Batching system for glass production

A batching system and glass technology, applied in glass manufacturing equipment, furnace feeding, manufacturing tools, etc., can solve problems such as energy waste at the kiln head, and achieve the effects of increasing humidity, improving mixing efficiency, and reducing the degree of powder splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

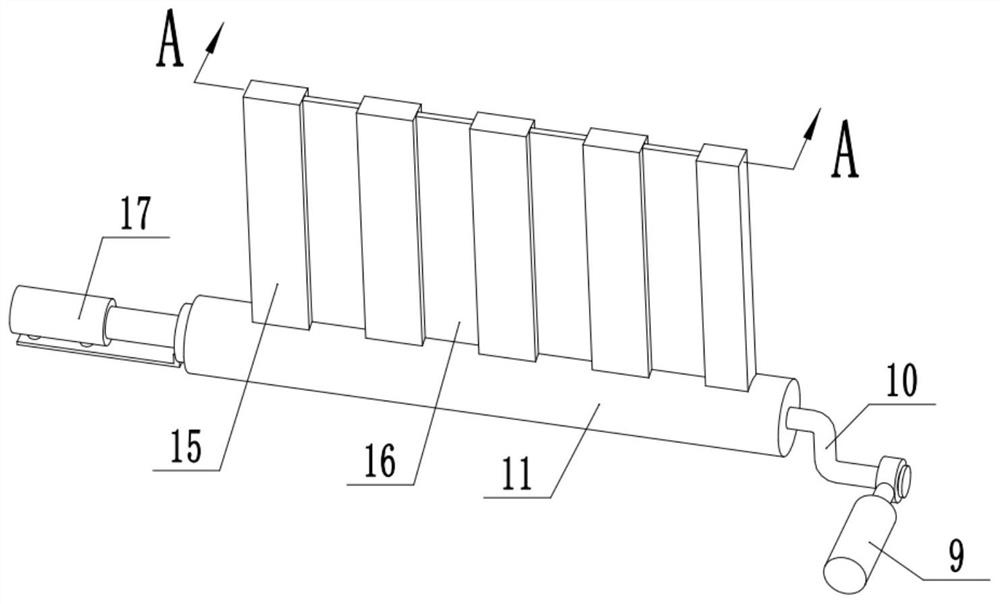

[0037] The difference between the second embodiment and the first embodiment is that the structure of the blocking part in this embodiment is different from that in the first embodiment, such as image 3 with Figure 4 As shown, in the present embodiment, the blocking portion includes fixed plates 15 and movable plates 16 arranged alternately, the side walls of the fixed plates 15 are provided with movable grooves arranged laterally, and the movable plates 16 are horizontally slidably connected in the movable grooves, and One end of the plate 15 is welded on the outer wall of the rotating shaft 11 .

[0038] The rotating shaft 11 is provided with a second driving part for driving the movable plate 16 to slide relative to the fixed plate 15. The second driving part includes a second driving cylinder 17 and a slide block 18 fixedly connected to the second driving cylinder 17 by screws. The driving cylinder 17 is fixedly connected to the end of the rotating shaft 11 by screws, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com