SMT welding solder paste printing device with automatic feeding function

A technology of solder paste printing and automatic feeding, applied in printing, printing presses, screen printing, etc., can solve the problems of re-cleaning of solder paste, continuous stirring of solder paste, poor fluidity of solder paste, etc., to reduce waste of solder paste, The effect of good cleaning effect and good blanking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

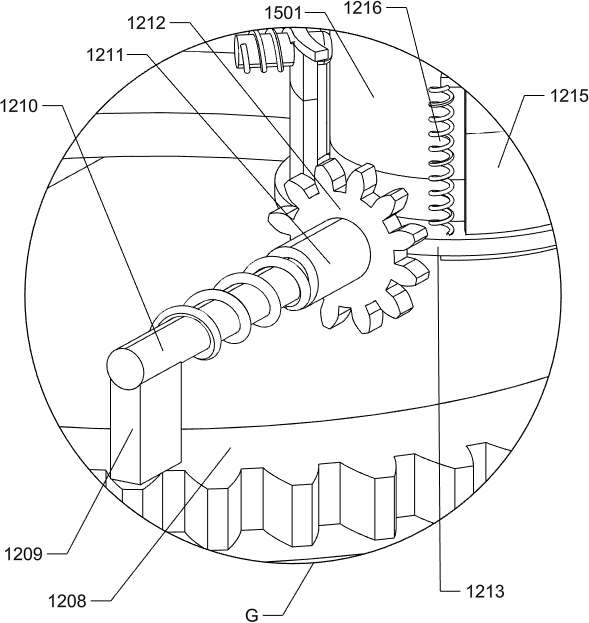

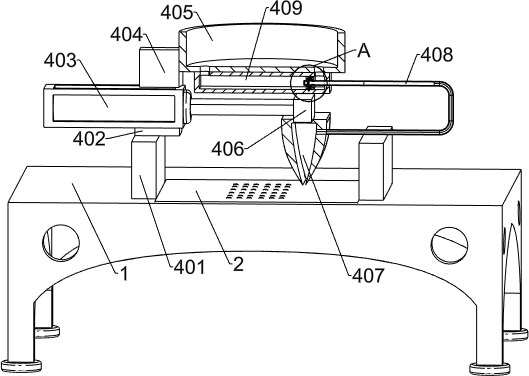

[0044] A SMT solder paste printing device with automatic feeding function, such as figure 1 , figure 2 and Figure 18As shown, it includes a workbench 1, a solder paste leakage plate 2, a first support block 3, a discharge mechanism 4, a first connecting plate 5, a first L-shaped rod 6, a first connecting block 7, and a material storage sleeve 8 , solder paste recovery mechanism 9, stirring mechanism 10, flip cleaning mechanism 11, feeding mechanism 12, bottle cap recovery mechanism 13, bottle body recovery mechanism 14, solder paste bottle body 1501 and solder paste bottle cap 1502, open in the middle of workbench 1 There is a rectangular groove, a solder paste leakage plate 2 is fixed in the rectangular groove of the worktable 1, two first support blocks 3 are symmetrically arranged on the left and right, and the lower ends of the two first support blocks 3 are respectively fixed on the upper surface of the worktable 1, A discharge mechanism 4 is arranged on the upper sur...

Embodiment 2

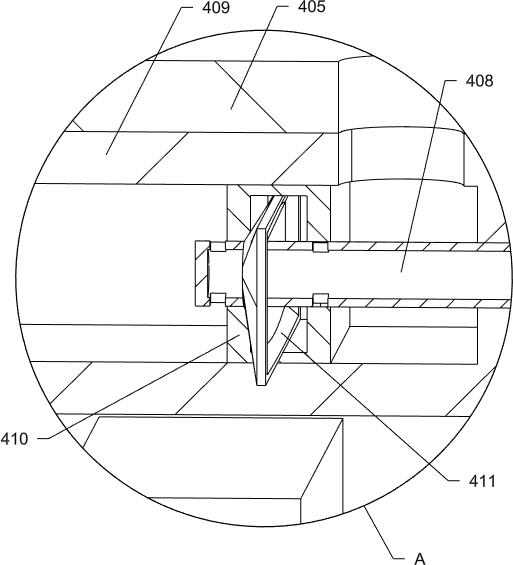

[0047] On the basis of Example 1, as Figure 3-Figure 6 As shown, the discharge mechanism 4 includes a first fixed block 401, a second fixed block 402, a first cylinder 403, a third fixed block 404, a storage box 405, a fourth fixed block 406, a blanking shell 407, U The shape tube 408, the square shell 409, the square push plate 410 and the square elastic plate 411, two first fixing blocks 401 are symmetrically arranged on the left and right sides, and the lower ends of the two first fixing blocks 401 are respectively fixed to the upper surface of the workbench 1, and the two A first fixing block 401 is located on both sides of the solder paste leakage board 2 , a second fixing block 402 is fixed on the upper part of the first fixing block 401 on the left side, a first cylinder 403 is fixed on the upper surface of the second fixing block 402 , and the first cylinder The upper part of 403 is fixed with a third fixing block 404, the right part of the third fixing block 404 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com