Intelligent assembly method and production line of roller counter of gas meter

An assembly line and counter technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of low assembly efficiency, high labor intensity, low assembly quality, etc., achieve reasonable assembly, avoid manual operation errors, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further explained below in conjunction with the accompanying drawings of the description.

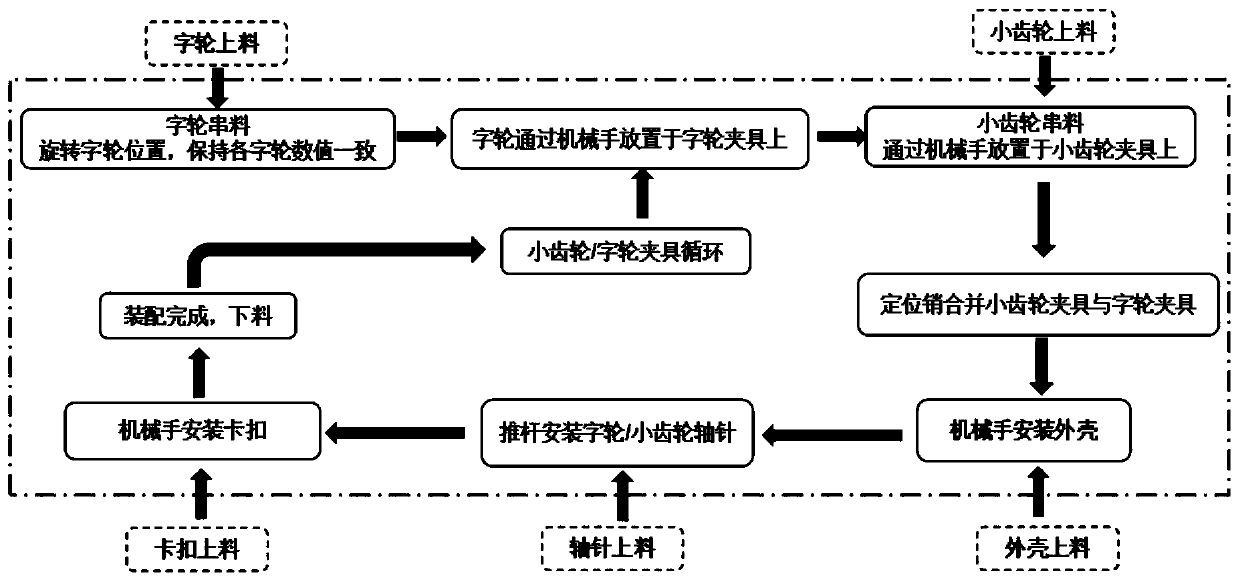

[0039] like figure 1 As shown, a gas meter roller counter intelligent assembly method is characterized in that: comprising the following steps:

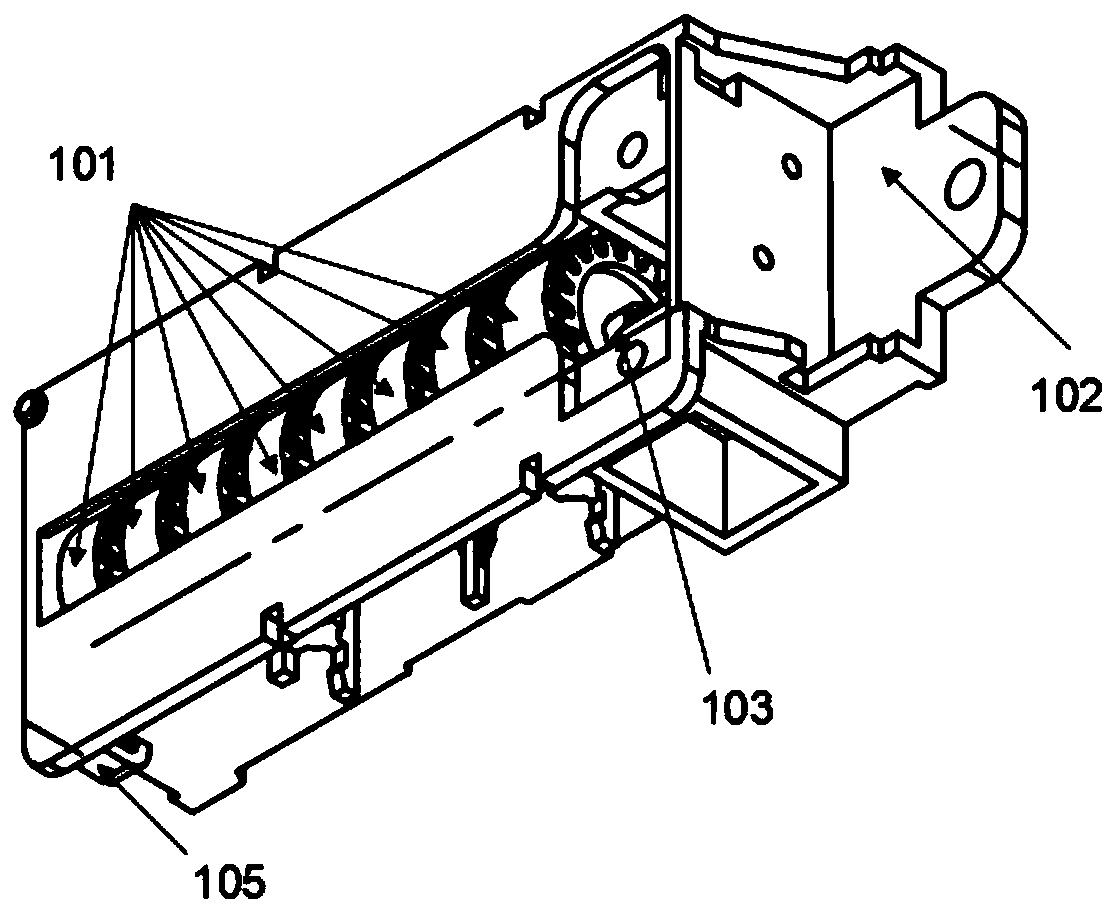

[0040] 7) Character wheel loading and stringing: the character wheel is fed through the vibrating plate, and after the character wheel stringing rod is used to string the material, the stepping motor drives the brush wheel to rotate the character wheel, so that the character wheel stop touches the zero return limit block, Thereby keeping all character wheel numbers at zero.

[0041] 8) Pinion feeding and stringing: After the pinion is fed by the vibrating plate, the pinion is clamped by the pinion manipulator and placed on the horizontally retractable clamping arm arranged in the vertical direction. String in a vertical row.

[0042] 9) Positioning of the word wheel and pinion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com