A fluidized residence conversion device and conversion method for producing α-alumina

A conversion device and alumina technology, applied in the field of metallurgy, can solve the problems of high construction and operation costs, high maintenance costs, and poor product quality, and achieve the effects of convenient and flexible production organization, long service life, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

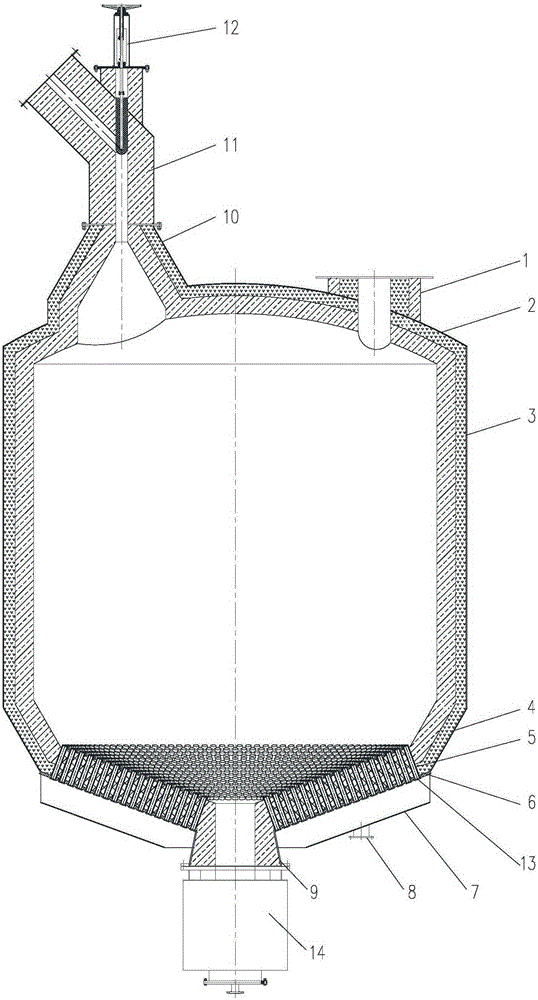

[0027] The structural schematic diagram of the fluidized residence conversion device for producing α-alumina of the present invention is as follows: figure 1 as shown,

[0028] figure 1 The device includes a cylinder 3, the top of the cylinder 3 is provided with a top cover 2, and the lower part is a cone 4; the top cover 2 communicates with the feed port 1, and an opening is arranged above the top cover 2, through which The opening communicates with the transition body 10, the transition body 10 communicates with the exhaust pipe 11, and the inner opening of the exhaust pipe 11 communicates with the valve core of the pressure regulating valve 12; the inner wall of the lower cone 4 of the cylinder body 3 is welded to the air distribution plate 6 As a whole, there is a discharge port 9 in the middle of the air distribution plate 6, and the discharge port 9 communicates with the feed port of the material level valve 14. The air distribution plate 6 is provided with installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com