Continuous purification system and method for spice-grade benzyl acetate

A technology of benzyl acetate and purification method, which is applied in the separation/purification of carboxylic acid esters, chemical instruments and methods, separation methods, etc., and can solve the problems of low-boiling point impurities and fine impurities that cannot meet the quality requirements of fragrance-grade benzyl phenylacetate Difficult to be removed, limiting the application of benzyl acetate and other problems, to achieve the effect of easy industrial production, good smell and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

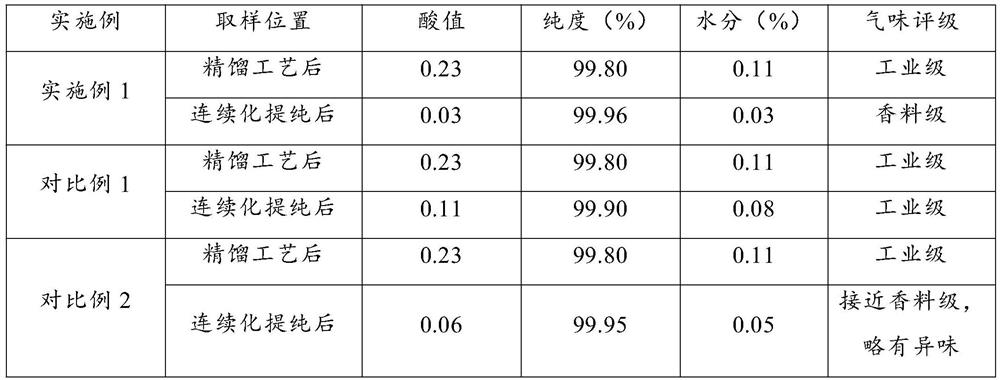

Embodiment 1

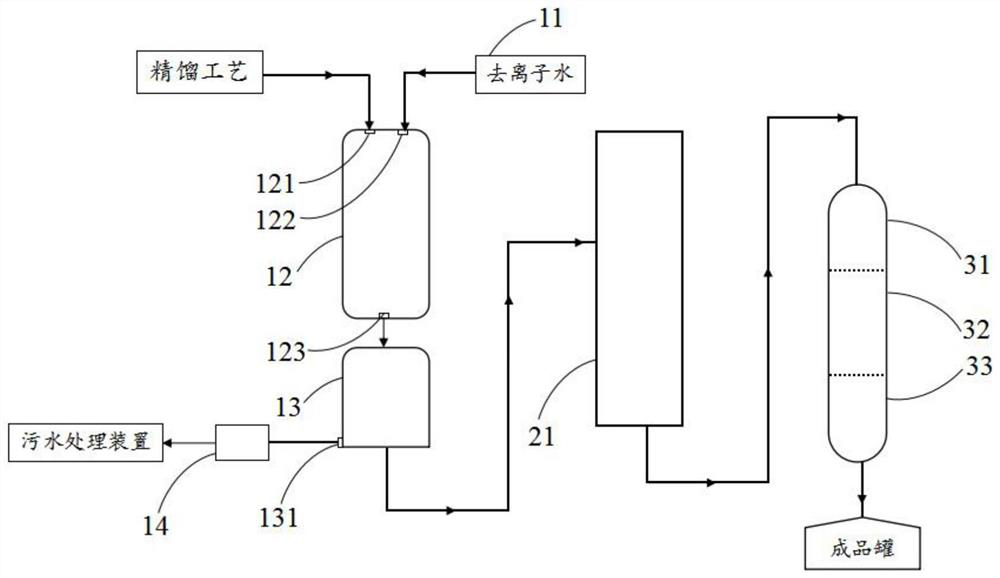

[0042] This embodiment provides a continuous purification method of perfume-grade benzyl acetate. The benzyl acetate after the rectification process is processed by a continuous purification system of perfume-grade benzyl acetate to obtain qualified perfume-grade benzyl acetate. . Specifically include the following steps:

[0043] S1, the benzyl acetate after the rectification process is input in the washing kettle of 2 tons of capacity from the feed port 121 by the conveying device 4, and the water inlet inputs deionized water simultaneously, and the mass ratio of benzyl acetate and deionized water is 1: 1. The input volume is 1 ton / hour. The stirring was turned on, the kettle heating was controlled at 60°C, and the water-washing kettle residence time was 30 min; the mixed solution of benzyl acetate and water entered the coalescing separator 13 at a flow rate of 2 tons / hour through the discharge port 123 at the bottom of the water-washing kettle, and the benzyl acetate The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com