Preparation method of camellia oleosa seed oil and linseed oil compound microcapsules

A technology of linseed oil and camellia oleifera oil, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of storage, transportation and processing difficulties, application and development restrictions, etc., so as to broaden the way of development and utilization and avoid flax Acid deficiency, avoiding the effect of easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

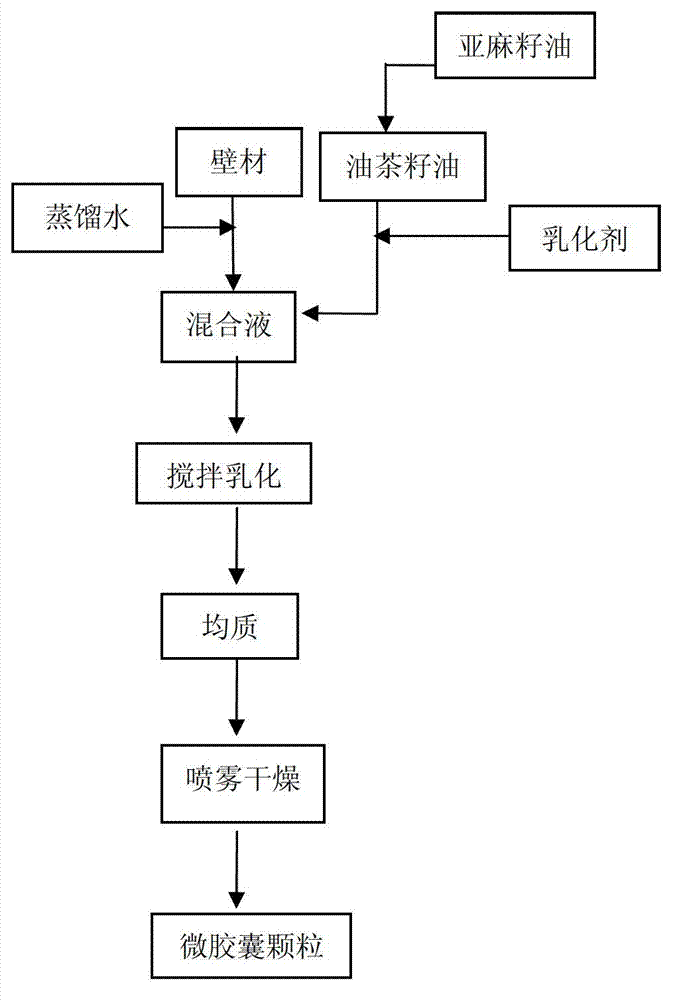

Image

Examples

Embodiment 1

[0012] Embodiment 1: the method for preparing microcapsules by compounding camellia oleifera seed oil and linseed oil as the core material according to the present invention, the specific steps are as follows:

[0013] (1) The wall material is soybean protein isolate and maltodextrin mixed in a ratio of 1:2 to 1:0.5;

[0014] (2) The core material is a mixture of camellia oil and linseed oil in a ratio of 1:1 to 10:1;

[0015] (3) The ratio of core material to wall material is 1:2~1:0.5;

[0016] (4) The emulsifier is a mixture of sucrose fatty acid ester and glyceryl stearate in a ratio of 1:1 to 8:1;

[0017] (5) The solid-to-liquid ratio is 10% to 30%.

[0018] Weigh an appropriate amount of the above-mentioned wall material. The ratio of soybean protein isolate and maltodextrin in the wall material is 1:2. After mixing, add distilled water and stir to mix and dissolve. Slowly add a certain amount of emulsifier and core material. The sucrose fat in the emulsifier The rat...

Embodiment 2

[0021] Example 2: The difference from Example 1 is that the ratio of soybean protein isolate and maltodextrin in the wall material is 1:1.5, the ratio of camellia seed oil and linseed oil in the core material is 1:1, and the emulsifier The ratio of sucrose fatty acid ester to glyceryl stearate is 1:1, and the concentration of the emulsion is 15%.

Embodiment 3

[0022] Example 3: The difference from Example 1 is that the ratio of soybean protein isolate and maltodextrin in the wall material is 1:1, the ratio of camellia oil and linseed oil in the core material is 5:1, and the emulsifier The ratio of sucrose fatty acid ester to glyceryl stearate is 2:1, and the concentration of the emulsion is 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com