Stator lamination stacking workbench

A technology of stator punching and workbench, which is applied in the direction of workbench, manufacturing stator/rotor body, manufacturing tools, etc. It can solve the problems that the positioning rod cannot automatically adjust the height, the stacking of punching pieces is inconvenient, and the degree of automation is low. Reliable stacking process, improved stacking efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

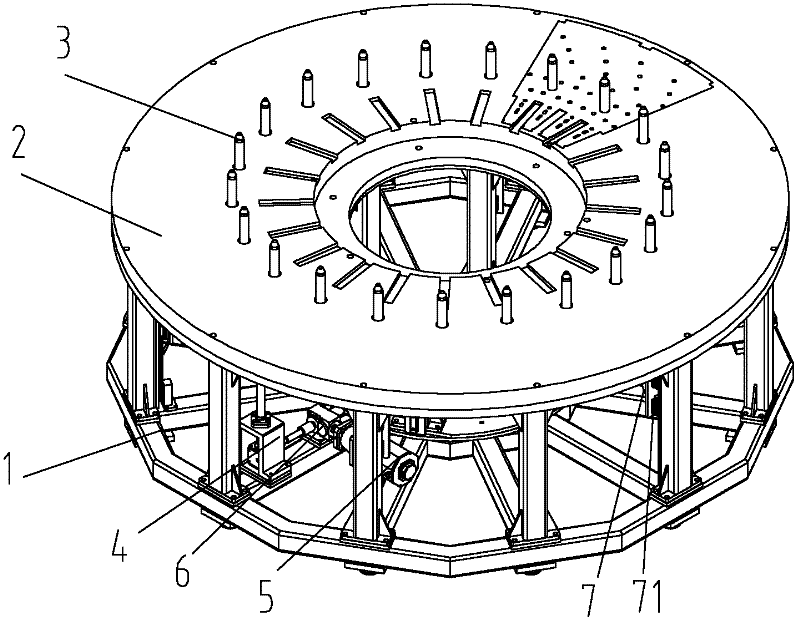

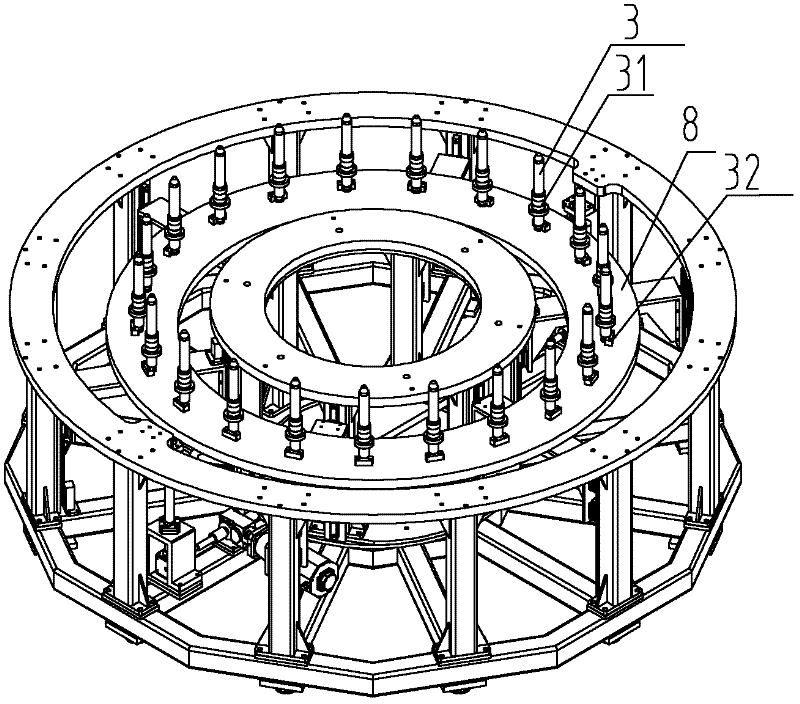

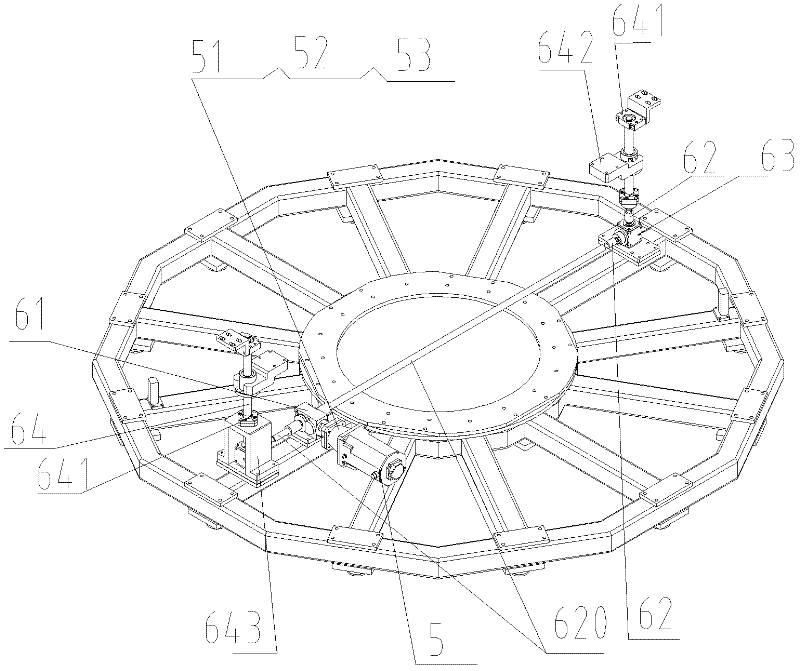

[0025] see figure 1 , figure 2 , image 3 and combine Figure 4 , a stacking workbench for stator punching of the present invention includes a stacking platform body 1, a stacking table top 2 and 21 positioning rods 3, and it also includes a positioning device 4, which includes a fixed connection The transmission device 6 driven by the servo motor 5 on the stacked platform body 1, a lifting bracket 7 with a linear guide rail 71 installed vertically, and an annular lifting plate 8 supported by the lifting bracket 7, wherein,

[0026] The number of positioning rods 3 is determined according to the difference of the stator punches, such as 21, 19 or 22. In the present embodiment, there are 21 positioning rods 3, which are evenly distributed on the ring-shaped lifting plate 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com