Rotary worktable for forging pie-shaped forging pieces

A technology of rotary table and mobile table, applied in the field of forging tools, can solve the problems of large friction resistance, high labor intensity, unreasonable rotation positioning, etc., and achieve the effect of small friction resistance, good friction effect and reducing equipment damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

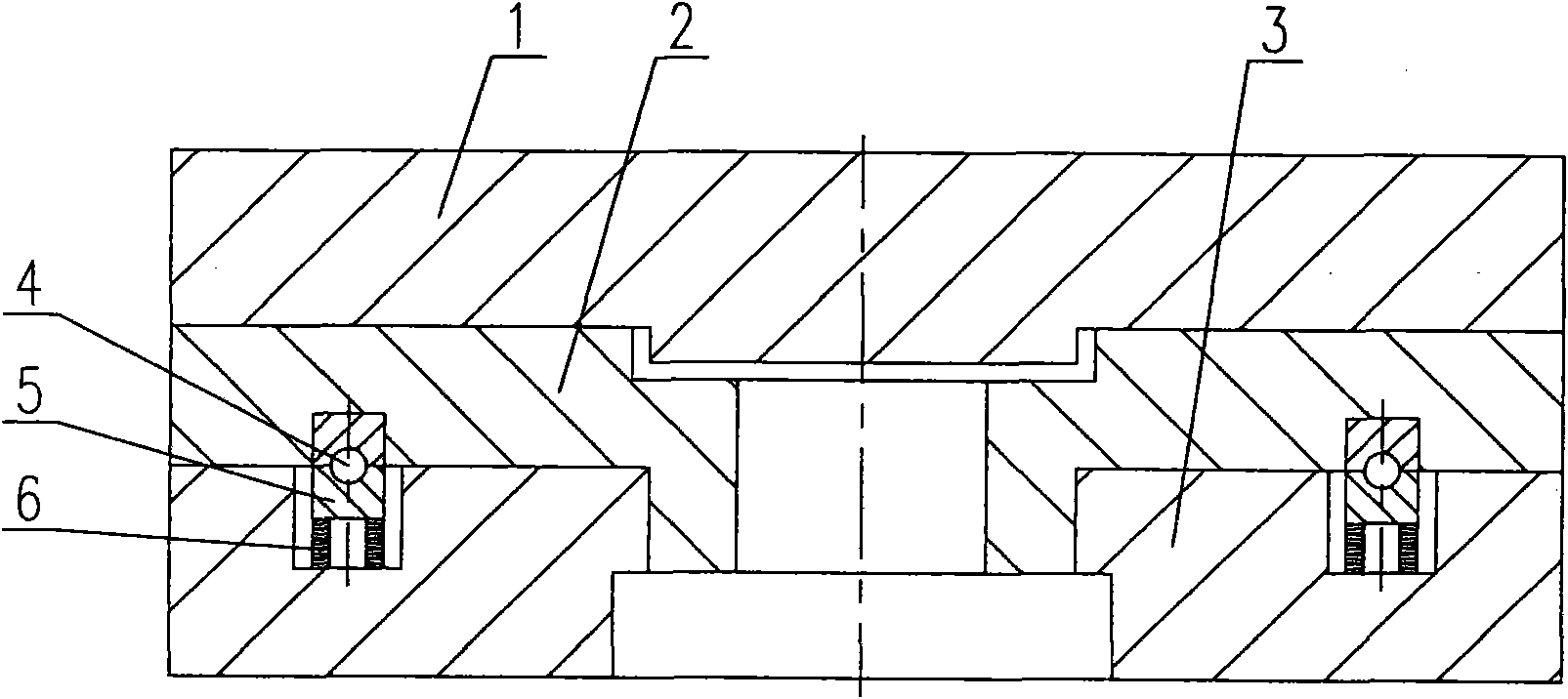

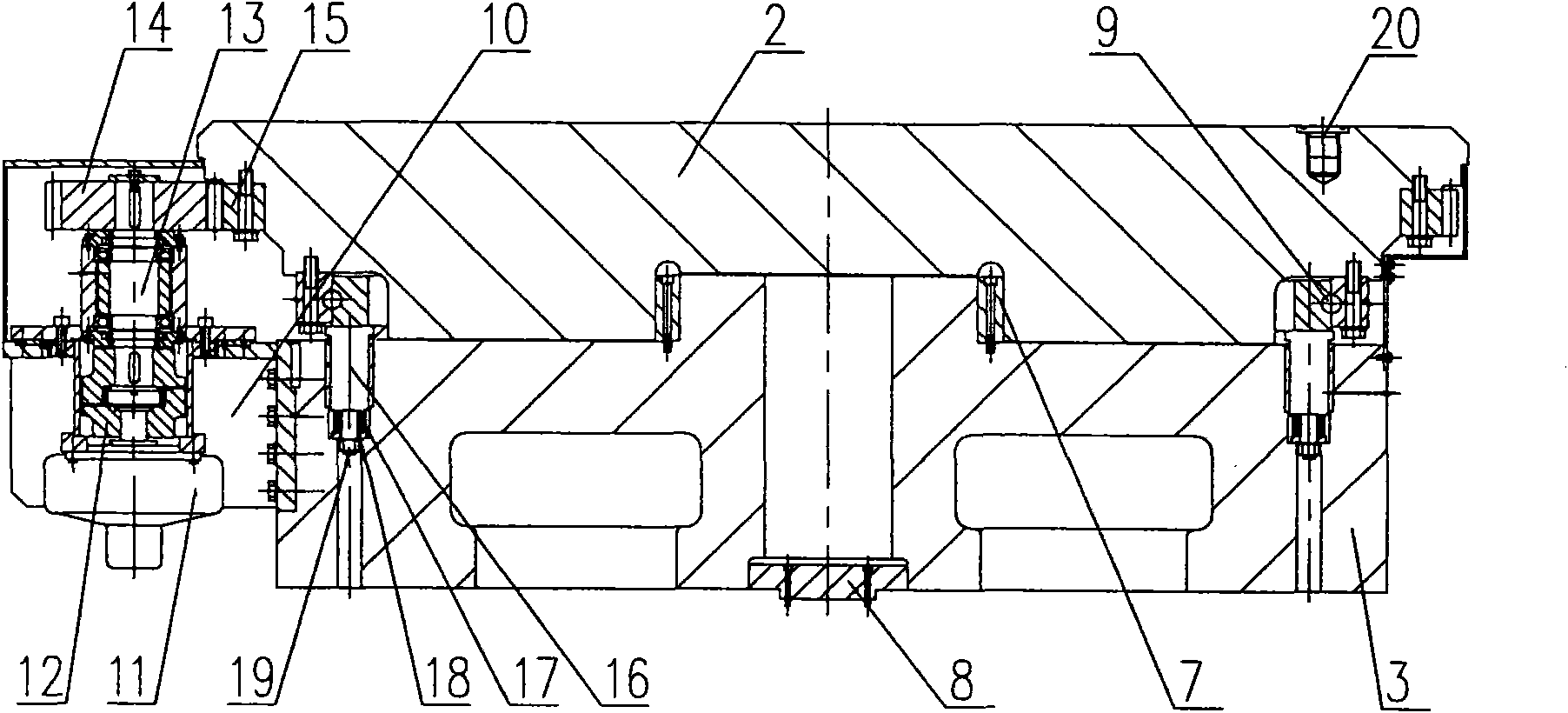

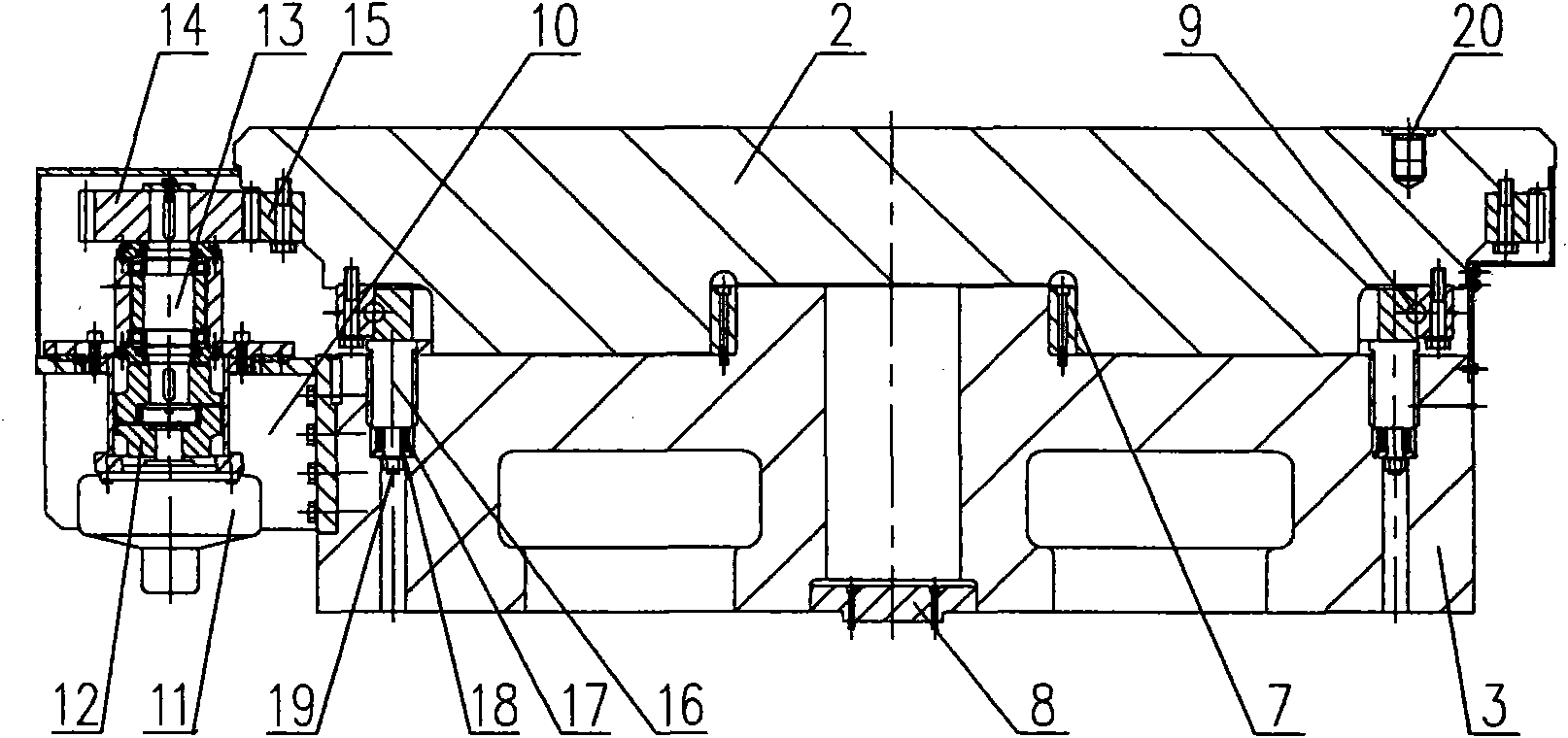

[0025] Such as figure 2 As shown, a rotary table for forging pie-shaped forgings includes: a turntable 2 and a base 3, and a guide sleeve 7 is provided in the vertical direction between the turntable 2 and the base 3; The positioning round key 8 connected to the platform; the turntable 2 is supported by the turntable bearing 9, and the turntable bearing 9 is supported by the disc spring group; a bracket 10 is installed on the side of the base 3, and the bracket 10 is equipped with a hydraulic motor 11, a coupling 12. The drive mechanism composed of the shaft 13, the pinion gear 14 and the large ring gear 15 can realize the forward and reverse rotation of the turntable at any angle from 0 to 360°.

[0026] The guide sleeve 7 is fixed on the base 3 by screws, and the horizontal positioning of the base 3 is realized by the guide sleeve 7 when the turntable 2 rotates

[0027] The positioning round key 8 is fixed on the mobile workbench by screws, and the base 3 realizes horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com