Electric wheel assembly device for overload vehicle and vehicle

An electric wheel and assembly technology, applied in the direction of power devices, control devices, vehicle components, etc., can solve problems such as sealing problems, unreasonable assembly force, etc., reduce torque load, simplify vehicle structure, meet The effect of braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

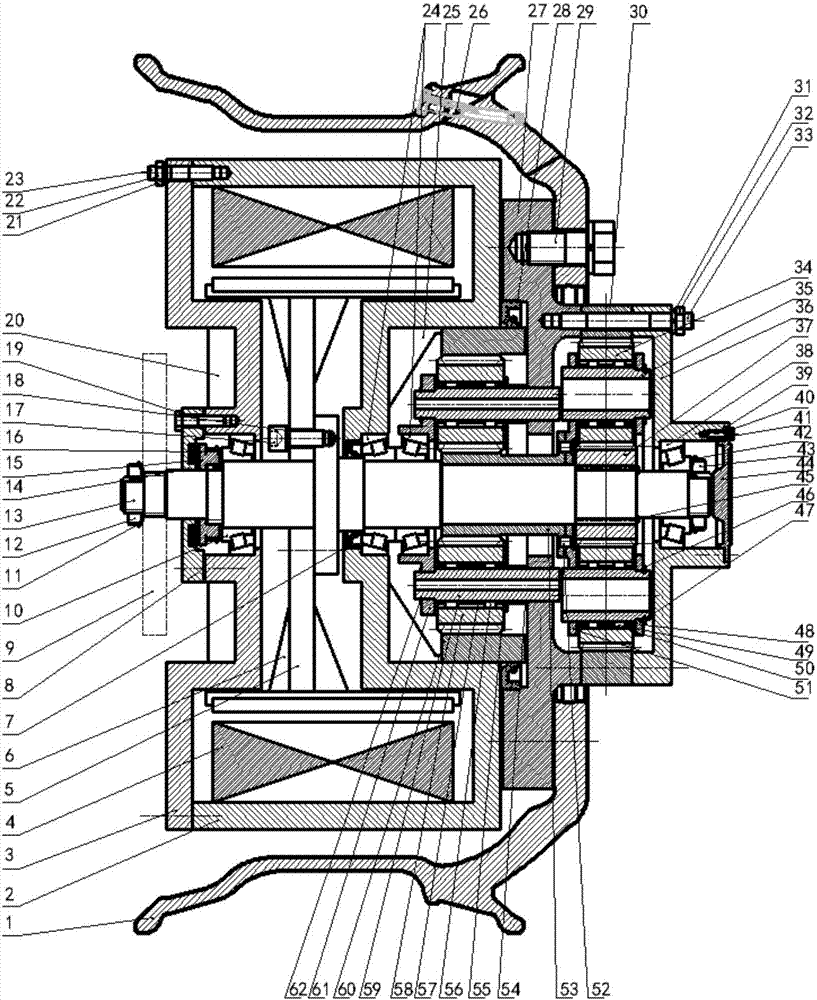

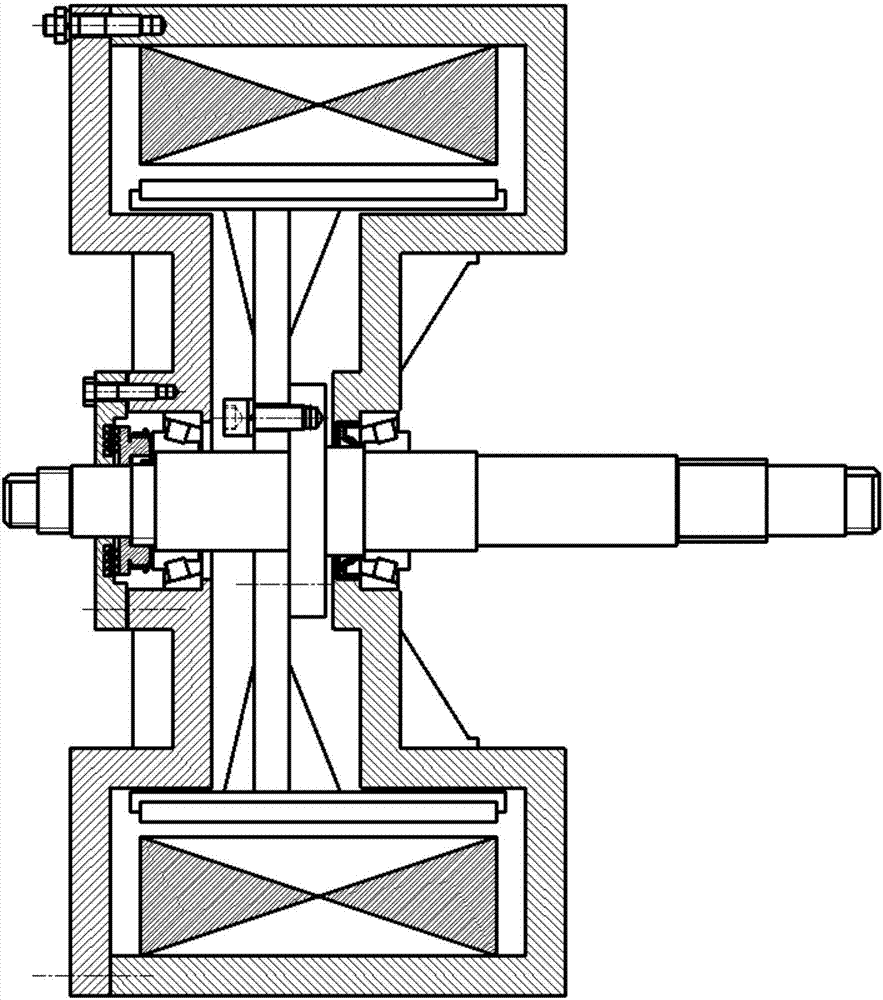

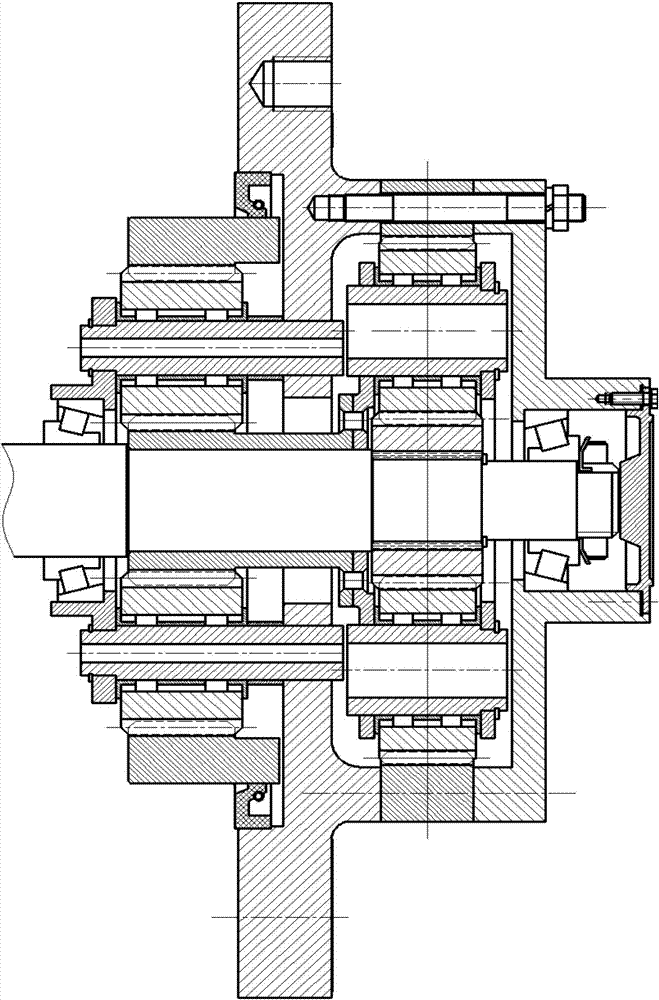

[0077] Attached below Figure 1~1 0 further describes the present invention in detail, so that those skilled in the art can implement it with reference to the description.

[0078] as attached figure 1 Shown is the electric wheel assembly mechanism integrating the two-stage planetary gear reducer of the present invention, the motor shaft 13 of the hub motor is connected to the first-stage sun gear 37 through an involute spline, and one end of the first-stage sun gear 37 is connected by the shaft Shoulder positioning, the other end is positioned by the circlip-A type 45 for the shaft; then the primary sun gear 37 meshes with the five primary planetary gears 34 evenly distributed around; the primary planetary gears 34 pass through their respective primary The planet shaft 35, the roller 49, the sleeve 50, and the L-shaped block 48 are supported and positioned between the first-level left-end planetary carrier 51 and the first-level right-end planetary carrier 47; The ring gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com