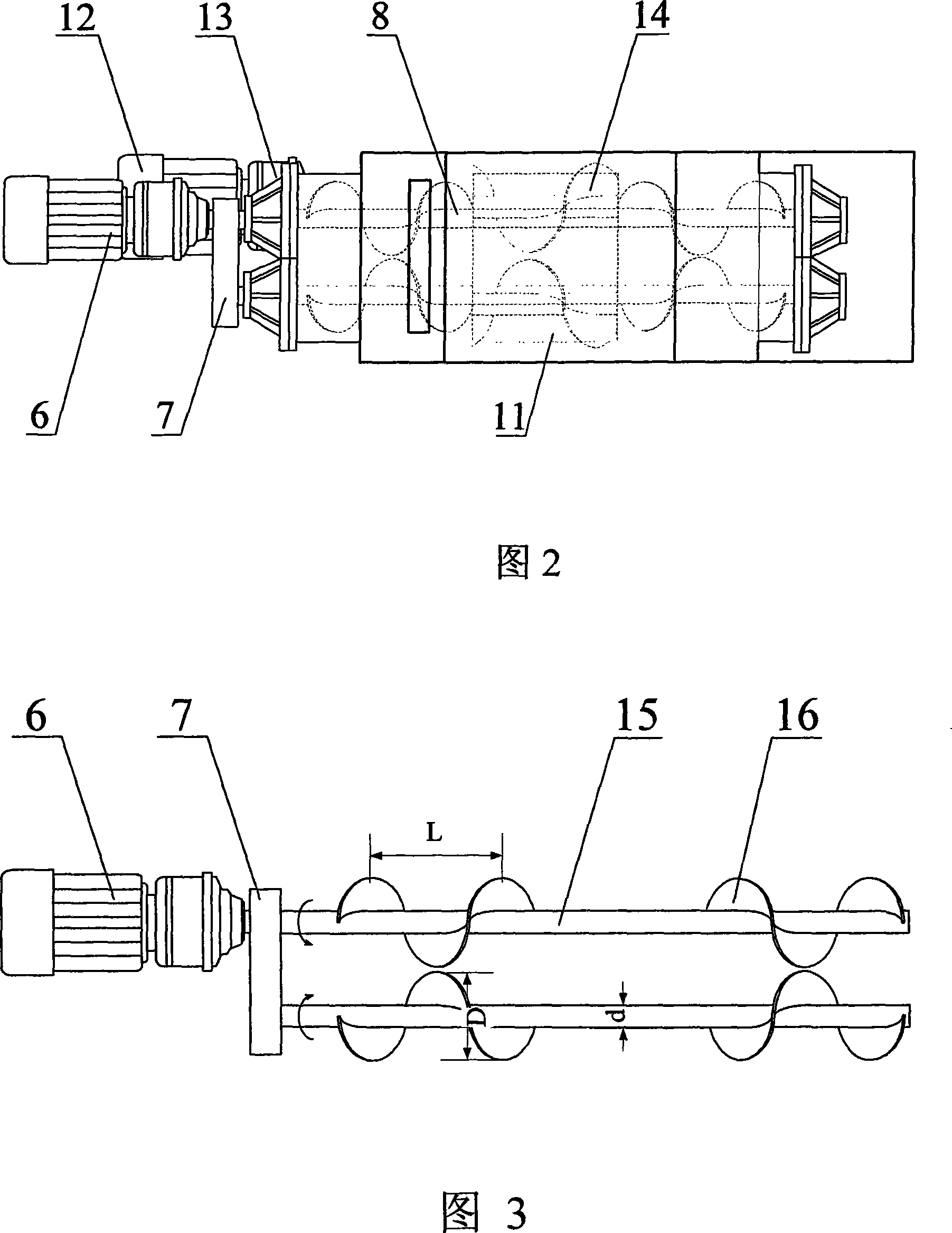

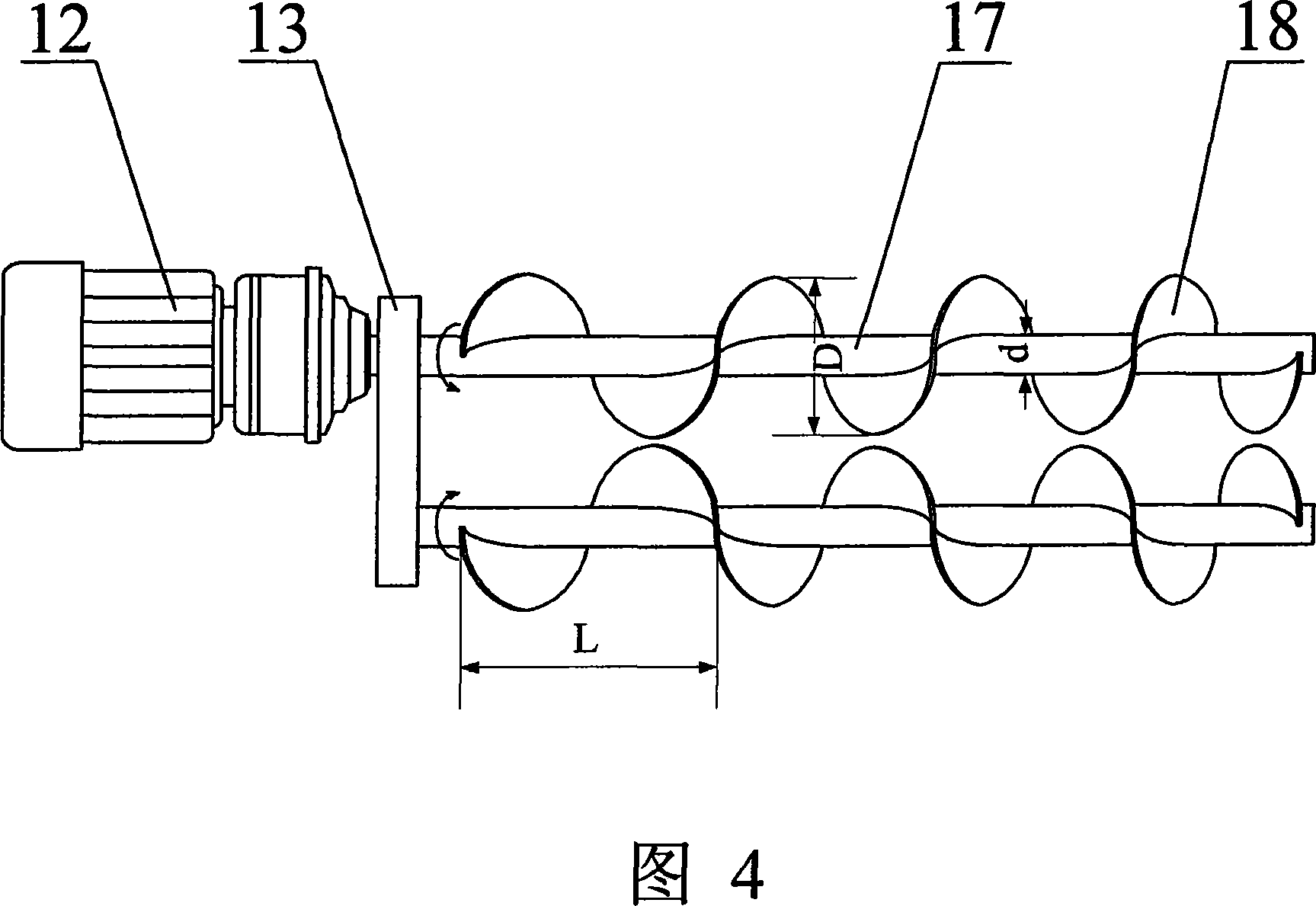

Biological matter straw burning-gasifying feeding apparatus

ActiveCN101025269AContinuous and stable feedingEliminate potential safety hazardsPackagingLump/pulverulent fuel feeder/distributionTransformerAgricultural engineering

The charging device of the straw burning and gasification uses the differential variable-pitch double helix to reach the charging continuously especially for the strip biological fuel. The device includes: material barn, the feeding helix, the middle hopper, the dehvery helix; the material barn is on the top which the upper mouth is connected with the upper side of the feeding helix middle which the material drop mouth is connected to the upper mouth of the middle hopper which the low mouth is connected to the upper side of the dehvery helix. The device transfers the straw of 10-200mm into the material barn by the double helix feeder, then it drops into the middle hopper, next the double helix transformer at the bottom of the hopper transfers the straw into the burning and gasification device.

Owner:SOUTHEAST UNIV

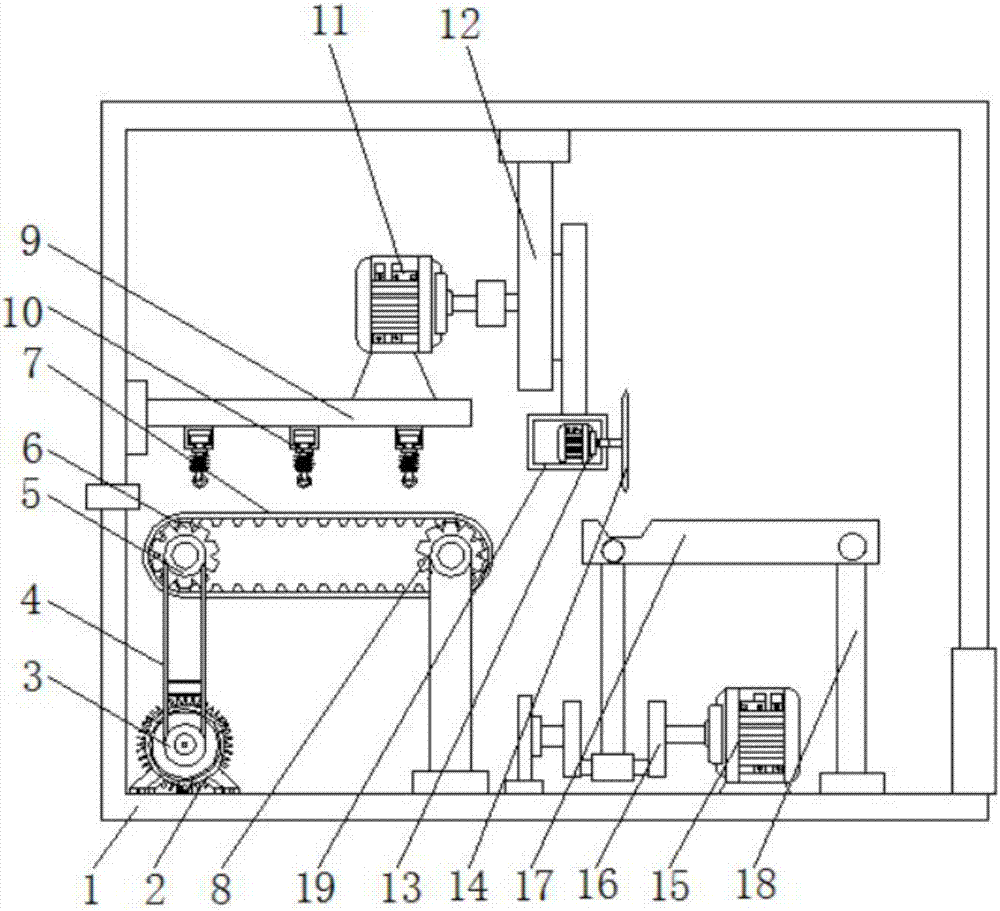

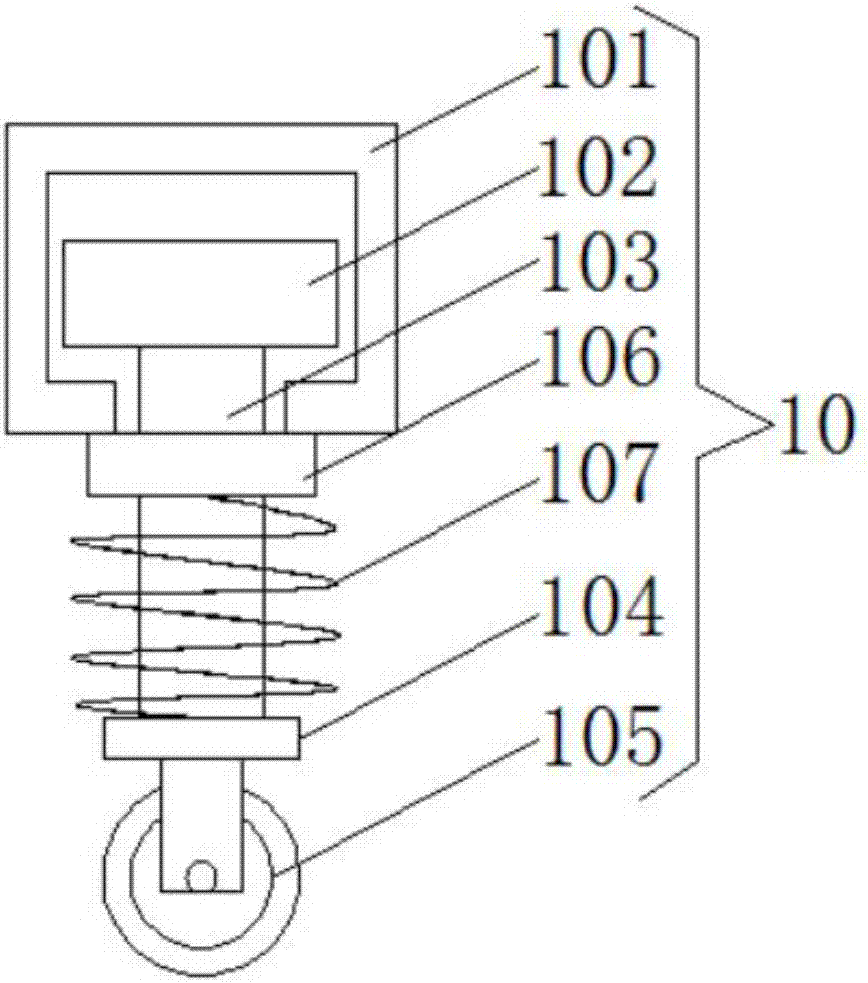

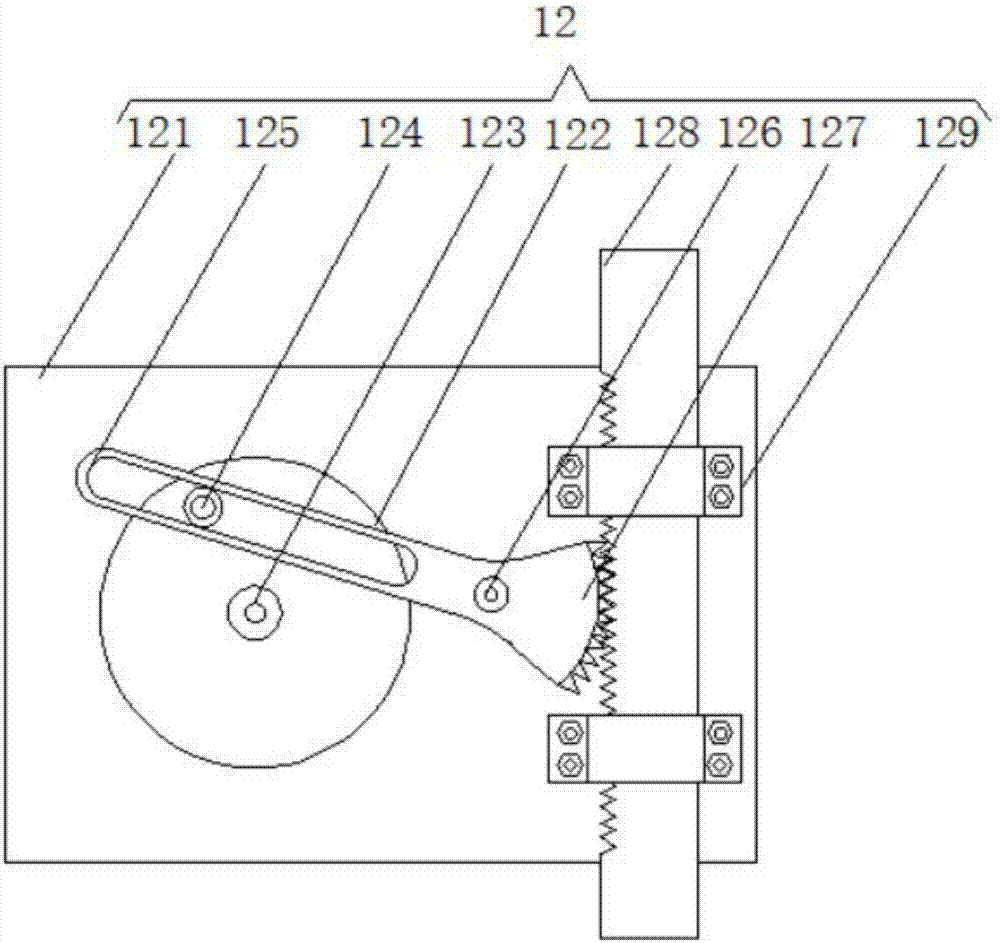

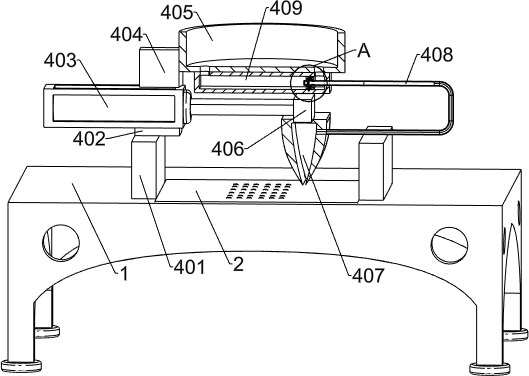

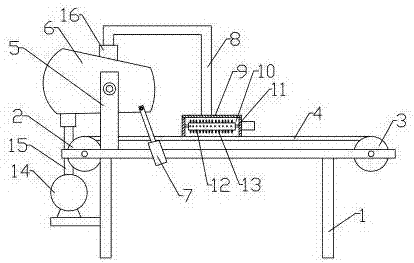

Plate cutting device used for computer manufacturing

ActiveCN107186767AContinuous and stable feedingEasy to useMetal working apparatusDrive wheelMotor drive

The invention discloses a plate cutting device used for computer manufacturing, and relates to the field of computer correlation technologies. The plate cutting device comprises a shell. The left side of the bottom of the inner wall of the shell is fixedly connected with a first motor. An output shaft of the first motor is fixedly connected with a first belt pulley. The surface of the first belt pulley is connected with a second belt pulley in a transmission mode through a first belt. The axis of the second belt pulley is fixedly connected with a first drive wheel. The surface of the first drive wheel is connected with a second drive wheel in a transmission mode through a drive belt. The left side of the inner wall of the shell is fixedly connected with a supporting plate, and the supporting plate is located above a conveying belt. According to the plate cutting device used for computer manufacturing, the first motor is used for driving the drive belt to move, plates are driven to move inwards, a material pressing roller compresses the plates, a second motor controls a moving device to drive a cutting sheet to cut the plates, a third motor drives a lifting device to jack up a workbench so that the plates can be conveyed out, using is convenient and working efficiency is high.

Owner:SHANDONG FANGYUAN BUILDING MATERIALS

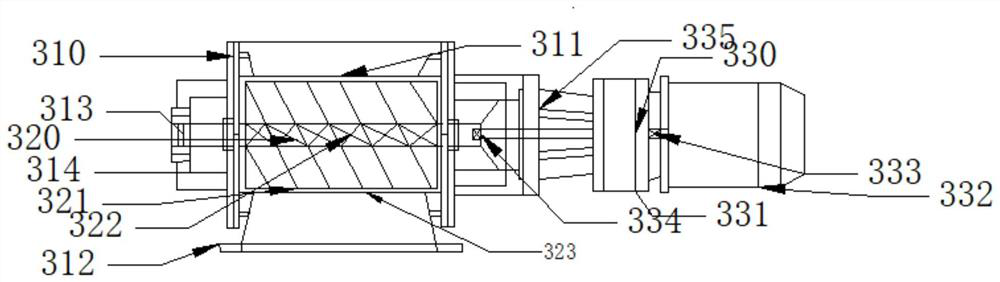

Rotary feeding pulverized coal quantitative feeding and conveying device and method

ActiveCN105775748AHigh measurement accuracyStable control of feed rateBulk conveyorsEngineeringControl valves

The invention discloses a rotary feeding pulverized coal quantitative feeding and conveying device and a method. The feeding device consists of a locking hopper system, a pulverized coal looser, a pressing feeder, a pulverized coal flow meter and related control valves; the locking hopper system realizes feeding of pulverized coals from normal pressure to increased pressure; the lower part of a feeding hopper is connected with the pulverized coal looser for preventing bridge blockage of the pulverized coals; the lower part of the pulverized coal looser is connected with the pressing feeder; the continuous and stable feeding of the pulverized coals is realized through a mechanical rotary feeding mode; the lower part of the pressing feeder is connected with a pneumatic conveying device; and materials are continuously fed into reaction equipment through a pneumatic conveying mode. The feeding device realizes pressed, continuous and quantitative feeding of the pulverized coals through matching the locking hopper feeding system with the pressing feeding system and the pneumatic conveying system, guarantees the stability of the feeding system, and is convenient for operation, simple in control, accurate in metering and capable of being widely applied to feeding of the pulverized coals with different particle sizes and other solid materials.

Owner:SHAANXI YANCHANG PETROLEUM GRP

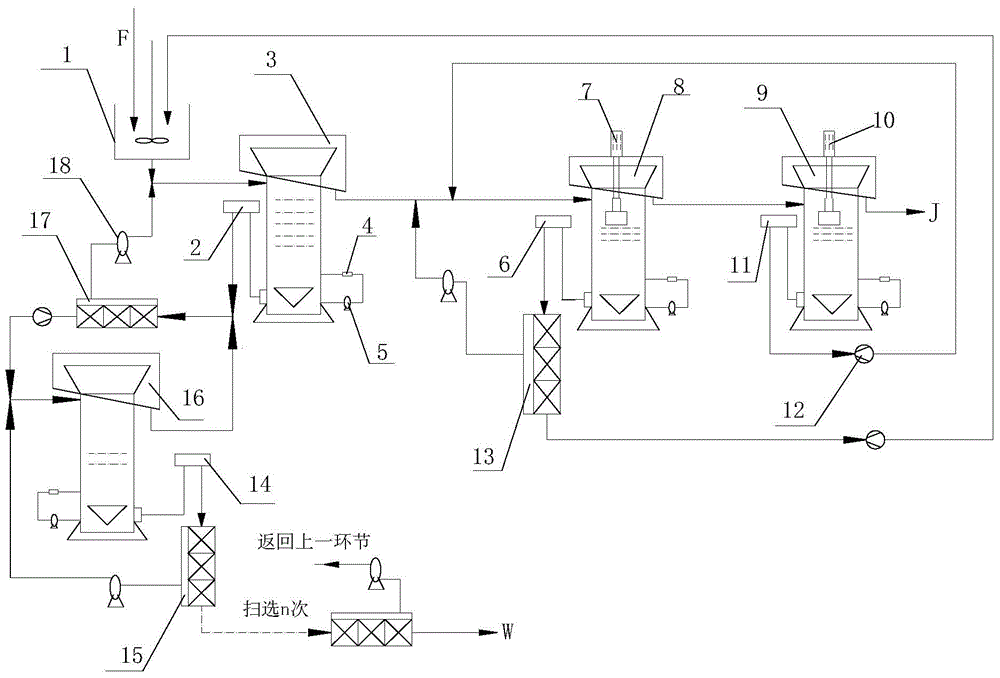

Co-platform flotation column and flotation machine combined separating technology and device

InactiveCN104923408ALarge amount of processingImprove flotation accuracyFlotationElectricitySeparation technology

The invention discloses a co-platform flotation column and flotation machine combined separating technology and device and belongs to mineral separation technologies and devices. The technology comprises the steps that raw ore and reagents are stirred to form ore pulp feeding, and by roughing through a roughing flotation column, two-time concentration through a concentration flotation column, multi-time scavenging on rougher tailings through a scavenging flotation machine and a scavenging flotation column and scavenging on refining I flotation column tailings through a fine scavenging flotation machine, final concentrate and tailings are obtained; at the same platform, the flotation column and the flotation machine combined separating technology is used for processing metal ore, the flotation columns are used in the roughing and concentration processes, the processing amount is large, separation accuracy is high, finally, high-grade concentrate products can be obtained, the flotation machine and the scavenging flotation column are used for carrying out multi-time scavenging on the roughing flotation column tailings, concentrate products in the tailings can be recycled to the maximum degree, refining I flotation column concentrate tailings are subjected to fine scavenging, the maximum recovery rate of the concentrate products is guaranteed, enterprise economy benefit is improved, the system technology is simple, consumed electricity is low, occupied space is small, and operation cost is low.

Owner:CHINA UNIV OF MINING & TECH

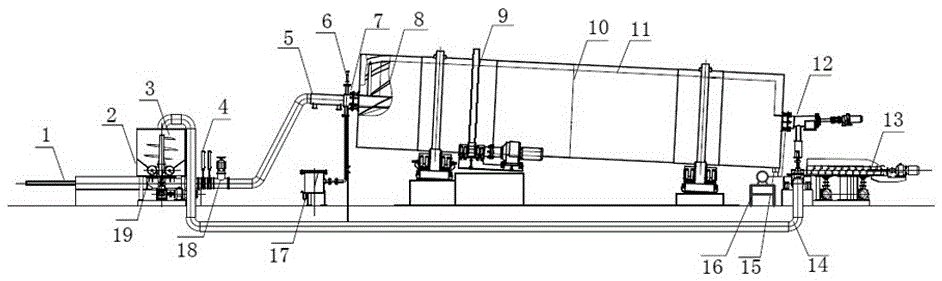

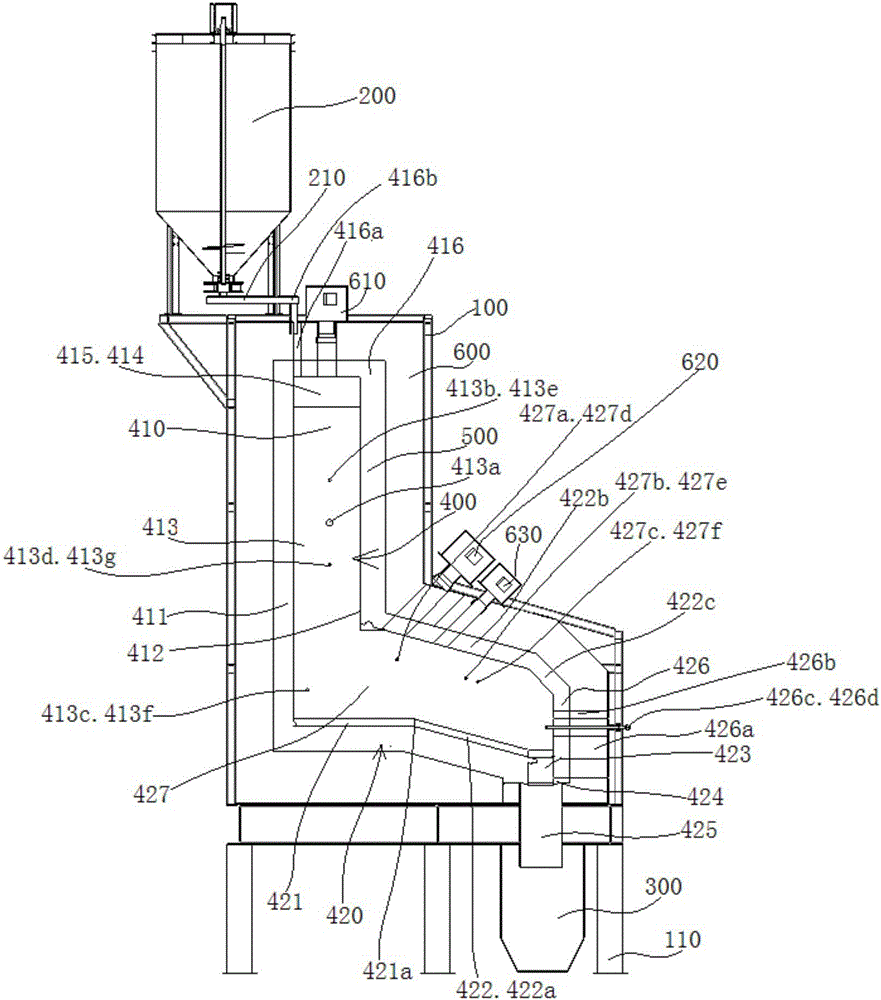

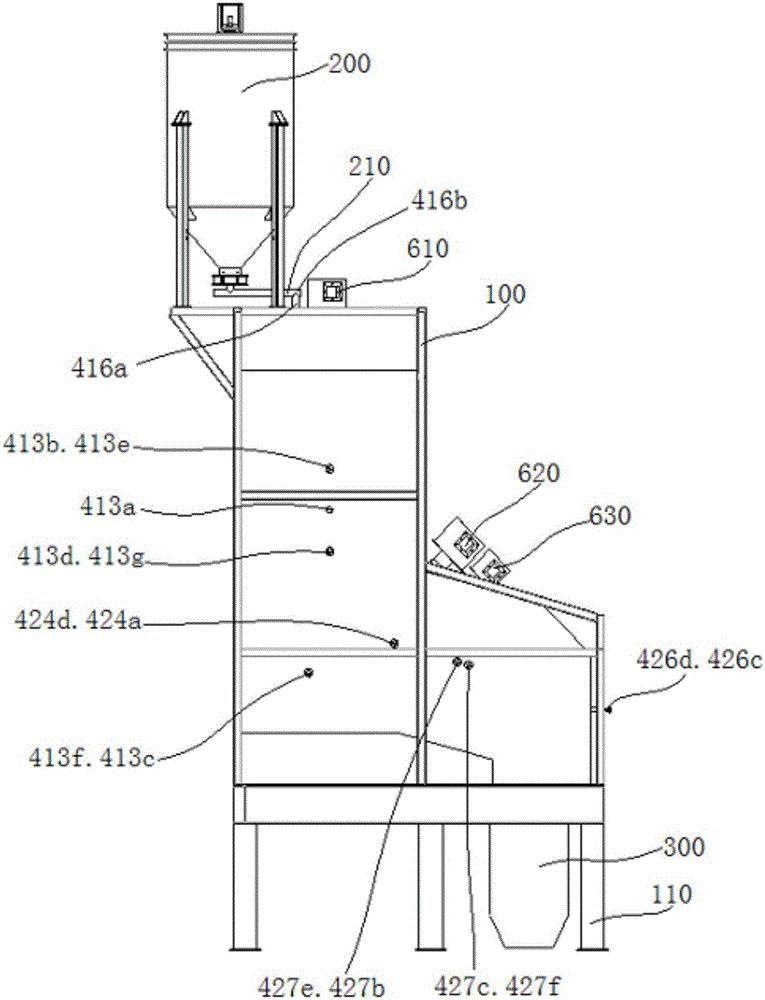

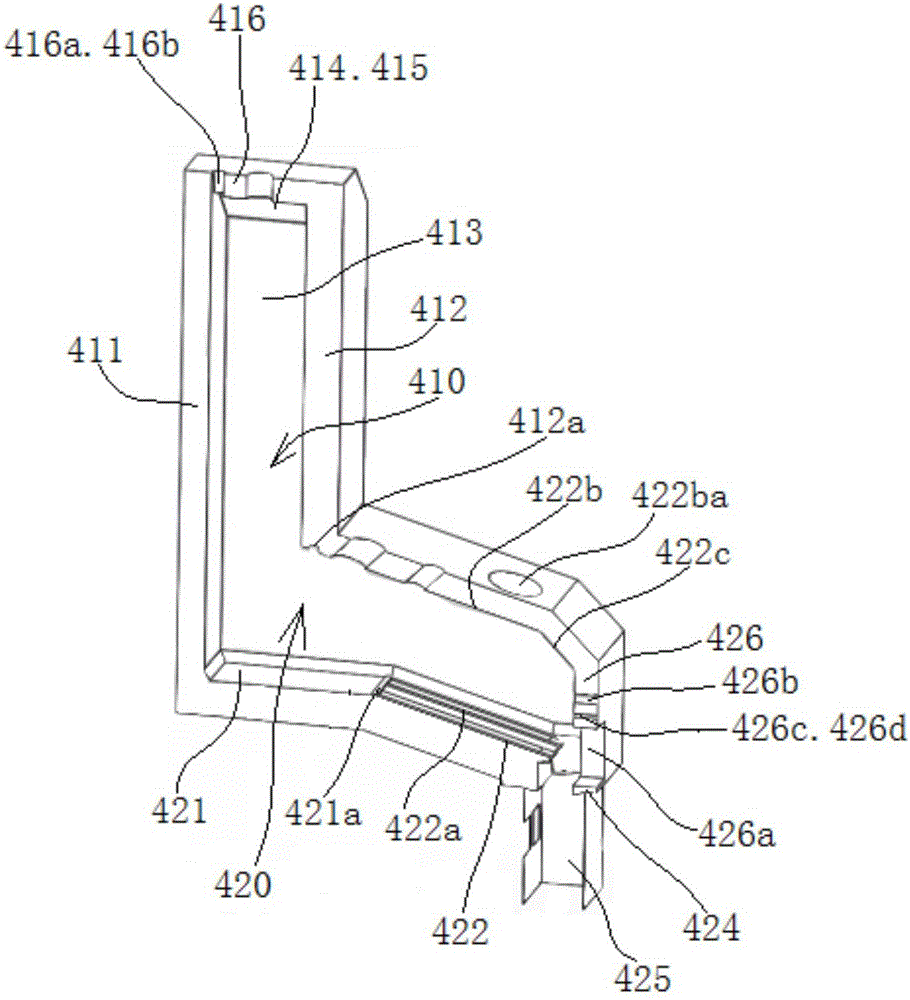

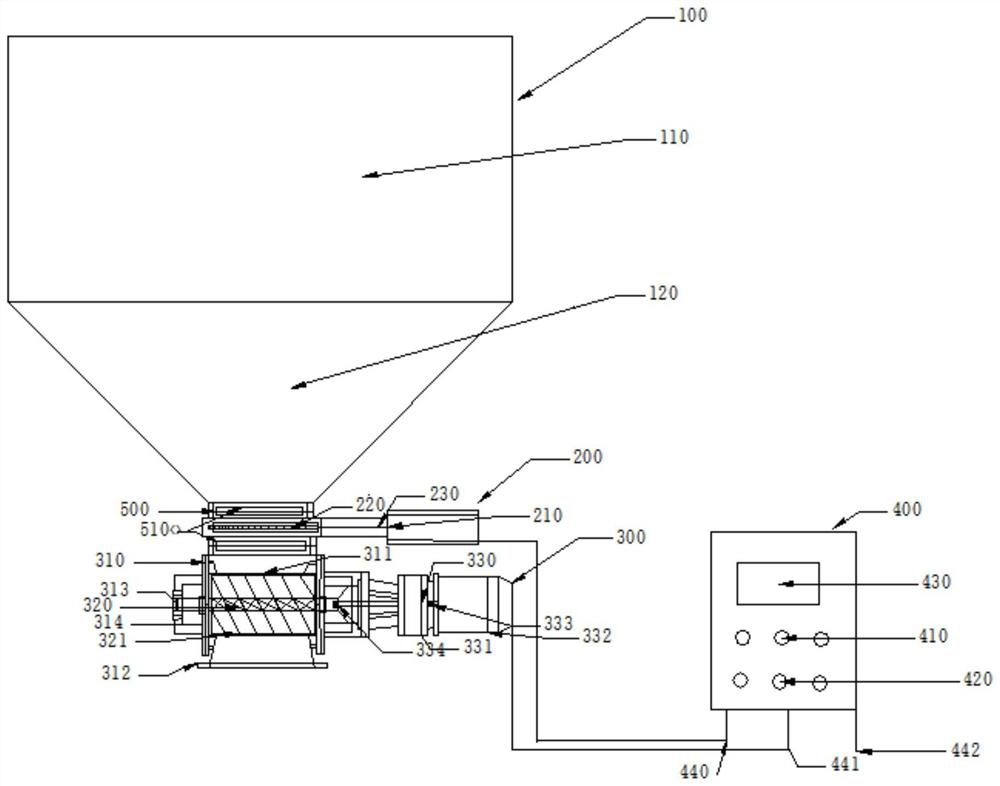

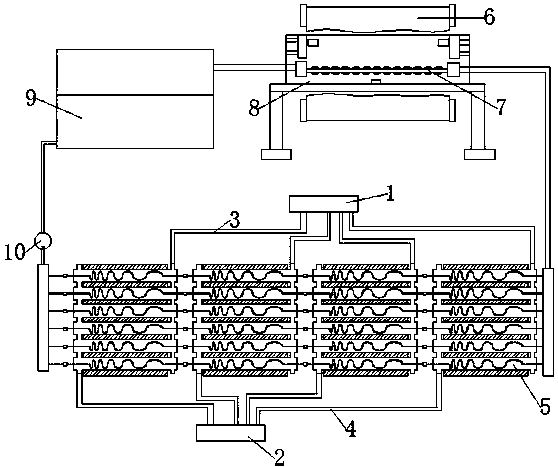

Continuous horizontal dry-process anaerobic fermentation system

InactiveCN105602843AImprove airtightnessRealize high-value utilizationBioreactor/fermenter combinationsBiological substance pretreatmentsRefluxAutomatic control

The invention provides a continuous horizontal dry-process anaerobic fermentation system, belonging to the technical field of fermentation plants. The continuous horizontal dry-process anaerobic fermentation system comprises a horizontal fermentation tank capable of rotating along the axis, wherein a biogas slurry reflux spray system is fixedly arranged in the fermentation tank; one end of the fermentation tank is a feed end, and the other end is a discharge end; the height of the feed end is greater than that of the discharge end; the feed end is connected with a mixing bin through a feed system; the feed end is provided with a biogas pipe; the discharge end is provided with a fermentation leftover discharge system; and a temperature measuring device is arranged inside the fermentation tank. Both ends of the obliquely-arranged horizontal fermentation tank are respectively connected with the automatic feed system and automatic discharge system, and the reflux spray system is arranged in the fermentation tank, thereby implementing continuous stable feed and discharge; and thus, the biogas slurry can implement circulating spray, and the marsh slag can implement circulating mixing. The continuous horizontal dry-process anaerobic fermentation system has the advantages of simple structure, reasonable design, high operation smoothness and low energy consumption, and can implement full-automatic control. The capacity aerogenesis rate is 1.0-1.5 m<3> / m<3>.d.

Owner:QINGDAO TIANREN ENVIRONMENT

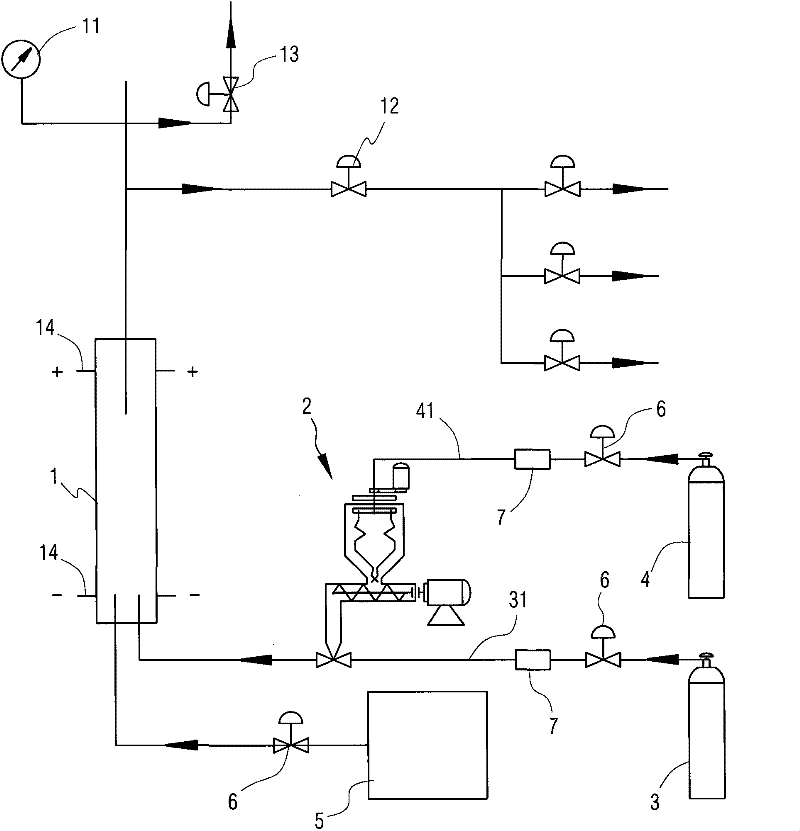

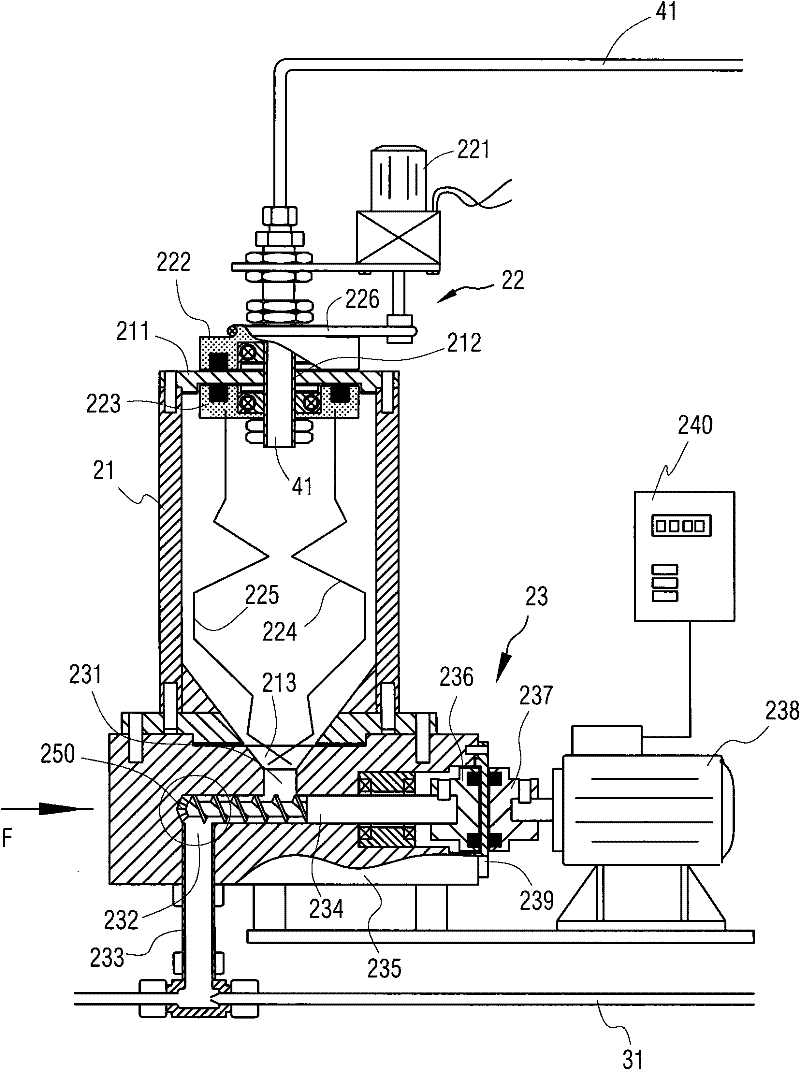

Pressurized fluidized bed gasifier and method for operating the same

InactiveCN101747946AImproved sealed driveInto continuous stabilityProductsReagentsFluidized bed gasifierWater vapor

The invention discloses a pressurized fluidized bed gasifier, comprising: a reactor, a biomass feeder, an inert gas conveying gas source, an air balance gas source and a vapor generator, wherein the reactor is respectively connected with the biomass feeder and the vapor generator via pipelines and is used for mixing and heating the biomass powders, input through the biomass feeder, and the vapor, input by the vapor generator, to generate combustible gas. The invention further provides a method for operating the pressurized fluidized bed gasifier. The pressurized fluidized bed gasifier and the method for operating the pressurized fluidized bed gasifier according to the invention are suitable for the gasification of biomass powders at high pressure, and particularly achieve the improvement on the sealing transmission of a stirring device and a spiral feeding device in the feeder so that both adapt to the feeding of biomass powders in high-pressure environment, thus the problem that low-density fine powders tend to bridging and are not liable to enter the reactor at next stage is solved.

Owner:TAIYUAN UNIV OF TECH

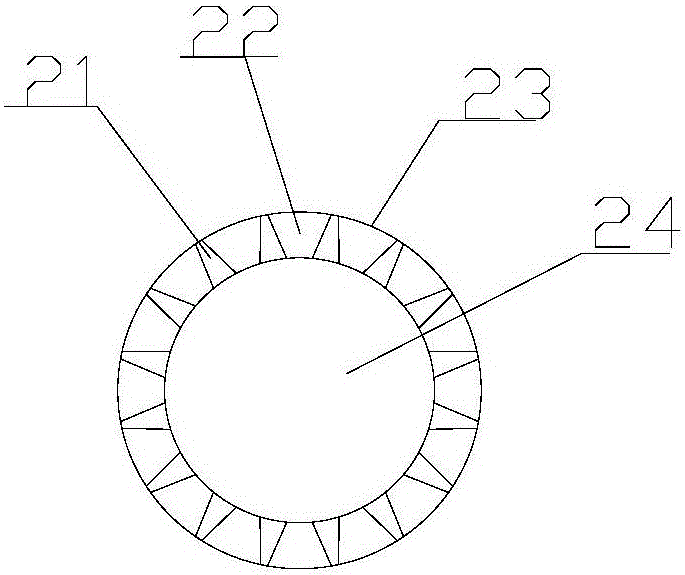

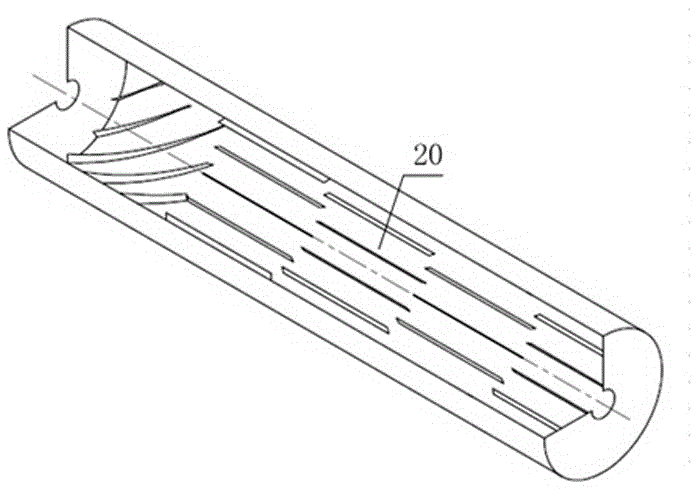

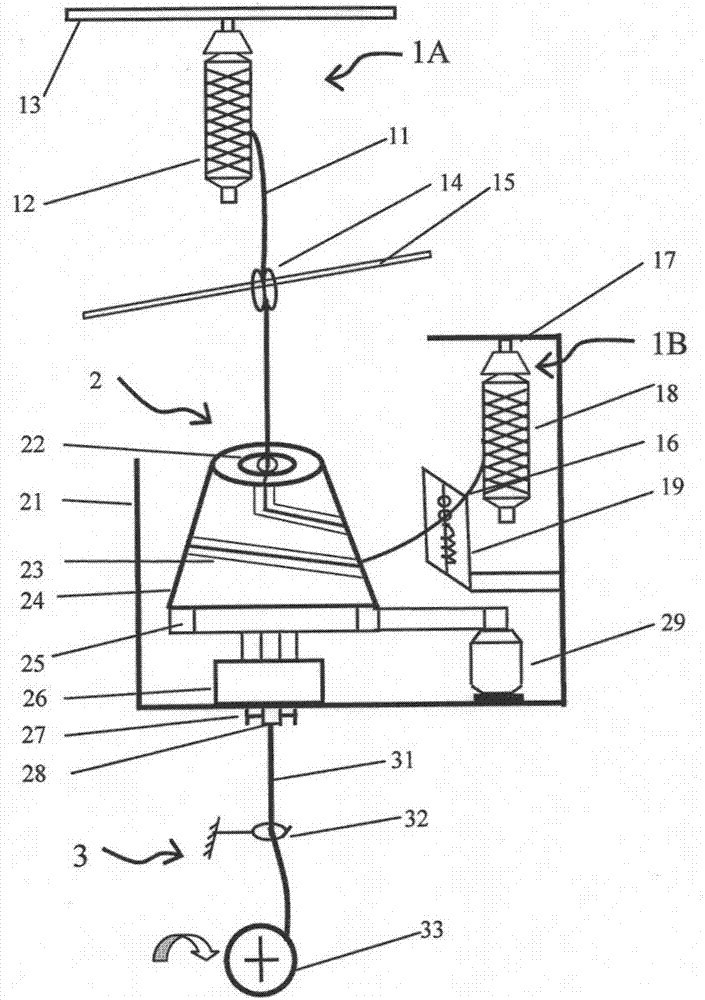

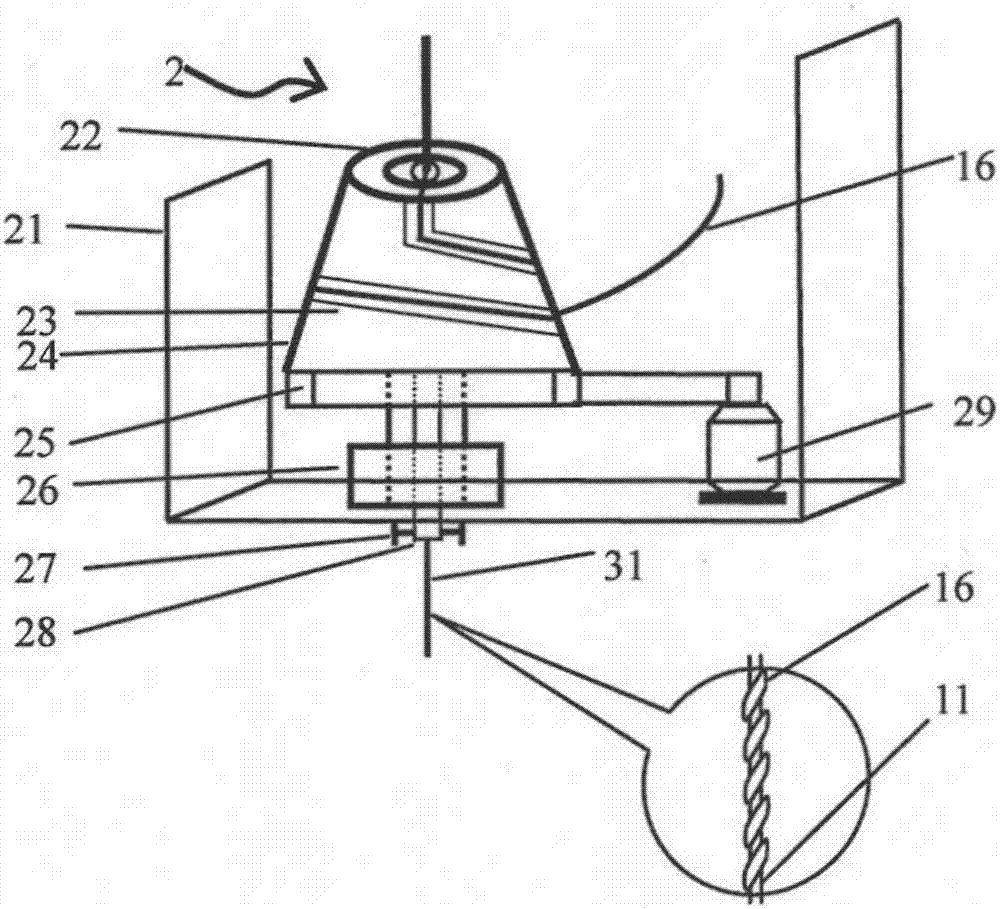

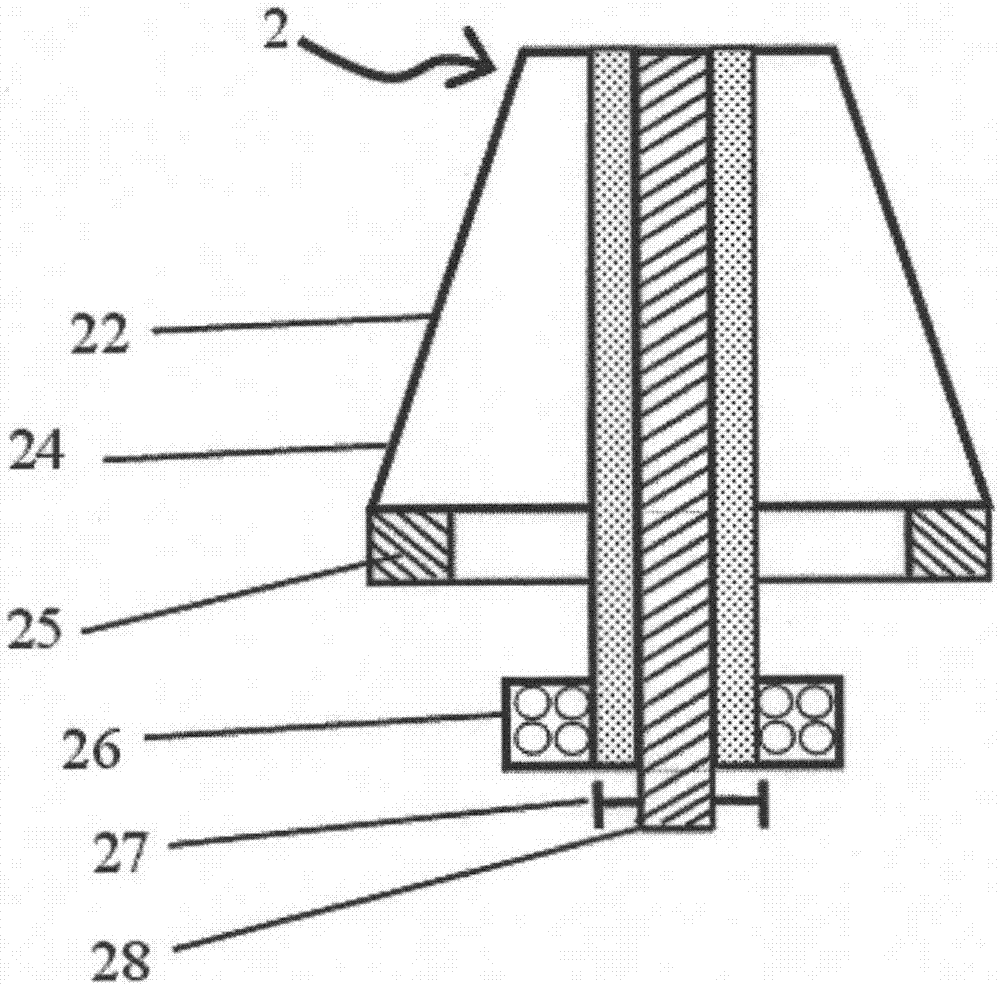

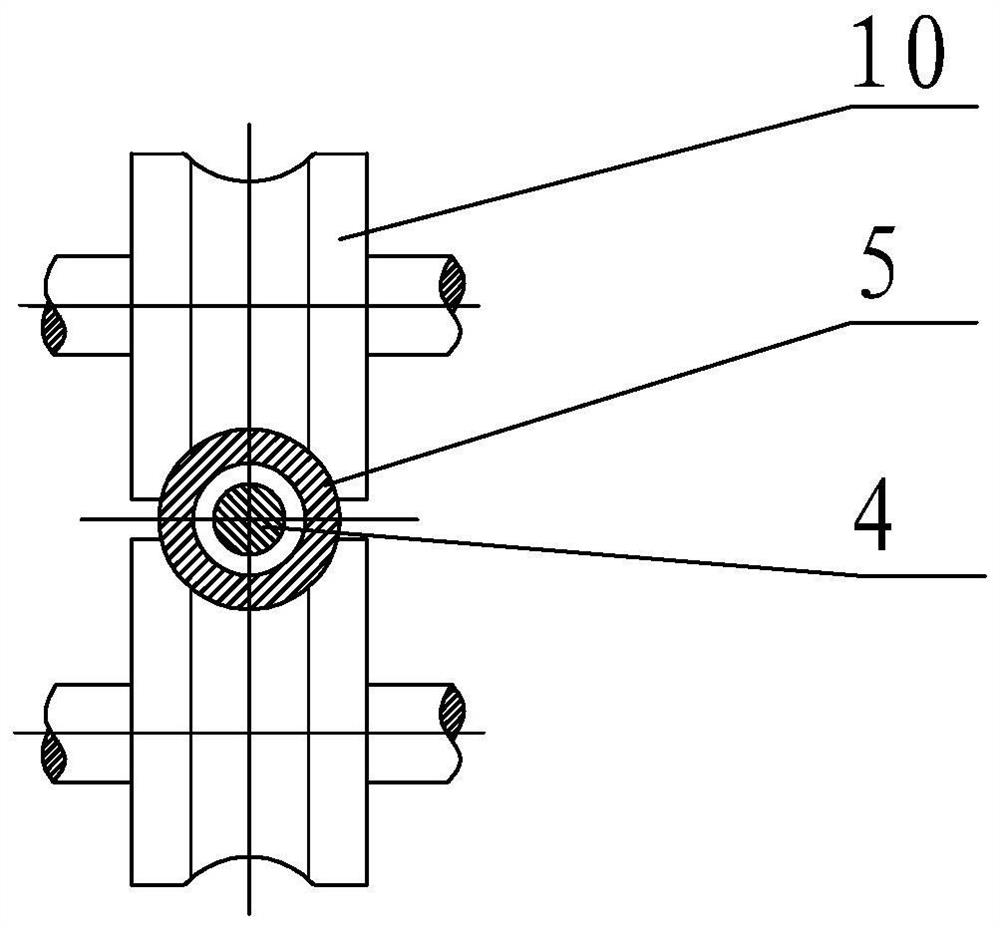

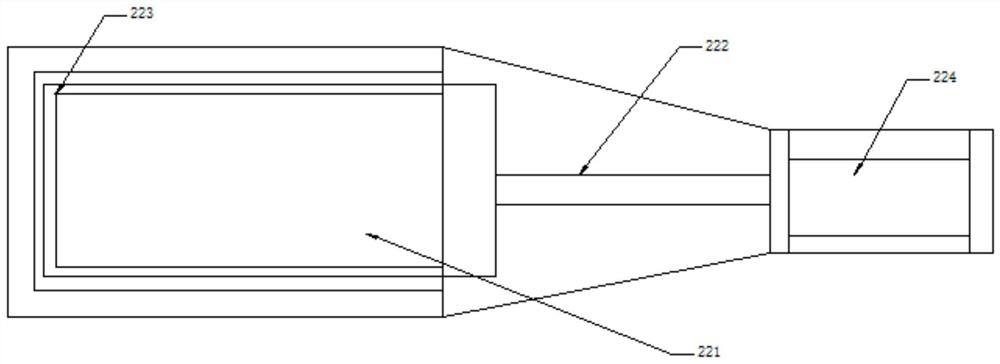

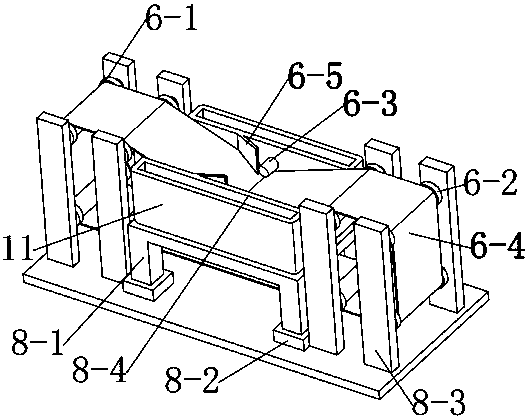

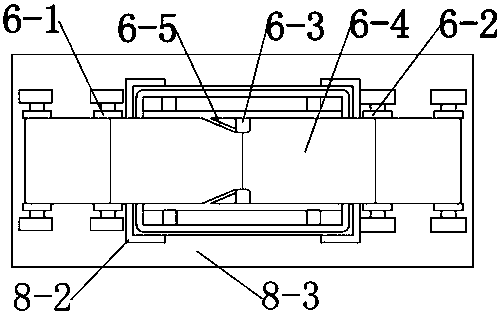

A device for preparing auxetic composite yarn through active wrapping of fine and hard low-elasticity yarn around thick and soft high-elasticity yarn

The invention relates to a device for preparing auxetic composite yarn through active wrapping of fine and hard low-elasticity yarn around thick and soft high-elasticity yarn and a method and use thereof. The device comprises yarn component supply and feeding control mechanisms, an active wrapping forming mechanism and a winding mechanism. The method is characterized in that thick and soft high-elasticity yarn unwound from bobbins passes through a tension disk and passes through a hollow pipe through pulling of certain tension; fine and hard low-elasticity yarn passes through a telescopic location yarn guide and is output to a head end of the hollow pipe along a spiral yarn guide groove of a speed-controllable rotor via rotation of the rotor, and then meets the thick and soft high-elasticity yarn and is wound around the thick and soft high-elasticity yarn actively to form auxetic composite yarn with a spiral wrapping structure. The device is easy to operate, low in cost, and suitable for continuous production, promotion and application, and can be installed on spinning machines for ring spinning, friction spinning, rotor spinning and electrostatic spinning. Auxetic composite yarn manufactured with the device is uniform in structure and unique in performance and can be used for buffering ropes, bulletproof and stab-resistant yarn, yarn for heat preservation fabric and sewing threads for medical surgery.

Owner:DONGHUA UNIV

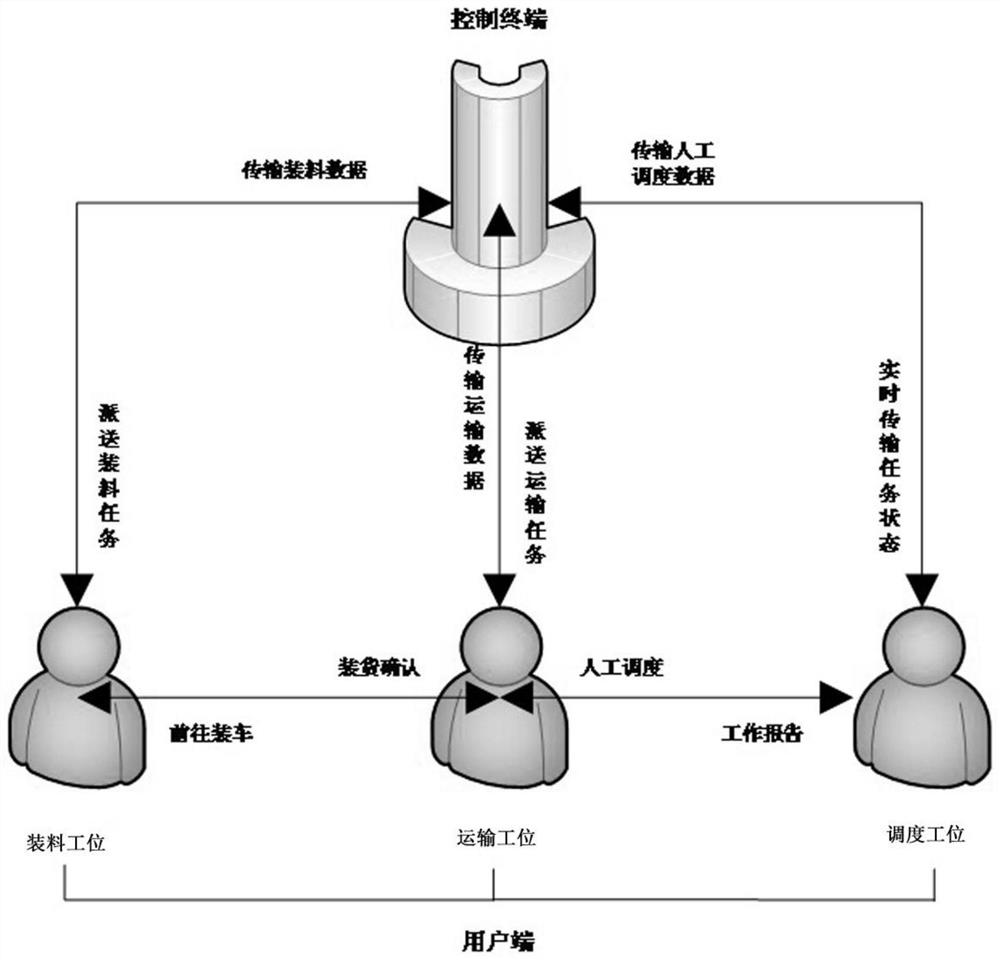

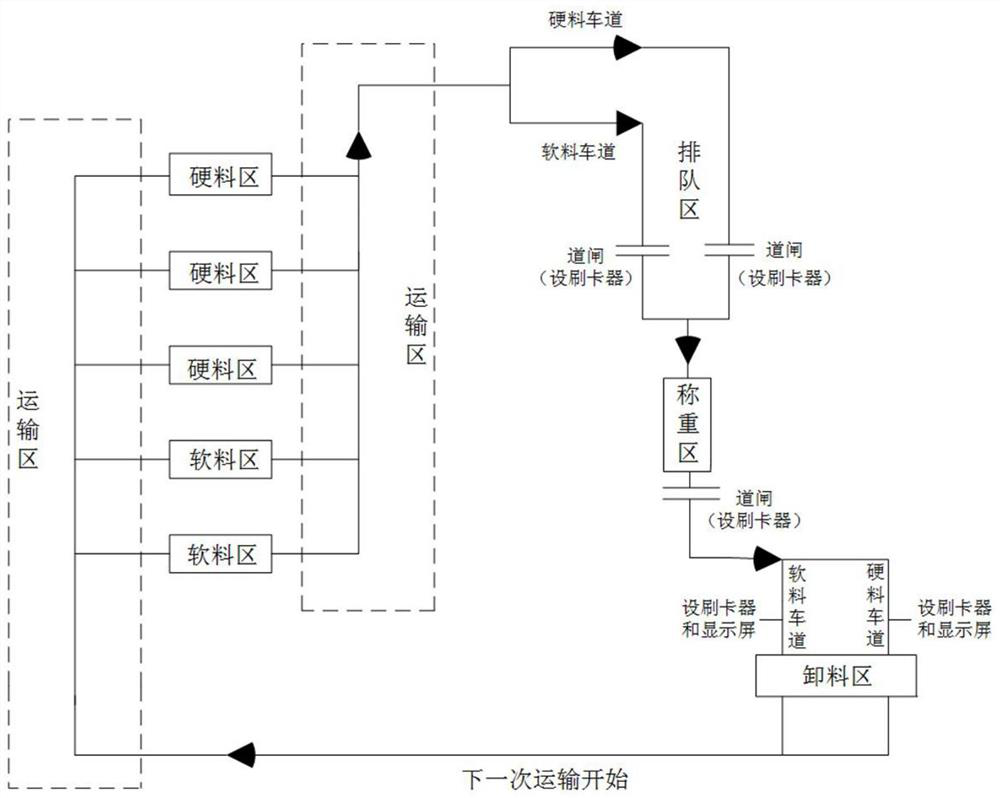

Transport vehicle intelligent scheduling system and method based on soft and hard material ore blending proportion

ActiveCN112348436ALow site requirementsLow maintenanceRegistering/indicating time of eventsRegistering/indicating working of vehiclesIn vehicleControl engineering

The invention discloses a transport vehicle intelligent scheduling system and method based on a soft and hard material ore blending proportion, and belongs to the technical field of information. The system comprises a control terminal, a user side, and a vehicle scheduling special App connected between the control terminal and the user side. The control terminal is provided with a management and control unit, and the user side comprises a loading station, a transportation station and a dispatching station; and the charging area is divided into a hard material area and a soft material area according to the hardness of the materials. The beneficial effects of the invention are that the management and control unit realizes the dispatching of the whole transportation process, and enables the proportion of the vehicle-mounted materials to be kept relatively stable. According to the scheduling method, dynamic adjustment can be carried out at any time according to the ore Principal coefficient of the material, the vehicle in the to-be-unloaded state and the specific situation of the mineral material matched in the vehicle in the to-be-unloaded state, and feeding is stably carried out in proportion; therefore, the problems that due to the crushing efficiency and the proportion and sequence of soft and hard materials during feeding, reasonable configuration of the soft and hard materials is difficult to guarantee due to external environment correlation, and feeding is conducted according to the proportion and sequence are solved.

Owner:SISHUI HUIFENG AGRI DEV ENG CO LTD

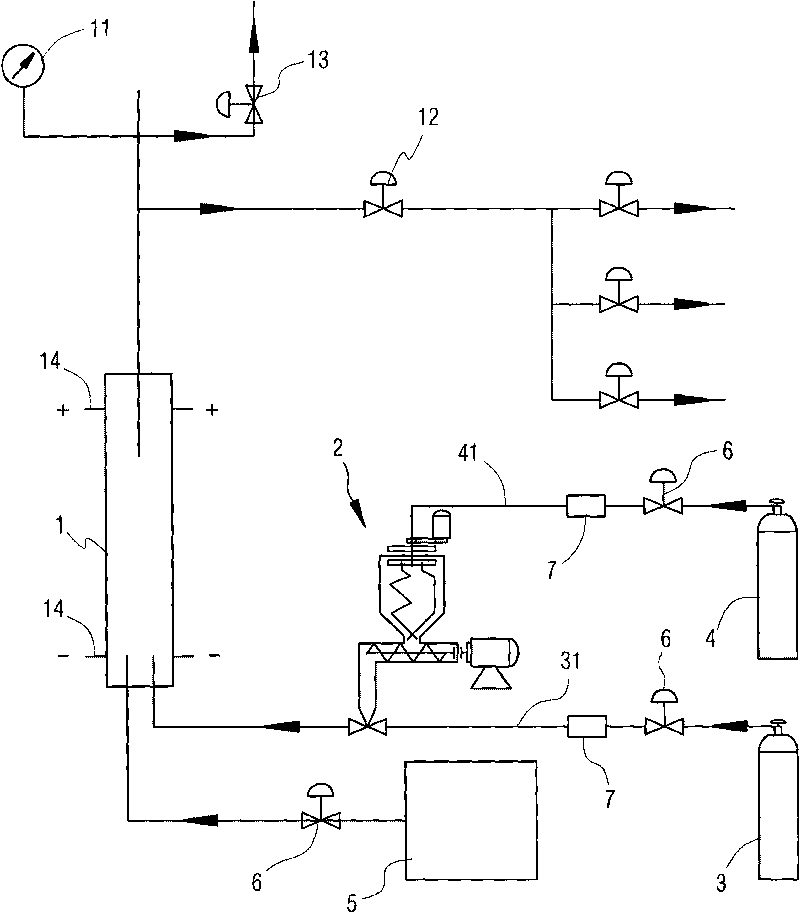

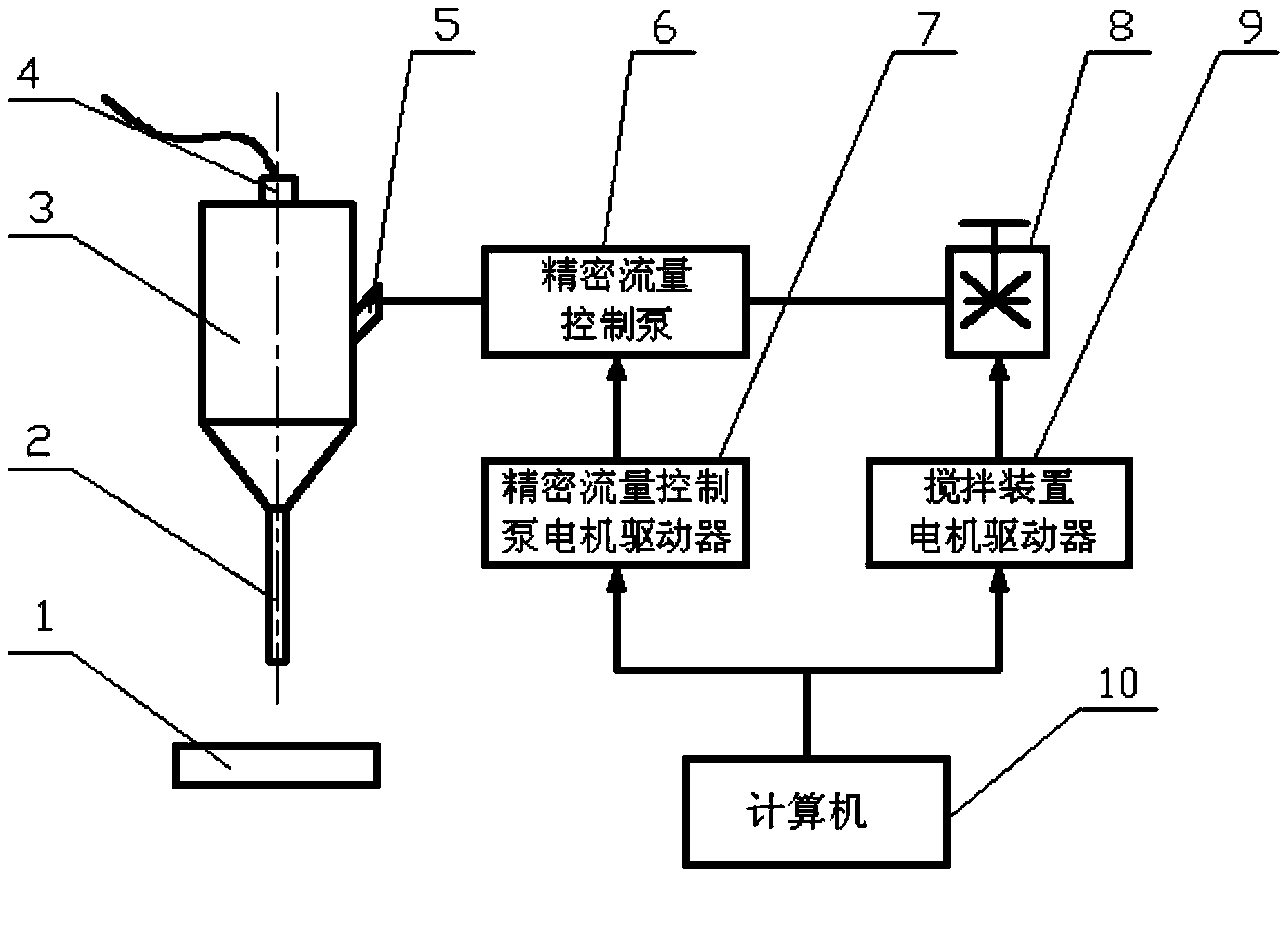

Accurate feeding apparatus and method for low-pressure post-mixed type micro abrasive jet

InactiveCN103395006AInto continuous stabilityWon't clogAbrasive feedersAbrasive machine appurtenancesSpray nozzleEngineering

An accurate feeding apparatus and a method for low-pressure post-mixed type micro abrasive jet belong to the technical field of difficult-processing material processing, and the problems in conventional low-pressure post-mixed type micro abrasive jet processing technologies are solved that micro abrasives are difficult to suck and accurate feeding of the abrasives is difficult to realize. According to the accurate feeding apparatus, a post-mixed jet device comprises a nozzle, a post-mixed chamber, an operating fluid inlet and an abrasive mixed liquor inlet; the nozzle disposed at the lower end of the post-mixed jet device is just opposite to the upper surface of a to-be processed workpiece; the post-mixed jet device is provide with the operating fluid inlet at the top, the post-mixed chamber in the interior, and the abrasive mixed liquor inlet at the side wall; an abrasive mixed liquor stirring device is connected with the inlet of a precision flow control pump via a pipeline; the outlet of the precision flow control pump is connected with the inlet of the abrasive mixed liquor inlet; a computer controls the rotating speed of the precision flow control pump via an electric motor driver of the precision flow control pump; and the computer controls the rotating speed of the abrasive mixed liquor stirring device via an electric motor driver of the abrasive mixed liquor stirring device.

Owner:HARBIN INST OF TECH

Spiral feeder with air locking valve

InactiveCN102913934AAvoid "feedback" phenomenonContinuous and stable feedingLump/pulverulent fuel feeder/distributionEngineeringChassis

The invention discloses a spiral feeder with an air locking valve. The spiral feeder with the air locking valve comprises a hopper, a spiral feeder, a motor, a reducing chassis, a feed inlet and a discharge outlet. The hopper is disposed at the upper end of the spiral feeder through the feed inlet, one end of the reducing chassis is connected with the motor, the other end of the reducing chassis is fixed on one side of the spiral feeder, the discharge outlet is disposed at one end of the lower side of the spiral feeder, the air locking valve is arranged in the discharge outlet, one end of the air locking valve extends into the discharge outlet, the other end of the air locking valve is arranged outside the discharge outlet to be connected with a handle, a ring of blowing pipes which are evenly distributed are arranged on the outer periphery of the feed inlet, one end of each blowing pipe faces the feed inlet and delivers cooling air into the feed inlet, and the other ends of the blowing pipes are connected with an air delivery pipeline through a hollow pipeline. The problems that the existing air locking device is complex in structure and high in operation cost can be solved, the discharge outlet is prevented from backfire, material is guaranteed to be delivered continuously and stably, feeding safety is guaranteed, and the spiral feeder with the air locking valve is simple in structure, low in cost and convenient to implement.

Owner:郭丰亮

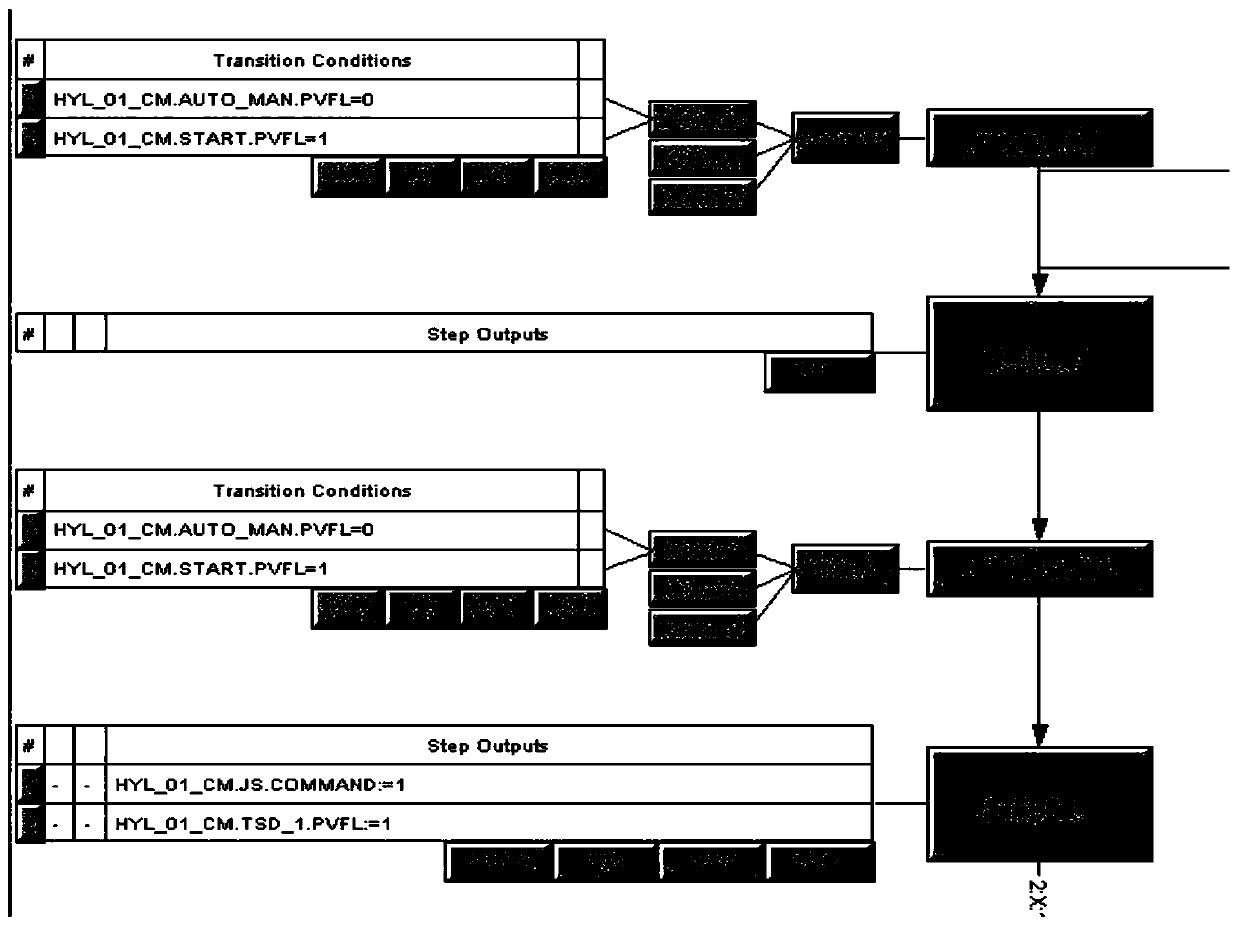

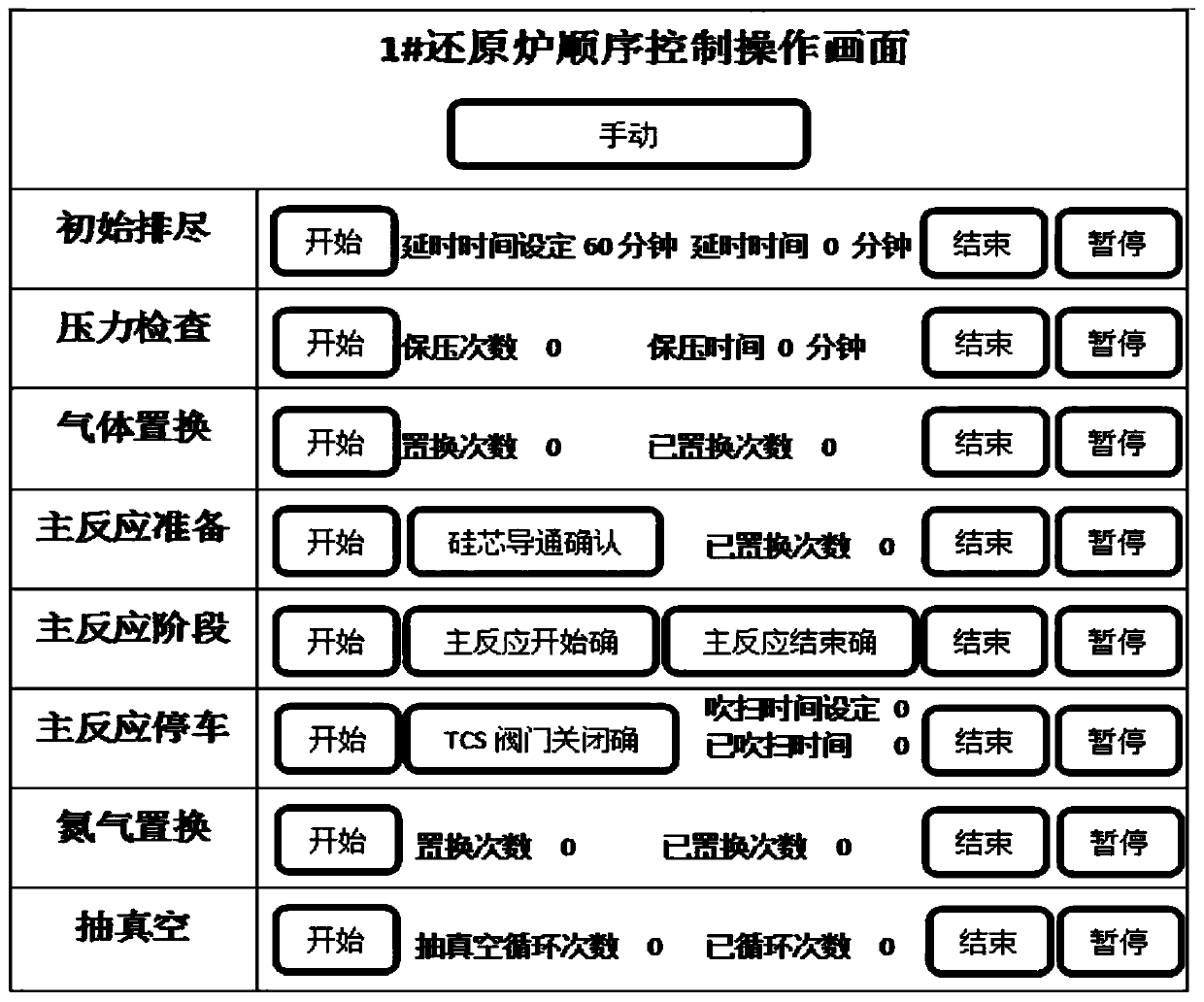

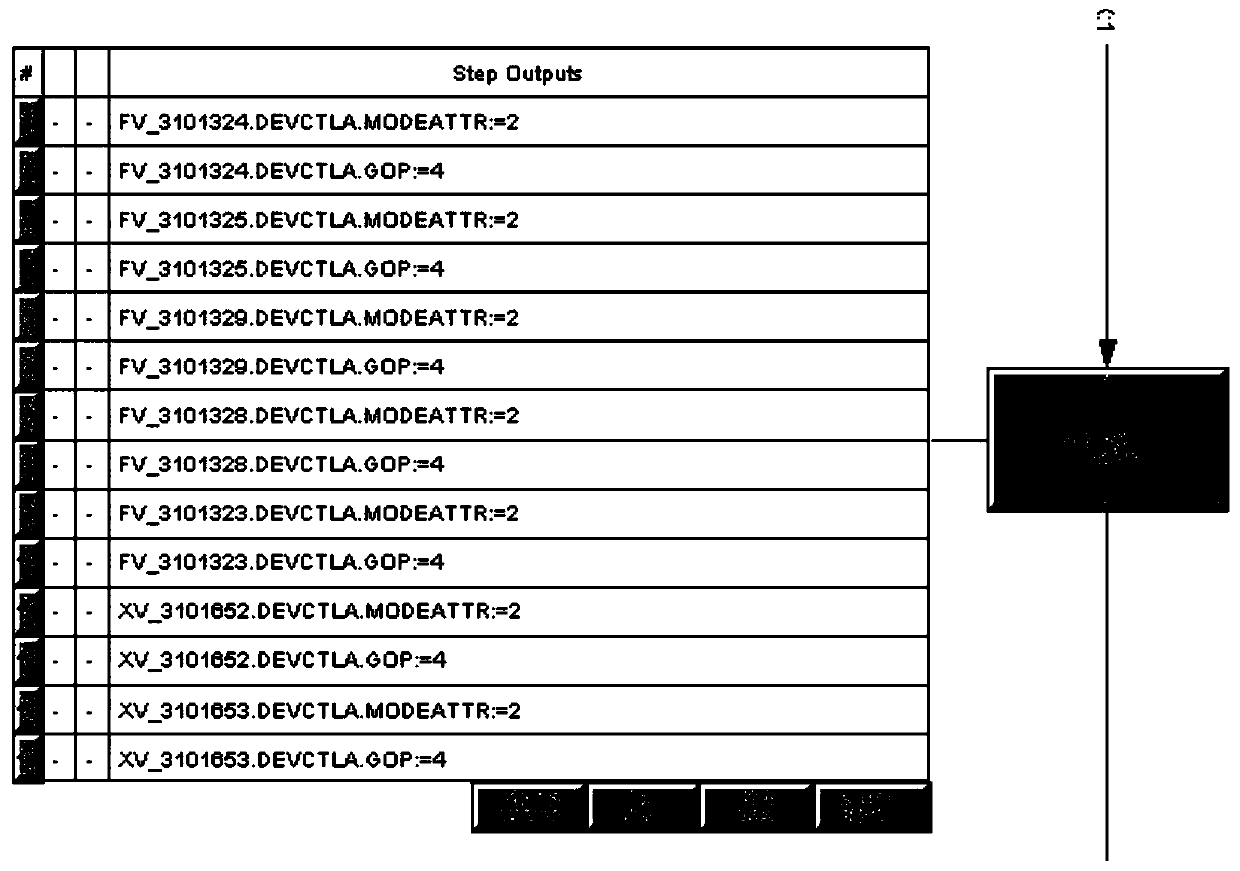

Reduction furnace sequence control method based on DCS of polycrystalline silicon production device

ActiveCN110879579AReduce operating frequencyReduce operating labor intensityTotal factory controlSimultaneous control of multiple variablesSequence controlAutomatic control

The invention discloses a reduction furnace sequence control method based on a DCS (Distributed Control System) of a polycrystalline silicon production device. The reduction furnace sequence control method comprises the following specific programs: S1, an initial emptying sequence control program; S2, a pressure check sequence control program; S3, a gas replacement sequence control program; S4, amain reaction preparation sequence control program; S5, a material feeding climbing program and a step switching program in the main reaction stage; S6, a main reaction shutdown sequence control program; S7, a nitrogen replacement sequence control program; and S8, a vacuumizing sequence control program. According to the invention, a highly automatic sequence control program is realized, frequent manual operation is not needed, the operation frequency and labor intensity of staff are remarkably reduced, interference of human factors is reduced, and safe and stable operation of the reduction furnace is guaranteed. Moreover, continuous and stable feeding in the polycrystalline silicon production process is achieved through an automatic control program, and the stability of product quality isremarkably improved.

Owner:青海黄河上游水电开发有限责任公司新能源分公司 +3

Method for continuously rolling copper pipe through planetary pipe mill

PendingCN114054506AEnough feed forceNo feeding synchronization issuesMetal rolling arrangementsFeeding forceControl theory

The invention relates to a method for continuously rolling a copper pipe through a planetary pipe mill, which is characterized in that a roller type feeder or a crawler type feeder is arranged at an inlet of a three-roller planetary pipe mill and is driven by a pipe blank rolled by the three-roller planetary pipe mill to be in a passive rotating state; the roller type feeder or the crawler type feeder passively rotates and continuously provides a feeding force for the pipe blanks at the same time, and the pipe blanks are continuously fed into the three-roller planetary pipe mill one by one in an end-to-end connection mode to be rolled. By the adoption of the technical scheme, the structure is simple, reliable and practical, the requirement for continuously rolling copper pipes is met, the defects in the prior art are overcome, and production efficiency is improved.

Owner:JIANGSU XINGRONG HI TECH

Vertical flame channel and hot bed-connected type powder material continuous melting furnace

ActiveCN106568086AIncrease time for homogeneous mixingSpeed up the outflowIncinerator apparatusThermal insulationSlag

The invention relates to a vertical flame channel and hot bed-connected type powder material continuous melting furnace. The vertical flame channel and heating bed-connected type powder material continuous melting furnace comprises a steel shell; a weighing silo is arranged on the top of the steel shell; the material discharging opening of the weighing silo is provided with a horizontal type spiral constant feeder; the bottom of the steel shell is provided with a water sealed slag remover; a continuous melting furnace is arranged in steel shell; a flame retardant layer and a thermal insulation layer are sequentially arranged between the outer surface of the continuous melting furnace and the inner surface of the steel shell; a vertical flame channel and a hot bed are arranged in the continuous melting furnace; the bottom of the vertical flame channel is communicated with the front portion of the hot bed; the top of the vertical flame channel is provided with a first combustor and a blanking opening; the blanking opening is communicated with the material discharging opening of the horizontal type spiral constant feeder; the joint of the vertical flame channel and the hot bed is provided with second combustors; the rear side of the bottom of the hot bed is provided with a slag out-flow opening; and the slag out-flow opening is in butt joint with the feeding opening of the water sealed slag remover. The vertical flame channel and hot bed-connected type powder material continuous melting furnace of the invention has the advantages of low investment, small size, convenient manipulation, low running cost and the like.

Owner:上海煜工环保科技有限公司

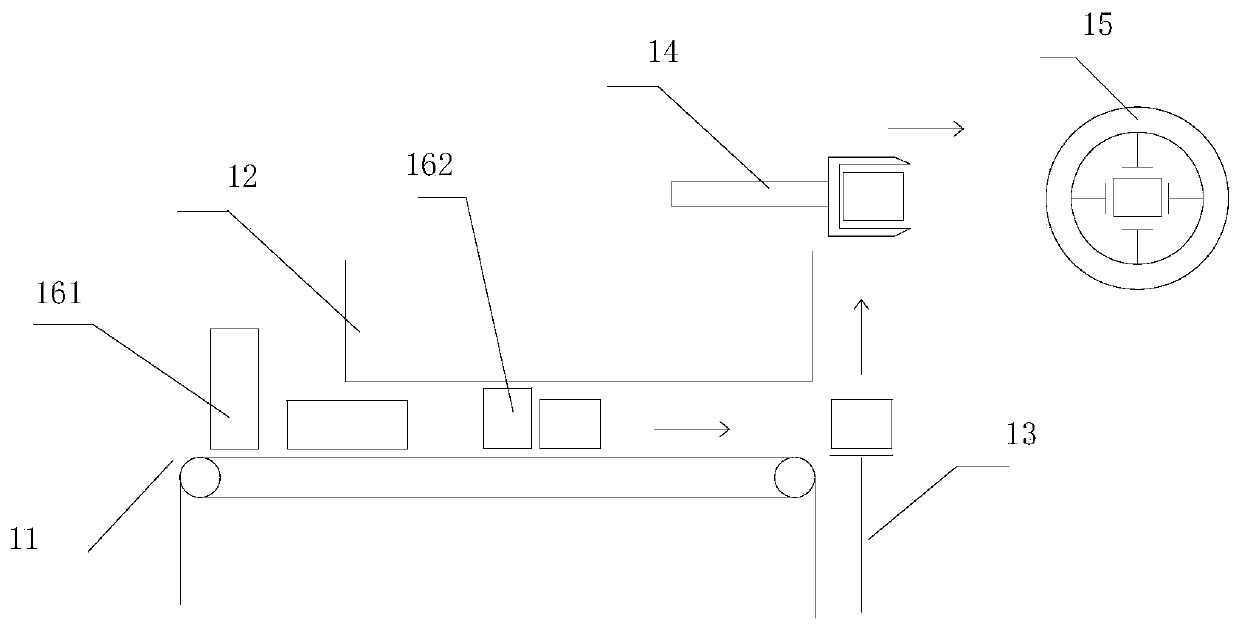

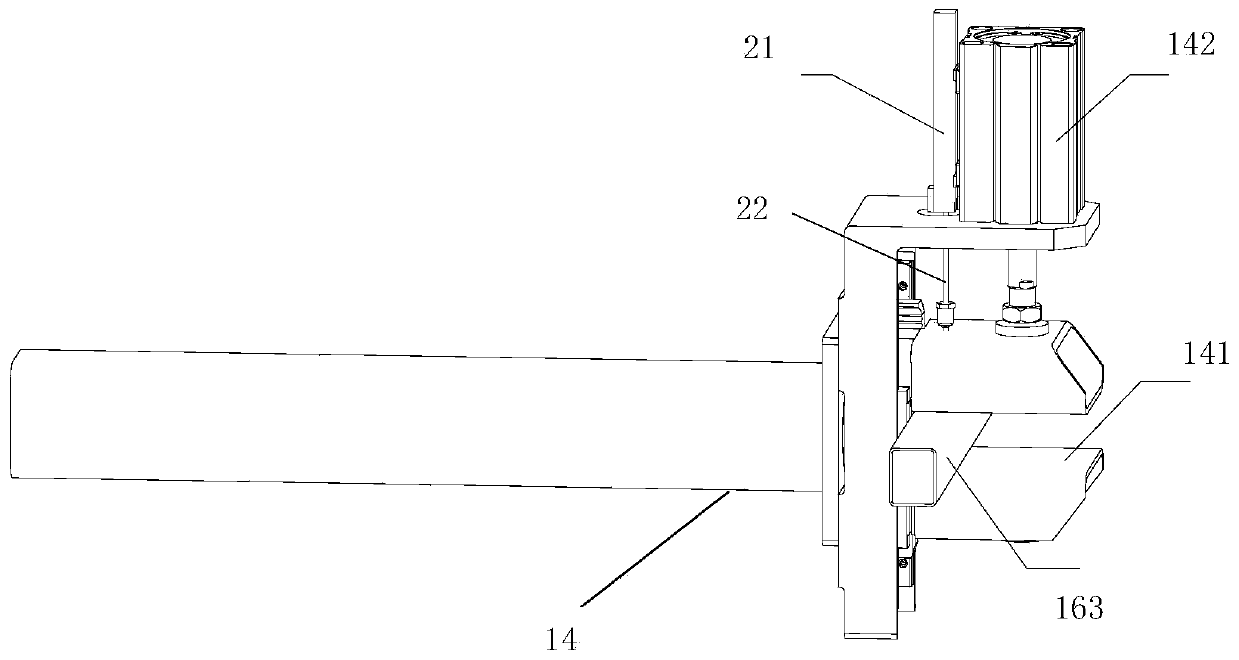

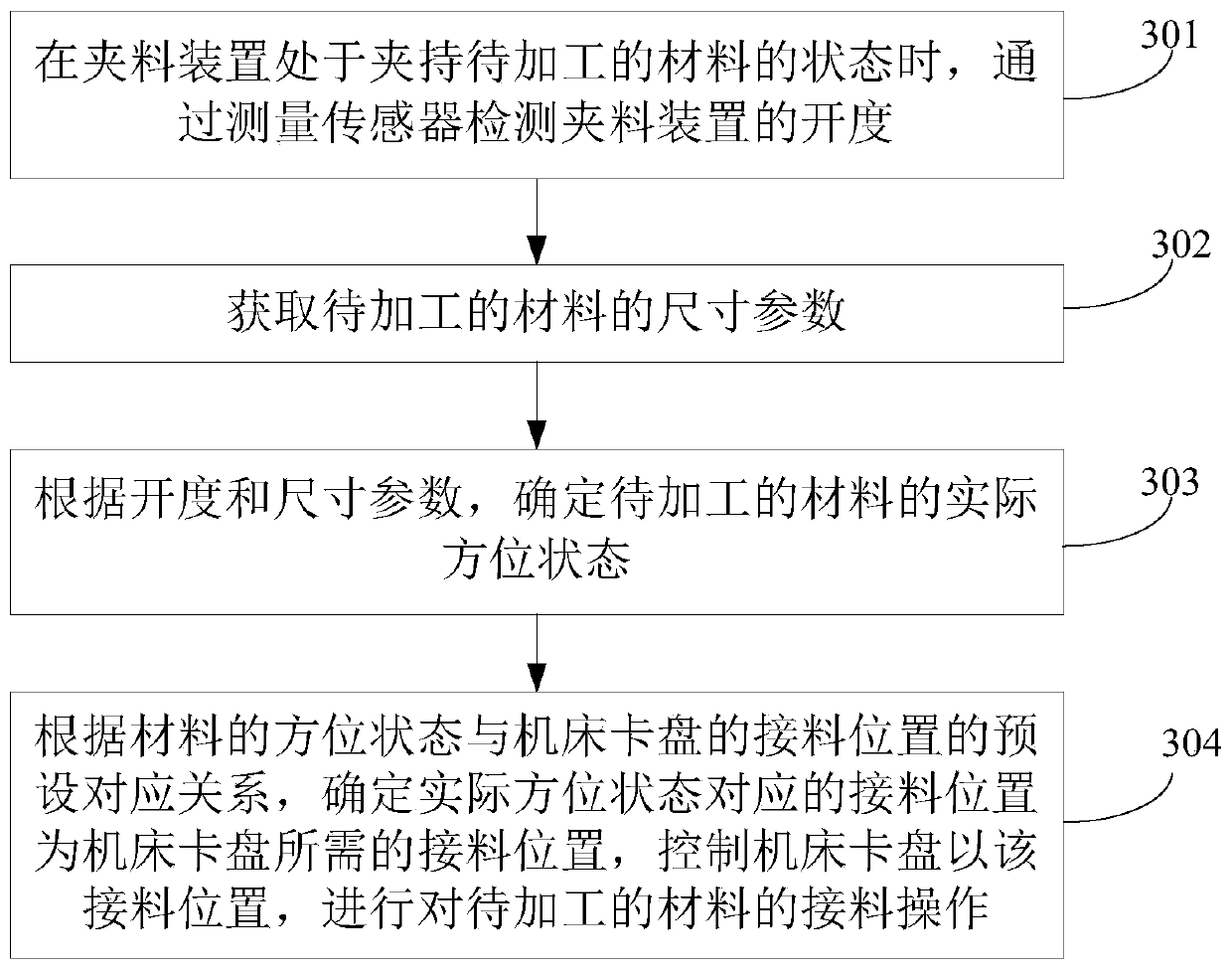

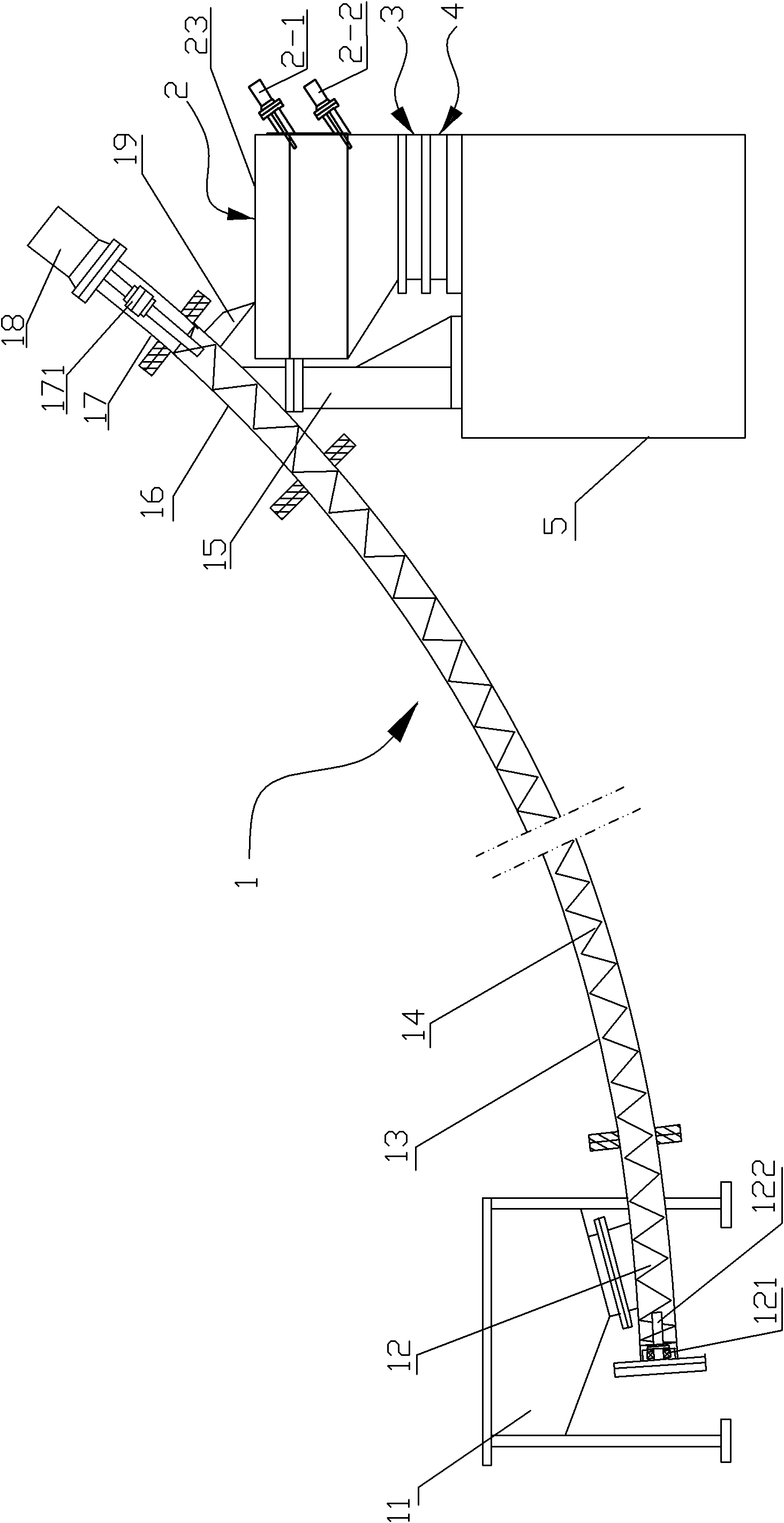

Automatic loading method and device, storage medium and automatic loading control device

ActiveCN109909603AReduce restrictionsContinuous and stable feedingLaser beam welding apparatusEngineeringMachine tool

The invention discloses an automatic loading method and device, a storage medium and an automatic loading control device. A measuring sensor is arranged on a feeding mechanism, and when a clamping device is in the state of clamping the material to be machined, through the measuring sensor, the opening degree of the clamping device is detected; the size parameter of the material to be machined is obtained; according to the opening degree and size parameters, the actual orientation state of the material to be machined is determined, accordingly, according to the preset corresponding relation between the orientation state of the material and the receiving position of a machine tool chuck, and the machine tool chuck is controlled to carry out receiving with the receiving position correspondingto the actual orientation state; through the scheme, limiting on the orientation state of the material clamped in the clamping device is greatly reduced, the device can achieve continuous stable loading for easy dialing material with the large long and short side difference or the difficult dialing material with the small long and short side difference, through the scheme, continuous stable loading can be achieved, the loading success rate and loading efficiency can be improved, and continuous machining is ensured.

Owner:HANS LASER TECH IND GRP CO LTD +1

Continuous feeding system for dispersion and accurate measurement of powder for production of rubber powder modified asphalt

ActiveCN101955671AContinuous and stable feedingGuarantee product qualityChemical industryBuilding insulationsAutomatic controlEngineering

The invention relates to a continuous feeding system for dispersion and accurate measurement of powder for production of rubber powder modified asphalt, which comprises a rubber powder conveyer and a storage bin, and is characterized in that a feeding mechanism is a spiral spring; a feed delivery pipe is made of a high polymer self-lubricating material; a feeding motor is a variable frequency motor; level gauges are arranged on the side wall of the storage bin; the storage bin is connected with a distributing device for accurate measurement and dispensing of the rubber powder; the distributing device mainly comprises a square cylinder-shaped shell open at top and bottom, a metering roll, a bearing seat and a rotating shaft; the distributing device is connected with a beating crusher for finely breaking the rubber powder; the beating crusher mainly comprises a square cylinder-shaped shell open at top and bottom, a steel tooth beating rod and a bearing seat; and the variable frequency motor, an upper limit level gauge, a lower limit level gauge, a stepping motor and a beating motor are connected with an automatic control system. The invention has the advantages of improving the production efficiency and product quality, saving manpower, ensuring continuous stable production of a reaction kettle, and adapting to application of the automatic control system.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

SMT welding solder paste printing device with automatic feeding function

PendingCN114590019AReduce wasteContinuous and stable feedingPrinted circuit assemblingScreen printersProcess engineeringSolder paste

The invention relates to the field of auxiliary printing equipment, in particular to an SMT welding solder paste printing device with an automatic feeding function. The SMT welding solder paste printing device can reduce solder paste waste and has an automatic feeding function. The invention discloses an SMT welding solder paste printing device with an automatic feeding function. The SMT welding solder paste printing device comprises a discharging mechanism, a solder paste recycling mechanism, a stirring mechanism, an overturning cleaning mechanism, a feeding mechanism and the like. A stirring mechanism is arranged above the discharging mechanism, an overturning cleaning mechanism is arranged above the stirring mechanism, a solder paste recycling mechanism is arranged below the discharging mechanism, and a feeding mechanism is arranged above the overturning cleaning mechanism. Solder paste is discharged through the discharging mechanism, the better discharging effect is achieved, the effect of reducing solder paste waste is achieved through the solder paste recycling mechanism, the solder paste in the solder paste tank is cleaned and the solder paste in the storage box is stirred through cooperation of the stirring mechanism and the overturning cleaning mechanism, and the solder paste in the storage box is fed through the feeding mechanism. And a better feeding effect is achieved.

Owner:刘树滨

Feeding device for hot process regeneration equipment

InactiveCN112061812ASmooth feedingAccurate speedLarge containersLoading/unloadingAutomatic controlProcess engineering

The invention relates to a full-automatic control device for hot process regeneration equipment. The device comprises a material storage tank, an automatic gate valve, a flexible star-type unloader and an automatic control cabinet. The automatic gate valve is connected below the material storage tank, the flexible star-type unloader is connected below the automatic gate valve, and the automatic control cabinet is connected to the automatic gate valve and the flexible star-type unloader. The device overcomes the problem that existing hot process regeneration equipment cannot feed materials stably under circumstances of high purities and large particles and cannot feed the materials automatically, plays roles of controlling feeding automatically and feeding the materials stably still under the circumstance of high impurity particles of the materials, and has the functions of controlling feeding automatically and controlling stable feeding to achieve full-automatic precise quantitative and continuous stable feeding by hot process regeneration.

Owner:KOCEL EQUIP

Batching system for glass production

ActiveCN112340963AQuick mixReduce powder spatterCharging furnaceGlass productionProcess engineeringConveyor belt

The invention relates to the technical field of glass manufacturing equipment, and discloses a batching system for glass production. The batching system comprises a rack and a feeding conveyor belt connected to the rack, the feeding conveyor belt is connected with a stirring mechanism, the stirring mechanism comprises two stirring units, and an adjusting mechanism used for adjusting the feeding conveyor belt to be intermittently connected with one of the stirring units is arranged on the feeding conveyor belt; and the stirring units are connected with a high-temperature air inlet part and a water inlet part. By arranging the two stirring units and the adjusting mechanism, continuous and stable feeding can be achieved through the feeding conveyor belt, and the problem that in the prior art,energy of a kiln head in a batching system for glass production is wasted seriously is solved.

Owner:CHONGQING YUHU GLASS

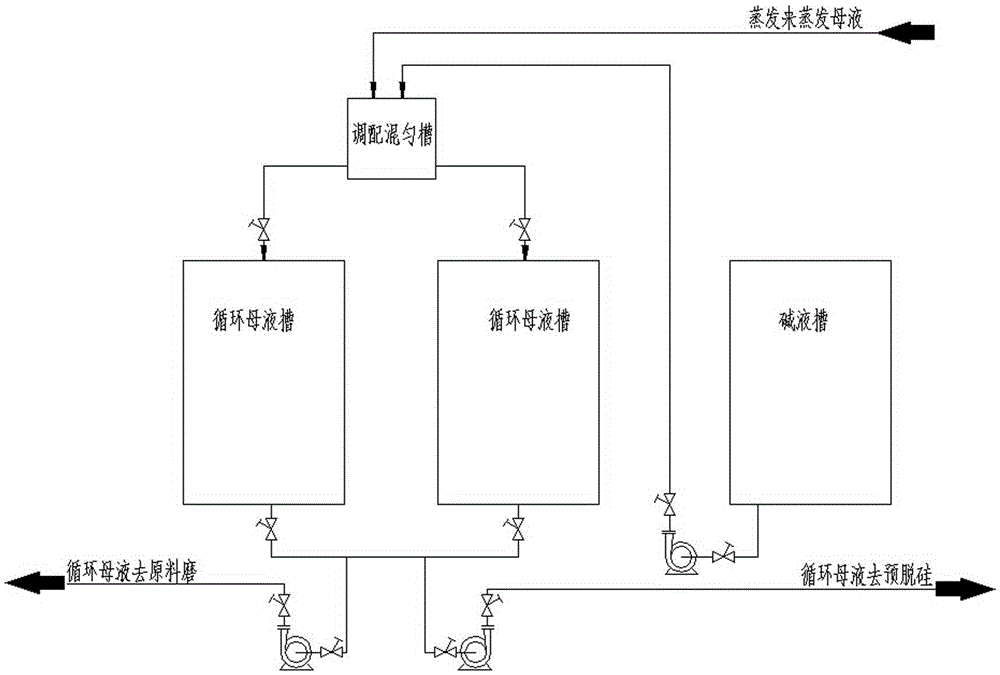

Circulating mother liquor feeding device for producing aluminum oxide and feeding method

InactiveCN105329927ASimple processReduce the number of power equipmentAluminium oxides/hydroxidesEvaporatorWorkload

The invention belongs to the technical field of aluminum oxide production, and particularly relates to a circulating mother liquor feeding device for producing aluminum oxide and a feeding method. According to the circulating mother liquor feeding device, a static mixer is horizontally installed on the top of a circulating mother liquor groove to make evaporation mother liquor and caustic soda liquid which come from an evaporator station enter from one end of the static mixer, the discharging position is 5 m or above higher than the tops of the mother liquor groove and a desilicication groove, circulating mother liquor automatically flows to the process of raw material grinding and predesilicification by means of residual pressure and a height difference, and the circulating mother liquor groove is only used for temporary storing when the evaporator station is shut down for maintenance. According to the circulating mother liquor feeding device and the feeding method, the process is simplified, the number of power devices is decreased, the energy is saved, the consumption is reduced, the workload of repair and maintenance is reduced, input of pipelines, valves, pipe fittings and the like is reduced, the investment is reduced, the construction investment can be reduced by about three million RMB, and the operating cost is reduced by about 5.65 million RMB.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

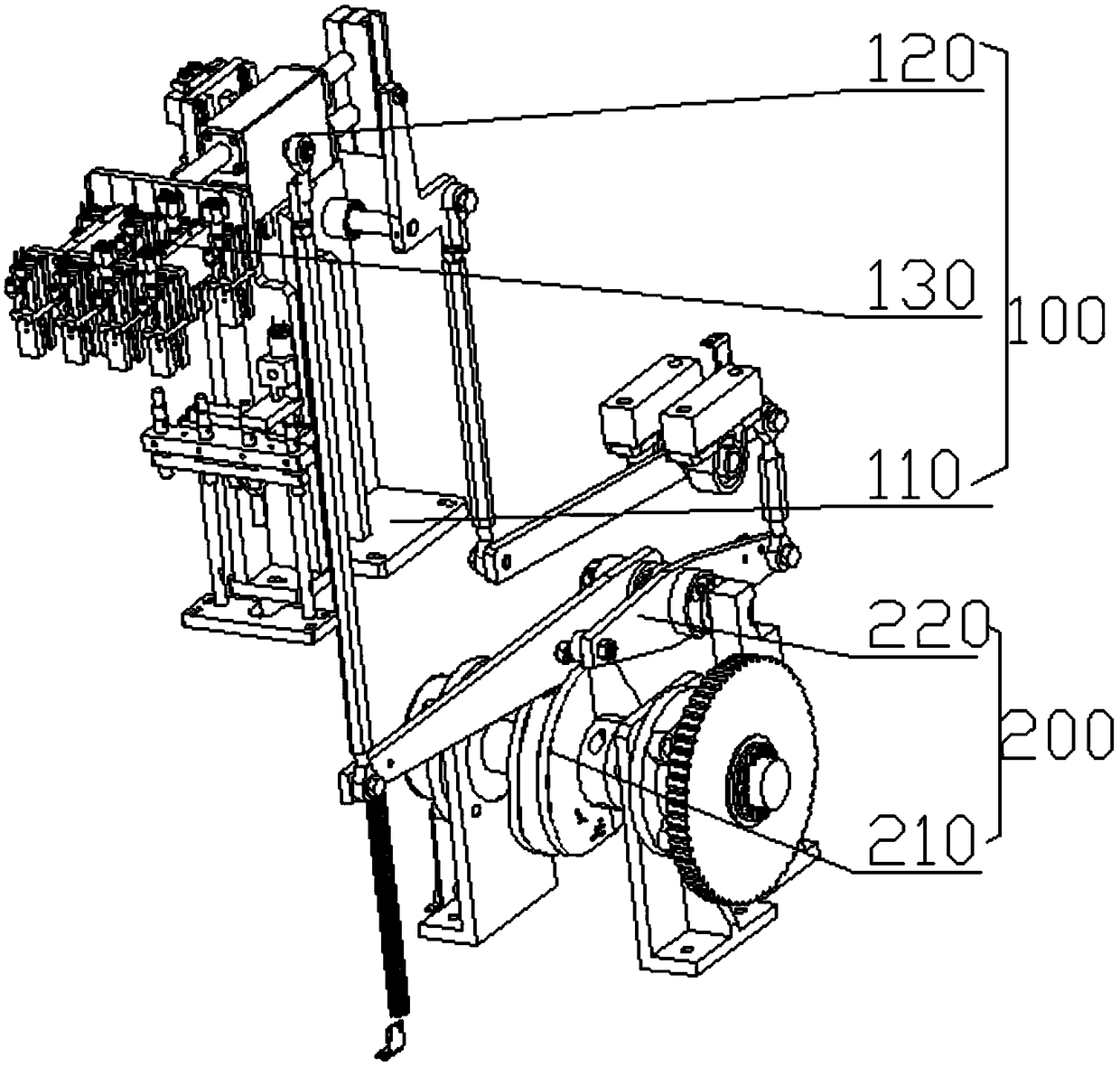

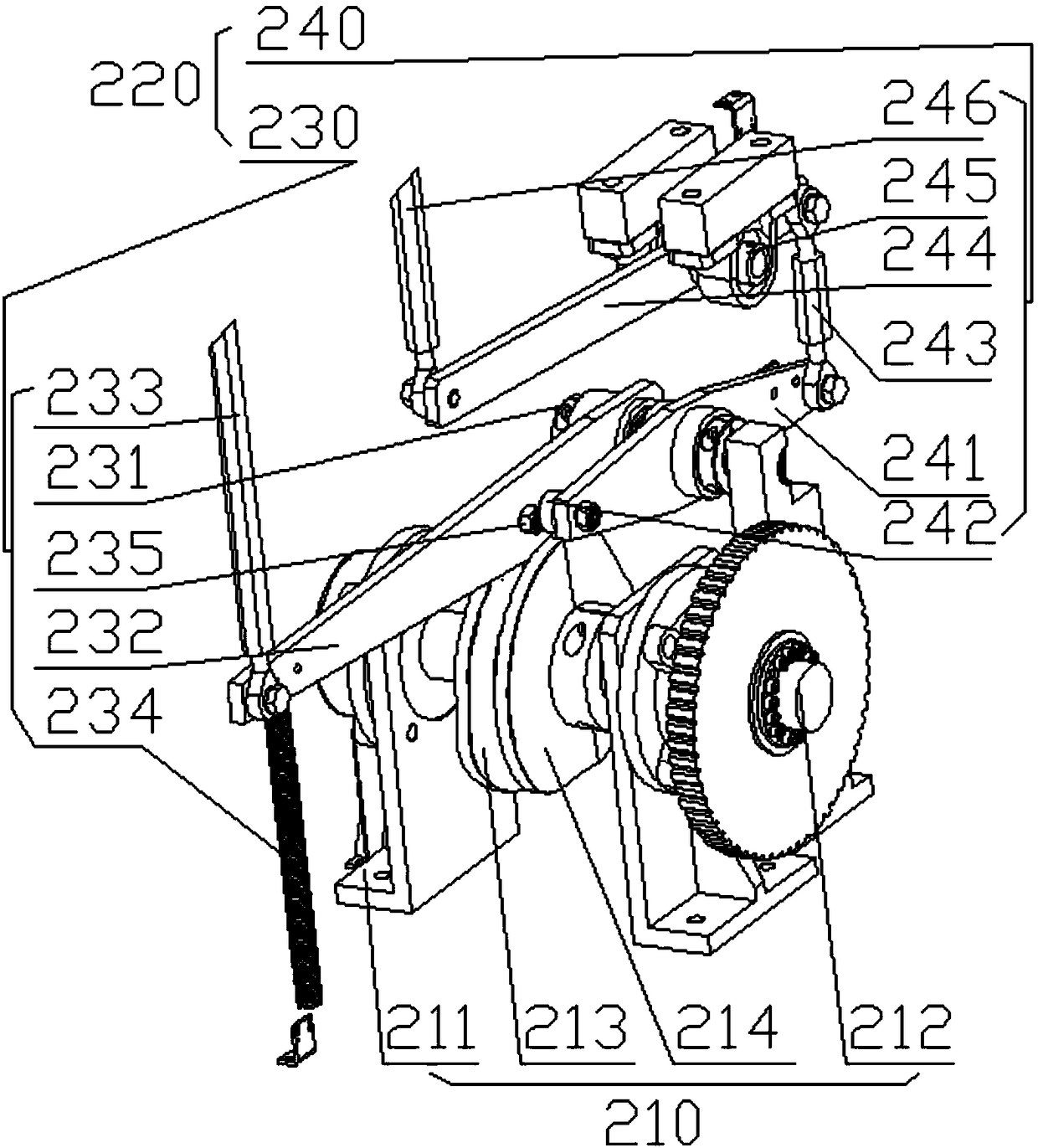

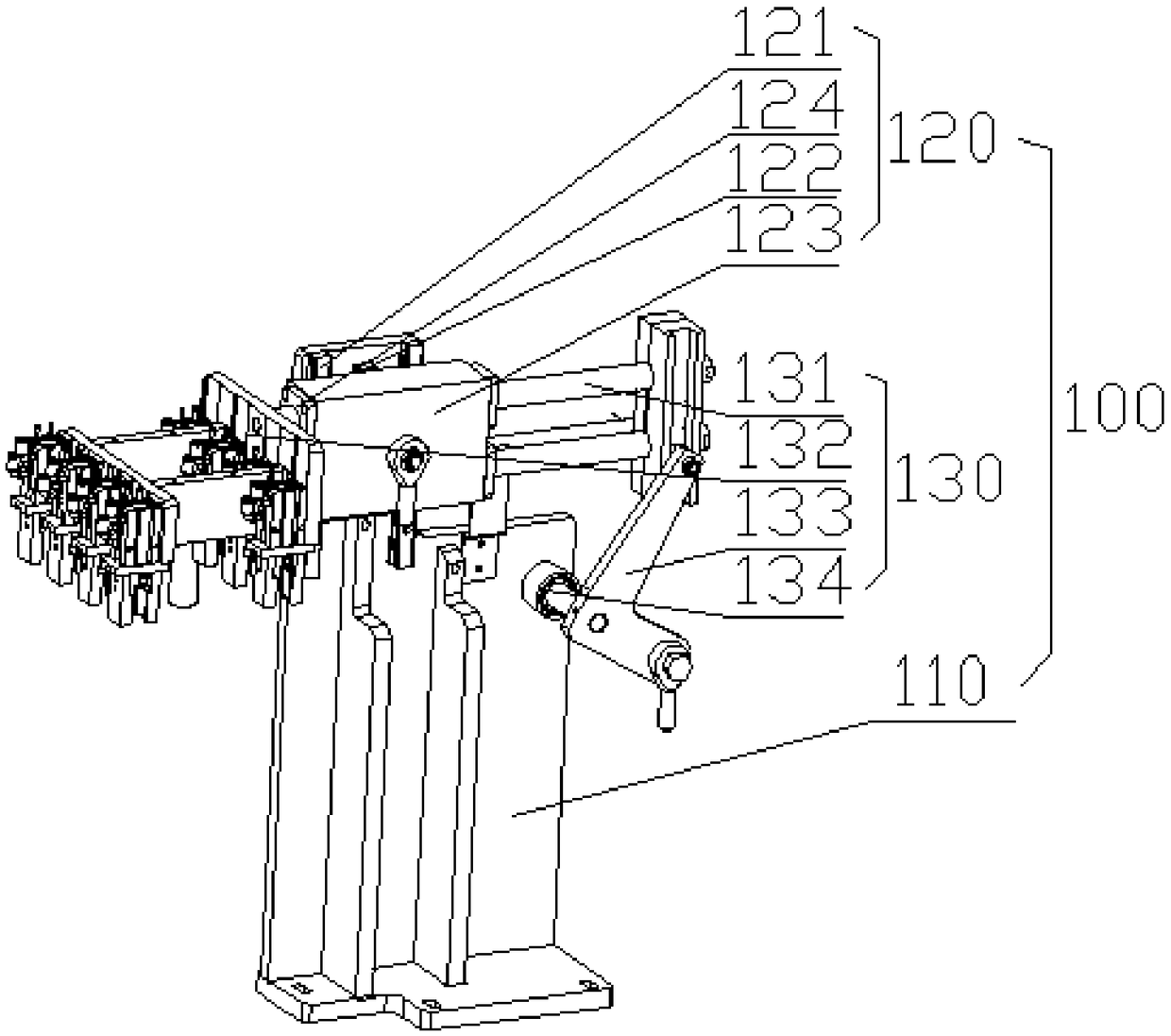

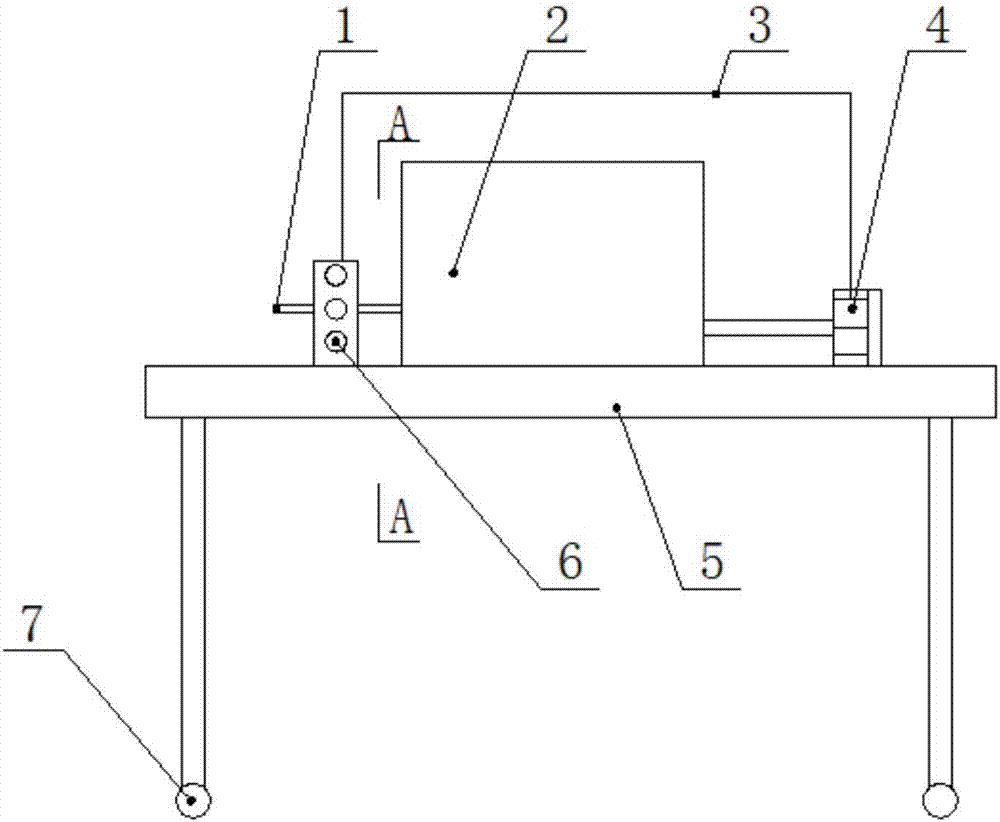

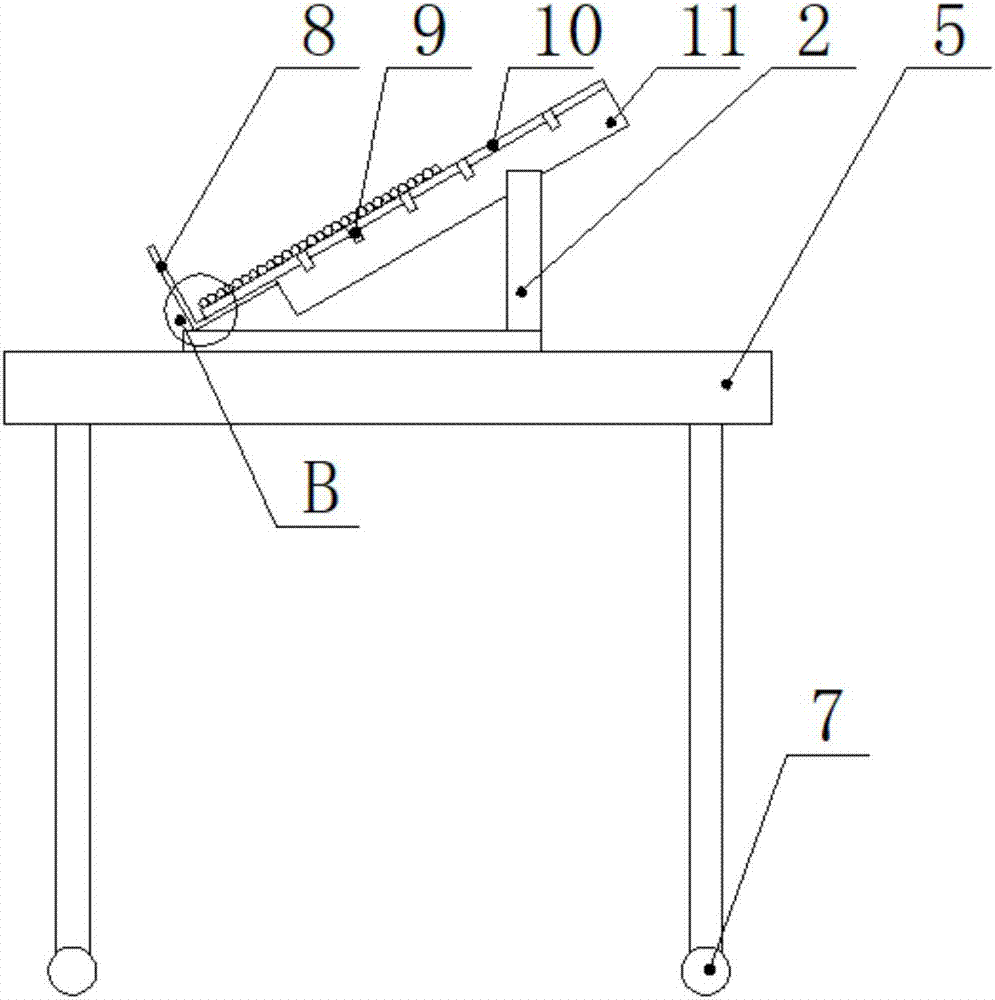

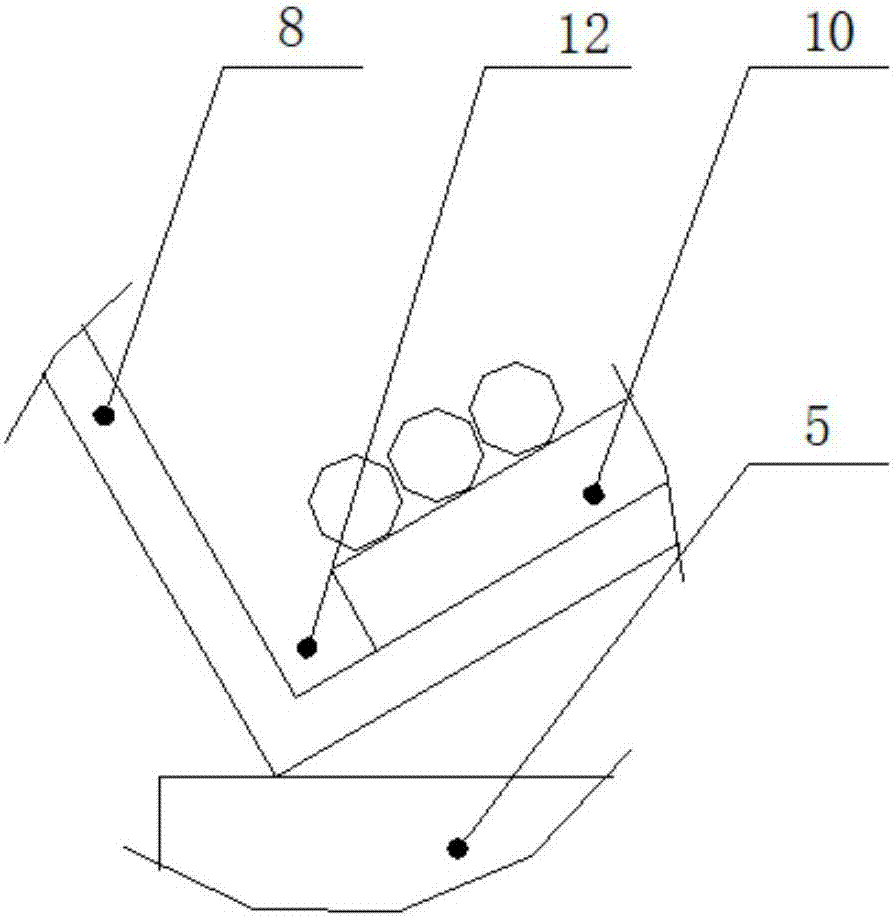

Cam-lever-type automatic feeding device

InactiveCN109019001AReasonable structural designContinuous and stable feedingConveyor partsCamEngineering

The invention provides a cam-lever-type automatic feeding device and belongs to the technical field of machining and mounting auxiliary equipment. The cam-lever-type automatic feeding device is provided with a rack and a worktable arranged on the rack. The worktable is provided with a feeding mechanism and a power mechanism, the feeding mechanism is mounted on the table top of the worktable, and the power mechanism is mounted on the rack and comprises a cam driving assembly and a lever power assembly. The cam driving assembly drives the feeding mechanism to conduct compound motion simultaneously in the X-axis direction and the Y-axis direction by driving the lever power assembly. The cam-lever-type automatic feeding device is reasonable, simple and effective in structural design; to-be-machined workpieces can be continuously and stably fed quickly and efficiently; and in addition, the cam-lever-type automatic feeding device is low in failure rate, so that the overhauling and maintenance cost is lowered, the production efficiency of the cam-lever-type automatic feeding device is improved in an assisted mode, and the needs of production and use are met.

Owner:HUIZHOU CHENGTAI AUTOMATION TECH CO LTD

A fluidized residence conversion device and conversion method for producing α-alumina

ActiveCN104692432BControl dwell timeGuaranteed uniformityAluminium oxides/hydroxidesResidencePulp and paper industry

Te invention belongs to the technical field of metallurgy, and particularly relates to a fluidization type stay reforming device and method for producing alpha-aluminum oxide. The device comprises a cylinder, wherein a top cover is arranged on the top of the cylinder, the lower portion of the cylinder is a cone body, the top cover is communicated with a feed inlet and an exhaust pipe, an inner port of the exhaust pipe is communicated with a valve element of a pressure regulating valve, the inner wall of the lower cone body of the cylinder and an air distributing plate are welded into a whole, a discharge outlet is formed in the middle of the air distributing plate, the discharge outlet is communicated with a feed inlet of a material level valve, an air distributor is installed on the air distributing plate, the upper portion of the air distributor penetrates through the cone body to enter the cylinder, the lower portion of the air distributor is communicated with an air chamber, and the bottom of the air chamber is communicated with an air inlet pipe. When the device works, 1300-1500 DEG C metallurgical aluminum oxide is fed into the cylinder via the top cover through the feed inlet, fluidizing air enters the air chamber through the air inlet pipe, and then alpha-aluminum oxide is discharged through a discharge outlet of the material level valve after crystal transfer is completed. Production processes are simplified, energy is saved by 60-80% compared with a rotary kiln, the fluidization technology is adopted to process powder materials, and product quality is good.

Owner:SHENYANG XINBO IND TECH

Multi-specification motor shaft feeding device

The invention relates to a multi-specification motor shaft feeding device. The multi-specification motor shaft feeding device is characterized by comprising a support, a feeding support and a pushingair cylinder, the feeding support and the pushing air cylinder are fixedly installed on the support, the feeding support comprises an L-shaped supporting plate, an inclined support plate, a storing plate and an L-shaped stopping plate, the inclined support plate is fixedly installed on the L-shaped supporting plate, a plurality of snap joints are arranged on the side wall of the inclined support plate, a plurality of clamping holes are formed in the upper surface of the storing plate, the storing plate is detachably clamped to the inclined support plate, the L-shaped stopping plate is fixed tothe L-shaped supporting plate, the L-shaped stopping plate is matched with the storing plate to form a material bayonet, and the pushing air cylinder corresponds to the material bayonet. The multi-specification motor shaft feeding device is scientific and reasonable in structural design, stable and continuous feeding of motor shaft materials can be guaranteed, the motor shaft quality can be guaranteed, motor shaft deformation is effectively prevented, the multi-specification motor shaft feeding device can be suitable for feeding motor shaft cutting machines in different machining sizes, the application scope is wide, manpower is saved, and the feeding efficiency is improved.

Owner:天津超金精密电子有限公司

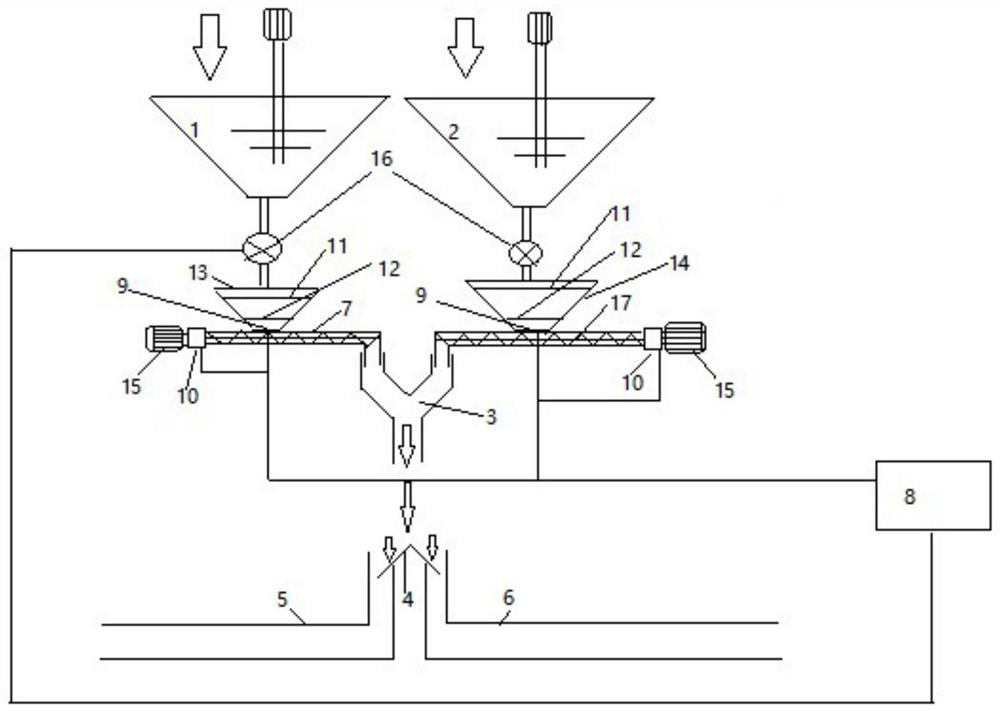

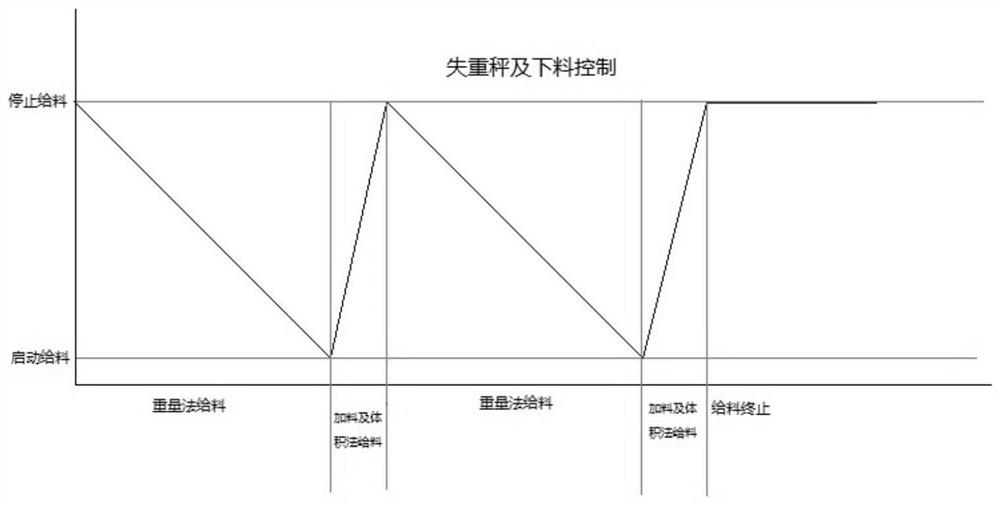

High-precision and stable discharging device in lithium battery industry and control method thereof

InactiveCN113247595AContinuous and stable feedingImprove work efficiencyControl devices for conveyorsPackagingLoop controlEngineering

The invention discloses a high-precision and stable discharging device in the lithium battery industry and a control method thereof. The high-precision and stable discharging device in the lithium battery industry comprises at least two temporary storage bins, a discharging opening of each temporary storage bin is connected with a feeding bin through a material conveying pipeline, a feeding valve is mounted on each material conveying pipeline, a weightlessness scale is mounted in the bottom of each feeding bin, a weightlessness scale sensor is arranged in the weightlessness scale, a speed-adjustable discharging mechanism is arranged below a discharging port of the feeding bin, the speed of the speed-adjustable discharging mechanism is adjusted through a controller, and the controller is connected with the feeding valve and the weightlessness scale sensor at the same time. According to the control method, closed-loop control is achieved through a control program, so that continuous, stable and uninterrupted discharging of the discharging device is achieved, and meanwhile, the batch feeding metering precision is improved, and interference of external factors is avoided. The high-precision and stable discharging device in the lithium battery industry and the control method thereof are suitable for online simultaneous stable discharging of two or more than two ultra-high molecular weight polyethylene, and guarantee can be provided for preparation of high-stability and high-consistency diaphragm products.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

Biomass feeder for pressurized fluidized bed gasifier

InactiveCN101760246BInto continuous stabilityContinuous and stable feedingProductsReagentsFluidized bed gasifierEngineering

The invention provides a biomass feeder for a pressurized fluidized bed gasifier, which comprises a sealed hopper with a non-magnetic conductive top cover, a stirring device and a spiral feeding device. The invention draws lessons from the basic working principle of magnetic transmission, respectively improves the stirring device and the spiral feeding device, so as to achieve the purpose of sealed transmission. The biomass feeder for the pressurized fluidized bed gasifier of the invention is applicable in the feeding of biomass powder under high-pressure condition and gasification in the gasifier, particularly improves the stirring device and the sealed transmission of the spiral feeding device so that the spiral device and the spiral feeding device are applicable in the feeding of biomass powder in high-pressure environment, thereby solving the problems that the low-density fine powder is easy to be lapped, bridged, channeled and cohered into a group, and is not easy to enter the next stage of reactor, so as to disclose a technical scheme which can realize continuous and stable feeding at high pressure and lead the material to enter the reactor continuously and stably.

Owner:TAIYUAN UNIV OF TECH

Chipfryer

ActiveCN107683871AAccurate timePrecisely control the frying timeOil/fat bakingHydraulic pumpFuel tank

The invention discloses a chip fryer. An existing chip fryer cannot precisely control frying time and frying temperature and a user can only operate the chip fryer when approaching edible oil. The chip fryer comprises a conveying mechanism, a frying mechanism and a heating system. The frying mechanism comprises an oil groove, a support frame, a heat insulation base, a mounting frame and a baffle.The conveying mechanism includes an inlet wheel shaft set, an outlet wheel shaft set, a steering belt pulley, a conveyor belt, a guide plate and a motor. The heating system includes a first collectingpipe, a second collecting pipe, a first pipeline, a second pipeline, a heat exchange component, a heat transfer component, a heat conduction oil tank and a hydraulic pump. The heat exchange componentcomprises a first collection outlet pipe, a heat exchanger and a first collection inlet pipe. According to the chip fryer, the time for fried chips to run through the oil groove can be precisely controlled by controlling the speed of the conveyor belt, so that the frying time is precisely controlled to ensure the frying quality. Moreover, the uniformity of quality of finished chips can be guaranteed.

Owner:广东裕生食品工业有限公司

Feeding device for sponge foaming machine

InactiveCN107443652AImprove automated productionImprove processing qualityMagnetic separationIron removalEngineering

The invention discloses a feeding device for a sponge foaming machine. The feeding device comprises a foundation support, a driving roller and a driven roller. The driving roller and the driven roller are correspondingly arranged at the two ends of the foundation support. The driving roller and the driven roller are sleeved with an annular conveying belt for transmission connection. The feeding device is characterized in that a support rod located on the foundation support is arranged on one side of the driving roller, a material cylinder is hinged to the support rod, and a first telescopic device located on the foundation support is hinged to one end of the material cylinder; and a feeding pipe is arranged on the top of the material cylinder, a material box located above the annular conveying belt is connected to the feeding end of the feeding pipe, and an iron removal device is arranged in the material box. According to the feeding device for the sponge foaming machine, the feeding angle of the material cylinder is adjusted through the telescopic device, discharging is facilitated, discharging is continuous and stable in the material cylinder, and the blocking problem is avoided; and besides the on-line iron removal function is achieved, and the machining quality and efficiency of sponge are improved.

Owner:苏州恒昇海绵机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com