Spiral filtration dehydrator

A filtration dehydration and spiral technology, applied in filtration separation, moving filter element filter, dewatering/drying/concentrating sludge treatment, etc. Low requirements for incoming materials, convenient operation and maintenance, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

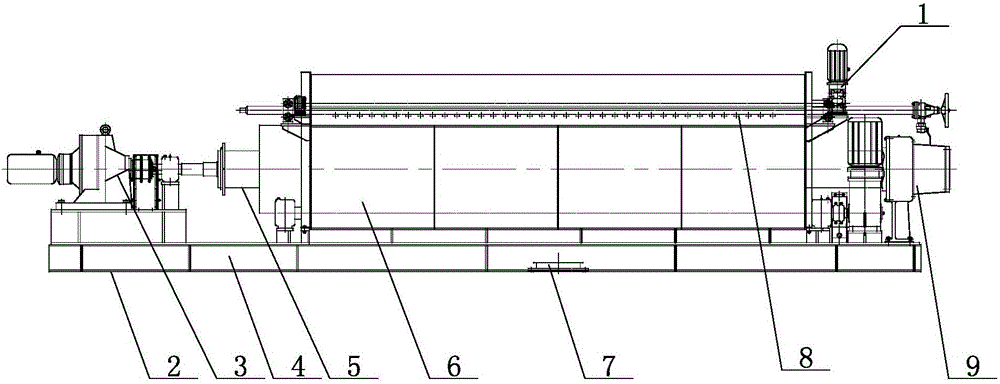

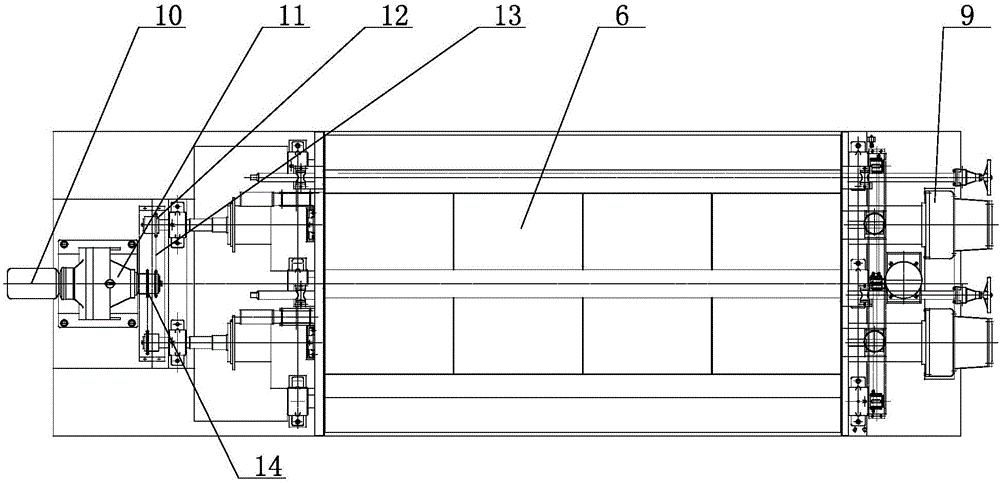

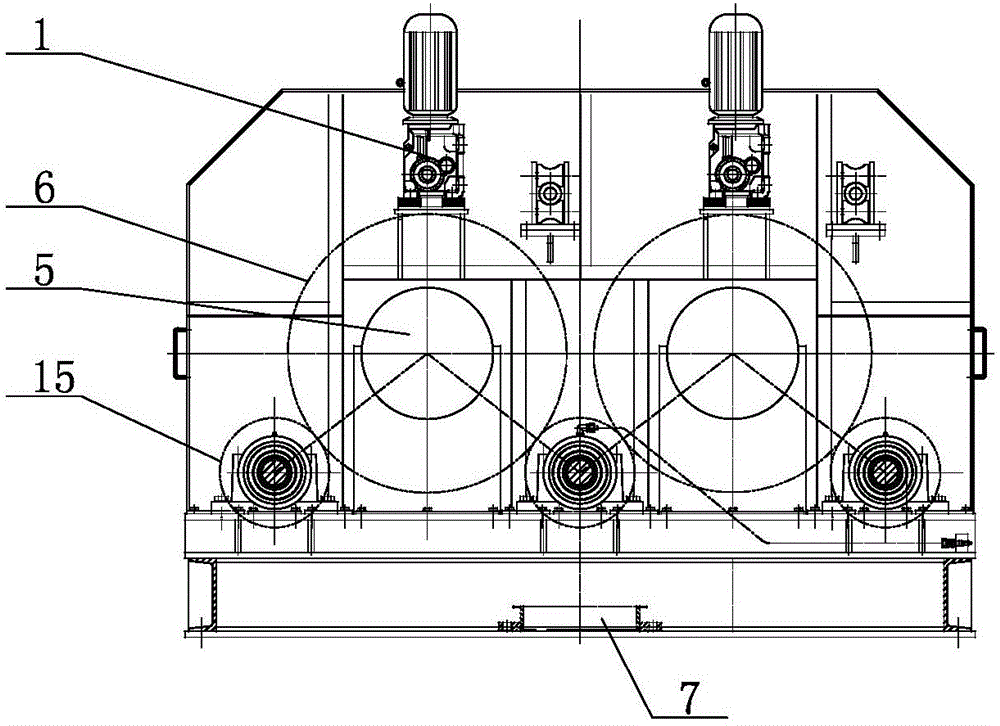

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] Such as Figure 1 to Figure 4 As shown, the spiral filter dehydrator of the present invention includes a frame 2, two screw shafts 5 are arranged side by side on the frame 2, one end of the screw shaft 5 is connected to the main shaft transmission device 3, and the two screw shafts 5 are installed on the two filter cartridges respectively. 6, a tugboat shaft 15 is set between the outer walls of the two filter cartridges 6 and between the filter cartridges 6, and one end of the tugboat shaft 15 is connected to the driving device, and the two ends of the filter cartridge 6 are respectively the feed inlet 9 and the discharge outlet, and the frame 2 Corresponding to the discharge port, the feeding port 4 is respectively set, the filtrate outlet 7 is respectively set at the middle position corresponding to the filter cartridge 6 on the frame 2, and the brush roller device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com