Combined insulating operating rod

An insulating operating rod and combined technology, which is applied to contact operating parts, lighting devices, emergency protection devices, etc., can solve the problem that the outer wall of the insulating rod body is easily wet or condensed water mist, and the long rod body of the insulating operating rod is inconvenient to carry. , operator's personal safety injury and other issues, to achieve the effect of easy night operation, avoid arm fatigue, simple and fast assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

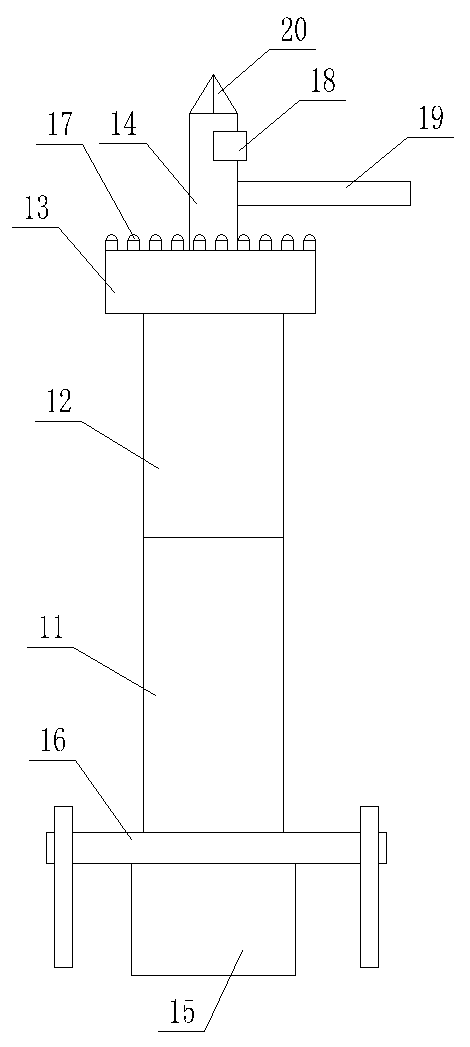

[0052] as attached figure 1 , 4 , 5 and 7;

[0053] A combined insulating operating rod, comprising a lower insulating operating rod 11, an upper insulating operating rod 12 connected to the lower insulating operating rod 11, and a back frame 16 arranged on one side of the lower insulating operating rod 11;

[0054] The back frame 16 is fixed on the lower insulating operating rod 11 through the arc back plate 15;

[0055] The upper end of the upper insulating operating rod 12 is provided with an operating base 13, an electric detection rod 14 vertically fixed on the operating base 13, a brake rod 19 fixed on the side of the electric detecting rod 14, and an operating base 13. The lighting strip 17 on the top and the side lamp 18 arranged on the side of the electric pole 14;

[0056] The light irradiation direction of the side light 18 is the same as that of the brake lever 19;

[0057] The top end of the test rod 14 is a metal pointed tip 20 used for testing equipment elec...

Embodiment 2

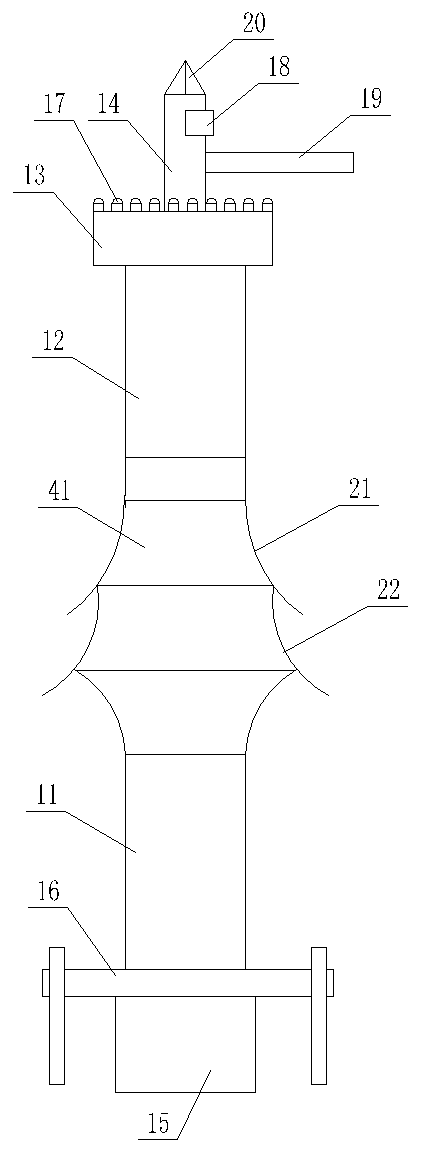

[0066] as attached figure 2 , 4 , 5, 6 and 7;

[0067] A combined insulating operating rod, comprising a lower insulating operating rod 11, an upper insulating operating rod 12 connected to the lower insulating operating rod 11, and a back frame 16 arranged on one side of the lower insulating operating rod 11;

[0068] The back frame 16 is fixed on the lower insulating operating rod 11 through the arc back plate 15;

[0069] The upper end of the upper insulating operating rod 12 is provided with an operating base 13, an electric detection rod 14 vertically fixed on the operating base 13, a brake rod 19 fixed on the side of the electric detecting rod 14, and an operating base 13. The lighting strip 17 on the top and the side lamp 18 arranged on the side of the electric pole 14;

[0070] The light irradiation direction of the side light 18 is the same as that of the brake lever 19;

[0071] The top end of the test rod 14 is a metal pointed tip 20 used for testing equipment ...

Embodiment 3

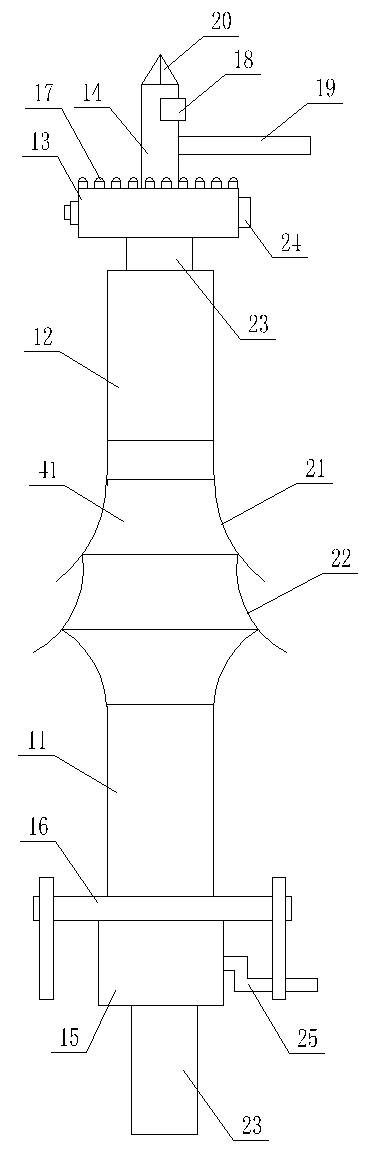

[0084] as attached image 3 , 4 , 8 and 9;

[0085] A combined insulating operating rod, comprising a lower insulating operating rod 11, an upper insulating operating rod 12 connected to the lower insulating operating rod 11, and a back frame 16 arranged on one side of the lower insulating operating rod 11;

[0086] The back frame 16 is fixed on the lower insulating operating rod 11 through the arc back plate 15;

[0087] The upper end of the upper insulating operating rod 12 is provided with an operating base 13, an electric detection rod 14 vertically fixed on the operating base 13, a brake rod 19 fixed on the side of the electric detecting rod 14, and an operating base 13. The lighting strip 17 on the top and the side lamp 18 arranged on the side of the electric pole 14;

[0088] The light irradiation direction of the side light 18 is the same as that of the brake lever 19;

[0089] The top end of the test rod 14 is a metal pointed tip 20 used for testing equipment elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com