Automatic storage system of industrial robot

An industrial robot and storage system technology, applied in the field of industrial robot automatic storage system, can solve the problems of manual sorting, hidden safety hazards of high-level shelves, and low space utilization of low-level shelves, achieve rapid start and smooth stop, and improve sorting input. Inventory efficiency, the effect of liberating workers' labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

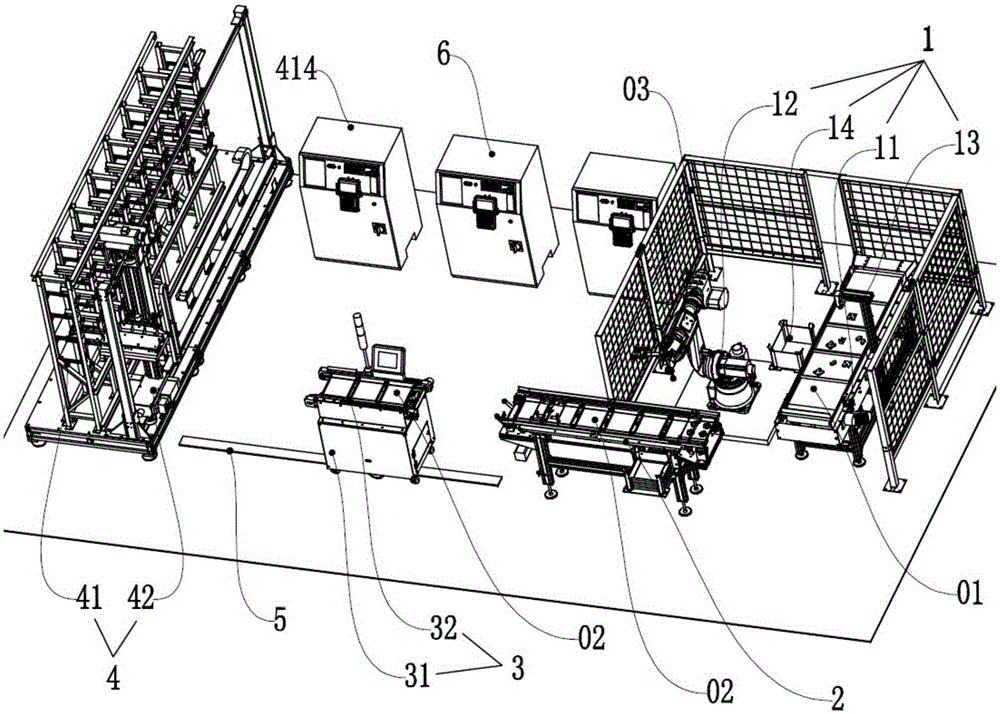

[0044] Such as figure 1 As shown, an industrial robot automatic storage system includes a robot sorting area 1, a double-speed chain 2, an AGV trolley 3, an intelligent three-dimensional warehouse 4, a magnetic guide rail 5 and a central controller 6; the magnetic guide rail 5 is arranged on the ground, and One end of the magnetic guide rail 5 is arranged adjacent to the double-speed chain 2, and the other end is arranged adjacent to the intelligent three-dimensional warehouse 4;

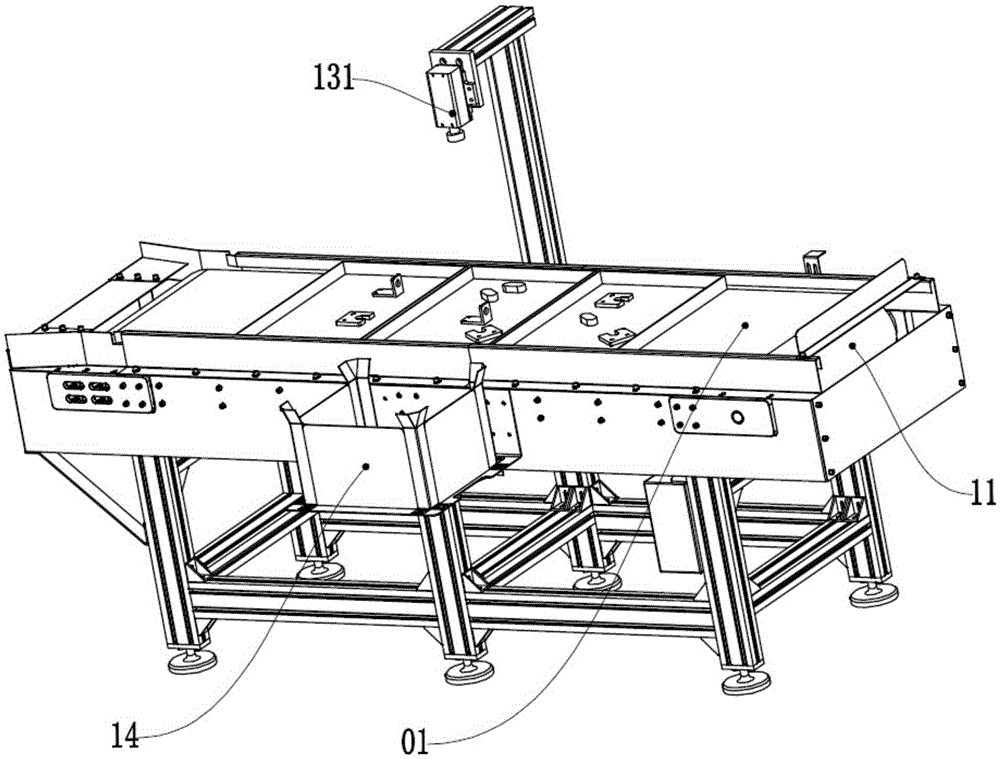

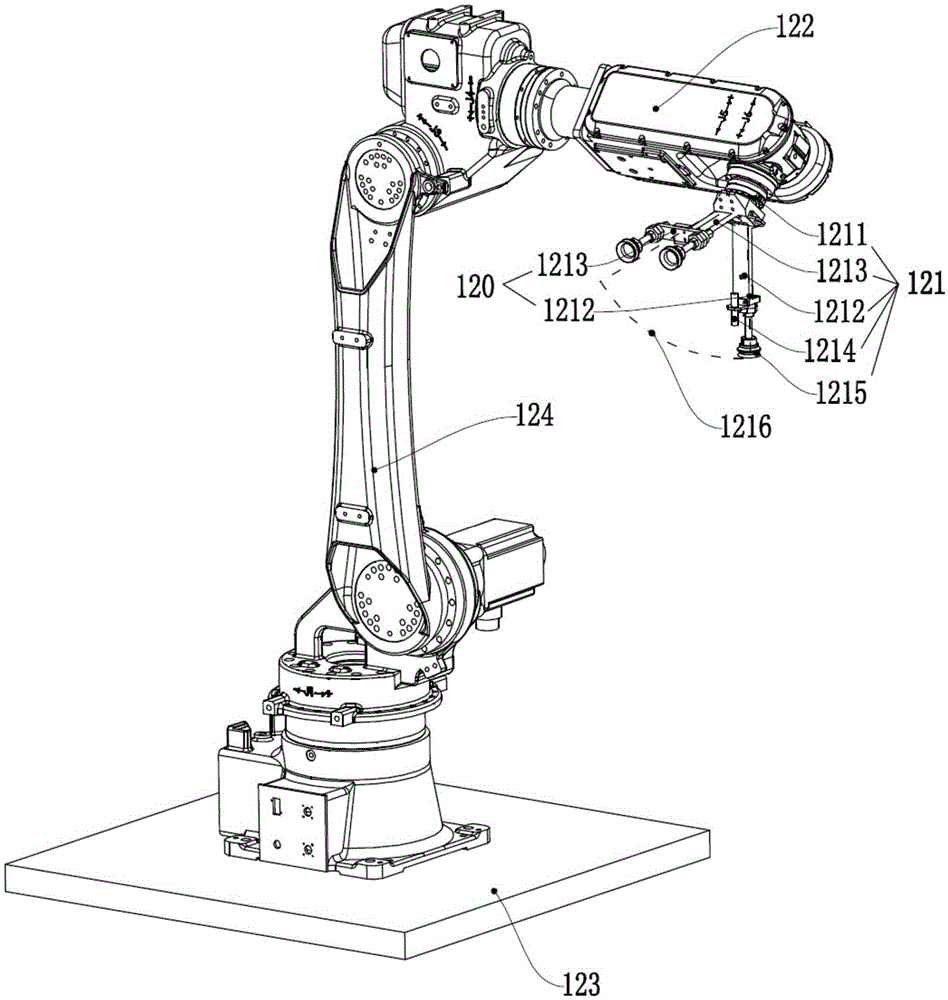

[0045] Such as Figure 2-4 As shown, the robot sorting area 1 includes a flat belt conveyor 11, a robot 12 and a visual recognition device 13, and a plurality of trays 01 for loading objects to be sorted are placed on the flat belt conveyor 11. The flat belt conveyor 11 receives the signal sent by the central controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com