Patents

Literature

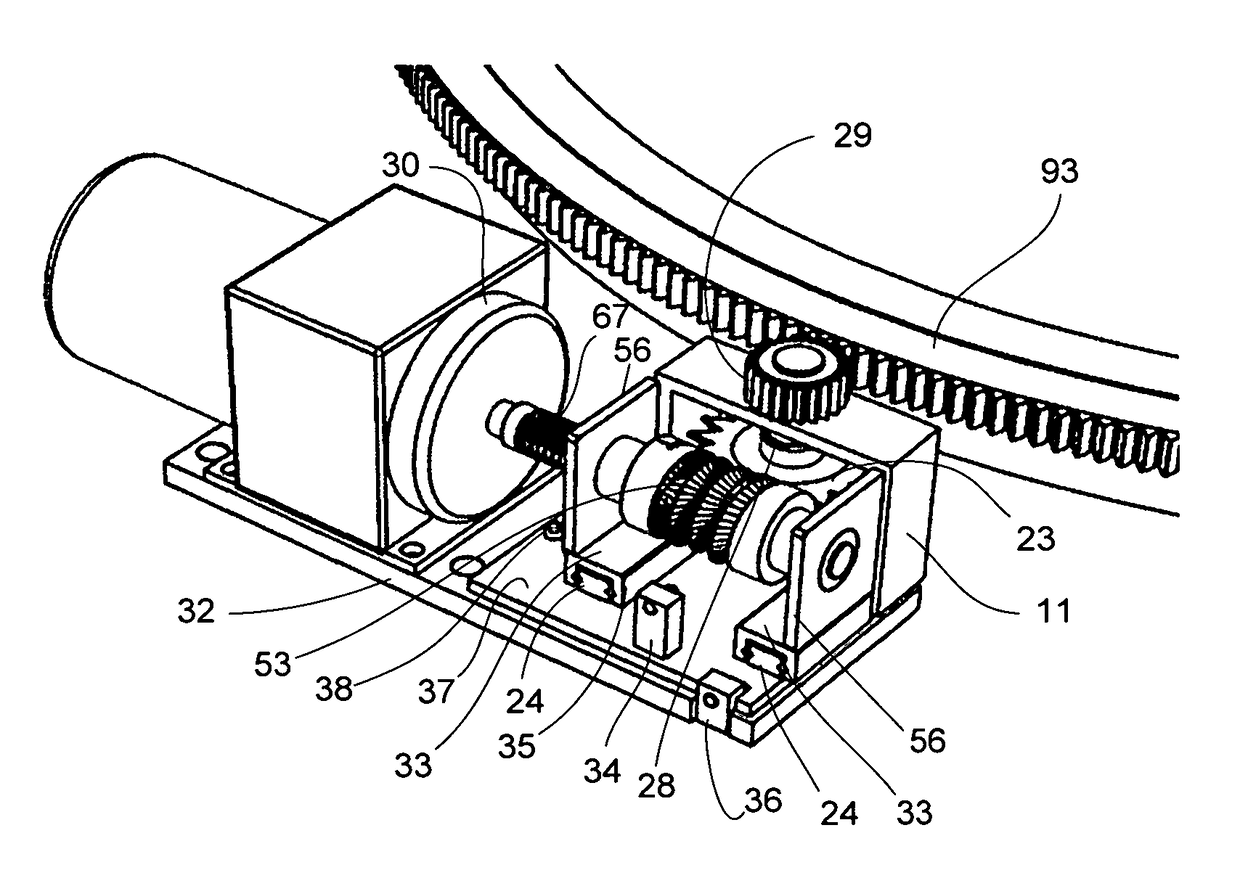

275 results about "Large tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

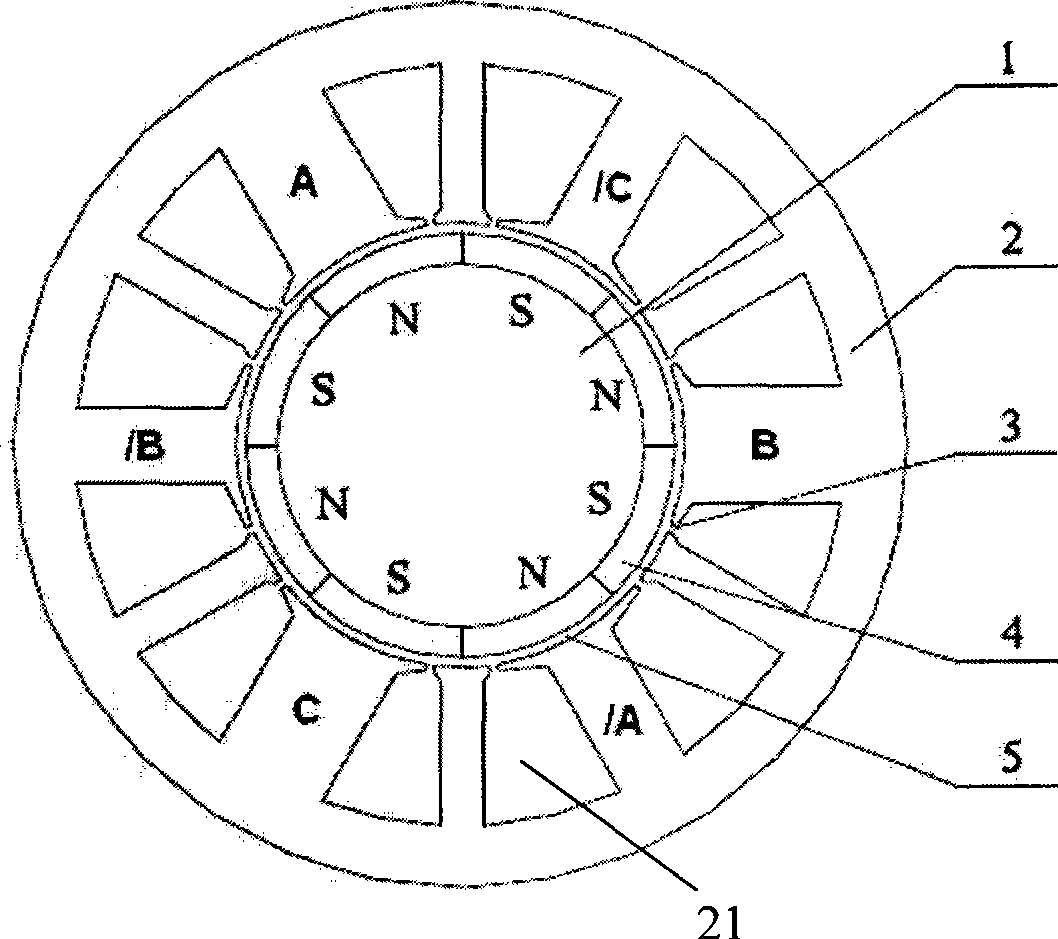

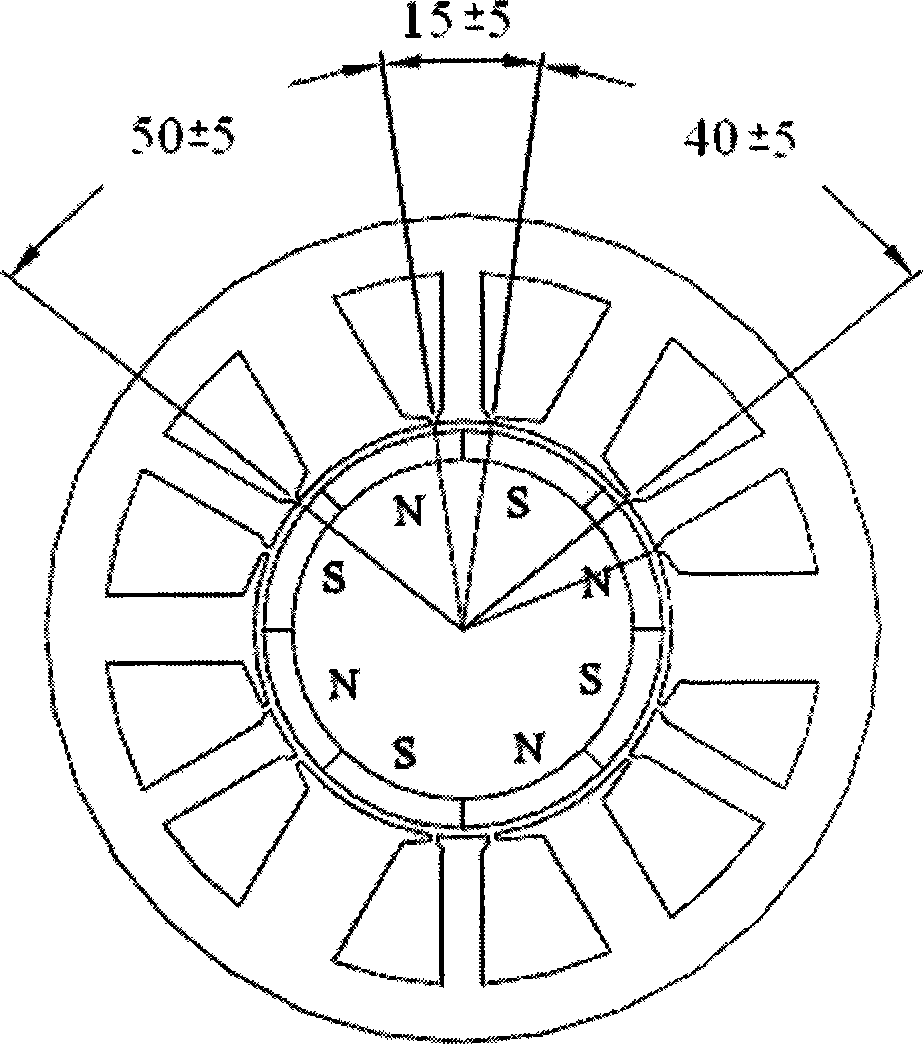

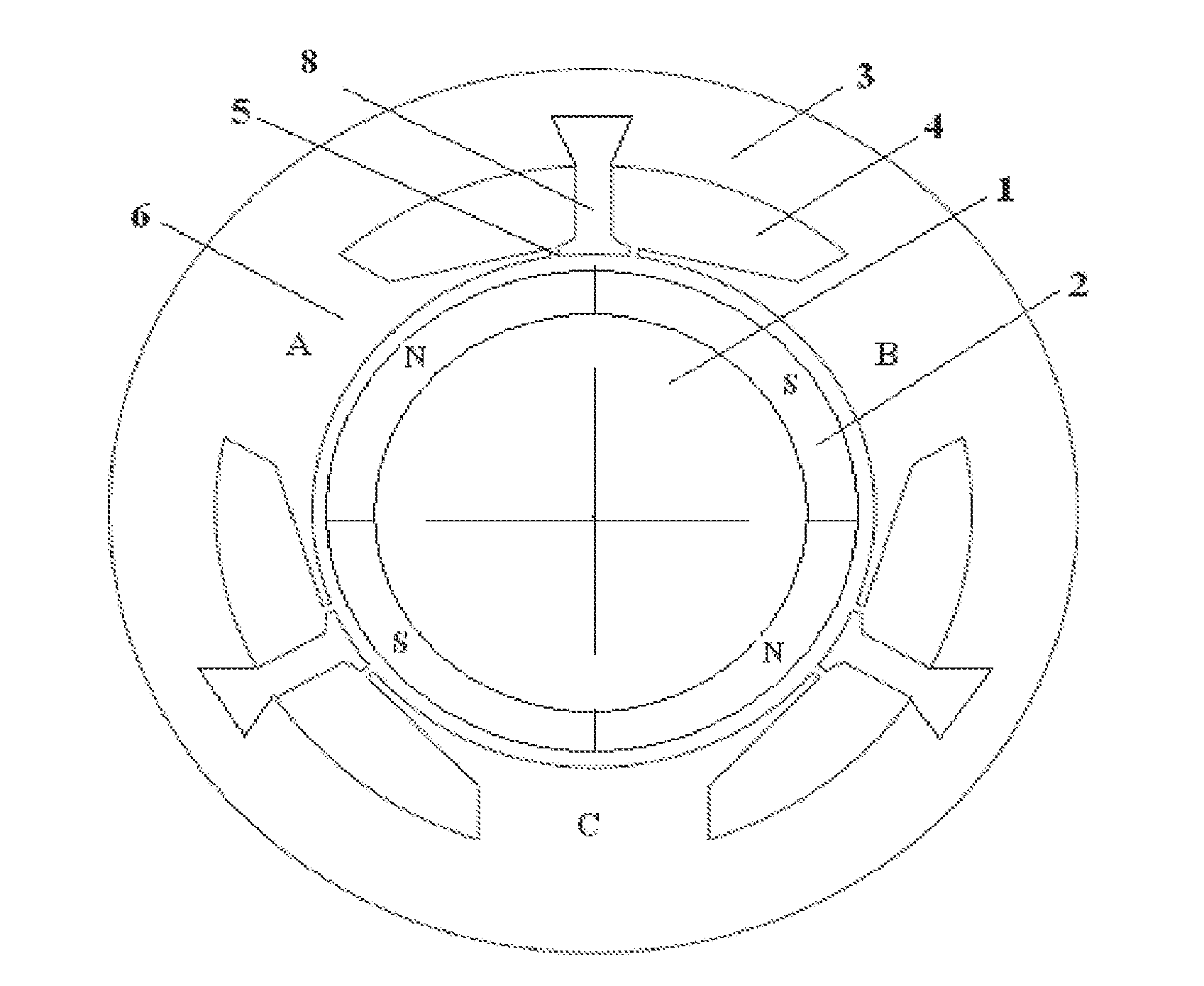

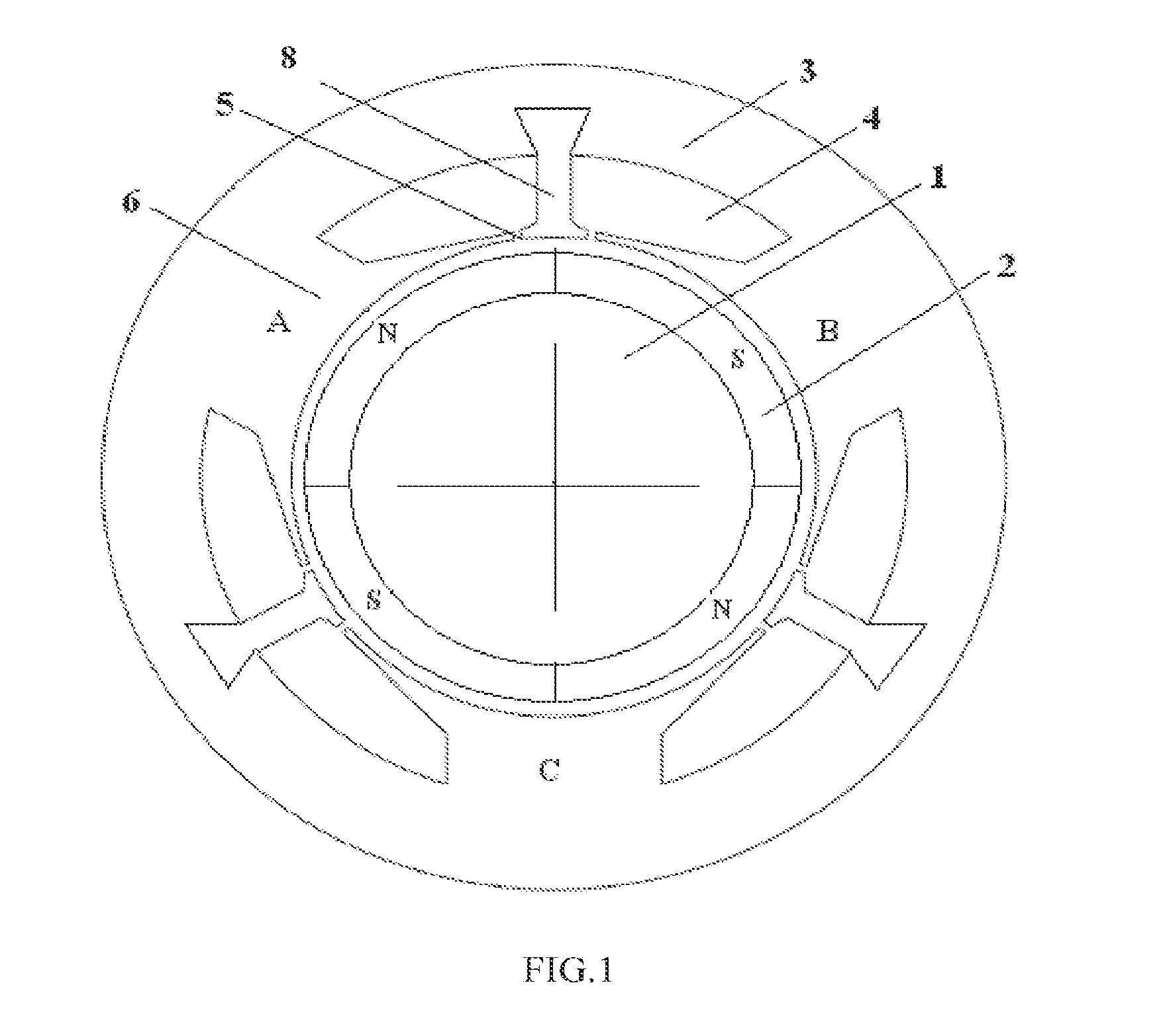

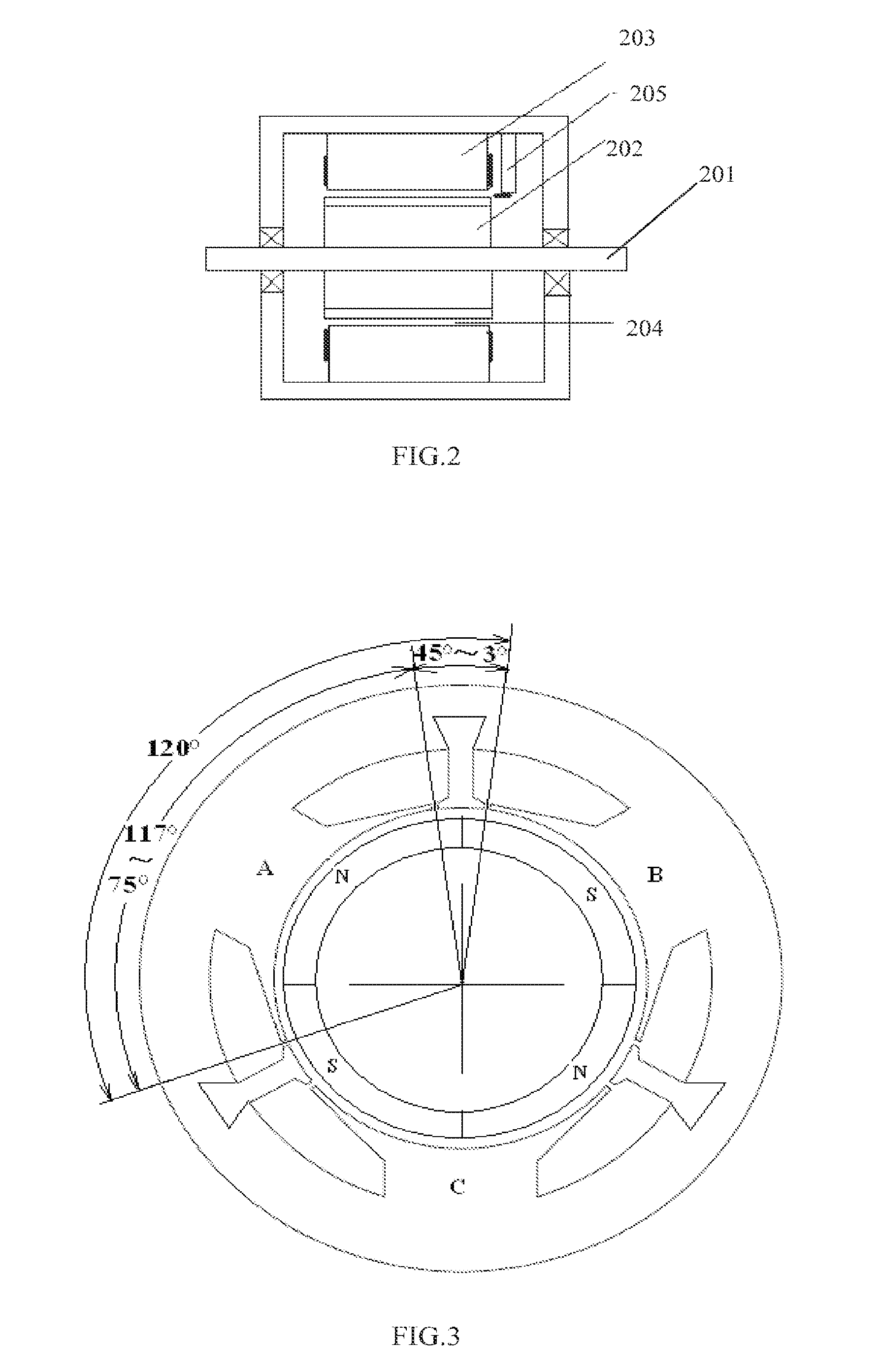

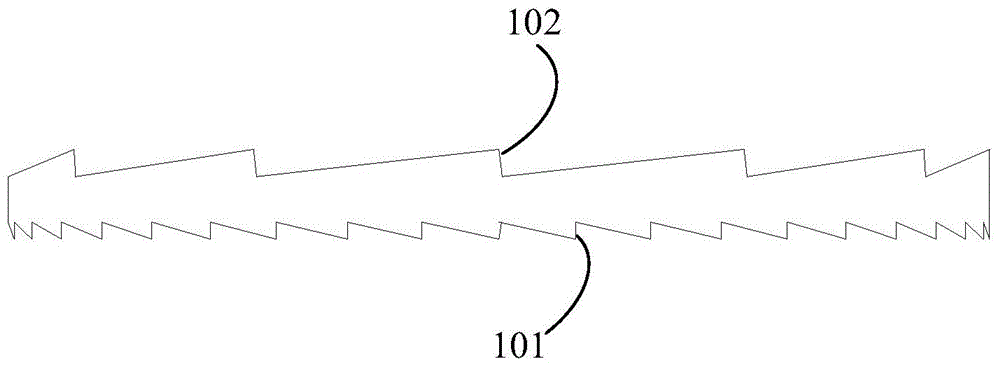

Square wave three-phase brushless permanent magnetic DC motor

ActiveCN101371425ASmall positioning torqueSimple structureMagnetic circuit rotating partsMagnetic circuit stationary partsLarge toothMagnetic poles

The invention relates to a square wave three phase brushless permanent magnet dc motor. In order to solve the problems existed in the prior square wave permanent magnet motor and sine wave permanent magnet motor, a magnetic pole number 2P is equal to 8 on a rotor iron core; a slot number Z is equal to 12 of a stator iron core, twelve teeth comprises three big teeth, three middle teeth and six small teeth;a mechanical angle ratio of the big teeth is 50 degree + / - 5 degree, the mechanical angle ratio of the middle teeth is 40 degree + / - 5 degree,the mechanical angle ratio of the small teeth is 15 degree + / - 5 degree,and a total mechanical angle ratio of one big tooth plus one middle tooth plus two small teeth is equal to 120 degree.The three phase concentrated windings respectively wind on the big teeth and middle teeth, each phase only has two concentrated windings and the three phase motor only has six concentrated windings. The motor can generate a stable torque when driven by a three phase square wave current and a torque fluctuation index is equivalent to that of the sine wave permanent magnet. The motor of the invention has a series of advantages of minimum winding end, minimum air gap, minimum material, minimum locating torque and minimum loss or the like.

Owner:SCBD (ANHUI) E TECH CO LTD

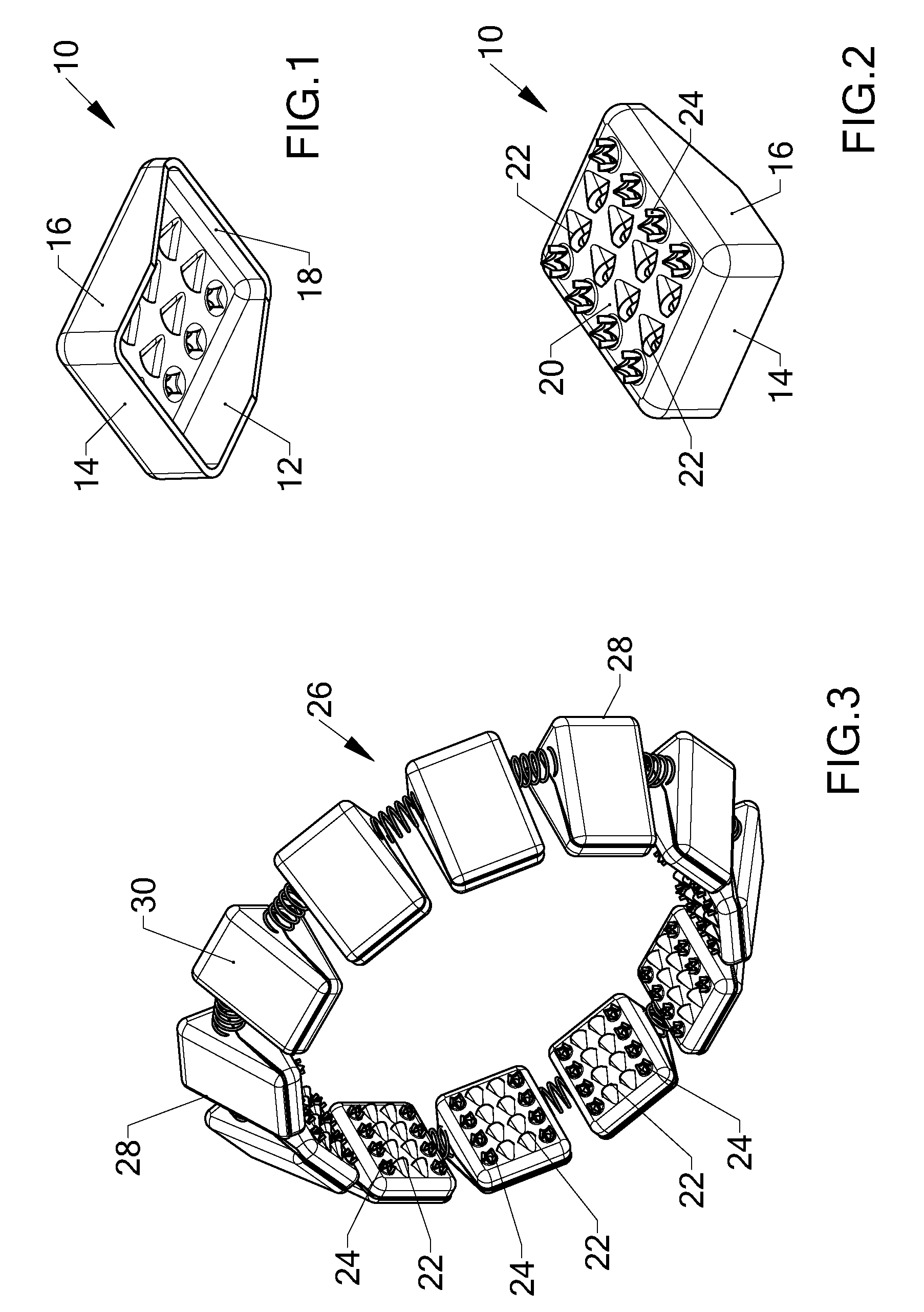

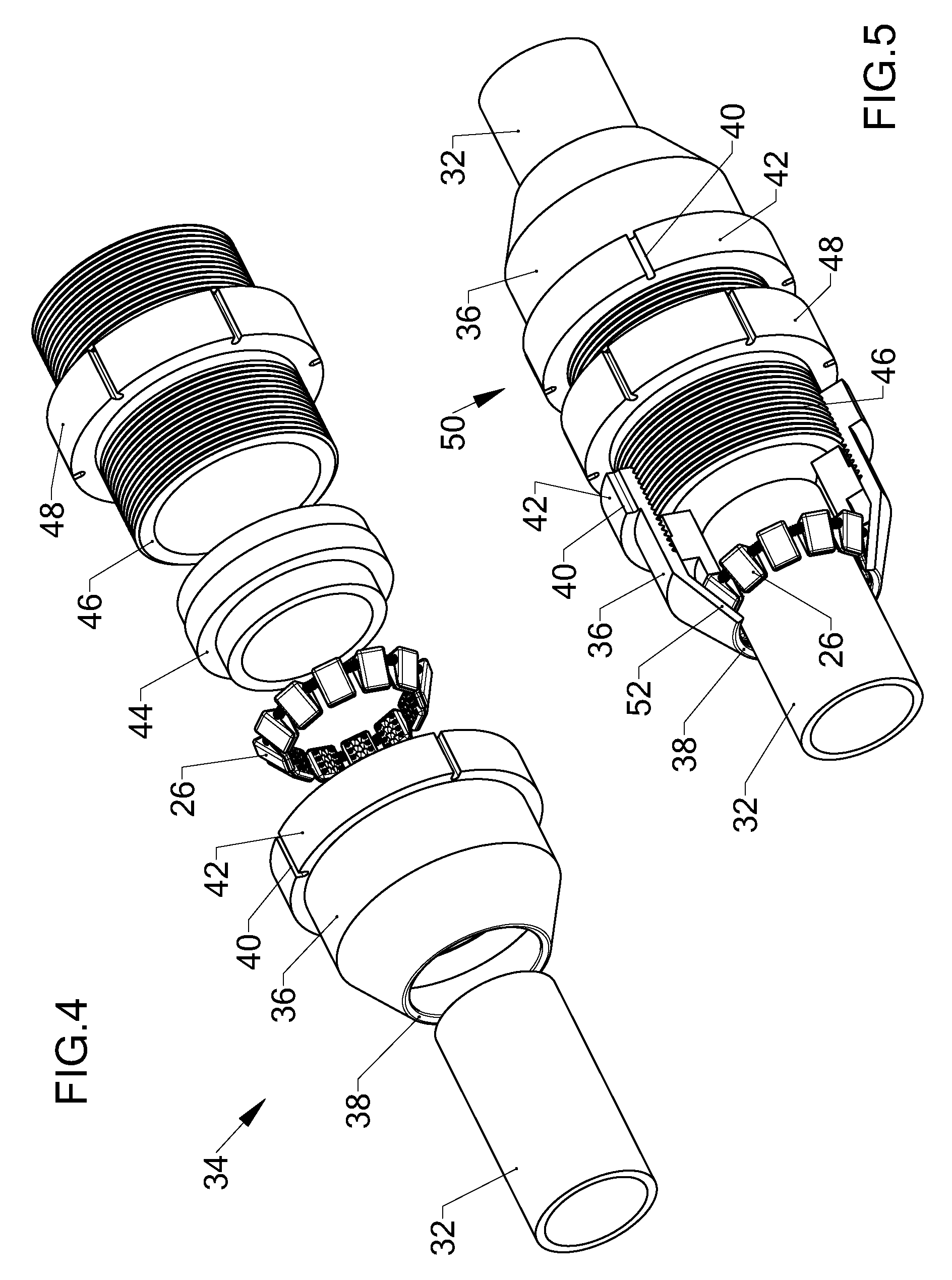

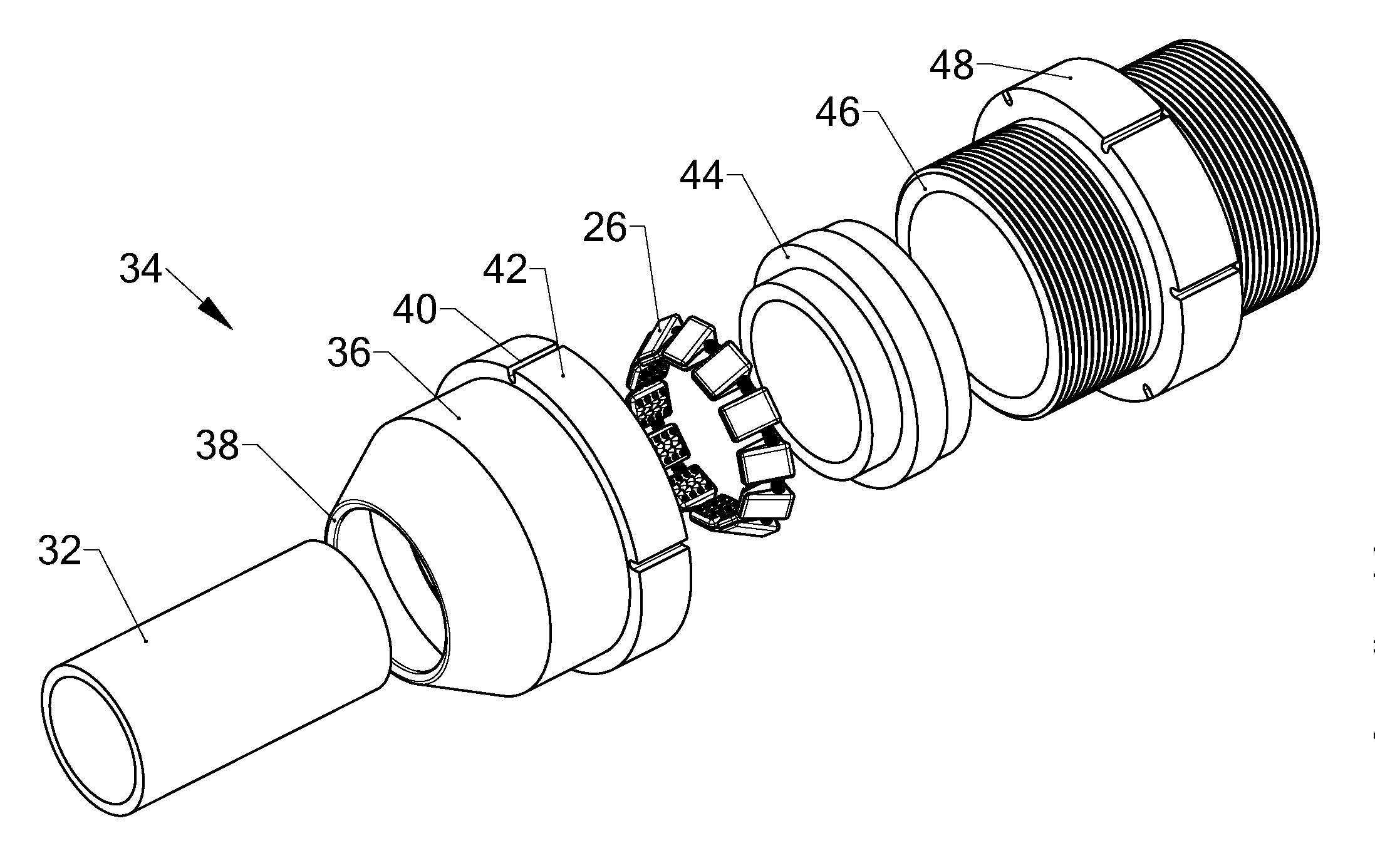

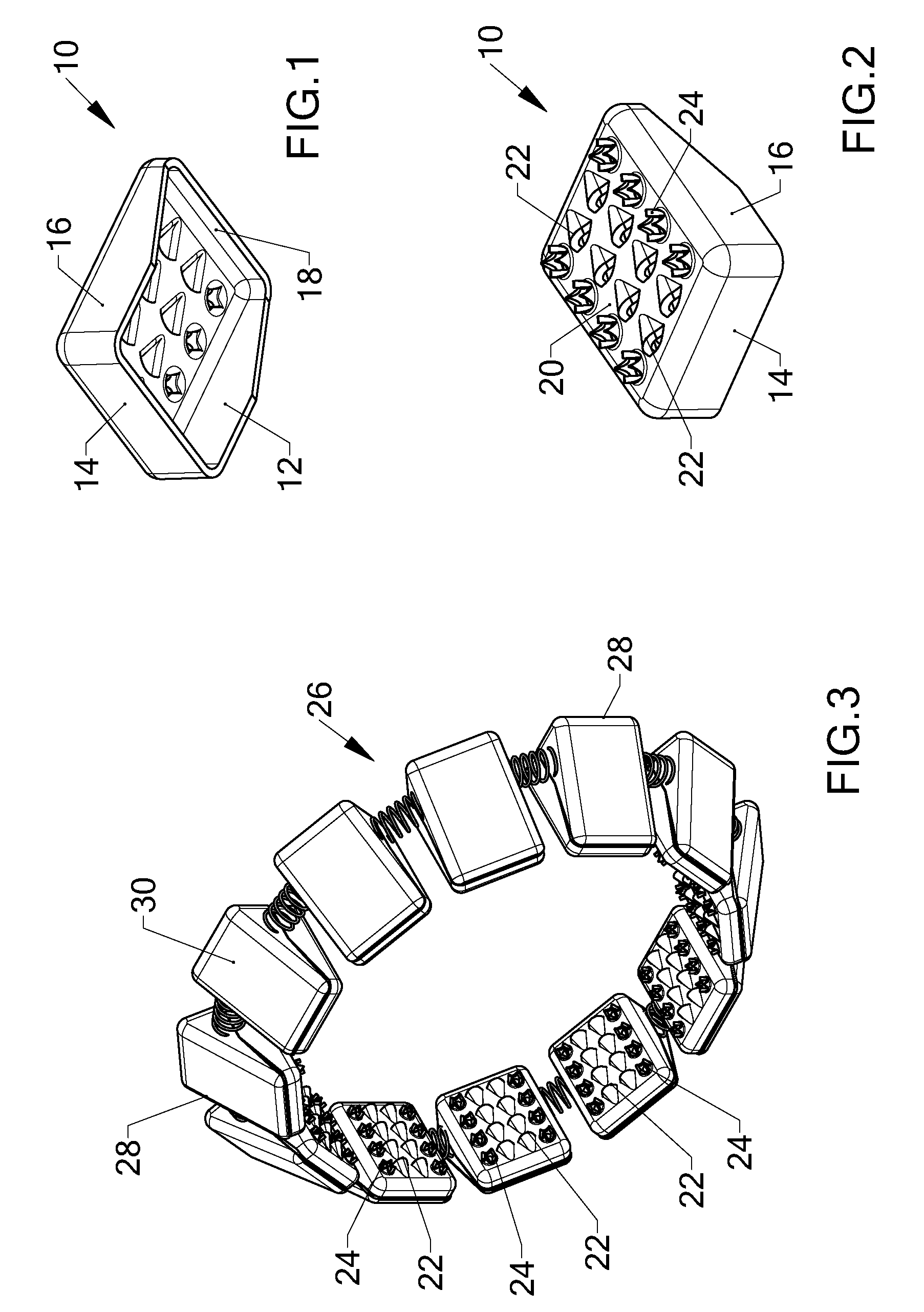

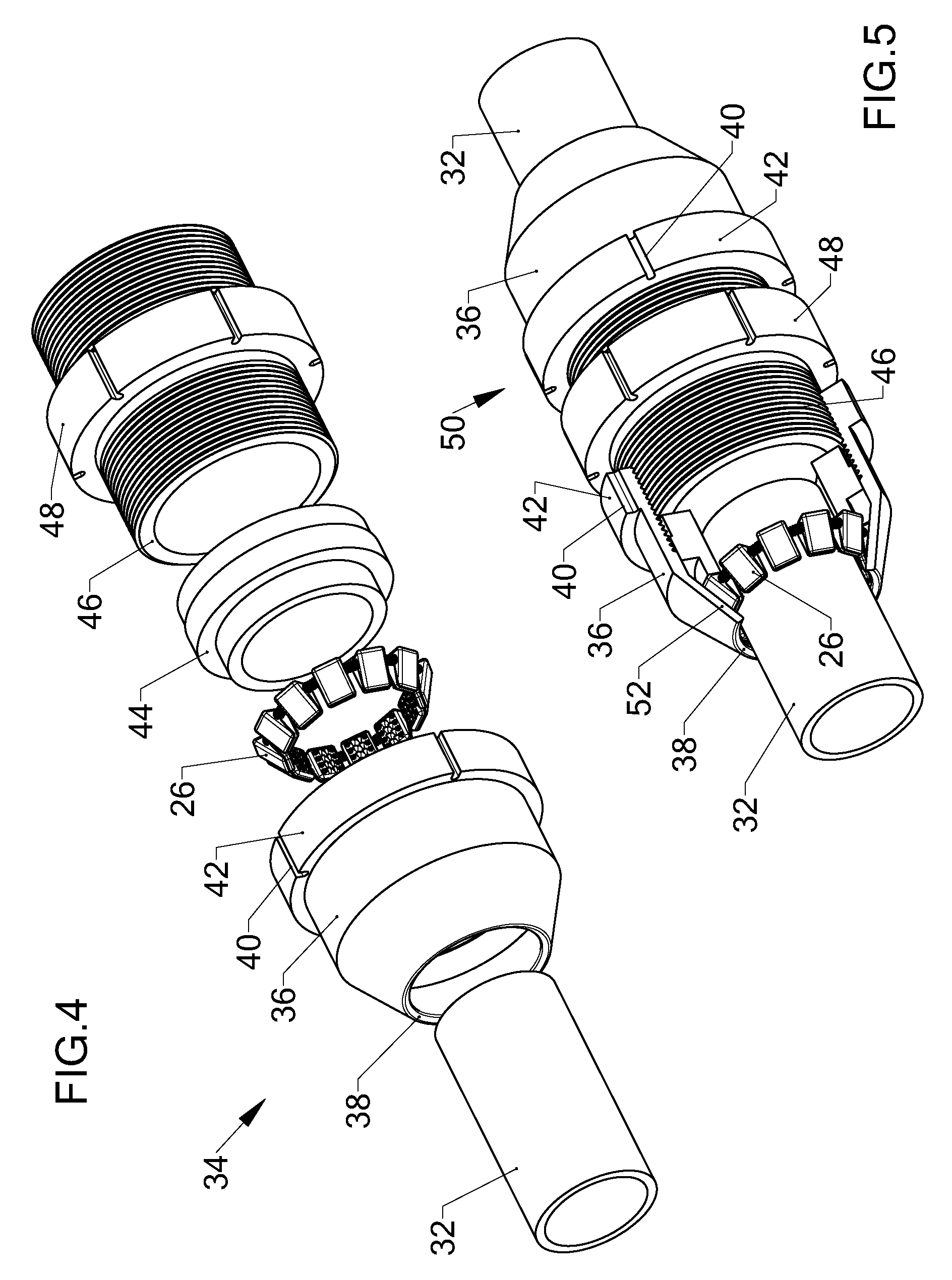

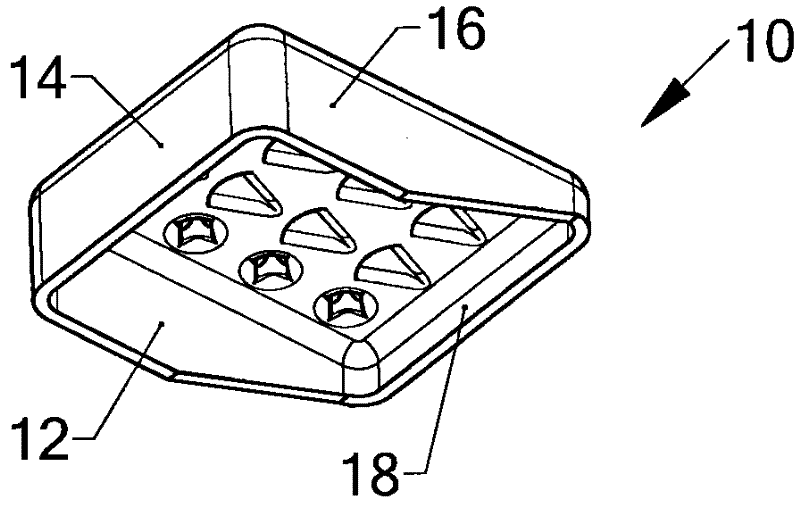

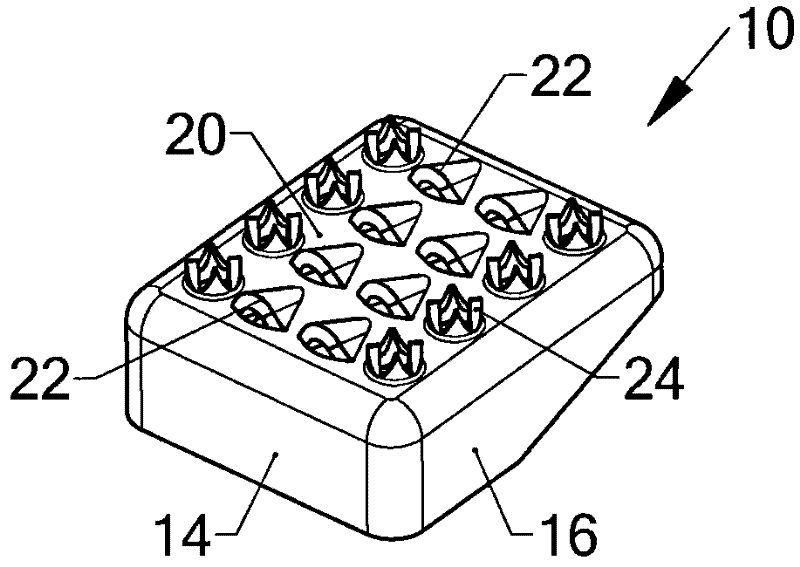

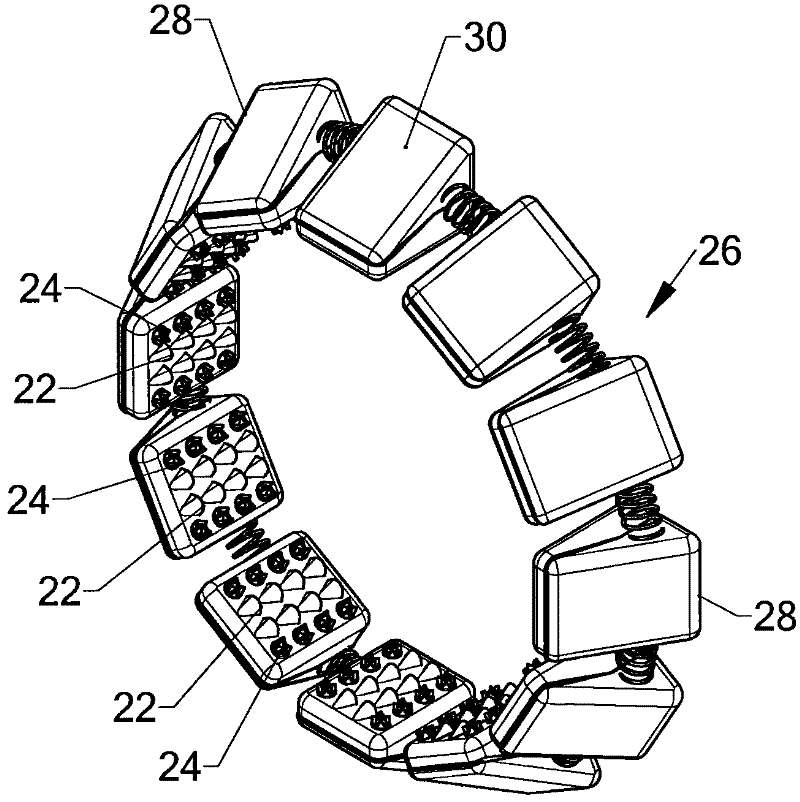

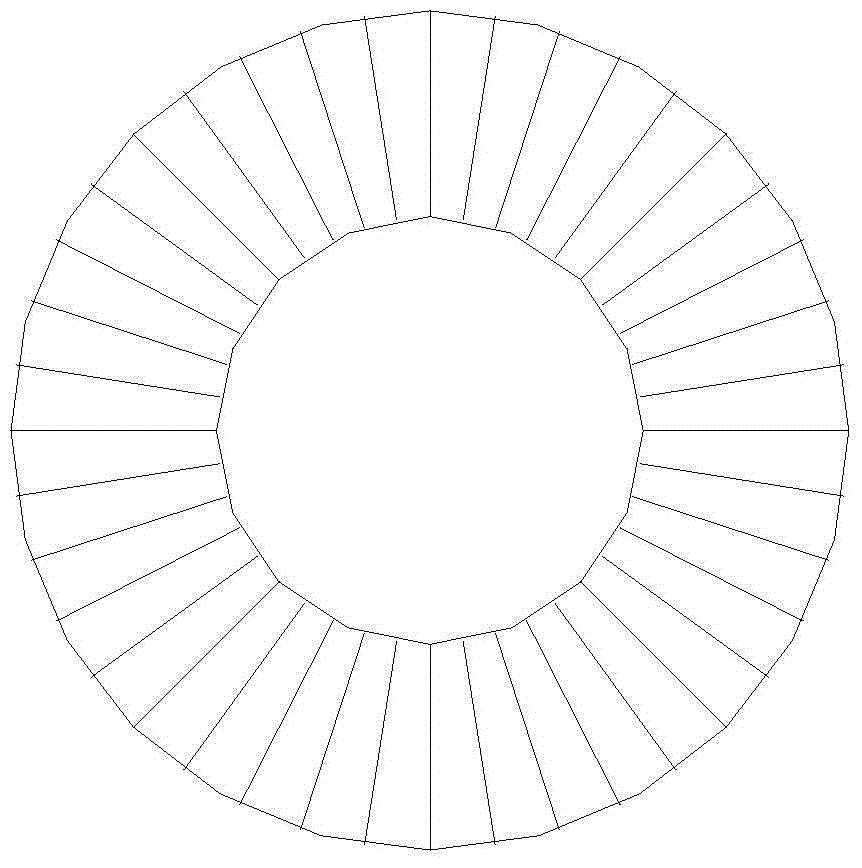

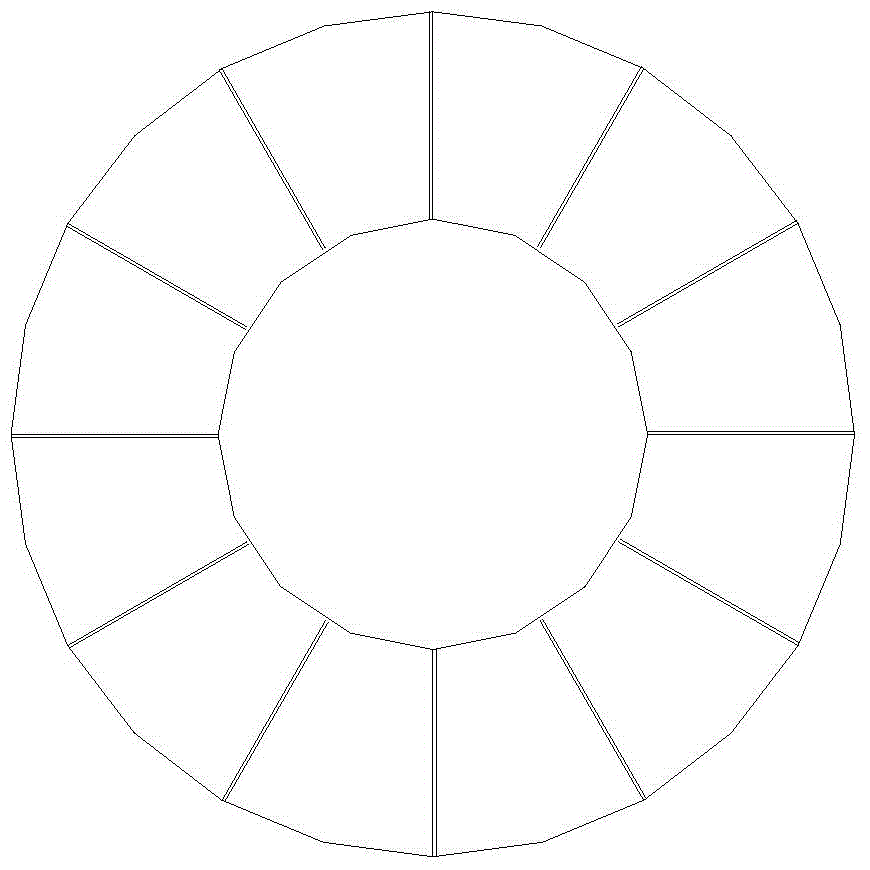

Pipe grip ring

ActiveUS7837238B2Improve pullout resistanceSleeve/socket jointsFluid pressure sealed jointsLarge toothEngineering

A grip element comprising a wedge-like structure supporting a metal plate, the exposed outer surface thereof being provided with an array of large and small gripping teeth. The large teeth project from the surface of said metal plate further than said small teeth. The invention further provides a grip element having a floor. The grip elements may be disposed around a ring for the purpose of pipe gripping. The ring is particularly useful in a pipe coupling to grip metal and plastic pipes.

Owner:KRAUSZ INDS DEVMENT

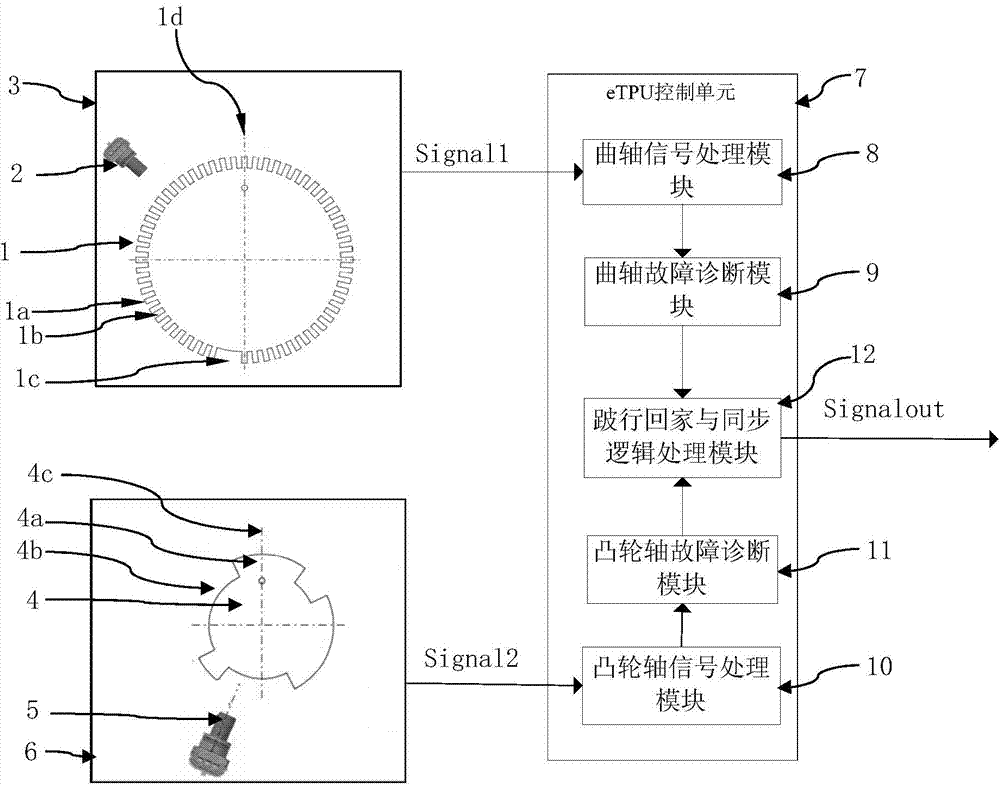

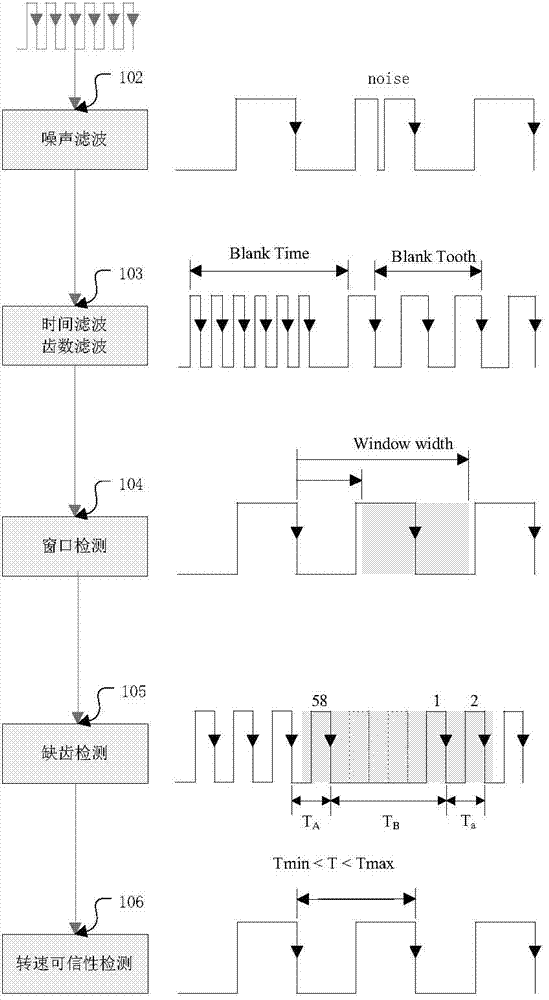

Engine position management system and management method

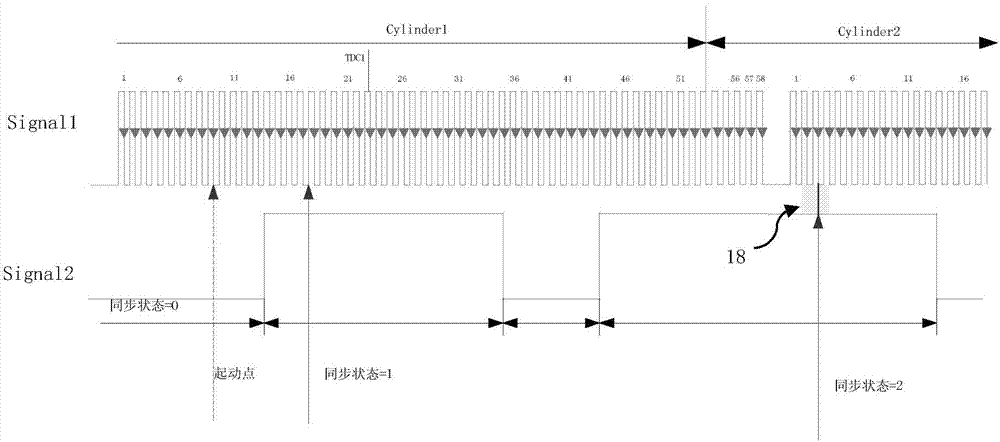

ActiveCN104747309AAchieve limp homeSync fastElectrical controlMachines/enginesLarge toothPosition sensor

The invention discloses an engine position management system. The engine position management system comprises a crankshaft signal panel, a crankshaft position sensor, a camshaft signal panel, a camshaft position sensor and an eTPU control unit, wherein the crankshaft signal panel comprises multiple convex teeth and tooth gaps; the tooth gaps have a large tooth gap for positioning; and the camshaft signal panel comprises three convex teeth with different central angles and tooth gaps. The eTPU control unit comprises a crankshaft signal processing module, a crankshaft fault diagnosis module, a camshaft signal processing module, a camshaft fault diagnosis module and a limp return and synchronous logic processing module. The engine position management system can use crankshaft signals and camshaft signals for realizing quick cylinder judgment and synchronization of an engine when the camshaft position sensor and the camshaft position sensor are normal, and can use another sensor for realizing the cylinder judgment synchronization and providing the angle information with limited precision to realize the limb return of the engine when one sensor is broken down. The invention further provides a management method of the engine position management system.

Owner:LIANCHUANG AUTOMOBILE ELECTRONICS

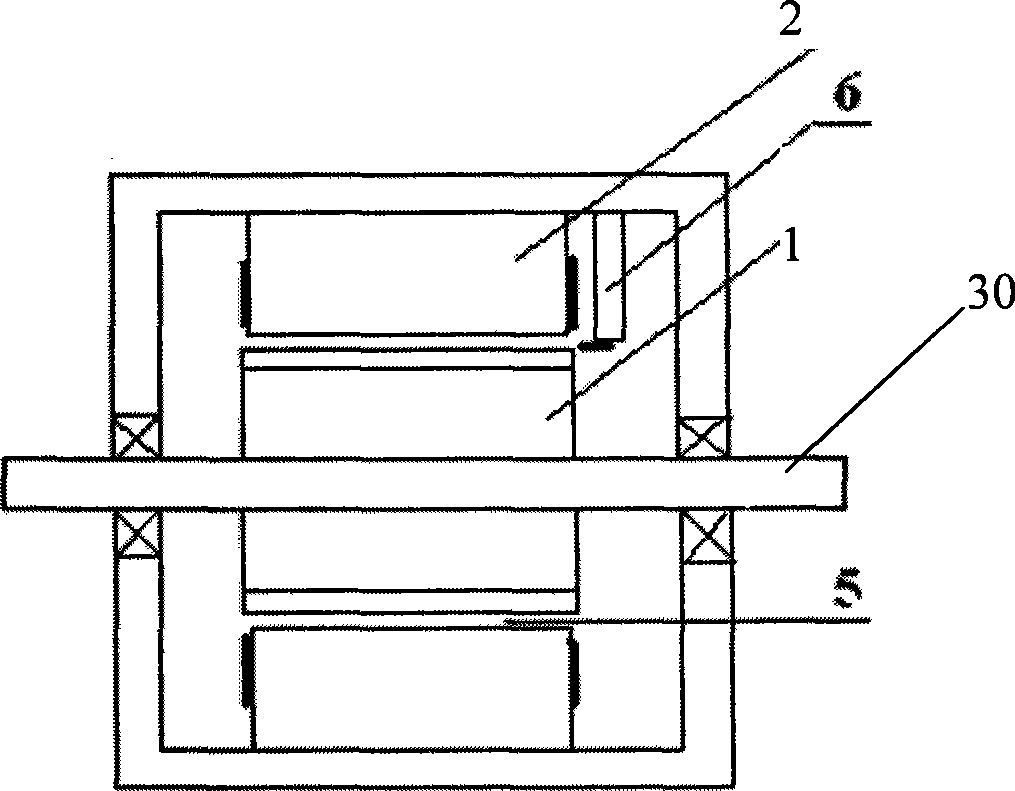

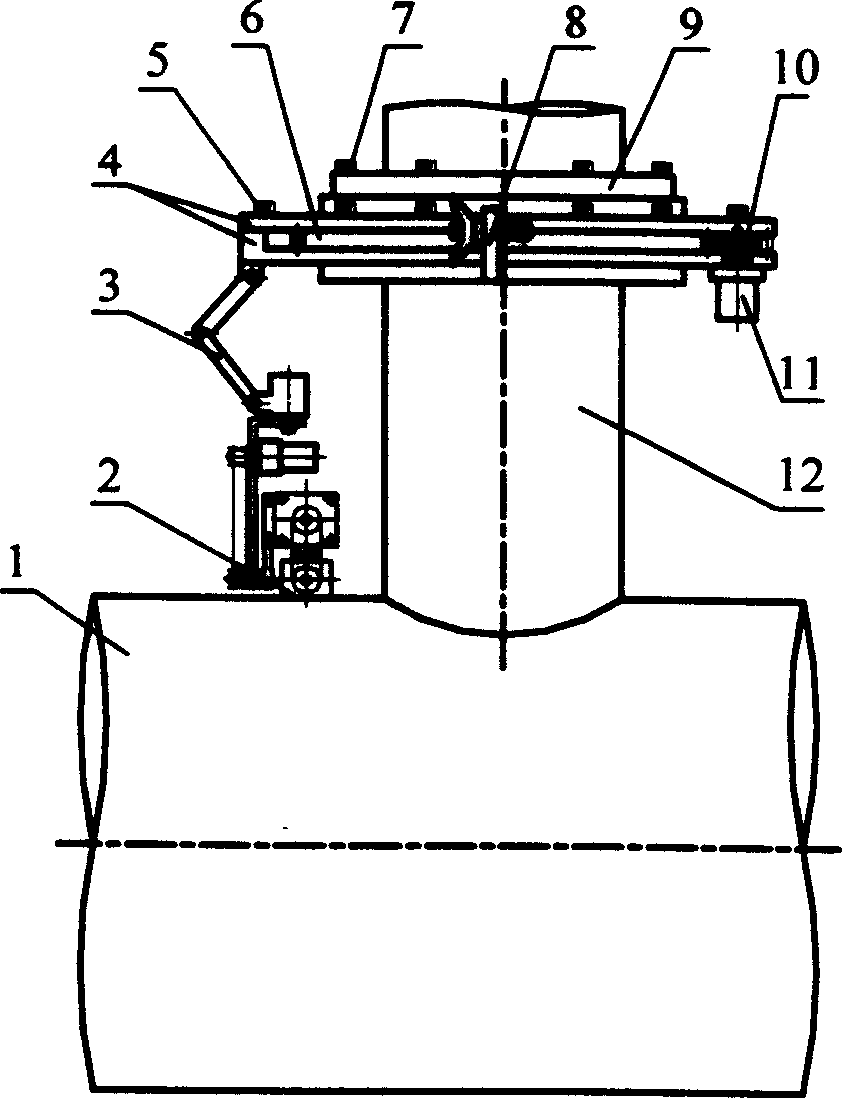

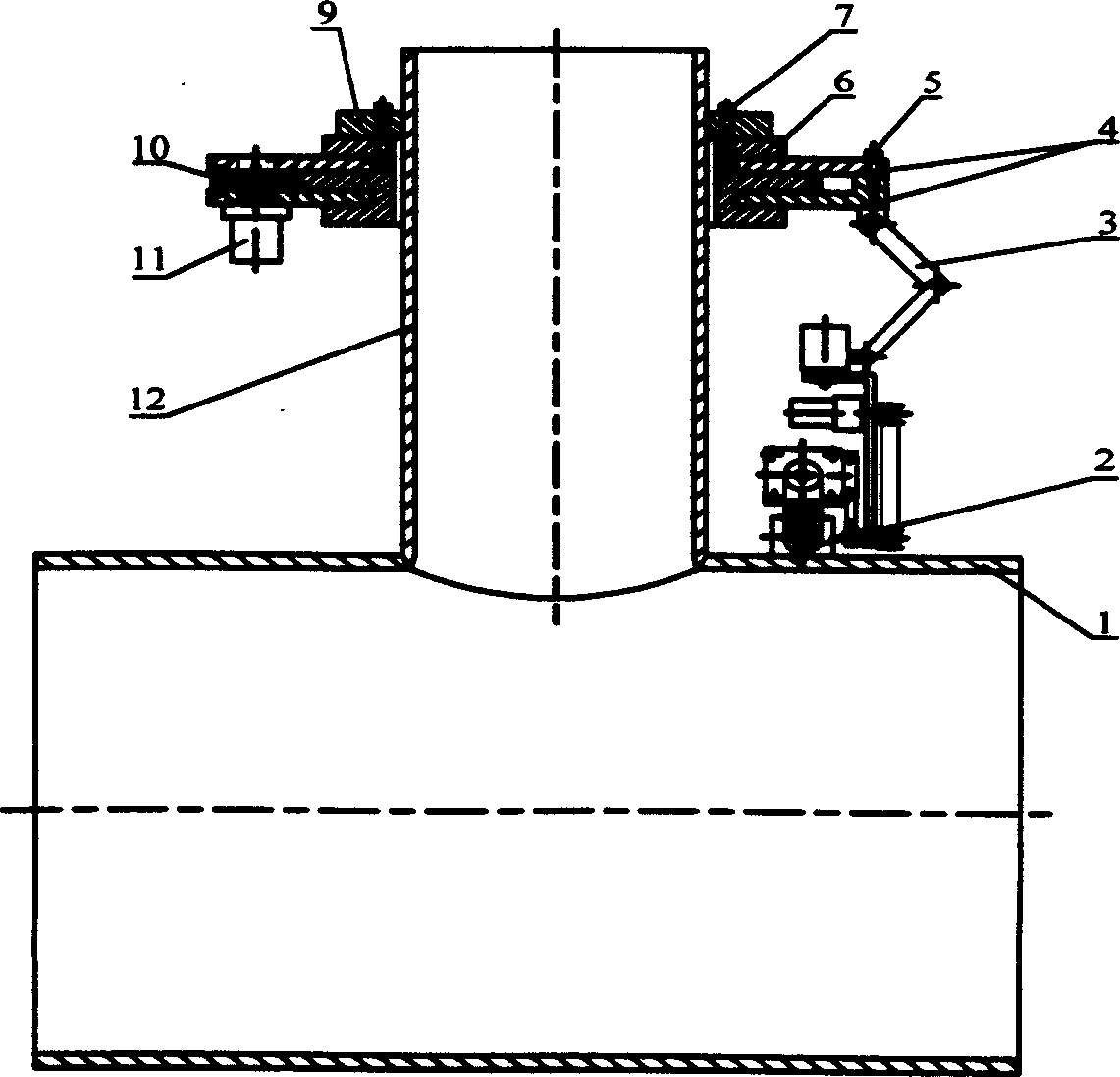

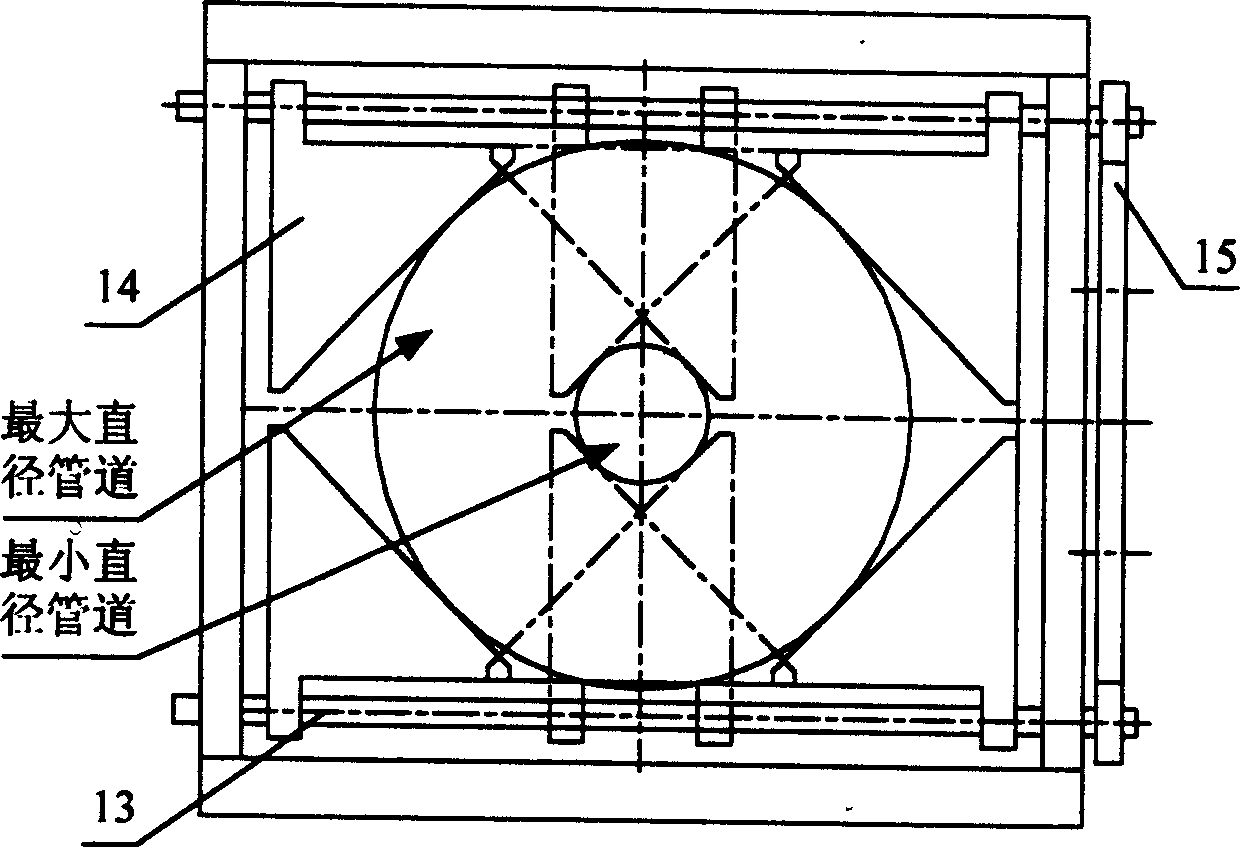

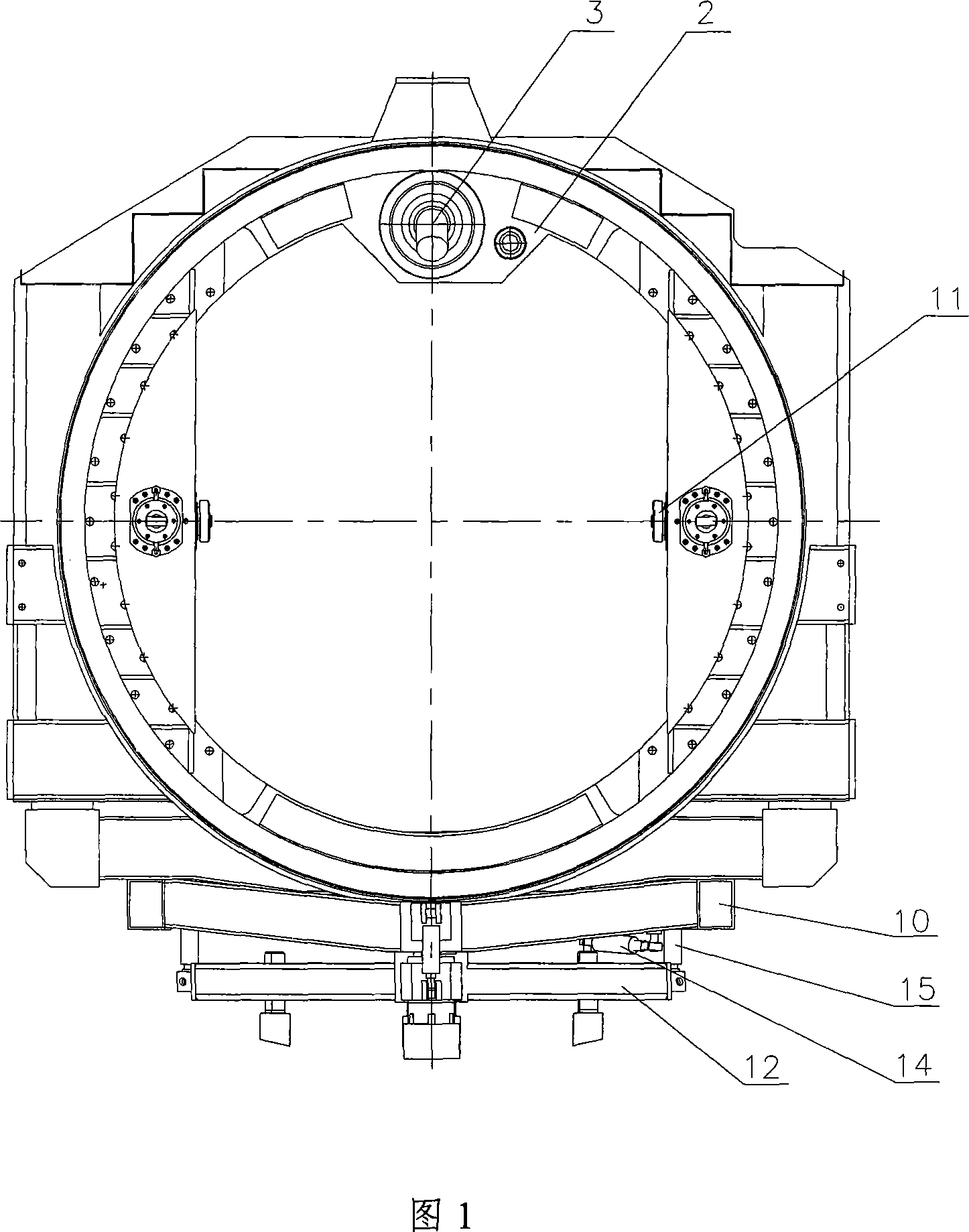

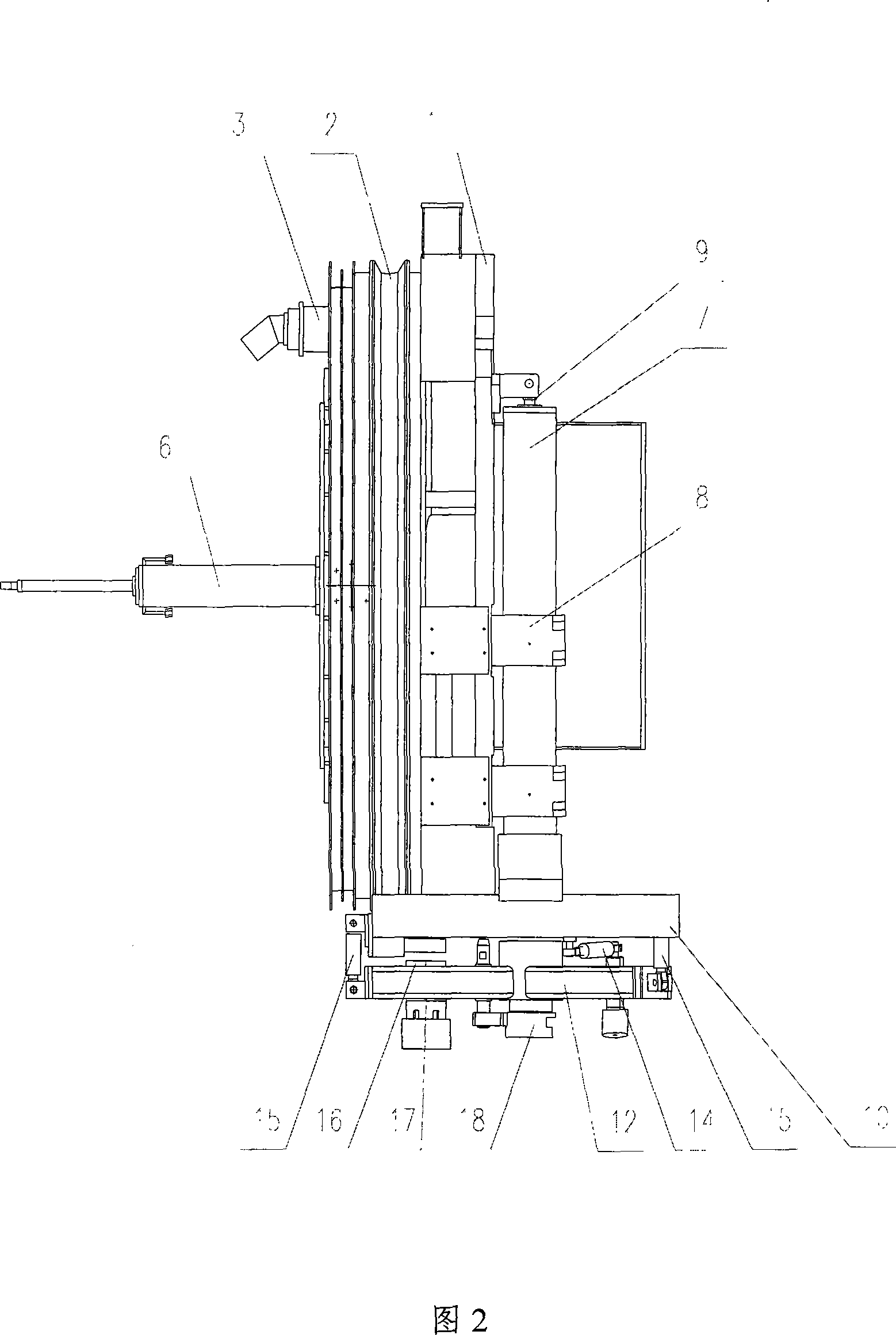

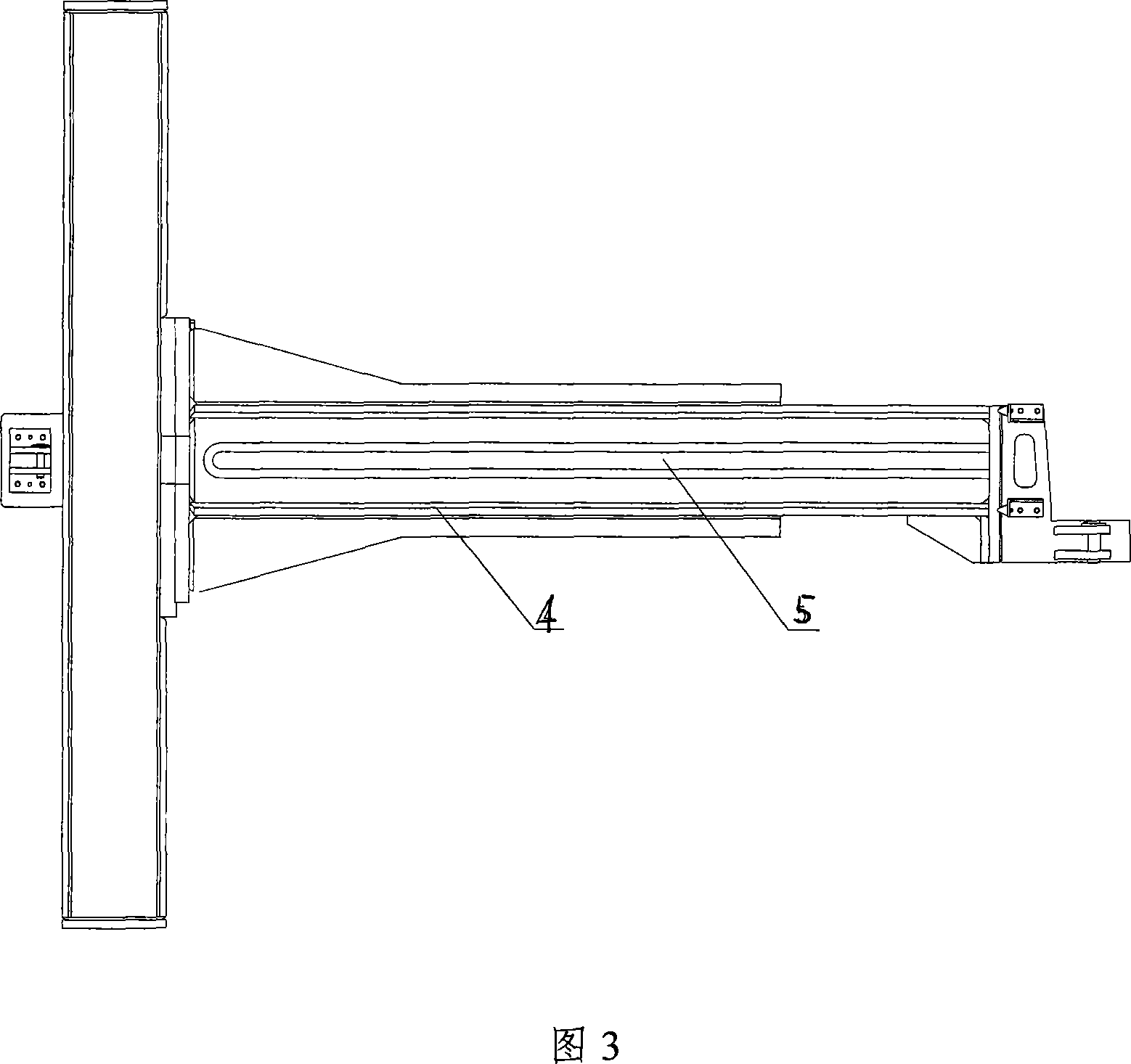

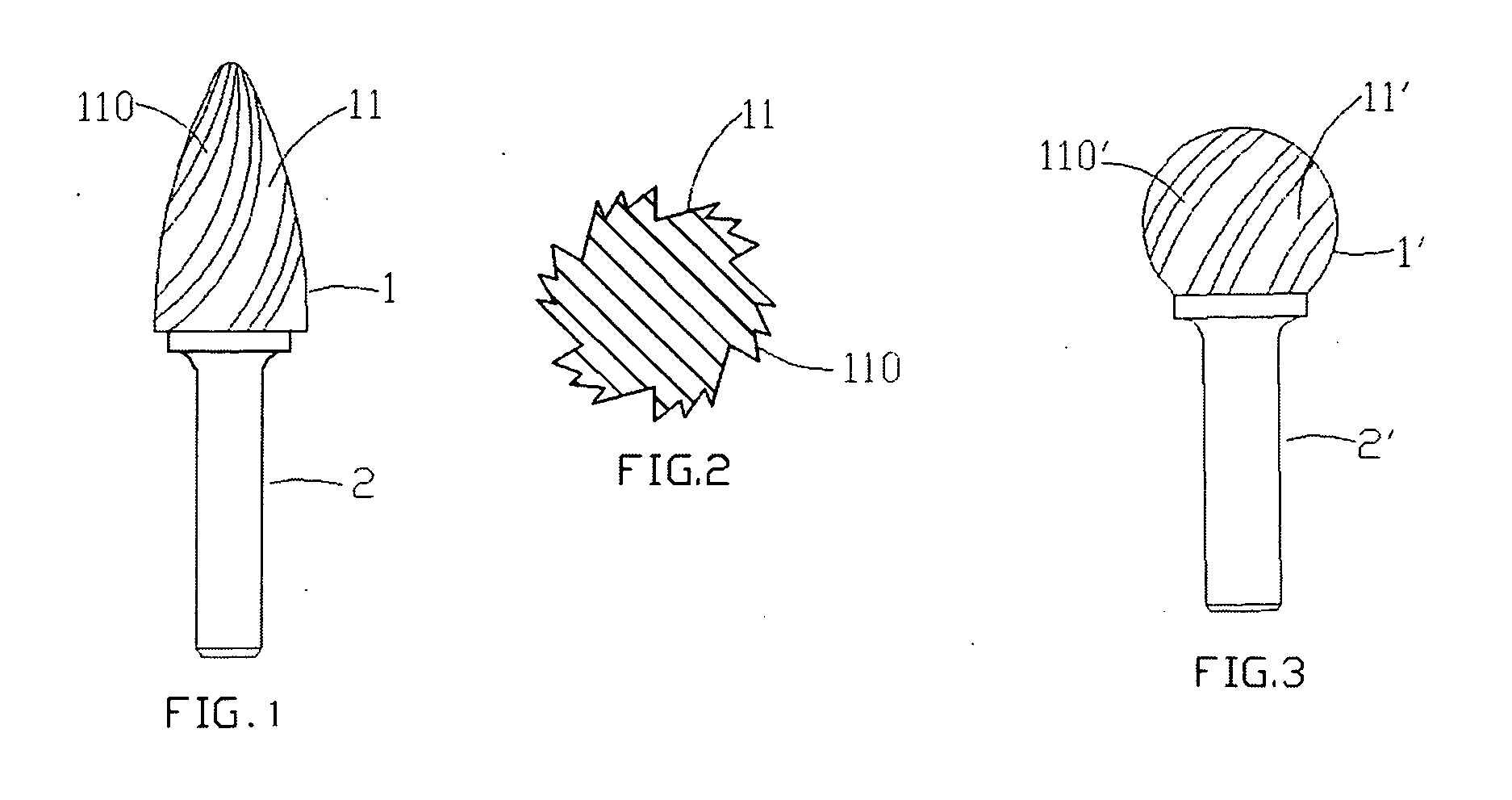

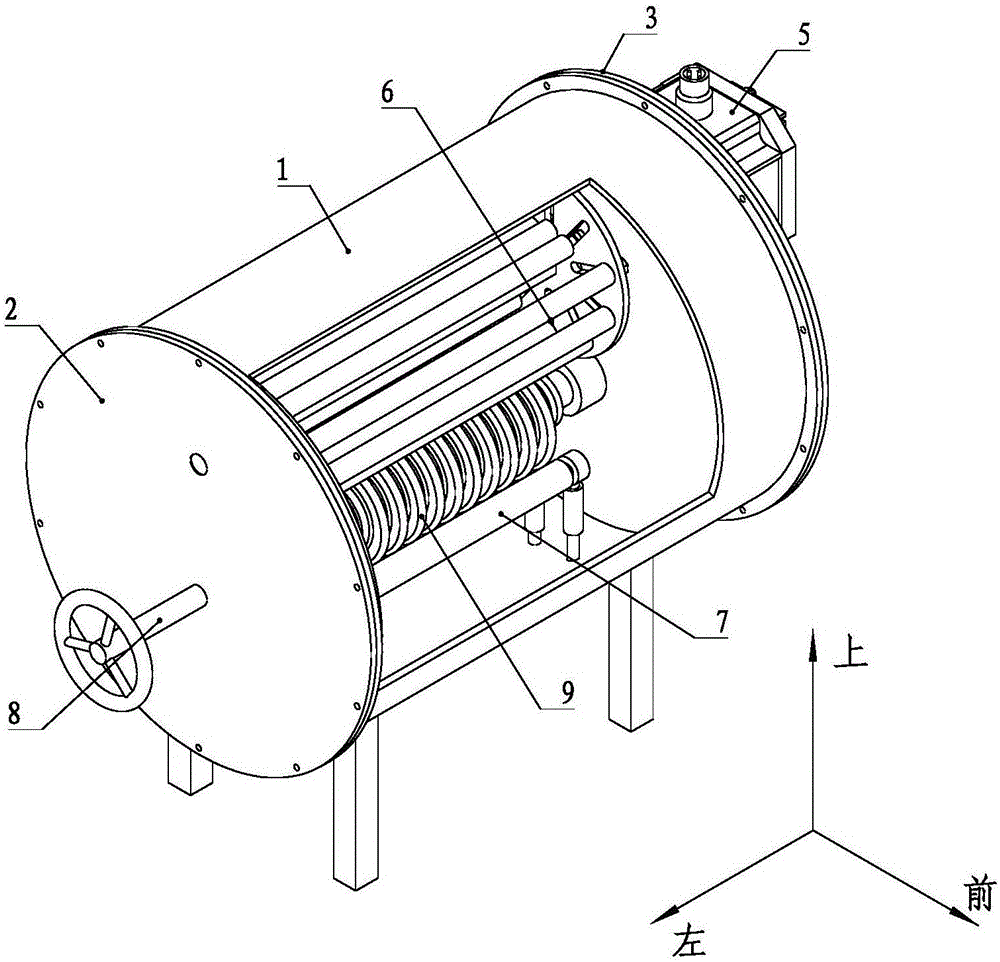

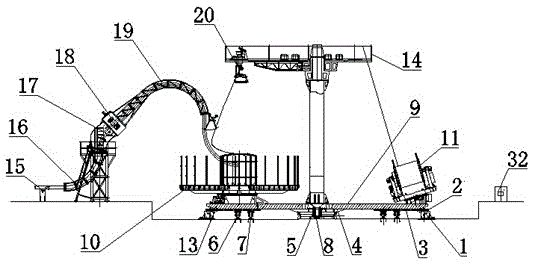

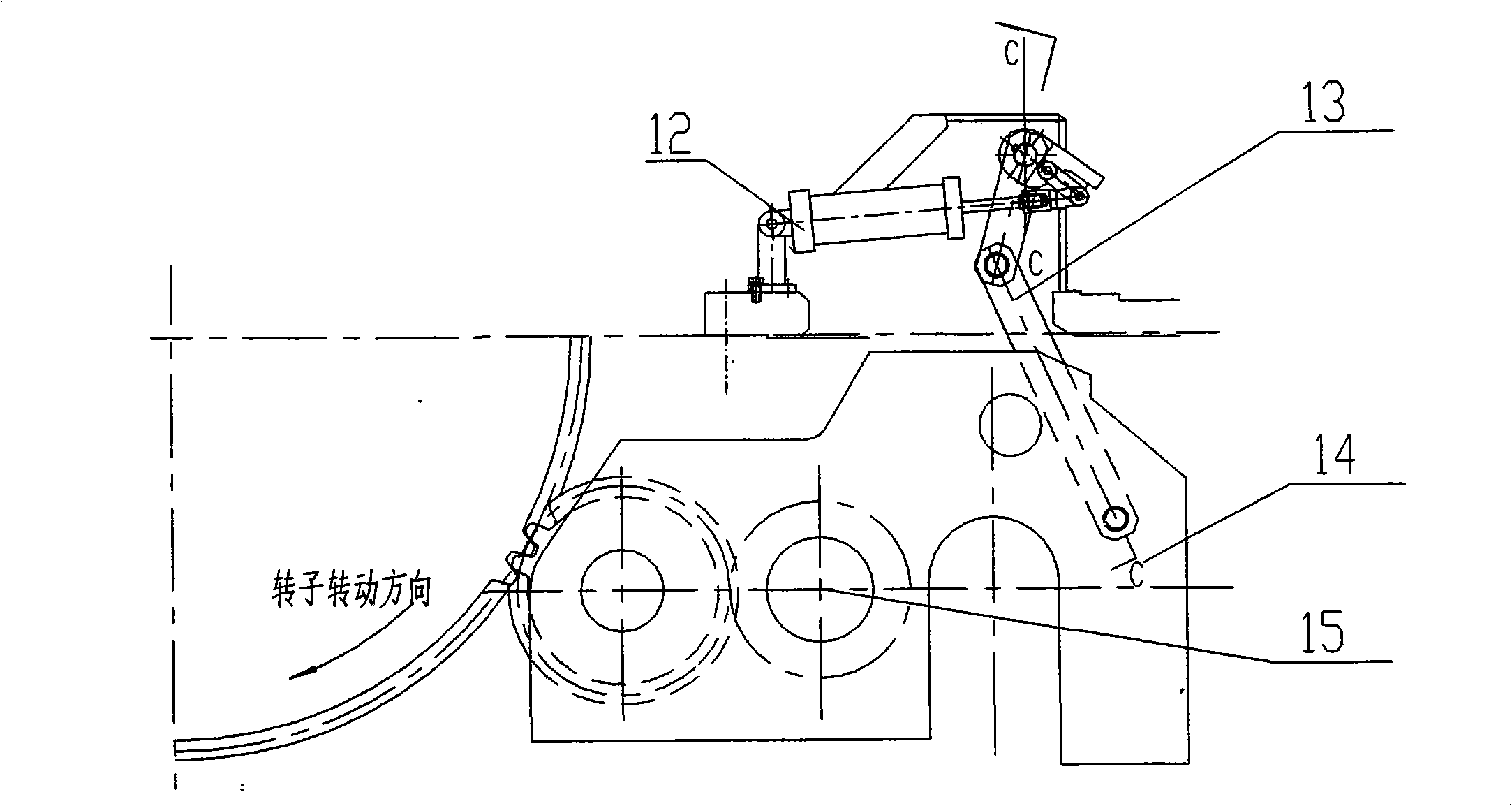

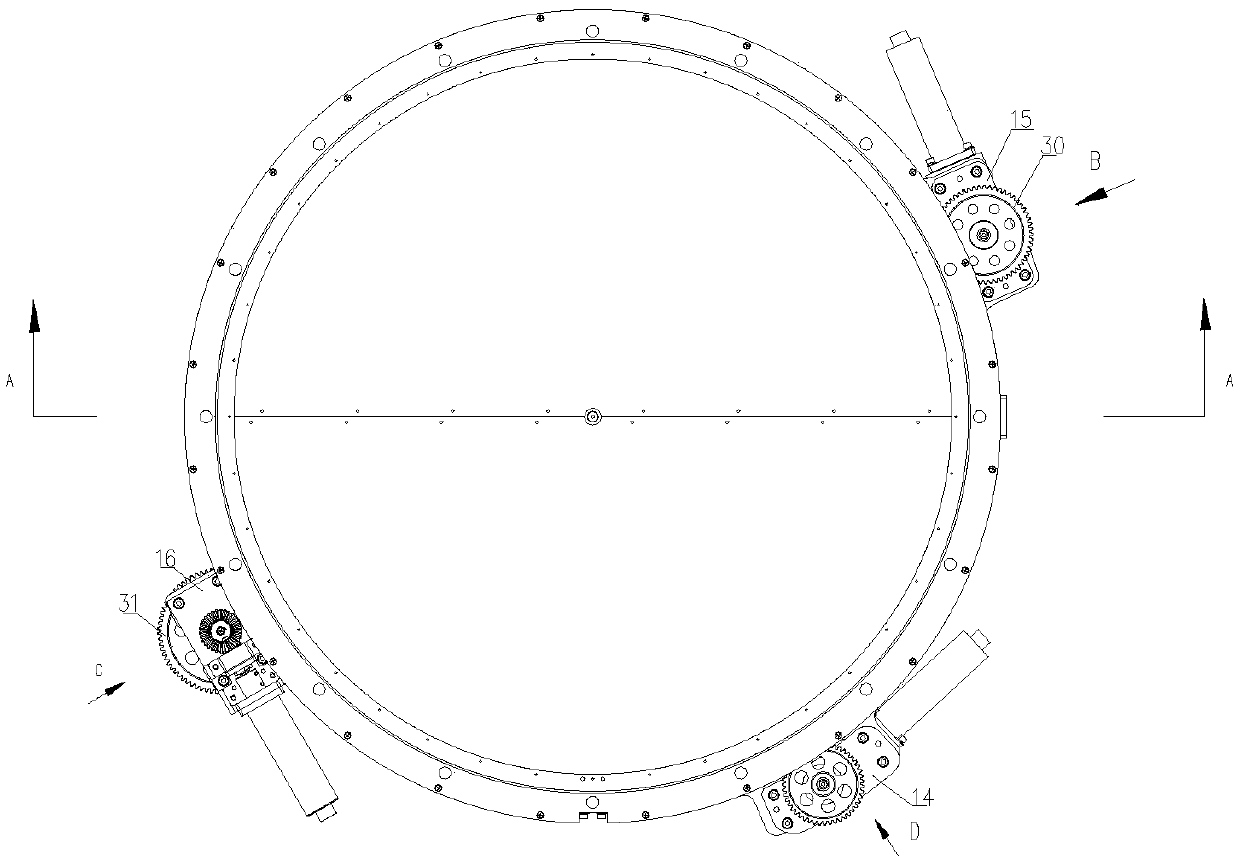

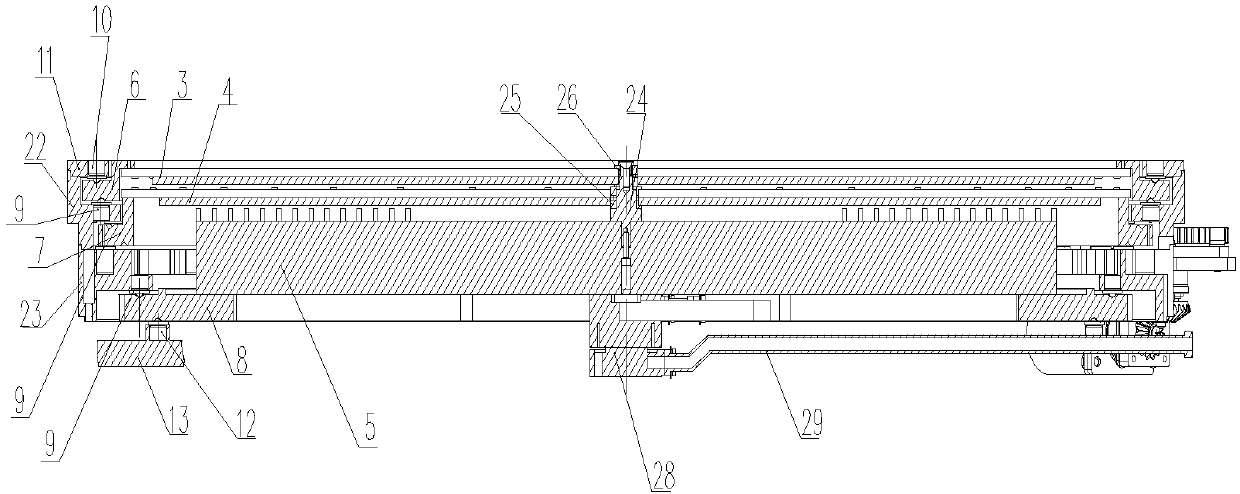

Robot automatic detection system of intersecting pipeline welded seam

InactiveCN1477392AAvoid being in dangerReduce labor intensityAnalysing solids using sonic/ultrasonic/infrasonic wavesLarge toothWeld seam

The robot automatic detection system for extra-long pipeline welding seam includes three portions of partial type fixing support seat, partial type periphery-directional rotating mechanism and robot arm. The partial type fixing support seat adopts movable slide block structure, the partial type periphery-directional rotating mechanism is formed from motor, planetary pinion, large teeth ring and upper and lower connecting plates. The partial type fixing support seat is fixed on the detected branch pipe by means of fast positioning connecting device so as to form mounting platform of said detection system and location reference, and the partial type periphery-directional rotating mechanism is mounted on the platform.

Owner:SHANGHAI JIAO TONG UNIV

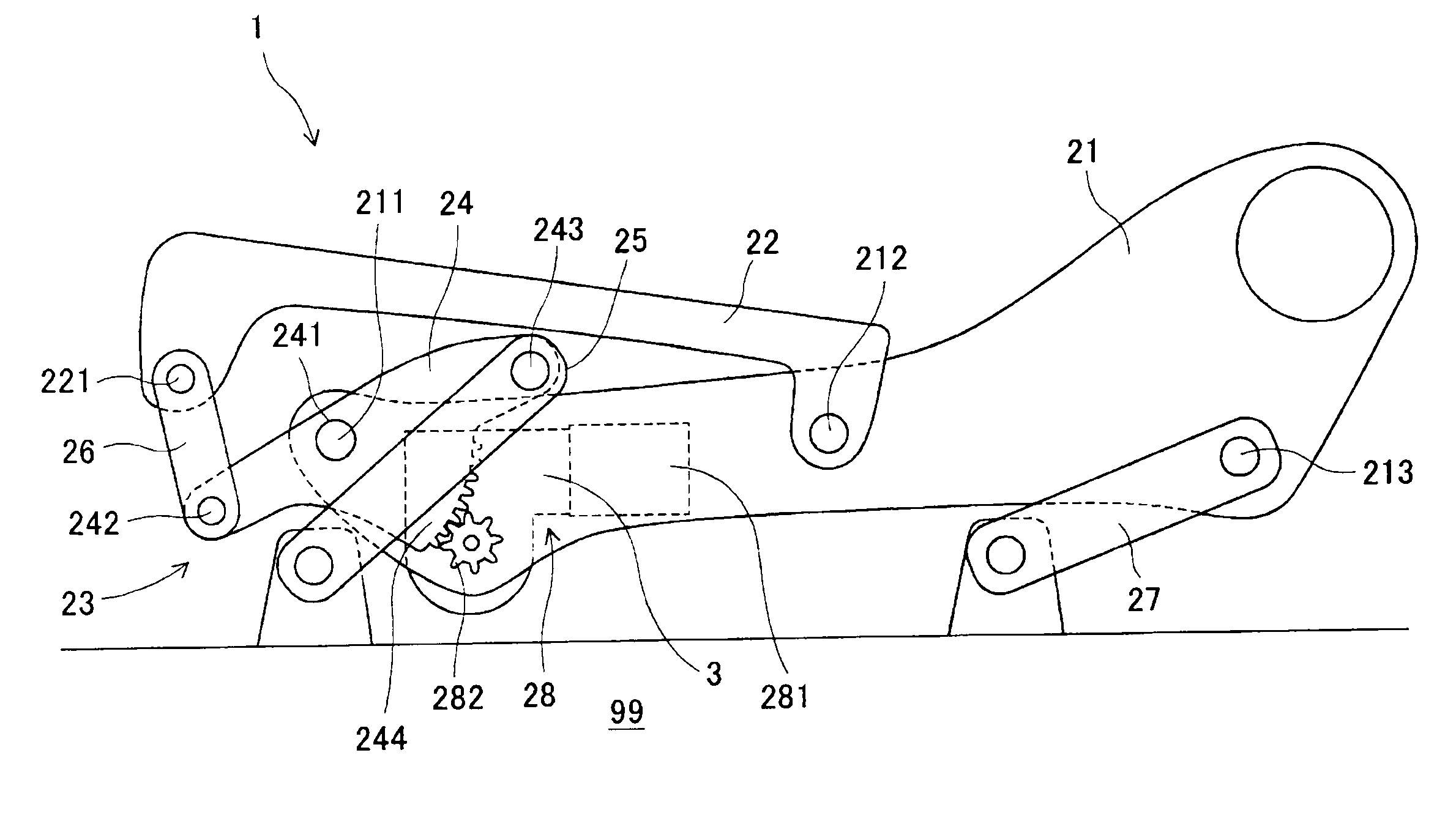

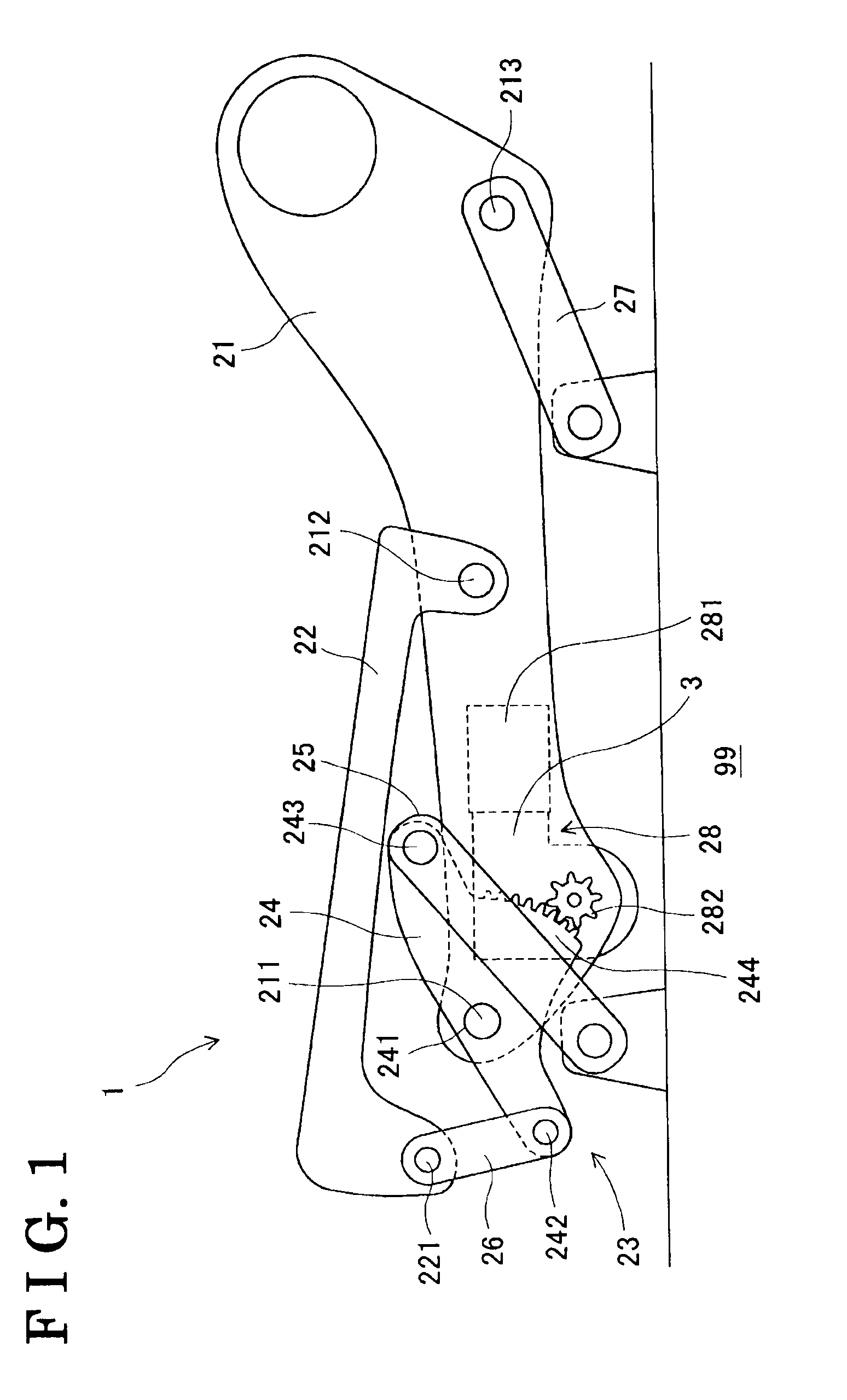

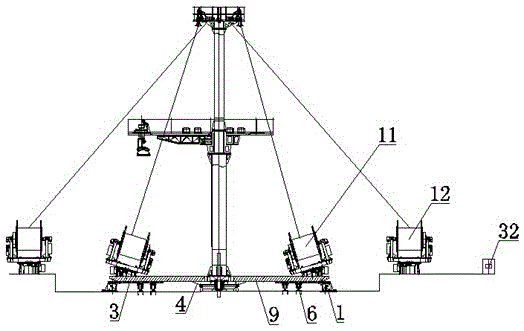

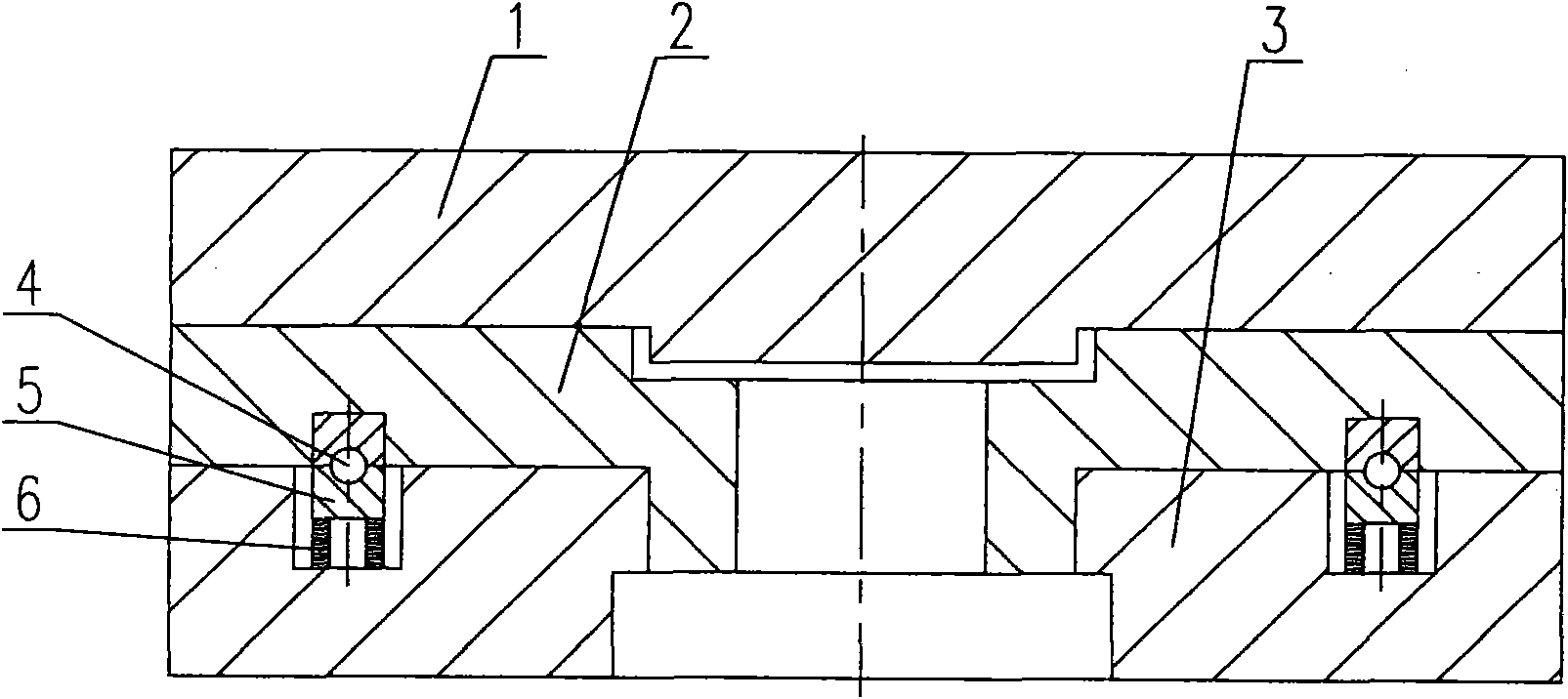

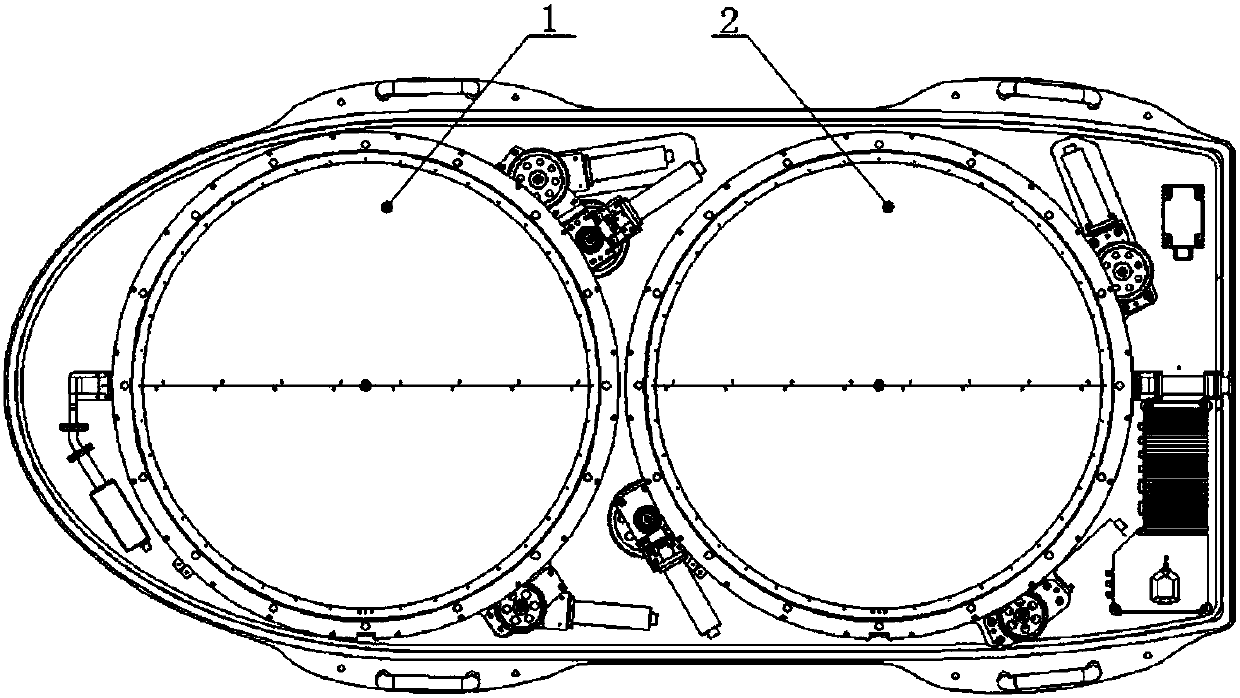

Manipulator of automatic positioning and rapid grasping pipe piece

InactiveCN101200063AImprove assembly efficiencyEasy to adjust postureUnderground chambersTunnel liningCantilevered beamHydraulic motor

Disclosed is a self-positioning manipulator for fast grasping segments used in tunnel engineering construction machine industry, which is composed of a rotating ring, a driving device, a cantilever beam, a lifting frame, four rolling wheels, a grasping platform, grasping oil cylinders and a grasping head. The axial direction of the tunnel is set as an X axis; the radial horizontal direction of the tunnel is set as a Y axis; the radial vertical direction of the tunnel is set as a Z axis. The axial lines of the rotating ring and a fixed ring coincide with the X axis; the driving device is fixed on the fixed ring; a hydraulic motor of the driving device drives a small gear through a reduction gear box so as to drive a big gear ring and the rotating ring connected with the big gear ring to rotate around the X axis, so that the lifting frame connected with the rotating ring is driven to move. The cantilever beam is fixed along and in parallel with the axial direction of a shield machine in the inner side of the shield machine; the outside of the shield machine are provided respectively with channel shaped railway for four rolling wheels rolling; the four rolling wheels are fixed respectively at the two sides of the inner wall of the fixed ring; the cylinder bodies of two translational oil cylinders are fixed on the cantilever beam; piston rods of the oil cylinders are fixed and hinged with the fixed ring. The device has the function to install the segments in omni direction, the segments can reach any preset installing position with more flexible grasping head and four movements, and the assembling efficiency of the segments is increased effectively.

Owner:SHENYANG HEAVY MACHINERY GROUP

Process for quenching hard-tooth surface canine tooth loop intermediate-frequency edge roller seating space

InactiveCN101509063ALight structureSmall sizeFurnace typesHeat treatment furnacesLarge toothIntermediate frequency

The invention provides a technique for quenching along the tooth space of a large tooth ring with hardened tooth surfaces on a medium-frequency basis, particularly for quenching and tempering the tooth surfaces along the tooth space on a medium-frequency induction basis. The technique comprises the following steps: 1), carrying out the tool preparation and on-site installation before quenching and tempering; 2), manufacturing medium-frequency copying inductors heating-quenching along the tooth space and taking the shape similar to the profile of the tooth space, and quenching and back-cooling the tooth surfaces in a synchronous manner; 3), quenching at intervals of 3 tooth spaces, wherein, one round of the rotation of the parts, that is, 54 teeth, constitutes a working cycle; 4) testing the hardness of a first quenching tooth surface every cycle; and 5), carrying out the tempering heat treatment in a half-tooth ring manner after the surface is quenched. The quenching level of the tooth surfaces of the large tooth ring with the hardened tooth surfaces reaches HRC40-45; the depth of effective hardening layers is larger than or equal to 4mm; the accuracy of the tooth wheel reaches the 988GE level; the tooth ring has the advantages of light and handy structure, large size and service life as long as two times of the ordinary tooth ring with the same specification; and the technique remarkably reduces the weight of the equipment, improves the reliability thereof, and improves the running efficiency thereof.

Owner:CITIC HEAVY INDUSTRIES CO LTD

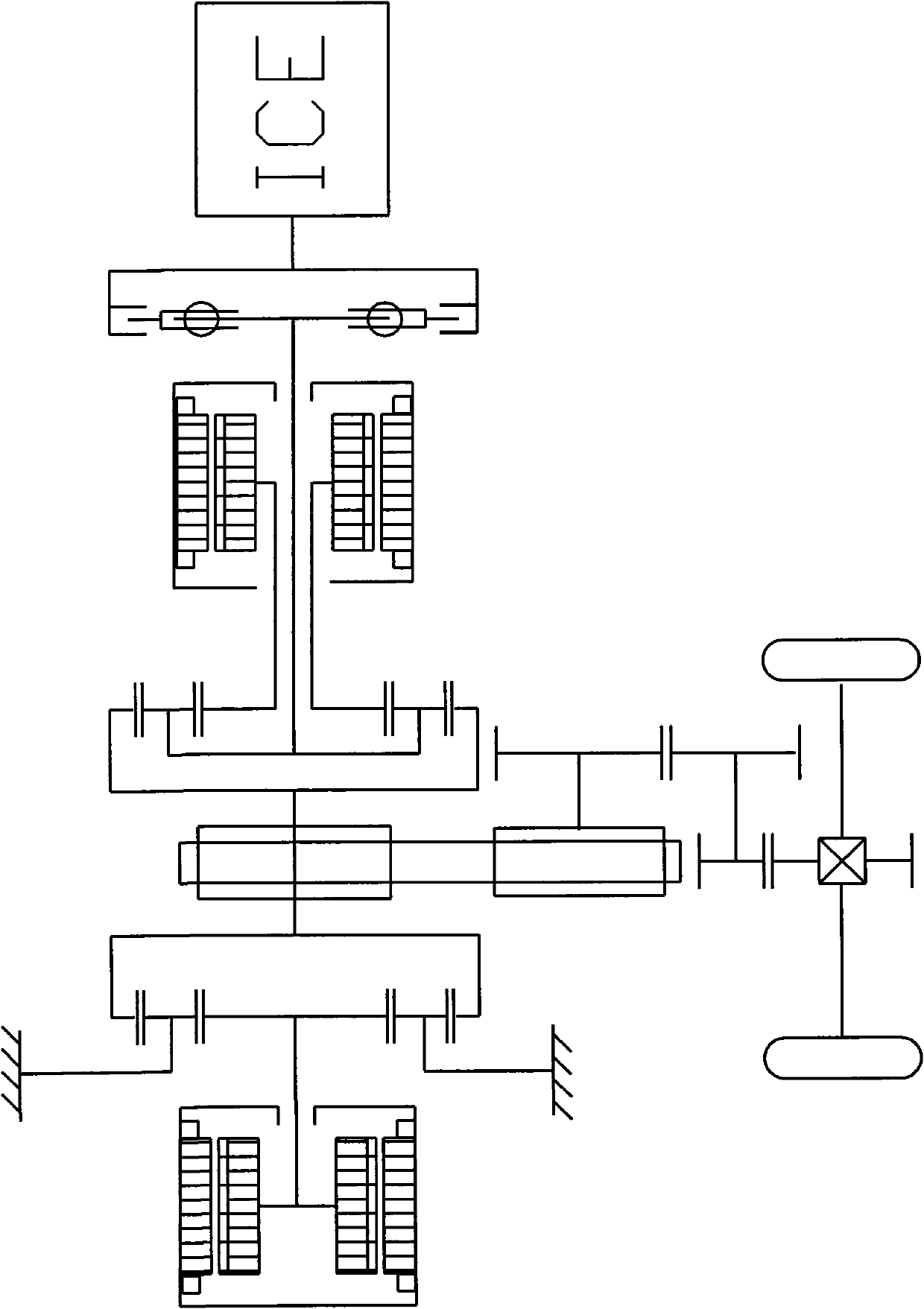

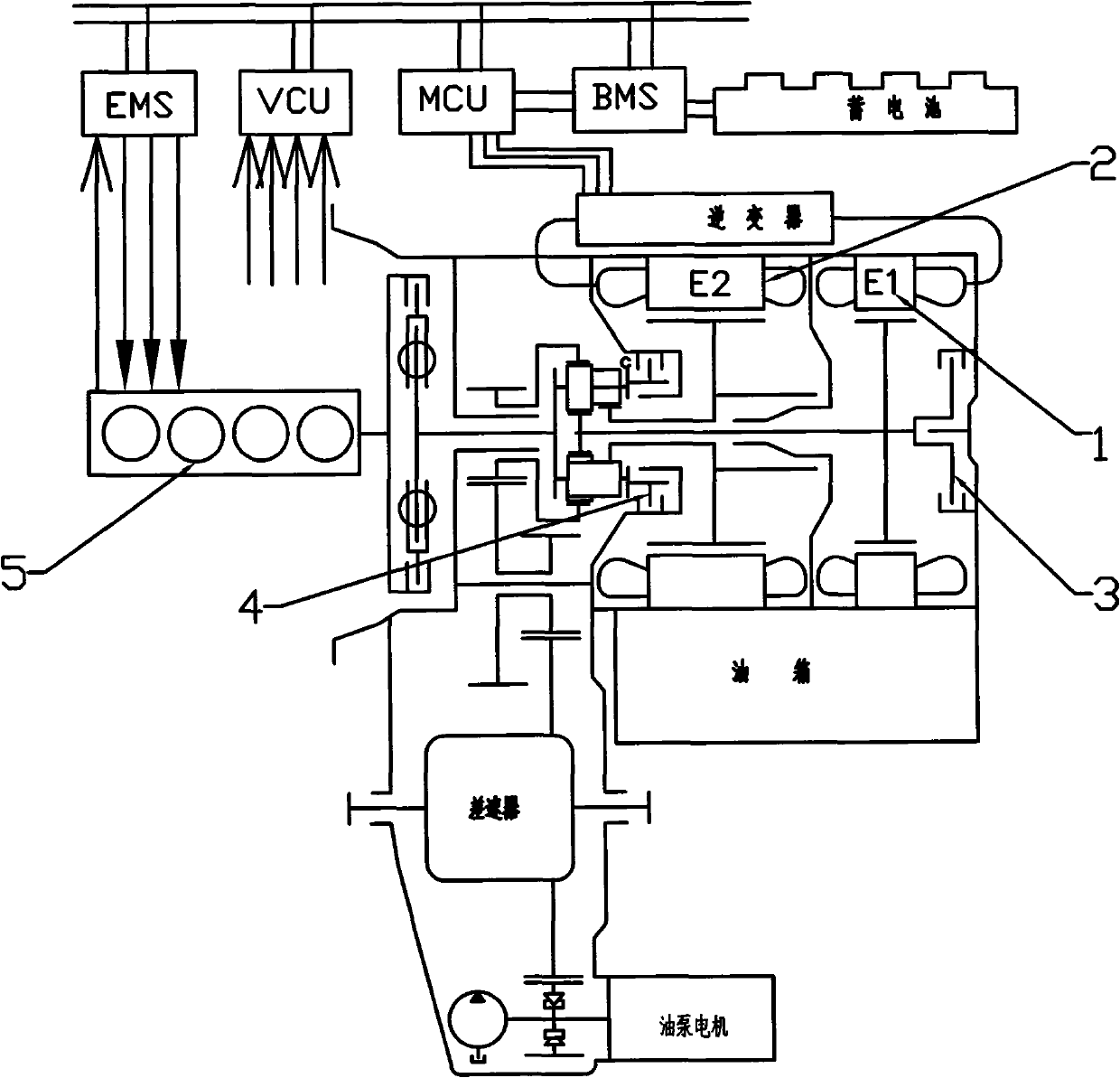

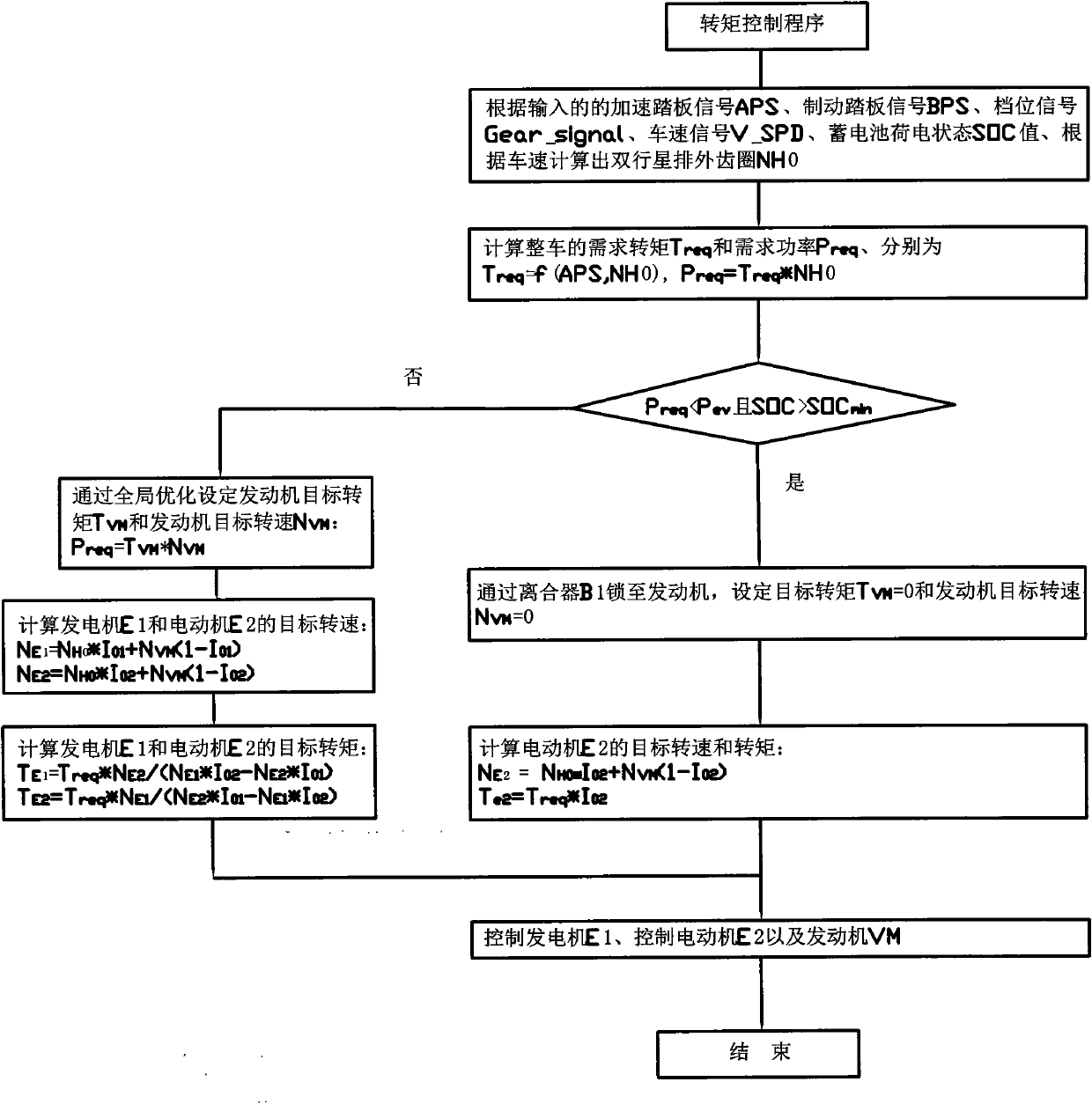

Hybrid output power balancing device and control method thereof

ActiveCN102019843ASolve hybridEasy to operateHybrid vehiclesElectric propulsion mountingLarge toothPower balancing

The invention relates to a hybrid four-shaft transmission device, which comprises an outer gear ring, a planet carrier, a planet row and sun gears and is characterized in that: the planet row has a double-planet row structure consisting of a front planet row and a back planet row; the front planet row and the back planet row correspond to a sun gear respectively; a front row of planetary gears have small tooth widths and large reference circles; a back row of planetary gears have large tooth widths and small reference circles; the front row of planetary gears are meshed with the outer gear ring and a small sun gear so as to form a front row gear train; and the back row of planetary gears are meshed with the front row of planet gears and a large sun gear so as to form a back row gear train. A double-planet row four-shaft transmission device with a large transmission ratio between the sun gear of the back row gear train and the outer gear ring is realized.

Owner:江西鼎盛新材料科技有限公司

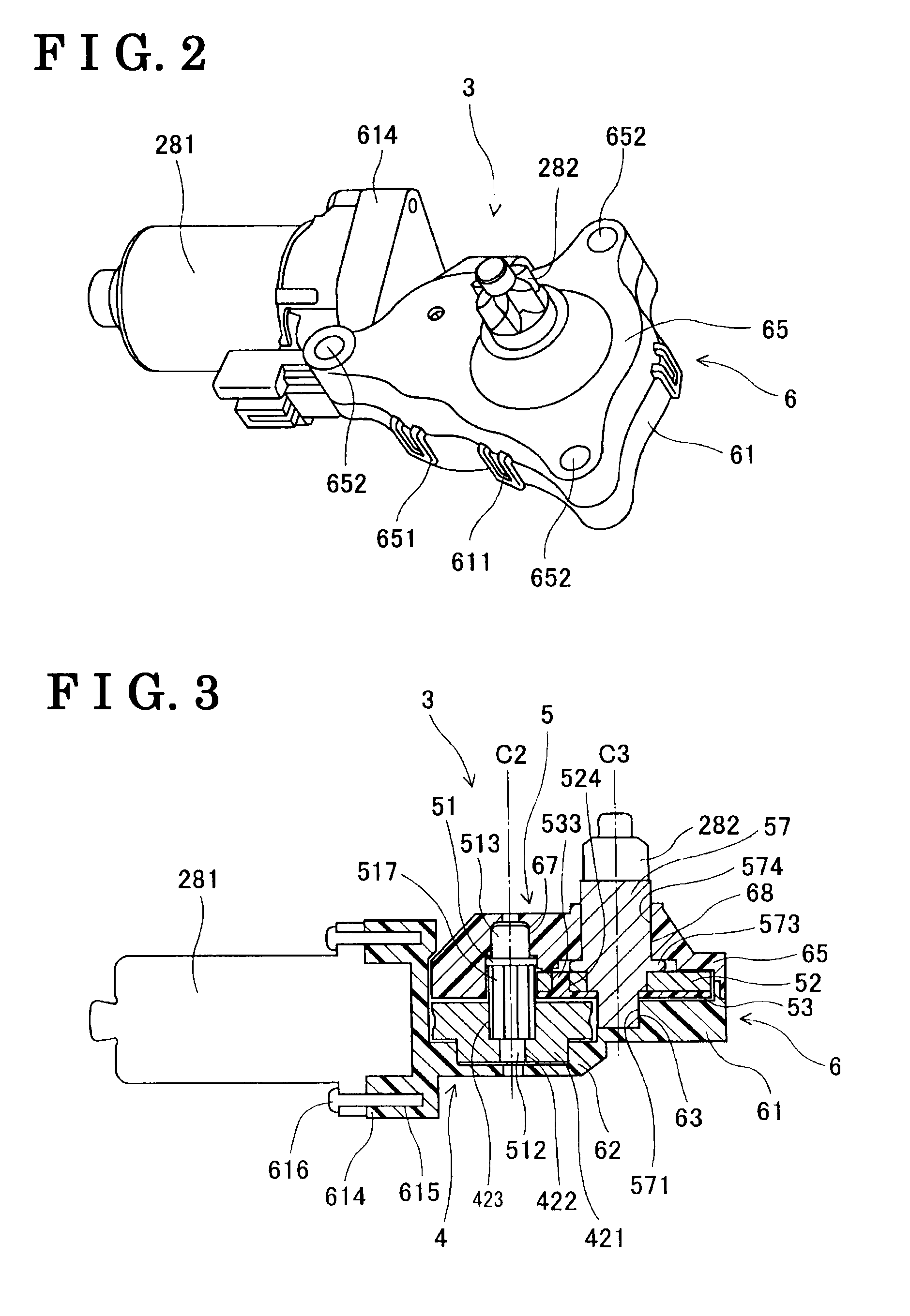

Power seat driving apparatus for vehicle

A power seat driving apparatus for a vehicle includes a moving unit and a decelerating mechanism. The deceleration mechanism includes a driving gear, a driven gear engaging with the driving gear and driven to rotate while decelerating a rotational speed of the driving gear, a supplemental gear coaxially connected to the driven gear in an interlocking manner, made of a resin material having elasticity and lower rigidity than the driven gear, having a larger tooth thickness than a tooth thickness of the driven gear by an amount corresponding to a backlash, and engaging the driving gear together with the driven gear, and a housing accommodating and rotatably supporting the driving gear, the driven gear and the supplemental gear.

Owner:AISIN SEIKI KK

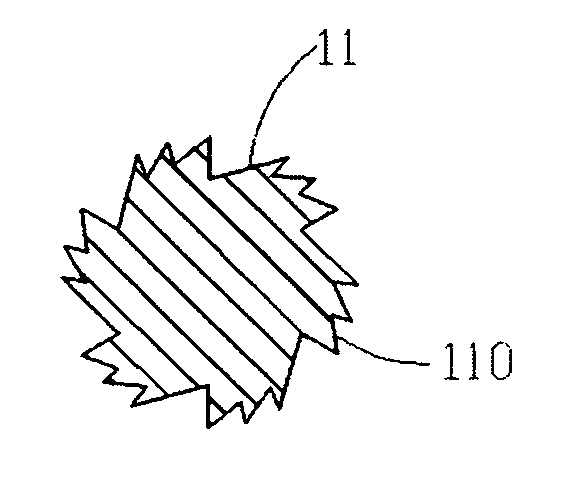

Burnishing burr drill

InactiveUS20050123364A1Increase feed rateHigh strengthMilling cuttersShaping cuttersLarge toothEngineering

A burnishing Burr drill having more than two large teeth and more than one small tooth formed on each back surface of the large tooth is disclosed. Large teeth is mainly used for cutting and obtaining a high feed speed. As the burnishing drill feed forward, the small teeth will meet a surface of a hole drilled by the large teeth and further finish a wall of the hole.

Owner:ZHOU QING

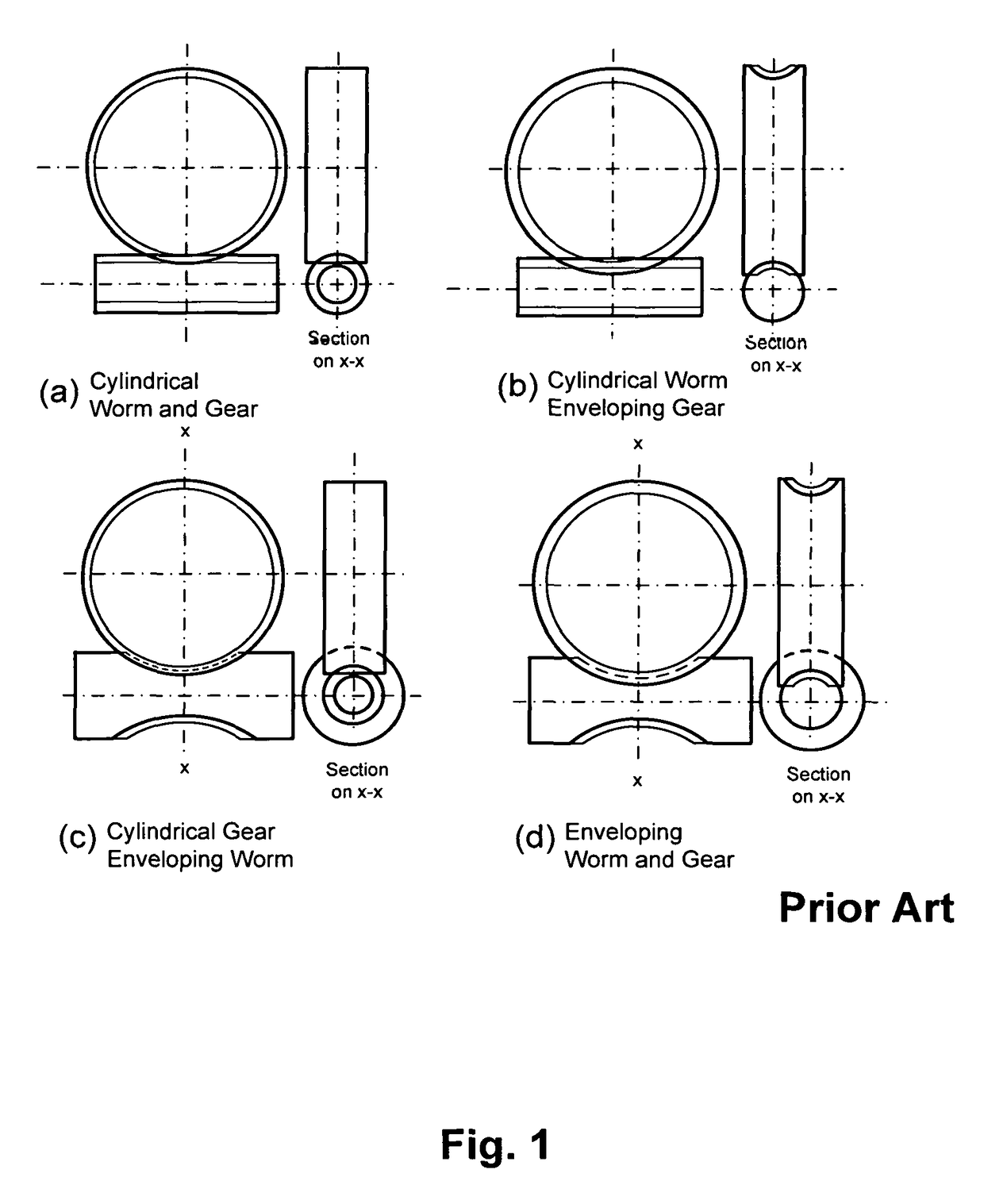

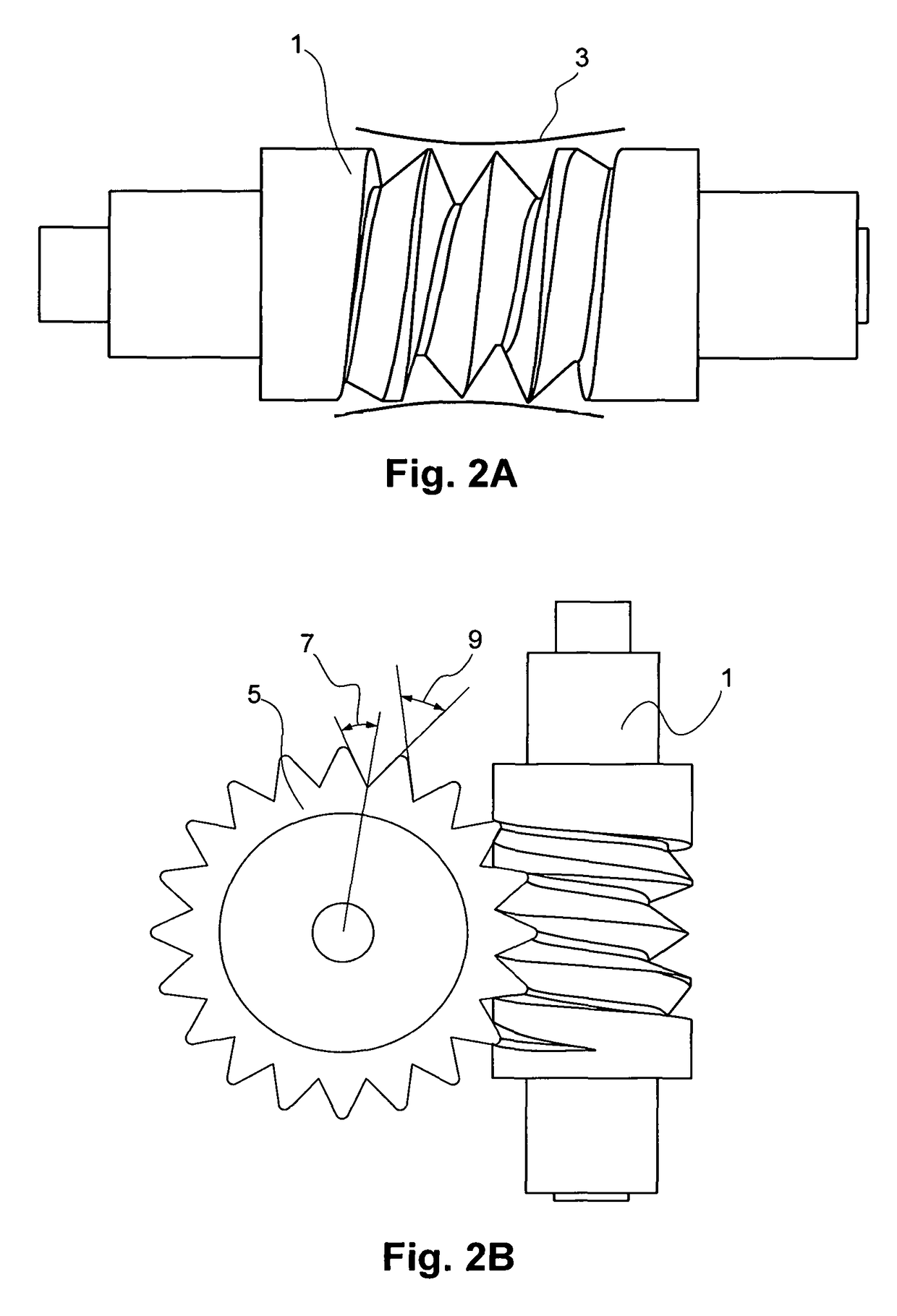

Precision positioning device and stage incorporating a globoid worm and its manufacture

The device is a precision motion right angle drive for use with linear and rotary stages which employs a combination of globoid worm and small diameter star gear. Coaxial with the star gear, on the same shaft, is a spur gear which drives the rotary stage gear or a linear rack. The thin star gear achieves meshing accuracy with the globoid worm permitting a large tooth angle for direct preloading without jamming. This gear combination eliminates backlash, allows a low gear ratio for low globoid worm speed, and enables the use of an ordinary spur gear to engage the stage gear without backdrive or backlash. Further, it allows for gear contact area to compensate for the thinness of the star gear. An embodiment including an integrated bearing rotary stage permits flexibility of application and avoidance of need for custom bearing designs by achieving high motion precision at low cost.

Owner:MAURO COMML IND OF VERO BEACH LLC

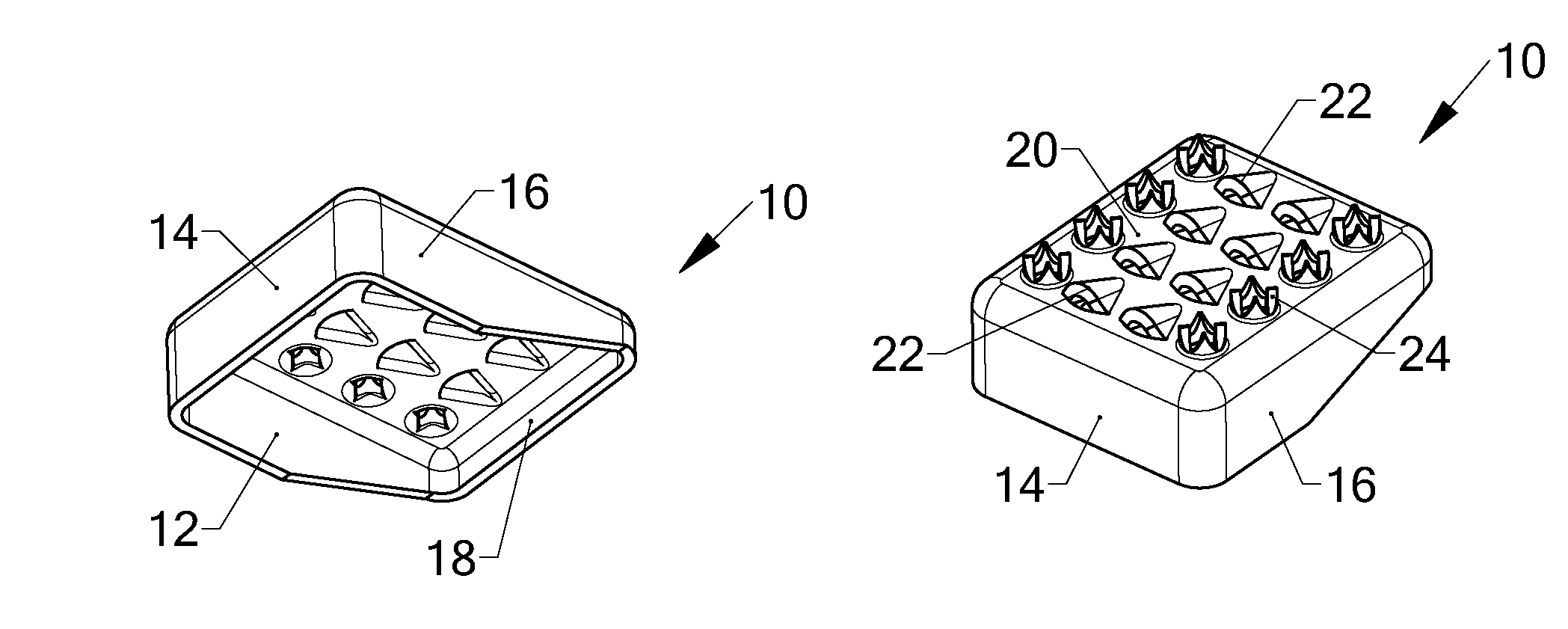

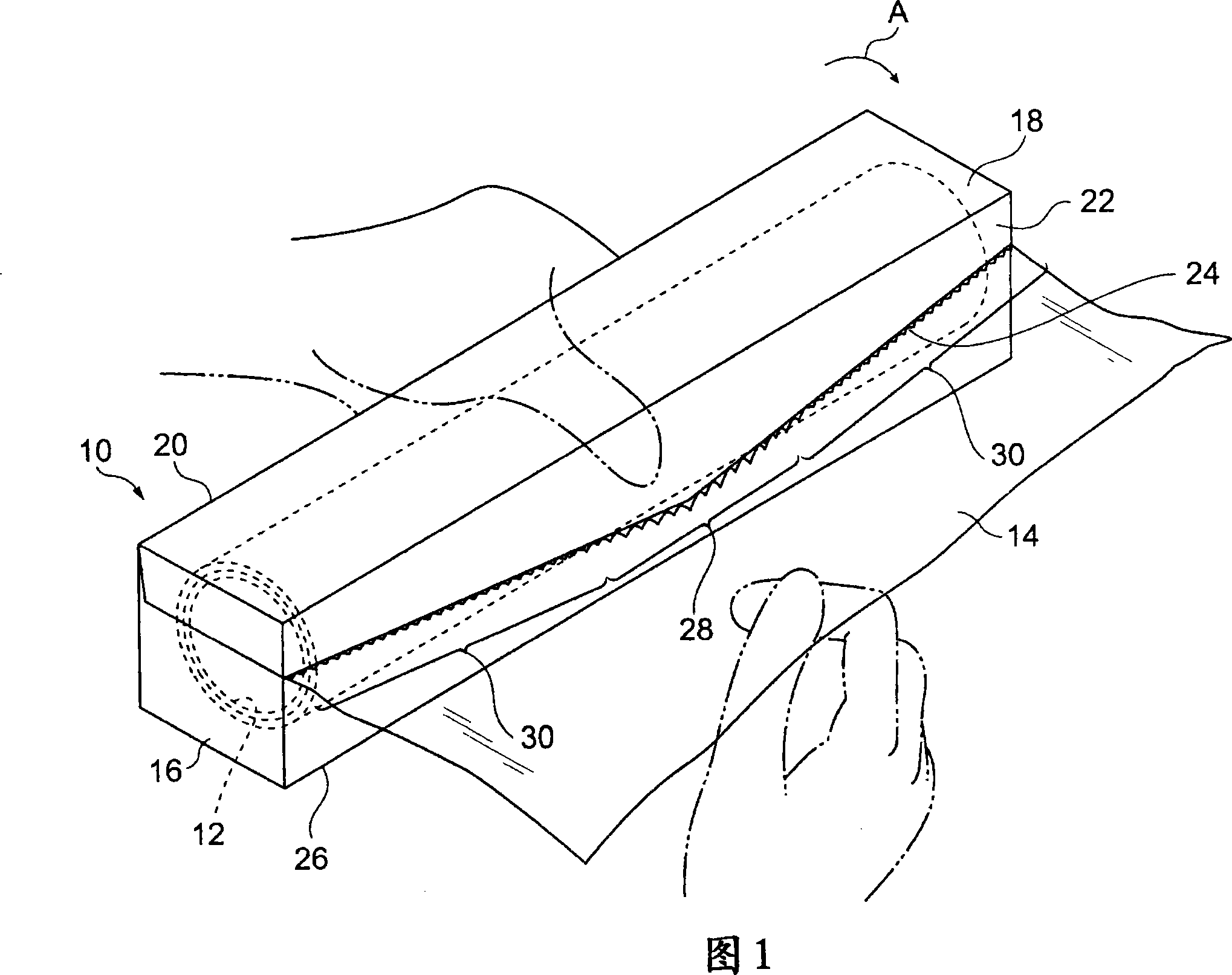

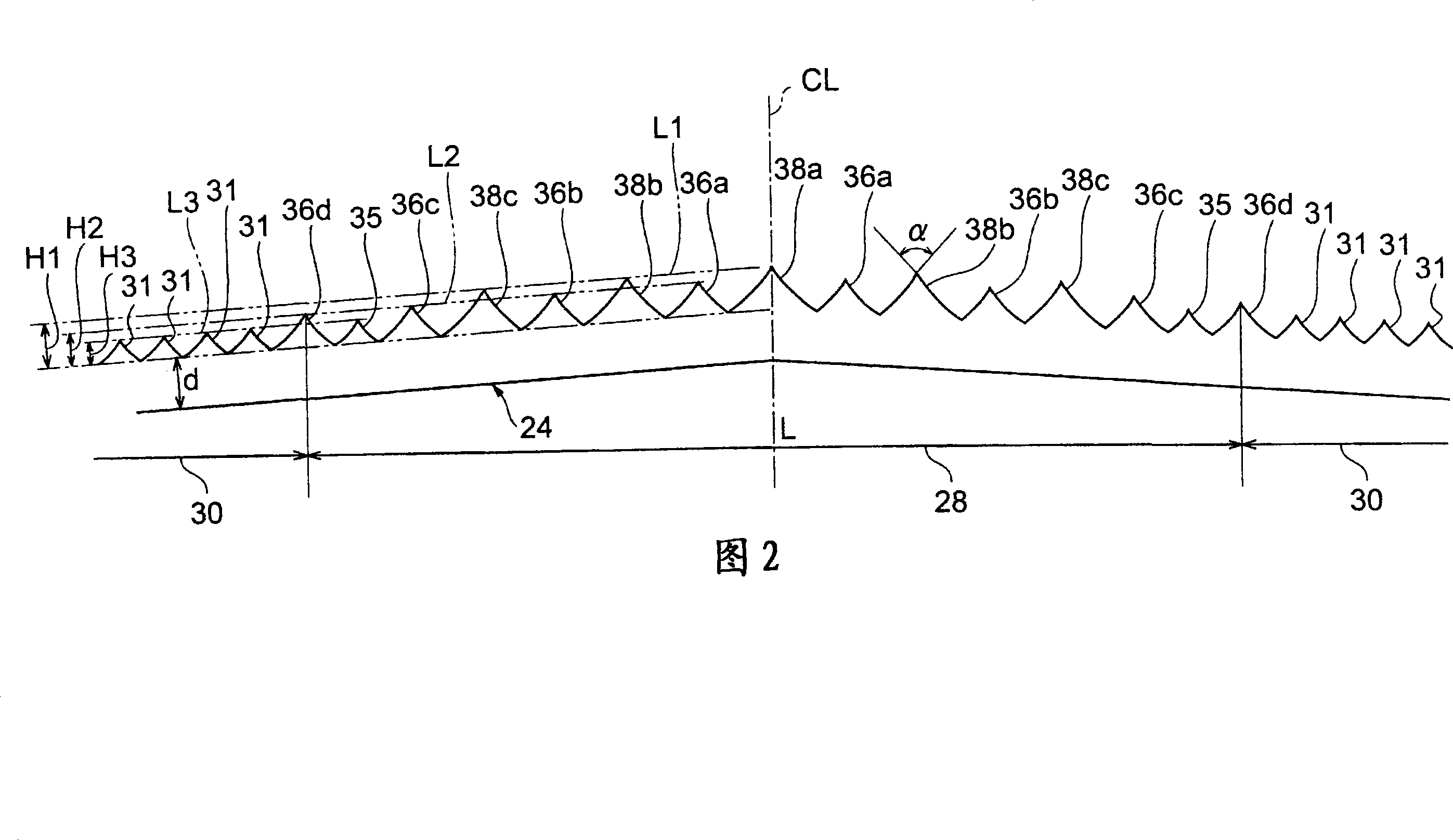

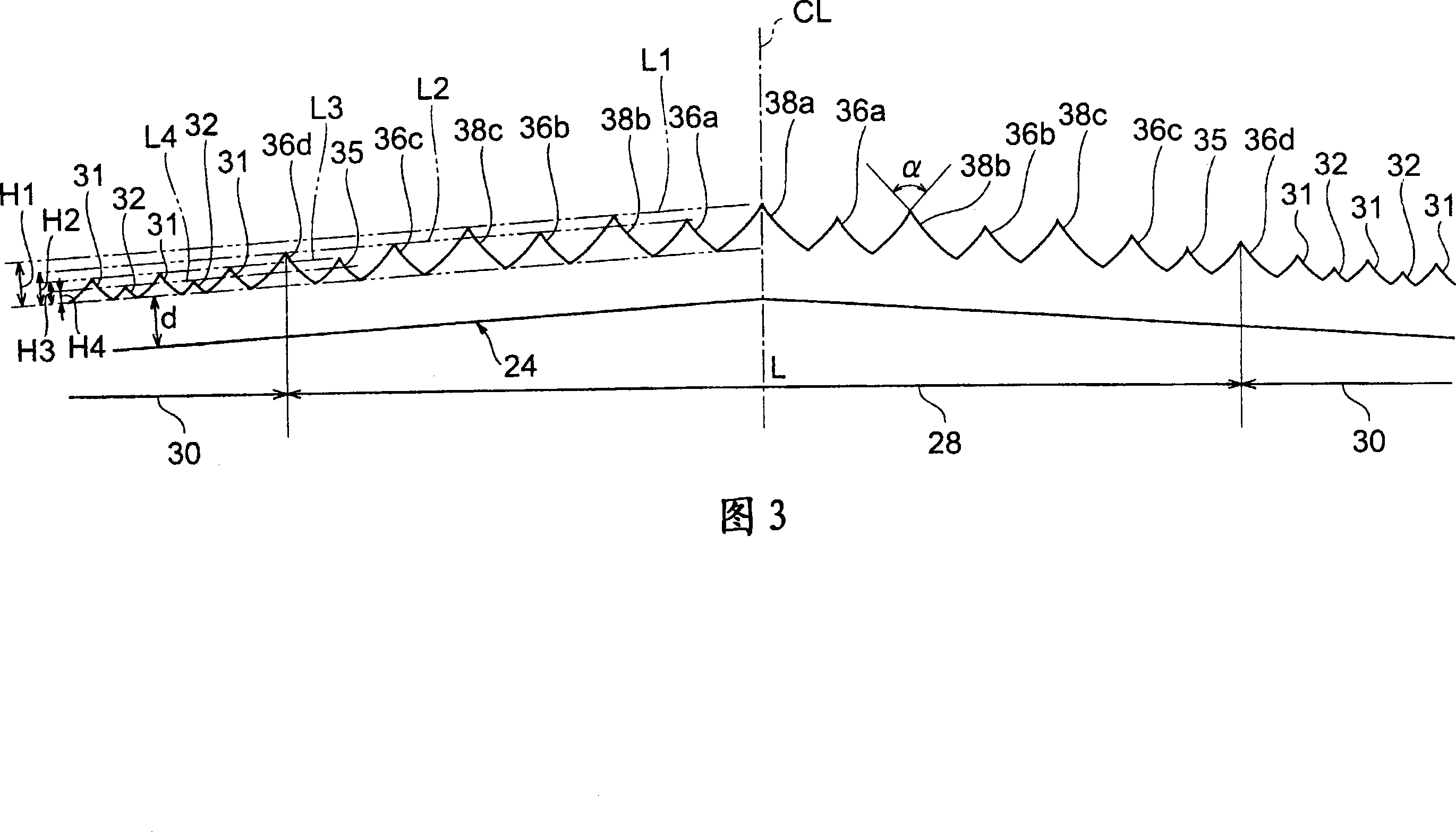

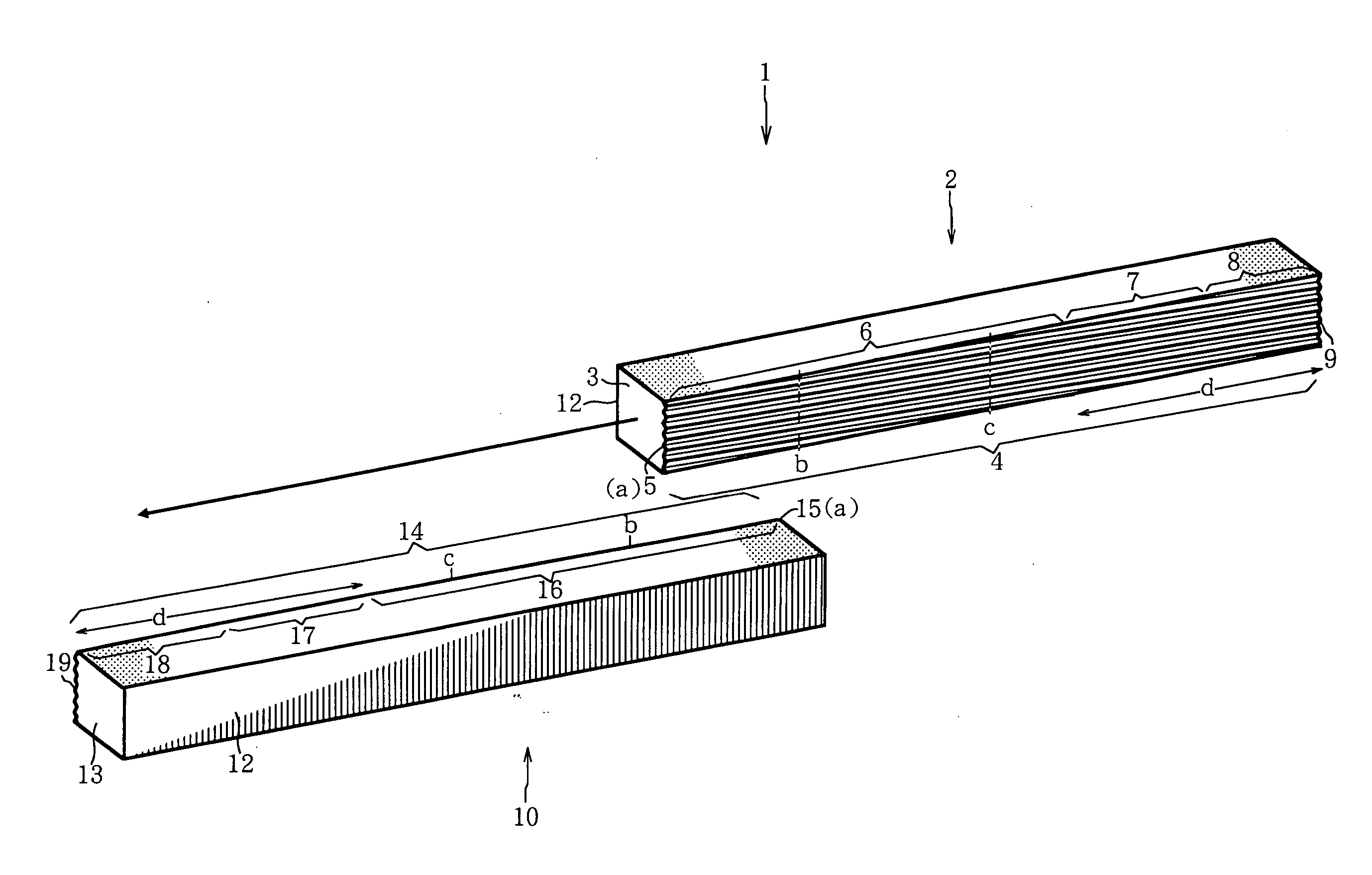

Cutting edge for package container and package container having the same

ActiveCN101081669AEasy to cutIncreased durabilityMetal working apparatusArticle deliveryLarge toothSide Tooth

Provided are a non-metallic V-shaped cutting blade capable of cutting roll-shaped packaging materials such as wrapping films with very light force, and a packaging container provided with the cutting blade. The cutting edge (24) of the present invention includes a central region (28) and side regions (30) that are arranged on both sides of the central region and are composed of a plurality of side teeth (31). A middle tooth (36) and a plurality of large teeth (38). One of the large and medium teeth is arranged at the apex of the V-shape, and the other large teeth are arranged at predetermined intervals so as to sandwich the teeth at the apex. The middle teeth are arranged between the large teeth. The large gear is more prominent than the middle gear. With this structure, when the cutting starts, the large teeth pierce the wrapping film (14) first, and then the middle teeth pierce the wrapping film. Since the wrapping film is pierced through such two stages, the force required for cutting is small.

Owner:KUREHA KAGAKU KOGYO KK +1

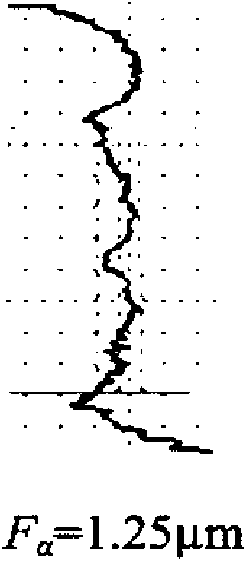

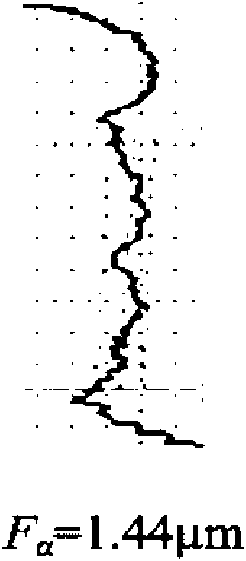

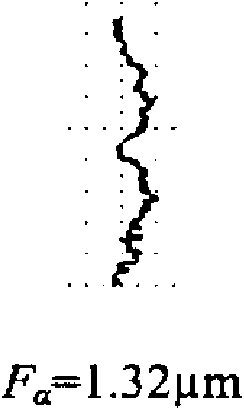

Measuring point accurate positioning method of generated involute tooth profile measuring apparatus

The invention discloses a measuring point accurate positioning method of a generated involute tooth profile measuring apparatus and belongs to the field of high-precision gear measurement by testing and measuring technology. A tooth profile angle comparison method compares tooth profile deviation curves measured by a measuring head at different positions to determine the position of a measuring point corresponding to a measured curve having the largest tooth profile angle as an optical position. A measuring point deviation value test compensation method tests values of the deviation of the position of a measuring point one by one and compensates for involute tooth profile deviation measured when the measuring point is at two positions having a known height difference by analyzing the influences of measuring point deviation on tooth profile deviation measurement to determine a value equal to the value of compensated tooth profile deviation as the deviation of the measuring point at an initial position. The measuring point accurate positioning method has high accuracy and can be widely used for accurate adjustment of the positions of measuring points in other high-precision generated involute tooth profile measuring apparatuses.

Owner:DALIAN UNIV OF TECH

Pipe grip ring

ActiveUS20100176588A1Improve pullout resistanceSleeve/socket jointsFluid pressure sealed jointsLarge toothEngineering

A grip element comprising a wedge-like structure supporting a metal plate, the exposed outer surface thereof being provided with an array of large and small gripping teeth. The large teeth project from the surface of said metal plate further than said small teeth. The invention further provides a grip element having a floor. The grip elements may be disposed around a ring for the purpose of pipe gripping. The ring is particularly useful in a pipe coupling to grip metal and plastic pipes

Owner:KRAUSZ INDS DEVMENT

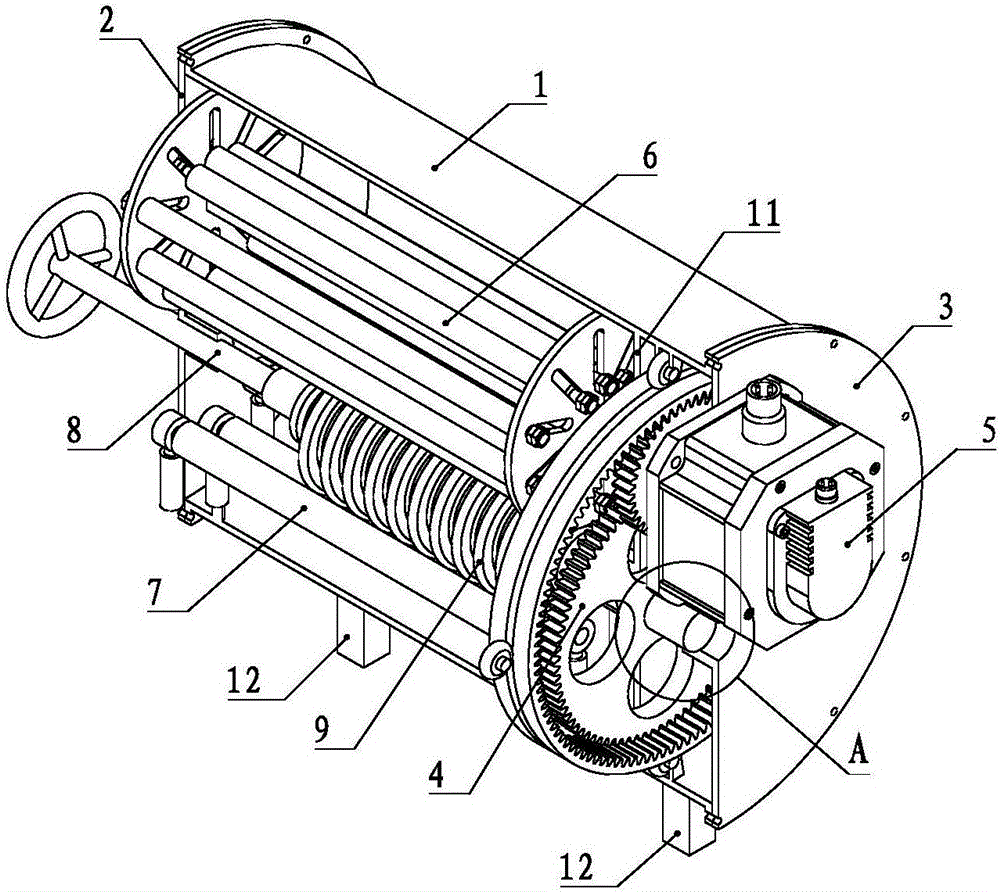

Single-drive multi-gear linkage insulator cleaning device

ActiveCN106362973AThere will be no dead ends for cleaningLow costCleaning using toolsCleaning using liquidsLarge toothGear wheel

The invention discloses a single-drive multi-gear linkage insulator cleaning device. The device comprises a cylindrical cylinder, a left end cover and a right end cover. A separation plate is arranged in the cylinder; the cylinder, the separation plate and the left end cover form a cleaning cavity; the cylinder, the separation plate and the right end cover form a transmission cavity; and a transmission mechanism is arranged in the transmission cavity. The transmission mechanism includes a large gear ring; and multiple first rollers are arranged between the outer side of the large gear ring and the cylinder. A driving gear and a driven gear are arranged in the large gear ring in sequence from top to bottom, and are respectively engaged with the large gear ring. A brush module, an ejecting module and a bracket are arranged in the cleaning chamber in sequence from top to bottom. The brush module is arranged between the driving gear and the left end cover; and the ejecting module is arranged between the driven gear and the left end cover. The device uses the separation plate for separating the cleaning cavity from the transmission cavity to effectively prolong the life of the transmission mechanism without leaky danger, and is low in energy consumption.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

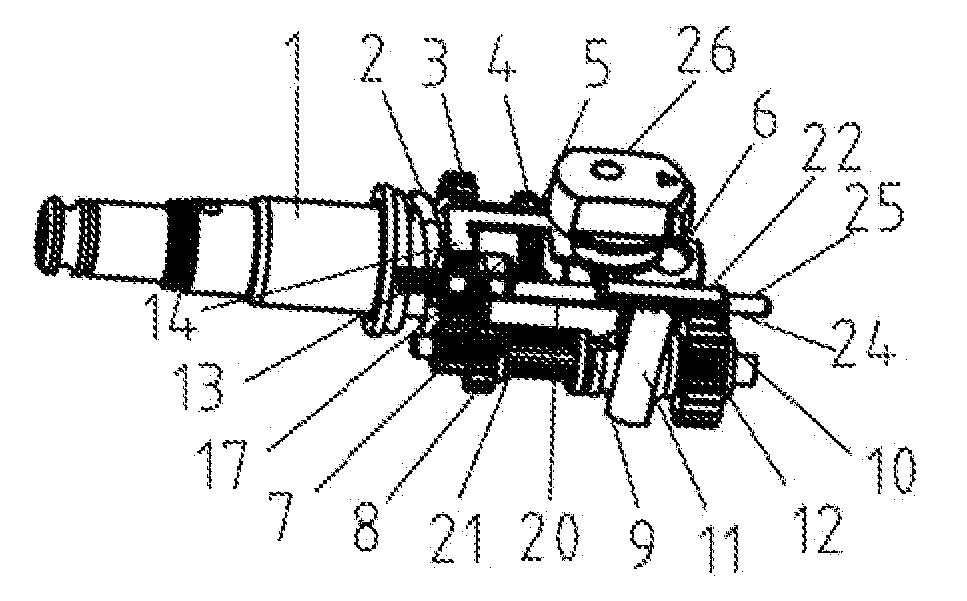

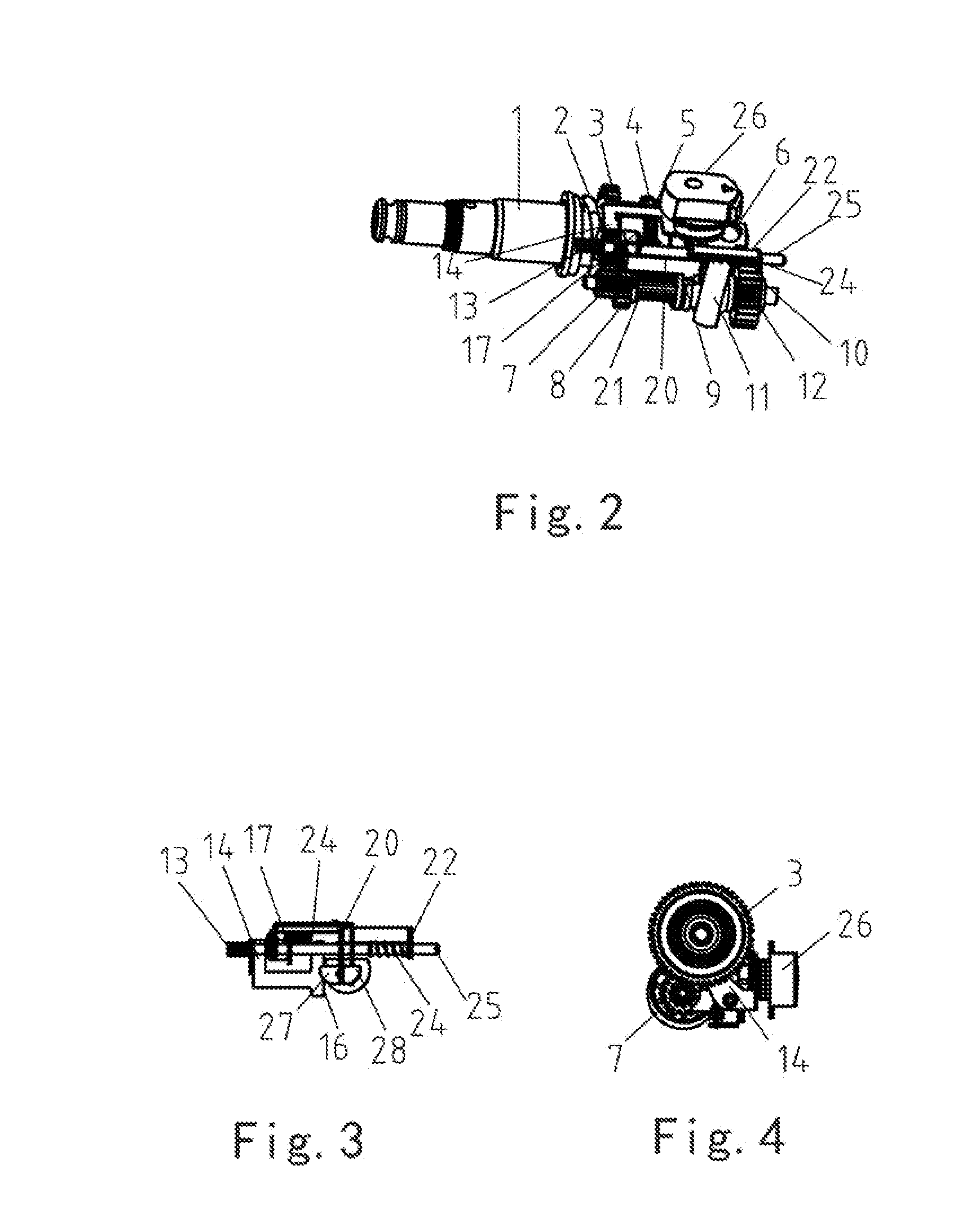

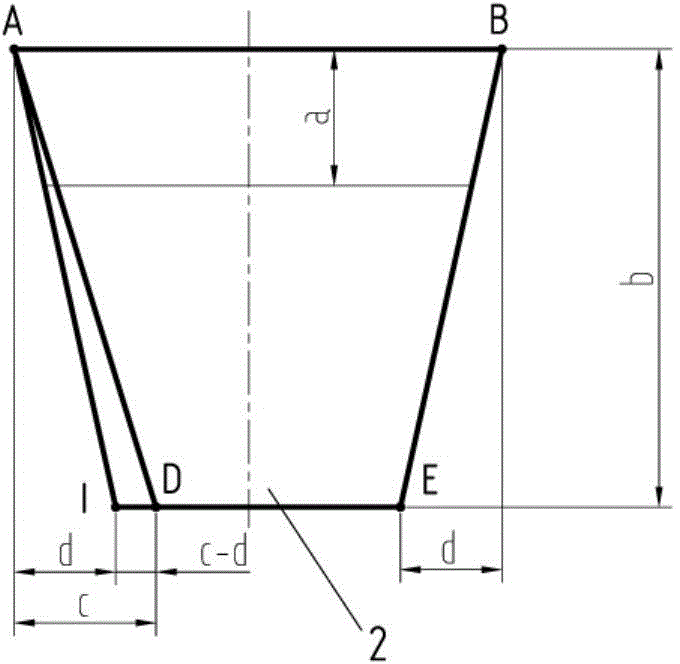

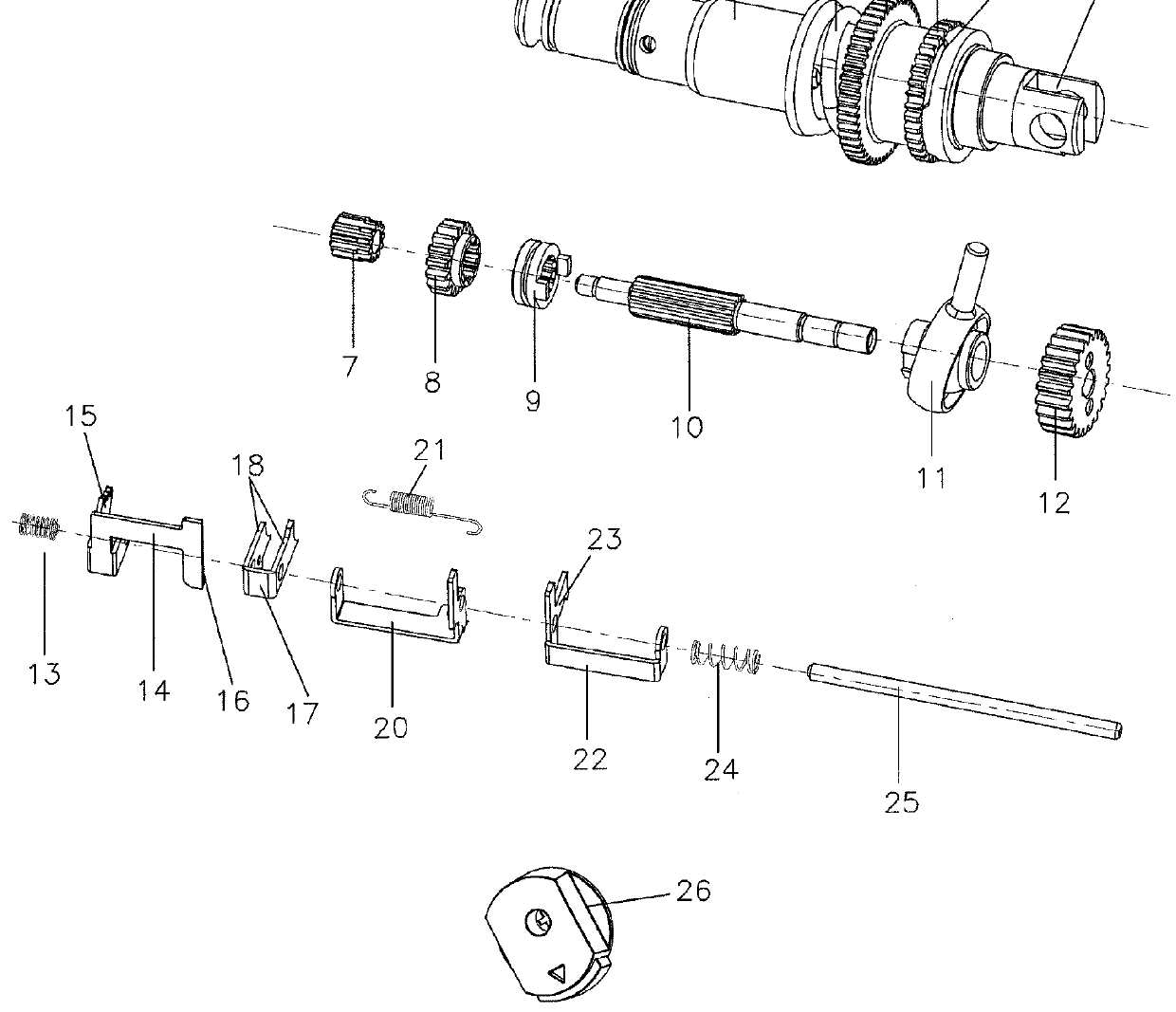

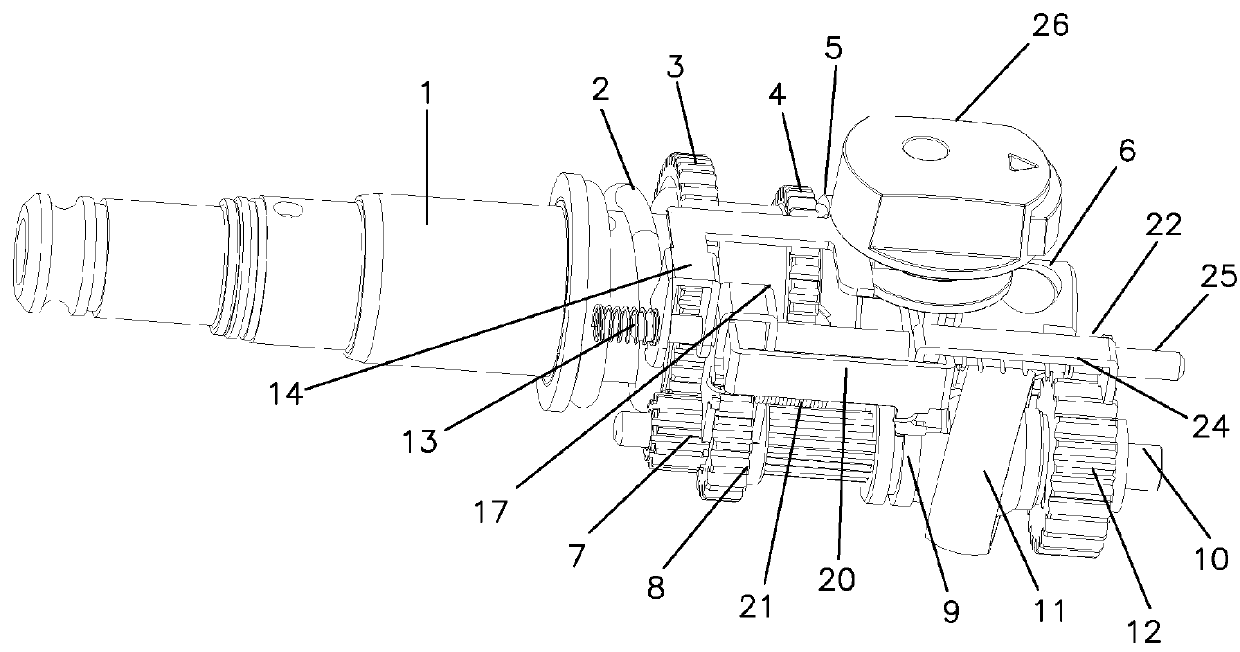

Light single-button multifunctional electric hammer

ActiveUS20120205132A1Simple structureFlexible and convenient switchPortable percussive toolsPortable power-driven toolsLarge toothPinion

A light single button multi-function electric hammer comprises a body, a motor, a rotation set assembly (1), a cylinder assembly (6), a torque spring (2), a knob (26), a gearwheel and a transmission mechanism of torque clutch. The transmission mechanism of torque clutch comprises a pinion (7), a gear clutch (8), a middle shaft (10), a hammer crosspiece clutch (9), a swing rod bearing (11) and a primary gear (12). The pinion is movably fitted with the middle shaft; the pinion meshes the large end teeth of the gearwheel and matches with the inner teeth of the gear clutch. The gear clutch meshes the small end teeth of the gearwheel and is fitted with the teeth shaft of the middle shaft. The gear clutch and the hammer crosspiece clutch are movably fitted with the teeth shaft of the middle shaft. The swing rod bearing is movably fitted with the middle shaft and is connected with the cylinder assembly through the swing rod. Matched concavo and convex slots are set on the hammer crosspiece clutch and swing rod bearing. The primary gear is tightly fitted with the middle shaft. The knob is connected with an operating mechanism linked to the large teeth end of the gearwheel, the gear clutch and the hammer crosspiece clutch. The electric hammer enables a simple and compact structure, flexible and convenient conversion, low cost, safe and reliable use.

Owner:JINHUA CITY JUJIE ELECTRIC MACHINE CO LTD

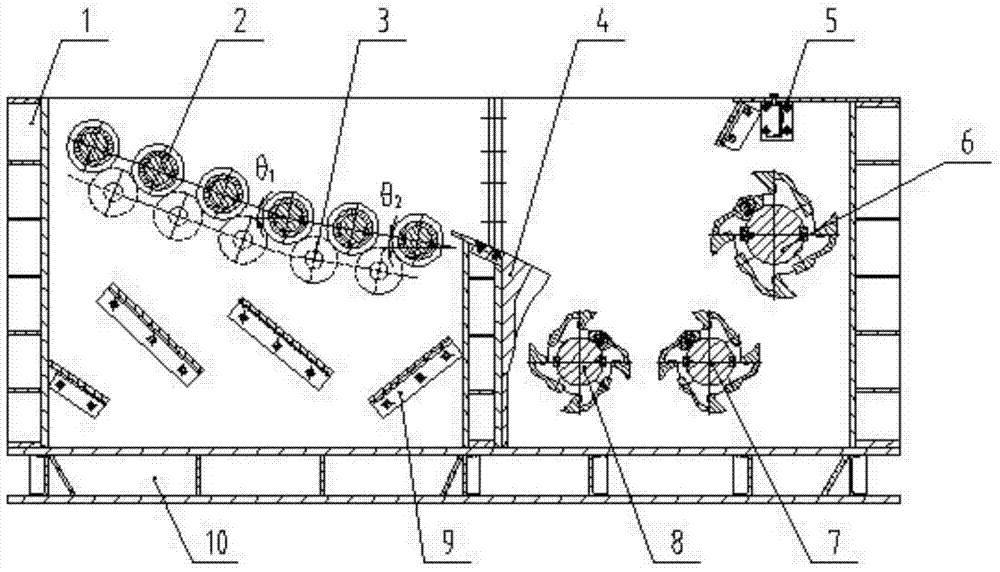

Mining differential three-roller tooth crusher

The invention discloses a mining differential three-roller tooth crusher, which comprises a front roller screen, a large tooth roller (6), a small driven tooth roller (7), a small driving tooth roller (8), a small tooth roller transmission gear (11) and a driving device, wherein the front roller screen is provided with six rollers (2) with wear-proof shaft sleeves; transmission between every two adjacent rollers (2) is realized through a roller idle wheel (3); each roller (2) is arranged according to a uniform thickness probability screening principle; materials are subjected to probability uniform-thickness screening after entering the roller screen from a feed end, a great amount of small materials are rapidly screened, and a small amount of large materials are rapidly conveyed to a three-roller crushing cavity; the three-roller crushing cavity is provided with a large crushing tooth roller and two small crushing tooth rollers; the materials are crushed through the three rollers in multiple stages under the comprehensive action of shearing, stretching and bending crushing mechanisms. The mining differential three-roller tooth crusher has the characteristics of high working efficiency, high processing capacity, high reliability, low energy consumption, no blocking, capability of avoiding excessive crushing of the materials and the like.

Owner:中国矿业大学盱眙矿山装备与材料研发中心

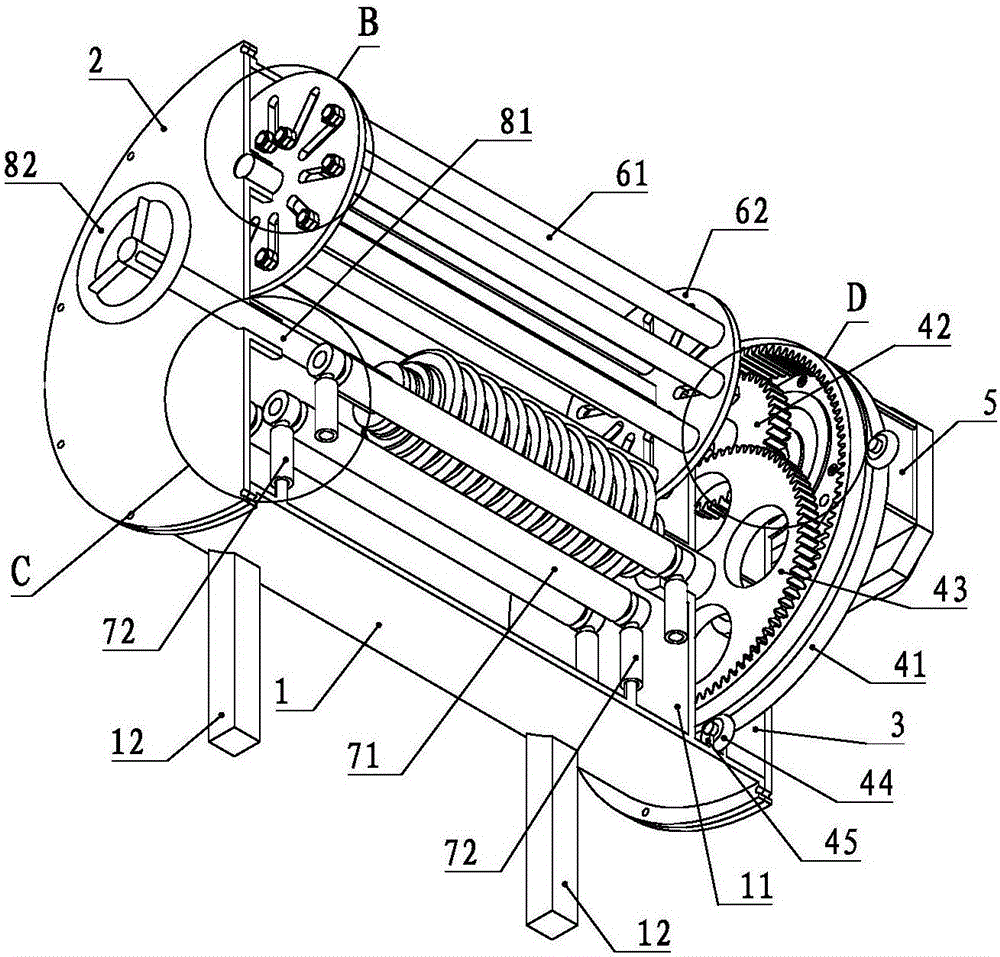

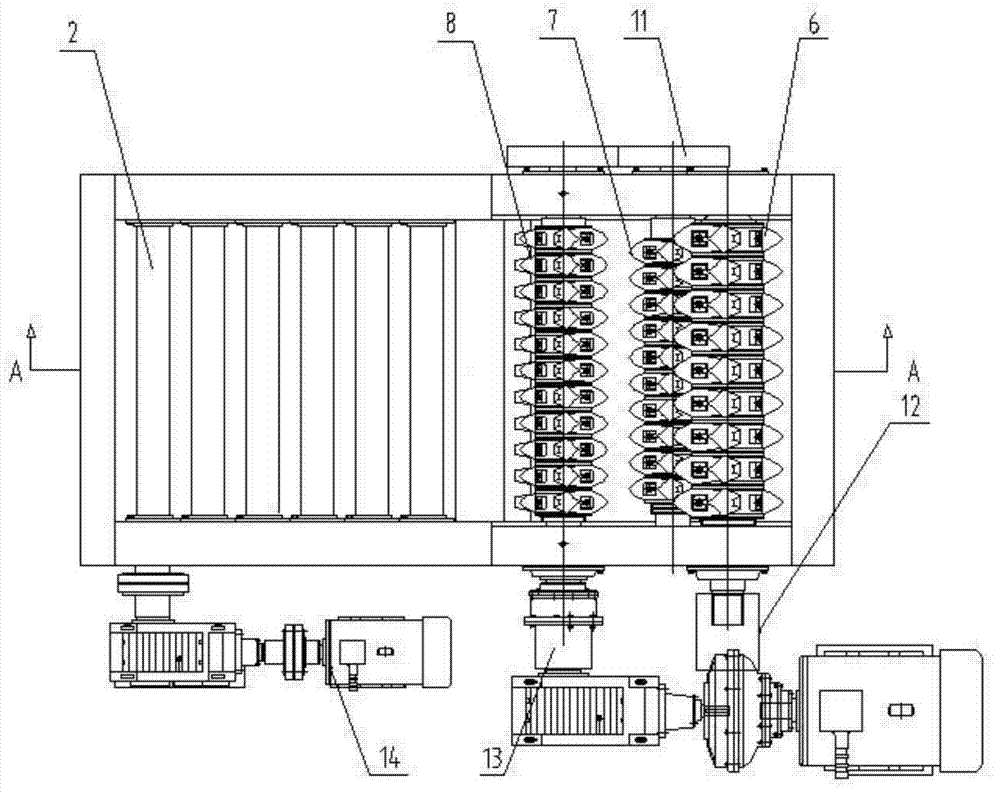

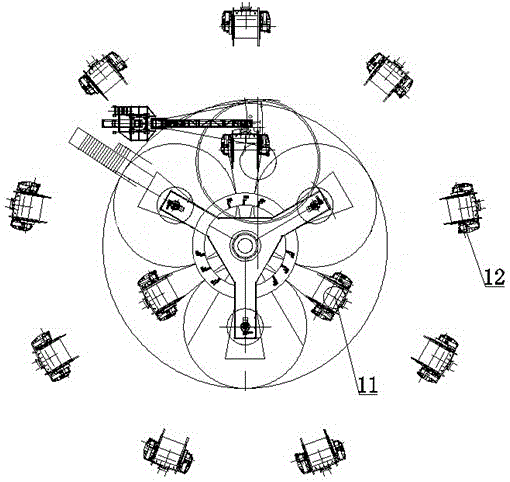

Multi-functional vertical type twisting and untwisting cable forming machine

ActiveCN105139966AImprove boot utilizationLow input costCable/conductor manufactureLarge toothGear wheel

A multi- functional vertical type twisting and untwisting cable forming machine comprises a main speed reduction variable frequency motor and a twisting rotation disc, wherein three large rotation discs and three fixed small rotation discs are uniformly arranged on the twisting rotation disc, the large rotation discs and the fixed small rotation discs are arranged in a crossed way, and nine movable small rotation discs are fixedly arranged at the outer side of the circumference of the twisting rotation disc and uniformly distributed; the processing of a submarine cable is achieved by the three large rotation discs and the three fixed small rotation discs, and the processing of a multi-core umbilical cable is achieved by the three fixed small rotation discs and the nine movable small rotation discs; and an annular large gear ring is arranged at the lower end of the twisting rotation disc, support wheel devices are arranged on the large gear ring, uniformly distributed and connected with a guide rail in a matching way, and the outer side of the large gear ring is engaged with a small gear arranged on the main speed reduction variable frequency motor. By the cable forming machine, the full untwisting before the long-length multi-core submarine cable is formed and twisted and the twisting and forming of the multi-functional umbilical cable can be achieved.

Owner:万达集团股份有限公司 +1

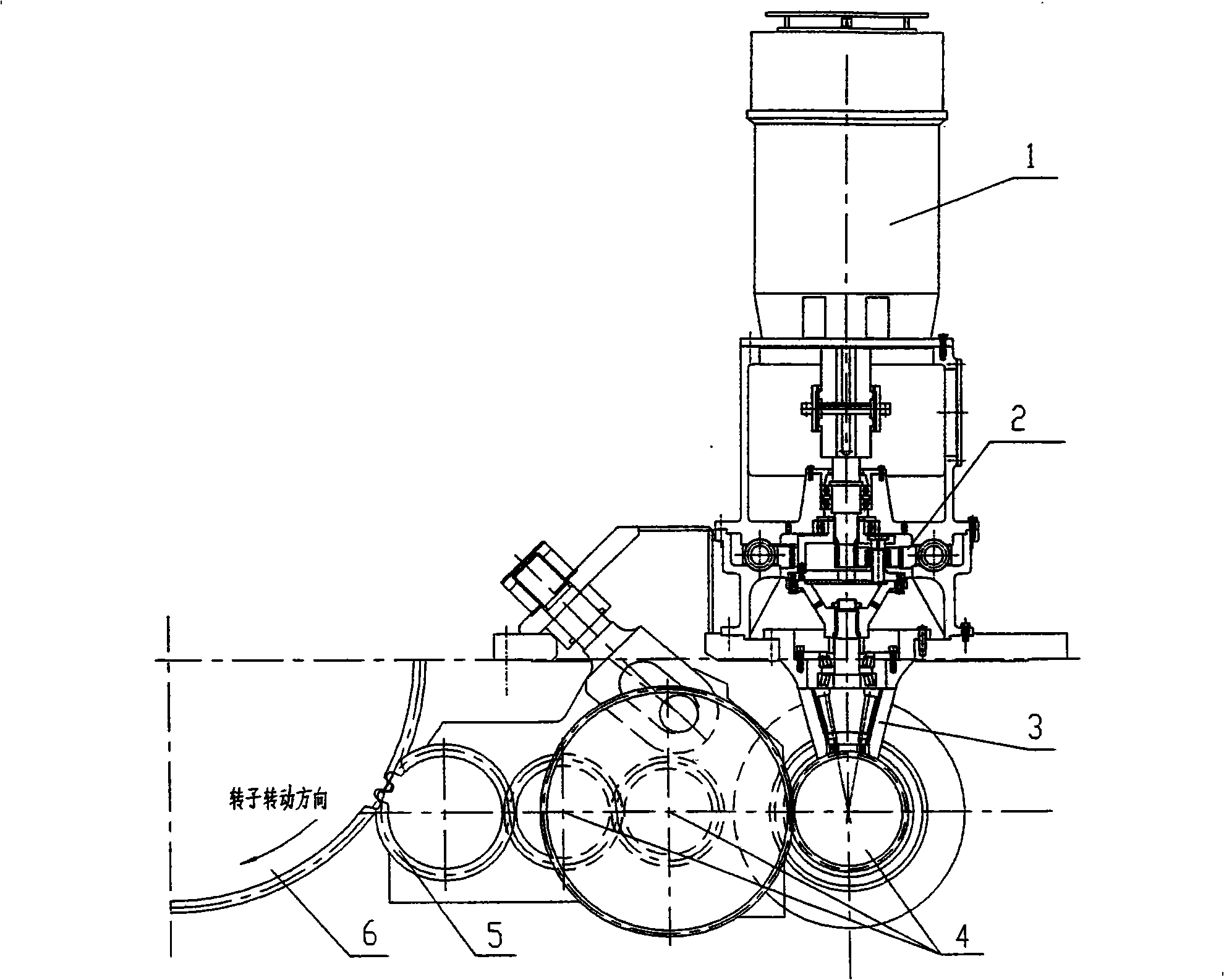

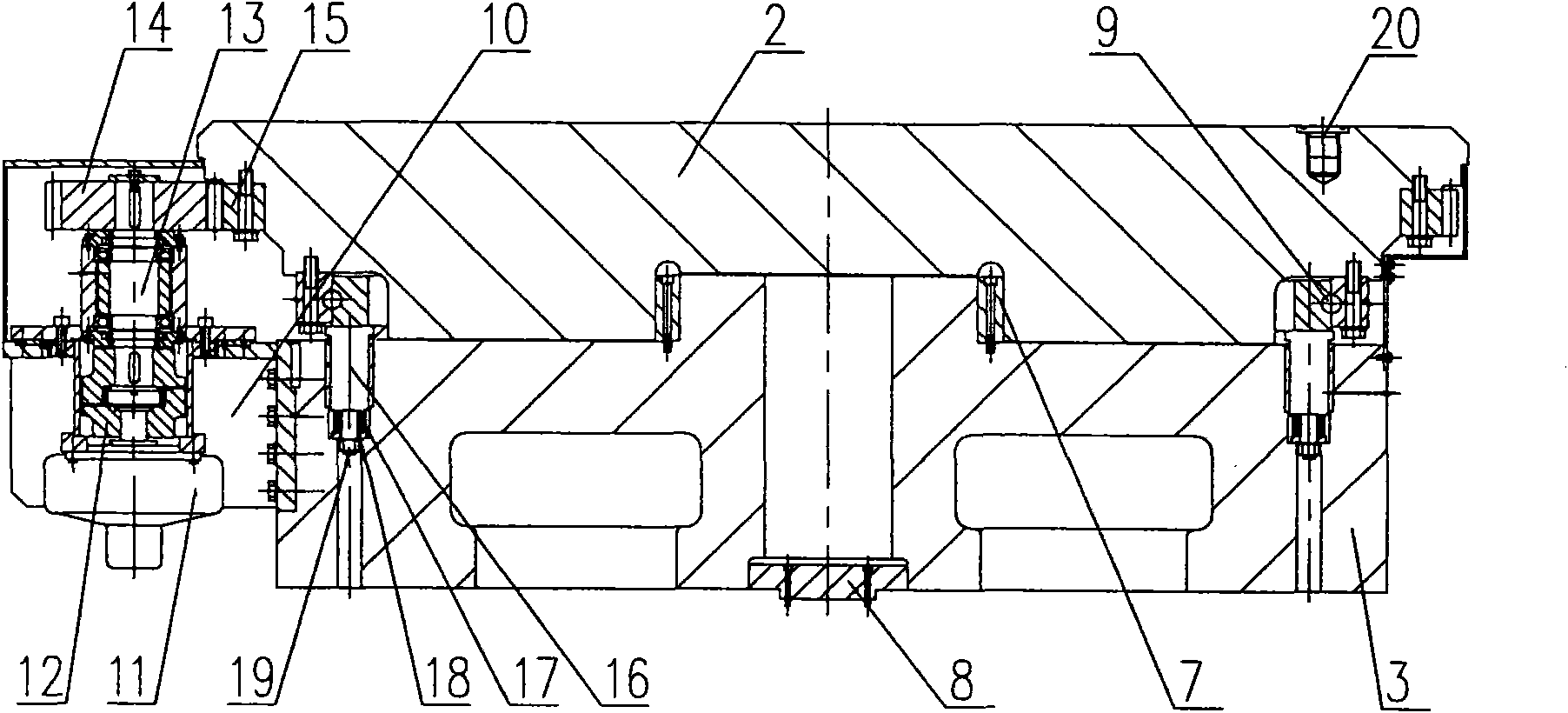

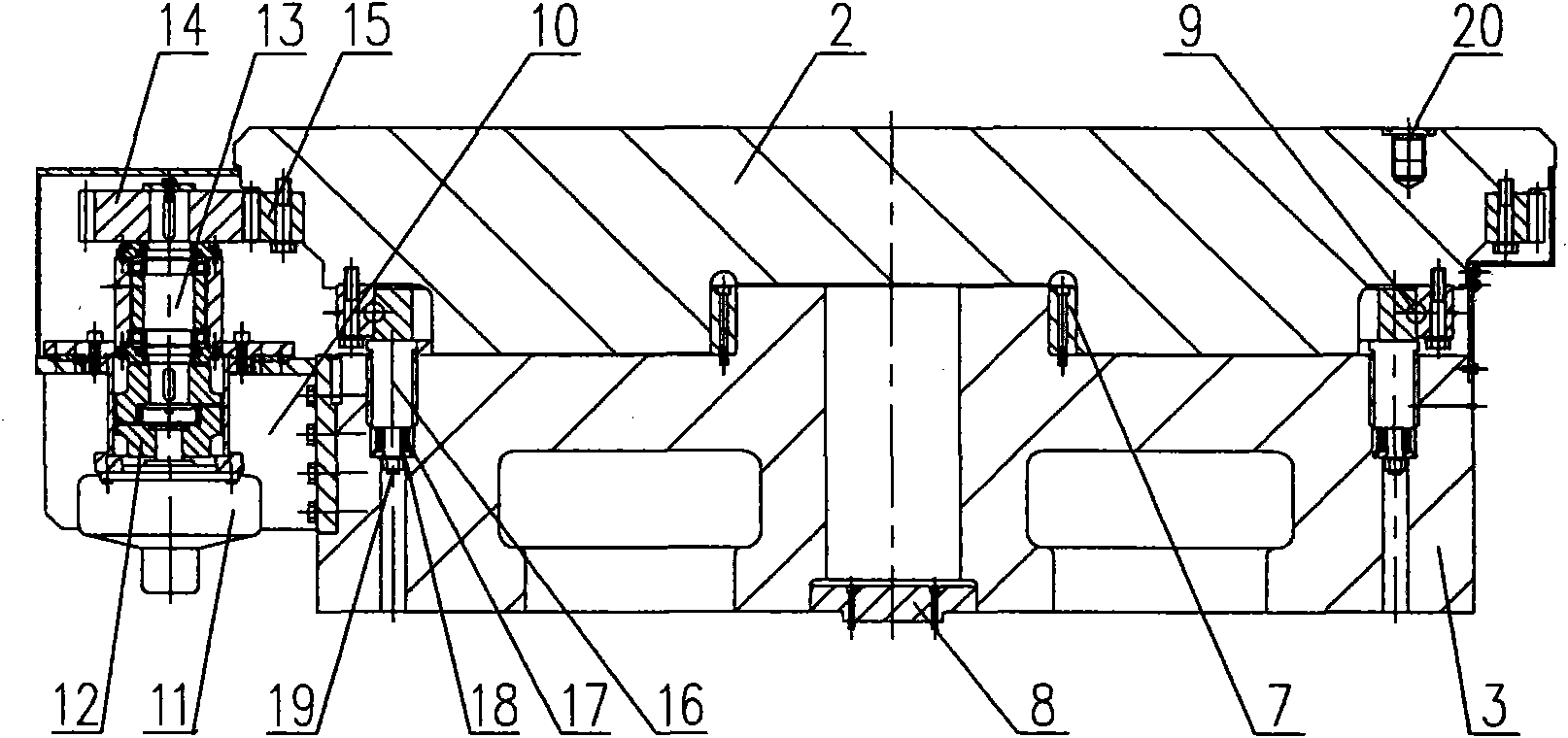

Rolling gear of turbine

InactiveCN101344018ADecrease the number of stages of decelerationMeet the requirements of 2r/min low speed crankingMachines/enginesEngine componentsMiscarriageReduction drive

The invention discloses a turning gear of a steam turbine, comprising a driving motor, a reducer, a swinging gear, a large tooth ring and a clutch mechanism of the swinging gear which are connected in sequence; the large tooth ring is arranged on a rotor of the steam turbine and the reducer is provided with a multilevel speed-reducing transmission pair; the first-level speed-reducing transmission pair of the reducer is a planetary gear transmission box, a second-level speed-reducing transmission pair is an umbrella gear transmission pair and the rest is a planar gear speed-reducing transmission pair; a buffering spring is arranged between an inner tooth ring of the planetary gear transmission box and the box; the bearings of the swinging gear and the planar gear are rolling bearings; the swinging gear is positioned below the middle section of the rotor of the steam turbine and is corresponding to the large tooth ring in a tangential mode. The invention has the advantages of compact structure and small occupied area and has the buffering function with safety and reliability and without miscarriage when in use.

Owner:DONGFANG TURBINE CO LTD

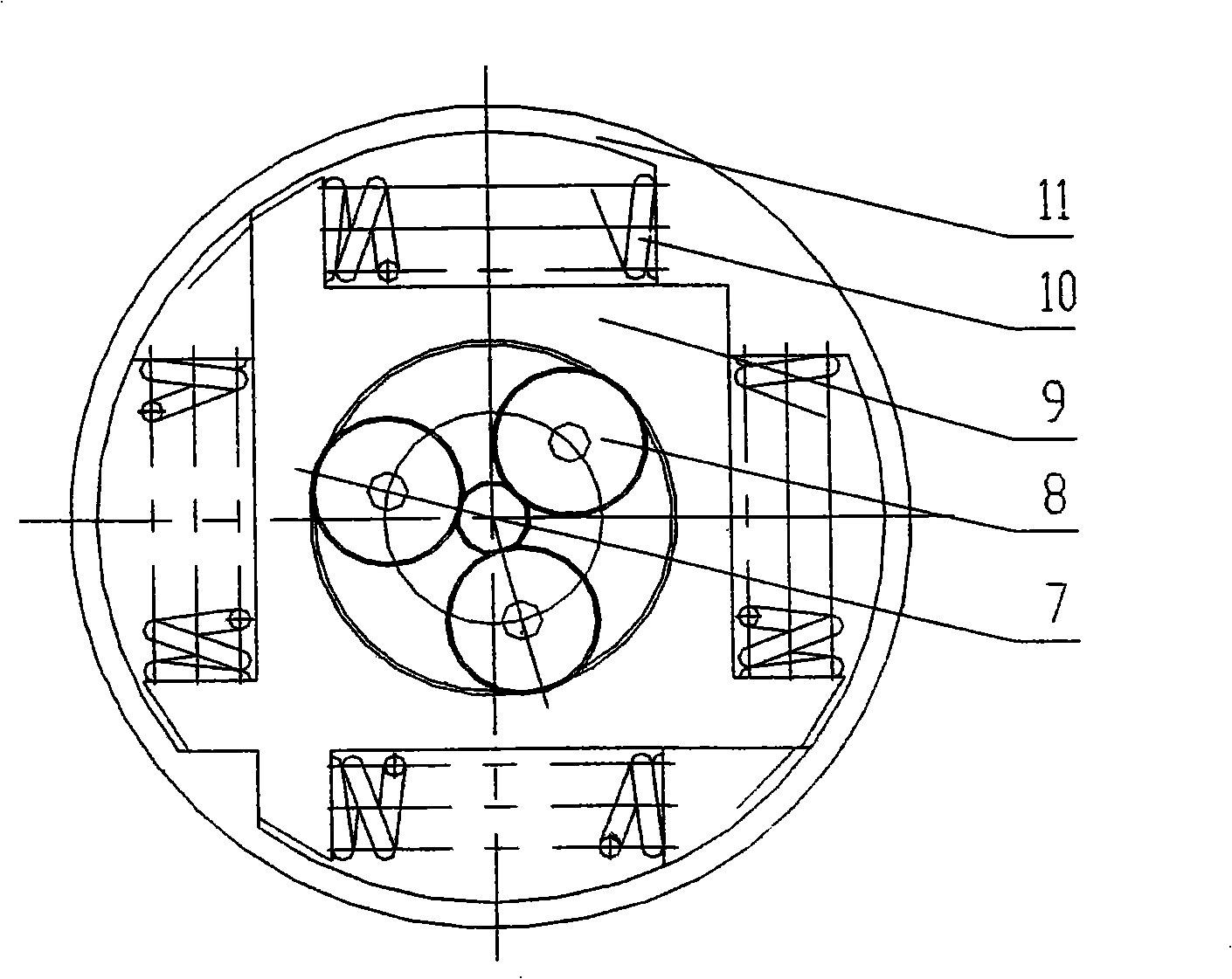

Rotary worktable for forging pie-shaped forging pieces

InactiveCN101972831AImprove friction performanceHigh degree of automationForging/hammering/pressing machinesHydraulic motorLarge tooth

The invention relates to a rotary worktable for forging pie-shaped forging pieces, relating to a forging tool and solving the problems of the prior art, such as unreasonable rotary positioning, great friction resistance, great labor intensity, and the like. The rotary worktable for forging pie-shaped forging pieces is characterized in that a guide sleeve is arranged in the vertical direction between a turntable and a base, a positioning round key connected with the movable worktable is mounted on the base, the turntable is supported by a turntable bearing which is supported by a belleville spring pack, a bracket is mounted at one side of the base, and a driving mechanism comprising a hydraulic motor, a coupler, a shaft, a pinion and a bull gear is mounted on the bracket. The invention avoids the adverse influence of unbalance loading caused in process of putting a forging piece in or separating the forging piece from the worktable, has favorable buffer effect, greatly prolongs the service life of spare parts and improves the working efficiency.

Owner:TAIYUAN HEAVY IND

pipe clamping ring

InactiveCN102272506AReduce defectsPull-out resistance can be improvedSleeve/socket jointsJoints with sealing surfacesLarge toothSmall tooth

Clamping elements (10) include a wedge-shaped ring pipe clamping structure supporting the plate, the exposed outer surface of the plate (20) is provided with an array of large clamping teeth (22) and small clamping teeth (24), and the large teeth (22) protrude more from the outer surface of the plate (20) than the small teeth (24).

Owner:KRAUSZ INDS DEVMENT

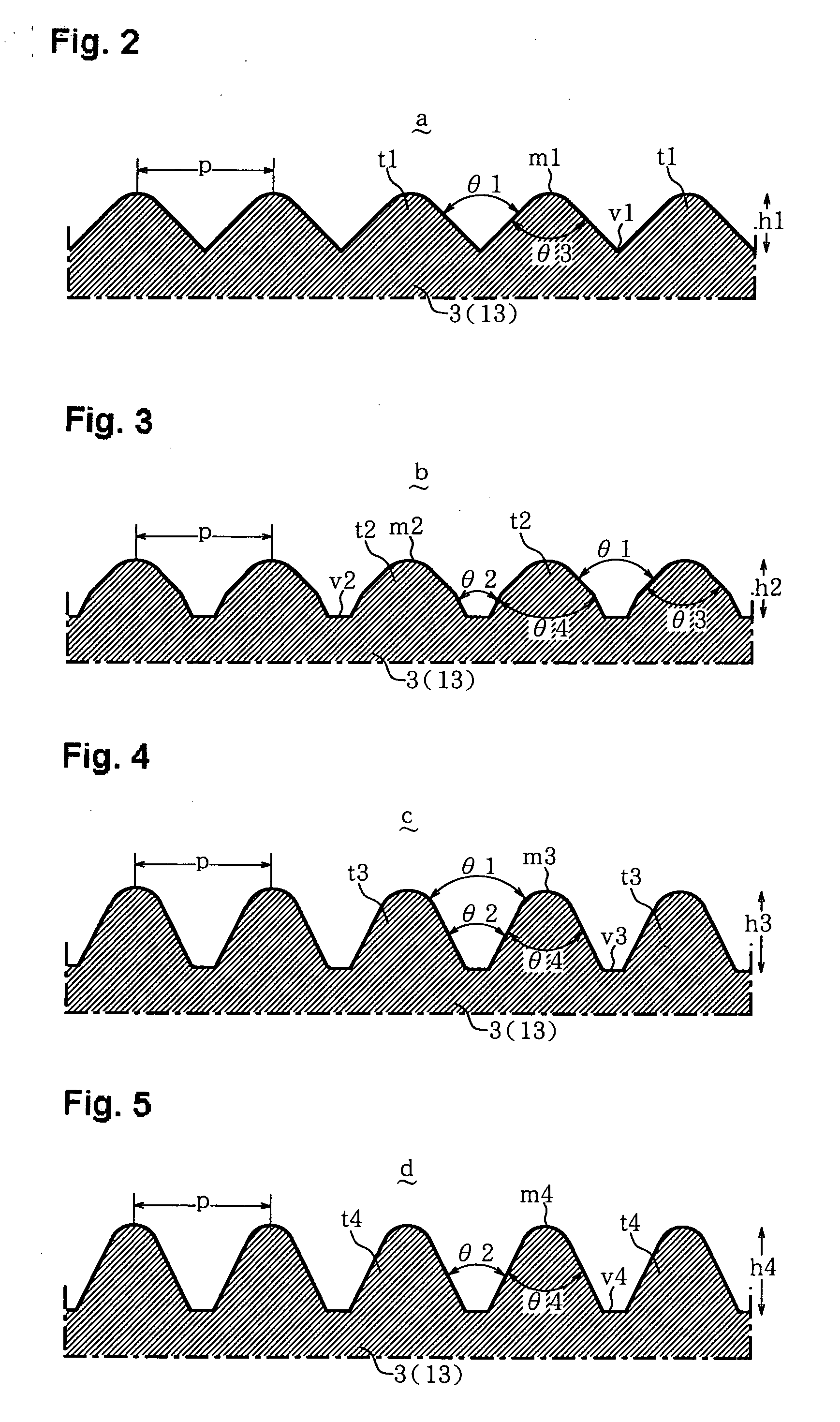

Rolling die

A rolling die is provided. The rolling die includes a bite portion having bite processing teeth at a bite starting point for a workpiece, and a finishing portion having finishing processing teeth. The bite processing teeth at the starting point in the bite portion have lower tooth height than the finishing processing teeth in the finishing portion. The bite processing teeth have a larger tooth tip angle and a larger trough angle than the finishing processing teeth.

Owner:SANMEI SEISAKUSHO

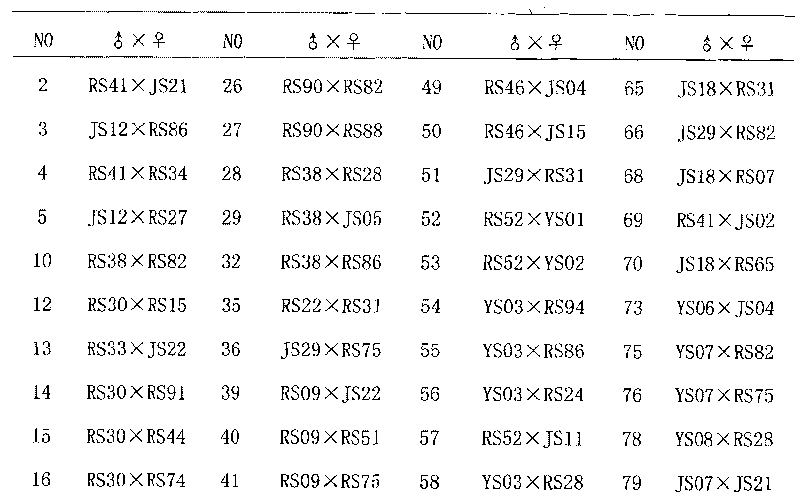

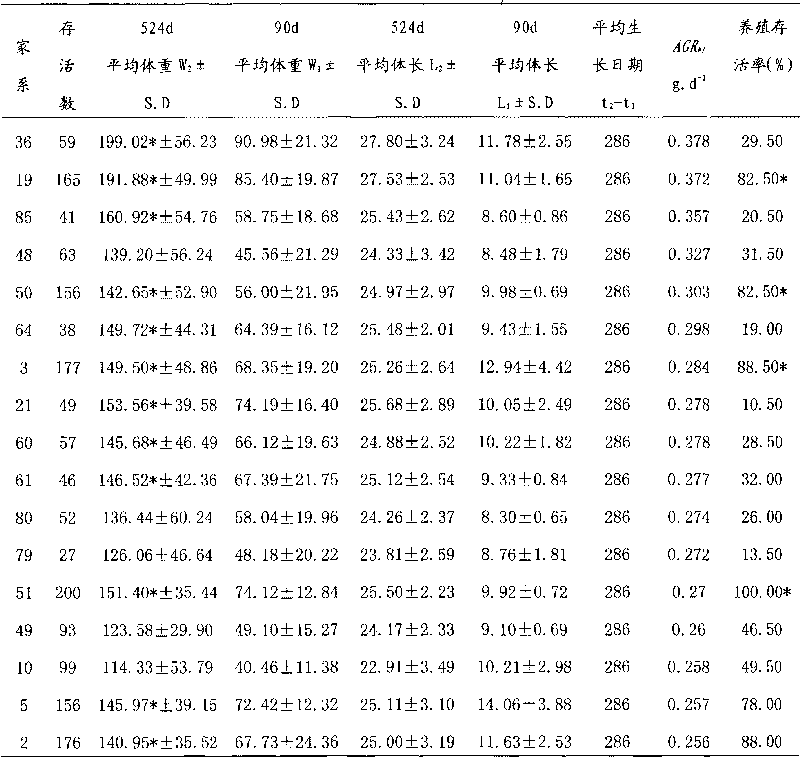

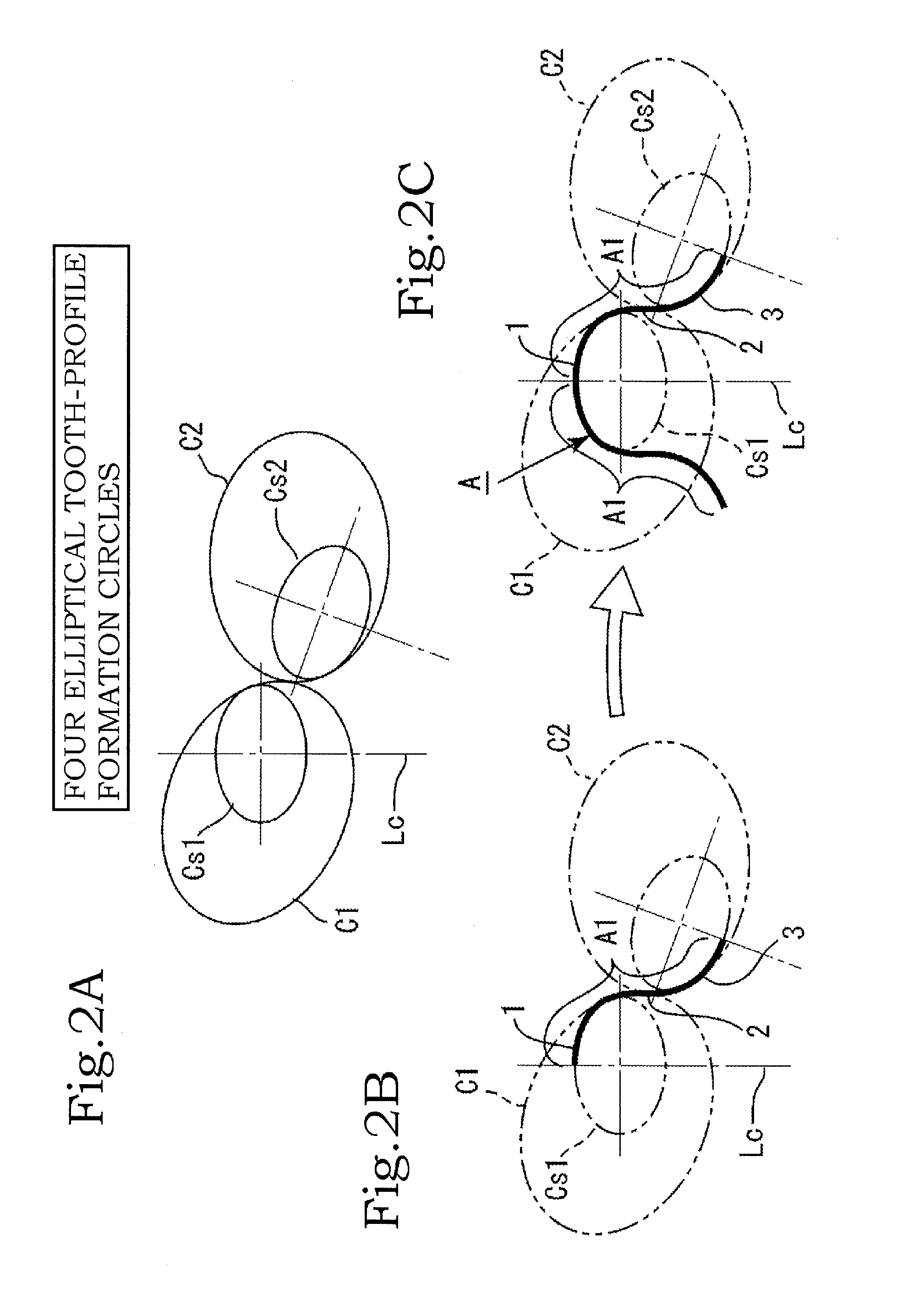

Selection and culture method of excellent breed large-tooth flounder featuring fast growth and high survival rate

InactiveCN101699998AImprove build efficiencyHomozygous speedClimate change adaptationPisciculture and aquariaSebastesLarge tooth

The invention relates to a selection and culture method of excellent breed large-tooth flounder featuring fast growth and high survival rate. The technical method comprises: culture and reproduction regulation and control of large-tooth flounder breeding group, establishment of family by sperm freezing technology, culture and standardization of the family, determination and analysis of number and properties, estimation of genetic parameters, screening of excellent family, and establishment of excellent breed by inducing thelykaryon of large-tooth flounder to develop by using heterologous frozen sperms. The invention can select and culture new breed of cultured large-tooth flounder featuring fast growth and high survival rate, screen out four excellent large-tooth flounder families featuring fast growth and high survival rate (0703, 0719, 0750 and 0751), and establish seven excellent breeds of large-tooth flounder developed from thelykaryon (0920, 0921, 0927, 0938, 0939, 0946 and 0947). The technical method can be applied to new variety culture of large-tooth flounder cultivation, solve the problems of culturing large-tooth flounder fish in sea water such as slow growth and low survival rate, and enhances economic benefit of large-tooth flounder cultivation.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

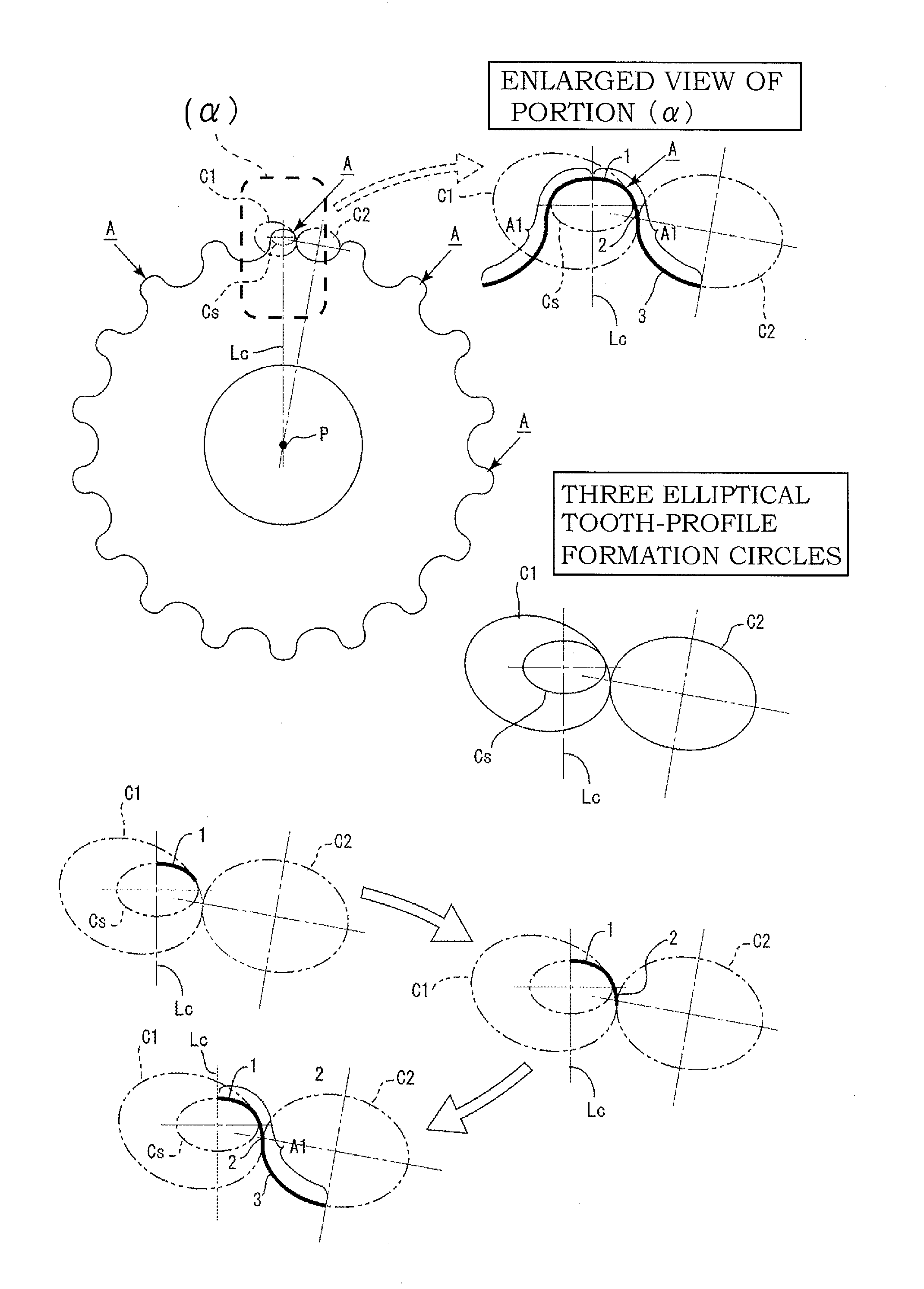

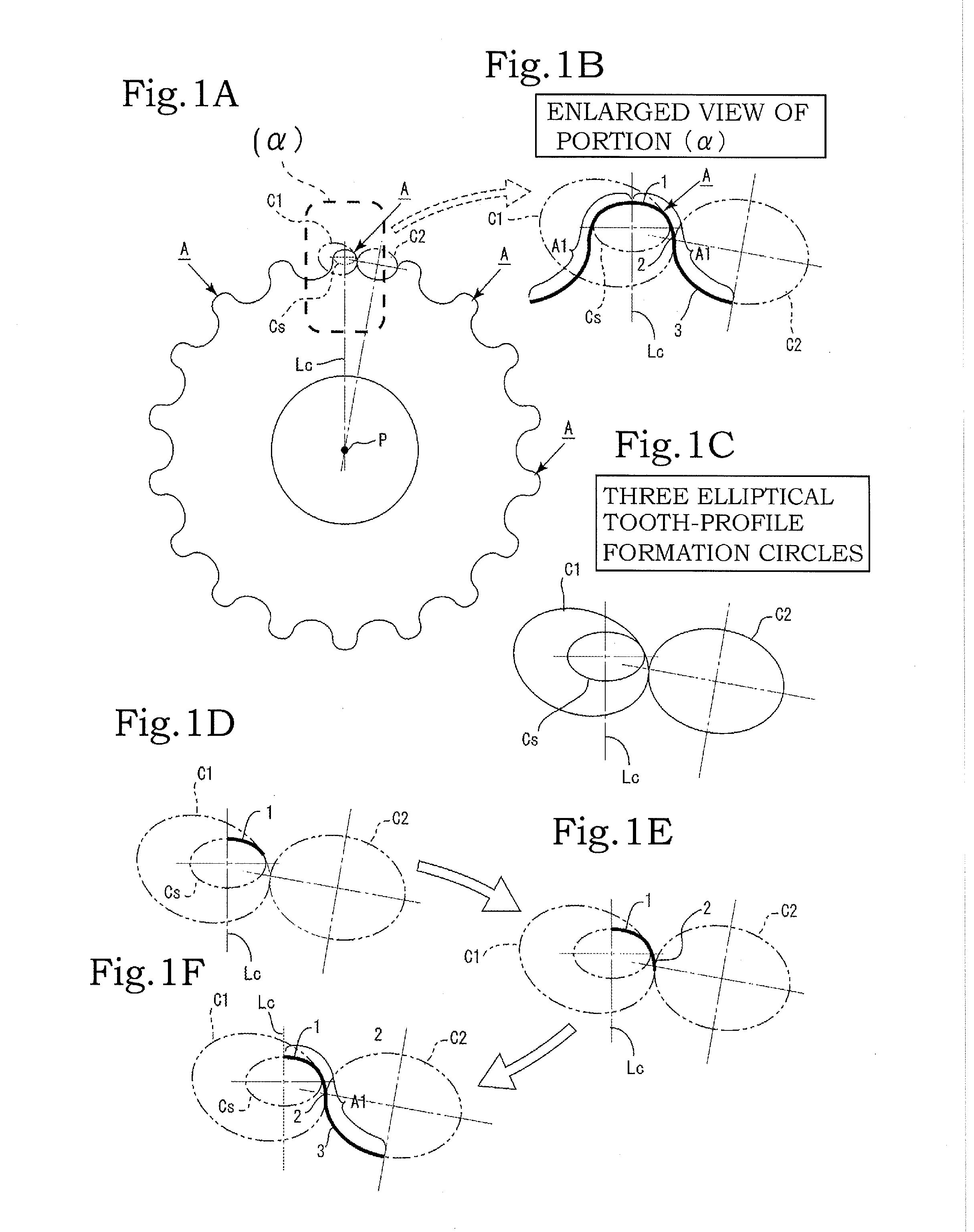

Pump rotor

ActiveUS20130112028A1Increase the number ofIncrease tooth heightPortable liftingRotary piston pumpsLarge toothEngineering

A pump rotor is an inner rotor of an internal gear pump, the inner rotor having a tooth profile, wherein a half-tooth portion of the tooth profile is formed of three tooth-profile formation circles that are elliptical or true-circular. Two of the tooth-profile formation circles are a combination of a small tooth-profile formation circle and a large tooth-profile formation circle in which the small tooth-profile formation circle is inscribed and is entirely included. A portion of the small tooth-profile formation circle forms an addendum portion of the half-tooth portion. A portion of the large tooth-profile formation circle in which the small tooth-profile formation circle is inscribed and is entirely included forms an engagement portion of the half-tooth portion. A portion of another tooth-profile formation circle that circumscribes the large tooth-profile formation circle forms a dedendum portion of the half-tooth portion.

Owner:YAMADA SEISAKUSHO KK

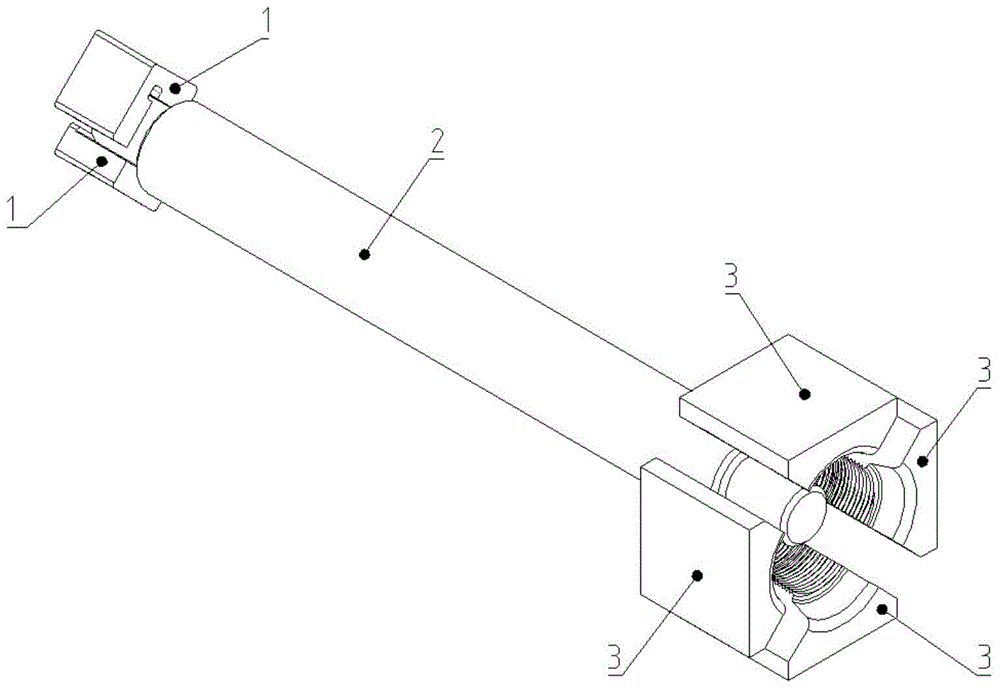

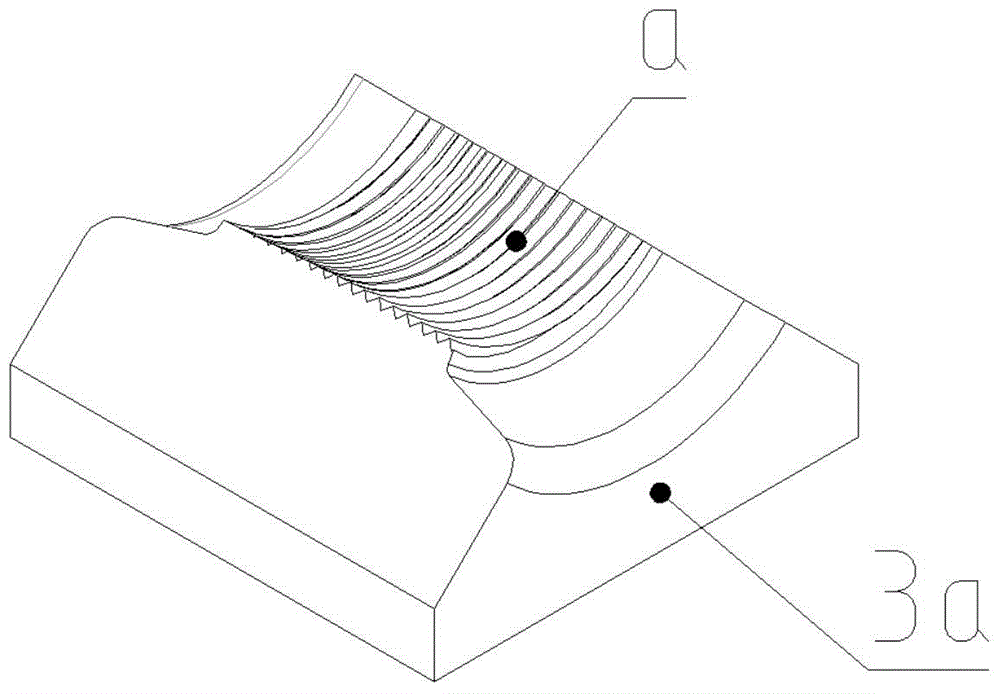

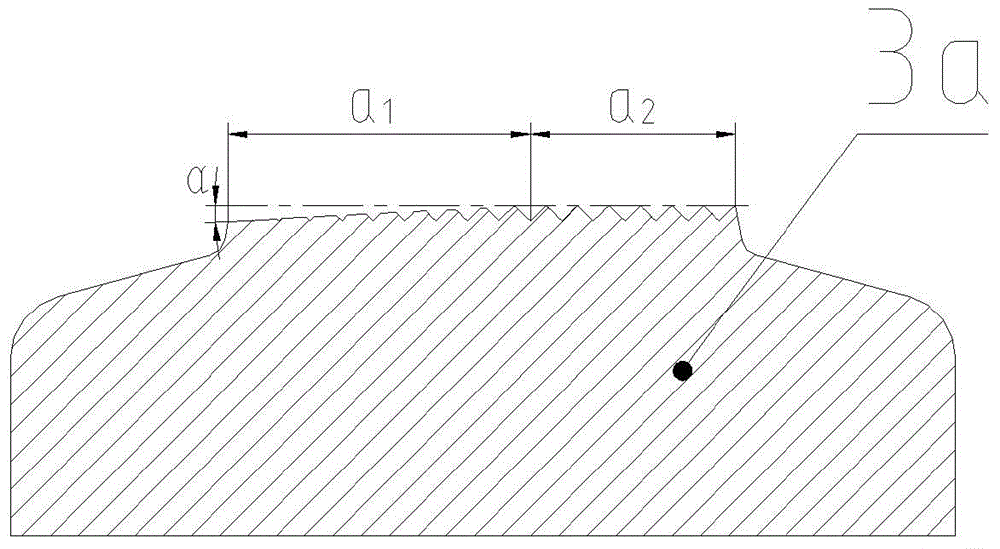

Radial forging and gradual-increment forming method for large-tooth-height thread element

ActiveCN103978147AImprove surface strengthHigh surface hardnessForging/hammering/pressing machinesEngine componentsLarge toothEngineering

The invention discloses a radial forging and gradual-increment forming method for a large-tooth-height thread element. According to the method, a hammerhead is gradually increased by a radial compression amount, the hammerhead is provided with a thread-shaped section, the thread shape comprises a gradual-increment-variable thread-shaped section and a gradual-increment-invariable thread-shaped section, a plurality of the hammerheads with the gradual-increment-variable thread-shaped sections are used for synchronously forging, and a workpiece is rotated and axially fed simultaneously, thus reducing a forming force, reducing forging defects, and improving surface accuracy and strength; isovolumetric forging is carried out to realize near-net forming, thus increasing material utilization rate, and shortening production period; forming manufacturing for thread components such as lead screws and screw rods with high performances, large diameters and high tooth heights can be realized.

Owner:XI AN JIAOTONG UNIV

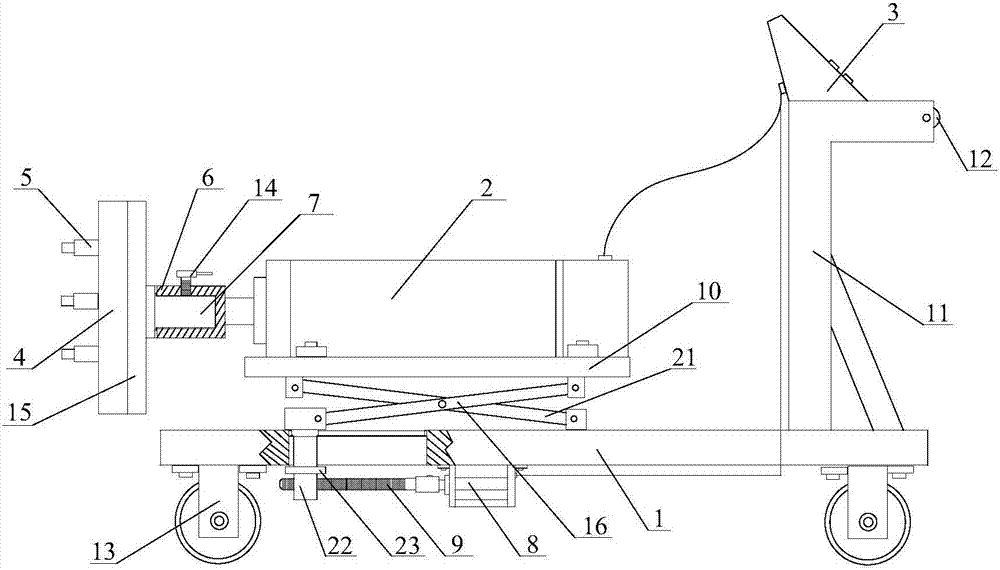

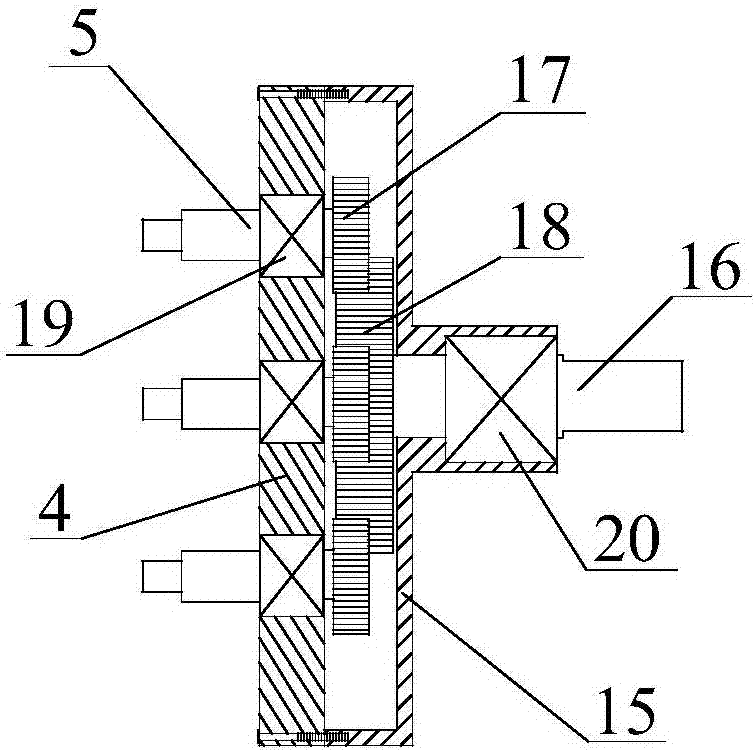

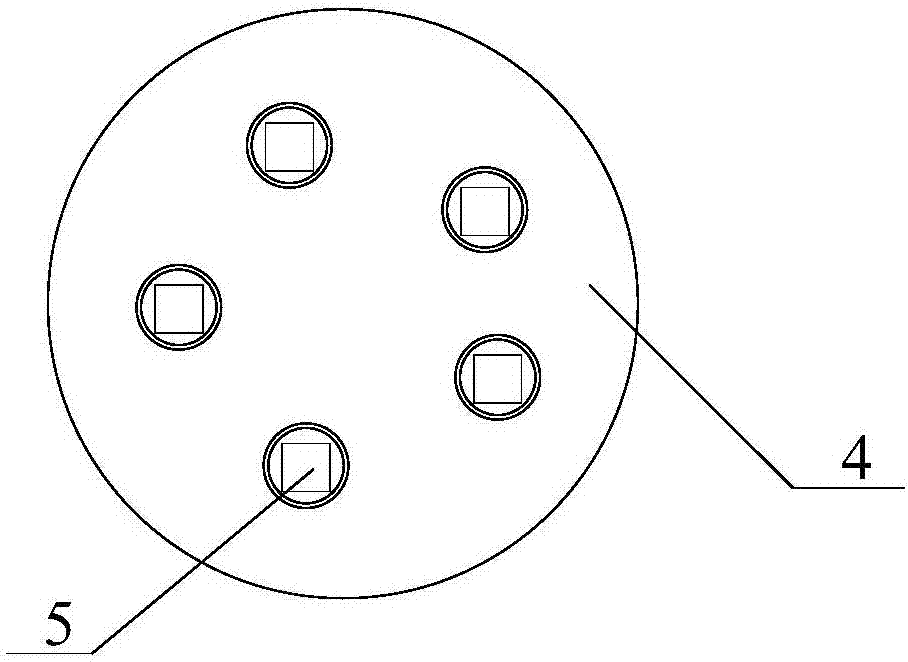

Tire dismounting equipment

InactiveCN107962909AImprove disassembly efficiencyRealize one-time disassemblyWheel mounting apparatusTyre repairingLarge toothEngineering

The invention discloses a tire dismounting device, which is characterized in that it comprises a base (1), a controller (3), and a multi-axis rotating head device; the wind gun (2) is connected with the controller (3). The multi-axis turret device includes a carrier (4), a housing (15), a secondary shaft (5), a small tooth (17), a main shaft (7), and a large tooth (18). The present invention has simple structure and strong practicability. The equipment cooperates with multiple nuts of the tire through a multi-axis turning device, and the multi-axis turning device realizes one-time disassembly of all the nuts of the tire under the action of the jackhammer. Thereby the present invention has improved the efficiency of tire dismounting very well.

Owner:四川新驱科为科技有限公司

Broad-Pole Type Square-Wave Three-Phase Brushless Permanent Magnet Direct Current Motor and Assembling Method Thereof

ActiveUS20130106254A1Simple structureReduce manufacturing costMagnetic circuit stationary partsDC commutatorLarge toothElectric machine

A broad-pole type square-wave three-phase brushless permanent magnet direct current motor and an assembling method thereof are disclosed. The number of magnetic poles on a rotor core is: 2P=4. The number of slots in a stator core is: Z=6. Six teeth on the stator are composed of three large teeth and three small teeth. The sum of mechanical angles of one large tooth and one small tooth is 120 degree. Electrical angles corresponding to the mechanical angles are: P*120=240°. Three-phase concentrated windings are wound on three large teeth separately, and only one winding is arranged at each phase. The advantages of the motor are low positioning torque, simple structure, effective production cost, convenient to wind the windings, and low copper loss, etc.

Owner:SHENZHEN TATFOOK POWER EQUIP CO LTD

Lock washer manufacturing method and lock washer

The invention discloses a lock washer manufacturing method and a lock washer. The manufacturing method comprises the following steps that (1), the lock washer which is made of stainless steel and has a tooth structure is manufactured, wherein the tooth structure is that the included angle between a long edge and a short edge of the cross section of a small tooth is 80-110 degrees, the depth of the small tooth is 0.1-0.3 millimeter, the included angle between the long edge of the cross section of the small tooth and the base plane of the washer is 5-10 degrees, and the included angle A between the long edge of the cross section of a large tooth and the base plane of the lock washer is larger than the lead angle B of a matched bolt or nut by 0.1-1 degree; (2), the surface of the lock washer is processed, and a passivated layer on the surface of the lock washer is removed; (3), the lock washer after processing of the step (2) is subjected to low-temperature carburization, or low-temperature nitridation or low-temperature nitrocarburizing, and a hardened layer is formed on the surface of the lock washer; (4), the finished lock washer is finally manufactured after washing. The lock washer manufactured through the manufacturing method is good in lock effect and low in manufacturing cost.

Owner:TRITREE METAL SHENZHEN

Communication-in-moving satellite antenna with low profile

PendingCN107799897APolarized realizationHigh precisionAntenna supports/mountingsAntenna adaptation in movable bodiesLarge toothAngular degrees

The invention relates to a communication-in-moving satellite antenna with a low profile. The communication-in-moving satellite antenna comprises a receiving part and an emission part which are same instructure, wherein the receiving part comprises an upper-layer phase modulation surface, an intermediate-layer phase modulation surface, a lower-layer feeding source surface and a rotation mechanismwhich are sequentially arranged from top to bottom, the rotation mechanism comprises an upper-layer large ring gear, an intermediate-layer large ring gear, a lower-layer large ring gear and a rotationdriving device, and the rotation driving device drives the lower-layer large ring gear, the intermediate-layer large ring gear and the upper-layer large ring gear to rotate so as to achieve rotationof the lower-layer feeding source surface, the intermediate-layer phase modulation surface and the upper-layer phase modulation surface. The beam pitching angle of the satellite antenna is adjusted according to angle difference between the upper-layer phase modulation surface and the intermediate-layer phase modulation surface which are driven by the upper-layer large ring gear and the intermediate-layer large ring gear to rotate, the upper-layer phase modulation surface and the lower-layer phase modulation surface simultaneously rotate, the beam directional angle of the antenna is adjusted according to a rotation angle, the lower-layer feeding source surface is driven to rotate by the lower-layer large ring gear so as to adjust a polarization angle of the satellite antenna, polarization adjustment is achieved, and a main beam of the antenna points to a satellite all the way during the moving process on a vehicle, an airplane and a boat and is maintained within certain accuracy.

Owner:SATPRO MEASUREMENT & CONTROL TECH

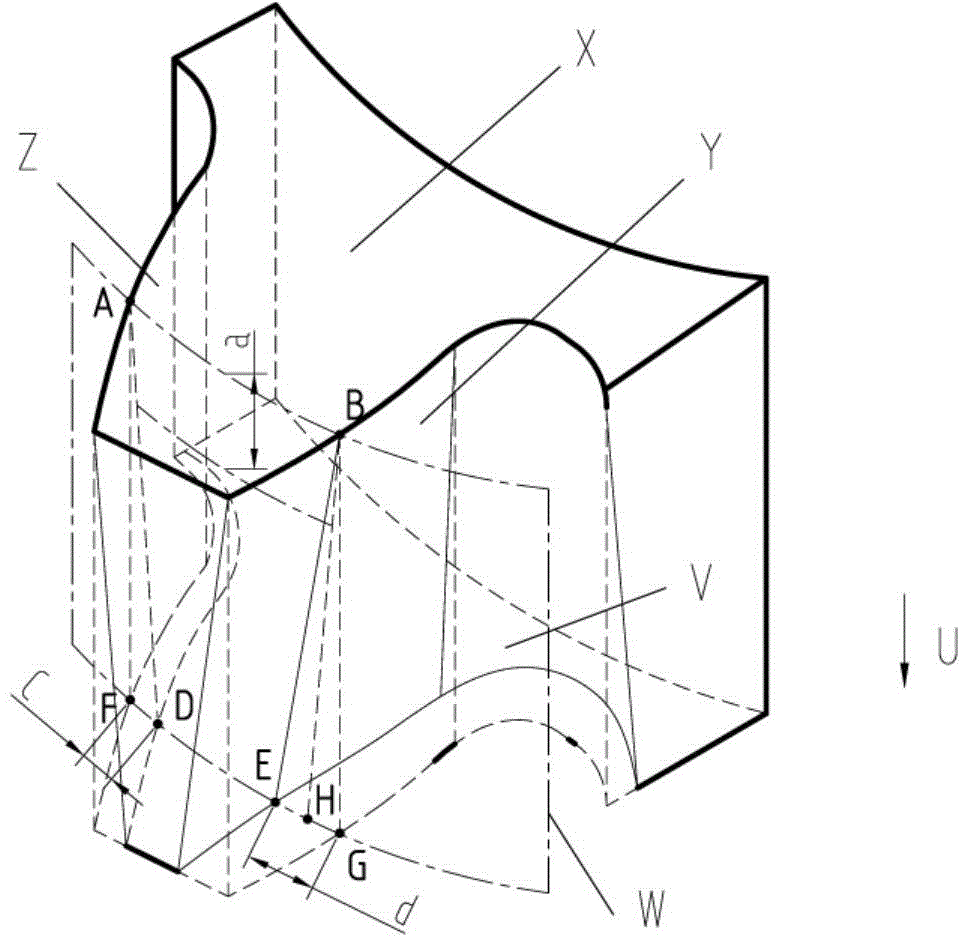

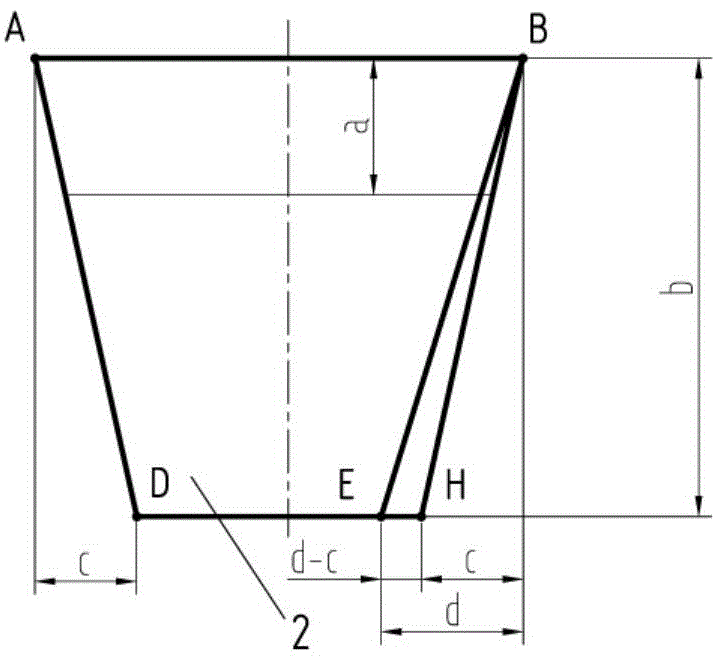

Gear with large tooth lead modification quantity and processing method thereof

ActiveCN104653749AImprove reliabilityTooth surface hardness is highPortable liftingGearing elementsHobbingLarge tooth

The invention discloses a gear with large tooth lead modification quantity and a processing method thereof. the modification coefficient of a tooth shape of the upper end face of the gear with large tooth lead modification quantity is x, and the common normal line of the tooth shape of the upper end face is W; the modification coefficient of the tooth shape of the section at a position, spaced from the upper end face by a, on the gear with the large tooth lead modification quantity is xa, and the common normal line of the tooth shape of the section at the position, spaced from the upper end face by a, on the gear with the large tooth lead modification quantity is Wa; the intersecting line of the left tooth surface and the cylindrical surface of the reference circle is a molded line AD, and the intersecting line of the right tooth surface and the cylindrical surface of the reference circle is a molded line BE; an intersection between the molded line AD and the upper end face X is a point A, and an intersection between the molded line AD and the lower end face V is a point D; an intersection between the molded line BE and the upper end face X is a point B, and an intersection between the molded line BE and the lower end face V is a point E; a point F is a projection of the point A on the lower end face V in the axial direction U; a point G is a projection of the point B on the lower end face V in the axial direction U. The processing method comprises a step of 1, performing hobbing processing on a gear blank, and further comprises a second step and a third step. According to the processing method, the tooth direction grinding modification quantity can be reduced, and the defects, such as reduction of the hardness of the tooth surface, caused by a large tooth grinding amount are avoided.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

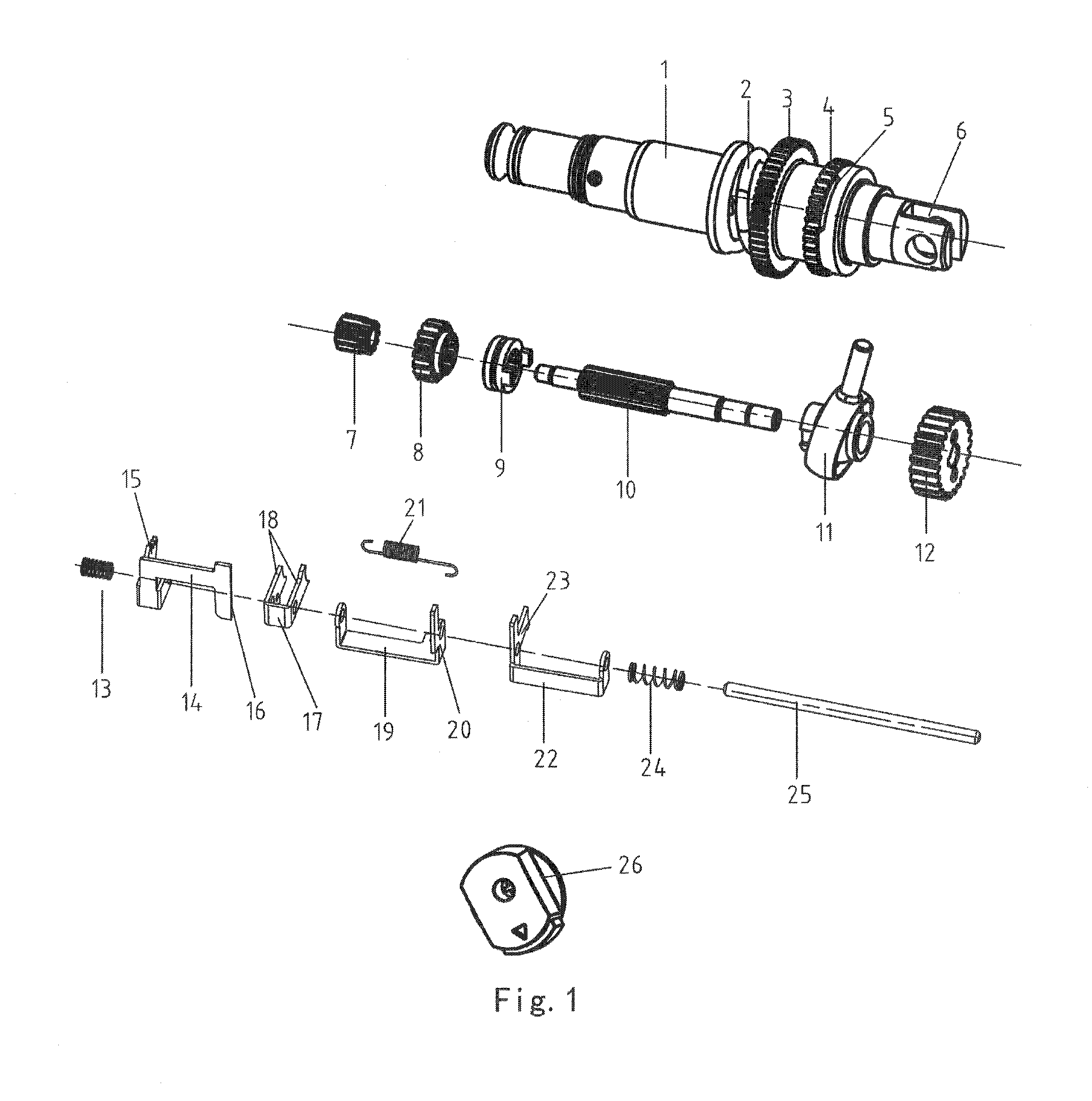

Light single-button multifunctional electric hammer

ActiveUS9227312B2Simple and reasonable structureLow costPortable percussive toolsBulkheads/pilesGear wheelLarge tooth

A light single button multi-function electric hammer comprises a body, a motor, a rotation set assembly, a cylinder assembly, a torque spring, a knob, a gearwheel and a transmission mechanism of torque clutch. The transmission mechanism comprises a pinion, a gear clutch, a middle shaft, a hammer crosspiece clutch, a swing rod bearing and a primary gear. The pinion is movably fitted with the middle shaft; the pinion meshes large end teeth of the gearwheel and matches with the inner teeth of the gear clutch. The gear clutch meshes small end teeth of the gearwheel and is fitted with the teeth shaft of the middle shaft. The gear clutch and the hammer crosspiece clutch are movably fitted with the teeth shaft of the middle shaft. The knob is connected with an operating mechanism linked to the large teeth end of the gearwheel, the gear clutch and the hammer crosspiece clutch.

Owner:JINHUA CITY JUJIE ELECTRIC MACHINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com