Patents

Literature

1618results about How to "Avoid odor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulosic fibers with odor control characteristics

ActiveUS20070077428A1Avoid odorMaintain activityEngine sealsInorganic pigment treatmentBiotechnologyAmmonia production

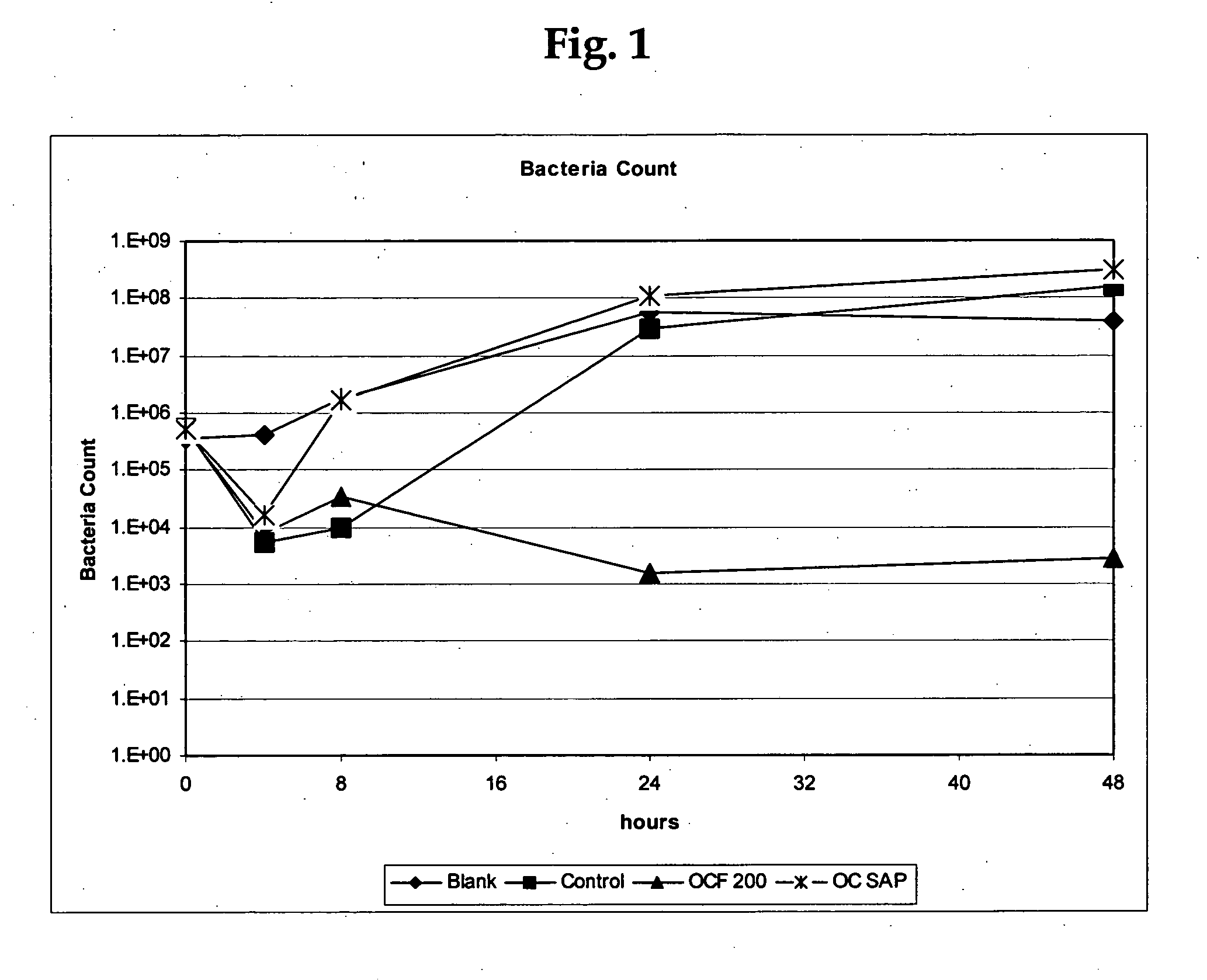

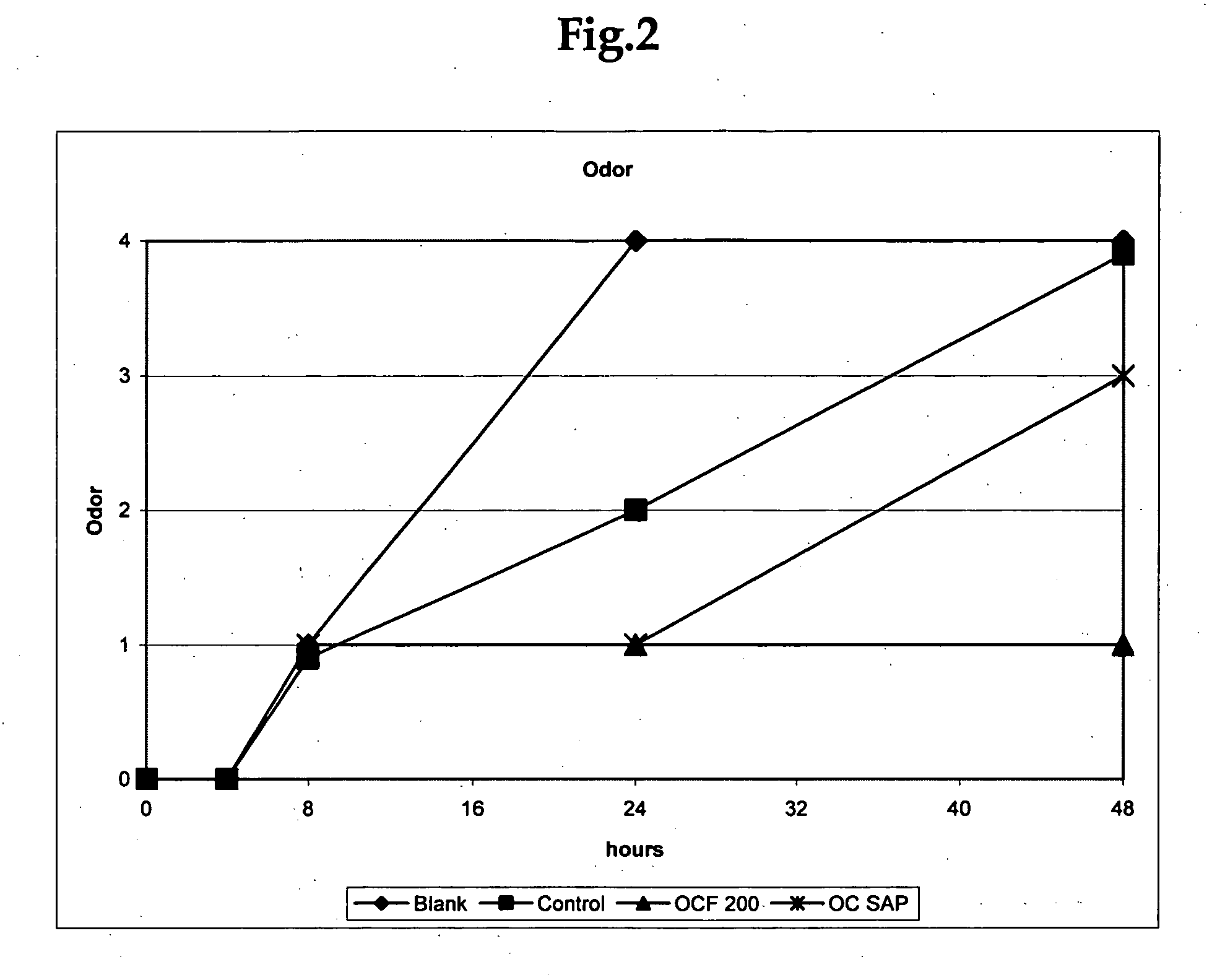

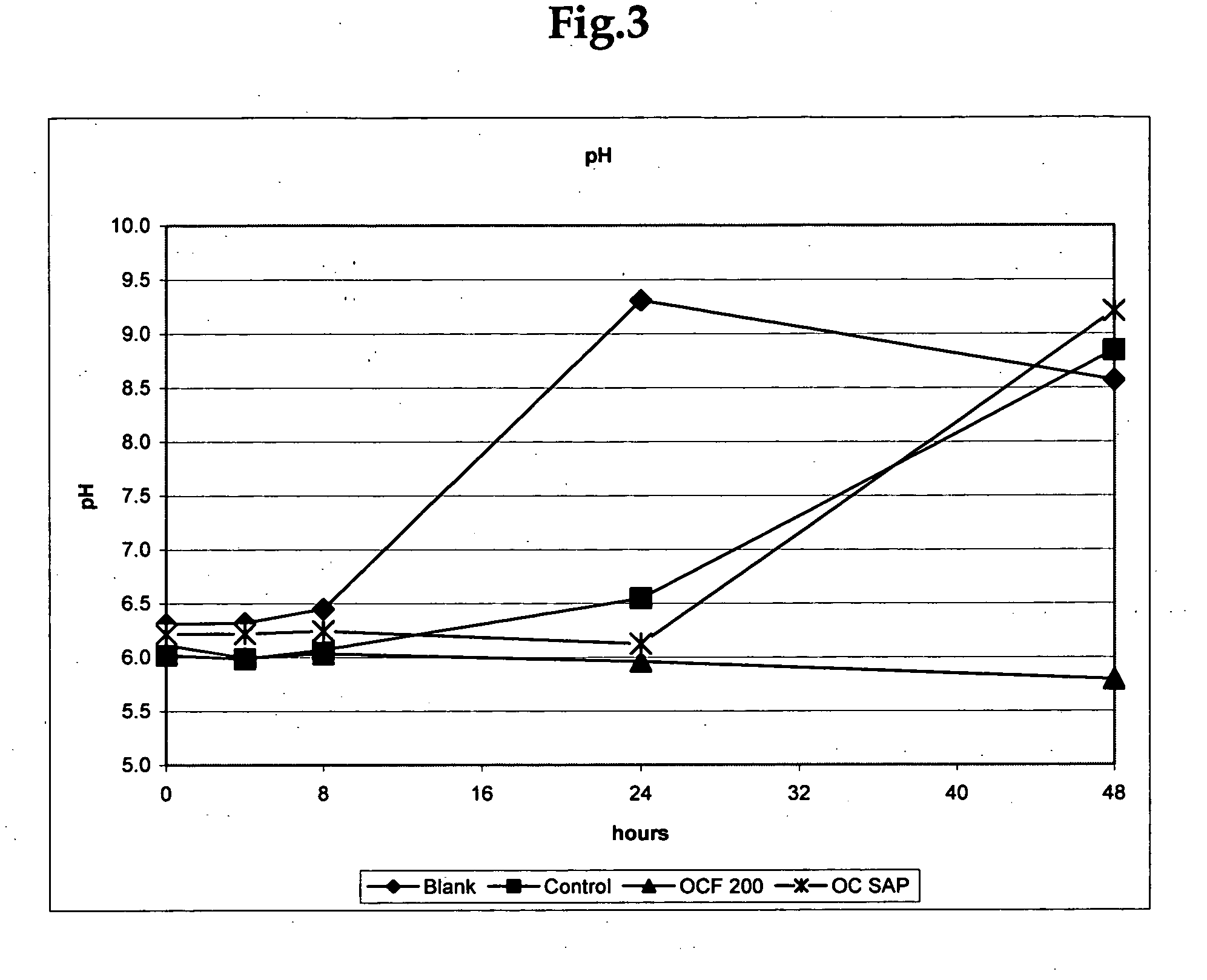

An odor-inhibiting fiber having a cellulosic fiber and an odor-inhibiting formulation. The odor-inhibiting formulation may contain an odor-inhibiting agent, such as a biocide, an enzyme, a urease inhibitor. The odor-inhibiting formulation also may contain a liquid carrier such as a hydrophobic or hydrophilic organic liquid, or a mixture of a hydrophobic and hydrophilic organic liquid. The cellulosic fiber is impregnated with the odor-inhibiting formulation to produce fiber having odor-inhibiting characteristics. The resultant odor-inhibiting fiber is useful in making absorbent articles with odor-inhibiting characteristics. The fiber of the embodiments prevents odor by inhibiting bacteria growth and ammonia production, especially when used in an absorbent article such as a diaper or adult incontinence device.

Owner:RAYONIER PERFORMANCE FIBERS

Antimicrobial, water-insoluble silicate glass powder and mixture of glass powders

An antimicrobial, water-insoluble silicate glass powder is provided. The starting glass includes 30 to 70 weight percent SiO2, 0 to 1 weight percent Na2O, 0 to 1 weight percent K2O, 0 to 40 weight percent MgO, 0 to 40 weight percent CaO, 0 to 40 weight percent SrO, 0 to 40 weight percent BaO, 0 to 25 weight percent Al2O3, 0 to 20 weight percent P2O5, 0 to 20 weight percent B2O3, wherein the sum of the alkali oxide contents is less than 1.5 weight percent in the total composition of the starting glass. The starting glass also includes, as biocidally active components, ions or atoms of the elements Ag, Zn, Cu, Ce, Te, or I with total proportions of greater than 2.5 weight percent.

Owner:SCHOTT AG

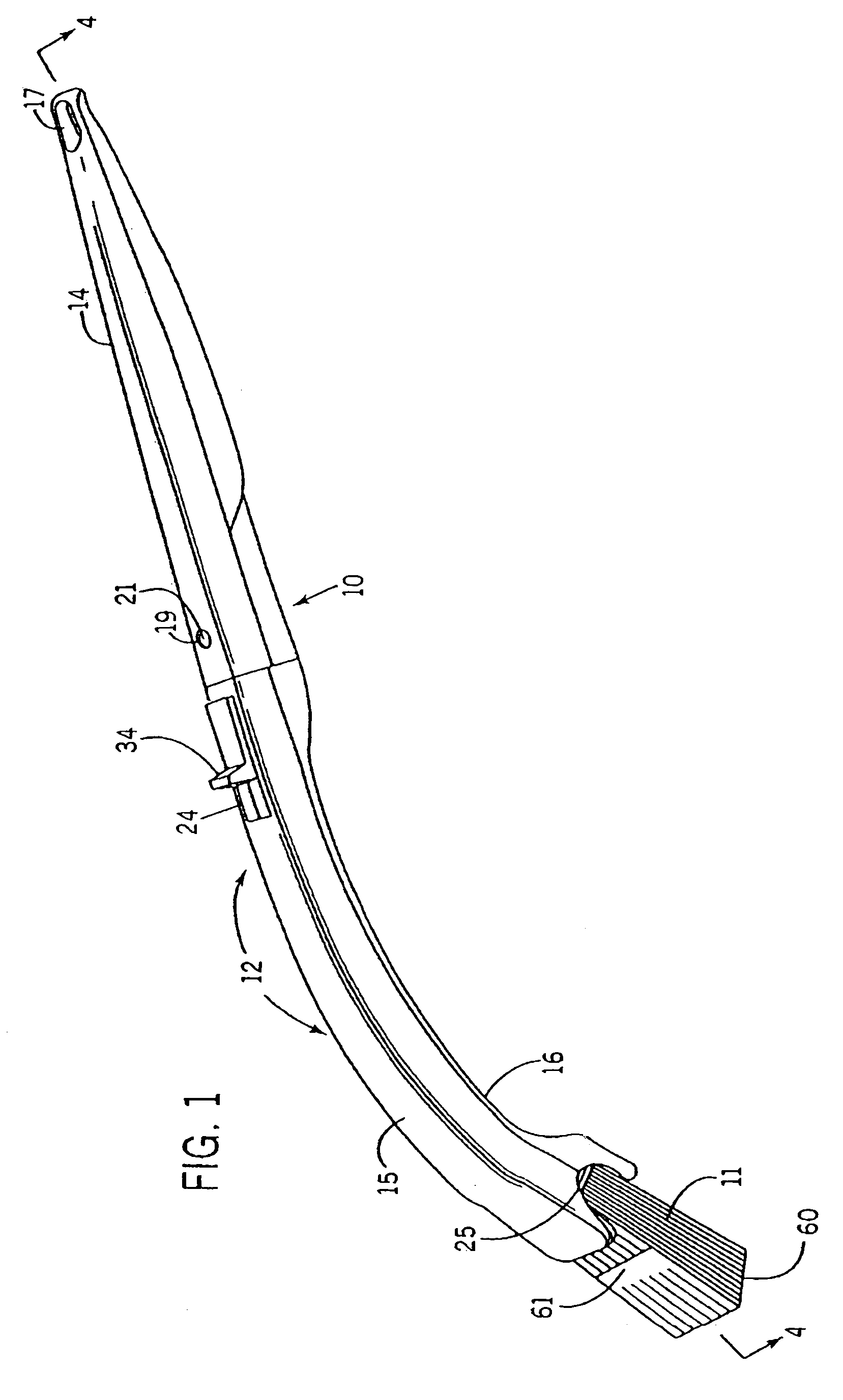

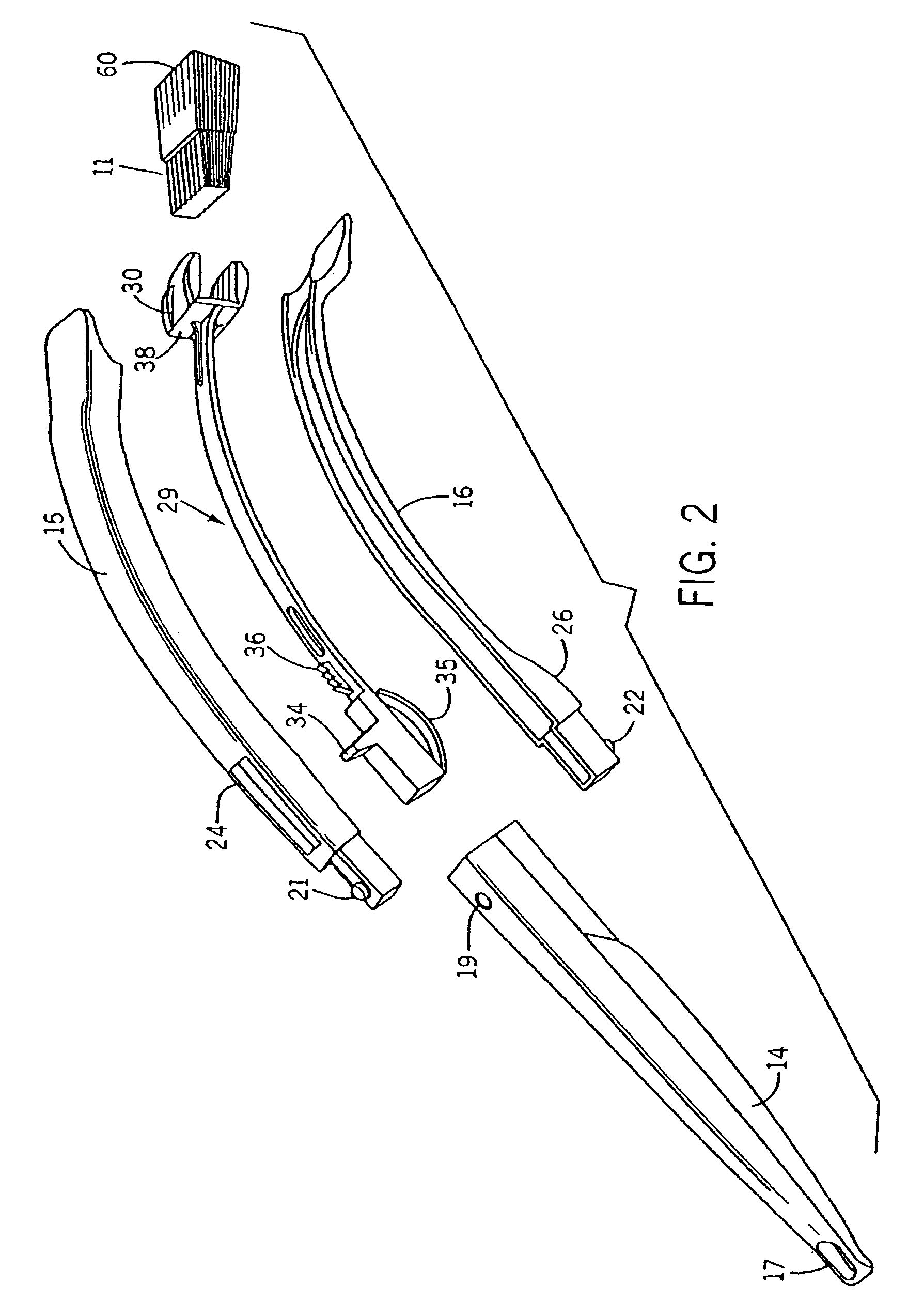

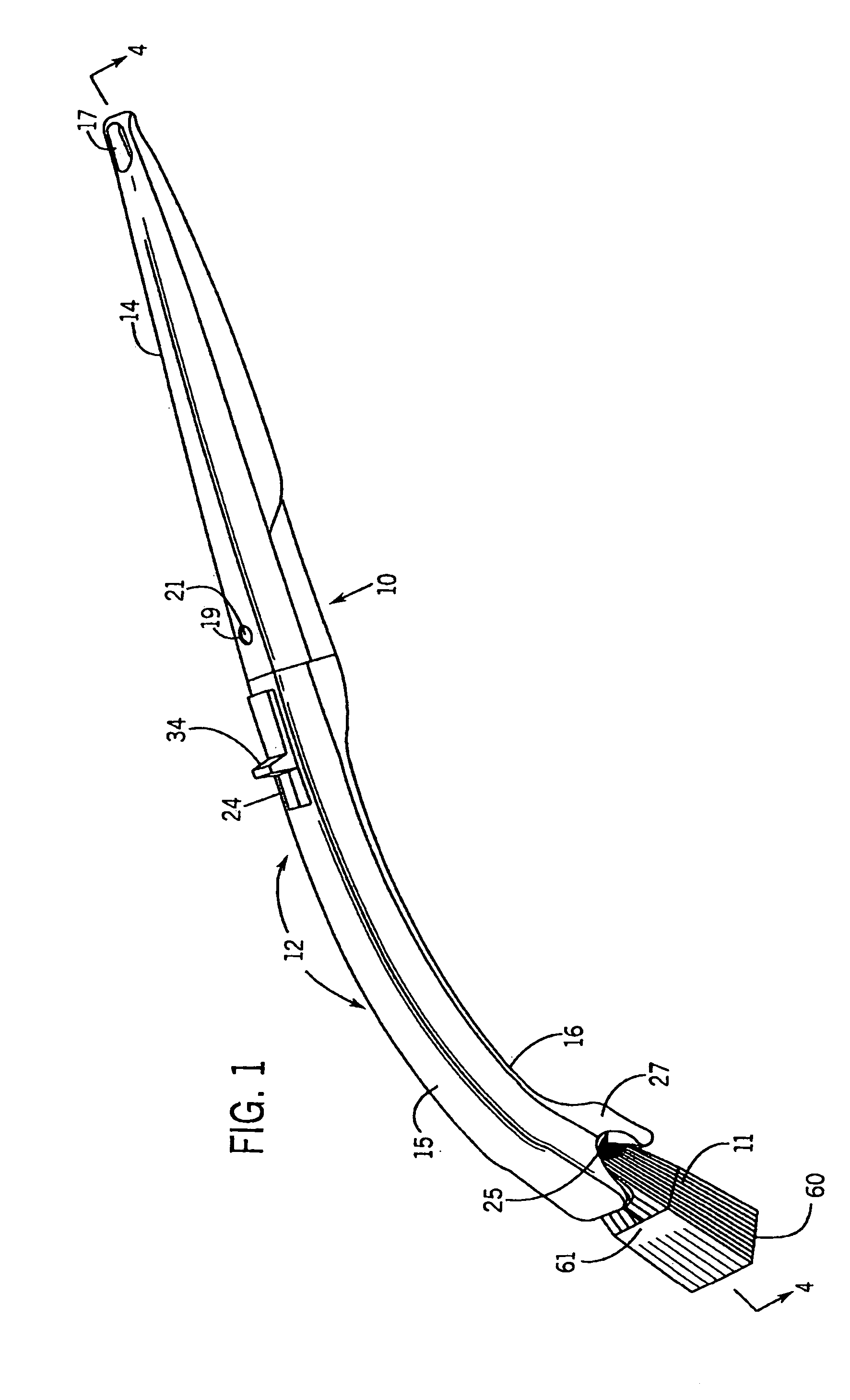

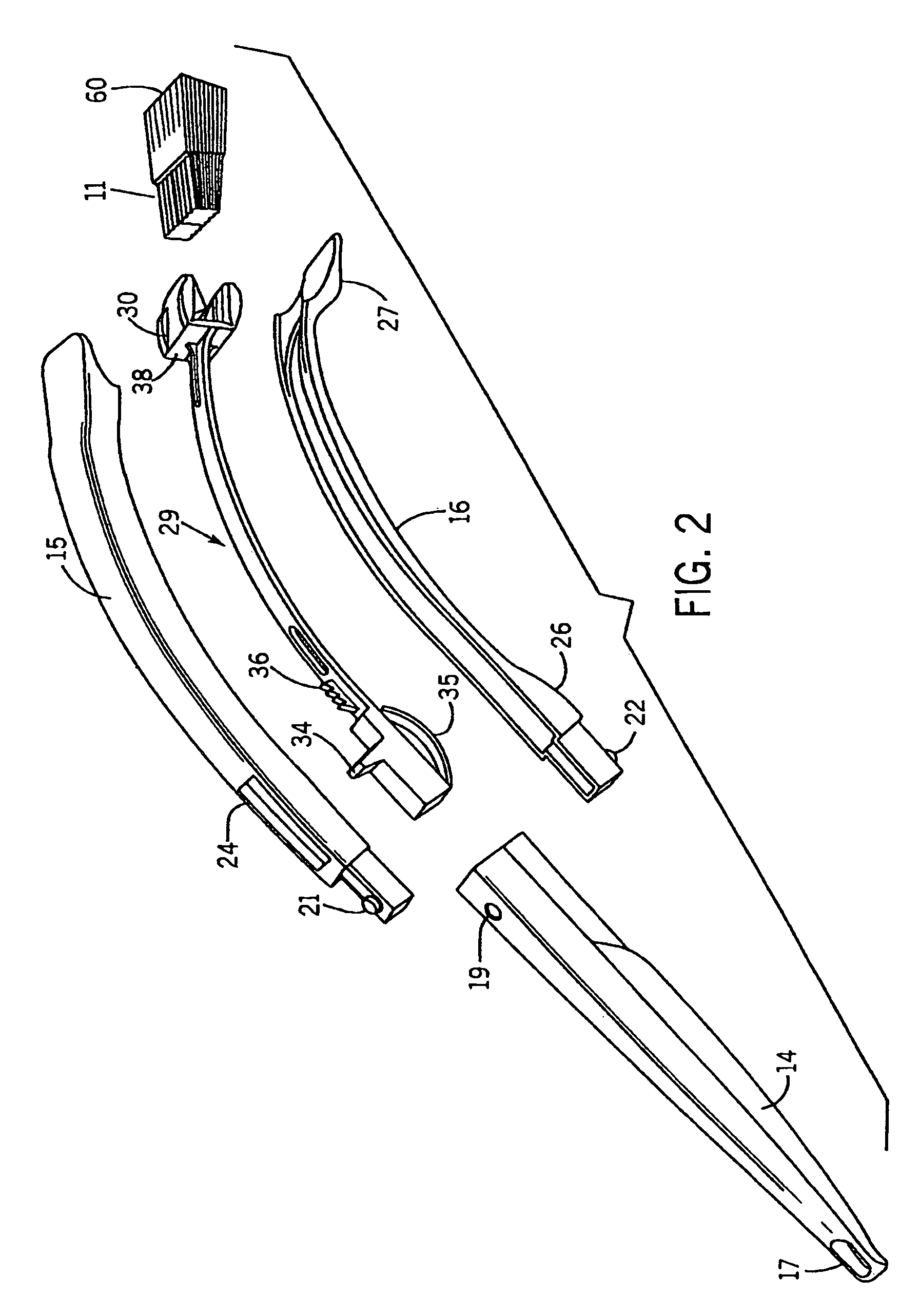

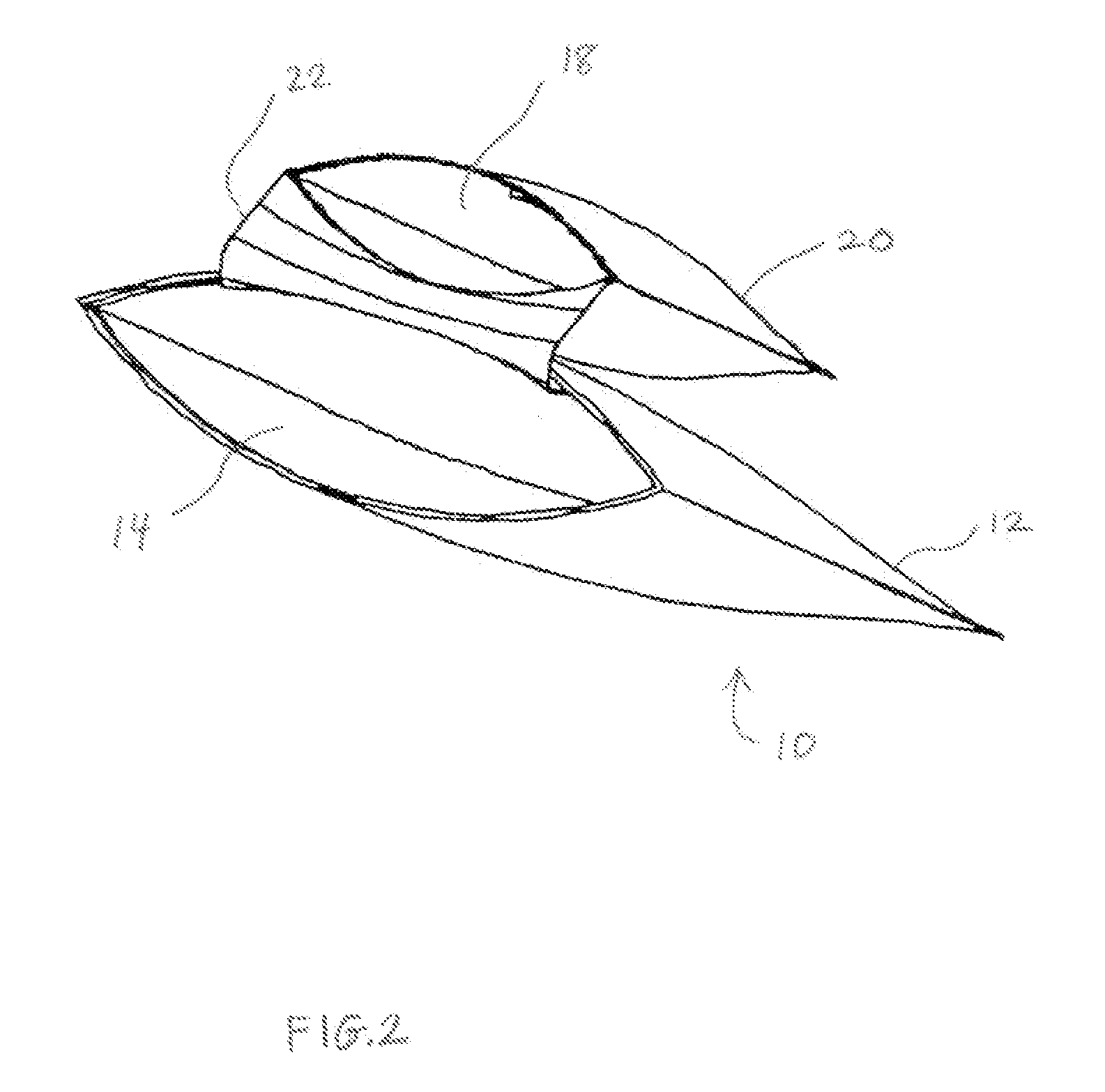

Cleaning brush with disposable/replaceable brush head

InactiveUS7316046B2Avoid odorLow production costBoard cleaning devicesCarpet cleanersRemote systemEngineering

Owner:SC JOHNSON & SON INC

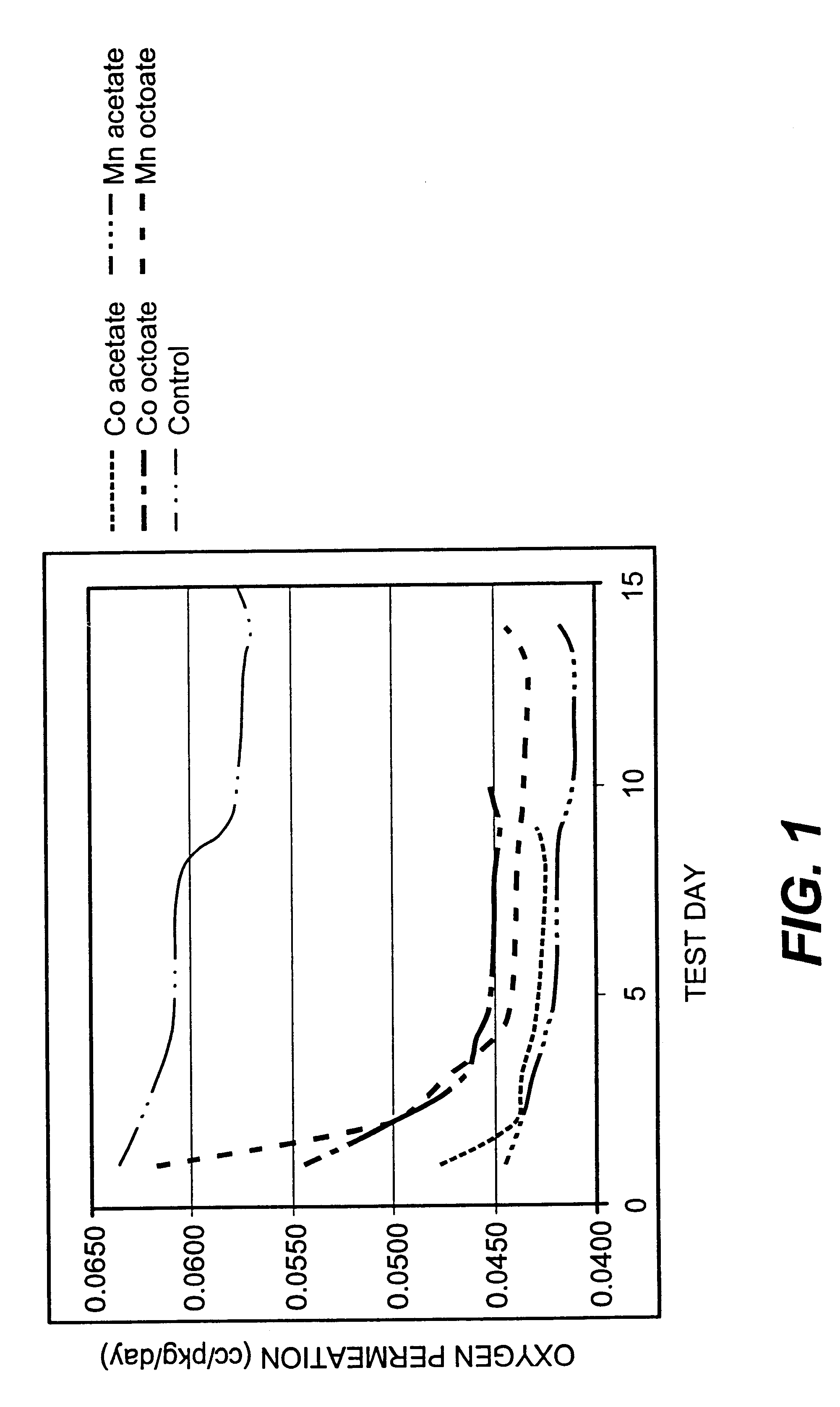

Process for reduction of acetaldehyde and oxygen in beverages contained in polyester-based packaging

InactiveUS6569479B2Reduce and eliminate migrationReduce and eliminate migration of oxygenReady-for-oven doughsFruit and vegetables preservationPolyesterAcetic acid

A process for reducing acetaldehyde concentration in beverages contained in polyester-based packaging, wherein oxygen permeation into the container is reduced or eliminated. The polyester contains an oxidation catalyst active for the oxidation of acetaldehyde to acetic acid. A composition comprising a polyester and said oxidation catalyst. A polyester-based container comprising said oxidation catalyst, and a bottled beverage having a polyester-based container comprising an oxidation catalyst active for the oxidation of acetaldehyde to acetic acid.

Owner:THE COCA COLA CO

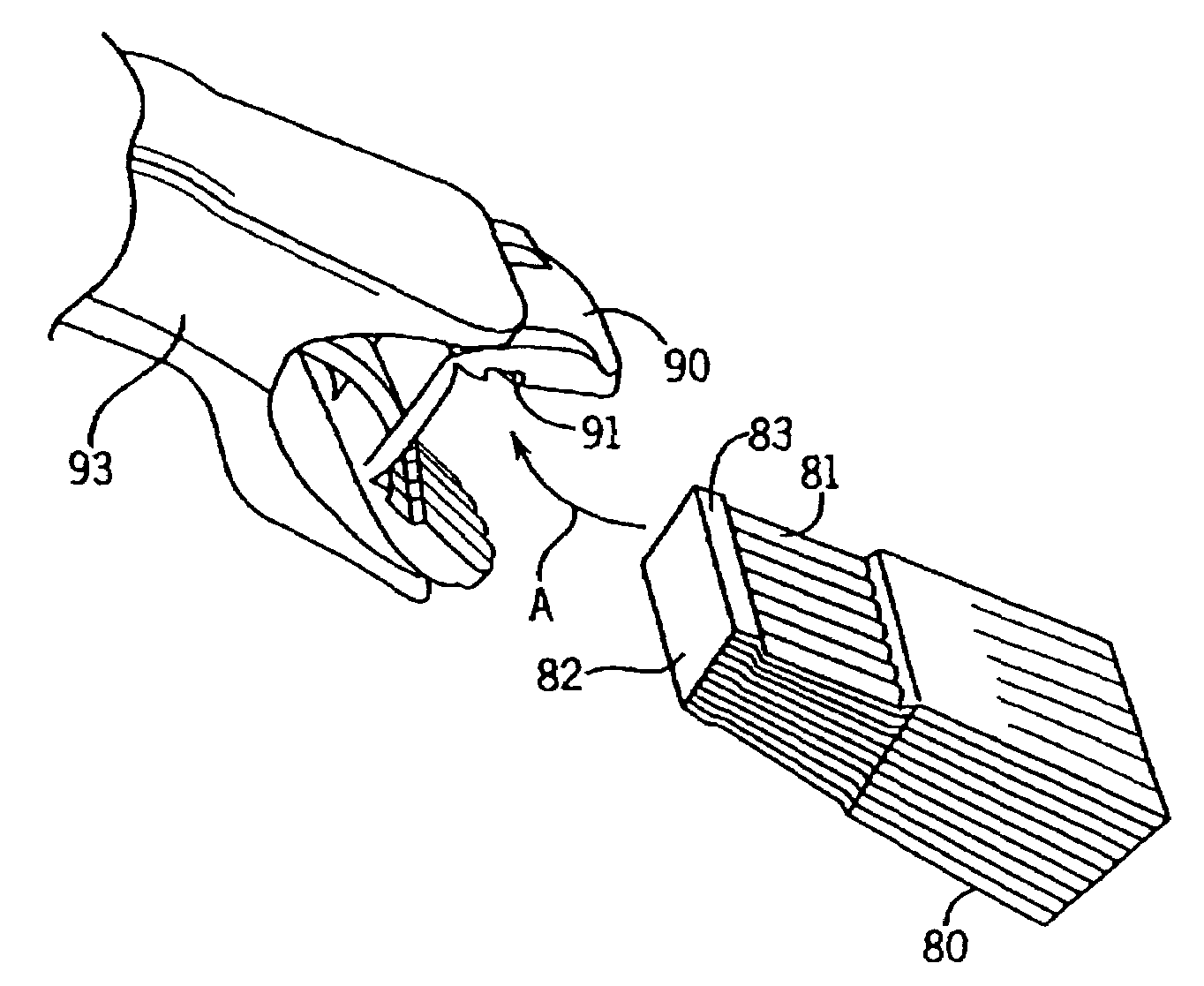

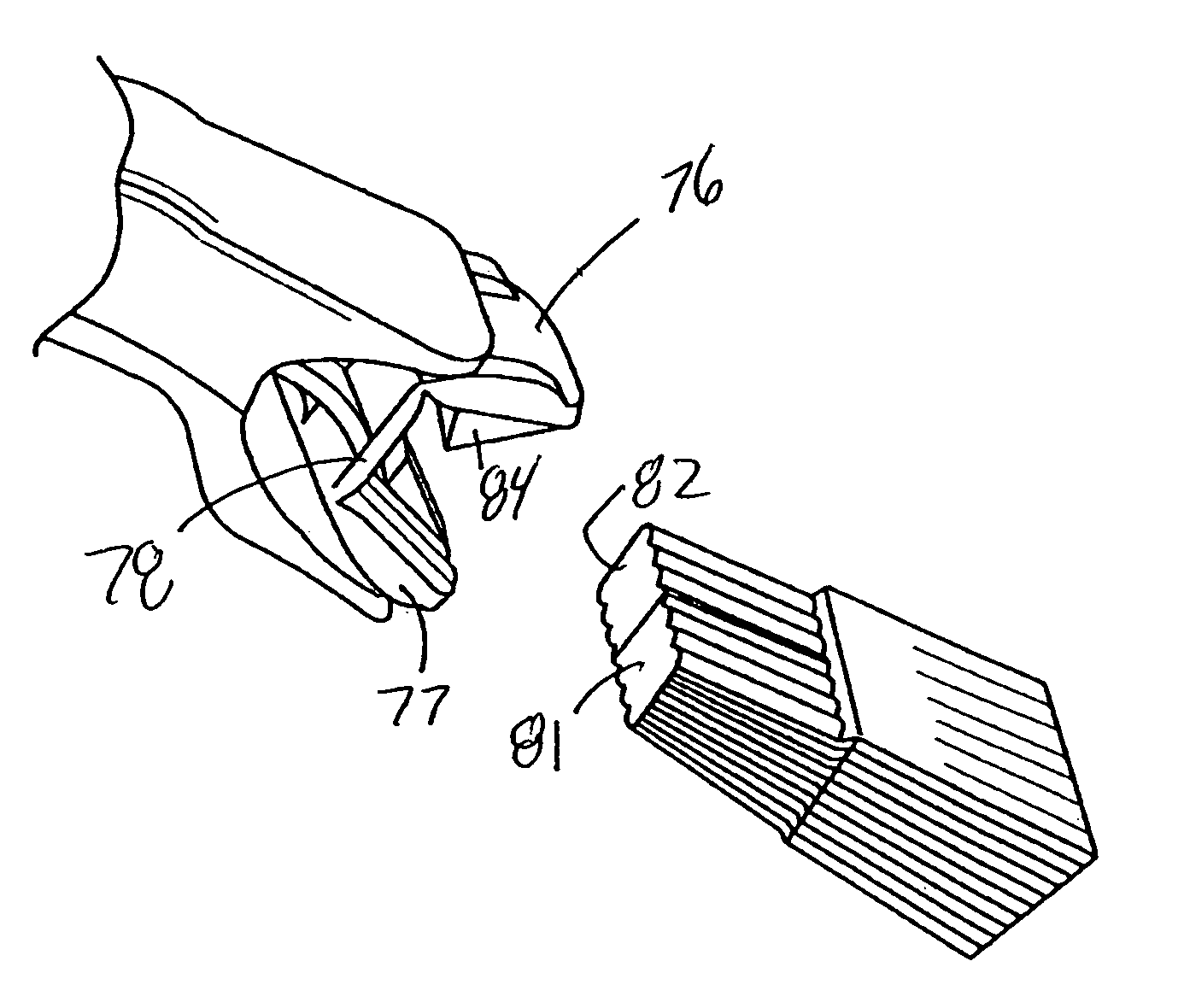

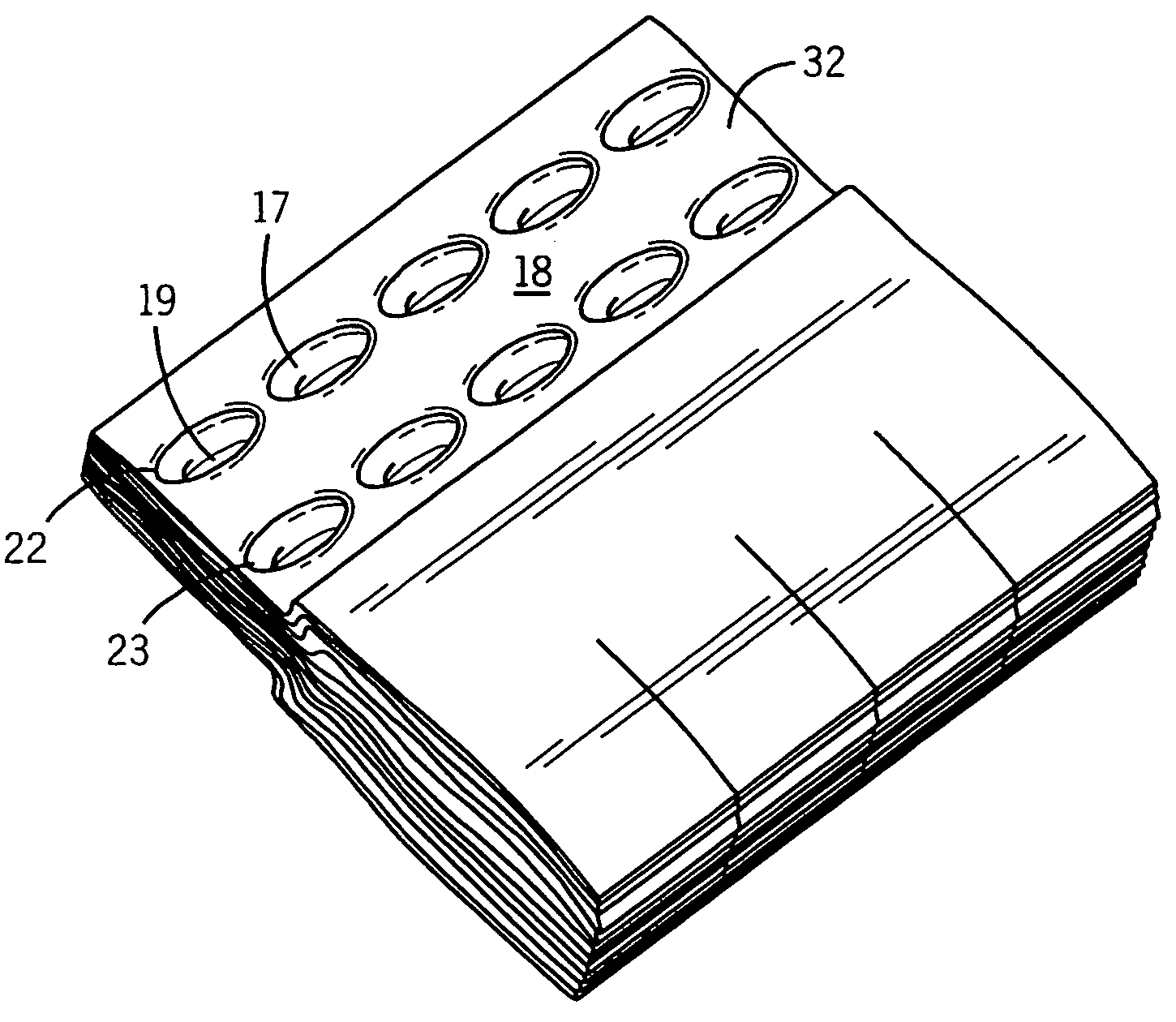

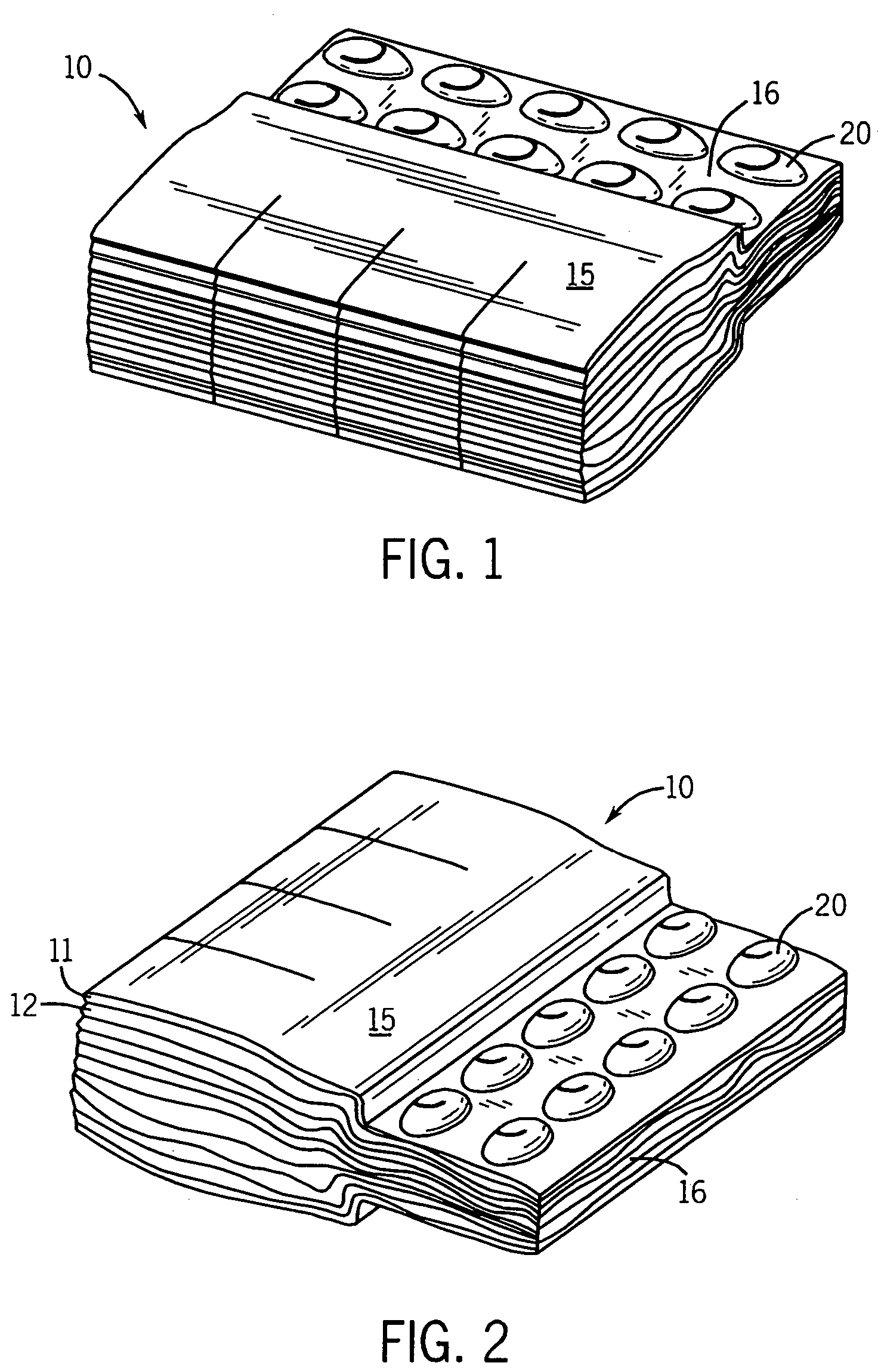

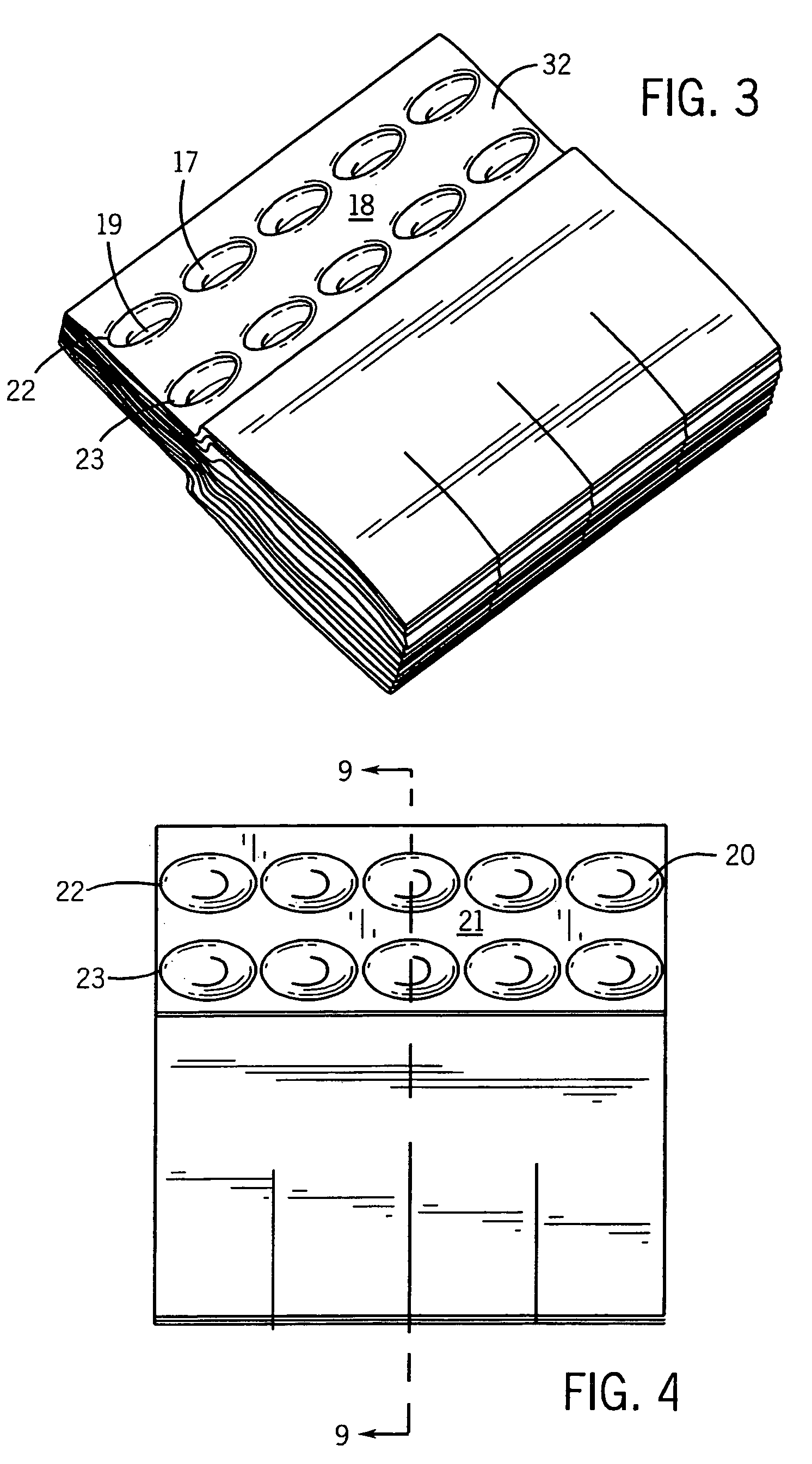

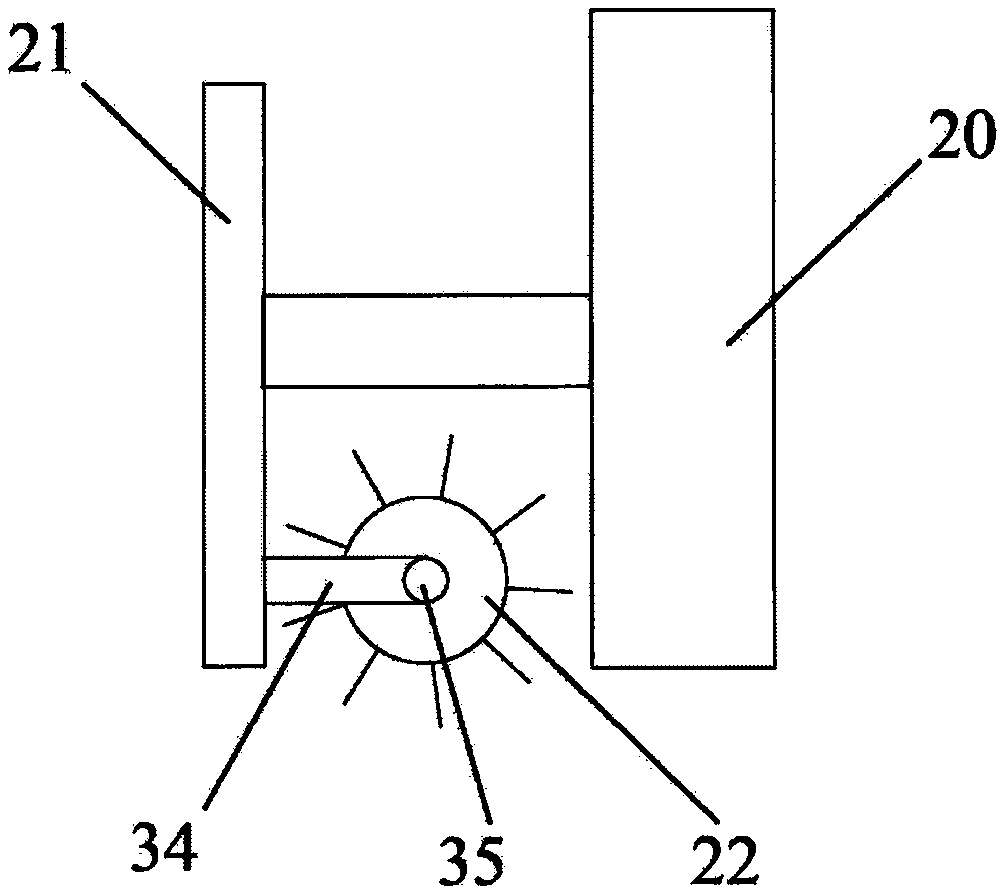

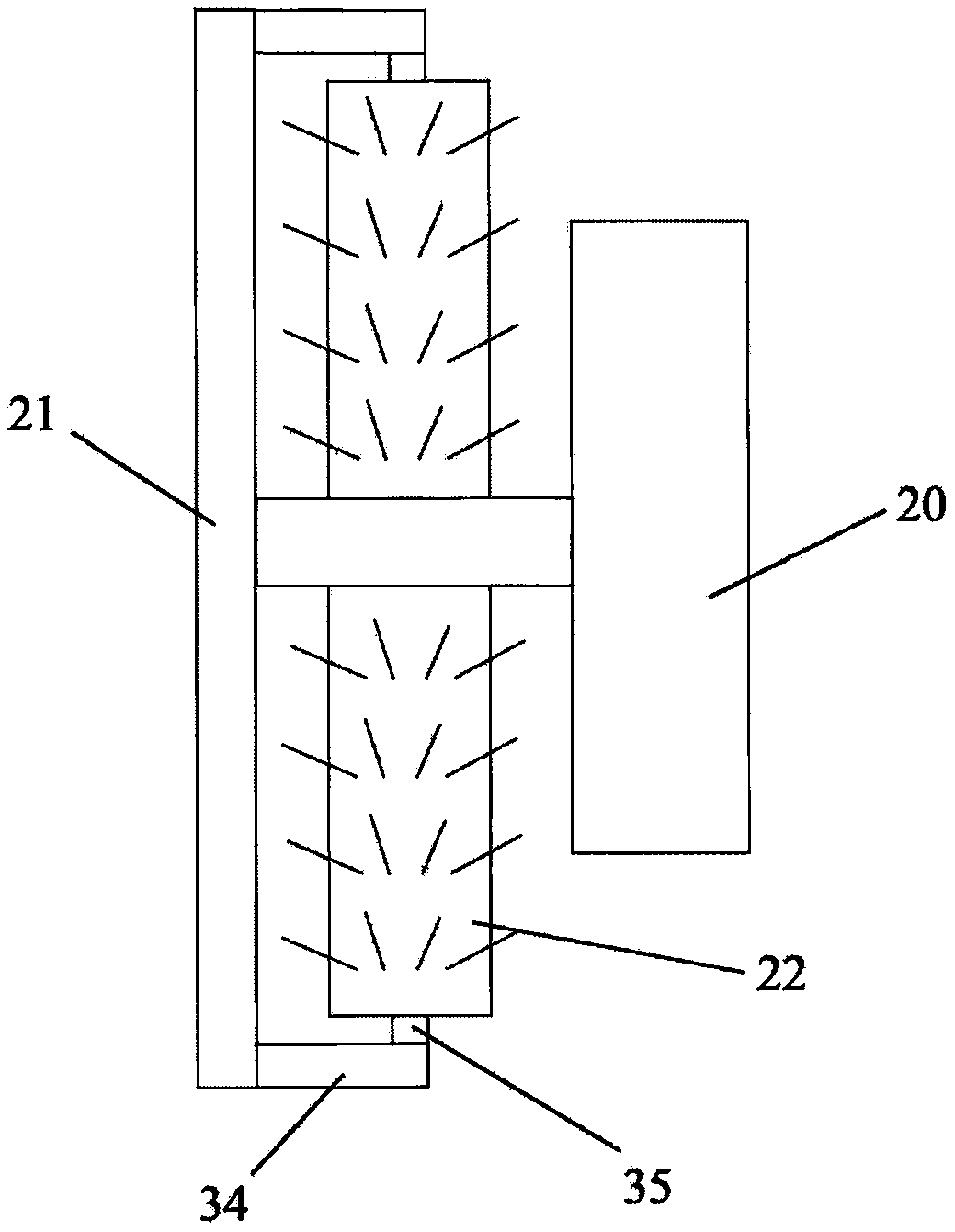

Cleaning brush with replaceable/disposable brush head

Disclosed is a brush for cleaning toilet bowls and the like. The brush has a permanent handle and can be used with a replaceable / disposable brush head that is flushable after use. The brush is a stack of sheets of water-dissolvable material. The sheets are compressed to both bind them together into a stack. There is a longitudinal slit in the rear of the brush head to create left and right rear attachment tabs. A wand provides a remote system for clamping and unclamping the brush head. The wand has a jaw whose mouth has two wedge shaped teeth that are offset from each other to clamp the corresponding tabs while driving the tabs in opposite directions in the jaw.

Owner:SC JOHNSON & SON INC

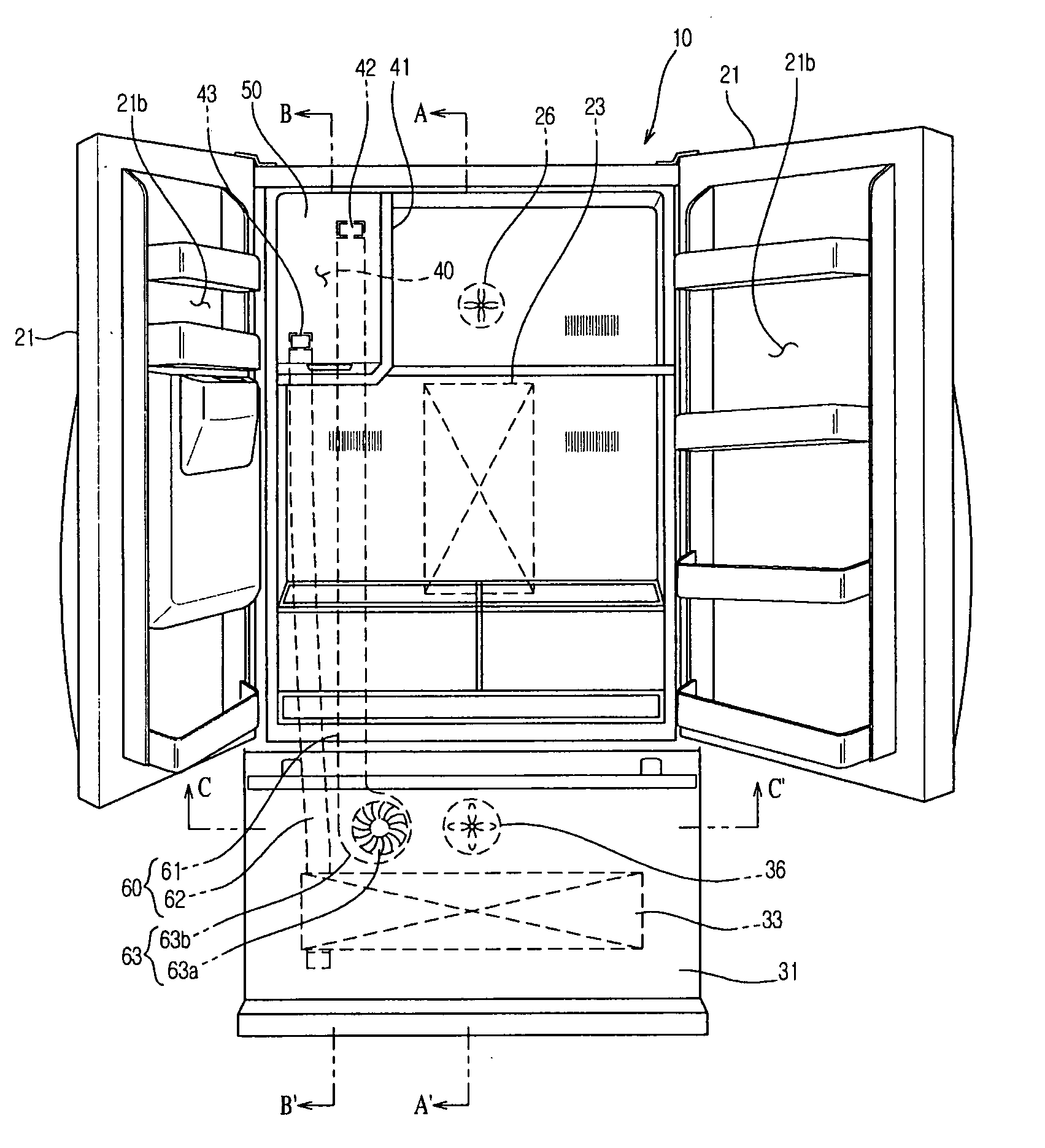

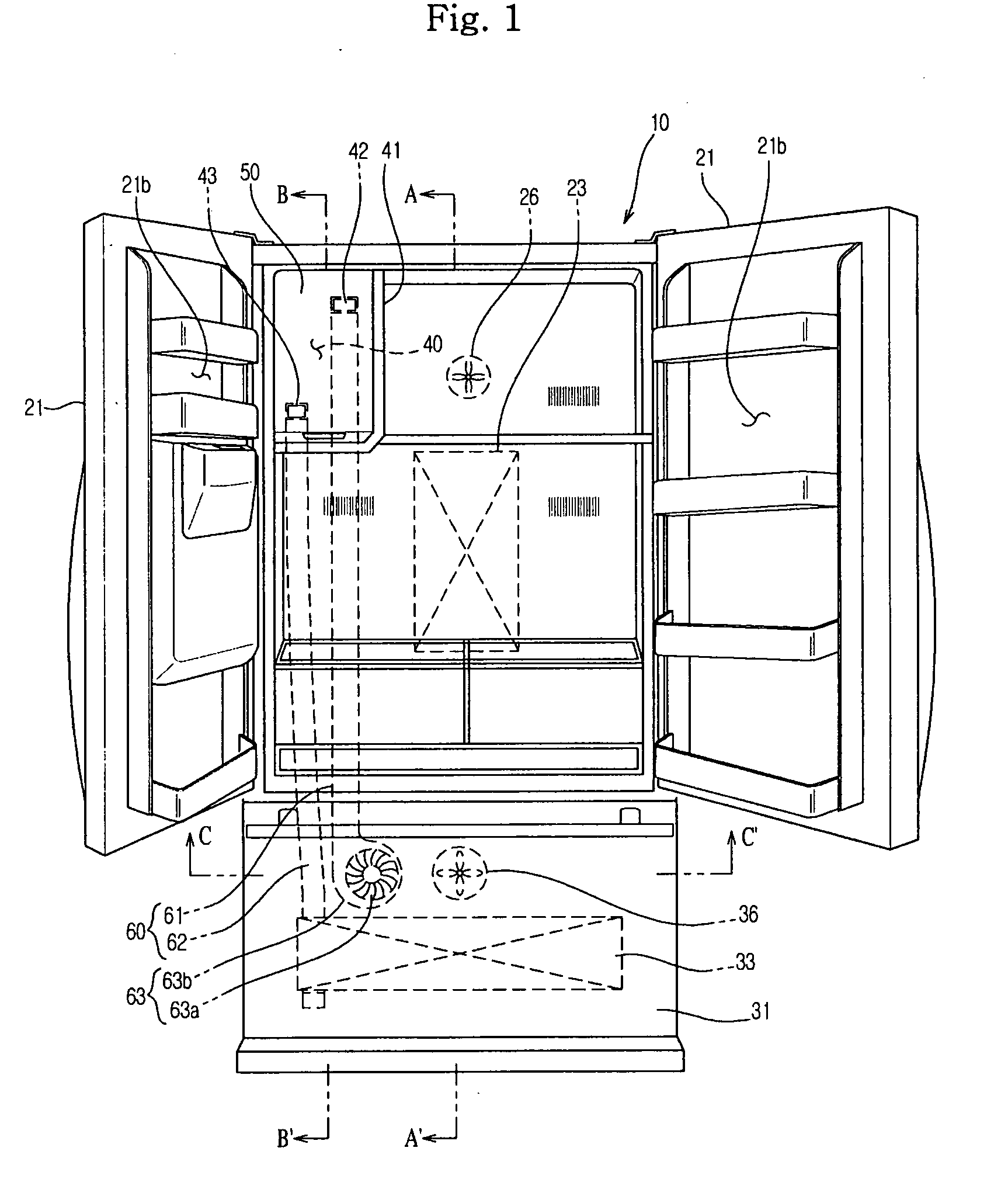

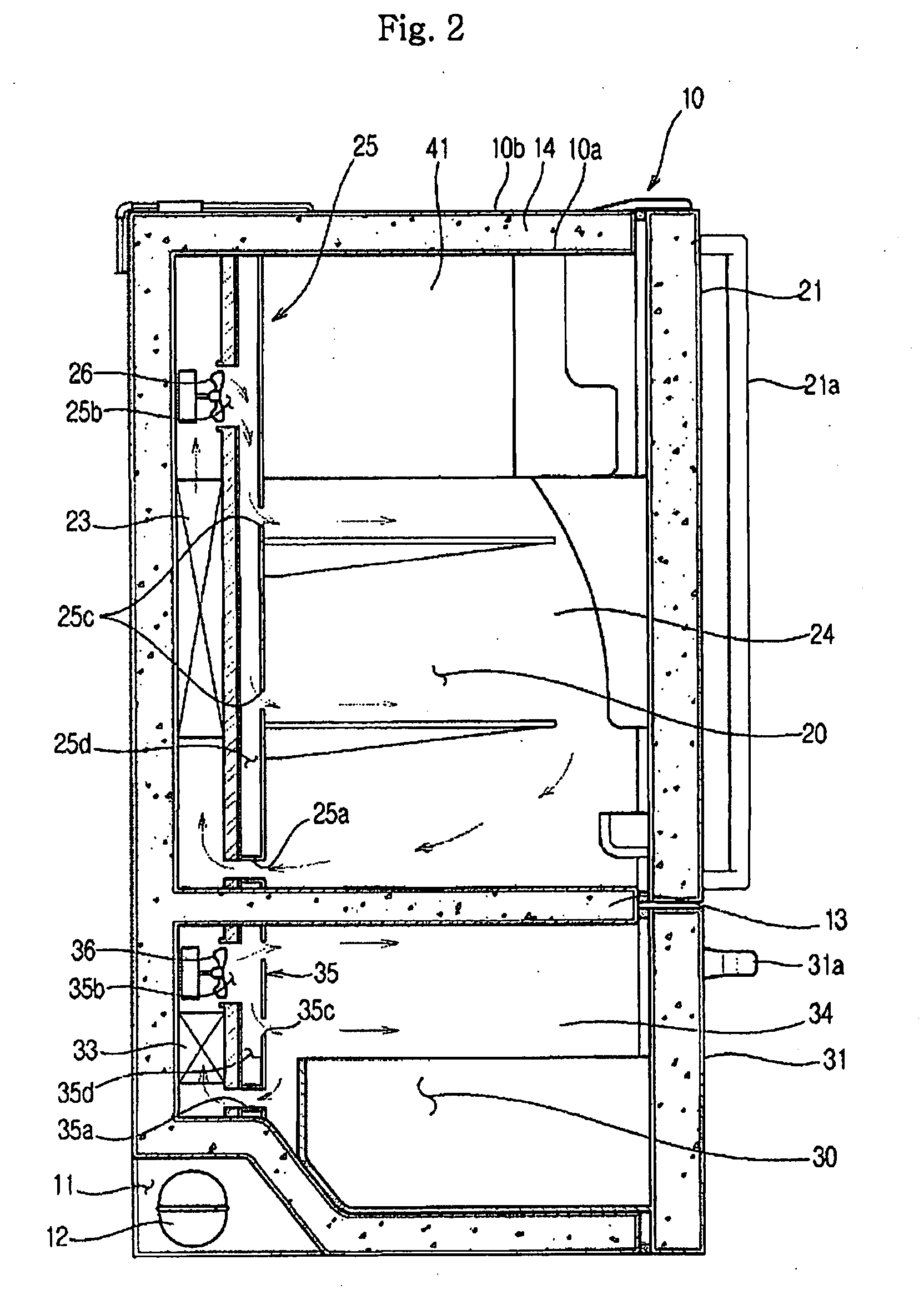

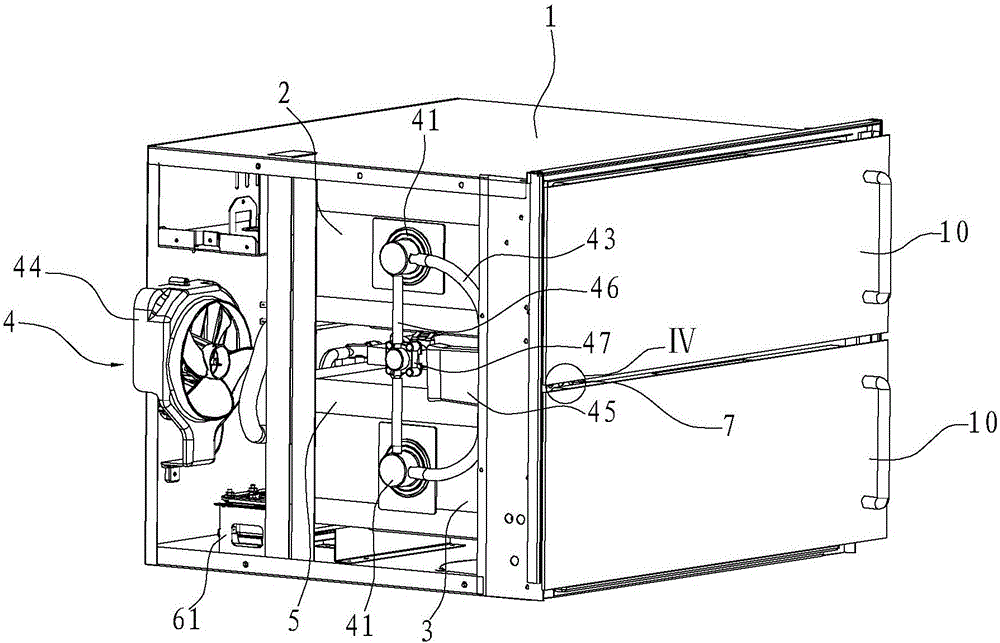

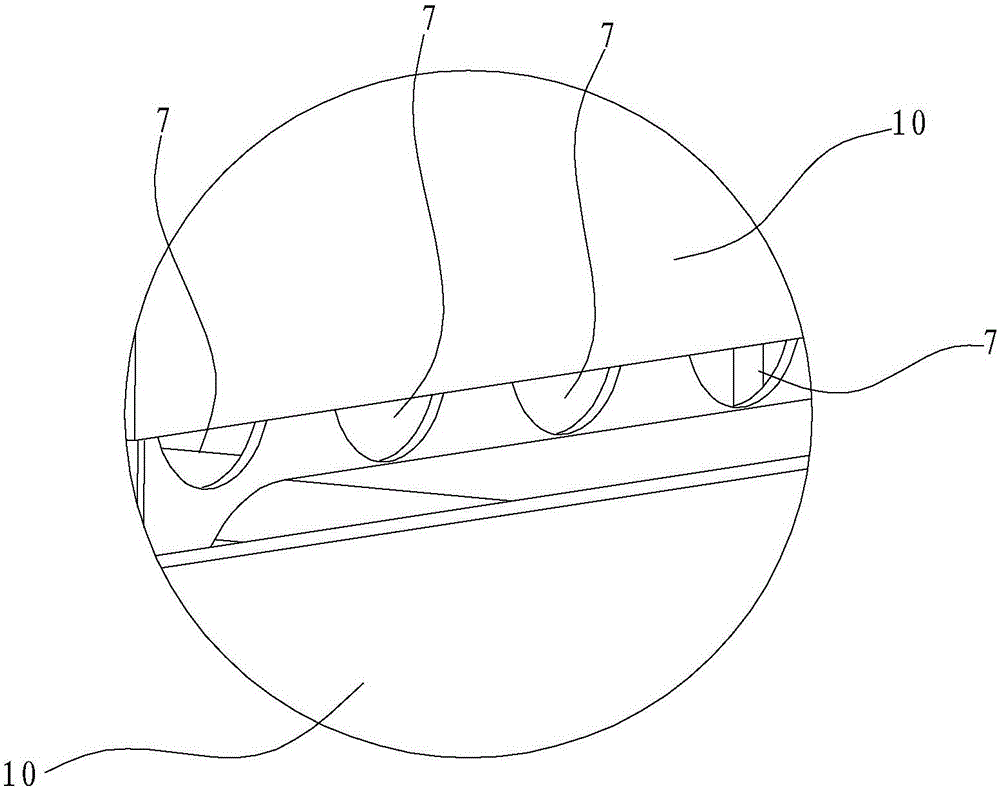

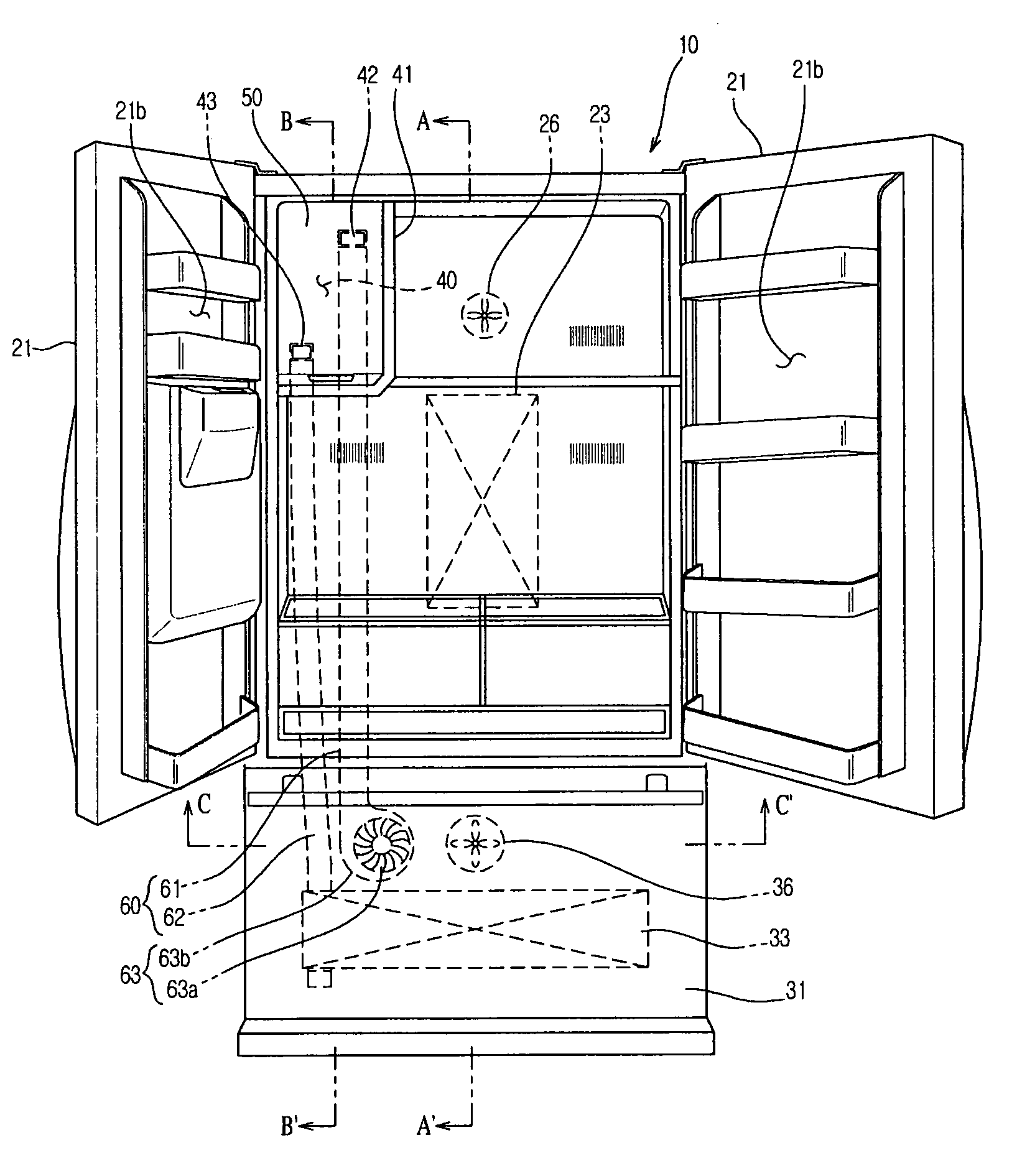

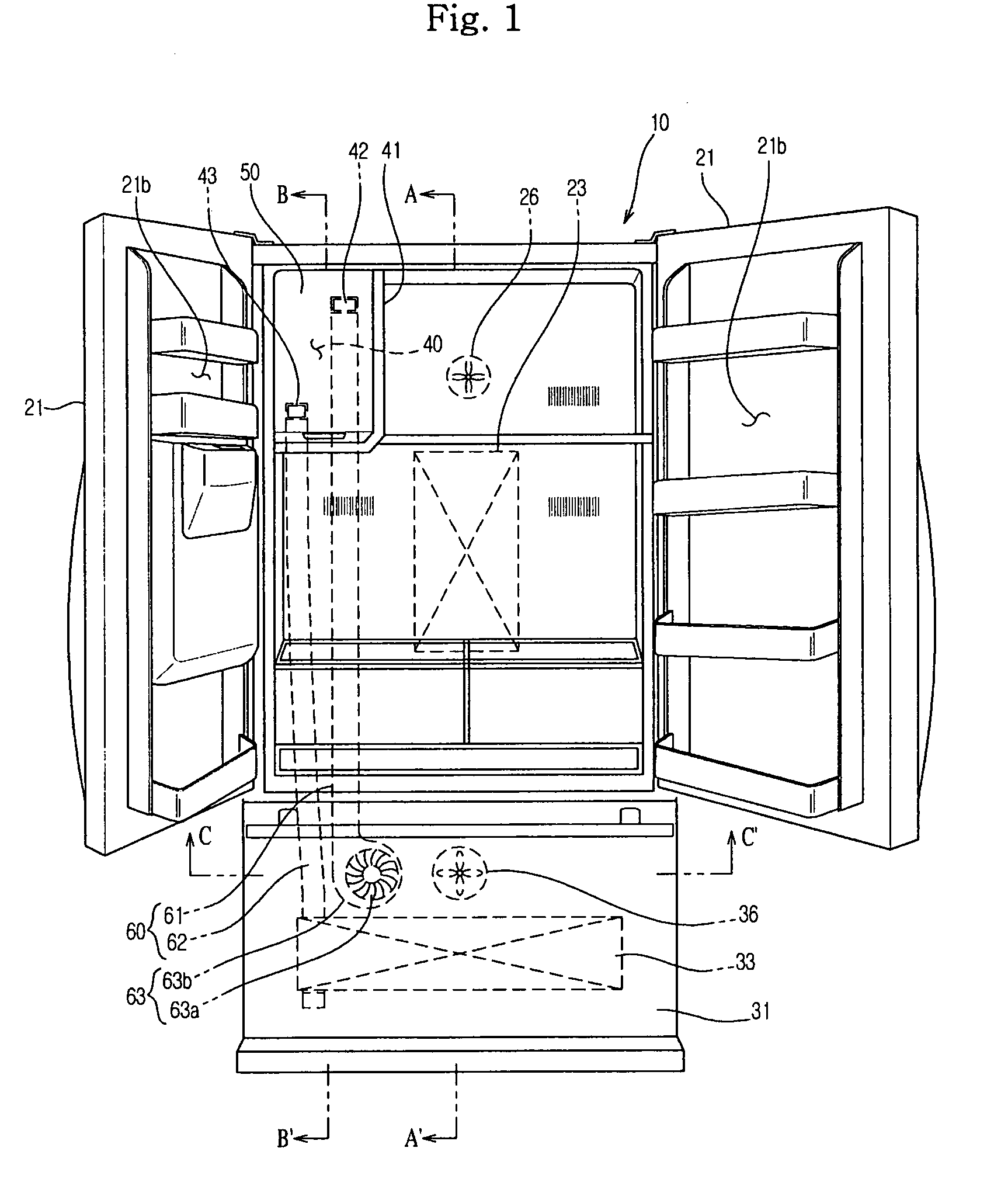

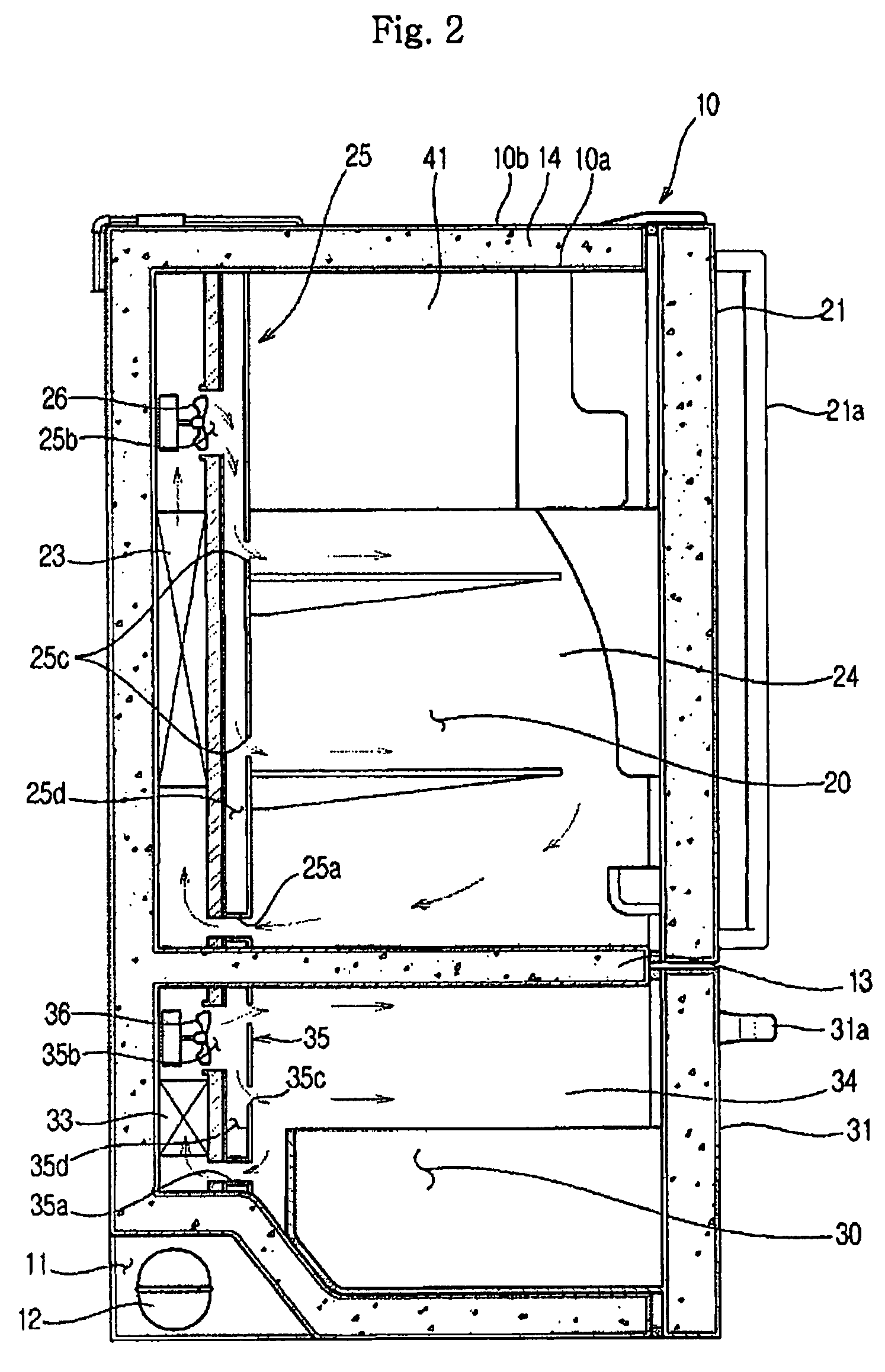

Refrigerator

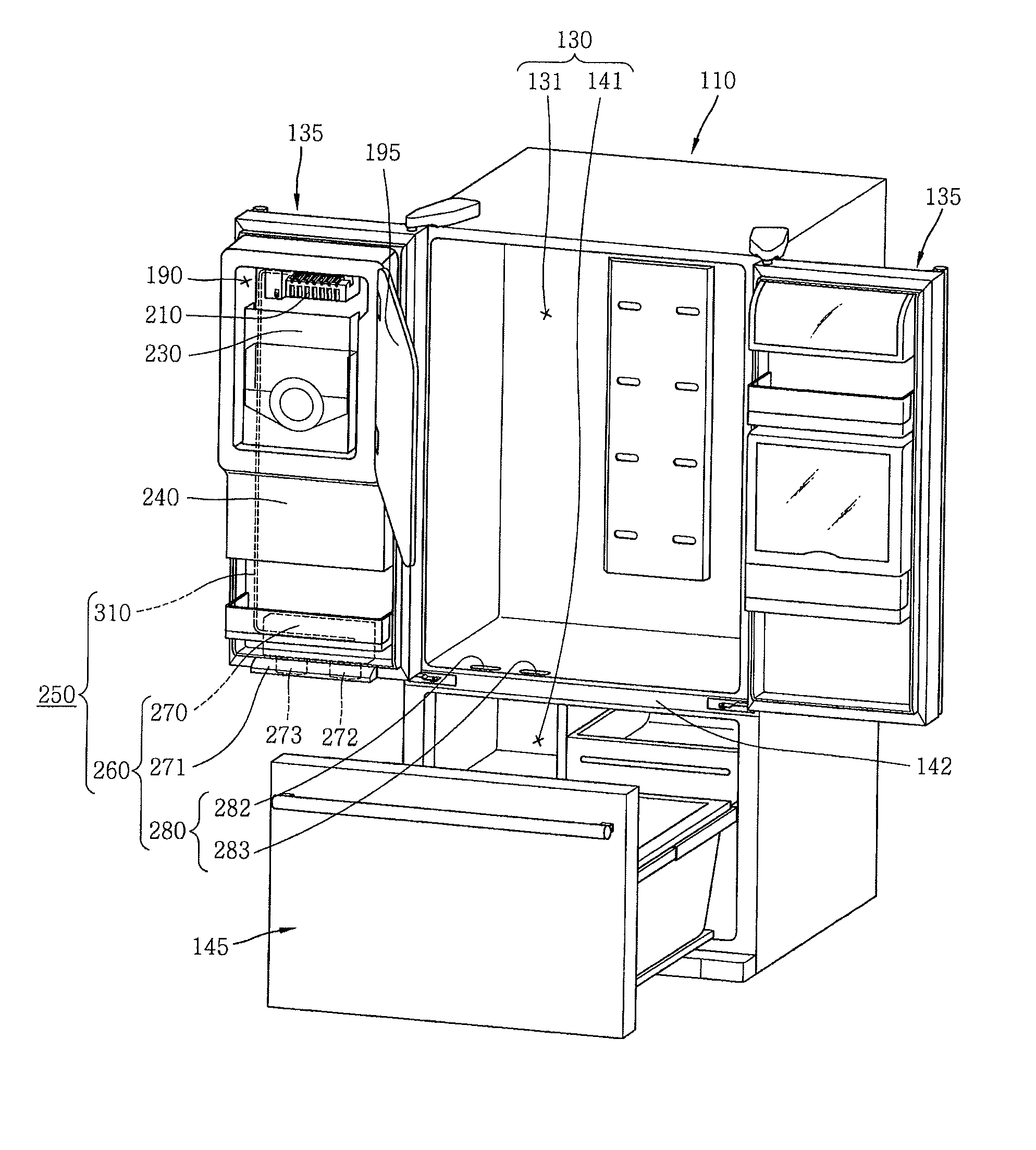

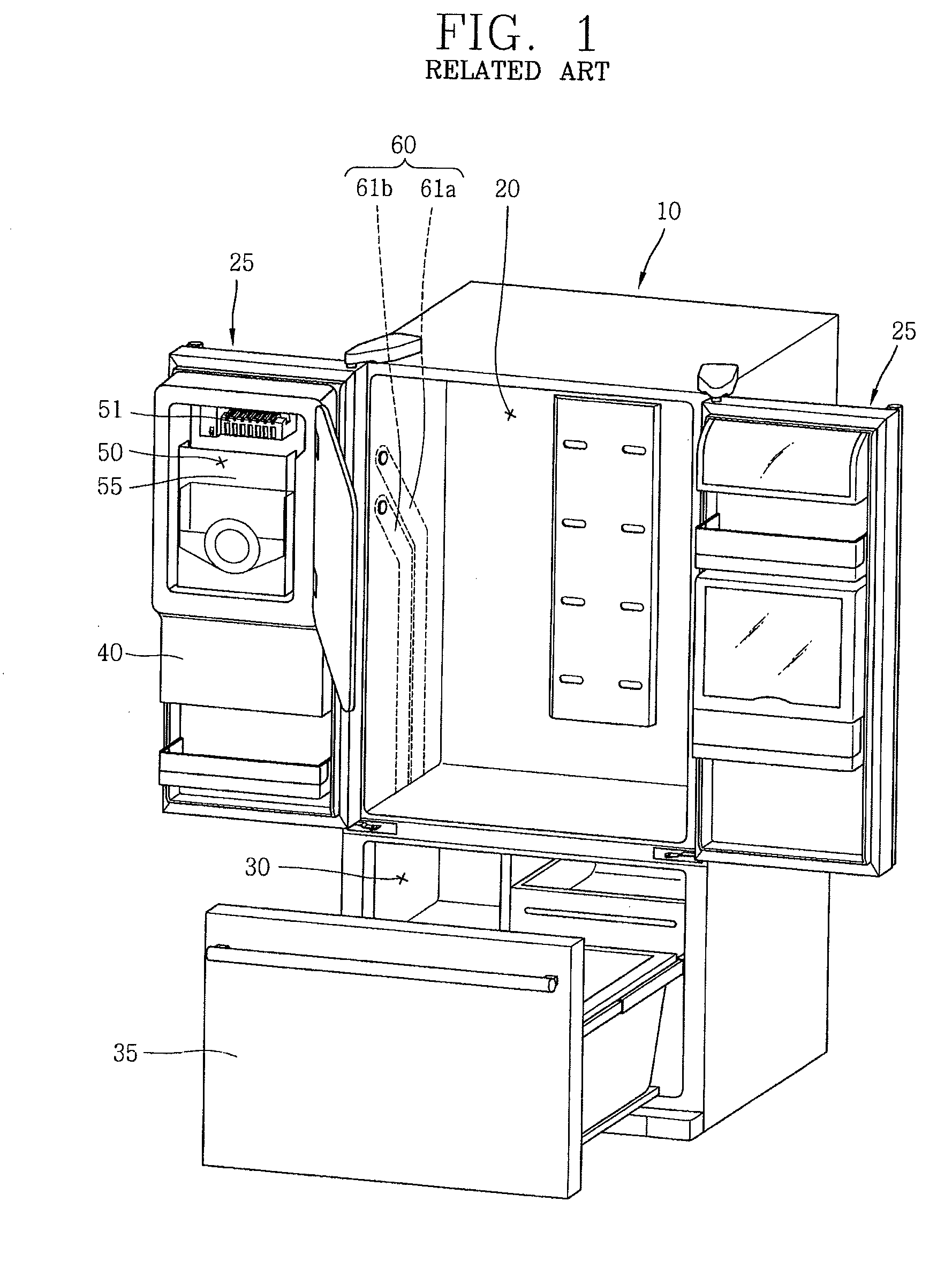

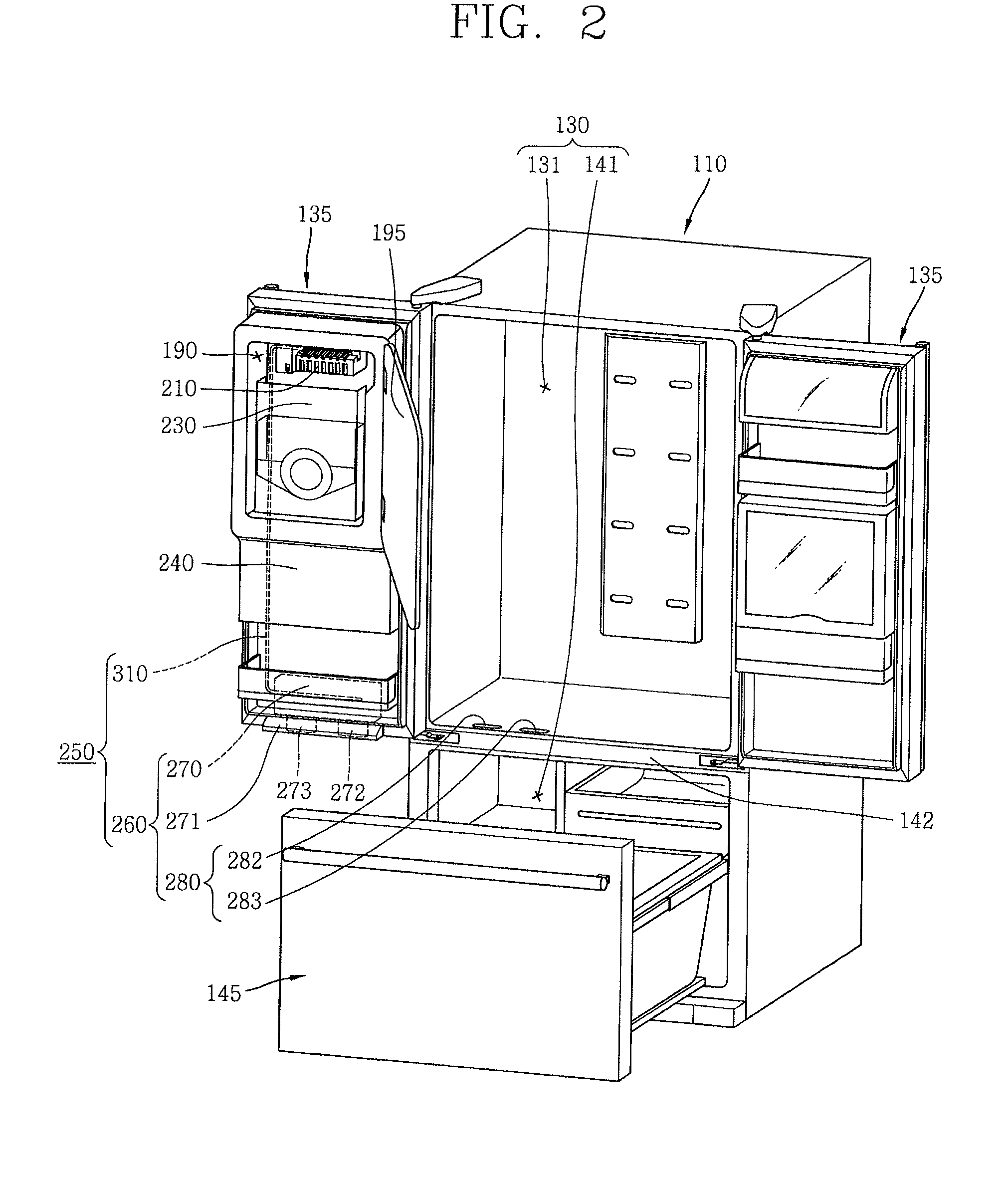

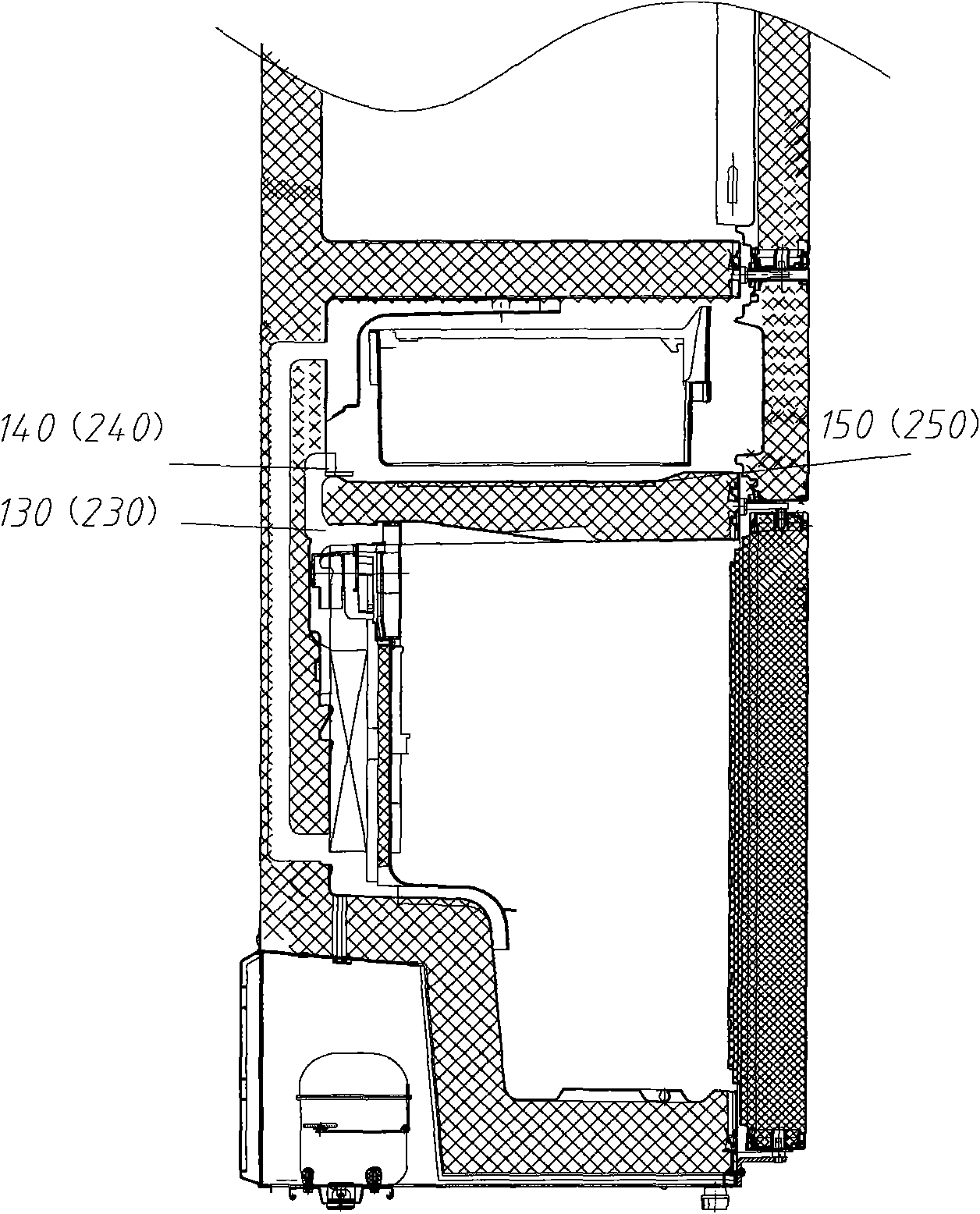

ActiveUS20080134708A1Ice-making performance can be improvedAvoid odorLighting and heating apparatusIce productionCold airEngineering

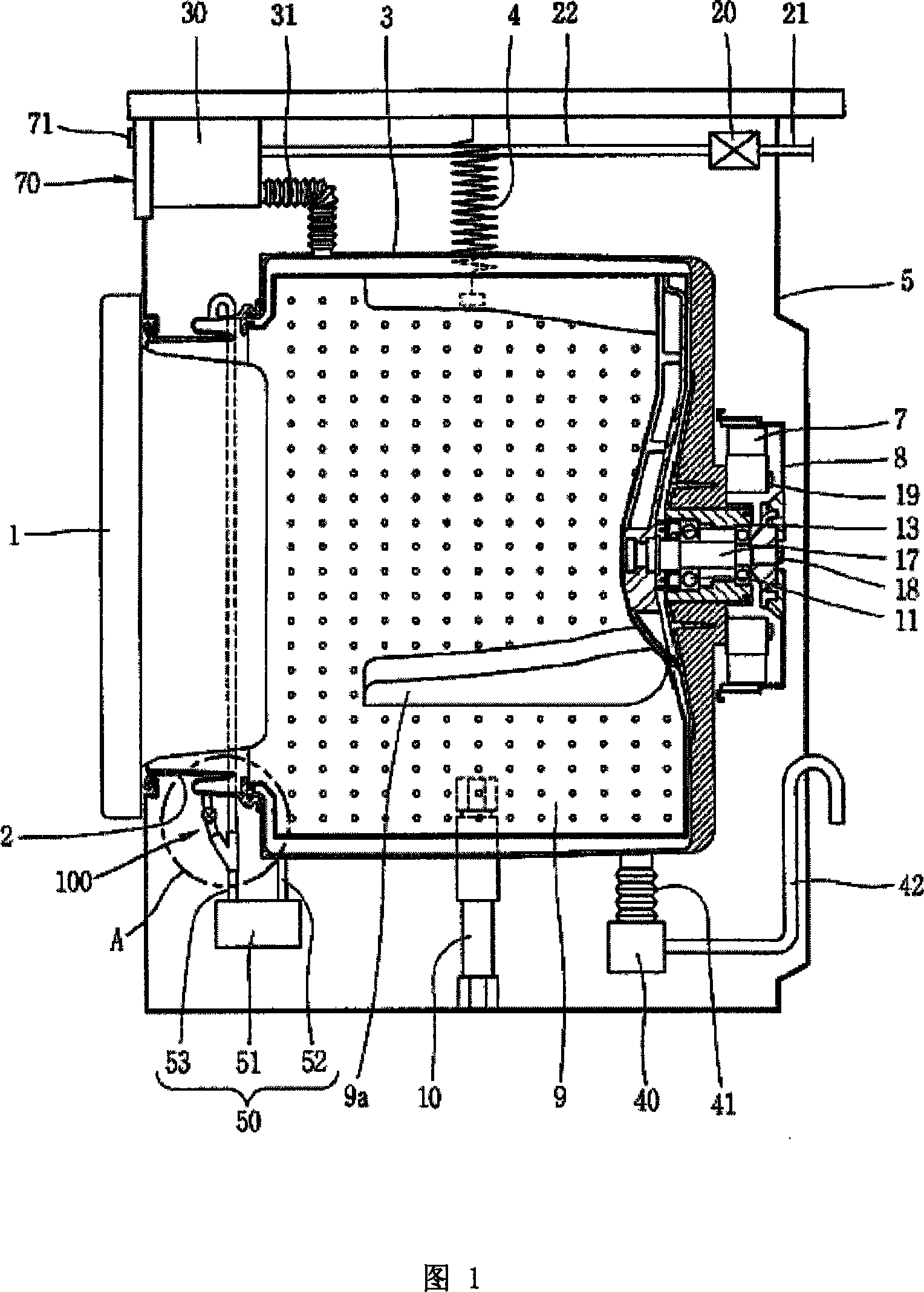

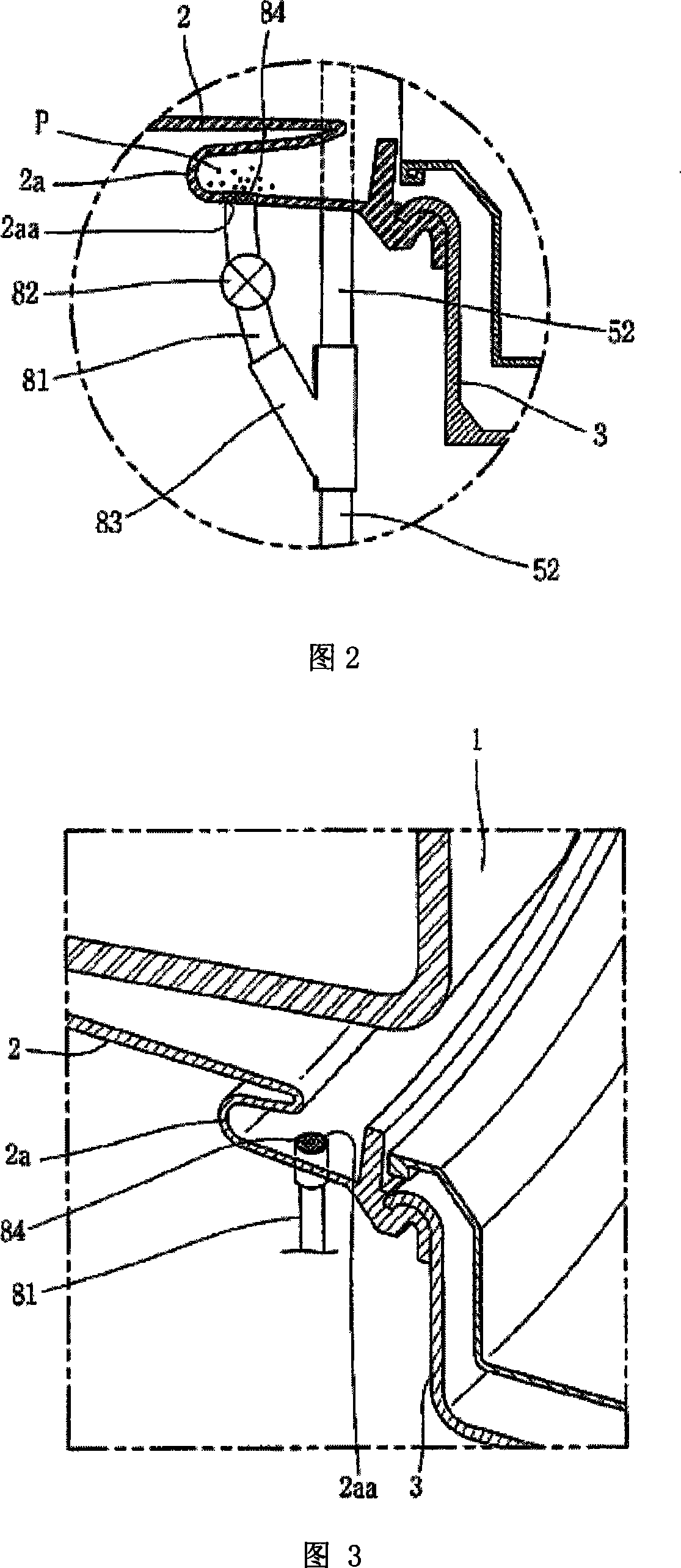

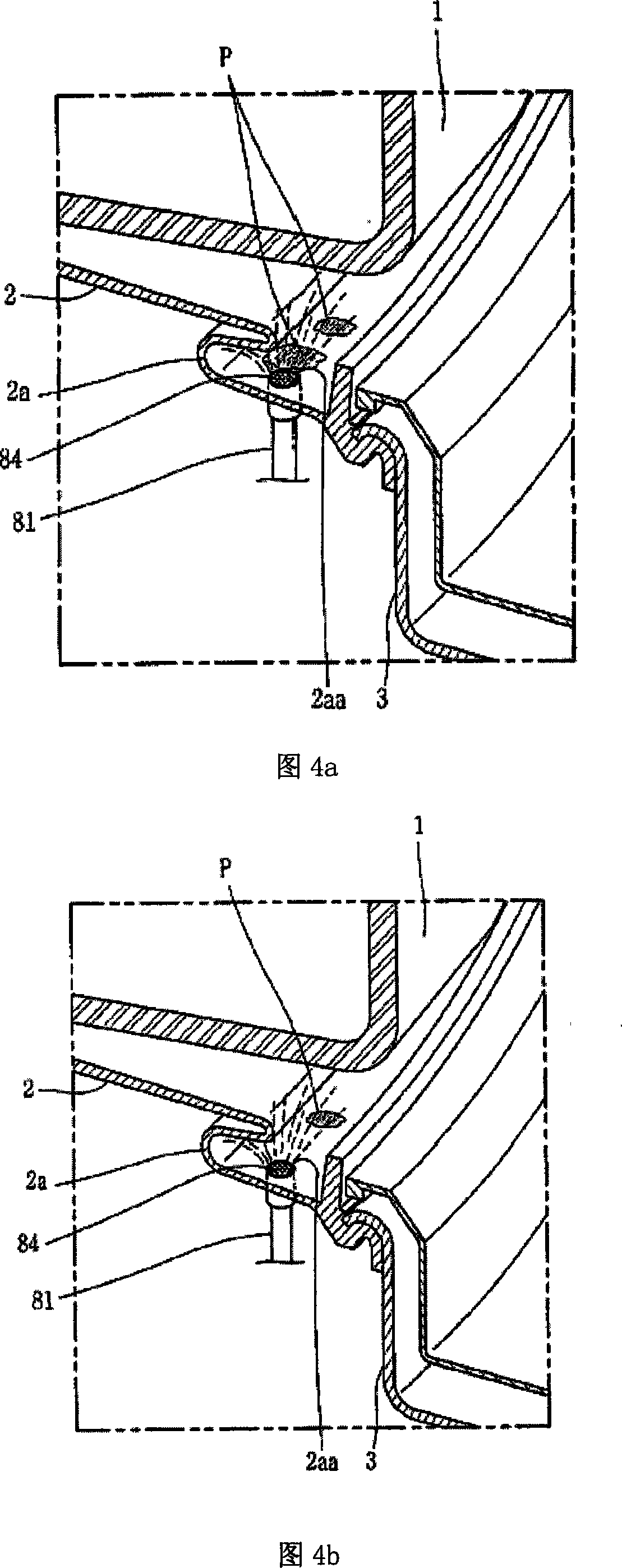

A refrigerator with an ice making device. The refrigerator includes a body defined with a refrigerating compartment, a freezing compartment, and an ice making compartment, the ice making compartment arranged in the refrigerating compartment while being thermally insulated from the refrigerating compartment, a first evaporator arranged in the refrigerating compartment, a second evaporator arranged in the freezing compartment, a refrigerating duct for circulating cold air from the first evaporator to the refrigerating compartment, a freezing duct for circulating cold air from the second evaporator to the freezing compartment, and an ice making flow passage for communicating the second evaporator and the ice making compartment. The second evaporator, ice making compartment, and ice making flow passage form a closed circuit such that the cold air in the ice making compartment does not enter the refrigerating compartment.

Owner:SAMSUNG ELECTRONICS CO LTD

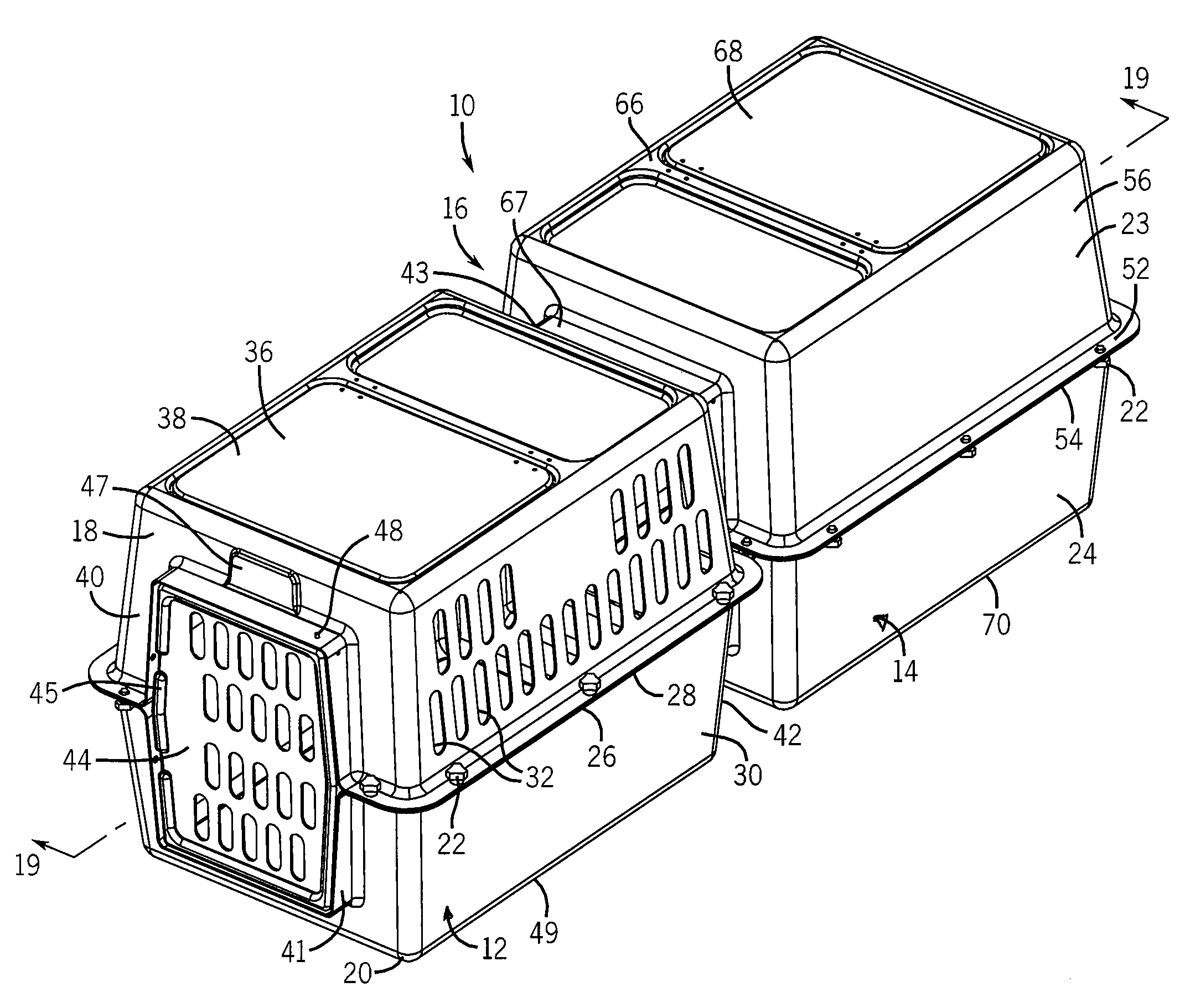

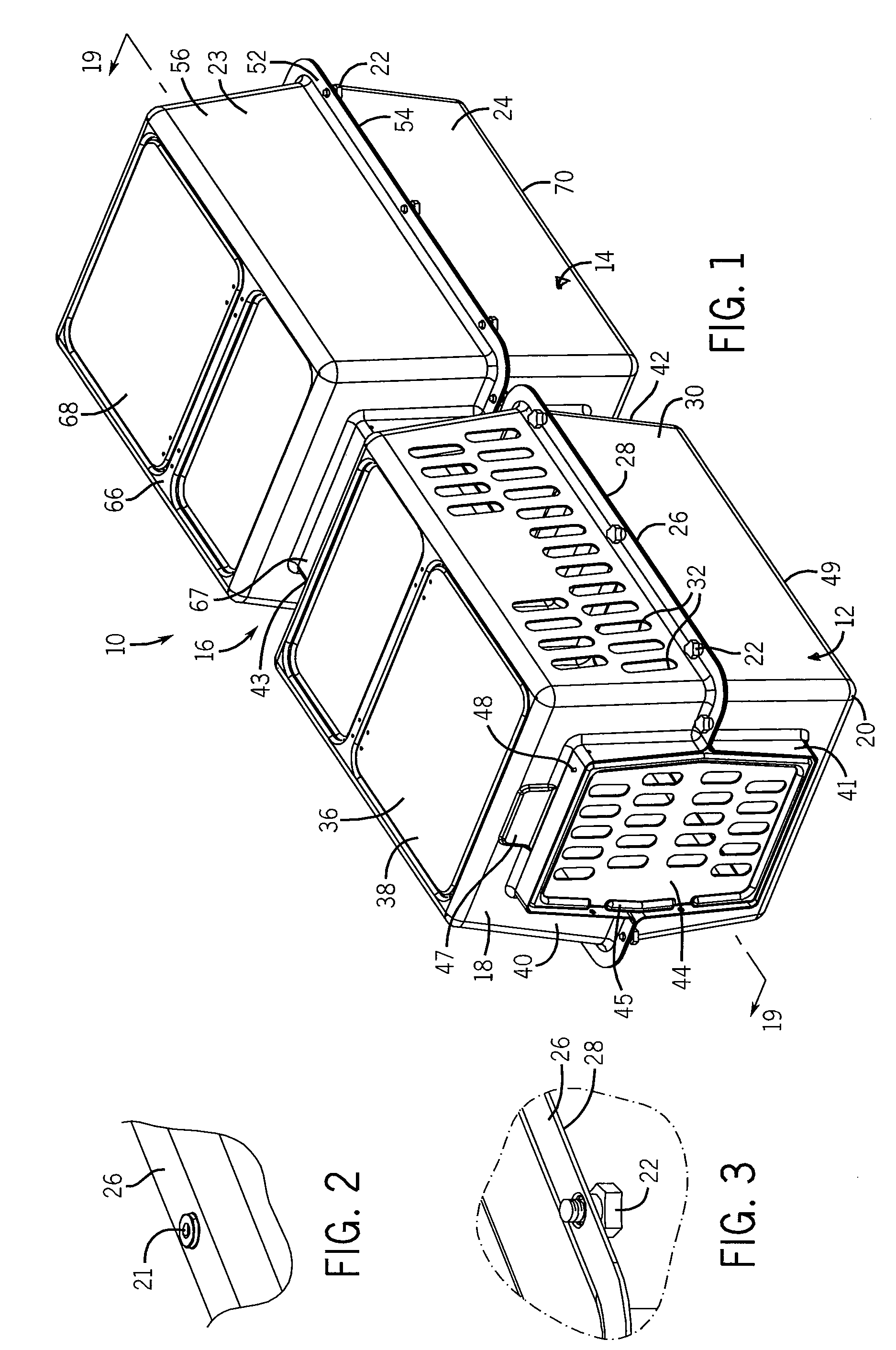

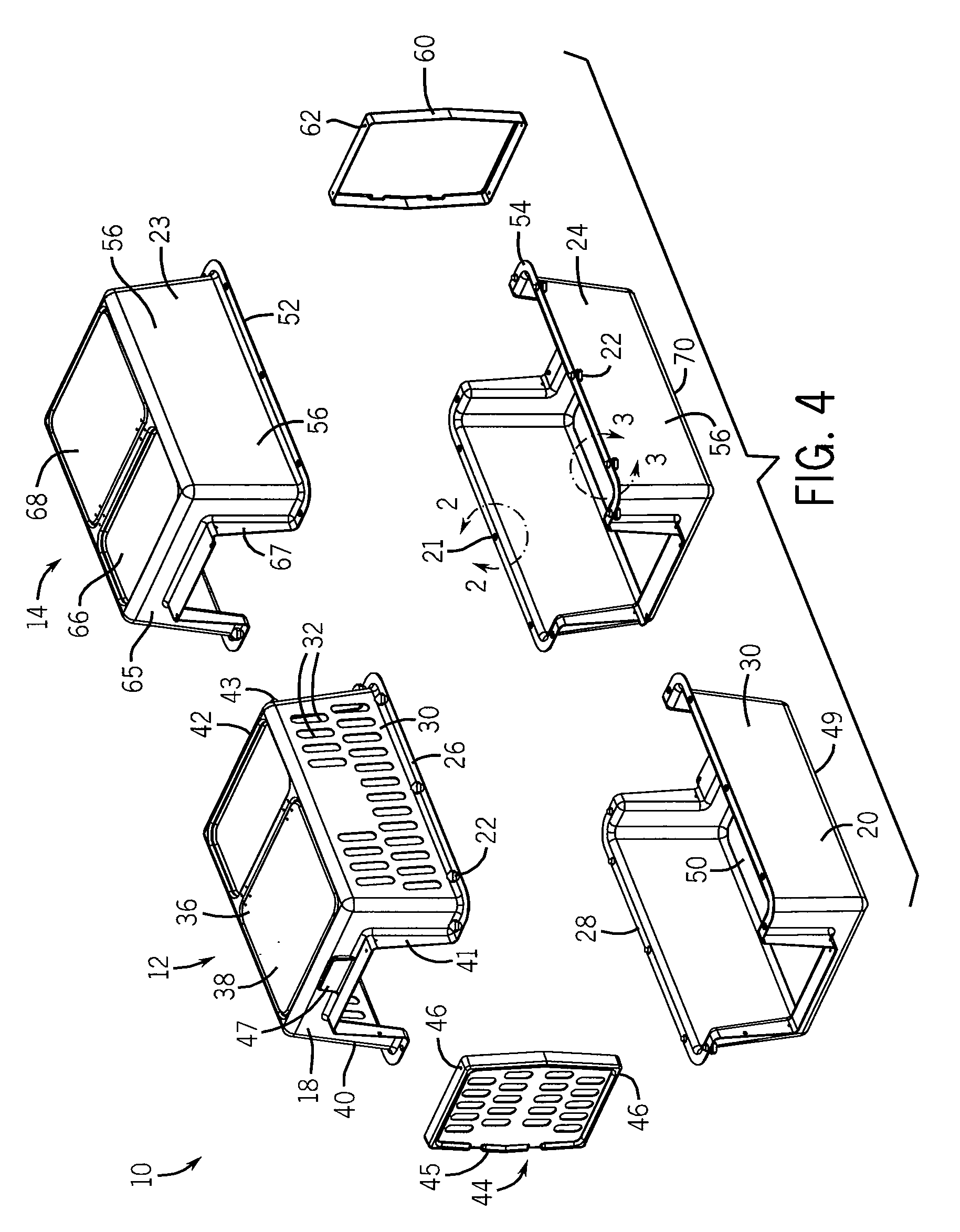

Multi-Compartment Pet Training System

InactiveUS20090223461A1Avoid odorAnimal watering devicesAnimal feeding devicesBiomedical engineeringCompanion animal

A multi-compartment pet training system includes a front compartment joined to a rear compartment to define a passage therebetween such that the pet may move freely between the front compartment and the rear compartment. The front compartment includes a front door for ingress and egress of the pet between a surrounding area and the front compartment. The front compartment provides an area in which the pet may eat, drink and sleep. The rear compartment is configured to allow the pet to carry out urinary and / or fecal elimination while its owner is away. As such, the pet may be trained to utilize the rear compartment for carrying out waste elimination activities while utilizing the front compartment for all other activities.

Owner:TRUNNELL DOUGLAS P +1

Yoghourt containing marmalade and making method thereof

The invention provides yoghourt containing marmalade and making method thereof. The yoghourt comprises marmalade and a main yoghourt material, and the marmalade and the main yoghourt material are separately placed. In the making method of the yoghourt, the main yoghourt material and the marmalade are respectively prepared and separately placed in the same yoghourt unit package in proportion so as to prepare the yoghourt containing marmalade. The yoghourt can ensure that consumers can add the marmalade to the yoghourt with a proper quantity according to per se health conditions and taste favor requirements and provides a healthy fruit yoghourt for people who do not eat sugar or wish to eat less sugar. The invention particularly provides an apple-flavored yoghourt and a making method thereof and fills the blank of the apple-flavored yoghourt in the market.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

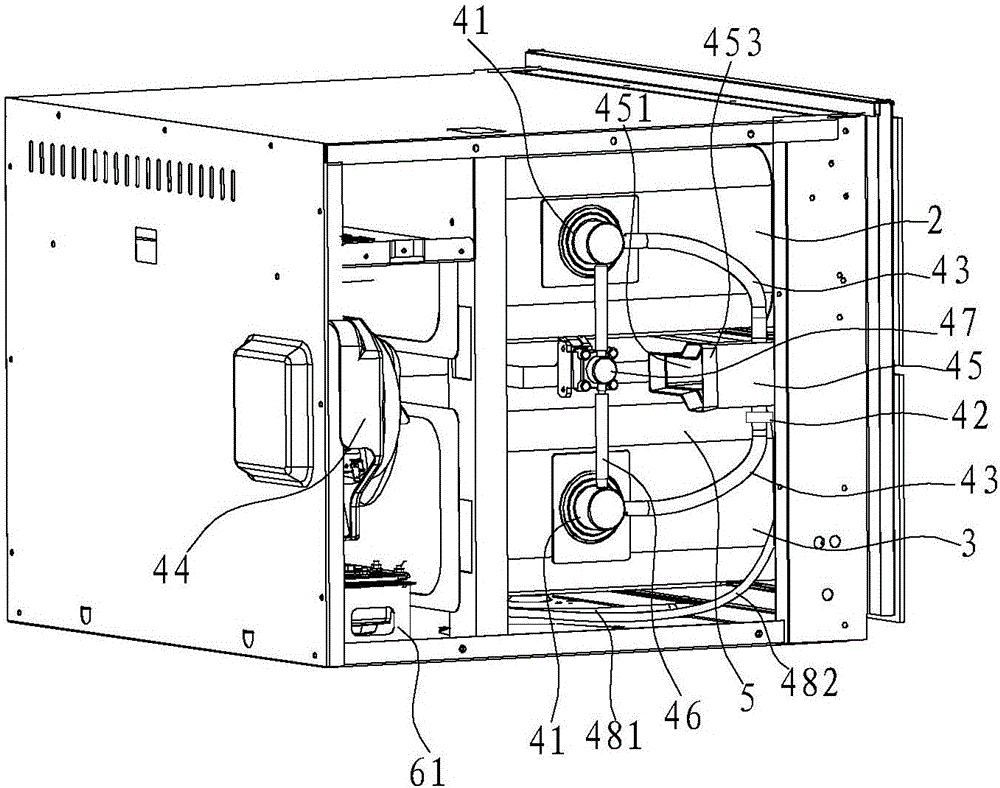

Steaming case

ActiveCN106473589AFunctional DiversificationSmooth functionSteam cooking vesselsWarming devicesSolenoid valveEngineering

The invention relates to a steaming case comprising a case body. At least one first liner and a second liner are disposed in the case body; the case body is further provided with a steam exhausting system; a steam returning pipe is arranged between steam exhausting joints of the first and second liners; the steam returning pipe is provided with a first solenoid valve controlling on-off of the steam returning pipe; a steam exhausting pipe of the second liner is provided with a second solenoid valve controlling on-off of the steam exhausting pipe; a wind guide cover is arranged on the inner side of a steam exhausting port and a wind guiding channel formed by the same is opposite to the steam exhausting port; discharged steam of steam discharging ports of each steam exhausting pipe are all accumulated in the wind guide channel of the wind guide cover; and an air outlet of a heat radiating fan is orderly opposite to the wind guide channel and the steam exhausting ports. Compared with the prior art, steam exhausting can be smoothly guaranteed and stagnation in the steaming case can be avoided; part steam can condensate on the wind guide cover, and steam external discharging amount can be reduced; liquid drops due to condensation of the steam in a furnace door part can be avoided, so user use experience can be improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

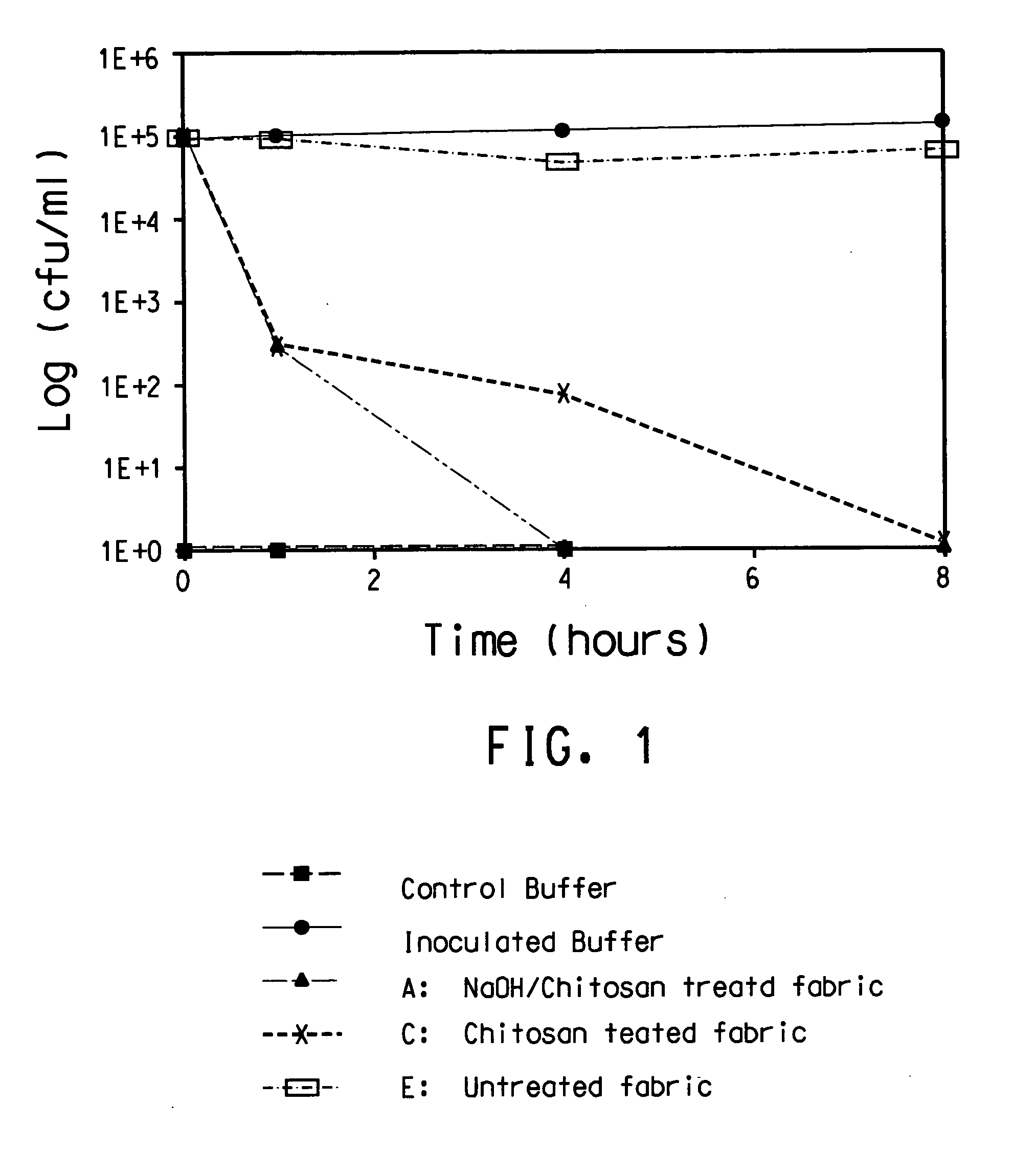

Antimicrobial ballistic fabrics and protective articles

InactiveUS20050181024A1Prevent development of odor and fungal and bacterial growthAvoid odorChemical protectionHeat protectionAntimicrobialEngineering

The present invention relates to methods for producing antimicrobial ballistic fabrics and protective apparel comprising aramid, polybenzazole or high-performance polyethylene, which articles are rendered antimicrobial by a chitosan agent, thereby preventing the development of odor and fungal and bacterial growth.

Owner:EI DU PONT DE NEMOURS & CO

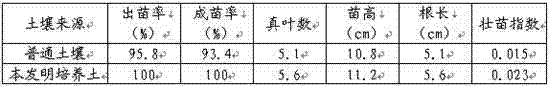

Seedling-cultivating substrate soil for micro agriculture

The invention relates to cultivation soil, in particular to seedling-cultivating substrate soil for micro agriculture. The seedling-cultivating substrate soil is formed by mixing a substrate with rural soil or clay and comprises the following components in weight percent: 25% to 45% of the substrate and 55% to 75% of the rural soil or clay; the substrate comprises 60% to 80% of organic matters in weight percent and includes 1% to 3% of nitrogen, 1.5% to 3.5% phosphorus, 2% to 4% of potassium, and 0.02% to 0.8% of trace elements including magnesium, calcium, iron, manganese and boron; the pH value of the substrate is 6.5 to 6.8; the organic matters comprise 1 to 4 parts of bamboo vinegar liquid, 1 to 3 parts of starch-acrylic acid graft copolymer, 15 to 40 parts of a straw decomposition agent, 15 to 40 parts of fermented human and animal excreta, 10 to 18 parts of edible fungus residue, 3 to 6 parts of waste bamboo, 2 to 5 parts of plant-charcoal powder, 5 to 10 parts of silt slag, 4 to 6 parts of bone meal and 4 to 9 parts of soybean meal. According to the invention, specific components and proportion are adopted to prepare the organic matters, and the organic matters are combined with inorganic matters to form the acidulous substrate, so that the seedling-cultivating substrate soil is high in nutritional ingredient and appropriate in proportion of trace elements, has an excellent odor removing effect, and avoids undesirable odors produced during planting of vegetables and other plants for urban families.

Owner:HUZHOU YIMENG CITY AGRI DEV

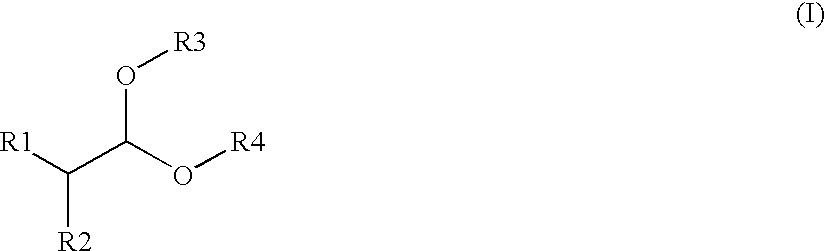

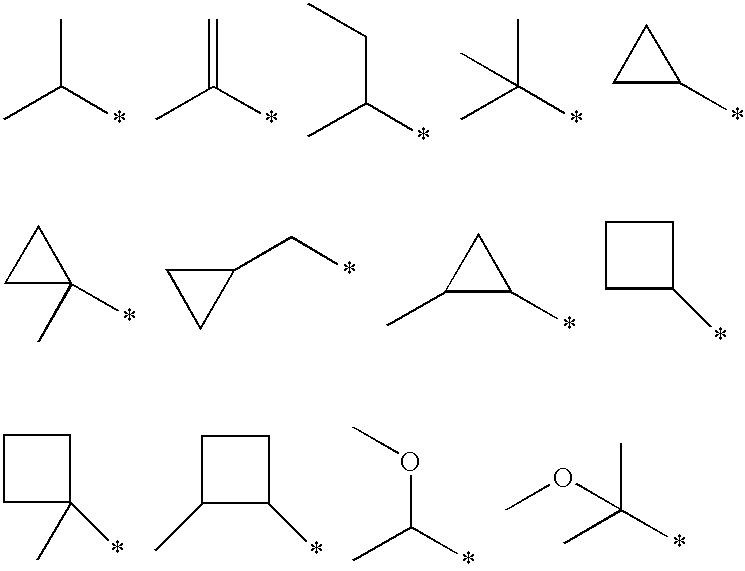

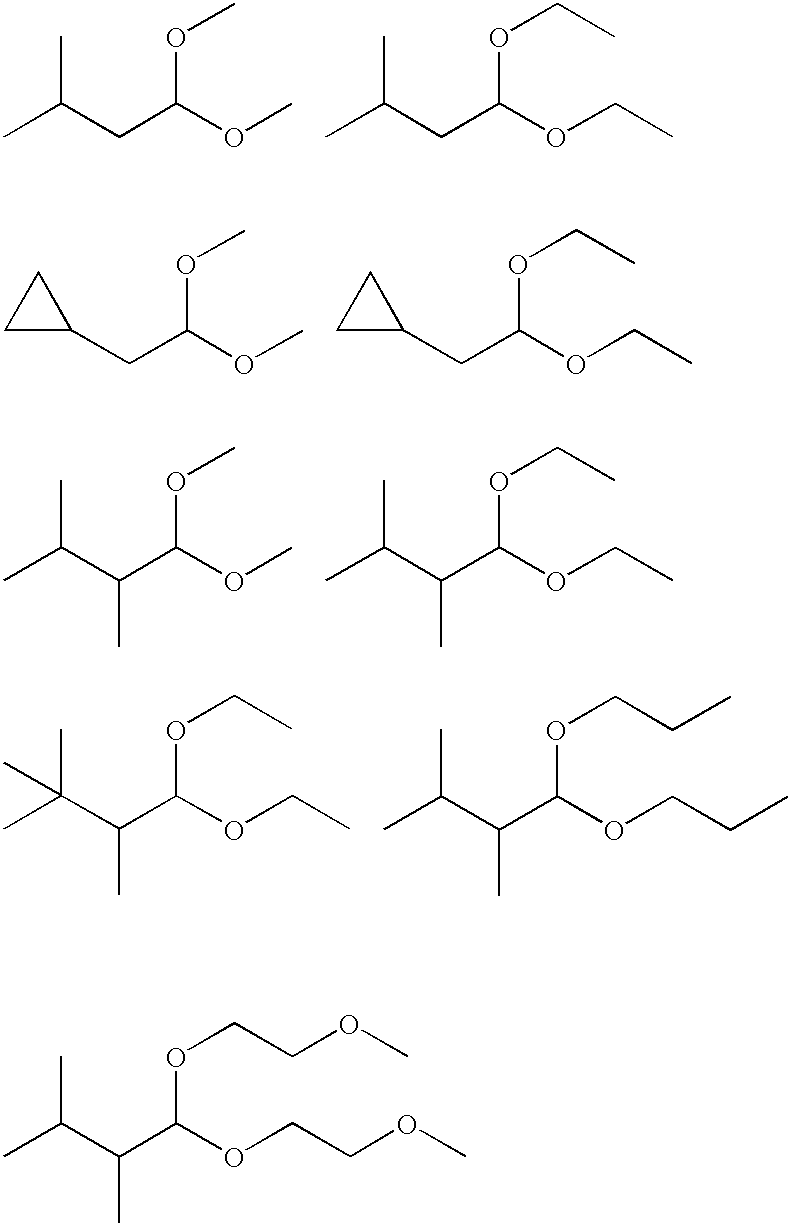

Use of low molecular weight acetal, alcohol, acylated alcohol and ester compounds to block or reduce odor of carboxylic acids

InactiveUS20030089885A1Avoid odorBlocking and reducing perceptionCosmetic preparationsOther chemical processesPropanoic acidFamily nursing

Low molecular weight acetal, alcohol, O-acylated alcohol and ester compounds are identified that block the odor of specific carboxylic acids especially propionic acid, butyric acid, isovaleric acid 3-methyl-2-hexenoic acid and hexanoic acid. These compounds exhibit surprisingly high odor blocking properties and are therefore useful additives to compositions such as: a) personal care products including underarm deodorant and antiperspirant, hair shampoo and conditioner, toilet soap, and skin lotion; b) fabric care products including laundry detergents, fabric conditioners, and fabric fresheners; c) pet care products including deodorant, shampoo, conditioner, and d) home care products including air fresheners, carpet fresheners, surface cleaners and hand wash dish detergent.

Owner:SENOMYX INC

Replaceable/disposable brush head

ActiveUS7650663B2Avoid odorLess degradableBoard cleaning devicesCarpet cleanersAdhesiveWater soluble

Owner:SC JOHNSON & SON INC

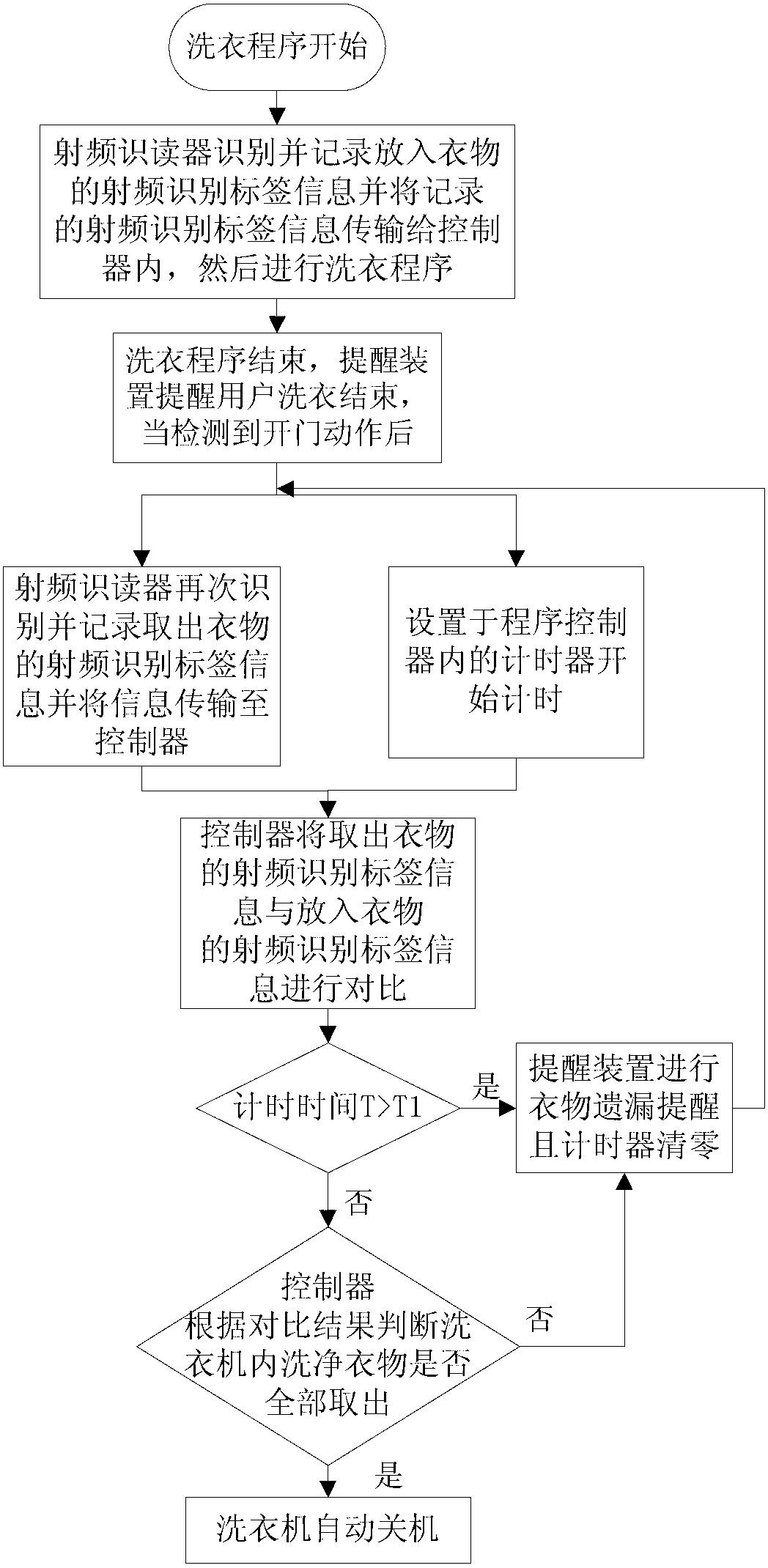

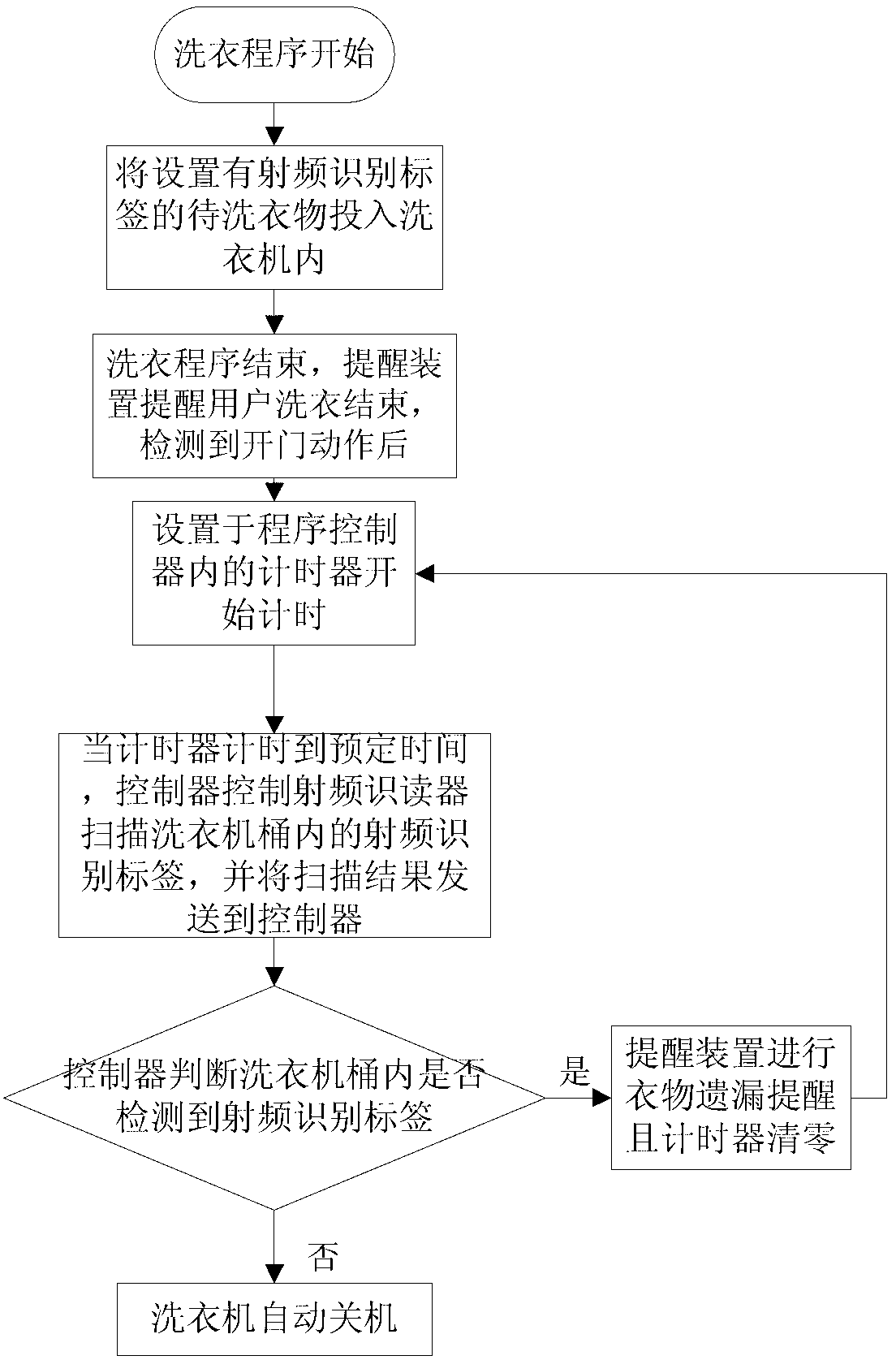

Washing machine control method and washing machine

ActiveCN103266444ATake it out to dry in timeAvoid odorOther washing machinesControl devices for washing apparatusProcess engineeringMachine control

The invention discloses a washing machine control method and a washing machine capable of achieving the control method. In order to solve the problem that after clothes washing is finished, partial clothes are missed in the washing machine for a long time, and abnormal smell, folds and the like occur, the washing machine control method and the washing machine are designed. According to the washing machine control method, the washing machine comprises a controller, a scanning device and a reminding device, clothes identification tags are arranged on the clothes to be washed, when a washing program is finished, the scanning device conducts scanning on the clothes identification tags and transmits scanning information to the controller, the controller judges whether all the clothes are taken out from the washing machine or not according to the received information, and if all the clothes are taken out, the washing program is finished, or the controller controls the reminding device to conduct clothes missing reminding. The method can ensure that a user can timely take out the clothes from the washing machine to conduct airing, and the problems, caused by the fact that the clothes are missed in the washing machine, of the abnormal smell, color changing, folds and the like are prevented from appearing.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Refrigerator with icemaker compartment having an improved air flow

ActiveUS8336330B2Ice-making performance can be improvedAvoid odorLighting and heating apparatusIce productionCold airEngineering

A refrigerator with an ice making device. The refrigerator includes a body defined with a refrigerating compartment, a freezing compartment, and an ice making compartment, the ice making compartment arranged in the refrigerating compartment while being thermally insulated from the refrigerating compartment, a first evaporator arranged in the refrigerating compartment, a second evaporator arranged in the freezing compartment, a refrigerating duct for circulating cold air from the first evaporator to the refrigerating compartment, a freezing duct for circulating cold air from the second evaporator to the freezing compartment, and an ice making flow passage for communicating the second evaporator and the ice making compartment. The second evaporator, ice making compartment, and ice making flow passage form a closed circuit such that the cold air in the ice making compartment does not enter the refrigerating compartment.

Owner:SAMSUNG ELECTRONICS CO LTD

Refrigerator having ice making room

InactiveUS20100251744A1Avoid odorLighting and heating apparatusIce productionEnergy transferCooling chamber

A refrigerator is provided. The refrigerator includes a refrigerator main body including a cooling chamber, a door for opening or closing the cooling chamber, an ice making chamber located at the door, a sub-chamber located at the door and spaced from the ice making chamber, the sub-chamber being configured to receive cool air from the cooling chamber, and a cold energy transfer unit configured to transfer energy of cool air of the sub-chamber to the ice making chamber.

Owner:LG ELECTRONICS INC

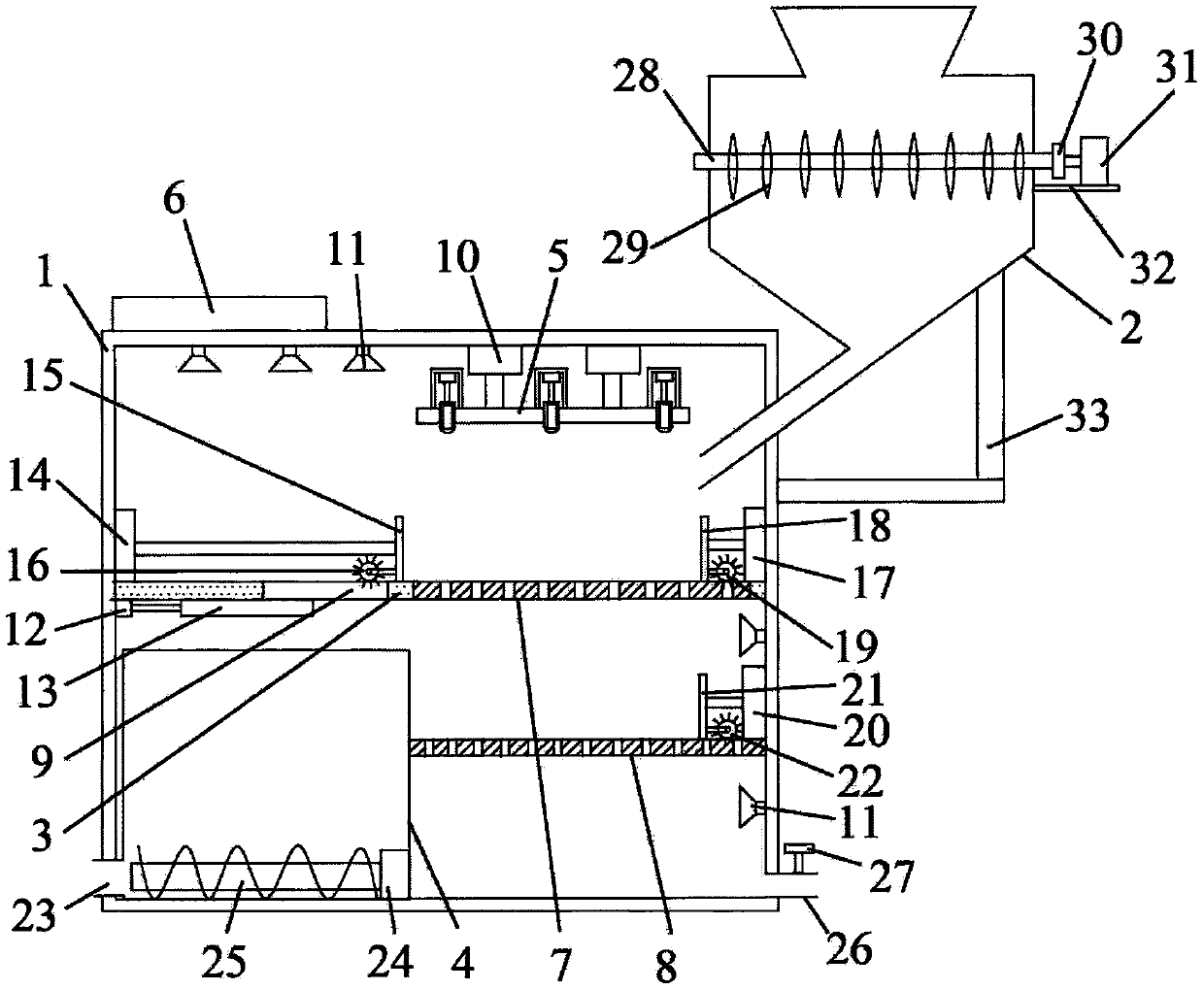

Environment-friendly solid-liquid separation device

The invention discloses an environment-friendly solid-liquid separation device, and relates to the technical field of garbage treatment. The environment-friendly solid-liquid separation device comprises a box body, a feeding hopper, a separation plate, a solid waste collecting box, a pressing plate and a controller, wherein the separation plate is arranged in the box body and divides the box bodyinto an upper part and a lower part, and the pressing plate is arranged at the top of the box body through a pressing plate power device. A first filter plate is arranged on one side of the separationplate, a discharging port is formed in the other side of the separation plate, and an adjusting baffle assembly is arranged on the lower surface of the discharging port. A first pushing cleaning assembly and a second pushing cleaning assembly are arranged on the two sides of the upper surface of the separation plate, the solid waste collecting box is arranged below the discharging port, a secondfilter plate is arranged below the first filter plate, a third push cleaning assembly is arranged on the second filter plate, and a liquid collecting cavity is formed below the second filter plate. The box body is internally provided with a spraying assembly. The environment-friendly solid-liquid separation device has the advantages of improving the solid-liquid separation efficiency and the solid-liquid separation effect, and cleaning up in time to avoid blockage and peculiar smell.

Owner:隆润新技术发展有限公司

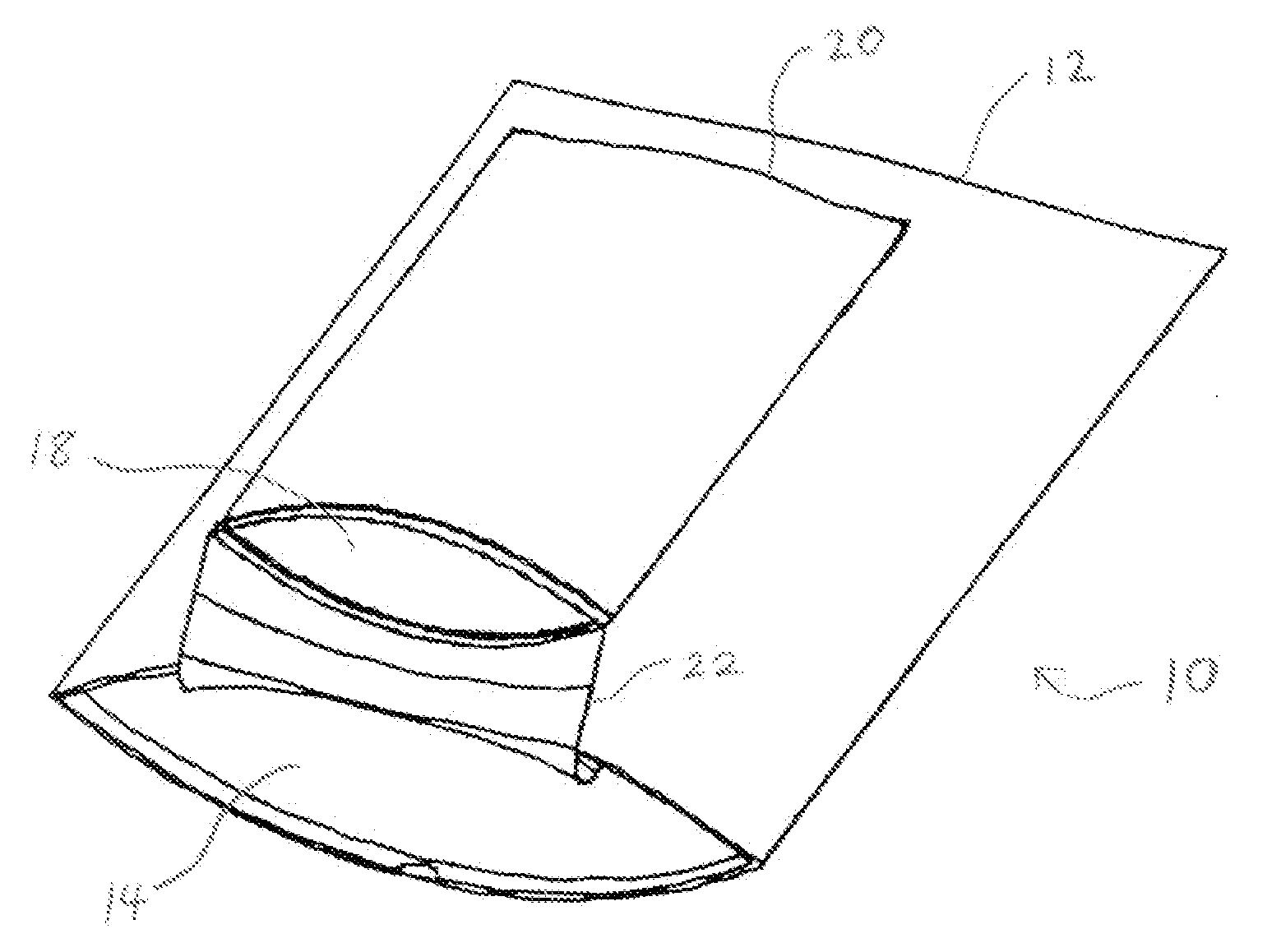

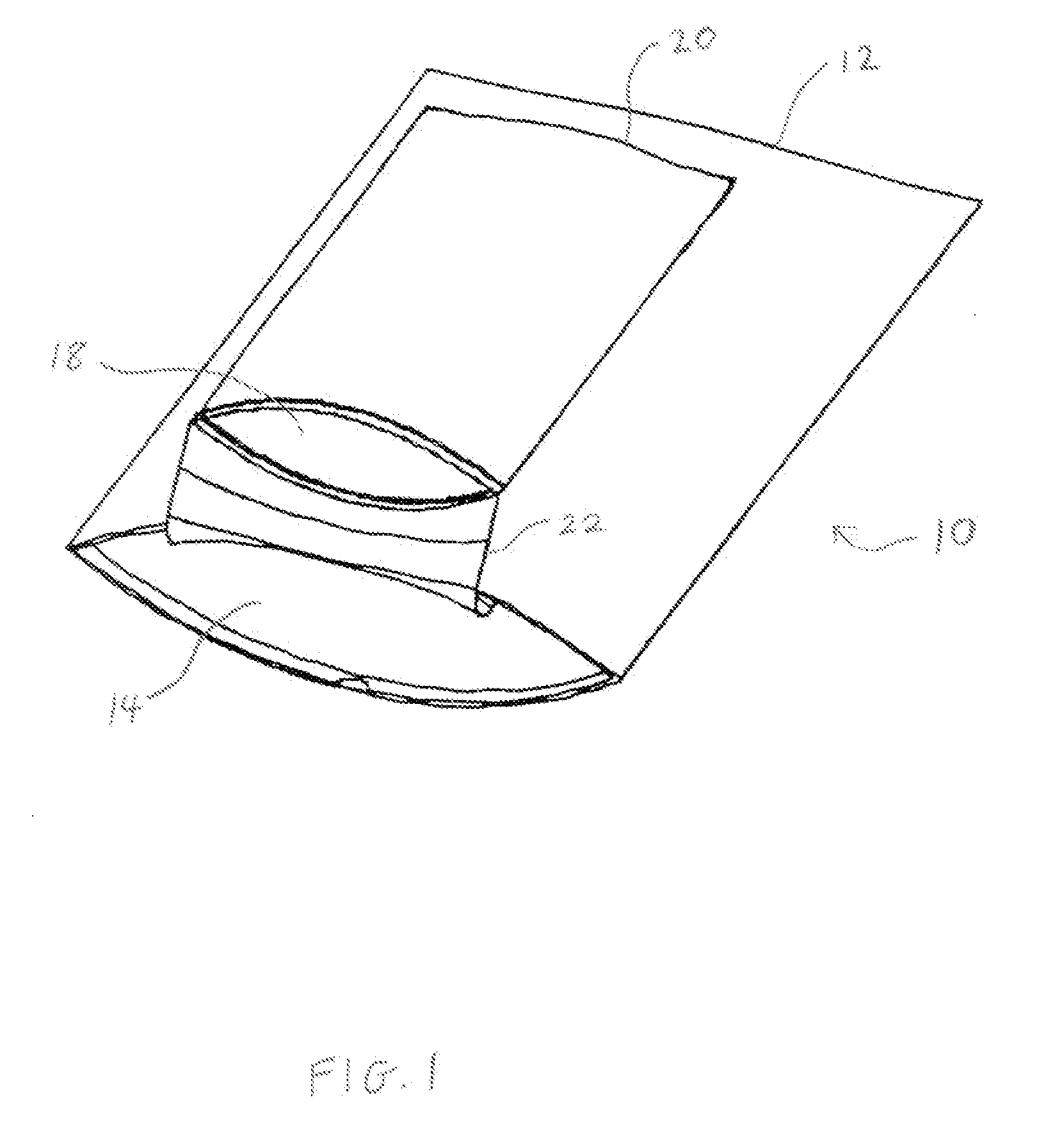

Bag within a bag

An improved trash bag that helps to minimize or eliminate the release of odors is disclosed. In one embodiment, the present invention is a trash bag having a first bag connected to a second bag, both bags having openings, where the second bag has a device capable of constricting the opening of the second bag in order to substantially prevent odor from escaping the second bag. Optionally, the second bag is capable of including a deodorizing patch. The deodorizing patch can be removably secured to the second ba. In another embodiment, the present invention is an improved trash bag having an outer bag and an inner bag within the outer bag, the outer bag and inner bag being formed with a common wall portion, wherein the inner bag has an inner opening closure device capable of constricting the inner opening in order to substantially prevent odor from escaping the inner bag. A deodorizing path can be removably secured to the inner bag.

Owner:REVNESS MICHAEL

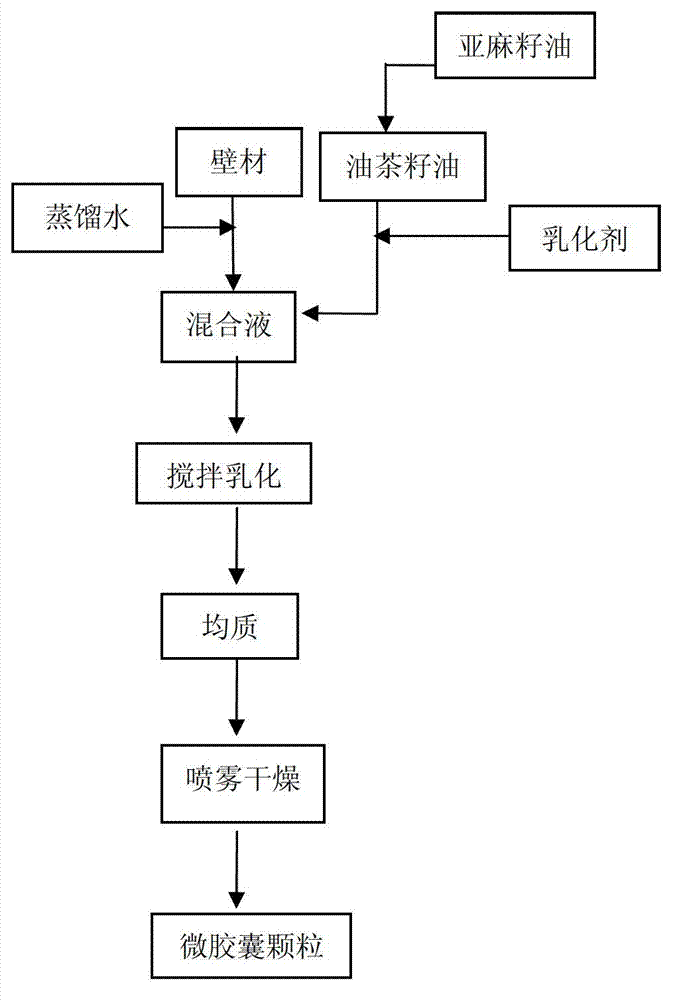

Preparation method of camellia oleosa seed oil and linseed oil compound microcapsules

InactiveCN103238675ABroaden the way of development and utilizationAvoid the risk of linolenic acid deficiencyEdible oils/fatsOil and greaseHigh pressure

The invention relates to a preparation method of camellia oleosa seed oil and linseed oil compound microcapsules. Two oils, namely camellia oleosa seed oil and linseed oil, are compounded in appropriate proportion as a core material. The preparation method comprises the following steps of: (1) weighing a wall material, adding distilled water, stirring, mixing and dissolving, and slowly adding an emulsifier and the core material; (2) stirring and emulsifying the mixed solution for 20 minutes at the temperature of 80 DEG C; (3) homogenizing the emulsion for twice at 40Mpa by adopting a high-pressure homogenizer, and naturally placing and cooling; and (4) carrying out spray drying on the emulsion to obtain the camellia oleosa seed oil and linseed oil compound microcapsules. The preparation method provided by the invention is simple and practicable, inherent nutritional ingredients of tea oil are kept, linolenic acid content is also increased, a fatty acid structure of oil can more meet body need, and oil property is more stable and difficult to be oxidized, a development and utilization approach of camellia oleosa seed oil and linseed oil is broadened, and good technical support is provided for deep processing utilization of camellia oleosa seed oil.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

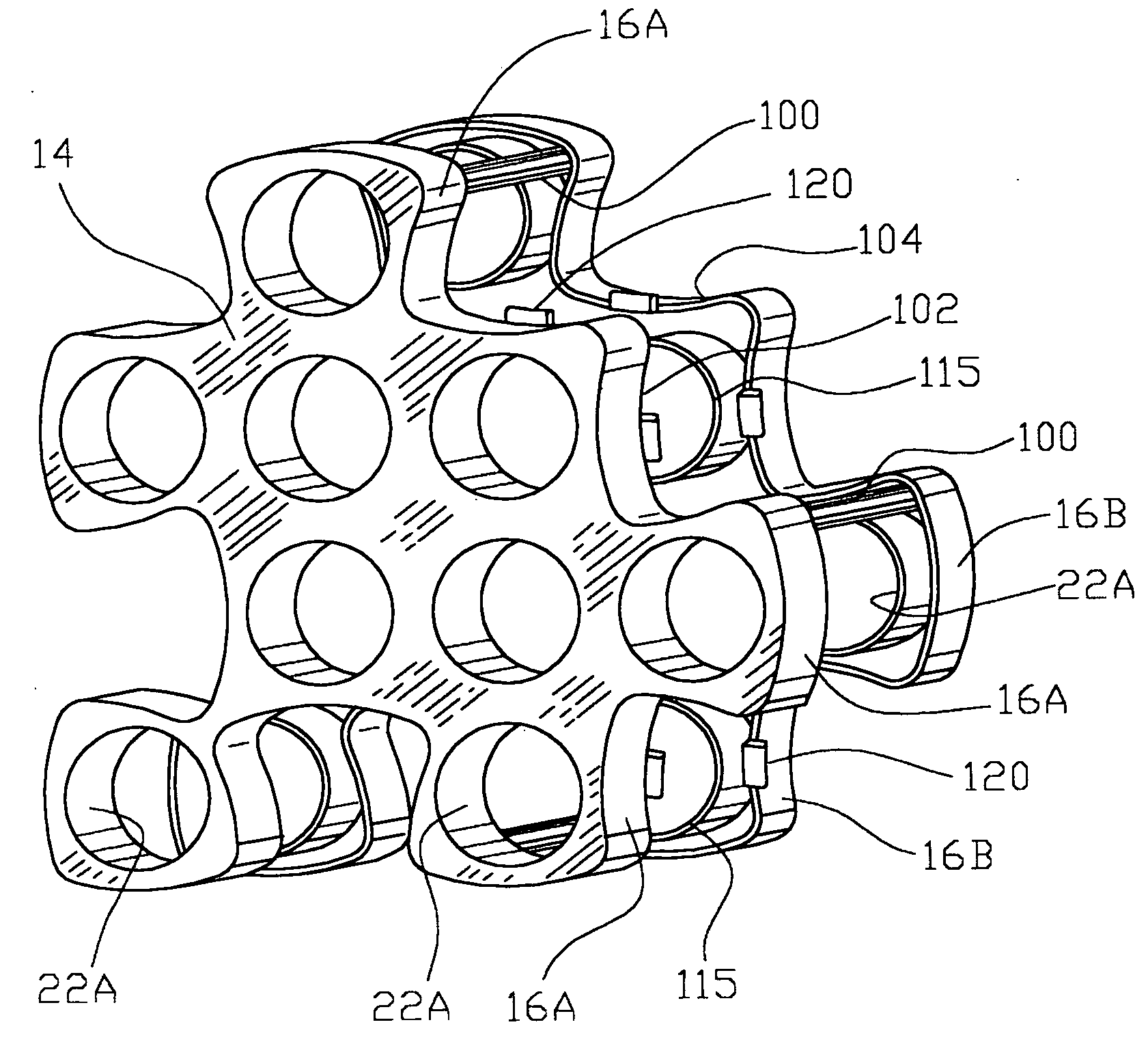

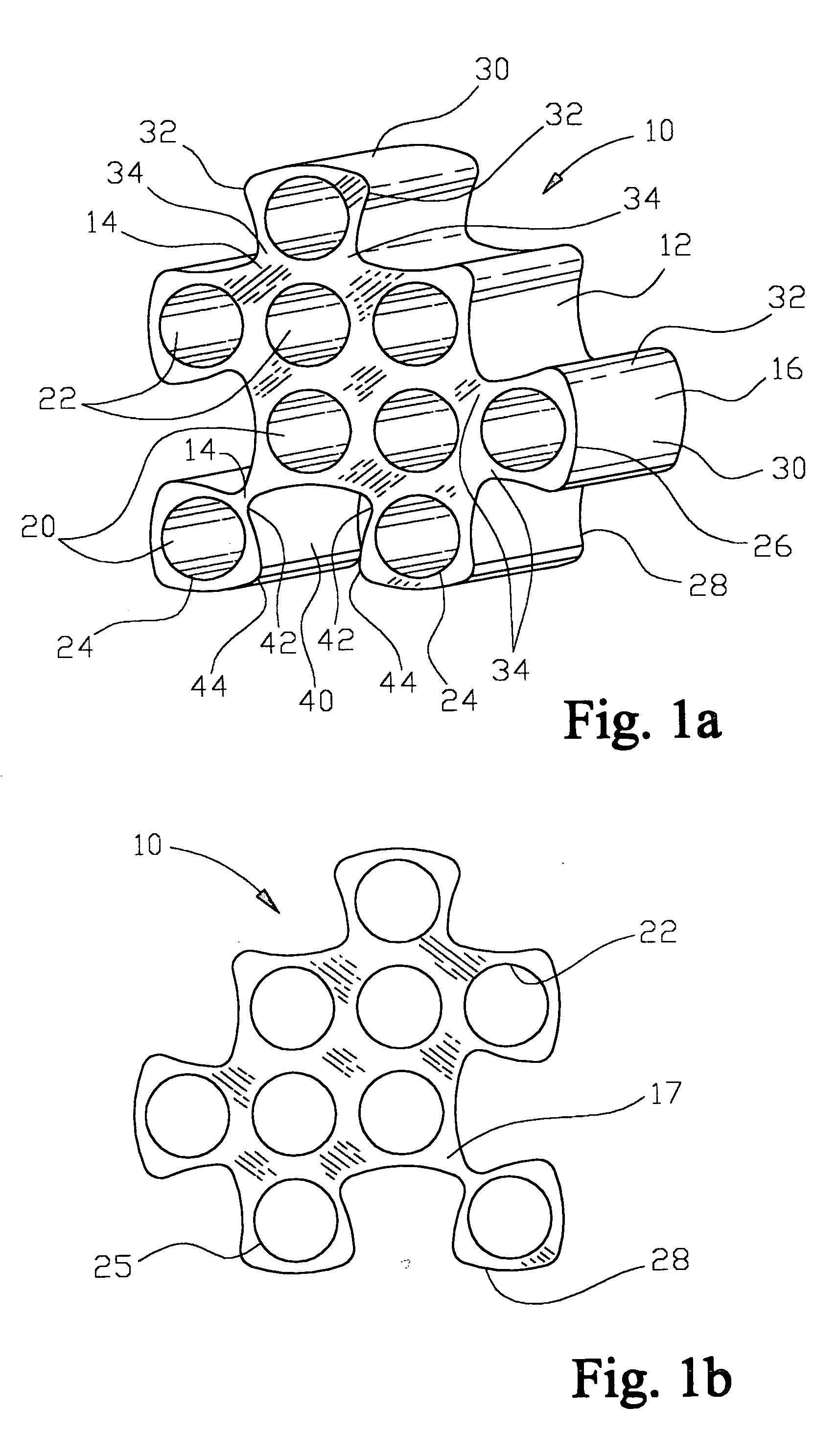

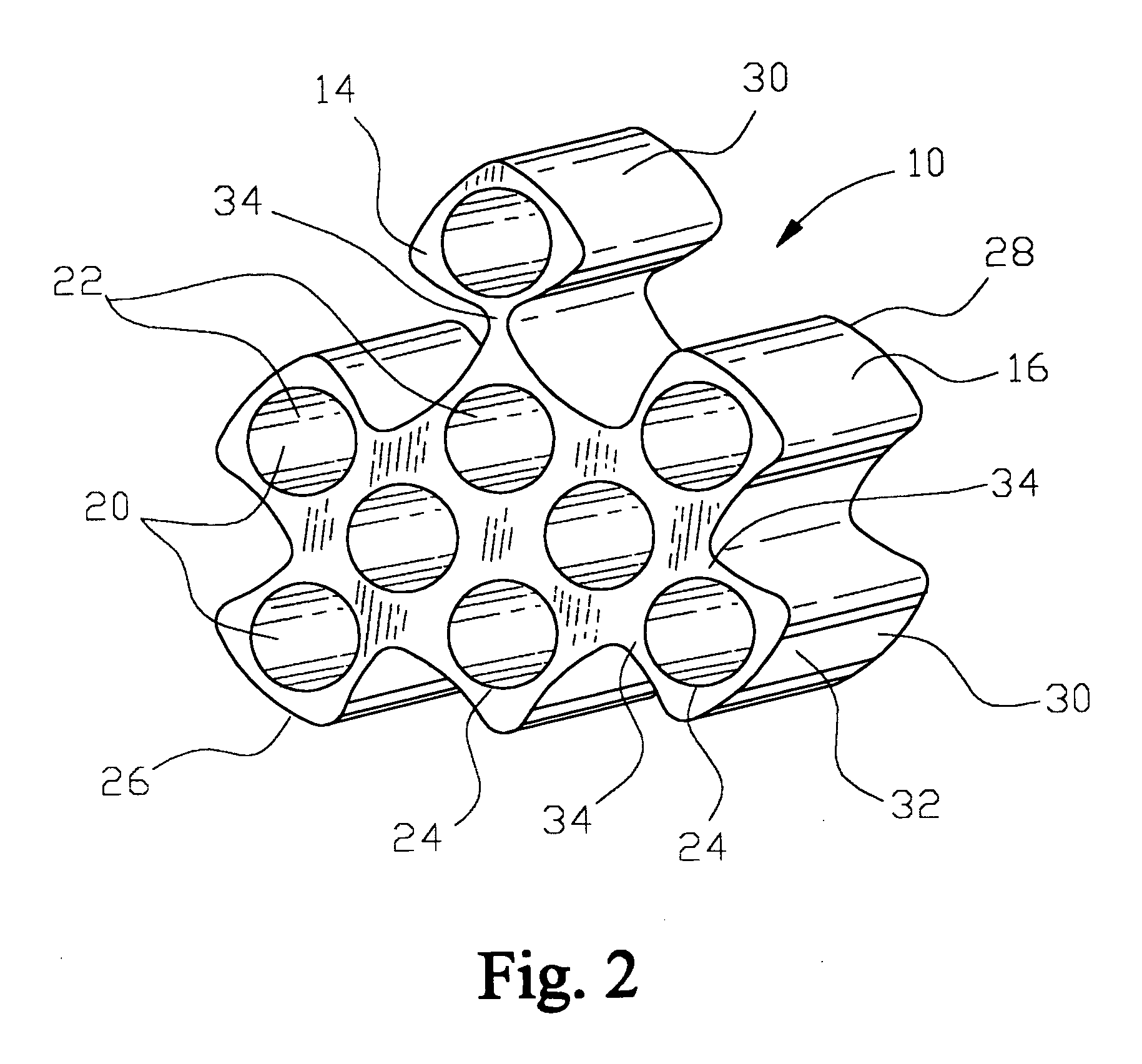

Storage rack for bottles and jars

A modular rack for storing objects. Each rack element has forward, rear, and side walls. The rack elements are configured to have a plurality of protrusions and recessions so that the protrusions and recessions of a rack element slideably interlock with complementary recessions and protrusions of other rack elements of generally similar appearance, so that the rack elements may be assembled into a modular rack without the need of tools or external fastening elements.

Owner:DAGAN GIDEON

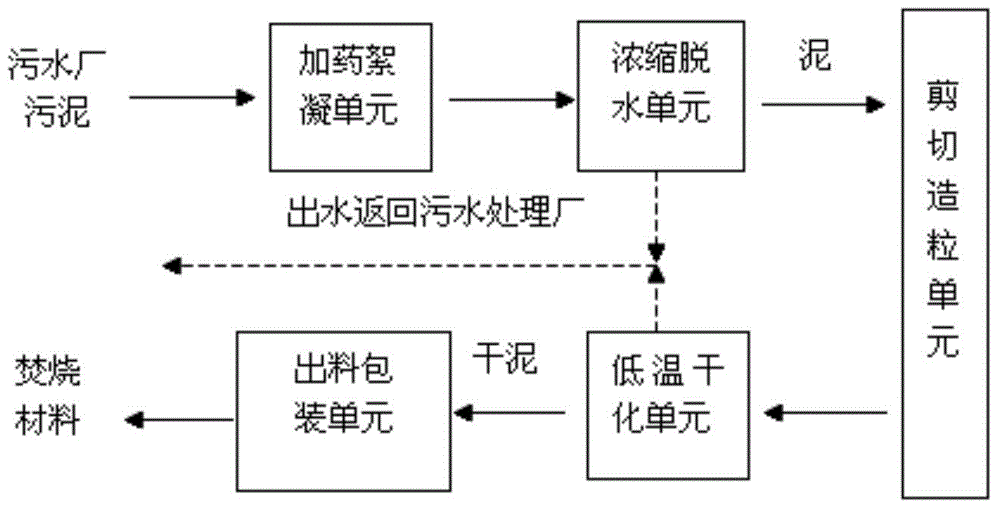

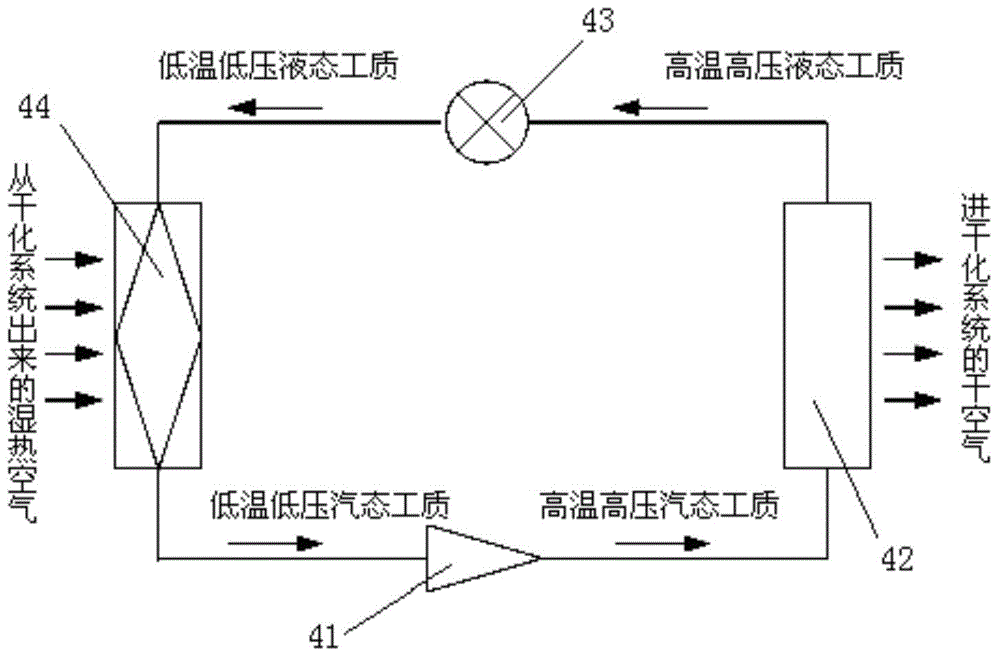

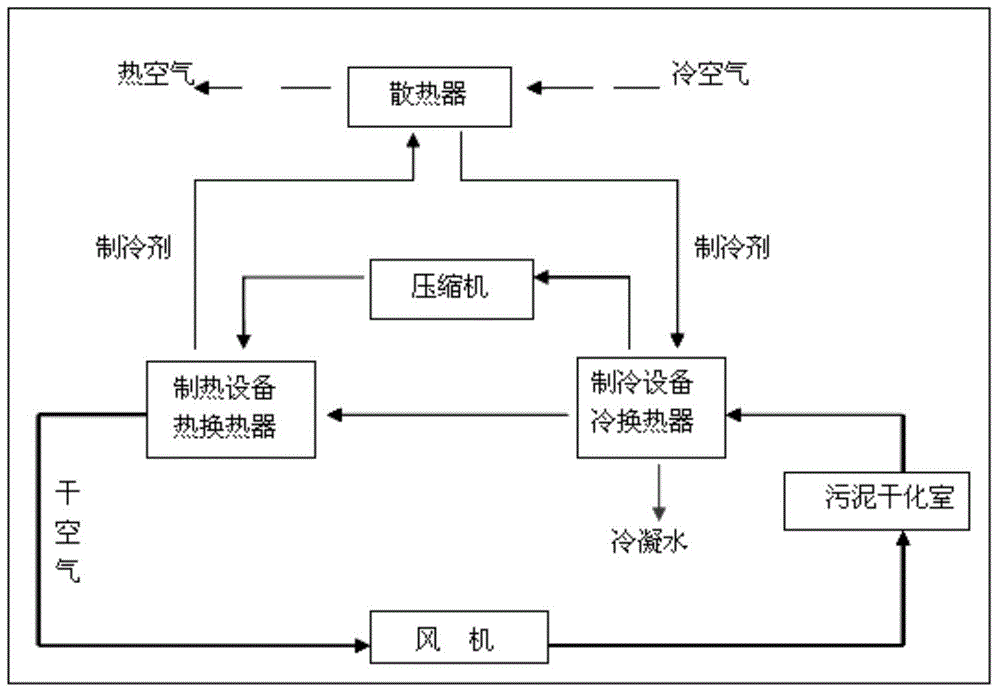

Low-temperature sludge drying treatment system and technology

ActiveCN103553291AReduce energy consumptionHigh degree of integrationSludge treatment by de-watering/drying/thickeningFlocculationDewatered sludge

The invention discloses a low-temperature sludge drying treatment system. The low-temperature sludge drying treatment system comprises a dosage and flocculation unit, a condensation and dewatering unit, a shearing and granulation unit, a low-temperature drying unit and a discharging and packaging unit which are sequentially connected, wherein the dosage and flocculation unit comprises a flocculation tank and a stirring device arranged in the flocculation tank, the condensation and dewatering unit comprises a sludge dewatering machine, the shearing and granulation unit comprises a shearing and granulator, the low-temperature drying unit consists of a low-temperature sludge drying machine, a fan and a heat pump system. The technology comprises the treatment steps of 1) feeding a flocculating agent into sludge so as to promote the dewatering property; 2) dewatering the flocculated sludge; 3) performing shearing and granulation treatment on the dewatered sludge; 4) performing low-temperature drying treatment on the granulated sludge at 50-100DEG C; 5) performing vacuum bagged packaging on the dried sludge. The treatment system is less in occupied area, high in equalization degree, low in energy consumption, and incapable of producing secondary pollution in the treatment process.

Owner:BEIJING BIOTECHINA ENVIRONMENT CORP

Carboxymethyl chitosan fruit preserving coating agent and preparation method thereof

InactiveCN101120697AReduce respirationSmall water absorptionFruits/vegetable preservation by coatingWater bathsGlycerol

A carboxymethyl chitosan fruit fresh-keeping coating agent in the technical field of food engineering and a preparation method thereof. The fresh-keeping coating agent is: 0.5%-4% of carboxymethyl chitosan, 0.1-1% of glycerin, 0.3-2.4% of Tween 80, 0.1-1% of DL-α-tocopheryl acetate, 92% of water -99%. Heat water in a water bath to constant temperature, add carboxymethyl chitosan, stir until completely dissolved, then add glycerin, stir well with Tween, then add DL-α-tocopheryl acetate and stir until completely dissolved, let it sit at room temperature Cooling, followed by filtering to remove undissolved substances, degassing under vacuum, standing overnight at room temperature, degassing again under vacuum, standing at room temperature, and obtaining carboxymethyl chitosan fruit fresh-keeping coating agent. The fresh-keeping coating agent of the present invention is coated on the surface of fruits by soaking or spraying to form a fresh-keeping film and maintain the quality of the fruits during storage.

Owner:上海伊禾农产品科技发展股份有限公司

Honey processing process

InactiveCN103549250AHigh purityTargetedFood thermal treatmentMulti-step food processesHeating timeFiltration

The invention relates to a honey processing process. The honey processing process is characterized by comprising the following steps: (1) raw honey inspection; (2) (a) melting, wherein the heating temperature is 45-60 DEG C, and the heating time is 30-60 minutes or 4-8 hours according to the state of raw honey; (b) filtration, namely carrying out pressure filtration in a sealing device at the temperature higher than 40 DEG C so as to remove impurities and larger crystals; (3) vacuum concentration; (4) cooling. According to the honey processing process, the filtration step sequentially comprises rough filtration, fine filtration and refined filtration, wherein the temperature of the fine filtration is higher than that of the rough filtration, and the temperature of the refined filtration is higher than that of the fine filtration. The different processing time can be set according to different states of the raw honey, so that the pertinence is strong, not only can melting quality and the smooth operation of subsequent steps be guaranteed, but also the efficiency is increased, and the unnecessary time waste is reduced; besides, the filtration is performed three times, and the filtering temperatures are different, so that the efficiencies of each filtration process and the whole filtration are increased, and the purity of finished honey is improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

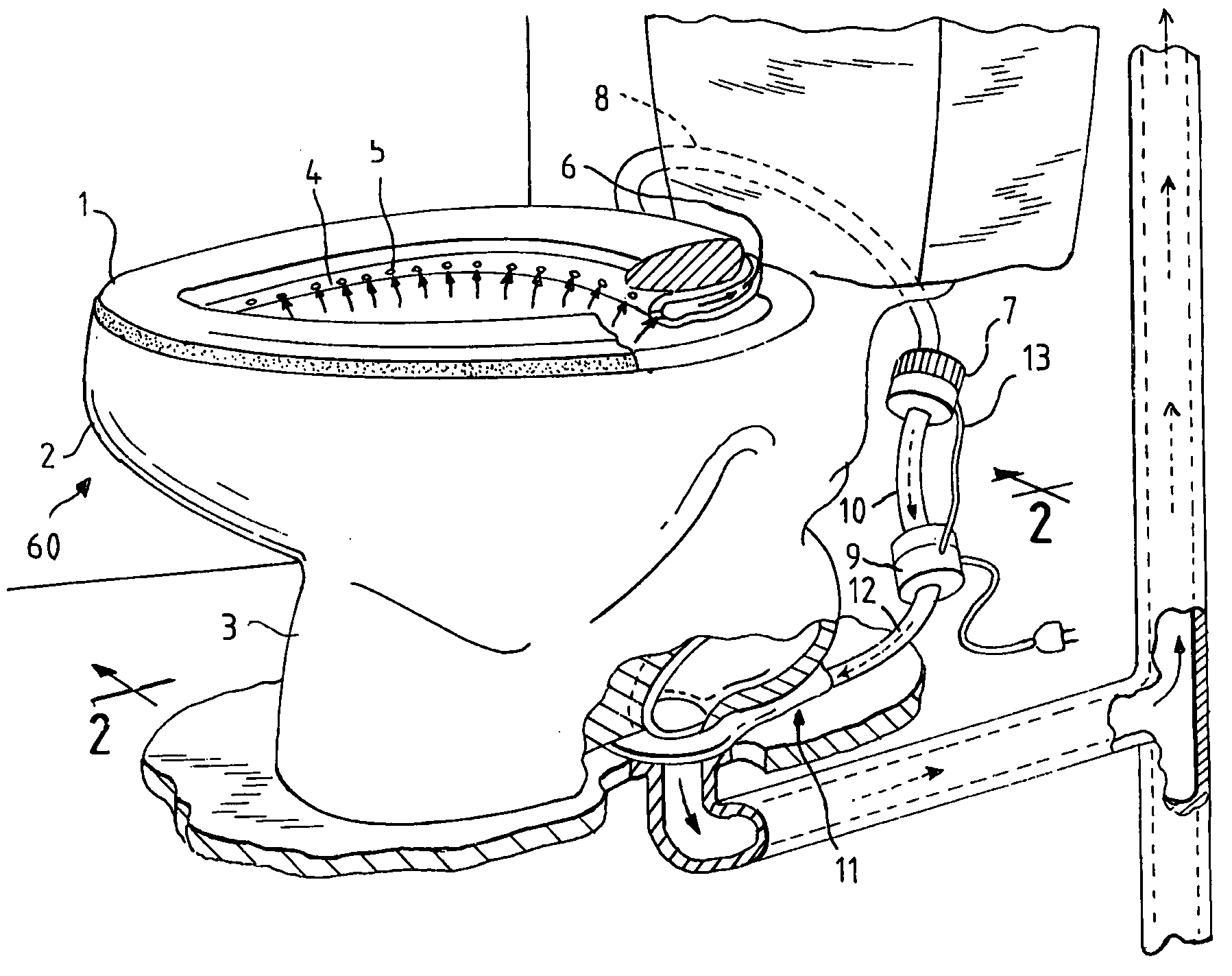

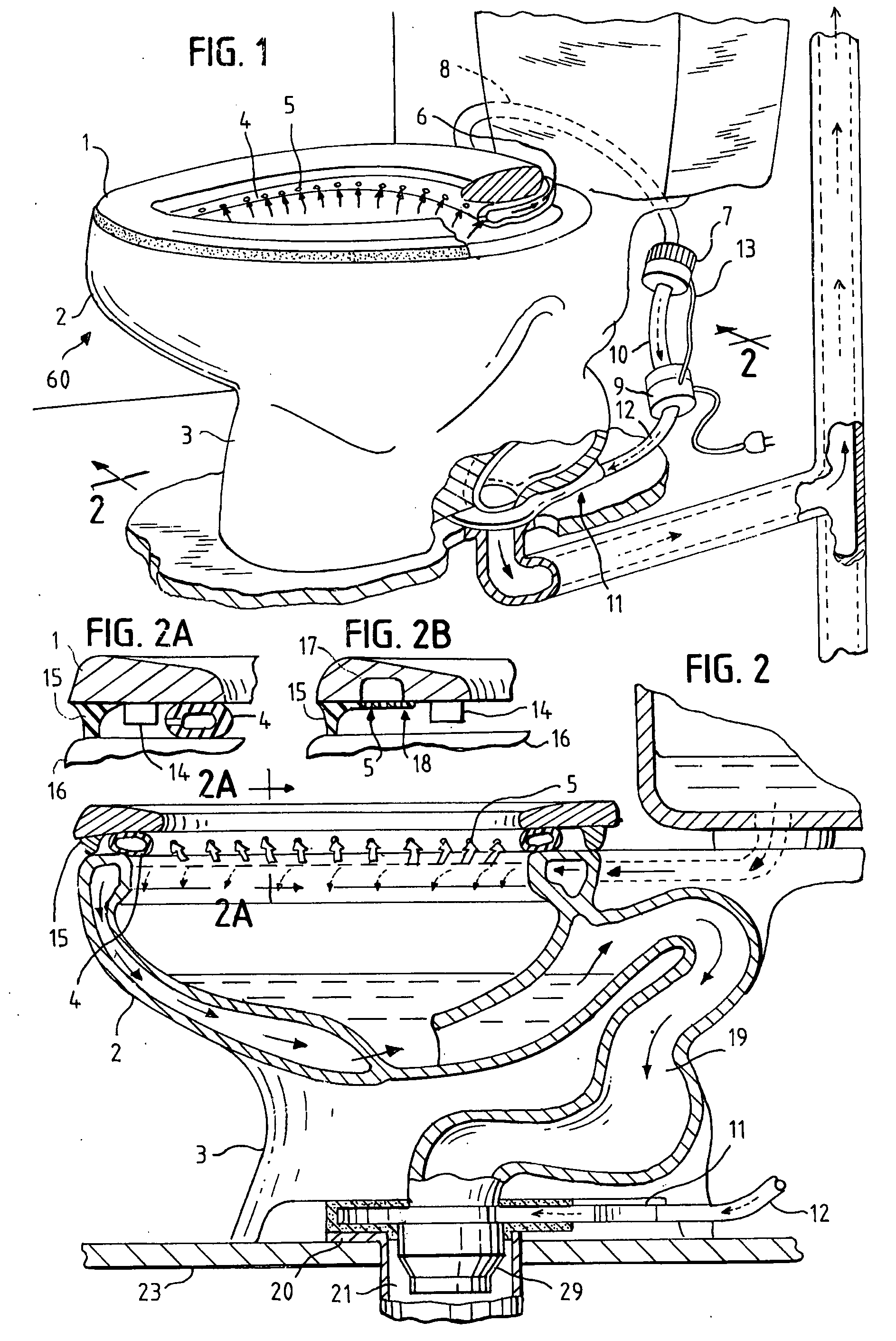

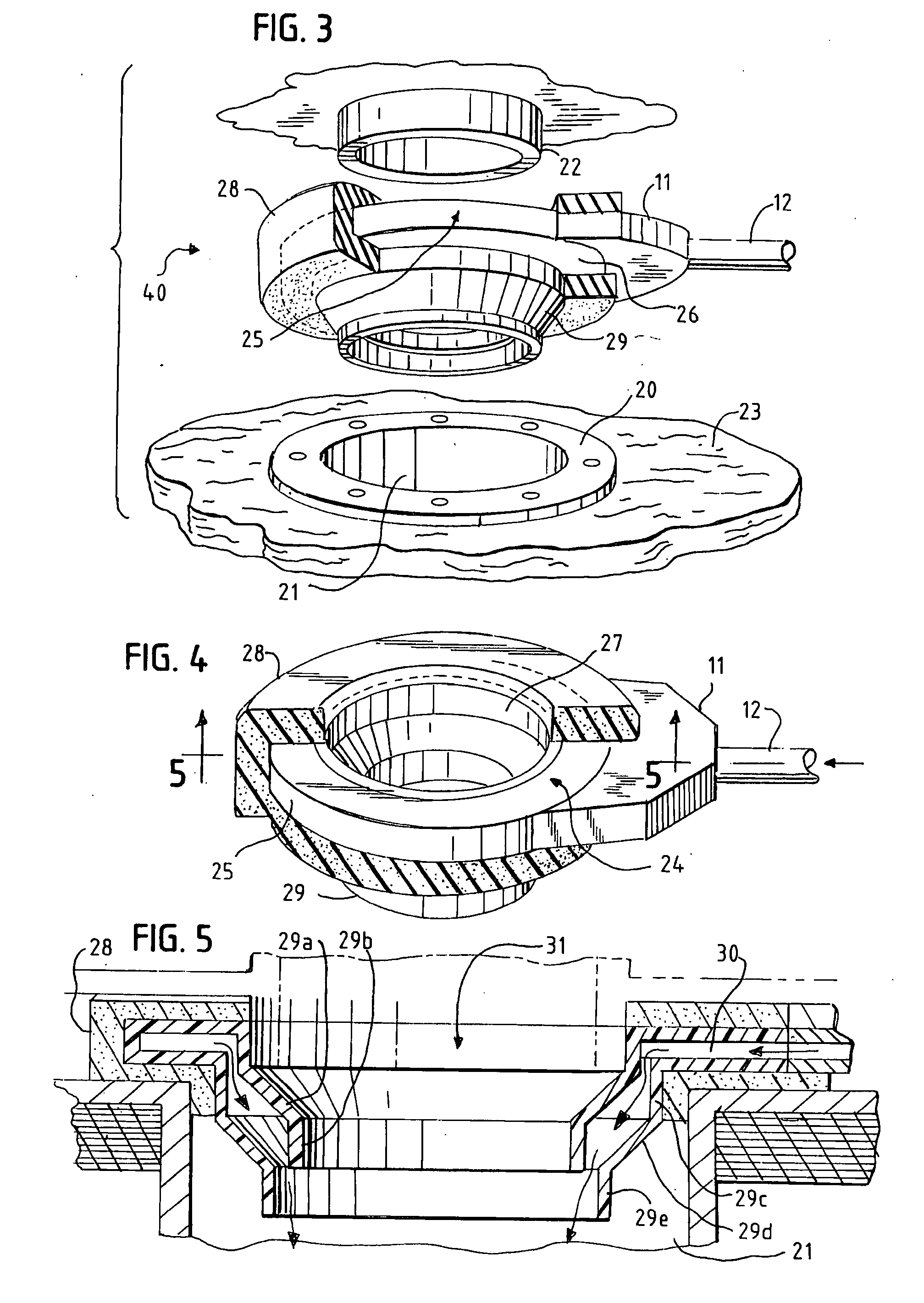

Odorless toilet

InactiveUS20080216220A1Avoid odorPrevent escapeOperating means/releasing devices for valvesSewerage structuresEngineeringHollow core

The present invention provides an odorless toilet comprising an adapter ring compressed between a toilet horn and a sewer pipe flange and having a hollow core, an adapter inlet and an exhaust vent; a seat having at least one intake port, a gas cavity and a gas cavity exhaust port; a fan having a fan inlet and a fan exhaust, the fan inlet connected to the gas cavity exhaust port and the fan exhaust connected to the adapter inlet, wherein when the fan is operating, a negative pressure develops in the seat gas cavity, and the odor is pulled into the seat gas cavity through at least one intake port and exhausted from the gas cavity exhaust port to the adapter inlet and then channeled into a sewer pipe through the exhaust vent, wherein the exhaust vent of the adapter ring extends below the sewer pipe flange, wherein the adapter ring has an opening through the center to allow unobstructed passage of waste matter from the toilet horn to a sewer pipe when the toilet is flushed.

Owner:MARKAJ VIKTOR

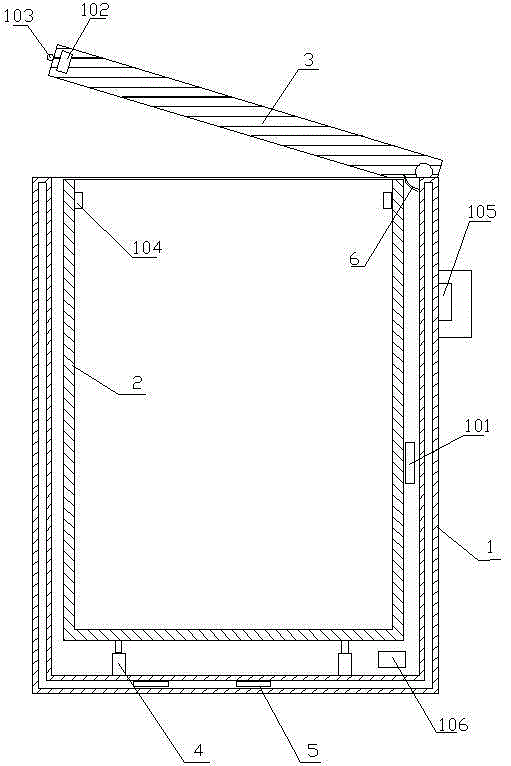

Intelligent deodorant dustbin and opening and closing method thereof

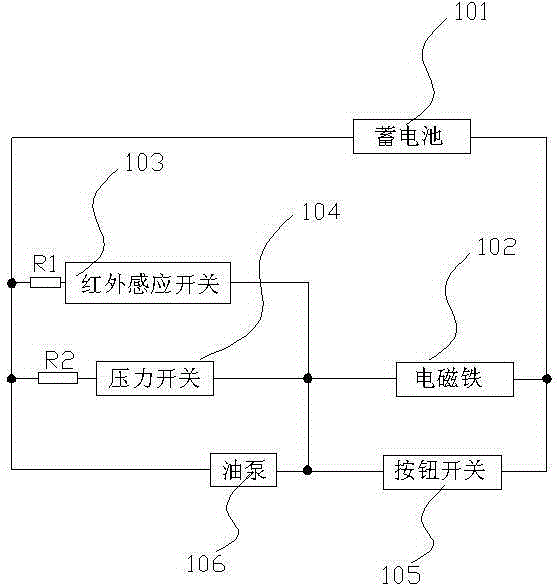

The invention discloses an intelligent deodorant dustbin and an opening and closing method thereof. The intelligent deodorant dustbin comprises a shell (1), an inner barrel (2) and a dustbin cover (3). A storage battery (101) is arranged in a gap between the shell (1) and the inner barrel (2). The shell (1) is made of metal. An electromagnet (102) is arranged in the dustbin cover (3). When the dustbin cover (3) is pressed on the shell (1), the electromagnet (102) is located above the shell (1). An infrared induction switch (103) is arranged on the dustbin cover (3). A plurality of pressure switches (104) are installed on the upper portion of the inner wall of the inner barrel (2). The infrared induction switch (103) is connected with the pressure switches (104) in parallel and then connected with the storage battery (101) and the electromagnet (102) in series to form a loop, and the opening and closing method of the intelligent deodorant dustbin is also provided. According to the intelligent deodorant dustbin and the opening and closing method thereof, foul smell in the dustbin can be effectively prevented from being diffused.

Owner:郁渝

Drum type washing machine

InactiveCN101177892AEfficient removalClear powerfulOther washing machinesTextiles and paperEngineeringCirculating pump

Owner:NANJING LG PANDA APPLIANCES

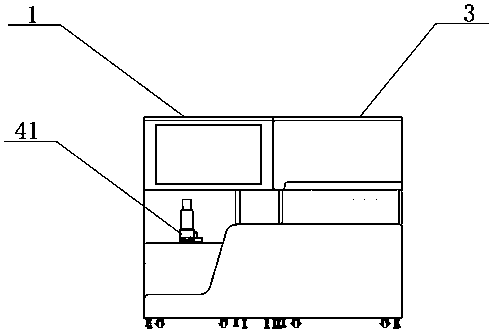

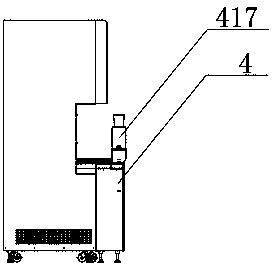

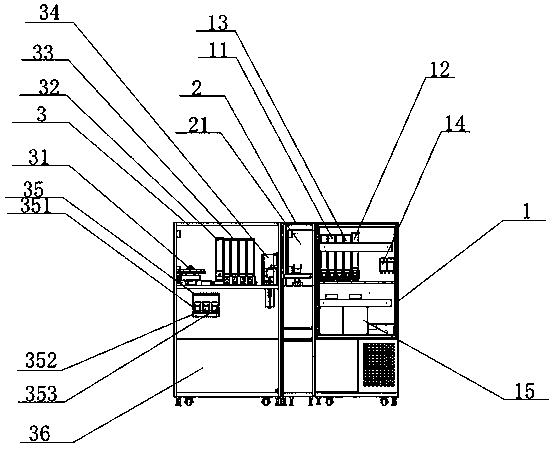

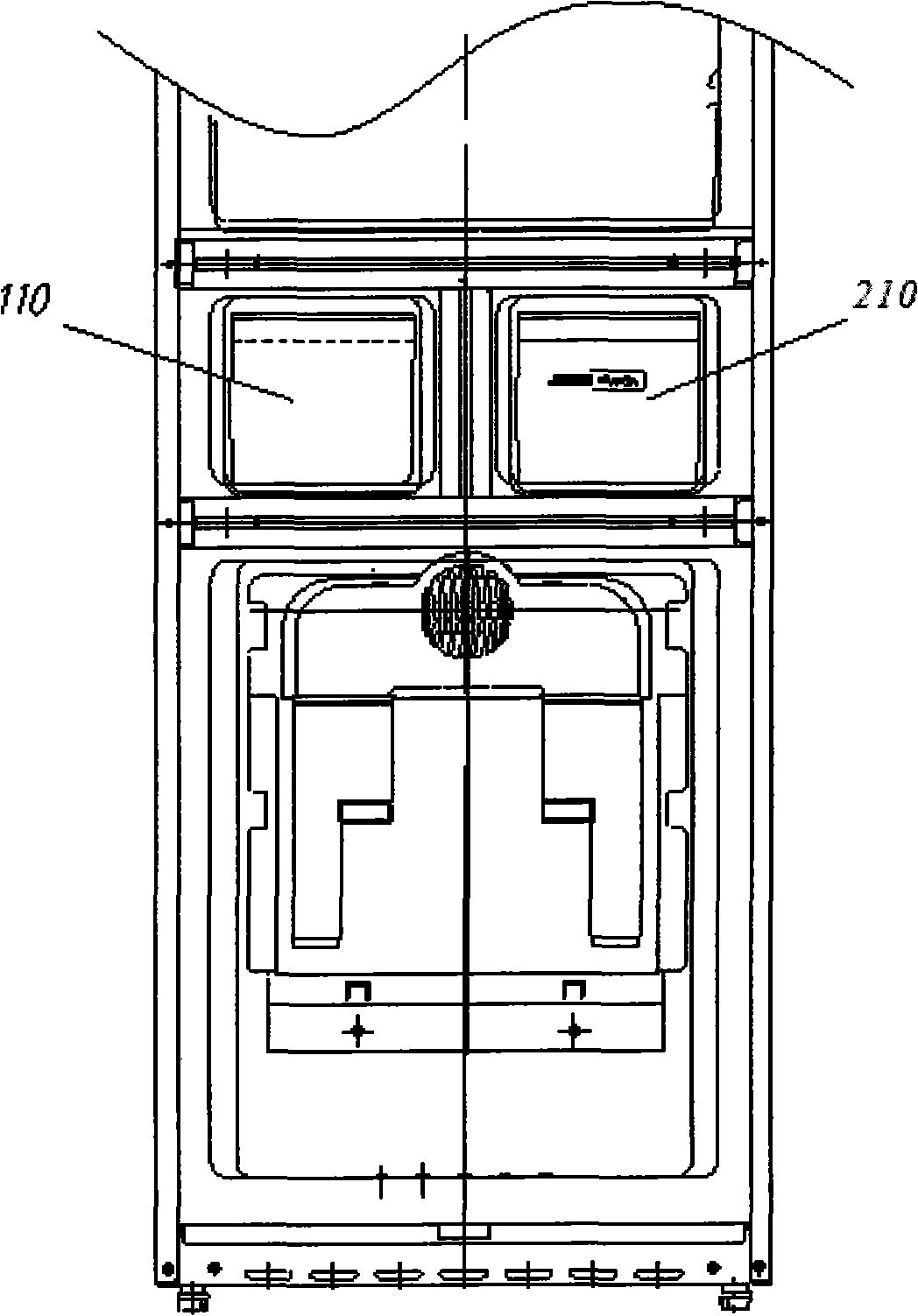

Automatic milky tea maker

An automatic milky tea maker comprises a low-temperature preservation chamber, an icemaker case and a normal-temperature chamber. A guide rail box is arranged in front of the low-temperature preservation chamber, the icemaker case and the normal-temperature chamber. A sauce output device, a large fruit grain output device, a cover output device and a juice pump are arranged in the upper portion ofthe low-temperature preservation chamber. A full-automatic icemaker is arranged in the icemaker case, a cup discharger, a fructose output device, a powder output device and a stirring device are arranged in the upper portion of the normal-temperature chamber, the middle of the normal-temperature chamber is internally provided with a tea water and purified water outlet, the lower portion of the normal-temperature chamber is provided with a water barrel placement area, and a milky tea conveying platform is arranged in the guide rail box. The automatic milky tea has advantages that cup discharging, water agent feeding, powder feeding, sauce feeding, stirring, milk cover feeding and final outputting are all realized mechanically, so that unmanned milky tea making is realized; by design of different feeding types and feeding sequences, a refrigerator is designed for materials requiring refrigeration, an ice making component is provided aiming at different demands of cold and hot drinks, and accordingly different customer demands can be met.

Owner:杭州黑石机器人有限公司

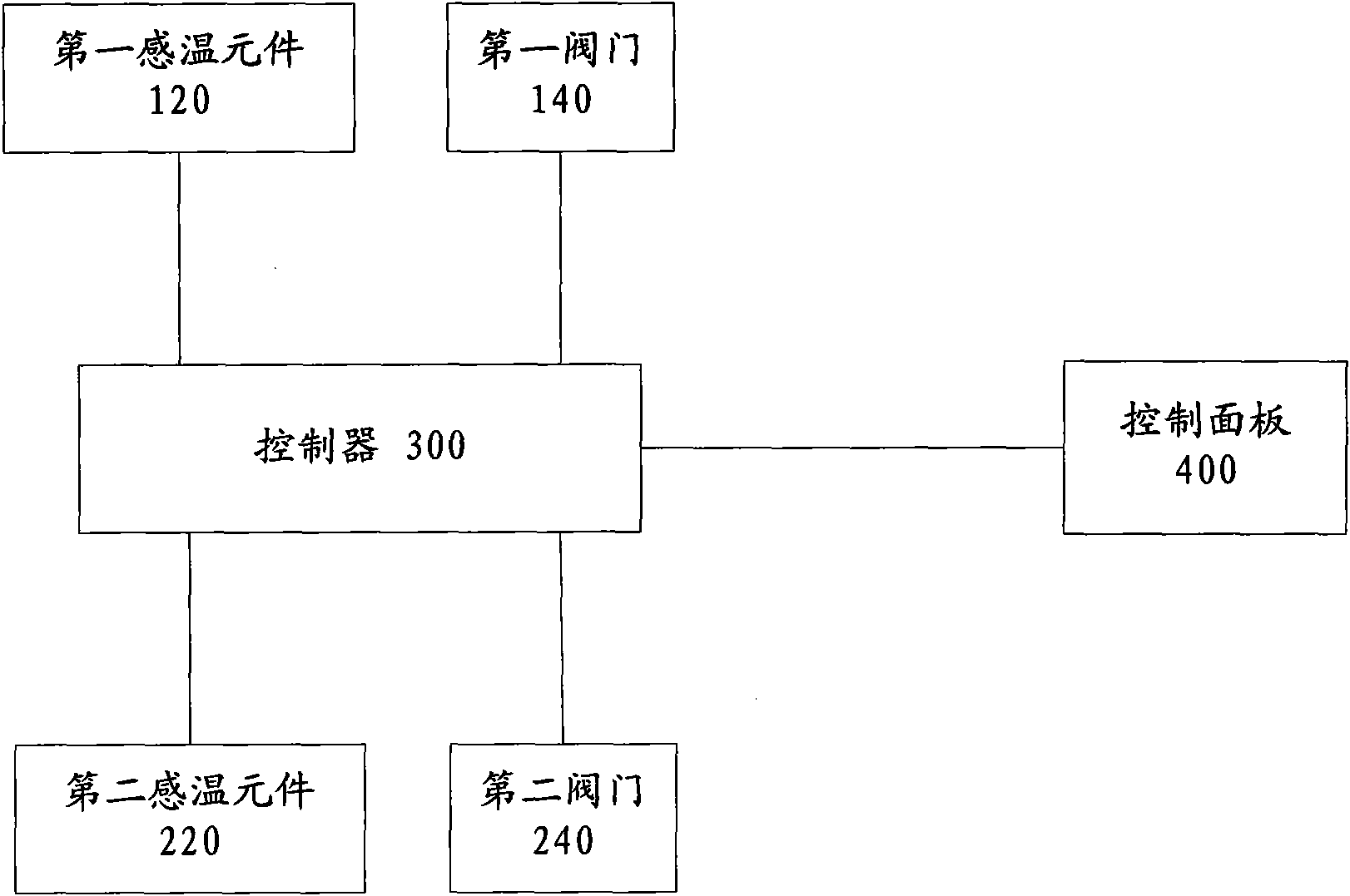

Refrigerator and temperature control method of variable-temperature chamber of refrigerator

InactiveCN102121779AMeeting timeSatisfy different fresh-keeping abilityLighting and heating apparatusDomestic refrigeratorsTemperature controlEngineering

The invention provides a refrigerator and a temperature control method of a variable-temperature chamber of the refrigerator. The refrigerator comprises two mutually independent variable-temperature chambers, wherein each variable-temperature chamber is provided with an air pipe and a temperature sensing element which are independent; and a controller controls to open / close the air pipe according to the temperature of the variable-temperature chamber measured by the temperature sensing element so as to control the temperature of the variable-temperature chamber. According to the invention, as two mutually independently-controlled variable-temperature chambers are arranged, a user can set different temperature ranges as necessary, thereby meeting the functional requirements of the user on various storage time, different freshness preservation capabilities, prevention of odor tainting and the like.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

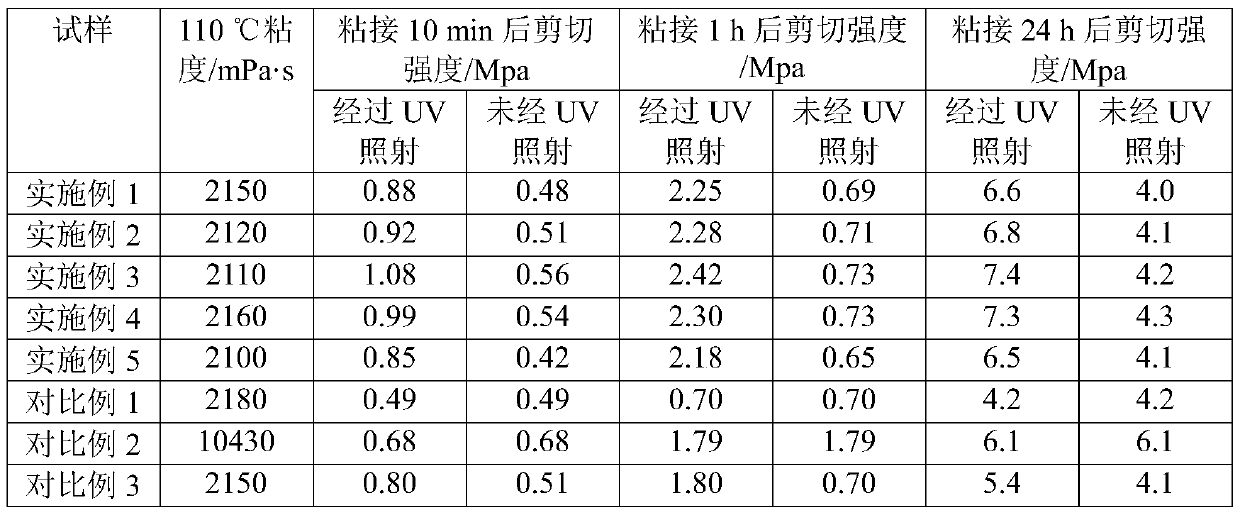

Low viscosity UV/moisture dual-curing polyurethane hot melt adhesive and preparation method thereof

ActiveCN109705794ALow viscosityStrong initial adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAntioxidant

The invention relates to a low viscosity UV / moisture dual-curing polyurethane hot melt adhesive and a preparation method thereof, belonging to the technical field of photocuring adhesives. The low viscosity UV / moisture dual-curing polyurethane hot melt adhesive comprises the following components in parts by weight: 95-97 parts of UV / moisture dual-curing polyester polyether polyurethane, 1-3 partsof free radical photoinitiator, 0.25-2 parts of cationic photoinitiator, 0.25-1 part of photosensitizer, 0.06-0.35 part of polyurethane catalyst, 0.01-0.02 part of water reducing agent, and 0.05-0.2 part of antioxidant. The hot melt adhesive can be used for the bonding of opaque substrates. The viscosity of the adhesive at the sizing temperature 110 DEG C is in the range of 2000-2500 mPa.s, the viscosity is low, the construction is convenient, the initial viscosity is strong, the positioning is fast, the holding time is shortened, even the holding pressure is not needed. The hot melt adhesivedoes not contain small molecular active diluent and is environmentally friendly. The preparation process is simple, easy to operate and suitable for industrial production.

Owner:重庆中科力泰高分子材料有限公司

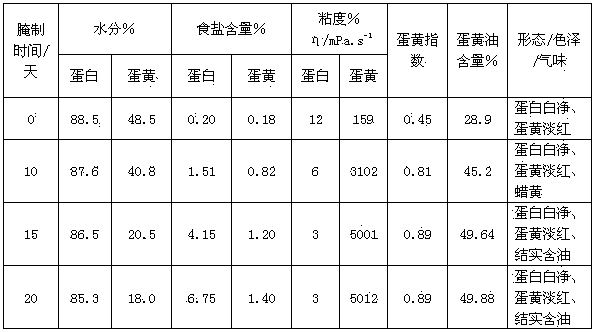

Spicy salted duck egg pickling liquid, preparation method and salted duck egg production method

The invention discloses spicy salted duck egg pickling liquid, a preparation method and a salted duck egg production method. The pickling liquid comprises following components in parts by weight: 20g-40g of peppers, 20g-40g of fresh ginger, 20g-40g of fennels, 3g-60g of garlic, 20g-40g of cinnamons, 5g-15g of fructus piperis longi, 150g-300g of table salt, 30g-60g of white spirit and the balance of water. The preparation method comprises the following steps: after washing and disinfecting fresh duck eggs; treating by using a pickling auxiliary agent; adding the fresh duck eggs into the prepared pickling liquid to be pickled to be cooked; washing and sterilizing; pre-boiling and bagging in vacuum; and sterilizing to obtain a finished product. Salted duck eggs produced by the preparation method disclosed by the invention are moderate in saltiness degree and small in air chamber; the egg white is pure white and tender and the yolk is red, yellow and bright in color and luster and is fine, soft and loose; an egg shell is brown or light brown; the salted duck eggs have slight faint scent, lasting taste and short pickling period. Material liquid can be repeatedly utilized so that the production cost is reduced.

Owner:JIANGXI TIANYUN AGRI DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com