A kind of solid acid catalyst, foam structure carbon material and preparation method

A technology of solid acid catalyst and foam structure, which is applied in the field of porous carbon materials, can solve the problems of low catalytic efficiency, etc., and achieve the effects of avoiding coking and carbonization, high process efficiency and low catalytic conversion temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

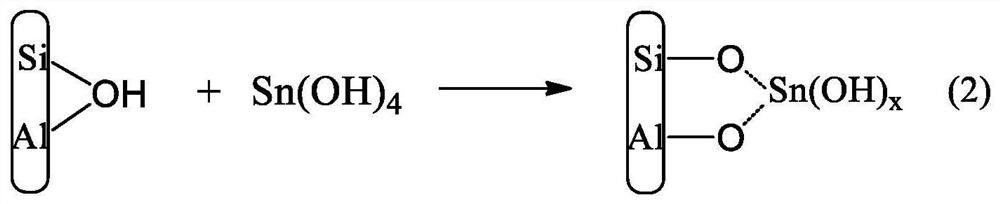

[0038] On the other hand, the present invention also provides a preparation method of solid acid catalyst tin-modified kaolinite, specifically comprising the following steps:

[0039] Step 1', dispersing the kaolinite powder with a particle size of 300-800 mesh (especially 500 mesh) in the crystalline tin chloride solution to form a suspension mixture, the mass fraction of the kaolinite powder in the suspension mixture is 10-20%, crystallization The mass fraction of tin chloride is 1.5 to 6%, and the rest is deionized water; the purpose of dispersing the kaolinite powder in the crystalline tin chloride solution is to allow the tin chloride solution to fully infiltrate and swell the kaolinite powder particles to control The mass fraction of kaolinite powder in the suspension mixture is 10-20% and the mass fraction of crystalline tin chloride is 1.5-6%, which is beneficial to realize the effective loading capacity of tin.

[0040] Step 2', dropwise add ammonia water with a mass co...

Embodiment 1

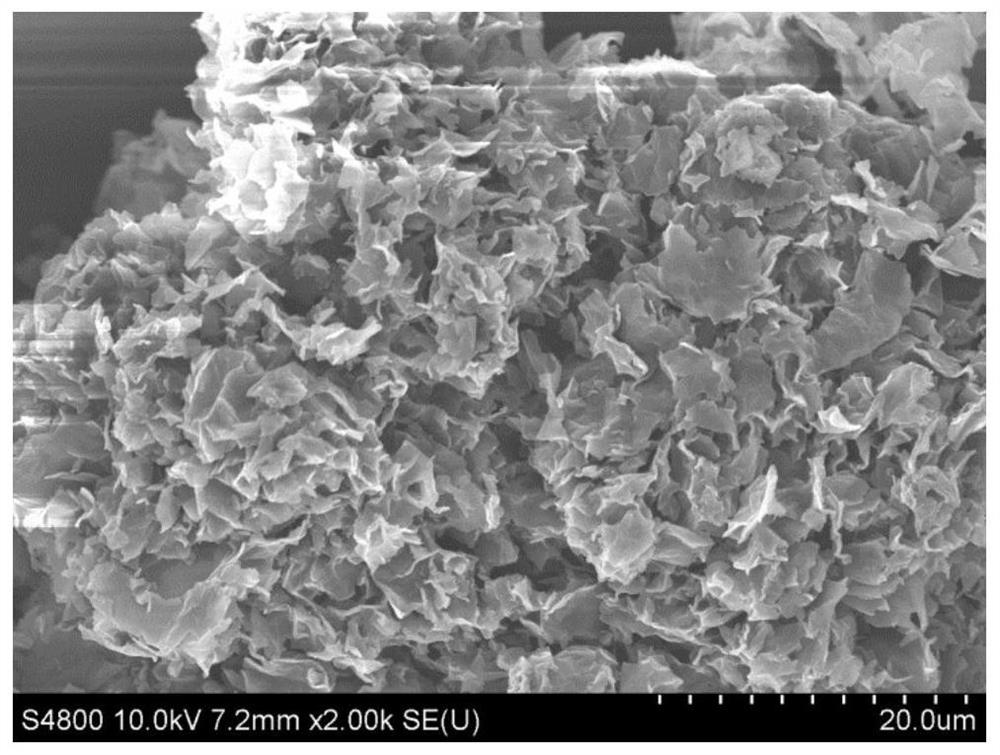

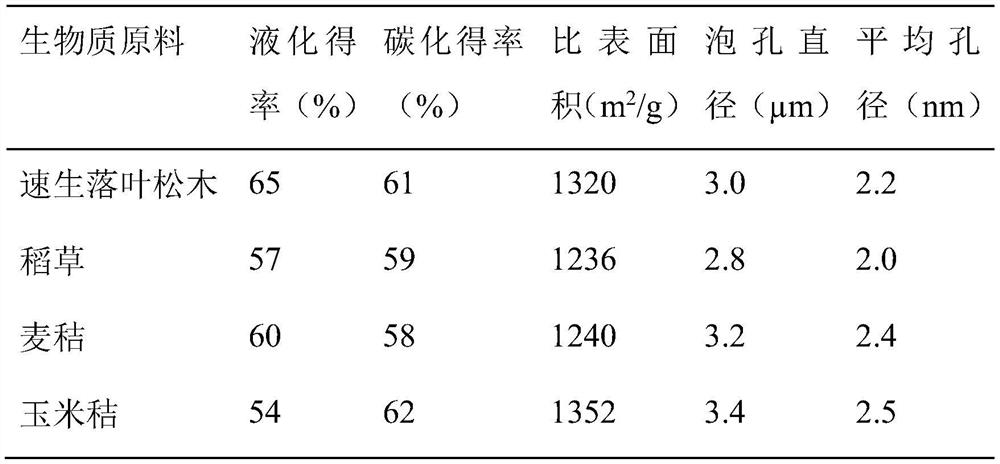

[0054] Fast-growing larch wood, rice straw, wheat straw, and corn stalk raw materials are preheated and dried and crushed to a particle size of 0.5mm. The sample characterization results for the preparation of fast-growing larch wood raw materials in Example 1 are as follows: figure 1 Shown; material and solid acid catalyst are mixed uniformly, and solid acid catalyst is 15% of biomass material quality. The catalytic liquefaction temperature range is 420°C, and the residence time of the mixture of biomass material and catalyst in the high temperature zone is 2 minutes. The liquefied product, that is, biomass pyrolysis oil, is collected by a water-cooled serpentine tube. After the solid catalyst is recovered, it is calcined in the air to remove the deposited carbon and then recycled.

[0055] Get 100g biomass pyrolysis oil and add its quality 5g of phenol, 5.2g of formaldehyde solution (mass concentration is 37%), until phenol dissolves completely, add the sodium alginate of bi...

Embodiment 2

[0059] The fast-growing larch wood raw material was preheated and dried, and then crushed to a particle size of 1.0 mm. The material was mixed evenly with a solid acid catalyst, and liquefied in the catalytic liquefaction temperature range. The liquefaction operating conditions are shown in Table 2. The liquefied product, that is, biomass pyrolysis oil, is collected by a water-cooled serpentine tube. After the solid catalyst is recovered, it is calcined in the air to remove the deposited carbon and then recycled.

[0060] Get 100g of biomass pyrolysis oil and add its quality 10g of phenol, 13g of formaldehyde solution (mass concentration is 37%), until phenol is completely dissolved, add the sodium alginate of biomass pyrolysis oil quality 1.0g in the system, form High viscosity mixture.

[0061] Dissolve biomass pyrolysis oil, 1.2 g of Span-20, and 4 g of liquid paraffin into each other, then add to the above biomass pyrolysis oil mixture, and stir to form a microemulsion sus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com