Micro-rail vehicle and braking system and method thereof

A braking system and micro-rail technology, applied in the field of rail vehicles, can solve the problems of unsuitable micro-rail vehicles, complex structure, large volume, etc., and achieve the effects of short braking response time, small size and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

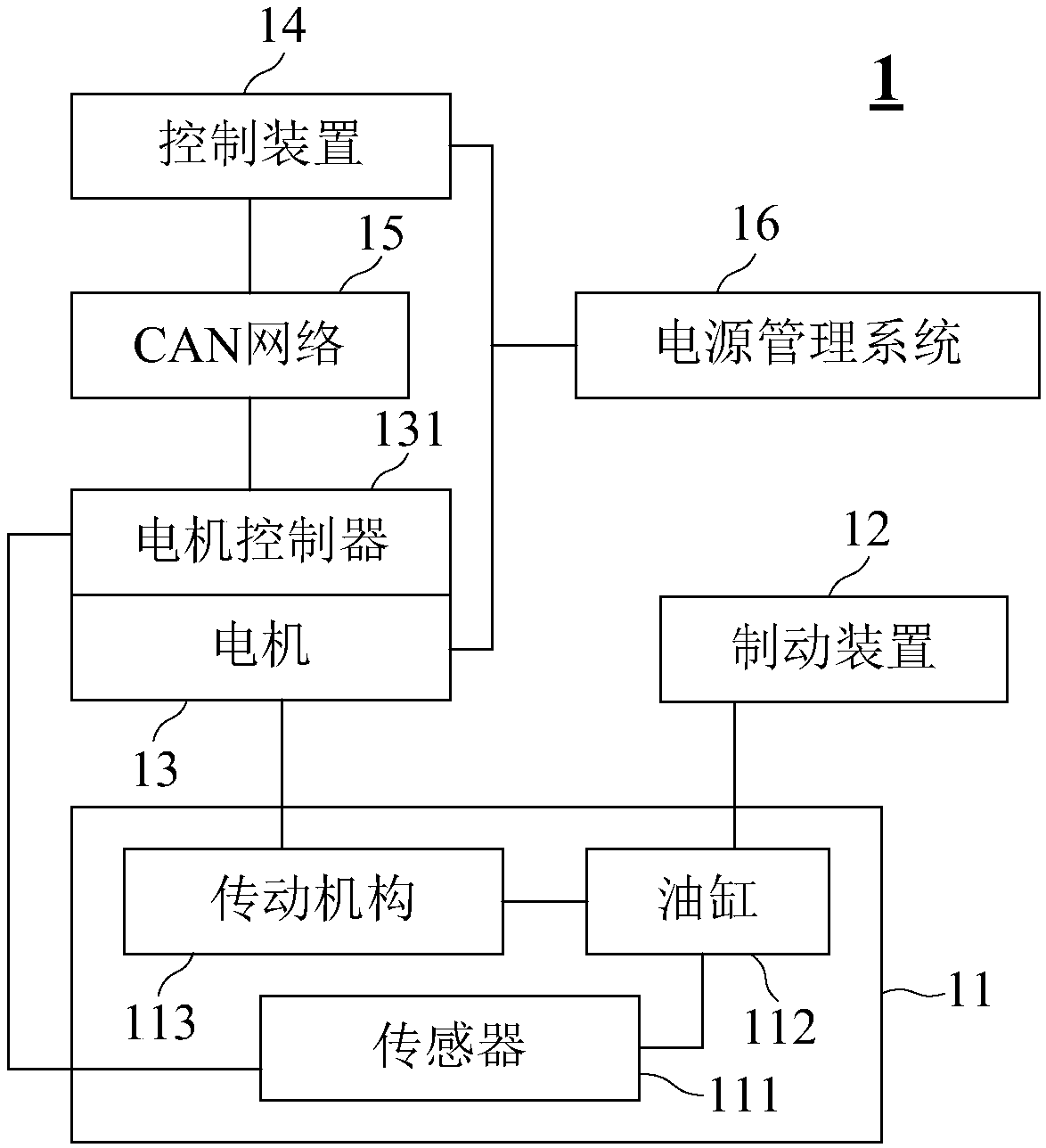

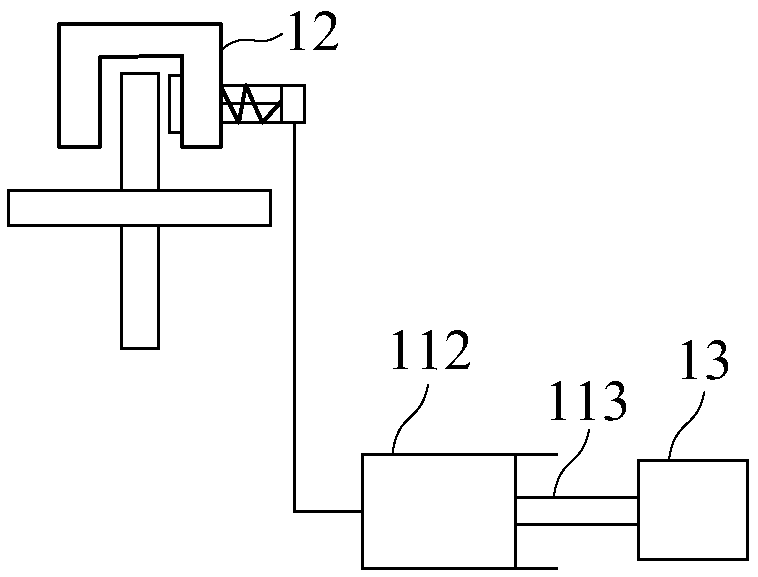

[0041] The embodiment of the present application provides a braking system 1, the braking system 1 can be used for micro-rail vehicles, such as figure 1 and image 3 As shown in the structure, the braking system 1 includes:

[0042] The control device 14 is used to obtain the braking distance information, weight information and speed information of the micro-rail vehicle, and calculate the required braking force of the micro-rail vehicle and the braking force according to the acquired braking distance information, weight information and speed information. The power corresponds to the rotational speed and torque of the motor 13 , and sends the calculated rotational speed and torque information to the motor 13 . Such as figure 1 As shown in the structure, the motor controller 131 can be connected to the control device 14 through the CAN network 15 or wireless network. torque, and make the motor run according to the calculated speed and torque to achieve the braking of the bra...

Embodiment 2

[0058] An embodiment of the present application provides a micro-track vehicle, including any braking system 1 provided in the above embodiments. The micro-rail vehicle adopts the above-mentioned braking system 1, which is beneficial to improve the braking efficiency of the micro-rail vehicle, shorten the braking time, and facilitate the improvement of the safety of the micro-rail vehicle.

Embodiment 3

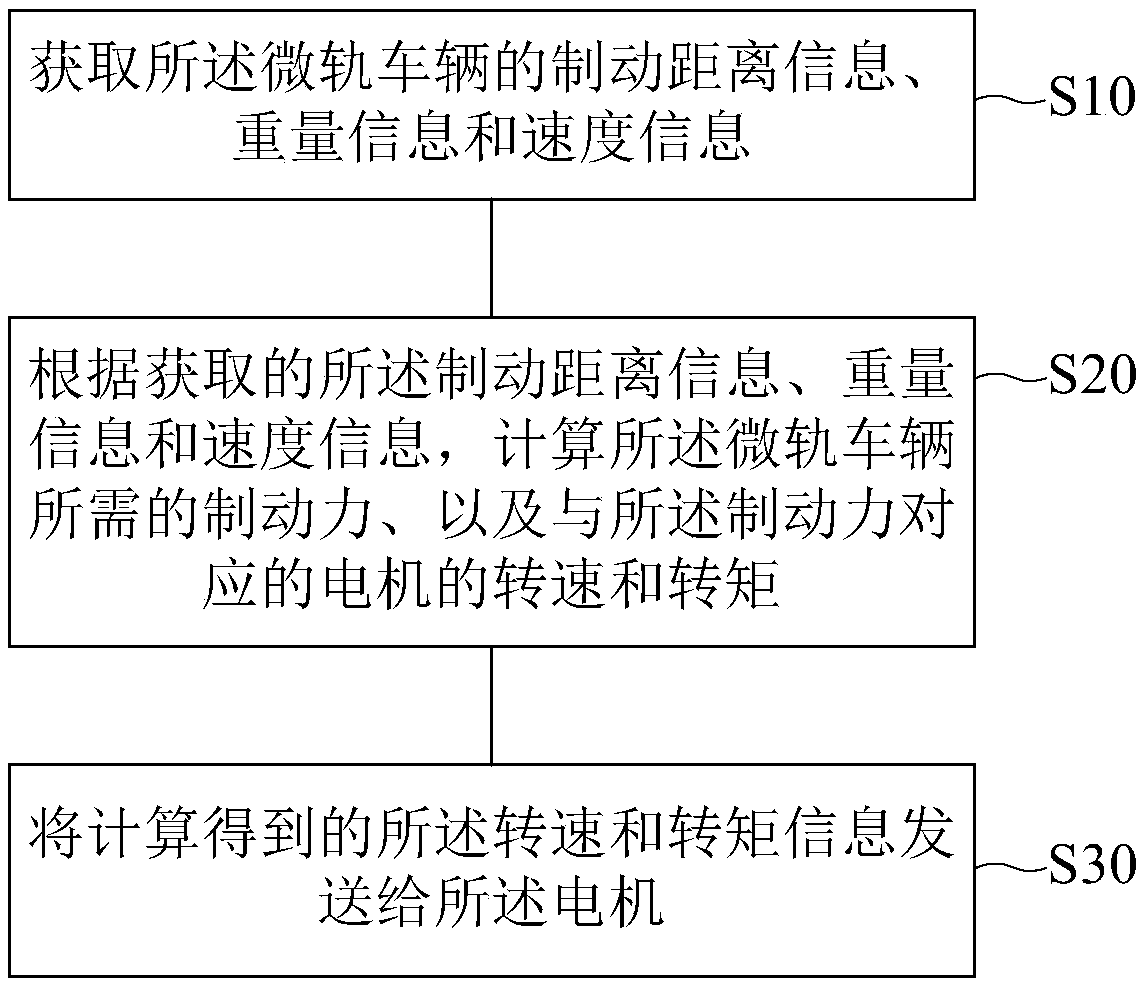

[0060] The embodiment of the present application provides a braking method for a micro-track vehicle, including:

[0061] Step S10, obtaining the braking distance information, weight information and speed information of the micro-rail vehicle; for example, various information of the micro-rail vehicle can be obtained through various detection devices;

[0062] Step S20, according to the obtained braking distance information, weight information and speed information, calculate the braking force required by the micro-rail vehicle, and the speed and torque of the motor 13 corresponding to the braking force; information, the braking distance and the braking acceleration of the micro-track vehicle can be calculated by the control device 14, to obtain the required braking force; when calculating the braking force of the micro-track vehicle, the braking force can be calculated using the following formula:

[0063]

[0064] Among them, F is the braking force, m is the weight of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com