Patents

Literature

110results about How to "Reasonable assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

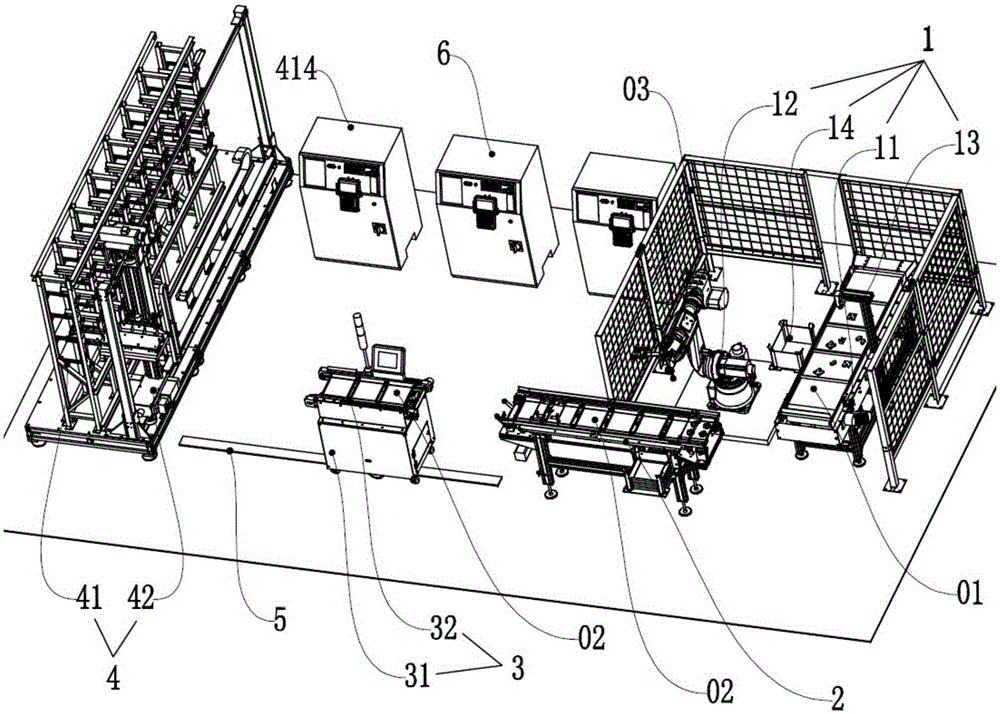

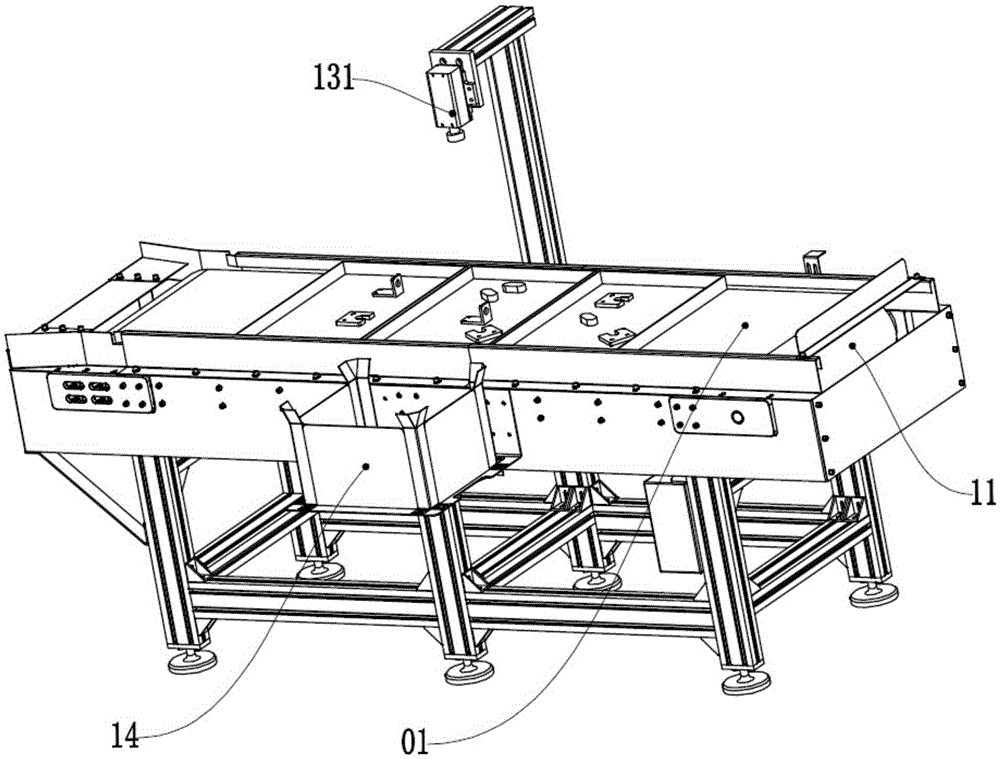

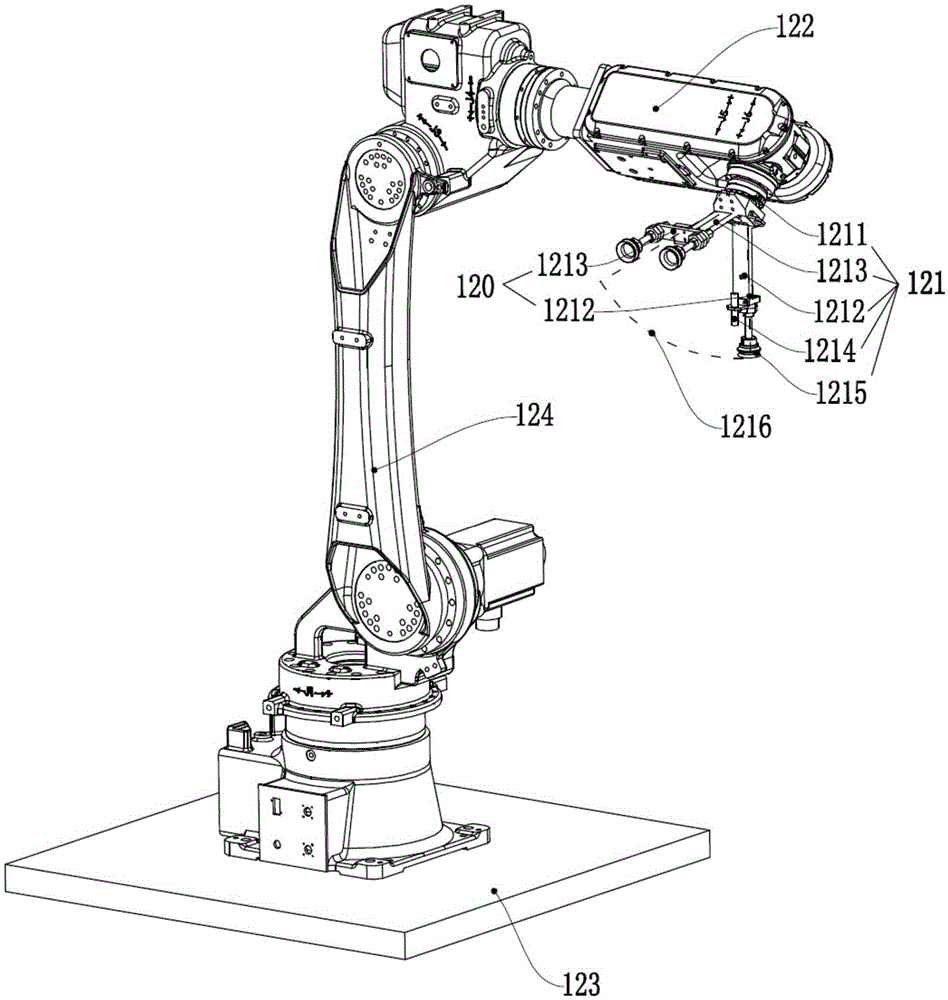

Automatic storage system of industrial robot

InactiveCN105292892AFree laborReasonable assemblyStorage devicesAcquired characteristicIdentification device

The invention discloses an automatic storage system of an industrial robot. The automatic storage system comprises a robot sorting area, a speed-fold chain, an AGV trolley, an intelligent three-dimensional warehouse and a central controller. The robot sorting area comprises a flat belt conveyor, a robot and a vision identification device. The flat belt conveyor receives a signal sent by the central controller and controls trays to move in the conveying direction of the flat belt conveyor. The vision identification device is installed on any side of the flat belt conveyor and located above the trays. A camera of the vision identification device is used for photographing the tray area below the camera, and the photographing area of the camera at least includes one tray. The vision identification device detects and identifies photos photographed by the camera, sends feature data obtained through identification to the central controller and sends a signal to the robot, and the robot receives the signal to transfer and put specified articles on the storage trays of the speed-fold chain to achieve sorting. According to the automatic storage system of the industrial robot, labor force of workers is liberated, and product detecting, sorting and storing efficiency is improved.

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD +1

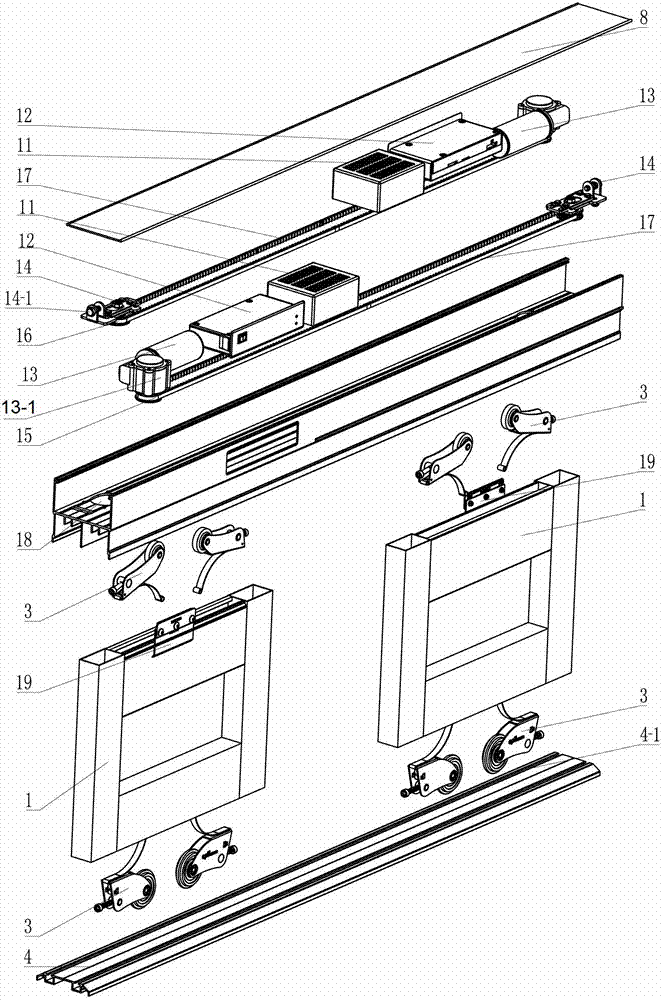

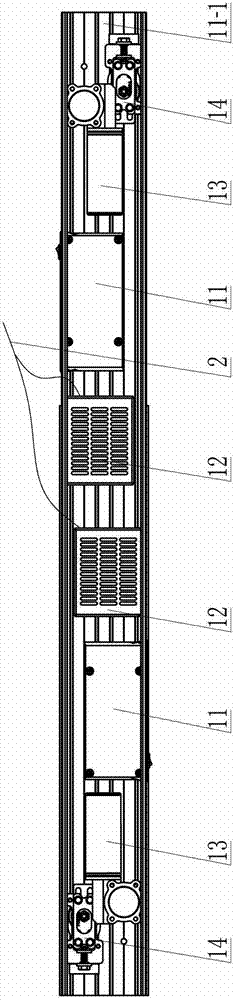

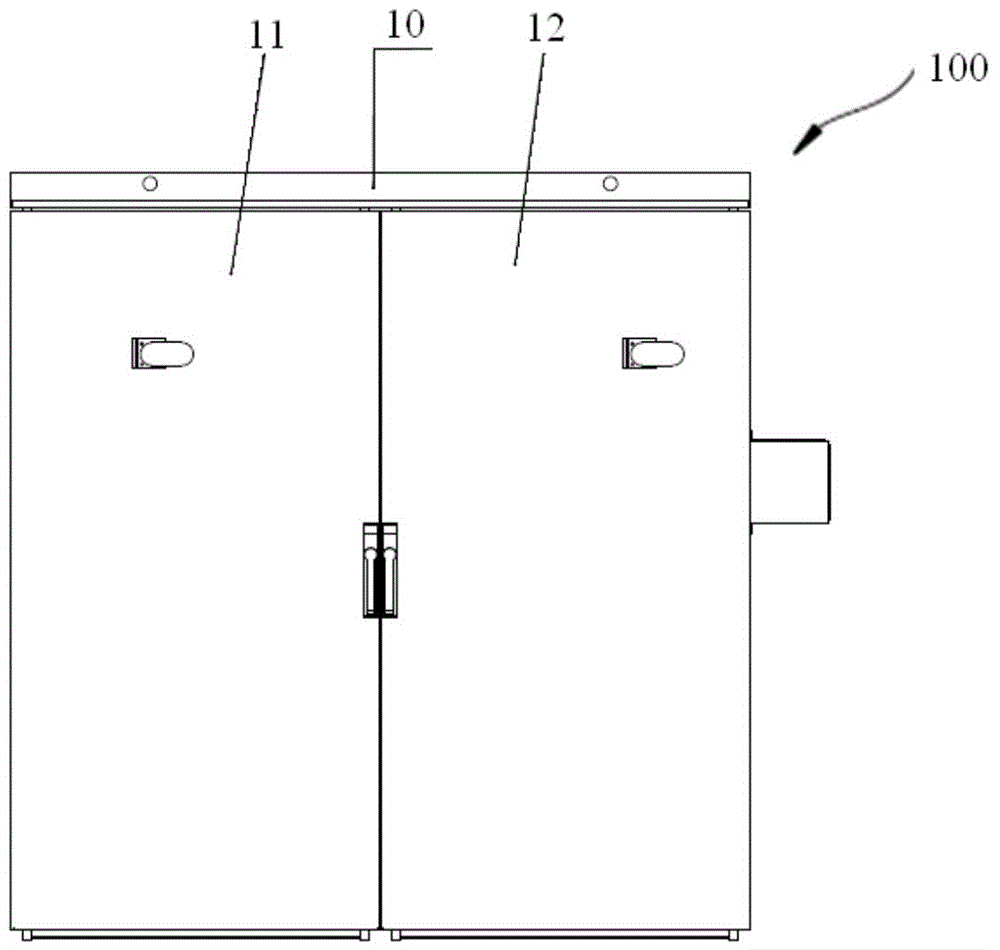

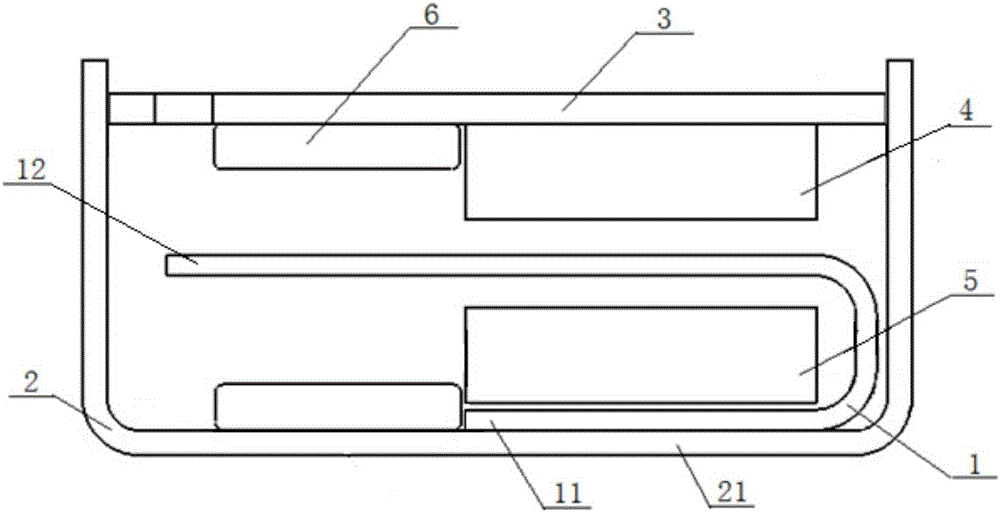

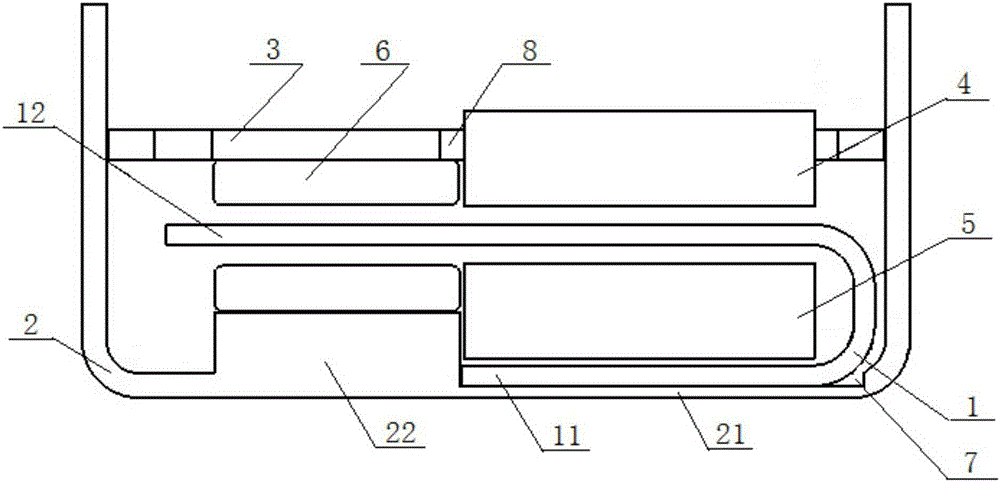

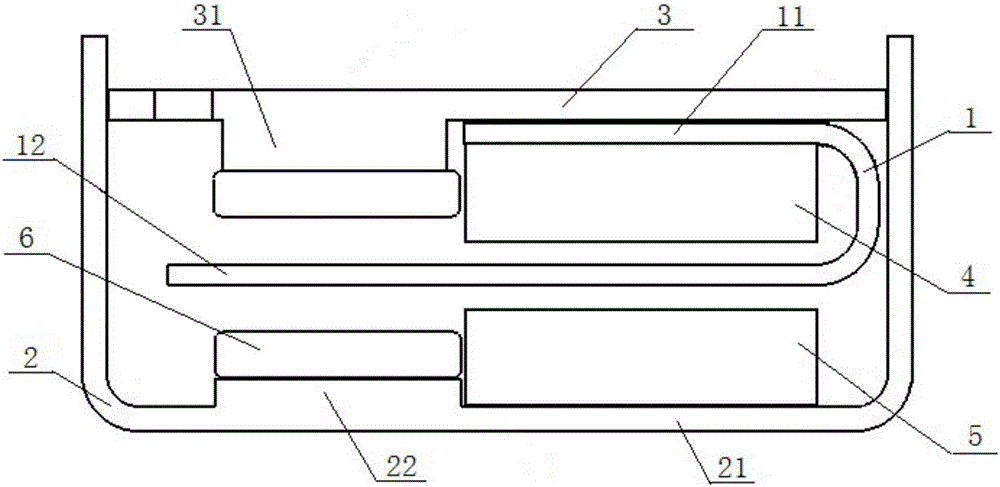

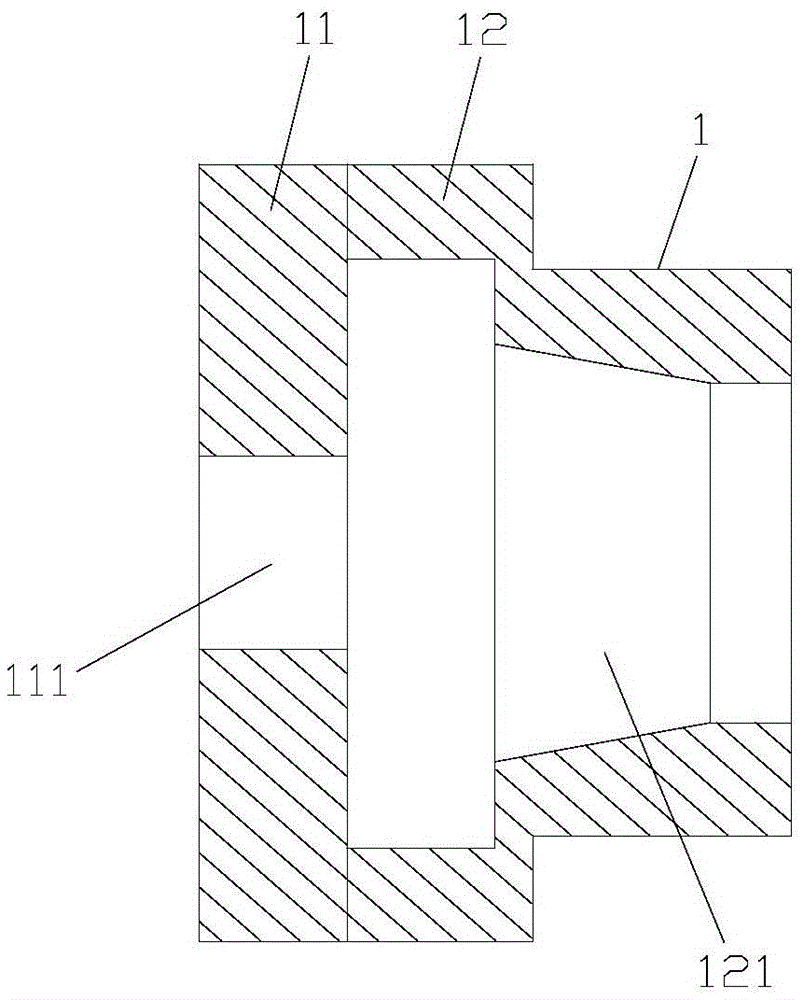

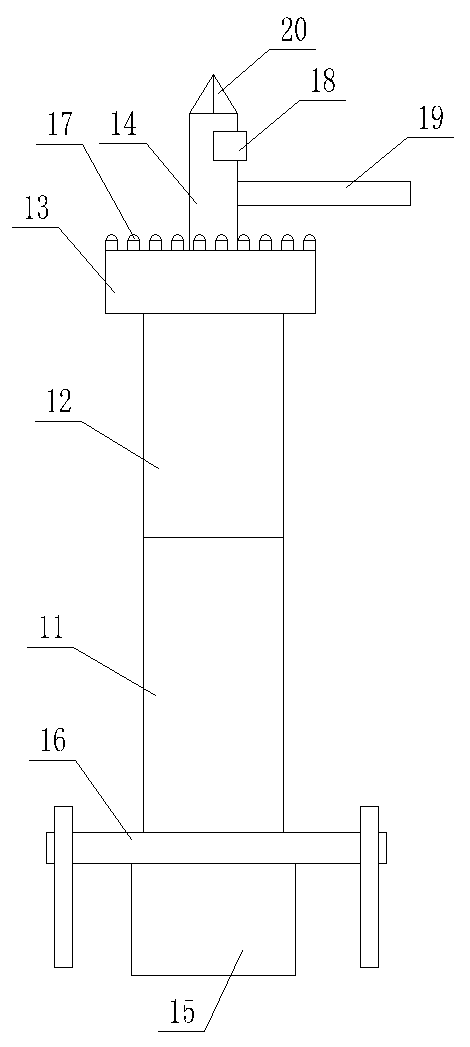

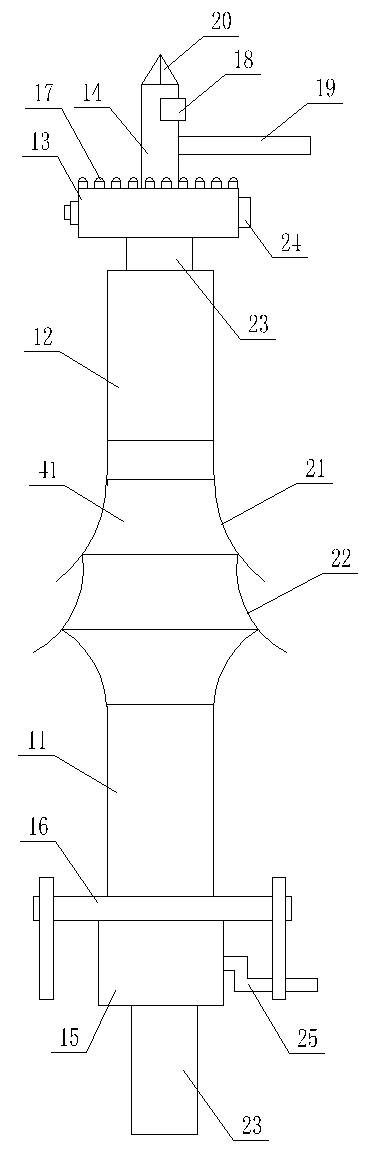

Transmission mechanism of closet type electric partition door

ActiveCN102733718AReasonable assemblyInnovative designPower-operated mechanismWing arrangementsManufacturing technologyRemote control

The invention relates to a transmission mechanism of a closet type electric partition door, belonging to a manufacturing technology of architectural decoration hardware fittings. A double-layer upper rail and a transmission mechanism are assembled at the upper part of a partition door leaf, wherein the partition door leaf is hung over the transmission mechanism, closet wheels are assembled at the upper part and lower part of the partition door leaf, and a hand-operated switch, an inductive switch or a remote-control switch is used for directing the partition door leaf to slide leftwards and rightwards. The transmission mechanism is novel in design, reasonable in structure and high in bearing capacity, and is safe and reliable. The transmission mechanism comprises components such as the partition door leaf (1) and the like, and is characterized in that: a switch power supply box (11), a circuit controller (12), a motor (13) and a synchronous belt tension adjuster (14) are assembled on the double-layer upper rail (10) at the upper part of the partition door leaf (1); synchronous belt driving wheels (15) are assembled on the motor (13) and an output shaft of a worm and gear transmission case (13-1); a synchronous belt driven wheel (16) is assembled on an output shaft of the synchronous belt tension adjuster (14); and a synchronous belt (17) is assembled at the peripheries of the synchronous belt driving wheels (15) and the synchronous belt driven wheel (16).

Owner:许姜德

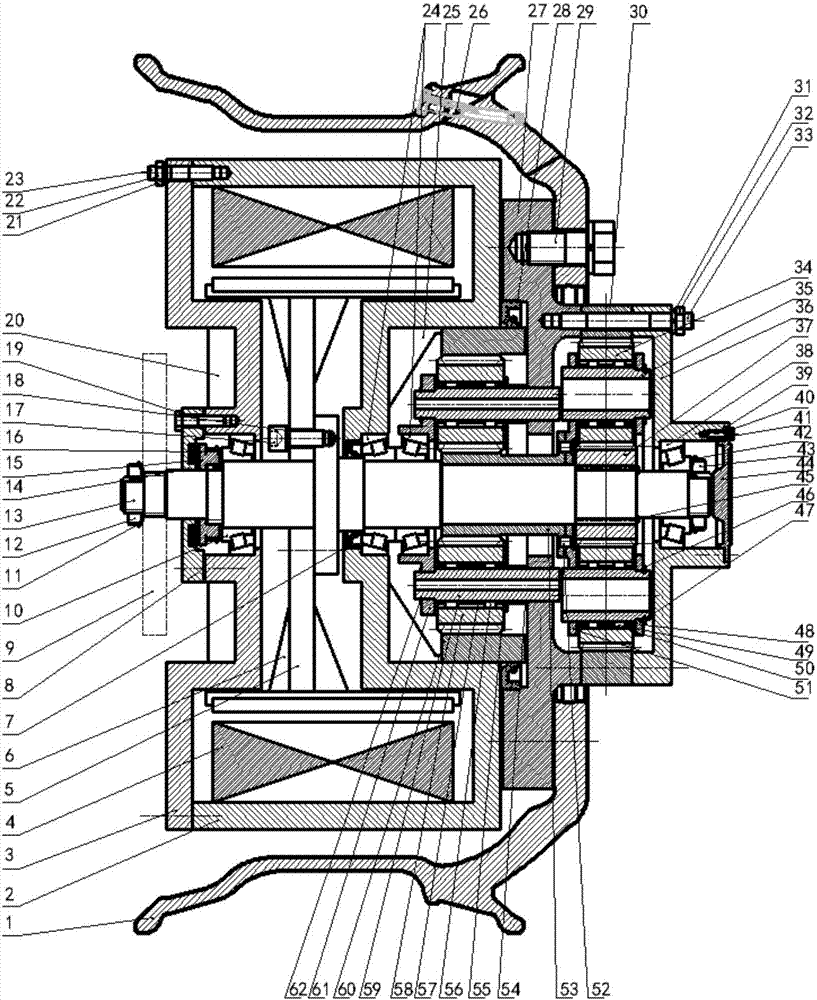

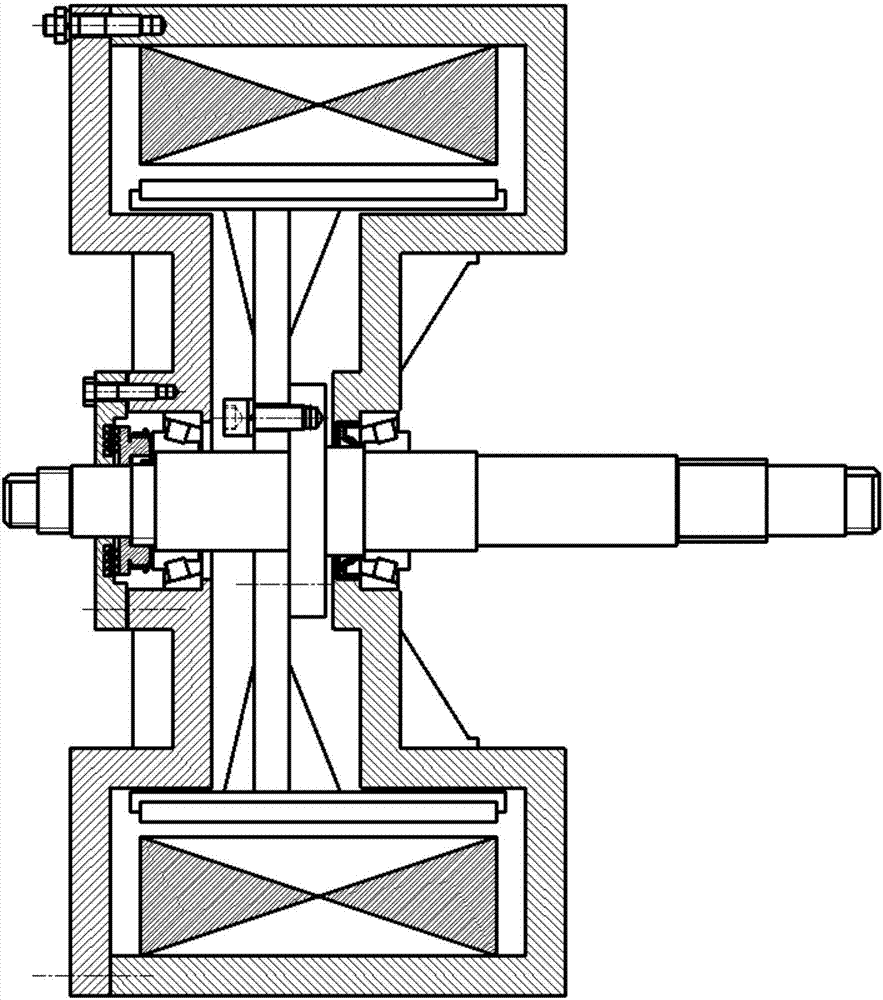

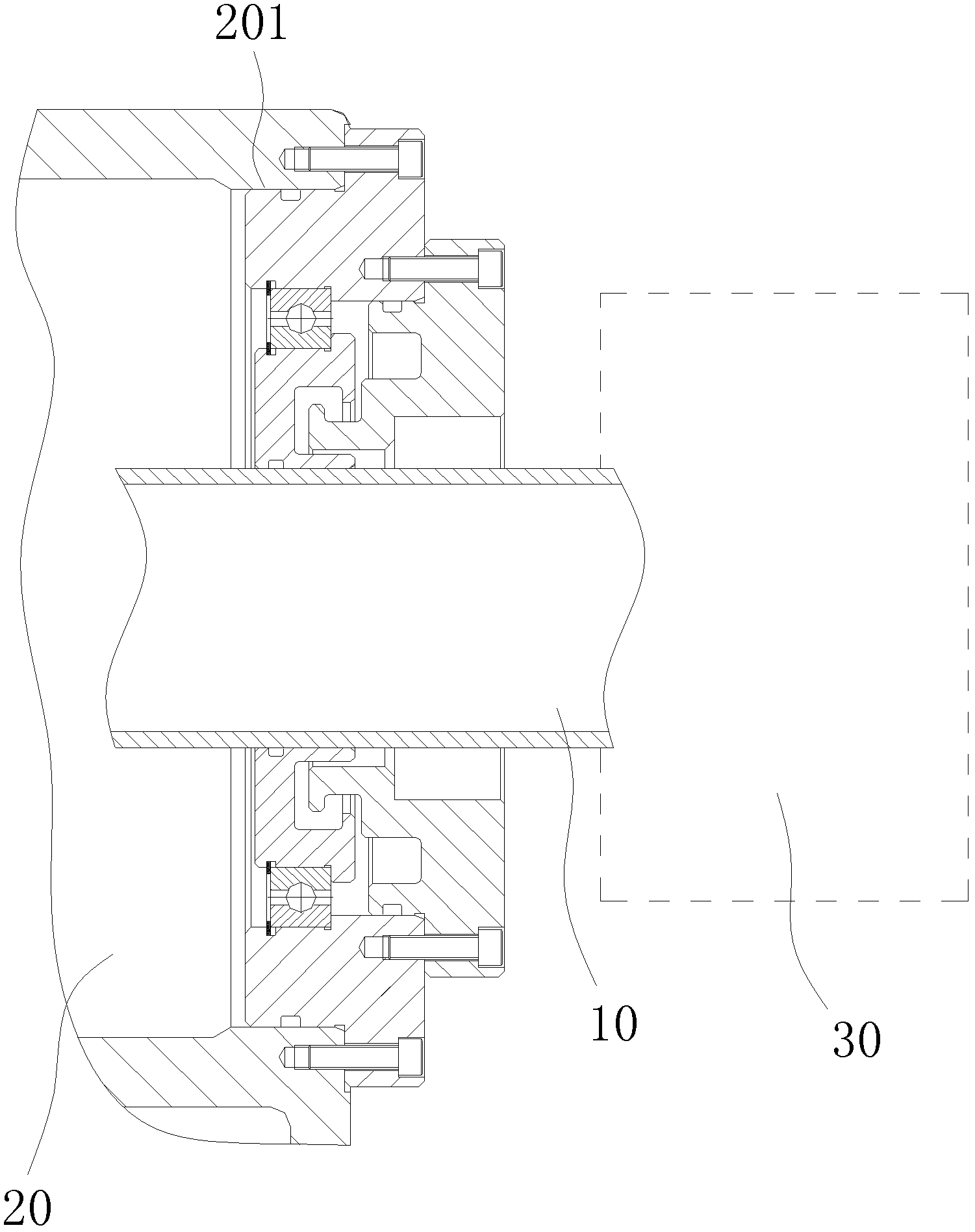

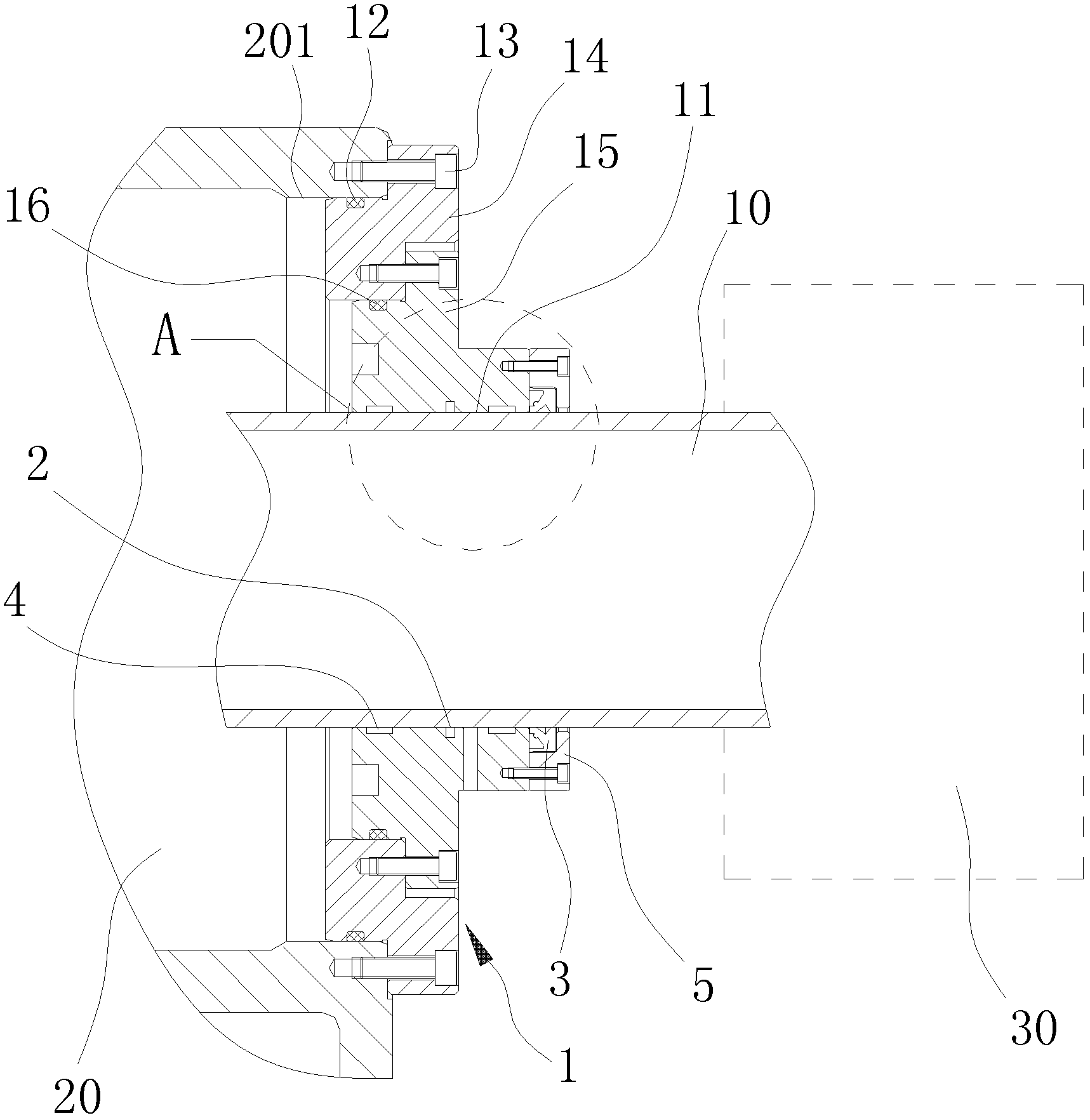

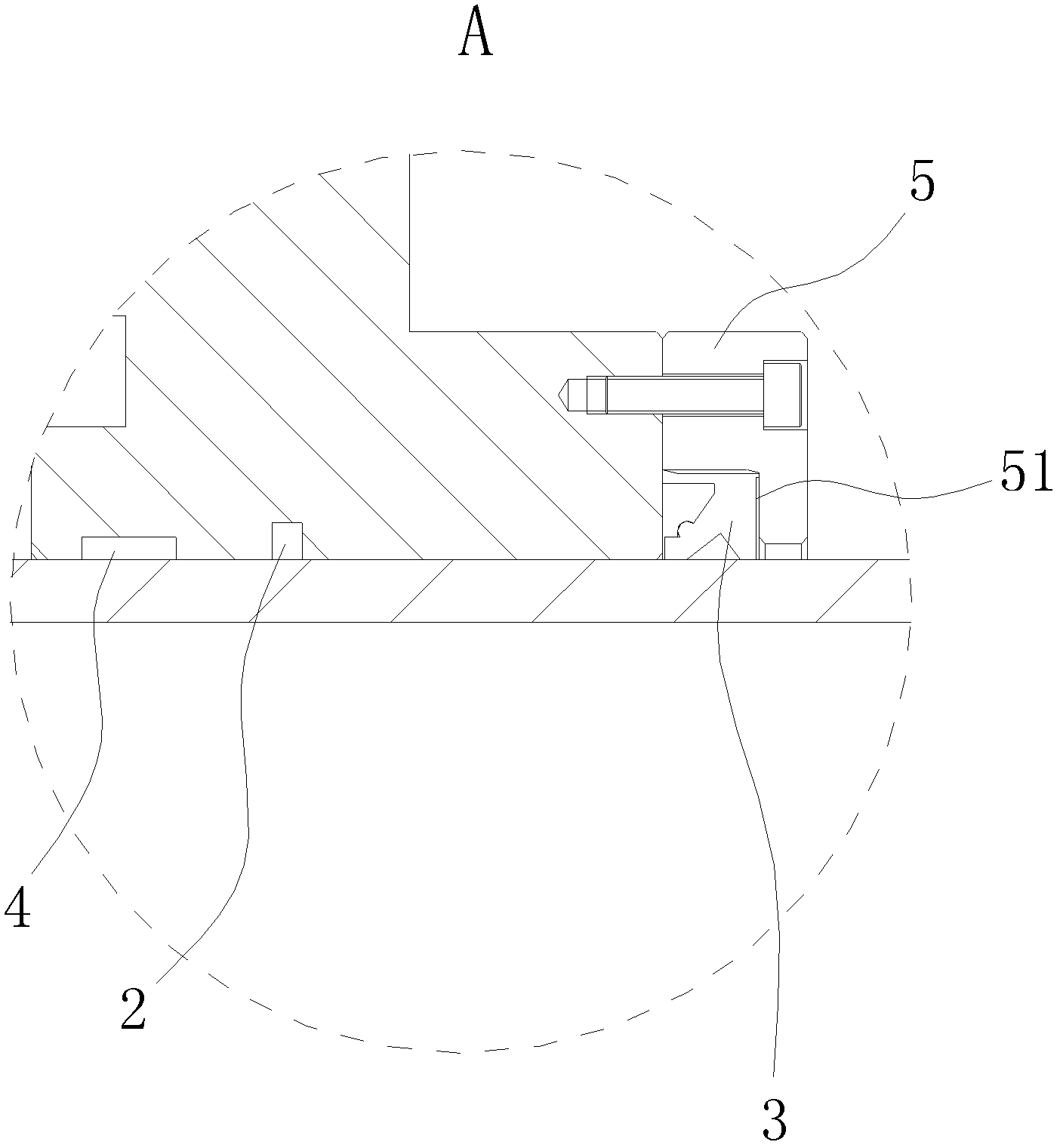

Electric wheel assembly device for overload vehicle and vehicle

PendingCN107128162AThe size of the space does not change muchMeet the requirements of braking performanceMotor depositionControl devicesElectric machineReduction drive

The invention discloses an electric wheel assembly device for an overload vehicle. The electric wheel assembly device comprises a hub motor and a two-stage planetary gear reducer, wherein the hub motor comprises a left motor casing, a right motor casing, a motor rotor, a stator coil and a motor shaft; the two-stage planetary gear reducer comprises a first-stage planetary gear pair and a second-stage planetary gear pair; the first-stage planetary gear pair comprises a first-stage sun gear, a first-stage planetary gear, a first-stage planetary shaft, a first-stage planetary carrier and a first-stage inner gear ring; and the second-stage planetary gear pair comprises a second-stage sun gear, a second-stage planetary gear, a second-stage planetary shaft, a second-stage planetary carrier and a second-stage inner gear ring. The invention further discloses the vehicle. The electric wheel assembly device has the advantages that the structure is simple, the technology is easy to implement, and meanwhile, integration is convenient to achieve by the electric wheel assembly device and the finished vehicle.

Owner:JILIN UNIV

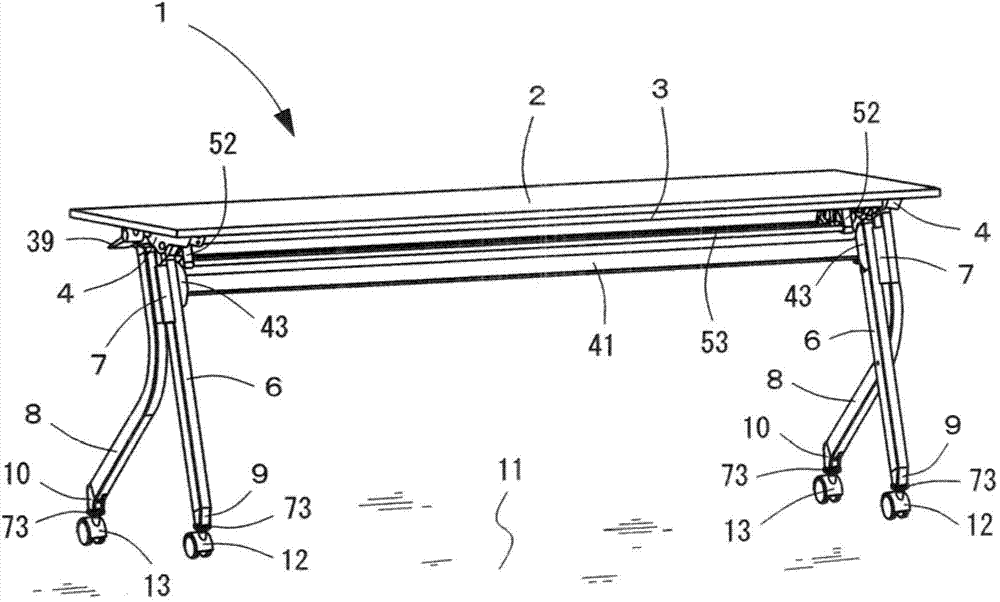

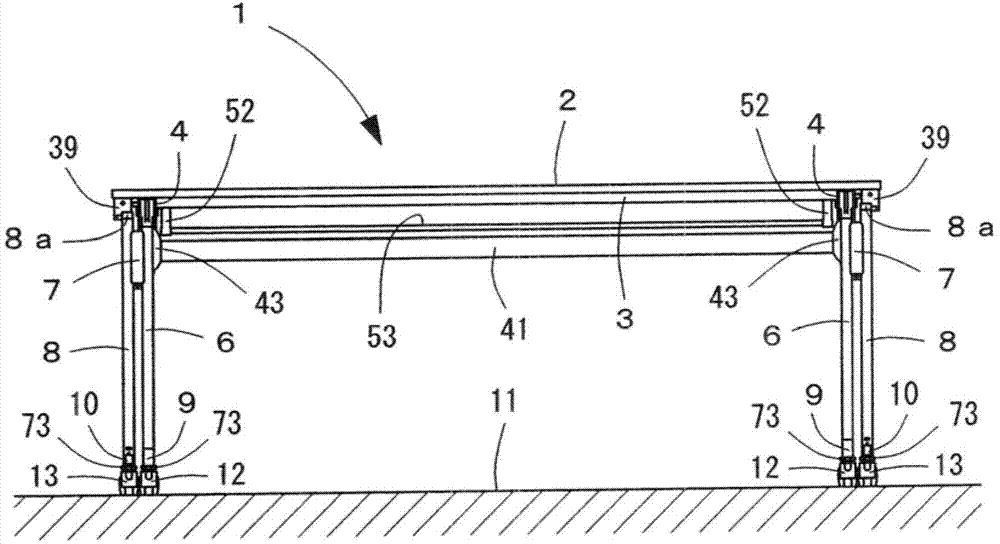

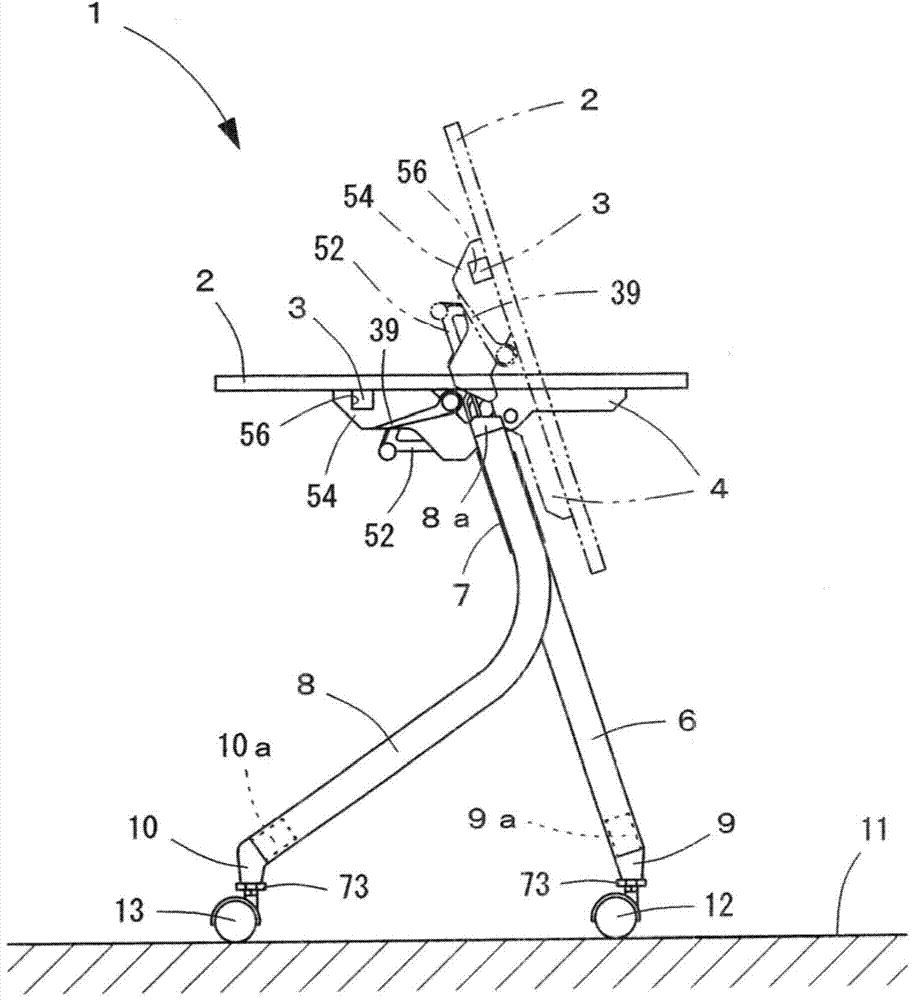

Folding table

ActiveCN103156384AAchieve compactnessConducive to lightweightFoldable tablesStowable tablesMechanical engineeringGround level

The invention provides a folding table, which comprises a height regulation device capable of easily and reliably regulating height from a leg or a top plate to the ground, while the folding table obtains reliable and stable using and folding states to the top plate. A locking connecting rod is arranged, and the locking connecting rod comprises a clamping part clamping or unclamping in a clamping groove. The clamping part of the locking connecting rod forms a plate on a same plane with the locking connecting rod. A peripheral surface on an upper end of a connection component is configured a same plane of a rotation area of the clamping part.

Owner:HUIBIES FURNITURE

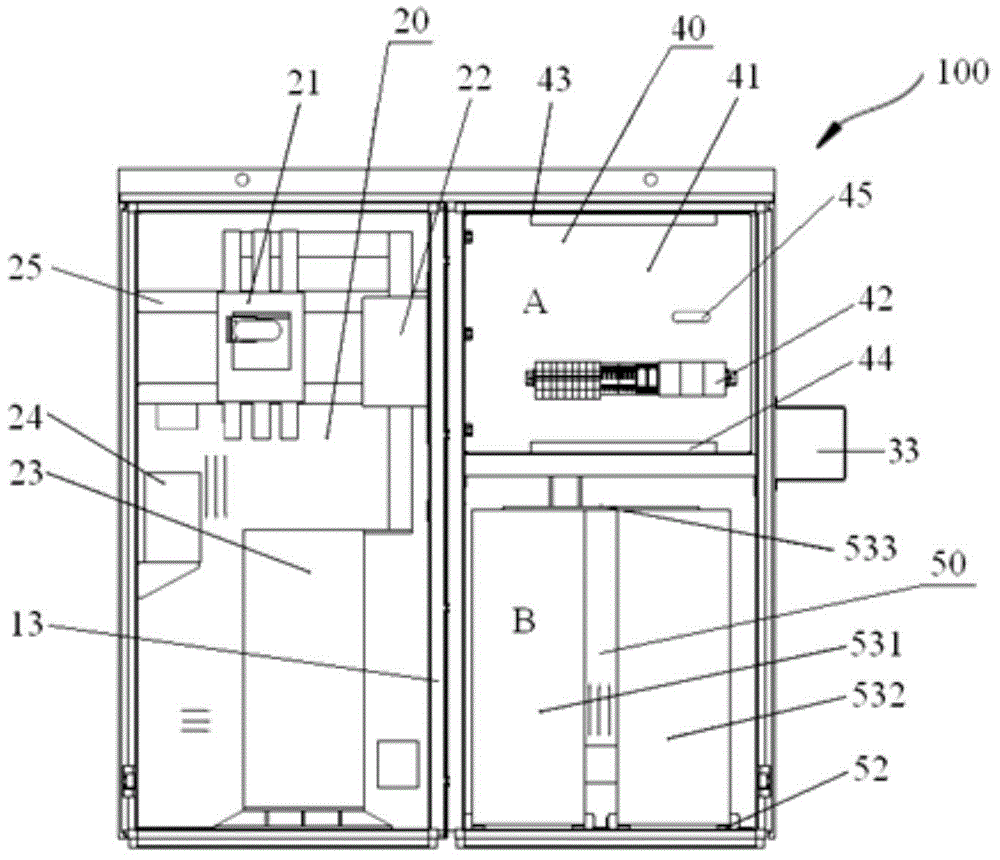

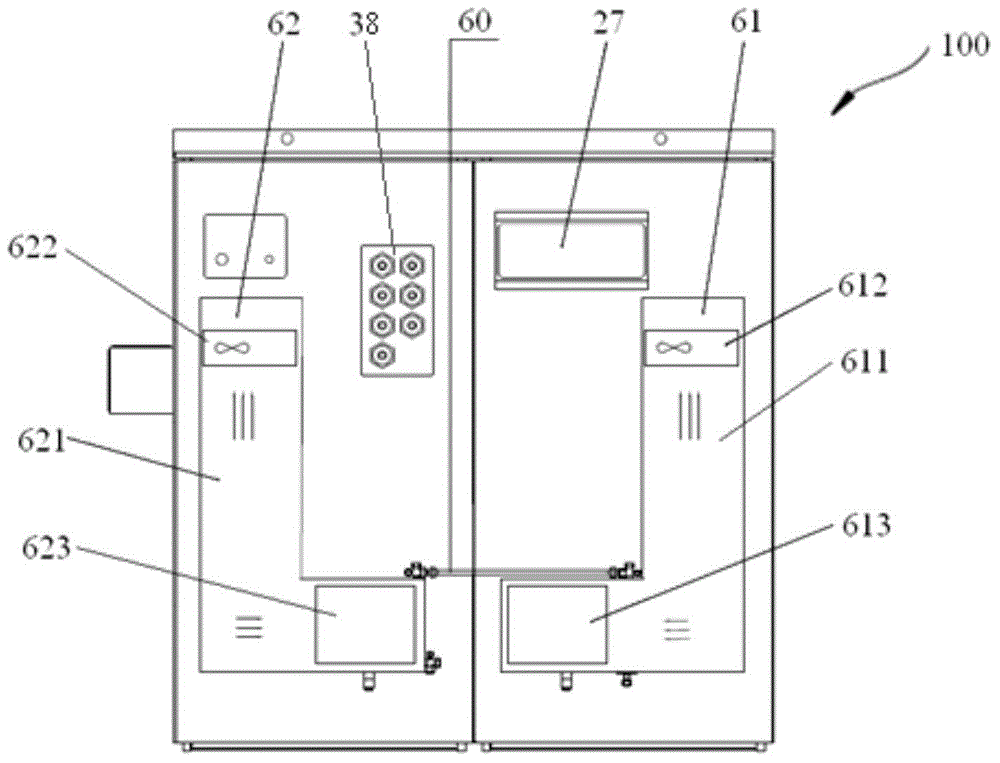

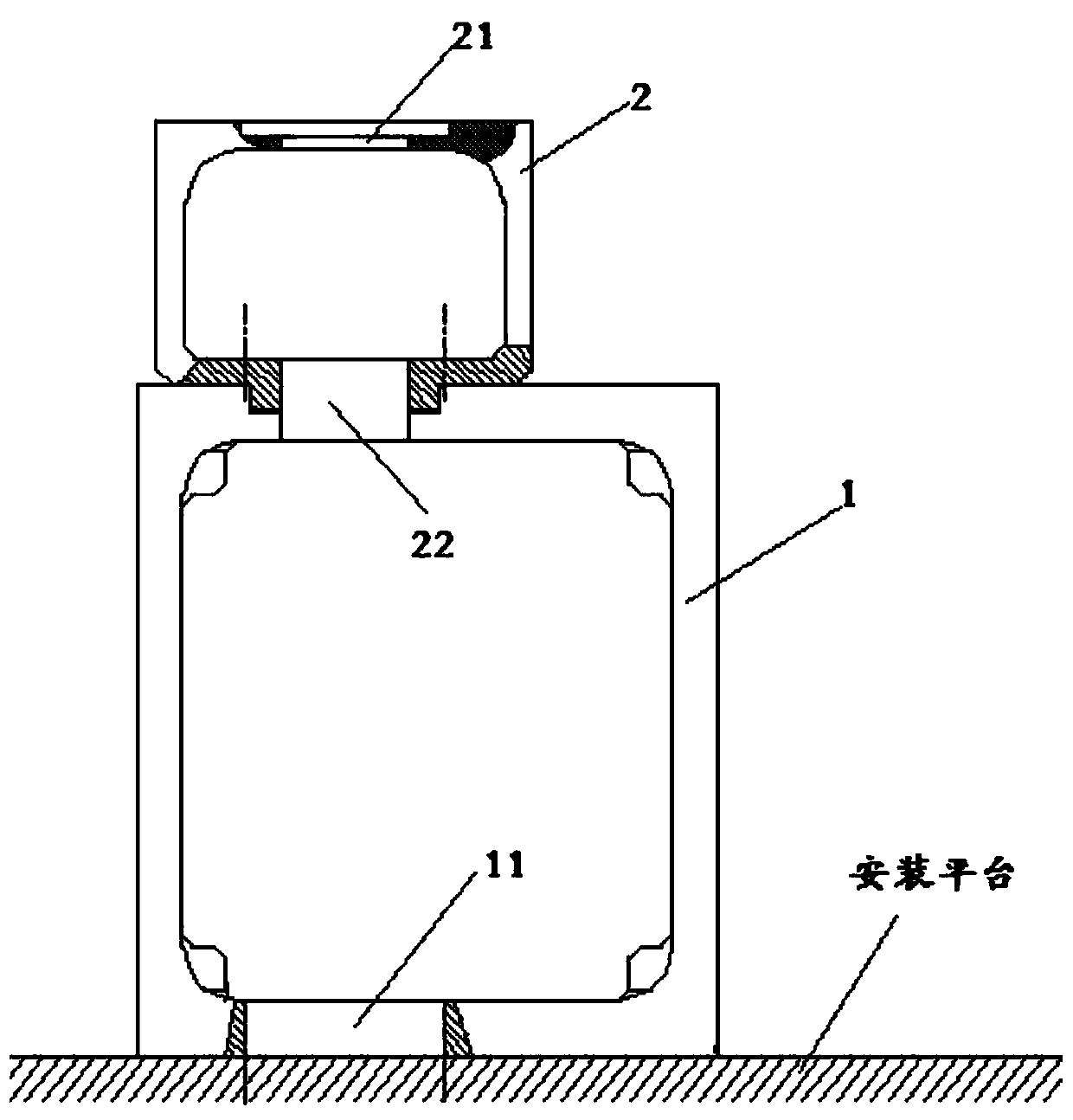

Frequency changer

ActiveCN104795968AImprove good performanceEasy to manufacture and installCooling/ventilation/heating modificationsPower conversion systemsFrequency changerModularity

The invention discloses a frequency changer which comprises a cabinet, a modularized component and a radiator component. The modularized component is arranged in the cabinet, the radiator component is arranged outside the cabinet, the modularized component comprises an alternating-current branch device set, a direct-current branch device set, an electrical device set and a power device set, the cabinet is divided into a first cabinet and a second cabinet through a partition, the first cabinet is used for containing the alternating-current branch device set, and the second cabinet comprises a first area used for containing the electrical device set, a second area used for containing the power device set, and a third area used for containing the direct-current branch device set. The modularized component is arranged reasonably, so that the frequency changer is enabled to be more reasonable and compact in assembly structure and easy to expand, maintain, manufacture and mount. In addition, power grid composite power supply and grid-connected power generation of the frequency changer can be realized, and the frequency changer has needed using functions and is good in heat radiating performance.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

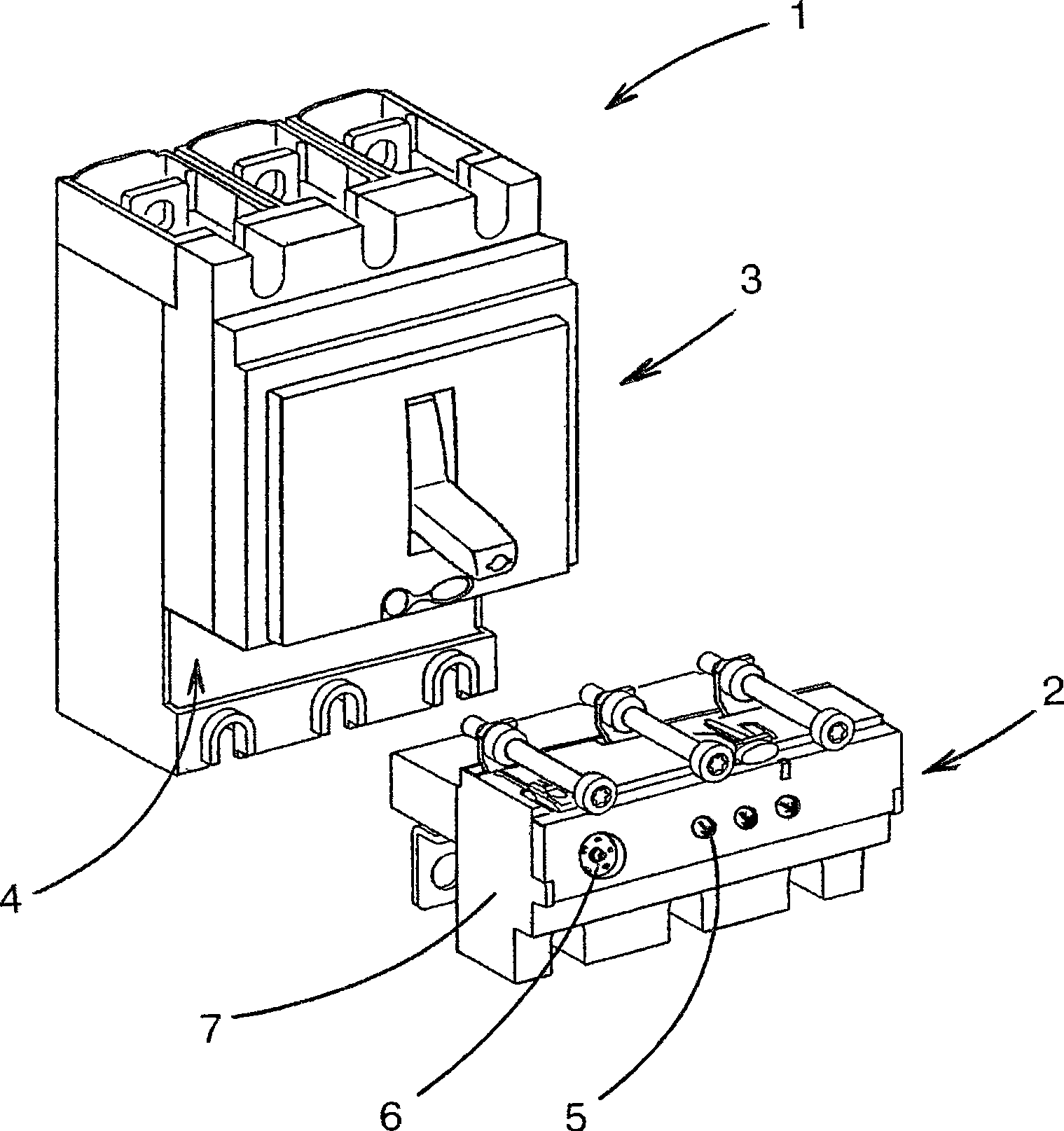

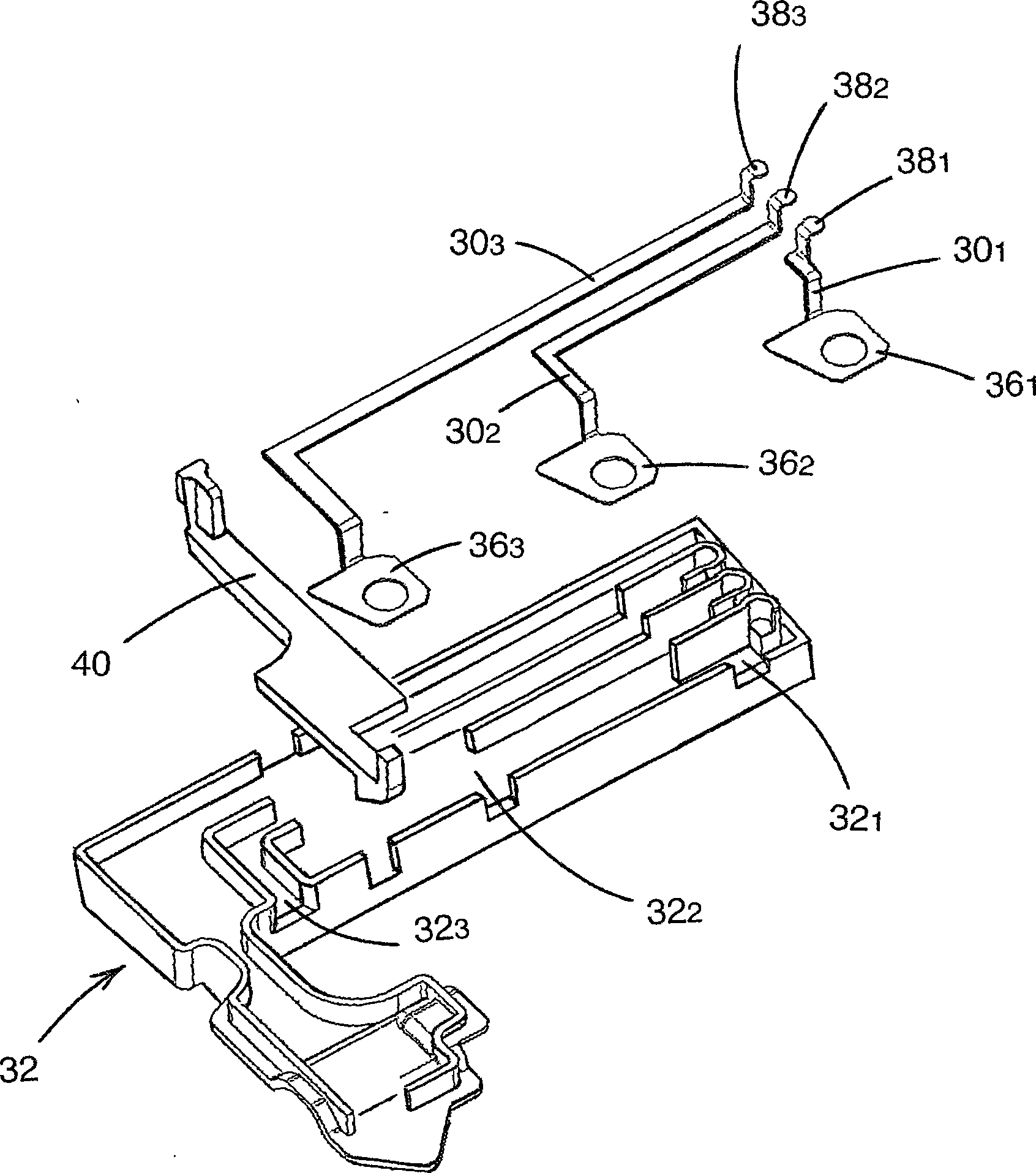

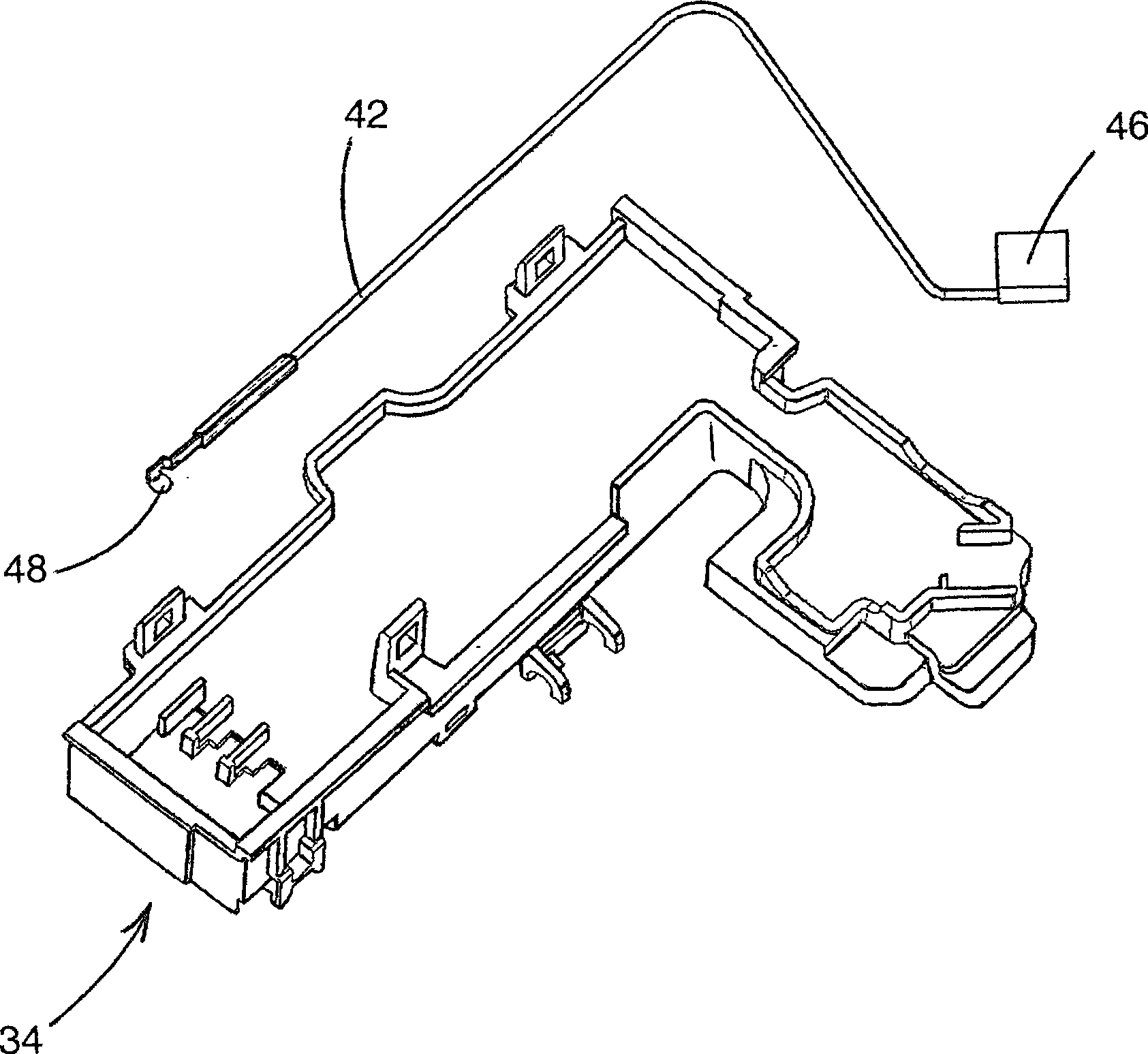

Electronic trip device case for a circuit breaker, electronic trip device and assembly method thereof

ActiveCN101483121AReduce disadvantagesReasonable assemblyProvisions for user interfaceProtective switch terminals/connectionsComputer moduleEngineering

An electronic module for a trip device has been optimised so as to integrate the known functionalities, in particular threshold parameter setting, current measurements, voltage taps, read-out display and communication. An electromagnetic actuator is further present in the electronic module to optimise breaking of the associated circuit breaker. The space occupation constraints inherent to location of the trip device in existing switchgear units have been respected.

Owner:SCHNEIDER ELECTRIC IND SAS

Multifunctional intelligent office furniture

InactiveCN105661903AIncreased versatilityEasy to useOffice tablesExtensible tablesSoftware engineeringOffice staff

The invention discloses multifunctional intelligent office furniture. The multifunctional intelligent office furniture comprises an office table top, supporting legs, lengthening plates, storage frames, storage drawers and a computer supporting base. The office table top is arranged on the supporting legs in a supported mode, the lengths of the supporting legs can be adjusted, the lengthening plates are arranged at the two ends of the office table top in a stretchable mode, the computer supporting base is arranged on the office table top, the height of the computer supporting base can be adjusted, and the storage frames are arranged on the front side of the office table top. The height of the office table top can be adjusted according to actual needs, the placement height of a computer can be adjusted, and office staff can use the computer conveniently; a partition plate is provided with the various storage frames, file folders, article hangers and the like, area classification is conducted on the office table top, the office staff can sort articles on the table at any time, and the multifunctionality of the office furniture is improved; an illuminating lamp is arranged and can slide, and use convenience is improved.

Owner:宿州学院

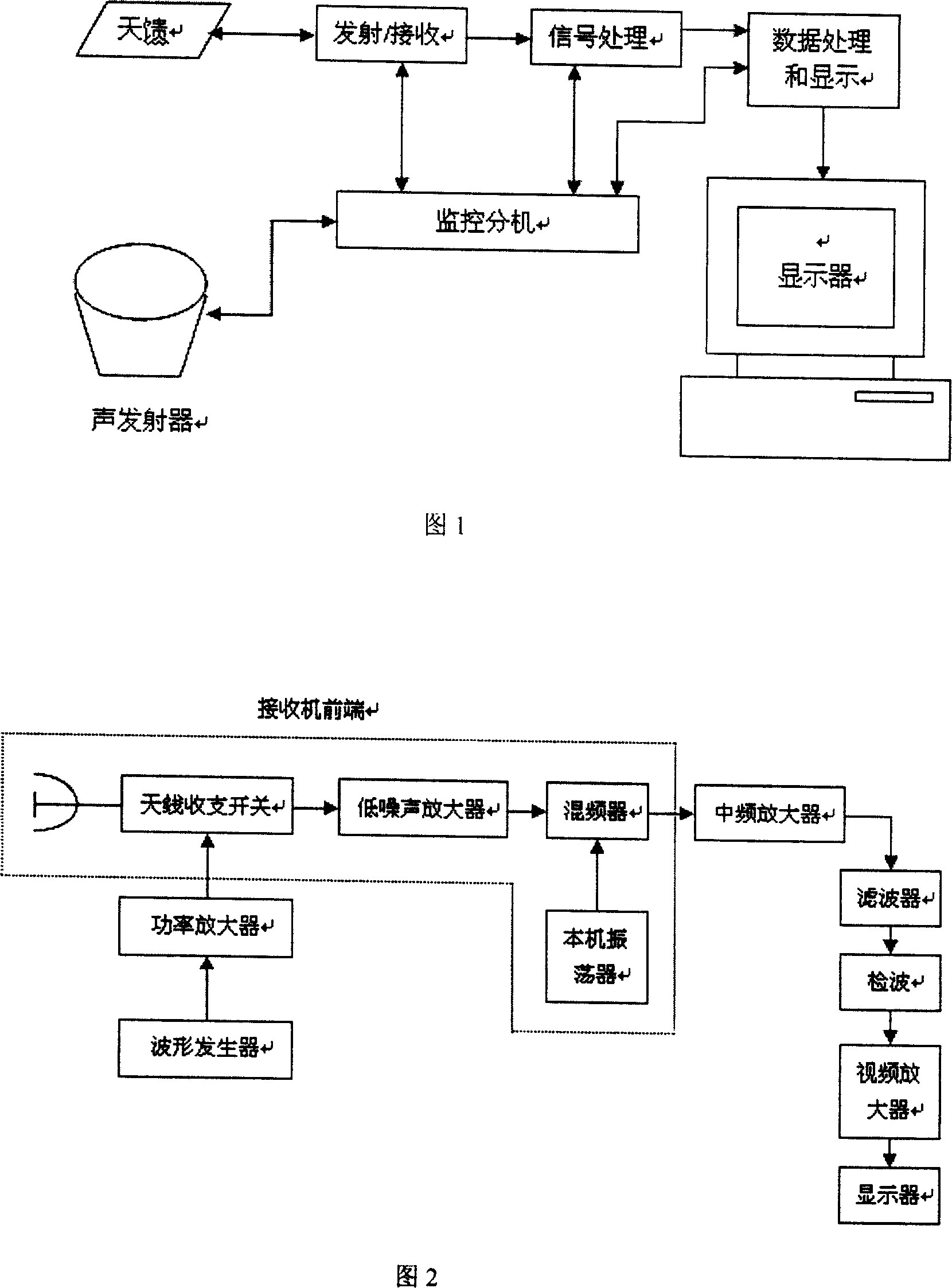

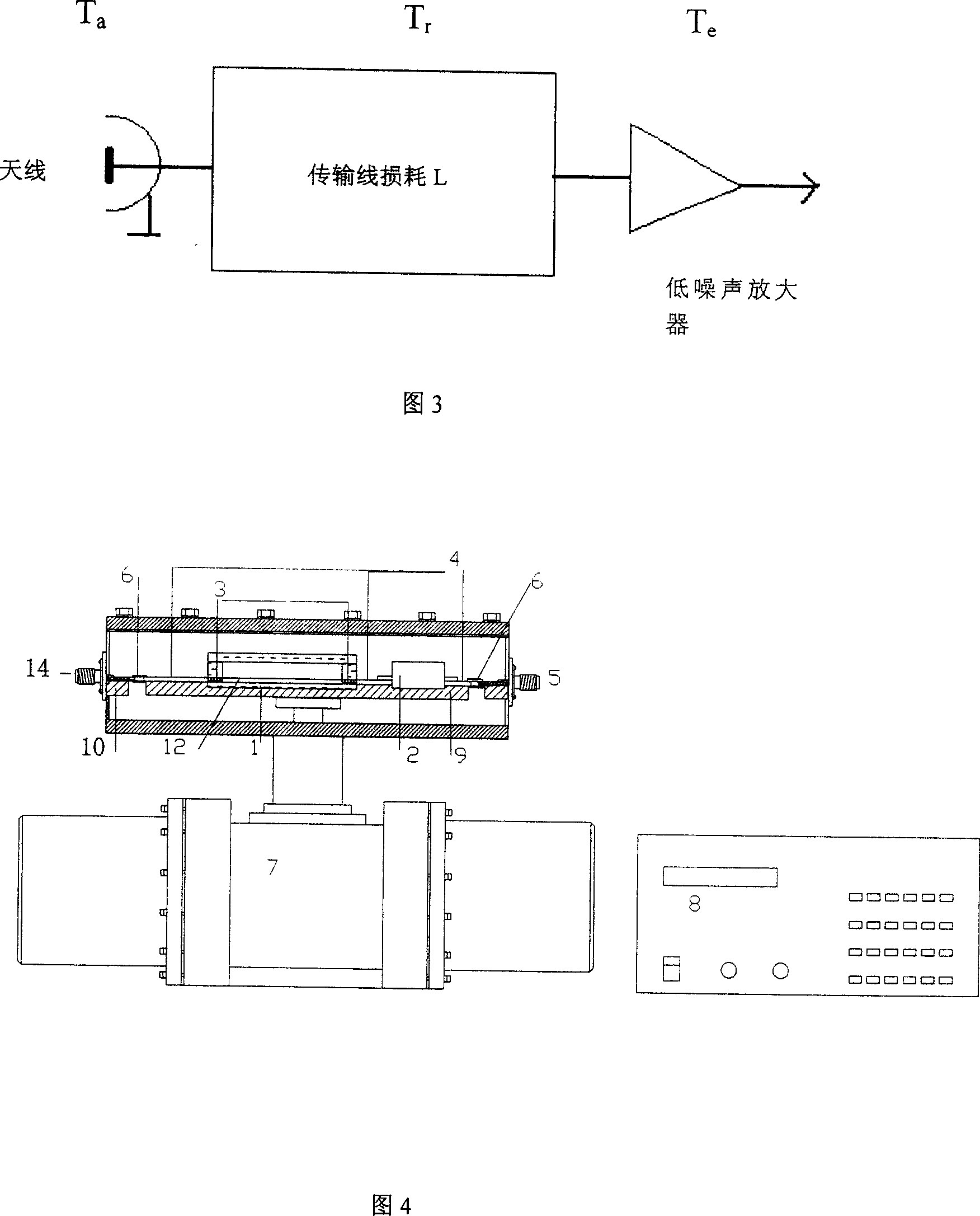

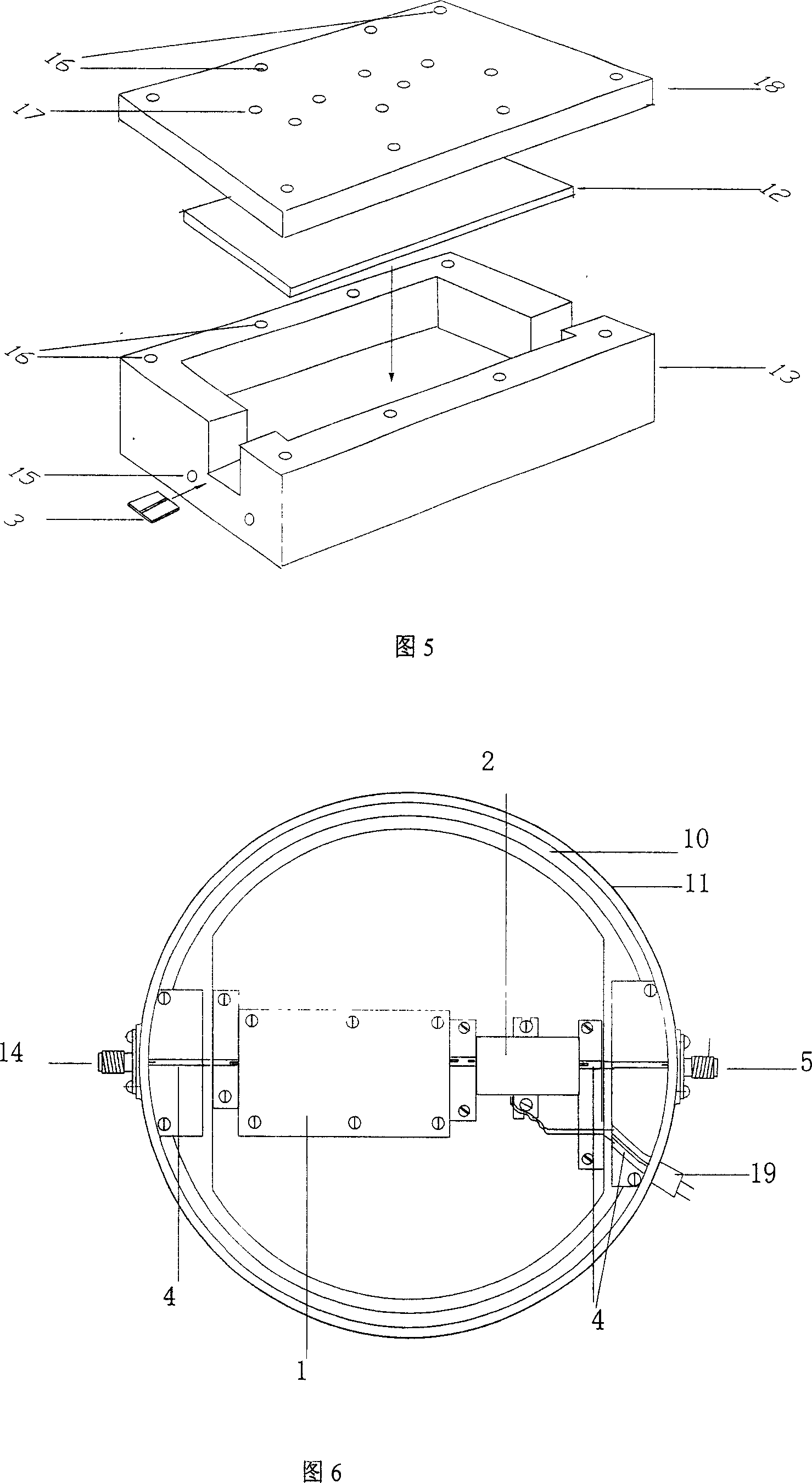

A high heat resistance microwave sub-system for weather radar receiver front end

The invention relates to a microwave subsystem of high heat resistance which is used in the fore end of the weather radar receiver, it includes: superconductive filter, low noise amplifier with table structure, tiny band transmission line, sealed shell, refrigeration machine and temperature control instrument; Said superconductive filter includes high temperature superconductive shield box and superconductive piece which is in the high temperature superconductive shield box; the output end of the superconductive filter is electric connected with the low noise amplifier via tiny band transmission line, both are installed on the heat transferring plate, the bottom of the heat transferring plate is fixed to the cool head of the refrigeration machine. The advantages of the invention are realizing the flat integrating technique and making the assembly of the subsystem more reasonable, so the noise of the subsystem is decreased further; the heat resistance of the invention is high, the cool quantity wastage of the subsystem cool head is small, so under the equal refrigeration power, flat integrating technique can load more components. For example, the same refrigeration machine can load several superconductive components or other device.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

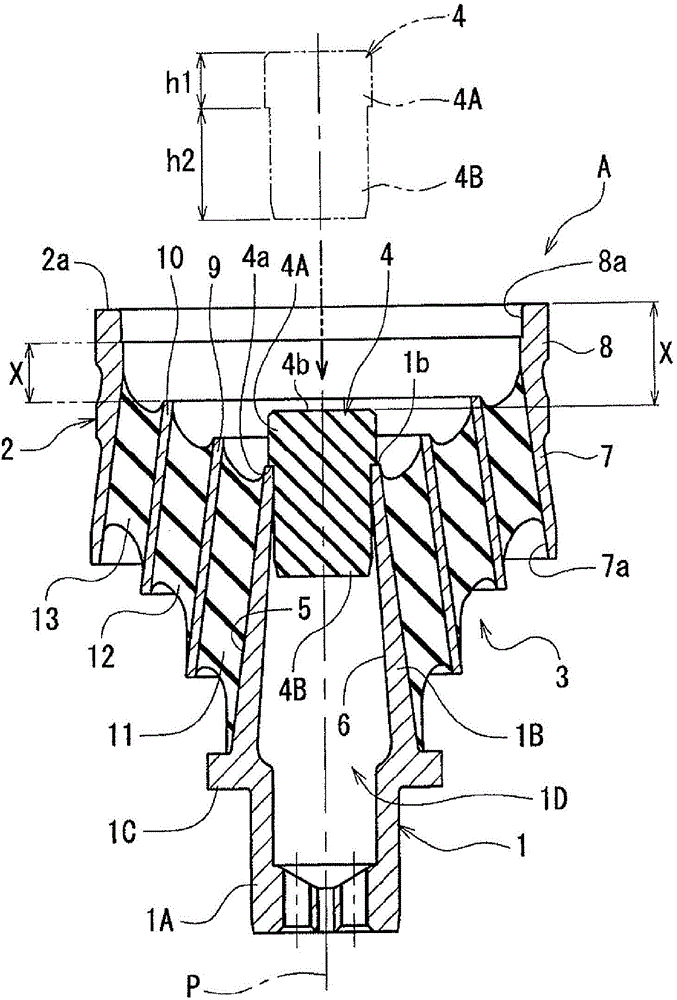

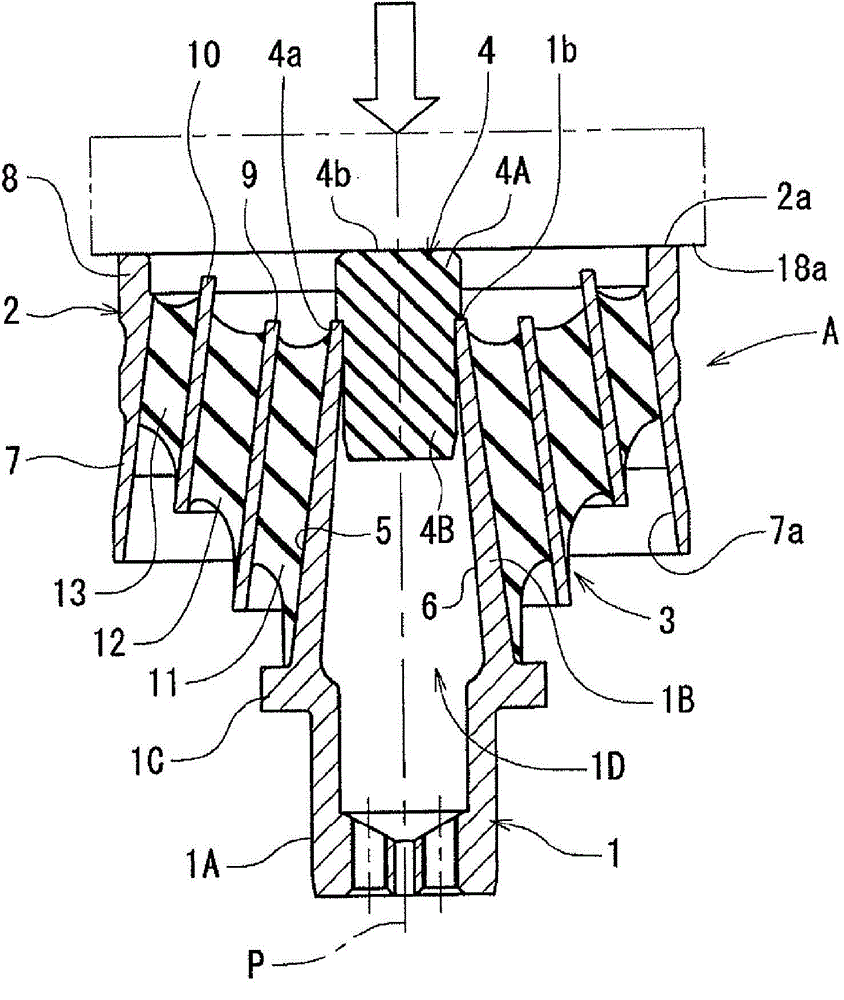

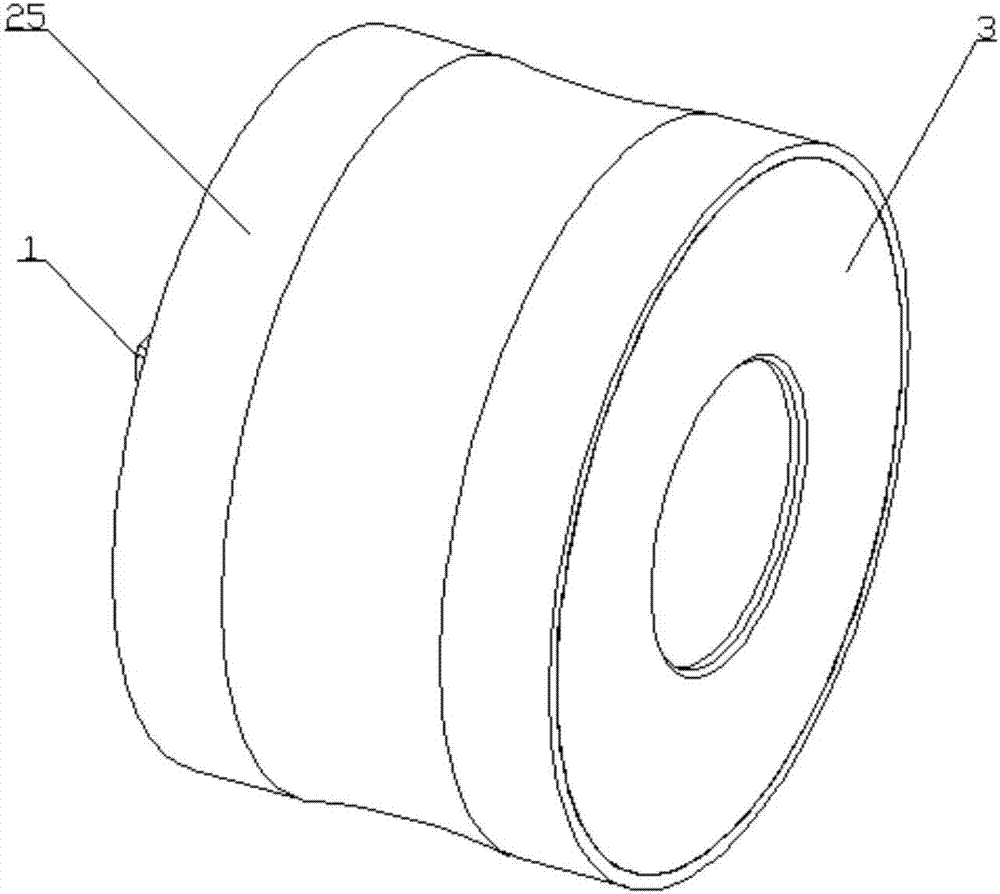

Shaft spring

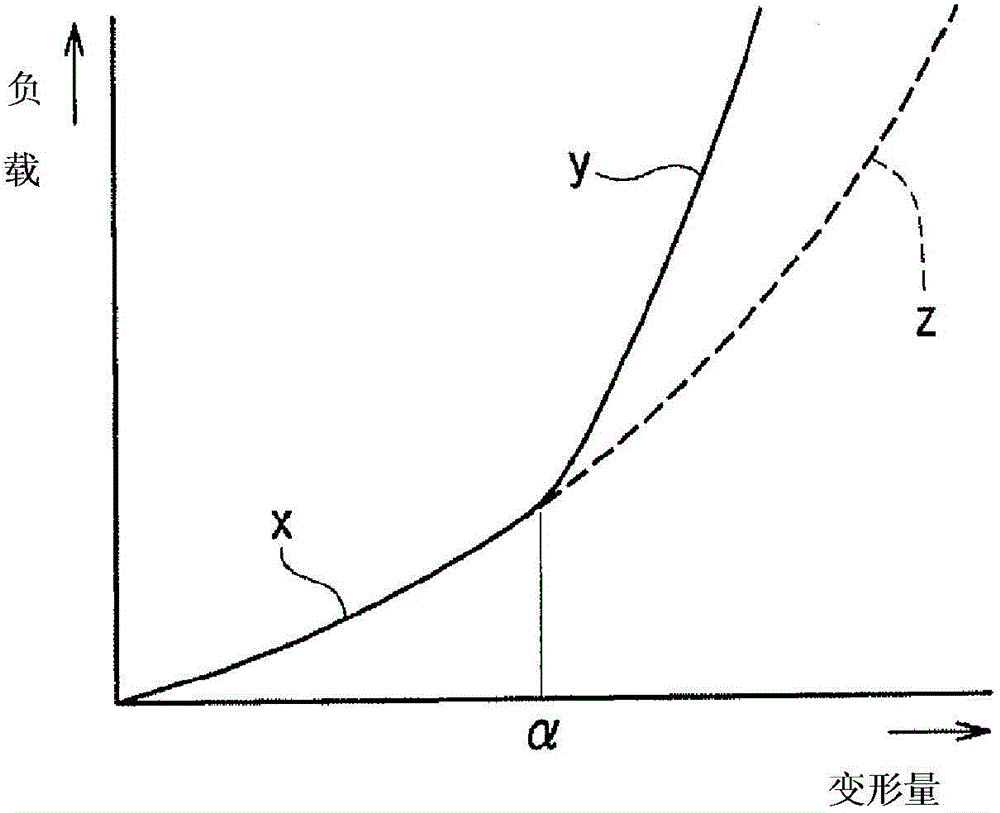

ActiveCN104913001AIncrease the spring constantEasy Balance ConfigurationNon-rotating vibration suppressionRubber-like material springsEngineeringMechanical engineering

Owner:NITTA CHEM IND PROD CO LTD

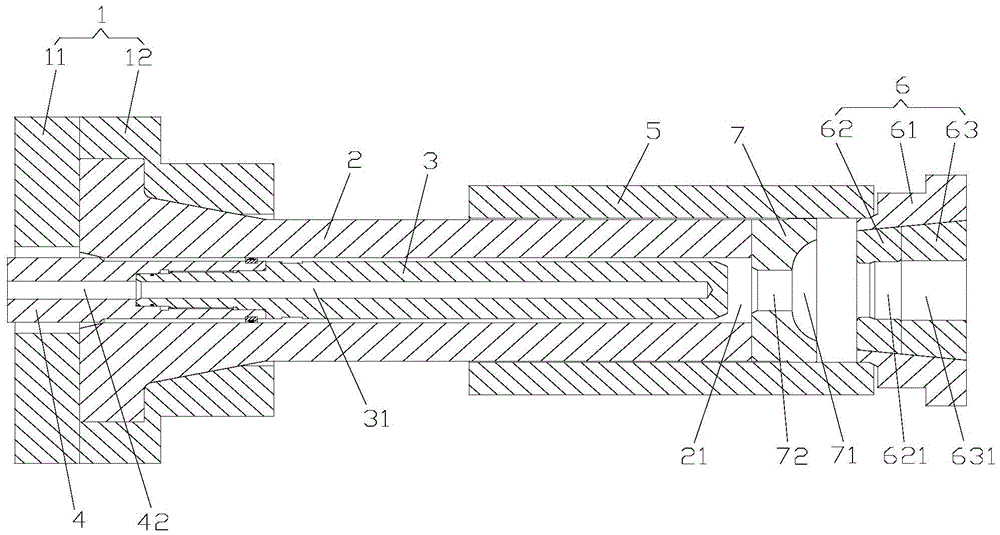

Scraping-rolling machine boring rod spiral sealing mechanism and scraping-rolling machine

InactiveCN102588596AGuaranteed uptimeImprove sealingEngine sealsBoring barsReciprocating motionEngineering

The invention discloses a scraping-rolling machine boring rod spiral sealing mechanism and a scraping-rolling machine, wherein the scraping-rolling machine boring rod spiral sealing mechanism comprises a flange plate, a reciprocating sealing piece and a rotary sealing piece; the outer edge of the flange plate is fixedly connected with a wall plate at an opening part of an oil receiver, so that the flange plate covers the opening part; an installation hole is arranged in the middle of the flange plate, and a boring rod is arranged in the installation hole in a penetrating way; the reciprocating sealing piece is arranged between the inner wall of the installation hole and the boring rod; and the rotary sealing piece is sheathed on the boring rod and is clung to the end surface of the flange plate, close to a boring rod box. The scraping-rolling machine boring rod spiral sealing mechanism and the scraping-rolling machine can realize the rotary sealing and the reciprocating sealing of the boring rod simultaneously, and are simple in structure and stable in performance.

Owner:SANY GRP

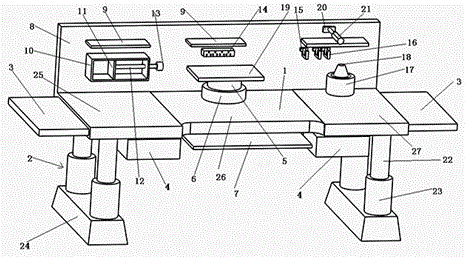

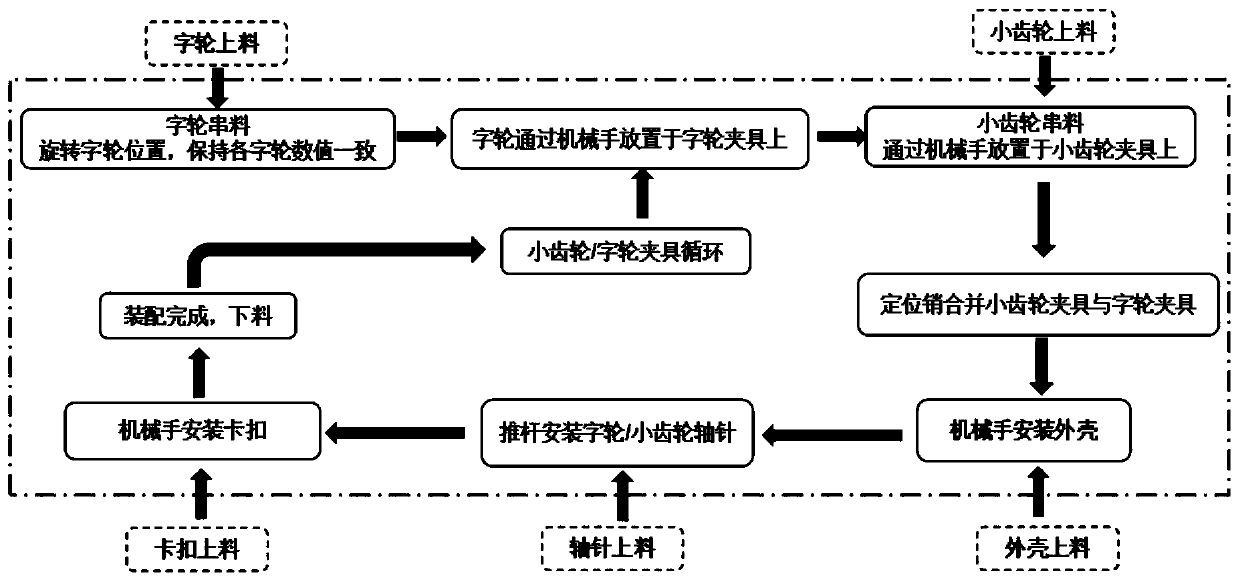

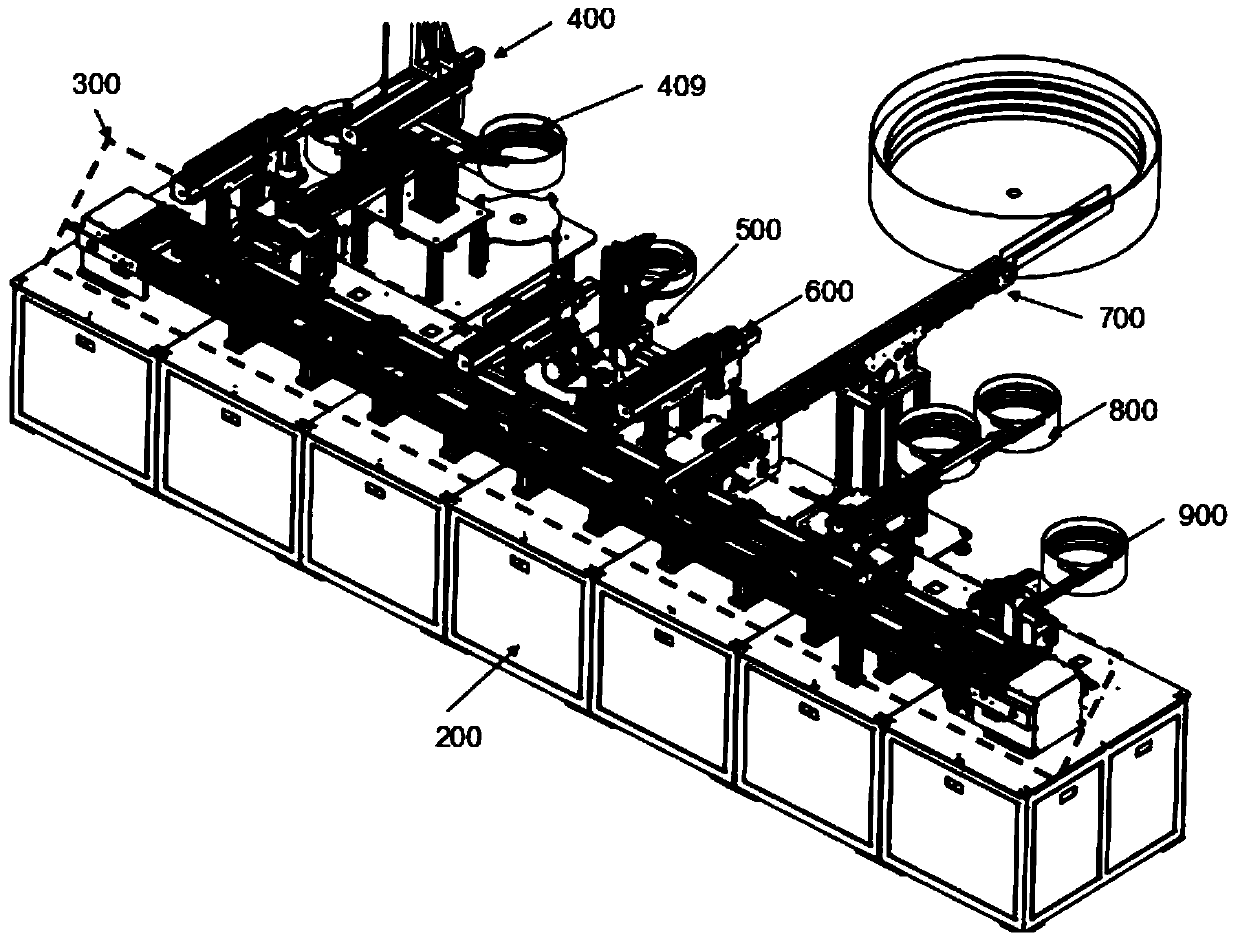

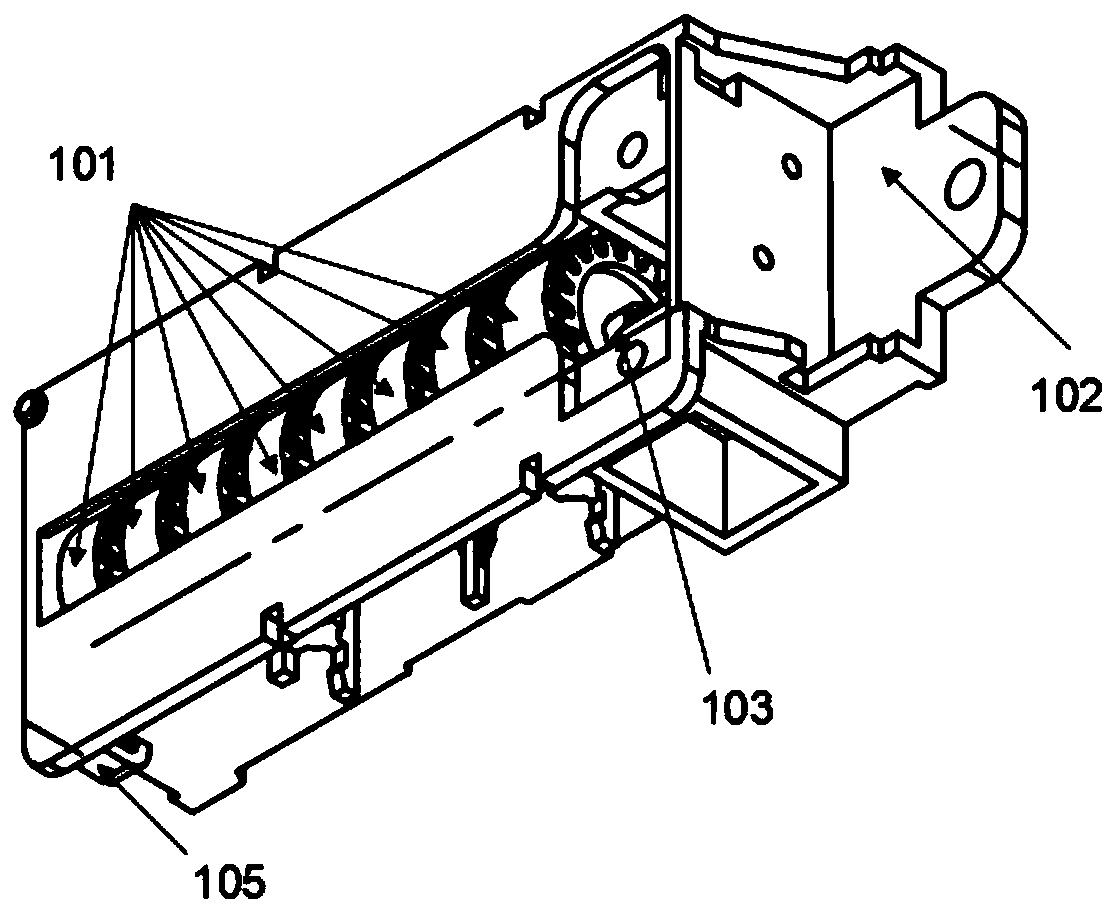

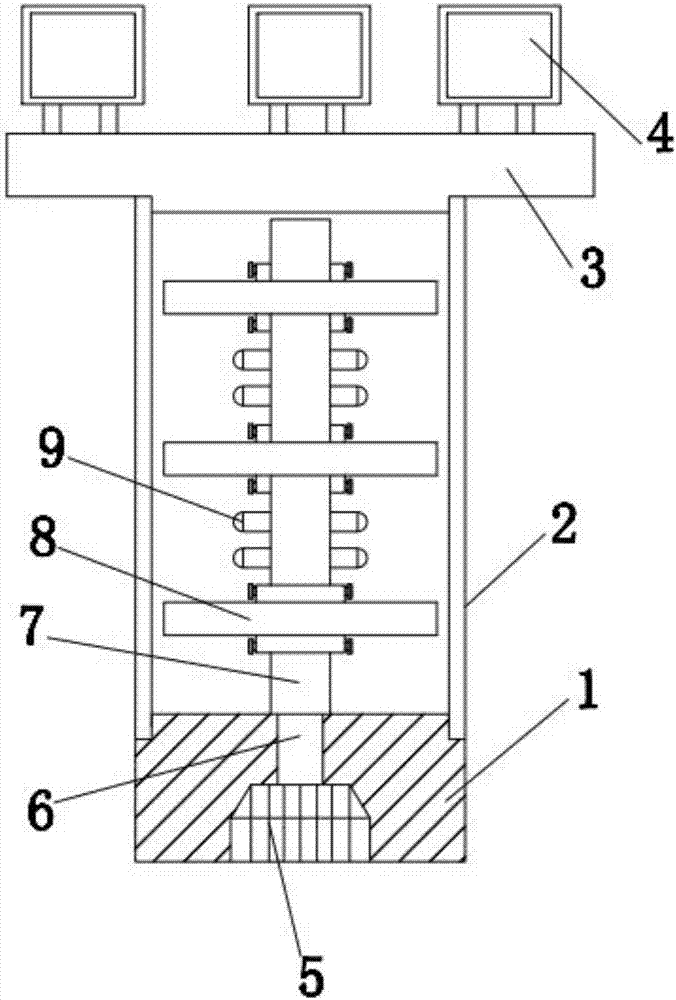

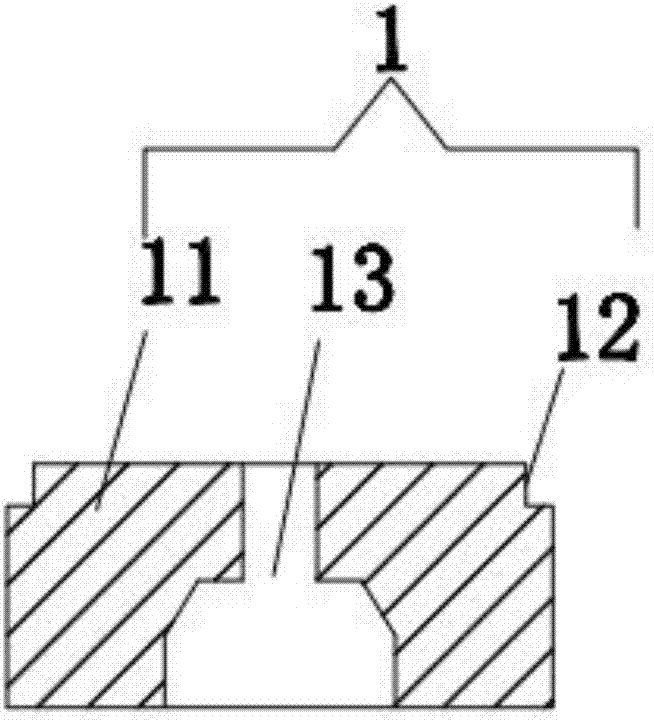

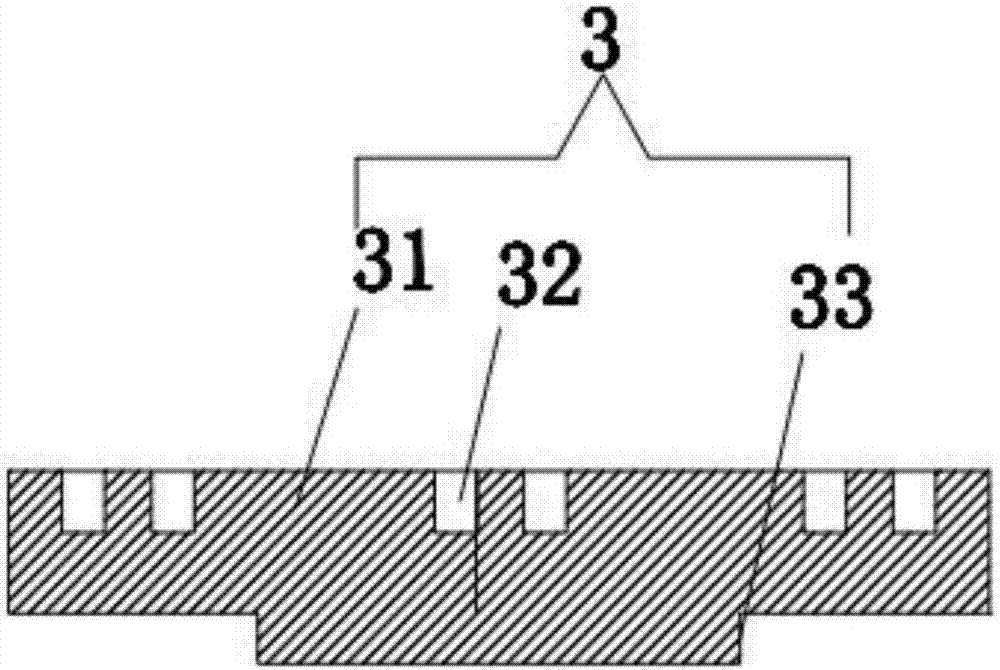

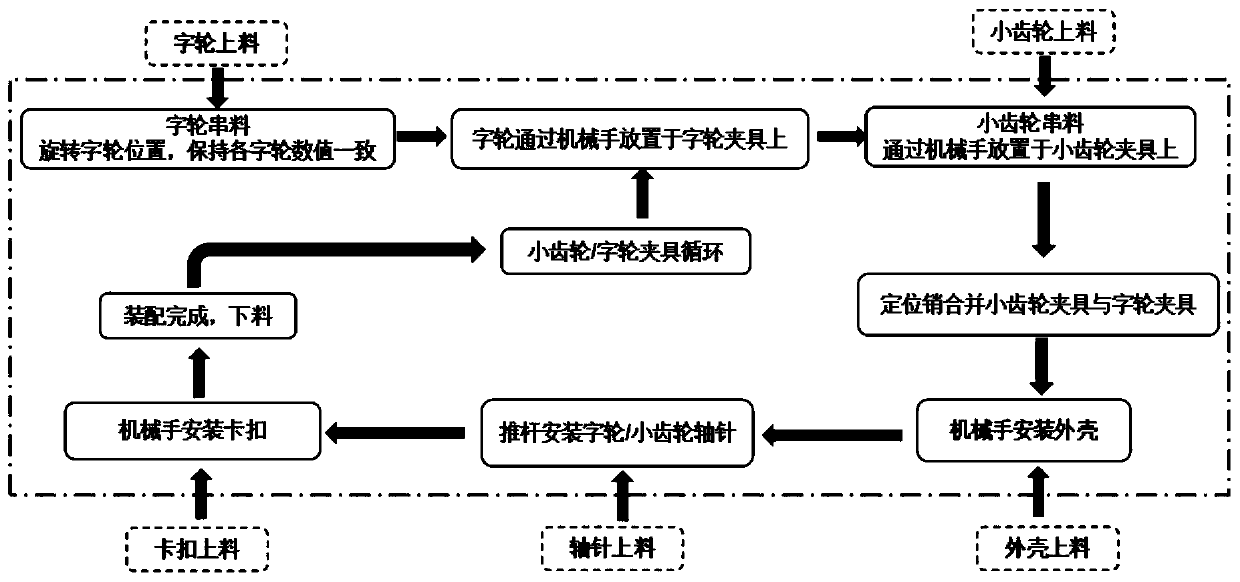

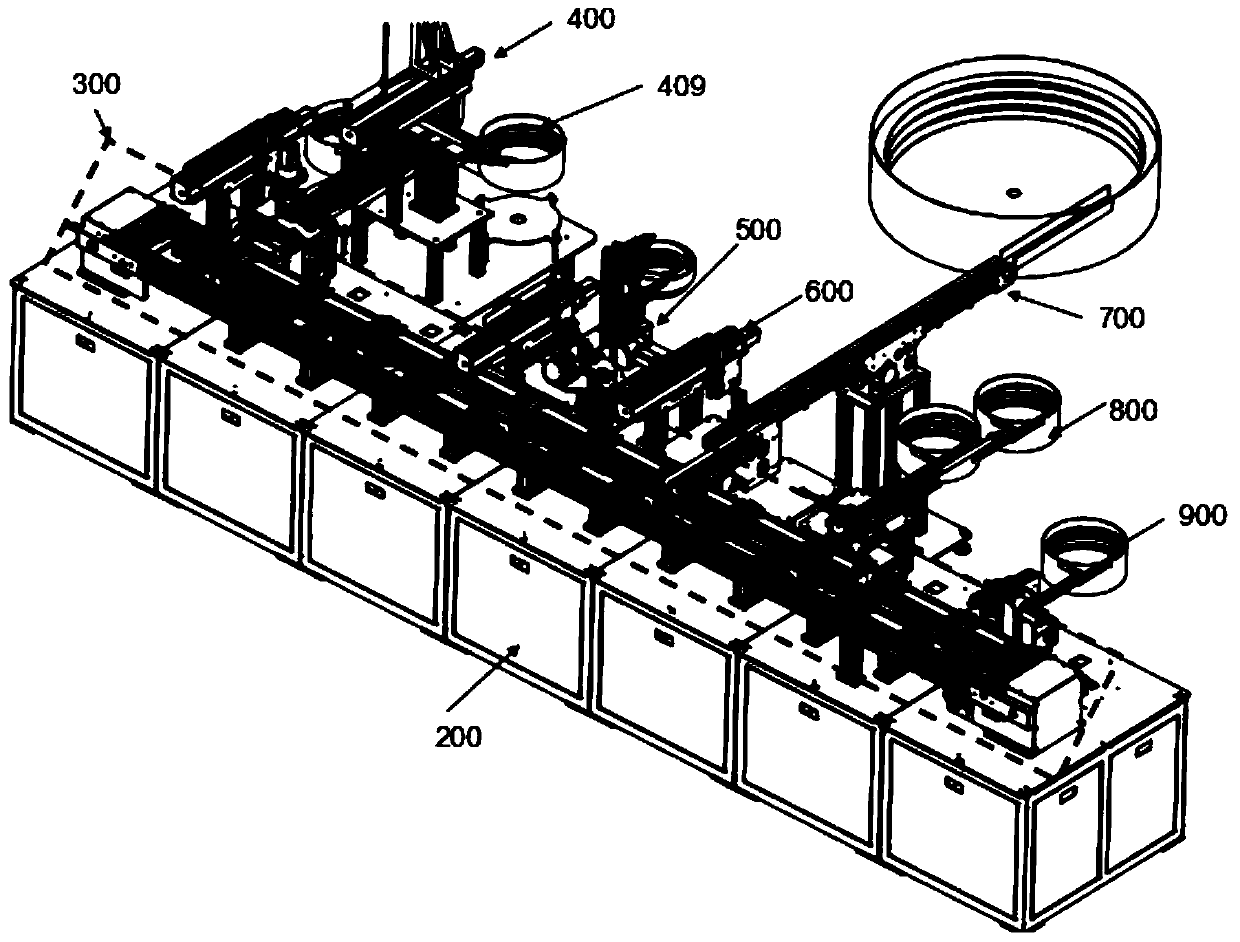

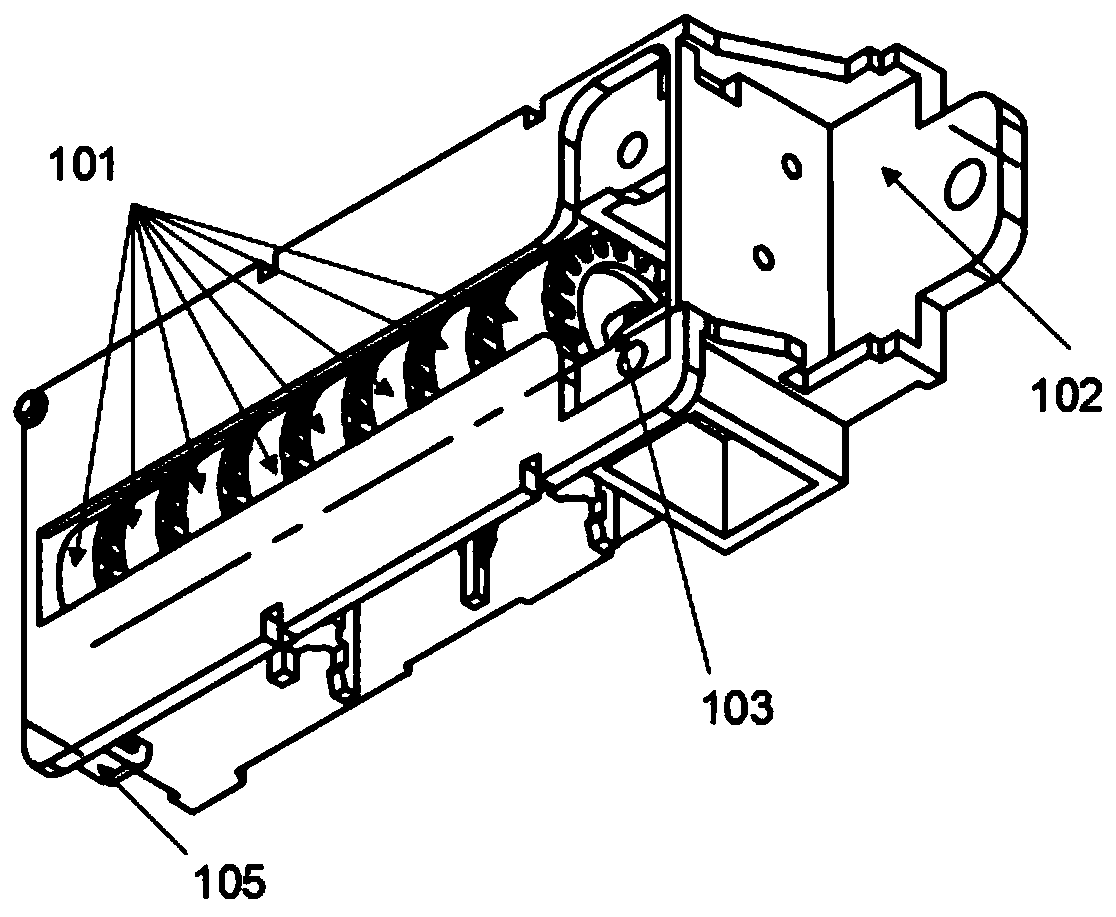

Intelligent assembly method and production line of roller counter of gas meter

PendingCN109940381AThe number of the character wheel is consistentReasonable assemblyAssembly machinesMetal working apparatusProduction lineGas meter

The invention provides an intelligent assembly method and production line of a roller counter of a gas meter. The intelligent assembly method and production line of the roller counter of the gas metercomprises stringing character wheels; string pinions; combining a character wheel clamp and a pinion clamp by a locating pin; feeding and installing a shell; feeding and installing a pintle; and feeding a shell buckle. The intelligent assembly production line comprises a production line counter, a production line workbench, a character wheel assembling module, a pinion assembling module, a character wheel and pinion locating module, a shell assembling module, a pintle assembling module and a shell buckle assembling module. The production line workbench comprises a counter locating clamp, a chain and a chain guide rail. The character wheel assembling module comprises a character wheel feeding device and a character wheel stringing device. The pinion assembling module comprises a pinion feeding device and a pinion stringing device. The shell assembling module comprises a shell feeding device and a shell mechanical arm. A character wheel and pinion pintle assembling module comprises a pintle feeding device and a pintle stringing device. The shell buckle assembling module comprises a buckle feeding device and a buckle installation mechanical arm.

Owner:浙江脉思科技有限公司

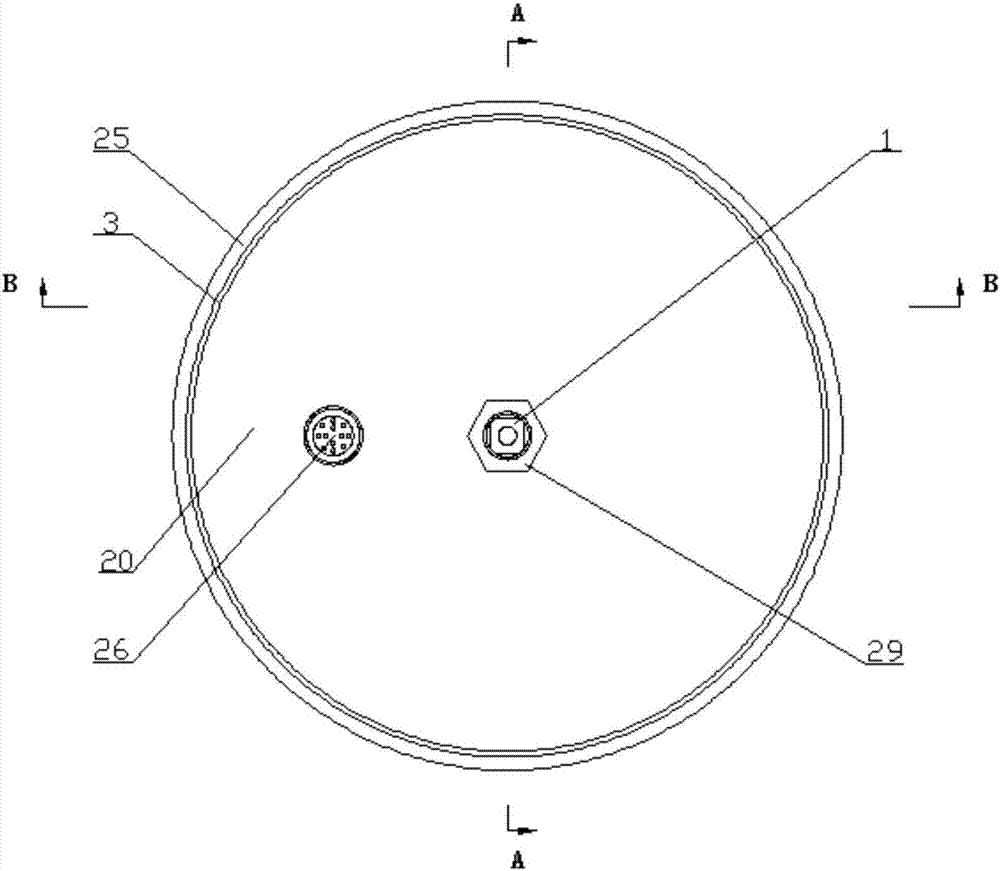

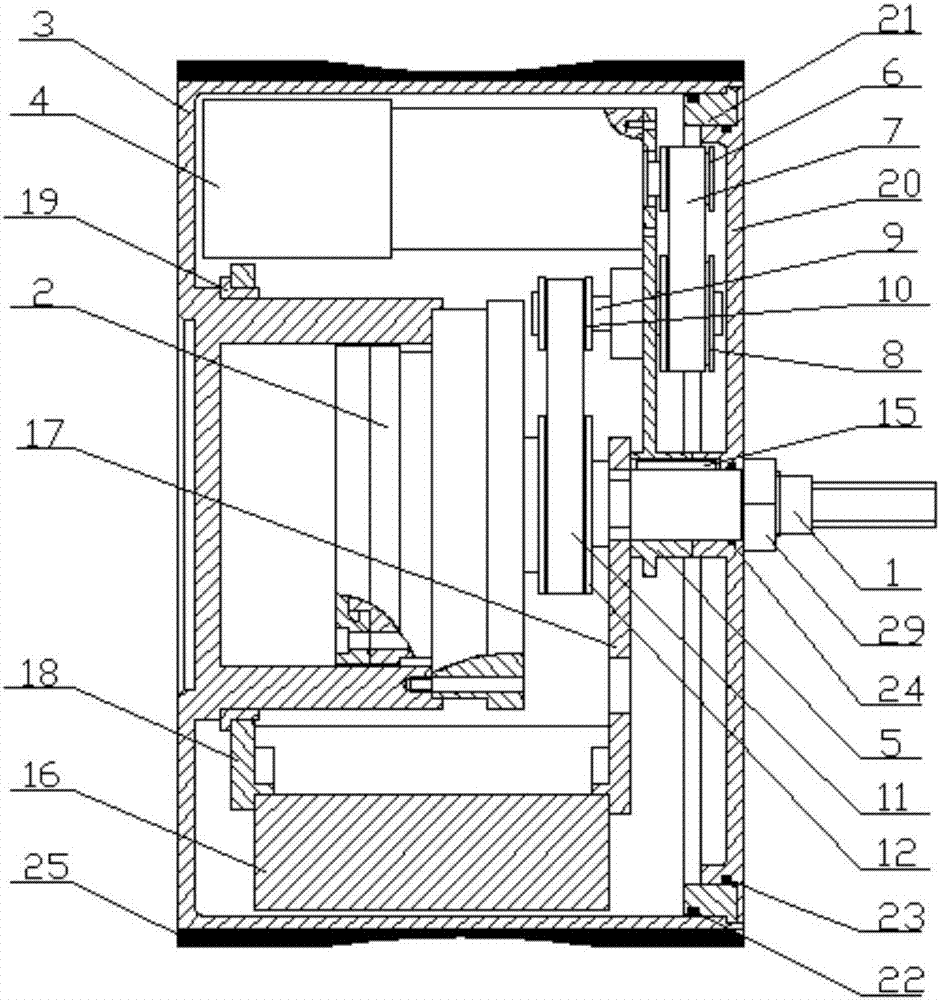

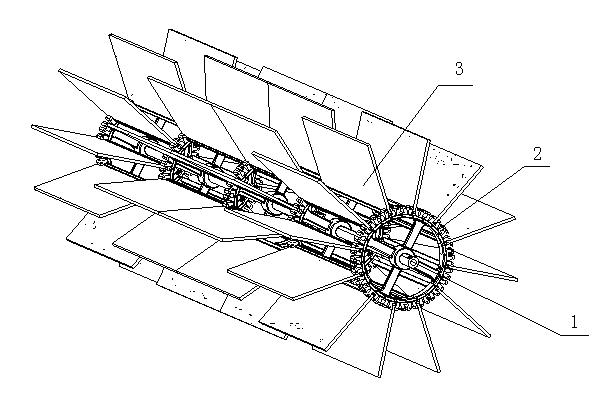

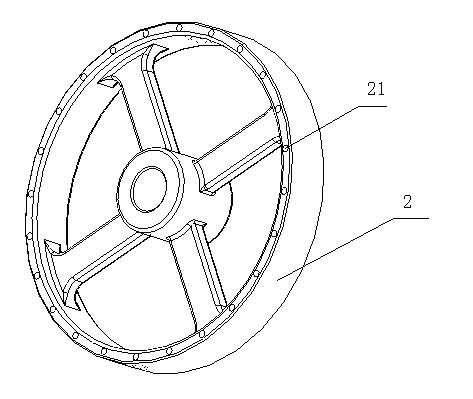

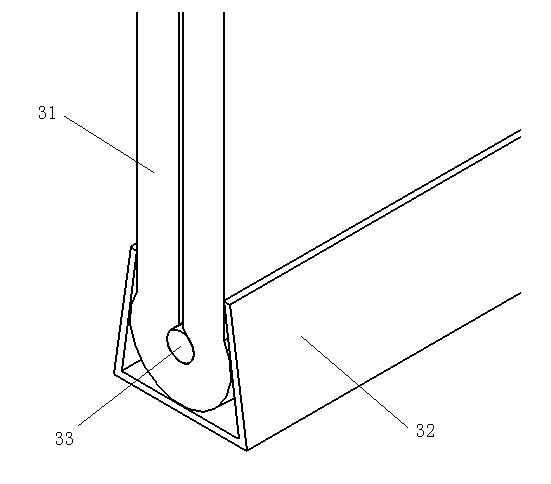

Driving integrated magnetic adsorption wheel type device

The invention relates to a driving integrated magnetic adsorption wheel type device. The driving integrated magnetic adsorption wheel type device is characterized by comprising a transmission shaft, a harmonic reducer, a wheel body rubber coating shell, a motor, a transmission support, a belt wheel shaft, a magnet and a wheel body end cover, wherein the wheel body rubber coating shell and the wheel body end cover are matched to form a closed space, the transmission shaft is installed on the center axis of the wheel body rubber coating shell, one end of the transmission shaft extends out of the wheel body rubber coating shell and the wheel body end cover and is connected with a car body, and the other end of the transmission shaft is connected with a rigid wheel through a flange plate; the motor and the magnet are arranged at the position, located at the two sides of the harmonic reducer, in the space of the wheel body rubber coating shell, one side of the magnet is fixed to a first copper sleeve through a second magnetic support, and the other side of the magnet is fixed to the transmission shaft through a first magnetic support; one end of the motor is fixed to the transmission shaft through the transmission support, the belt wheel shaft is fixed to the portion, between the transmission shaft and the motor, of the transmission support, an output shaft of the motor, the belt wheel shaft and the transmission shaft are parallel and transmit power in the mode of a synchronous belt.

Owner:HEBEI UNIV OF TECH

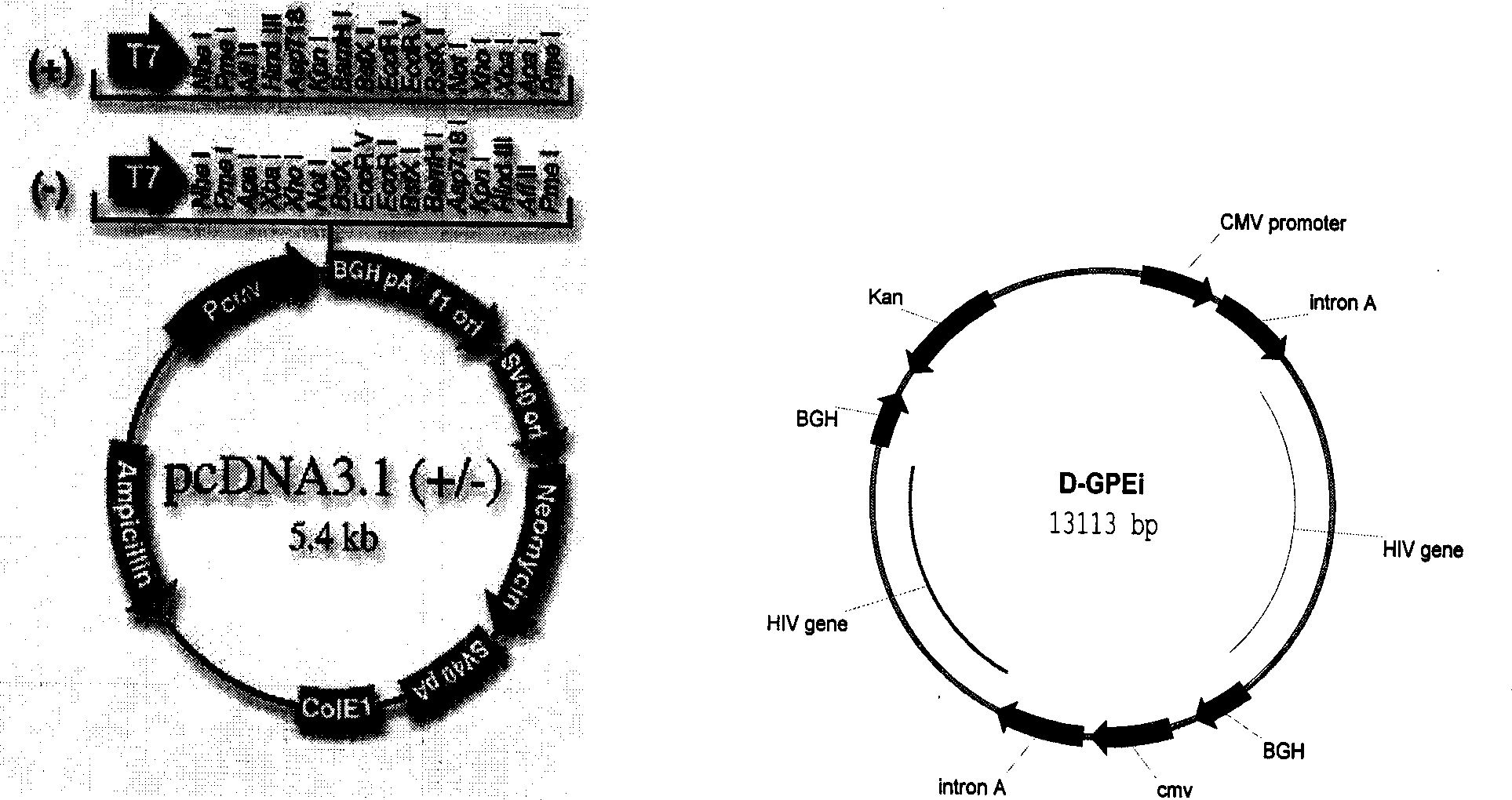

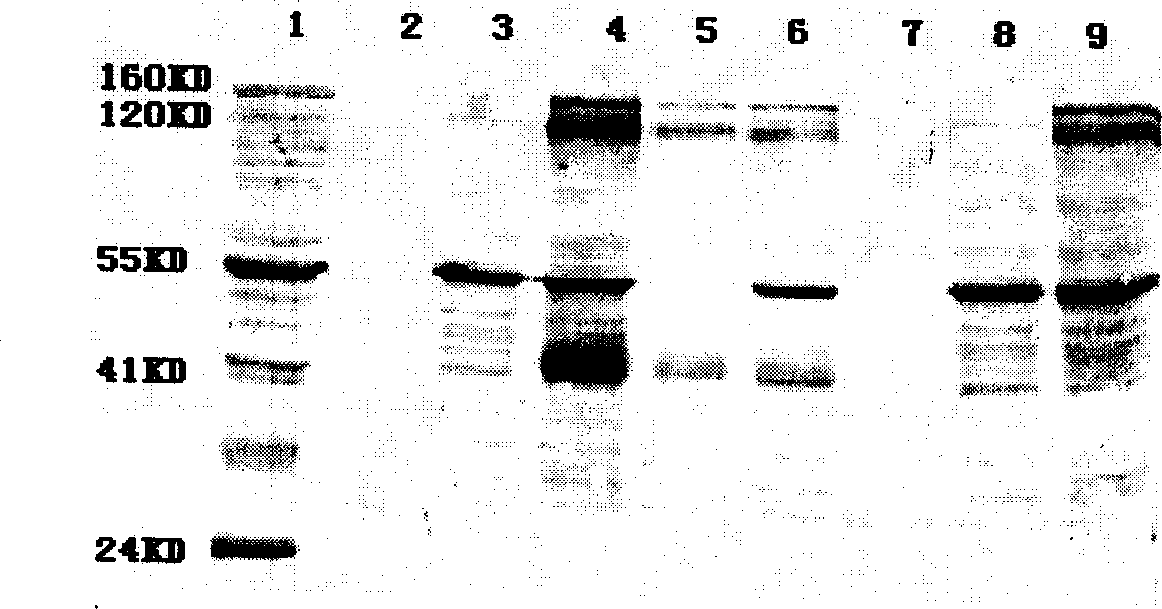

HIV-1 virus-like particle and its prepn and use

InactiveCN1772892AImprove securityReasonable assemblyViral antigen ingredientsViruses/bacteriophagesVirus-like particleCell Membrane Proteins

The present invention relates to one kind of and its preparation and use, and belongs to the field of biotechnology. The HIV-1 virus-like particle contains complete core protein gag, encoding enzyme protein pol and outer membrane protein env of HIV-1, and is nonreplication type. The present invention is superior in that stably expression cell line is established through cotransfection and monoclonal cell screening. The cell line can secrete HIV-1 virus-like particle stably and continuously, and the HIV-1 virus-like particle contains no virus nucleic acid and has high safety. The constituted VLP has reasonable assembling form and high similarity with natural virus in structure, and may be used as HIV-1 treating vaccine.

Owner:JILIN UNIV +1

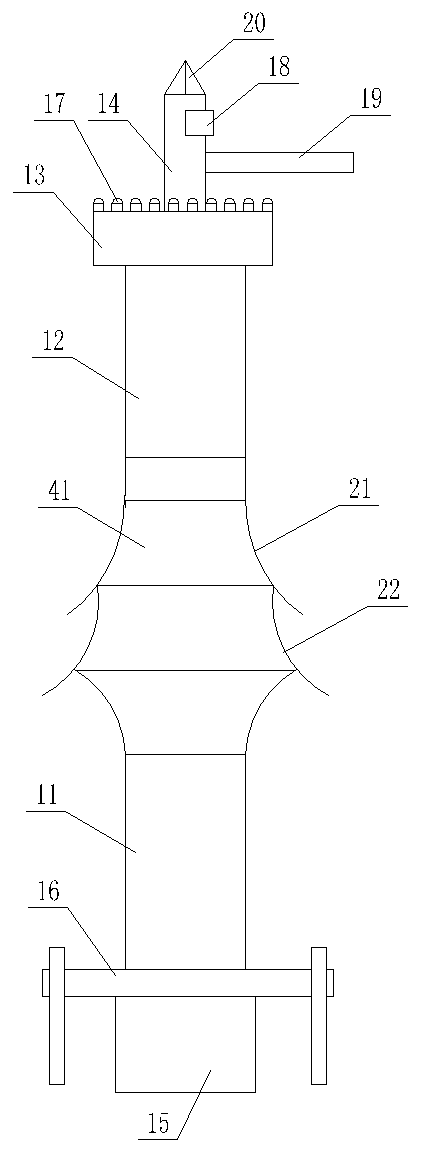

Roller cleaning device for wall surface cleaning robot

InactiveCN101978927ACompact structureReasonable assemblyCarpet cleanersFloor cleanersDrive shaftSurface cleaning

The invention discloses a roller cleaning device for a wall surface cleaning robot. The device is characterized by comprising a transmission shaft, wheel hubs and roller brush assemblies, wherein the transmission shaft is a long hollow shaft; a plurality of wheel hubs are arranged on the transmission shaft uniformly; and a plurality of groups of roller brush assemblies are uniformly arranged between every two adjacent wheel hubs, and the adjacent roller brush assemblies are arranged in a staggered mode in the axial direction of the transmission shaft to form a roller structure. The roller cleaning device is a non-integrated structure, and roller brushes are divided into a plurality of parts, so that the roller cleaning device has a compact structure and reasonable assembly, and is convenient to disassemble and assemble, maintain and replace; the structure is suitable for the field of automated wall-surface cleaning, and the roller brush assemblies are arranged in the staggered mode, so that the cleaning capacity is strong; compared with the conventional roller cleaning device, the structure of the invention is optimized greatly; and the plurality of wheel hubs are arranged linearly at certain intervals, so that the weight of the roller cleaning device is lightened greatly.

Owner:昆山市工业技术研究院有限责任公司

Display stand for exhibition in artistic design room and assembling method of display stand

InactiveCN107411440AEasy to assembleEasy to disassembleShow shelvesShow hangersLED displayEngineering

The invention discloses a display stand for exhibition in an artistic design room and an assembling method of the display stand in the technical field of display stands. The display stand comprises a base; the outer wall of the top of the base is sleeved with a tempered glass sleeve; the top of the tempered glass sleeve is inserted with a top seat; the top of the top seat is inserted with three groups of LED display screens; a motor is fixedly mounted in an inner cavity of the base; a rotary shaft is connected to the output end of the motor; the top of the rotary shaft is sleeved with a rotary rod; and flash lamp groups are uniformly and fixedly mounted on the outer wall of the rotary rod. According to the display stand for exhibition in the artistic design room and the assembling method of the display stand, the display stand is reasonable in design and elegant in appearance; all structure parts are convenient to assemble and disassemble; the assembling time is short and the assembling speed is high; fixation is performed through bolts, so that the mounting is stable; rotary display can be performed; text and video introduction is performed through the LED display screens; and irradiation is performed through the flash lamp groups at night, so that displayed articles are more beautiful.

Owner:HENAN INST OF ENG

Magnetic driving mechanism and receiver comprising same

ActiveCN105187987ASimple structureReduce volumeEarpiece/earphone attachmentsTransducer circuitsMagnetic fluxElectrical and Electronics engineering

The invention provides a magnetic driving mechanism and a receiver comprising the same. The magnetic driving mechanism comprises a U-shaped balance armature, a lower shell and a middle-layer partition board; one end of the U-shaped balance armature is fixedly connected with the bottom of the lower shell, and the other end of the U-shaped balance armature is located in a first hollow cavity enclosed by the middle-layer partition board and the lower shell in a suspended manner; and the lower shell and the middle-layer partition board are used for providing a magnetic flux path. The magnetic driving mechanism and the receiver comprising the same of the invention have the advantages of simple structure, small size and the like.

Owner:SUZHOU YICHUAN TECH CO LTD

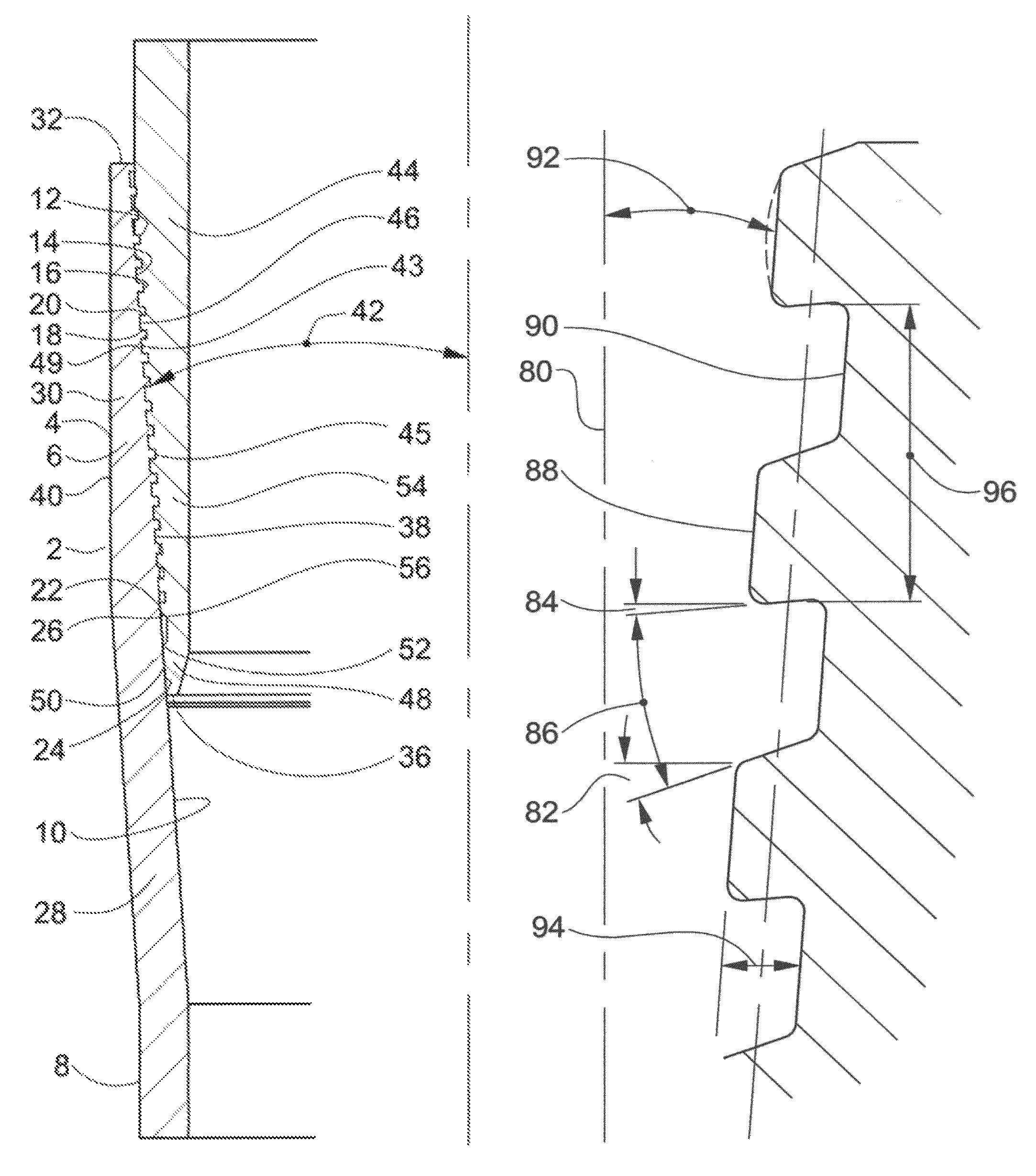

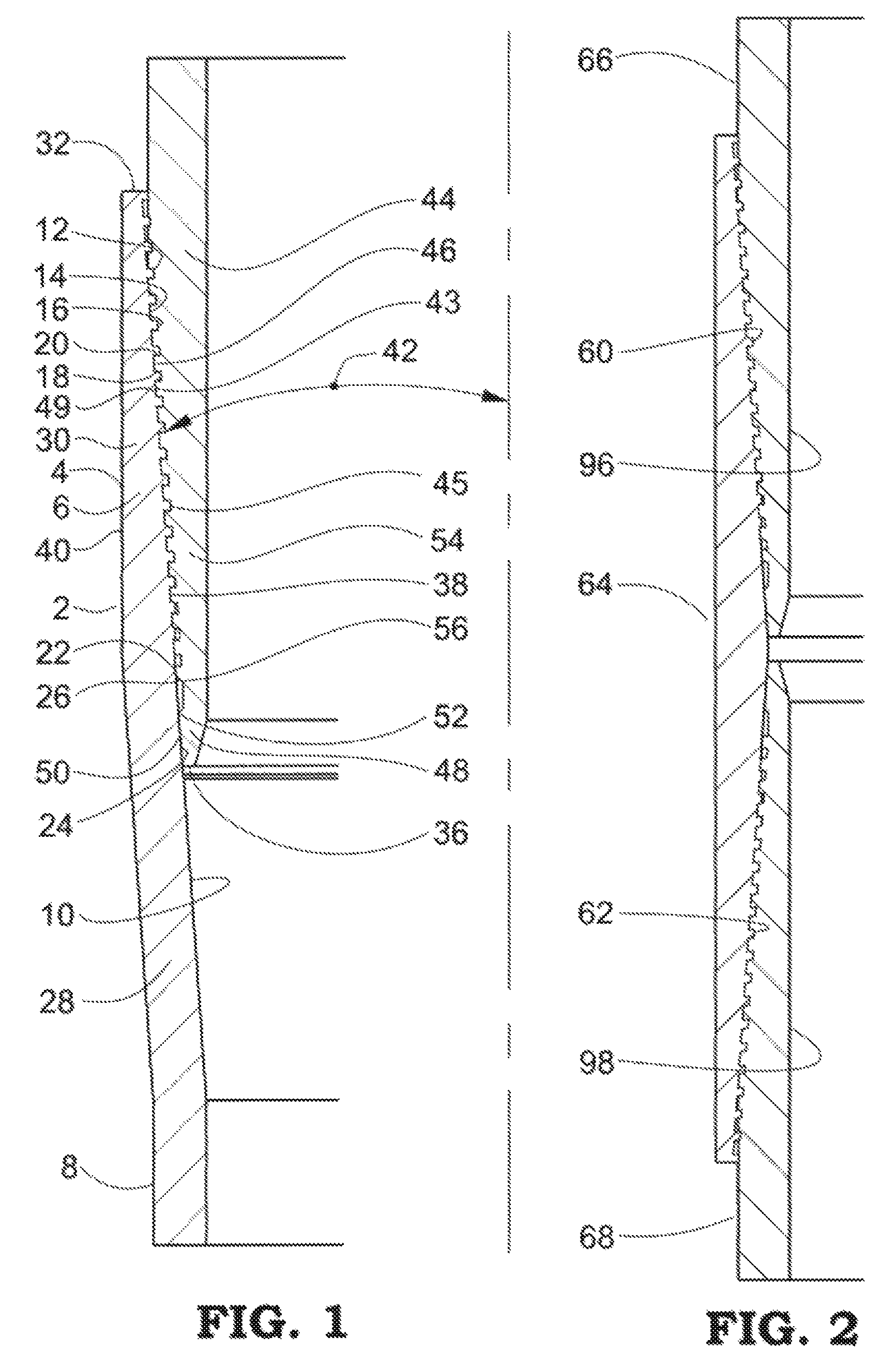

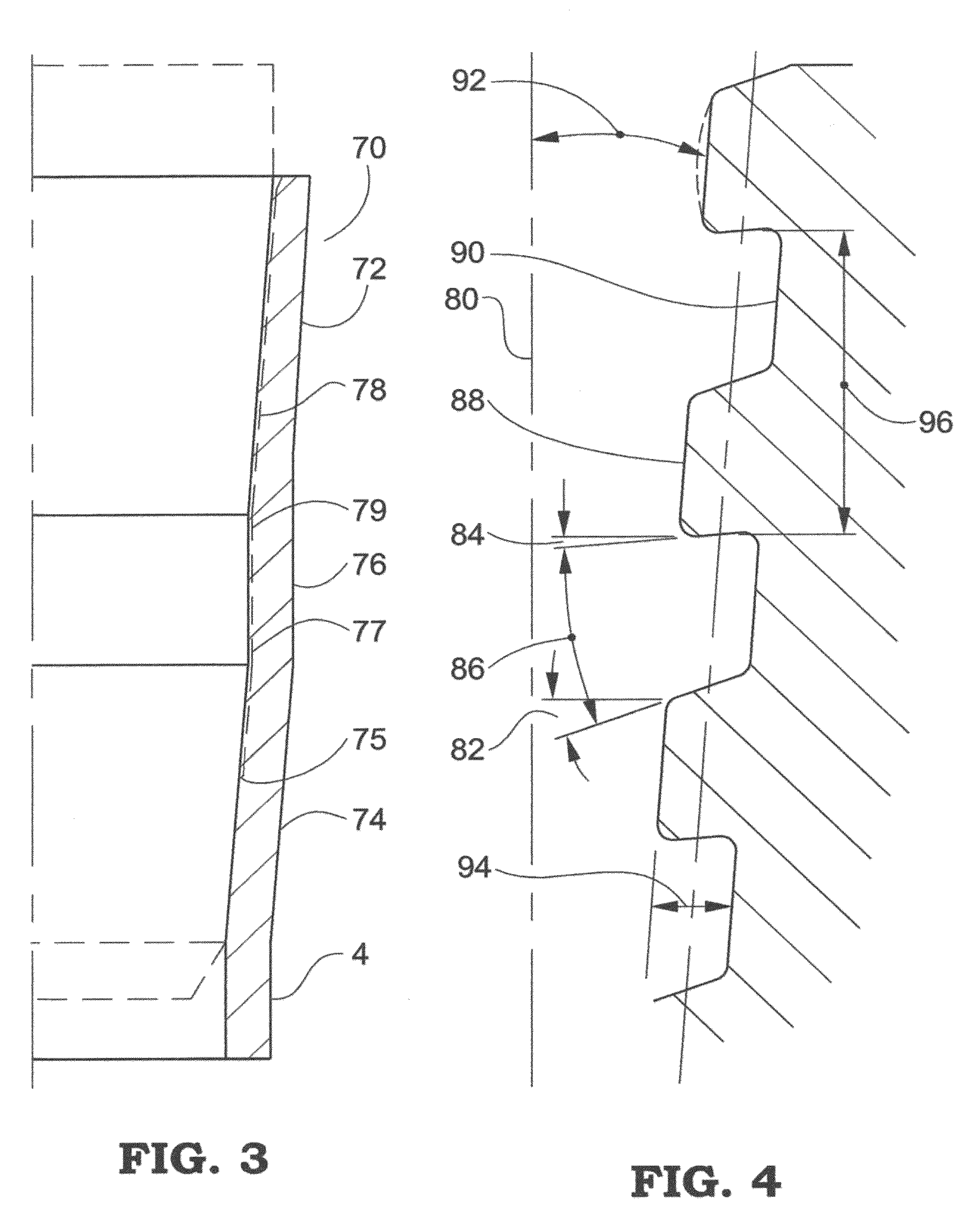

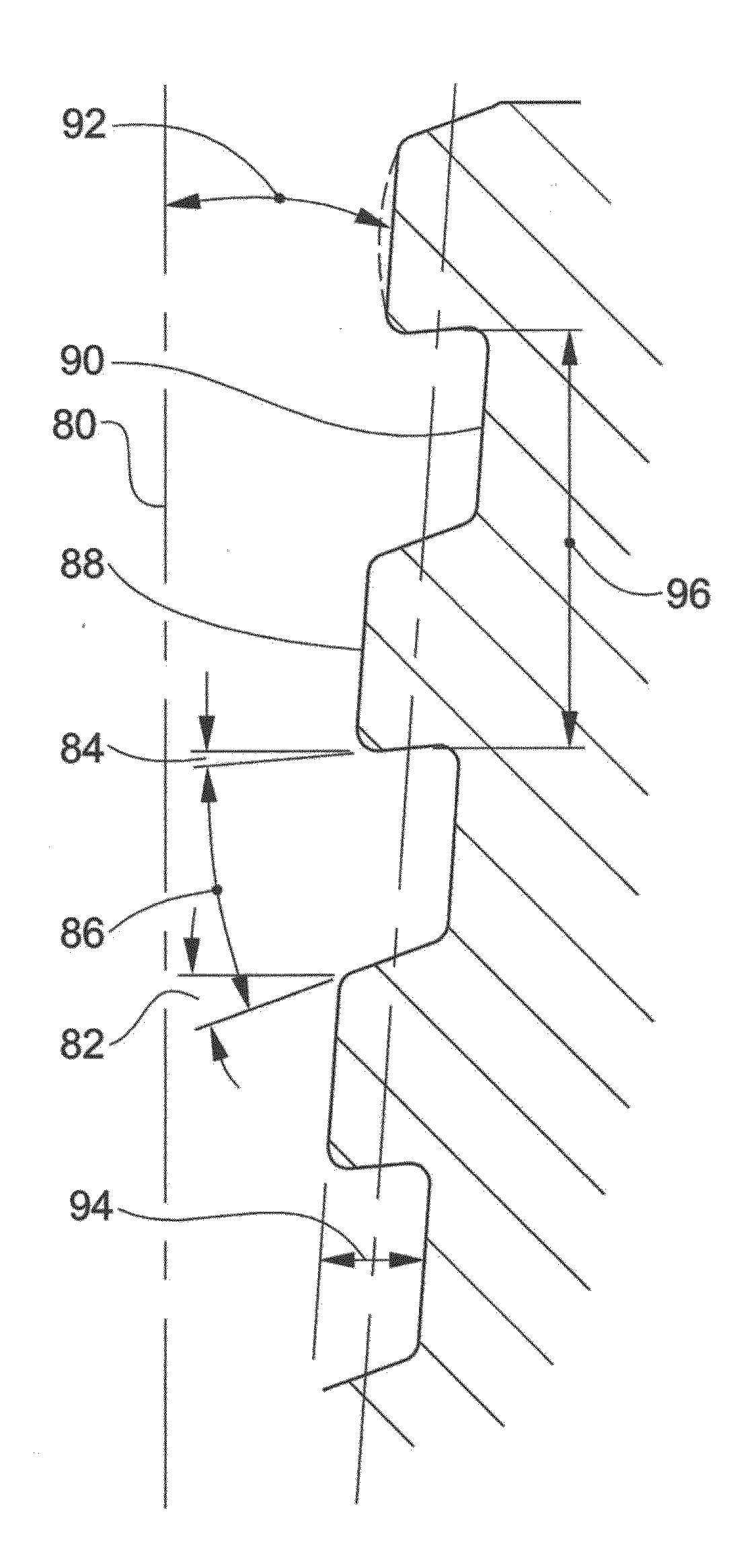

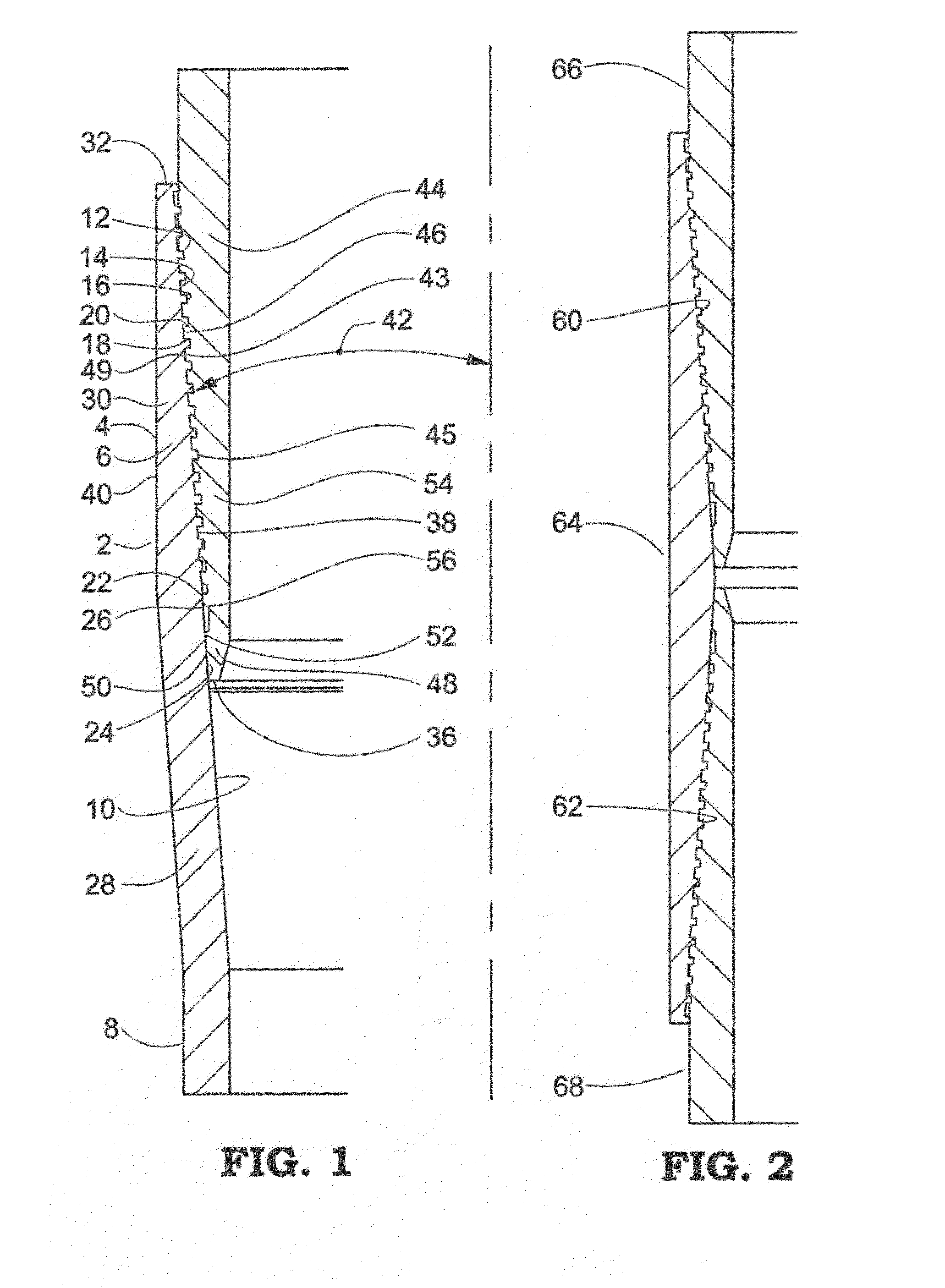

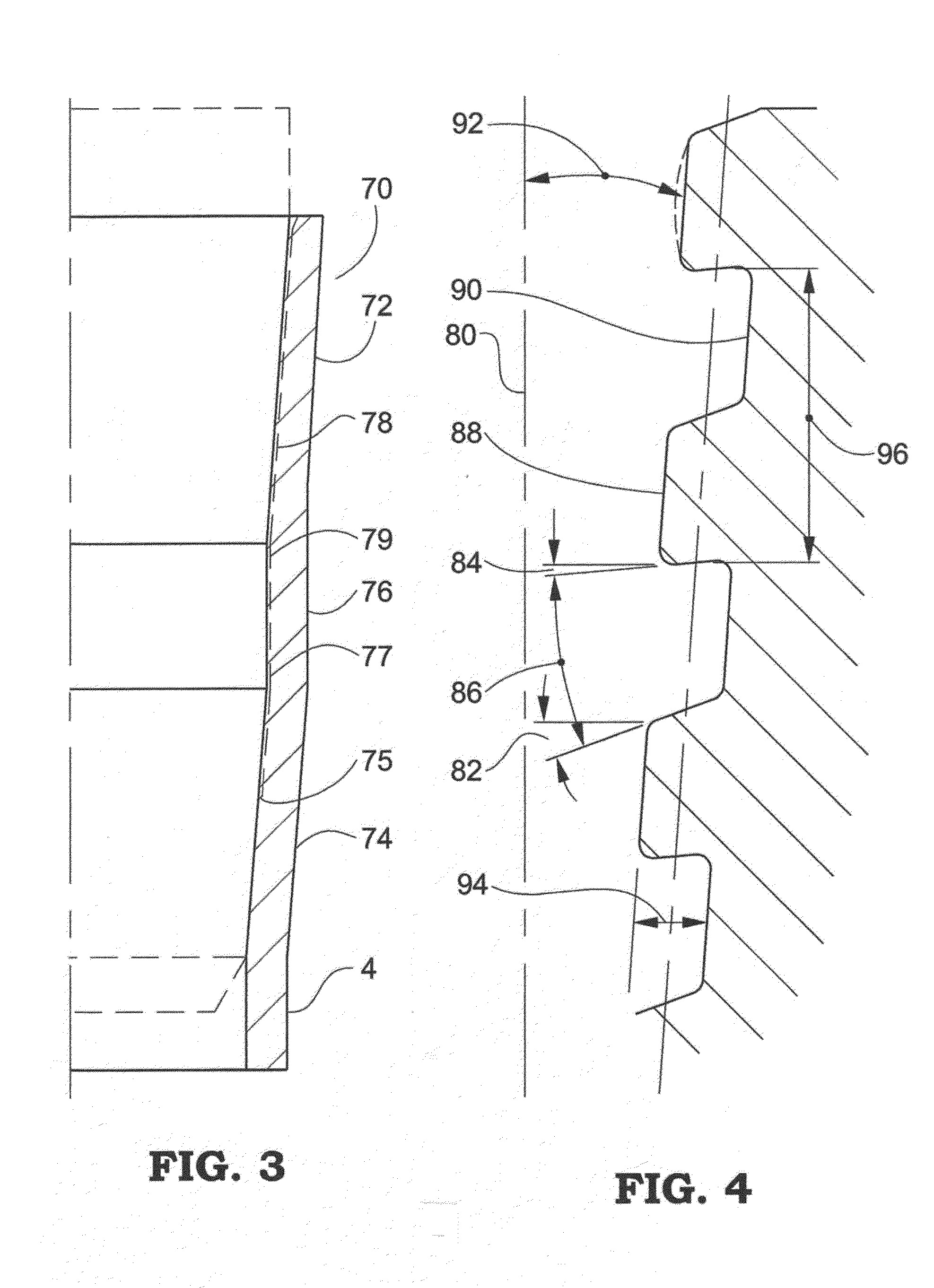

Low cost, high performance pipe connection

InactiveUS8246086B2Reasonable assemblyLow costDrilling rodsMetal-working feeding devicesThreaded pipeEngineering

A low cost threaded pipe connection for virtually any service is provided, that has selectively, unique sealing threads for general use that can be supplemented with a pin nose seal when specified by the user.

Owner:RAMOS BEVERLY WATTS

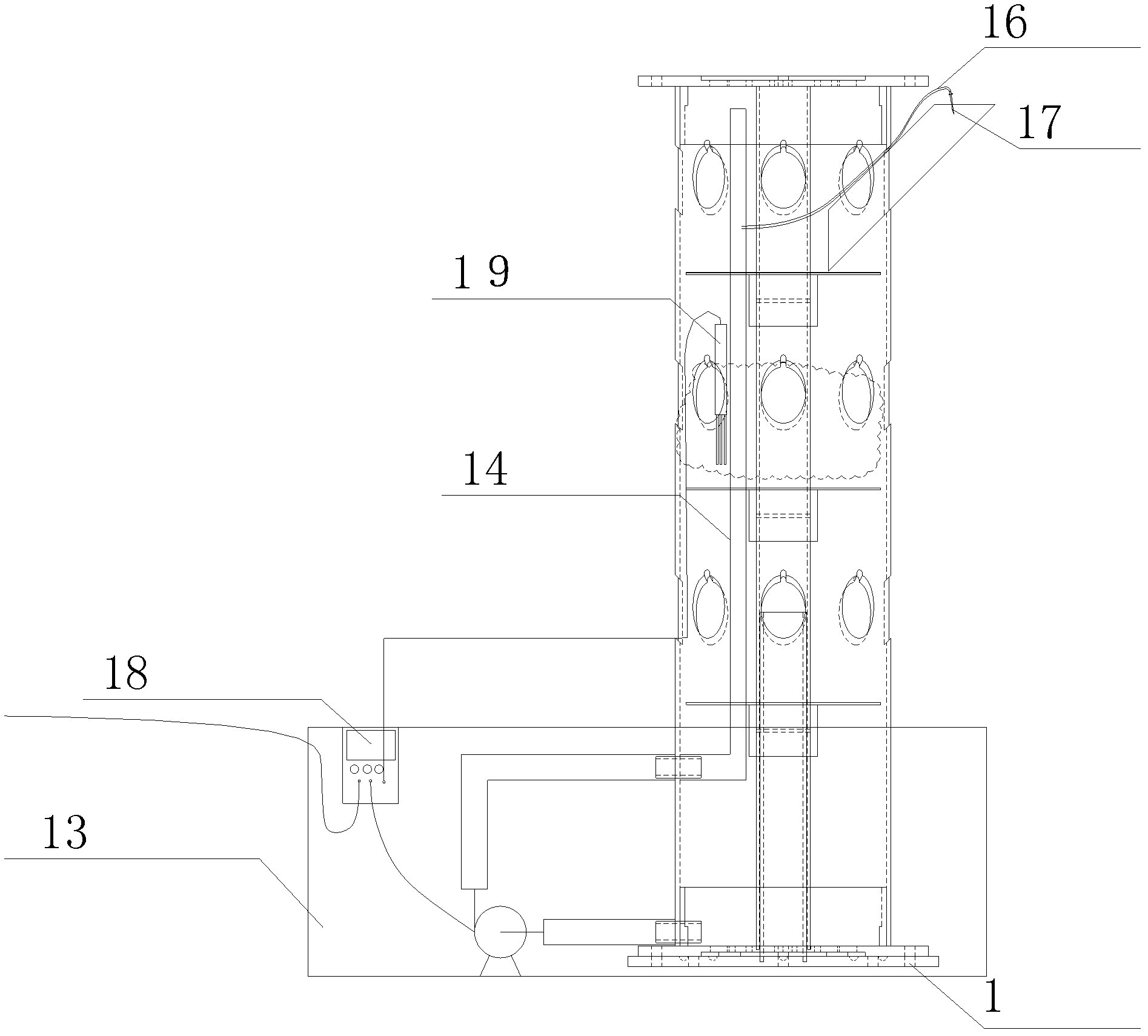

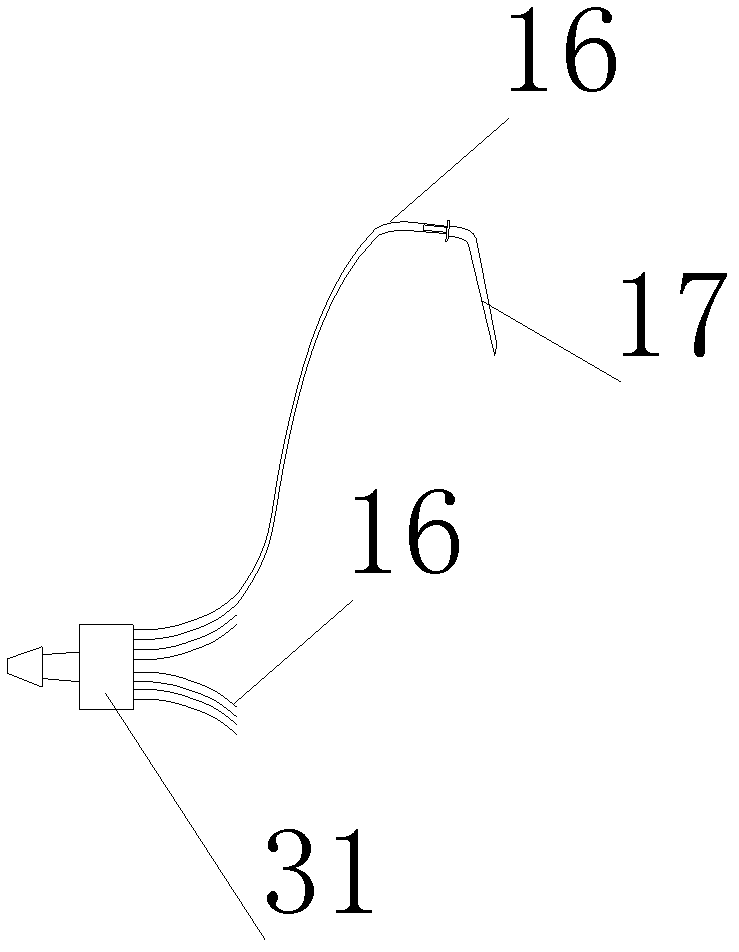

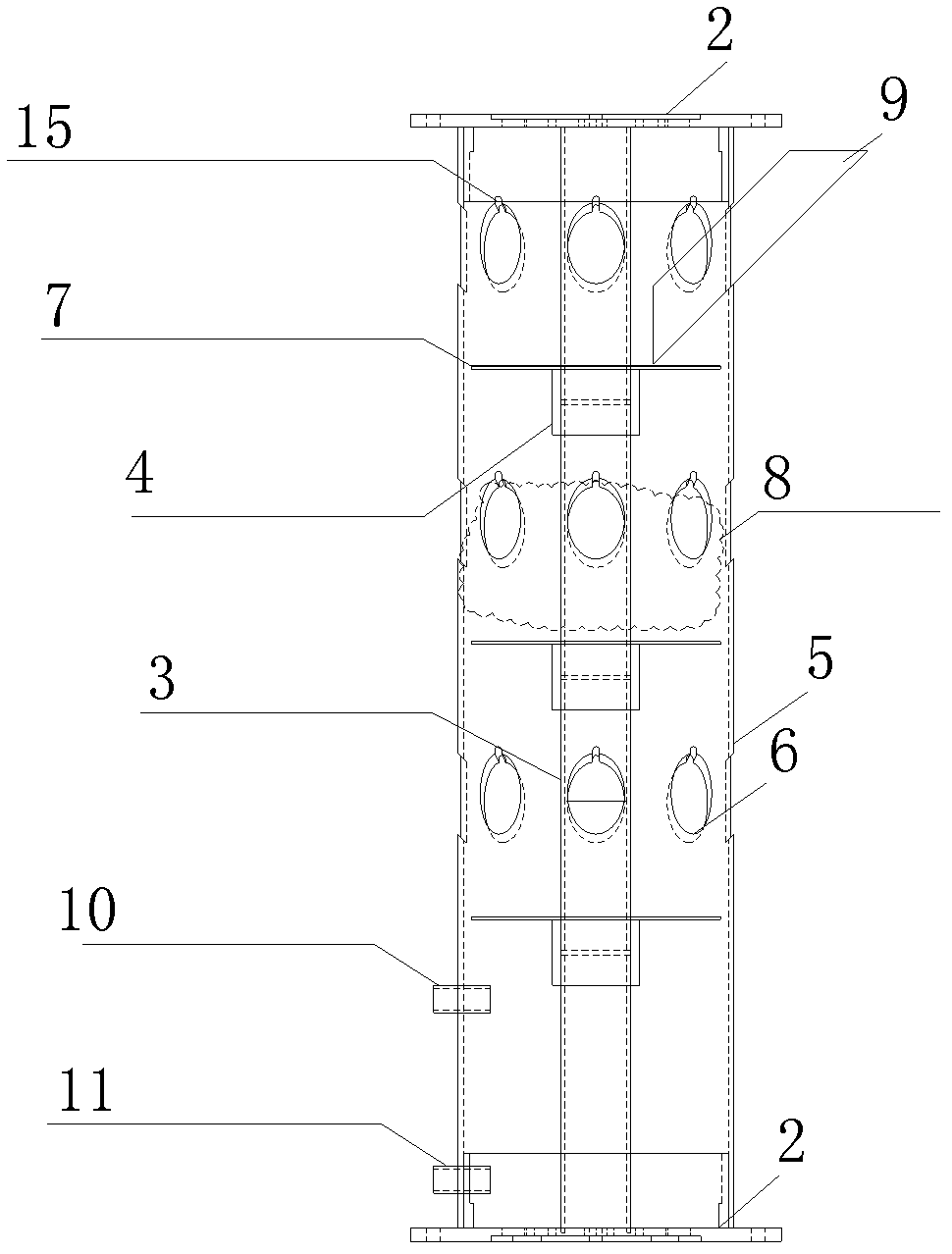

Intelligent stereo cultivation machine

InactiveCN102487803AReasonable assemblyPrecise positioningWatering devicesAgriculture gas emission reductionAutomatic controlPiping

The invention provides an intelligent stereo cultivation machine. The machine comprises a center pivot with a base, a stereo cultivation column main body, a drip irrigation system and cultivation bowls, wherein the stereo cultivation column main body is inserted into the center pivoted with the base and comprises porous stereo shaping columns, central axle sleeve columns with snap rings, bearing and positioning flange plates, inner clapboards and filter screens with water permeable holes and water retention fibers; the porous stereo shaping columns and the central axle sleeve columns with snap rings are respectively fixedly connected on the bearing and positioning flange plates; the inner clapboards and filter screens with water permeable holes and the water retention fibers are put on the snap rings in sequence; the cultivation bowls are laterally inserted into positioning holes of the porous stereo shaping columns; an irrigation pipeline and a water outlet pipe are connected on the porous stereo shaping columns; the drip irrigation system comprises drip irrigation water pipes, multi-port adapters and emitters; the drip irrigation water pipes penetrate through the holes on the inner clapboards; the water pipes between the clapboards are perforated to insert the multi-port adapters; and then capillary pipes of the multi-port adapters are connected with the irrigation arrow type emitters. The machine utilizes the advanced automatic control water and fertilizer integrated drip irrigation technique, can take full advantage of the stereo space to cultivate crops and ensures stereo cultivation to enter thousands of households.

Owner:TIANJIN LELONG IRRIGATION TECH

Low cost, high performance pipe connection

InactiveUS20100230959A1Less-efficient productionLow costDrilling rodsMetal-working feeding devicesThreaded pipeEngineering

Owner:RAMOS BEVERLY WATTS

Intelligent assembly method and equipment for gas meter roller counter

PendingCN109848697AThe number of the character wheel is consistentReasonable assemblyAssembly machinesVolume meteringProduction linePinion

The invention provides an intelligent assembly method and equipment for a gas meter roller counter. The assembly method comprises the steps of stringing of print wheels; stringing of pinions; locationof a print wheel fixture and a pinion fixture by pins; feeding and installation of a shell; feeding and installation of axial needles; and buckling and feeding of the shell; the assembly equipment comprises a production line counter, a production line working table, a print wheel assembly module, a pinion assembly module, a print wheel and pinion locating module, a shell assembly module, an axialneedle assembly module and a shell buckle assembly module; the production line working table comprises a counter locating fixture, a chain and a chain guide rail, and the print wheel assembly modulecomprises a print wheel feeding device and a print wheel stringing device; the pinion assembly module comprises a pinion feeding device and a pinion stringing device, and the shell assembly module comprises a shell feeding device and a shell manipulator; and a print wheel and pinion axial needle assembly module comprises an axial needle feeding device and an axial needle stringing device, and theshell buckle assembly module comprises a buckle feeding device and a buckle mounting manipulator.

Owner:浙江脉思科技有限公司

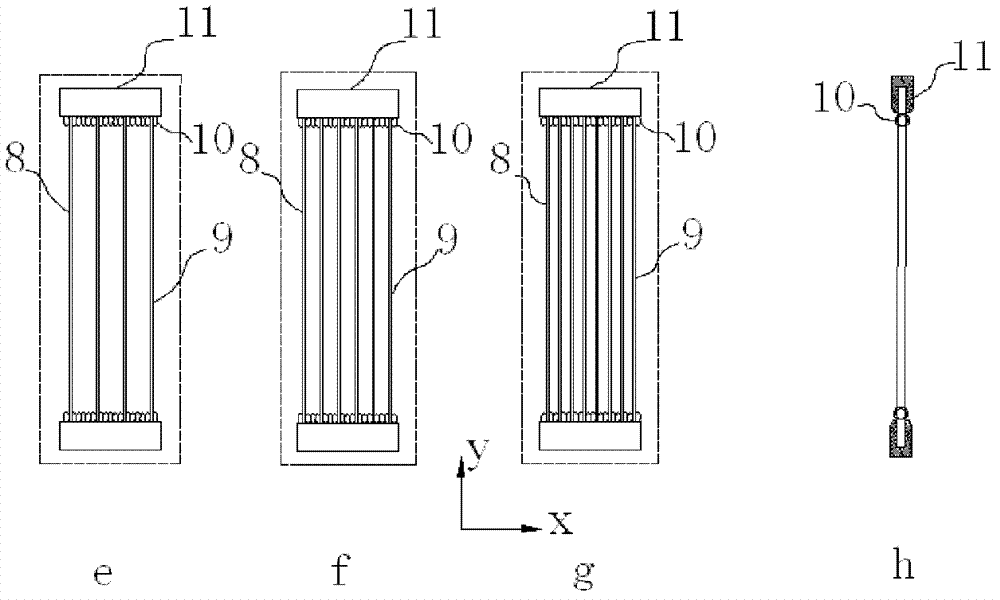

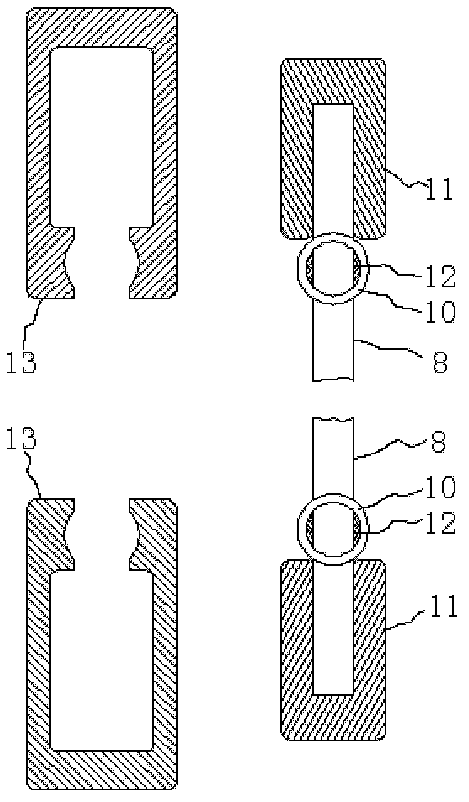

Variable-density square frame beam metallic combination reed

The invention discloses a variable-density square frame beam metallic combination reed, which is characterized in that a plurality of unit reeds in different density specifications are parallelly arranged in a square hollow casing pipe of a reed frame according to the design requirements of warp density; two ends of the casing pipe are screwed to be fixed by a bolt; each unit reed is a short reed which is demountable, and equivalent in height; two ends of the frame beam of each unit reed are flat-top ends; and the adjacent unit reeds are butted by the flat-top end. The variable-density square frame beam metallic combination reed provided by the invention is not only suitable for producing various variable-density textiles, but also suitable for balancing on-loom density textiles and off-loom density textiles; and meanwhile, a structure of the reed is easy to assemble, disassemble and reassemble, and is suitable for low-volume production of the textiles in various varieties. Compared with the traditional reed in fixed density, the variable-density square frame beam metallic combination reed provided by the invention can be well suitable for the requirements of market variations; and the unit-combined variable-density reed is simple in structure, reasonable in assembly, convenient in dismounting, and is also suitable for standardized manufacturing and production of accessories.

Owner:苏州赛力菲陶纤有限公司

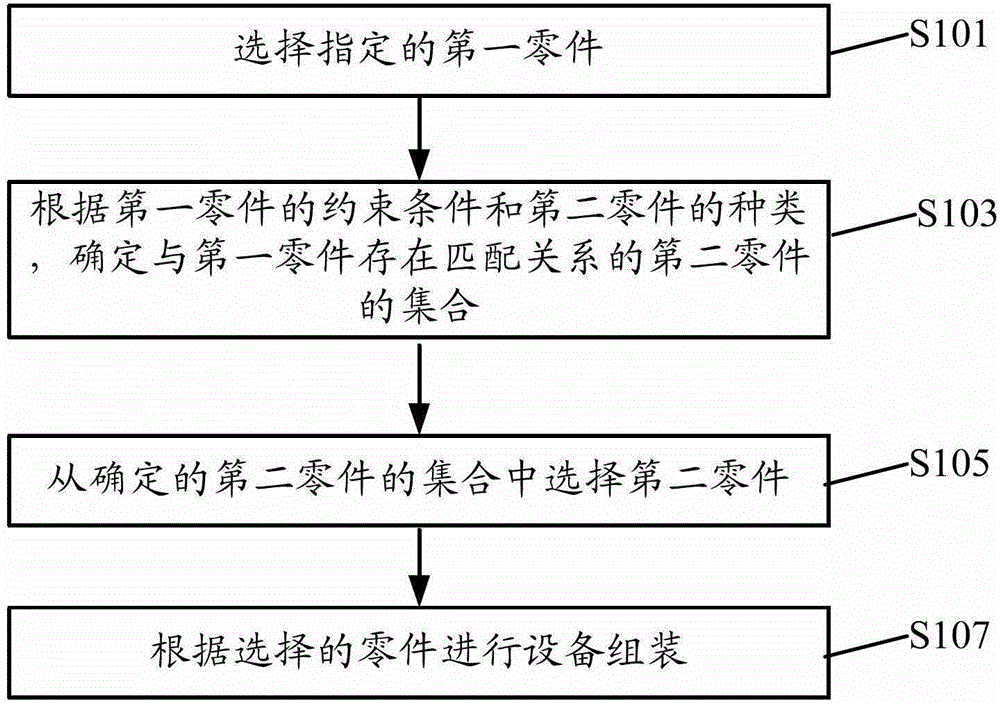

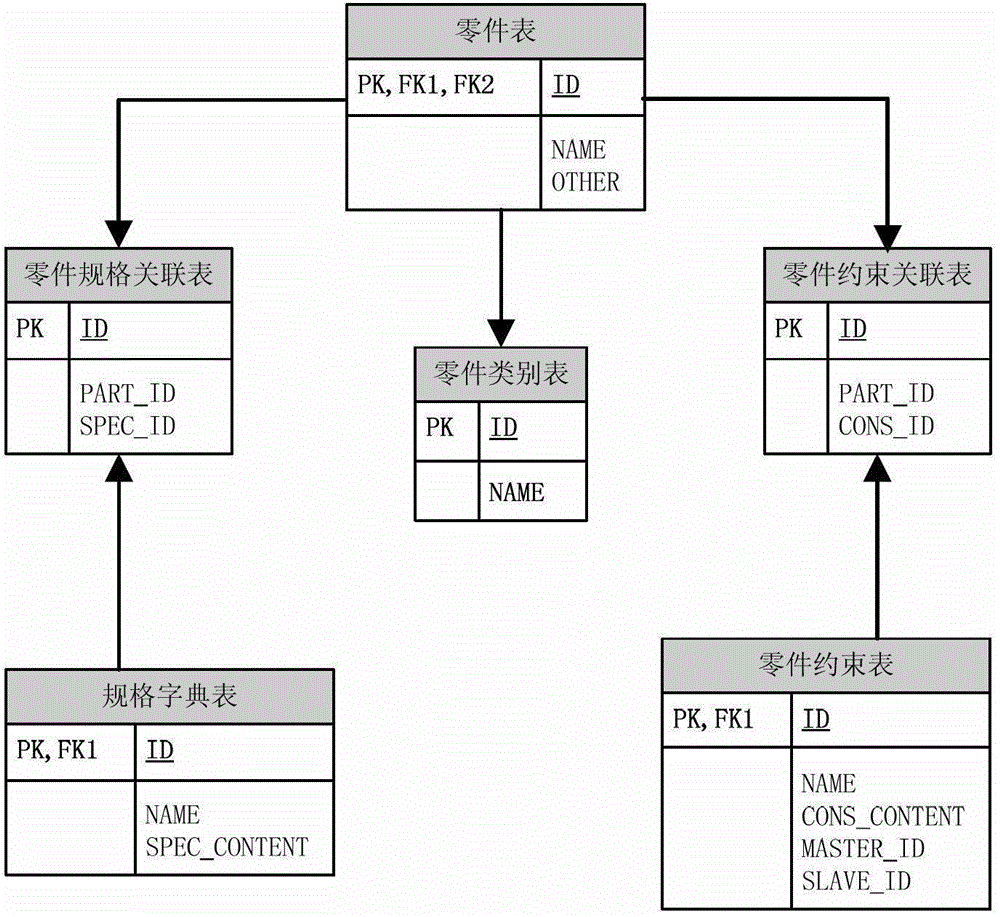

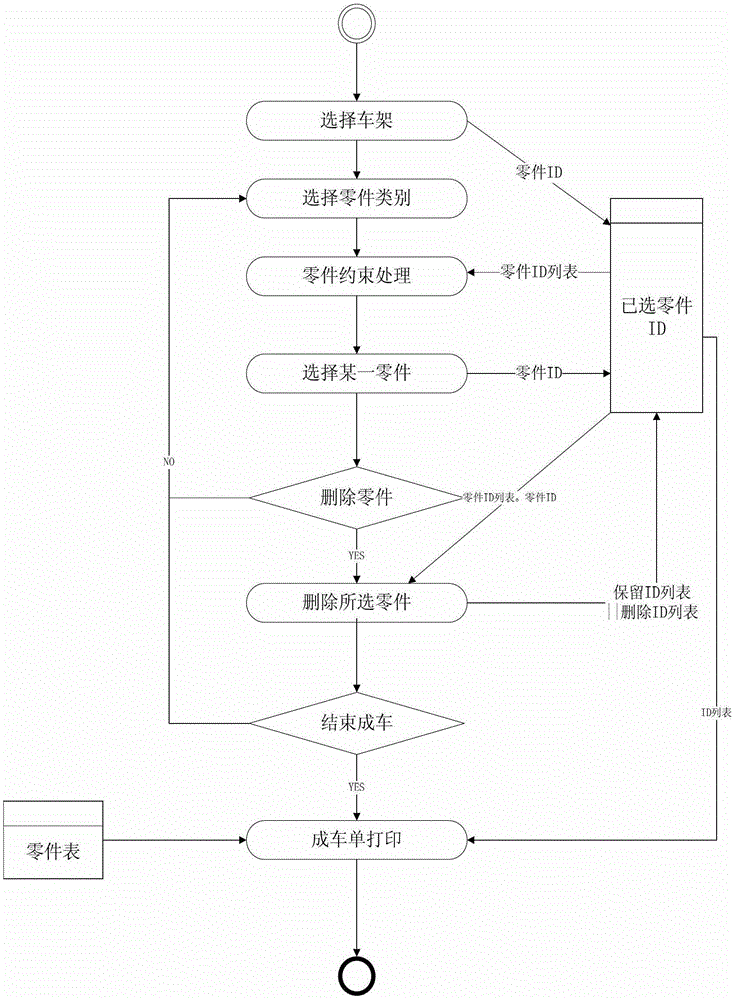

Method and device for implementing assembly of equipment

InactiveCN102945300AImprove assembly efficiencyReasonable assemblySpecial data processing applicationsError reductionComputer science

The invention discloses a method and a device for implementing assembly of equipment. The implementation method comprises the following steps: selecting an appointed first part, determining a set of second parts in a matched relation with the first part according to the restrain conditions of the first part and the types of the second parts, selecting the second part from the determined set of second parts, and assembling the equipment according to the selected parts. According to the invention, the set of second parts in a matched relation with the first part is determined according to the restrain conditions of the first part and the types of the second parts, the second part is selected from the determined set of second parts, and the equipment is assembled according to the selected parts, so that assembly technology software is simulated, the development speed of a technician is increased, the probability of wrong assembly is reduced, and the technician can master the assembly technology faster.

Owner:DAWNING CLOUD COMPUTING TECH CO LTD

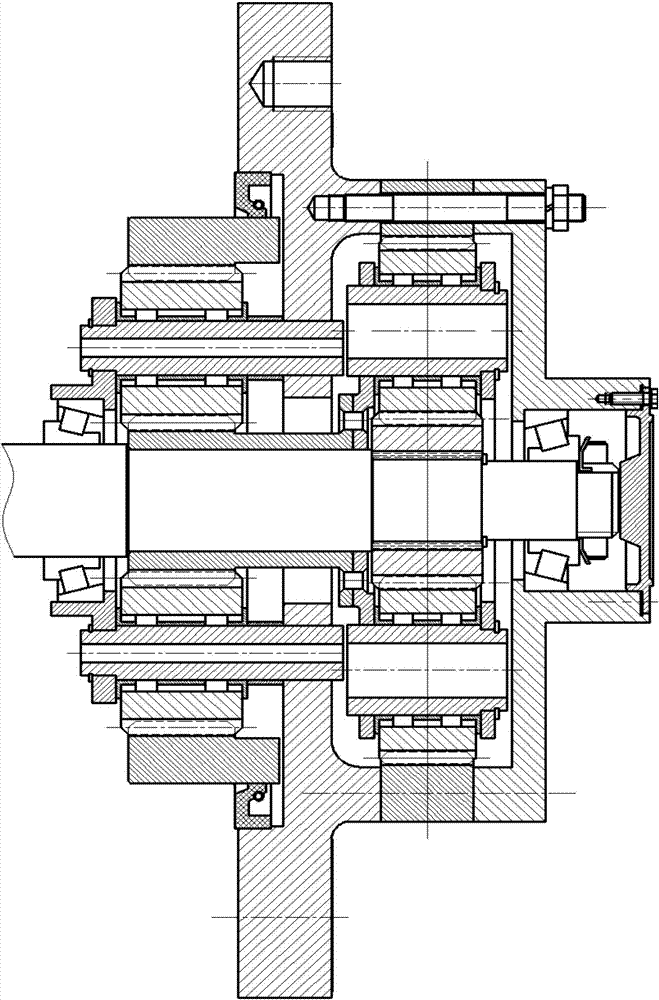

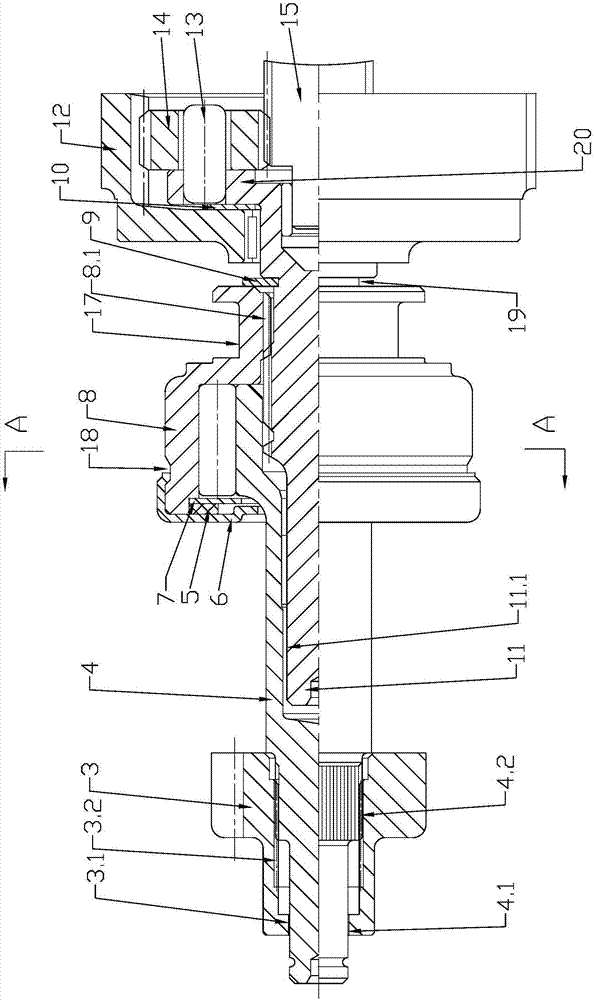

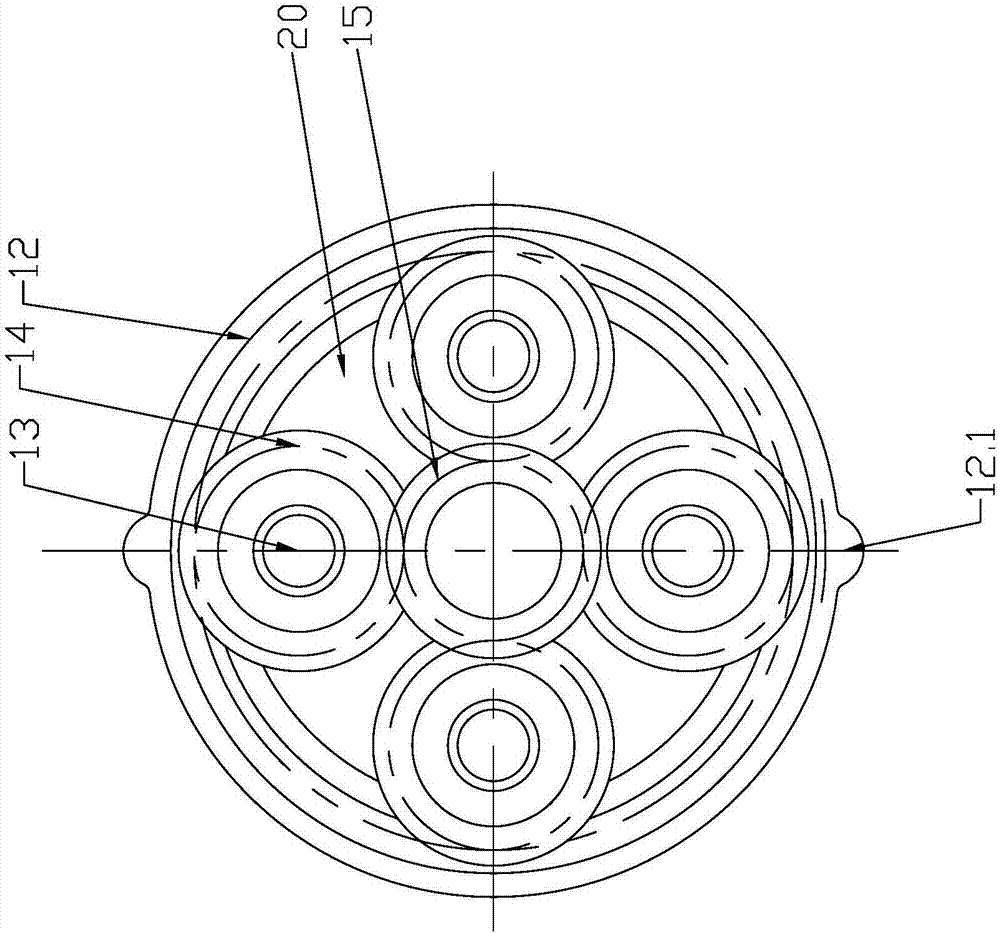

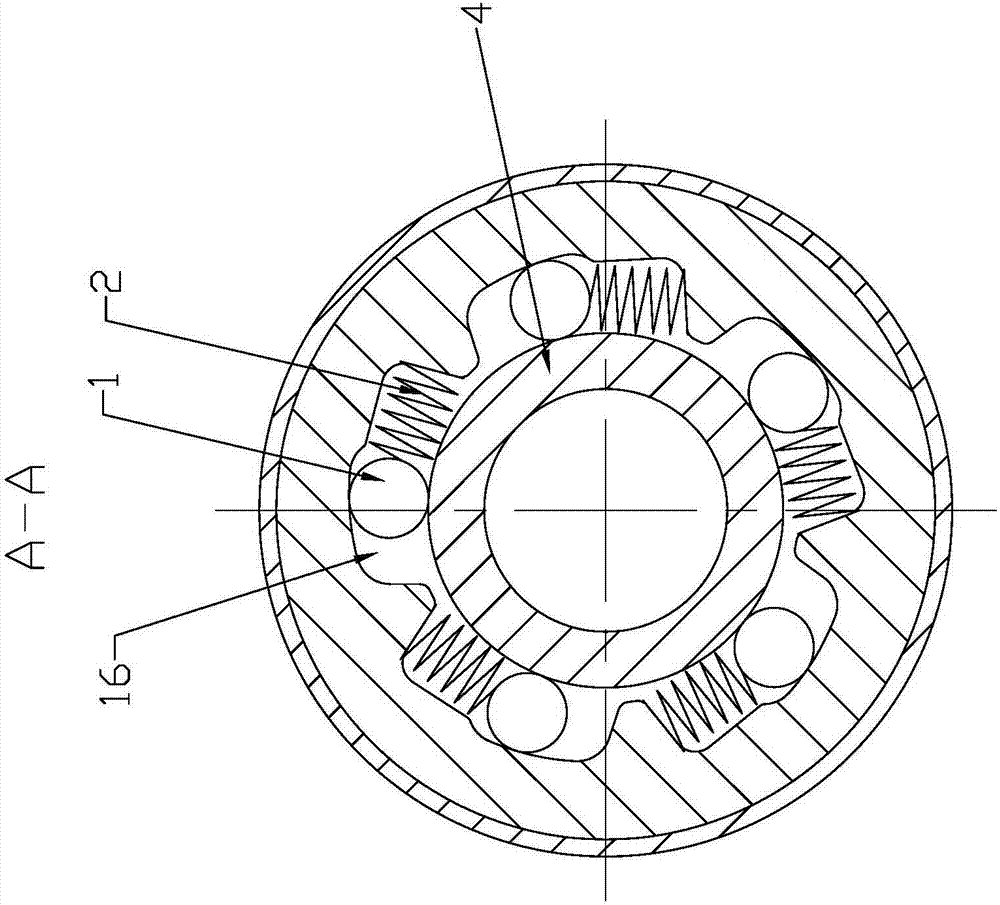

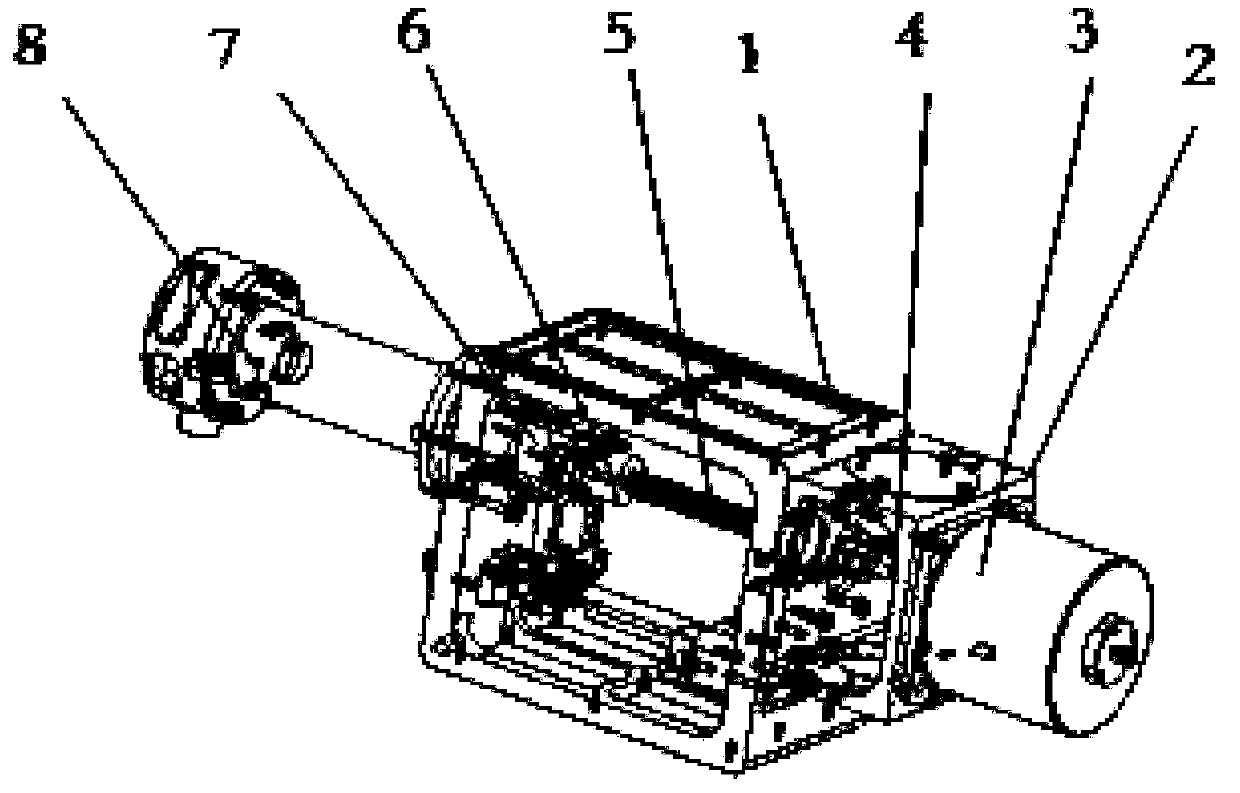

Cantilever-type planetary transmission one-way clutch

The invention relates to a cantilever-type planetary transmission one-way clutch, in particular to a one-way clutch with an internal combustion engine and a starter transferring power uniaxially and slipping reversely, and belongs to the technical field of clutches. The clutch comprises a one-way clutch mechanism, a planetary shaft, an annular gear, a planetary gear, and a input shaft. The left part of a hollow pipe is sequentially provided with a smooth part of a pipe and a spline part of a pipe. Inside a driving gear is sequentially provided with an inner bore part of a gear and an inner spline part of a gear, wherein the inner bore part of a gear of the driving gear is connected with the smooth part of a pipe of the hollow pipe in a sliding mode, and the inner spline part of a gear of the driving gear is connected with the spindle part of a pipe of the hollow pipe in a meshed mode; a splined sleeve is arranged on the right part of the hollow pipe in a sleeved mode, and the inner side faces of the spline sleeve face a plurality of wedge-shape rollaway nests on the end face of the spline sleeve. A pin roller and a spring is arranged inside each wedge-shape rollaway nest, and the springs tightly press the pin rollers in the circumferential direction. The clutch has the advantages of convenient and easy assembly, secure connections, stable quality, and stable and reliable engaging; the size of the clutch is compact and small, and the driver torque of the clutch is large.

Owner:无锡市神力齿轮冷挤有限公司

Water pump with long service life and high sealing performance and assembling method

ActiveCN110566429AEasy to assembleIncrease the digital measurement process methodPositive displacement pump componentsAssembly machinesMotor driveButt joint

The invention provides a water pump with long service life and high sealing performance and an assembling method, and relates to the technical field of assembling of the water pump with high sealing performance. The water pump comprises a pump body support, a motor support, a motor, a coupler, a lead screw, a commutator, a piston and a cylinder body. The pump body support and the motor support arein butt joint. The motor is fixedly mounted on the motor support. The coupler is arranged in the motor support. The lead screw and an output shaft of the motor are coaxially arranged. One axial end of the lead screw stretches into the motor support and is in butt joint with the output shaft of the motor through the coupler. The piston is in butt joint with the other axial end of the lead screw through the commutator. The cylinder body sleeves the outer wall of the piston. The motor drives the lead screw to rotate through the coupler. Rotation of the lead screw is converted into axial transverse movement of the piston through the commutator. The problems that movement of a piston part of a water pump with high sealing performance is blocked, radial runout is large, the service life of thewater pump is short, and the sealing leak rate exceeds standards are solved, and the purposes that the assembling process is digitally detected, the problem about the performance of the water pump ischecked in time, the production efficiency is improved, and the development period is shortened are achieved.

Owner:BEIJING SATELLITE MFG FACTORY

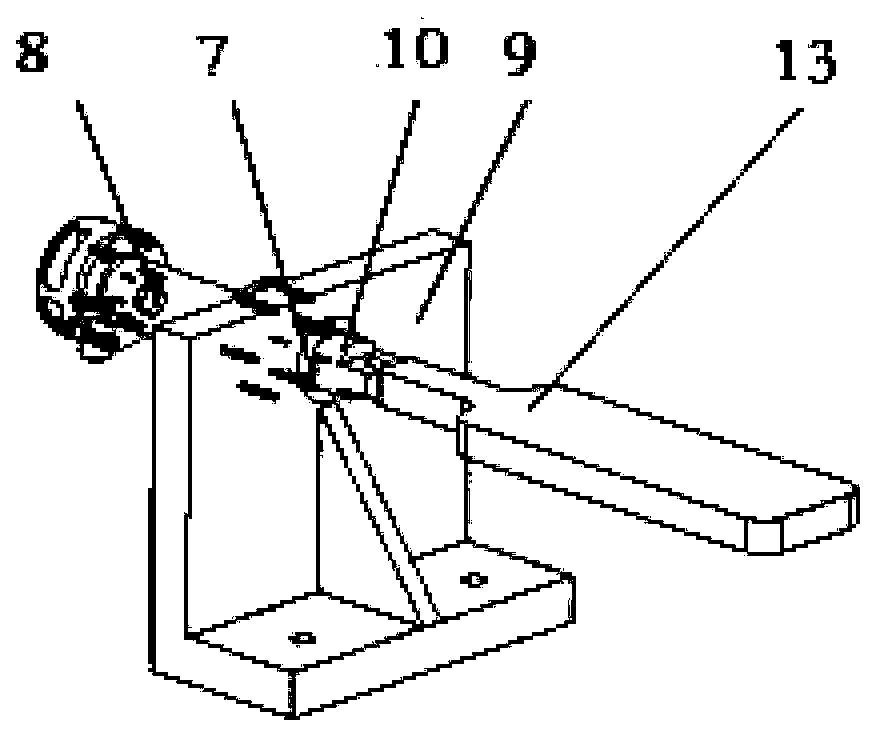

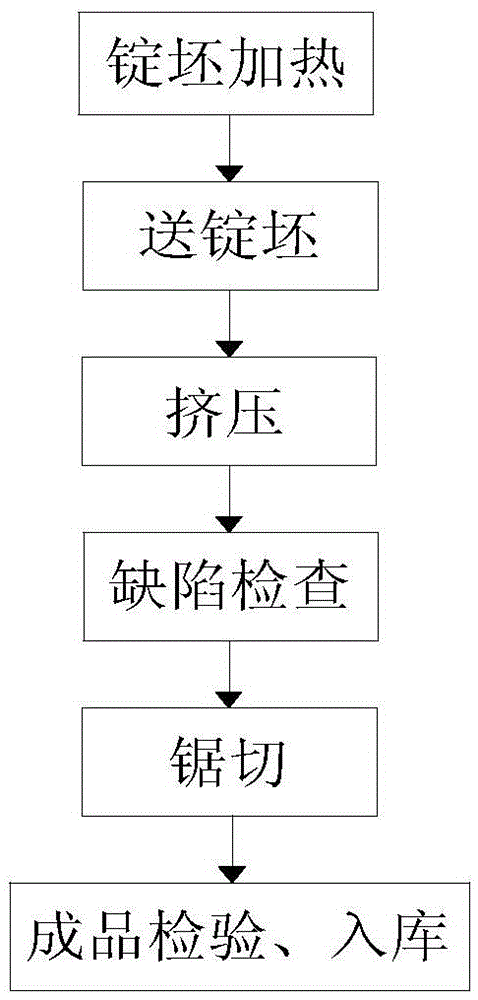

Concave extrusions for non-ferrous metals

ActiveCN104353688BEasy to operateImprove yieldExtrusion diesRams/plungersNonferrous metalEconomic benefits

The invention relates to a concave extrusion method and an extrusion device suitable for a nonferrous metal. The extrusion method comprises the following steps: enlarging the metal volume in the central zone to form reverse resistance for resisting against metal flow forming shrinkage, that is, to form a centrosymmetric concave curved surface shape in the central zone of the working end face of the conventional biplane round panel shaped dummy block, utilizing the dummy block to form a convex surface at the tail end of the blank to be deformed during the compressional deformation process, and enforcing the change of the metal deformation at the different degrees. The extrusion device comprises an extrusion seat, an extrusion shaft, an inner core shaft, a core shaft sleeve, an extrusion liner, an extrusion die and a concave dummy block. The extrusion method disclosed by the invention is simple and convenient to operate, and capable of eliminating or shortening the forming process of the shrinkage in the center of the rod-like bar, so as to increase the yield of the material and achieve the remarkable economic benefit. The extrusion device disclosed by the invention is simple and reasonable in structural design, convenient in assembling, low in cost, stable and reliable in use, and high in extrusion efficiency and extrusion precision.

Owner:SHAANXI PROVINCE MILITARY GRP SHAANXI COPPER

Novel shortcut drill bush and assembling method thereof

InactiveCN101457266AReasonable assemblyRealize the assemblyBlast furnace componentsBlast furnace detailsEngineeringCavity wall

The invention discloses a novel quick drill bushing and an assembly method thereof. A first seal ring and a second seal ring are placed in an annular groove at the periphery of the drill bushing, a gear sleeve clamping ring is arranged at the middle section of a hollow drill rod, and a nut gear sleeve thread is assembled at a thread section of the hollow drill rod and is meshed with the gear sleeve clamping ring. A wing plate is opposite to a mounting notch on a lock nut, the hollow drill rod, the nut gear sleeve and the gear sleeve clamping ring are sheathed in a centre hole of a drill bushing body, and a handle is held to rotate the lock nut to cause the gear sleeve clamping ring and the nut gear sleeve to drive the hollow drill rod to be in synchronous motion, thus causing a conical section or a circular section of the hollow drill rod to form compact conical surface contact or spherical surface contact with a cavity wall of the drill bushing body. The novel rapid drill bushing has the advantages of compact structure, good sealing performance, and extremely convenient and quick assembly and disassembly; and the novel rapid drill bushing can be applicable to a blast furnace taphole drill and can be taken as an accessory of a drill used in the mining of a metal mine or a non-metal mine.

Owner:戴光荣

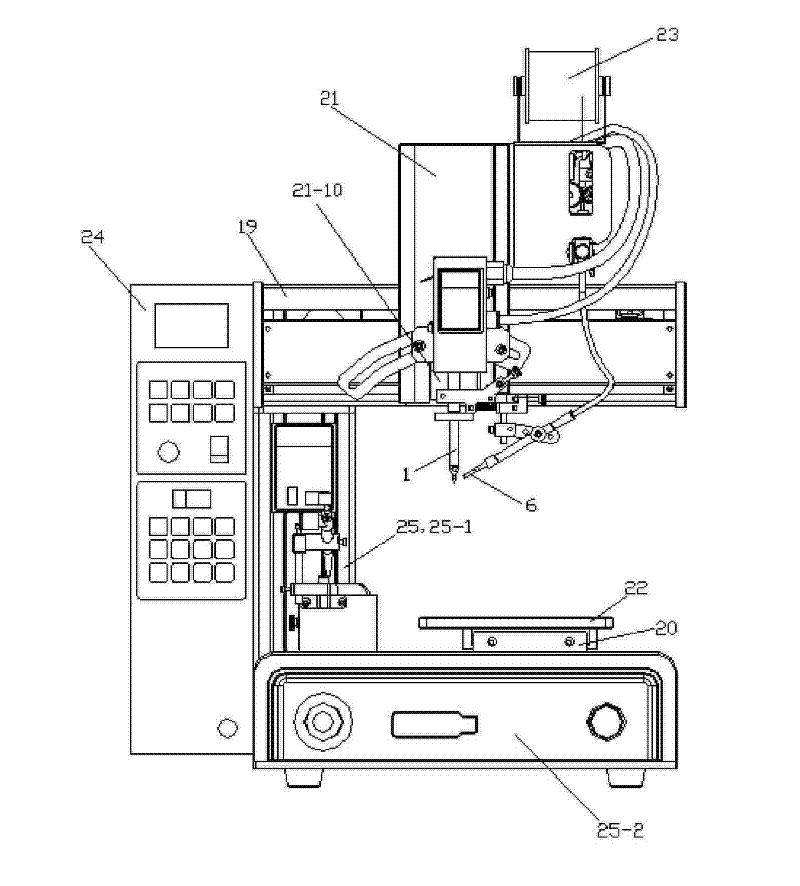

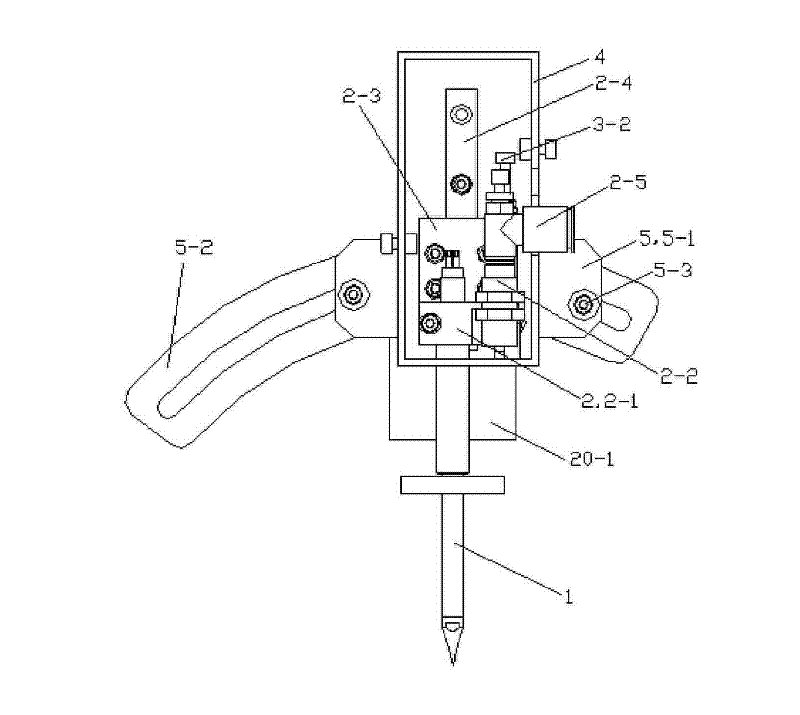

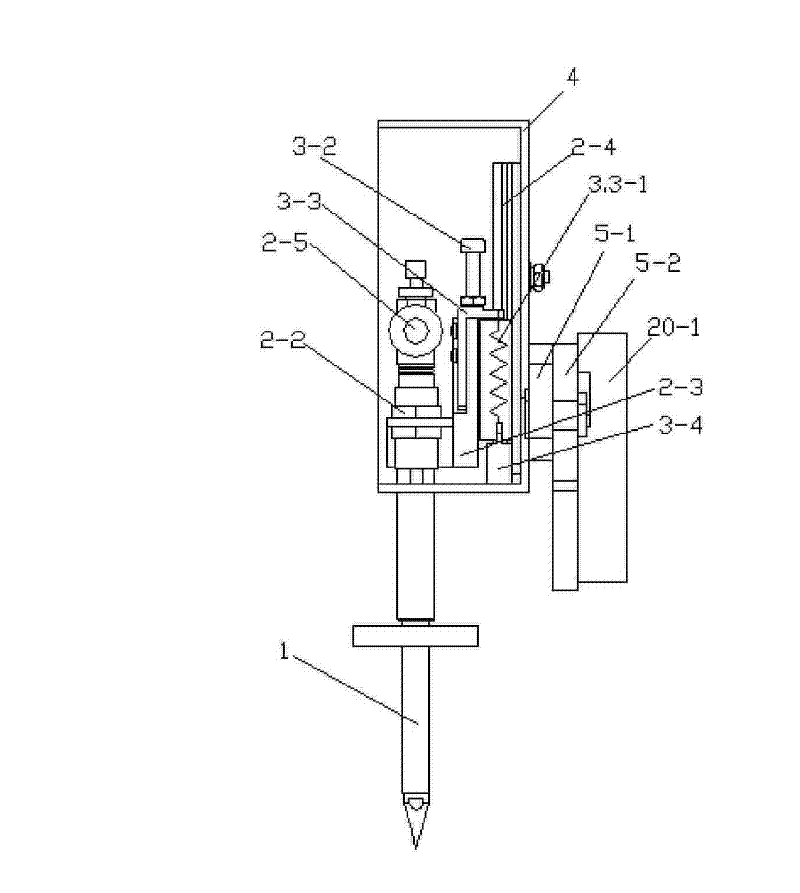

Automatic solder robot

ActiveCN102069255BExtended service lifeGuaranteed accuracyPrinted circuit assemblingWelding/soldering/cutting articlesSlide plateEngineering

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

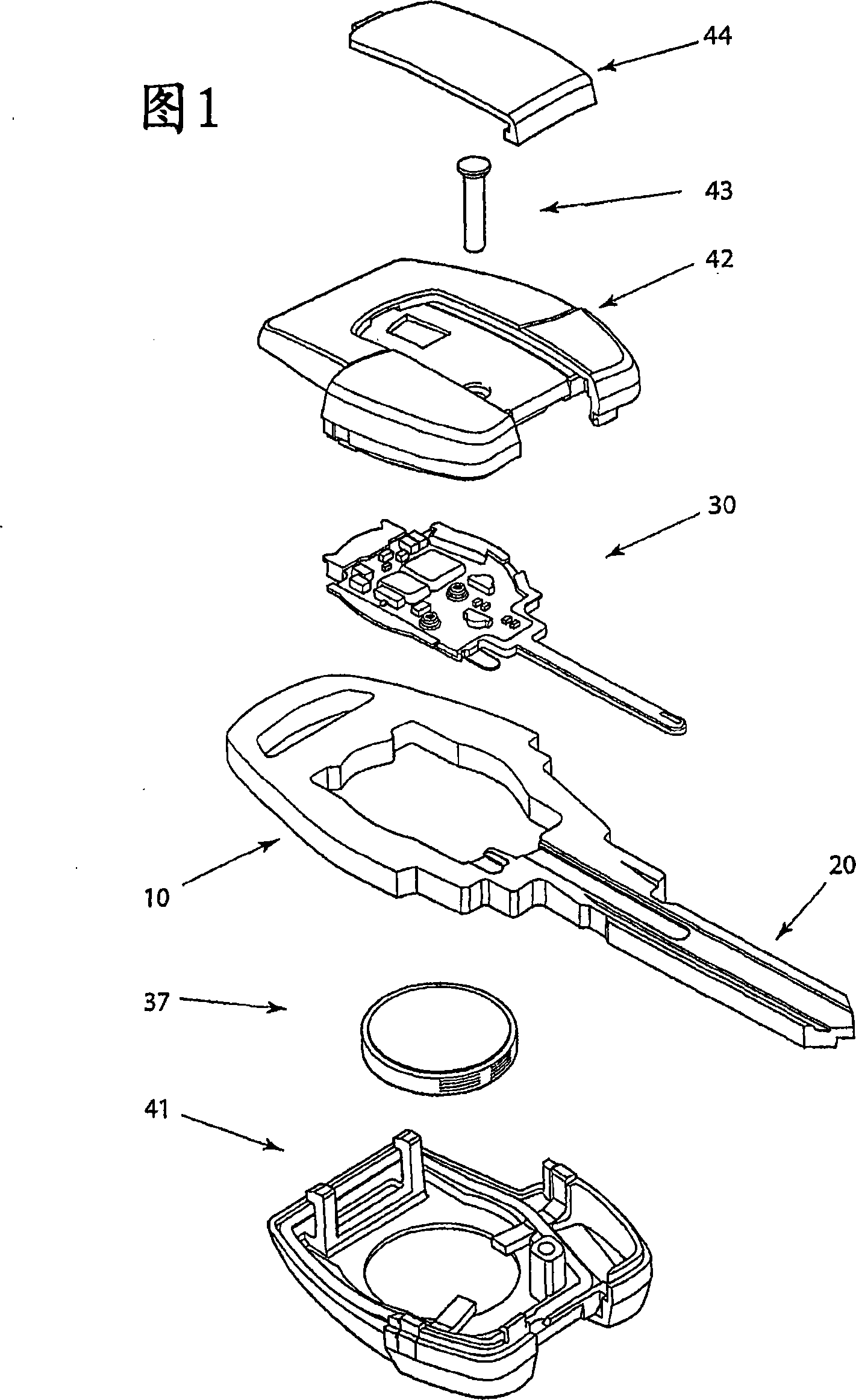

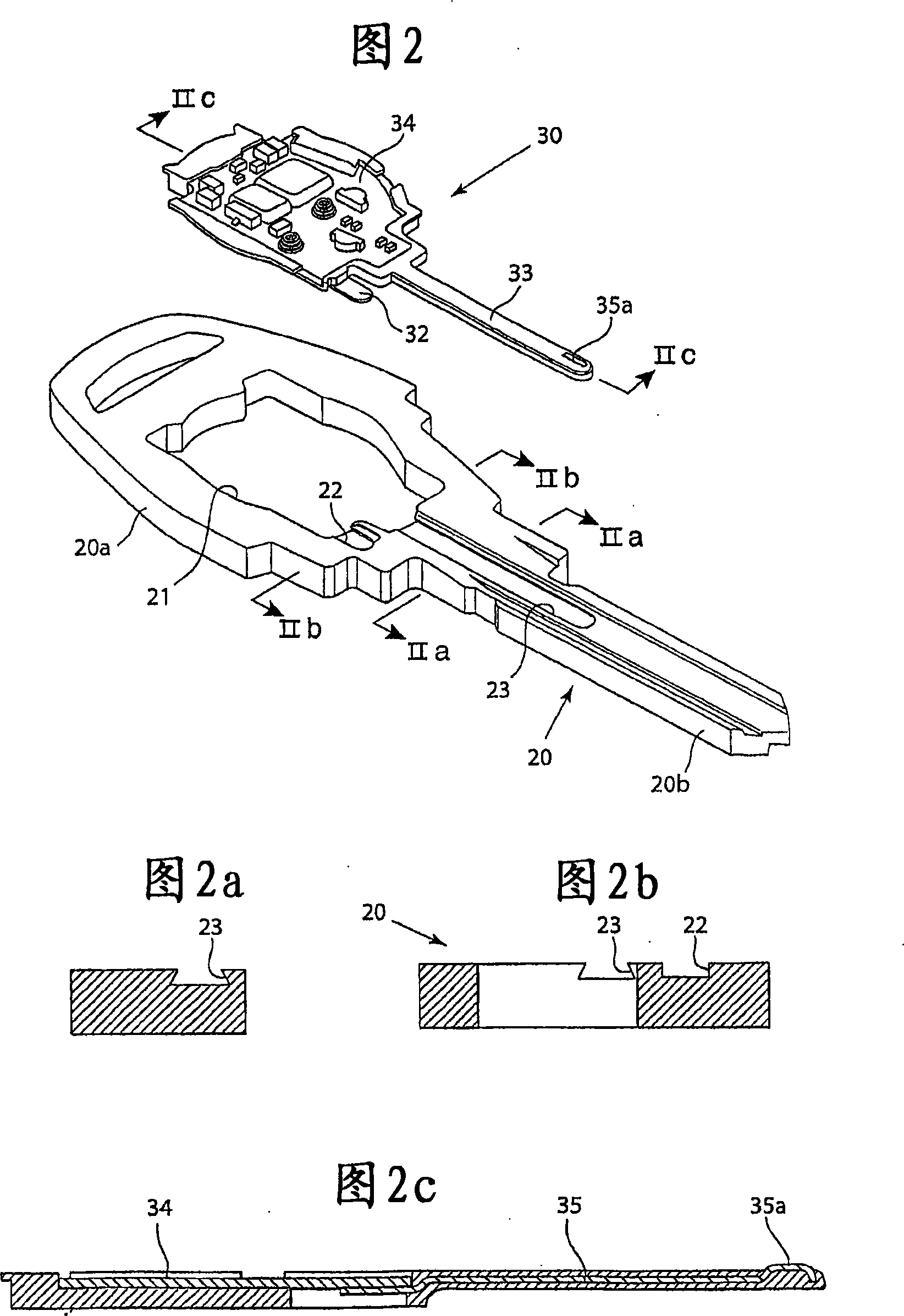

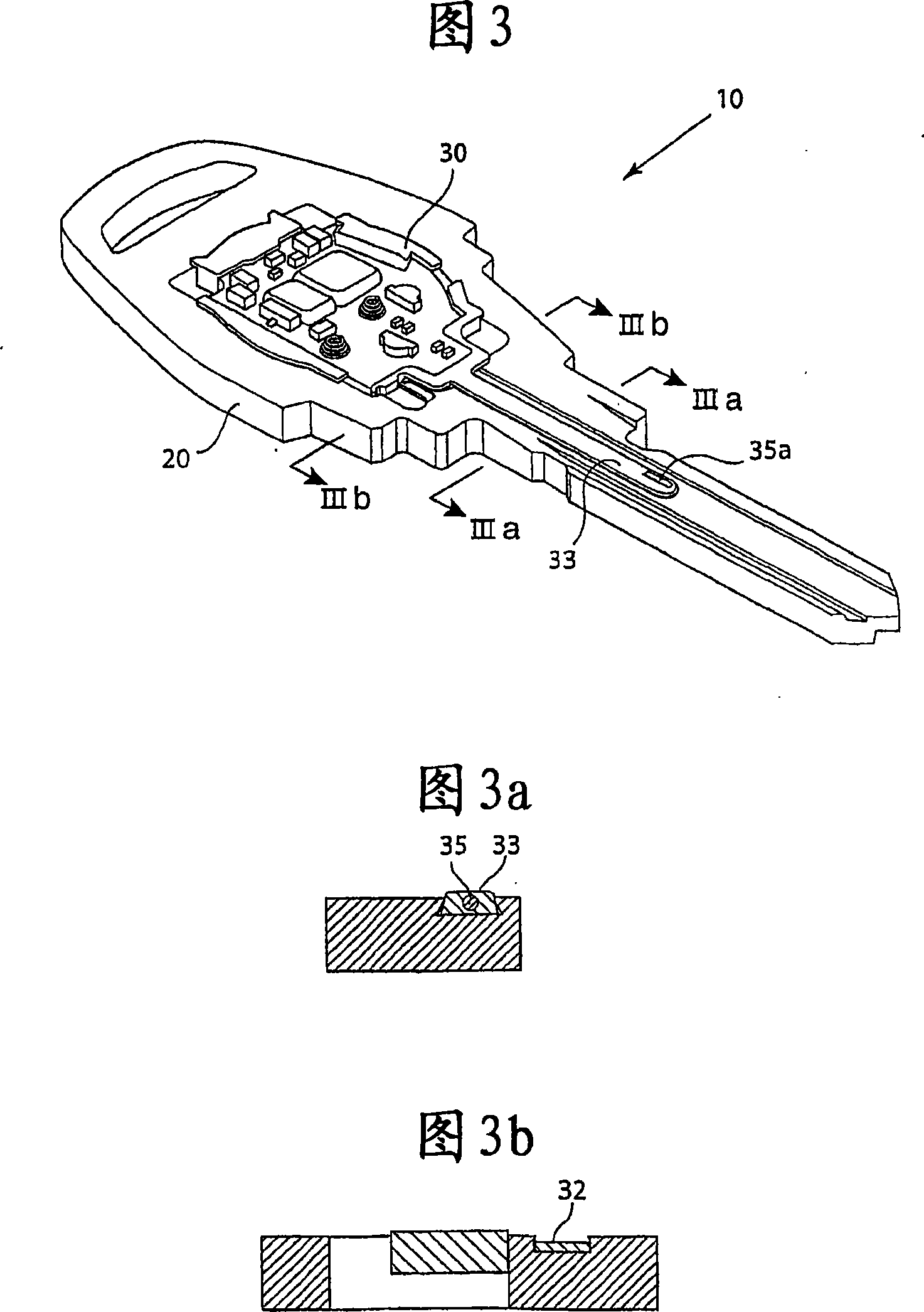

A lock key and a method of its manufacture

InactiveCN101194292APrecise positioningReasonable assemblyKeysIndividual entry/exit registersElectricityConductive materials

A lock key, comprising: a key blank (20), including a handle portion (20a) and a key head portion (20b). Housed in a circuit board holder (30) supported by a non-conductive material are: a circuit board (34) mounted with an electrical circuit; and a key contact portion (35) electrically connected to the electrical circuit. The circuit board holder is assembled to the key blank. The placement of the circuit board and the electrical contact conductors in a non-conductive material enables a rational manufacture of the device. It is thus possible to fix the circuit board carrier made of non-conductive material in the key blank, so that the electrical contact conductors can be placed precisely, thereby ensuring a reliable electrical contact function.

Owner:ASSA

Anti-buffering waterproof solar cell module

ActiveCN106057941AIncrease the areaReasonable assemblyPhotovoltaic energy generationSemiconductor devicesEngineeringAuxiliary electrode

The invention discloses an anti-buffering waterproof solar cell module, and the sun-facing surface of a solar cell panel is provided with bus bar electrodes. The adjacent bus bar electrodes are connected through one fine grid line, and each fine grid line is radial. The back surface of each bus bar electrode is provided with a finger-shaped electrode, and a region, opposite to each finger-shaped region, is provided with an auxiliary electrode plate. A side plate of the solar cell panel is fixed through an annular sealing ring, and the annular sealing ring is set to be oval. The central part of the annular sealing ring is provided with a waterproof film. The external surface of the waterproof film is provided with flow guide stripes. The area of each bus bar electrode is set to be bigger, and the power generation efficiency is improved. The assembly of the solar cell module is enabled to be more reasonable, and the anti-buffering performance is high. After the solar cell module is assembled, a more closed environment is formed. The waterproof film with the flow guide stripes plays a good role in water resistance.

Owner:安徽靖科机电有限公司

Combined insulating operating rod

InactiveCN110581033AIncrease the lengthAvoid fatigueLighting elementsContact operating partsBiochemical engineeringOperation safety

The invention discloses a combined insulating operating rod, which comprises a lower insulating operating rod, an upper insulating operating rod connected to the lower insulating operating rod, and aback frame arranged on one side of the lower insulating operating rod, wherein the back frame is fixed on the lower insulating operating rod through an arc-shaped back plate. The combined insulating operating rod has the advantages of being simple in structure and convenient and reliable to operate. The upper insulating operating rod, the lower insulating operating rod and a middle rainproof insulating rod are assembled through threaded connectors, on-site assembly is simple and rapid, labor is saved in operation, and the operation safety is high. The device is convenient to carry due to the strap structure, and arm fatigue caused by long-time hand lifting is avoided. When not in use, the rod can be detached into short rods and is convenient to carry, and the working efficiency is improved. The middle rainproof insulating rod is added, so that the rod is suitable for waterproof operation in cloudy and rainy days. A simple worm and gear mechanism is adopted to adjust the operation height, two hands for rod lifting can be thoroughly liberated, and more time and labor are saved.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com