Method for preparing 6-aminocapronitrile

A technology of aminocapronitrile and ammonia gas is applied in the field of preparation of 6-aminocapronitrile, which can solve the problems of many by-product impurities, high reaction temperature, low efficiency and the like, and achieves high selectivity, simple preparation process and uniform heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

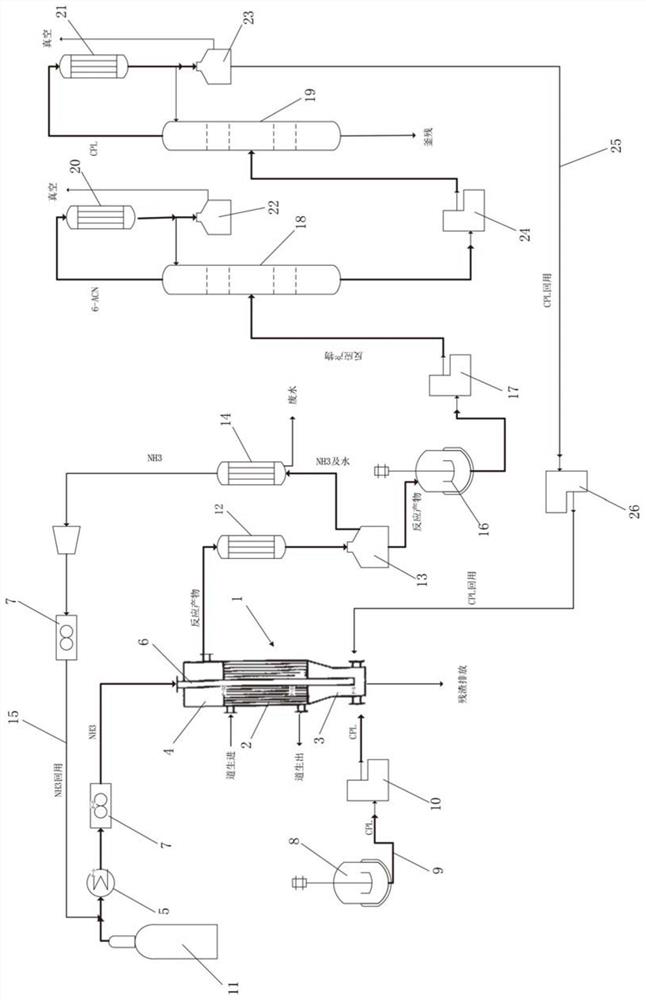

Method used

Image

Examples

Embodiment 1

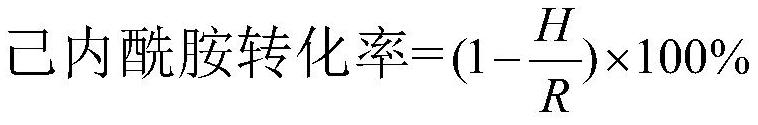

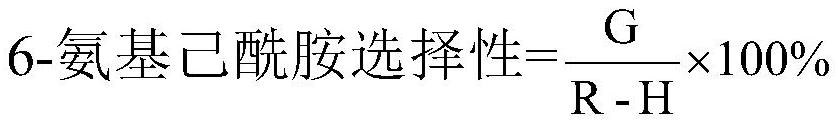

[0051] The caprolactam is preheated to 80°C in the preheater 8, and the caprolactam is in a liquid state, and 0.002% by mass of phosphoric acid (based on the quality of the caprolactam) is added therein as a catalyst, fully mixed with the liquid caprolactam, and then passed through the first temperature-controlled metering pump 10 into the main reactor 1, the temperature of the first temperature-controlled metering pump is set at 70-140°C, the temperature of the main reactor is controlled at 250°C; the ammonia gas preheating temperature is 250°C, and the ammonia gas flow meter 7 is passed into the upper end of the main reactor 1 Inlet, followed by bubbling at the bottom of the reactor to fully contact with caprolactam and catalyst, the temperature of tube-and-tube reaction zone 2 is controlled at 300°C, and the molar ratio of ammonia gas to caprolactam is 40:1.

[0052] The reaction product and excess ammonia gas overflow from the outlet at the upper end of the main reactor 1 a...

Embodiment 2

[0058] The caprolactam is preheated to 80 ℃ in the preheater 8, and the caprolactam is in a liquid state, and a mass ratio of 0.01% phosphoric acid (based on the quality of the caprolactam) is added therein as a catalyst, fully mixed with the liquid caprolactam, and then passed through the first temperature-controlled metering pump 10 into the main reactor, the first temperature-controlled metering pump is set at a temperature of 70-140°C, the temperature of the main reactor is controlled at 200°C; the ammonia gas preheating temperature is 200°C, and the ammonia gas flow meter 7 is passed into the upper inlet of the main reactor 1 , and then bubbling at the bottom of the reactor to fully contact with caprolactam and the catalyst, the temperature of tube-and-tube reaction zone 2 is controlled at 250°C, and the molar ratio of ammonia gas to caprolactam is 30:1.

[0059] The reaction product and excess ammonia gas overflow from the outlet at the upper end of the main reactor 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com