Preparation method of high-entropy oxide ceramic

A technology of oxide ceramics and oxide powder, which is applied in the field of preparation of high-entropy oxide ceramics, can solve problems such as being unsuitable for the preparation of high-entropy oxide ceramics, and achieve the effects of shortening sintering time and reducing synthesis temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of high-entropy oxide ceramics, comprising the following steps:

[0027] Step 1: Weigh 4 or less than 5 metal oxide powders according to the molar ratio of the metal atoms to 1:1:1:1 or 1:1:1:1:1; the oxide powders include: MgO , ZnO, NiO, CuO, CaO, CoO, ZrO 2 , CeO 2 、Al 2 o 3 、Gd 2 o 3 , La 2 o 3 、Er 2 o 3 , Y 2 o 3 , Fe 2 o 3 、Co 3 o 4 , CaCO 3 ;

[0028] Step 2: Ball mill, dry and granulate the powder weighed in step 1;

[0029] Add deionized water to the weighed powder, mix in a planetary ball mill, the speed of the ball mill is 50-180r / min, and the ball milling time is 10-50 h. The obtained slurry is dried, the drying temperature is 100°C, and the holding time is 10-30 h to obtain a uniformly mixed ceramic powder. Add PVA to the dried ceramic powder for granulation, and the concentration of PVA is 3wt%.

[0030] Step 3: Compressing the granulated powder to obtain a green body;

[0031] The granulated powder was molded into...

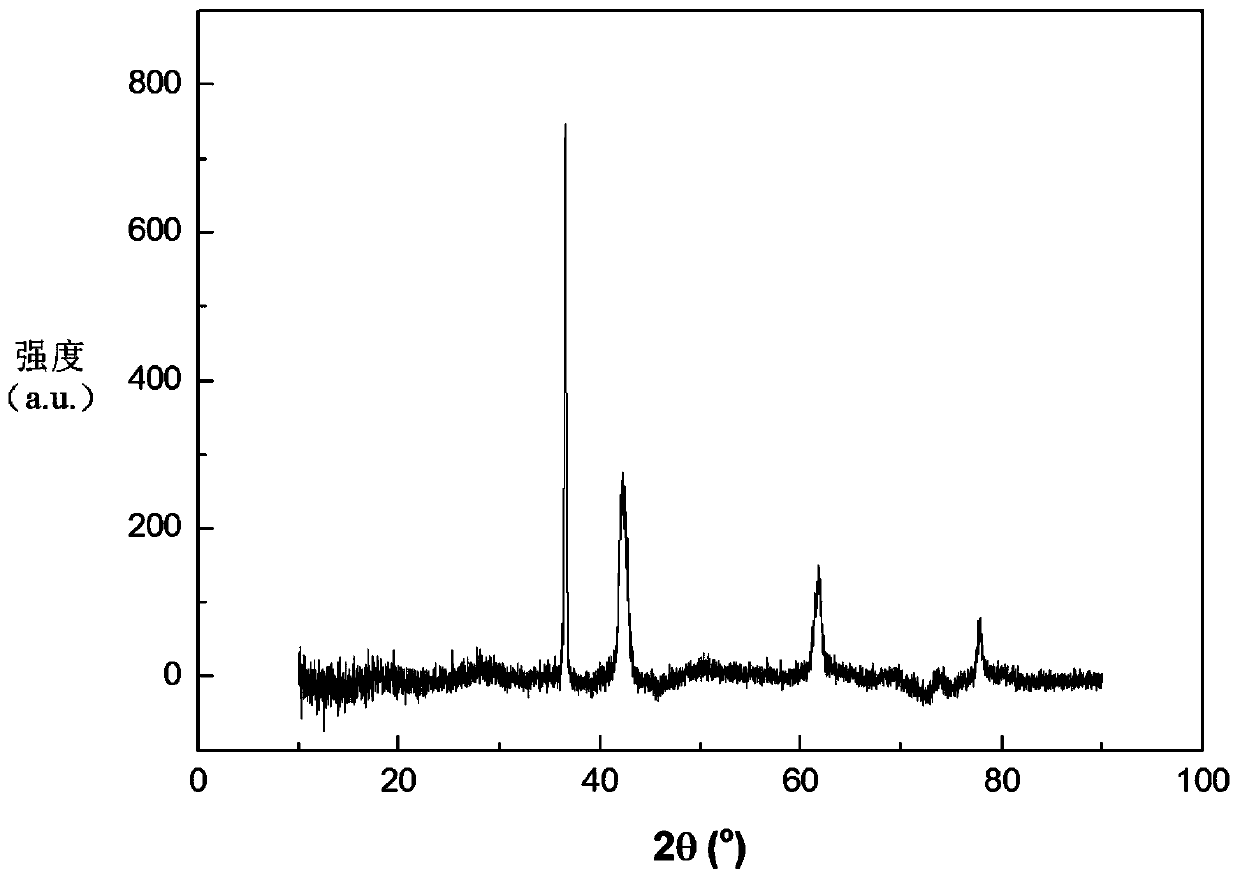

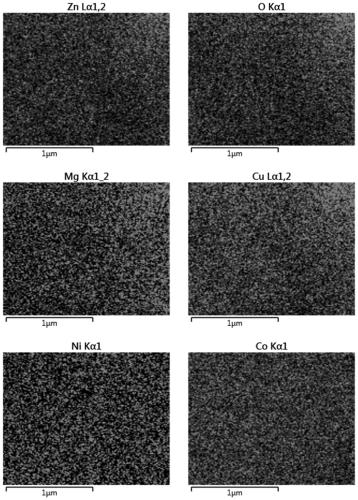

Embodiment 1

[0038] A preparation method of high-entropy oxide ceramics, comprising the following steps:

[0039] Step 1: Weigh the oxide powder according to the following molar ratio, ZnO: MgO: NiO: CuO: Co 3 o 4 =3:3:3:3:1 Weigh the powder, a total of 21.37 g.

[0040] Step 2: Add 200 mL of deionized water to the weighed powder, mix in a planetary ball mill, the speed of the ball mill is 180 r / min, and the ball milling time is 12 h; dry the obtained slurry at At 98°C for 24 h, uniformly mixed ceramic powder was obtained; the dried ceramic powder was added to PVA for granulation, and the concentration of PVA was 3 wt%.

[0041] Step 3: The granulated powder is molded into a dog-bone sample (to facilitate the connection of the sample to the electrode in the flash furnace); under the condition of a pressure of 200 MPa, hold the pressure for 60 s. The sample was placed in a cold isostatic press for secondary pressure at a pressure of 290 MPa.

[0042] Step 4: heat-treat the green body ob...

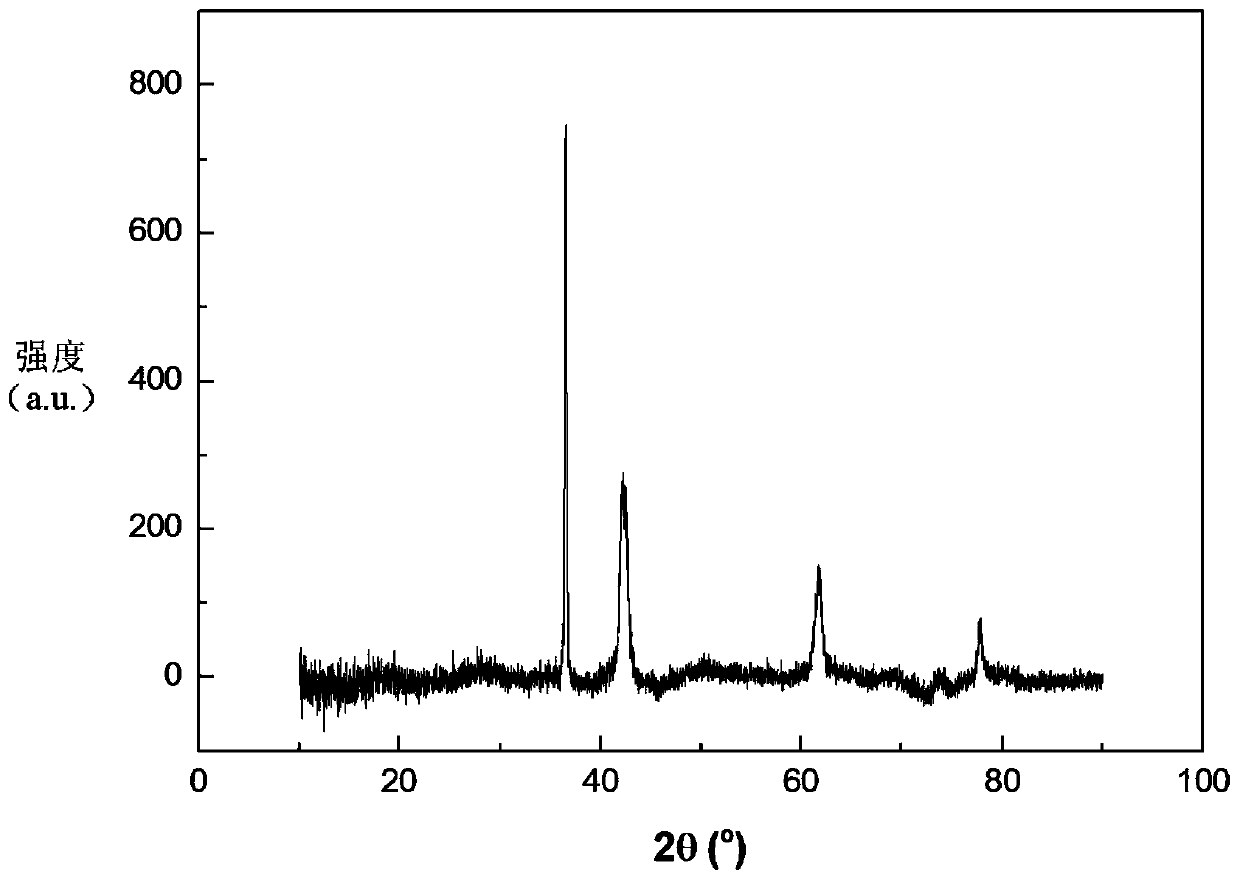

Embodiment 2

[0046] A preparation method of high-entropy oxide ceramics, comprising the following steps:

[0047] Step 1: Weigh the oxide powder according to the following molar ratio, ZnO:NiO:CuO:Co 3 o 4 =3:3:3:1 Weigh the powder, a total of 20g.

[0048] Step 2: Add 200 mL of deionized water to the weighed powder, mix in a planetary ball mill, the speed of the ball mill is 180 r / min, and the ball milling time is 12 h; dry the obtained slurry at At 98°C for 24 h, uniformly mixed ceramic powder was obtained; the dried ceramic powder was added to PVA for granulation, and the concentration of PVA was 3 wt%.

[0049] Step 3: The granulated powder is molded into a dog-bone sample (to facilitate the connection of the sample to the electrode in the flash furnace); under the condition of a pressure of 200 MPa, hold the pressure for 60 s. The sample was placed in a cold isostatic press for secondary pressure at a pressure of 290 MPa.

[0050] Step 4: heat-treat the green body obtained in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com