Method for preparing magnesium hydroxide and calcium hydroxide flame retardant from dolomite

A technology of magnesium hydroxide and calcium hydroxide, which is applied in the direction of magnesium hydroxide, calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of cumbersome process and unavoidable large amount of waste liquid, and achieve simple process and easy The effect of industrialization and widening the way of development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

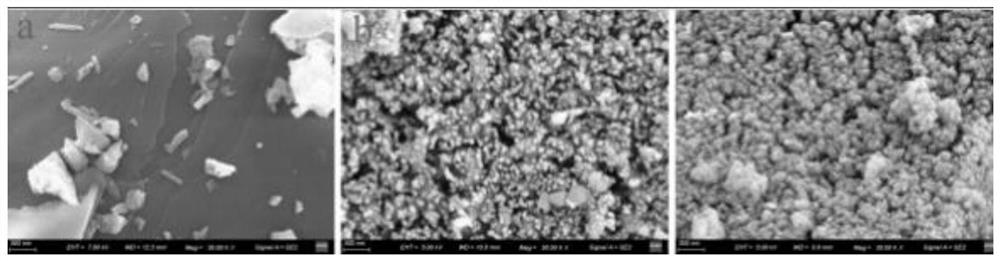

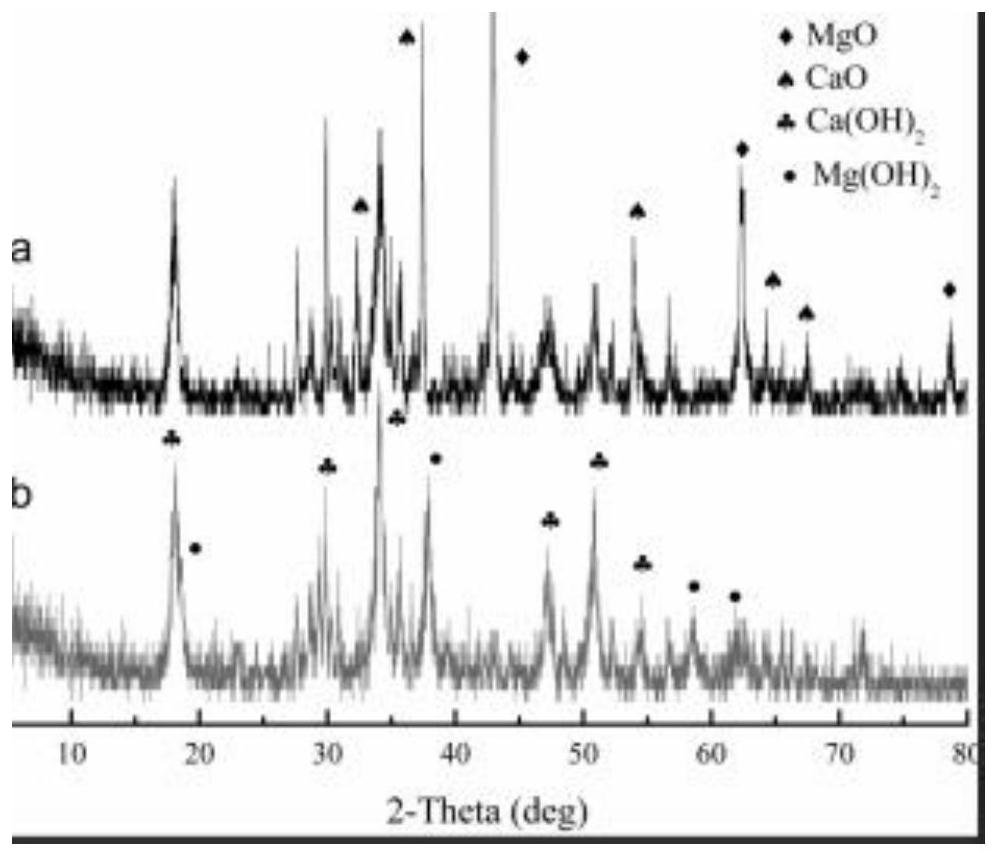

[0024] Embodiment 1: Weigh 30g of dolomite powder in a high-temperature crucible, place it in a high-temperature energy-saving box-type furnace at 950°C for calcination for 90 minutes, pass through a 200-mesh sieve after cooling for later use, and put a certain amount of calcined dolomite powder into a steamer. Keep it in a high-temperature steam environment for 1 hour, take it out and dry it in an oven at 80°C.

Embodiment 2

[0025] Embodiment 2: Weigh 30g of dolomite powder in a high-temperature crucible, place it in a high-temperature energy-saving box furnace at 950°C for calcination for 90 minutes, pass through a 200-mesh sieve after cooling, and put it into a steamer for subsequent use. Keep it in a high-temperature steam environment for 2 hours, take it out and dry it in an oven at 80°C.

Embodiment 3

[0026] Embodiment 3: Weigh 30g of dolomite powder in a high-temperature crucible, place it in a high-temperature energy-saving box furnace at 950°C for calcination for 90 minutes, pass through a 200-mesh sieve after cooling, and put it into a steamer for subsequent use. Keep it in a high-temperature steam environment for 3 hours, take it out and dry it in an oven at 80°C. The basic principles and main features of the present invention and the advantages of the present invention have been shown and described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com