Patents

Literature

78results about How to "Realize unmanned production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

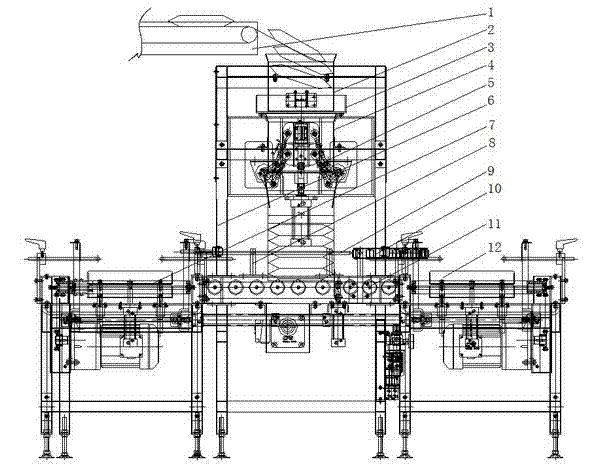

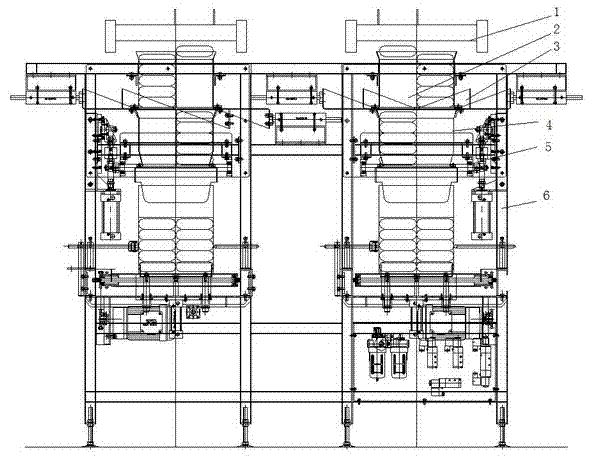

Medicine bottle filling production device with production quantity counting unit

ActiveCN106697416ARealize unmanned productionFully automatedCapsThreaded caps applicationCharging stationMedicine bottles

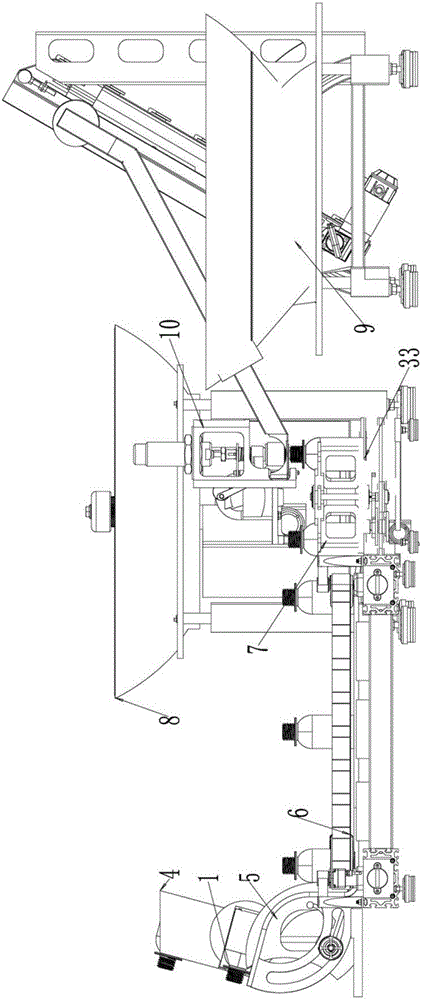

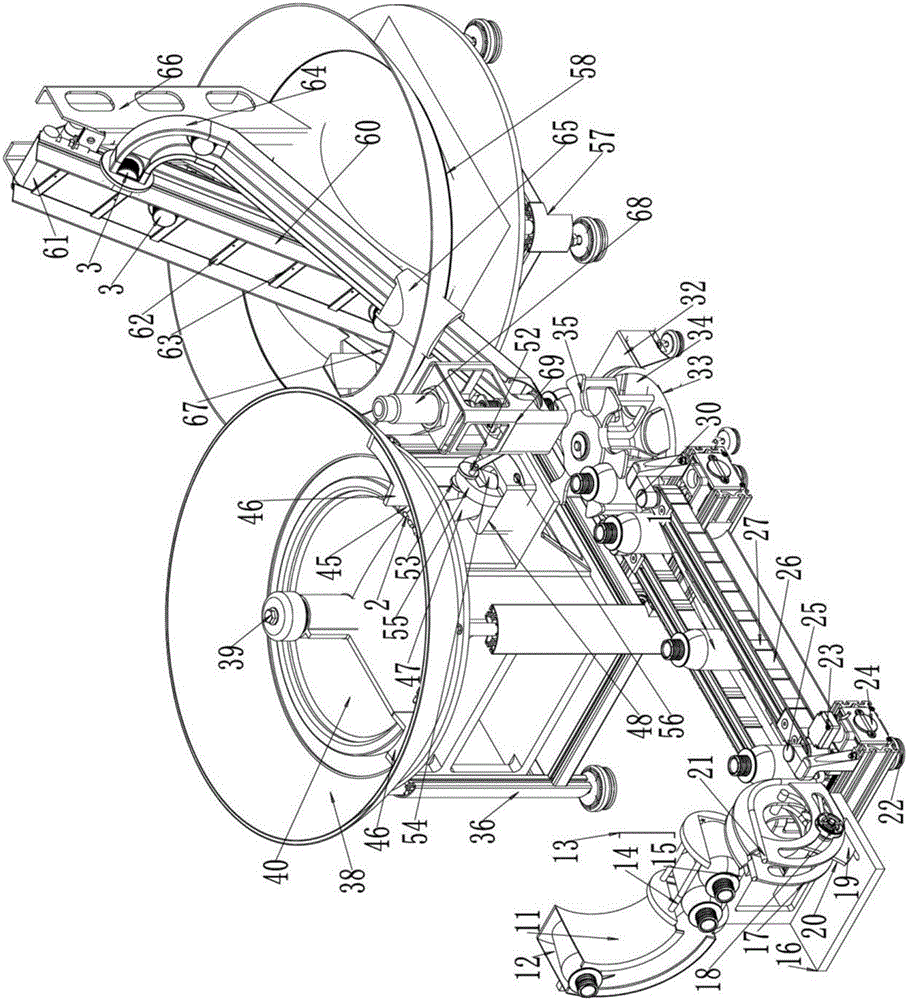

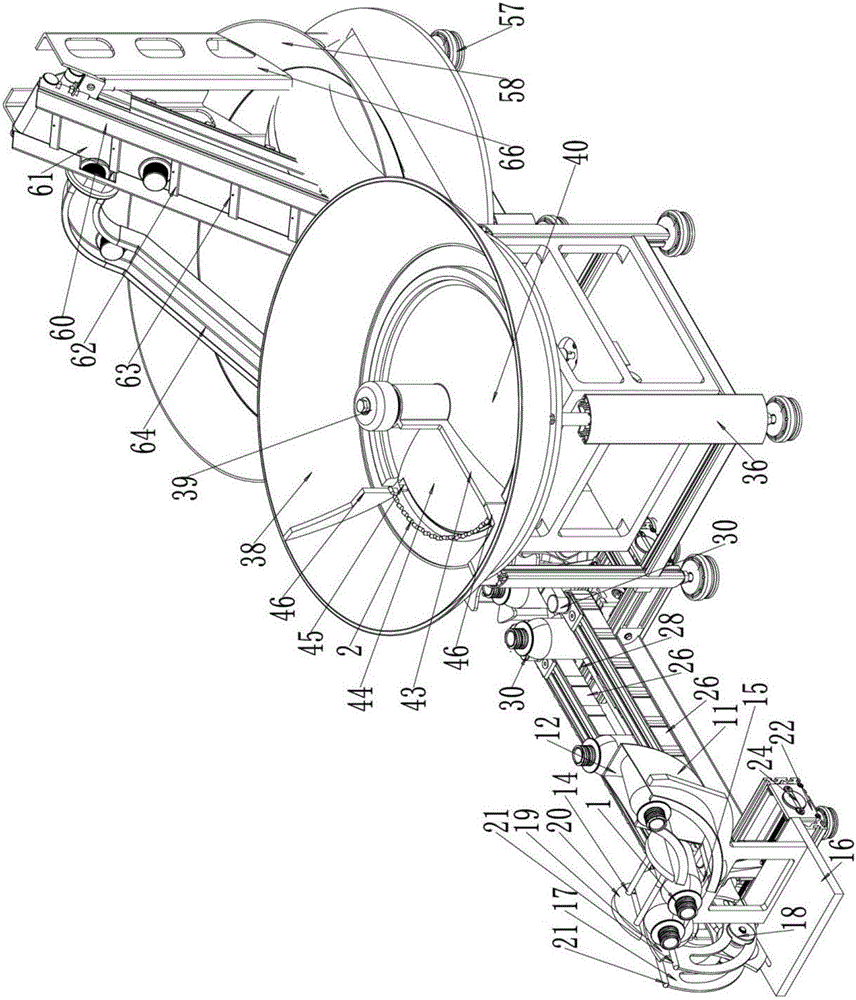

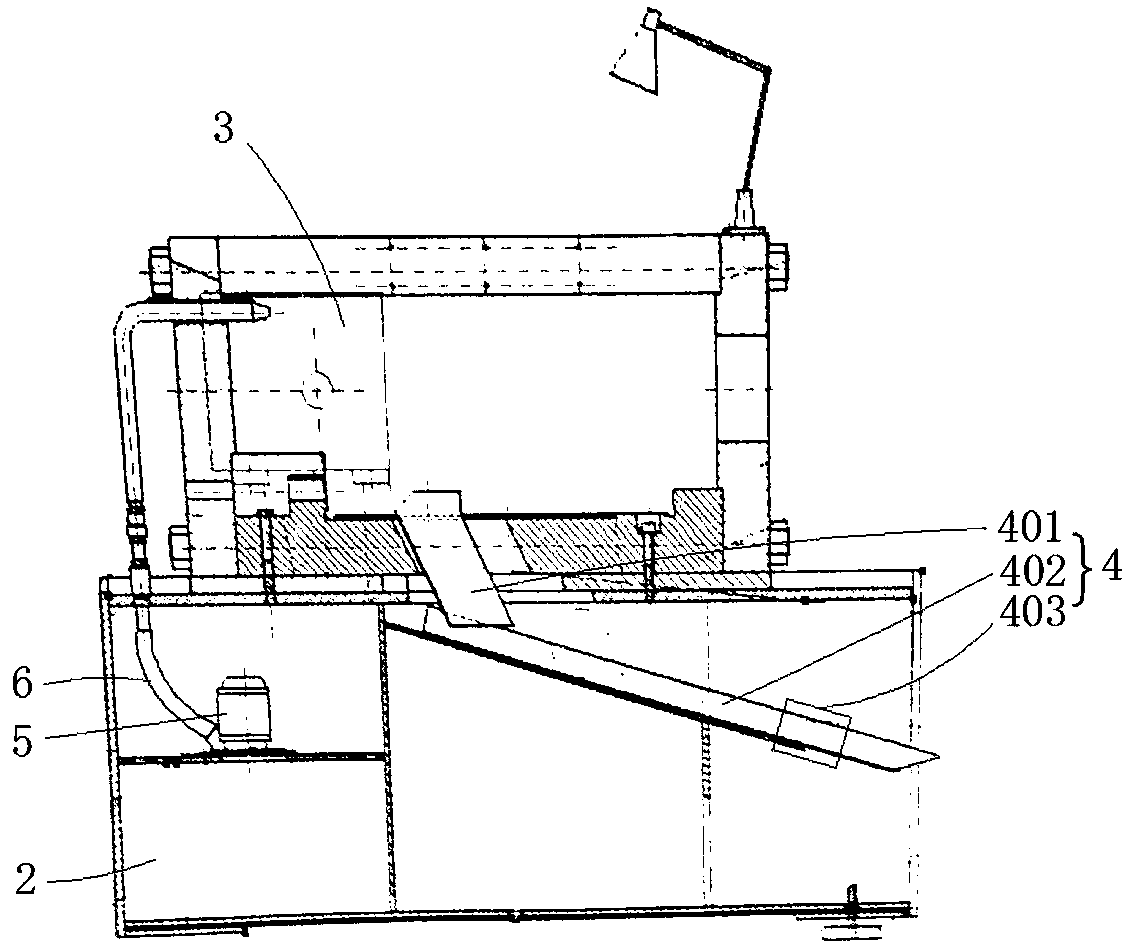

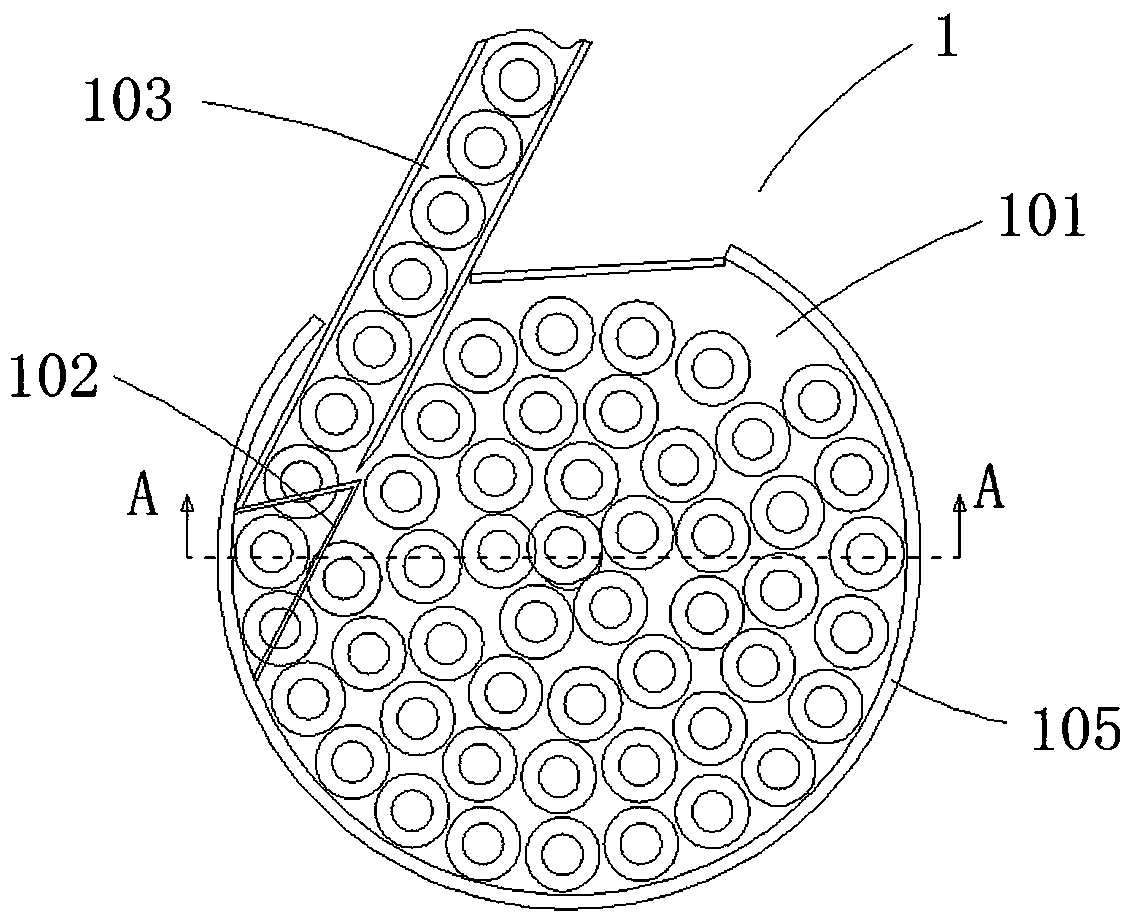

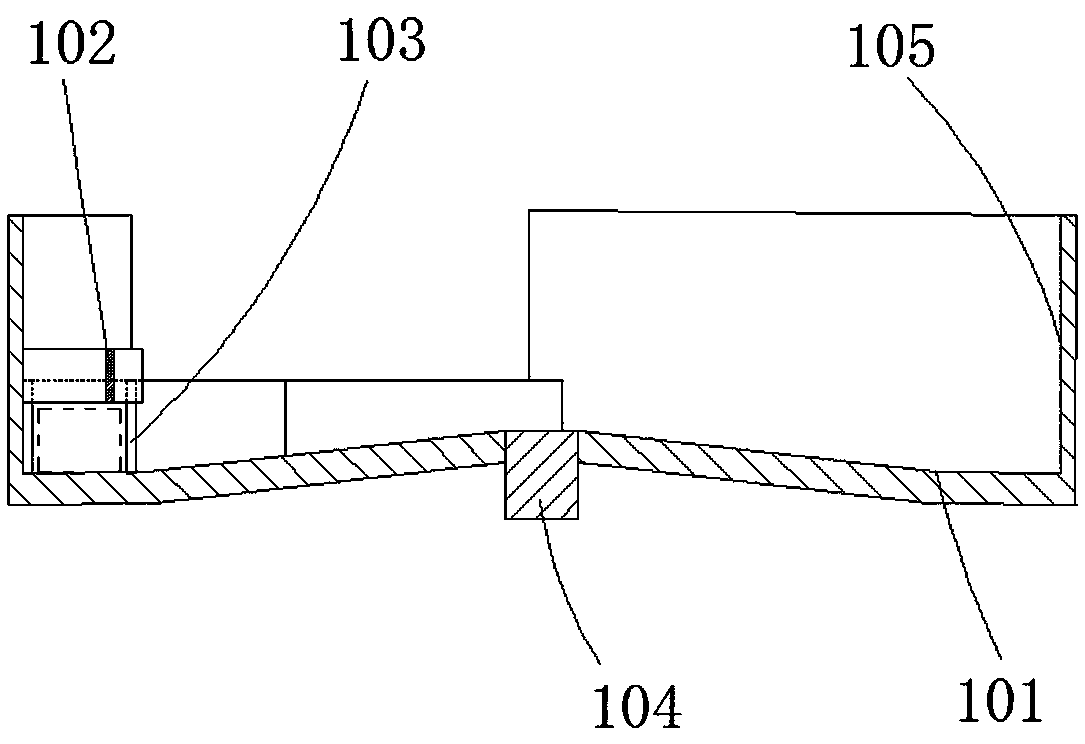

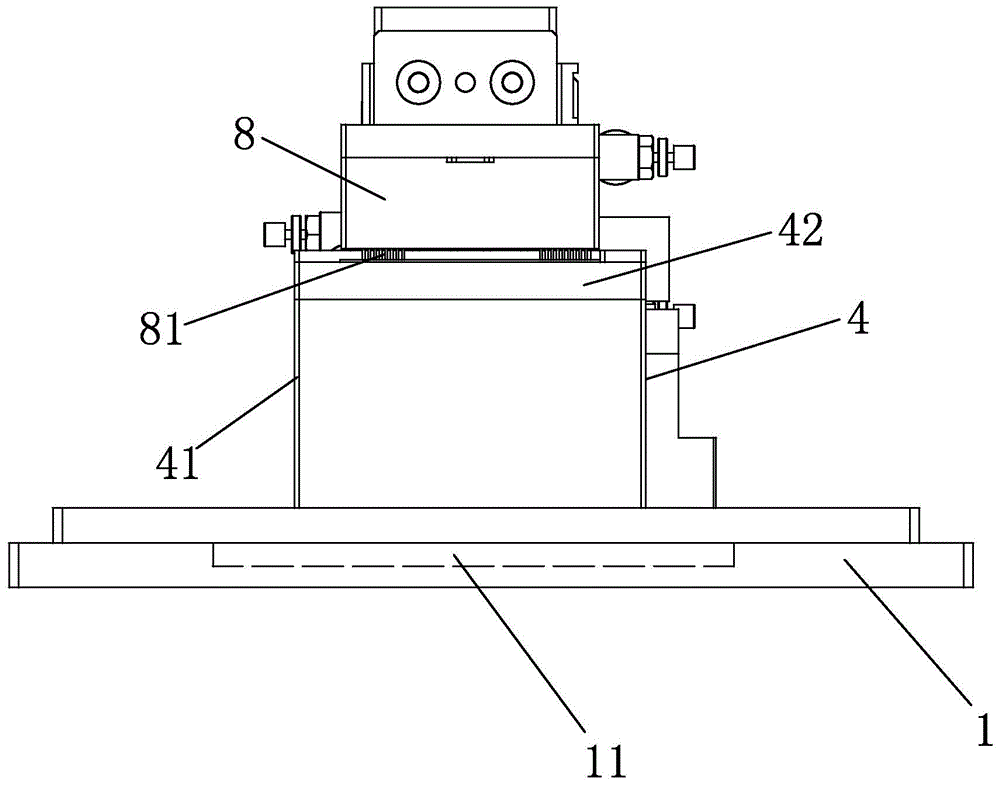

The invention relates to a medicine bottle filling production device with a production quantity counting unit. The medicine bottle filling production device with the production quantity counting unit comprises a feeding device, a turnover device, a conveying device, a dividing device, a charging device, a cover delivering device, a cover sealing device, a discharging synchronous suspension rotary plate and a discharging conveying device. The dividing device comprises four stations sequentially connected according to working procedures, that is, the charging station for clamping vertically-arranged bottle bodies, the filling station for filling bottle bodies with capsules, the cover sealing station for installing bottle covers on bottle bodies filled with capsules and the discharging station for conveying out bottle bodies with bottle covers installed. The medicine bottle filling production device with the production quantity counting unit is reasonable in design, compact in structure and convenient to use.

Owner:WENZHOU MEDICAL UNIV

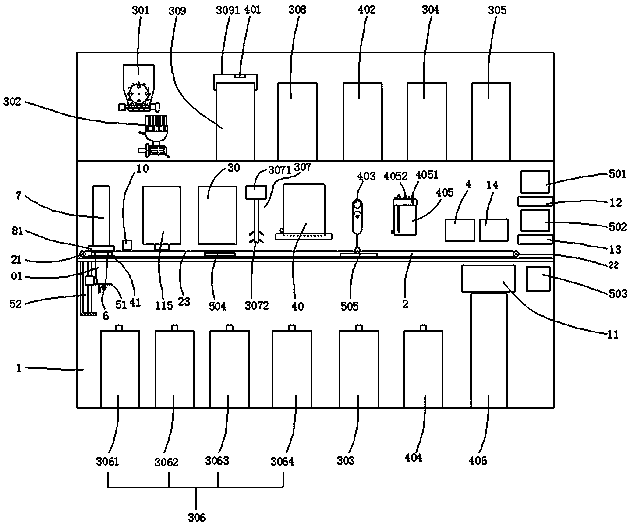

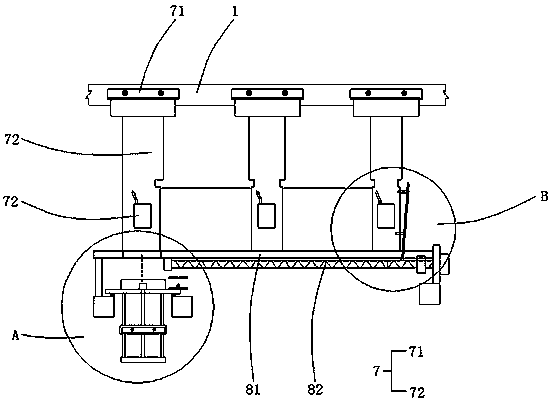

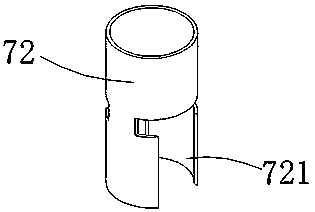

Automatic milky tea maker

An automatic milky tea maker comprises a low-temperature preservation chamber, an icemaker case and a normal-temperature chamber. A guide rail box is arranged in front of the low-temperature preservation chamber, the icemaker case and the normal-temperature chamber. A sauce output device, a large fruit grain output device, a cover output device and a juice pump are arranged in the upper portion ofthe low-temperature preservation chamber. A full-automatic icemaker is arranged in the icemaker case, a cup discharger, a fructose output device, a powder output device and a stirring device are arranged in the upper portion of the normal-temperature chamber, the middle of the normal-temperature chamber is internally provided with a tea water and purified water outlet, the lower portion of the normal-temperature chamber is provided with a water barrel placement area, and a milky tea conveying platform is arranged in the guide rail box. The automatic milky tea has advantages that cup discharging, water agent feeding, powder feeding, sauce feeding, stirring, milk cover feeding and final outputting are all realized mechanically, so that unmanned milky tea making is realized; by design of different feeding types and feeding sequences, a refrigerator is designed for materials requiring refrigeration, an ice making component is provided aiming at different demands of cold and hot drinks, and accordingly different customer demands can be met.

Owner:杭州黑石机器人有限公司

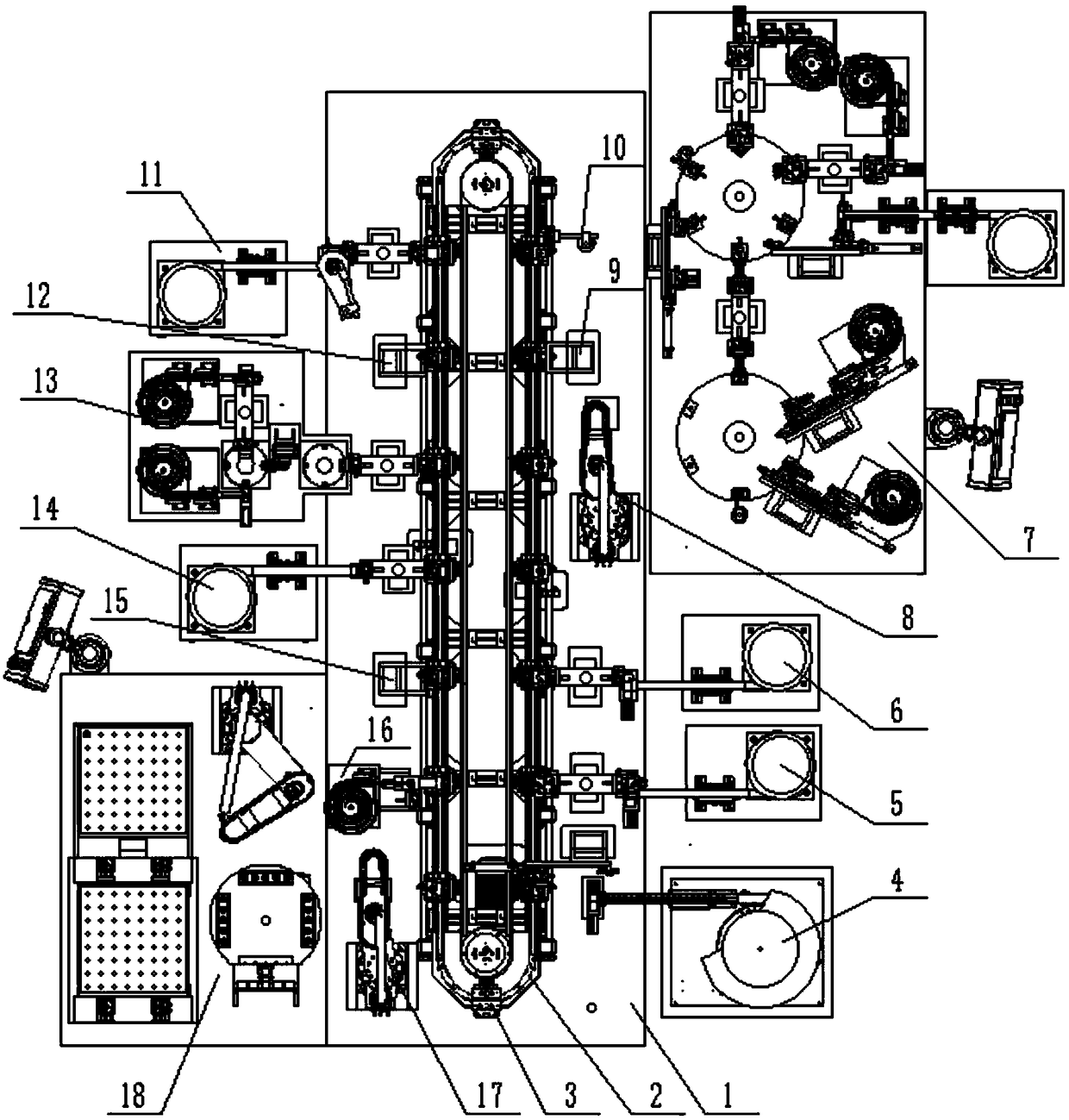

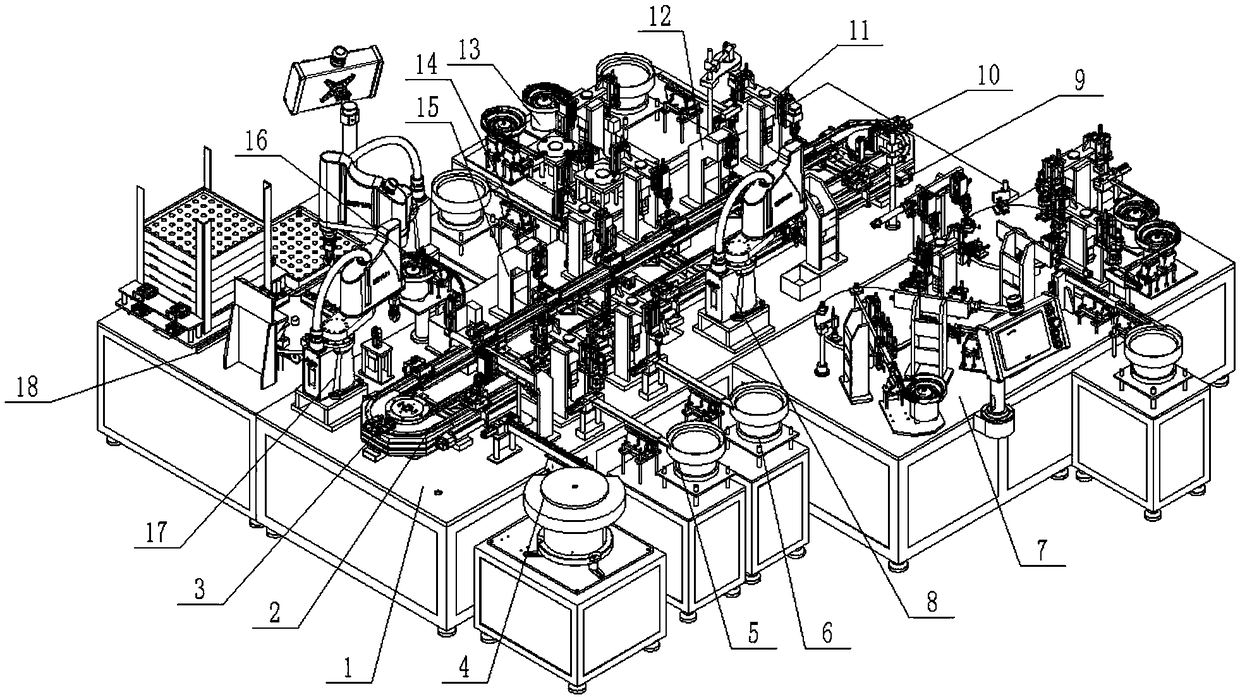

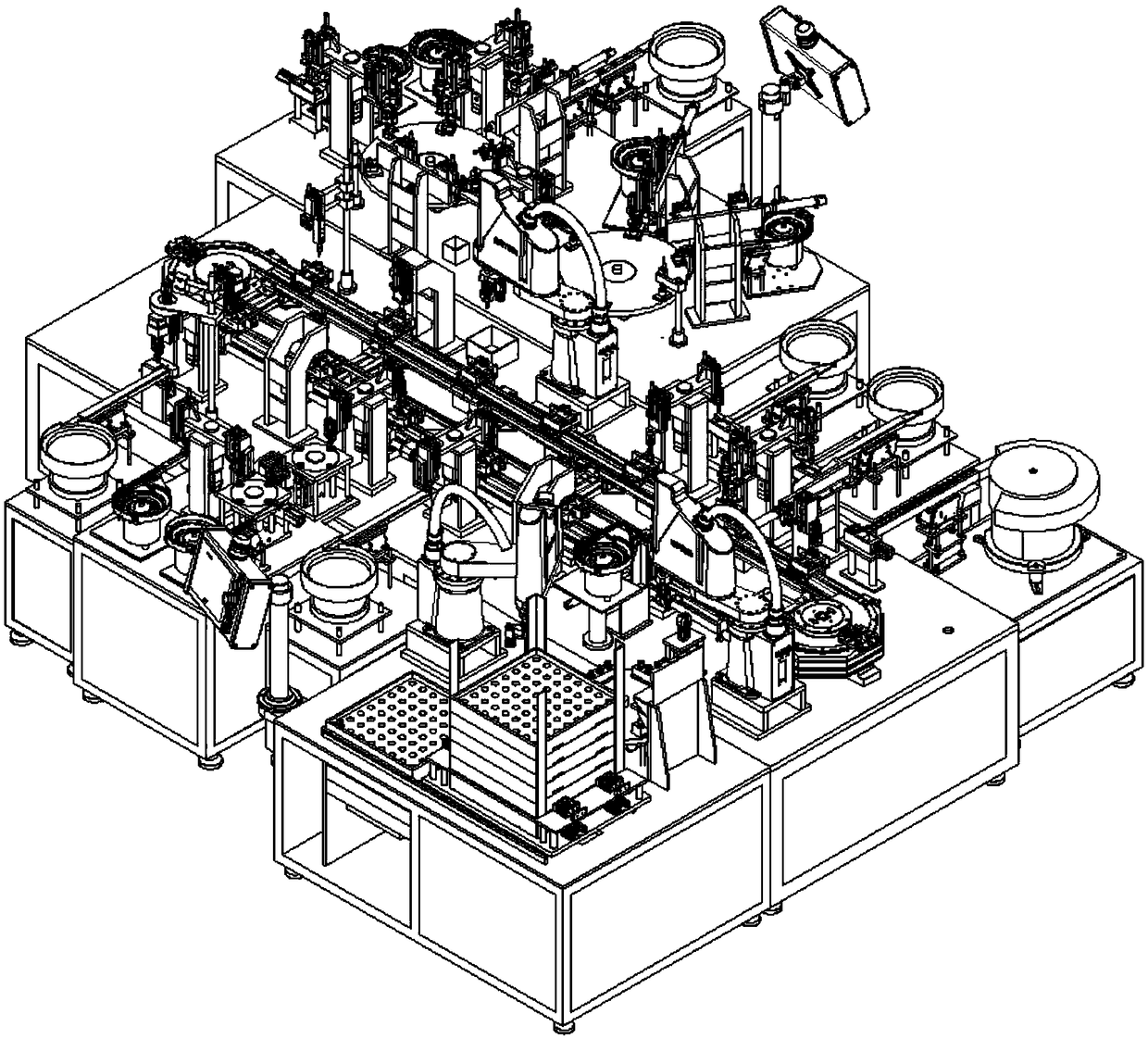

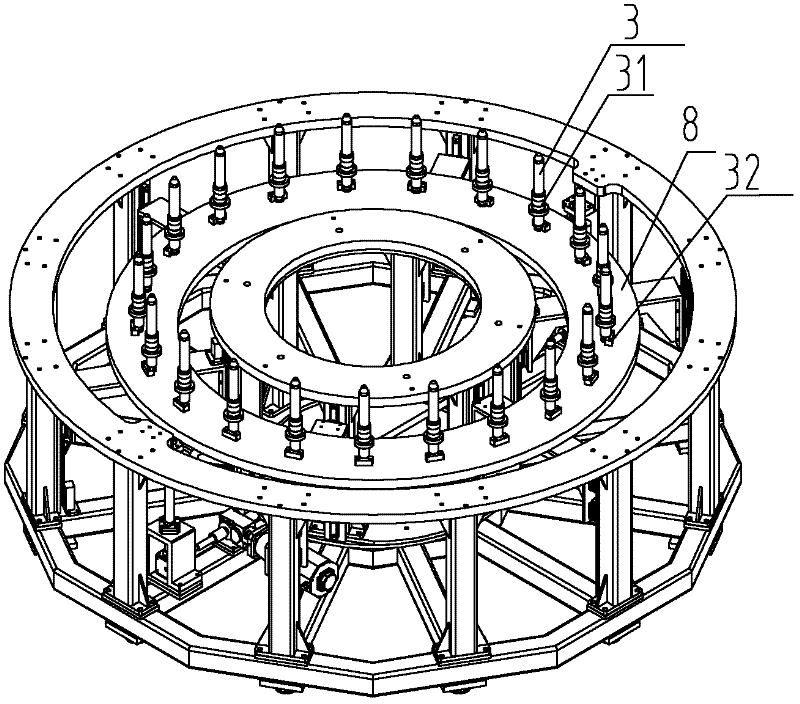

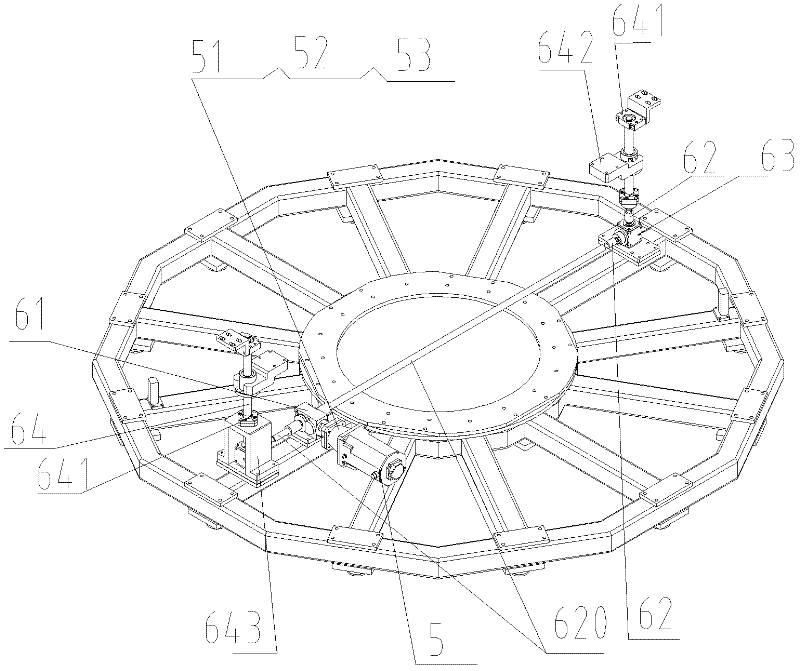

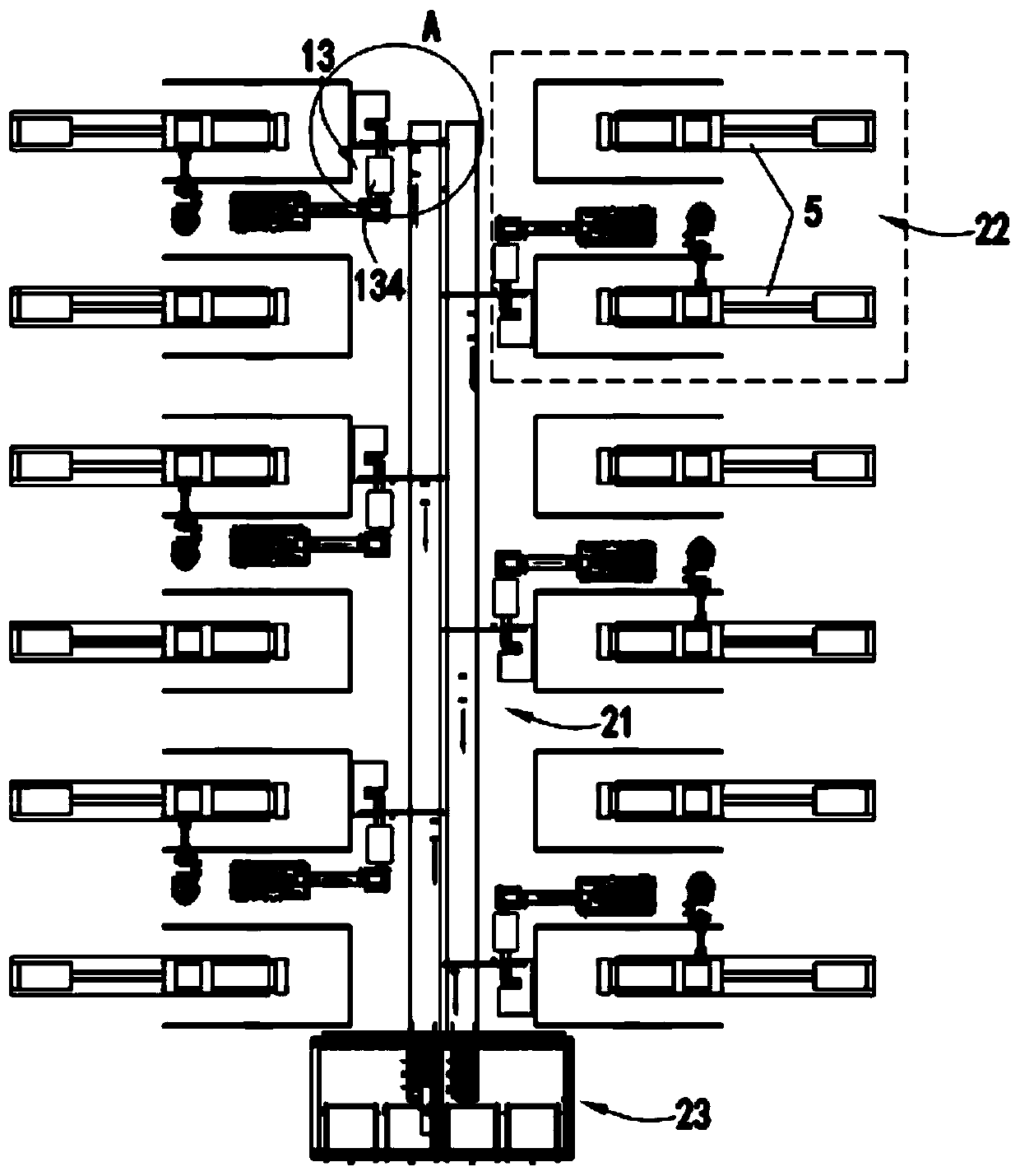

Automatic assembly line of valve element of water valve

PendingCN109290792AAssembly line compactHigh positioning accuracyAssembly machinesMetal working apparatusAssembly lineEngineering

The invention discloses an automatic assembly line of a valve element of a water valve, and belongs to the field of automatic assembly. The automatic assembly line comprises a worktable which is provided with an annular assembly line. The annular assembly line is provided with a plurality of workpiece tools, and the periphery of the annular assembly line is sequentially provided with a valve element shell feeding device, a first sealing ring assembly device, a wear-resisting pad assembly device, a valve stem assembly device, a valve stem assembly feeding device, a valve stem assembly press fitting device, a ceramic piece oil filling device, a fixed ceramic piece assembly device, a gasket assembly device, a sealing pad assembly device, a sealing pad press fitting device, a jump ring assembly device, a valve element discharging mechanical arm and a valve element detecting device.

Owner:山东红宝自动化有限公司

System and method for automatically controlling coal mining machine and automatically straightening working face on basis of video inspection

ActiveCN108561133ASolve the problem of straightness automatic controlRealize automated productionMining devicesSlitting machinesAutomatic controlIndustrial engineering

The invention discloses a system and a method for automatically controlling a coal mining machine and automatically straightening a working face on the basis of video inspection. The system comprisesthe coal mining machine and a hydraulic support which are arranged on the working face, an inspection rail arranged in the stretching direction of the working face, and an inspection device, wherein the inspection device is slidably mounted on the inspection rail; the inspection device is used for detecting coal-rock interface data and the working face straightness, and outputting a control instruction according to the coal-rock interface data and the working face straightness; the coal mining machine performs automatic coal cutting control according to the control instruction; the hydraulic support performs automatic working face straightening control according to the control instruction. After the adoption of the system and the method, influence of a production environment with a severefully mechanized coal mining working face on a video system can be avoided, the number of working face cameras is reduced, and working face coal-rock interface identification and working face straightness detection are completed.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD +1

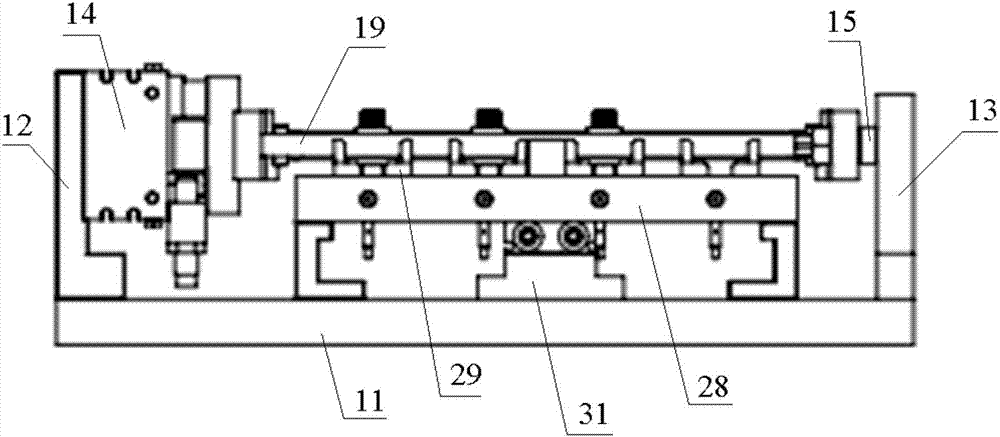

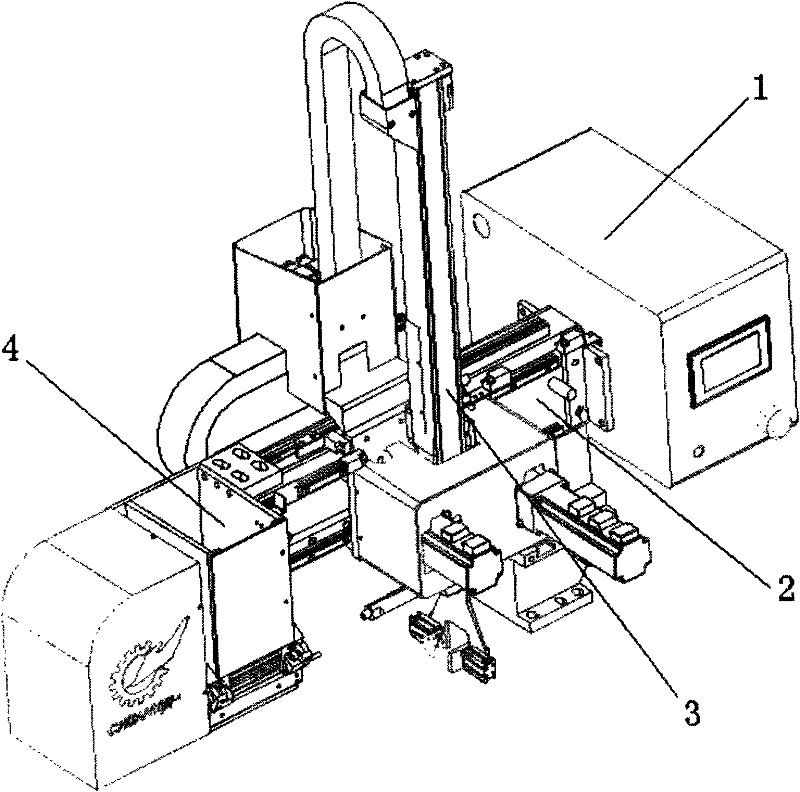

Automatic loading device of lathe applicable to disc-type parts

ActiveCN102198603AReduce labor intensityRealize unmanned productionMetal working apparatusNumerical controlSlide plate

The invention discloses an automatic loading device of a lathe applicable to disc-type parts. A sliding plate is arranged in the square-shaped hole of a rectangular frame in a penetrating manner; the left plate surface of the sliding plate is vertically provided with a dovetail groove which is in sliding fit with a dovetail guide rail on the right plate surface of a fixed plate; the top surface of the fixed plate and the bottom surface of the rectangular frame are fixed; the front side surface of the fixed plate is fixedly provided with a limited block; the right part of the limited block is vertically provided with stripy holes which are internally provided with limit screws in a penetrating manner; and the limit screws and the front side surface of the sliding plate are fixed simultaneously. The automatic loading device can be used for replacing workers to realize automatic loading, so that the labor intensity of the workers is greatly reduced, and the working efficiency is also greatly improved; and the loading device can be matched with a numerical control lathe so as to realize unattended production, and is simple in structure, smart in concept and suitable for large-scale promotion and application.

Owner:CHONGQING MACHINE TOOL GROUP

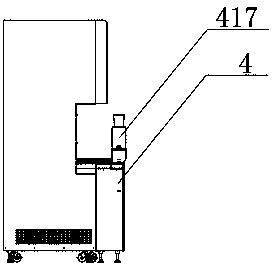

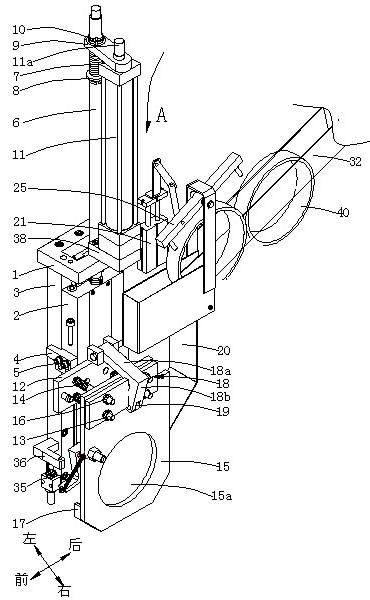

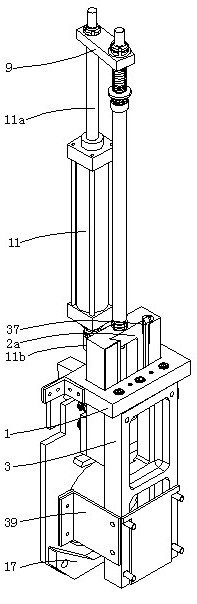

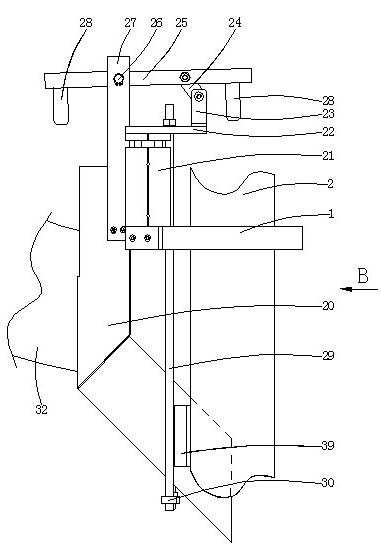

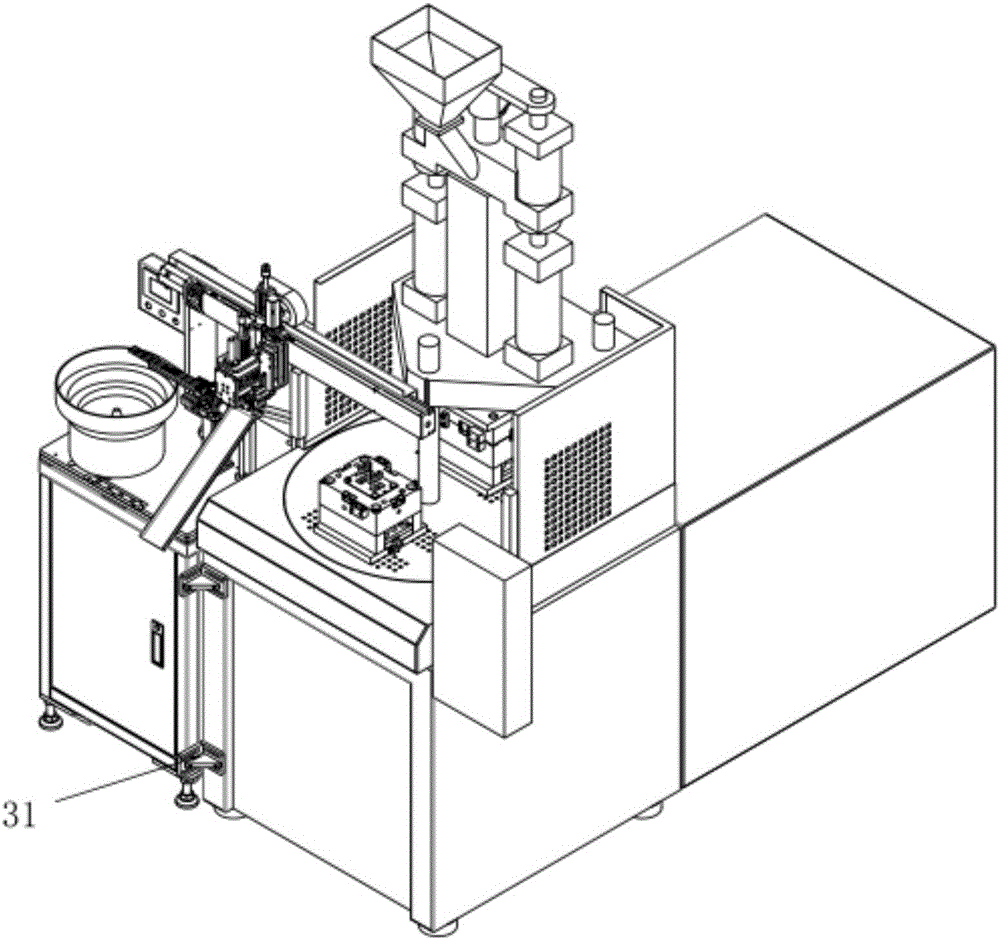

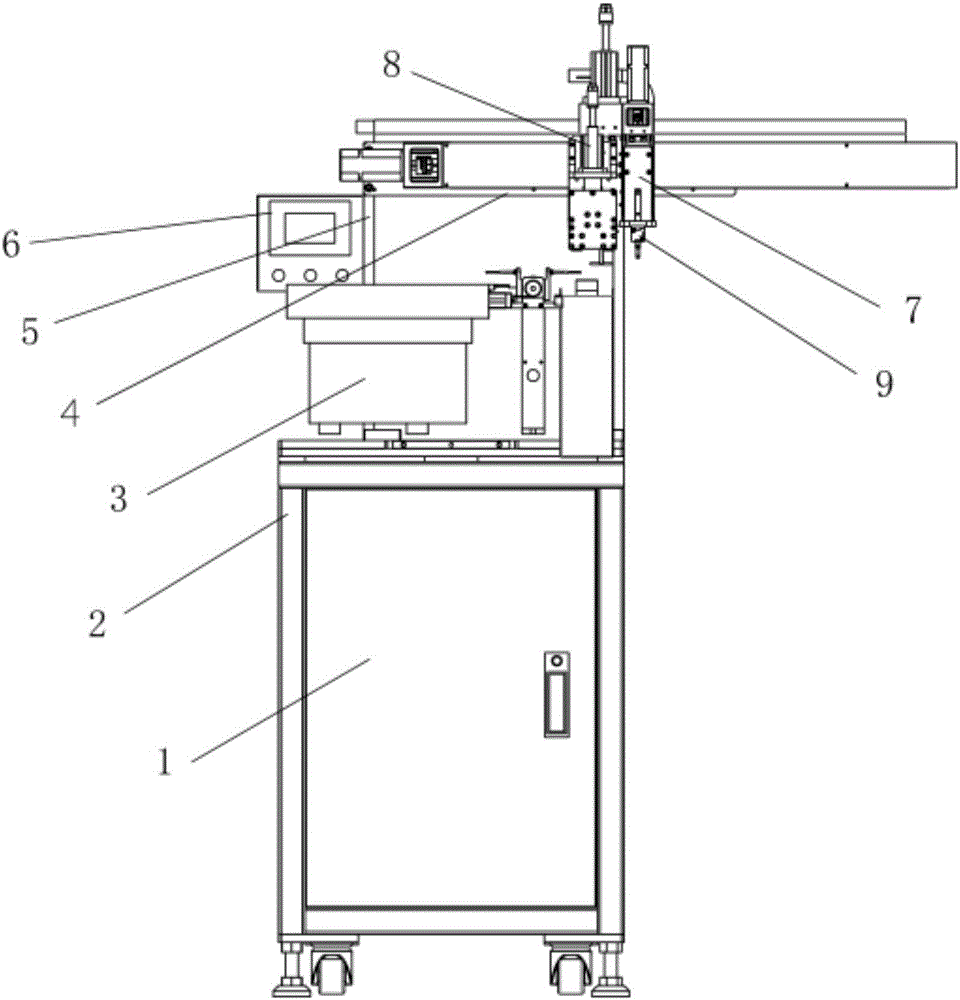

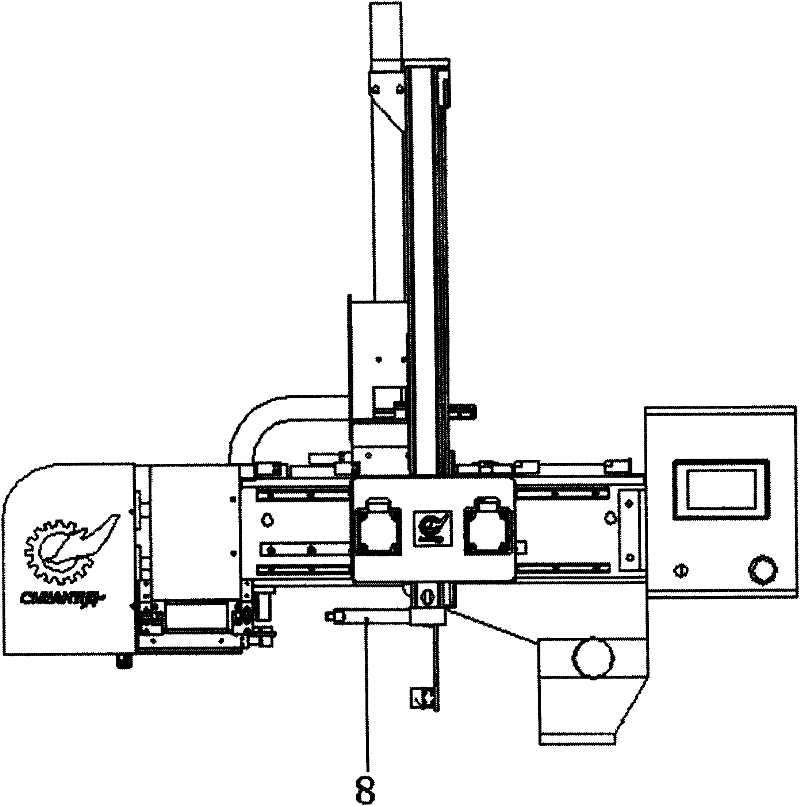

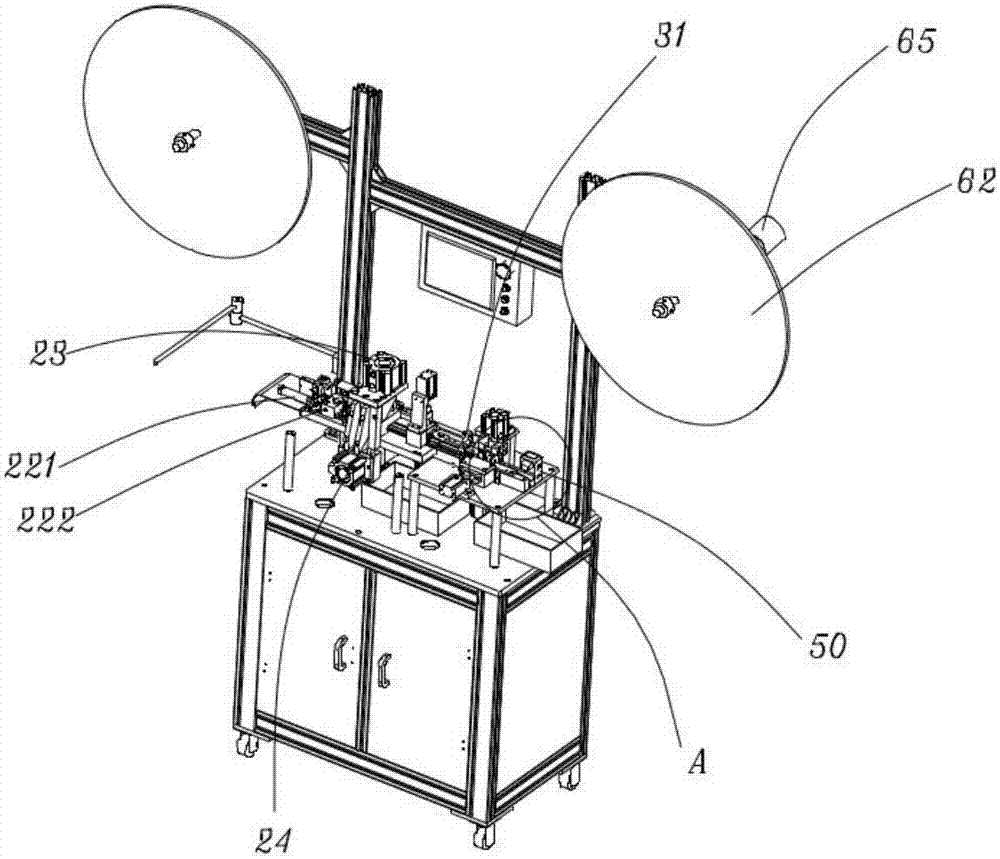

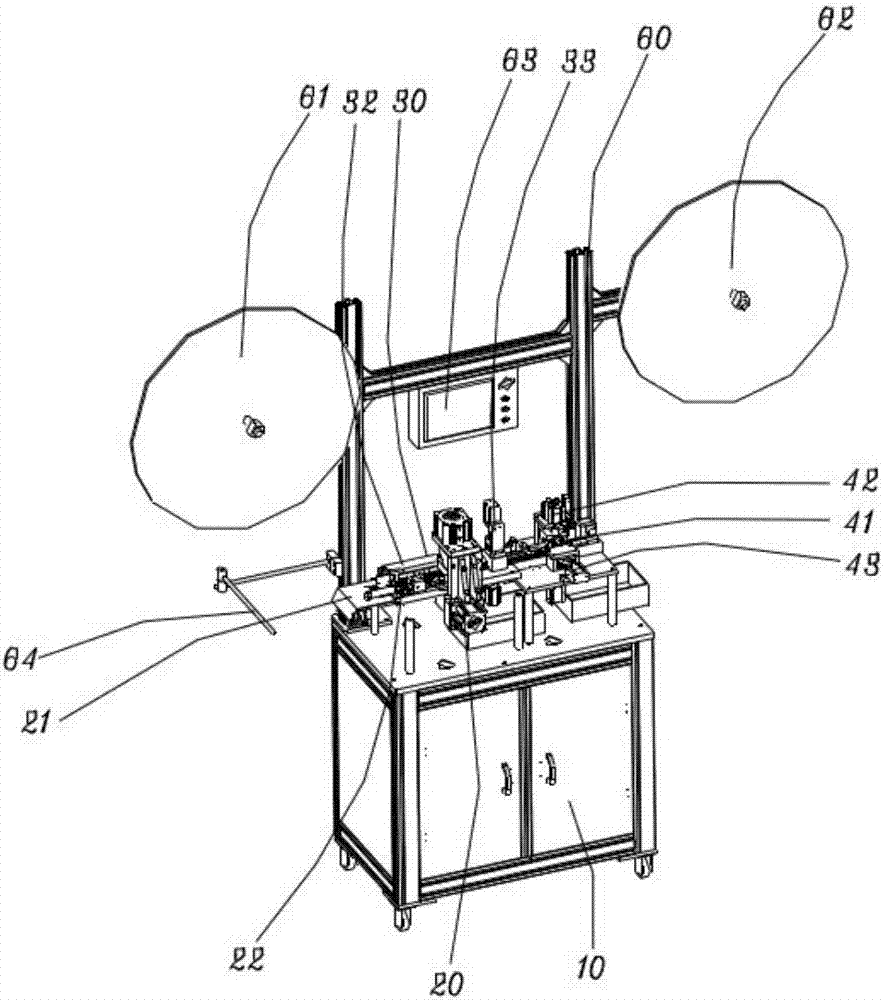

Inserting piece assembling equipment of vertical injection molding machine

The invention relates to technical field of formation of plastic products, in particular to automatic inserting piece assembling equipment of a vertical injection molding machine, which needs to insert hardware into a mold to perform injection molding. An inserting piece supply device is arranged on a machine frame on a control box; hardware is transferred between the inserting piece supply device and the injection molding machine through an X-axis carrying mechanism and a Z-axis platform; the Z-axis platform drives an inserting piece chuck to carry a plurality of hardware inserting pieces; a material taking device is arranged on one side of the inserting piece chuck; and the position of the material taking device corresponds to a workbench of the injection molding machine. The fully-automatic hardware assembling equipment can automatically clamp a water gap and can feed and sort finished products so as to greatly improve production efficiency and realize unmanned operation; during production, the equipment automatically supplies the hardware, automatically takes out the finished product and the water gap in the mold and automatically assembles the hardware; and hardware assembling in-place detection and material (comprising the finished product and the water gap) taking non-leakage detection are set on the material taking device, so the condition that a mold closing plane and a cavity are damaged after material leakage is effectively avoided.

Owner:DONGGUAN XINGBO PRECISION MOLD

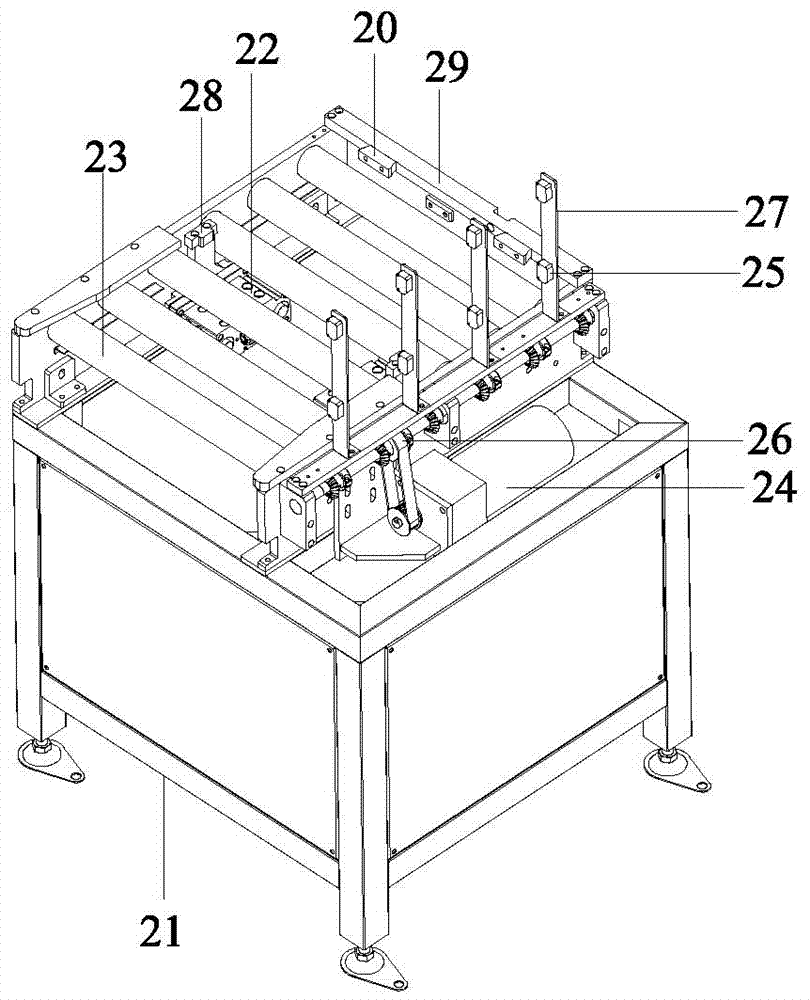

Soft bag material alignment and packing work station machine

The invention discloses a soft bag material alignment and packing work station machine. The soft bag material alignment and packing work station machine comprises a frame body, a packing work station conveyor, an empty carton conveyor, a full carton conveyor, a separation feeder, a material collection box and an alignment box; the packing work station conveyor is arranged on the lower portion of the frame body; the bilateral sides of the packing work station conveyor, along the conveying direction, are connected with the empty carton conveyor and the full carton conveyor respectively; the separation feeder is arranged on the upper portion of the material collection box; the material collection box and the alignment box which are of bottomless structures are connected with each other, fixed on the frame body from top to bottom in turn and are corresponding to the packing work station conveyor which is arranged on the lower portion of the frame body; the lower end of the material collection box is provided with a drawing plate discharging device; the lower end of the alignment box is provided with a turning plate discharging device. According to the soft bag material alignment and packing work station machine, the structure is simple, the occupied area is small, the arrangement is convenient, the mechanical performance is stable, the automatic control is achieved, the production operation can be continuous, the operation time is greatly saved, the production efficiency is significantly improved, the unmanned production is achieved, and the labor productivity can be greatly saved.

Owner:DALIAN JIALIN EQUIP MFG

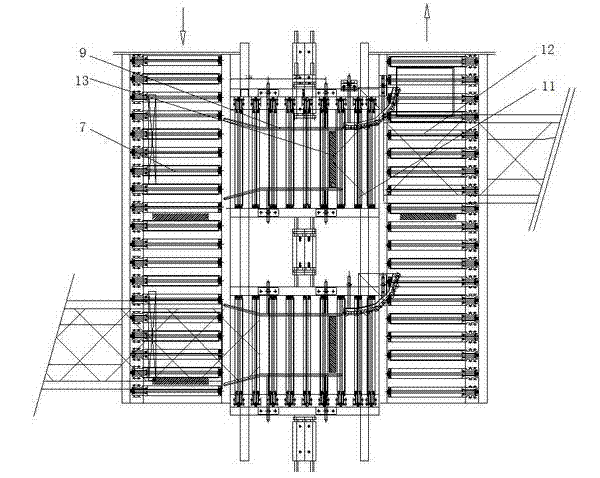

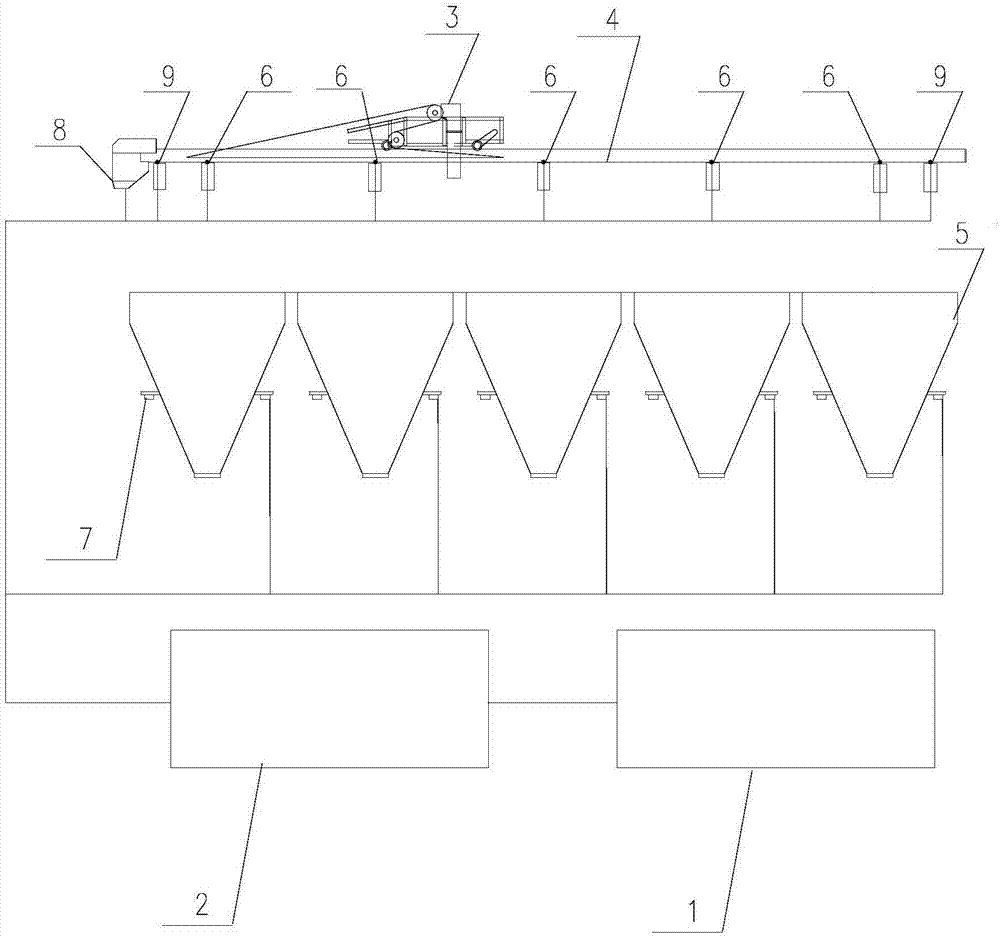

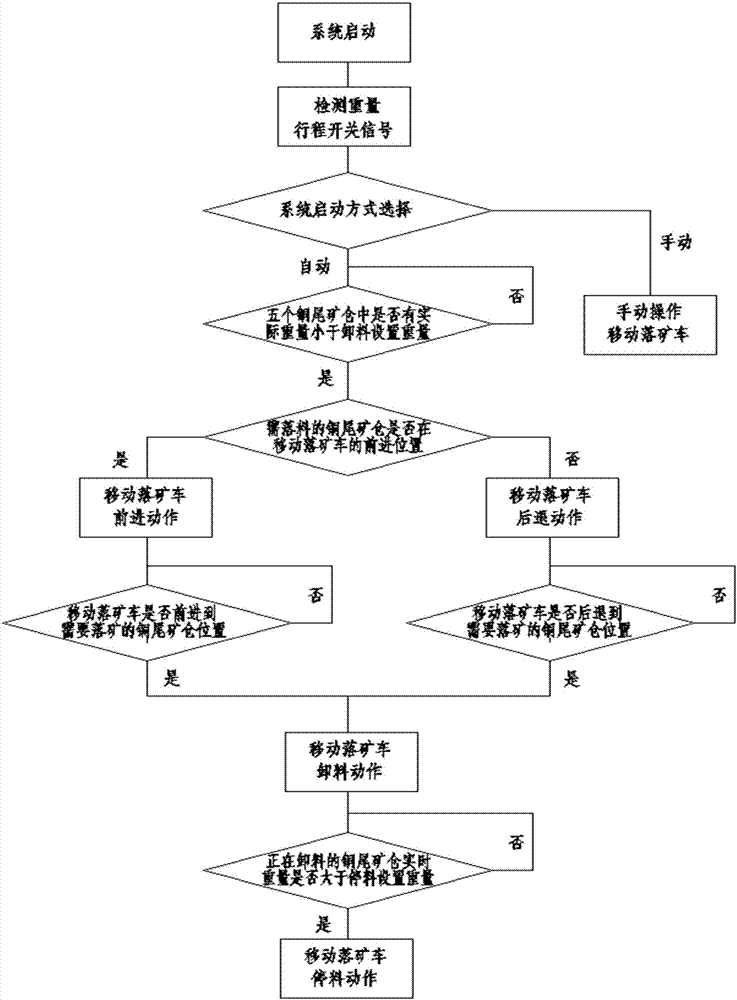

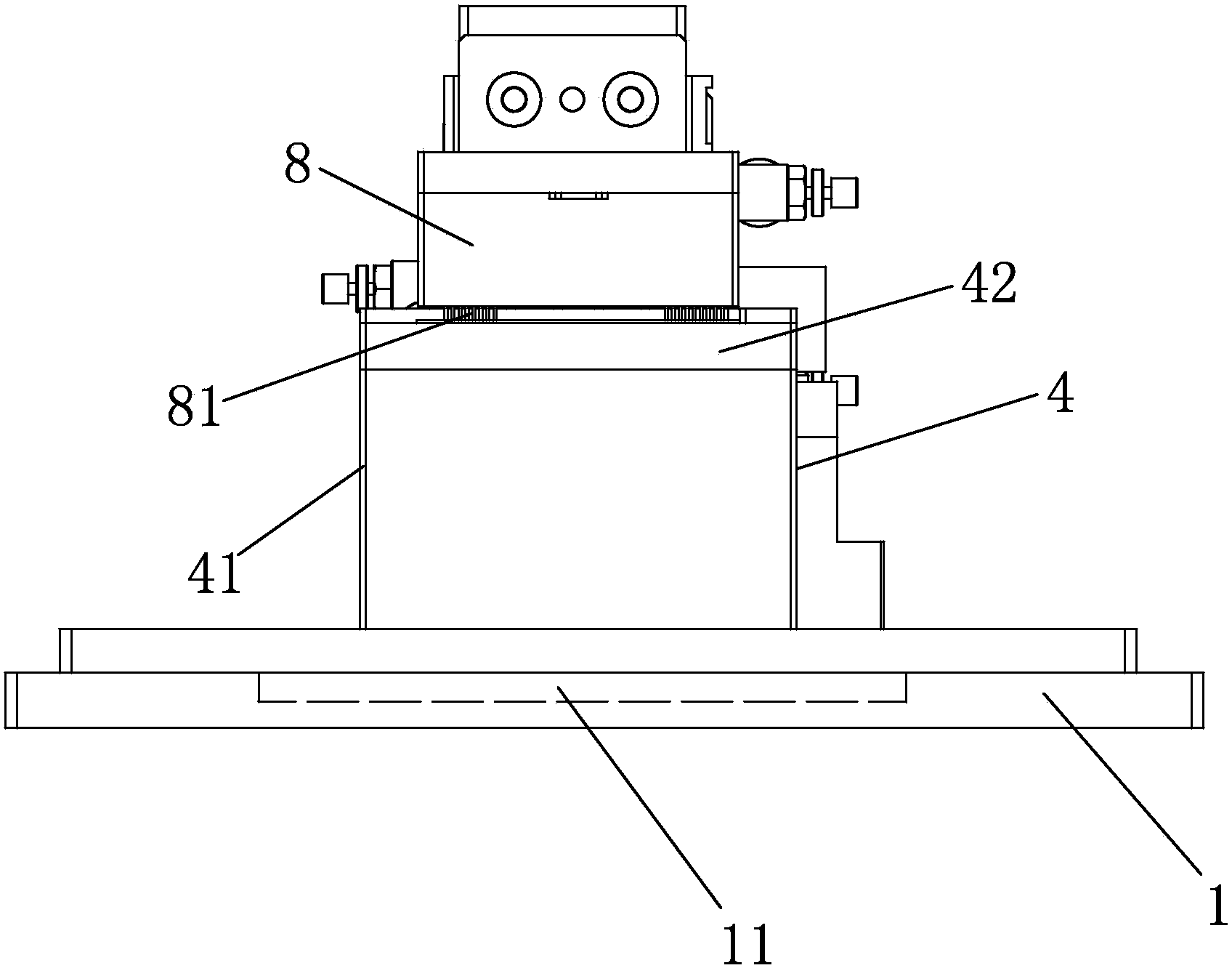

Automatic dropping control system and control method for mobile ore dropping vehicle

PendingCN107381086ATime-consuming and labor-intensive solutionEasy to operateLarge containersLoading/unloadingHuman–machine interfaceProgrammable logic controller

The invention discloses an automatic dropping control system and a control method for a mobile ore dropping vehicle. The automatic dropping control system comprises a human-computer interface, a PLC (Programmable Logic Controller), the mobile ore dropping vehicle, a rail, ore pockets, travel switches and weighing sensors, wherein the ore pockets are distributed in a straight line; the rail is arranged above the ore pockets; the travel switches are arranged on the rail; one travel switch corresponds to one ore pocket; the distance between each two adjacent travel switches is not larger than the length of the mobile ore dropping vehicle; the weighing sensors are arranged on the peripheries of the ore pockets; and the PLC is used for receiving signals of the travel switches and the weighing sensors, marking the ore pockets to be dropped, sending moving, dropping and stopping commands to the mobile ore dropping vehicle, and displaying a detection status on the human-computer interface. According to the automatic dropping control system and the control method for the mobile ore dropping vehicle provided by the invention, the PLC is utilized for automatically controlling the mobile ore dropping vehicle, the operation is carried out simply and conveniently, the problem that the loss is generated due to process interruption caused by manual operation negligence such as forgetting supplementary is solved, the production need is met, the manpower resource is saved, the manless production is realized, and an automatic mode and a manual mode can be selected for use according to the needs.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

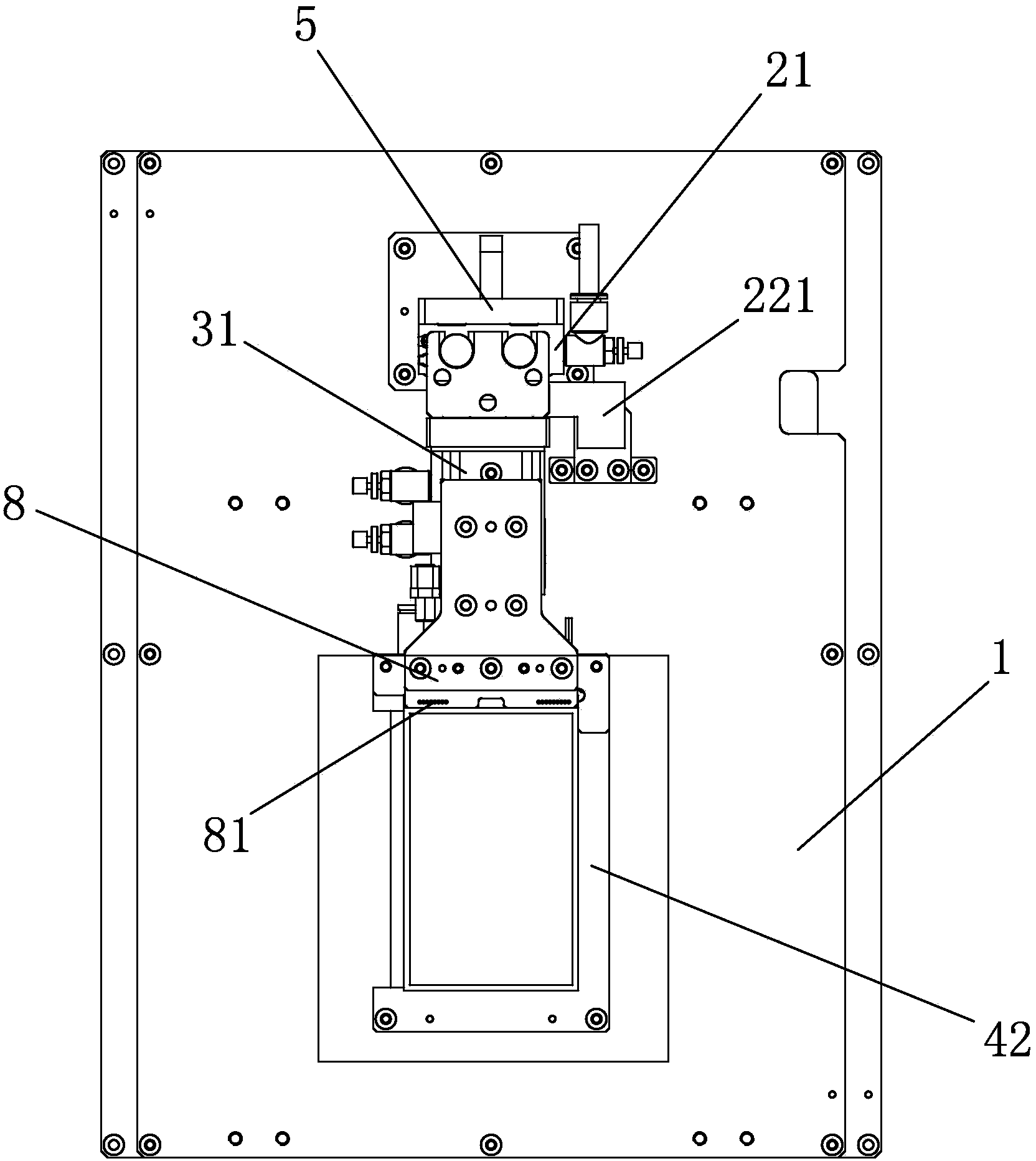

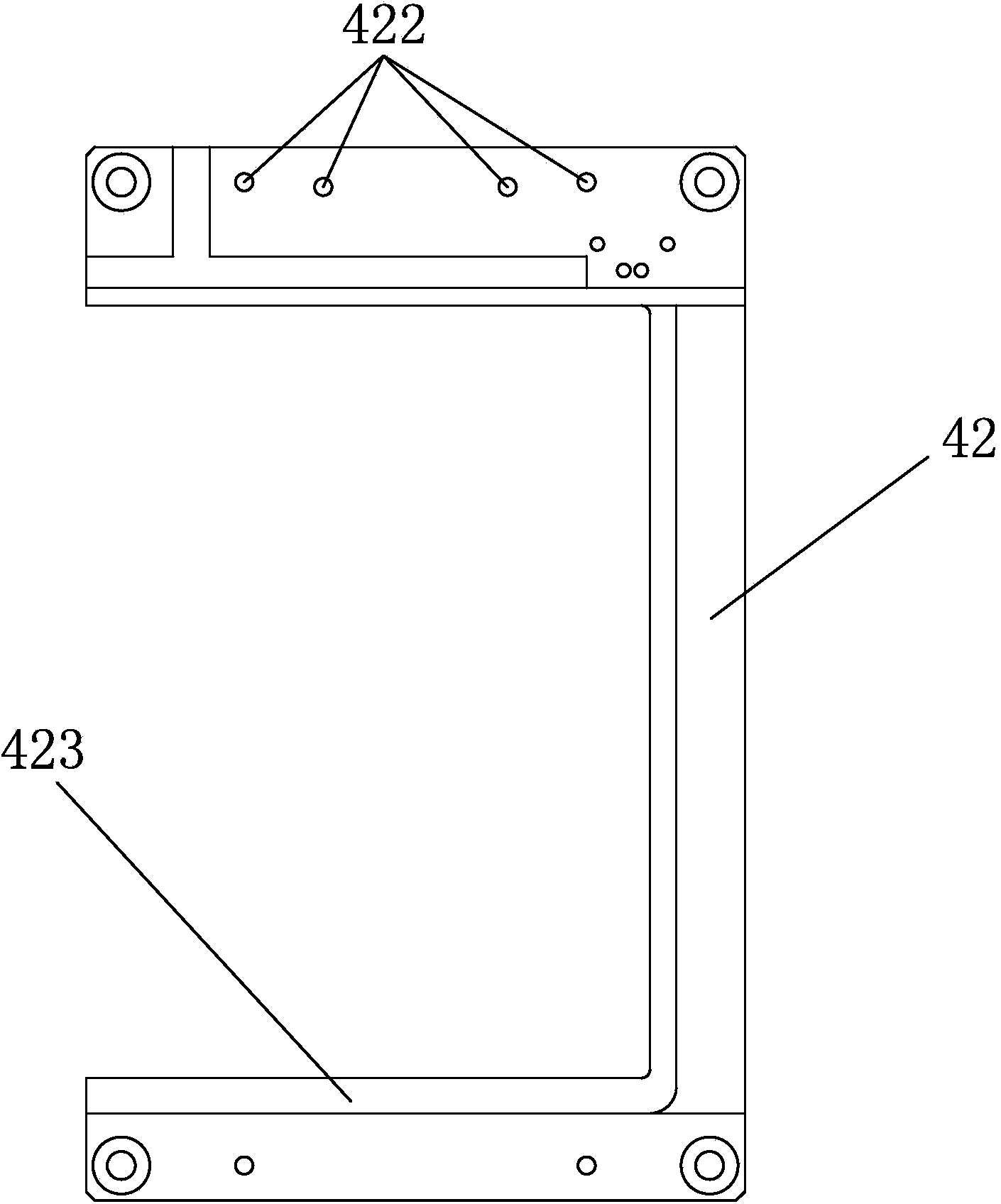

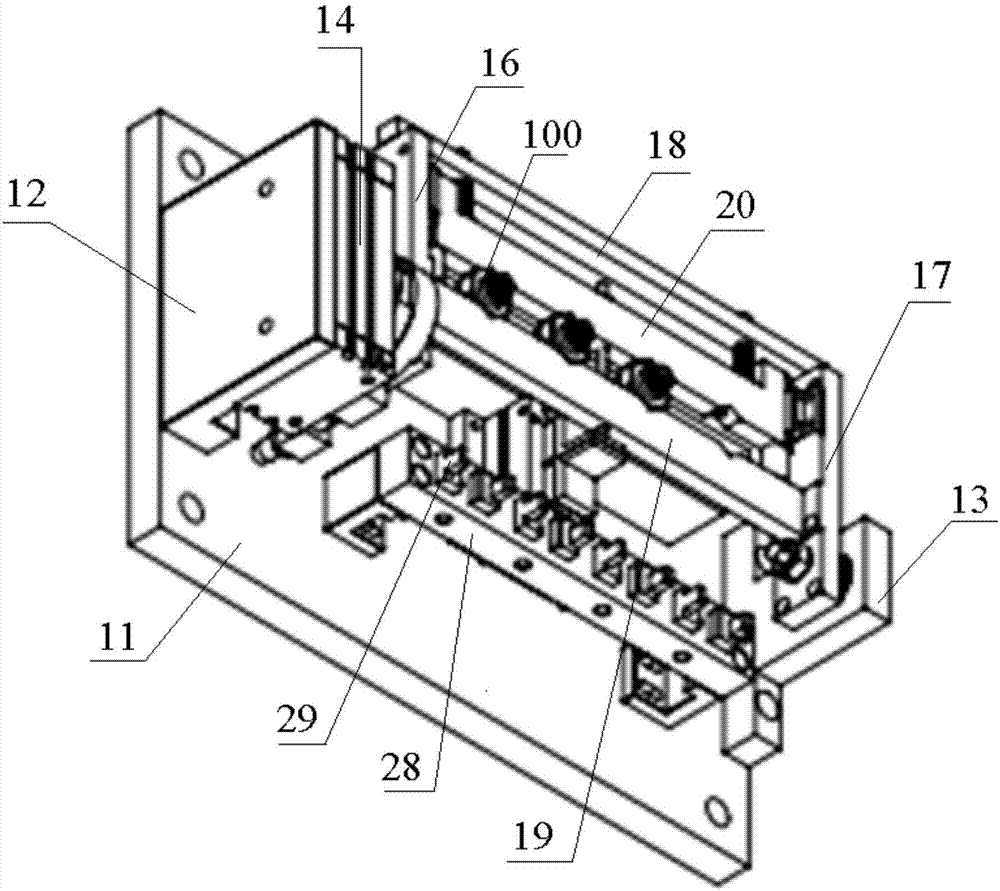

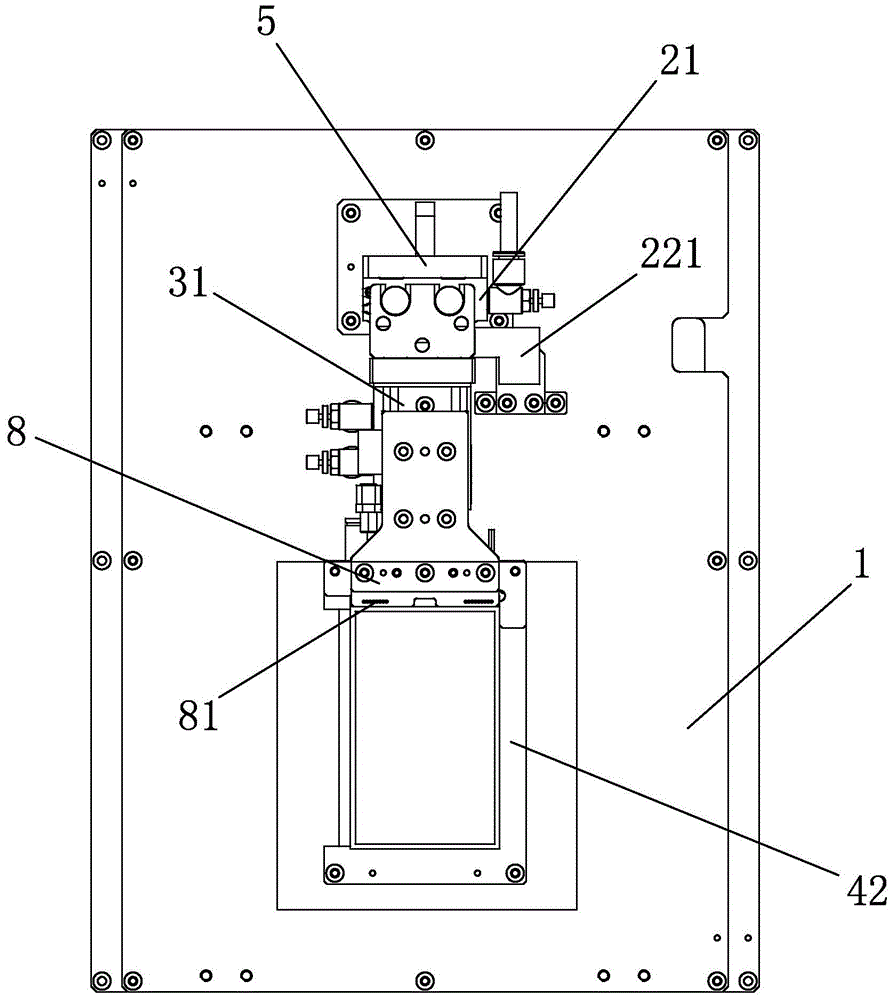

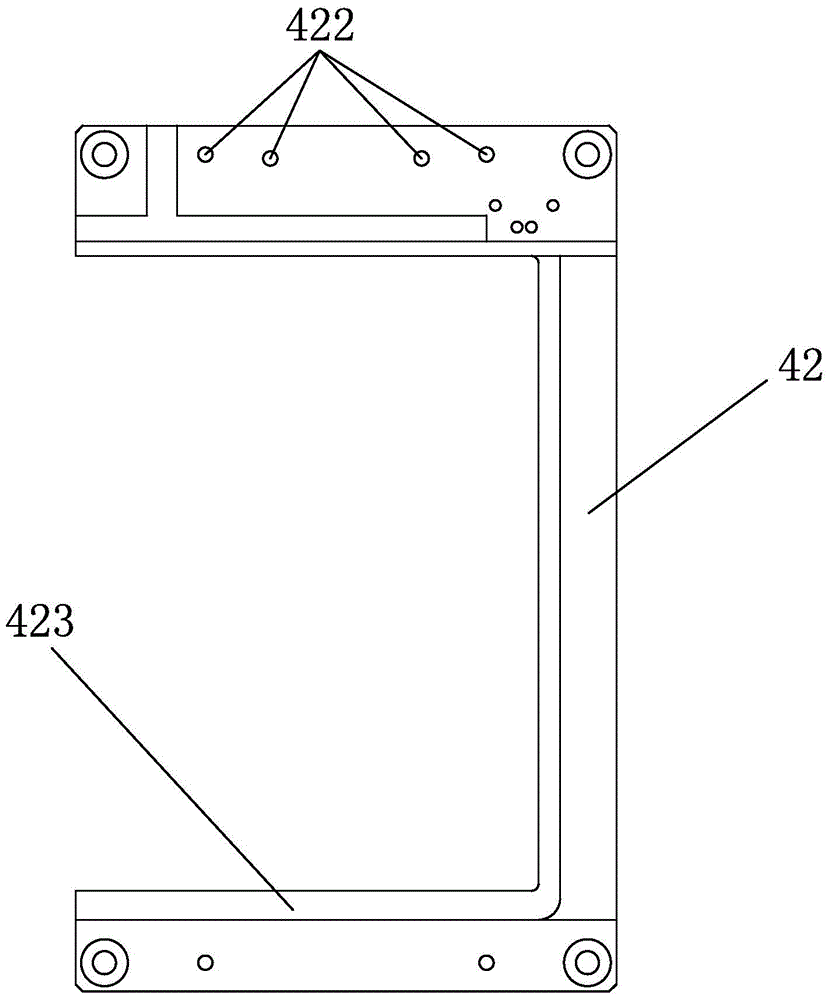

Automatic pressure connecting testing device for liquid crystal display panels

ActiveCN104076217AAvoid damageReduce repetitive mechanical laborElectrical testingLiquid-crystal displayLiquid crystal

The invention discloses an automatic pressure connecting testing device for liquid crystal display panels. The automatic pressure connecting testing device comprises a base plate, a vertical air cylinder, a horizontal air cylinder and a supporting frame for containing the liquid crystal display panels to be tested; fixed parts of the supporting frame and the vertical air cylinder ate respectively and fixedly arranged on the plate face of the base plate; a fixed part of the horizontal air cylinder is fixedly arranged on a sliding part of the vertical air cylinder through a fixed support; the horizontal air cylinder can move up and down in the vertical direction along with the sliding part of the vertical air cylinder; a pressing head is arranged at the front end of a sliding part of the horizontal air cylinder, and probes electrically connected testing ends on the liquid crystal display panels to be tested are arranged on the pressing head; backlights are arranged at the position, corresponding to the liquid crystal display panels to be tested in position in a matched mode, of the base plate. By means of the automatic pressure connecting testing device, automatic pressure connecting can be achieved, repeated mechanical labor of workers is greatly reduced, and the production efficiency is improved; when the liquid crystal display panels to be tested are taken from or placed on the supporting frame in the testing device, damage caused when the liquid crystal display panels to be tested are taken or placed can be effectively reduced.

Owner:SUZHOU HUAXING YUANCHUANG TECH CO LTD

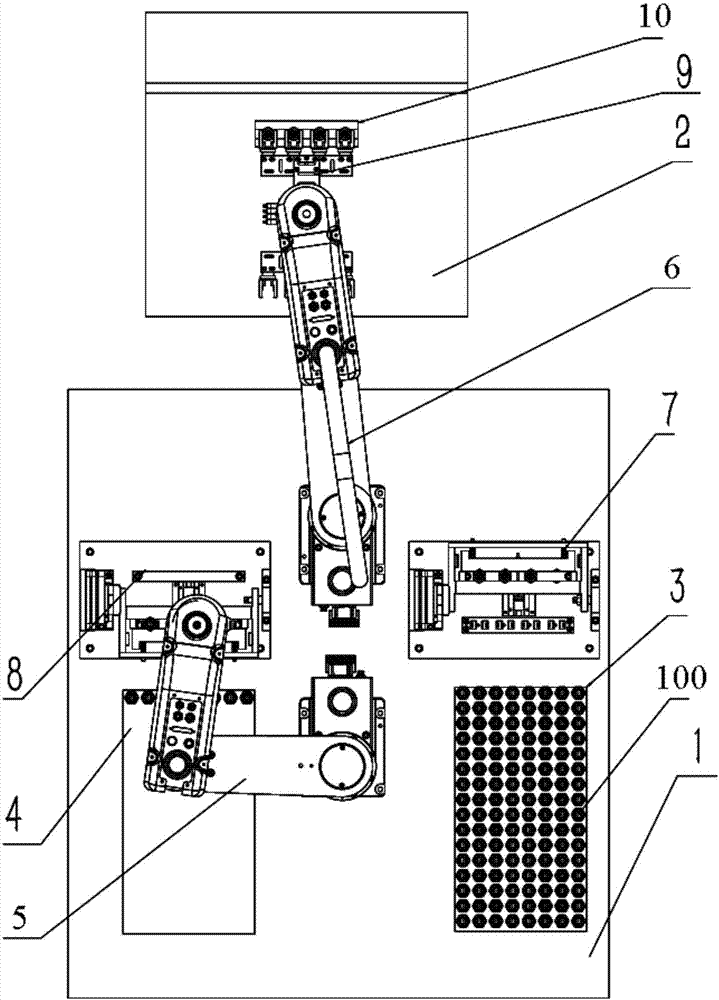

Automatic feeding and discharging work station of automobile sensor robot

PendingCN107263507ALow costReduce manufacturing costWork benchesManipulatorEngineeringInstalled base

The invention discloses an automatic loading and unloading workstation for an automotive sensor robot, which includes a robot installation base, a detection platform, a first robot, a second robot, an extraction tray for materials to be inspected, an extraction tray for inspected materials, an overturning platform for loading materials, and an overturning for unloading materials platform, the robot installation base and the detection platform are arranged in tandem; the inspection platform is provided with inspection platform fixtures; the first robot and the second robot are arranged in tandem on the robot installation on the base; the extraction tray to be inspected, the extraction tray that has been inspected, the loading and unloading turnover table are respectively fixed on the robot installation base; the end of the first robot and the end of the second robot are respectively There is a jaw mechanism. The automatic loading and unloading workstation of the automobile sensor robot of the present invention can realize automatic detection of automobile sensors, realize unmanned production, reduce detection cost, improve detection process safety, and improve product consistency.

Owner:上海诺银机电科技有限公司

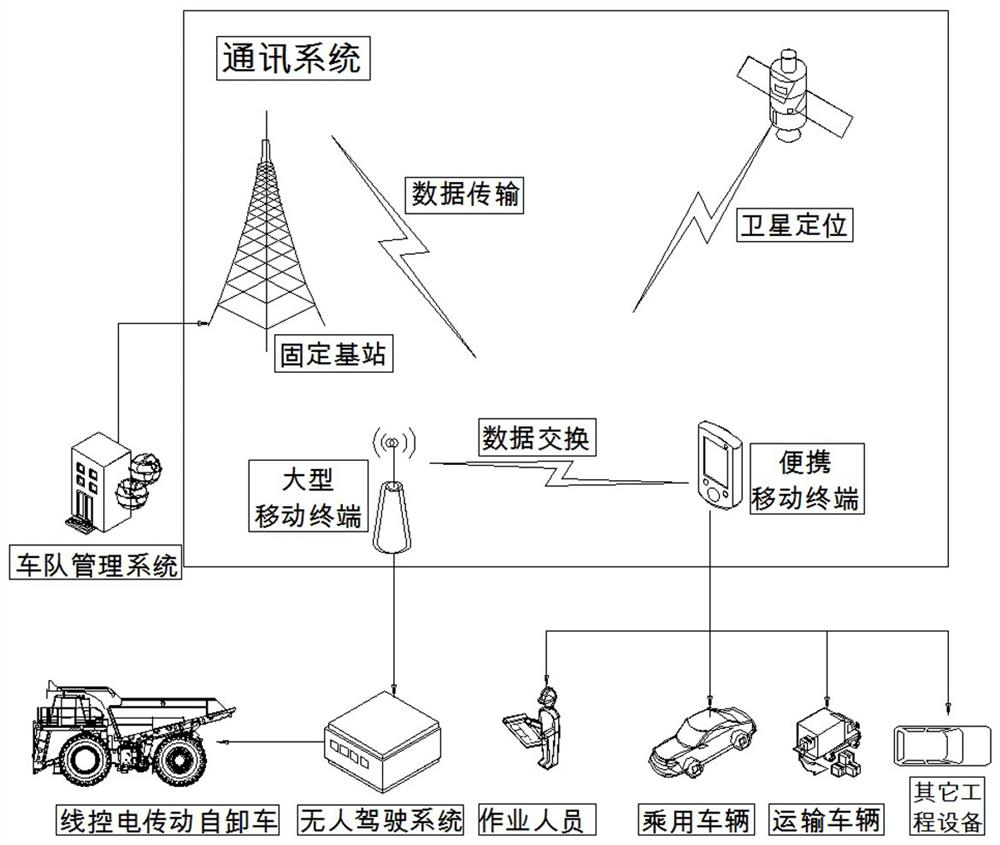

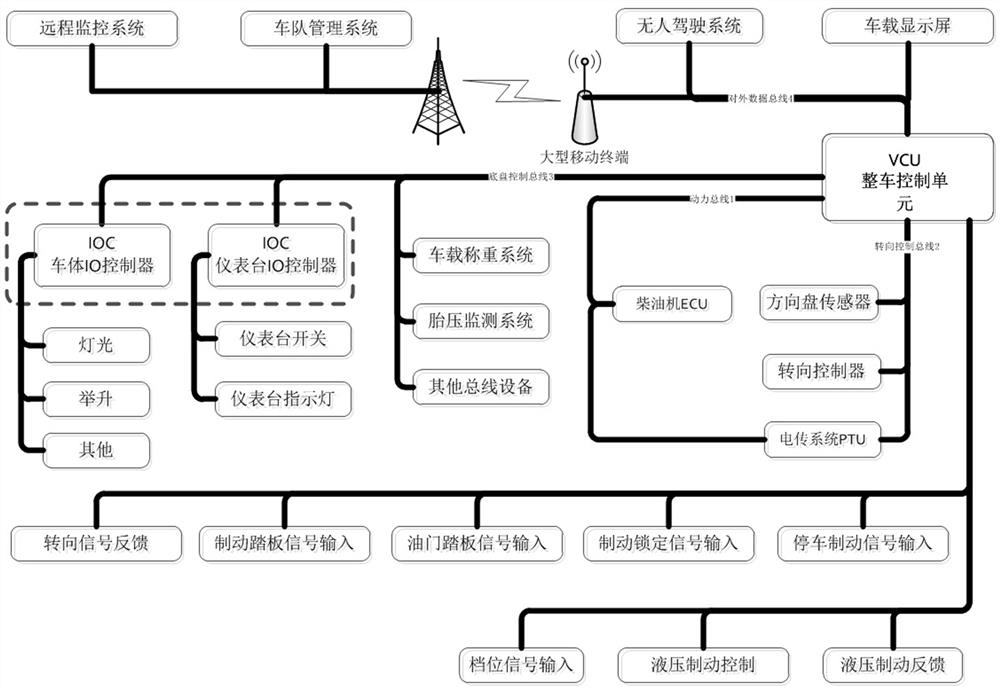

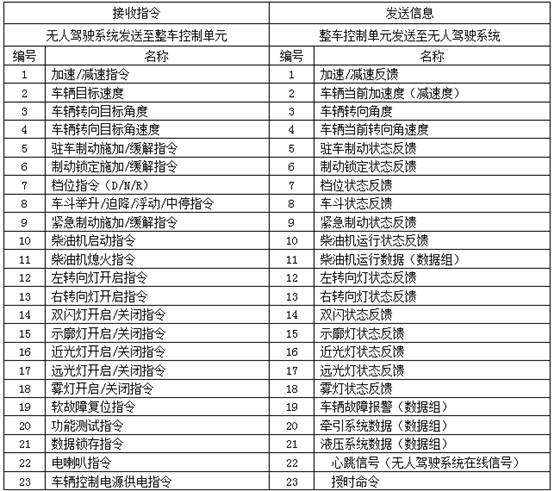

Unmanned mining electric transmission dump truck

PendingCN111913477AImprove mine productivityReduce mine production costsElectric testing/monitoringBus networksElectric driveFleet management

An unmanned mining electric drive dumper comprises a mining electric drive dumper body and is characterized by further comprising: a fleet management system used for mine car production management andmining area map construction and updating; a communication system which is used for information interaction between vehicles and fleet management systems, between vehicles, between vehicles and production equipment, and between vehicles and production workers, and has a positioning function; an unmanned driving system which is used for sensing the ground environment, updating a mining area map, planning a driving path and controlling the action of the vehicle; and a drive-by-wire system which can control acceleration, steering, deceleration, lifting and sound-light signal sending of the vehicle according to the control instruction. By means of the system, unmanned production of the strip mine transportation system can be achieved, the mine production efficiency can be improved, the mine production cost can be reduced, and mine safety accidents can be reduced.

Owner:湖南湘电绿能智控有限公司

Automatic beverage machine

PendingCN110718020ARealize unmanned productionReduce labor costsBeverage vesselsApparatus for dispensing fluids/granular materialsFructoseLiquid level measurement

The invention provides an automatic beverage machine. The beverage machine comprises a case, wherein a cup drop system, a lemon cutting system, a rotation quantitative sauce output system, a quantitative fructose output system, a quantitative powder output system, a quantitative tea output system, a liftable stirring system, a quantitative ice block output system, a quantitative milk discharging system, a quantitative cover output system, a quantitative water output system, a liftable liquid level measurement system, a quantitative bubbly water output device, a cup sealing system, a cup feeding system, a cover outlet system and a straw outlet system are arranged in the case, and the automatic beverage machine also comprises a beverage selection system and a payment system. In the beveragemachine, all operation of cup drop, lemon slice discharging, sauce discharging, fructose discharging, powder discharging, stirring, ice block discharging, milk discharging, cover discharging, water discharging, liquid level measurement, bubbly water discharging, cup sealing and cover outlet are completed through controlling corresponding systems by a controller according to selection of a client,and unmanned fabrication of beverage is achieved, and the labor cost is greatly reduced.

Owner:刘林林

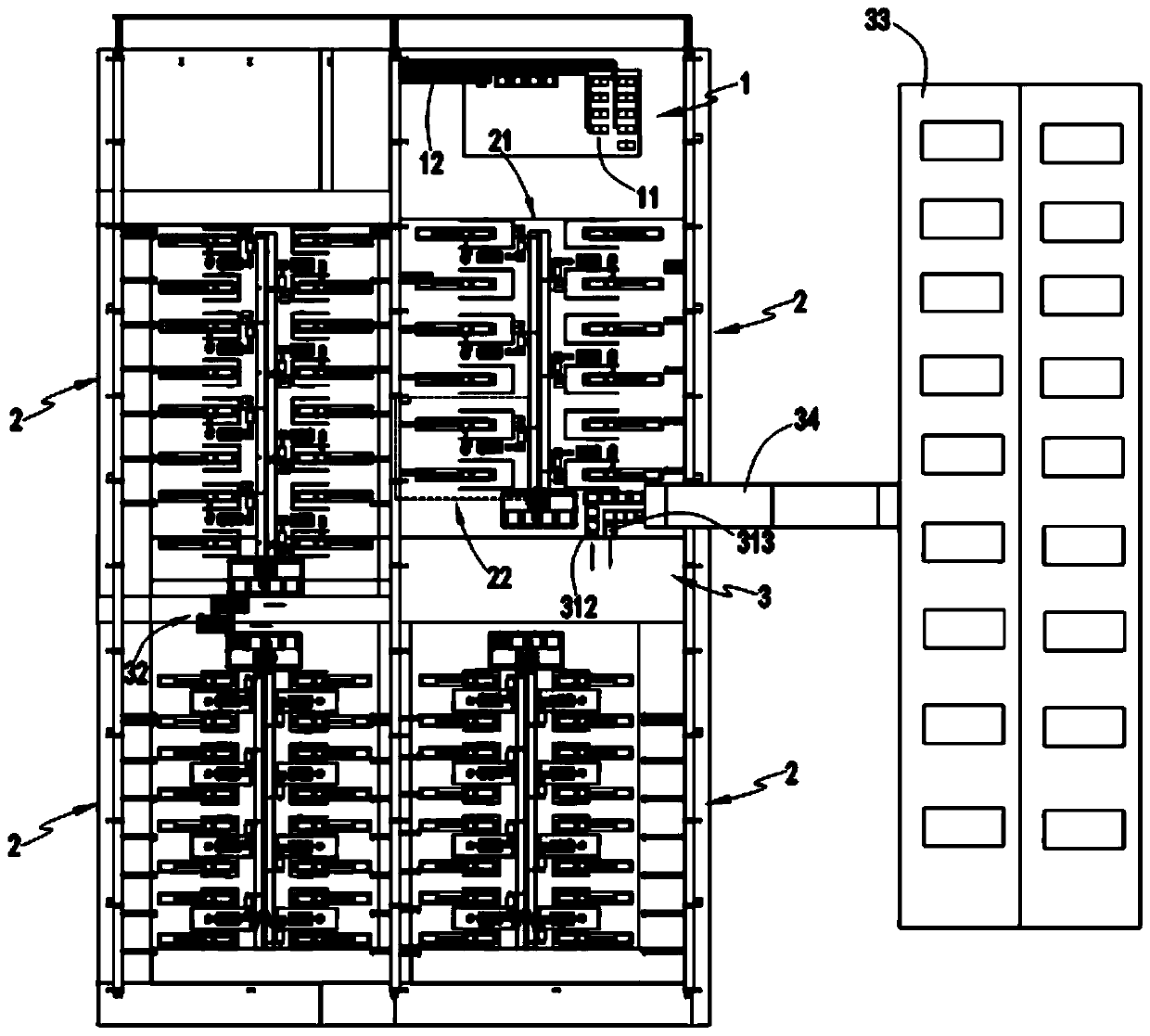

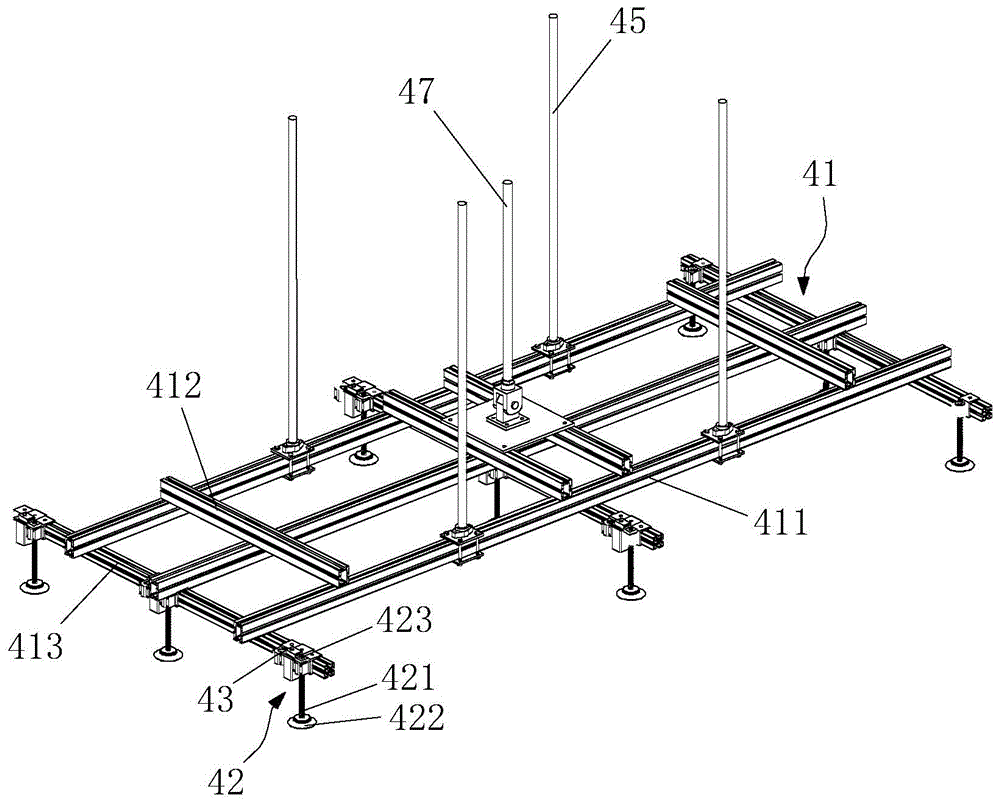

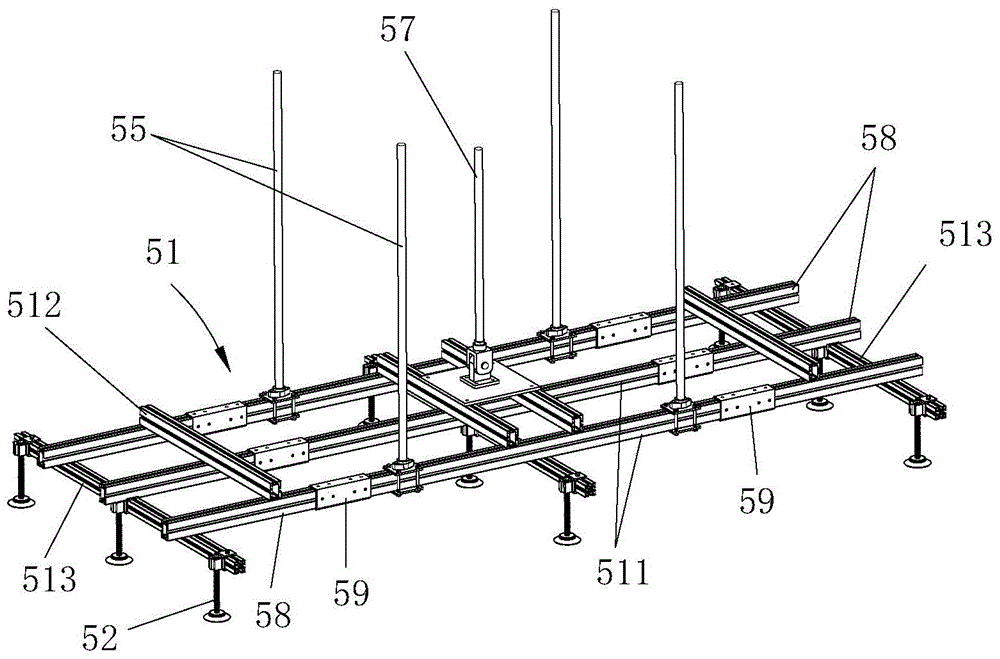

Stator lamination stacking workbench

InactiveCN102306981AGuaranteed accuracyLift automaticWork benchesManufacturing stator/rotor bodiesBall screwCoupling

The invention discloses a stator lamination stacking workbench, which comprises a stacking platform body, a stacking workbench tabletop and a plurality of positioning rods. The workbench further comprises a positioning device. The positioning device comprises a transmission device driven by a servo motor, a lifting bracket vertically provided with linear guide rails and an annular lifting plate supported by the lifting bracket. By the stator lamination stacking workbench, power is provided by the servo motor and transmitted by a precision reducer, a servo special coupling, a precision steering gear and a precision ball screw, and action guidance is performed by the linear guide rails to realize the accurate positioning of the positioning rods, thereby realizing the automation of stator lamination stacking operations, reducing cost and improving production efficiency.

Owner:SHANGHAI FANUC ROBOTICS

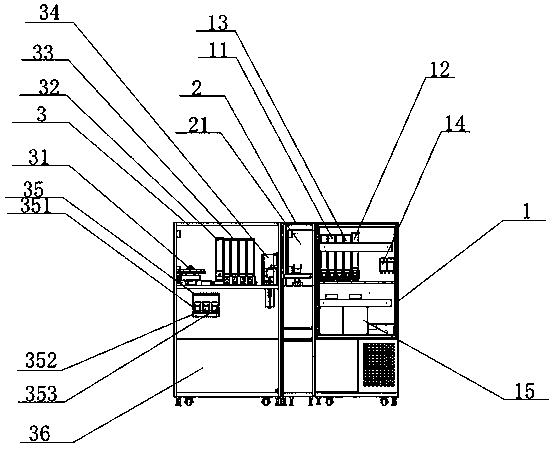

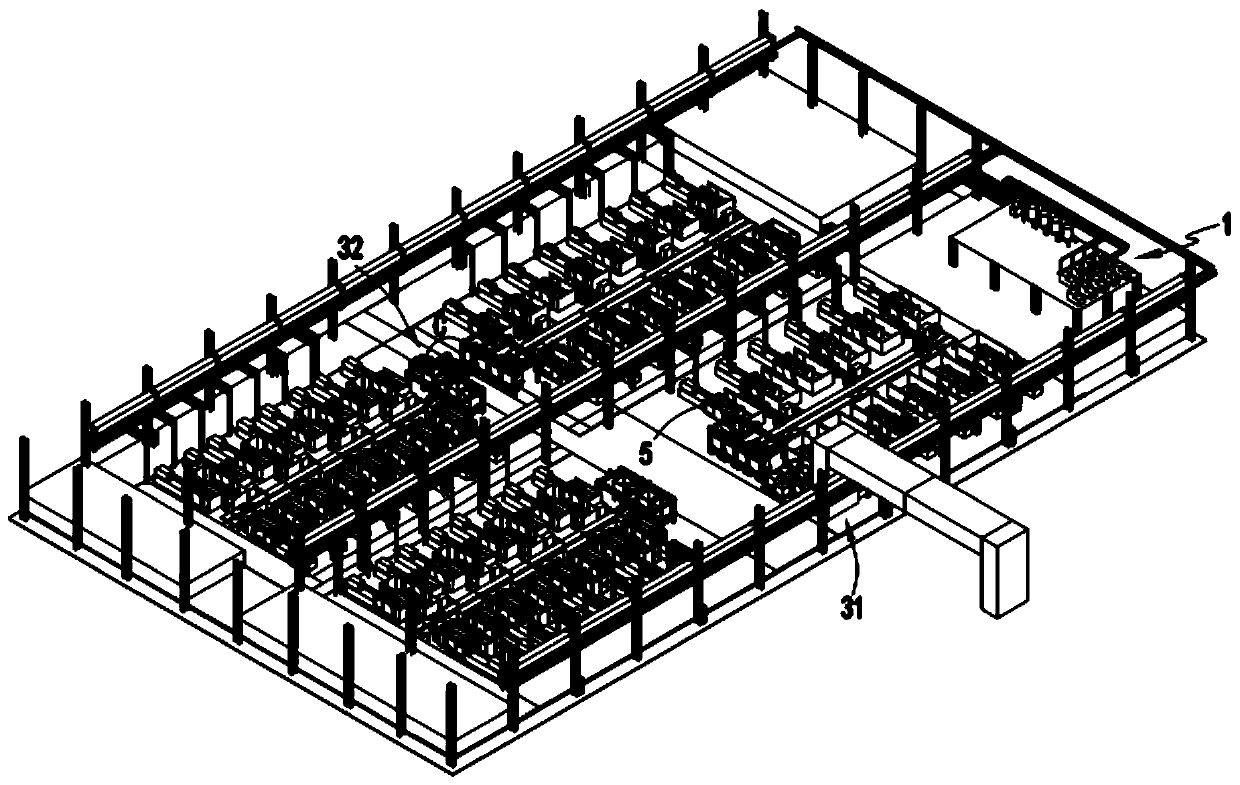

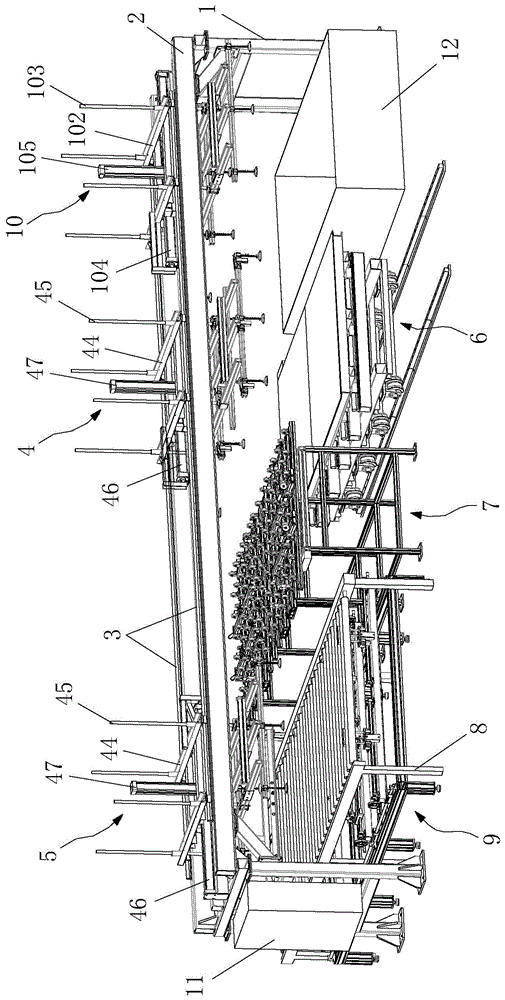

Unmanned intelligent production system with multiple production lines for battery plastic housings

PendingCN110182421AImprove packaging efficiencyImprove output efficiencyWrappingPackaging automatic controlProduction lineElectrical battery

The invention relates to an unmanned intelligent production system with multiple production lines for battery plastic housings. The unmanned intelligent production system with the multiple productionlines for the battery plastic housings comprises a feeding part, multiple production parts and a transferring part, wherein the feeding part is used for concentratedly feeding raw materials for the production parts; the transferring part comprises an in and out device and multiple transferring devices; multiple battery boxes which are automatically processed and formed, trimmed, detected and removed with defectives through the production parts are sequentially and automatically stacked into packaging boxes one by one through packaging devices correspondingly matched with the production parts,and the fully stacked packaging boxes are conveyed to the in and out device through the transferring devices so as to be automatically transferred to the next working procedure; and meanwhile, the transferring devices load the empty packaging boxes on the in and out device and transfer the packaging devices requiring the empty packaging boxes. The unmanned intelligent production system with the multiple production lines for the battery plastic housings provided by the invention solves the problems that a battery box production workshop is low in production efficiency, high in labor intensity,poor in workshop environment so as to influence the product quality, and low in automation degree.

Owner:德玛克(浙江)精工科技有限公司

Full-automatic paper box capping machine

PendingCN111716813AReduce labor intensityRealize unmannedPaper-makingBox making operationsMolding machineMechanical engineering

The invention discloses a full-automatic paper box capping machine. The full-automatic paper box capping machine comprises a box piece storage mechanism, a box body forming mechanism, an iron cover storage mechanism, an iron cover taking and pressing mechanism, a paper box feeding mechanism, a conveying belt and a machine frame and is characterized in that (1) the box piece storage mechanism is arranged, namely, a large number of box pieces are stored at a time, and the box body forming mechanism automatically pulls the box pieces into square box bodies; (2) the paper box feeding mechanism isarranged, and namely, the formed square box bodies are transferred to the position below the iron cover taking and pressing mechanism; (3) the iron cover storage mechanism is arranged, namely, a largenumber of iron covers are stored at a time, and the iron cover taking and pressing mechanism automatically takes out the iron covers and turns over downwards by 90 degrees to be pressed on the squarebox bodies; (4) the feeding mechanism continues to transfer the pressed paper boxes to the conveying belt to be conveyed out, the whole working process is completed, (5) the whole process is in full-automatic mechanical line production, unmanned production is achieved, the working efficiency is high, the labor intensity of workers is relieved, defective goods are reduced, and the product qualityis improved.

Owner:SHENZHEN FAME AUTOMATION EQUIP

Special manipulator for producing shoe heels

InactiveCN102672885ARealize unmanned productionHigh speedDomestic articlesElectronic control systemEngineering

The invention belongs to a special manipulator for producing shoe heels. The special manipulator mainly comprises an electronic control system, an arm drawing device, an arm and a pin box. The special manipulator has the main advantages that the manipulator is specially used for producing the shoe heels and can completely substitute for hands to complete the operations of loading insertion pins and taking out the finished shoe heels, thereby realizing unmanned production in an injection workshop; and by virtue of a biaxial servo drive mode, the speed and efficiency are high, and the action is accurate. According to the special manipulator, the time of in-mould operation can be controlled to be within 2 seconds, and the whole cycle time can be controlled to be within 4 seconds; the accuracy of machine adjustment can reach up to 0.01mm; and the repeatability precision of machine operation is controlled to be within 0.03mm. The special manipulator is rational in integral structure design and convenient and efficient to adjust, can be applicable to the production of all shoe heel products on the market, is high in safety performance in use, and adopts more than ten induction detection switches to perform synchronous detection on each position of product operation so as to ensure operation security.

Owner:佛山市南海区川一精密机械有限公司

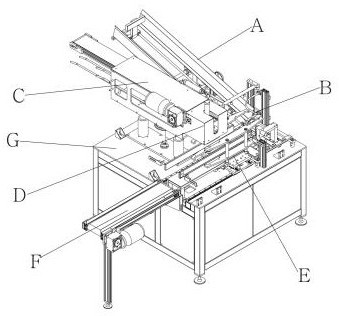

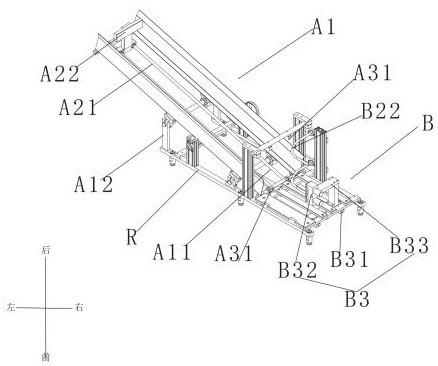

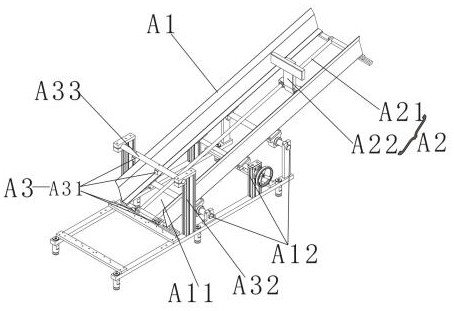

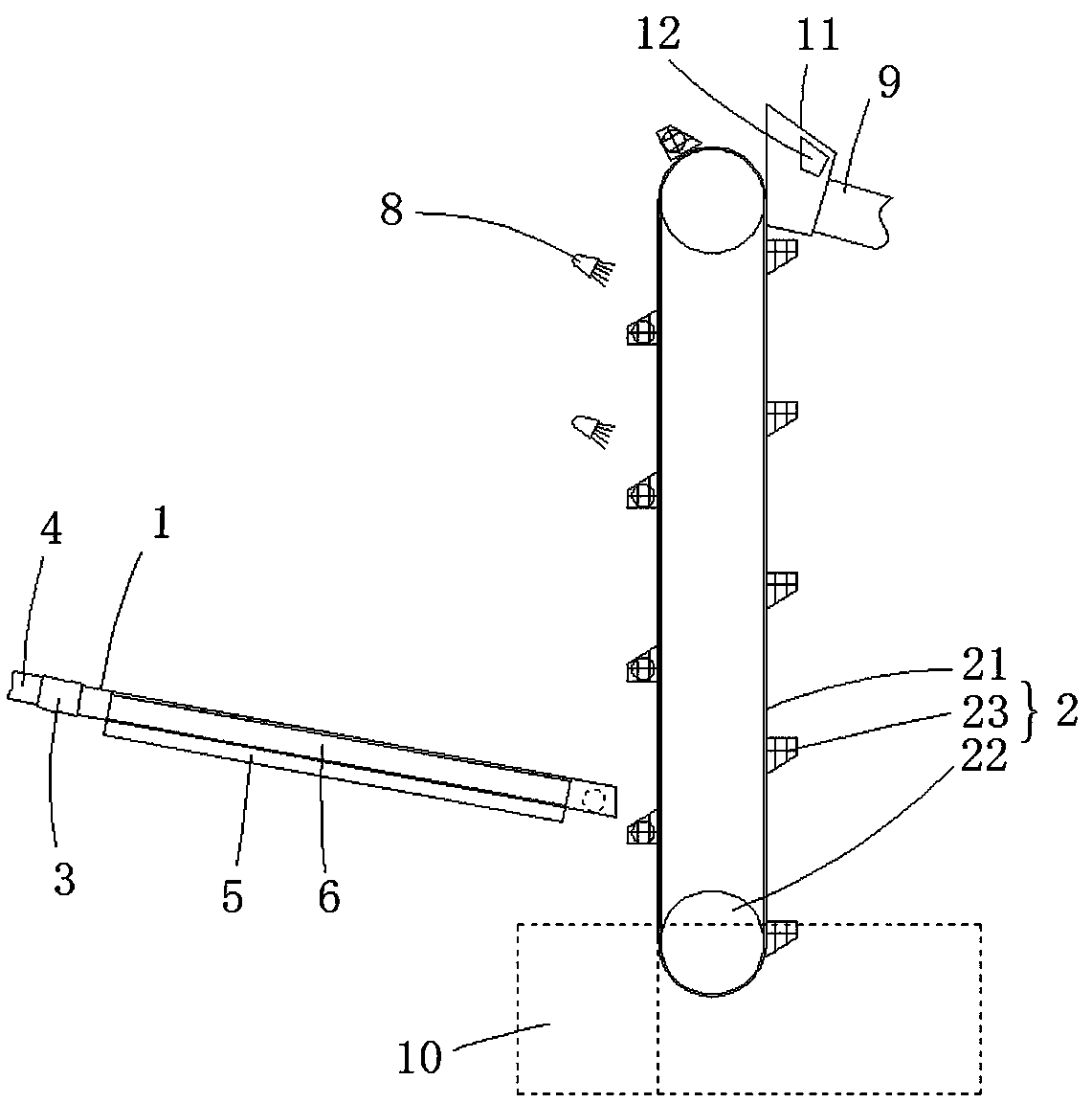

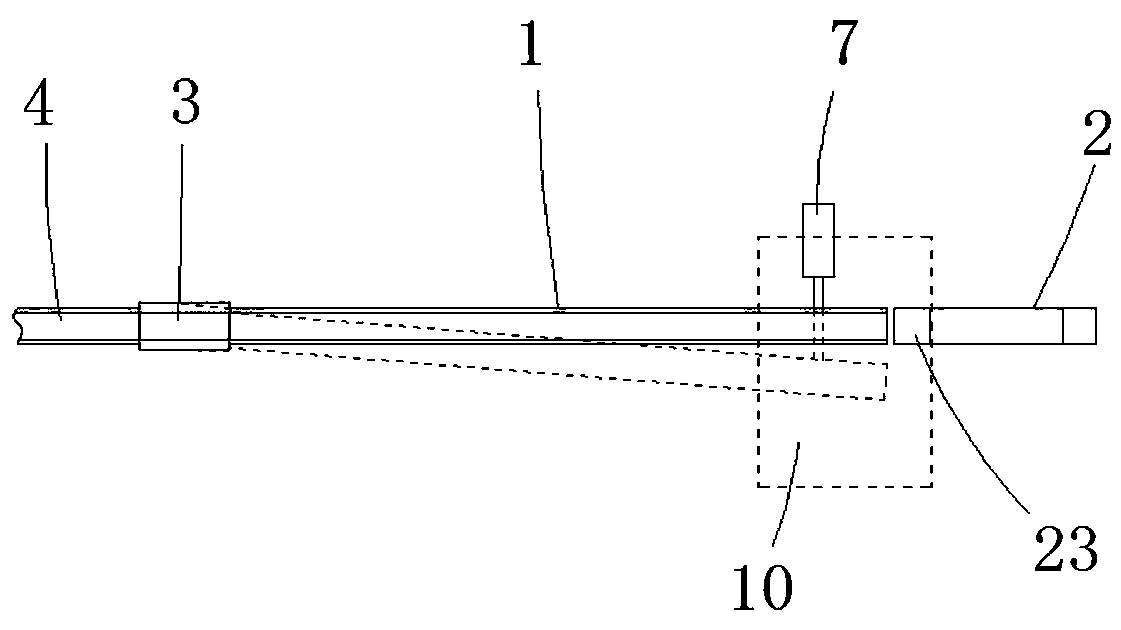

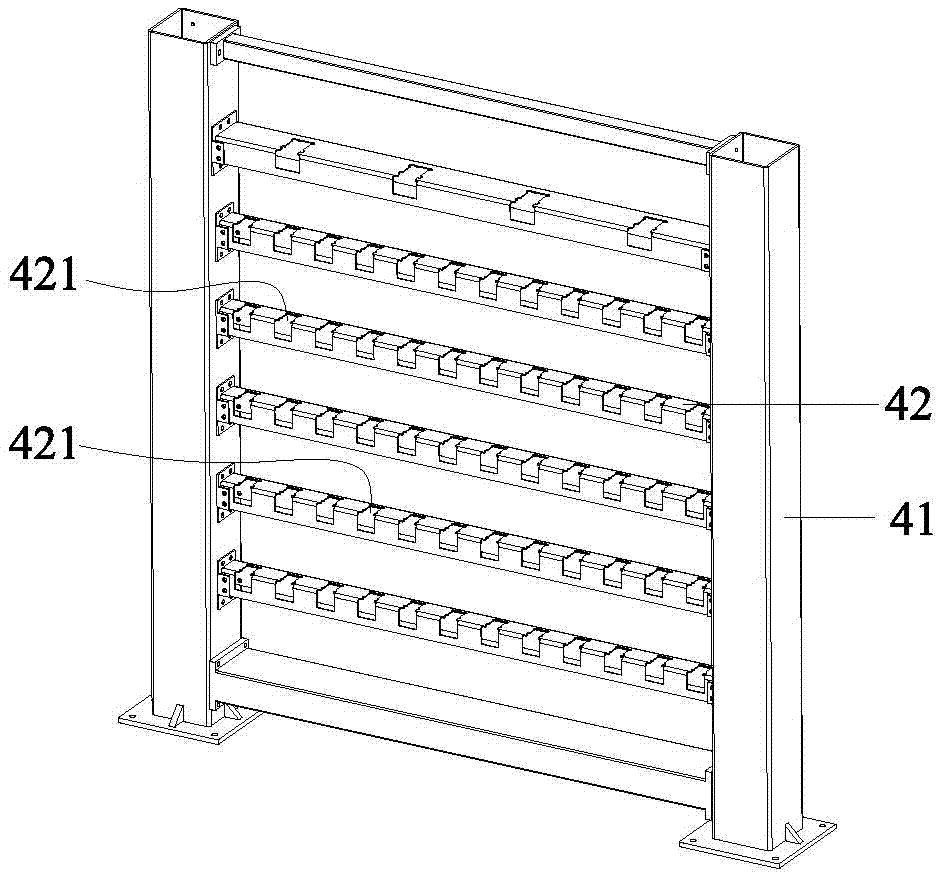

Full-automatic assembly machine with three groups of cover boards for flat plate collector

InactiveCN104353981ARealize unmanned productionIncrease productivityMetal working apparatusMetal-working hand toolsPaper sheetCollector device

The invention discloses a full-automatic assembly machine with three groups of cover boards for flat plate collectors. The full-automatic assembly machine comprises a rack, a first lead rail, an adjustable cover board grabbing mechanism, an adjustable cover board assembly mechanism, a partition paper grabbing mechanism, an adjustable cover board loading car, an adjustable cover board positioning mechanism and an adjustable border positioning mechanism, wherein the adjustable cover board grabbing mechanism descends to grab cover boards on the adjustable cover board loading car one by one, and places the cover boards on the adjustable cover board positioning mechanism for positioning along the first lead rail; the partition paper grabbing mechanism moves to the position above the adjustable cover board loading car along the first lead rail, and descends to grab partition papers between the grabbed cover boards and the lower cover board one by one; the adjustable cover board assembly mechanism moves to the position above the adjustable cover board positioning mechanism along the first lead rail, descends to grab the positioned cover boards and assemblies the cover boards to the border which is positioned into an assembly region of the adjustable border positioning mechanism along the first lead rail. The full-automatic assembly machine has the advantages of being high in assembly efficiency and high in capacity; the production cost can be lowered; the product is wide in specification adaptability.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

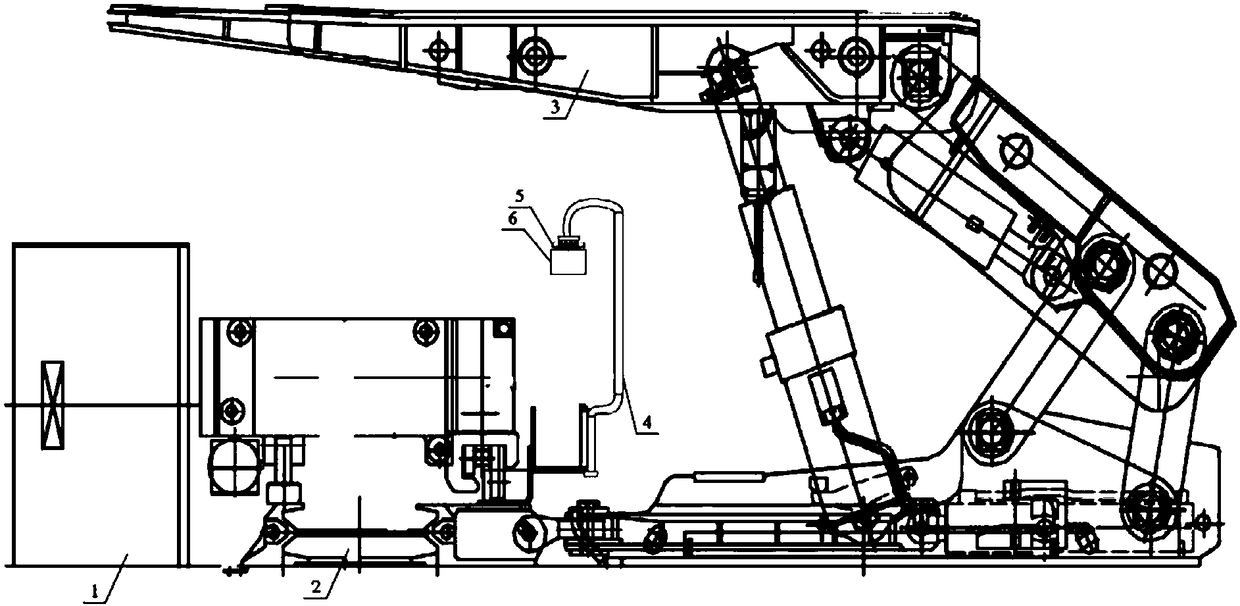

Appearance screening and cleaning integrated device for gears and work method of appearance screening and cleaning integrated device

InactiveCN108465650ASimple structureImprove work efficiencyDrying gas arrangementsCleaning using liquidsFace detectionChain structure

An appearance screening and cleaning integrated device for gears comprises a detection channel which is obliquely arranged, and a conveying chain structure which is vertically arranged. The detectionchannel is connected with a feeding port through a flexible piece, a tooth face detecting device is arranged at the bottom of the detection channel, end face detection devices are arranged on the twoside walls, and the detection channel is provided with a position changing drive device. The conveying chain structure comprises a circular movement chain, a set of chain wheels engaged with the chain, and a set of loading frames arranged on the chain, the chain wheels are connected with a chain wheel drive device, and the opening direction of the loading frames is consistent to the moving direction. The side, close to the detection channel, of the conveying chain structure is provided with a cleaning device, and a discharging channel is arranged at the upper end of the other side of the conveying chain structure. Tooth face and end face appearance detecting and screening and automatic qualified piece cleaning and unloading integrated actions are achieved, the integral structure is simple,the work efficiency is high, and the automation degree is high.

Owner:苏州聿知新机械科技有限公司

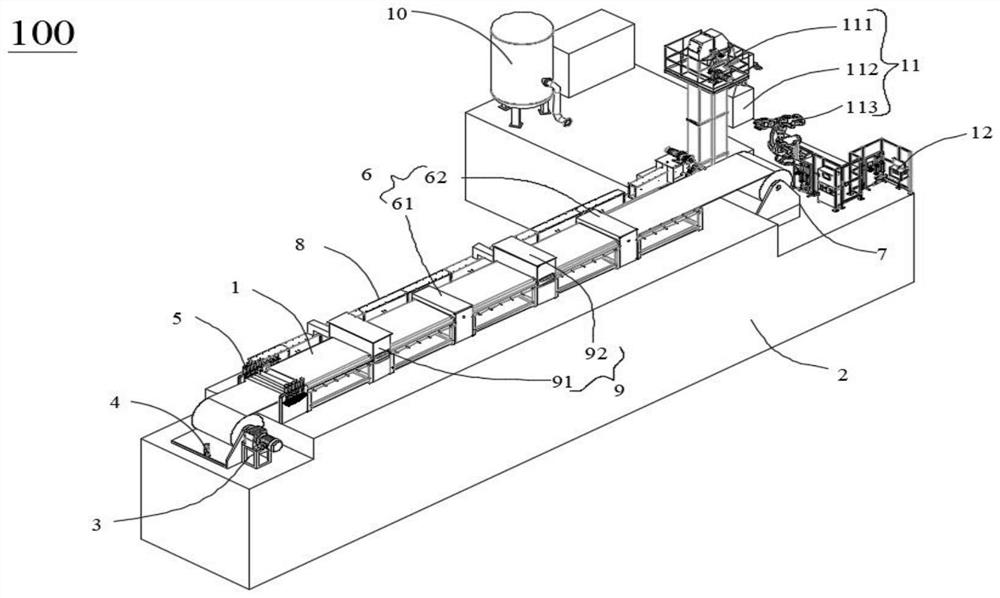

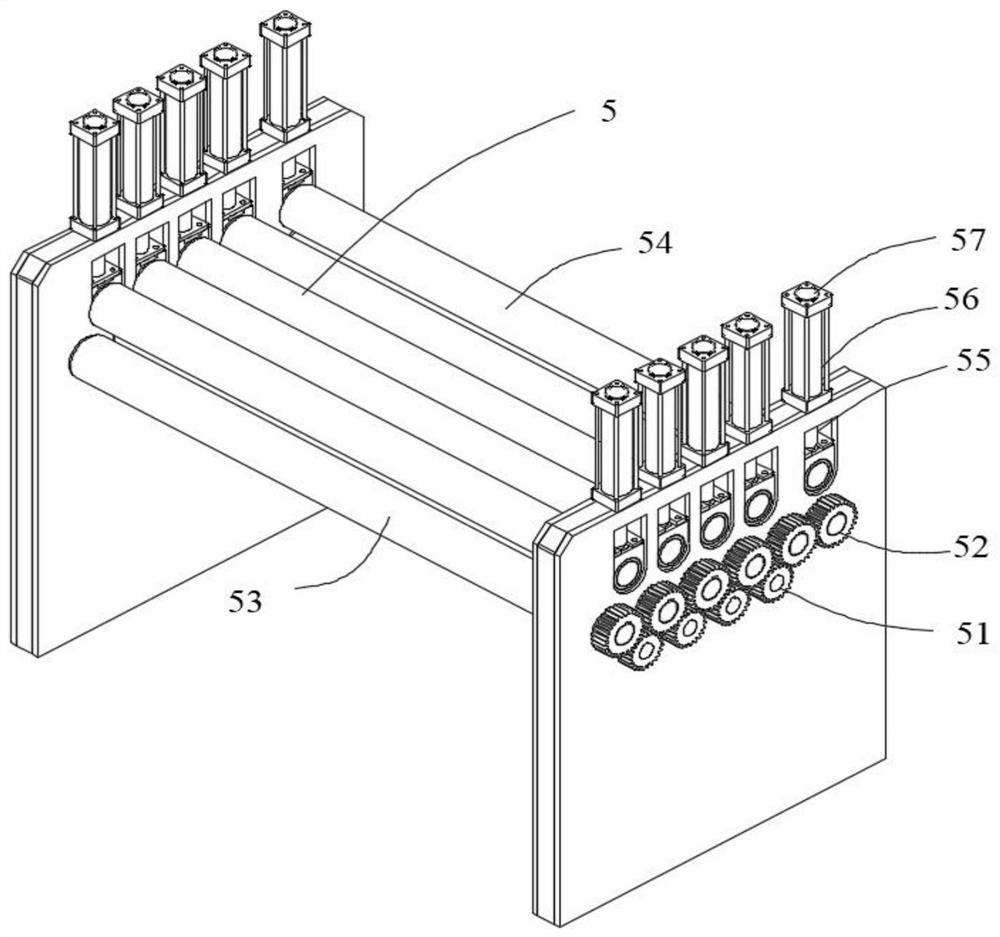

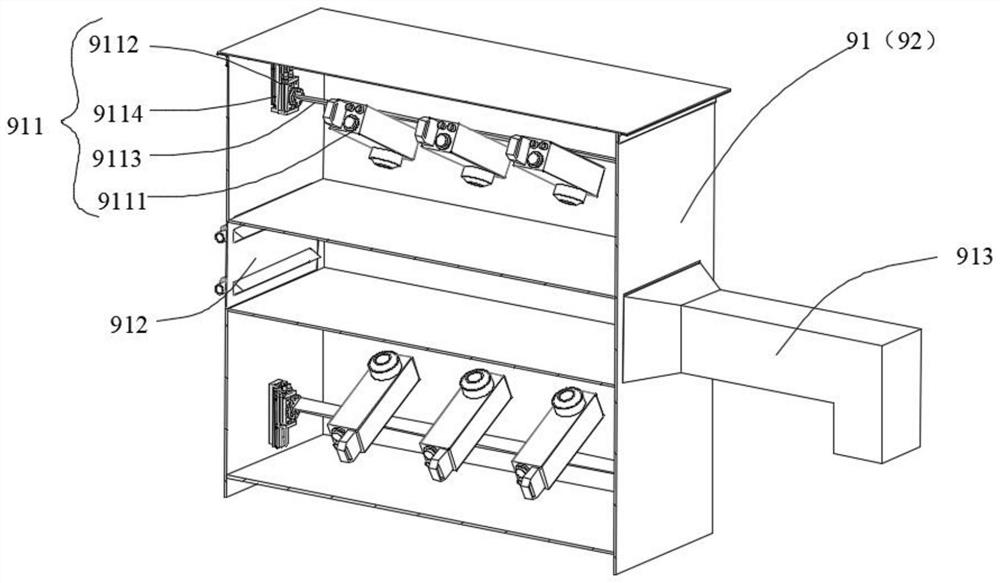

Steel plate surface treatment device and steel plate surface treatment method

ActiveCN113787060AProduction neatImprove the efficiency of electrical automationDirt cleaningCleaning using toolsPhysical chemistryDust control

The invention provides a steel plate surface treatment device and a steel plate surface treatment method. The steel plate surface treatment device comprises a rack, a feeding device, a monitoring device, a rolling plate device, a sweeping device, a discharging device, an air source supply device, a laser double-face cleaning device, an oxidized waste treatment device, a control device and a safety protection device, and the feeding device, the monitoring device, the rolling plate device, the sweeping device, the discharging device, the air source supply device, the laser double-face cleaning device, the oxidized waste treatment device, the control device and the safety protection device are arranged on the rack. A steel plate is fed through the feeding device, is rolled to be flat through the rolling plate device, enters the laser double-face cleaning device to remove surface metal oxide, is subjected to oxidized waste sweeping through the sweeping device, is subjected to dust removal through a scraper dust removal device, and finally enters the discharging device to be discharged. After the oxidized waste is collected, secondary cyclic utilization of metal oxide is completed through the oxidized waste treatment device. Compressed air provided by the air source supply device is environment-friendly energy, so that steel plate production is neat and pollution-free; the electrical automation efficiency is high, and the occupied area is small; protection is standard, and unmanned production can be achieved; and the oxidized waste is reutilized, and energy conservation and emission reduction are achieved.

Owner:高峰

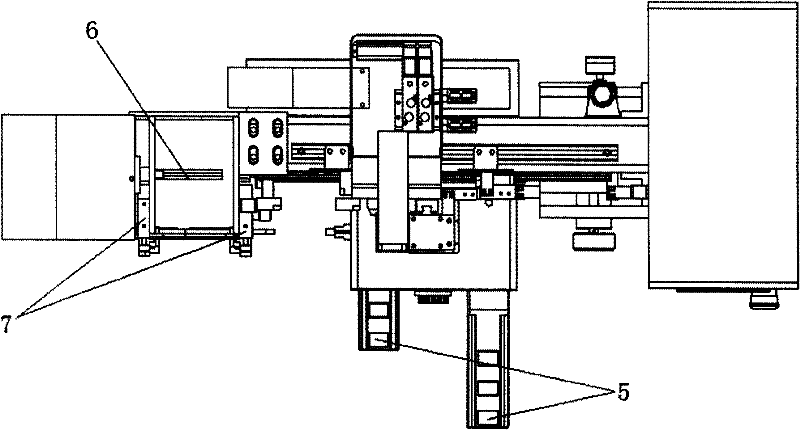

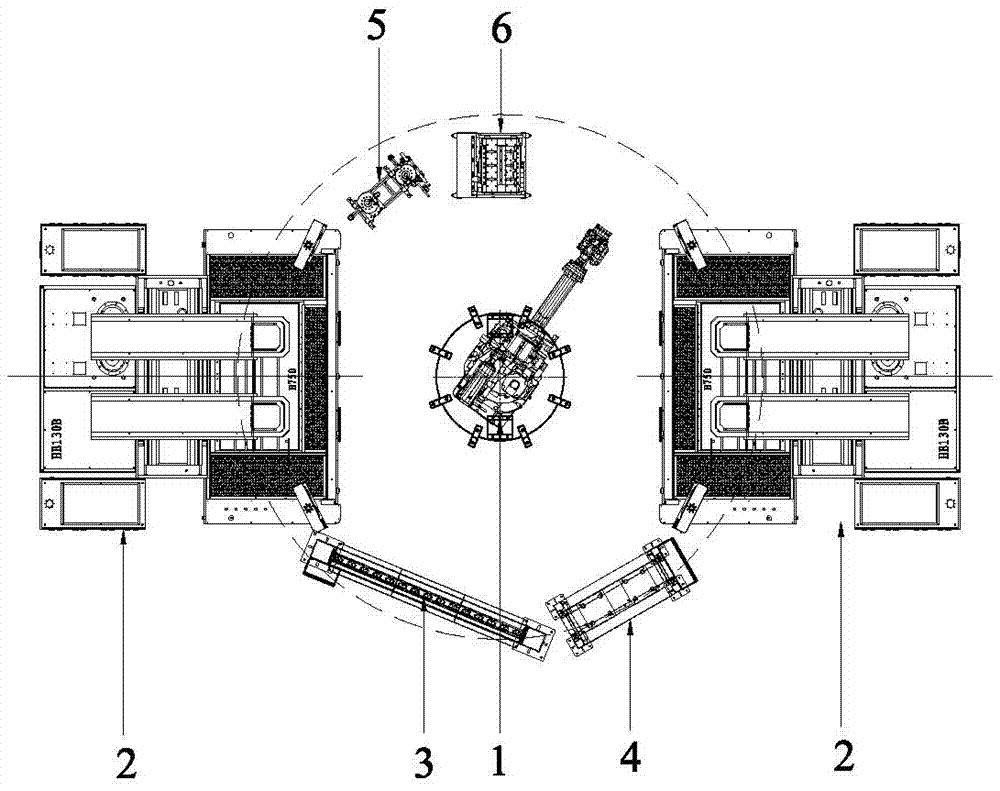

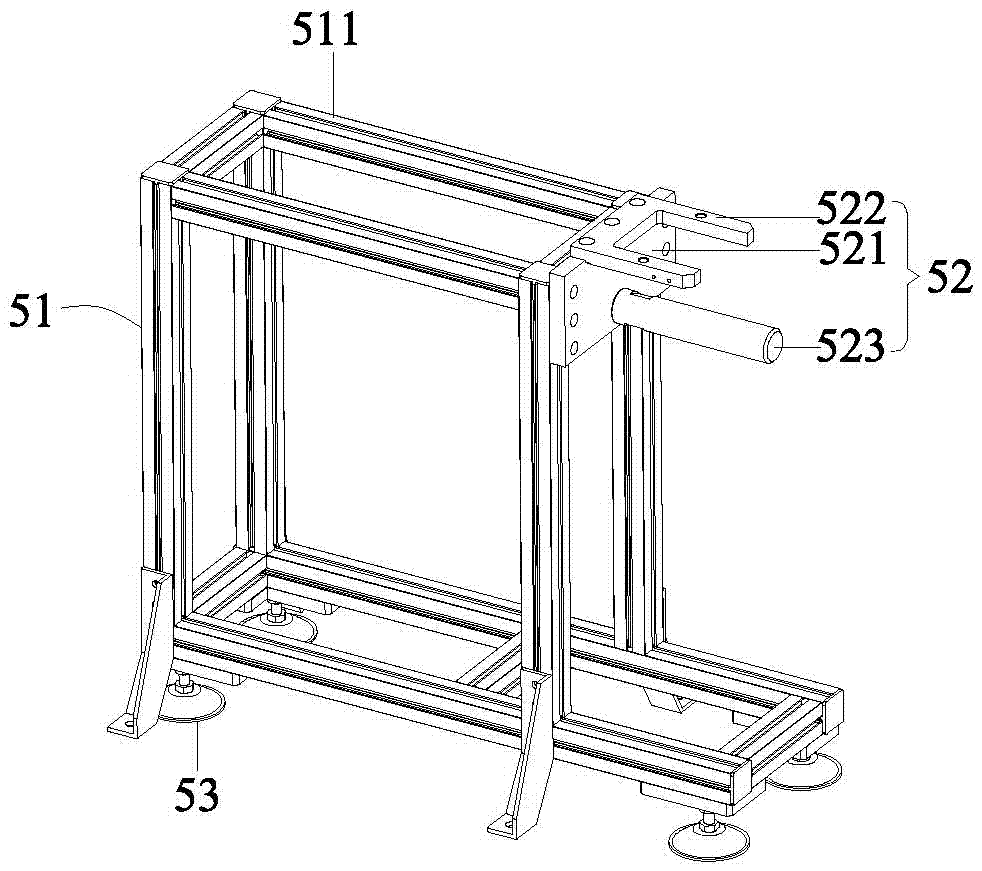

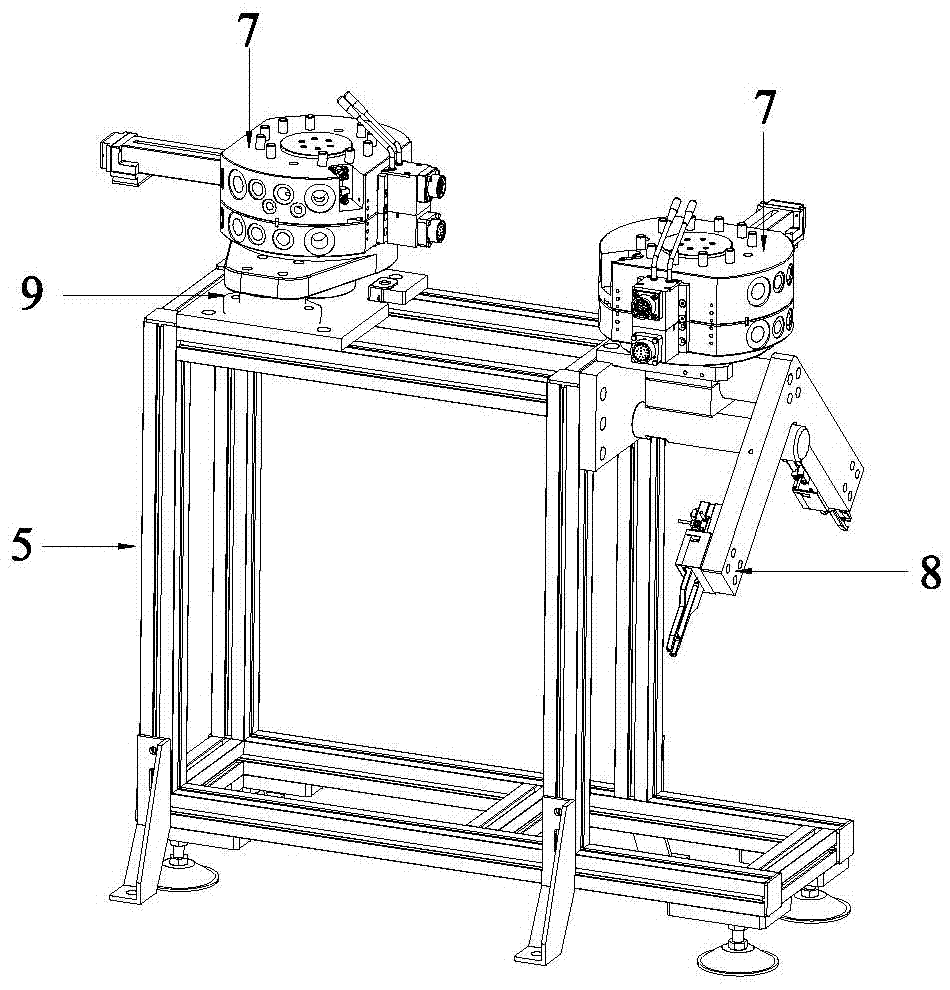

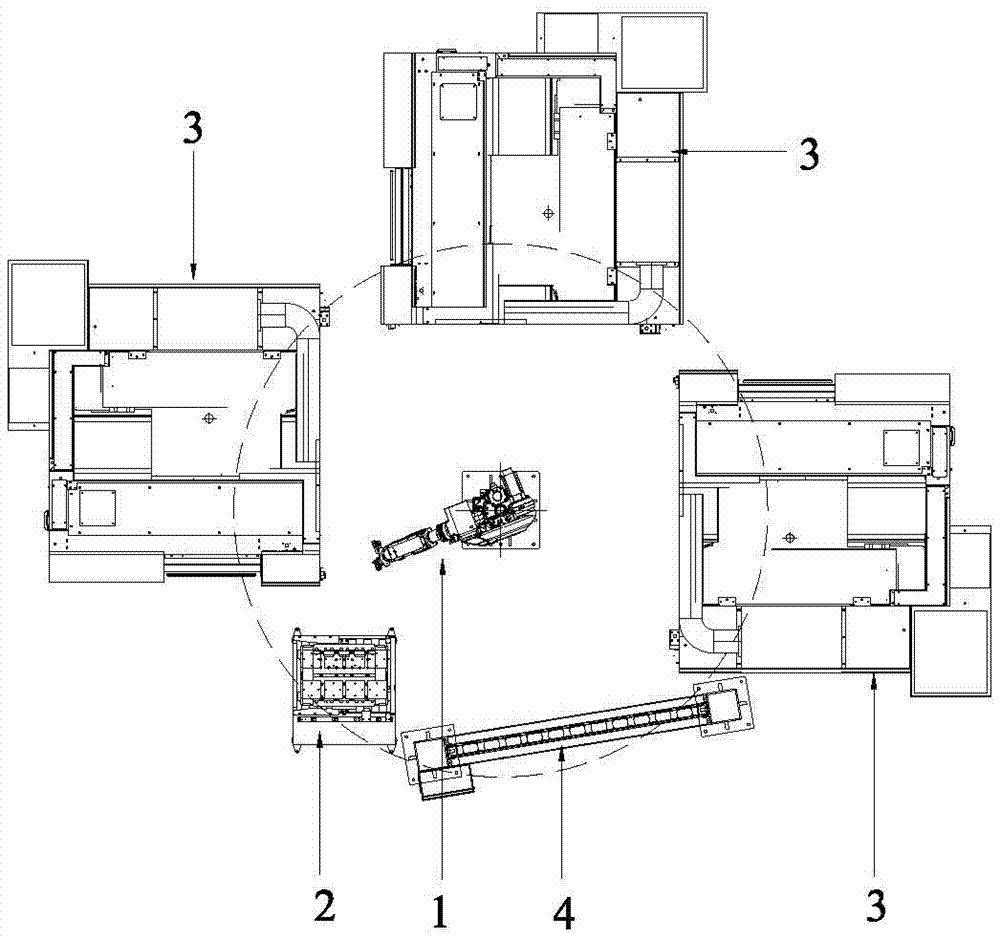

Mould steel material automatic machining unit module

InactiveCN107511544AMeet crawling requirementsRealize unmanned productionElectrical-based auxillary apparatusProduction rateButt joint

The invention discloses a mould steel material automatic machining unit module which comprises a mechanical arm, and electrical discharge machines, an electrode material support, a steel material holding frame, a quick-changing clamp holding table and a butt-joint transfer station which are arranged on the periphery of the mechanical arm. An electrode gripper and a steel material gripper are arranged on the quick-changing clamp holding table. A quick-changing device is arranged on the mechanical arm. The electrode gripper or the steel material gripper can be conveniently and quickly replaced through the quick-changing device, so that grabbing requirements of different objects are met; accordingly the purposes that electrodes or a steel material is grabbed without needing manpower and transferred to the electrical discharge machines, the electrode material support, the steel material holding frame and the butt-joint transfer station are achieved, seamless butt joint between all equipment is achieved, furthermore, the utilization rates of all the equipment are fully used, and the production rate of the mould steel material is increased to a great extent; and meanwhile, workshop manless production is achieved, the machining quality is effectively guaranteed, the mould steel material can be automatically, intelligently and fast machined, and batch industrialized production of moulds can be achieved easily.

Owner:东莞市隆凯精密制造有限公司

Mould graphite automated machining unit module

InactiveCN107538091AFast processingImprove work efficiencyElectrical-based machining electrodesButt jointGraphite

The invention discloses a mould graphite automated machining unit module. The mould graphite automated machining unit module comprises a mechanical arm, a butt joint transfer station, a graphite machining center and a material frame. The butt joint transfer station, the graphite machining center and the material frame which are centered in the mechanical arm are correspondingly distributed on theperiphery of the mechanical arm. The mould graphite automated machining unit module is ingenious in structural design, the butt joint transfer station, the graphite machining center and the material frame are reasonably distributed on the periphery of the mechanical arm, the mechanical arm is provided with a clamping hand, a human hand can be replaced with the clamping hand to achieve the purposeof grabbing graphite blank materials or electrodes and transferring the graphite blank materials or the electrodes to the butt joint transfer station and the material frame, seamless butt joint of each equipment is achieved, the using ratio of each equipment is fully used, the working efficiency of graphite machining is improved to a large extent, meanwhile, workshop manless production is achieved, the machining quality is effectively ensured, the graphite blank materials can be automatically, intelligently and fast machined, mass industrialization production of moulds is facilitated, and wideapplication and promotion are facilitated.

Owner:东莞市隆凯精密制造有限公司

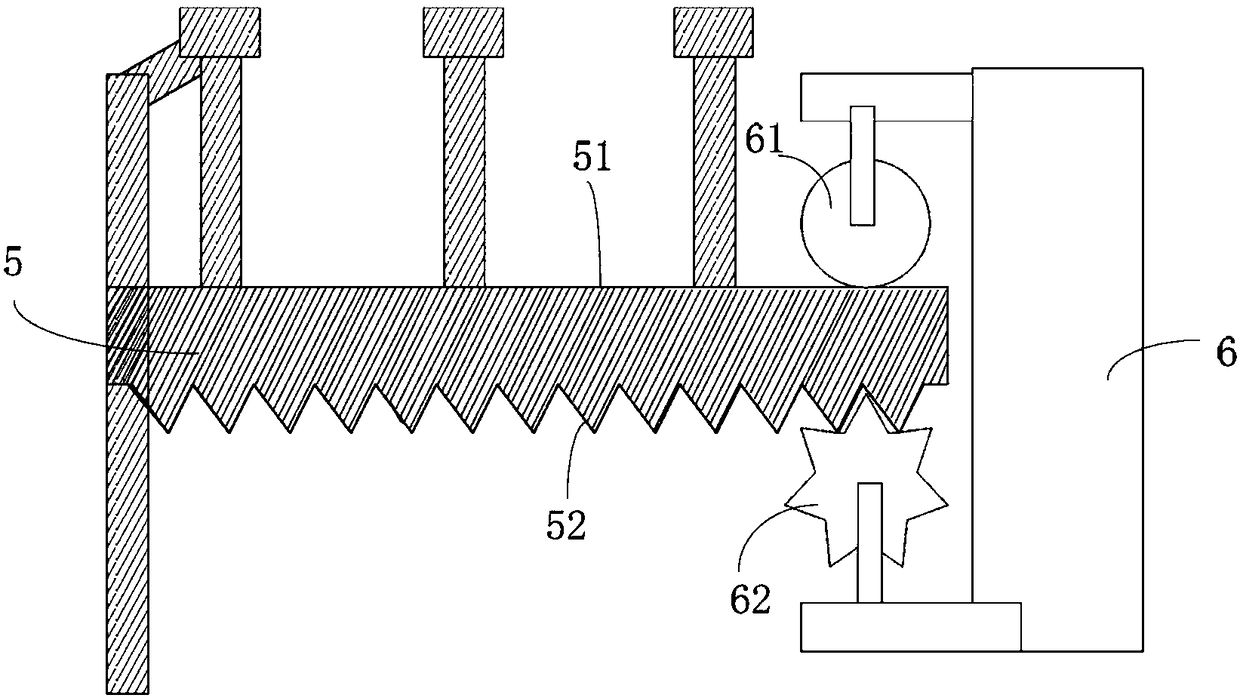

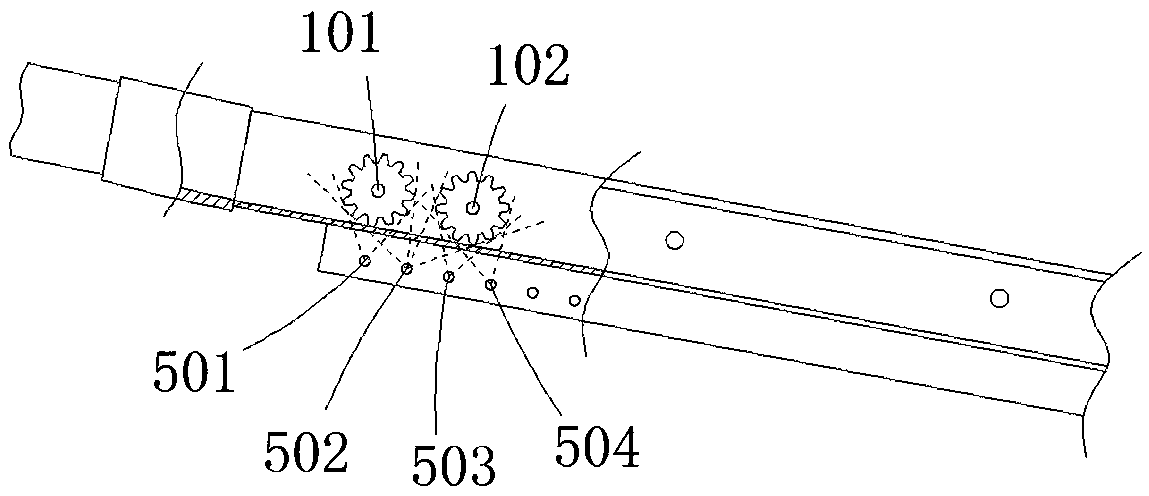

Cutting-off machine with automatic counting device

ActiveCN106925667AAvoid error conditionsRealize unmanned productionMetal working apparatusTime informationTerminal equipment

The invention provides a cutting-off machine with an automatic counting device. The cutting-off machine comprises a cutting-off device, a material pushing device, a bending device and a counting device which are sequentially arranged on a rack and a controller; automatic cutting-off, material pushing and bending of a mobile phone loudspeaker support are achieved through the controller, the counting device is arranged at a discharging outlet of a material guiding tank, the quantity of produced products is counted through a counter, time information corresponding to production of each product is generated through operation of a built-in chip of a processor, and the production information is stored in a storage and can be sent to terminal equipment connected with a network at a fixed time through a WIFI wireless network by setting time to enable a report to be automatically generated. Therefore, administrative staff can more visually monitor actual condition generated in production, specialized counting personnel are saved, production data errors caused by the counting personnel are avoided, the production cost is reduced, and unmanned production is achieved.

Owner:FOSHAN HEHONG TAIYE TECH CO LTD

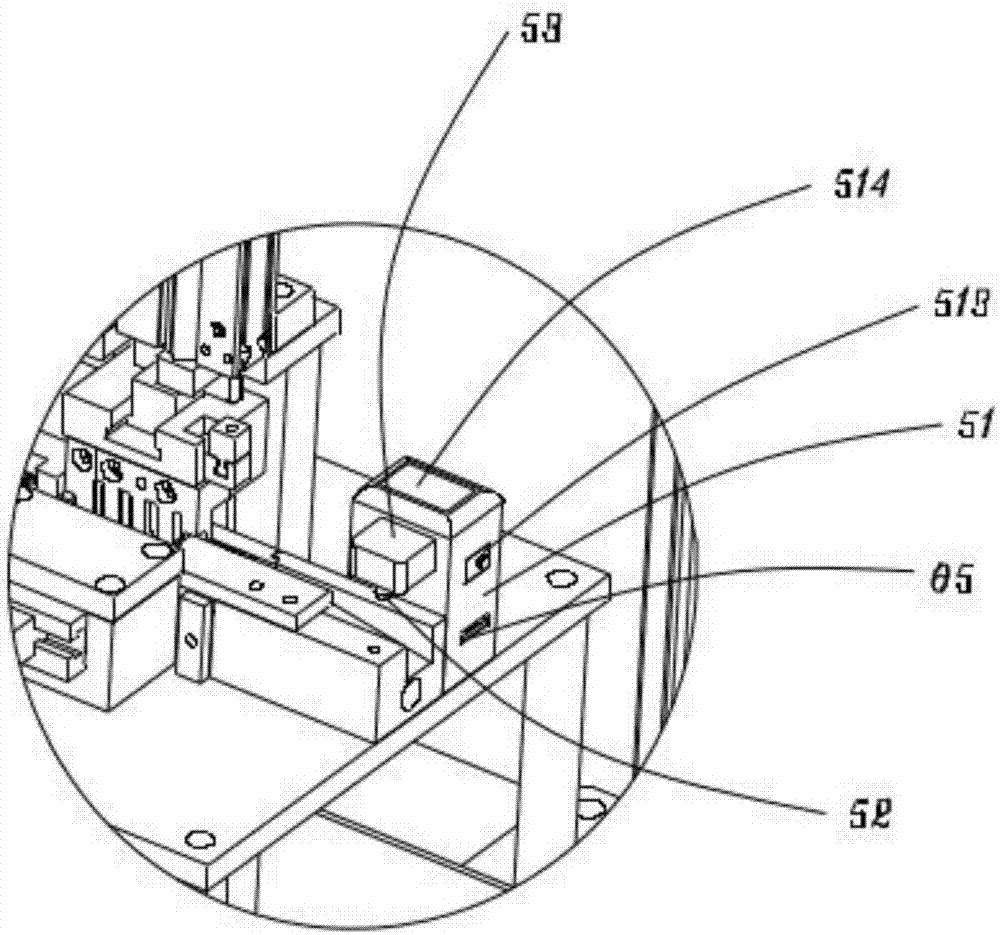

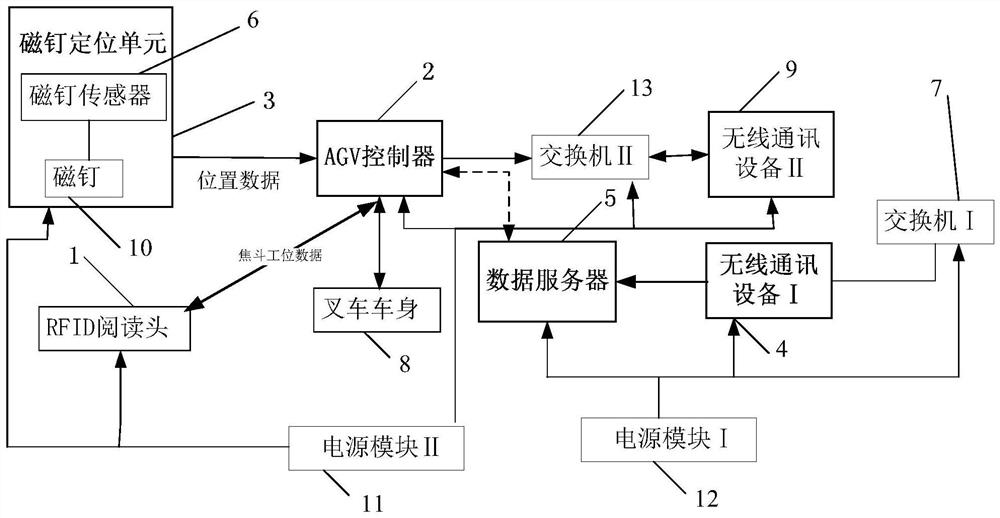

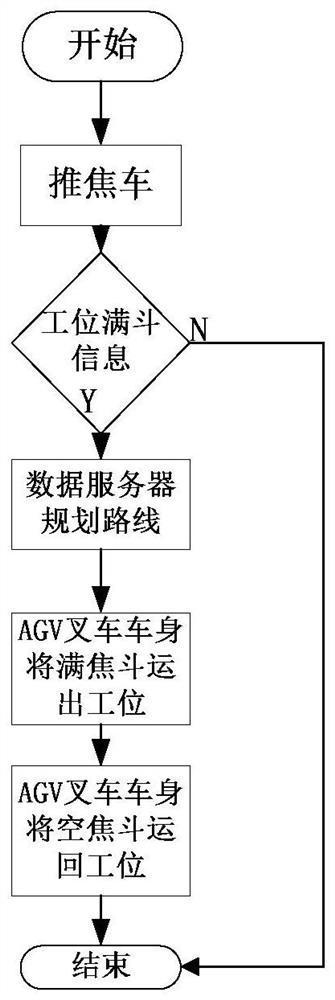

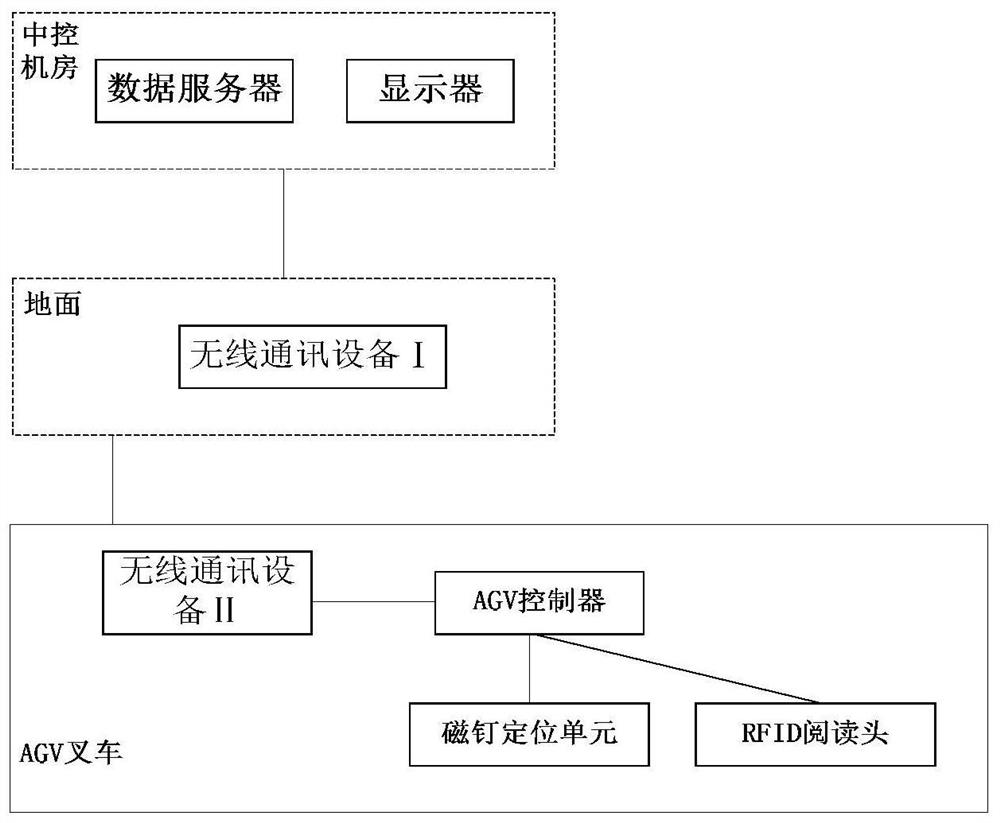

Coke oven head and tail coke unmanned transfer control system

InactiveCN112779027ARealize unmanned productionFacilitate unmanned productionCoke oven safety devicesDischarging devicesControl systemProcess engineering

The invention discloses a coke oven head and tail coke unmanned transfer control system, which belongs to the field of coke ovens, and comprises a data server for receiving station signals of head and tail coke buckets full of coke detected by a coke pusher and planning routes to the stations of the head and tail coke buckets full of coke; an AGV controller used for receiving a route plan transmitted by the data server and arrives at the head and tail coke bucket stations full of coke; a forklift body receiving the route plan transmitted by the AGV controller to reach the head and tail coke bucket stations full of coke, and reaching the head and tail coke bucket stations full of coke; anda magnetic nail positioning unit, a wireless communication device I, a wireless communication device II, a switch and a power supply module. The forklift body reads station information of the head and tail coke buckets through an RFID reading head, the head and tail coke buckets are forked to dump coke according to the planned route, then the head and tail coke buckets are put back to the original station according to the planned route, and the AGV controller transmits dumping completion information to the data server for recording . The system improves the production efficiency, and is convenient for realizing unmanned production of the coke oven.

Owner:DALIAN HUARUI HEAVY IND COKE OVEN VEHICLE EQUIP +1

Mechanized continuous making method of Yongxi huoqing

ActiveCN107996745AUniform qualityDark green colorPre-extraction tea treatmentStandardizationCooking & baking

The invention relates to a mechanized continuous making method of Yongxi huoqing. The mechanized continuous making method comprises specific operation steps and working procedures of performing mechanized tedding, performing fixation, performing spreading for cooling, performing light kneading, performing deblocking, performing spreading for cooling, performing re-roasting, performing spreading for cooling, performing primary shaping, performing spreading for cooling, performing secondary shaping, performing sieving, performing color selection, performing baking and the like. The processed Yongxi huoqing is dark green in color, oily, moistening and glossy black, and peculiar properties of being clear, green and bright in soup color, clear and rich in fragrance, long in aftertaste and the like are formed; the Yongxi huoqing is round, tight and coiled like coiled buns and homogeneous in quality; the method is suitable for mechanized processing and continuous clean production of the Yongxi huoqing, the standardized production degree of the Yongxi huoqing is increased, the added value of products is increased, the market competitiveness is strengthened, and the method conforms to the industrialized development trend of the Yongxi huoqing.

Owner:ANHUI AGRICULTURAL UNIVERSITY

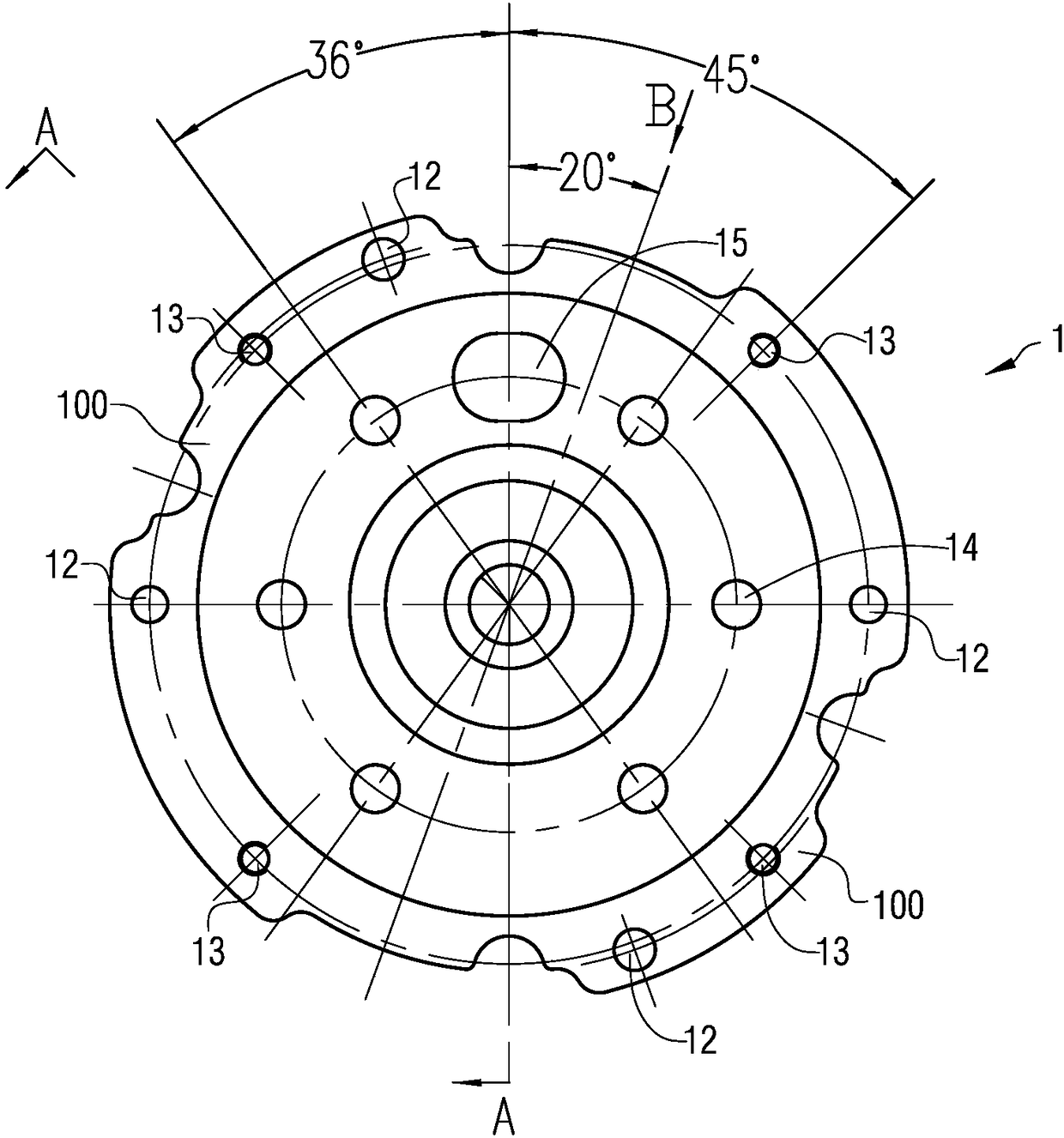

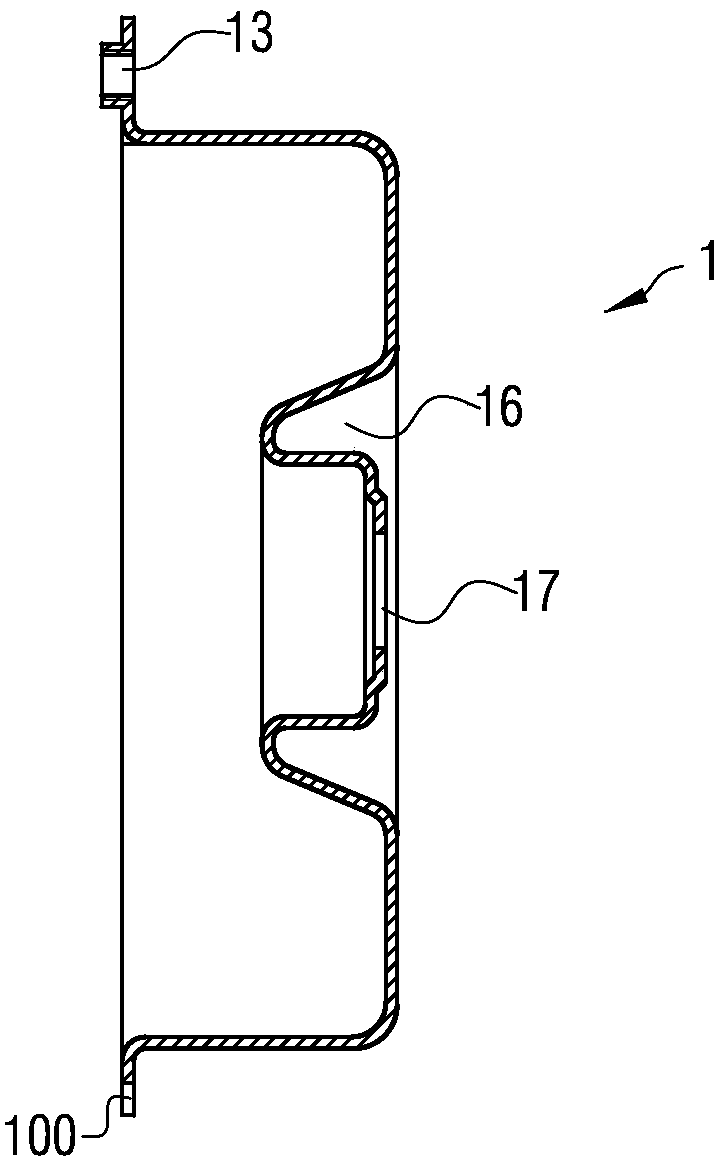

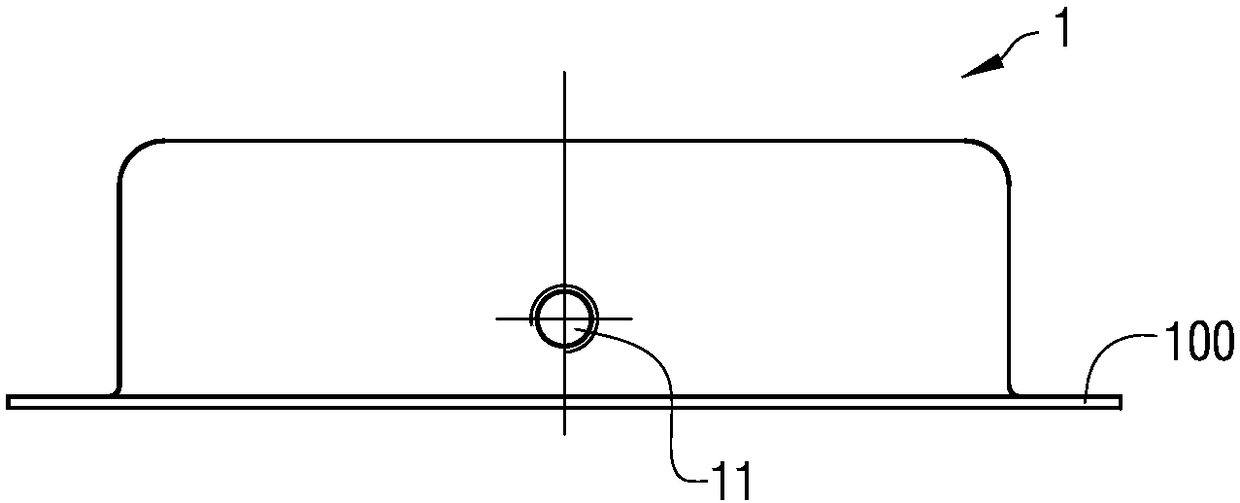

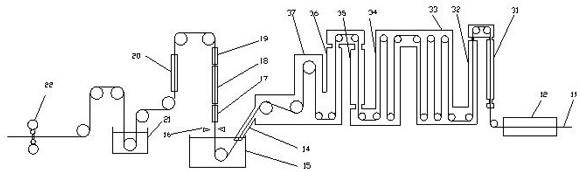

Preparation method for electromotor mounting shell

ActiveCN108097797ARealize unmanned productionReduce demandShaping toolsOther manufacturing equipments/toolsPunchingEngineering

The invention provides a preparation method for an electromotor mounting shell. The preparation method for the electromotor mounting shell comprises the following steps of (A) providing a progressivedie, wherein the progressive die comprises thirteen stations of, sequentially punching a technology gap -> flattening -> first deep drawing -> reverse deep drawing -> second deep drawing -> roughing -> finishing -> punching -> hole flanging -> punching a side opening -> tapping -> blanking -> waste material cutting; (B) conveying a material belt on the progressive die provided by the step (A) andfinishing the operation of punching the side opening when the material belt is conveyed to the station of punching the side opening; (C) finishing the operation of tapping on a horizontal threaded hole when the material belt is conveyed to the station of tapping; and (D) enabling a finished electromotor mounting shell to fall down to finish the preparation when the material belt is conveyed to the station of blanking. By means of the preparation method for the electromotor mounting shell, the unmanned production of a high-accuracy electromotor stator and rotor mounting shell body can be realized and the requirements for punching workers and punching equipment can be greatly reduced.

Owner:CHINA HANGFA SOUTH IND CO LTD

Method for automatically controlling annealing speed of strip steel

ActiveCN114480831ARealize unmanned productionMeet the annealing process requirementsFurnace typesHeat treatment process controlAutomatic controlStrip steel

The invention relates to the technical field of strip steel continuous heat treatment, and discloses a strip steel annealing speed automatic control method, which comprises the following processes: the strip steel annealing speed of a unit is automatically controlled by a program, the maximum production capacity of the unit is controlled by default, the output of the unit is maximized, and the maximum production capacity is represented by a target TV value; the target TV value is the product of the thickness of the incoming strip steel and the maximum running speed of the strip steel unit with the thickness allowed by the capacity of the unit, and the unit strip steel annealing speed automatic control program uses the target TV value to divide the thickness of the strip steel at the inlet of the annealing furnace to obtain a unit strip steel annealing speed target value Vaim; automatic control over the speed of the unit is achieved, unmanned production of strip steel annealing can be achieved, the limit capacity of the unit can be exerted when the unit has abnormal limitation, the unit is made to conduct production under the real-time maximum hourly yield, process control is considered, the requirement of the annealing process is met, a certain margin is reserved, and the situation that the annealing process is inconsistent is avoided.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

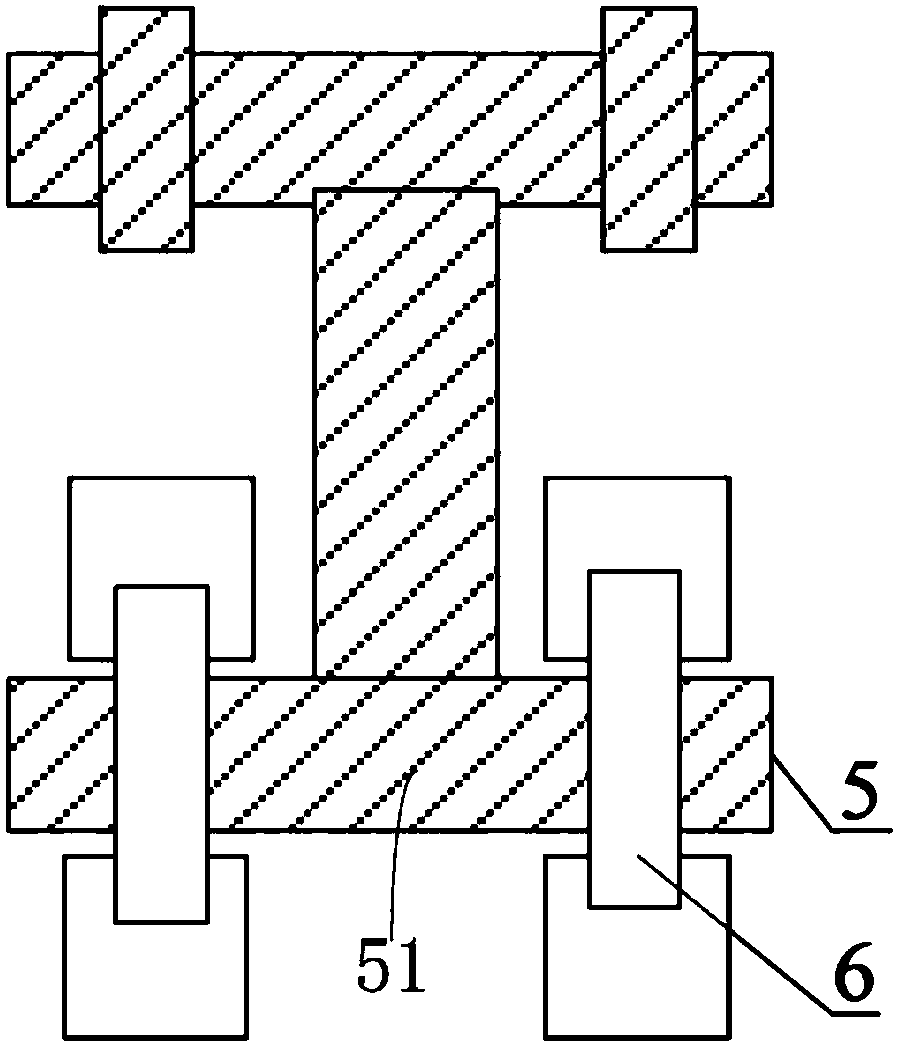

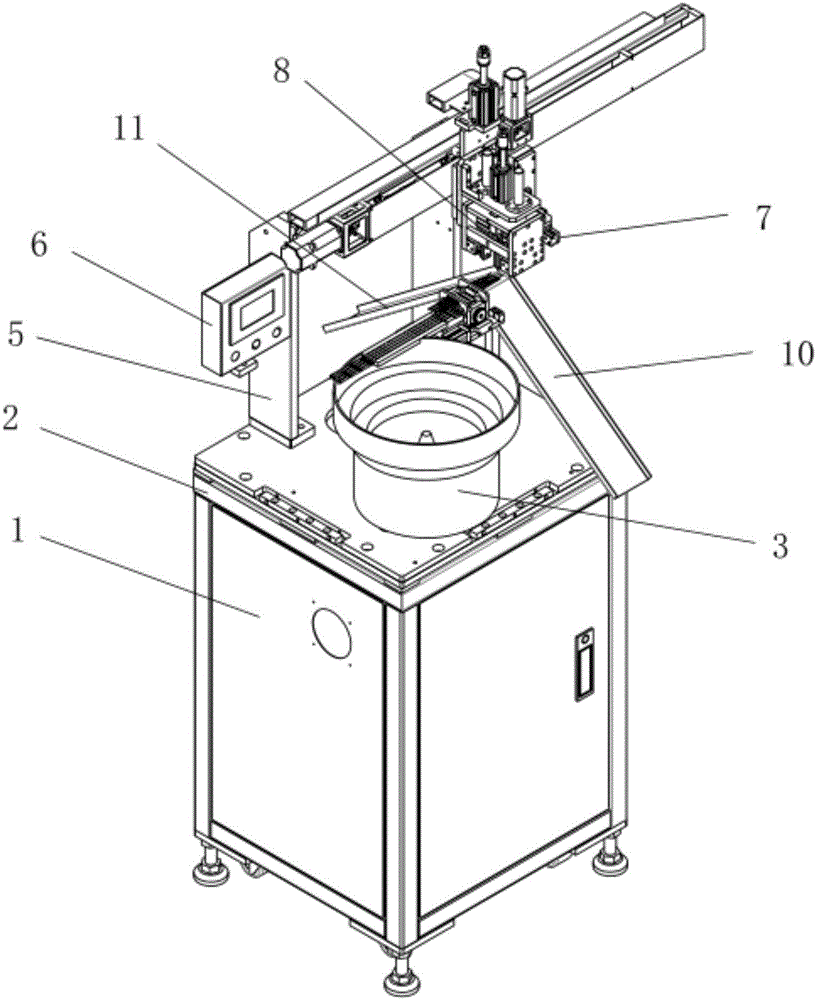

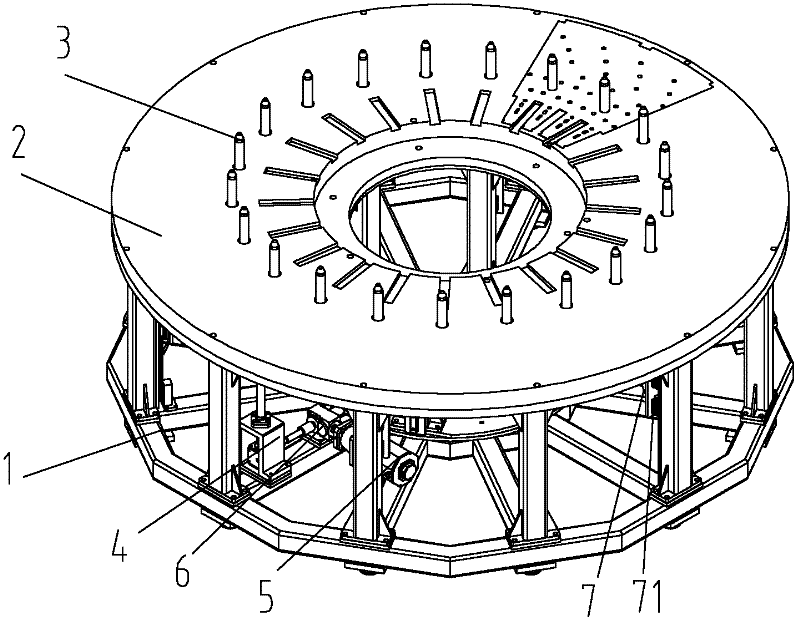

Full-automatic cold grinding and chambering equipment for bearing ring component and work method of full-automatic cold grinding and chambering equipment

InactiveCN108480532ASimple structureReliable feeding processMetal-working feeding devicesBearing componentsEngineeringMachining process

The invention discloses full-automatic cold grinding and chambering equipment for a bearing ring component, and relates to the technical field of advanced manufacturing and automation. The full-automatic cold grinding and chambering equipment comprises an automatic feeding device, a base, a cold grinding and chambering device and an unloading device. The automatic feeding device is arranged on oneside of the base. The cold grinding and chambering device and the unloading device are arranged on the base. A feeding port of the cold grinding and chambering device is connected with the automaticfeeding device, and a discharging port is connected with the unloading device. The automatic feeding device comprises a feeding rotary disc and further comprises a limiting baffle and a feeding regulation channel which are arranged on the feeding rotary disc. A rotation shaft part is arranged at the center of the feeding rotary disc and connected with a rotation driving device. A series of actionsincluding automatic feeding, cold grinding and chambering machining and automatic unloading are achieved, and unmanned producing and machining are achieved in the whole process. The automatic feedingdevice is simple in structure, the feeding process is stable and reliable, the repeated conveying preventing function is better achieved, and stability and safety of the integral machining process are guaranteed.

Owner:江苏保捷精锻有限公司

An automatic crimping test device for liquid crystal panels

ActiveCN104076217BAvoid damageReduce repetitive mechanical laborNon-linear opticsLiquid-crystal displayLiquid crystal

Owner:SUZHOU HUAXING YUANCHUANG TECH CO LTD

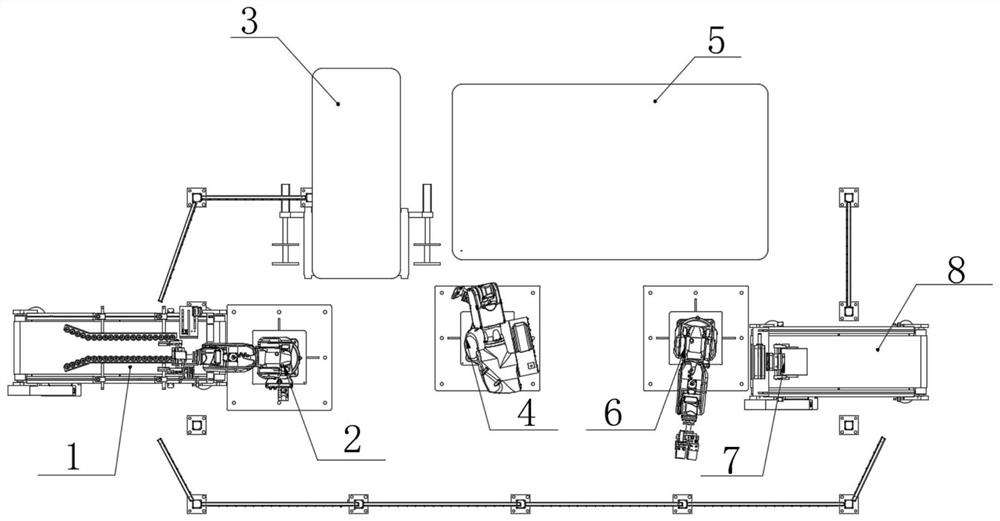

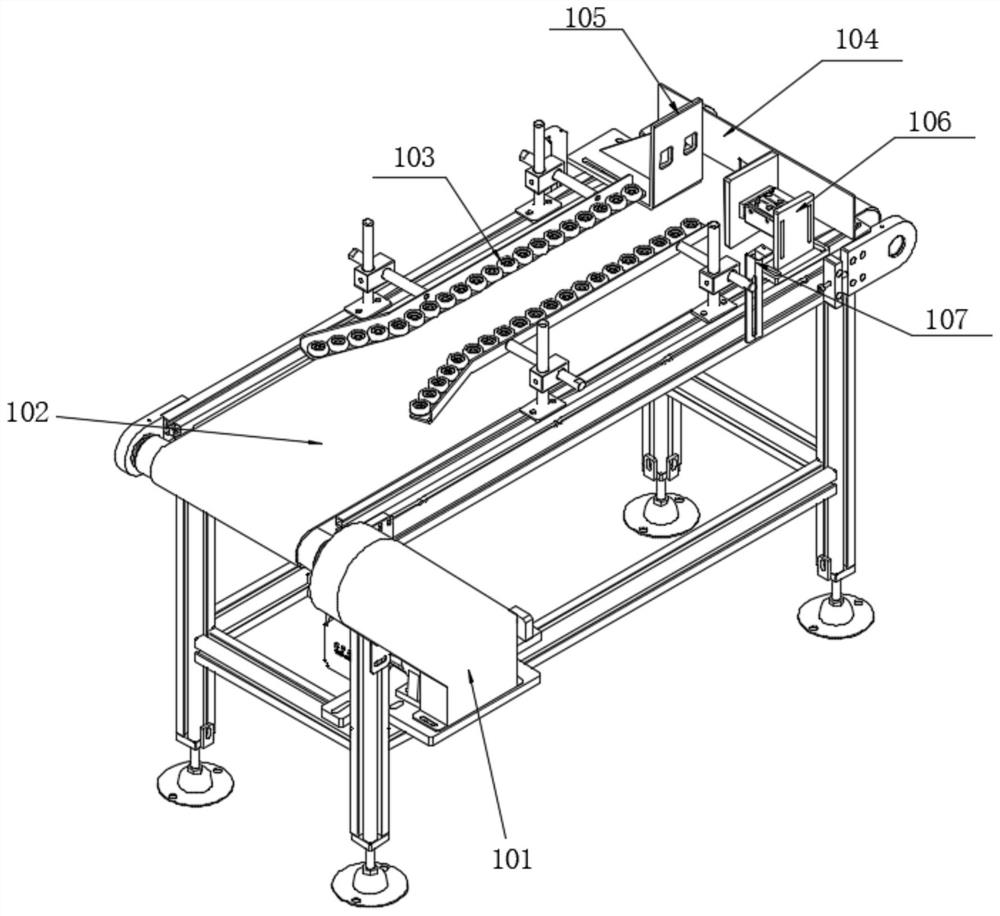

Robot hot stamping and transfer printing work station for white spirit packaging boxes

PendingCN112810231ARealize automatic ironing/transfer printingSimplify manual workloadPaper-makingBox making operationsCartoning machineHot stamping

The invention relates to the technical field of packaging equipment, in particular to a robot hot stamping and transfer printing workstation for white spirit packaging boxes. The robot hot stamping and transfer printing workstation is characterized in that a positioning conveying line is used for conveying the packaging boxes to an operation station of a first robot; the first robot is used for grabbing the positioned packaging boxes on the positioning conveying line and placing the packaging boxes on a hot stamping machine for hot stamping; a second robot is used for grabbing the packaging boxes subjected to hot stamping of the hot stamping machine, the packaging boxes are rotated and then are placed on the transfer printing machine for transfer printing; and a third robot is used for grabbing the packaging boxes subjected to transfer printing and placing the packaging boxes on a discharging conveying line, or placing the packaging boxes needing to be overturned on overturning equipment to be overturned and then placing the packaging boxes on the discharging conveying line. According to the robot hot stamping and transfer printing workstation, a series of technological processes such as automatic positioning, hot stamping, transfer printing and overturning of the white spirit packaging boxes of different types and shapes can be completed, unmanned production of hot stamping / transfer printing of the white spirit packaging boxes is achieved, the labor intensity of workers is relieved, and the stability and quality of products are improved.

Owner:埃斯顿(湖北)机器人工程有限公司

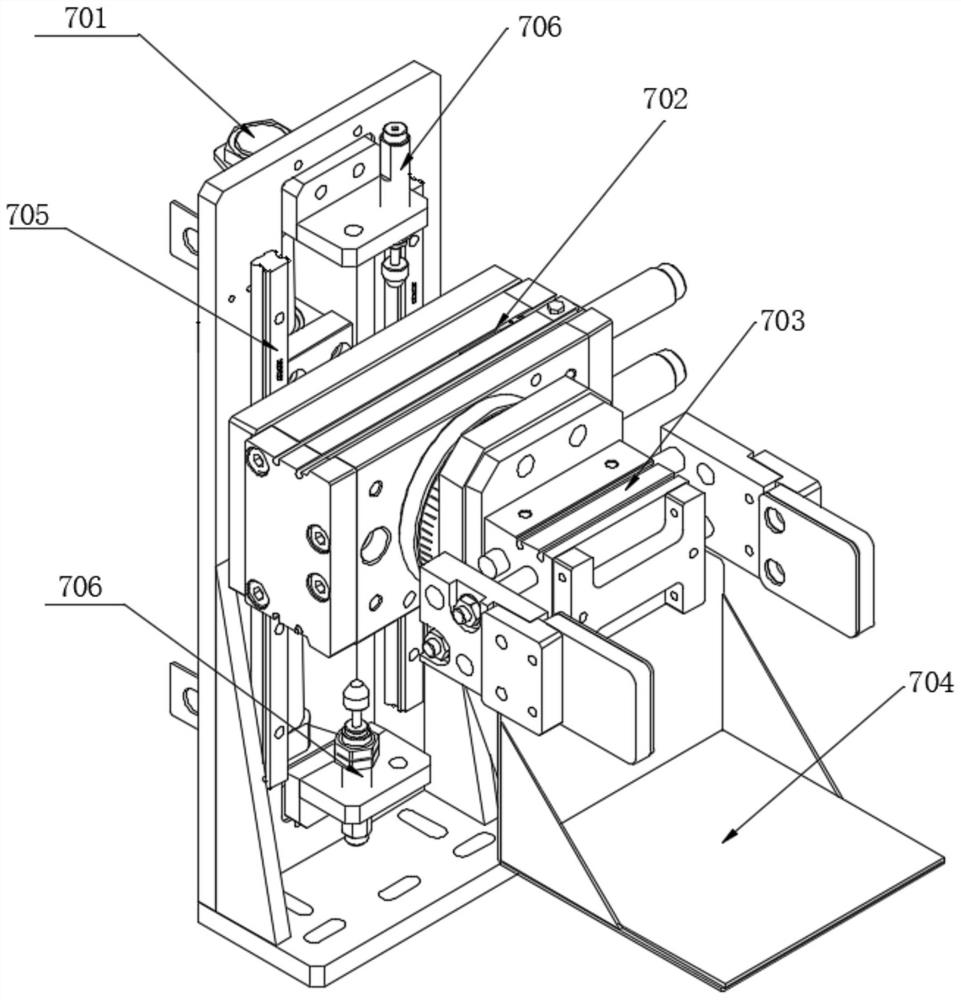

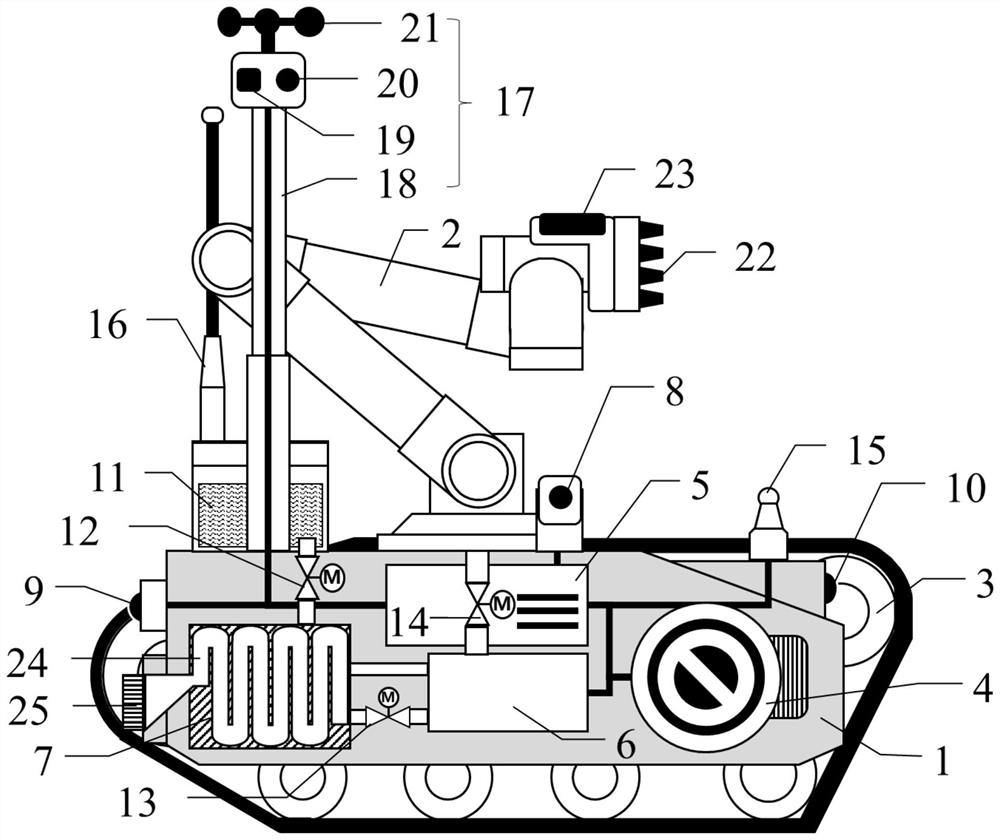

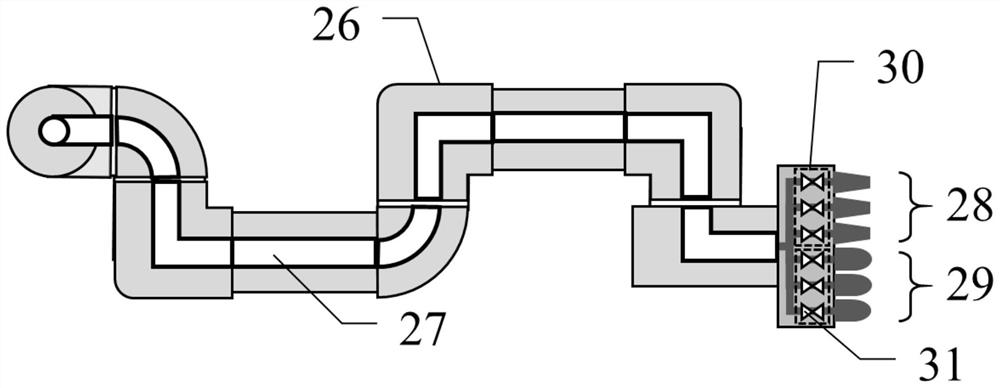

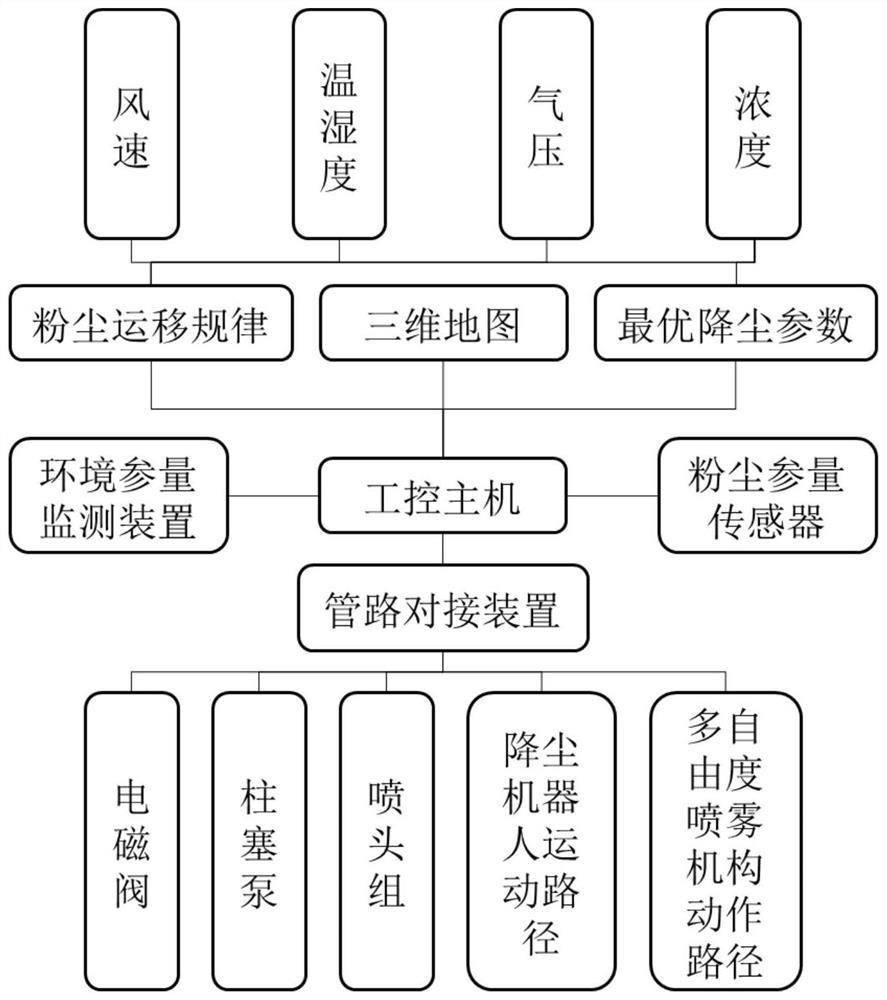

Intelligent dust falling robot and dust falling method thereof

PendingCN114109481ARealize intelligenceSolve the problem of poor dust suppression effect of "extensive"Mining devicesDust removalAir velocityControl theory

The invention discloses an intelligent dust falling robot and a dust falling method thereof. The intelligent dust falling robot comprises a movable chassis and a multi-degree-of-freedom spraying mechanism; crawler-type moving mechanisms are installed on the two sides of the dust fall robot moving chassis, a motor is installed on the front portion in the moving chassis, an industrial control host and a plunger pump are installed in the middle, and a water supply device is installed on the rear portion. A positioning navigation device, a multi-degree-of-freedom spraying mechanism, a foaming agent adding device, a wireless signal receiving device and an environment parameter monitoring device are sequentially mounted above the movable chassis from front to back, and high-definition cameras are mounted on the periphery of the movable chassis; the industrial control host is connected with the high-definition camera, the positioning navigation device, the environment parameter monitoring device, the motor and the electromagnetic valve. According to the equipment, a multi-degree-of-freedom spraying mechanism can complete dust falling operation in a narrow space of a complex environment, and when the equipment runs, an optimal dust falling strategy can be formulated according to environment temperature and humidity, air pressure, air speed and dust concentration, so that unmanned treatment on dust pollution is realized.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com