Patents

Literature

110 results about "Brake response time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reaction times vary greatly with situation and from person to person between about 0.7 to 3 seconds (sec or s) or more. Some accident reconstruction specialists use 1.5 seconds. A controlled study in 2000 (IEA2000_ABS51.pdf) found average driver reaction brake time to be 2.3 seconds.

Driving-safety ancillary white-flash alerting-system

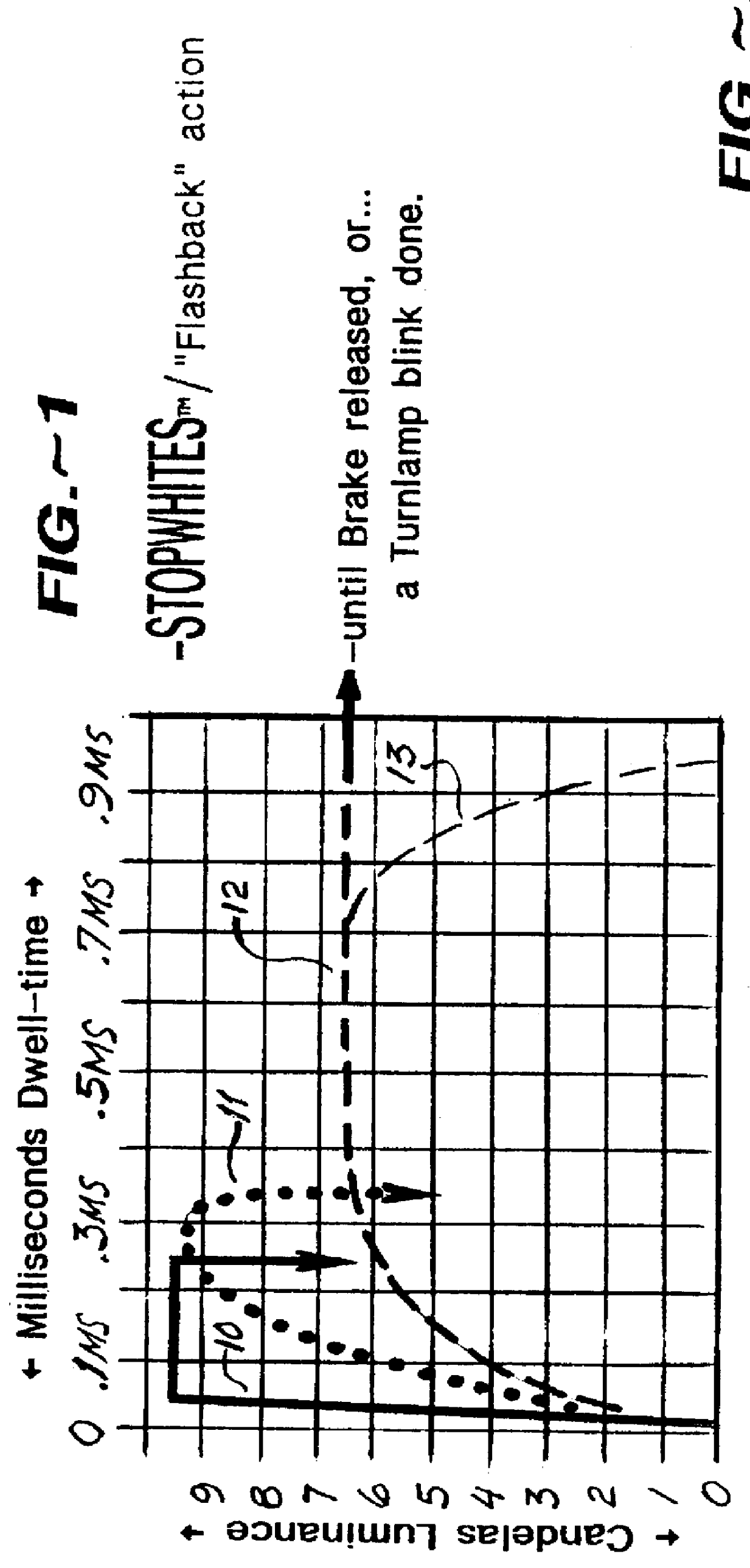

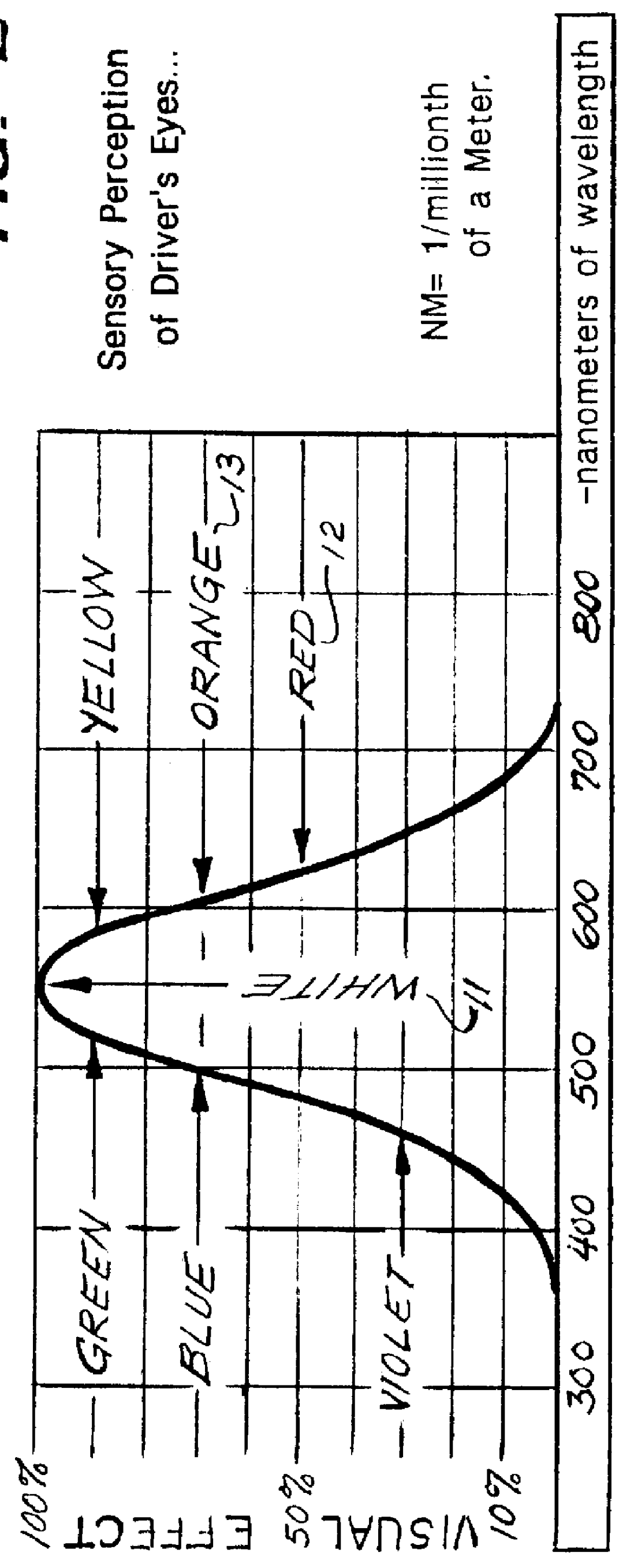

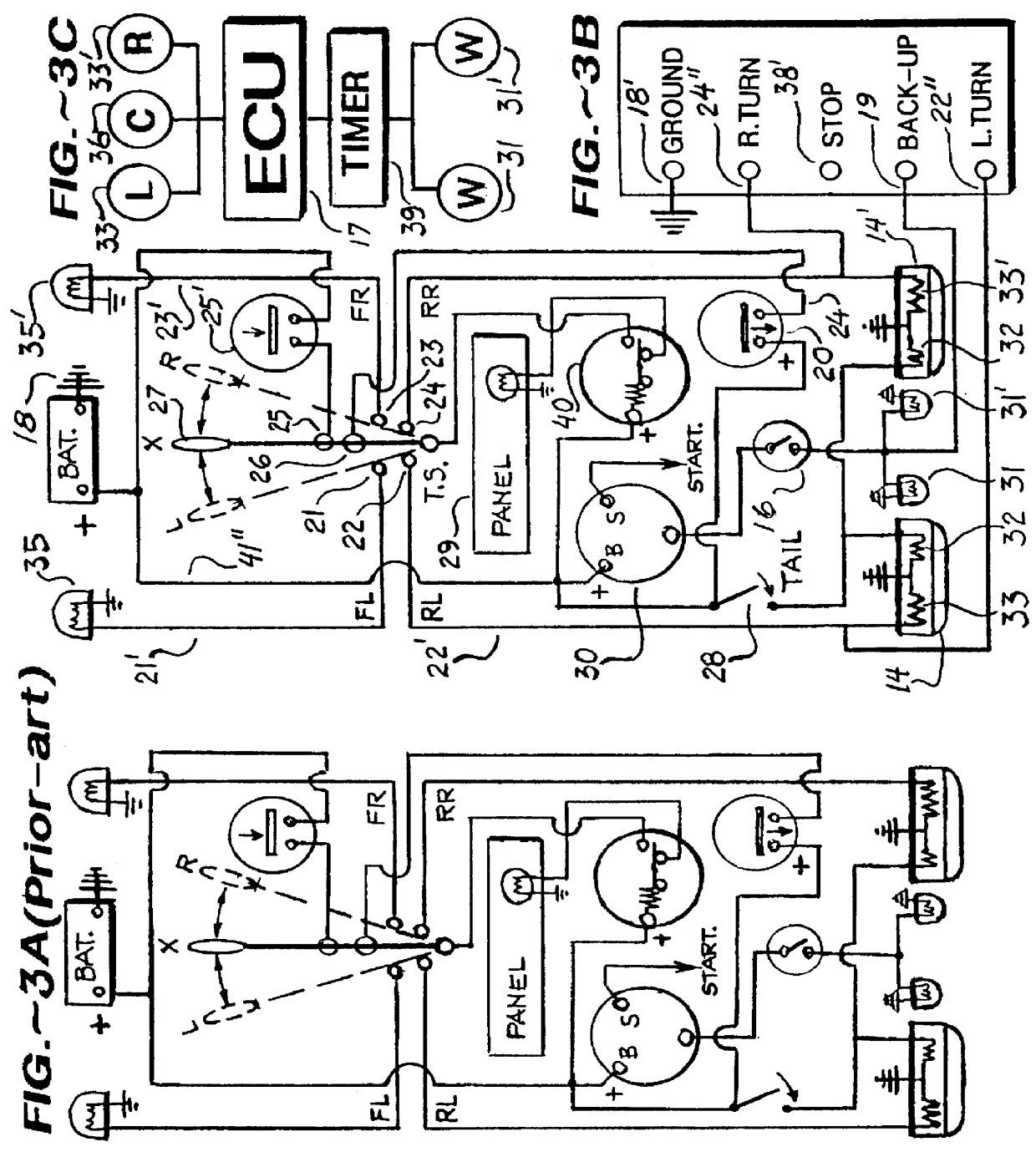

InactiveUS6025775AReduced brake response timeShorten the construction periodOptical signallingDriver/operatorEffect light

The notion of an easily retrofitable passive lighting-safety device designed to be generally installed into the existing rear lighting wiring-circuit of any motor-vehicle from motorcycles to cars and trucks, -so as to significantly boost a following driver's visualacuity cognition threshold of awareness regarding the state of a leading vehicle's sudden breaking procedure. The invention provides an intense quasi-precognitive white-light "flashback" alerting effect, preferably appearing (particularly under nighttime conditions) as a nearly subliminal approximate 100-200 / millisecond flashback of visually non-deacclimating "white-light", emanating from a vehicle's existing back-up lights (or integrated with the DOT high-center brake-light). The effect being to essentially arouse a following motorist's attention to the simultaneous light-up of the preceding vehicle's stoplights. Regardless as to how long braking action continues, the so called STOPWHITES TM only illuminate in flashback once for a brief instant per actuation of the brakes; -having served their sole purpose in attracting a following driver's attention to need for braking. A following driver being thus able to react substantially sooner than viewing conventional stoplights only; -thereby significantly shortening the braking response-time. Additionally, exemplary circuits teach wiring the preferably solid-state electrical-module with directional-signal lights, as well as the 4-Way / Emergency-flasher system.

Owner:ERLANDSON GLENN E

Method and system for testing brake of high-speed motor train unit

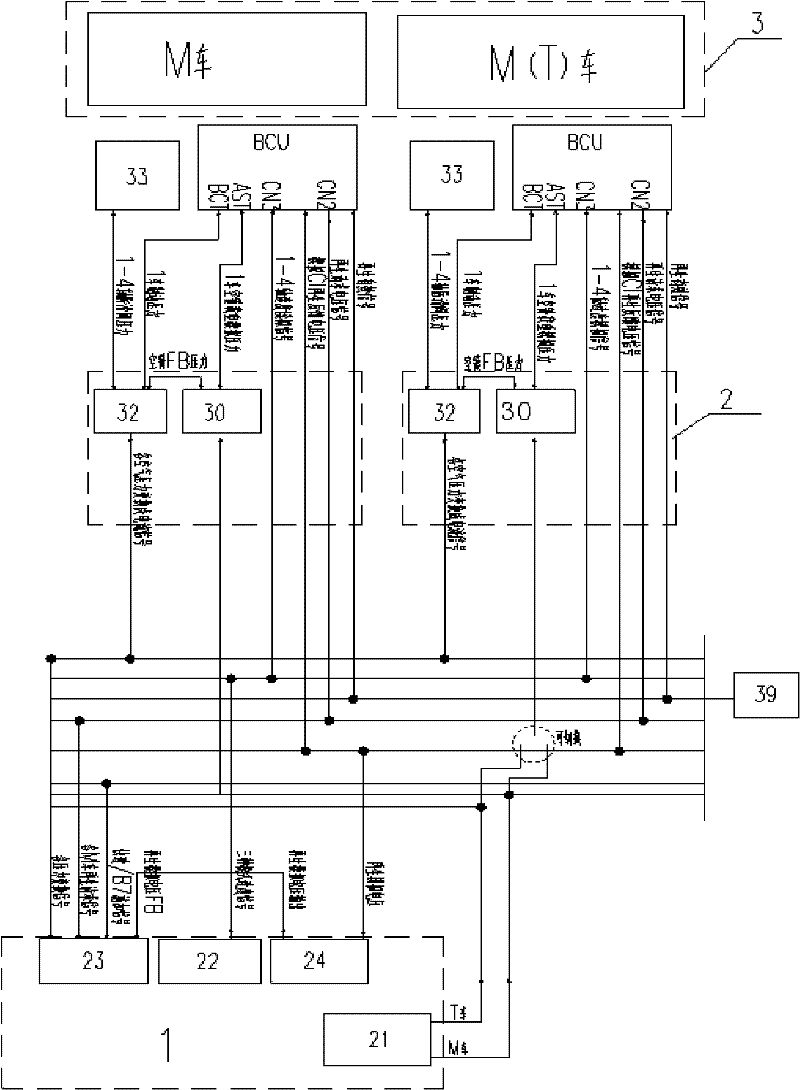

The invention relates to a method and a system for testing the brake of a high-speed motor train unit. The method comprises the following steps of: in a stationary state of a motor train unit, simulating various speed signals, train air spring load signals and regeneration brake analog signals by utilizing the testing system; after various analog signals are received by the motor train unit, applying a brake action by a train brake system, and outputting brake information; and acquiring and analyzing brake information data and judging whether the design requirements for various performance indexes of the brake system are met. According to the method and the system, in the stationary state of the motor train unit, various performance indexes of the motor train unit brake system can be comprehensively and effectively tested through simulating the train speed signals and the train air spring load signals, wherein the performance indexes comprise brake response time of the motor train unit, logic motions of an anti-slip system, regenerated brake feedback, air brake, sequential coordination control of regenerated brake, and the like, so that intensive study of complete train debugging key technologies of the motor train unit is realized so as to achieve the purpose of all-around high-precision analogue simulation of the test of the brake system.

Owner:CHINA RAILWAYS CORPORATION +1

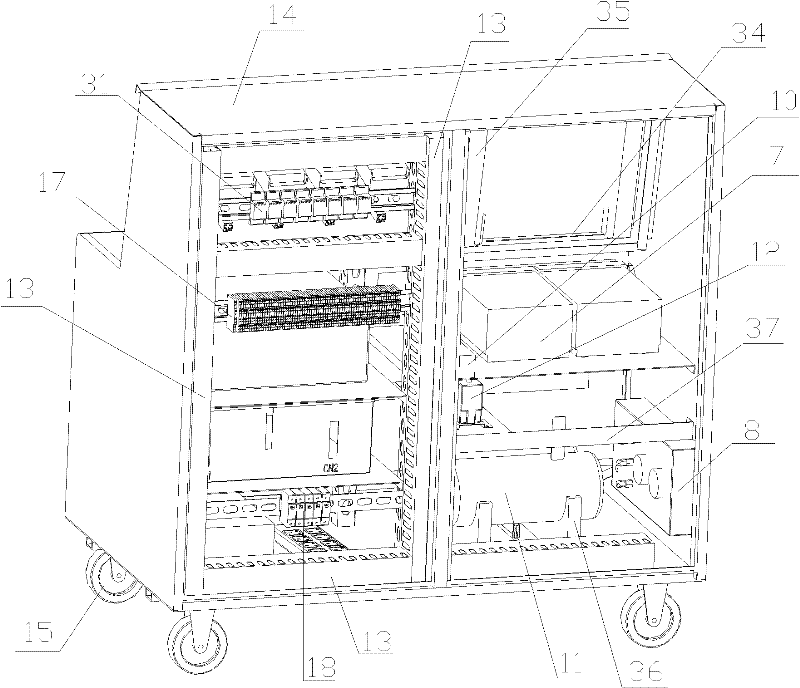

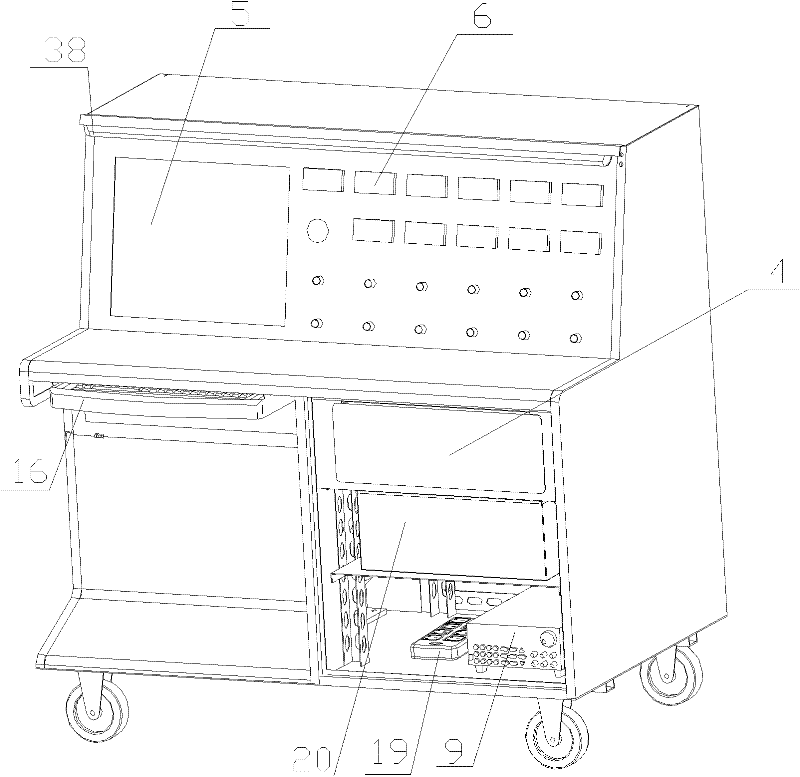

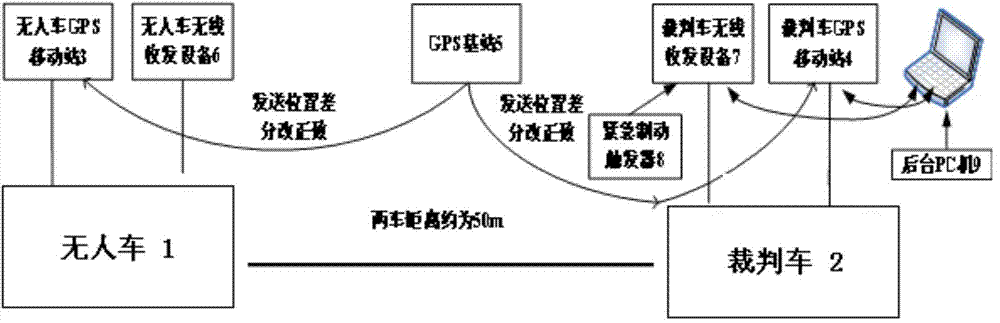

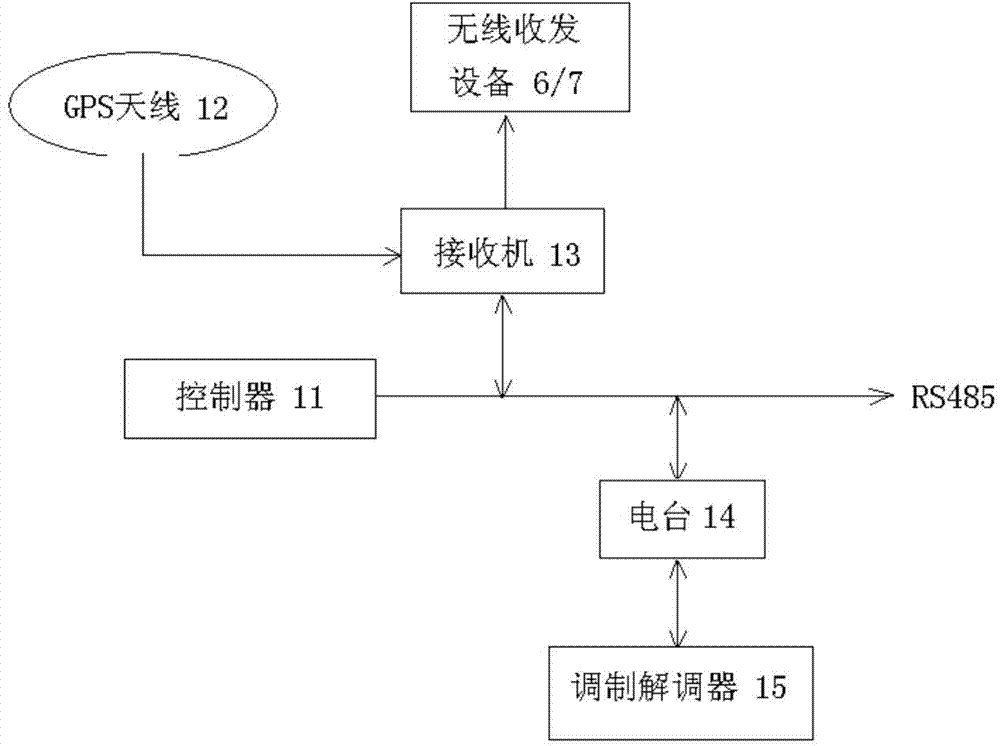

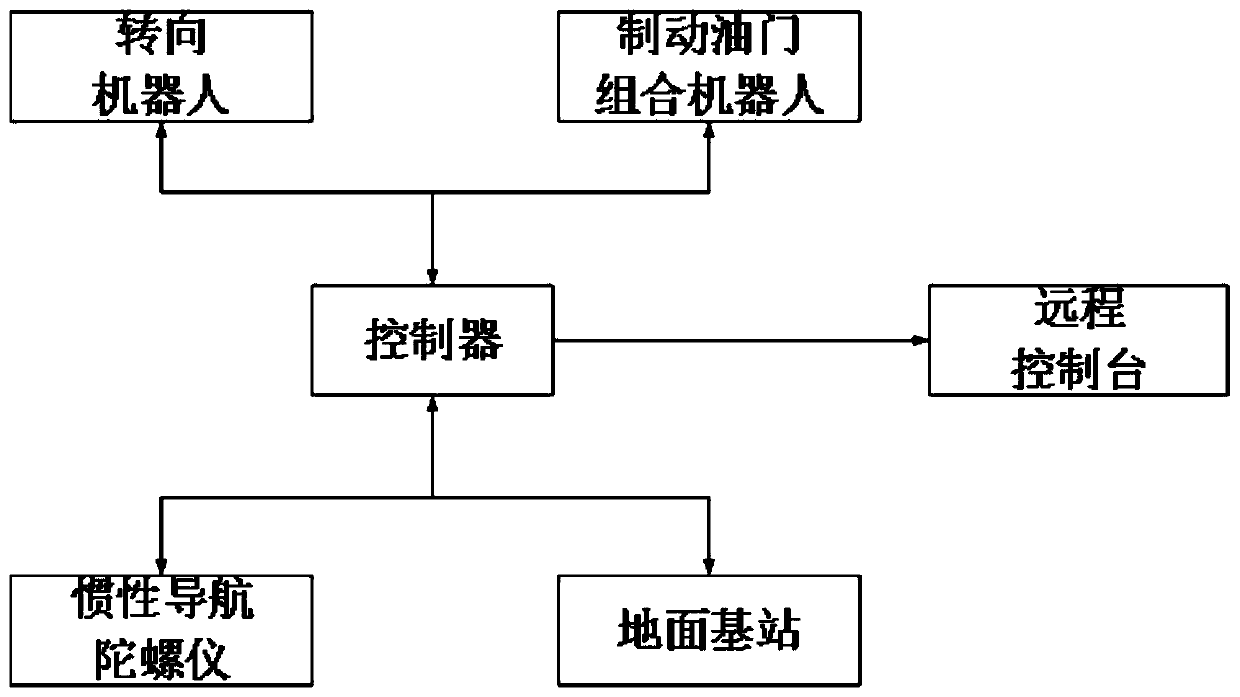

Unmanned vehicle remote control brake performance testing and assessment method

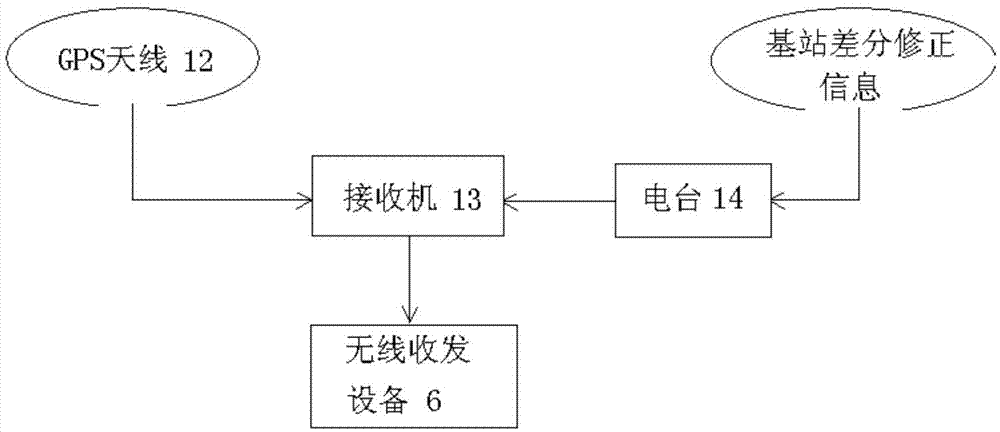

ActiveCN104502122AIntelligent brake braking performance is good or badEfficient collectionVehicle testingWireless transmissionInformation transmission

The invention discloses an unmanned vehicle remote control brake performance testing and assessment method. A judgment vehicle is adopted to perform comparison testing on the brake response time and speed of an unmanned vehicle, a GPS mobile station and a wireless transmitting-receiving device are arranged on the unmanned vehicle, a GPS mobile station and a wireless transmitting-receiving device are arranged on the judgment vehicle as well, another GPS base station is arranged, the GPS mobile stations are positioned in a GPS differential positioning mode, GPS information transmission is performed through the wireless transmitting-receiving device of the unmanned vehicle and the wireless transmitting-receiving device of the judgment vehicle, and GPS information is transmitted to a background Pc to perform calculation processing. The unmanned vehicle remote control brake performance testing and assessment method effectively solves the problem that at present, the unmanned vehicle remote control brake performance testing and assessment are difficult based on a differential positioning technology and a wireless transmission technology.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

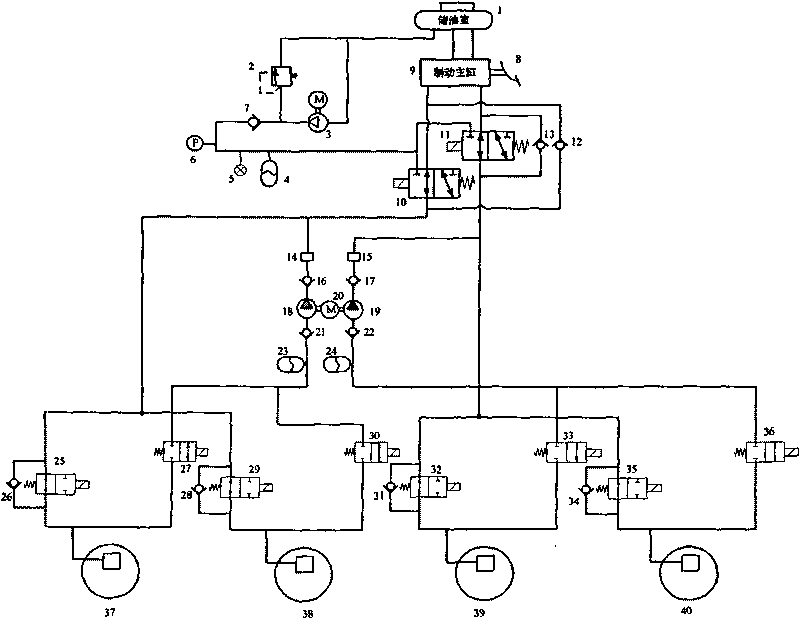

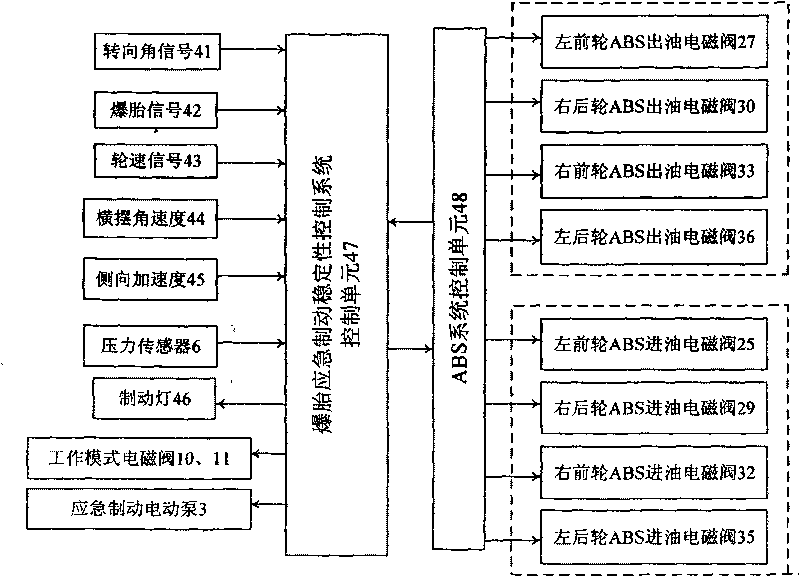

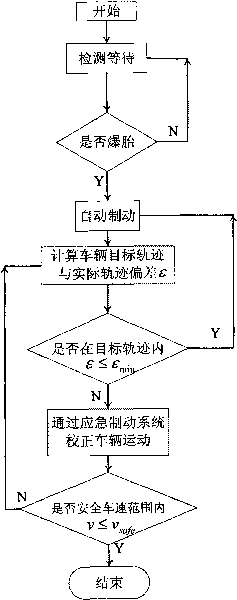

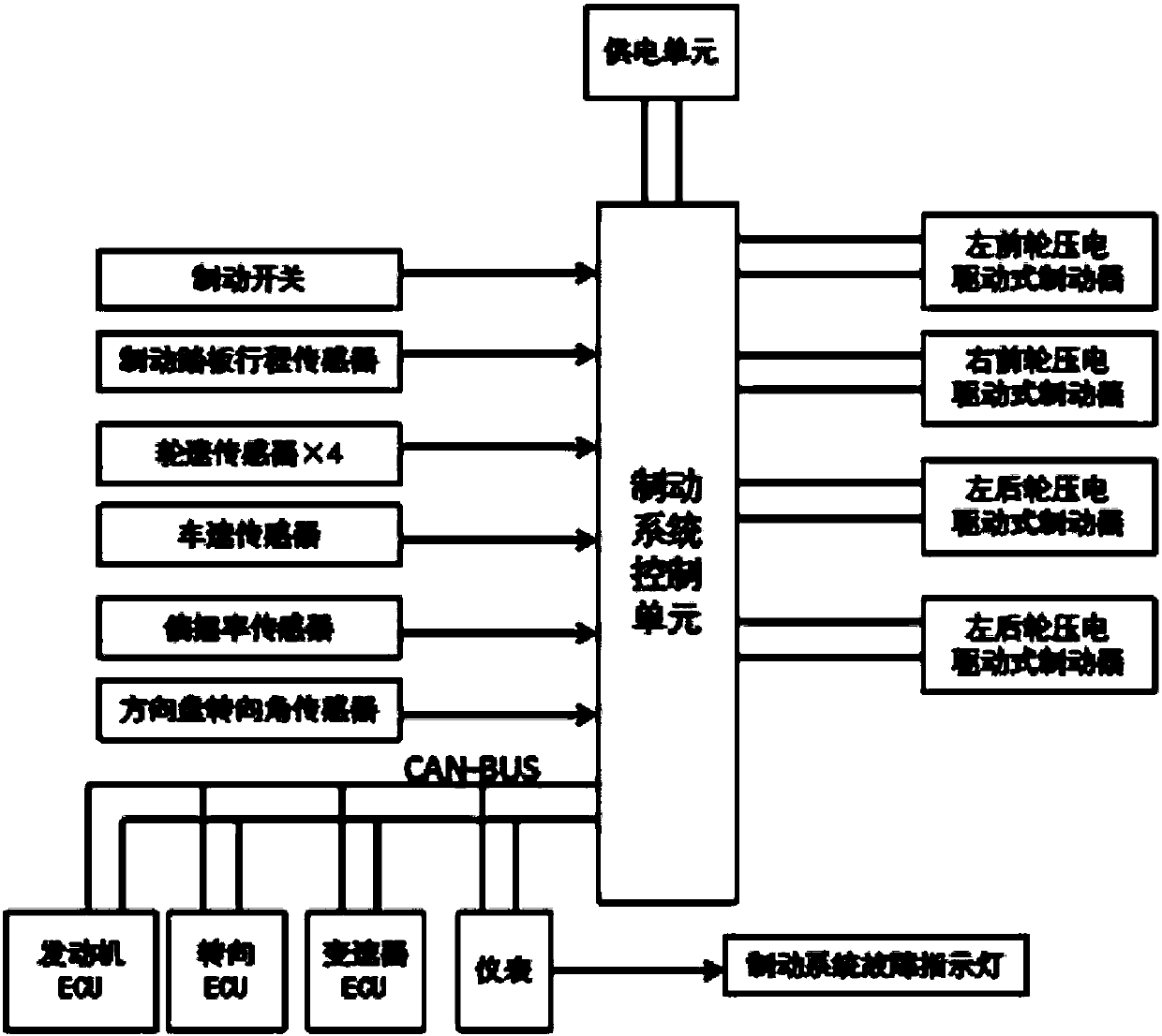

Automobile high-speed tire explosion emergency braking stability control system

InactiveCN101734243ACompensate for delayed brake reaction timesAchieve safe parkingAutomatic initiationsDelayed reaction timeControl system

The invention discloses an automobile high-speed tire explosion emergency braking stability control system, comprising a power source part of an automobile tire explosion emergency braking system, a control part of a tire explosion emergency braking stability system and a hydraulic anti-lock braking part. When a tire explosion signal is monitored by an automobile tire explosion monitoring system, an emergency braking mode is determined according to the tire explosion state (tire explosion target wheel orientation and number of tire explosion wheels) and the automobile motion state; an emergency braking system works to perform automobile automatic brake after tire explosion under the action of a working mode switching valve; and on the basis of a conventional hydraulic ABS hardware, the emergency braking control system unit is used for calculating the automobile motion state, sends an automobile stability control instruction to an ABS control unit to control and regulate the braking pressure in each wheel braking cylinder of an automobile, and ensures that the speed is lowered to a safe speed range until the automobile stops according to an anticipated automobile path as soon as possible. The system in the invention can remedy the delay problem of braking response time of a driver and assist the automobile with exploded tires to realize safe stopping.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

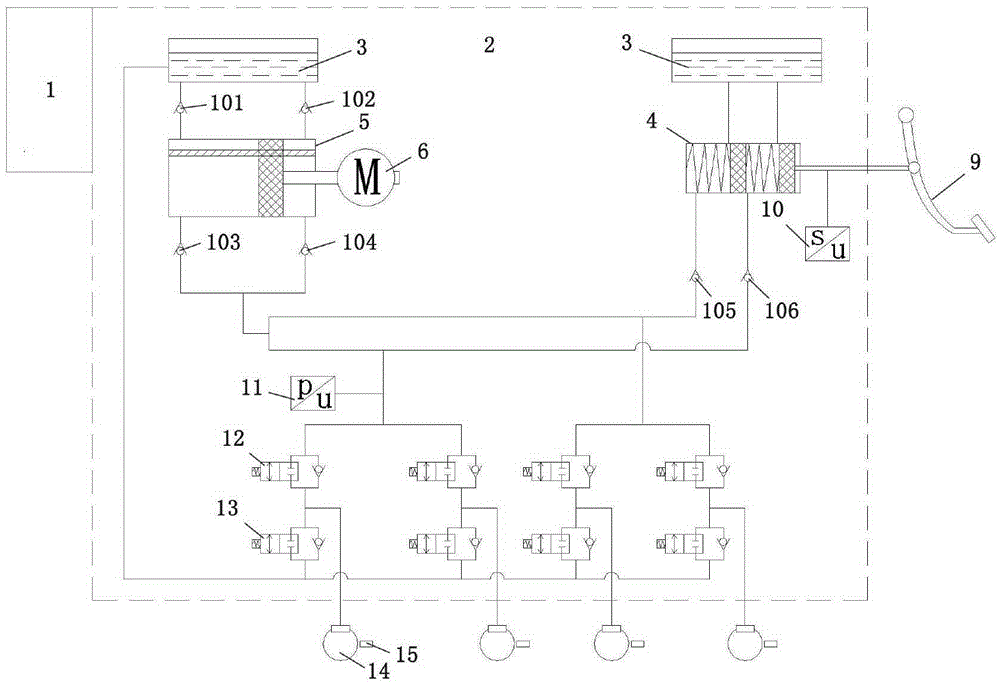

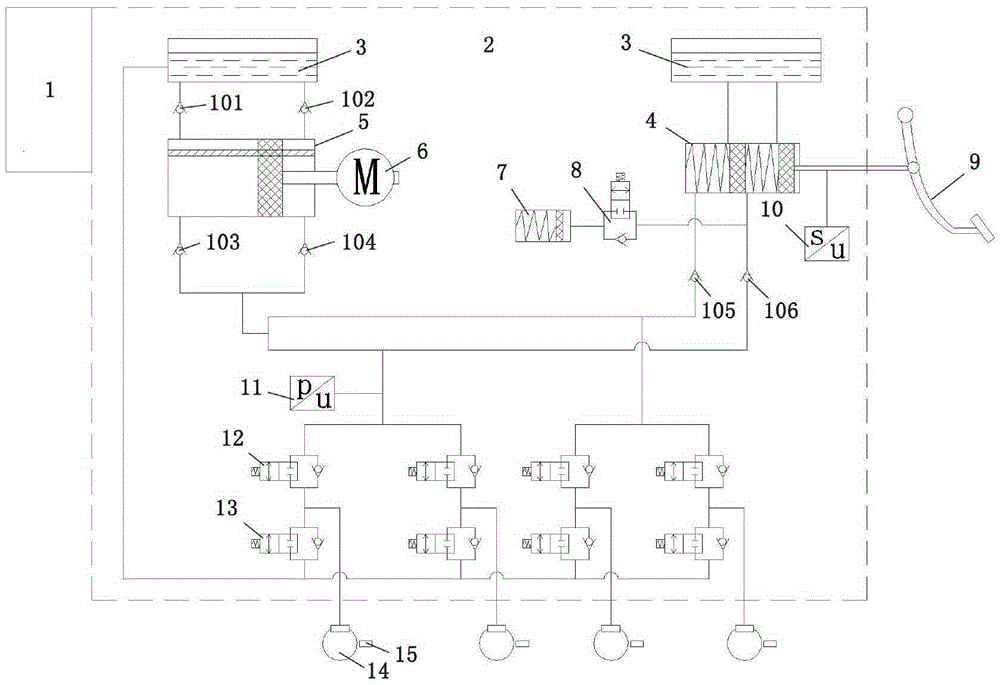

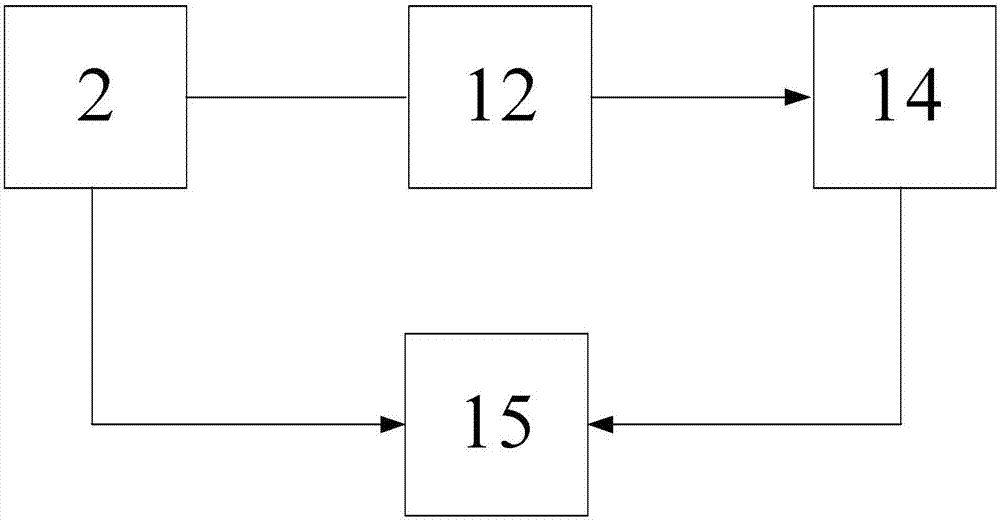

Integrated double-main-cylinder line control braking system

ActiveCN105346531AFast dynamic responseReduce in quantityBraking action transmissionMaster cylinderBrake response time

The invention relates to an integrated double-main-cylinder line control braking system. The system comprises an ECU electronic control unit, an electronic pedal, a pedal displacement sensor, a first braking passage, a second braking passage and a braking liquid loop. Double-main-cylinder design is adopted in the system, an assisting main cylinder, namely the second main cylinder is additionally arranged, pressure is applied through a motor and a lead screw instead of a plunger pump and an energy accumulator originally, a working cavity and a liquid supplementing cavity of the second main cylinder can be switched freely, the motor does not need to rotate forwards and reversely frequently, the service life of the motor is prolonged, and braking response time is shortened. Meanwhile, multiple braking manners can be provided through the system, especially in the micro-braking process, the assisting main cylinder does not work, a conventional main cylinder applies pressure, the working time of the motor is shortened, and the service life of the motor is prolonged.

Owner:ZHEJIANG WANXIANG PRECISION IND +1

Detection method of braking response time of brake of elevator

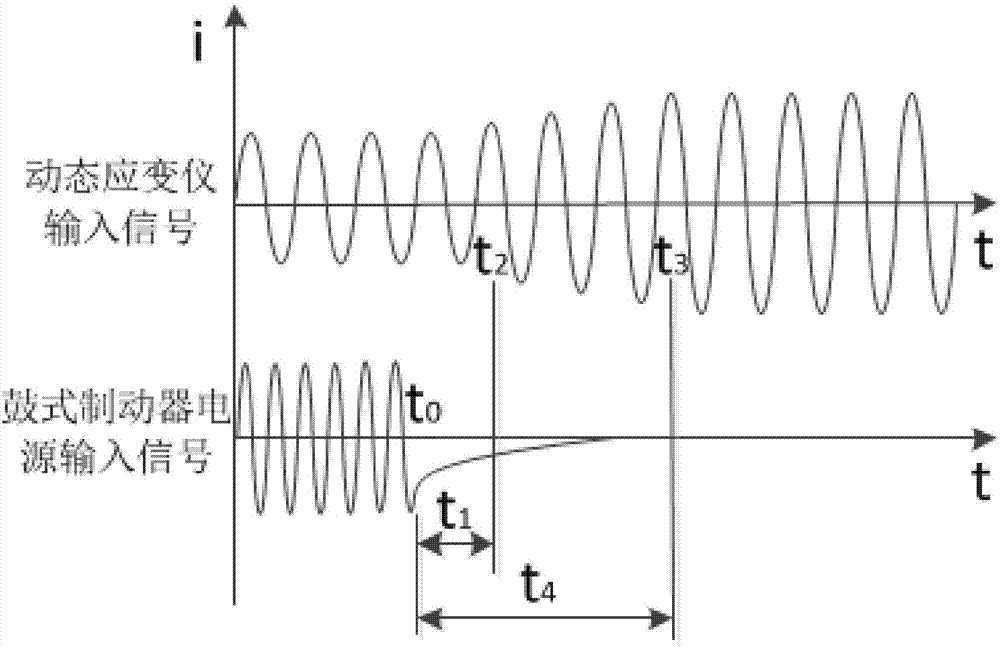

The invention discloses a detection method of braking response time of a brake of an elevator. A method for detecting the braking response time of the brake of the elevator by the aid of a band brake micro-switch is relatively large in error and low in accuracy. According to the method, a spring plate with a resistance strain gauge attached is additionally mounted at one end of each brake spring, when the brake performs braking, the compression amounts of the brake springs are gradually reduced, when the brake completes braking, the compression amounts of the brake springs are minimum, the strain of the spring plates is minimum at the moment, the strain of the resistance strain gauges is also minimum, the change of the brake springs is detected through the resistance strain gauges and strain indicators, the braking response time of the brake is the time difference between an outage signal and the minimum strain moment of the resistance strain gauges, and the time difference can be directly read through a two-channel oscillography recording instrument. The method has the very high detection accuracy and universality and is also easy to operate.

Owner:ZHEJIANG SCI-TECH UNIV

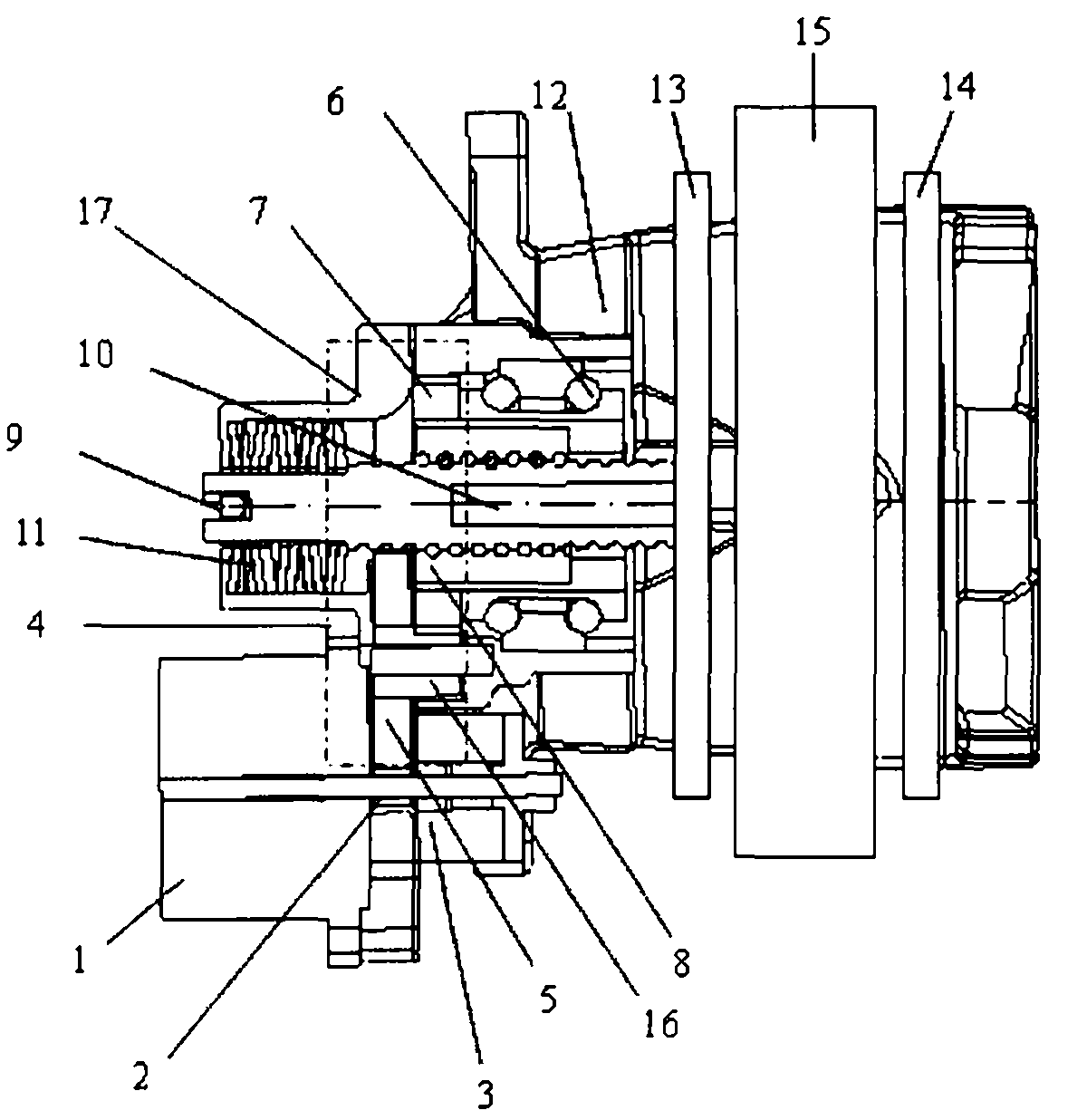

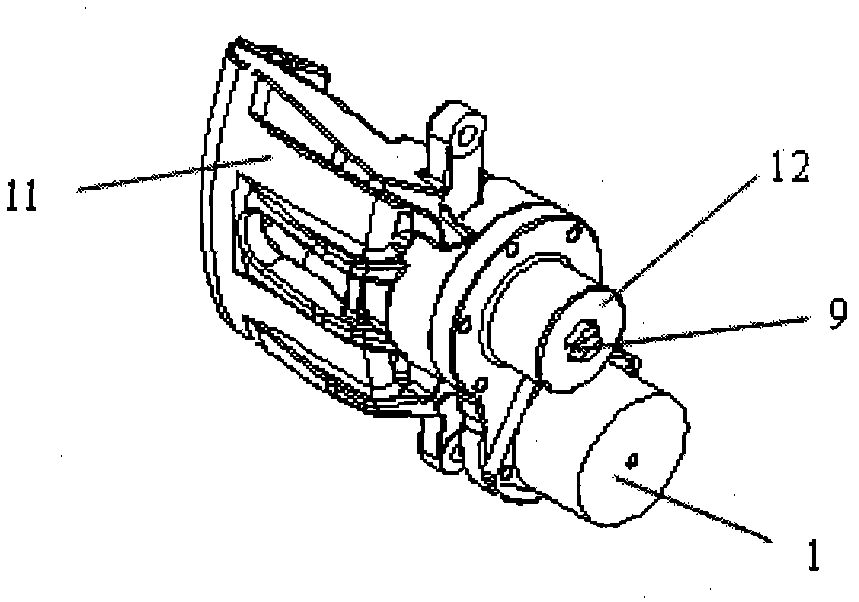

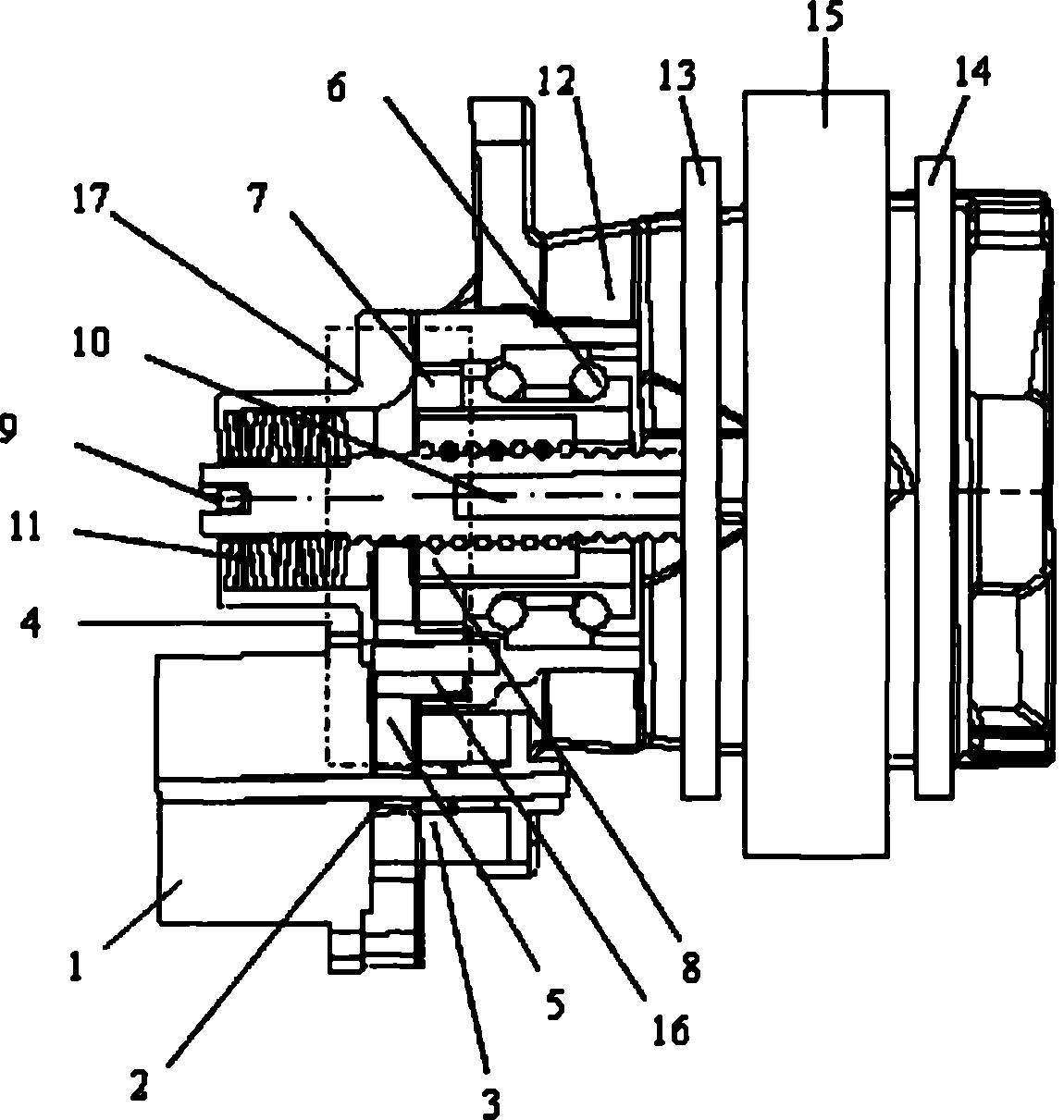

Electric brake and automobile

ActiveCN102518716AAvoid time delayAvoid wear and tearBrake actuating mechanismsActuatorsEngineeringBrake response time

The invention provides an electric brake, comprising a shell (17), a brake disc (15), a brake block and a power mechanism which can push the brake block to move forwards so as to clamp the brake disc, wherein the power mechanism comprises a motor (1) and a movement mechanism which is connected with an output end of the motor, the movement mechanism can transform the rotating movement of the motor into straight line movement, and the brake block is arranged in front of the movement mechanism. The electric brake is characterized in that: the power mechanism also comprises a torque amplification mechanism which is arranged between the motor and the movement mechanism, an input end of the torque amplification mechanism is connected with the output end of the motor, and an output end of the torque amplification mechanism is connected with the movement mechanism. The electric brake is compact in structure, is short in brake response time and can generate greater brake clamping force.

Owner:CHERY AUTOMOBILE CO LTD

Pressure control method for brake cylinder of magnetically levitated train

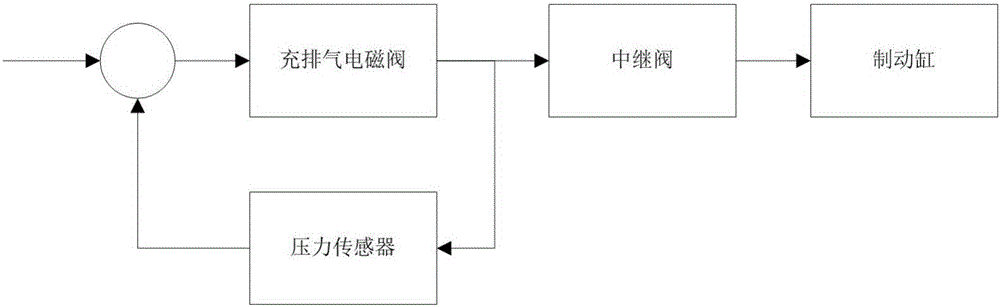

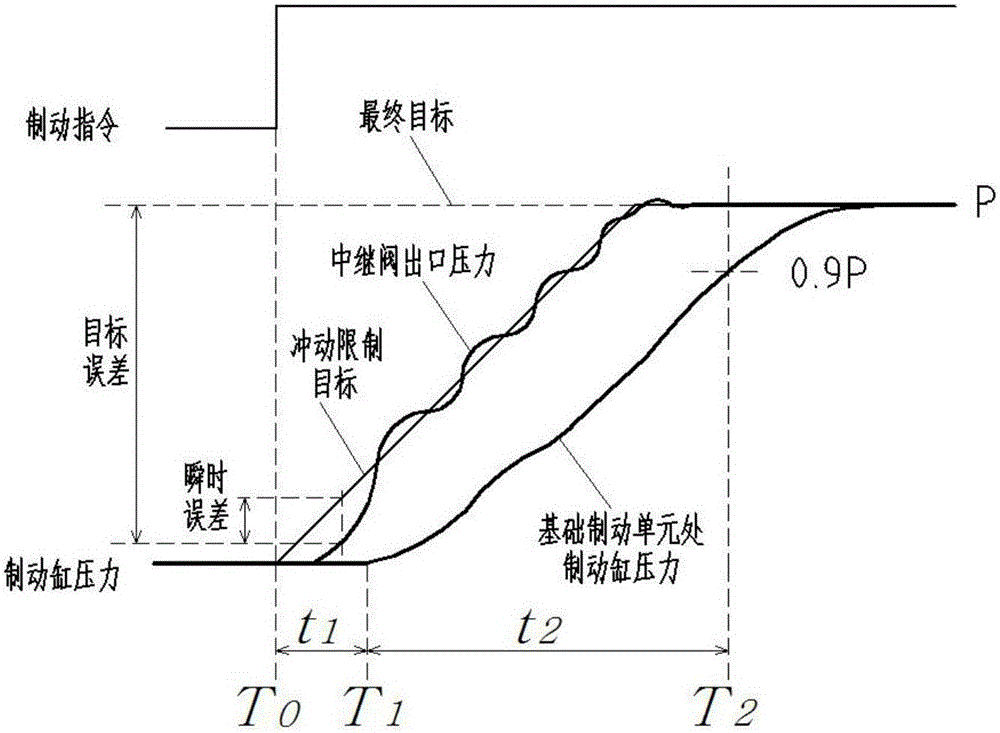

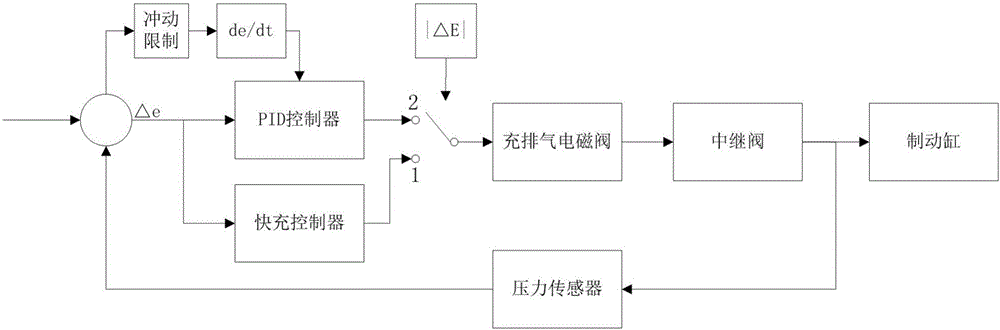

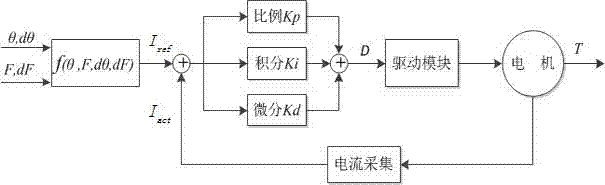

InactiveCN105946838AImprove steady state performanceEasy to controlRailway hydrostatic brakesRailway hydrodynamic brakesControl theoryBrake response time

A pressure control method for a brake cylinder of a magnetically levitated train comprises the steps that the error between an actual value of the brake cylinder pressure and a final target value of the brake cylinder is worked out and recorded as a target error; the error between the actual value of the brake cylinder pressure and a target value of the impulse limit of the brake cylinder is worked out and recorded as a transient error; a first threshold value and a second threshold value are set; when the target error is larger than the first threshold value, an inflating and deflating electromagnetic valve is opened normally; when the target error is larger than the second threshold value but smaller than the first threshold value, the open time of the inflating and deflating electromagnetic valve during one control cycle is adjusted according to the transient error and recorded as a rough adjusted duty ratio; when the target error is smaller than the second threshold value, the open time of the inflating and deflating electromagnetic valve during one control cycle is adjusted according to the transient error and recorded as a fine adjusted duty ratio; and the rough adjusted duty ratio is larger than the fine adjusted duty ratio. The method is conducted based on the target pressure and the impulse limit target, on the premise that the impulse limit target and the target pressure of the brake cylinder are met, more precise control can be achieved, the brake response time is shortened, the brake distance is decreased, and the steady-state performance of the brake cylinder is improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

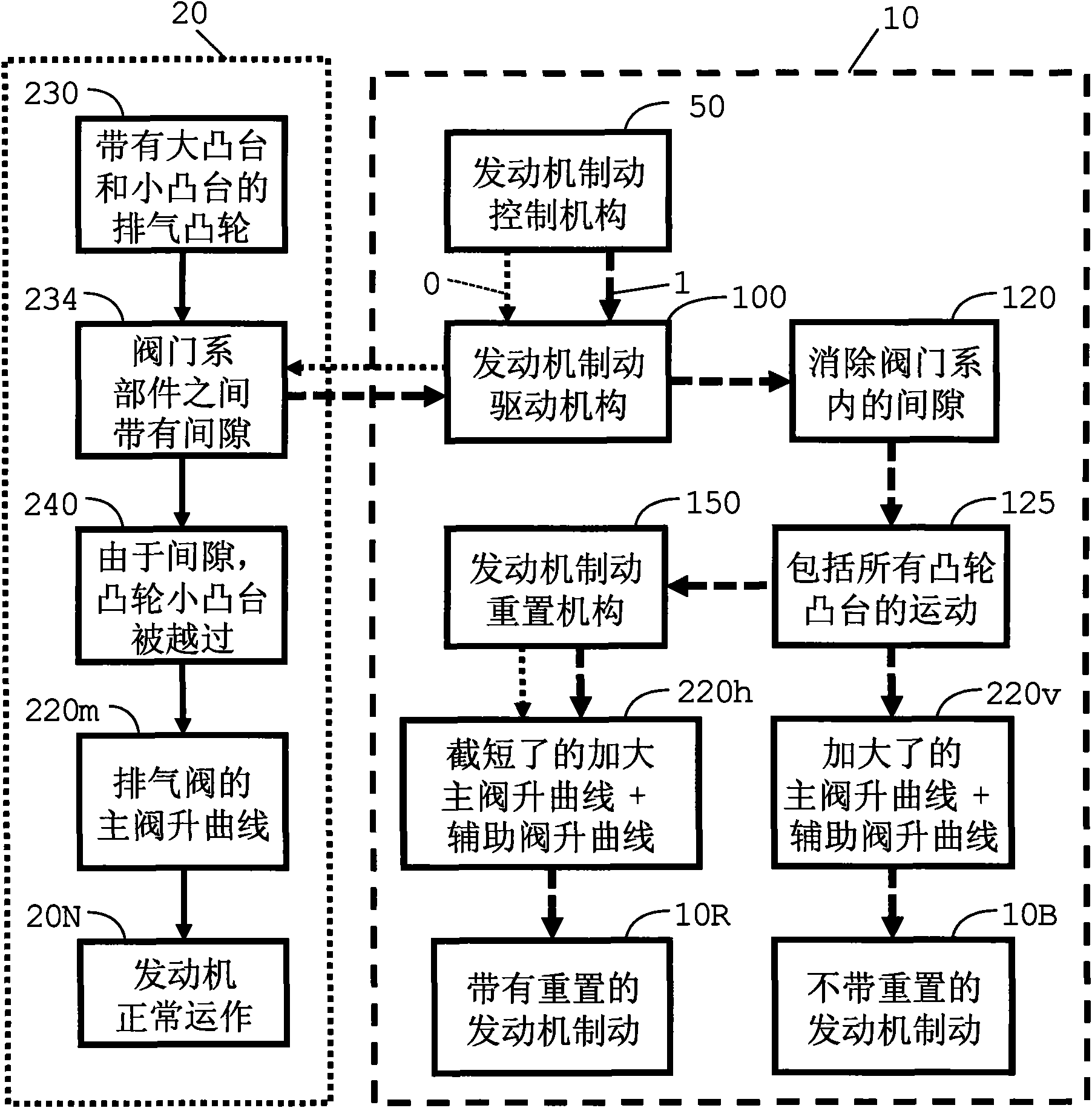

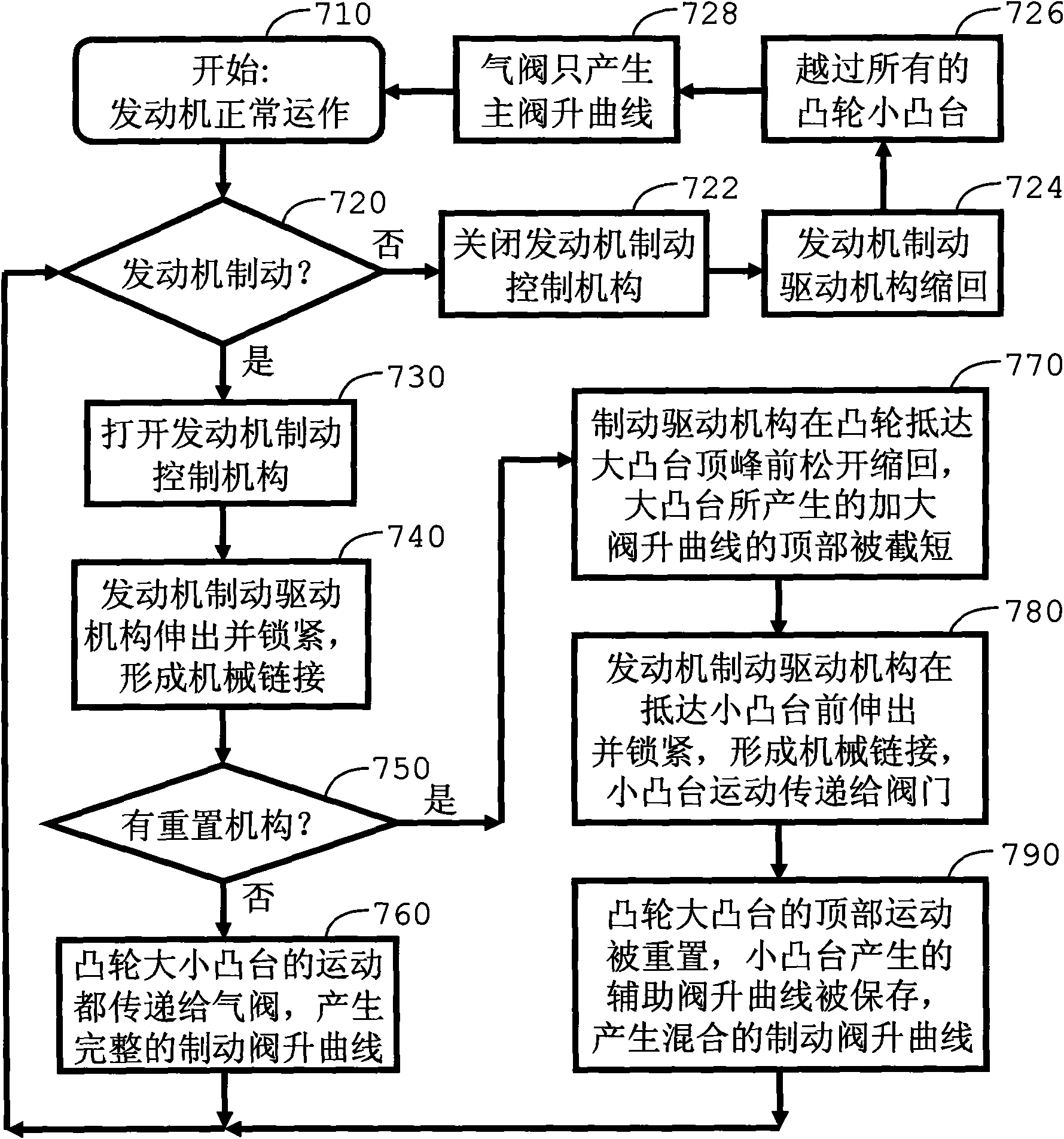

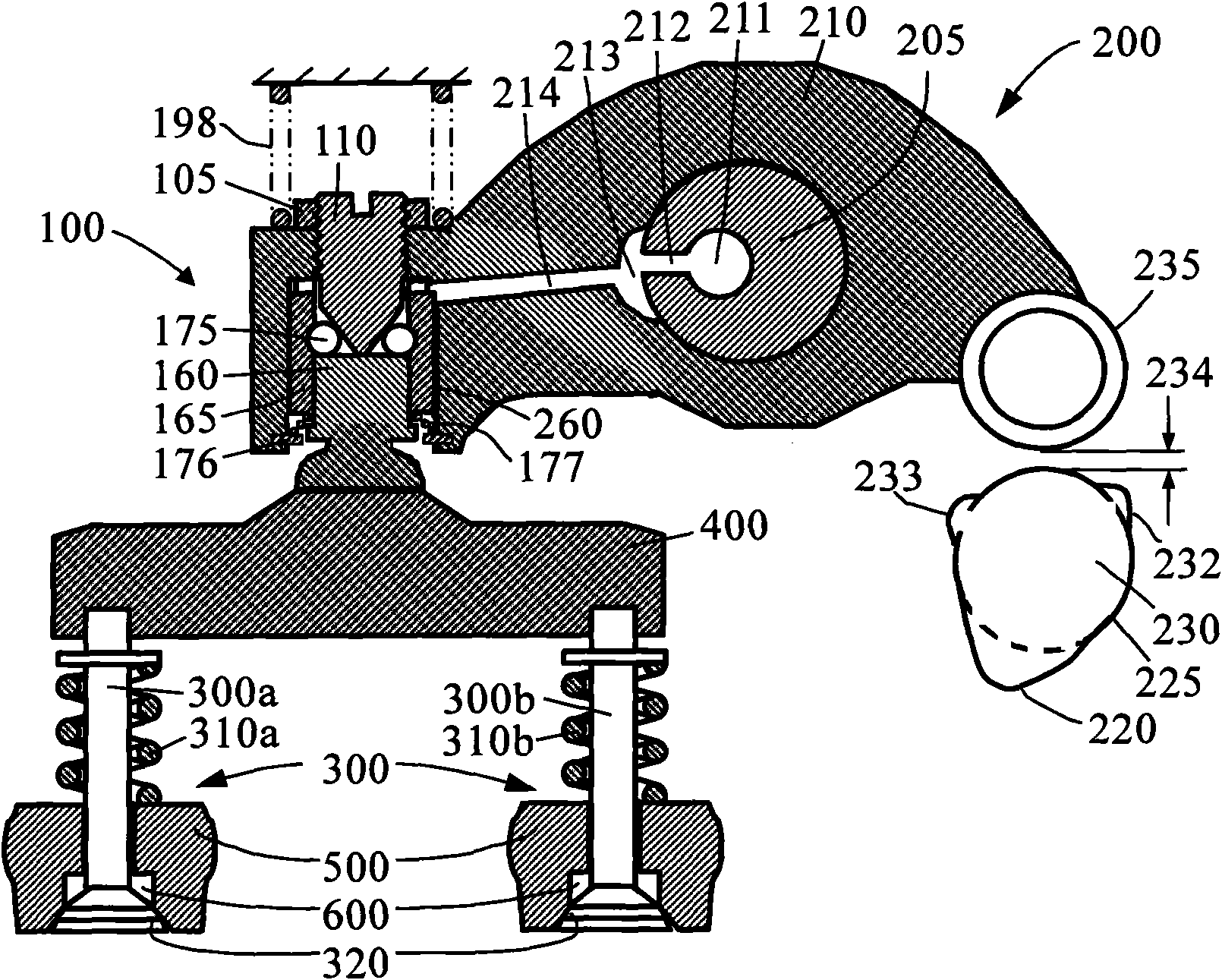

Integrated engine braking device with mechanical chaining and method for changing movement of engine air valve

ActiveCN101769185AShort reaction timeGuaranteed uptimeValve arrangementsMachines/enginesEngine valveBrake response time

The invention discloses an integrated engine braking device (engine retarder) with mechanical chaining and a method for changing the movement of an engine air valve. A driving mechanism of the device is partially or completely integrated in one or more components of a vent valve train of the engine and can move between a non-operating position and an operating position. On the non-operating position, the driving mechanism retracts and is separated from the normal operation of the engine; and on the operating position, the driving mechanism extends out to form mechanical chaining, and the vent valve of the engine is opened to generate the operation of braking the engine. On the top of the valve lift curve, the resetting mechanism of the device leads the driving mechanism to retract from an extending position so that the valve lift curve can be reset to be small. The invention also provides a method for changing the movement of the engine air valve, comprising the steps of operating and resetting the braking device. The device adopts the mechanical chaining, has simple structure and reliable running, avoids the problem of great compression of hydraulic chaining and reduces the braking response time.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

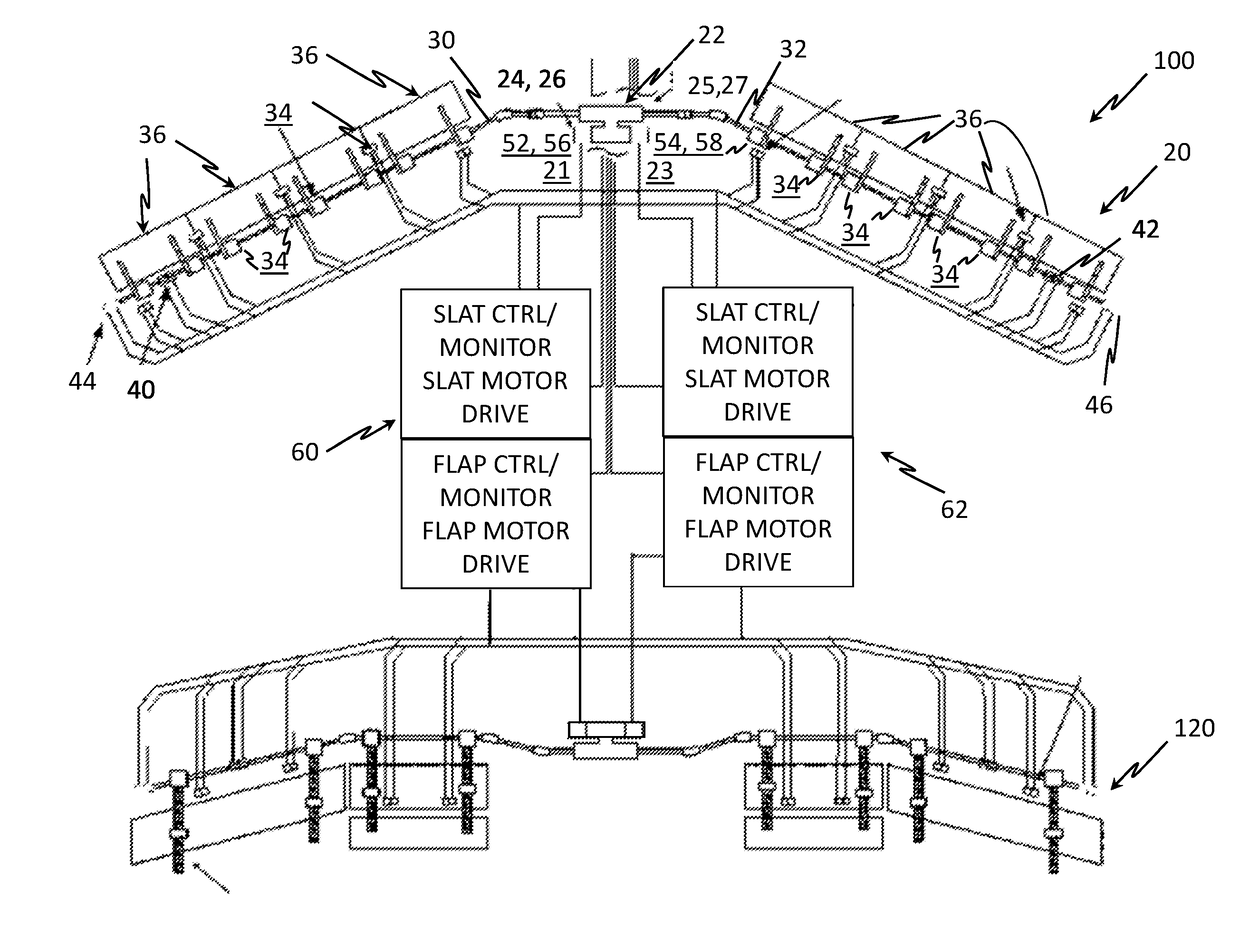

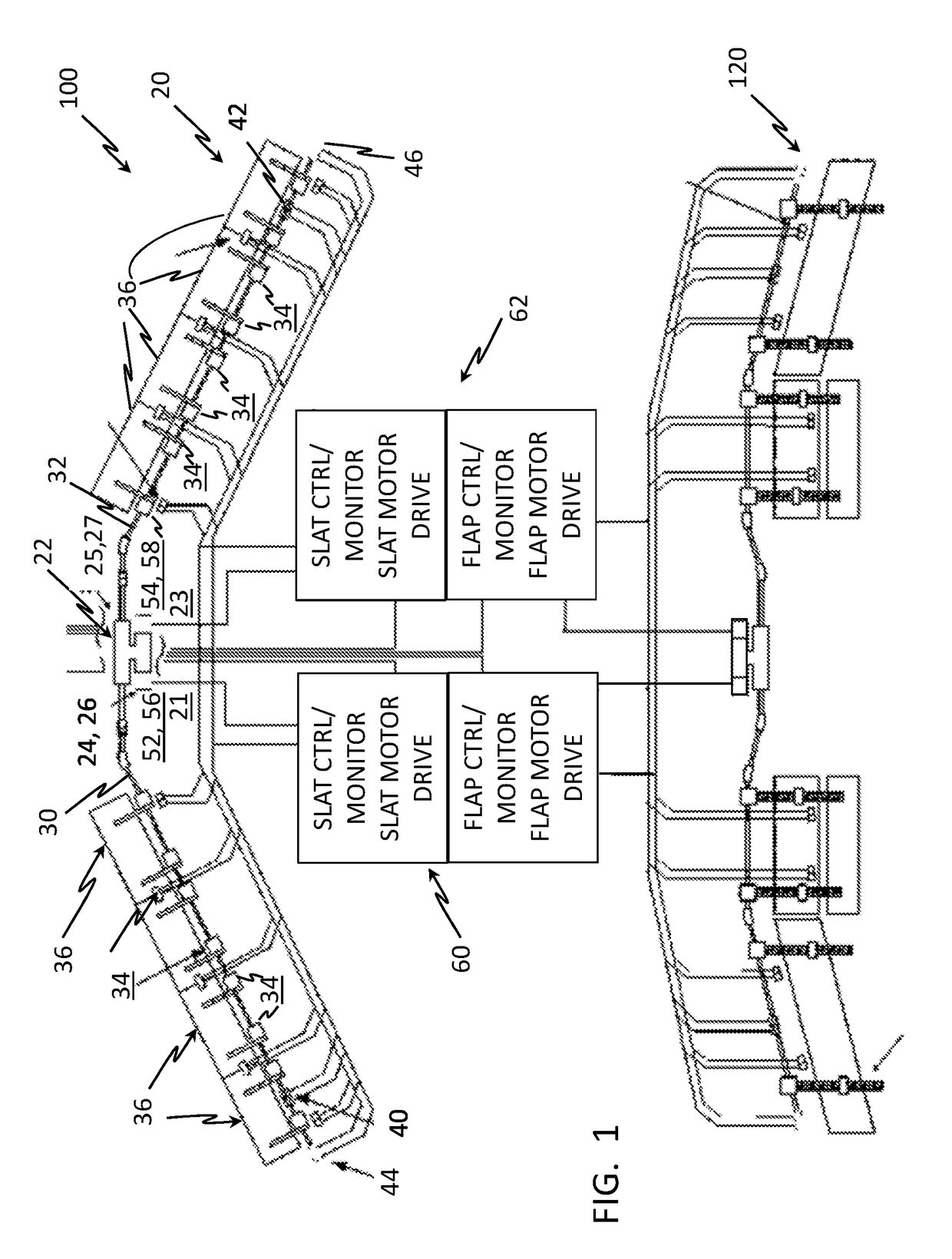

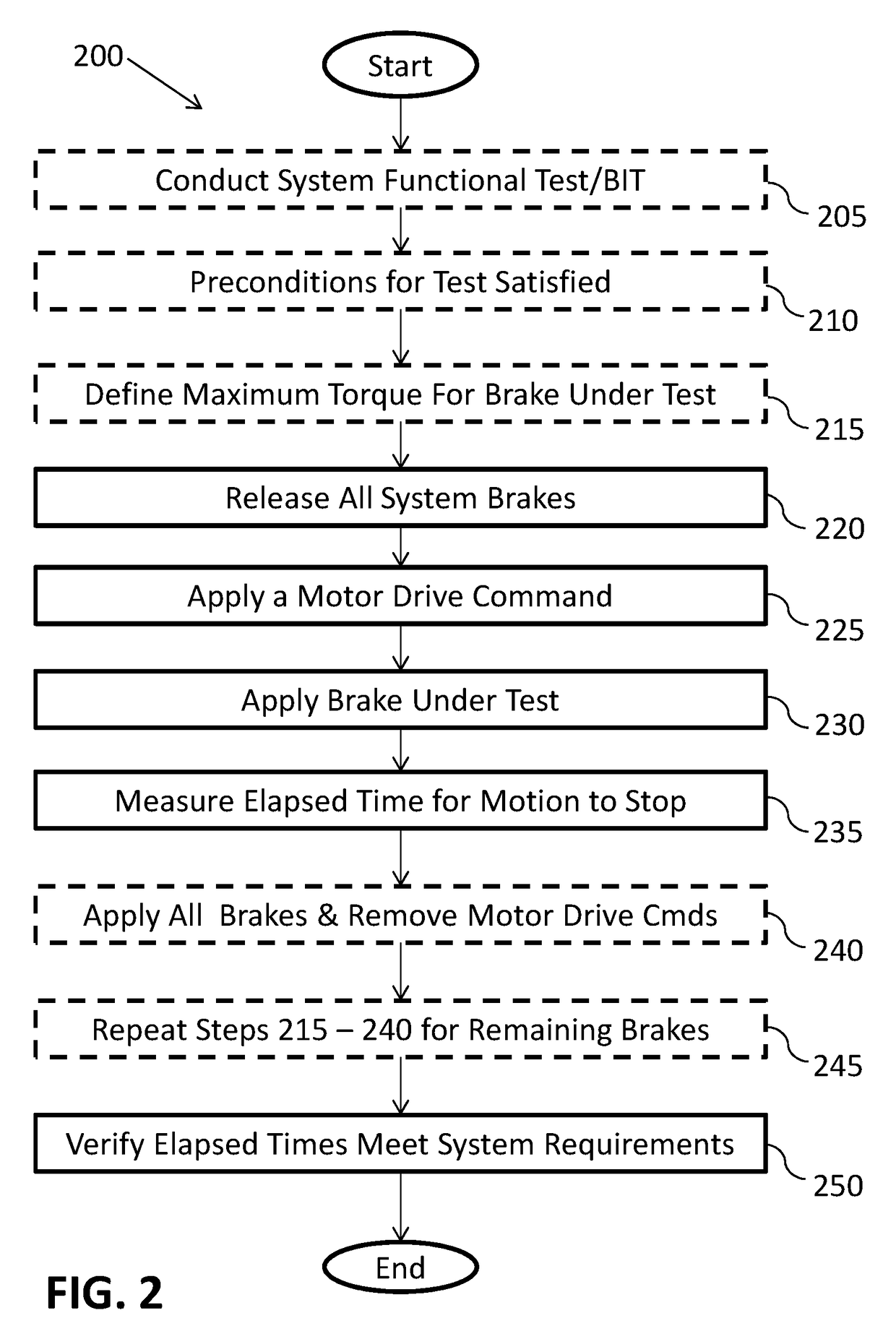

Method to measure aircraft high-lift system brake response time

A braking test for a high lift system. The system including a plurality of high lift surfaces movably arranged at a wing, a plurality of drive stations coupled with the high lift surfaces via a transmission shaft, a power drive unit coupled with the transmission shaft including an electric motor operably coupled with a brake, and a control unit operably coupled to the power drive unit. The control unit executing a method for testing the brake, including actuating an electric motor, acquiring a sensor output of a sensor coupled during the actuating of the motor and determining a motion of the motor, activating a selected brake under test, measuring an elapsed time until the brake has arrested the motion, and determining if the elapsed time is less than a threshold. Generating a brake failure signal for the selected brake if the elapsed time exceeds the threshold.

Owner:HAMILTON SUNDSTRAND CORP

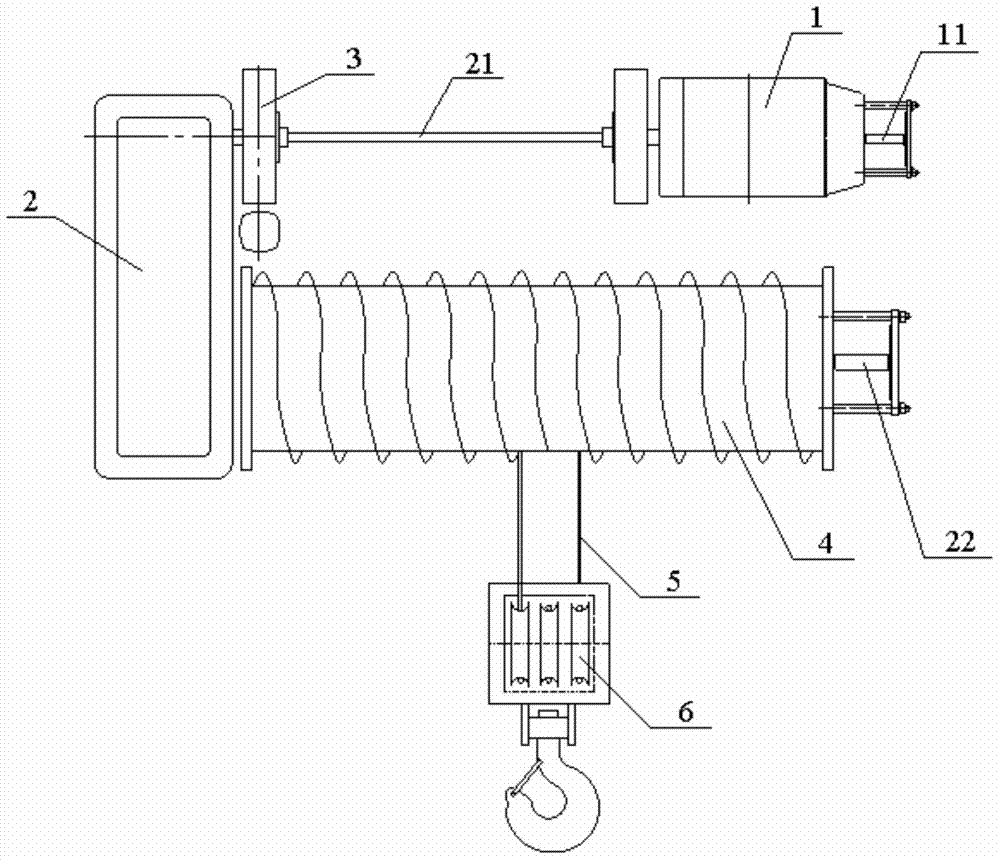

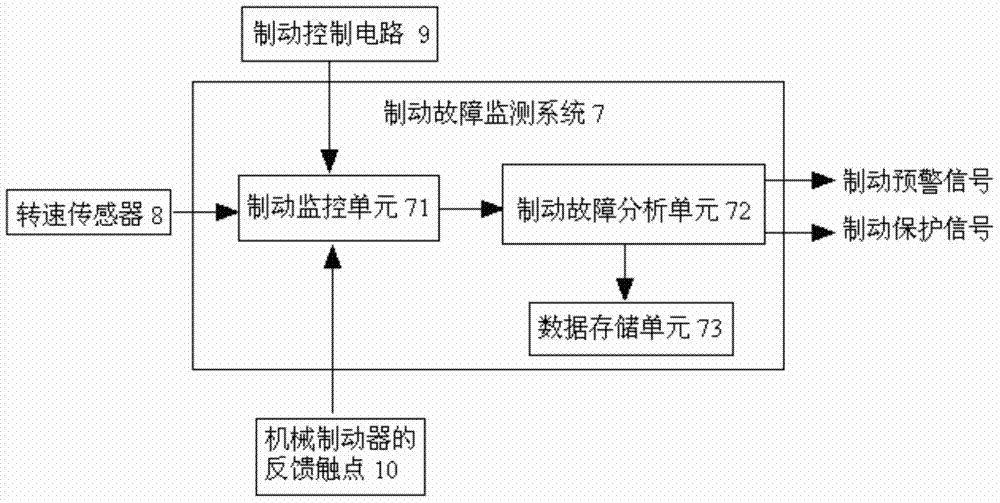

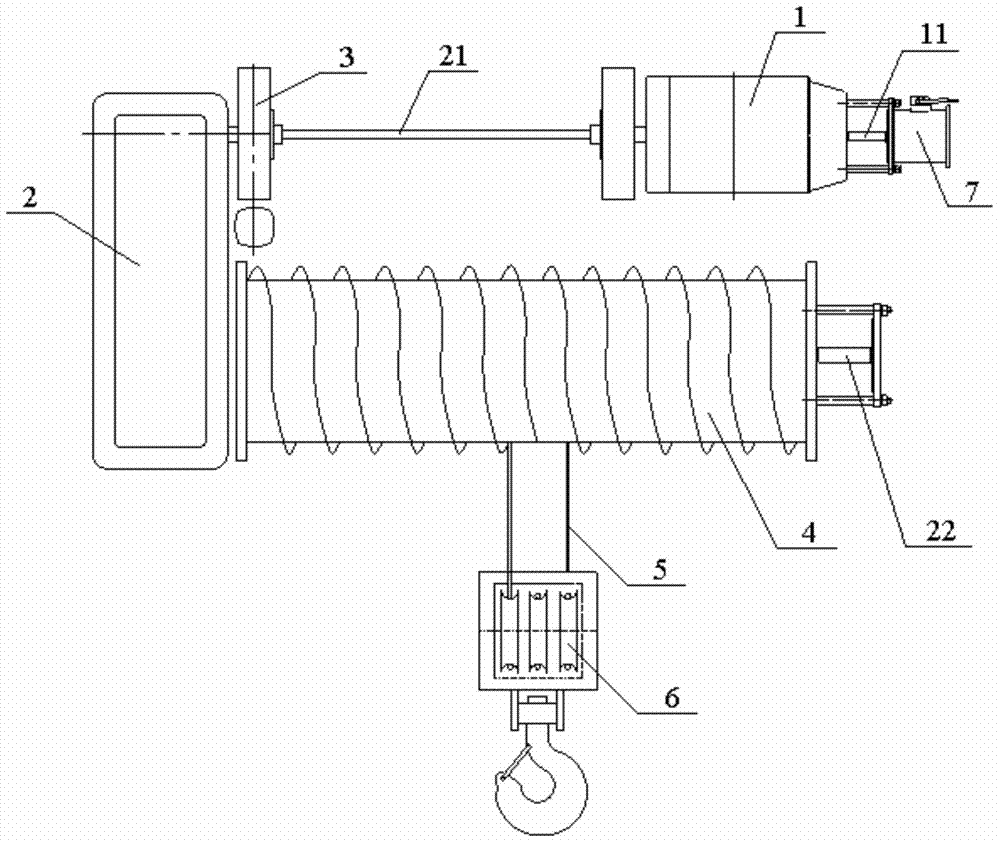

Monitoring method of braking fault of elevating mechanism in crane

The invention discloses a monitoring method of a braking fault of an elevating mechanism in a crane. In the method, calculation of a braking time, a braking response time, a braking distance and a braking acceleration are carried out with installation of a braking fault monitoring system on the elevating mechanism in the crane, through detection of rotational speed and the number of rotation of a high-speed shaft or a low-speed shaft of the elevating mechanism, and by means of output of a braking control signal from a braking control circuit to a mechanical brake and output of a time point of a brake feedback signal from a feedback contact in the mechanical brake; and then differences between the four calculation values and a preset hidden danger threshold value, an early warning time threshold value and a fault threshold value are analyzed, thereby obtaining brake early warning or brake protection signals. The monitoring method can not only achieve early warning of a fault hidden danger of the brake system and protection of the fault, which is beneficial to elimination of the fault within an earlier stage for avoiding accidences; but also being beneficial for maintainers to quickly detect the fault with cooperation of positioning a fault point, thereby reducing a maintaining time.

Owner:SHANGHAI EECTRL ELECTRIC

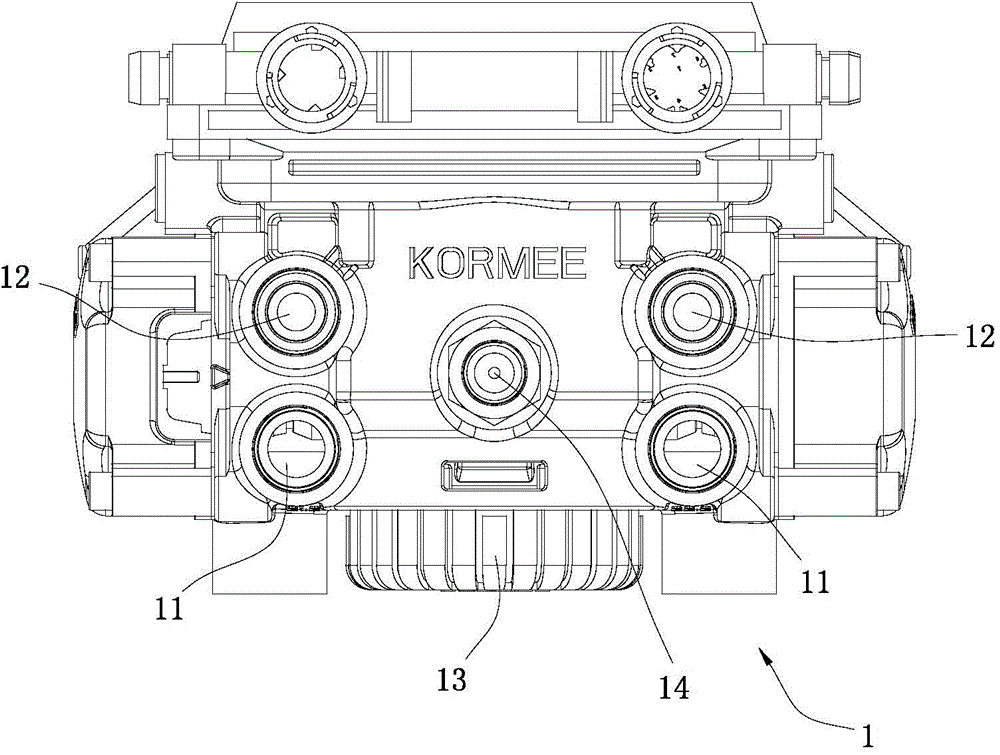

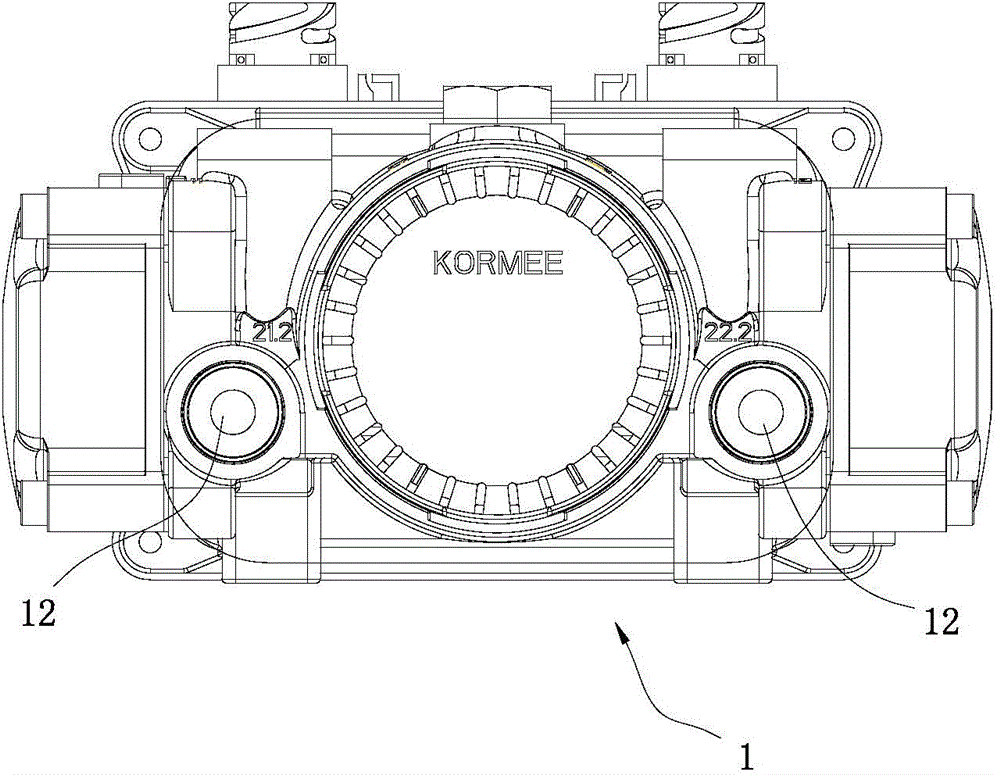

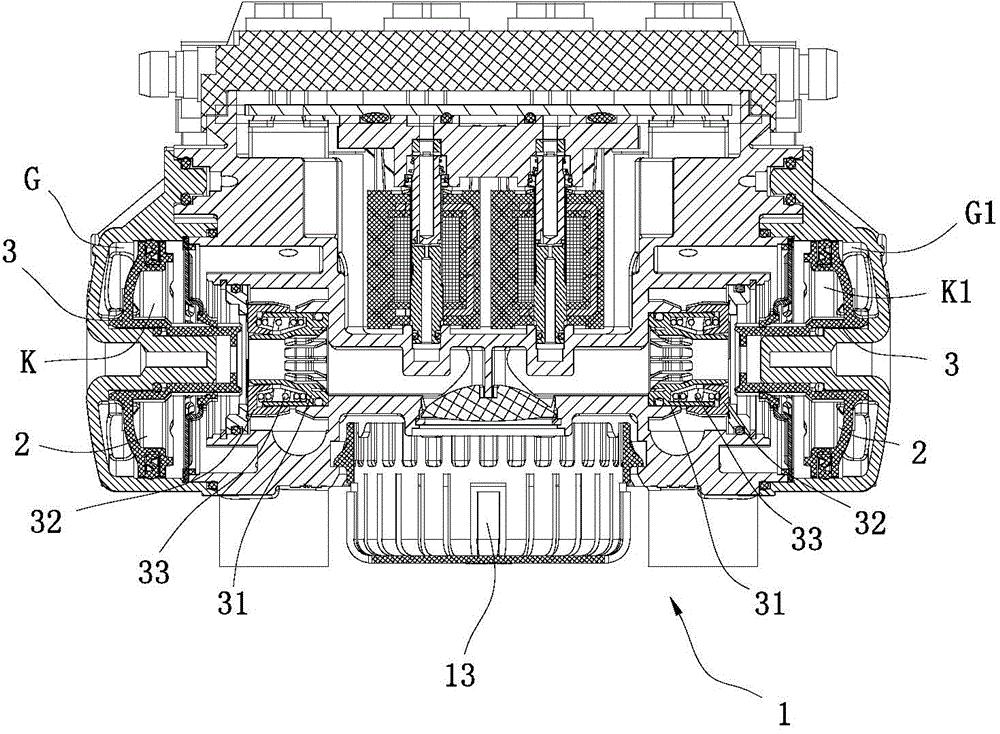

Electronic control relay valve assembly of anti-lock brake system

InactiveCN104309601APedal responsiveAccurate judgmentABS control systemsApplication and release valvesDriver/operatorSolenoid valve

The invention discloses an electronic control relay valve assembly of an ABS (anti-lock brake system). The electronic control relay valve assembly of the ABS comprises a valve body and a solenoid valve group; a pressure sensor used for detecting the pressure of brake air chambers is arranged in the valve body; the valve body comprises two main air inlets, four air outlets and an exhaust port; two air chambers are symmetrically distributed in the valve body; one of the two brake chambers is respectively communicated with one of the two main air inlets, two of the four air outlets and the exhaust port; a valve capable of controlling whether the main air inlet is communicated with the corresponding air outlets or not is arranged in each air chamber; a main control piston capable of abutting on the corresponding valve is arranged in each air chamber; the valves are controlled by the solenoid valve group connected with the valve body; the internal valve operation of the valve body is controlled through the solenoid valve group, and the pressurization working condition, the pressure-maintained working condition and the pressure-reduced working condition are realized through an internal logic operation method and threshold value control; the electronic control relay valve assembly is adapted to various working conditions; as an electronic control air brake vehicle is adopted, the reaction to stepping of a driver is more sensitive, and judgment on brake performance is more accurate; brake can be realized more rapidly, and the defects that the mechanical brake response time is slow, the brake comfort is poor and the like are eliminated.

Owner:GUANGZHOU KORMEE AUTOMOTIVE ELECTRONICS CONTROL TECH

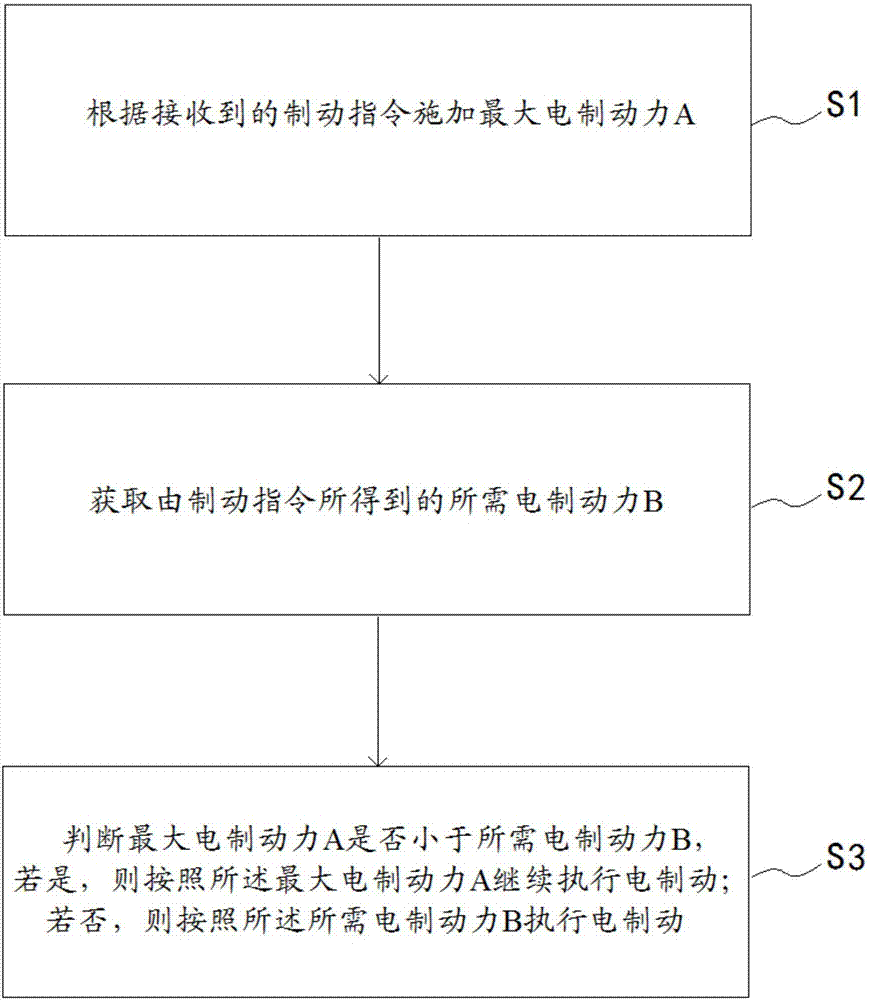

Maglev train and braking control system and method thereof

ActiveCN107444371ASolve the problem of energy consumptionSolve the costBraking action transmissionElectrodynamic brake systemsElectricityHigh energy

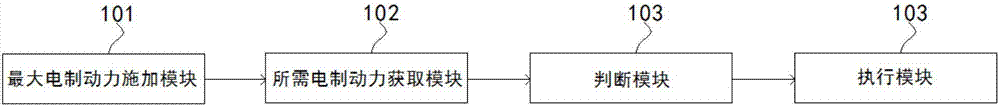

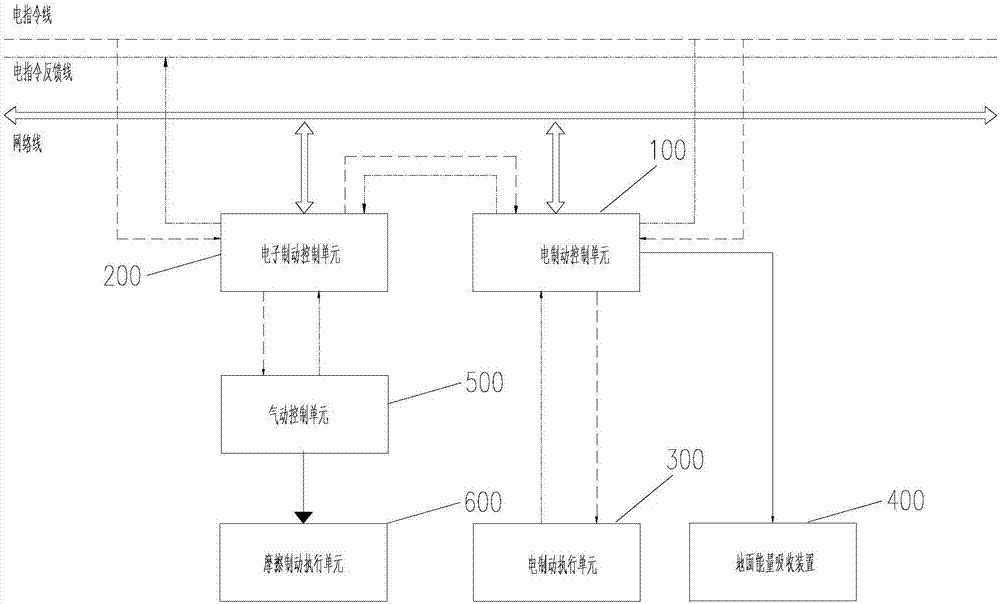

The invention discloses a braking control method for a maglev train. The braking control method comprises the steps that the maximum electric braking force A is applied according to a received braking instruction; required electric braking force B obtained by the braking instruction is acquired; and whether the maximum electric braking force A is smaller than the required electric braking force B or not is judged, if yes, electric braking continues being carried out according to the maximum electric braking force A, and if no, electric braking is carried out according to the required electric braking force B. The invention further discloses a braking control system for the maglev train and the maglev train comprising the braking control system. According to the braking control method, the problems that according to an existing method, the braking response time is long, and electric braking is not fully utilized can be solved, the braking response time and the braking distance can be shortened, the advantages of electric braking is given to maximum play, accordingly the safety of the system is improved, and the problems of high energy consumption and high maintenance cost are solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

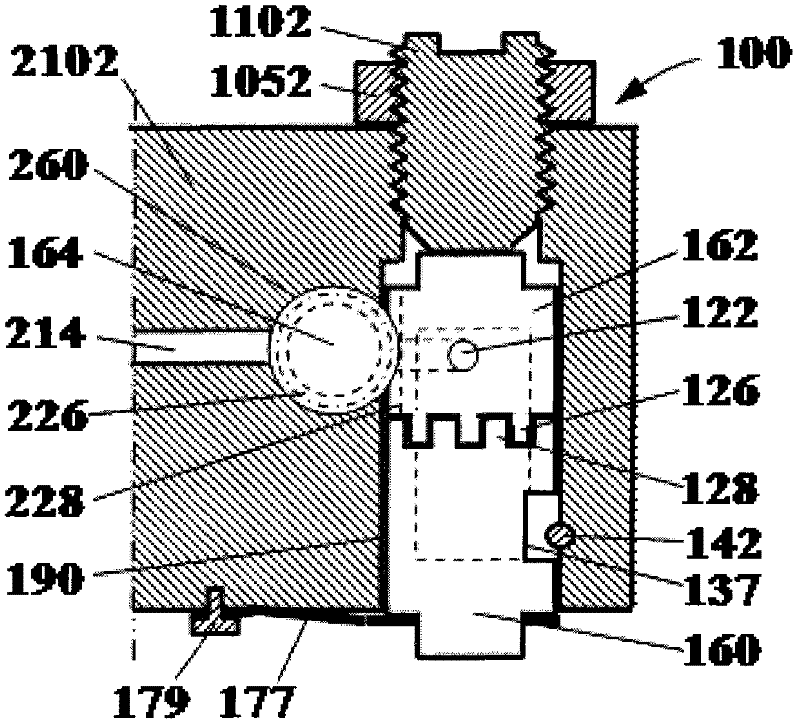

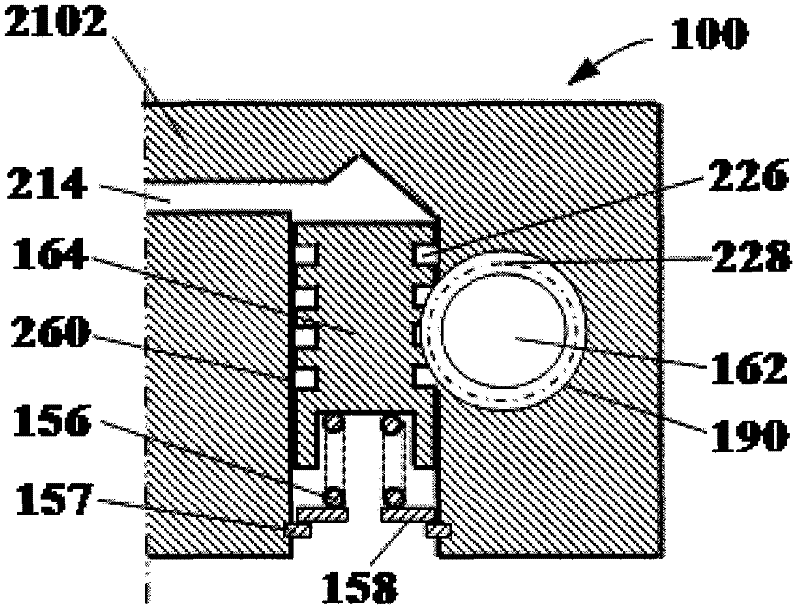

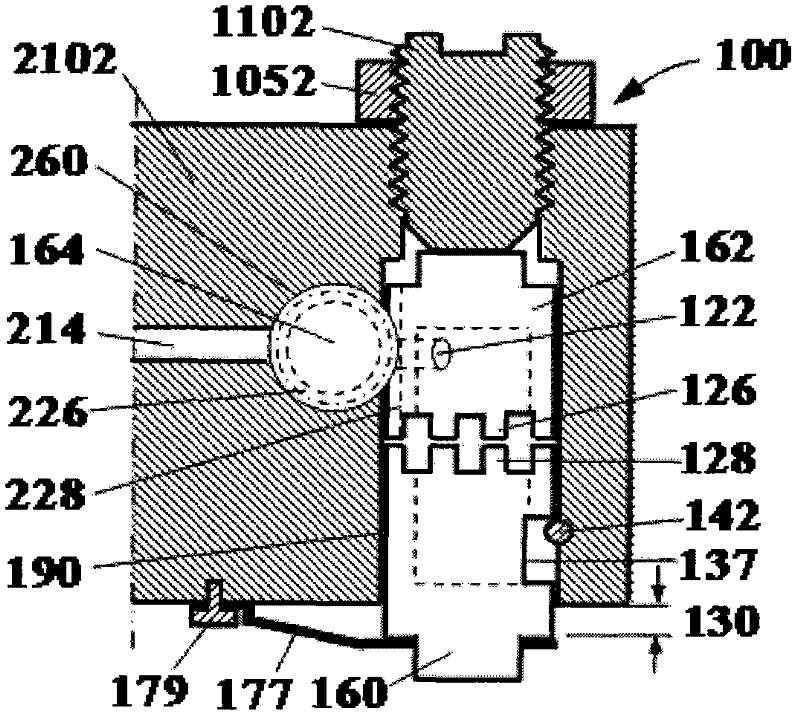

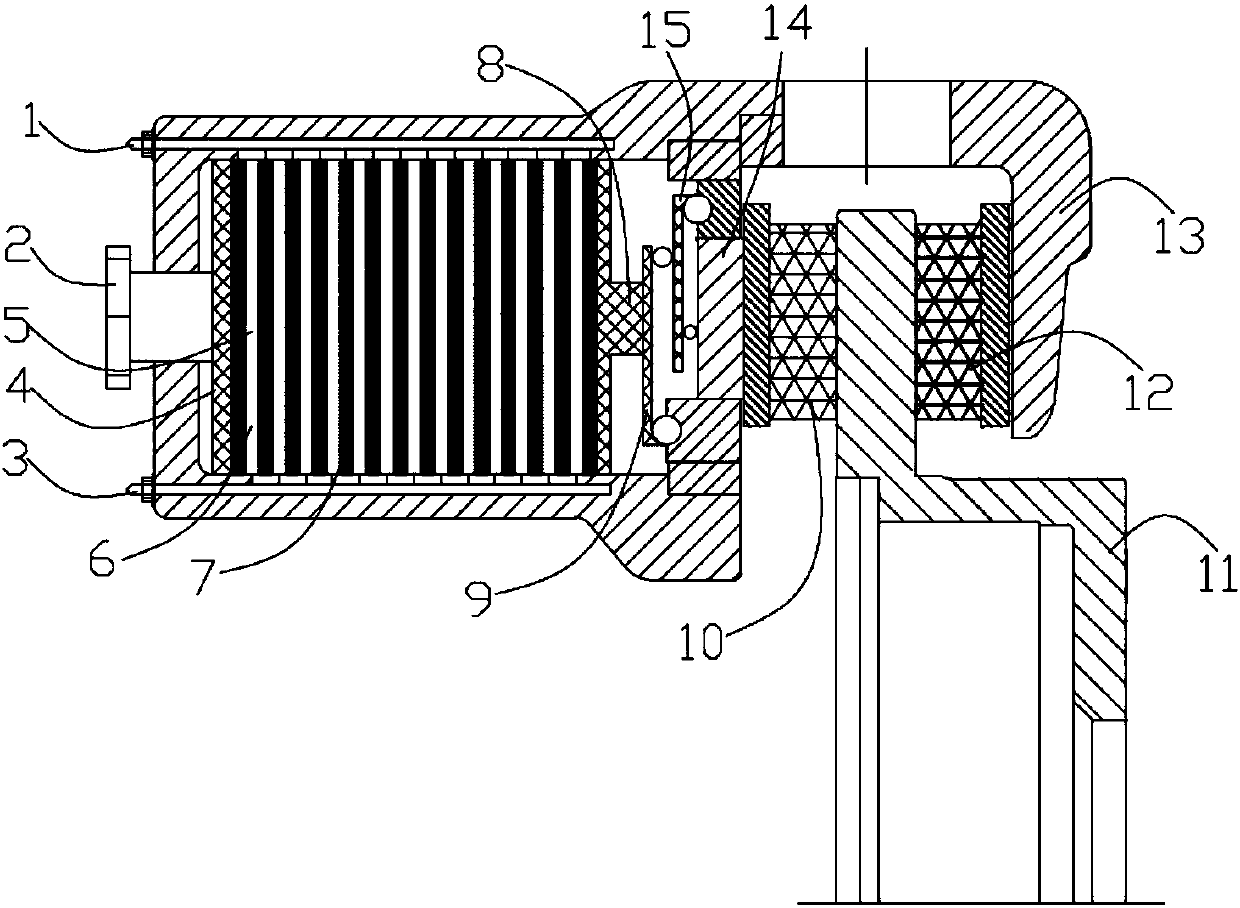

Electric power-assisted braking system used for automobile

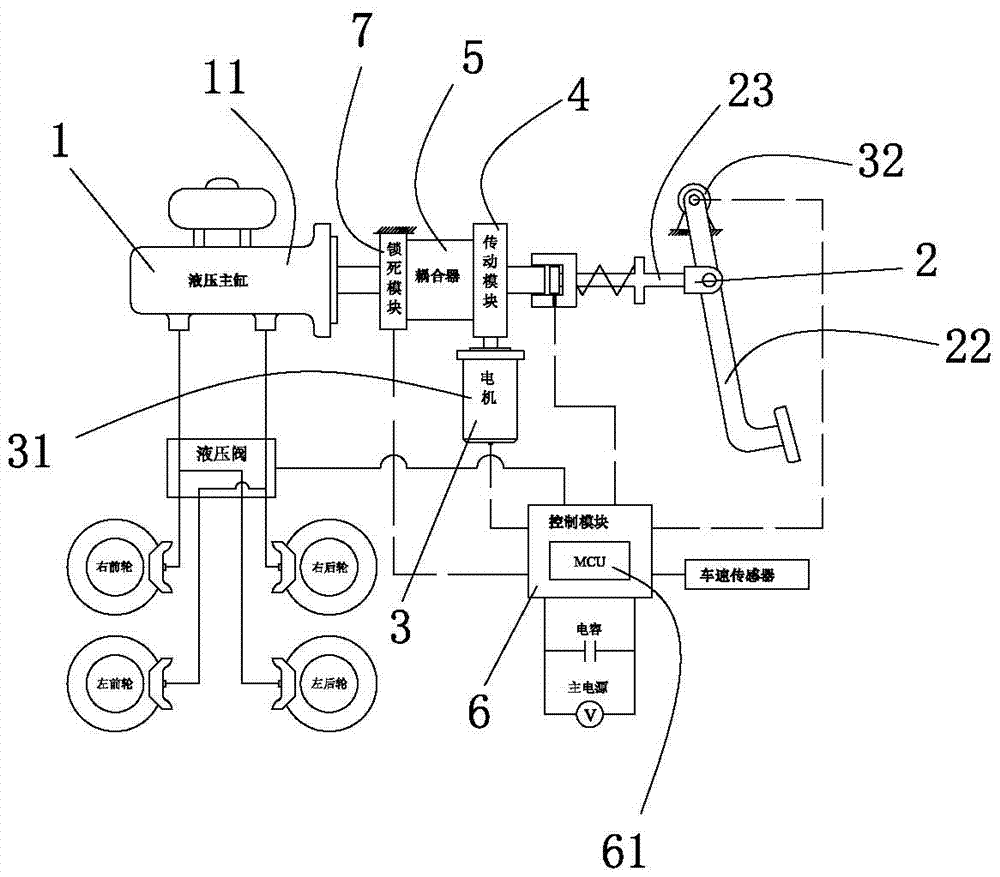

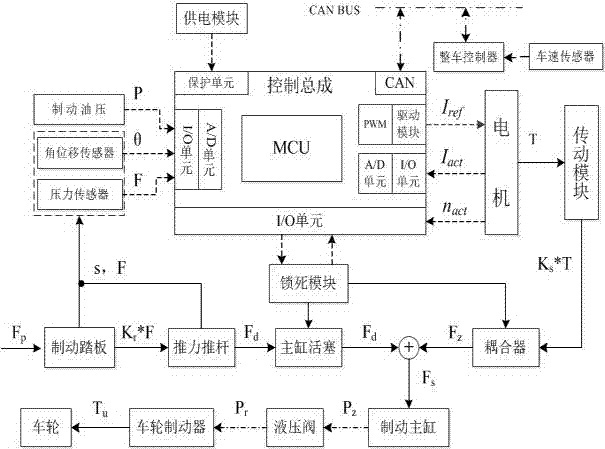

ActiveCN106938646ASimple structureCompact structureBraking action transmissionElectric power systemOperation mode

The invention relates to the technical field of automobile braking and particularly discloses an electric power-assisted braking system used for an automobile. The electric power-assisted braking system comprises a braking force output hydraulic module, a braking force input mechanical module, an electric power-assisted input module and a control assembly. The electric power-assisted input module comprises a motor, a transmission module and a sensor. The braking force input mechanical module directly acts on the braking force output hydraulic module through a coupler. The motor is connected with the coupler through the transmission module. The control assembly is used for setting a control strategy and is in electrical signal connection with the motor and the sensor. According to the electric power-assisted braking system used for the automobile, the modular design is adopted, the braking response time is shortened, the braking reliability and the braking efficiency are improved, and the occupied space is reduced; the braking system is provided with a protection unit with redundant measures and has a driver pedal force braking way and a motor braking way, and a traditional operation mode by a driver is retained; and the control mode can be adjusted, man-machine interaction can be conducted, a plurality of driving styles are provided, and the electric power-assisted braking system can meet the braking requirements of automatic driving and can further be matched with a regenerative braking system to achieve braking together.

Owner:SUN YAT SEN UNIV +1

Braking device of toothed solid chain type engine

ActiveCN102477880ALower the altitudeReduce volumeMachines/enginesNon-mechanical valveChain typeEngineering

The invention discloses a braking device of a toothed solid chain type engine, and the braking device comprises a first plunger piston and a second plunger piston arranged in vertical plunger piston holes, and a plunger piston rotation driving mechanism. The lower end surface of the first plunger piston and the upper end surface of the second plunger piston are respectively provided with a tooth surface; the tooth surfaces are matched with each other; a matching non-operating position and an operating position exist between teeth of the two matched tooth surfaces; at the non-operating position, tooth crests of teeth of the first plunger piston are aligned with tooth roots of teeth of the second plunger piston; at the operating position, the tooth crests of the teeth of the first plunger piston are aligned with tooth crests of the teeth of the second plunger piston; and the plunger piston rotation driving mechanism enables the two matched tooth surfaces of the two plunger pistons to rotate between the non-operating position and the operating position. By using the braking device of the toothed solid chain type engine, the height, the volume and the weight of the engine cannot be increased or can be increased less; the design is simplified; the cost is decreased; the braking response time is reduced; the solid chain interlinkage is adopted; the lifting of a braking valve can adopt a smaller value; and the requirements on a gap of a piston and an air valve of the engine can be decreased.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

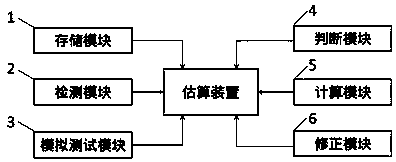

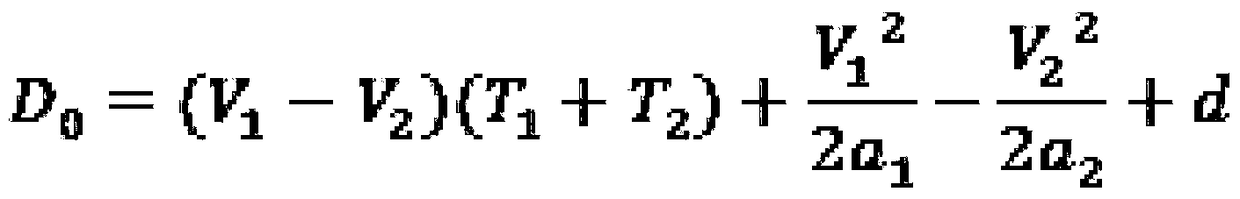

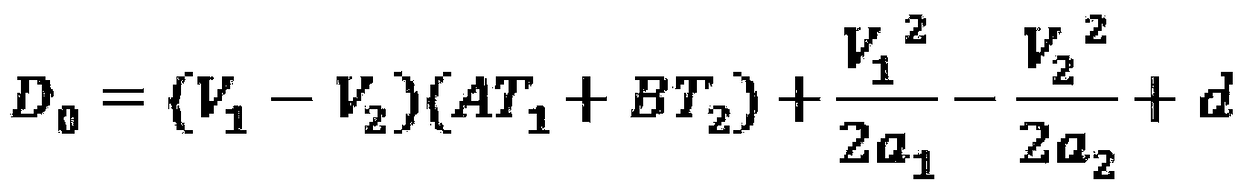

A safety distance estimation device and method

ActiveCN109050538AAvoid large or small safety distancesThe estimated result of safe vehicle distance is reasonableExternal condition input parametersBrake response timeVehicle type

A safety distance estimation device and method which can calculate the driver brake reaction time stored in the storage module by the calculation module, Driver Brake Response Time, Brake decelerationof the vehicle, Front brake deceleration, the minimum safety distance to be kept when the two vehicles are stationary and the estimated safety distance between the vehicle speed and the vehicle speedin front detected by the detection module, and further based on the perceptual characteristic value given by the simulation test module, Judging characteristic value and operating characteristic value, and correcting and estimating safety distance of vehicle type and driving road type obtained by judging module can effectively avoid that the estimated safety distance is too large or too small, which not only improves the accuracy of distance estimation and anti-collision probability of the system, but also ensures driving and riding comfort and driving efficiency.

Owner:XIANGTAN UNIV

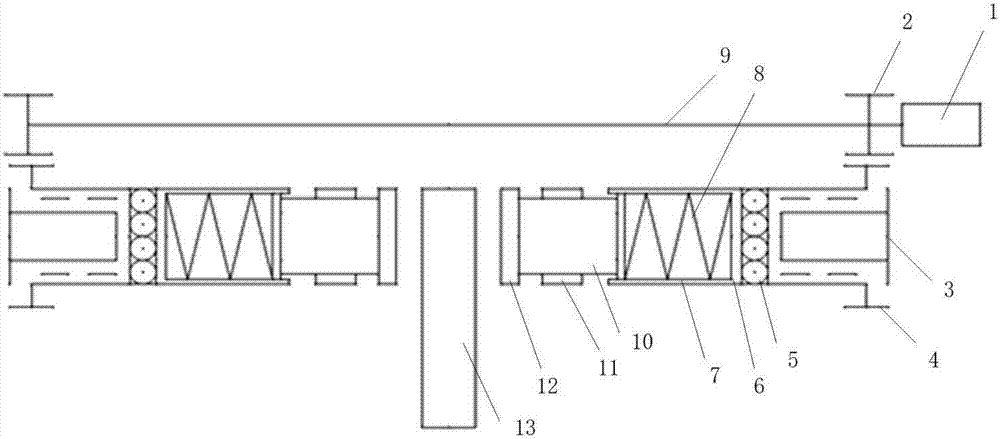

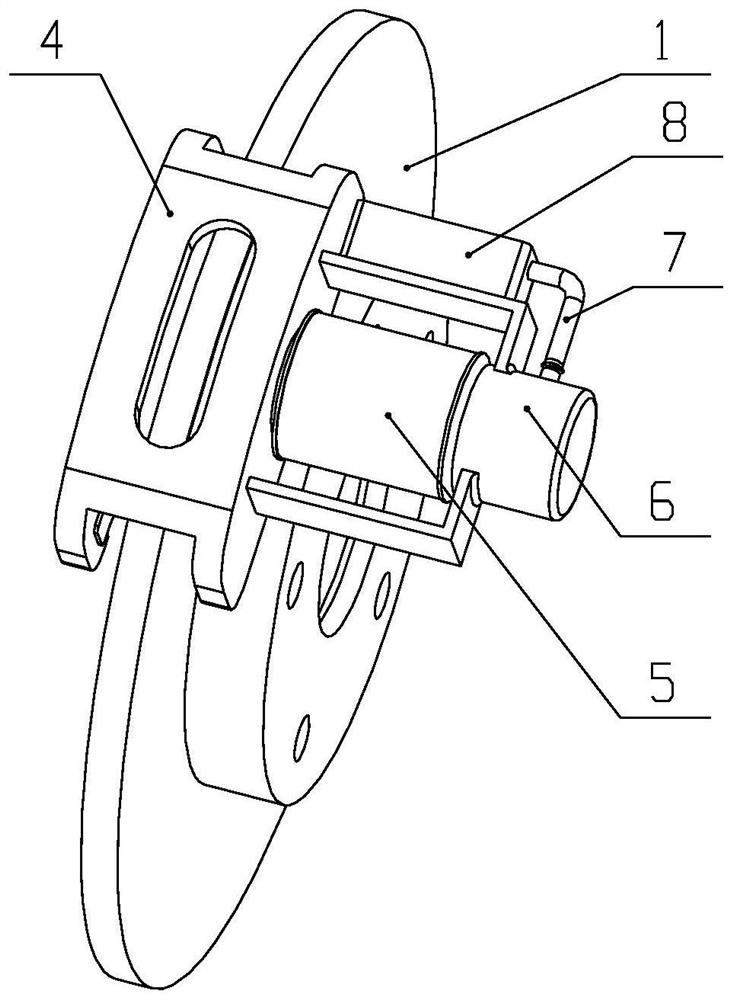

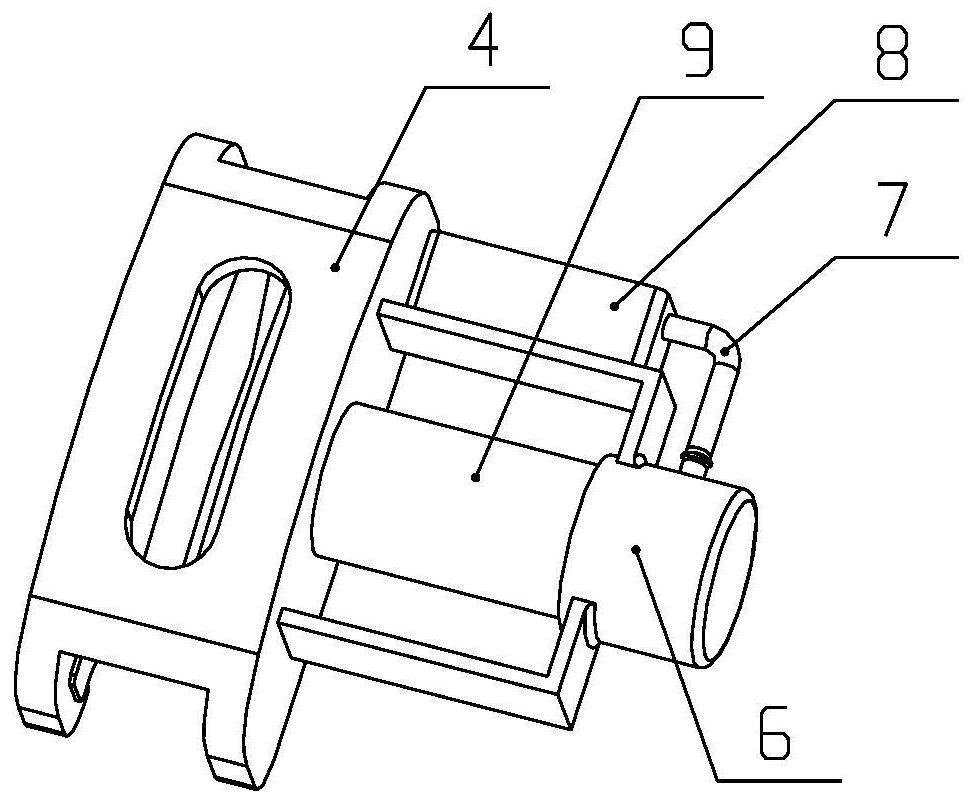

Piezoelectric driving brake

InactiveCN107554503AAchieving brake regulationEnsure driving safetyBraking systemsEngineeringBrake response time

The invention provides a piezoelectric driving brake comprising a wiring column positive electrode, a wiring column negative electrode, a piezoelectric assembly, a first end face located on the outerside of the piezoelectric assembly, a second end face located on the inner side of the piezoelectric assembly, a displacement enlarging mechanism, an inner brake friction piece, an outer brake friction piece, a gap adjusting bolt for adjusting the gap between the inner brake friction piece and the outer brake friction piece and a floating type brake clamp shell. The piezoelectric assembly comprises a piezoelectric negative electrode layer connected with the wiring column positive electrode and a piezoelectric positive electrode layer connected with the wiring column negative electrode, whereinthe piezoelectric negative electrode layer and the piezoelectric positive electrode layer are alternately arranged. After being powered-on, the piezoelectric assembly moves to deform, so that the gapbetween the inner brake friction piece and the outer brake friction piece is decreased, and the displacement deformation of the piezoelectric assembly is enlarged through the displacement enlarging mechanism. According to the piezoelectric driving brake, car brake adjustment can be achieved, the brake response time is prolonged, the travelling safety of a car is ensured, and meanwhile the gap between the inner brake friction piece and the outer brake friction piece can be adjusted.

Owner:JIANGSU UNIV OF TECH

Automobile braking system adopting electric execution mechanism

ActiveCN107269741AReduce quality problemsImprove securityBrake actuating mechanismsActuatorsElectric machineBrake response time

The invention discloses an automobile braking system adopting an electric execution mechanism, and belongs to the technical field of automobile braking. The system comprises an execution motor, two fixed gears and two rotating nuts, wherein the two fixed gears and the two rotating nuts are symmetrically arranged on two sides of a brake disc; the two rotating nuts are separately and fixedly connected with two planar bearings; the two planar bearings are respectively separately and fixedly connected with two spring bases; springs are arranged in the two spring bases; the two springs are respectively and separately connected with two push rods; the two push rods are respectively and separately connected with two friction sheets; the two friction sheets are respectively and symmetrically arranged on the two sides of the brake disc; and the braking of the two friction sheets are realized while the braking disc is clamped at the same time. According to the automobile braking system disclosed by the invention, the total quality of the automobile is reduced, the maintenance is simple, braking force directly acts upon the brake disc, and the braking speed is higher, and the braking response time is obviously shorter than conventional automobile braking time, so that the braking efficiency is effectively improved, the braking distanced is shortened, and the security of vehicles is improved.

Owner:JIANGSU UNIV OF TECH

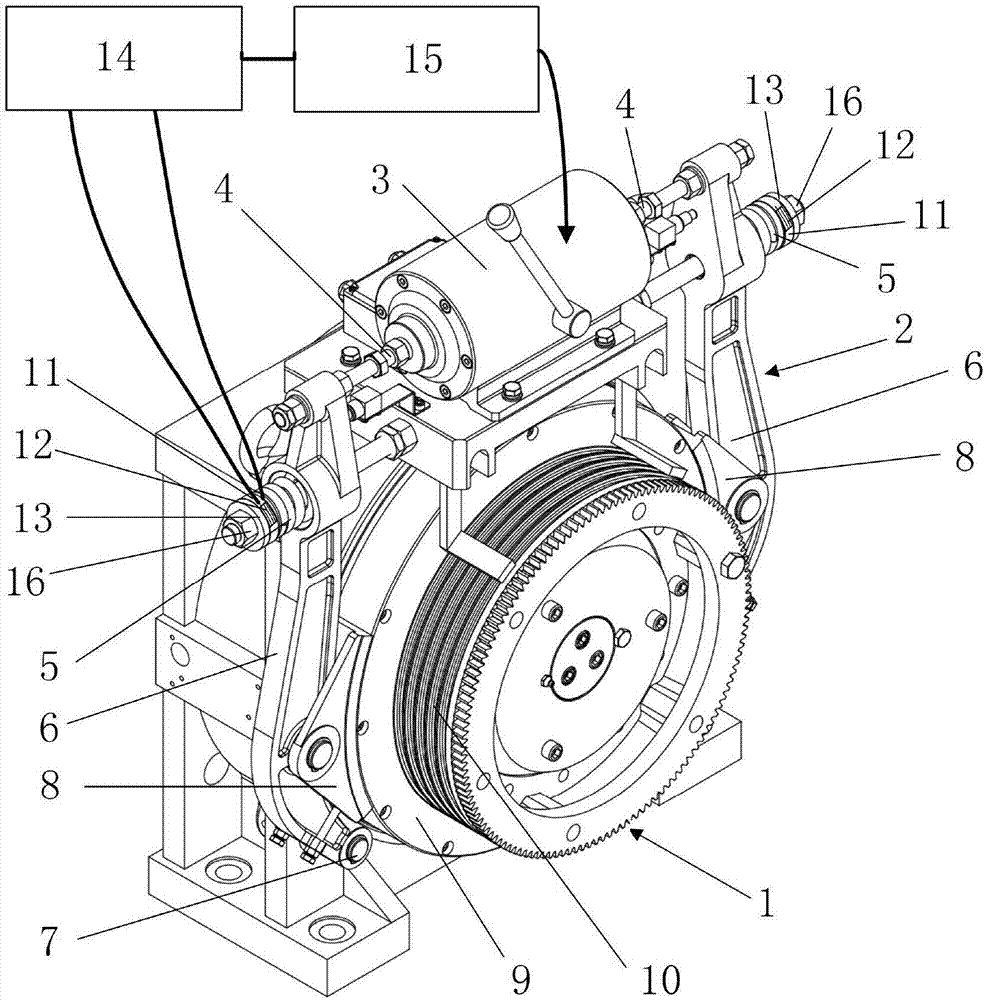

Driving device of engine brake

ActiveCN102191965AReduce the overall heightReduce volumeMachines/enginesNon-mechanical valveAir contentControl valves

The invention provides a driving device of an engine brake. The driving device comprises a braking box body, connecting rods, a driving piston and a braking plunger, wherein a vertical blind hole and a horizontal blind hole which intersect with each other are arranged in the braking box body; the driving piston is arranged in the horizontal blind hole; the braking plunger is arranged at lower part of the vertical blind hole; the connecting rods comprise an upper connecting rod and a lower connecting rod; a revolute pair is arranged between the upper connecting rod and the braking box body; another revolute pair is arranged between the lower connecting rod and the braking plunger; and a fluid channel is arranged in the braking box body to connect the horizontal blind hole with an engine oil fluid network. The driving device has the following beneficial effects: the driving device can be integrated with the engine, thus reducing the height, volume and weight of the engine brake; the hydraulic braking control valve is not needed, thus lowering the cost and reducing the brake response time; the brake load is not borne by liquid, thus enabling the driving device not to be subjected to leakage, deformation and load fluctuation caused by high oil pressure and high oil temperature; and the lift of the brake valve is not affected by the oil temperature and pressure and the air content,thus ensuring that the lift of the brake valve can be a small value, and reducing the requirements for the gap between the engine piston and the air valve.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

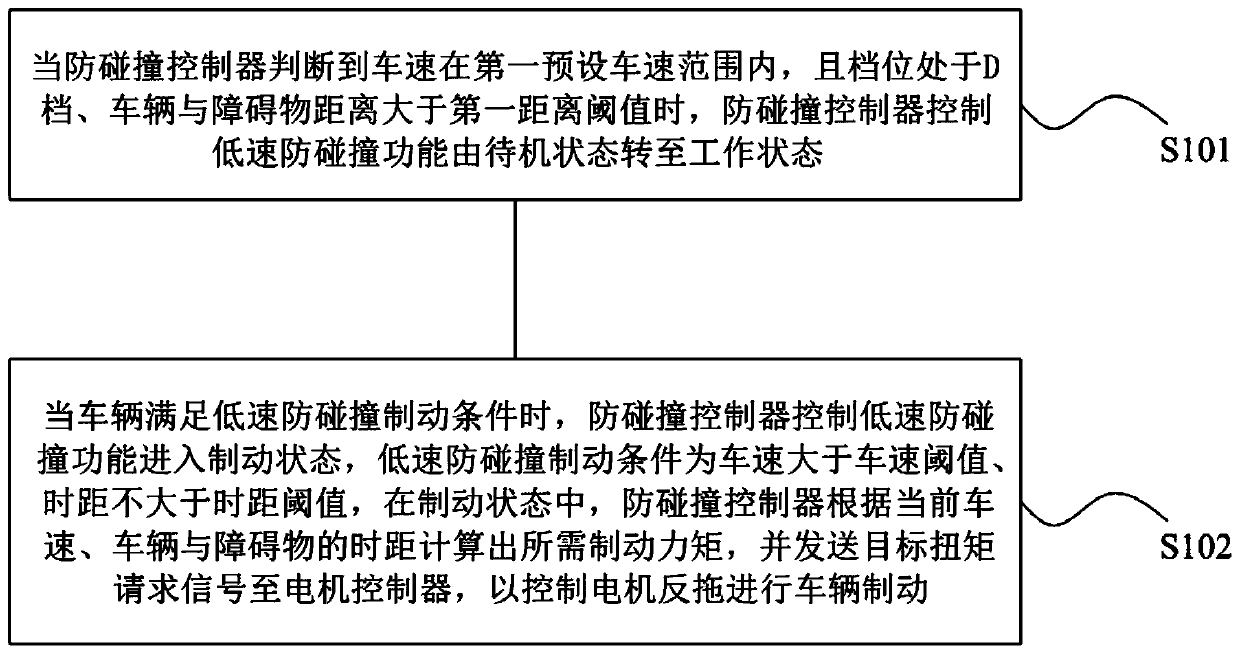

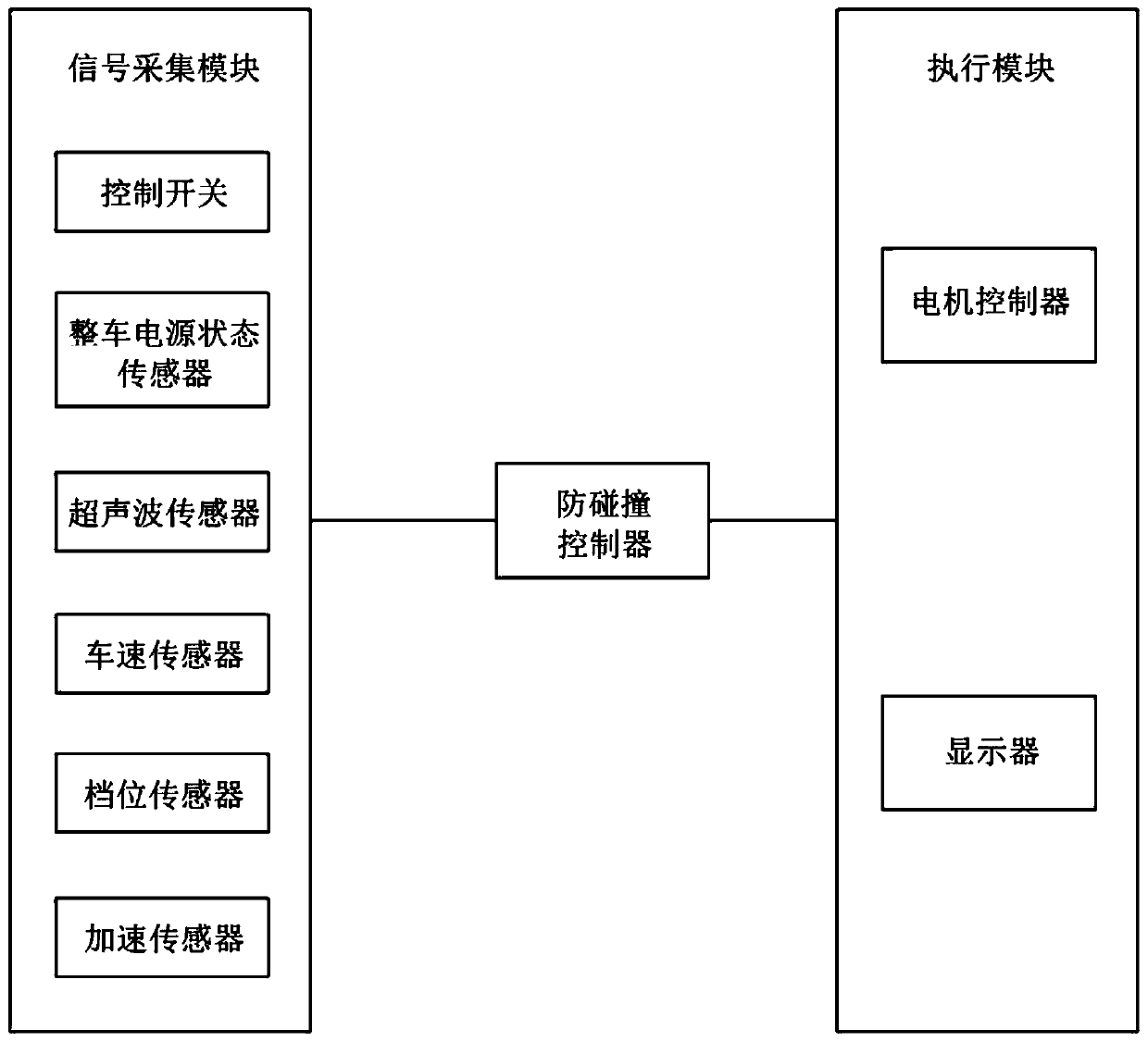

Electric vehicle low-speed anti-collision method and system

The invention discloses an electric vehicle low-speed anti-collision method and system. The method comprises the following steps: an anti-collision controller controls a low-speed anti-collision function to be switched from a standby state to a working state when the anti-collision controller judges that the vehicle speed is in a first preset vehicle speed range and the gear is in a D gear and thedistance between a vehicle and an obstacle is greater than a first distance threshold; when the vehicle meets a low-speed anti-collision braking condition, the anti-collision controller controls thelow-speed anti-collision function to enter a braking state, wherein the low-speed anti-collision braking condition is that the vehicle speed is larger than a vehicle speed threshold and the time interval is not larger than a time interval threshold; and in the braking state, the anti-collision controller calculates the required braking torque according to the current vehicle speed and the time interval between the vehicle and the obstacle and sends a target torque request signal to the motor controller so as to control a motor to drag reversely to brake the vehicle. The problems that in the prior art, the safety distance precision is low, and the braking response time is long can be solved.

Owner:JIANGXI JIANGLING GRP NEW ENERGY AUTOMOBILE CO LTD

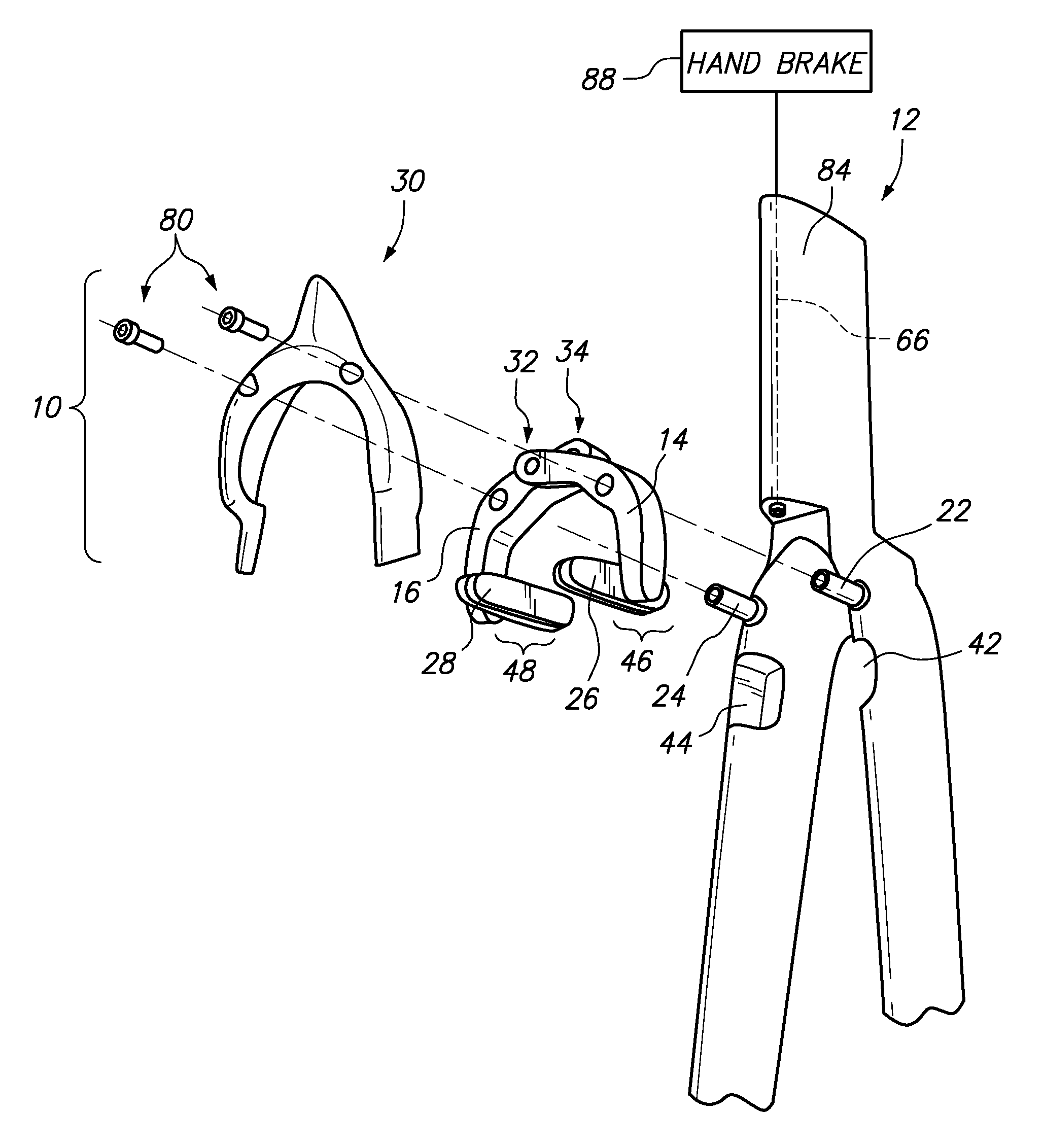

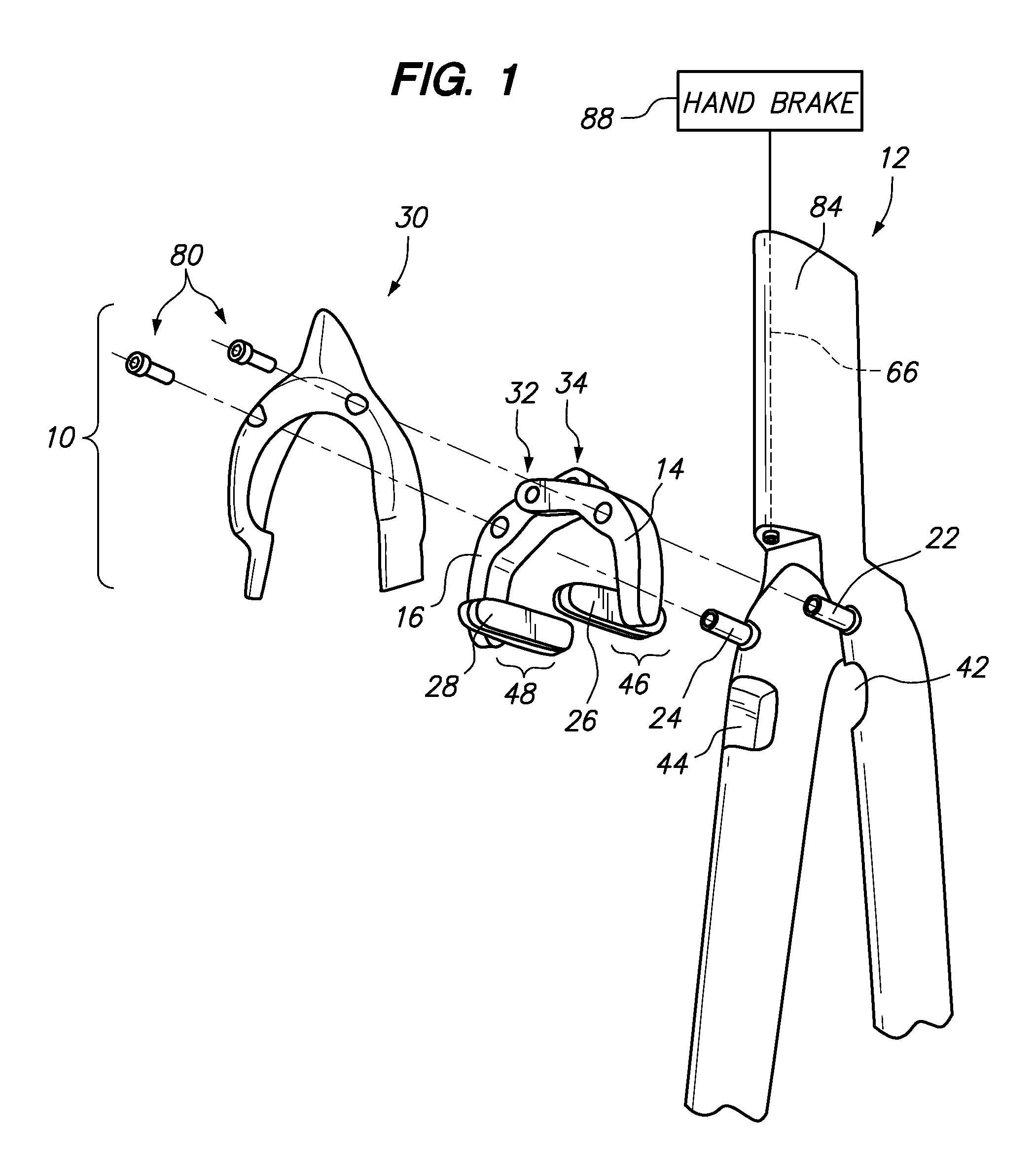

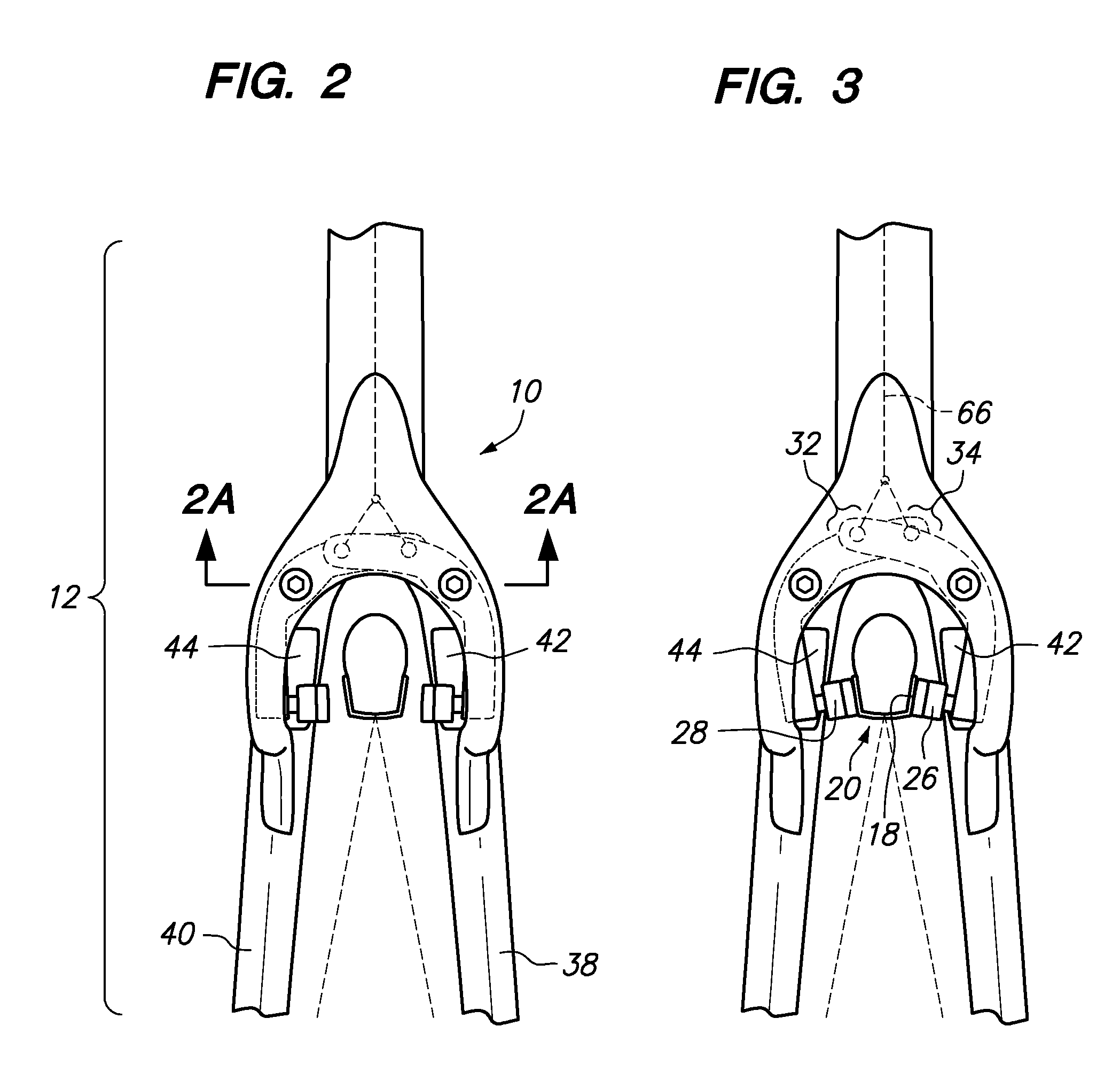

Brake booster stiffening plate

InactiveUS7775331B1Quicker brake response timeStabilizes bending momentBraking element arrangementsCycle brakesBrake response timeBraking system

An aerodynamic brake booster stiffening plate is provided which attaches to pivot posts of a center pull brake system. The aerodynamic brake booster stiffening plate mitigates outward bending of the posts upon actuation of the brake to allow for faster brake response times. Additionally, a front surface of the aerodynamic stiffening plate may be aerodynamically shaped and blended with the fork or frame of the bicycle to encourage a laminar flow of air past the brake.

Owner:FELT RACING

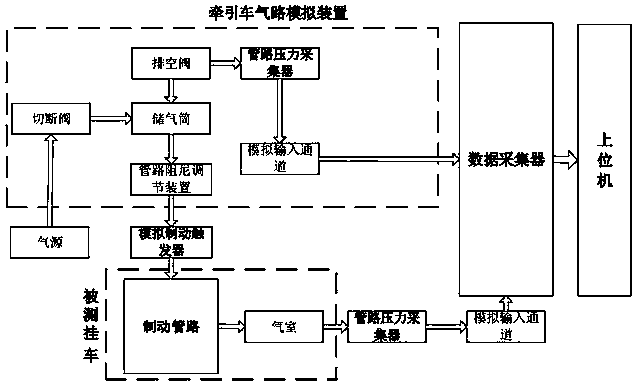

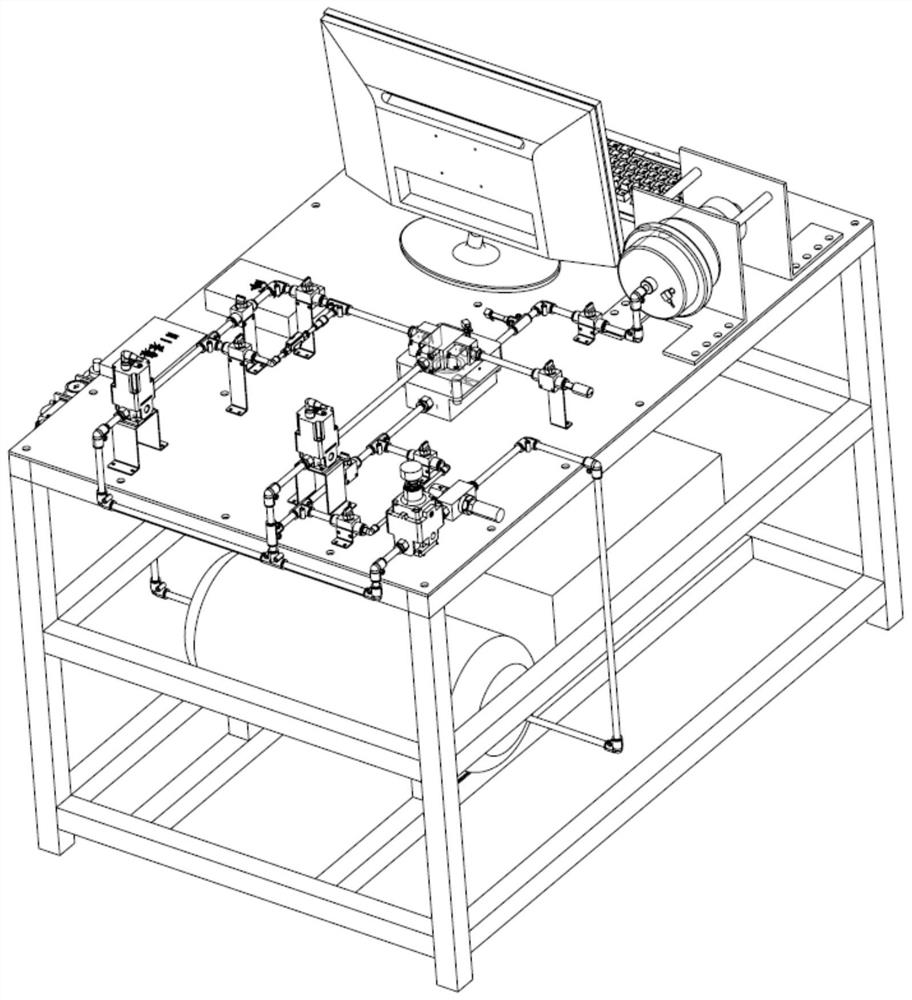

Portable trailer pneumatic braking response time integrated measuring device

PendingCN109109852AImprove portabilityEasy to operateBrake safety systemsPneumatic circuitMeasurement device

The invention provides a portable trailer pneumatic braking response time integrated measuring device which comprises a simulation brake trigger, a tractor pneumatic circuit simulating device and a data acquisition device. The simulation brake trigger comprises a manual-controlled mechanical valve body and an accessory, and is connected with a tractor pneumatic circuit simulating device; the tractor pneumatic circuit simulating device comprises a gas storage device, a pipeline damping adjusting device and a pipeline pressure collector; a part of the pipeline pressure collector is fixed on theupper part of the tractor pneumatic circuit simulating device and is connected with the air storage device, and the other part is connected with the brake air chamber of the tested trailer. The pipeline pressure collector is connected with the data collector through an analog input channel. The data collector is also connected to the upper computer. The invention is convenient to carry, high in integration, fast and accurate in data analysis and processing, greatly improves the working efficiency of the response time measurement of the trailer pneumatic braking system, and greatly enhances theconvenience of the test work.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +1

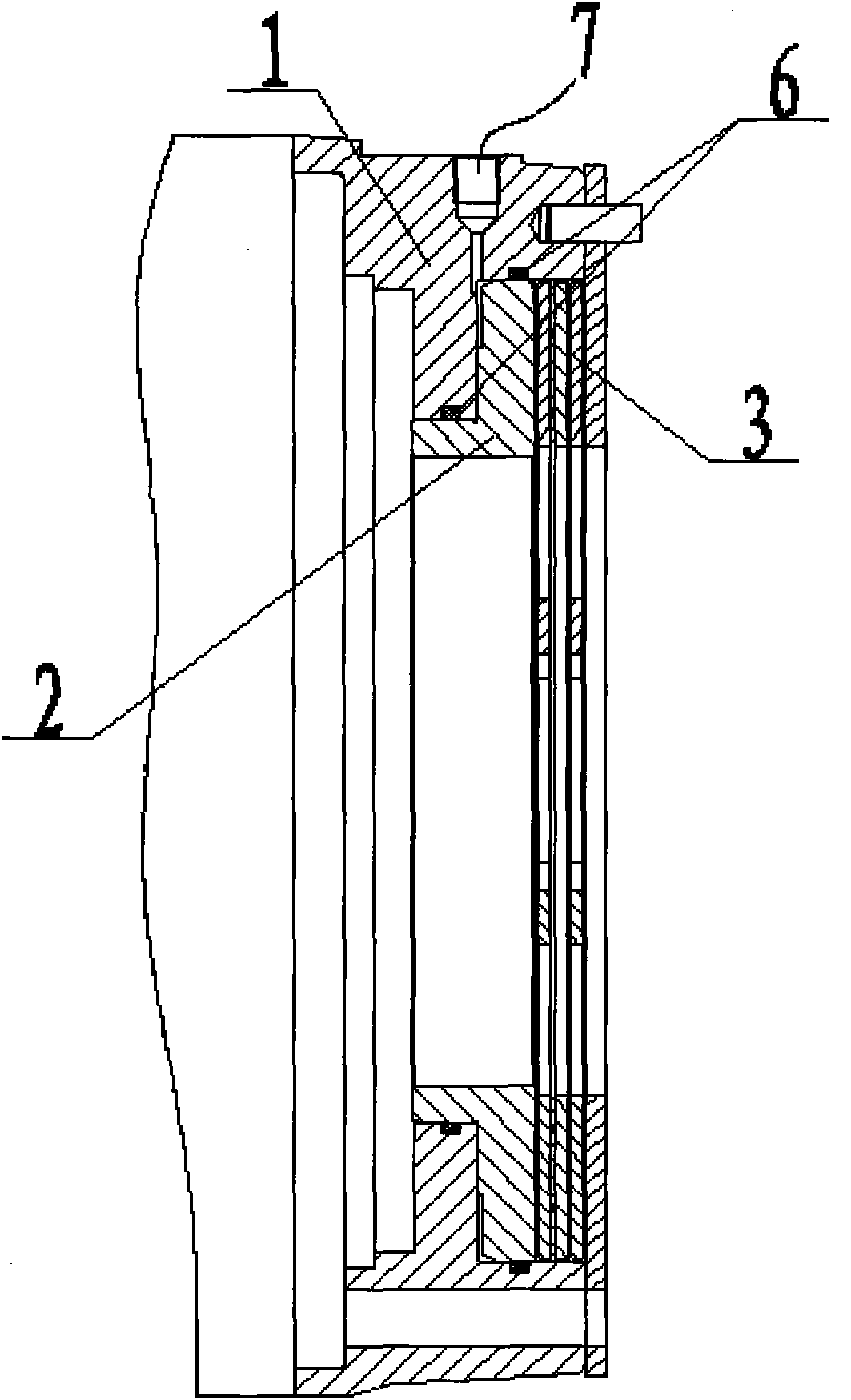

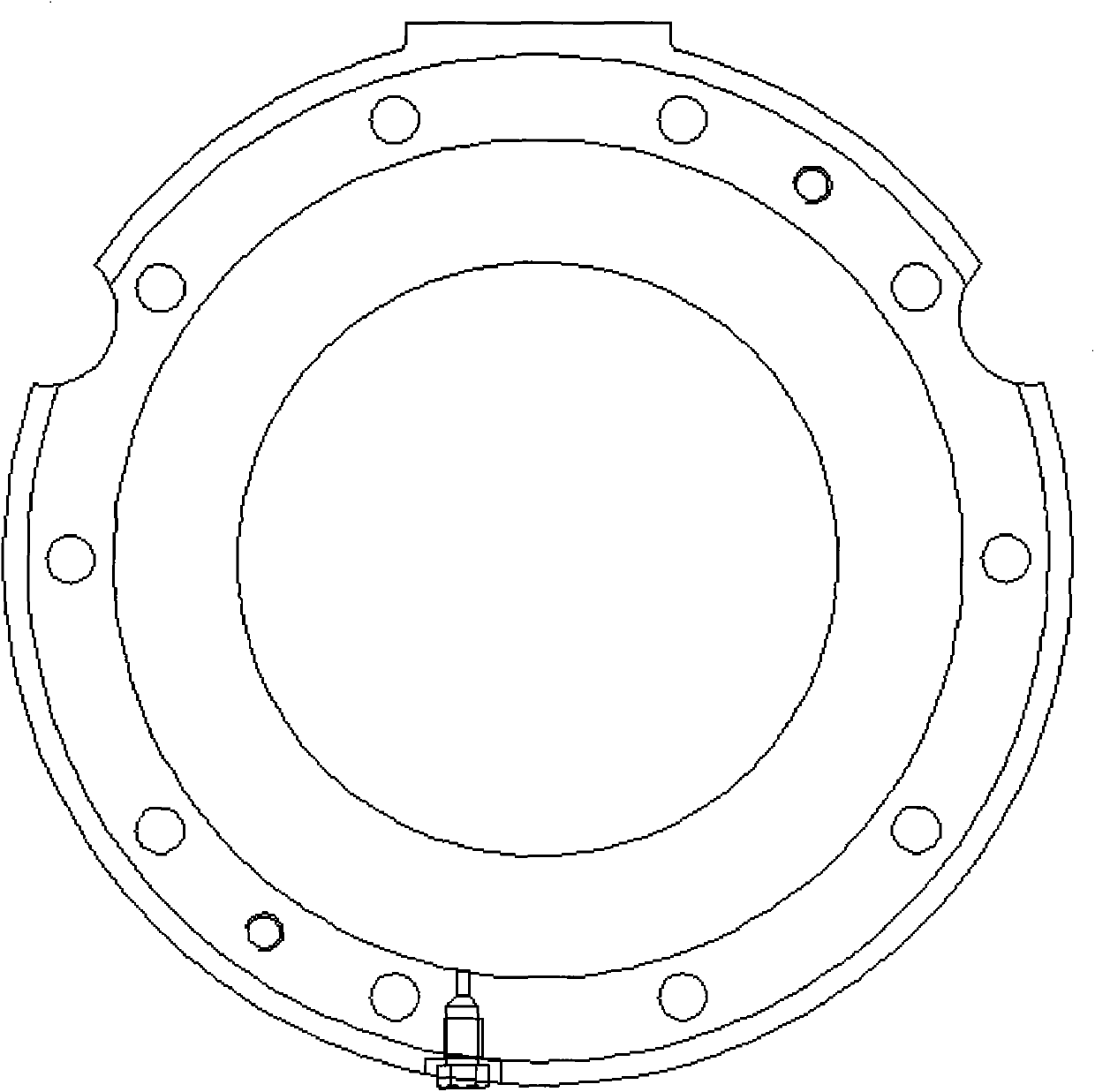

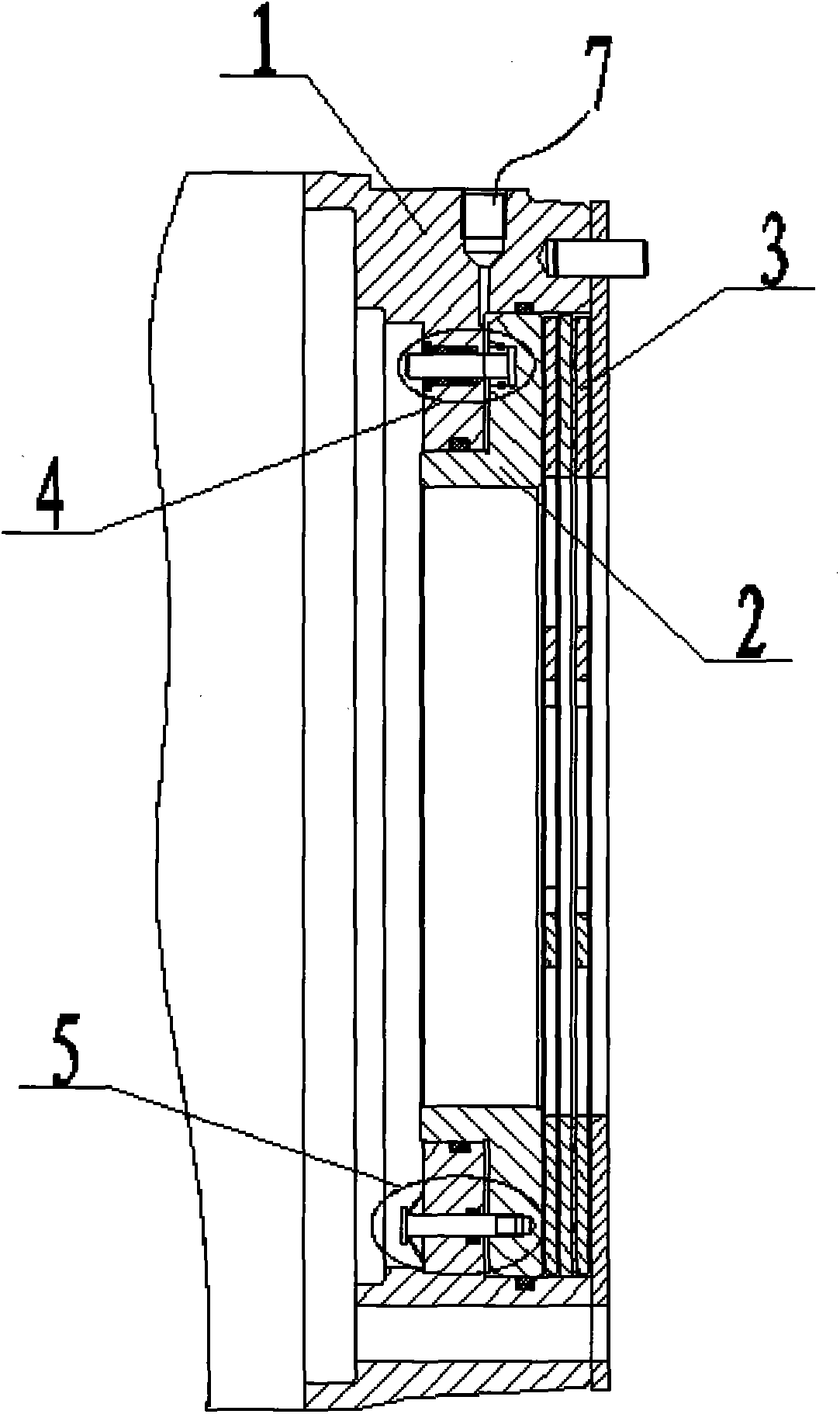

Wet brake for tractor

ActiveCN103807337ASolve draggingExtended service lifeBrake actuating mechanismsActuatorsStatic frictionEngineering

The invention relates to a brake, in particular to a wet brake for a tractor. The brake comprises a shell body, pistons, friction piece components, friction limit mechanisms and piston return mechanisms, wherein each friction limit mechanism comprises a friction positioning rod, a friction resistance ring and a first clamping spring; each friction positioning rod is provided with a first positioning shaft shoulder and a second positioning shaft shoulder from left to right; each friction positioning rod is connected with the corresponding friction resistance ring through a friction pair; each piston return mechanism comprises a pull rod and a disk spring; each pull rod is connected with the shell body in a sliding way; the right end of each pull rod is in threaded connection with the corresponding piston; the sum of the static friction between each fiction positioning rod and the corresponding friction resistance ring is greater than the sum of the maximum force of all disk springs. By the wet brake for the tractor, the dragging caused by a return gap can be overcome effectively, the service life is prolonged by over 20 percent, the automatic compensating function for the abrasion of a friction piece is provided, the return gap of each piston is kept at the range of 0.4-0.6 mm all the time, and the problems that the brake response time is long and the liquid amount required for braking is deficient caused by an over-large brake gap are avoided.

Owner:青岛华瑞汽车零部件股份有限公司

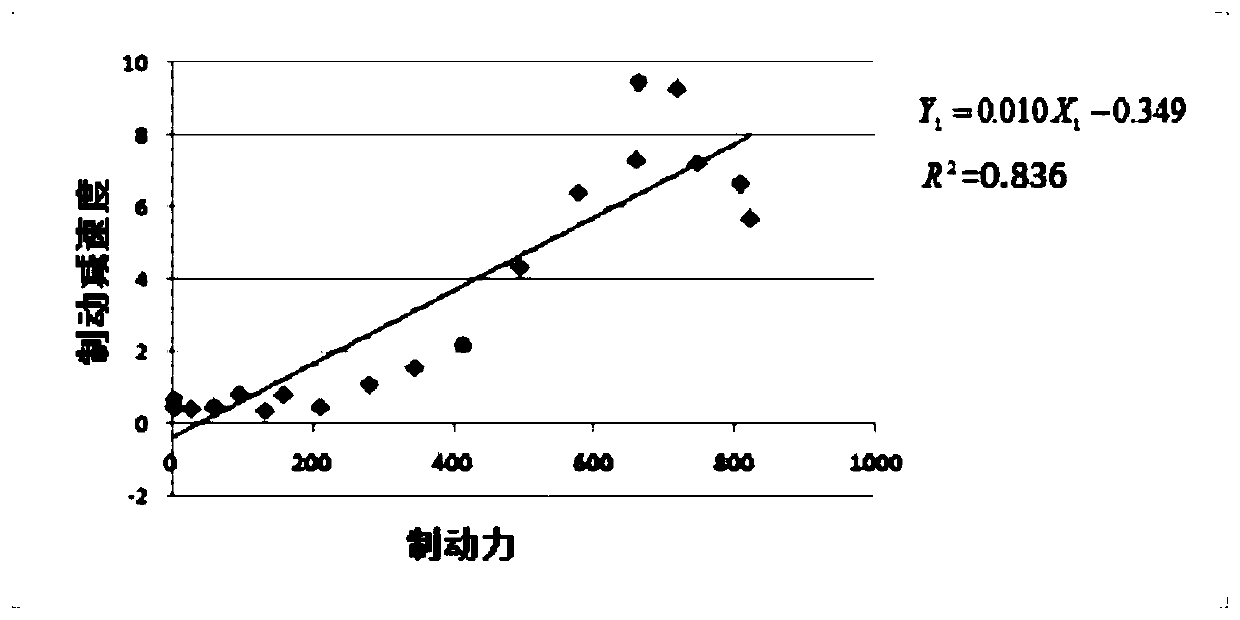

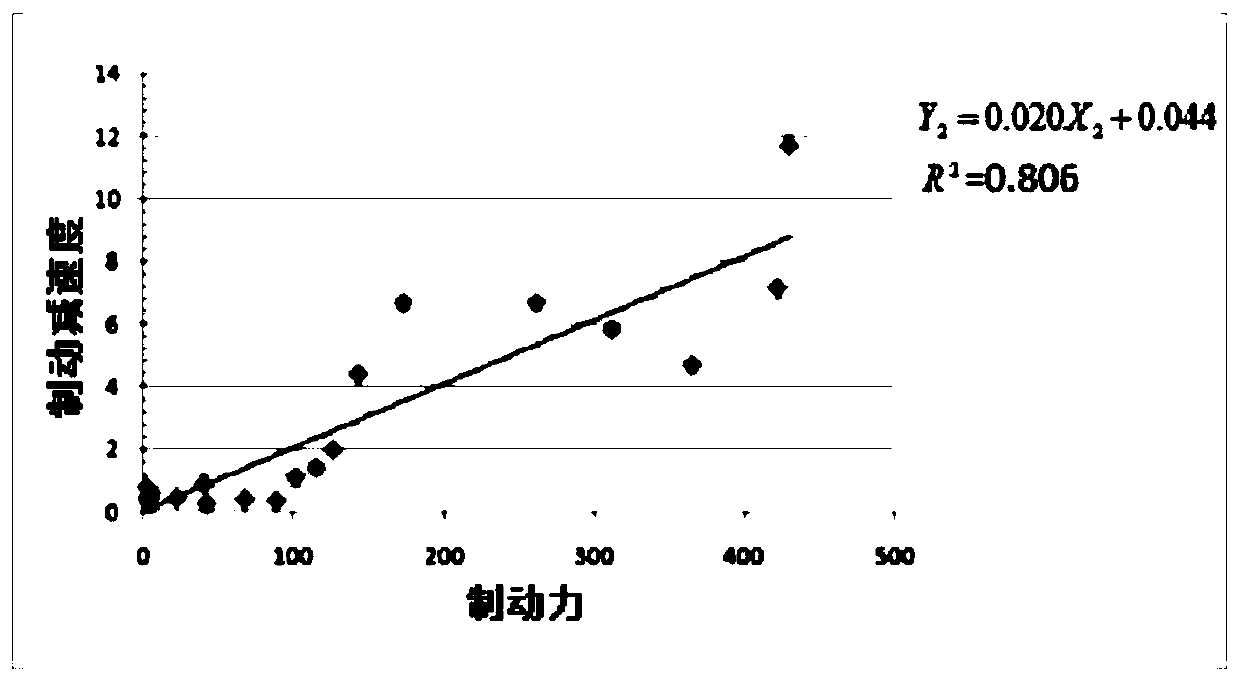

Sensory evaluation method for brake pedal of passenger vehicle based on intelligent unmanned test platform

InactiveCN110686907AImprove test accuracyEase of evaluationVehicle testingLinear correlationControl theory

The invention discloses a sensory evaluation method for a brake pedal of a passenger vehicle based on an intelligent unmanned test platform. The sensory evaluation method comprises the following steps: performing a vehicle brake response test, and evaluating sensitivity of the brake pedal of the vehicle by a brake response time, wherein the shortest brake response time corresponds to the highest sensitivity of the brake pedal; testing linearity of the brake pedal of the vehicle, recording an applied brake force and a corresponding brake deceleration, and evaluating the linearity of the brake pedal of the vehicle according to a squared value of a linear correlation coefficient, wherein the linear correlation coefficient is R, and R2 is an element of a set (0,1), when the R2 is the closest to 1, the linearity of the brake pedal of the vehicle is the best. In the formula, Y is the applied braking force, X is the brake deceleration corresponding to the applied brake force, [Y-bar] isan average value of scattered points of the brake force, and [X-bar] is an average value of the scattered points of the brake deceleration. The sensory evaluation method of the invention uses a brakepedal sensitivity test and a brake pedal linearity test to evaluate sensory performance of the brake pedal of the vehicle, and has high test accuracy and good evaluation effect.

Owner:CATARC AUTOMOTIVE TEST CENT TIANJIN CO LTD +1

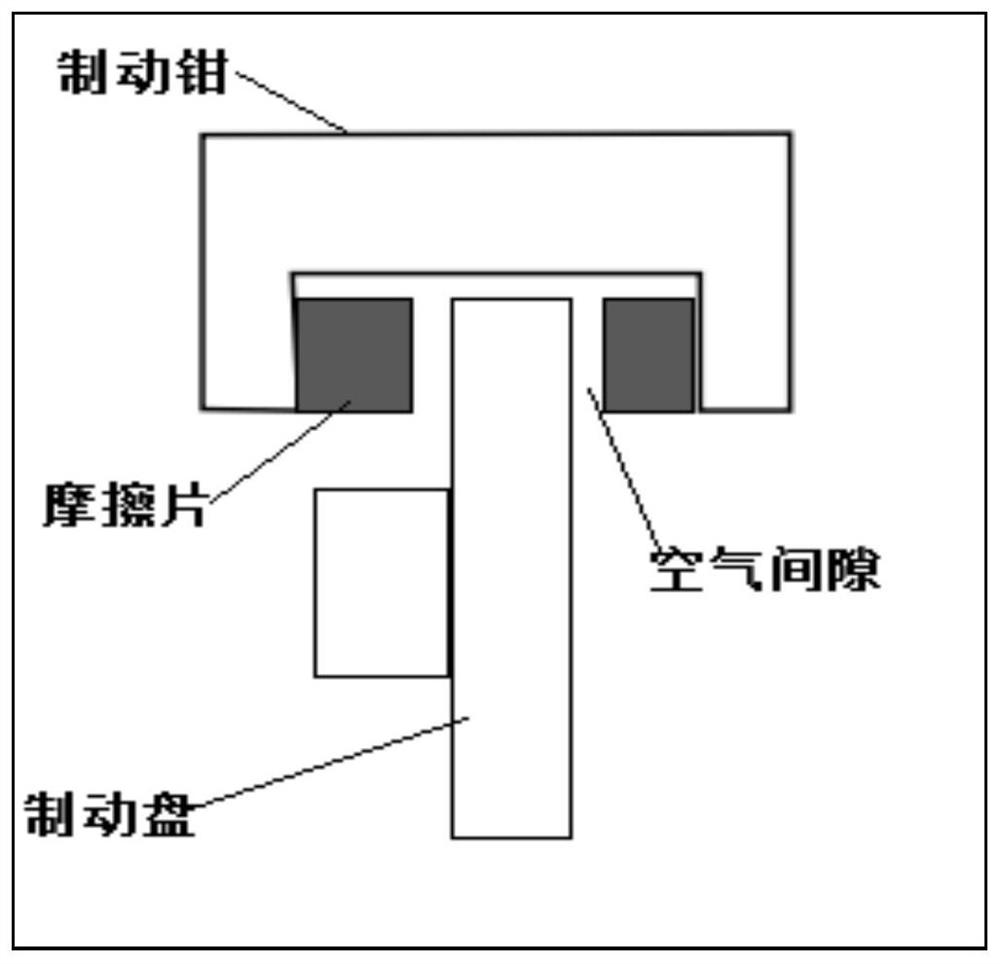

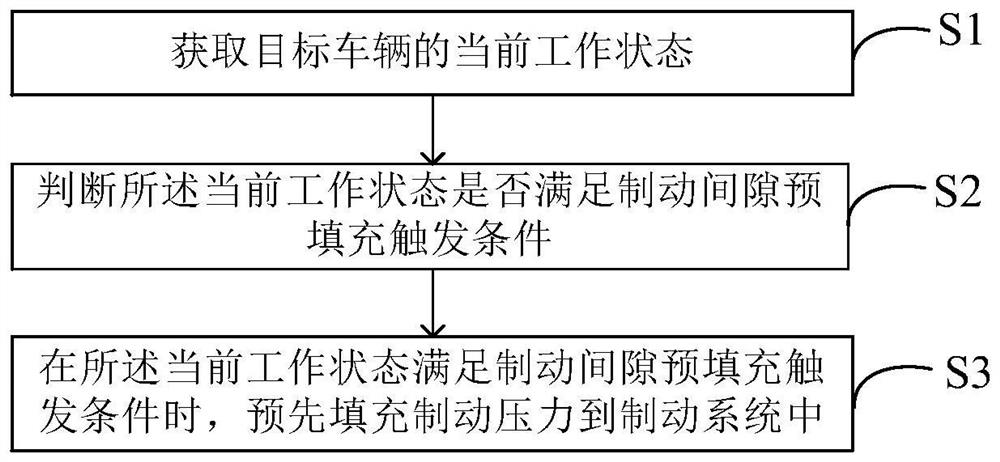

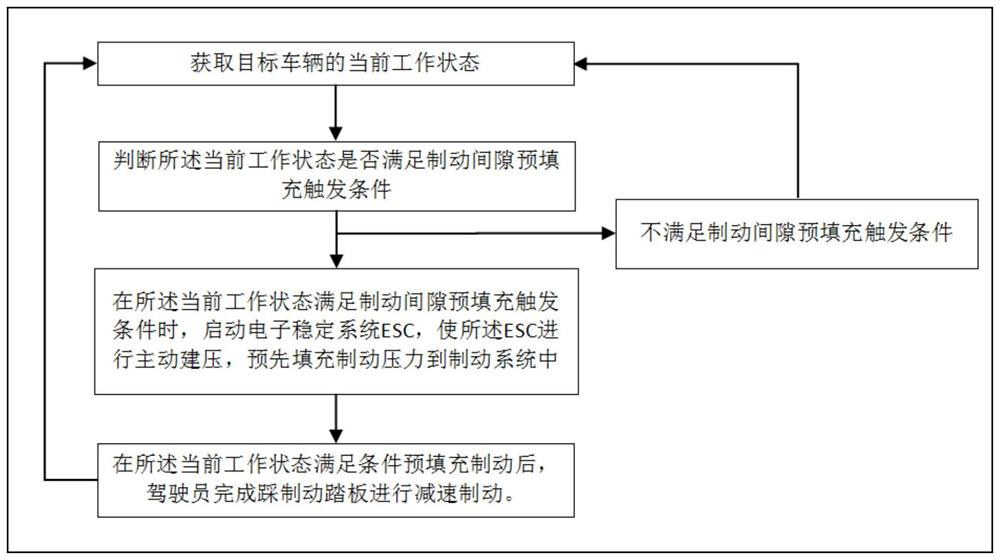

Brake clearance pre-filling control method, equipment, storage medium and device

InactiveCN113500985AReduced brake clearanceReduced brake response timeBraking action transmissionApplication and release valvesDriver/operatorControl theory

The invention discloses a brake clearance pre-filling control method, equipment, a storage medium and a device. The method comprises the steps that the current working state of a target vehicle is obtained; it is judged whether the current working state meets a brake clearance pre-filling triggering condition or not; and when the current working state meets the brake clearance pre-filling triggering condition, the brake system is pre-filled with brake pressure. When the current working state meets the brake clearance pre-filling triggering condition, the brake system is pre-filled with the brake pressure so as to reduce the air clearance between the brake disc and the brake friction plate, then if the brake pedal is treaded down again, the effective brake pressure can be generated immediately, and therefore, the braking response time and the time for achieving the target deceleration are shortened, when a driver conducts emergency braking, the air gap between the brake disc and the friction plate can be actively eliminated, the braking response time is shortened, and the purpose of improving the driving safety is achieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Drive-by-wire system with redundancy function

ActiveCN112776786AImprove driving safetyEliminate Braking BacklashBrake safety systemsWheel speed sensorVehicle driving

The invention relates to a drive-by-wire brake system with a redundancy function. The drive-by-wire brake system comprises a drive-by-wire brake in modular design, a brake pump shell, a liquid storage chamber, a first spring, a first piston assembly, a check ring, a rubber ring, a second spring, a second piston assembly, a brake pedal, an angle sensor and a controller; wherein the drive-by-wire brake comprises a brake disc, a left friction plate, a right friction plate, calipers, an electromagnetic coil, a cylinder body assembly, a brake pipeline, a hydraulic control unit, a brake piston, a magnetostriction rod and a wheel speed sensor. In the invention, the magnetostriction actuator is adopted as a power source of the electronic mechanical braking system, the energy accumulator device is adopted, the braking clearance can be rapidly eliminated, the braking response time is shortened, and high braking control precision and response frequency are achieved; thus, even if the electronic mechanical braking system fails, the vehicle can still be braked by means of a conventional hydraulic braking system, and the reliability is high; in addition, the braking distance can be effectively shortened, and the vehicle driving safety is improved.

Owner:SHANDONG JIAOTONG UNIV

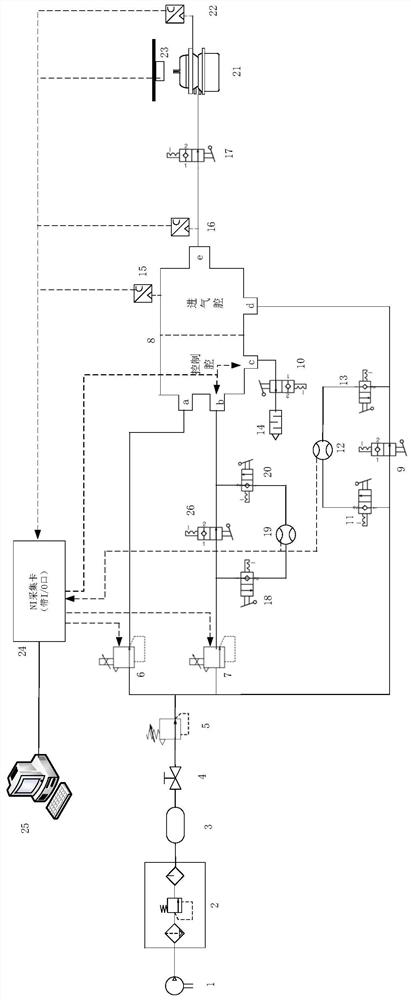

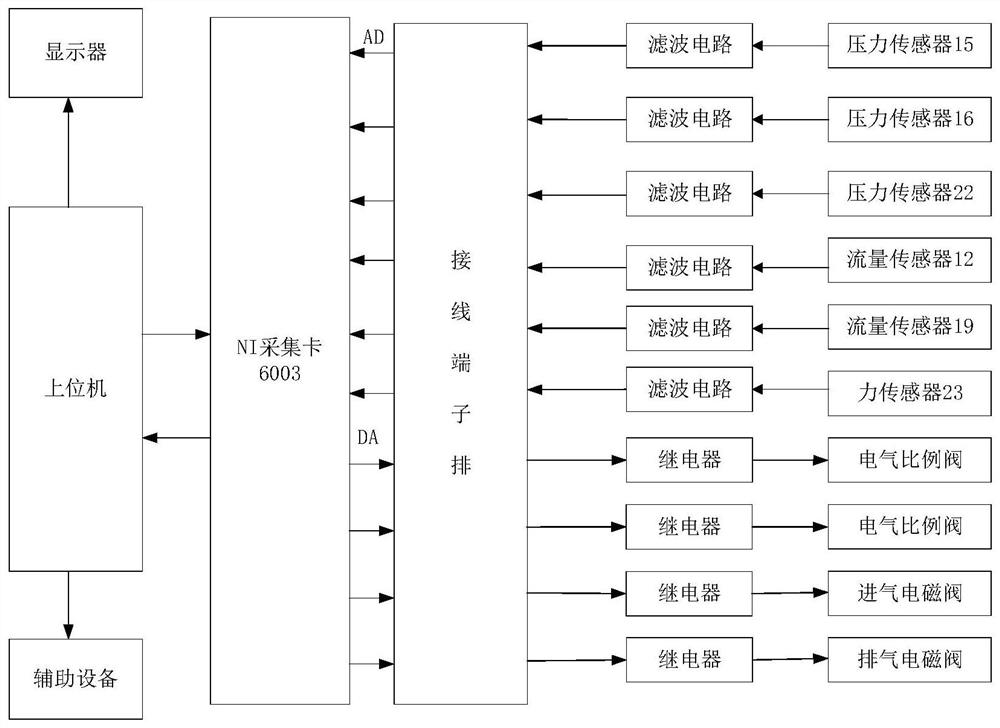

Testing device and testing method for automatic pressure regulating valve of electric control pneumatic braking system

ActiveCN111766060AReduce riskImprove test efficiencyMeasurement of fluid loss/gain rateMachine valve testingControl cellVehicle detection

The invention provides a testing device and testing method for an automatic pressure regulating valve of an electric control pneumatic braking system. The testing device comprises an air source, a pneumatic loop, a valve, a sensor, a signal processing unit and a control unit. The automatic pressure regulating valve is subjected to rack testing including function testing, static performance testing, dynamic performance testing, air tightness testing, leakage testing and braking force testing, so that high risk of real vehicle detection is avoided, the testing efficiency is improved, and the testing consistency is guaranteed. According to the invention, the automatic pressure regulating valve is checked before loading; the performance is improved by continuously modifying the parameters of the automatic pressure regulating valve through testing, so that the automatic pressure regulating valve meets the real-time, rapid, independent and accurate requirements required by the commercial vehicle electronic control pneumatic braking system, the braking response time of the commercial vehicle electronic control pneumatic braking system is shortened, and the reliability of the commercial vehicle electronic control pneumatic braking system is improved. Data of the automatic pressure regulating valve are collected and displayed in real time, and operation is convenient; detection processis high in automation degree.

Owner:WUHAN UNIV OF TECH

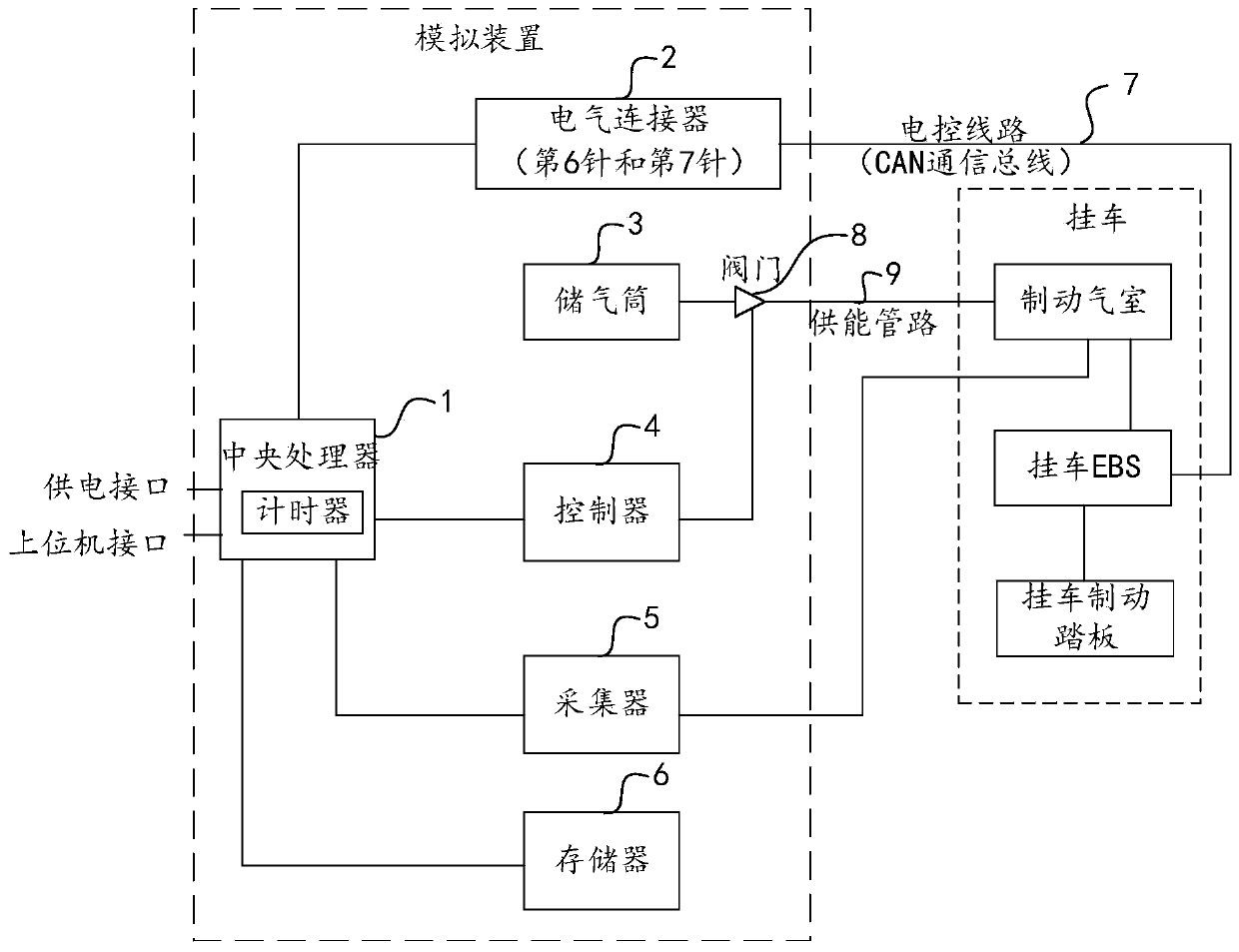

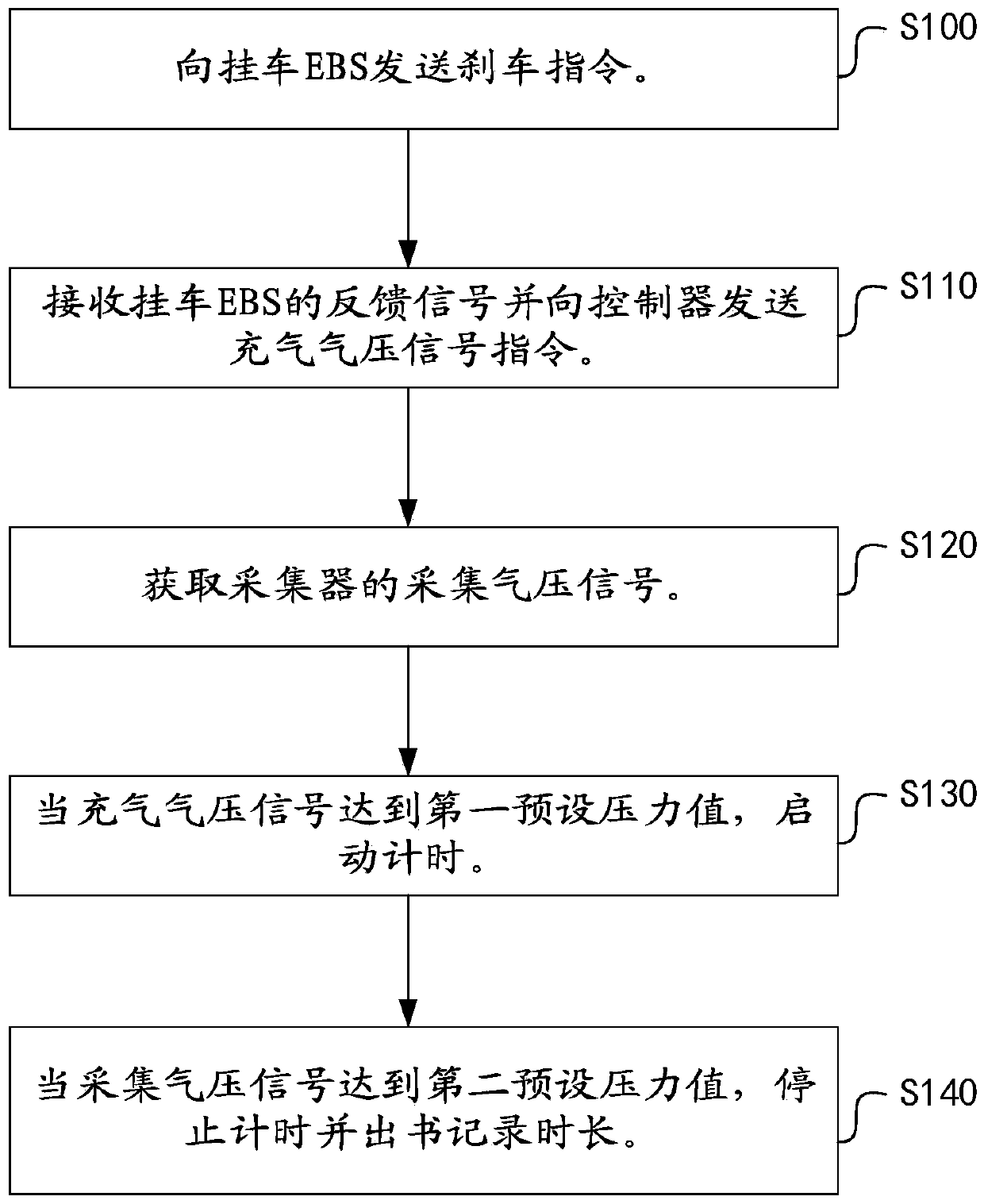

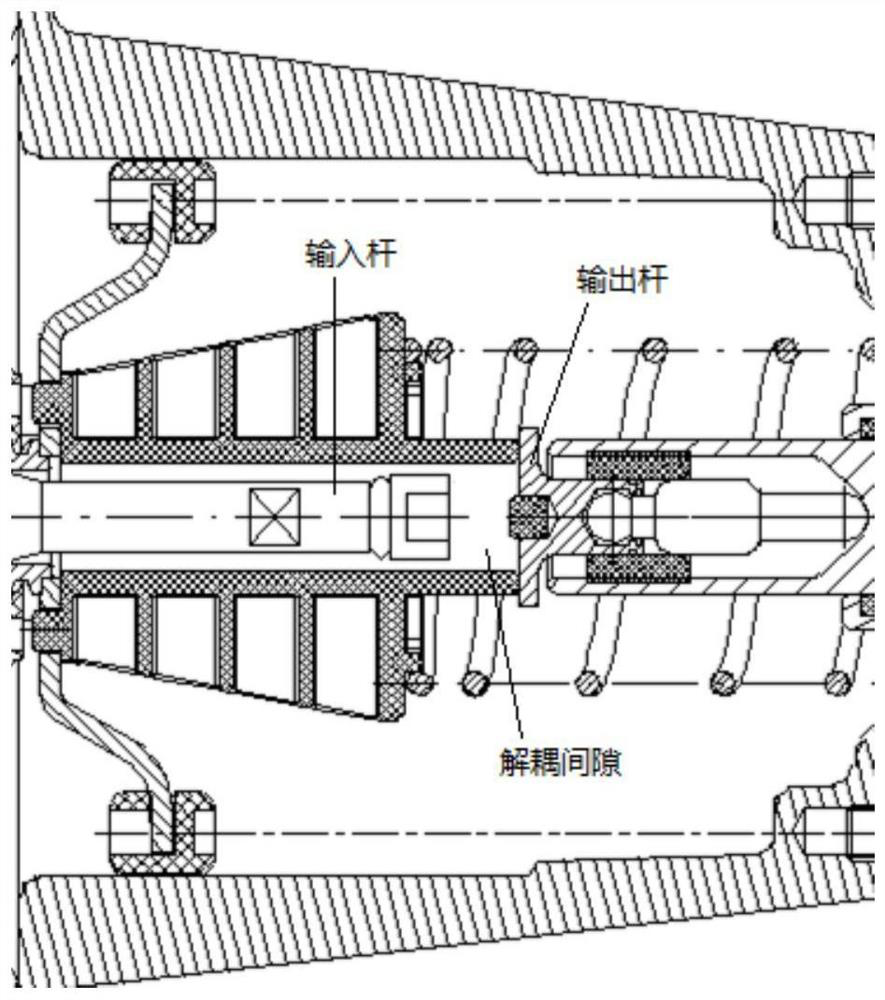

Trailer EBS braking response time simulation device and control method thereof

The invention provides a trailer EBS braking response time simulation device and a control method thereof, and belongs to the technical field of trailer braking. The trailer EBS braking response timesimulation device comprises a gas storage tube, a central processing unit, a controller and a collector, wherein the controller and the collector are respectively and electrically connected with the central processing unit; the central processing unit is electrically connected with a trailer EBS so as to send a braking instruction to the trailer EBS; a pressurization instruction is sent to the controller according to a feedback signal of the trailer EBS; the gas storage tube is connected with a braking gas chamber of a trailer; the controller controls the gas storage tube to perform inflationinto the braking gas chamber; the collector is arranged in the braking gas chamber of the trainer, and is used for collecting the gas pressure in the braking gas chamber; and the central processing unit calculates the braking response time of the trailer EBS according to the gas pressure collected by the collector. The simulation device can replace a main vehicle to be used for intelligently detecting the braking response time of the trailer EBS; the precise testing is realized; the portability is high; and the braking test can be performed on the trailer at any time in any place.

Owner:WUHAN HUAWEI SECIAL PURPOSE AUTOMOBILE DETECTION

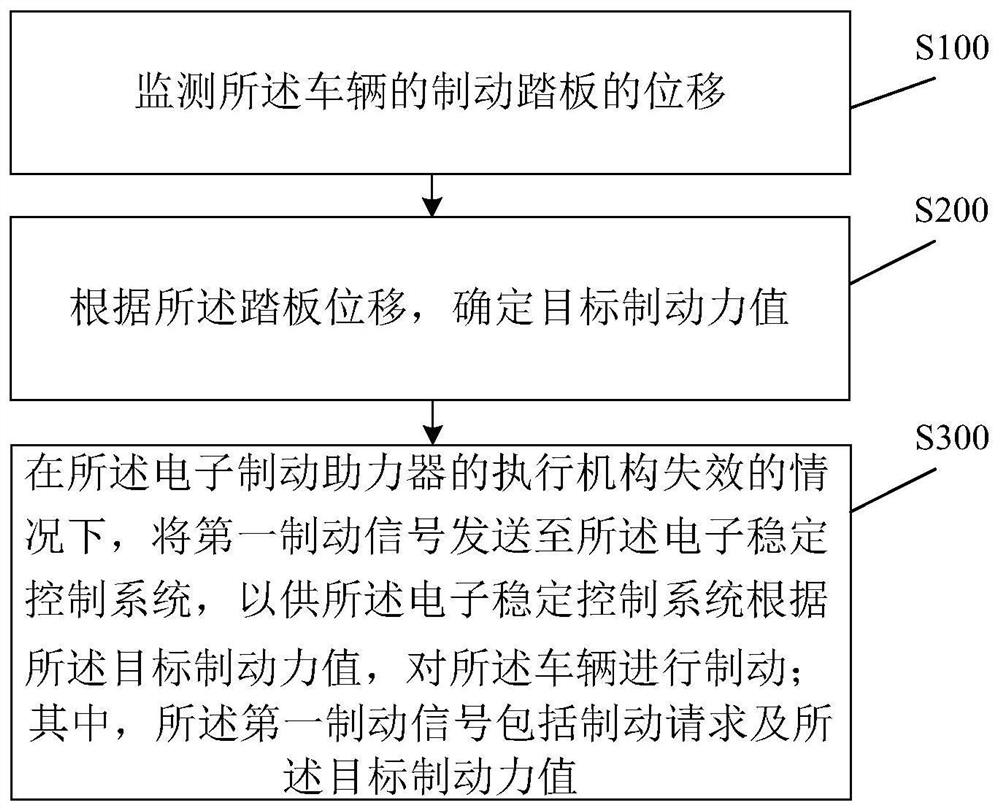

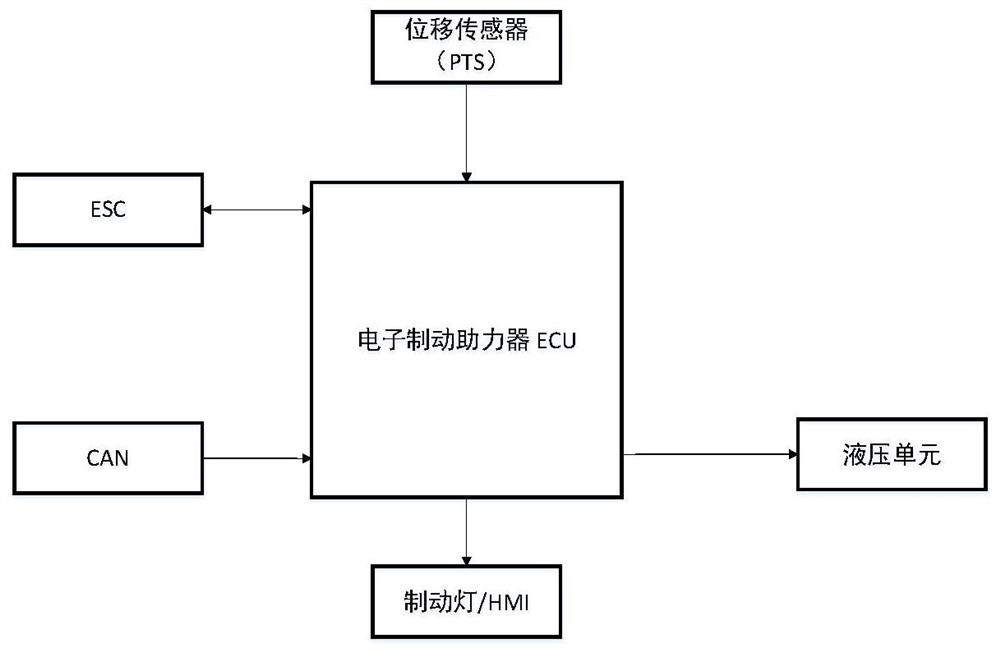

Brake control method, device and system

ActiveCN112677950ASolve the problem of driving safetyBraking action transmissionElectric vehicle charging technologyControl systemMechanical engineering

The invention provides a brake control method, device and system, the method is applied to a decoupling type electronic brake booster of a vehicle, the vehicle further comprises an electronic stability control system, and the method comprises the steps of monitoring the displacement of a brake pedal of the vehicle; determining a target braking force value according to the displacement; under the condition that it is determined that an executing mechanism of the electronic brake booster fails, sending a first brake signal is sent to the electronic stability control system, so that the electronic stability control system responds to a brake request and brakes the vehicle according to the target brake force value, wherein the first braking signal comprises the braking request and the target braking force value. The decoupling type electronic brake booster solves the problems that when an executing mechanism of an existing decoupling type electronic brake booster fails, due to the decoupling gap, the brake distance and the brake response time are long, and the driving safety of a vehicle is affected.

Owner:精诚工科汽车系统有限公司

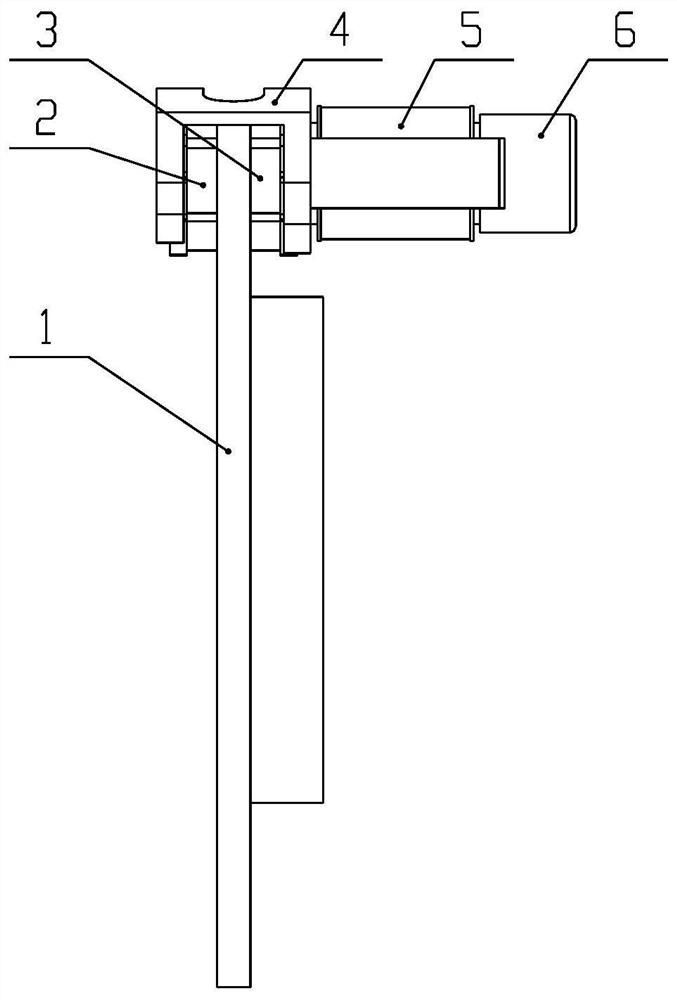

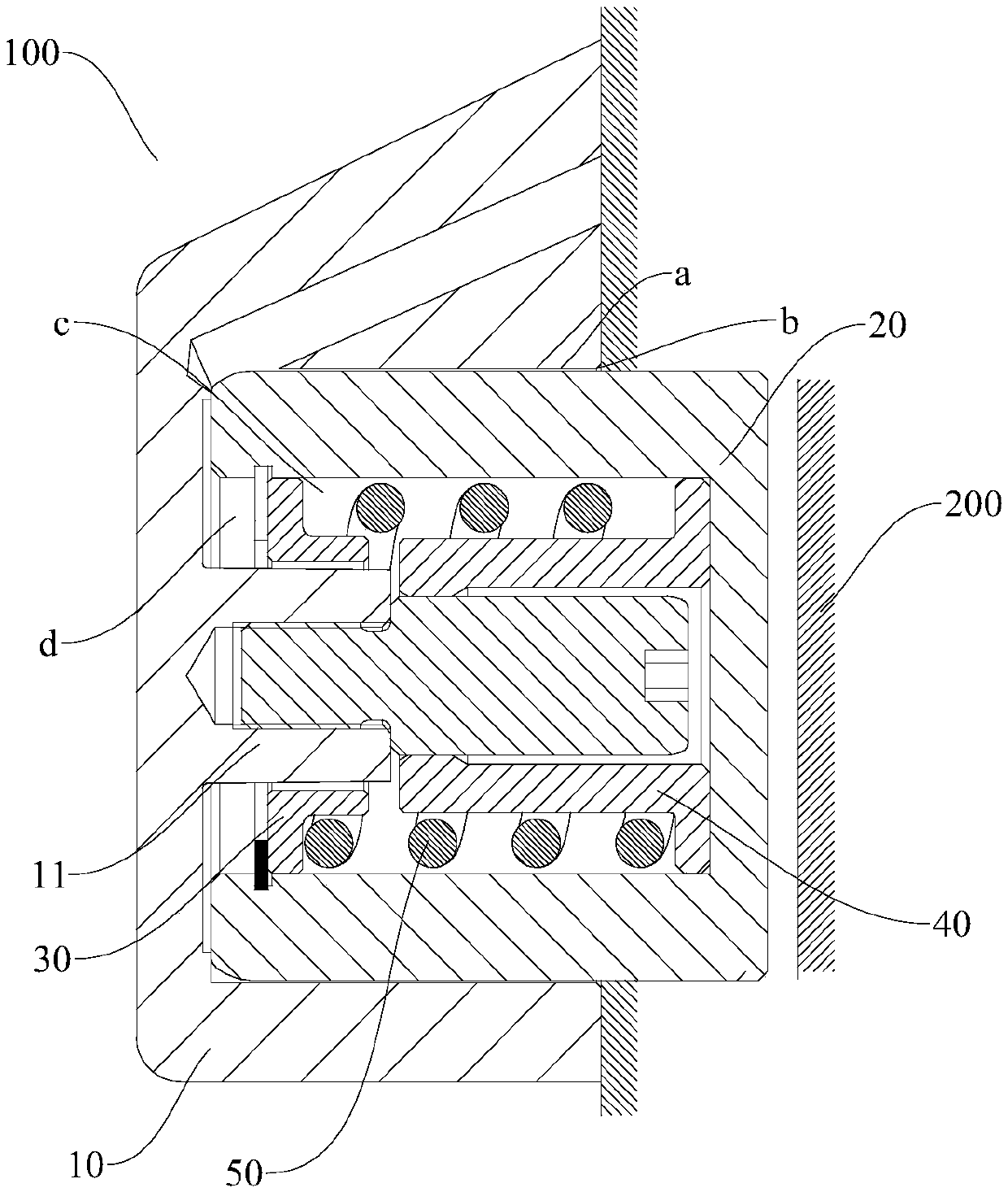

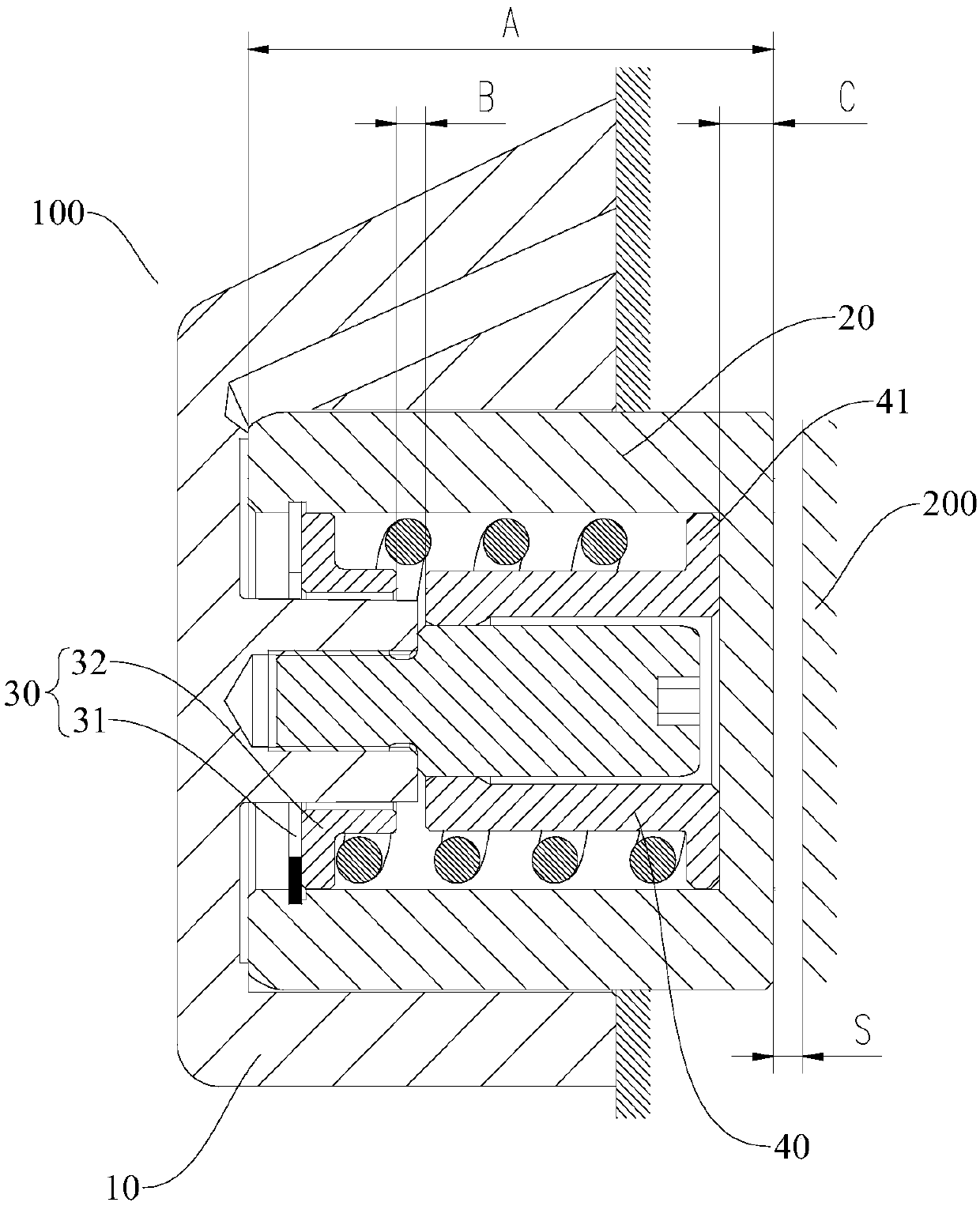

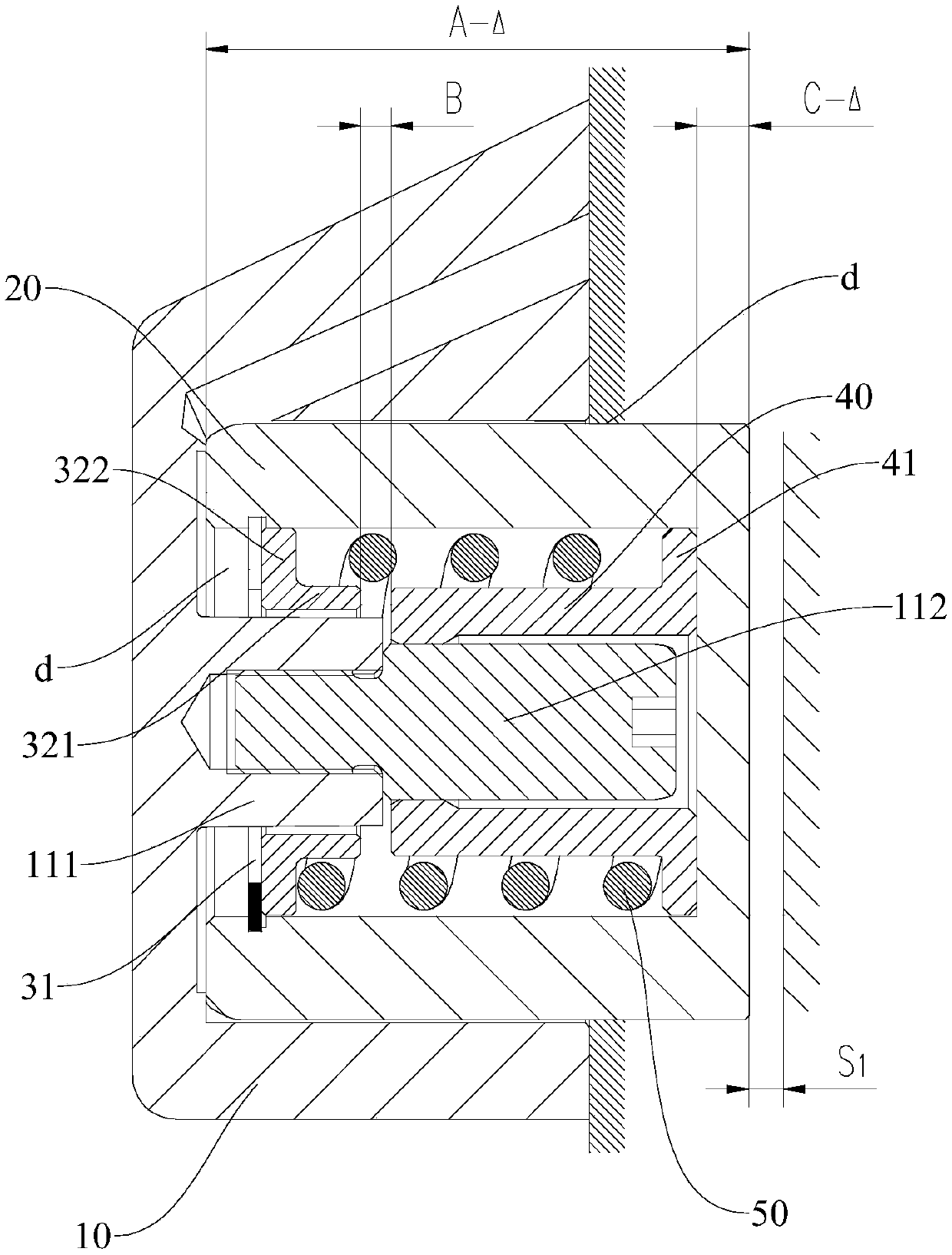

Clearance adjusting device for disc brake

PendingCN111322331ASteady Brake Response TimeImprove braking performanceSlack adjustersStructural engineeringMechanical engineering

The invention discloses a clearance adjusting device for a disc brake. The clearance adjusting device comprises a cylinder shell, a piston, a stopping assembly, a tensioning sleeve and an elastic part. A movable channel is arranged in the cylinder shell, and one end of the movable channel is open to form an opening part. A fixed boss extending towards the opening part is arranged on the bottom wall of the movable channel. The piston is movably arranged in the movable channel, the outer side of the bottom wall of the piston stretches out of the opening part, and a friction sheet is arranged onthe outer side of the bottom wall of the piston. The blocking assembly is arranged in a mounting chamber, and can be driven by the piston to move. The tensioning sleeve is arranged on the fixed boss,and is in clearance fit with the fixed boss. The tensioning sleeve and the stopping assembly are aligned to each other and are separated. One end of the elastic part is connected with the stopping assembly, and the other end of the elastic part is connected with the tensioning sleeve. Thus, on one hand, the braking clearance is kept stable, and the braking response time and the braking effect areboth kept stable; and on the other hand, a driving part and a transmission assembly do not need to be arranged, the structure is simpler, the occupied space is small, and the production cost is low.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com