Patents

Literature

541results about How to "Improve stacking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

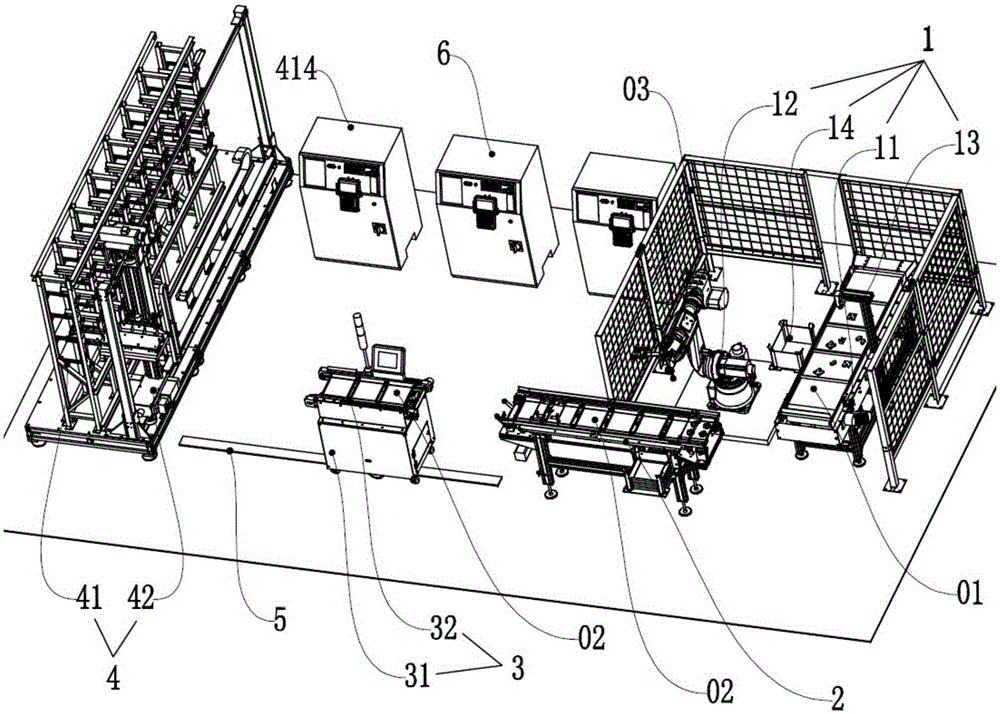

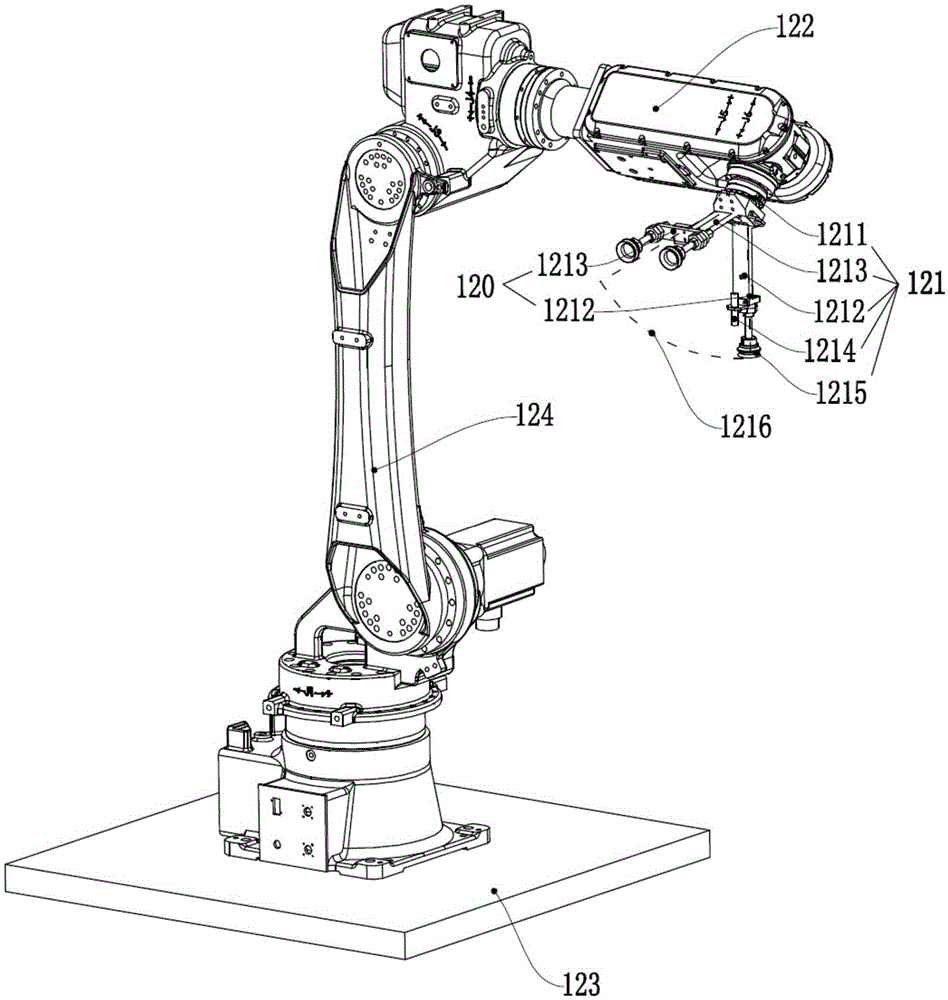

Automatic storage system of industrial robot

InactiveCN105292892AFree laborReasonable assemblyStorage devicesAcquired characteristicIdentification device

The invention discloses an automatic storage system of an industrial robot. The automatic storage system comprises a robot sorting area, a speed-fold chain, an AGV trolley, an intelligent three-dimensional warehouse and a central controller. The robot sorting area comprises a flat belt conveyor, a robot and a vision identification device. The flat belt conveyor receives a signal sent by the central controller and controls trays to move in the conveying direction of the flat belt conveyor. The vision identification device is installed on any side of the flat belt conveyor and located above the trays. A camera of the vision identification device is used for photographing the tray area below the camera, and the photographing area of the camera at least includes one tray. The vision identification device detects and identifies photos photographed by the camera, sends feature data obtained through identification to the central controller and sends a signal to the robot, and the robot receives the signal to transfer and put specified articles on the storage trays of the speed-fold chain to achieve sorting. According to the automatic storage system of the industrial robot, labor force of workers is liberated, and product detecting, sorting and storing efficiency is improved.

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD +1

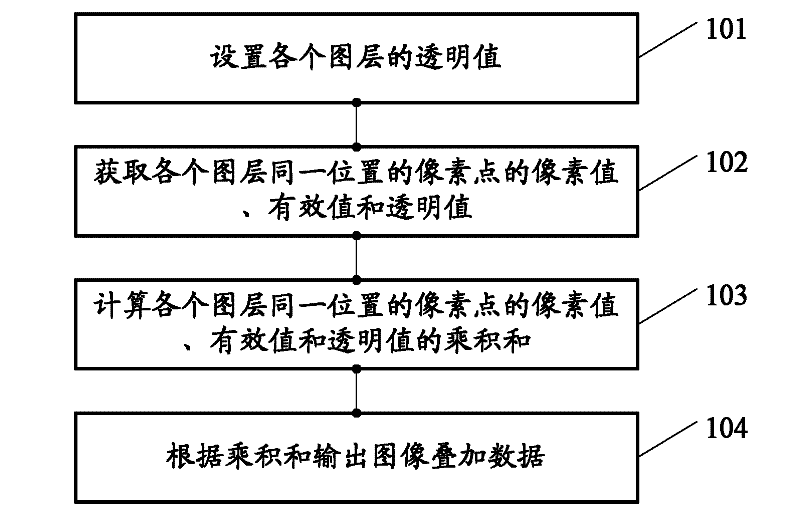

Image addition processing method and device

InactiveCN102572304AImprove efficiencyImprove stacking efficiencyTelevision system detailsColor television detailsValid ValueReal time display

The invention provides an image addition processing method which comprise the following steps of: setting the transparency of each image layer, wherein the sum of transparency of all image layers is less than or equal to 1; obtaining pixel values, effective values and transparency of pixels of all image layers at the same position; calculating the product sum of the pixel values, effective values and transparency of pixels of all image layers at the same position; and displaying the product sum of all image layers at the same position. The invention provides an image addition processing device which can simultaneously add a plurality of image layers, improve addition processing efficiency of the plurality of image layers and can display the image layers in real time.

Owner:GUANGDONG VTRON TECH CO LTD

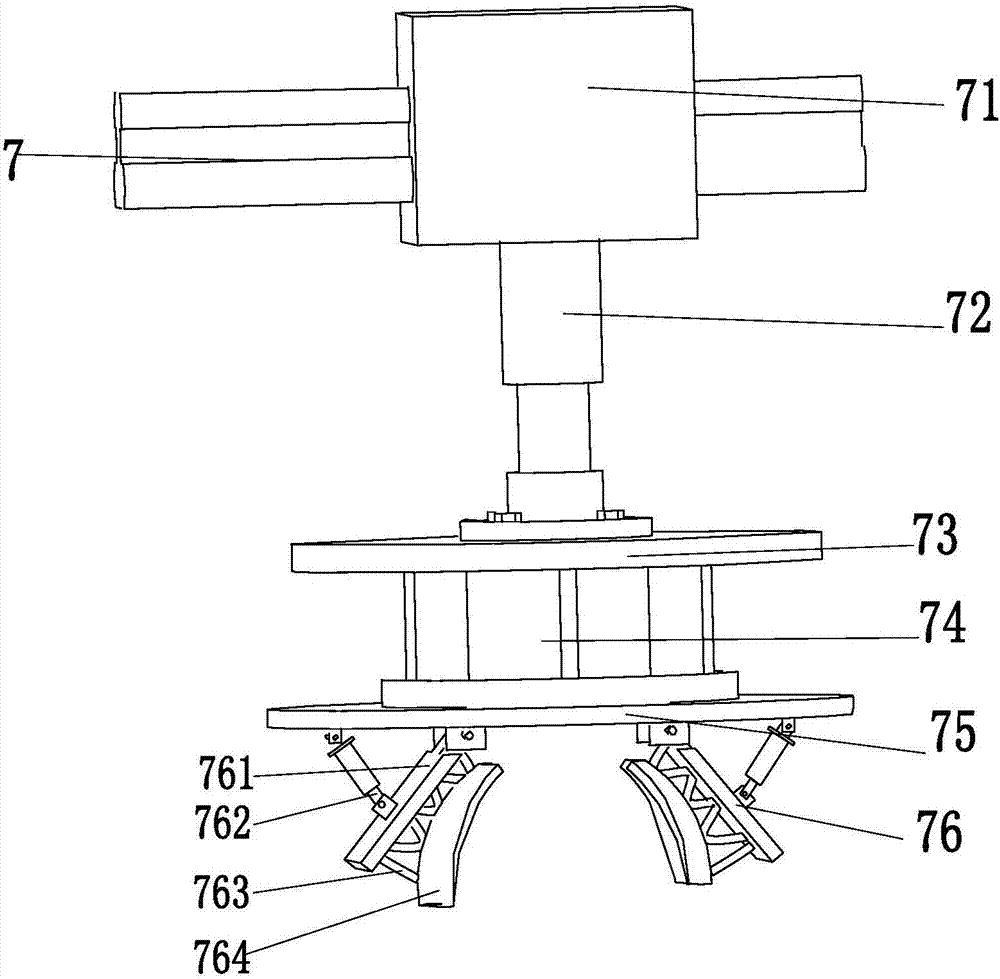

Intelligent brick stacking machine

ActiveCN106429465AMake sure to staggerStack stableStacking articlesConveyor partsBrickAgricultural engineering

The invention discloses an intelligent brick stacking machine and mainly relates to the technical field of building material machinery. The intelligent brick stacking machine comprises a support and a PLC controller, wherein a rotating platform is arranged on the support; a supporting frame and a servo air cylinder are arranged on the rotating platform; a bearing frame is arranged at the upper end of the servo air cylinder; a bearing cross rod is arranged at the front end of the bearing frame; a transmission rod is vertically arranged at the front end of the bearing cross rod; one end, far away from the bearing cross rod, of the transmission rod is connected with a clamping mechanism; the clamping mechanism comprises a transverse clamping part and a longitudinal clamping part; a balancing weight is arranged on the rotating platform. The intelligent brick stacking machine has the beneficial effects that the intelligent brick stacking machine can stack the bricks quickly and efficiently, can increase the working frequency, can move automatically according to the actual stacking requirement and can adjust the placing position of the bricks so as to guarantee the brick stacking stability.

Owner:LUOYANG INST OF SCI & TECH

Intelligent stacker and stereoscopic warehouse system using same

The invention discloses an intelligent stacker and a stereoscopic warehouse system using the same. The intelligent stacker controls the movement speed of a walking mechanism through relative induction of transverse sensors and sensor boards; the movement direction of the walking mechanism serves as the initial end, when the first transverse sensor transversely passes through the sensor board appointed by a control system, the first transverse sensor sends a speed reduction signal, and the walking mechanism starts to move slowly; when the last transverse sensor passes through the same appointed sensor board, the last transverse sensor sends a stopping signal, and the walking mechanism decelerates to stop moving. Control drive of a servo motor is replaced, so that the cost is greatly reduced. Rapid starting and stable stopping of the walking mechanism can be achieved. The invention further provides the stereoscopic warehouse system using the intelligent stacker. The aerial space is utilized reasonably, and the efficiency of putting products in a storage is high.

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD +1

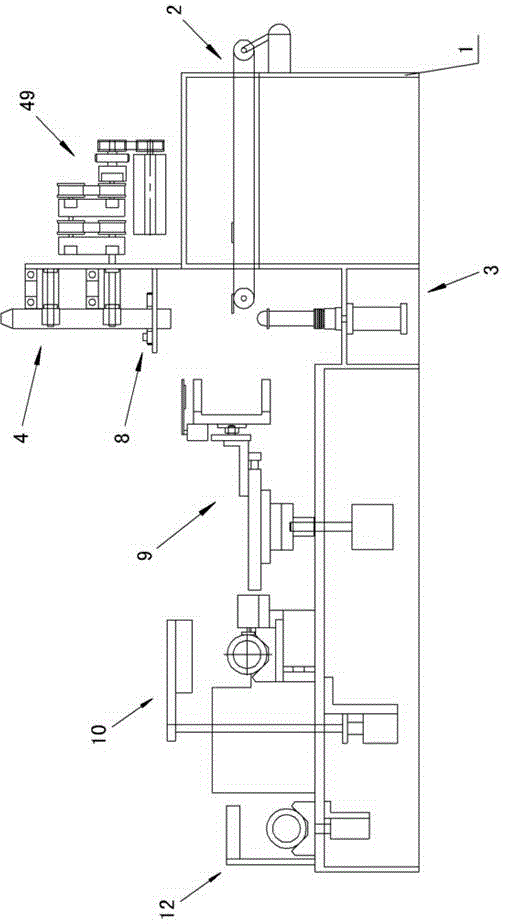

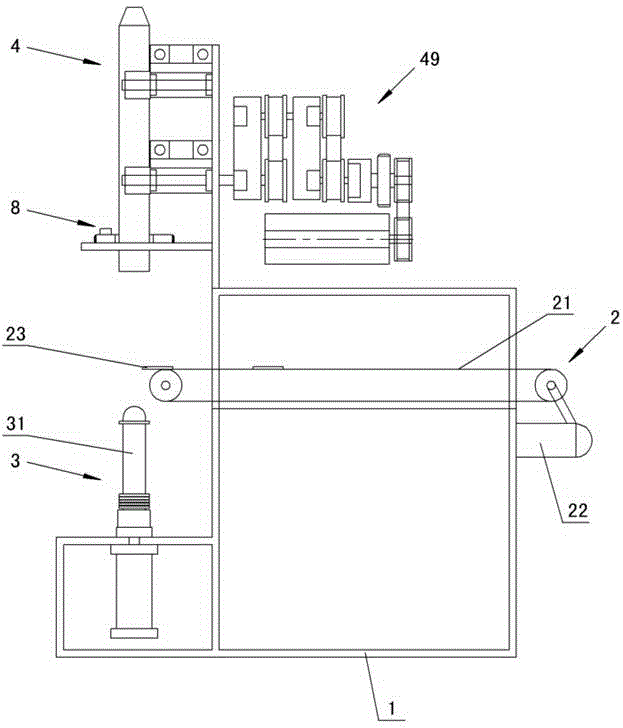

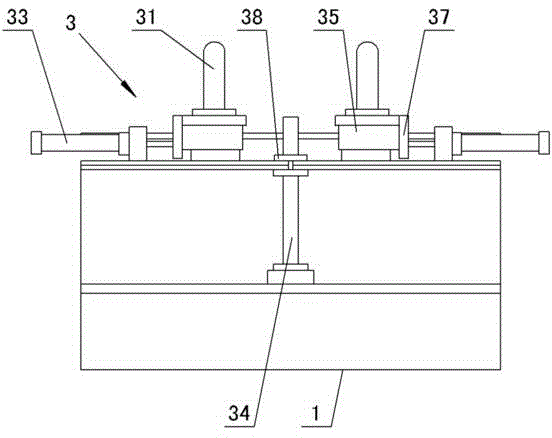

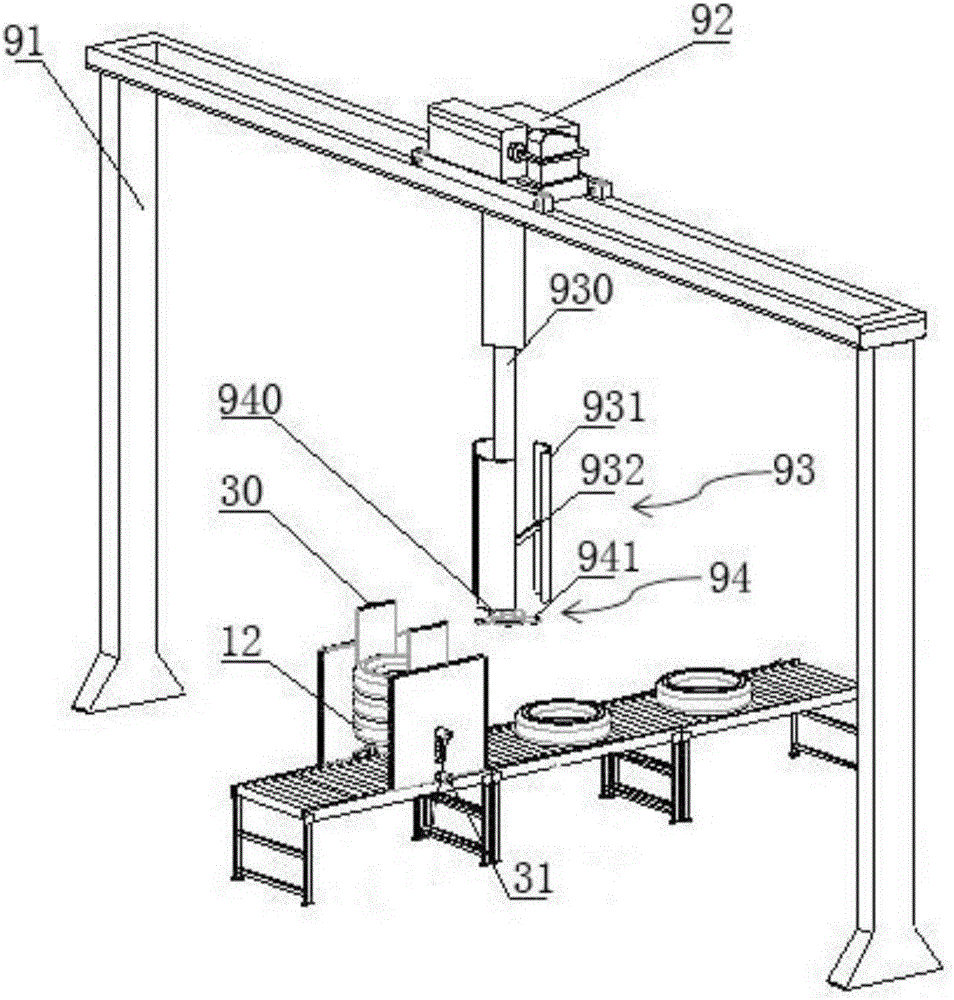

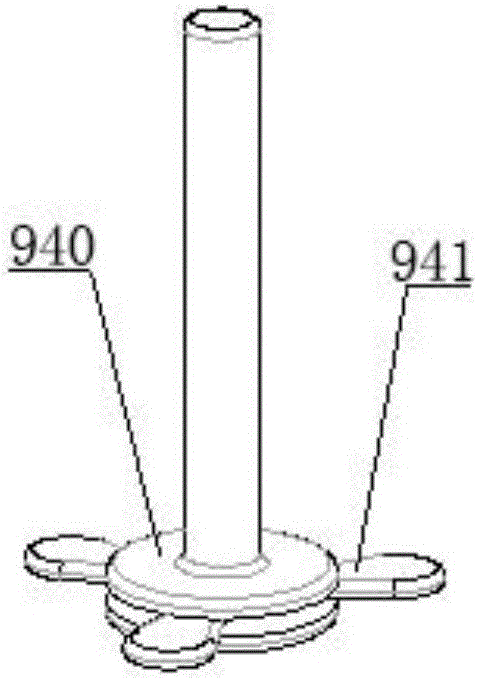

Full-automatic overlapping and packaging processing equipment for bearing retainer

ActiveCN104670545AImprove stacking efficiencyEasy to adjustWrappingWrapper twisting/gatheringEngineeringUltimate tensile strength

The invention discloses full-automatic overlapping and packaging processing equipment for a bearing retainer. The full-automatic overlapping and packaging processing equipment is characterized by comprising a frame, wherein an automatic overlapping and thin film covering mechanism and an automatic edge sealing and thermal shrinkage mechanism are arranged on the frame; the automatic overlapping and thin film covering mechanism comprises a retainer conveying and loading device, an overlapped mandril conveying device, a thin film pipe covering and conveying device, a thin film cutting device and a manipulator transmission device; the automatic edge sealing and thermal shrinkage mechanism comprises a sealing and edge folding device and a thermal shrinkage device. Retainers are automatically overlapped, and a thin film automatically sleeves the overlapped retainer group; then the whole group of retainers are automatically subjected to sealing, pressing and edge folding, and finally the packaging thin film is subjected to thermal shrinkage, so that the package is compacter, and the whole appearance is more attractive; furthermore, all the operations are automatically completed by a cylinder, a motor and the like; the labor intensity of a worker is reduced, and the production efficiency is improved.

Owner:台州市进宇轴承有限公司

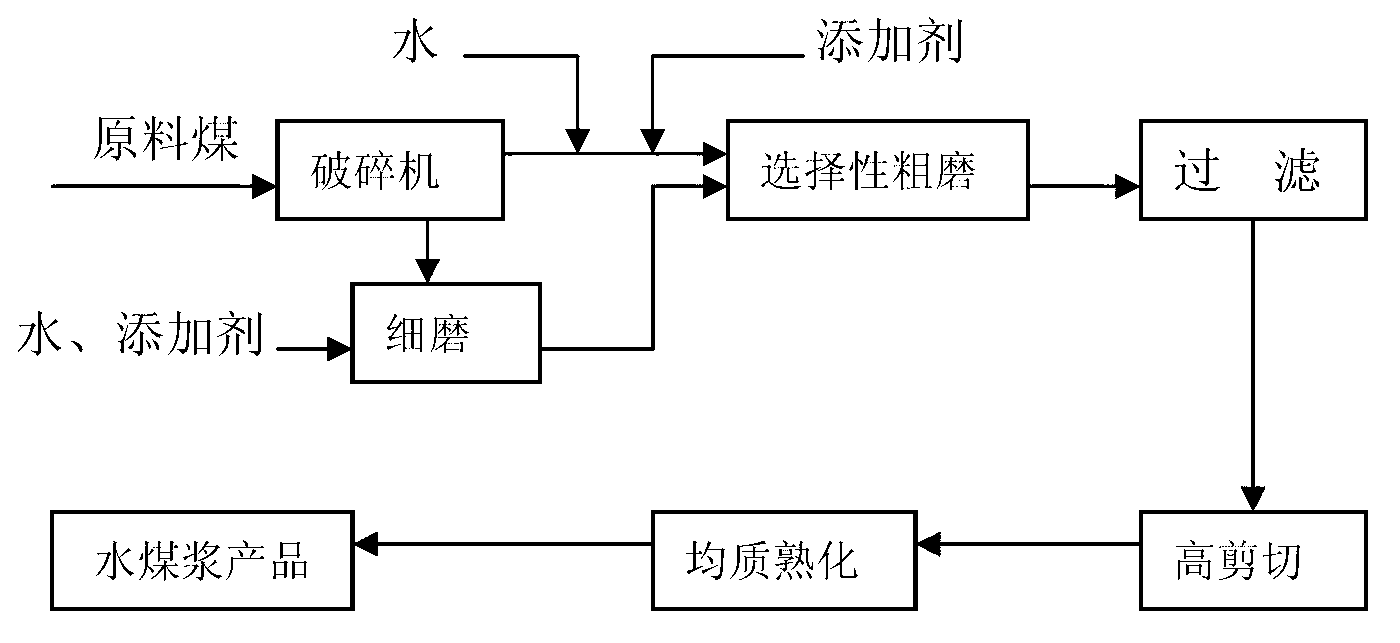

Gasified water-coal-slurry and preparation method thereof

ActiveCN103305297AOptimize particle size distributionImprove stacking efficiencyLiquid carbonaceous fuelsCoal slurryHigh concentration

The invention discloses a preparation method of gasified water-coal-slurry. The method comprises the following steps: (1) crushing low-rank coal to pulverized coal, wherein the grain diameter of the pulverized coal is less than 13mm; (2) inputting pulverized coal a to a roughing machine, and adding an additive and water to carry out high concentration pulping; (3) inputting pulverized coal b to an atomizer mill, adding an additive and water and grinding to prepare water-coal-slurry, wherein the mass concentration of the water-coal-slurry is 40-45% and the granularity of the water-coal-slurry is less than 40 mu m; and (4) inputting the water-coal-slurry prepared in the step (3) to the roughing machine in the step (2), and grinding to obtain the gasified water-coal-slurry. According to the preparation method disclosed by the invention, the original graded grinding process, i.e., after all coal passing through the crusher enters into the roughing machine to carry out ore grinding, part of crushed coal is directly fine-grinded and then enters into the roughing machine carry out mixed ore grinding is changed, so that not only is coal slurry granularity distribution of the atomizer mill more suitable for granularity distribution of gasified coal slurry, but also the grinding load increased by 10-30% caused by repeated grinding of the roughing machine is reduced. Therefore, the grinding energy consumption is further reduced.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

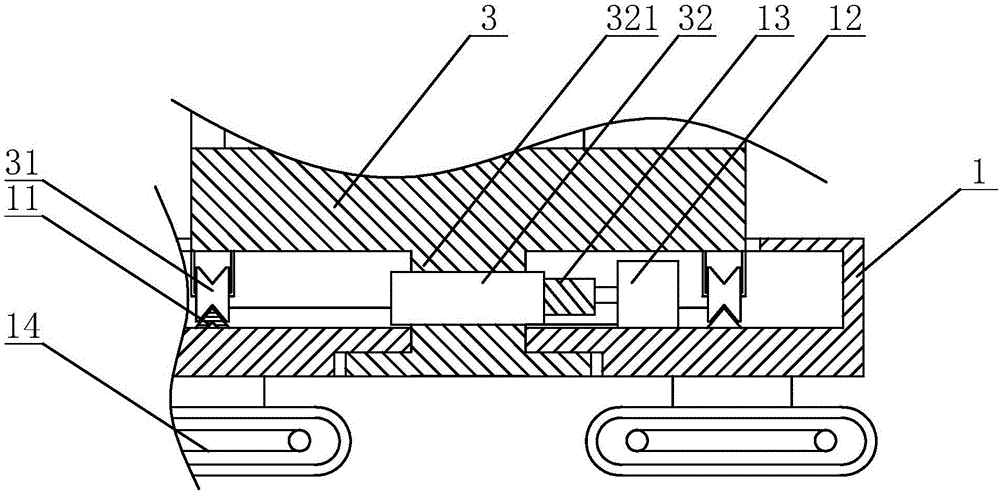

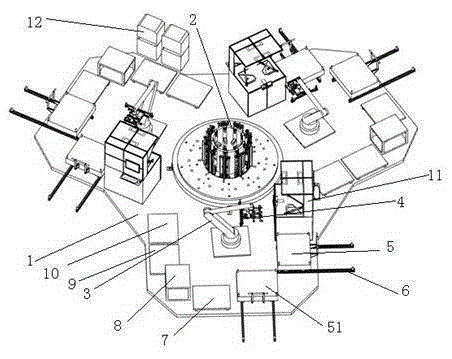

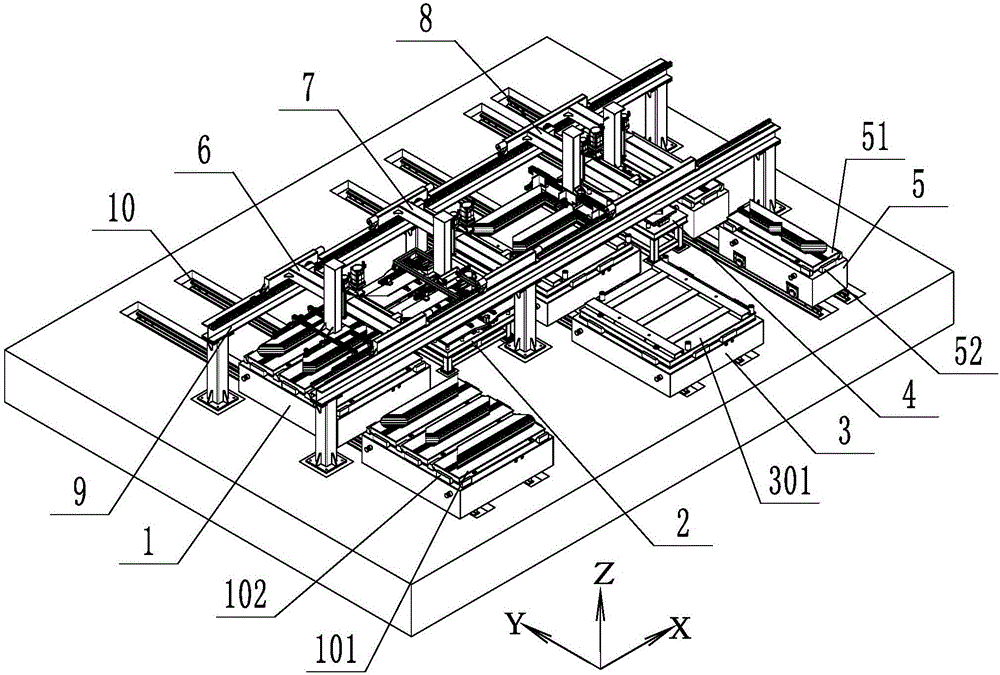

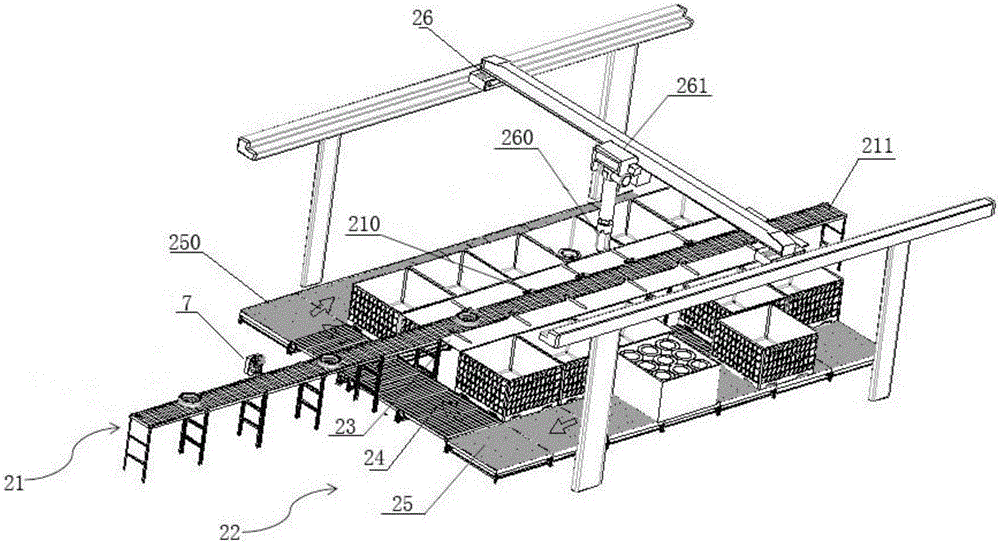

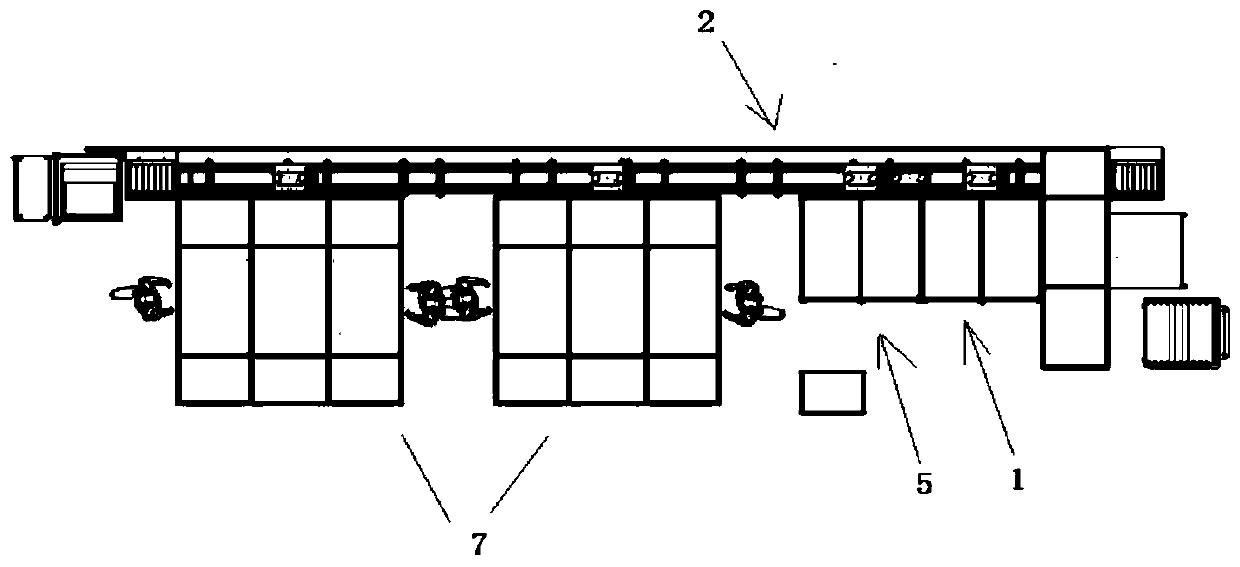

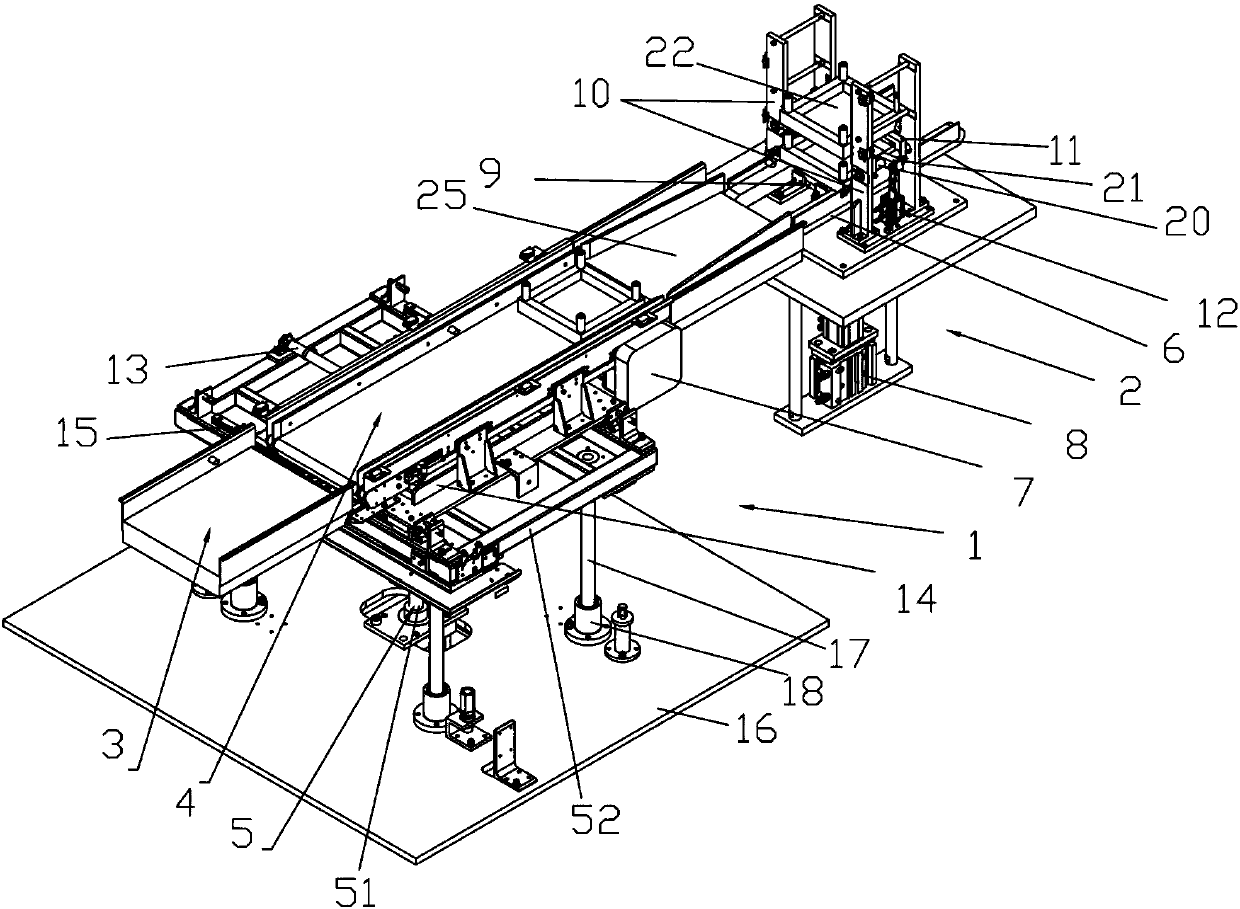

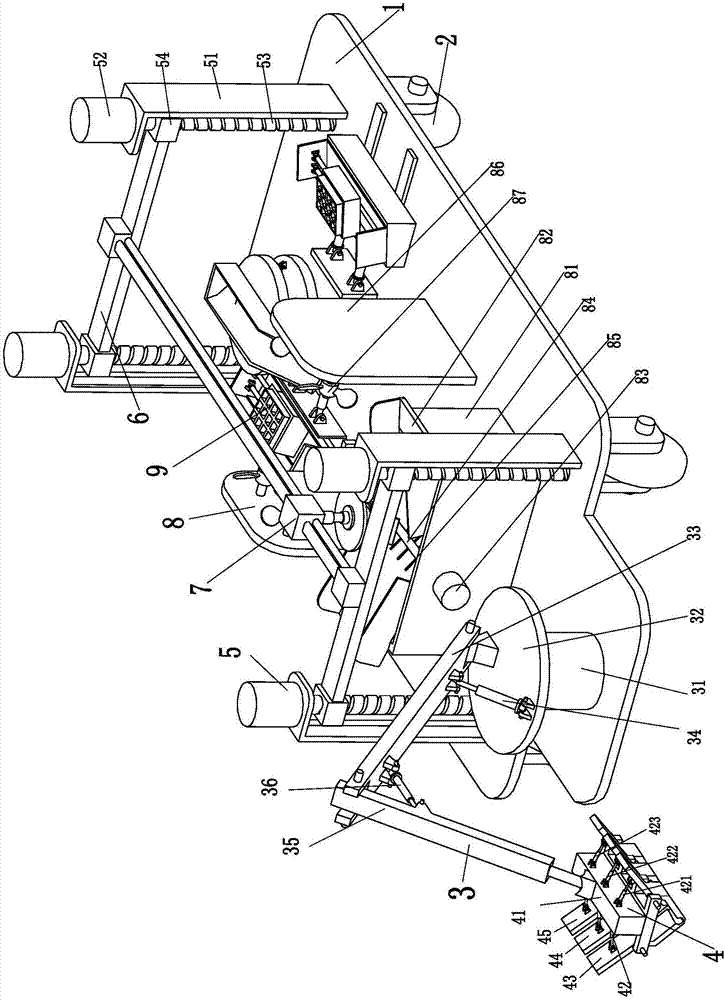

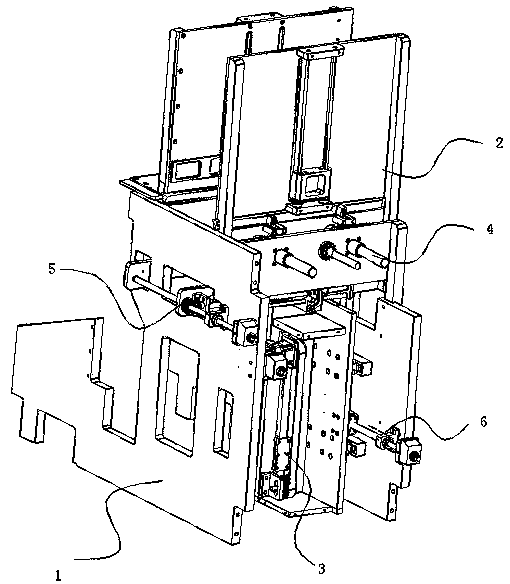

Automatic external laminating method and automatic external laminating device of motor stator core

ActiveCN106849533AImprove stacking accuracyEfficient separationManufacturing stator/rotor bodiesPunchingEngineering

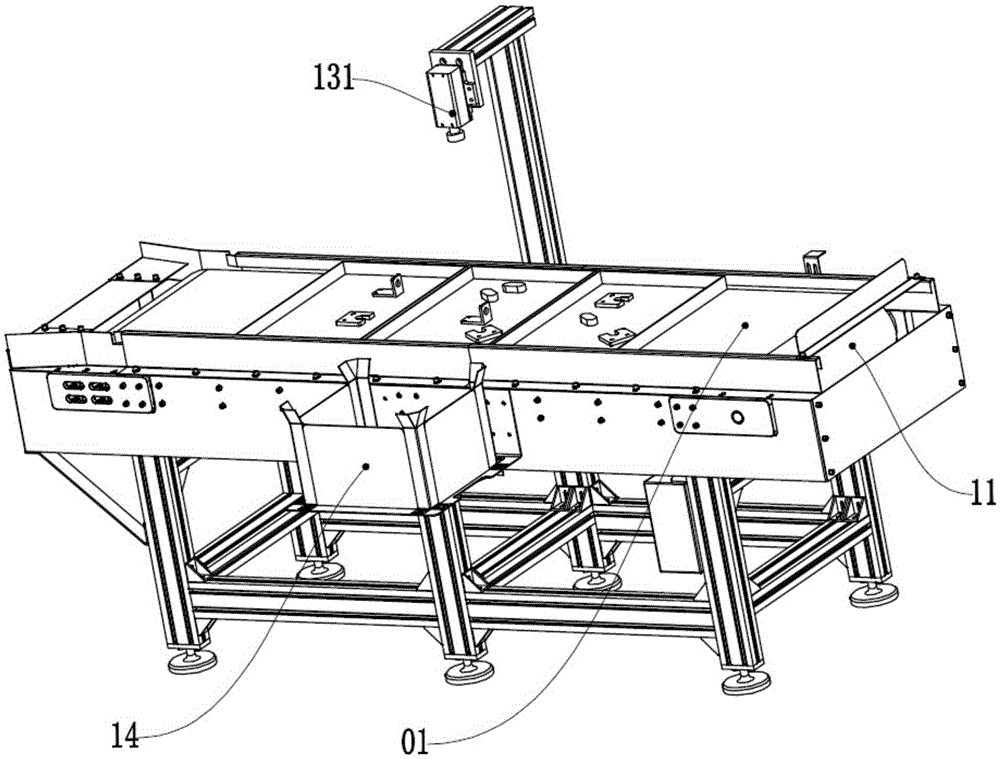

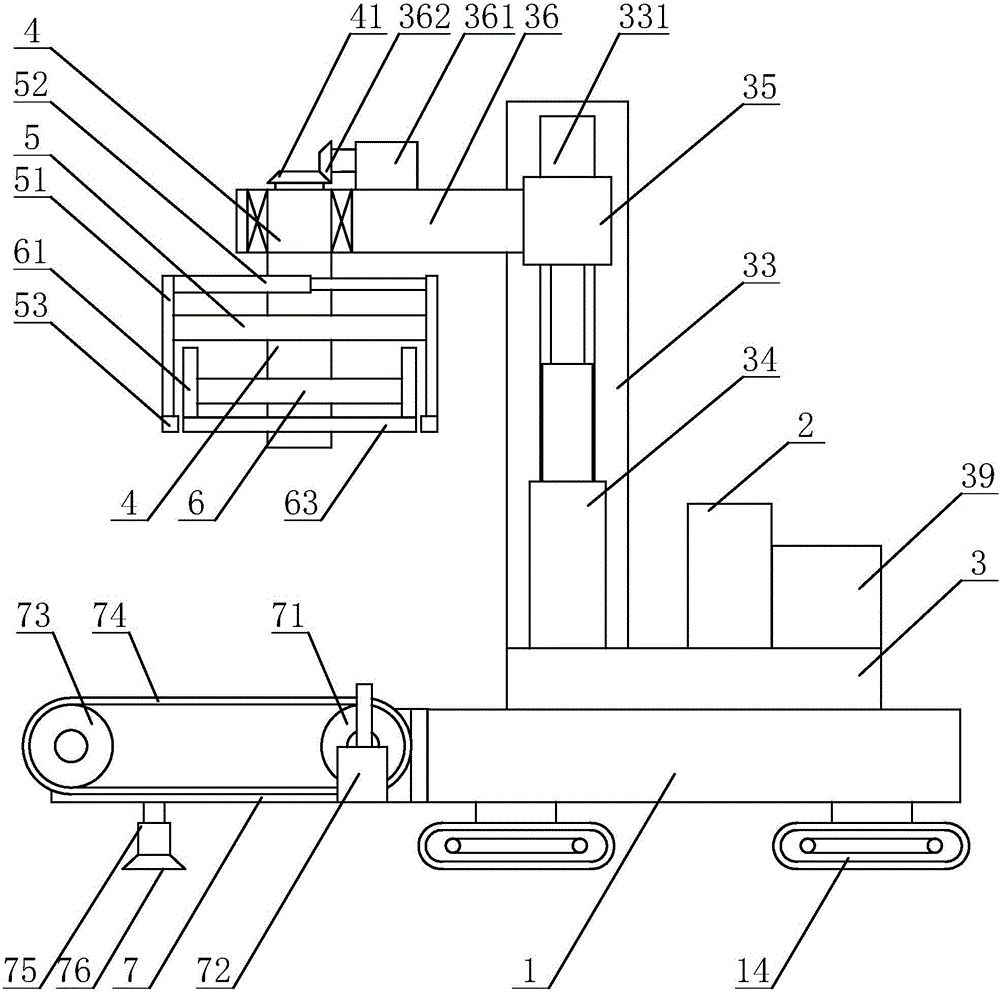

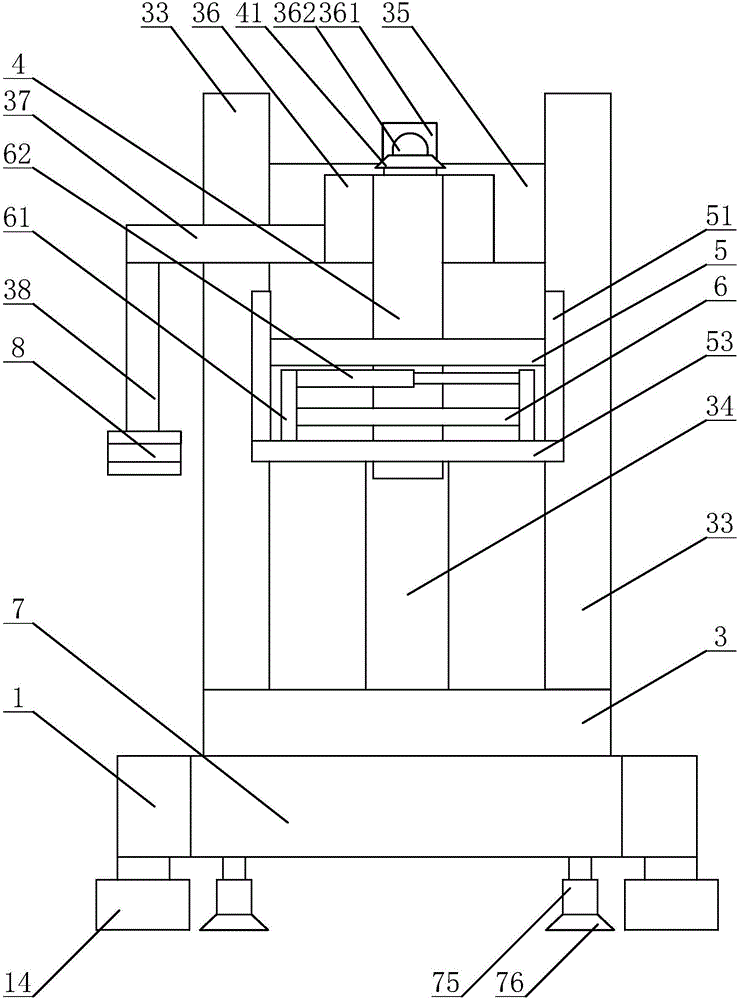

The invention discloses an automatic external laminating method and an automatic external laminating device of a motor stator core. The device comprises a working table (1), robots (3), centering tables (11), a laminating location table (2) and punching sheet material discs (5), wherein the laminating location table (2) is arranged in the center of the working table (1); the working table (1) is equally divided into three parts; each part is provided with one robot (3); tail end suction discs (4) are arranged at the ends of the robots (3); and the centering tables (11), the punching sheet material discs (5), iron sheet material discs (7), waste material discs (8), ventilation slot plate material discs (9) and compensating sheet material discs (10) are arranged around the robots (3). According to the method and the device, laminating of the core is accomplished by mechanical, automatic and standard movement, so that an error caused by a human factor is effectively reduced; a dust-free requirement of a laminating environment can be ensured; and the laminating efficiency can be improved.

Owner:DONGFANG ELECTRIC MACHINERY

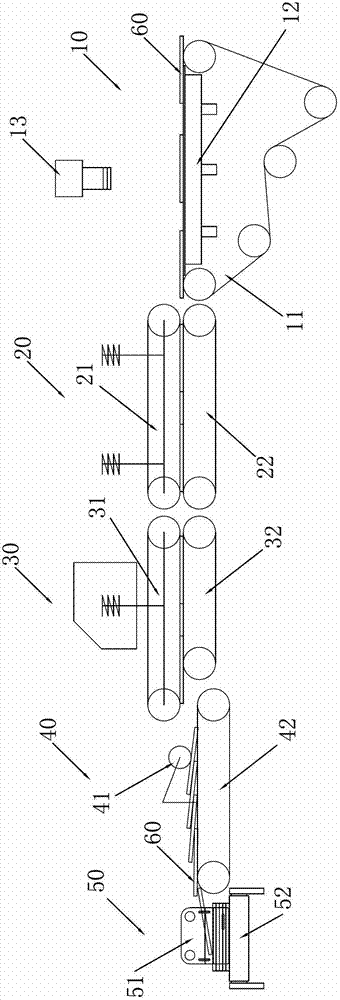

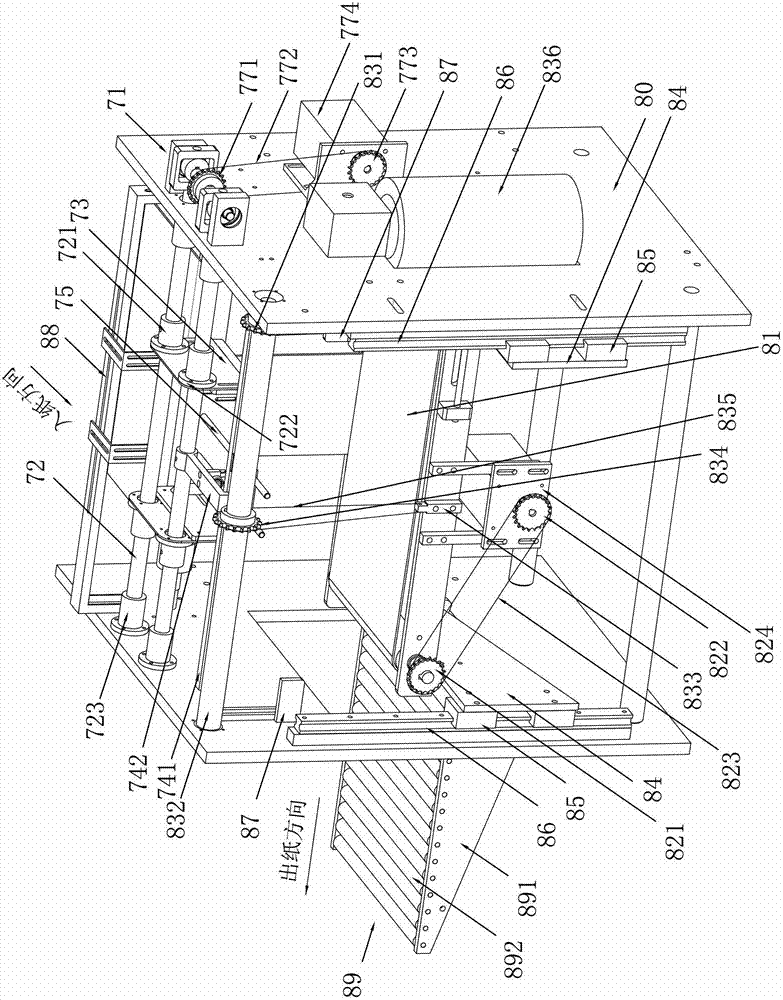

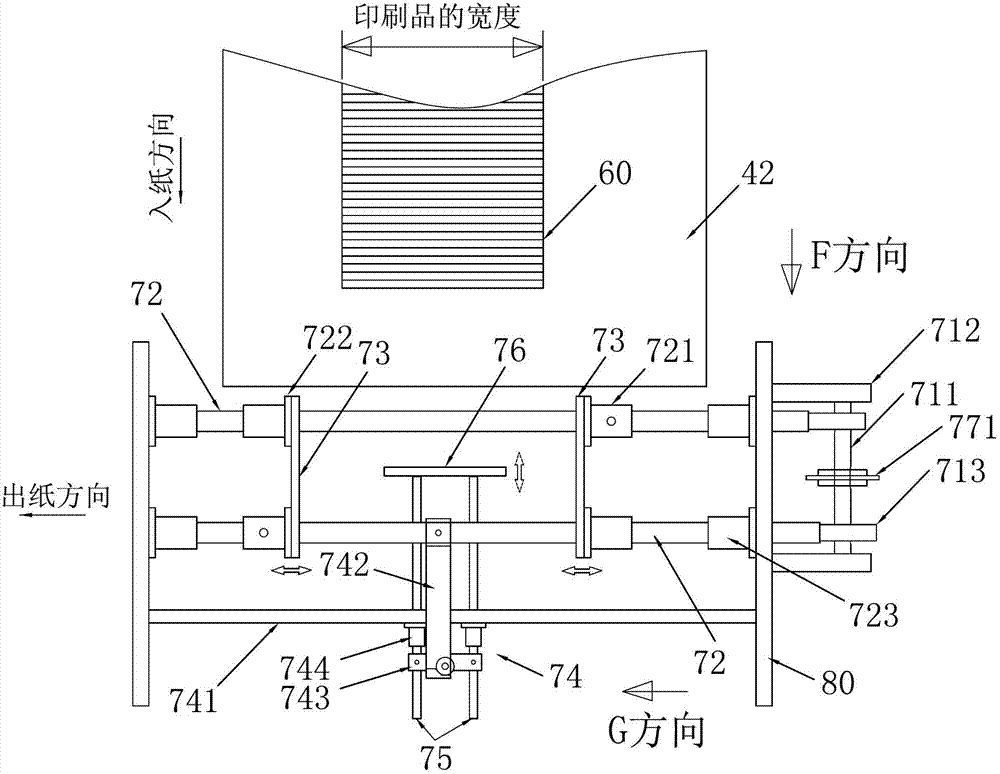

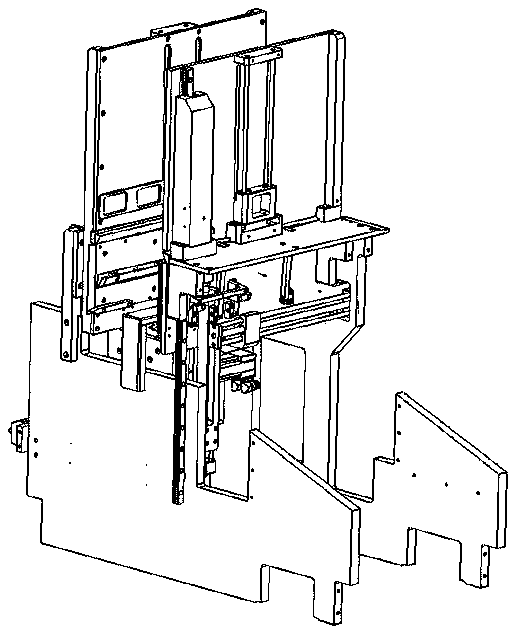

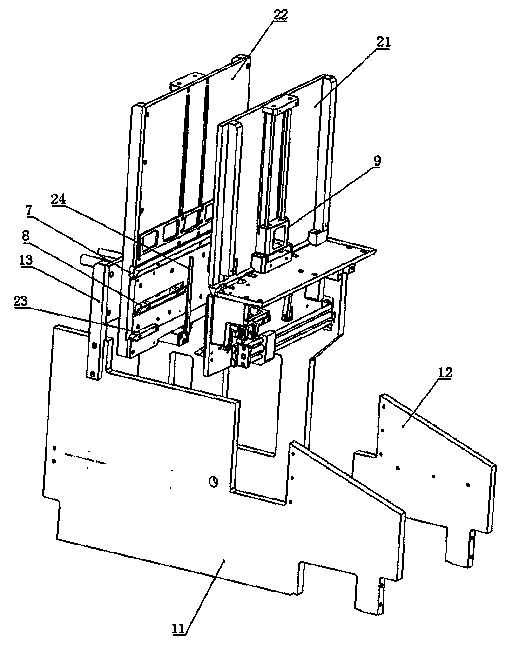

Stacking and collecting mechanism, stacking and collecting method and quality testing machine for small-size prints

The invention discloses a stacking and collecting mechanism, a stacking and collecting method and a quality testing machine for small-size prints. The stacking and collecting mechanism comprises two main wallboards. The two main wallboards are partially provided with clapping devices. A stacking output device is arranged under the clapping device. The clapping device comprises a supporting beam mounted between the two main wallboards. One end of the supporting beam is connected with a cam mechanism. A pair of lateral pushing boards is mounted on the supporting beam, and is used for pushing two lateral sides of prints. A rear pushing board is arranged between two lateral pushing boards, is connected with the supporting beam through a supporting rod and a slope driving mechanism, and is used for hooking-in and clapping the upper surface of the prints. The stacking output device comprises a lifting platform which is driven to move up and down by a lifting motor through a lifting conveying mechanism. The stacking and collecting method and the quality testing machine for small-size prints are realized based on the stacking and collecting mechanism. Automatic stacking and collecting of the small-size prints are realized at a high speed in high efficiency with low vibration and noise.

Owner:HEBEI TIANYUHENG TECH CO LTD

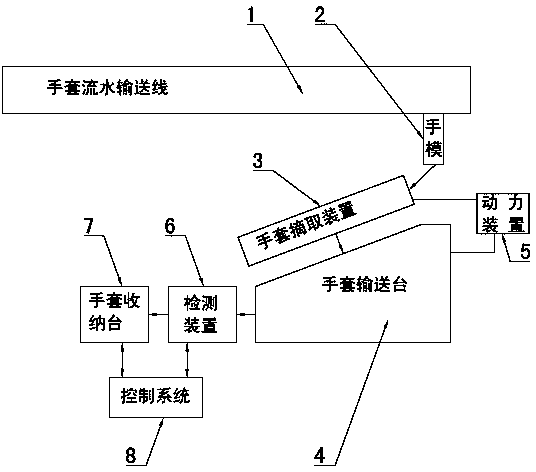

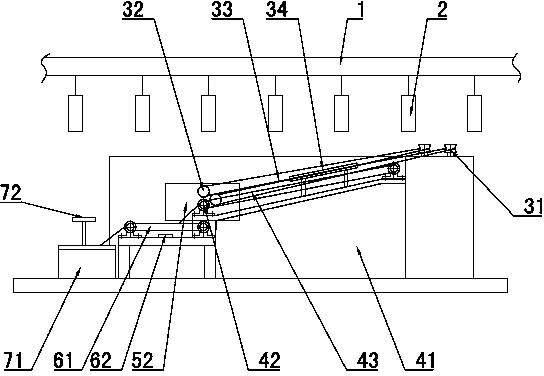

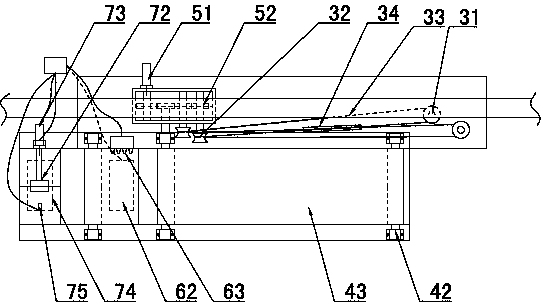

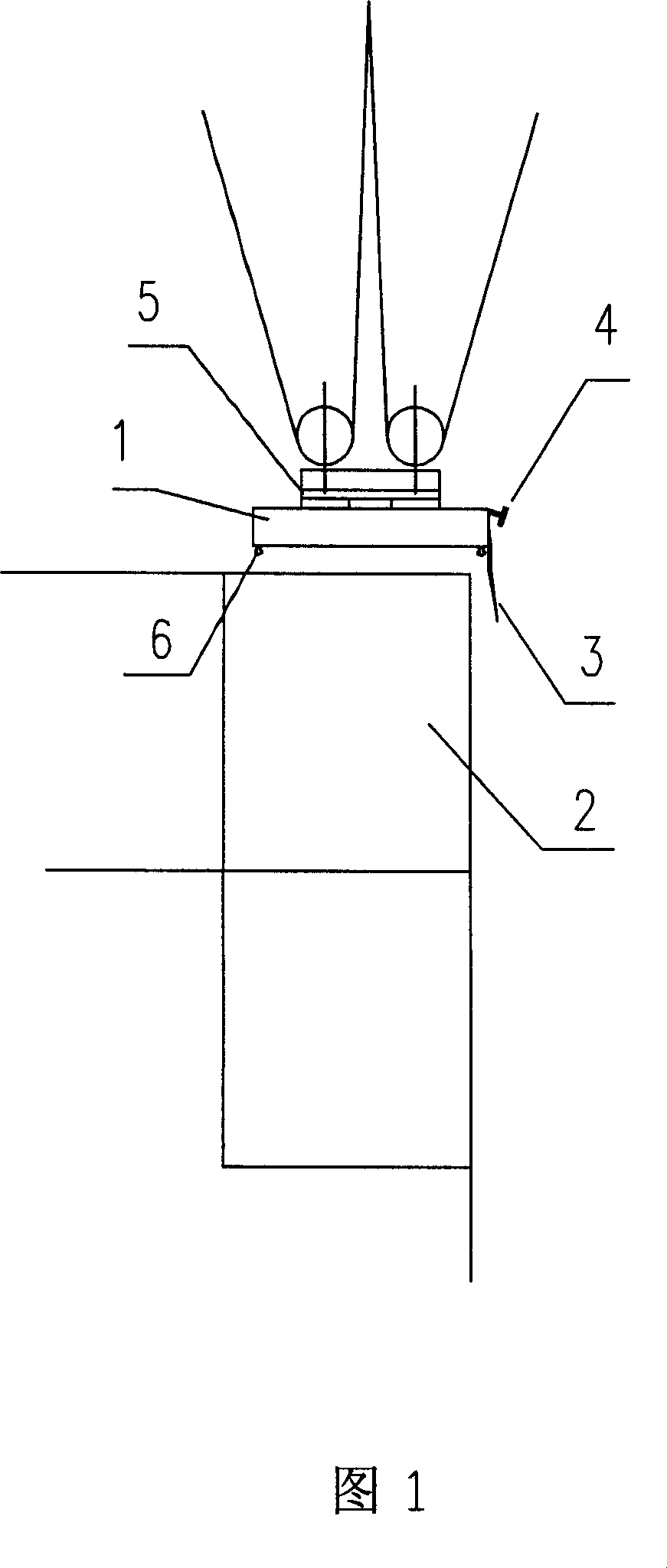

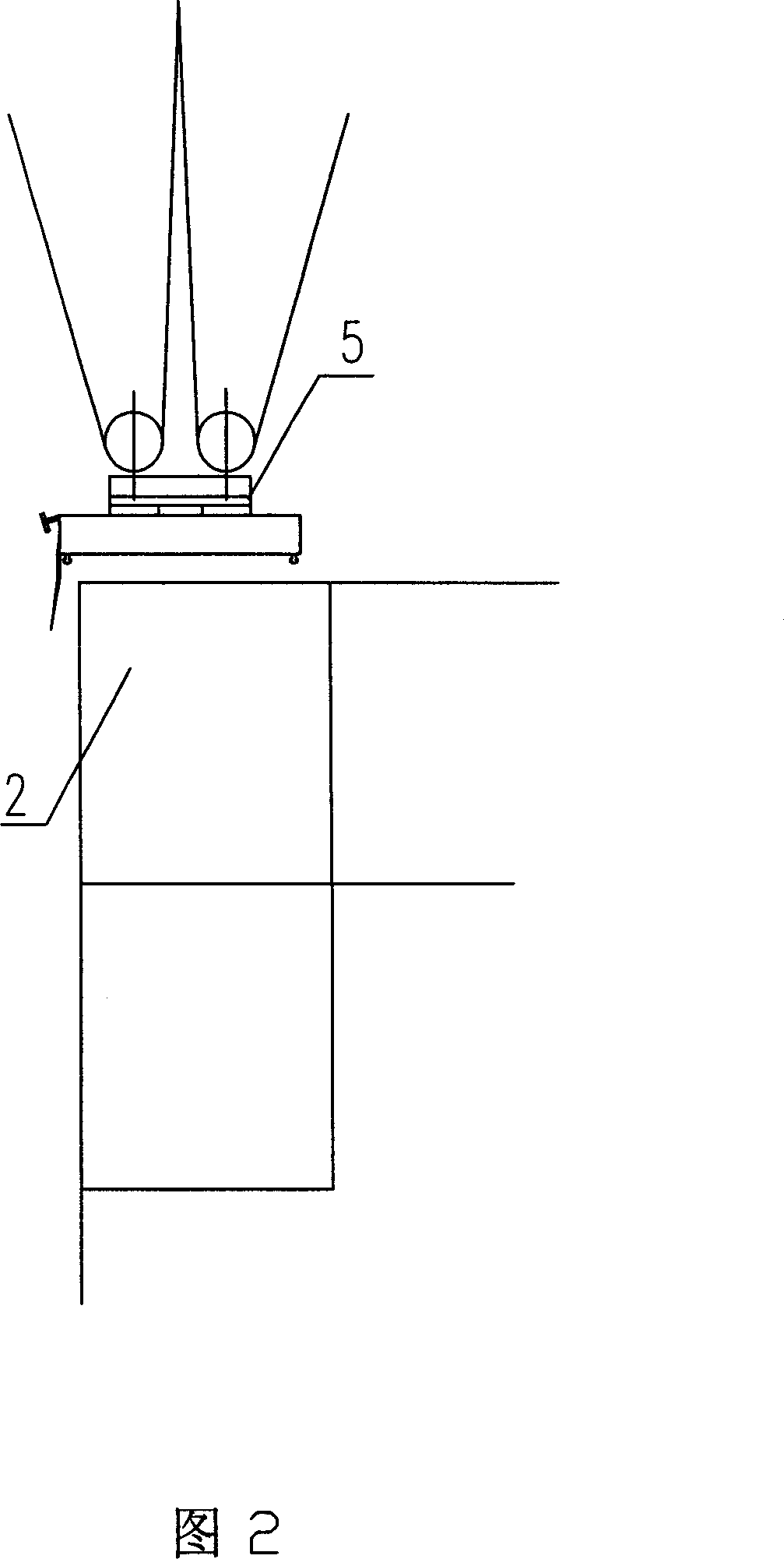

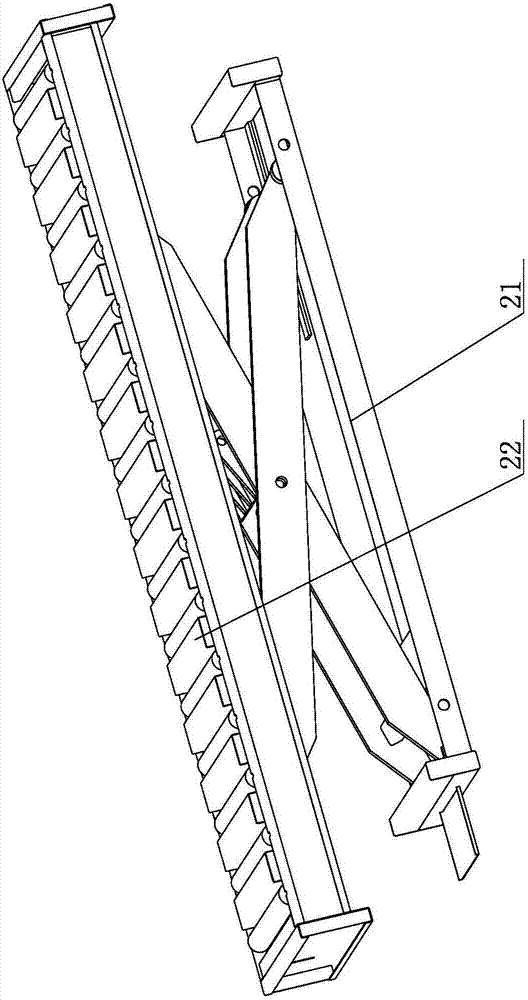

Full-automatic glove counting and stacking machine

The invention provides a full-automatic glove counting and stacking machine, and belongs to the field of production devices of vinyl gloves, butyronitrile gloves and latex gloves. The full-automatic glove counting and stacking machine comprises a glove assembly conveying line (1), a plurality of hand moulds (2) are hung on the lower portion of the glove assembly conveying line (1), and gloves are arranged on the surfaces of the hand moulds (2) in a sleeved mode in the conveying process. The full-automatic glove counting and stacking machine is characterized in that a glove picking device (3) and a power device (5) are arranged below the glove assembly conveying line (1), a glove conveying table (4) with an inclined conveying face is arranged on one sides of the glove picking device (3) and the power device (5), the power device (5) drives the glove conveying table (4) and the glove picking device (3) to work at the same time, a detection device (6) is arranged at the output end of the glove conveying table (4), and the rear portion of the detection device (6) is connected with a glove storing table (7). The full-automatic glove counting and stacking machine is simple in structure, high in efficiency, free of cylinder control, convenient to maintain, and capable of achieving glove picking, detecting, conveying, and stacking functions.

Owner:ZIBO CHENGXUN AUTOMATION EQUIP

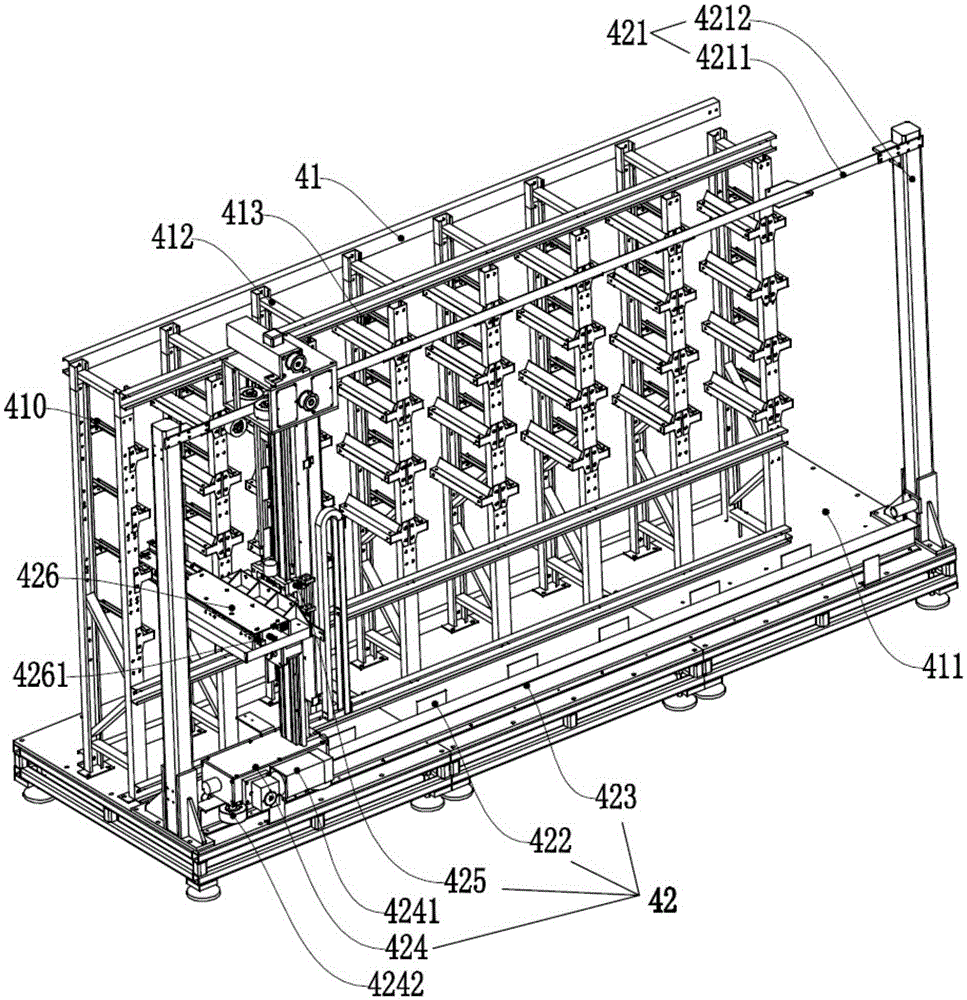

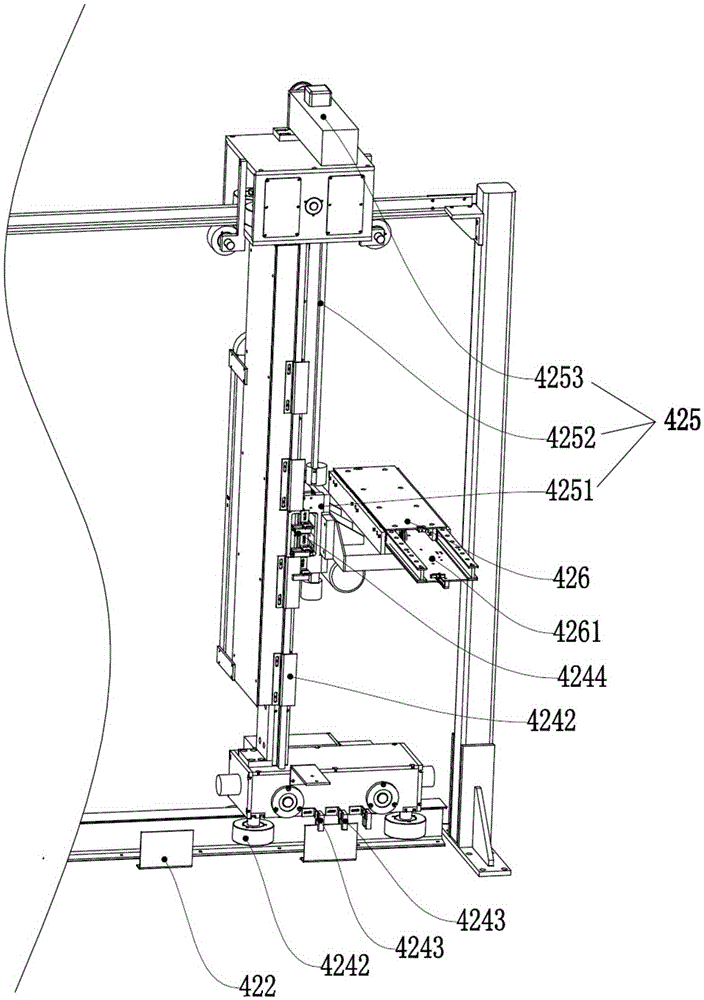

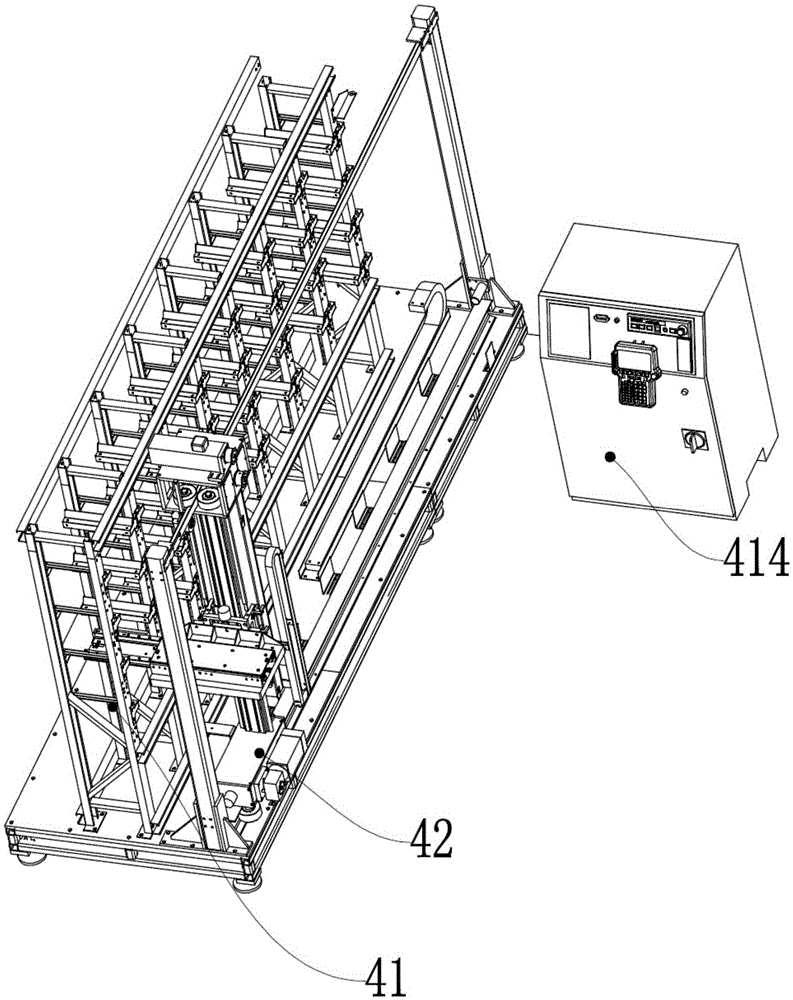

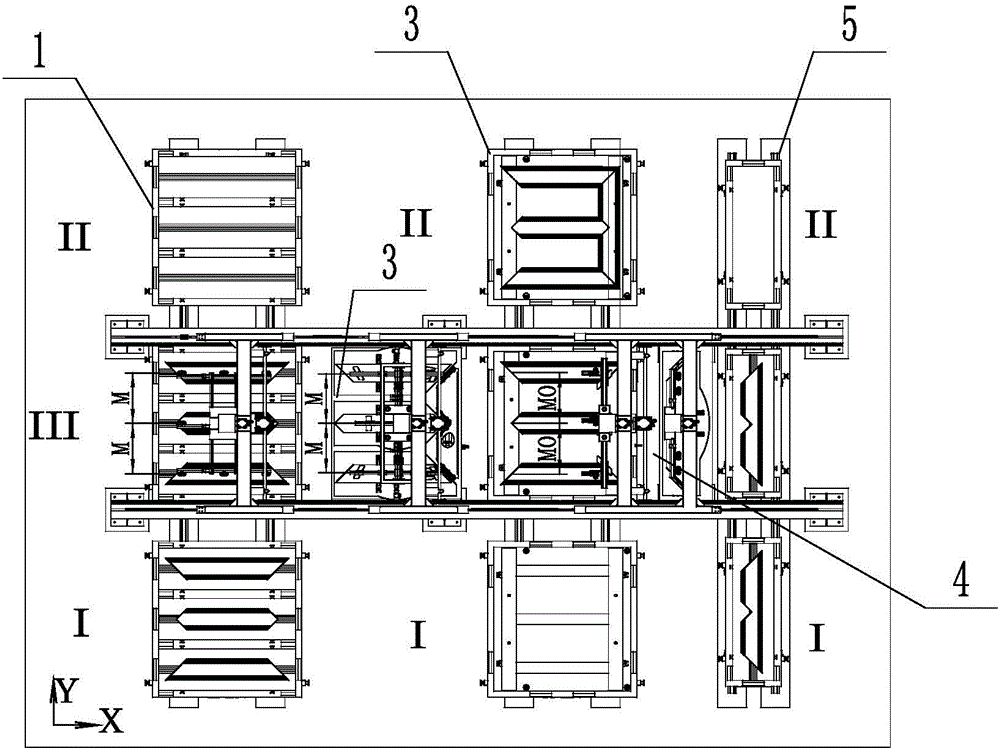

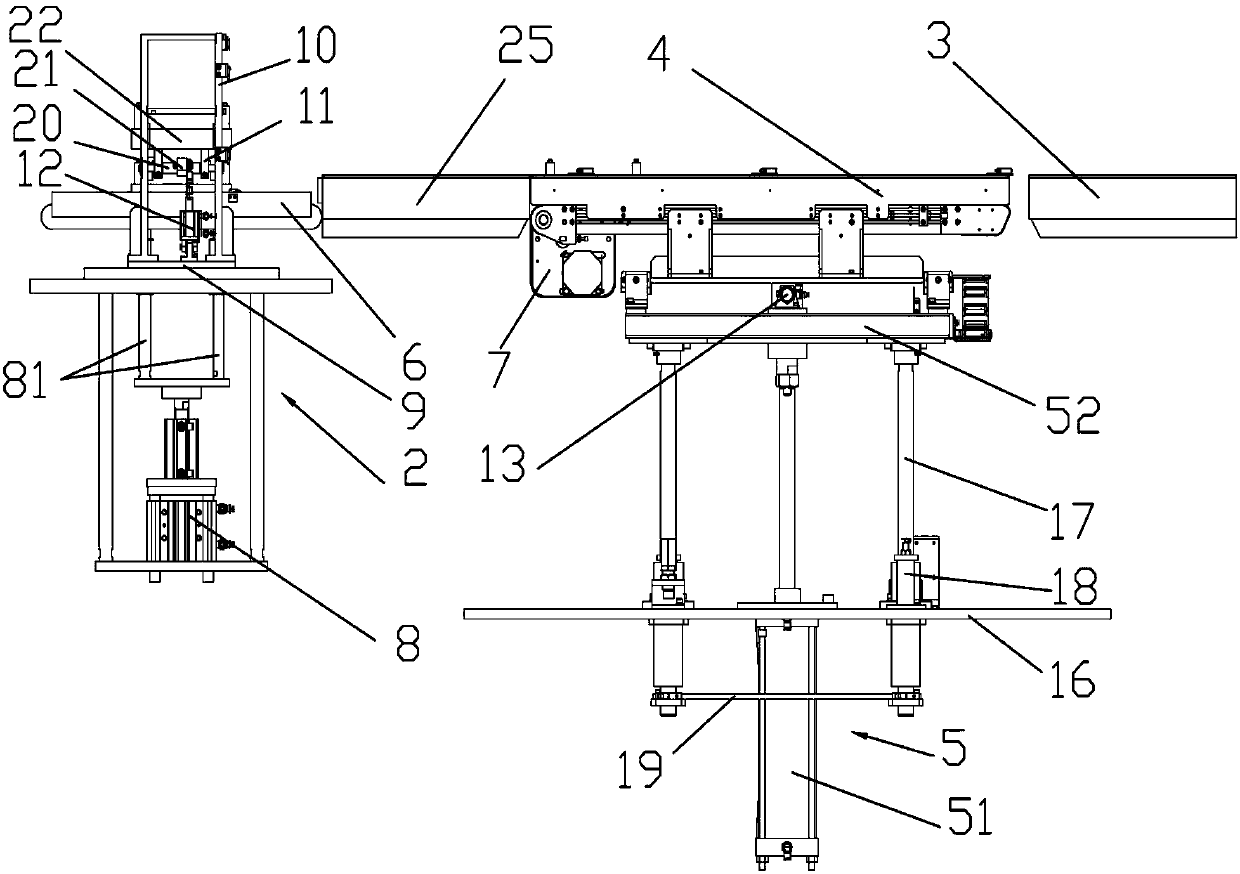

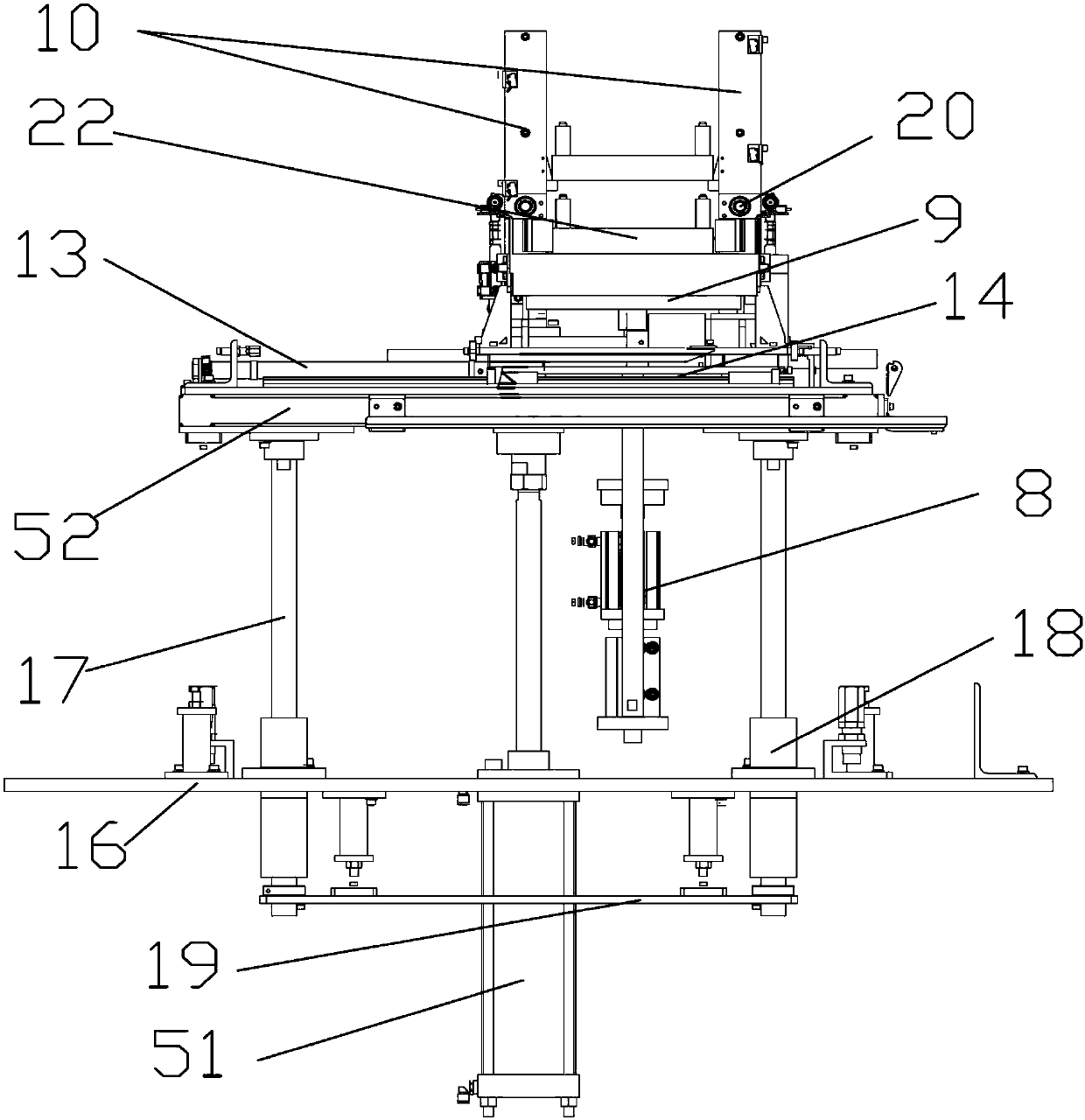

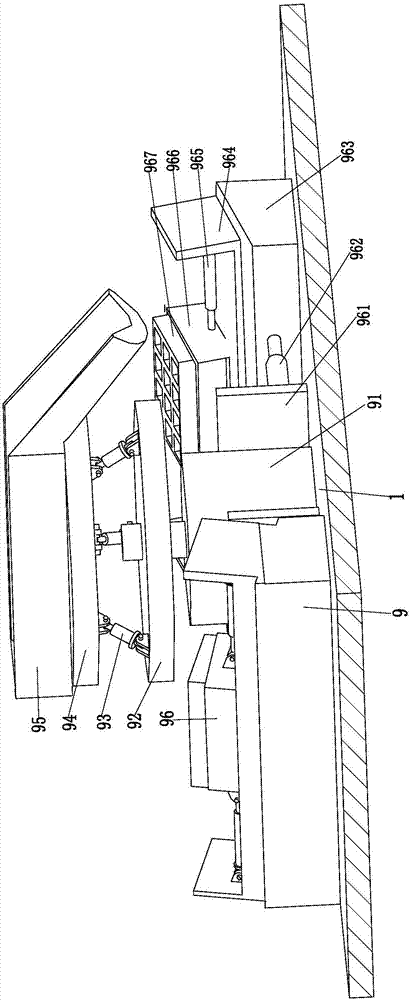

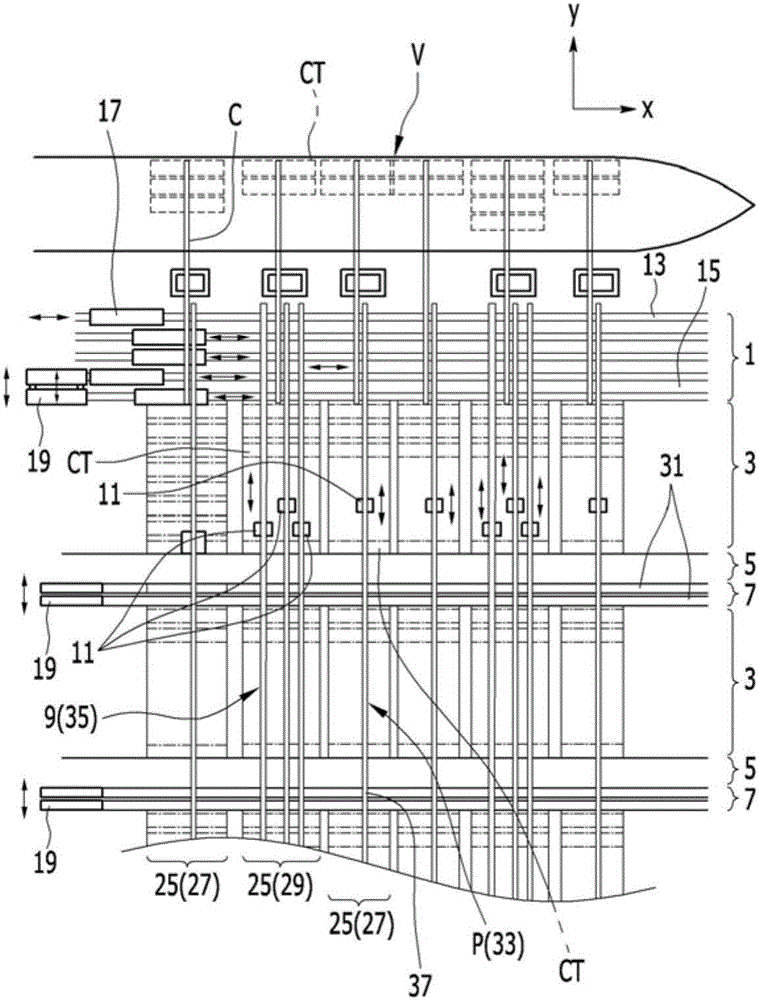

Automatic transformer iron core stacking system

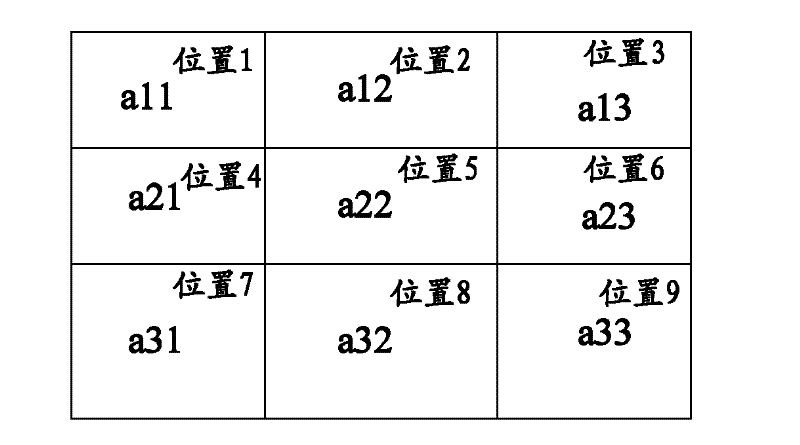

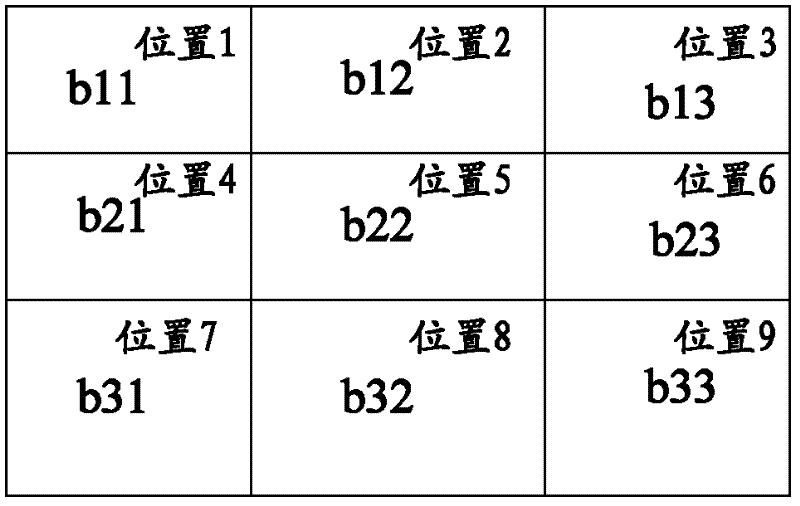

ActiveCN106697973AGuaranteed alignmentIncrease productivityStacking articlesDe-stacking articlesChinese charactersTransformer

The invention discloses an automatic transformer iron core stacking system which comprises a preparation station I area, a turnover station II area and a work station III area, and the preparation station I area and the turnover station II area play corresponding roles alternatively. The work station III area comprises a three-pillar-piece single-layer automatic stacking system, a servo stacking opposite seaming mechanism and an extra-thin-piece X-axis Y-axis bidirectional centering platform. The work station III area is divided into a ground layer and an overhead layer, and the ground layer is provided with a pillar piece feeding station, a pillar piece centering station, a final assembly station, a lower yoke piece centering station and a lower yoke piece feeding station in sequence in the X direction; and the overhead layer is provided with a pillar piece A mechanical arm, a pillar piece B mechanical arm and a lower yoke piece mechanical arm in sequence in the X direction. According to the automatic transformer iron core stacking system, when pieces are taken, whether multiple pieces are taken or not can be recognized automatically, and stacking of an iron core shaped like a Chinese character 'shan' can be completed according to requirements; and the automatic transformer iron core stacking system has the advantages of being high in efficiency and stable in quality, and a plenty of manpower can be saved.

Owner:JINAN AOTTO TECH

Tire stack disassembling device

ActiveCN106241160ASimple structureHigh degree of automationConveyorsStacking articlesRange of motionEngineering

The invention relates to a tire stack disassembling device. The tire stack disassembling device comprises an input roll table and an output roll table, and a lifting device and a telescopic propelling device located above the lifting device are sequentially arranged between the input roll table and the output roll table. The lifting device comprises a lifting platform and a hydraulic device controlling the lifting platform to ascend and descend. The telescopic propelling device comprises a piston rod air cylinder, a limiting component and a telescopic end face which is controlled by the piston rod air cylinder to move towards or away from the limiting component. Firstly, the lifting device conveys a tire stack upwards to the moving range of the telescopic end face, wherein under the action of the limiting component, the tire stack can be precisely conveyed to the part between the limiting component and the telescopic end face, and tires in the tire stack can be prevented from sliding in the ascending process; then, the telescopic end face moves towards the limiting component, and the tires on the upper portion of the tire stack are disassembled and then conveyed into the subsequent links through the output roll table. The tire stack disassembling device has the advantages of being high in efficiency, low in cost, easy to maintain, high in adaptability and the like.

Owner:SOUTHWEST JIAOTONG UNIV

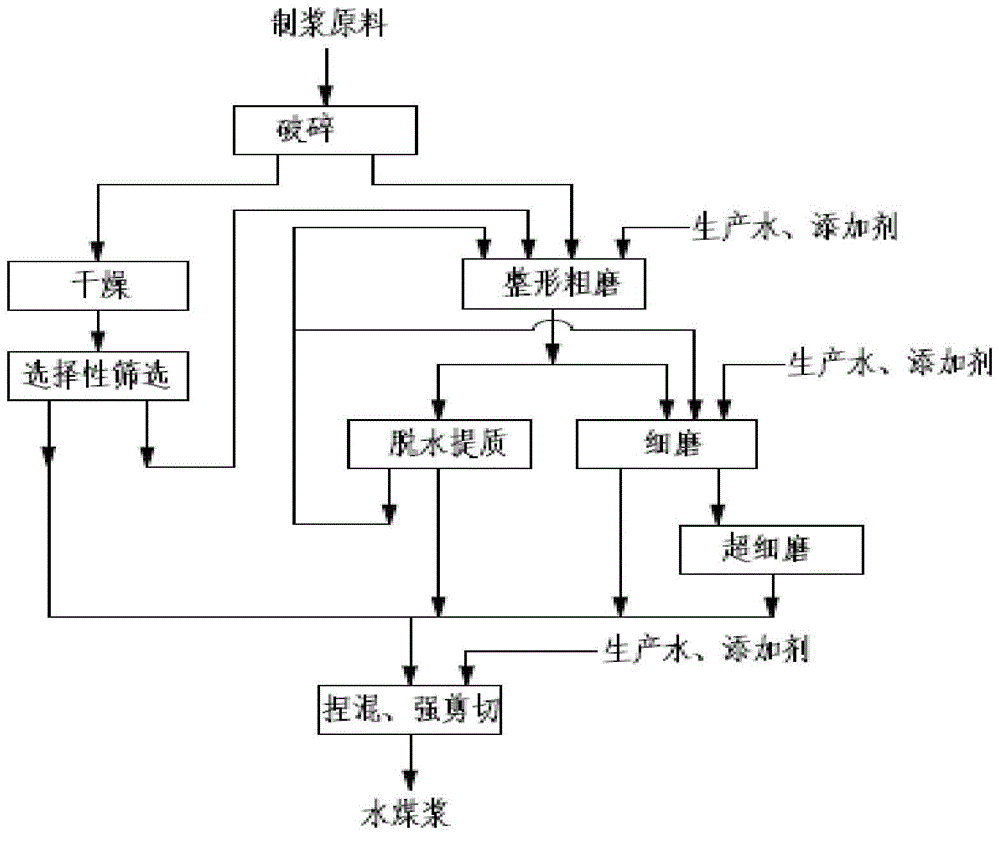

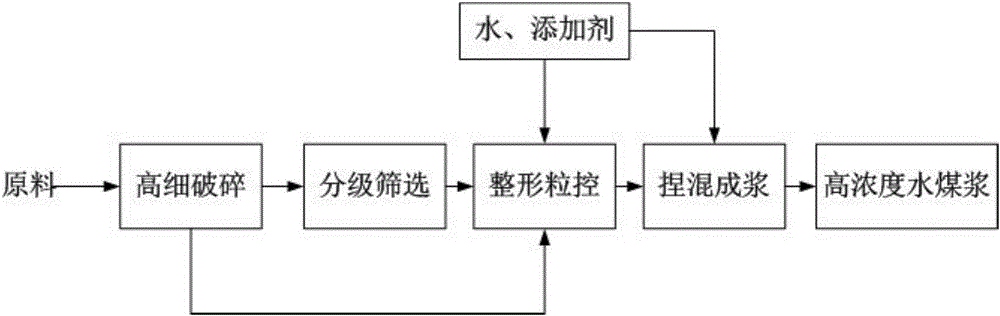

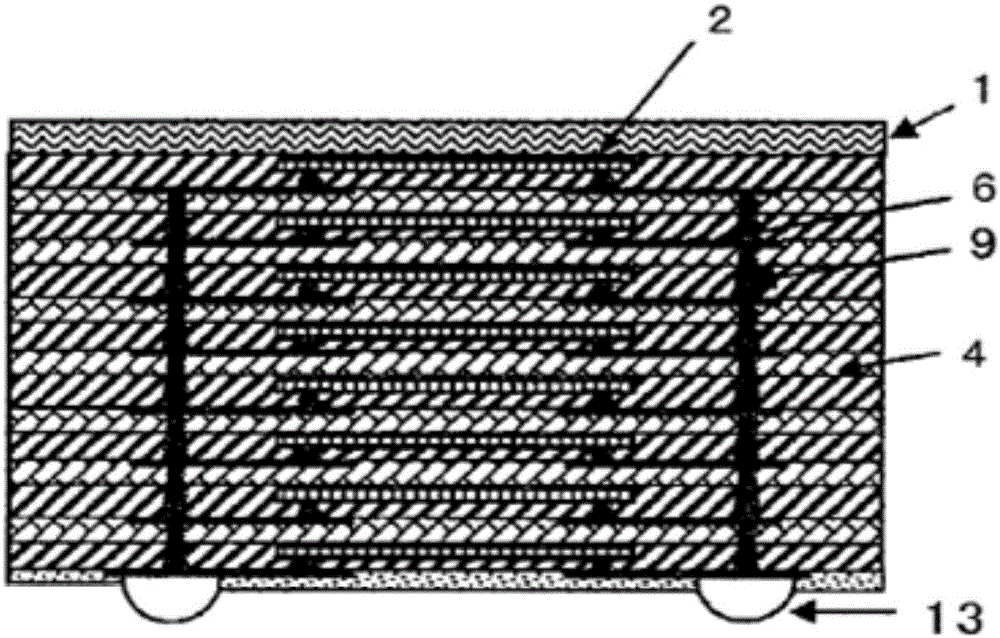

Method for preparing coal water slurry

ActiveCN105038878AIncrease concentrationImprove stacking efficiencyLiquid carbonaceous fuelsCoal waterCoal particle

The invention relates to a method for preparing coal water slurry. Dry coal which is difficult to form slurry is crushed in steps; and then, steps such as coarse grinding, dehydrating, fine grinding, super-fine grinding and the like are carried out in parts; after the dry coal is mixed in a specific proportion, a gap formed during coal particle stacking is perfectly filled, and the stacking efficiency is improved, so that the concentration of the coal water slurry is improved; and the prepared coal water slurry can meet needs of gasification and combustion application. The method for preparing coal water slurry provided by the invention has the characteristics of a wide application scope of coal types, capacity of carrying out long-period continuous production, and convenience in parameter regulation.

Owner:CCTEG CLEAN ENERGY CO LTD

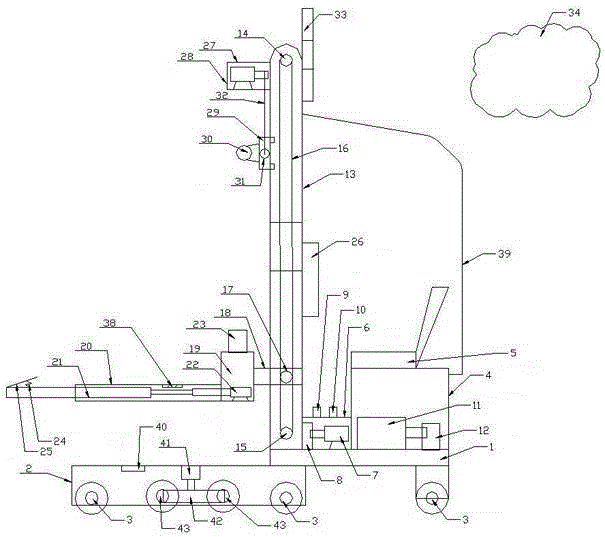

Efficient stacking device for carrying goods

ActiveCN105036003AEfficient handlingRelieve physical fatigueLifting devicesComputer moduleTransportation technology

The invention belongs to the technical field of goods transportation and particularly discloses an efficient stacking device for carrying goods. The efficient stacking device for carrying goods comprises a base, a fork body base connected with one side of the base, a guiding beam frame arranged on the base, a first motor arranged on the base, a gear transmission box connected with the first motor, a first chain wheel, a second chain wheel, a third chain wheel arranged between the first chain wheel and the second chain wheel and connected with a transmission chain, a first fork body, a second fork body, a protective cover and an auxiliary assembly arranged in the fork body base. The first chain wheel and the second chain wheel are arranged at the upper end and the lower end of the guiding beam frame respectively. The first fork body and the second fork body are arranged on the two sides of a fork body box respectively. The protective cover is arranged above a seat. The two ends of the protective cover are connected with the guiding beam frame and a seat installing frame respectively. When the efficient stacking device is used for carrying goods and performing stacking operation and the size of the goods is too large, a second cylinder is controlled to be pressed downwards through a monitoring module, an auxiliary running wheel makes contact with the ground, and stable carrying is completed; and the visible range is wide due to the full-transparent protective cover, and meanwhile injuries to operators caused when the goods slide can be effectively prevented.

Owner:米亚斯物流设备(昆山)有限公司

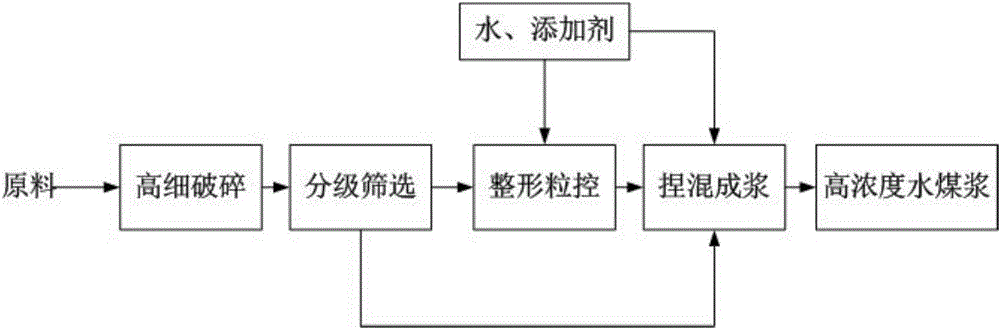

High-concentration coal water slurry and method for efficient classified grain control preparation of high-concentration coal water slurry

ActiveCN106244268AIncrease concentrationReasonable particle size distributionLiquid carbonaceous fuelsHigh concentrationCoal water

The invention provides high-concentration coal water slurry and a method for efficient classified grain control preparation of the high-concentration coal water slurry. Components of the high-concentration coal water slurry comprise coarse-grained coal powder, fine-grained coal slurry or fine-grained coal powder, an additive or water, and the concentration of the coal water slurry is 50 to 75 weight percent, wherein the mass ratio of the dry basis content of the coarse-grained coal powder, the dry basis content of the fine-grained coal slurry or the fine-grained coal powder and the additive is (0-90):(10-100):(0.1-1.0). The high-concentration coal water slurry is reasonable in grain size distribution and high in coal slurry concentration, flowability, stability and atomization performance. By the preparation method, the accumulation efficiency of the coal slurry can be improved, grain size distribution of the coal slurry can be optimized, and compared with a conventional single-rod / ball mill water coal slurry preparation process, the method has the advantage that the concentration can be increased by 4-6 percent or above; the flow is simple, extremely high in operability and extremely low in energy consumption, and long-term safe and continuous production requirements can be met; the prepared coal slurry can meet requirements on gasifying water coal slurry and combustion coal water slurry.

Owner:CCTEG CLEAN ENERGY CO LTD

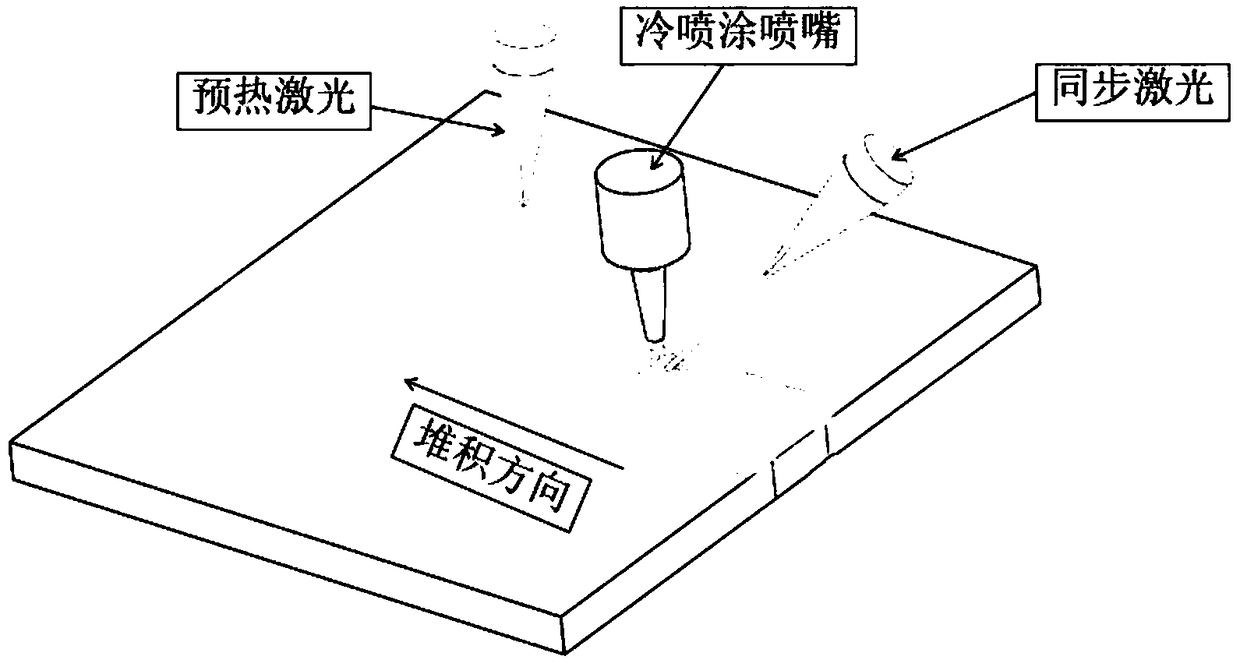

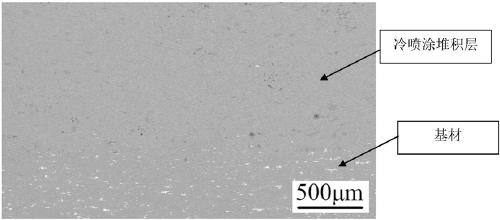

Laser-assisted cold spraying method for manufacturing additives

InactiveCN109161886AGuaranteed speedQuality assuranceAdditive manufacturing apparatusIncreasing energy efficiencySpray coatingLaser assisted

The invention discloses a laser-assisted cold spraying method for manufacturing additives. The method comprises the following steps: preheating a base material by preheating laser to enable the temperature of the base material to be raised to 300-400 DEG C and lower than the melting point of the base material by at least 200 DEG C to obtain a preheated base material; performing additive accumulation on the preheated base material with a cold spraying technology, and performing surface treatment on cold sprayed coatings obtained by additive accumulation synchronously by synchronous laser. The accumulation combination effect of cold spraying additive manufacturing can be substantially improved, the accumulation coatings are not prone to falling off, accumulation efficiency is higher, flexibility is better, quality of the additives is substantially improved, and surface molding can be effectively controlled.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Container sling

InactiveCN1978306AImprove stacking efficiencyEasy to operate manuallyLoad-engaging elementsDisplay deviceEngineering

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

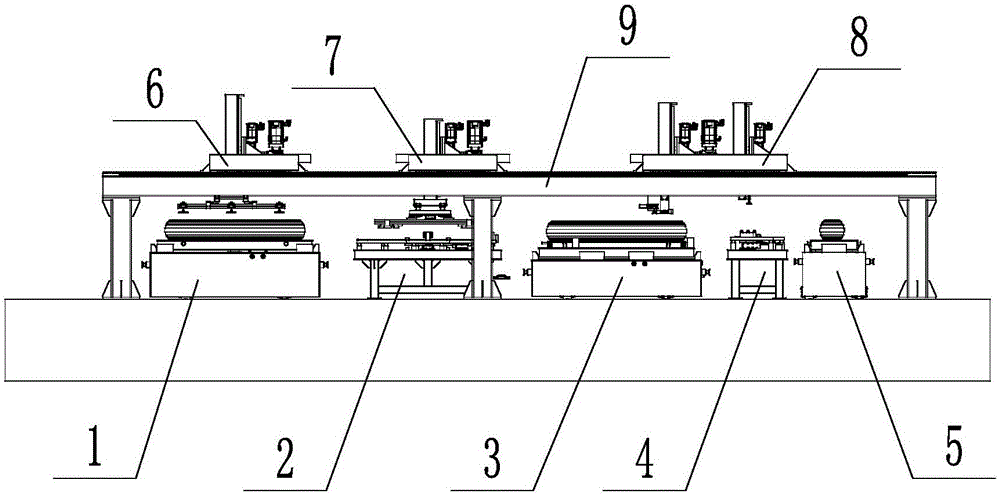

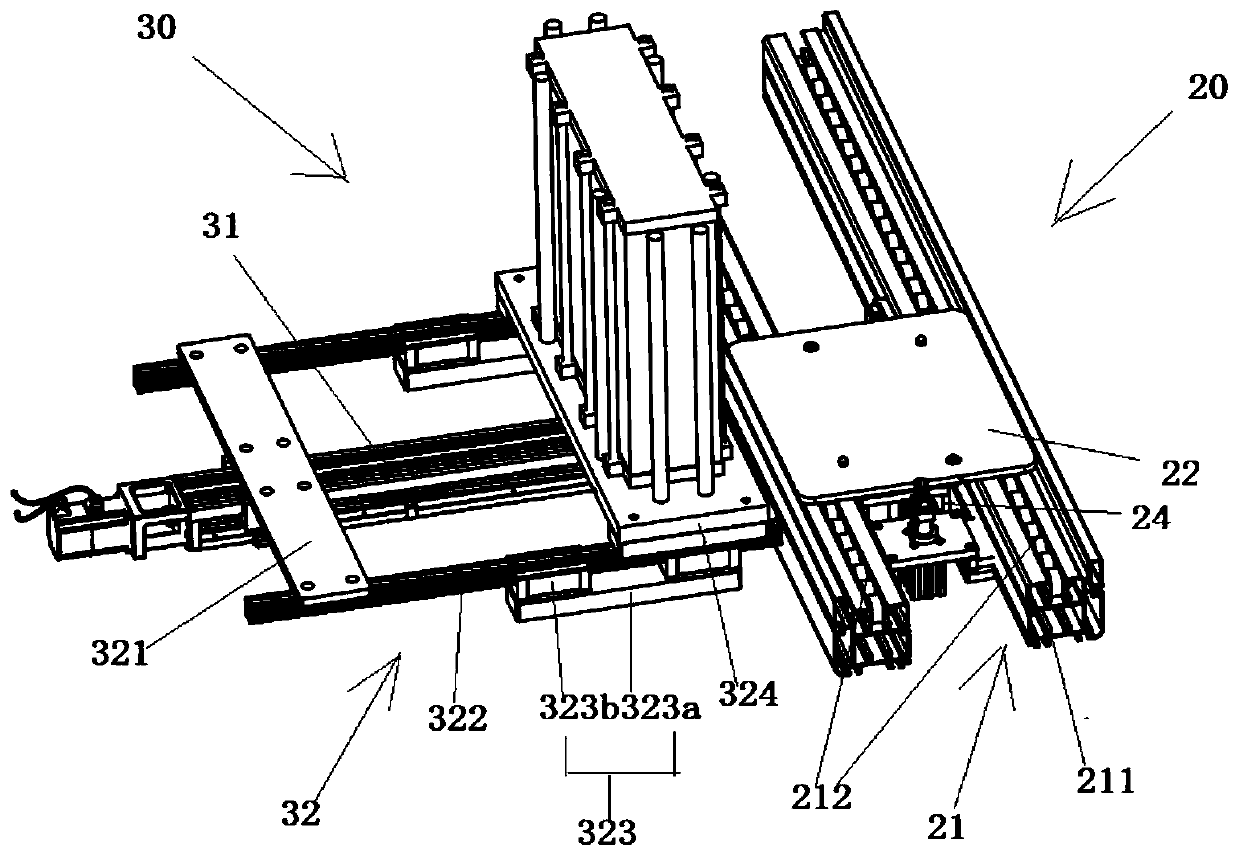

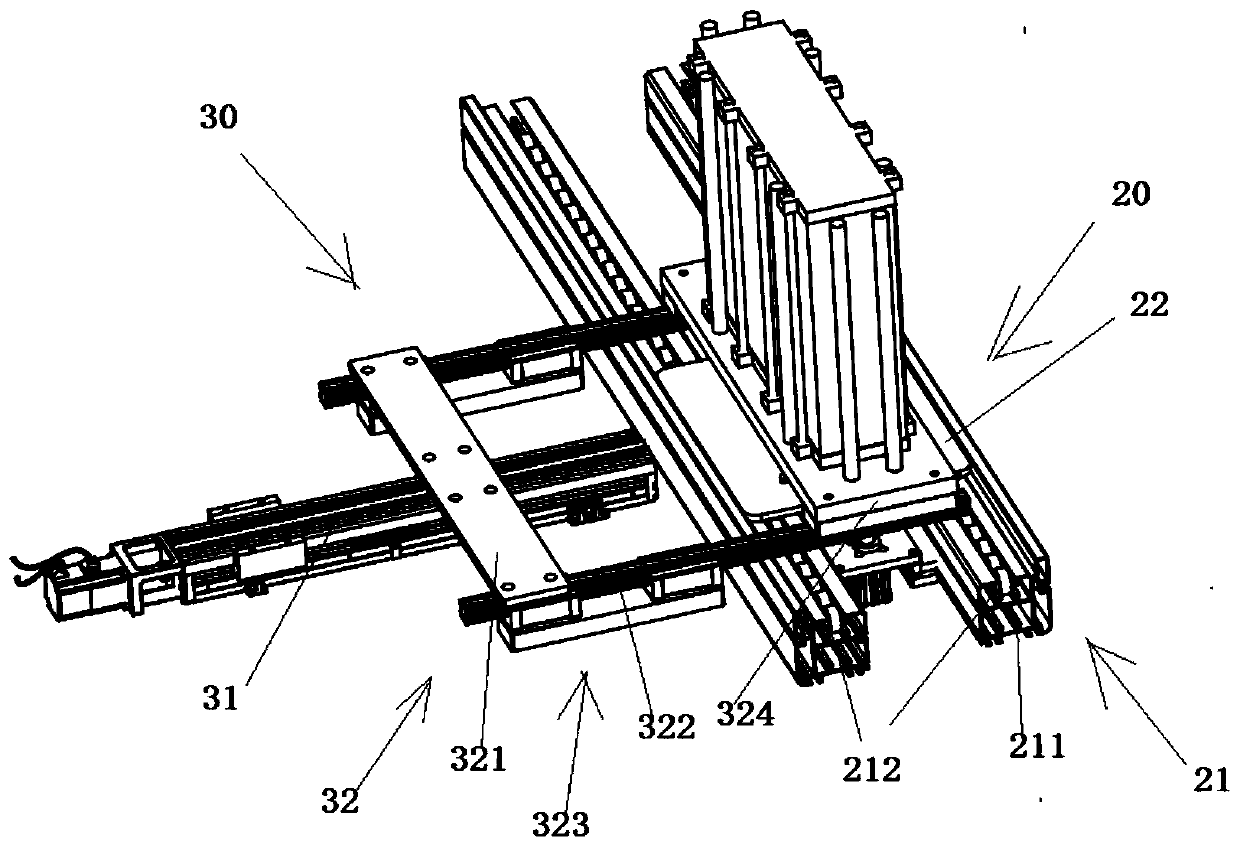

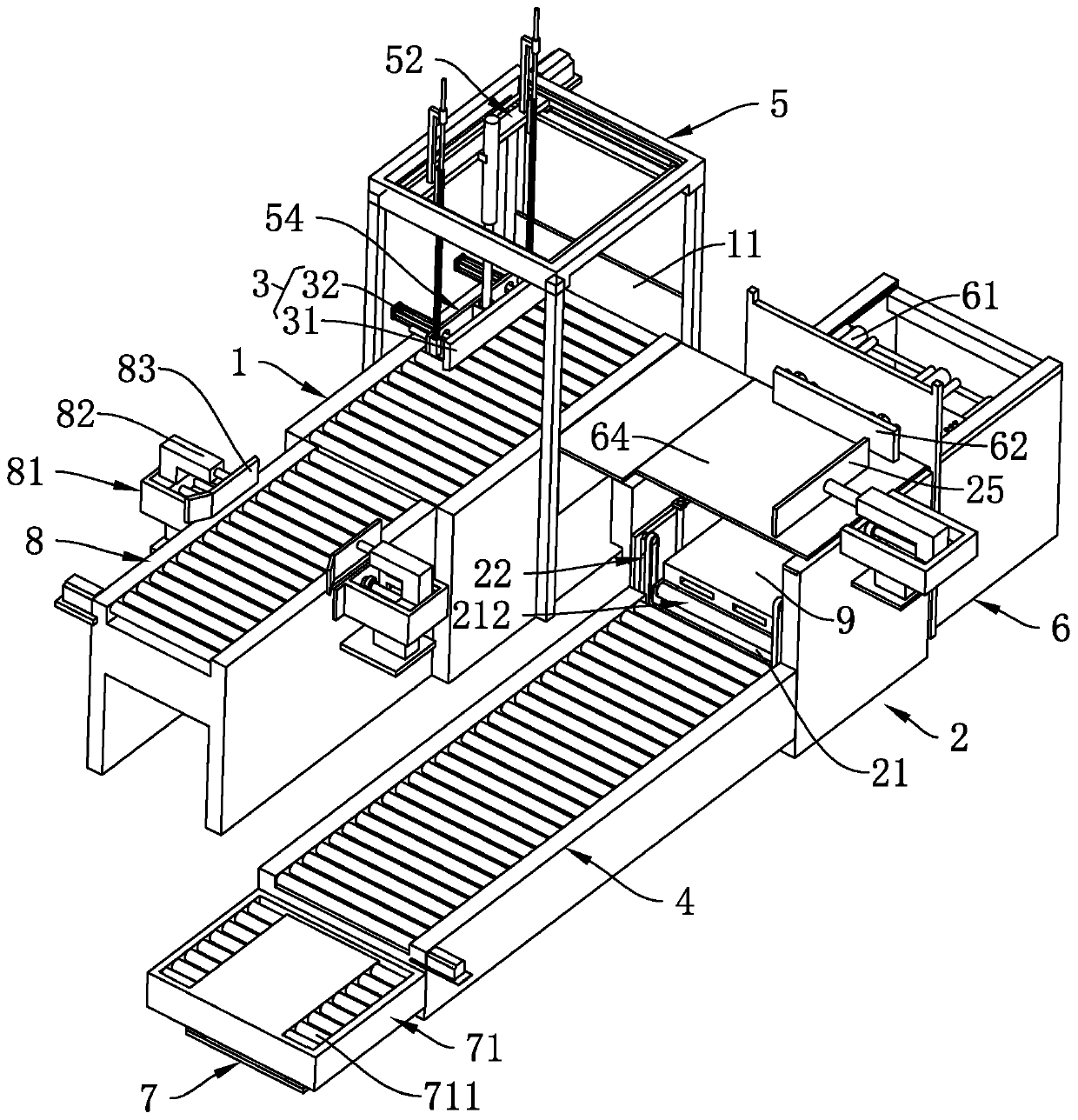

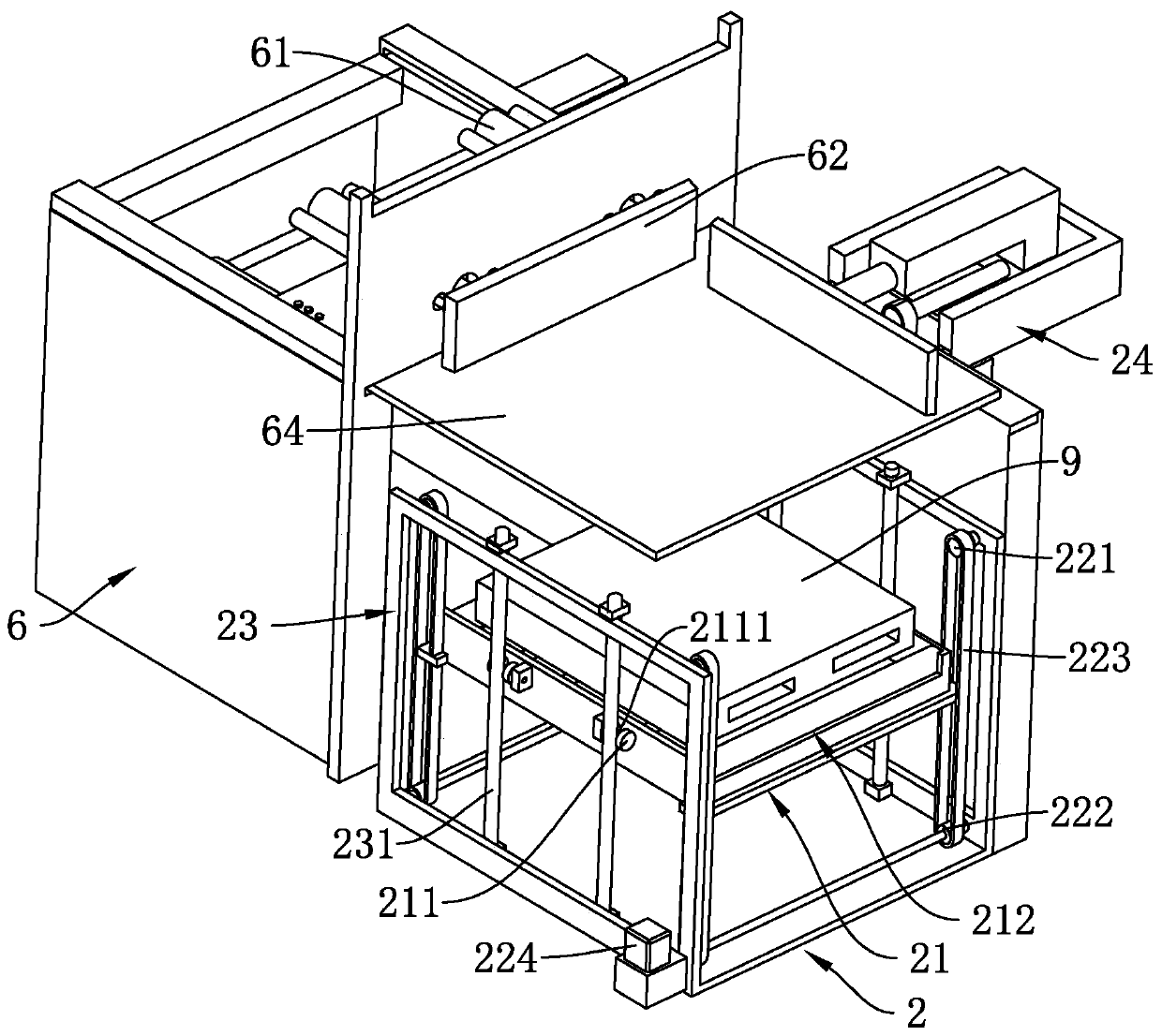

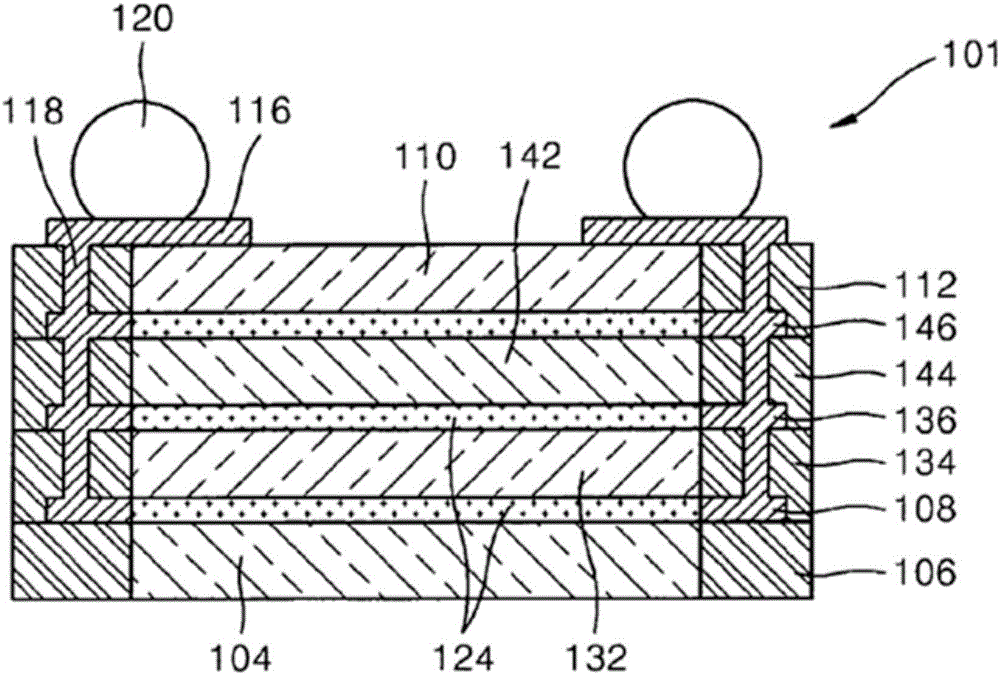

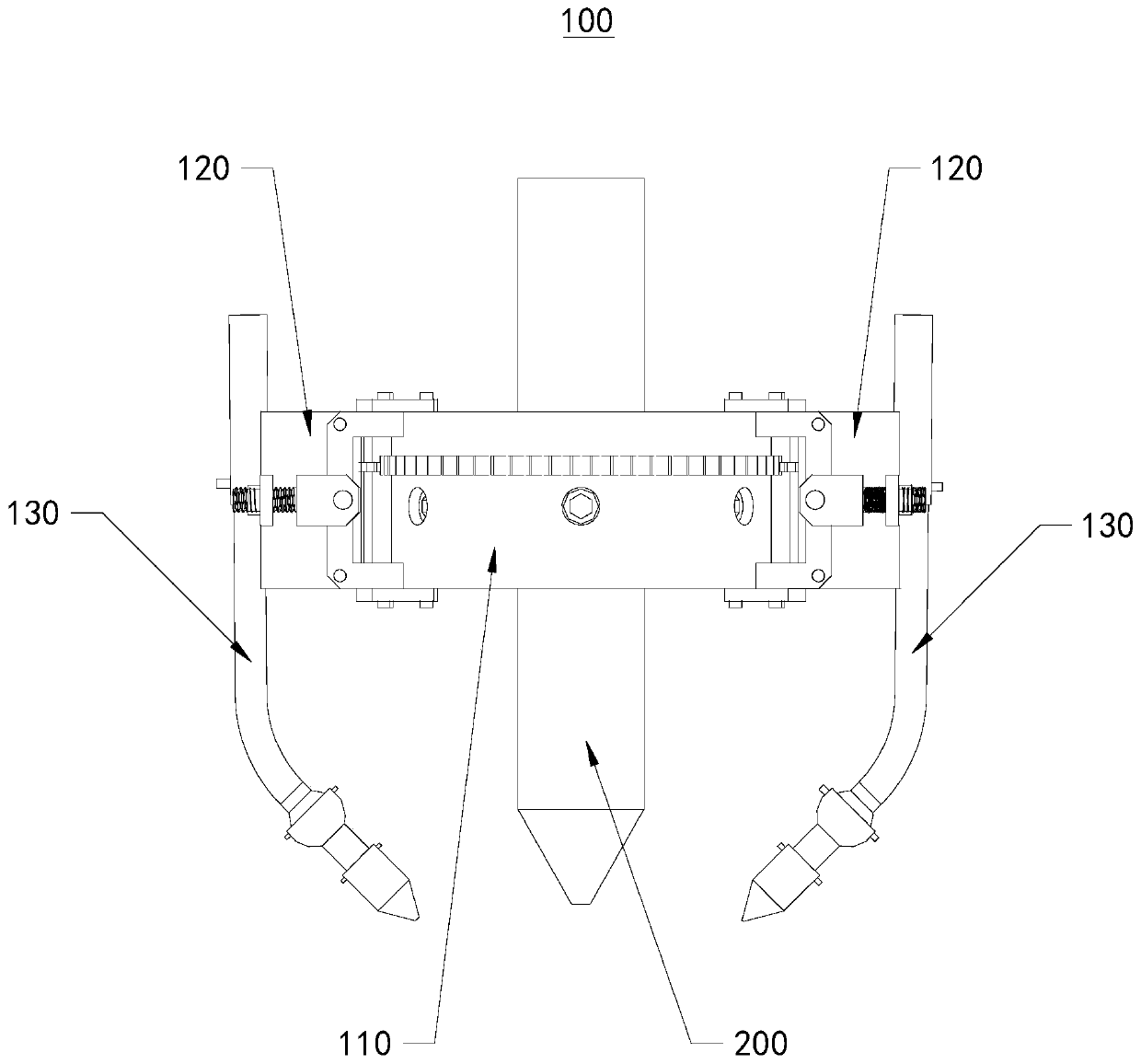

Automatic fuel cell stacking system

The invention discloses an automatic fuel cell stacking system. The system comprises a transferring and conveying device, an electric pile stacking device, a press fitting and locking device and a detection device, wherein the electric pile stacking device is used for stacking electrode plates into an electric pile assembly module, the press fitting and locking device is used for carrying out press fitting and locking on the electric pile assembly module, and the detection device is used for carrying out air tightness and insulation detection on the electric pile assembly module; the transferring and conveying device comprises a conveying mechanism and a plurality of transferring mechanisms. The electric pile stacking device, the press fitting and locking device and the detection device are sequentially arranged at intervals in the conveying direction of the conveying mechanism; the plurality of transferring mechanisms are respectively arranged in one-to-one correspondence with the electric pile stacking device, the press fitting and locking device and the detection device; and the electric pile assembly module is transferred between the conveying mechanism and the electric pile stacking device and between the press fitting and locking device and the detection device. High-precision automatic assembly of the fuel cell stack is realized, and the stack efficiency of the fuel cellstack is greatly improved.

Owner:魔方氢能源科技(江苏)有限公司

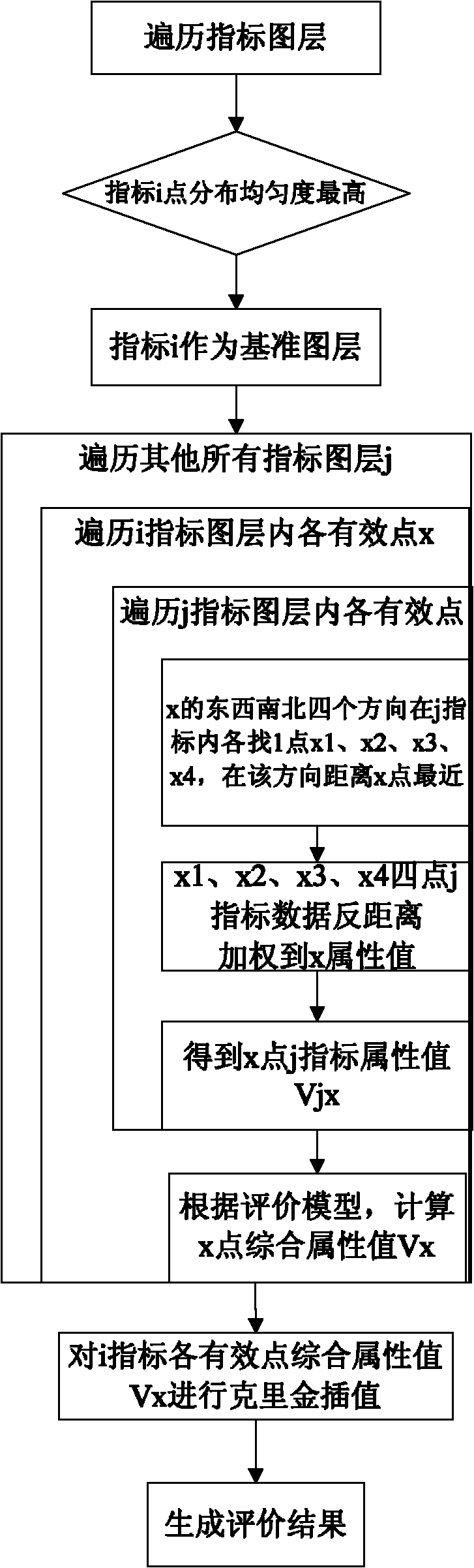

GIS (geographic information system) layer point data stacking method

InactiveCN102609535AIncrease flexibilityImprove stacking efficiencySpecial data processing applicationsObject pointComputer science

The invention relates to a GIS (geographic information system) layer point data stacking method, which includes the steps: 1) selecting a layer with the highest stacking object point distribution uniformity as a reference layer; 2) reading data of another to-be-stacked layer c, and mapping the data onto stacking objects of the reference layer; 3) mapping point data of stacking objects on the layer c onto points of the reference layer according to the proximity effect principle; 4) traversing all the points on the reference layer until all the points on the reference layer have data mapping of the layer c; 5) traversing all the layers needing to be stacked until the data of the layers needing to be stacked are mapped onto the reference layer; 6) performing stacking computation according to a given stacking algorithm, so as to obtain a stacking result Up: Up=f(v, v', v'',......) of the points P; and 7) performing Kriging interpolation for the area on the reference layer according to the stacking result Up of all the points, so as to obtain a final result. Compared with the prior art, the GIS layer point data stacking method has the advantage that stacking efficiency is improved.

Owner:SHANGHAI TONGYAN CIVIL ENGINEERING TECHNOLOGY CORP LTD +1

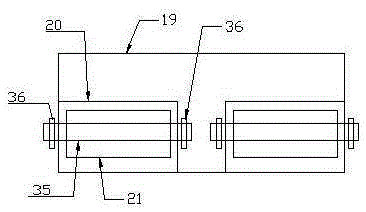

Double-layer plate sorting equipment and use method thereof

PendingCN107234070AQuick stackFast transferControl devices for conveyorsSortingSingle plateEngineering

The invention discloses double-layer plate sorting equipment and a use method thereof. The double-layer plate sorting equipment comprises a circuit controller, and a charging device, a bar code reading device, a wrong plate output device, a double-layer sorting device, a transfer device and an output device that are controlled by the circuit controller. Compared with the prior art, every single plate on which a bar code is pasted is conveyed to the bar code reading device by the charging device, the bar code reading device can pick out the plates not belonging to the batch, and the plates not belonging to the batch are output by the wrong plate output device; in the double-layer sorting device, the plates can be conveyed at the lower layer, and be sorted and stacked at the upper layer, finally the plates stacked at the upper layer are output through the output device, and the stacking speed and the transfer speed of the plates are high, so that the stacking efficiency and the transfer efficiency of the plates are improved substantially, the plate cutting overall efficiency is improved substantially, the automaticity is improved, the labor intensity is lowered, the work force is reduced, and the cost is lowered.

Owner:广东中造动力智能设备有限公司

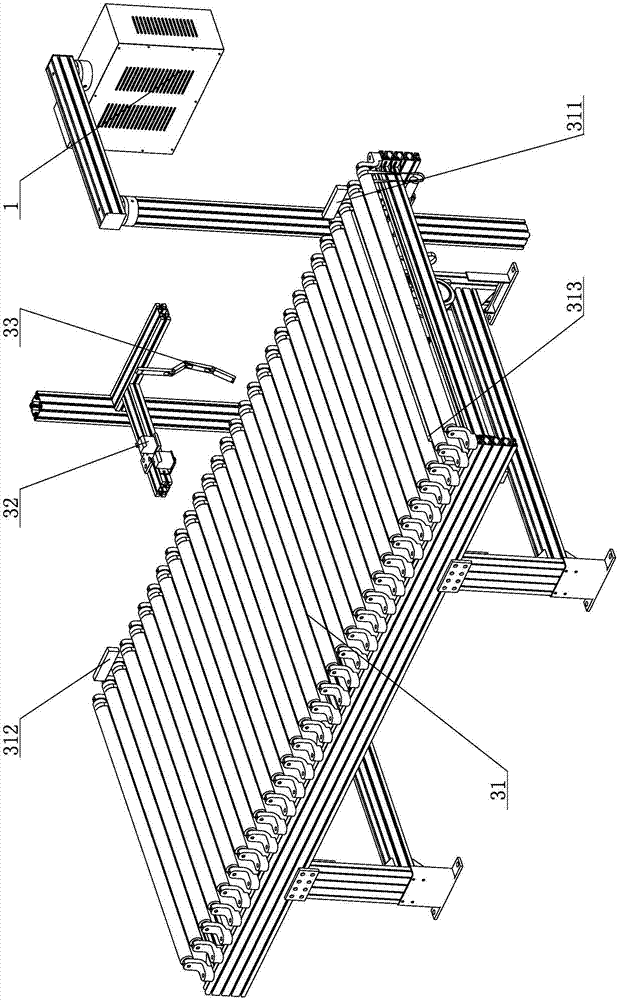

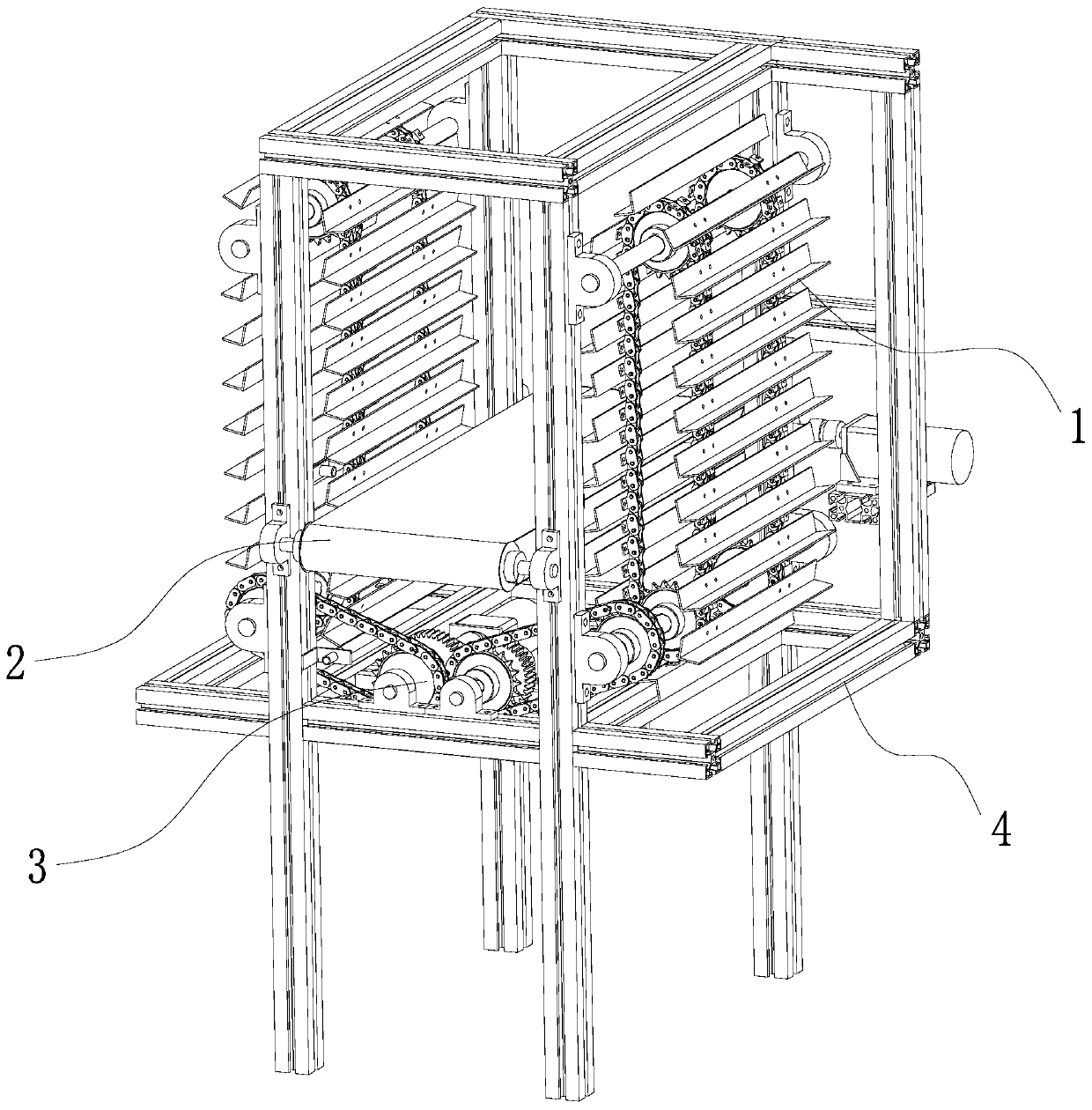

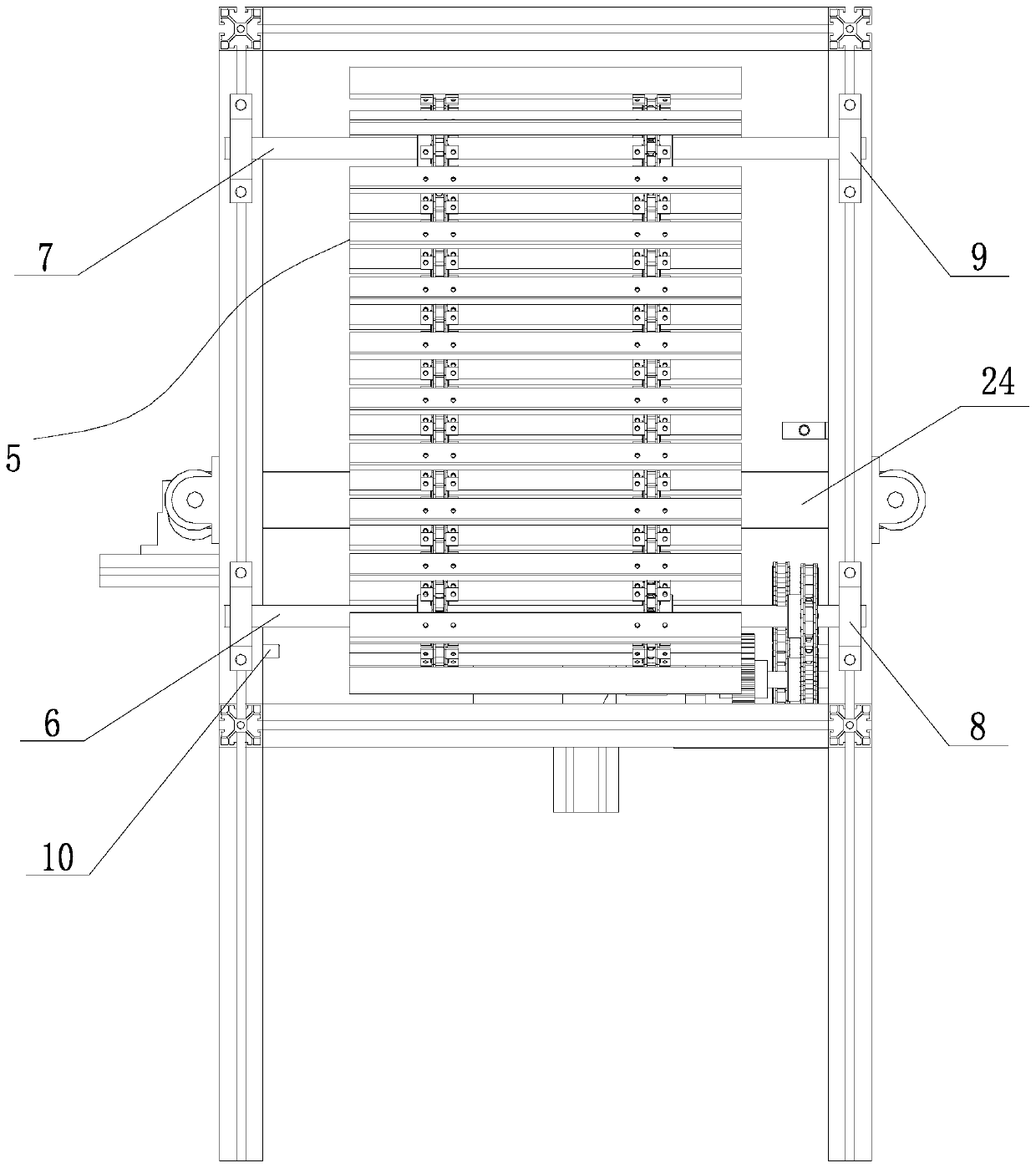

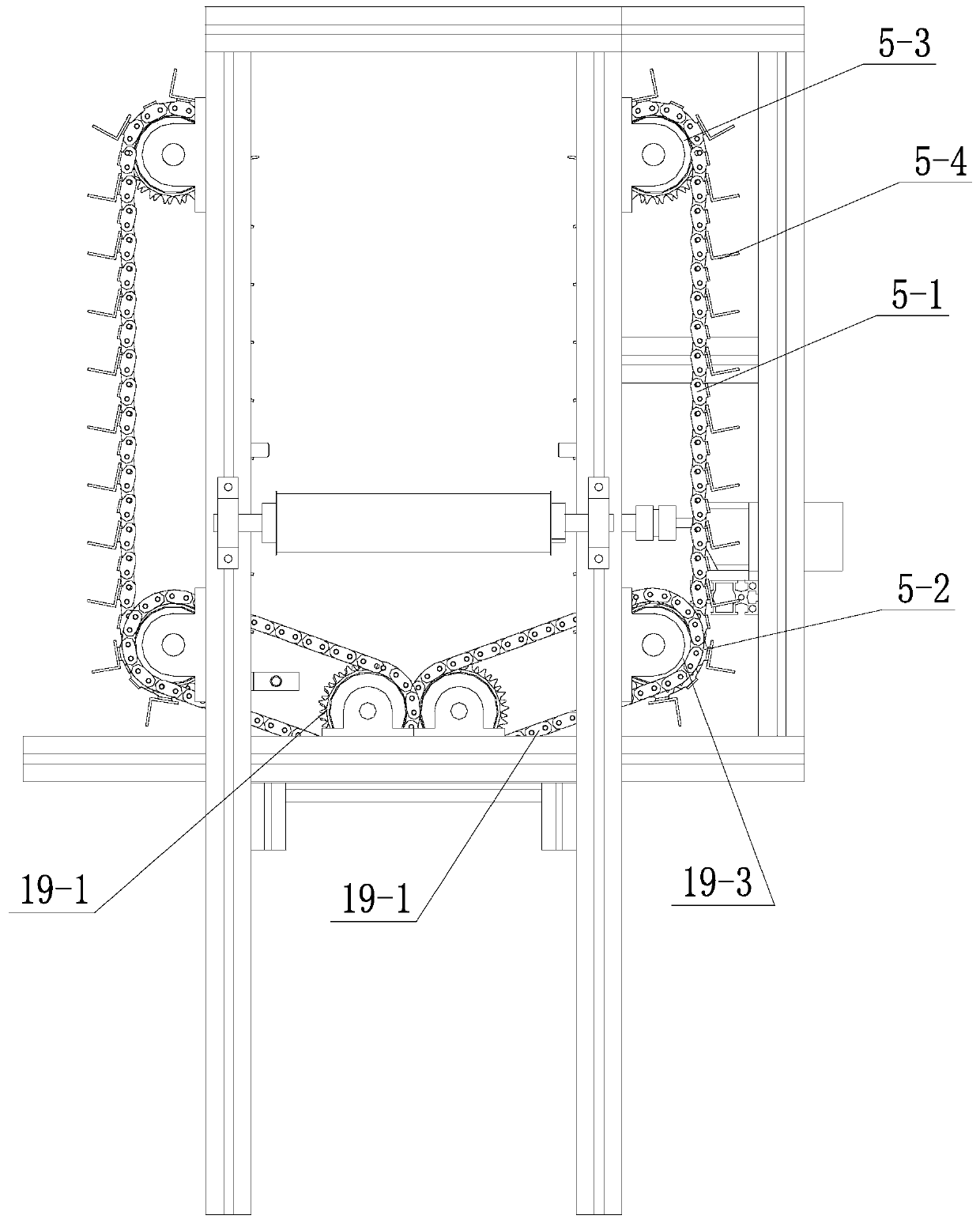

Conveying-chain stacking device and method for seedling plugs

PendingCN110626805AStable jobSmall shock and vibration effectConveyorsControl devices for conveyorsEngineeringMechanical engineering

The invention discloses a conveying-chain stacking device and method for the seedling plugs. The device comprises a rack, a plug conveying mechanism, plug lifting mechanisms and a lifting drive mechanism, wherein the plug conveying mechanism is arranged at the middle part of the rack, the plug lifting mechanisms are arranged at the two sides of the plug conveying mechanism separately, and each plug lifting mechanism is connected with the lifting drive mechanism; and in each plug lifting mechanism, a plurality of plug lifting elements are arranged on a rotary conveying assembly, and the distance between each two adjacent plug lifting elements is greater than the height of a single plug. The method comprises the following steps: the planes of the two sides of each plug to be stacked are supported by virtue of the plug lifting mechanisms, the plugs to be stacked are lifted and separated one by one, after the number of the lifted plugs reaches a set number, the plug lifting mechanisms reversely descend by a certain height, and the lifted plugs are sequentially stacked onto a conveying belt and conveyed out by the conveying belt. The conveying-chain stacking device and method for the seedling plugs are capable of effectively increasing the stacking efficiency for the plugs, stable in working, low in impact vibration action on matrixes and seeds in the plugs, and applicable to high-speed sowing working production.

Owner:SOUTH CHINA AGRI UNIV

Pallet stacking and conveying device

InactiveCN107640565AConvenient handoverAvoid position shiftConveyorsStacking articlesEngineeringPallet

The invention discloses a pallet stacking and conveying device which comprises a conveying lifting mechanism and a pallet stacking mechanism. The conveying lifting mechanism comprises a first conveying belt, a second conveying belt, a lifting mechanism driving the second conveying belt to ascend and descend and a third conveying belt which are sequentially distributed in a conveying direction, thelifting mechanism comprises a first linear executor in vertical placement and a load bearing frame connected with an output shaft of the first linear executor, the third conveying belt is arranged inthe middle of the pallet stacking mechanism, and the pallet stacking mechanism comprises a second linear executor in vertical placement, a lifting frame fixedly connected with an output shaft of thesecond linear executor and two supporting frames fixed on two sides of the third conveying belt. Pallets among the conveying belts at different heights can be transferred through the lifting mechanism, the pallet stacking mechanism stacks the pallets together, and finally the pallets are conveyed again. The pallet stacking and conveying device is simple in structure and high in stacking efficiency, and deflection during conveying and stacking of the pallets is avoided.

Owner:黄润豪

Stacking equipment

PendingCN111115274AImprove stacking efficiencyBoost Push JobsStacking articlesConveyor partsStructural engineeringMechanical engineering

The invention discloses stacking equipment, and relates to the technical field of plate stacking. The stacking equipment comprises a first conveyor, a first positioning plate is fixedly erected on a first conveyor frame body along the downstream side of the conveying direction of the first conveyor, and the length direction of the first positioning plate is parallel to the width direction of the first conveyor; a rack is arranged on the side, in the length direction of the first positioning plate, of the first conveyor, a lifting table is arranged on the rack in a lifting mode, and the rack isfurther provided with a first driving assembly used for driving the lifting table to ascend and descend; and the rack is provided with a second positioning plate on the side, deviating from the firstconveyor, of the lifting table, the length direction of the second positioning plate is parallel to the conveying direction of the first conveyor, and the side, deviating from the lifting table, of the first conveyor frame body is provided with a pushing assembly used for pushing plates on the first conveyor onto the lifting table. The stacking equipment has the advantage of improving the stacking efficiency of the plates.

Owner:上海飓尔包装机械有限公司

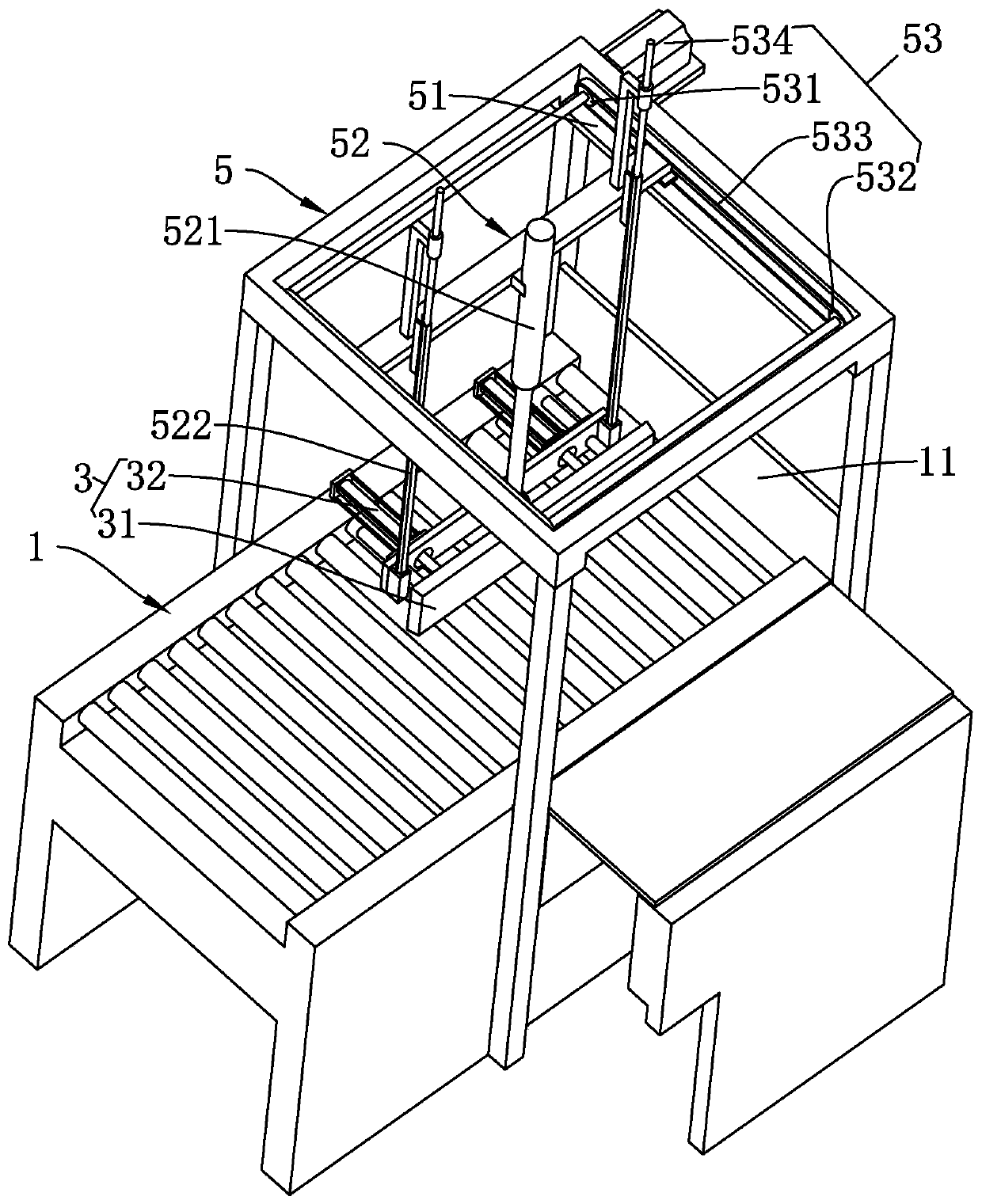

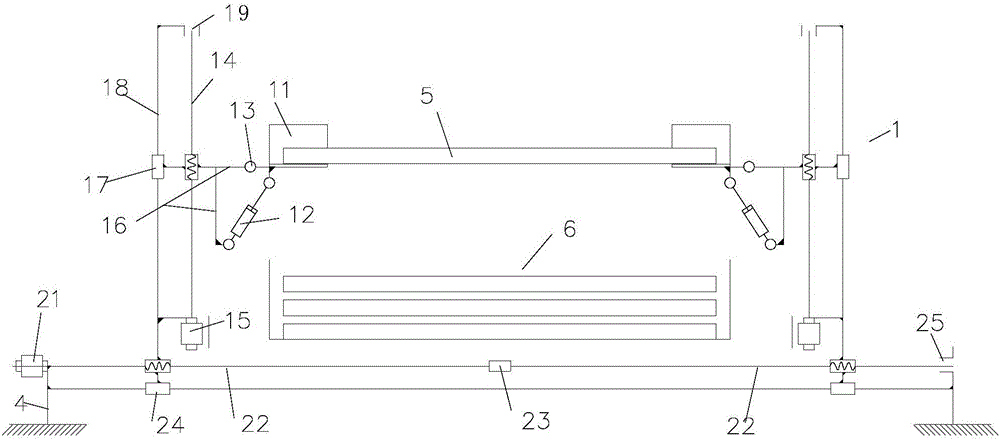

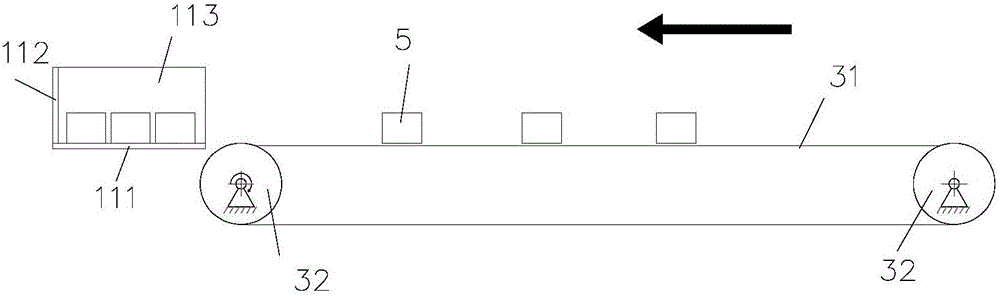

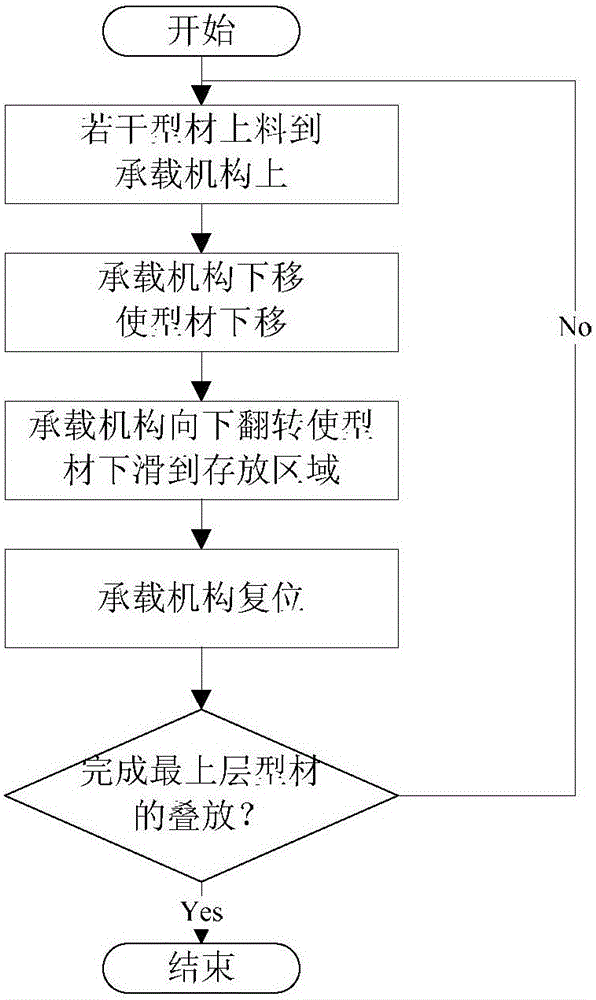

Full-automatic profile stacking equipment and method

Owner:FOSHAN UNIVERSITY

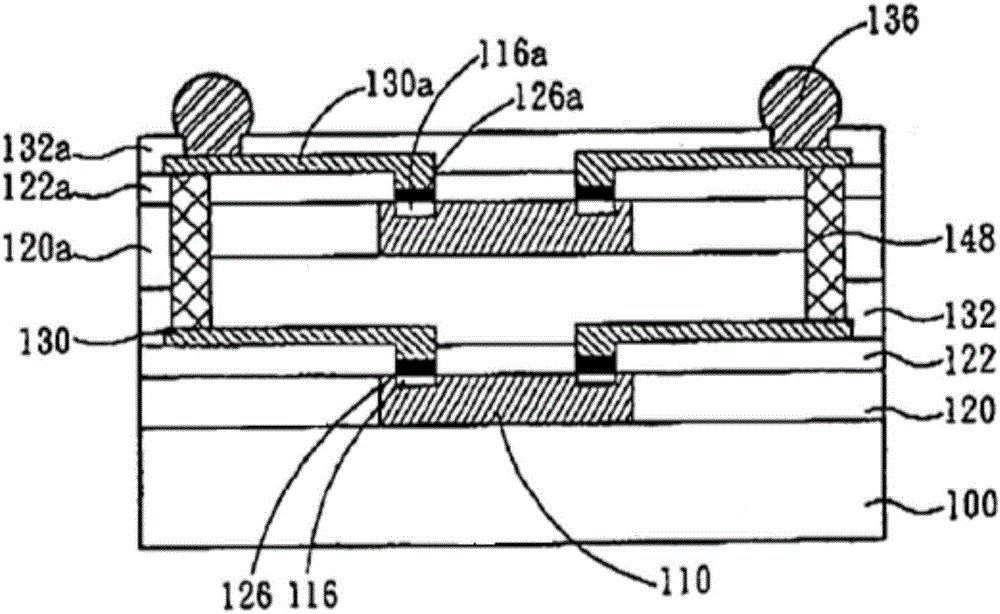

Semiconductor memory and manufacturing method thereof

ActiveCN106653628AAchieve large capacityHighly integratedSemiconductor/solid-state device detailsSolid-state devicesMemory chipInter layer

The invention discloses a semiconductor memory and a manufacturing method thereof. The semiconductor memory comprises at last two memory chipsets stacked successively from bottom to top, re-wiring layers of two adjacent memory chipsets are electrically connected with inter-layer conductive poles, and a re-wiring layer of the bottommost memory chipset is electrically connected with external connecting projections; and each memory chipset comprises at least two memory chips stacked successively and a composite insulating layer positioned under the memory chips, the memory chips are packed into an integrated structure, the re-wiring layer is arranged in the composite insulating layer, and intra-layer conductive poles of the memory chips are staggered from each other for a preset angle, and are electrically connected with the re-wiring layer. According to the invention, large capacity and high integrated degree of the semiconductor memory are realized, the stacking efficiency of the memory is improved effectively, and the stacking difficulty is reduced.

Owner:NAT CENT FOR ADVANCED PACKAGING

Automatic finishing device specially used for secondary recovery of glass beer bottles

The invention relates to an automatic finishing device specially used for secondary recovery of glass beer bottles. The automatic finishing device comprises a bottom plate; a rotary adjusting device is installed at the front end of the bottom plate; the tail end of the rotary adjusting device is provided with a clamping device by threads; two pairs of lifting devices are symmetrically installed at the left end and the right end of the bottom plate, and a transverse plate is used for connecting each pair of lifting device; a cleaning and air drying device is installed at the middle part of the bottom plate, and a stacking device is installed at the rear end of the bottom plate; an automatic finishing technology of the glass beer bottles is completed by cooperatively using the rotary adjusting device, the clamping device, the lifting devices, a mobile conveying device, the cleaning and air drying device and the stacking device. The automatic finishing device specially used for the secondary recovery of the glass beer bottles can solve the problems that when being used for finishing the glass beer bottles, the existing small-sized recycle bin is not thorough in manual cleaning, long in time consumed by natural air drying, complicated in operation and low in manual stacking efficiency, easily causes the glass bottles to be broken due to long-time work, causes resource waste, and the like, and can realize the function of automatically finishing the glass beer bottles.

Owner:SHANDONG JINGYAO GLASS GRP

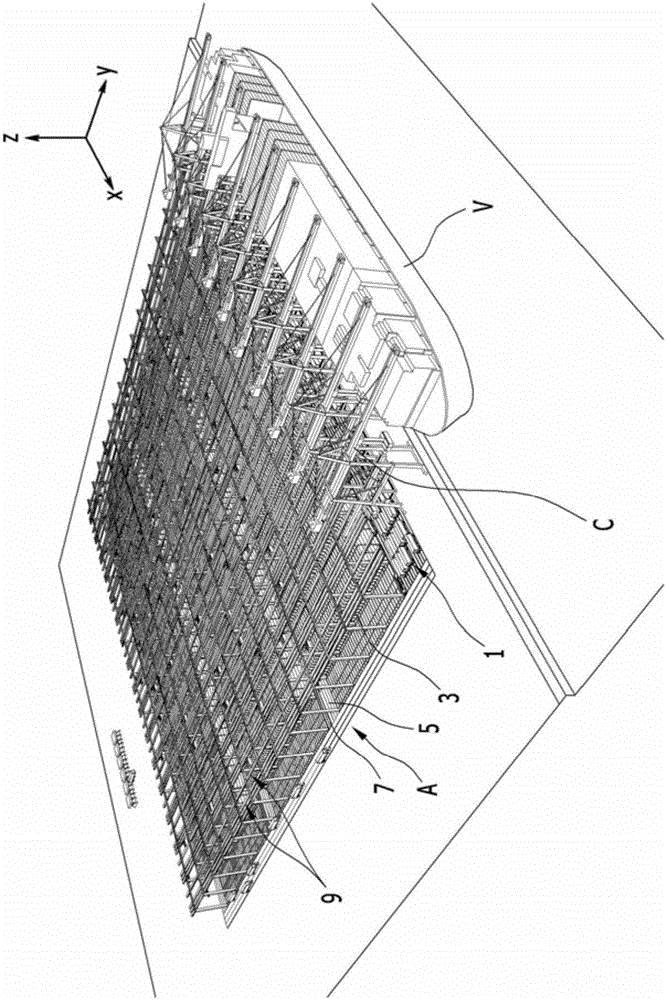

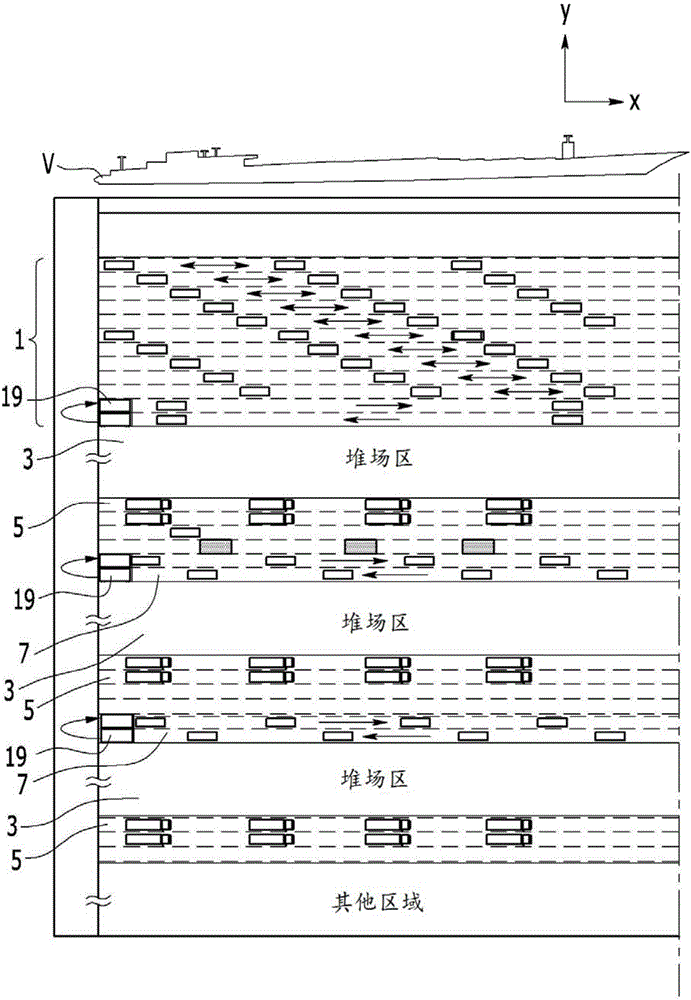

Container terminal system

InactiveCN106232510ASave loading and unloading timeReduce movementStorage devicesLoading/unloadingEngineeringMechanical engineering

The present invention provides a container terminal system capable of efficiently loading, unloading, and storing containers in a container terminal or capable of moving containers into / out of a container terminal. The container terminal system according to the present invention comprises: a main automatic transfer area arranged near a quay wall such that containers are transferred in a direction parallel with the quay wall; a yard area adjacent to the main automatic transfer area, containers being stored in the yard area; a vehicle transfer area arranged adjacent to the yard area; an overhead rail unit installed over the main automatic transfer area, the yard area, and the vehicle transfer area in a direction perpendicular to the quay wall; and a shuttle for moving along the overhead rail unit and transferring containers.

Owner:KOREA MARITIME INST

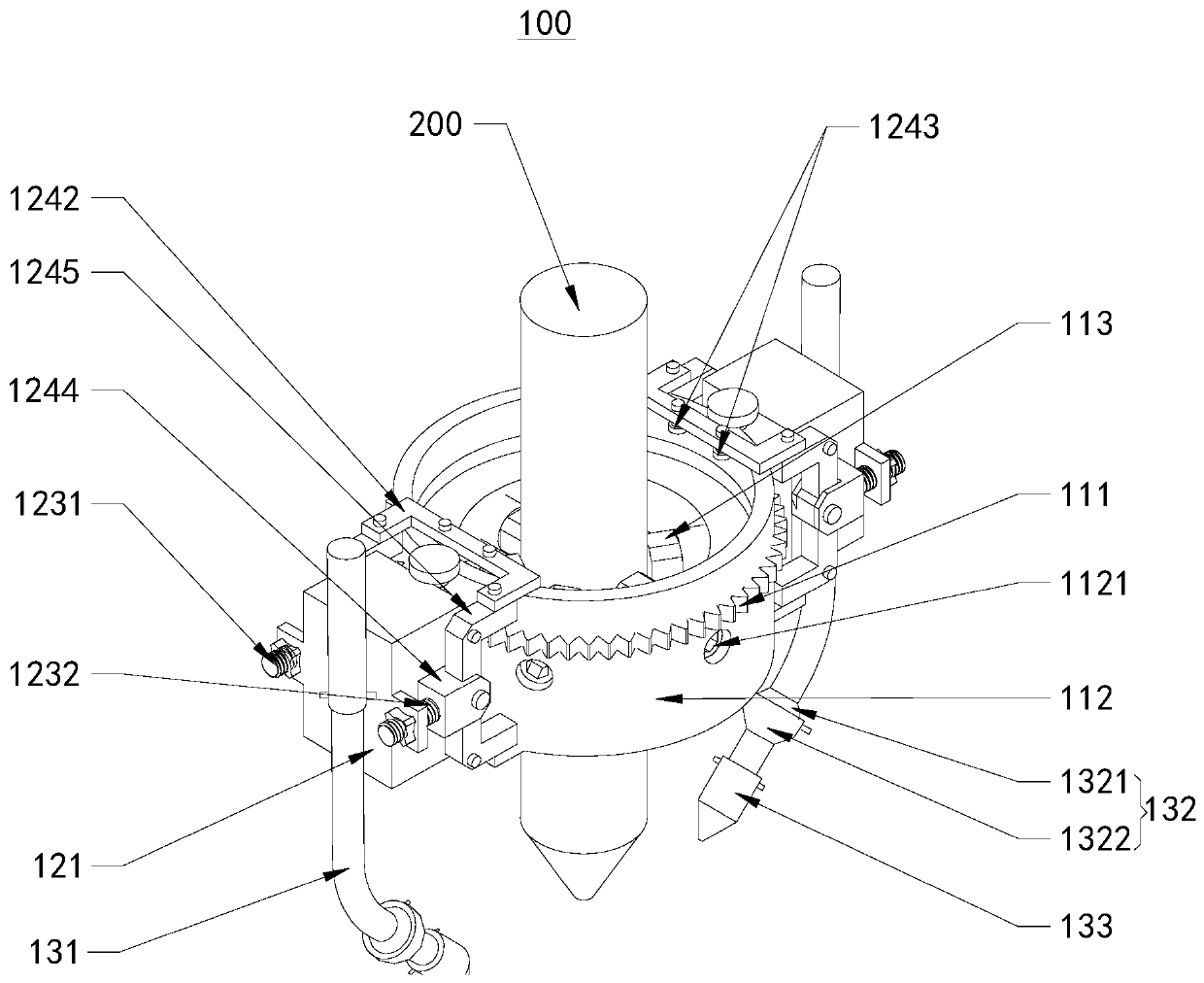

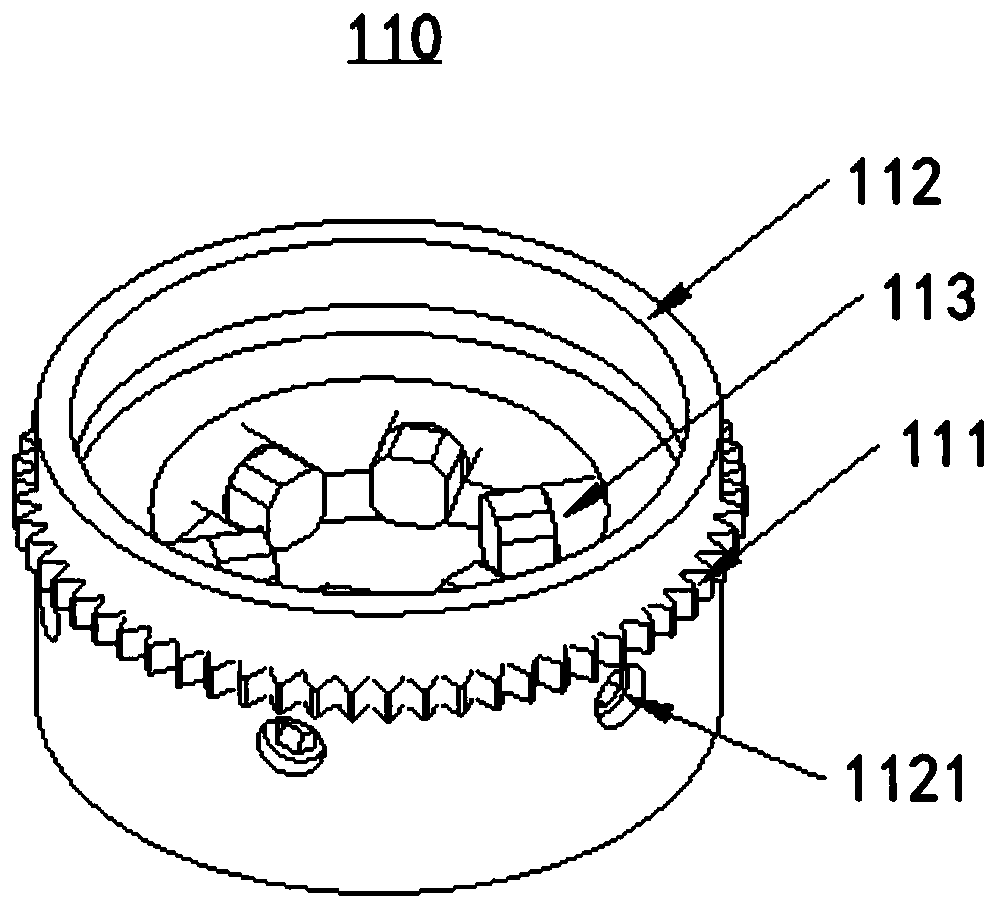

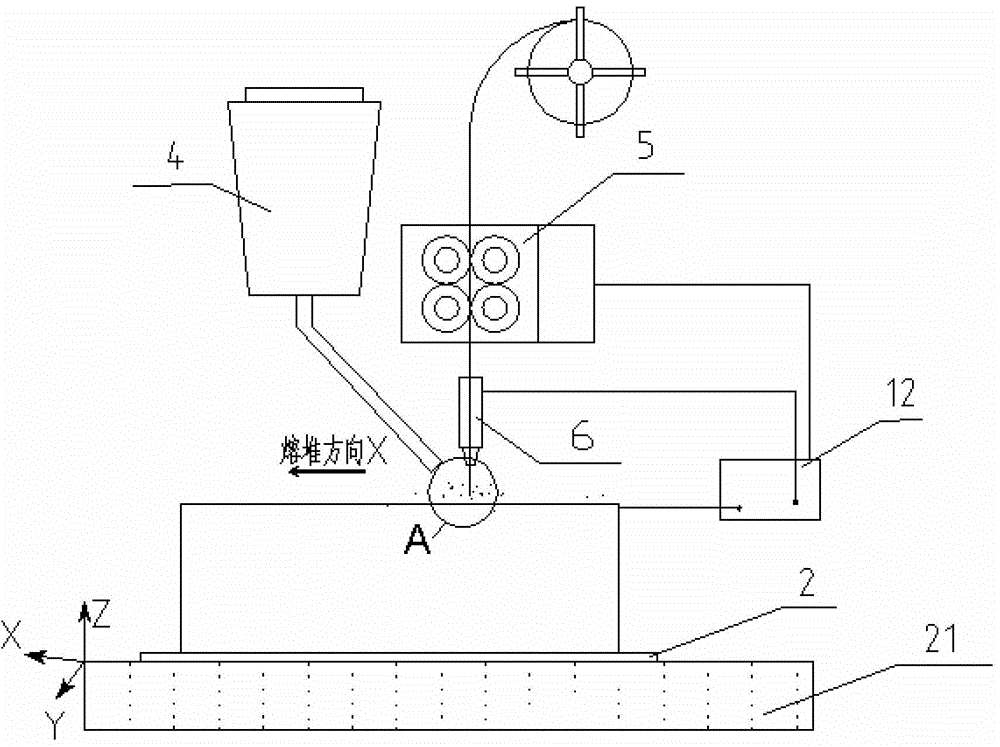

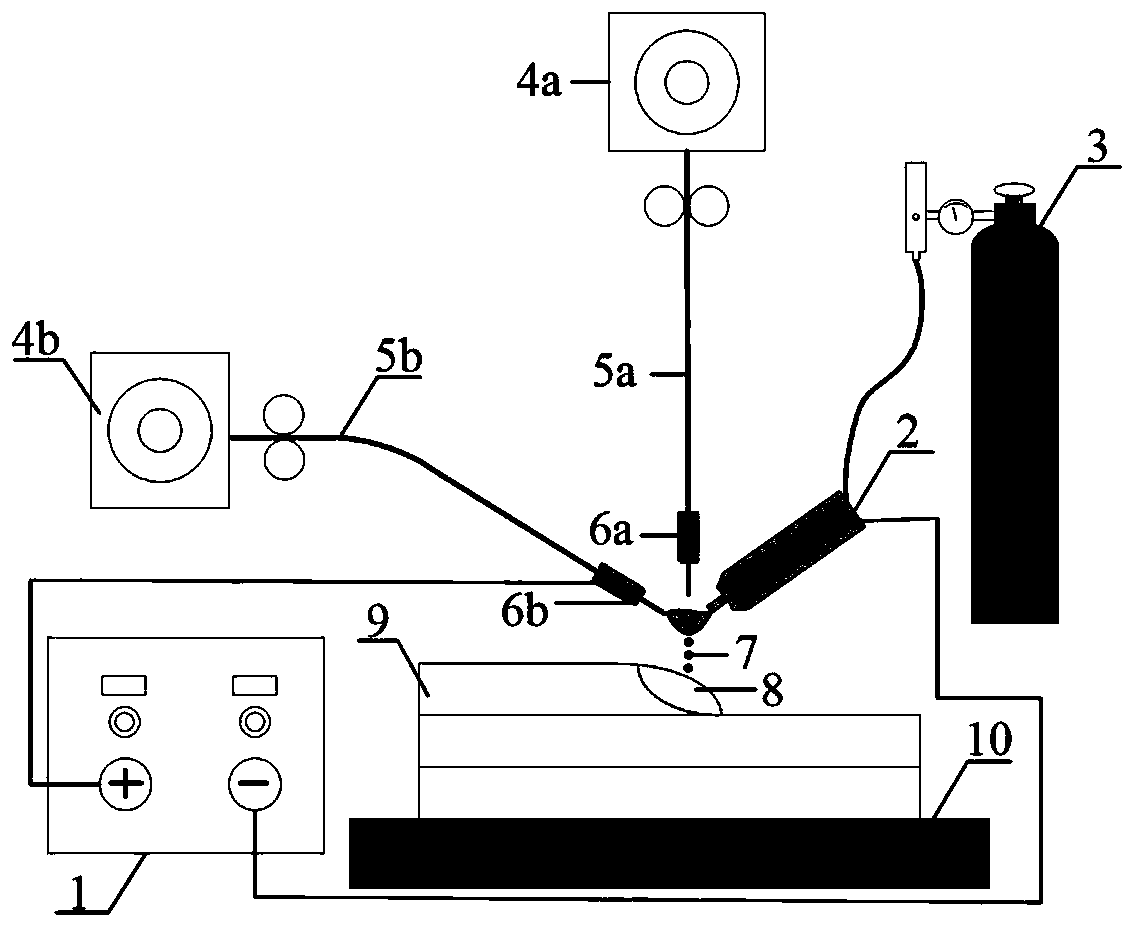

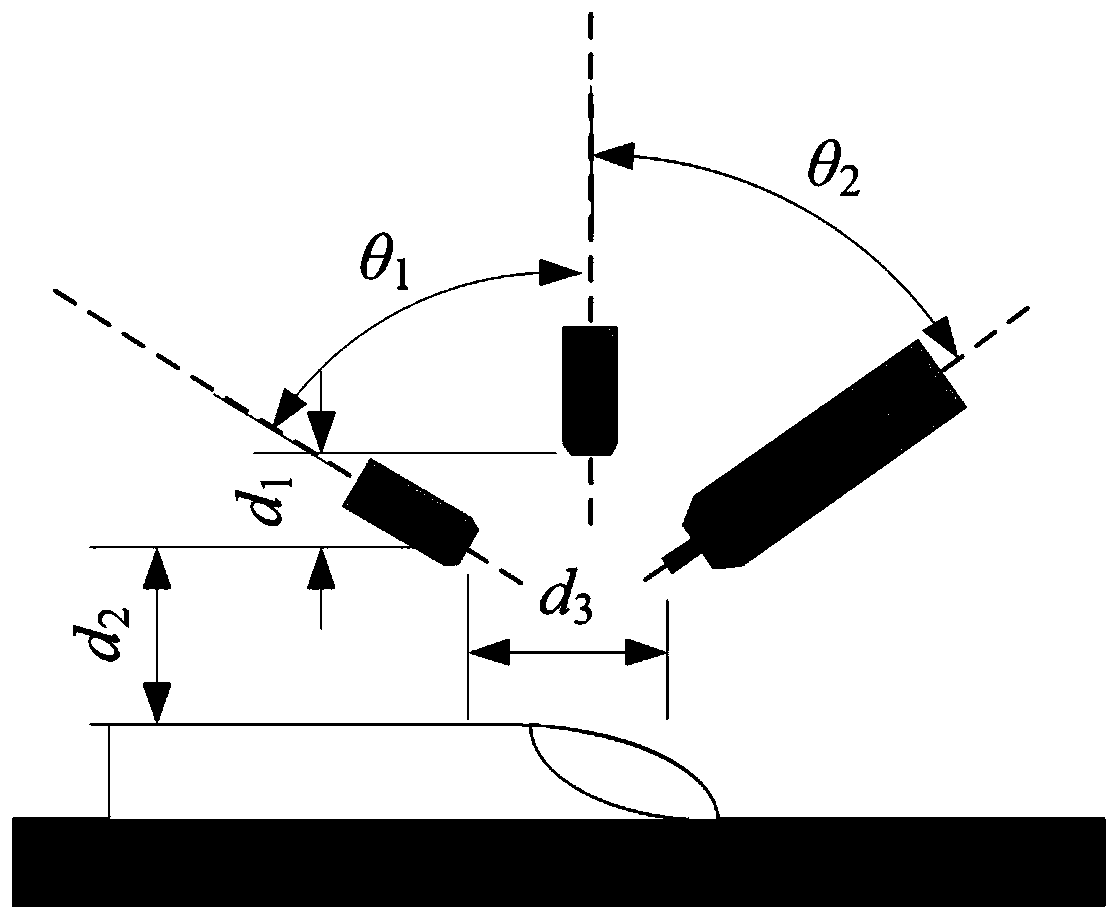

Paraxial wire feeding device and additive manufacturing system

ActiveCN110421231AGood wire feeding angleGood welding performanceWelding accessoriesIncreasing energy efficiencyEngineeringManufacturing systems

The invention discloses a paraxial wire feeding device and an additive manufacturing system, and relates to the field of additive manufacturing equipment. The device comprises a mounting mechanism, atravelling mechanism and a wire guide mechanism, wherein the mounting mechanism is used for mounting a welding gun; the travelling mechanism comprises a fixed part and a drive part; the fixed part ispositioned at the outer side of the welding gun; the drive part is connected to the fixed part, and the fixed part is driven to perform peripheral motion at the periphery of the welding gun; the wireguide mechanism is mounted on the fixed part, and is provided with a wire guide nozzle towards the welding gun; the wire guide mechanism is provided with a movable part for regulating an angle of thewire guide nozzle and / or length of the wire guide mechanism. The paraxial wire feeding device can regulate a wire feeding direction and an included angle between a welding wire and the welding gun inreal time, so that forming quality is guaranteed and stacking efficiency is improved. Besides, the additive manufacturing system provided by the invention is good in universality, is high in degree ofautomation, easily achieves a proper wire feeding direction and a proper wire feeding angle, and is good in additive manufacturing effect.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

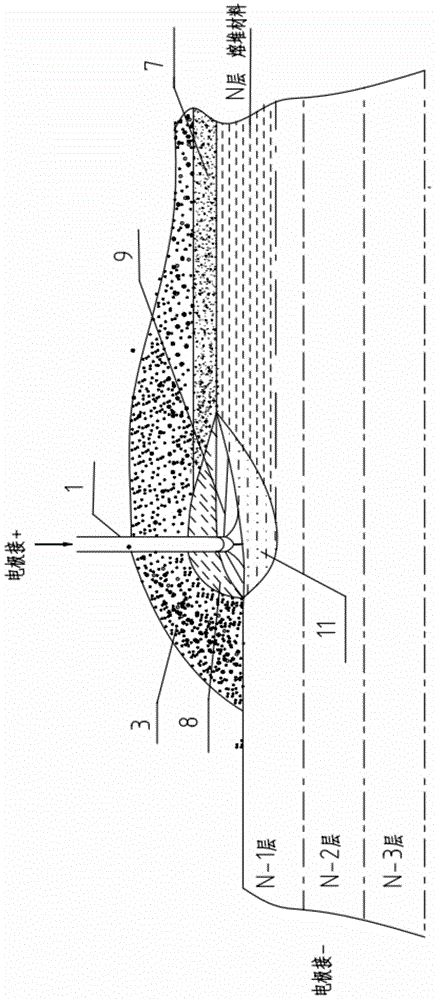

Electric smelting forming method of CAP1400 main steam pipe penetration piece

The invention provides an electric smelting forming method of a CAP1400 main steam pipe penetration piece which is efficient, low in cost and excellent in mechanical properties. According to the method, an electric smelting head and a substrate are connected to the two poles of a power source; while forming, a metal raw material wire is conveyed to the surface of the substrate by a conveying mechanism and the electric smelting head; under the protection of the accumulation of granular accessories, the electric arc is generated between the raw material wire and the substrate to melt partial surfacing accessories to form a molten slag pool; the current flows through the raw material wire and the molten slag pool to form resistance heat and electro-slag heat; under the actions of the three composite high-energy heat sources, namely the electric arc heat, the resistance heat and the electro-slag heat, the raw material wire is melted to form a local molten pool on the surface of the substrate; the raw material wire and the accessories are fed continuously; the relative movement of the electric smelting head and the substrate is controlled by a computer according to the stratified slicing data of a formed part so as to realize quick cooling and layer-by-layer solidification accumulation of the molten pool on the substrate, and finally, the main steam pipe penetration piece is formed by virtue of layer-by-layer accumulation.

Owner:NANFANG ADDITIVE MFG TECH

Box filler double-channel stacking system

ActiveCN103523272AReduce ascent heightDoes not affect speedPackagingStacking articlesClassical mechanicsStructural engineering

The invention relates to a box filler double-channel stacking system which is characterized in that a machine frame is included, a stacking mechanism is arranged at the upper end of the machine frame, a jacking mechanism is arranged in the machine frame, the stacking mechanism is arranged at the upper end of the machine frame and comprises a pair of first blocking plate and second blocking plate, the first blocking plate and the second blocking plate are parallel to each other and are vertically arranged, a stacking zone is formed between the first blocking plate and the second blocking plate, a single-direction bearing component is arranged in the middle of the stacking zone, at least one middle buffering mechanism placed below the single-direction bearing component is arranged in the middle of the stacking zone, and starting of the middle buffering mechanism can be controlled by an action air cylinder. The middle-transition middle buffering mechanism is added and is started or closed correspondingly according to the size of a product, then the lifting height of a jacking pushing plate is lowered, stacking efficiency is improved, and accordingly the system can meet the requirements for box filling of products of different sizes, and the speed of a whole line cannot be affected.

Owner:NANTONG UNIVERSAL MACHINERY

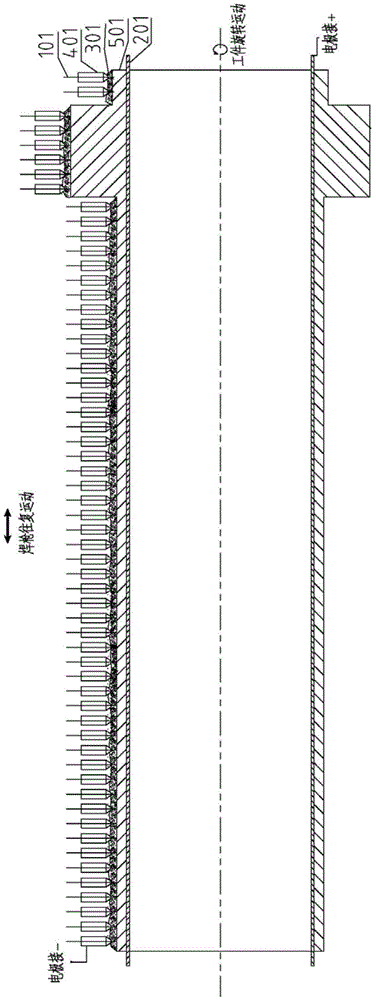

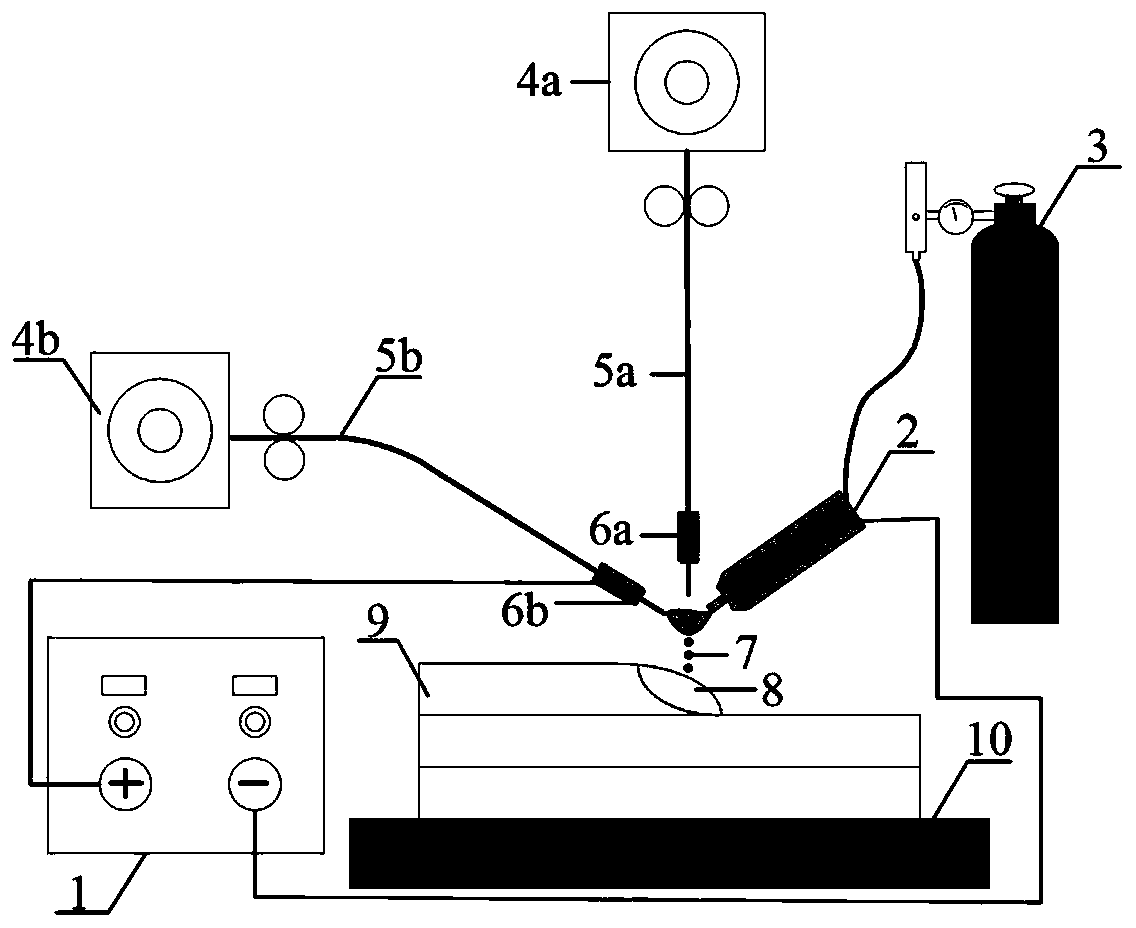

Tungsten-wire electric-arc additive manufacturing device and method under action of auxiliary wire

ActiveCN110039156AImprove stacking efficiencyReduce excessive injuryAdditive manufacturing apparatusArc welding apparatusGradient materialEngineering

The invention provides a tungsten-wire electric-arc additive manufacturing device and method under action of an auxiliary wire. A wire feeding machine in the device is used for conveying a metal wire,the other end of the metal wire is connected to a wire guide nozzle; a second wire guide nozzle and a welding gun are separately connected to a positive electrode and a negative electrode of an electric-arc additive manufacturing power supply; electric arcs are generated between a main wire and the welding gun; the main wire is used for a great number of fuse wires to manufacture a base part of aformed part; and the auxiliary wire is positioned between the main wire and the welding gun for consuming electric-arc heat, so that deposition efficiency in an additive manufacturing process is improved or an intermetallic compound component and a functional gradient material are prepared. According to the method provided by the invention, process parameters are regulated to determine positionsof different kinds of equipment, so that a stable electric-arc form is obtained, forming quality of a stacked layer is ensured by regulating an auxiliary wire feeding time, and continuous component regulation can be realized in case of not replacing the metal wire. The tungsten-wire electric-arc additive manufacturing device effectively solves the technical problem that the stacked layer in a conventional electric-arc additive manufacturing process is excessively damaged, and stacking efficiency is not high.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com