Wet brake for tractor

A technology of wet brakes and tractors, which is applied in the direction of brake actuators, mechanical equipment, gear transmission mechanisms, etc., to achieve the effects of increased service life, low difficulty in assembly and maintenance, and reduced difficulty in use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and example the present invention will be further described:

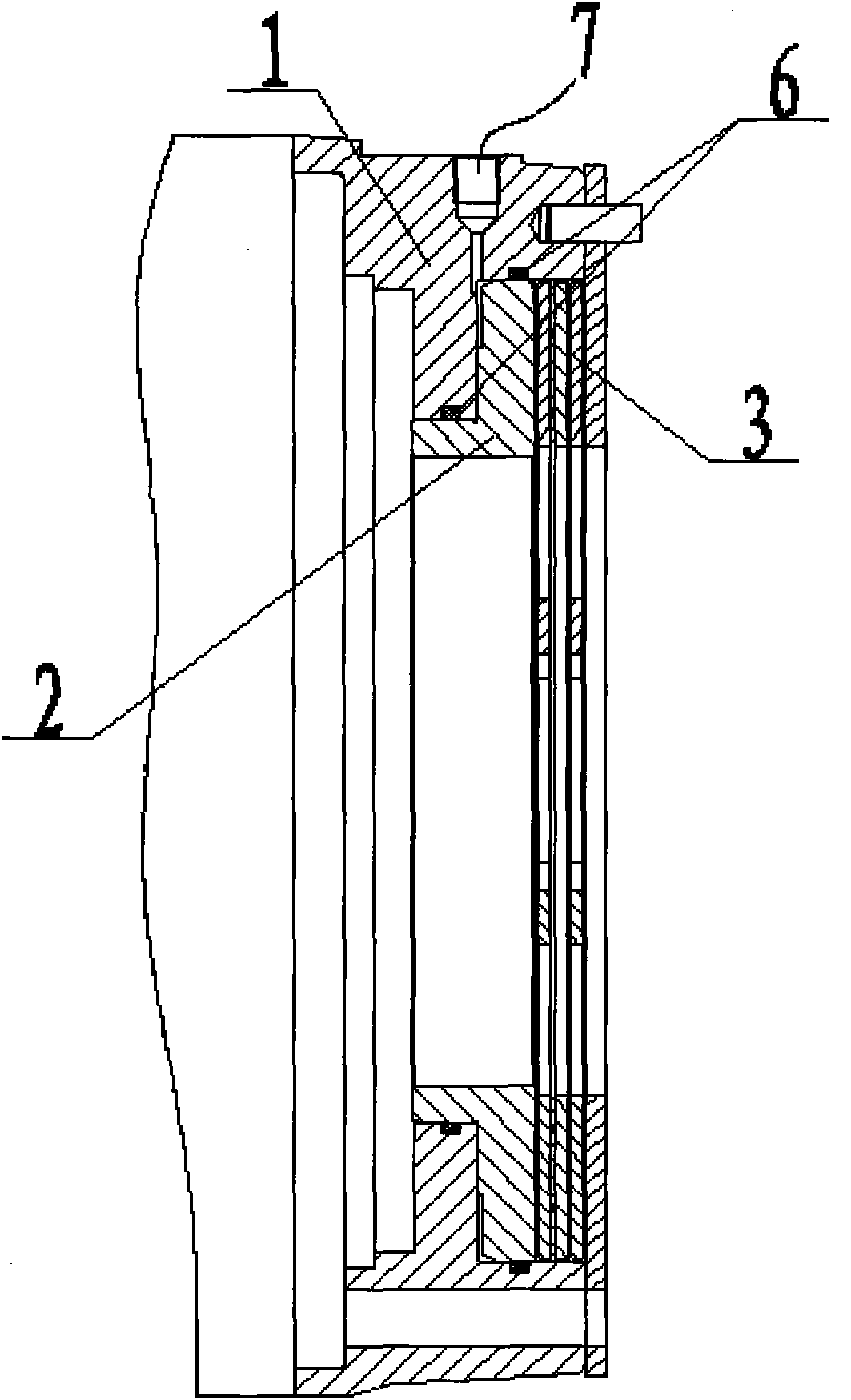

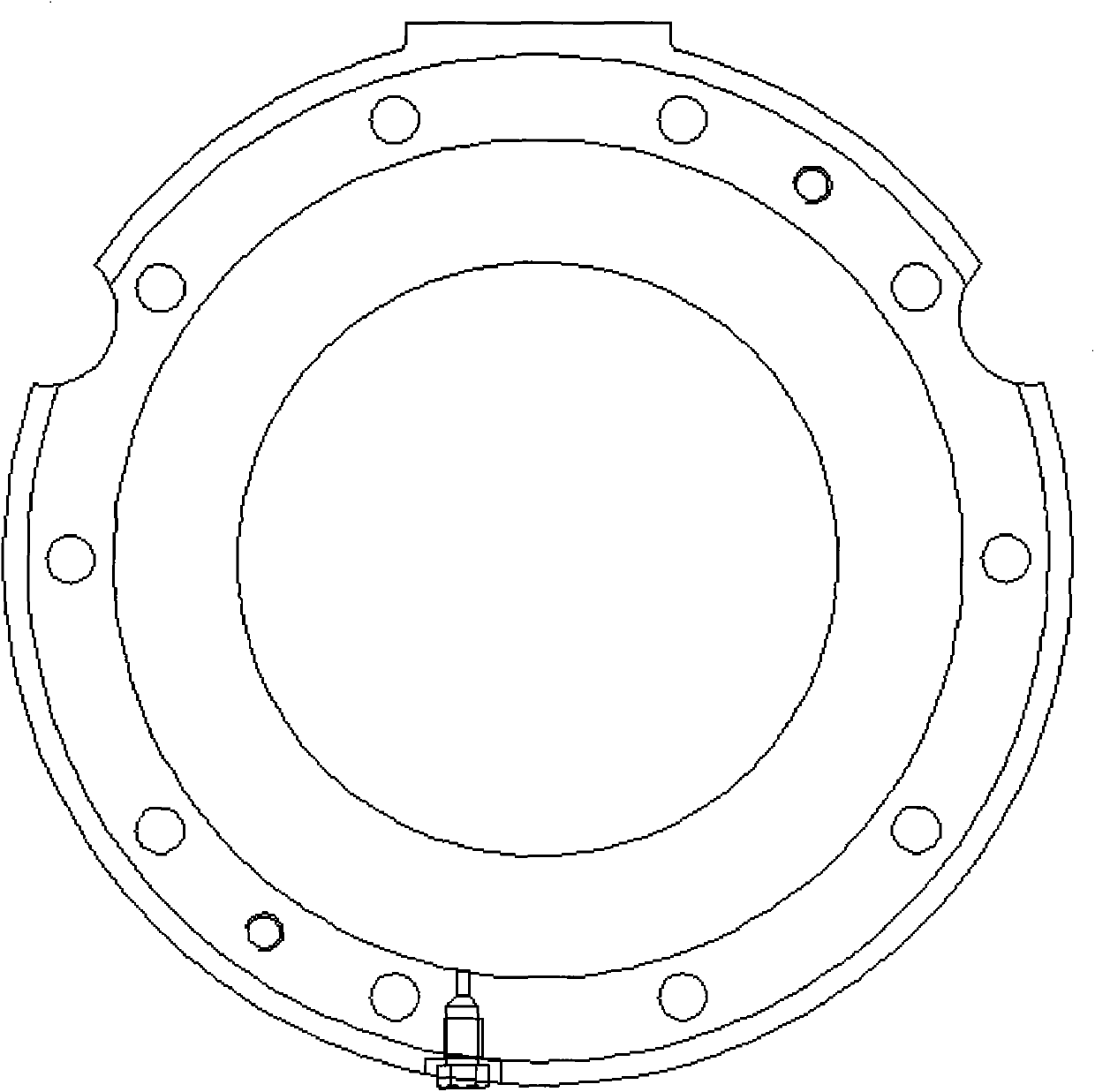

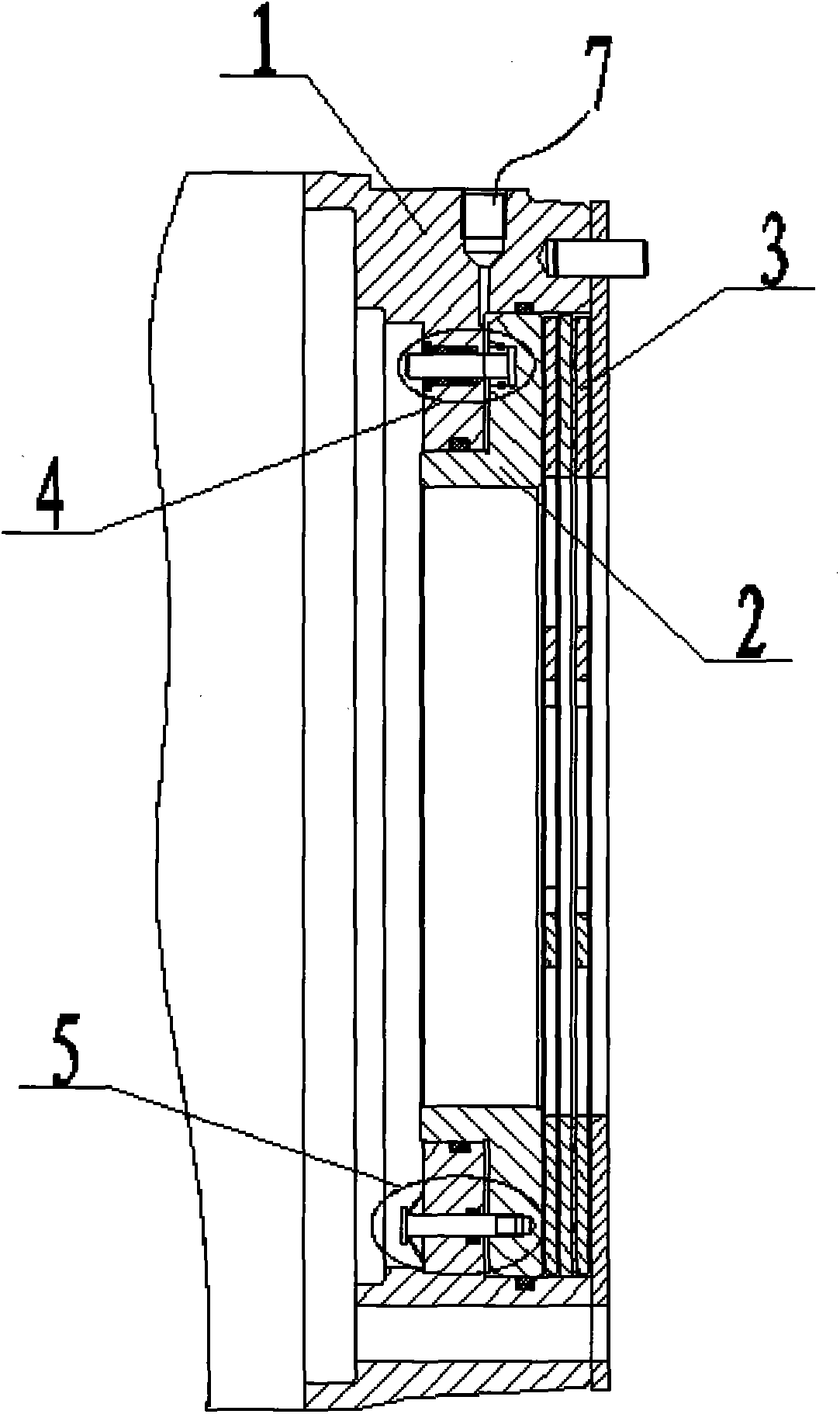

[0030] Such as Figure 3 to Figure 7 As shown, a wet brake for a tractor is characterized in that it includes: a housing 1, a piston 2, a friction plate assembly 3, a friction limit mechanism 4 and a piston return mechanism 5;

[0031] The friction limiting mechanism 4 includes: a friction positioning rod 10, a friction resistance ring 11 and a first snap spring 12, and the friction positioning rod 10 has a first positioning shoulder 14 and a second positioning shoulder 15 from left to right, The casing 1 is provided with an accommodating hole 16, the piston 2 is provided with a blind hole 17, and the frictional resistance ring 11 is mounted in the accommodating hole 16. It should be noted here that the frictional resistance ring 11 is always relative to the The housing 1 is fixed, and there are many ways to fix it. Existing fixing ways can be used, such as int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com