System and method for treating industrial waste salt by fluidized bed

A technology of industrial waste salt and fluidized bed, which is applied in the field of industrial waste salt treatment, can solve problems such as difficulty in scale-up and large-scale operation, affecting the effect of gas lift, difficult to handle, etc., to avoid local overheating and coking, and avoid equipment that is difficult to scale up , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

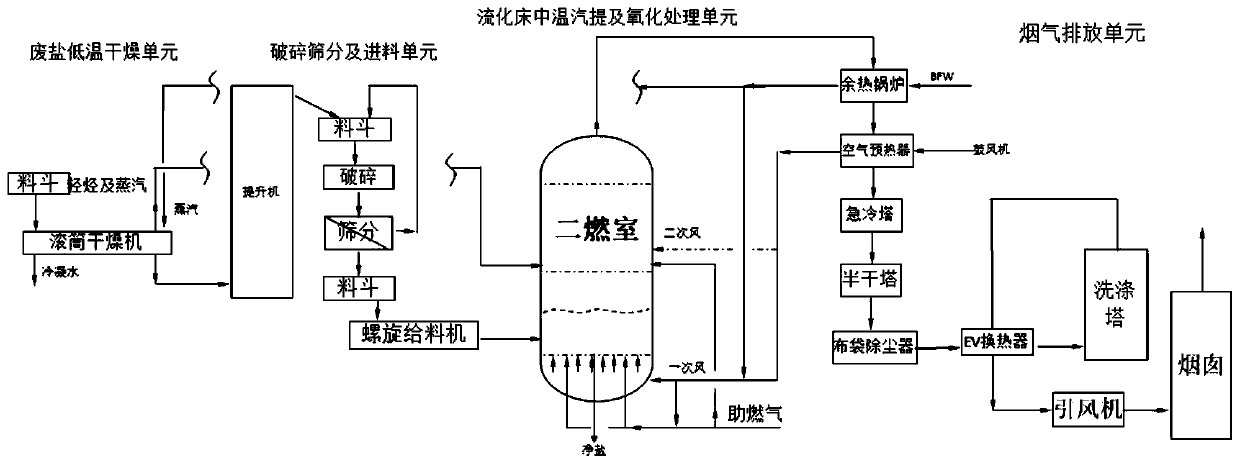

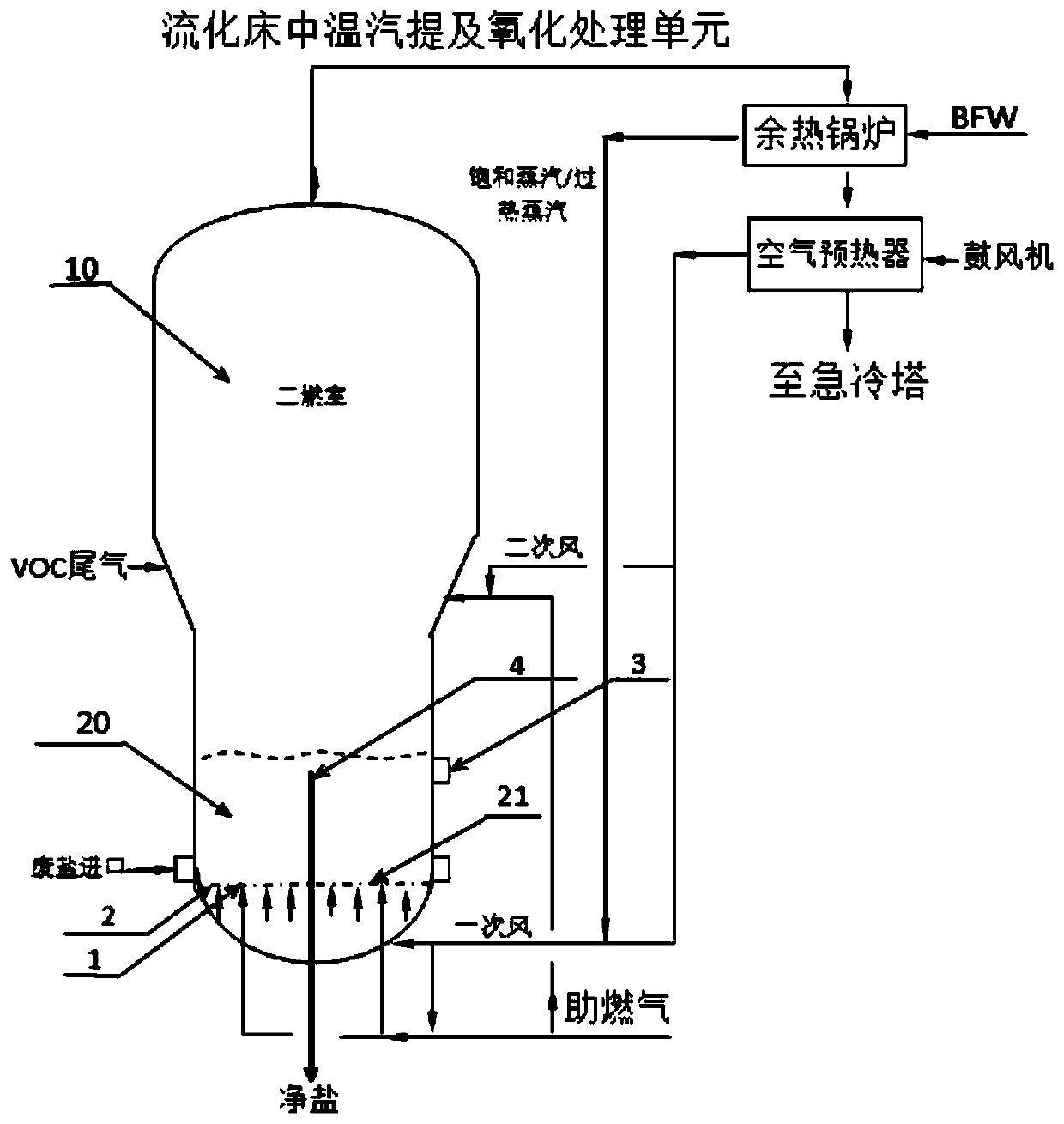

[0046] refer to figure 1 and figure 2 As shown, the present invention provides a system for treating industrial waste salt in a fluidized bed, including a low-temperature drying unit for waste salt, a crushing and screening and feeding unit, a medium-temperature stripping and oxidation treatment unit in a fluidized bed, and a flue gas discharge unit;

[0047] The waste salt low-temperature drying unit is equipped with a low-temperature drying dehydrator, which is used to remove the surface water and part of volatile organic matter of waste salt, that is, VOC tail gas;

[0048] The low-temperature drying and dehydrating machine can be heated indirectly or directly, preferably indirect heating. The low-temperature drying and dehydrating machine is a drum dryer, and the heating medium is saturated steam supplied outside the system. It can also b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com