Patents

Literature

541 results about "Uniform rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Panoramic shooting method

InactiveCN104320581AGet evenlyQuality improvementTelevision system detailsColor television detailsComputer graphics (images)Shooting method

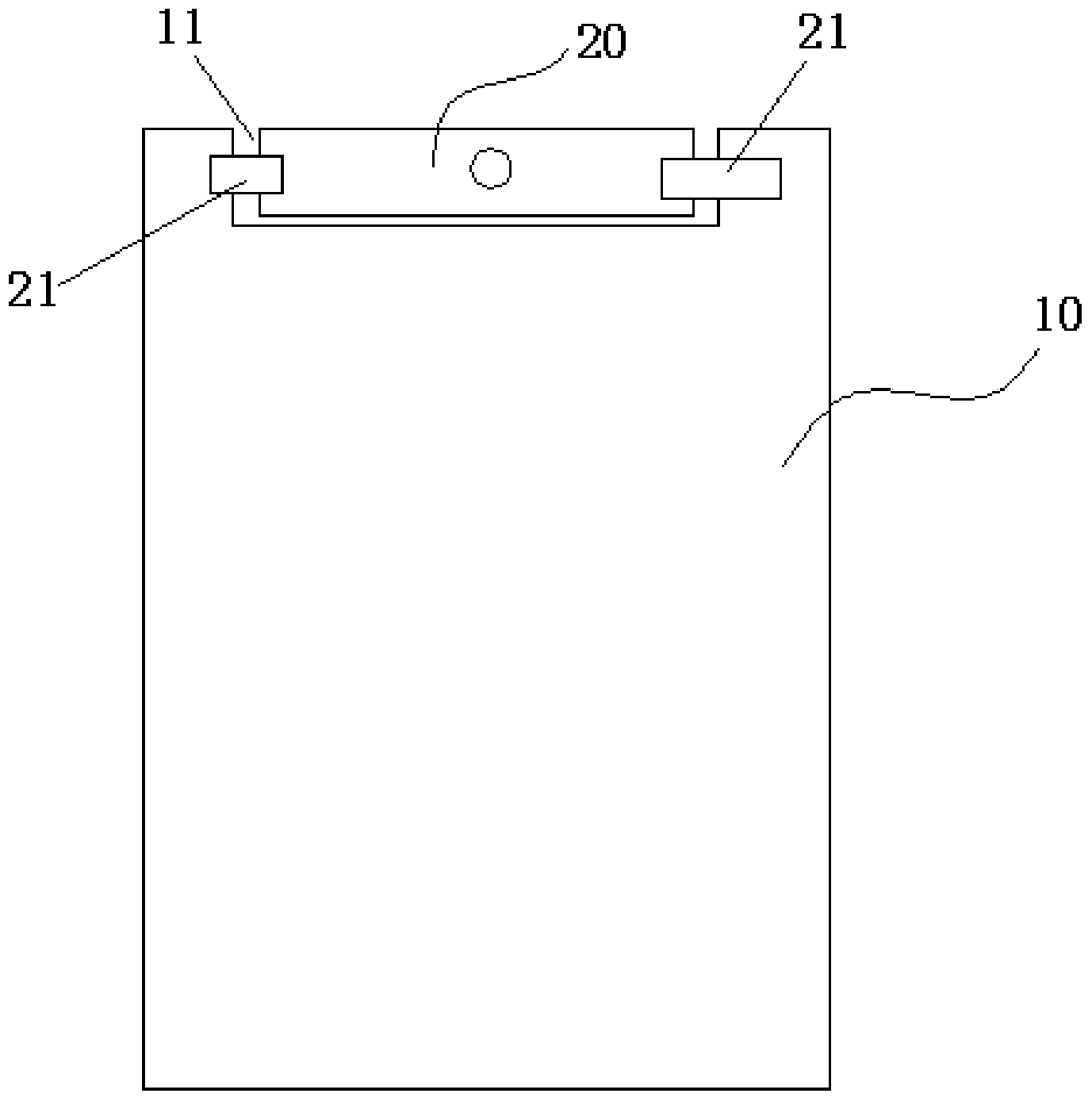

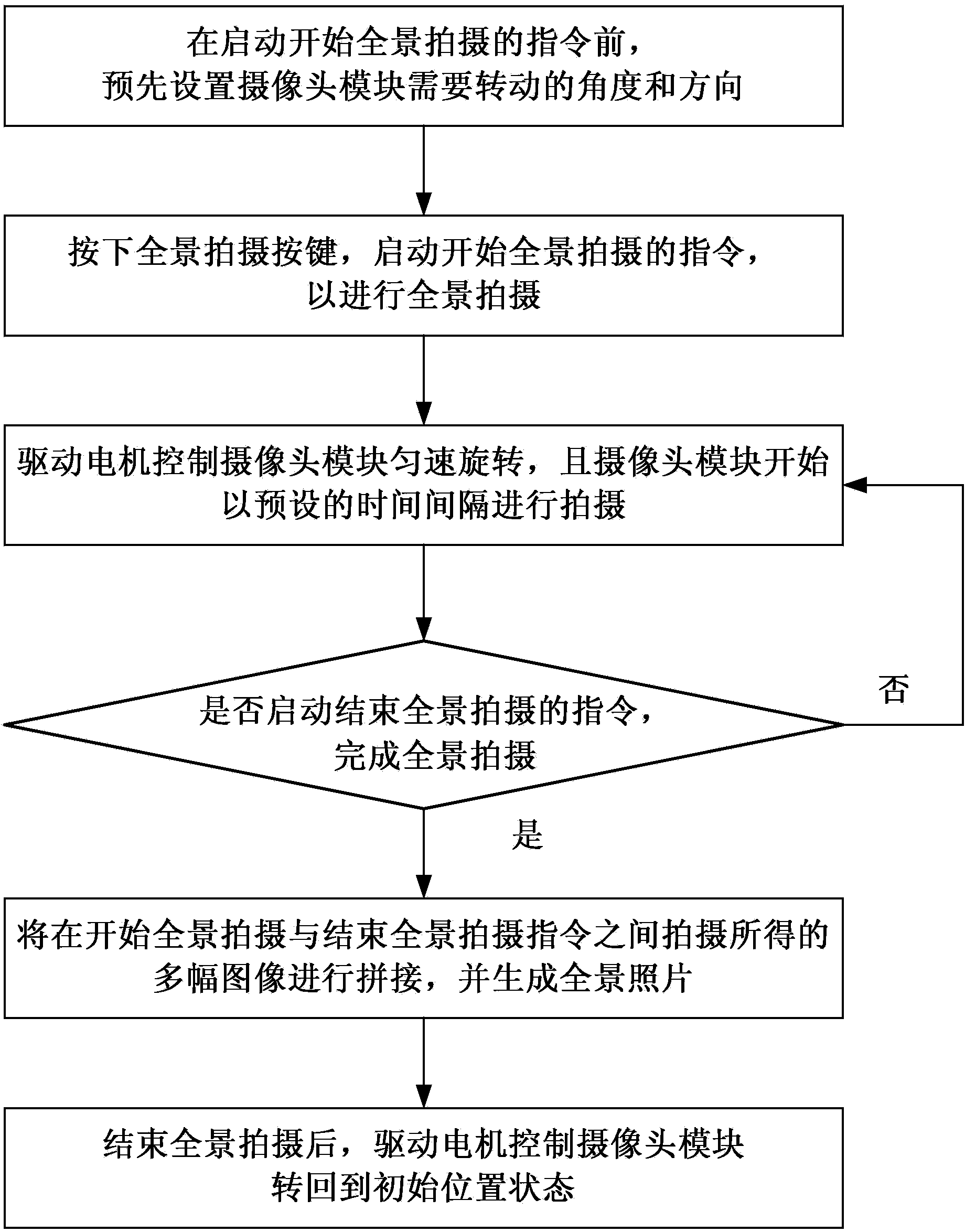

The invention provides a panoramic shooting method. The panoramic shooting method comprises the steps that after an instruction of starting panoramic shooting is started, a driving motor controls a camera module to rotate at a constant speed, and the camera module starts to carry out shooting with the preset time interval; after an instruction of finishing the panoramic shooting is started, the driving motor controls the camera module to stop rotating, and the camera module stops shooting; multiple images obtained through shooting between the panoramic shooting starting instruction and the panoramic shooting finishing instruction are spliced, and a panoramic picture is formed. The rotatable camera module is arranged on a mobile terminal, the camera module can be controlled by the driving motor to rotate, when the panoramic shooting is carried out, the constant-speed rotation of the camera module is controlled by the driving motor, it can be guaranteed that the camera module can evenly obtain the images for splicing and forming the panoramic picture, and therefore the quality of panoramic shooting pictures is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

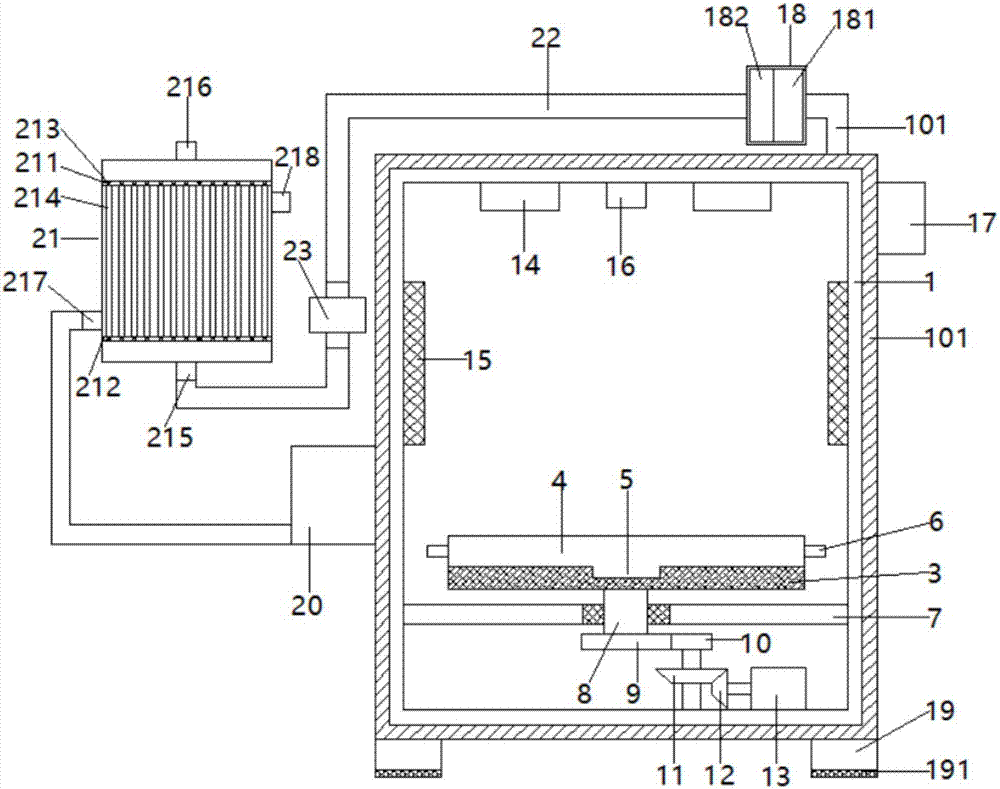

Thermal infrared imaging technology based method and device for detecting the early defect of fruit surface

InactiveCN101713747AEasy accessRadiation pyrometryOptically investigating flaws/contaminationTemperature curveInfrared lamp

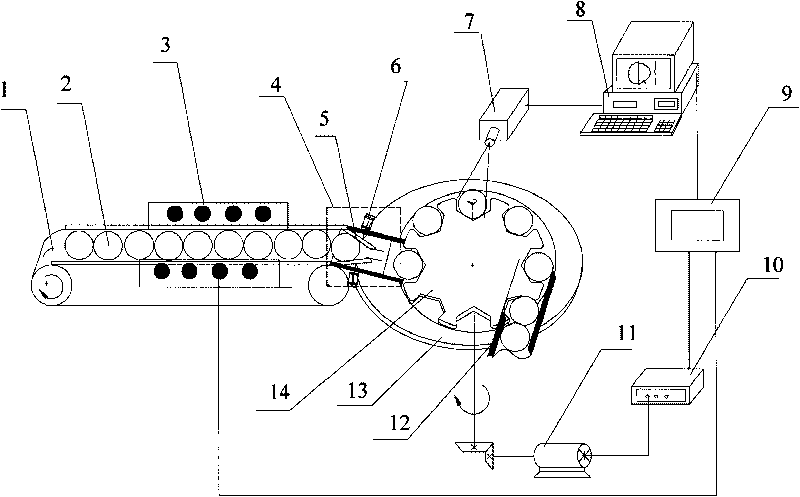

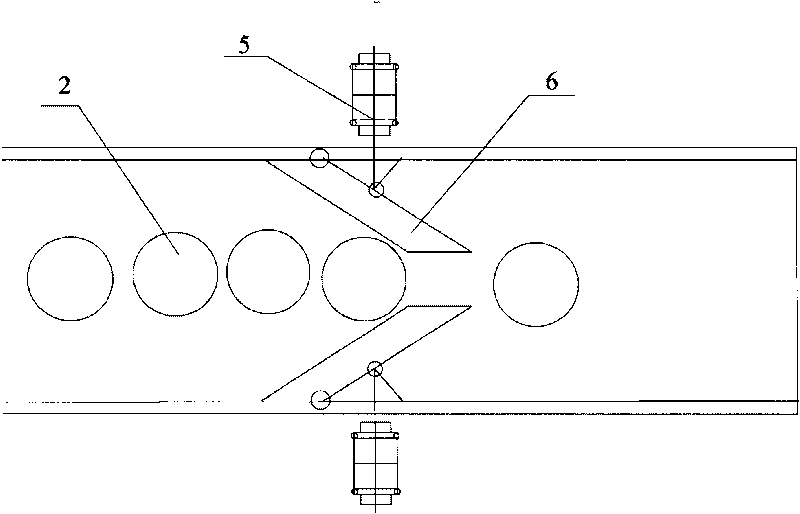

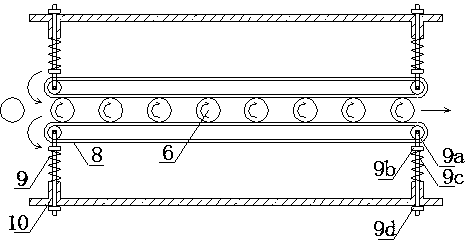

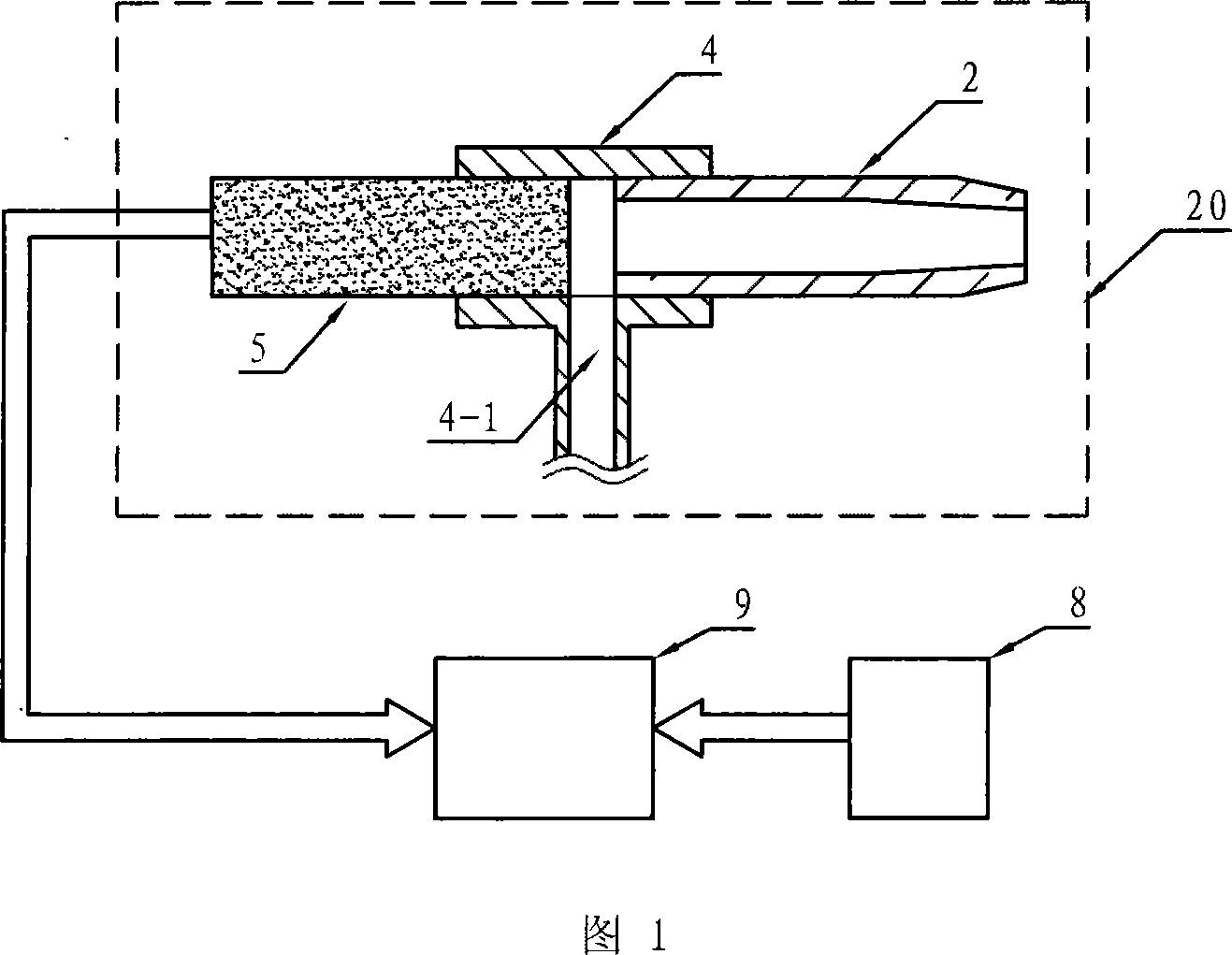

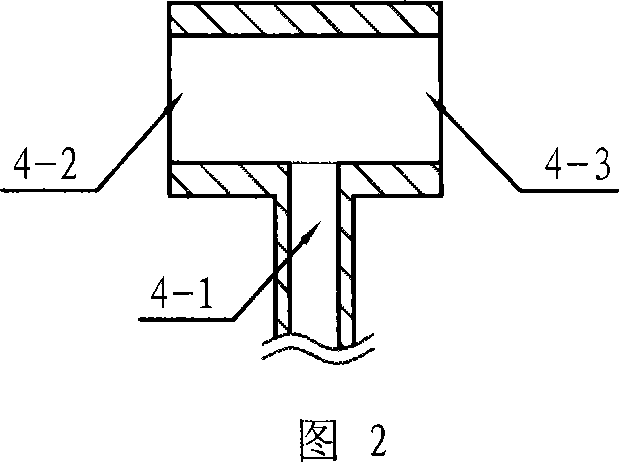

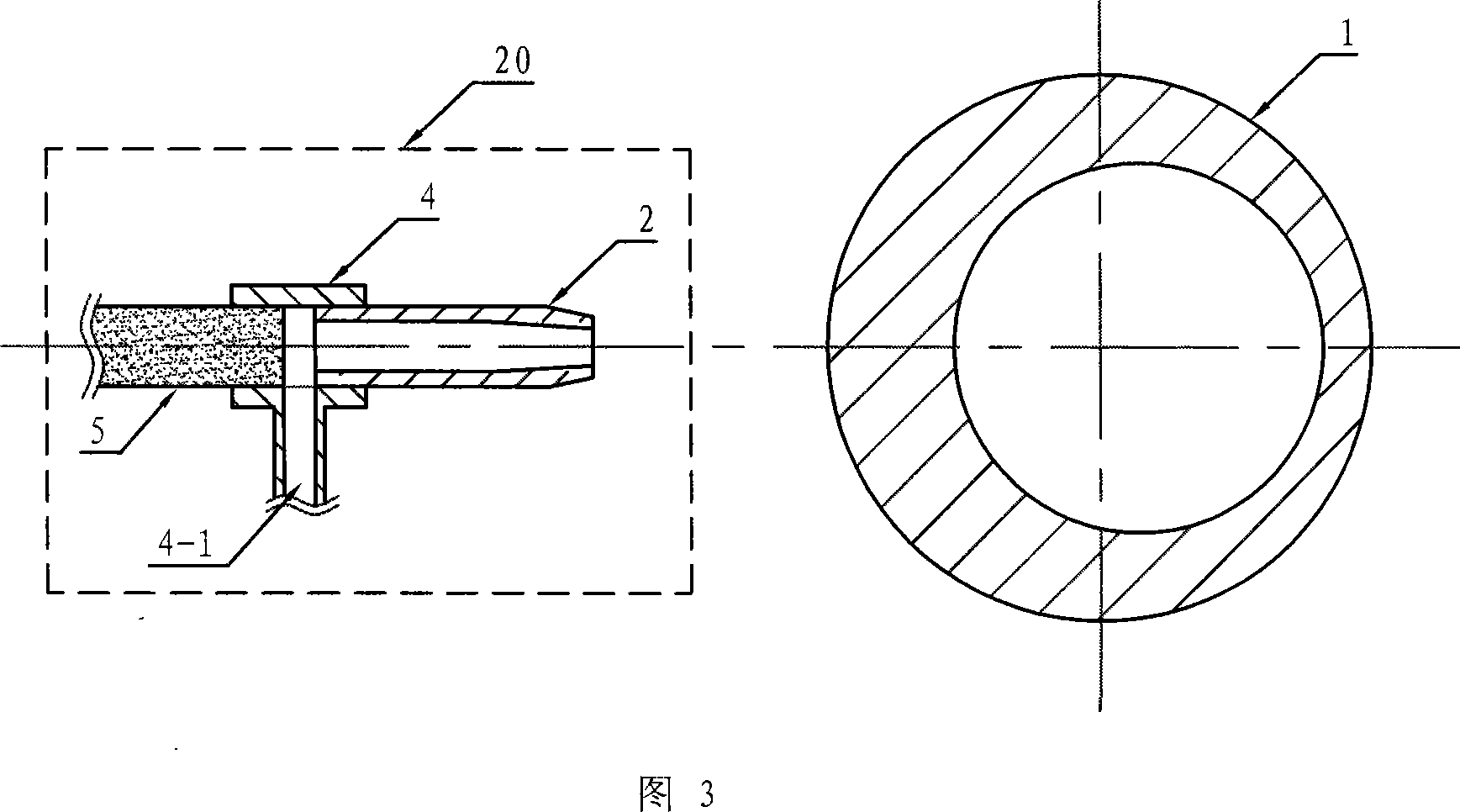

The invention discloses thermal infrared imaging technology based method and device for detecting the early defects of fruit surfaces. The device comprises belt type transmission system, an infrared lamp, a beat fixing system, a dividing turnplate, a fixed bed, a step drive system, a salver, an electric motor, an thermal infrared imager, a computer and fruit defect detection software. Fruits are excited by a thermal light source of the controlled infrared lamp in transportation and rotate at constant speed during detection; a vertical temperature measuring line of the thermal infrared imager aims at the centers of the fruit surfaces and dynamically collect the temperature information of the fruit surfaces at angles of 360 degrees; and the fruit defect detection software denoises and reinforces acquired images and temperature curve information, contrasts thermal images and judges the early defects of the fruit surfaces according to waveform inference. The invention coverts the fruit surface information into one-dimensional temperature information and can well realize the detection of the early defects of the fruit surfaces by combining image information, thereby creating conditions for the refined classification of the fruits.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Dual-detector segmenting gamma-scanning measuring device and scanning method thereof

InactiveCN102135625AImprove measurement accuracyHigh measurement accuracyX/gamma/cosmic radiation measurmentNuclear radiationMeasurement device

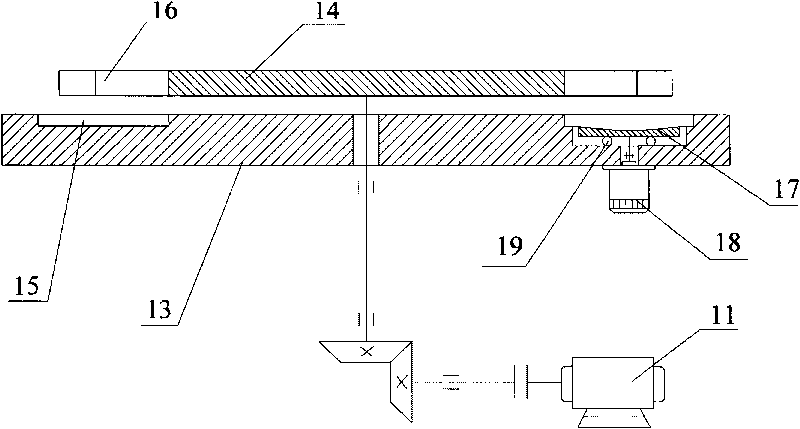

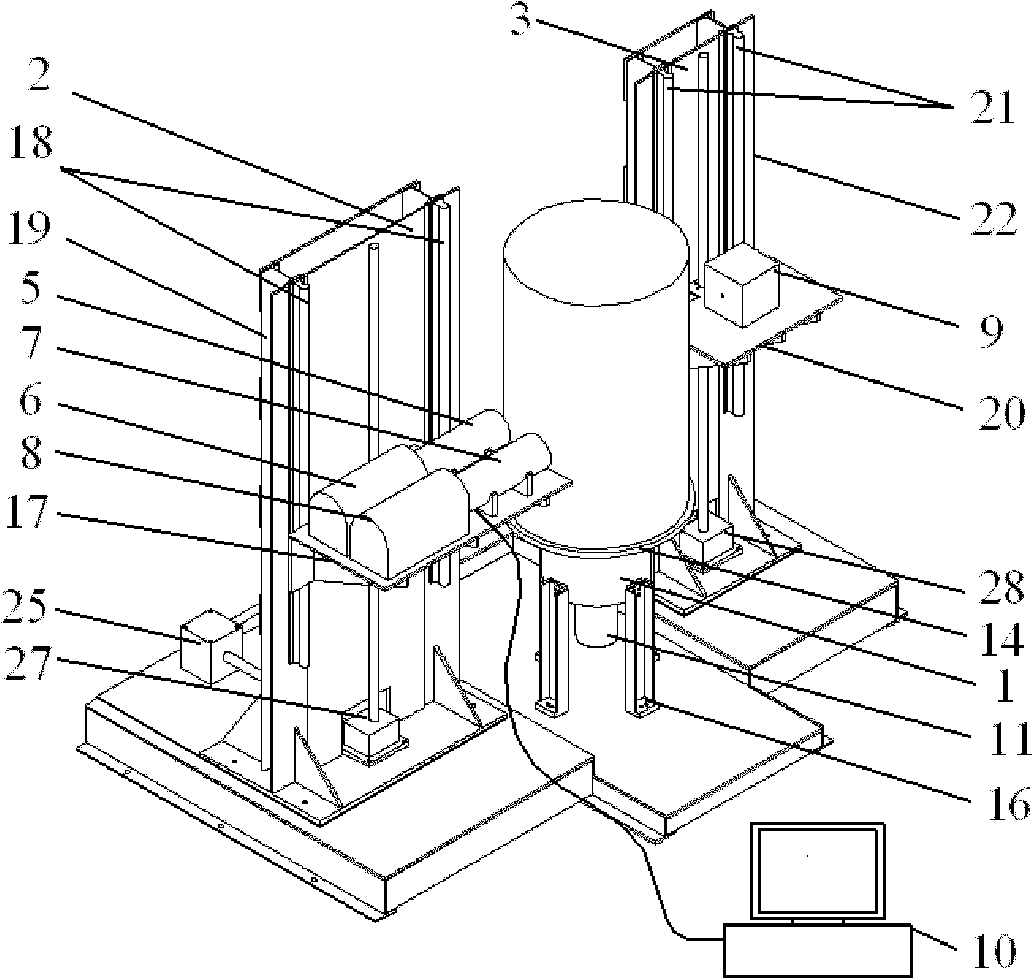

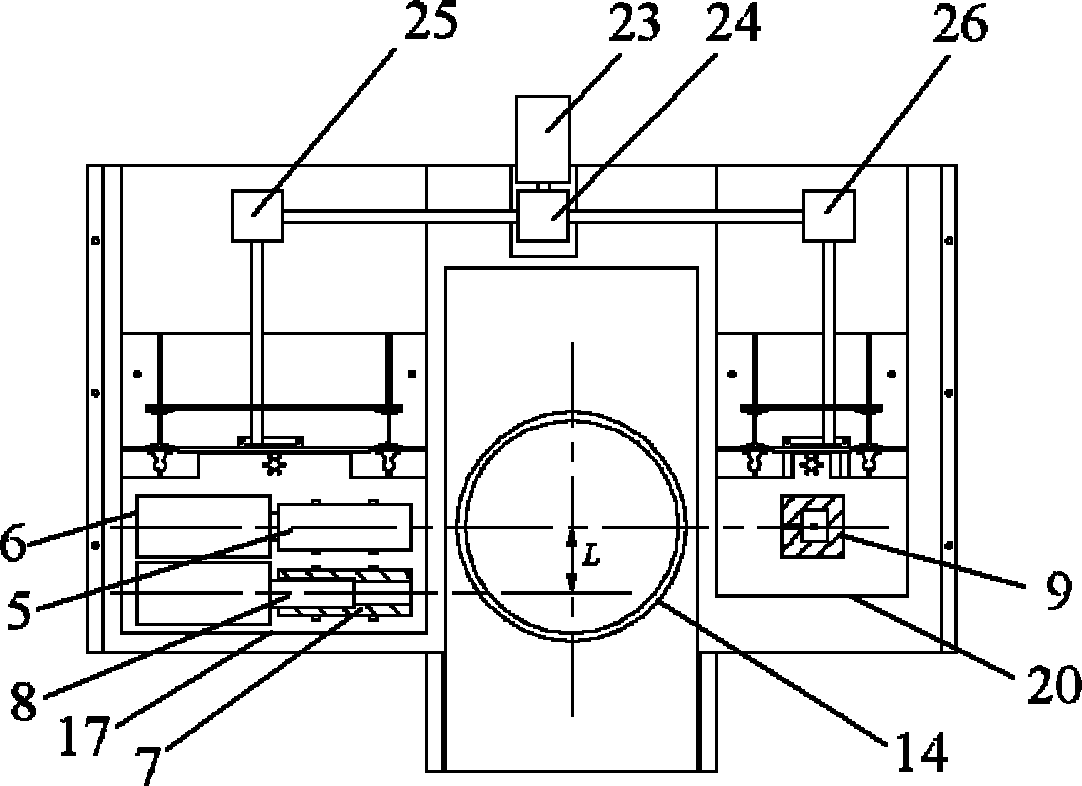

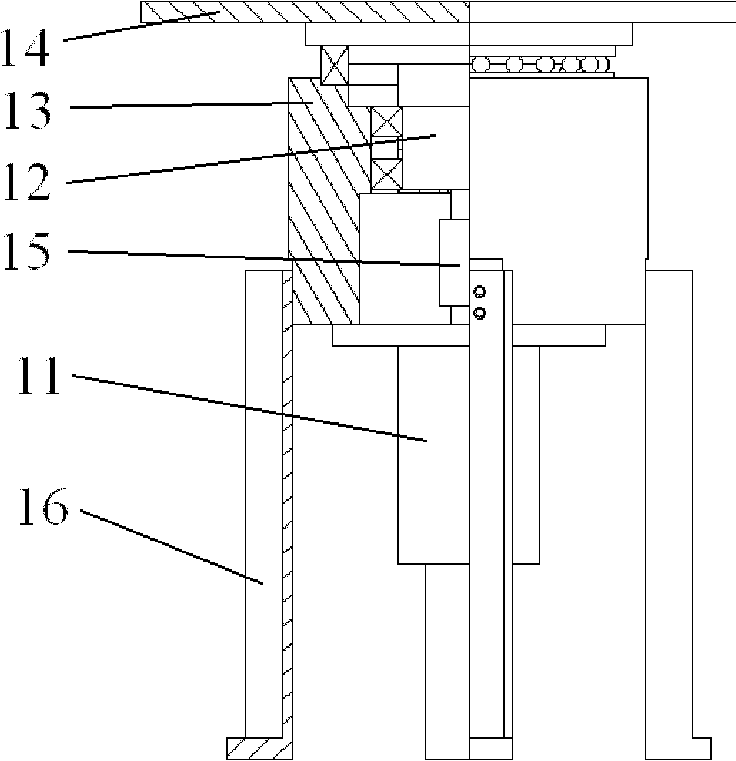

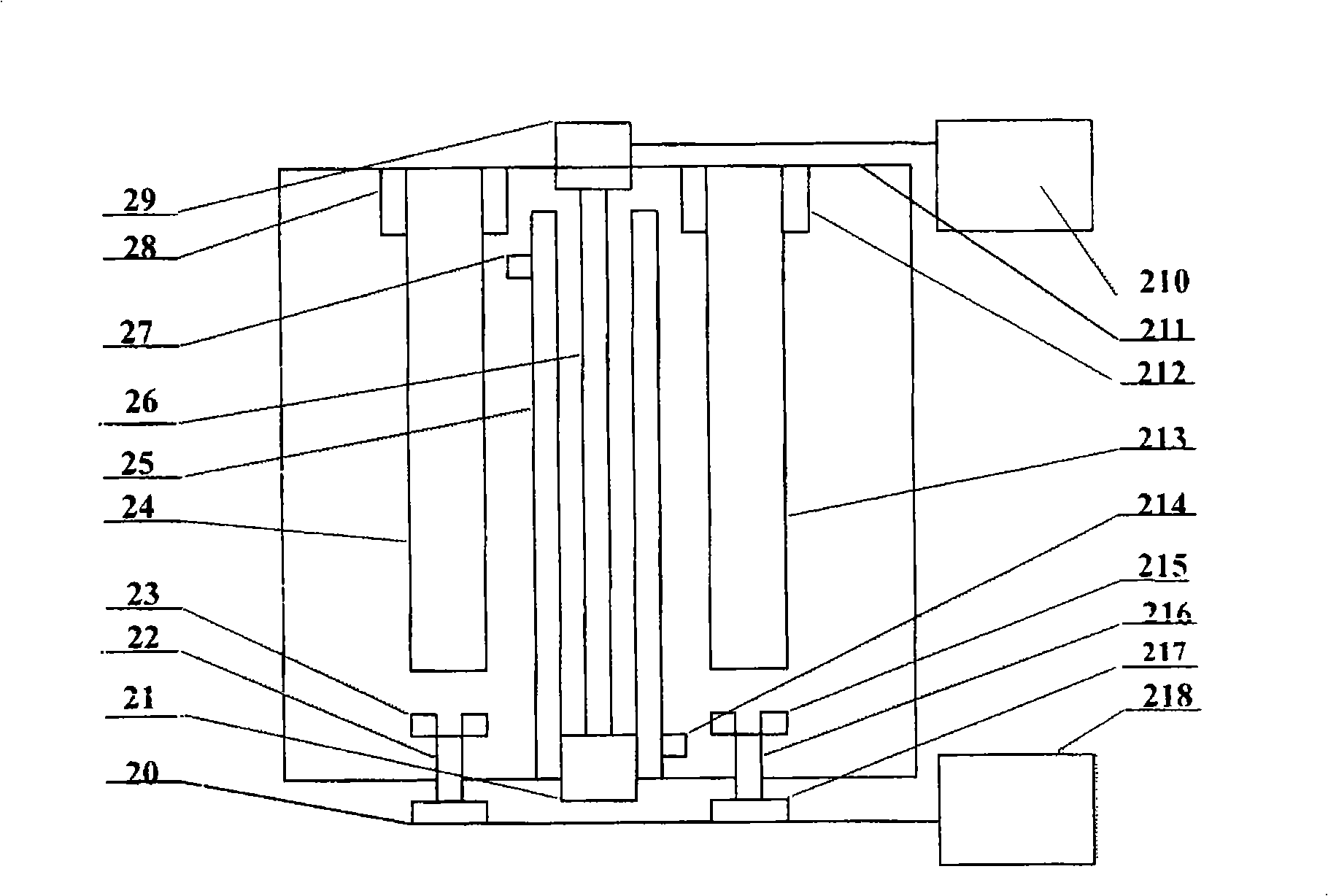

The invention relates to a dual-detector segmenting gamma-scanning measuring device based on equivalent radius correction, belonging to the technical field of nuclear radiation measurement. The dual-detector segmenting gamma-scanning measuring device comprises a rotary table, a detector platform assembly, a transmission source platform assembly, a platform lifting and driving assembly, two same high-purity germanium detectors, a transmission source, a shielding part of the transmission source and an analysis module, wherein the two same high-purity germanium detectors are provided with collimators. In the invention, the influence of the nonuniformity of materials inside a wastebin is reduced through the constant rotation of the wastebin, layered measurement is carried out on the wastebin undergoing the constant rotation by placing the two same high-purity germanium detectors on different horizontal positions, the radial equivalent radius of each radionuclide layer is obtained through analysis, and the radionuclide activity of the radionuclide layer is accurately computed according to the detection efficient of the radial equivalent radius. Because an assumption of uniform radionuclide distribution is eliminated, the characteristics of an actual wastebin are better accorded with so that the measurement accuracy of the traditional segmenting gamma-scanning technology is greatly enhanced.

Owner:SHANGHAI JIAO TONG UNIV

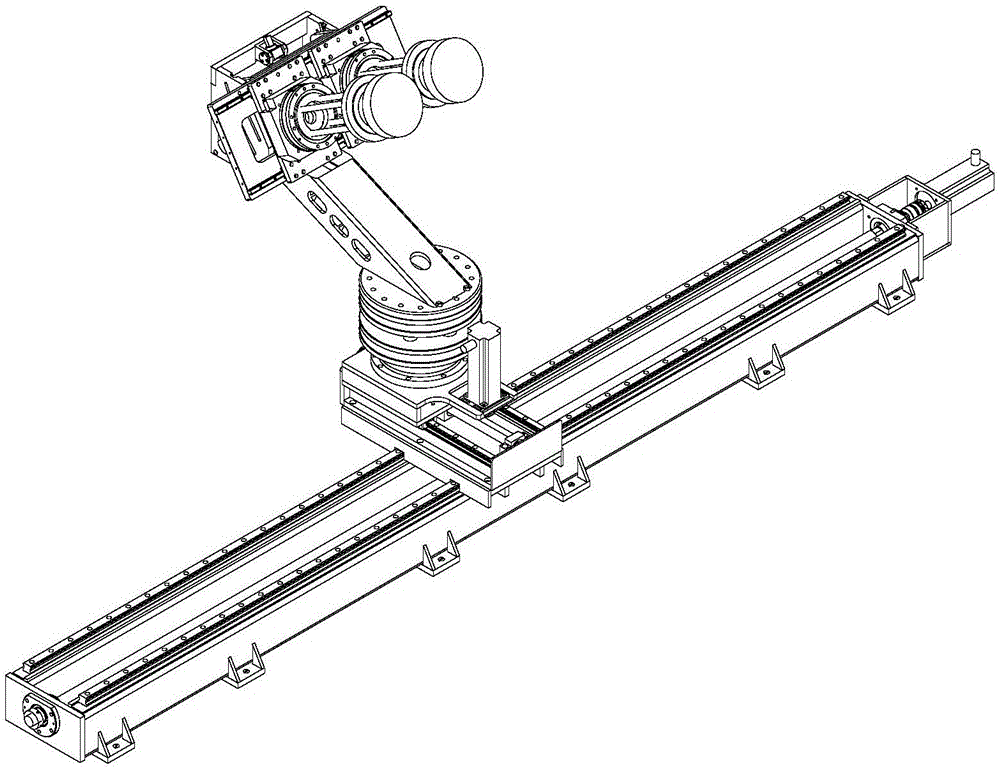

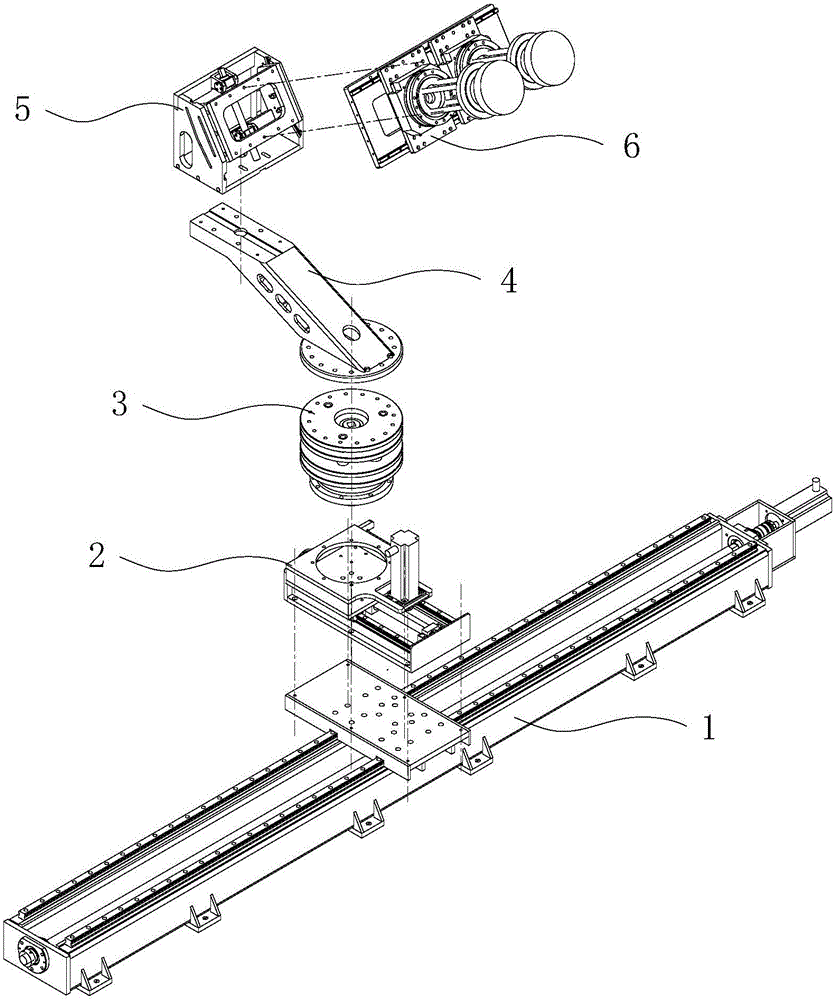

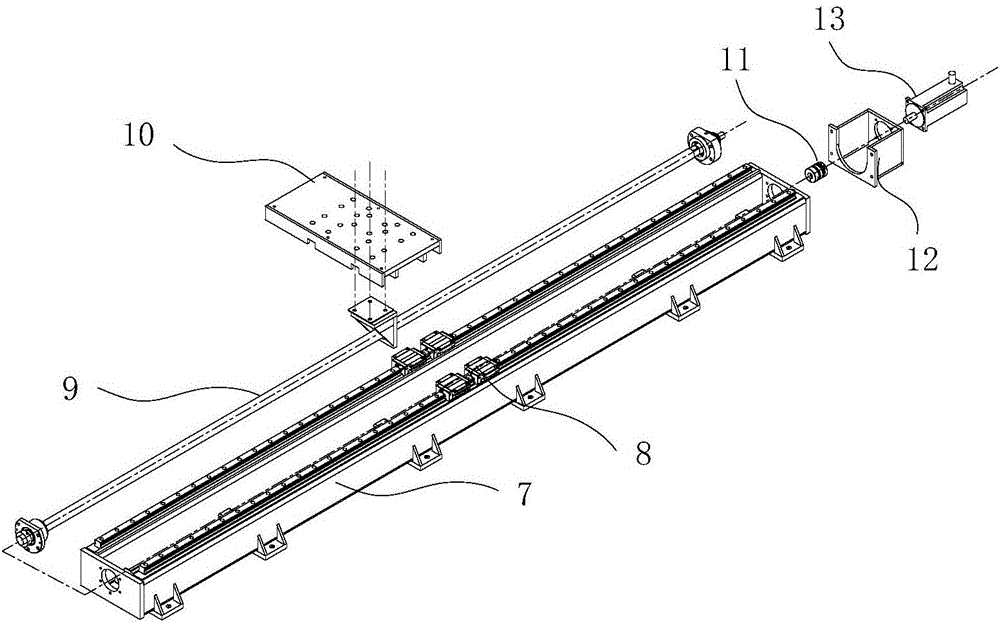

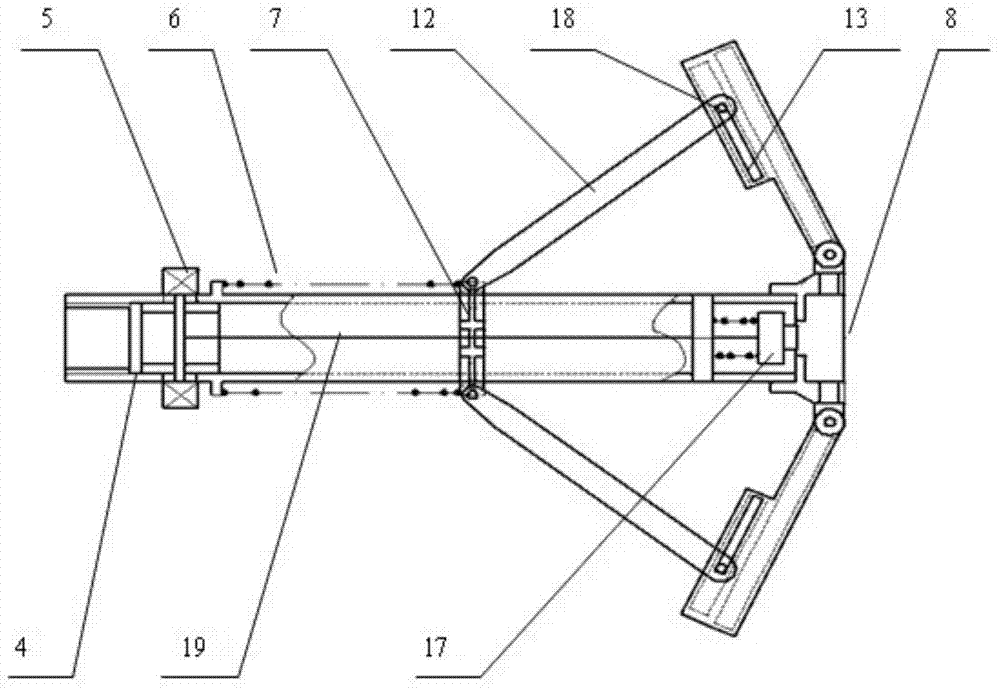

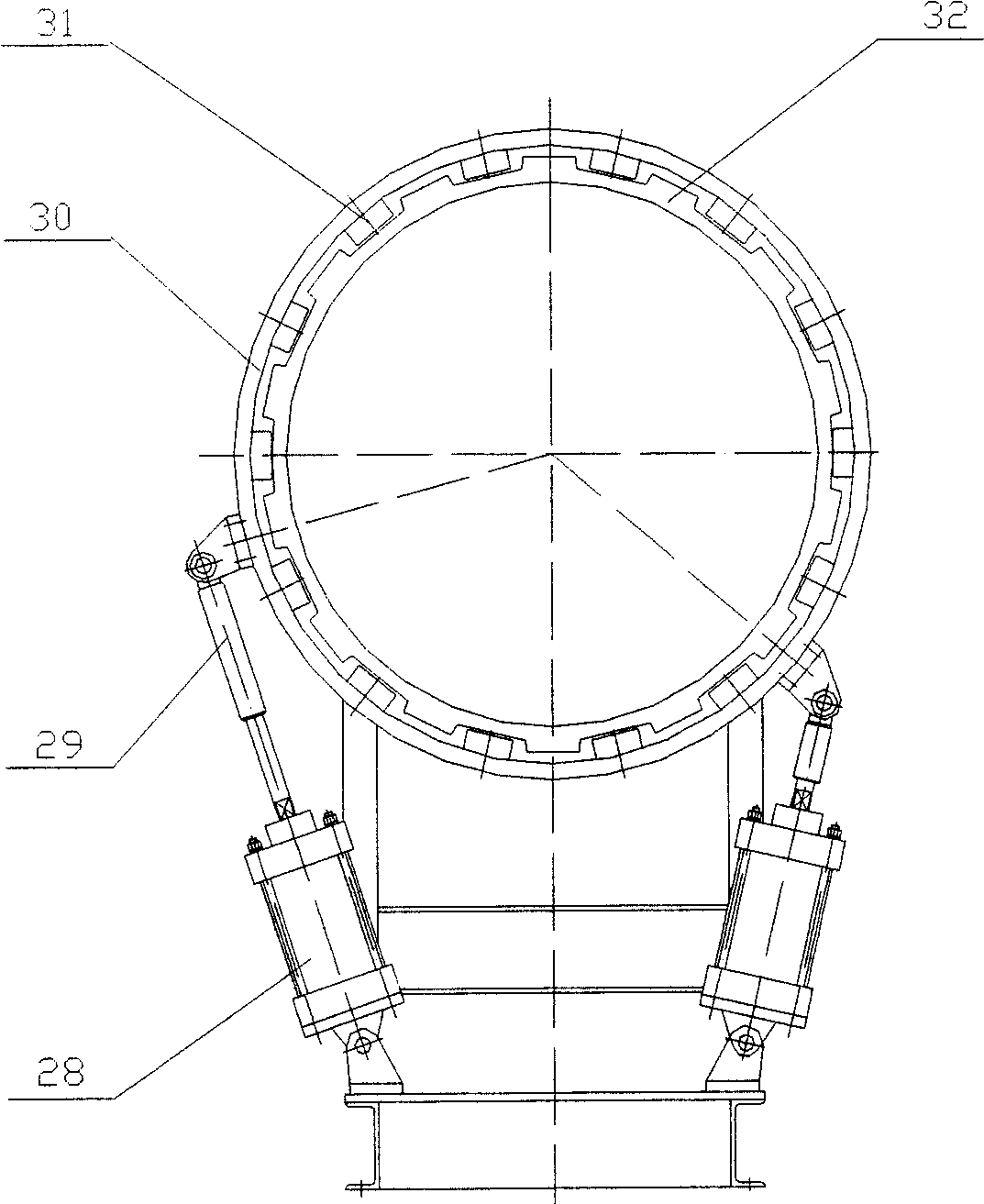

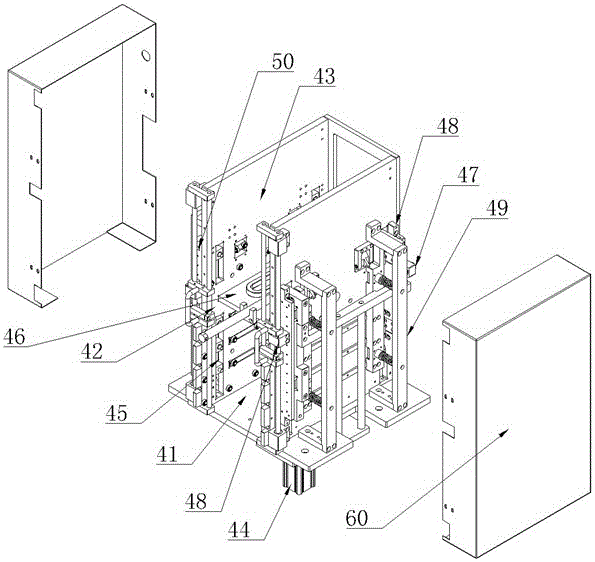

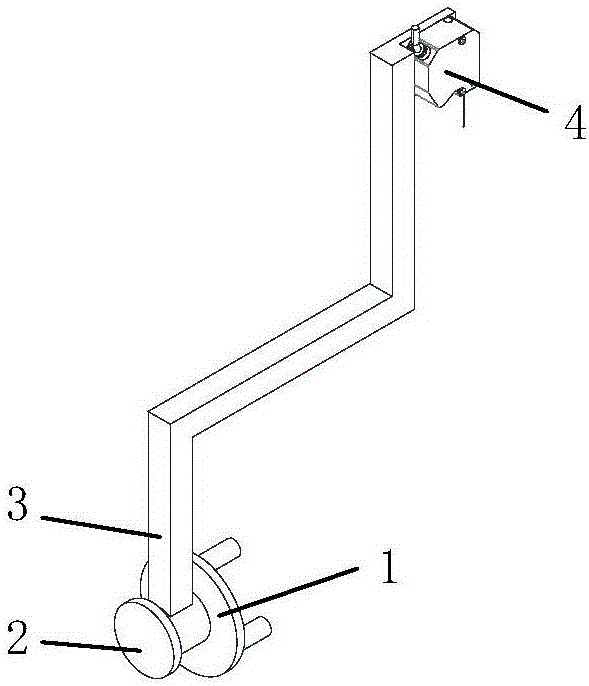

Feed source locating and focus offset device for compact range measurement

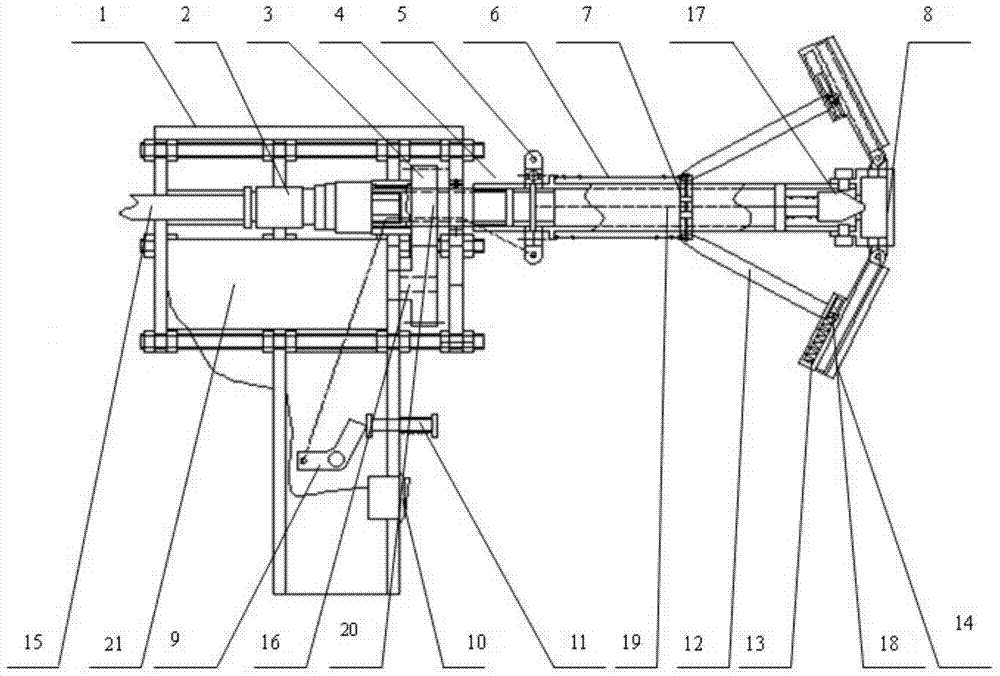

ActiveCN106356634AAchieve left and right translationHigh precisionWaveguide hornsAntennas earthing switches associationCompact rangeUniform rotation

The invention provides a feed source locating and focus offset device for compact range measurement. The device is used for precise location and focus offset motion of a feed horn in an electromagnetic measurement process of a compact range. The device mainly comprises left and right transverse movement along the X axis, front and back longitudinal movement along the Y axis, rotation and translation around the Z axis and pitching movement around the phase center of a feed source. Accurate locating and focus offset of the feed source are realized through movement of five freedom degrees, and focus offset measurement is completed. By means of servo control, polarization rotation and uniform rotation at a certain rotation speed of the feed horn can be realized, and RCS (radar cross-section) measurement or antenna measurement is completed. The device comprises an X-axial moving unit, a Y-axial compensation unit, a Z-axial rotating and height adjusting unit, an offset arm, a feed source pitching unit and a feed source polarization unit. Different from a fixed feed source locating device, the device can not only be used for precise location of the feed source during measurement of the compact range in a traditional manner, but also be used for measurement of new demand ways such as focus offset and the like; the device has the advantages of high measurement efficiency, high locating precision and simple and reliable control process.

Owner:BEIHANG UNIV

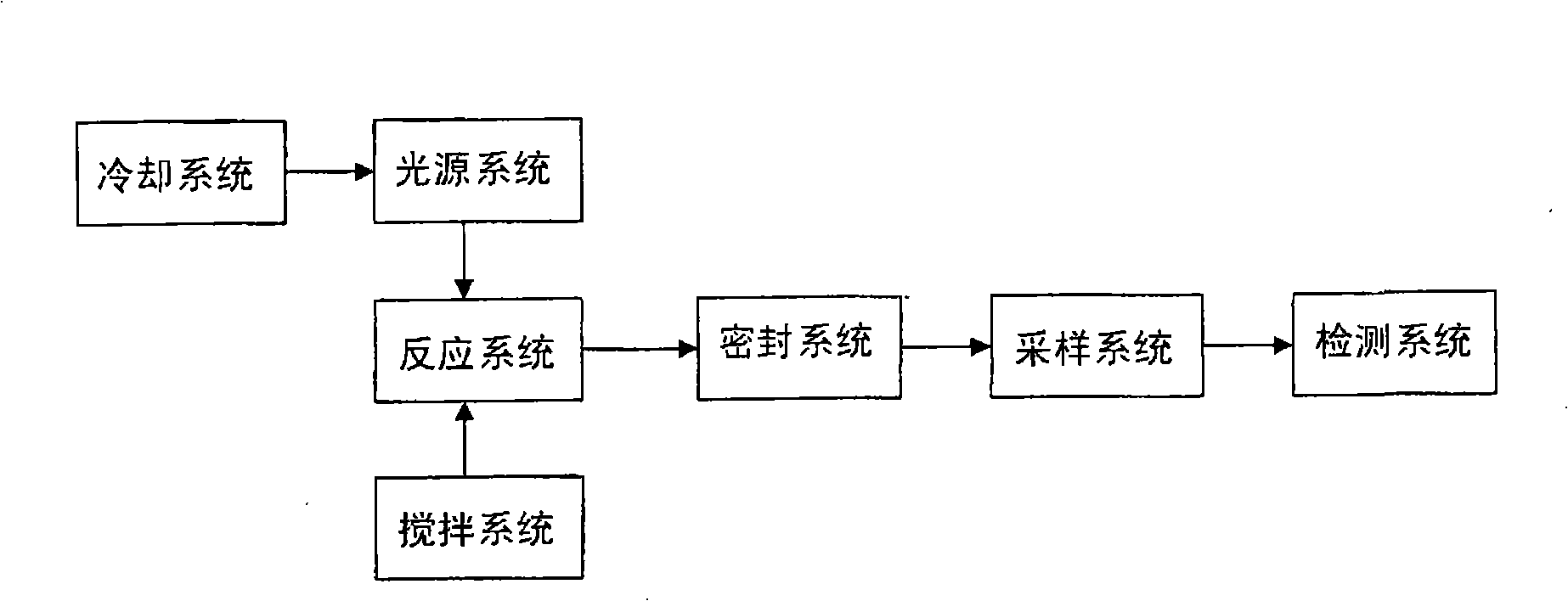

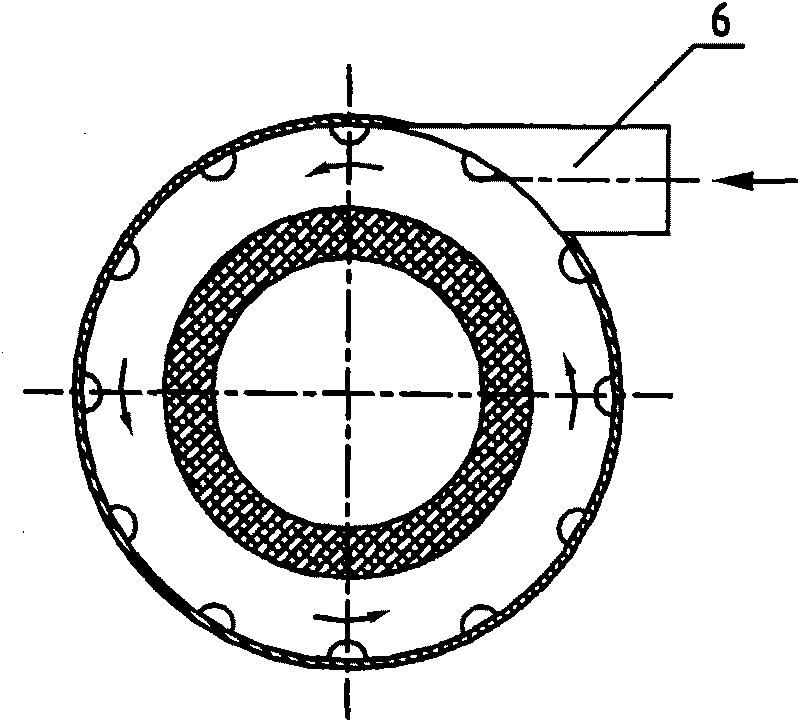

Multi-channel reaction device for fast appraisement of hydrogen manufacturing performance of photocatalyst

InactiveCN101315357AImprove evaluation efficiencyImprove efficiencyChemical methods analysisGas phaseEngineering

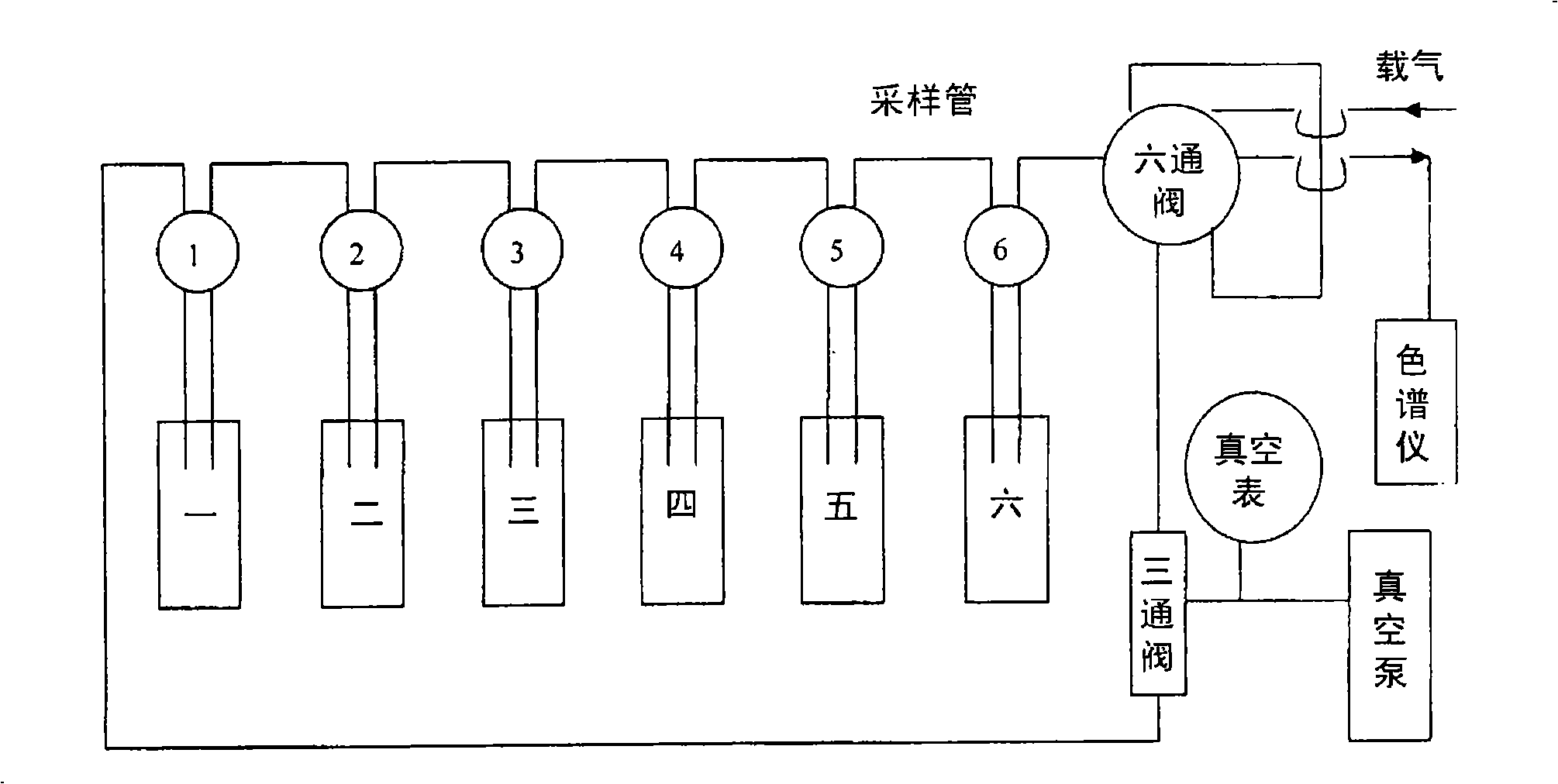

A multi-way reaction device for rapid appraisement of photo-catalysis hydrogen production activity is composed of a light source system, a reaction system, a stirring system, a sealing system, a cooling system, a sampling system and a detection system. The multi-way reaction device includes a light reactor, a tubular light source which is driven by a decelerating motor to rotate at an uniform speed is arranged in the center of the light reactor, the light source is arranged in a quartz jacket, and cooling water or a sodium nitrite solution is introduced into the quartz jacket for cooling the light source; a plurality of quartz reaction tubes are uniformly distributed around the light source, the opening part of each quartz reaction tube is in closed connection with the light reactor, a magnetic stirrer is arranged at the lower part for driving rotary at the uniform speed, all volumes of the quartz reaction tubes are the same, and the quartz reaction tubes are connected with a gas chromatography through arranging vacuum pumps and sampling pipelines. The multi-way reaction device can carry out a plurality of groups of photo-catalysis hydrogen production reactions at the same time, and rapidly screen different photolysis hydrogen production catalysts; in addition, when different detectors are selected, the multi-way reaction device can perform rapid multi-way appraisement of various photo-catalytic reactions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Self-adaptive cleaning device

ActiveCN103495584ARotate at a constant speedTo achieve the purpose of removing dirtHollow article cleaningWater flowEngineering

The invention discloses a self-adaptive cleaning device. An electromotor is used as a prime motor, power is transmitted to brush heads through rotation of the electromotor and gear engagement transmission, and therefore uniform rotation of the brush heads is achieved. A rotating main shaft is a hollow shaft, a rotating connector is communicated with a water supply hose, water current is adjusted through a water control switch on a handle according to requirements, and a hairbrush rubs a contact surface under the flushing effect of water for washing. The free change of the aperture angle of a brush plate is achieved within certain limits through a four-link mechanism of a brush head part, and therefore vessels with multiple curved surfaces or deep openings or shallow openings are washed, and then the purpose of removing dirt is achieved with the help of friction generated between the device and the surface to be cleaned. The cleaning device is provided with the two brush heads, one is the jaw type self-adaptive brush head for protruded curved surfaces and planes, and the other is the dandelion type brush head for concave curved surfaces. The self-adaptive effect is achieved by the two brush heads through the combined effect of connecting rods, a crank sliding block and a spring mechanism, the different brush heads can be replaced according to requirements in the using process, and the device is easy and flexible to operate.

Owner:西安华桑科技发展有限公司

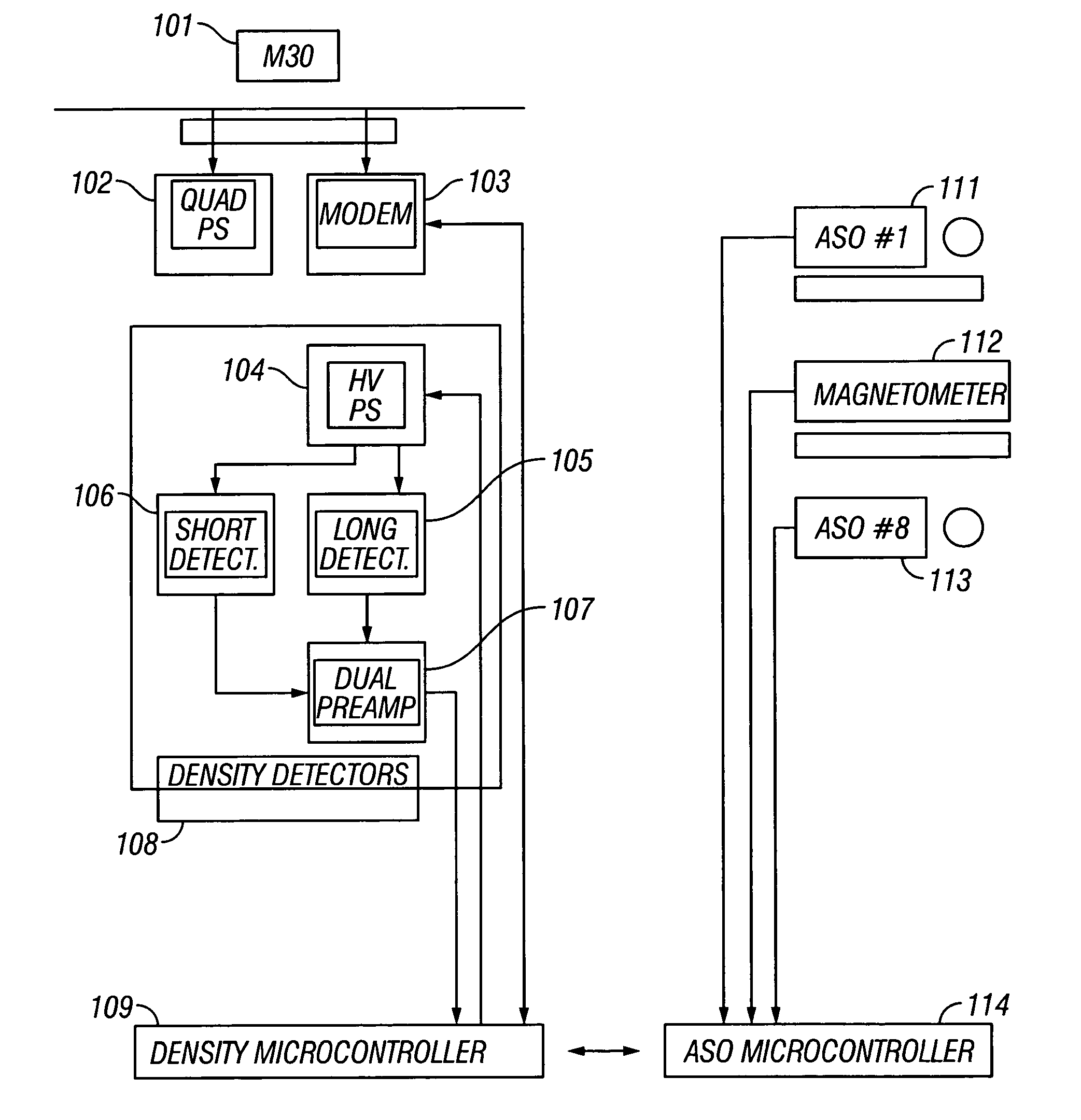

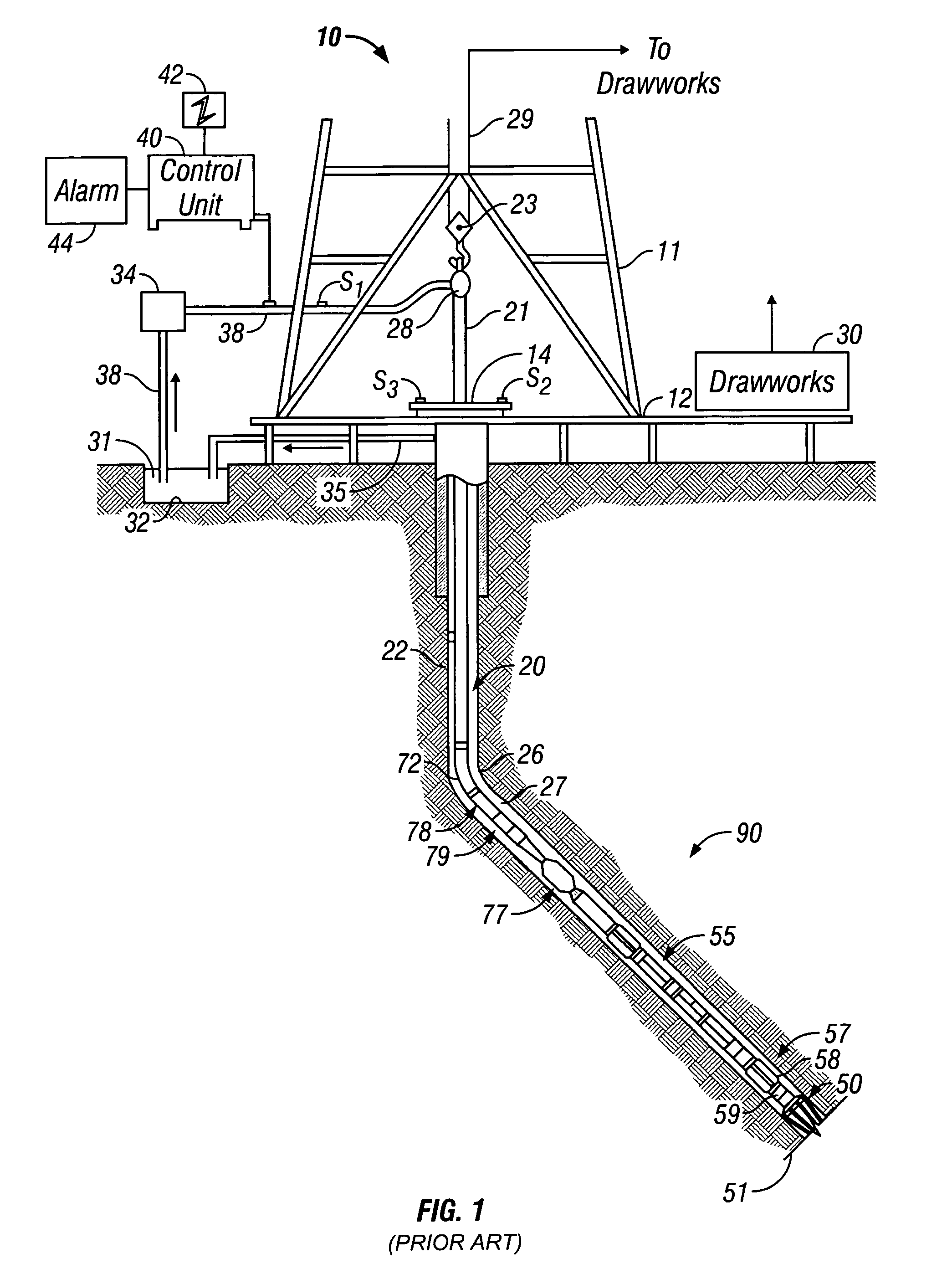

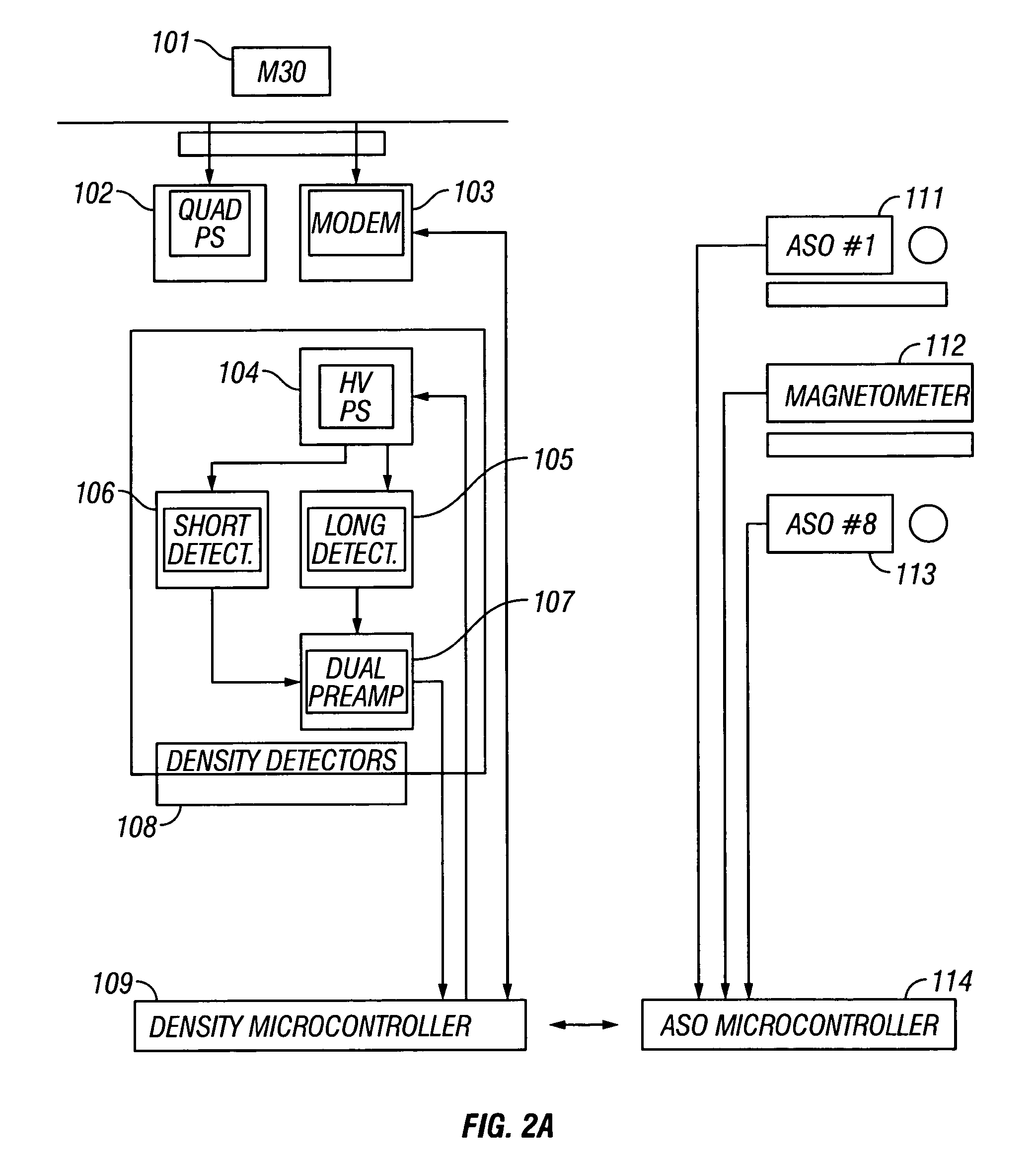

Magnetometers for measurement-while-drilling applications

ActiveUS20050199425A1Accurate measurementElectric/magnetic detection for well-loggingSurveyEngineeringUniform rotation

A nuclear sensor on a bottomhole assembly (BHA) makes measurements of a property of an earth formation during continued rotation of the BHA. Magnetometers that are susceptible to bias error are deployed on the BHA to make measurements of the magnetic toolface angle. A processor separates the sensor measurements into azimuthal sectors while compensating for inherent time delays in the electronics, non-uniform rotation, and bias.

Owner:BAKER HUGHES INC

Sensing fiber used in reflective all-fiber current sensor

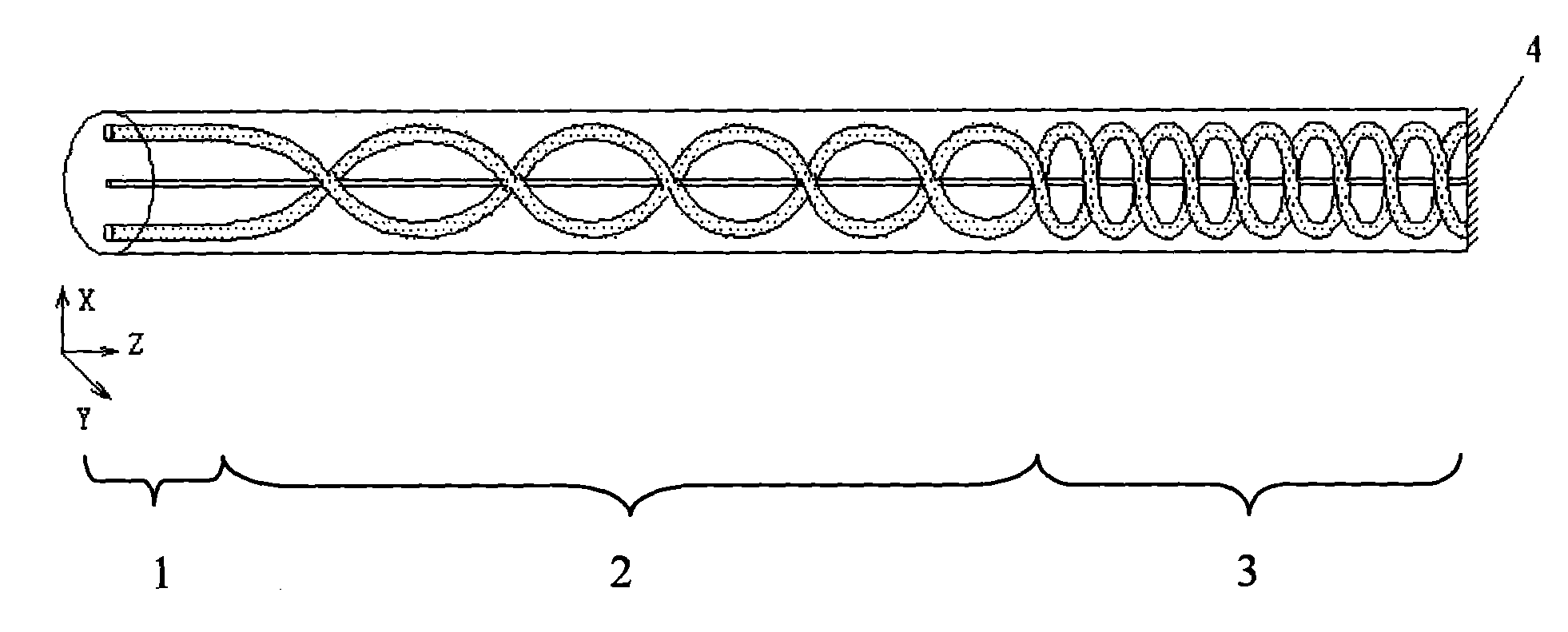

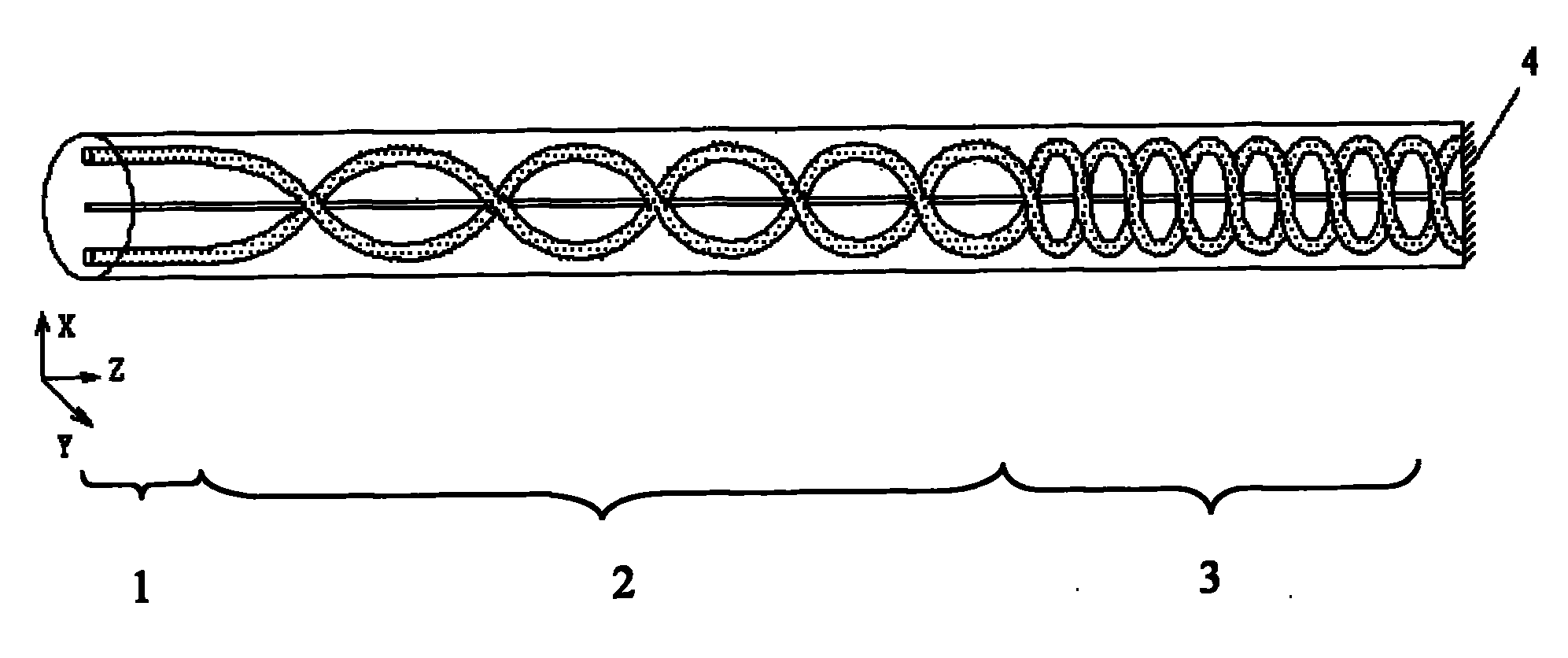

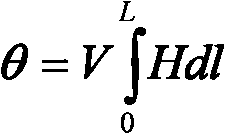

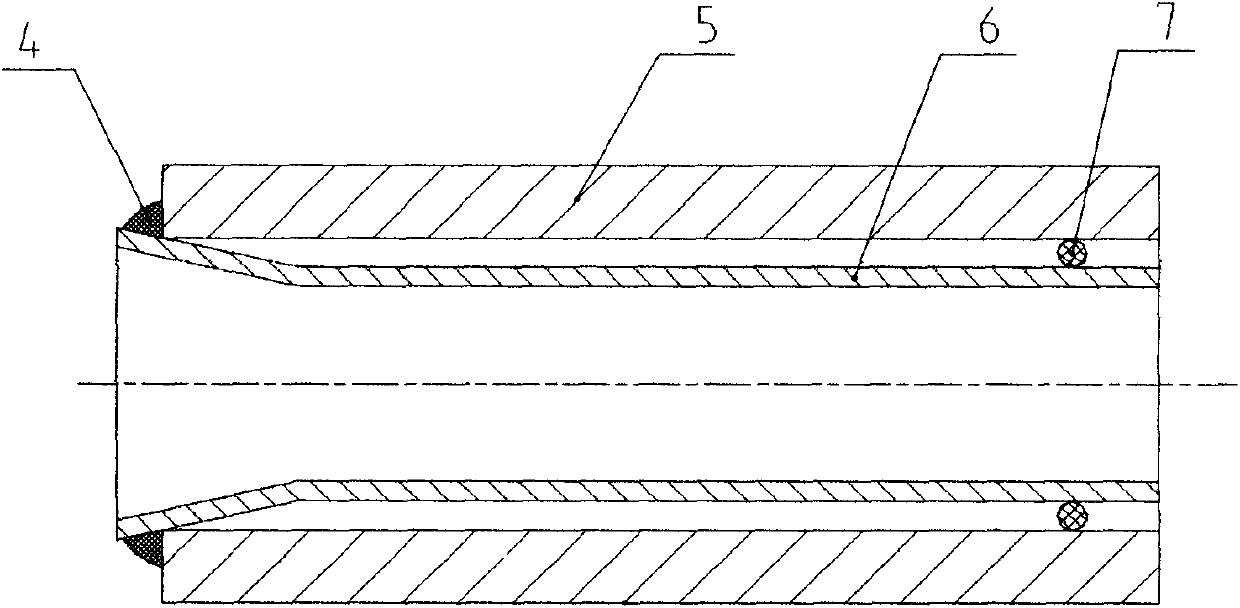

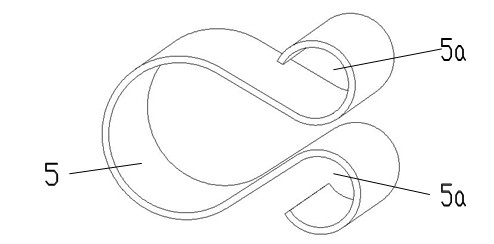

InactiveCN101876723ADoes not affect normal workReduce speedCladded optical fibreCurrent/voltage measurementPolarization-maintaining optical fiberCurrent sensor

The invention discloses a sensing fiber used in a reflective all-fiber current sensor. The sensing fiber comprises a polarization-preserving fiber, wherein the polarization-preserving fiber comprises a non-rotating section, a rotation-starting section and a uniform rotation section in turn; and a reflective film is plated at the tail end of the uniform rotation section. The sensing fiber has the characteristics of simple manufacturing and low cost.

Owner:COMCORE OPTICAL TECH

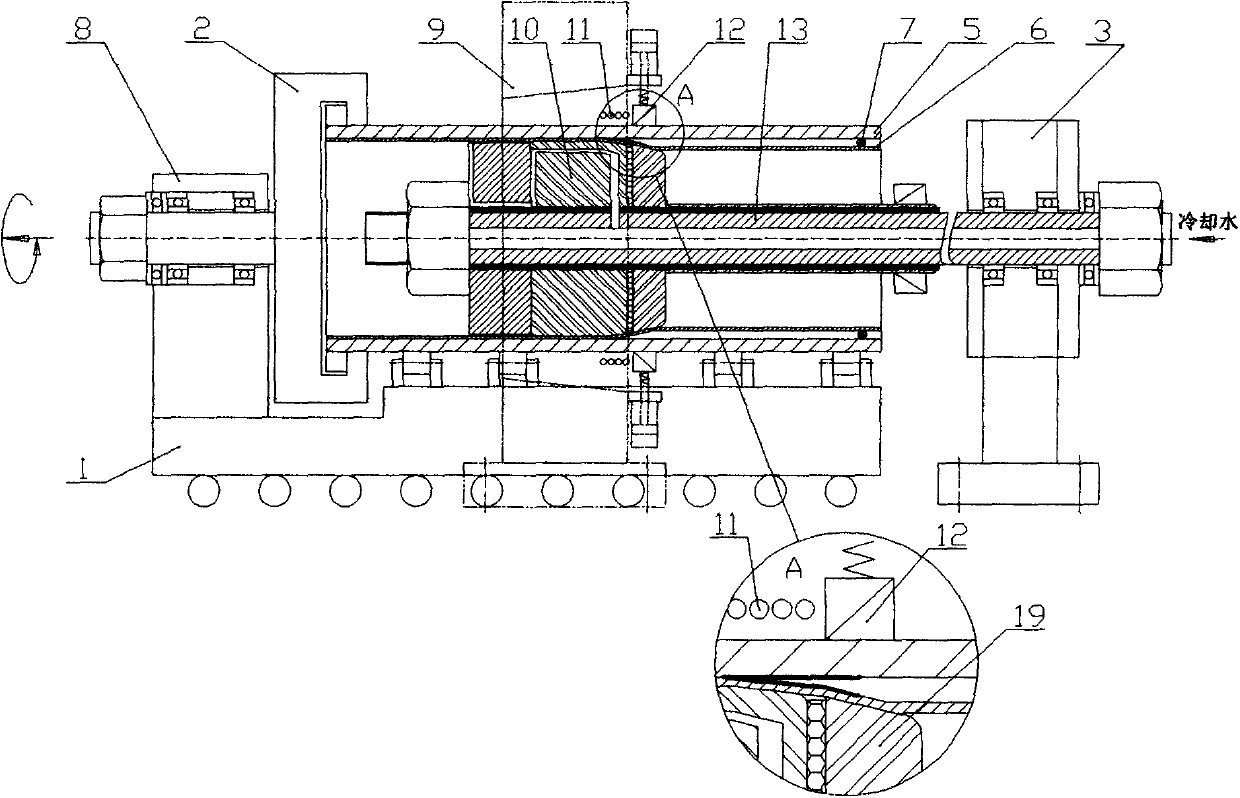

Method for manufacturing thermometal metallurgy composite tube in pressure welding composite mode

ActiveCN103433636AHigh adhesion between inner and outer layersReduce manufacturing costHigh frequency current welding apparatusResistance welding apparatusCircular coneUniform rotation

Owner:唐勇 +1

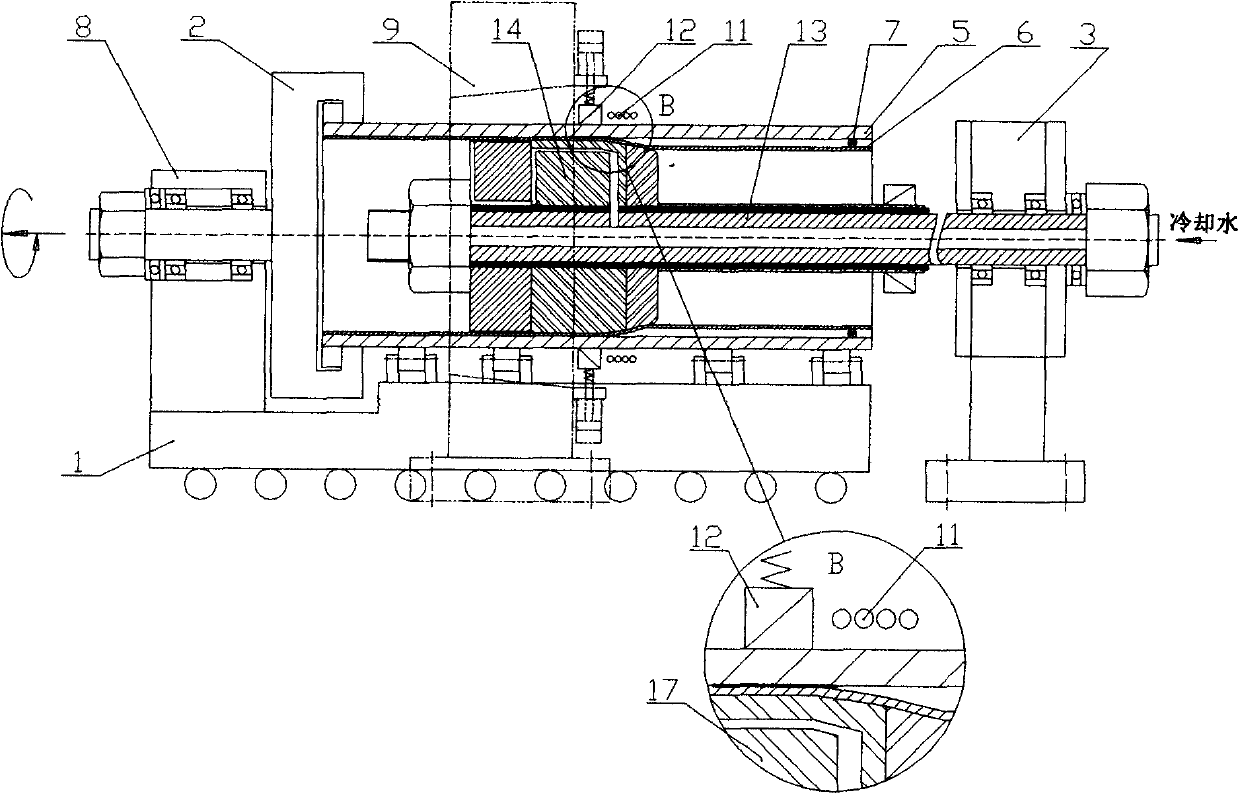

Film coating method of self-expanding stent

InactiveCN102078643AEasy to controlOrientationSpinning head liquid feederSurgeryFiberUniform rotation

The invention discloses a film coating method of a self-expanding stent, which is characterized in that polymer nano-fibers are ejected by utilizing an electrostatic spinning method and cover the net structure surface of the self-expanding stent to form a polymer film. According to the film coating method of the self-expanding stent, a coating film on the outer surface of the stent is composed of the polymer nano-fibers; a fiber film is formed through ejection by utilizing the electrostatic spinning method; a tubular self-expanding stent is sleeved on a drum-type collector and used for collecting nano-fibers following the uniform rotation of the drum-type collector; a plurality of collectors can be arranged in parallel to be a parallel collect group to synchronously carry out film coating on a plurality of stents; and the nano-fibers of the stent coating film contain drugs and developers. The self-expanding film coated stent prepared by utilizing the method has the advantages of simple process, high collection efficiency, and low cost, is environmentally friendly, can be widely applied to interventional therapies of blood vessel, trachea, bronchi, esophagus, alimentary canal, bile duct, nasolacrimal duct and the like and has a wide application prospect.

Owner:苏州同科生物科技有限公司

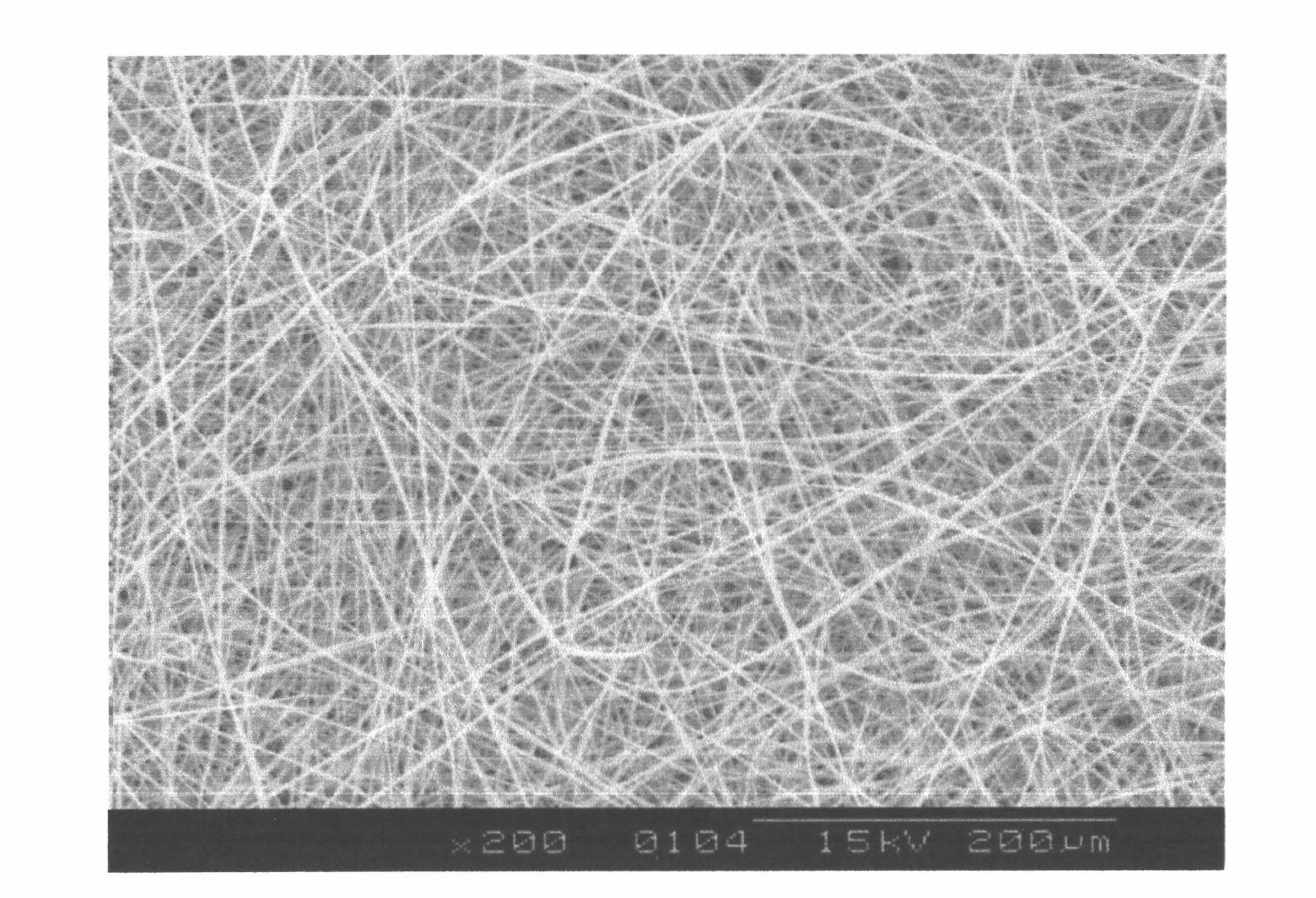

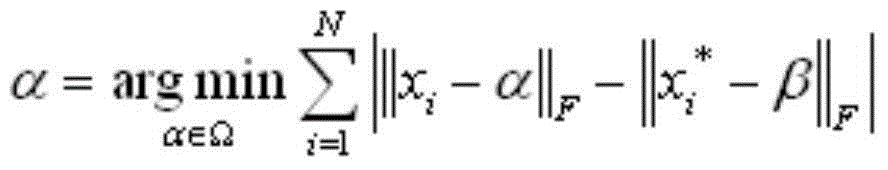

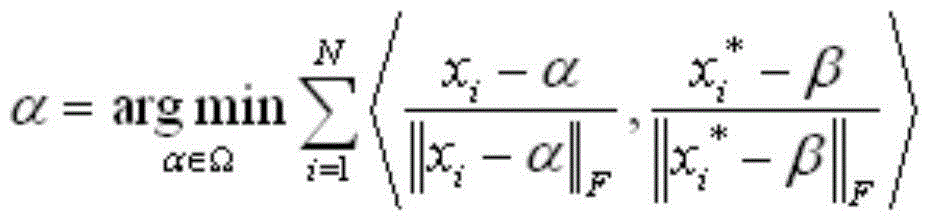

Method for performing typhoon location on current satellite image according to history satellite image

ActiveCN104992434ARealize automatic positioningSimplify positioning stepsImage enhancementImage analysisSatellite imageUniform rotation

The invention belongs to the technical field of meteorological prediction. Aiming at solving the problems of the large meteorological staff labor intensity, complex operation steps and long positioning time which exist in a method for determining a typhoon center manually, the invention provides a method for performing typhoon location on a current satellite image according to a history satellite image. The method comprises extracting an SIFT characteristic of the history satellite image, intercepting a search region, a side length of which is L+2*(T*60 / P), on the current satellite image, extracting an SIFT characteristic of the search region then, performing characteristic matching on the history satellite image and the search region using an SIFT algorithm, removing a wrong matching relationship based on time-space consistency, performing screening on characteristic points through uniform rotation distribution then, traversing the search region, and determining the typhoon center. Automatic positioning of typhoon is achieved, typhoon positioning steps are simplified, the meteorological staff's workload is reduced, and typhoon positioning time is shortened.

Owner:NAT SATELLITE METEOROLOGICAL CENT

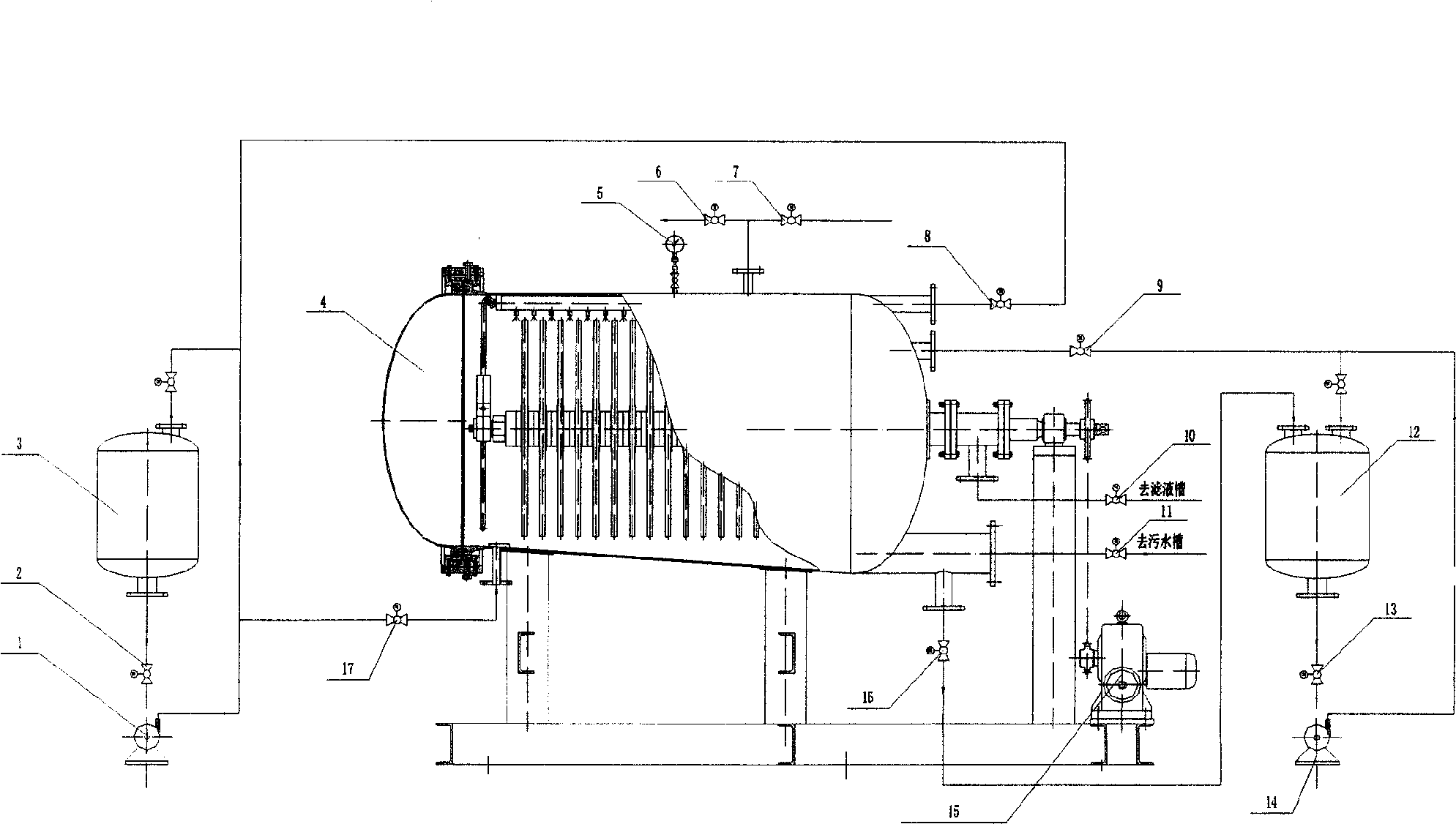

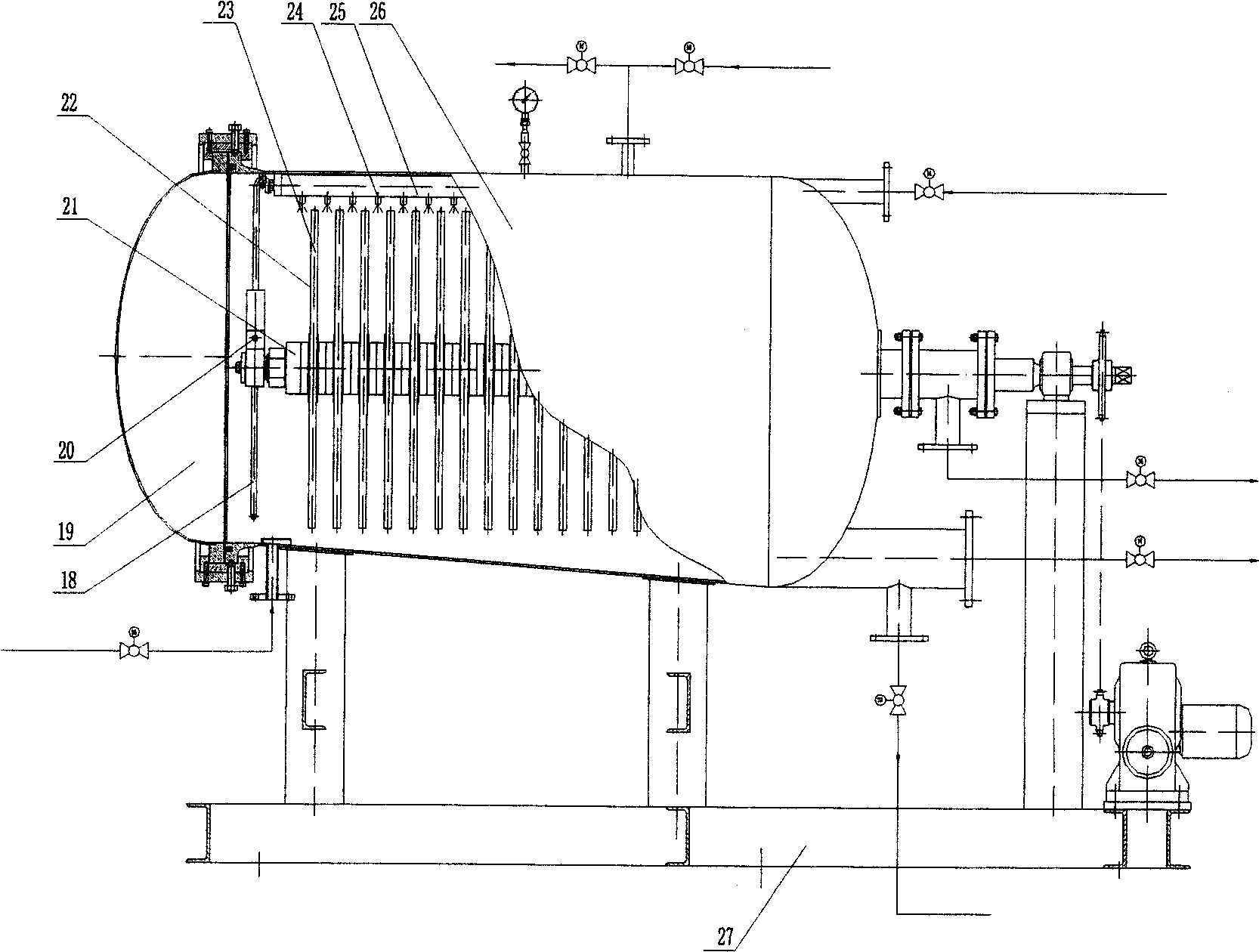

Liquid solid separating method for regenerating filtrate medium in filter

ActiveCN101530691AImprove work efficiencyEasy to replaceMoving filtering element filtersUniform rotationHigh pressure water

The invention relates to a liquid solid separating method for regenerating filtrate medium in filter, comprising the steps of: separating liquid solid two phases, removing filter cake, removing the filtrate medium and replacing the filtrate medium. Suspending liquid which is to be separated and includes fine solid grain is pumped into a novel quick opening type pressure leaf filter; under the function of the pressure of the pump, the solid phase grain is intercepted on the surface of the filtrate medium so as to form the filter cake; and the filtrate liquid passes through the filter cake and the filtrate medium and enters into the centre pipe of a filtrate disc so as to be discharged after being gathered. After the step of separating, a rotate positioning device drives a filter element to be rotated at an uniform speed, high-pressure water disassembles and cleans the filter cake which is covered on the filtrate medium by a nuzzle, and the filtrate medium is regenerated. The step of replacing the filtrate medium is carried out by fast switching the filter by a pneumatic control quick opening device. Compared with the prior art, the invention has the advantages of reasonable structure, safe operation, high work efficiency, high equipment automation degree, less management and maintenance workload, safe use, wide application range, etc.

Owner:SHANGHAI RES INST OF CHEM IND

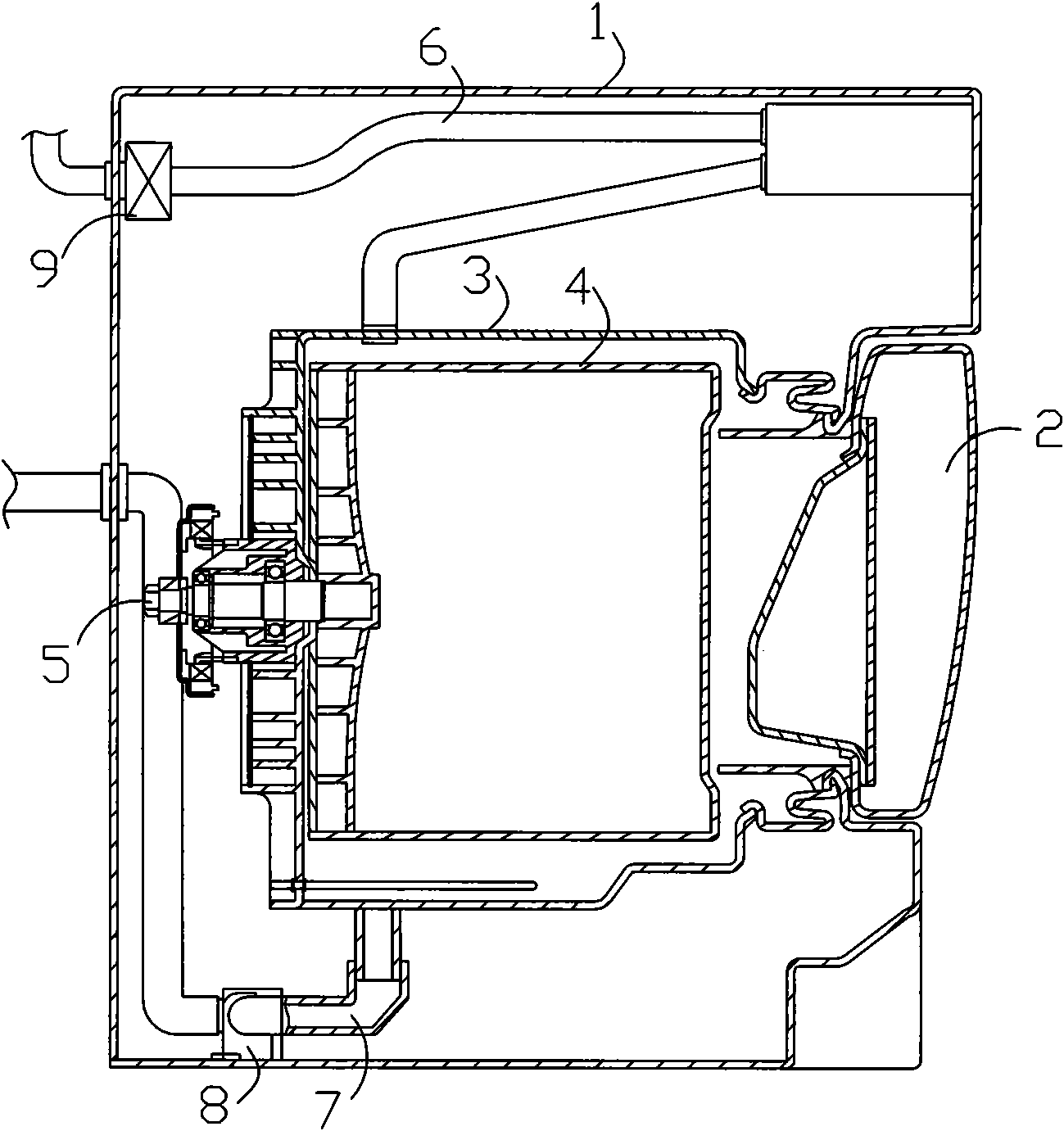

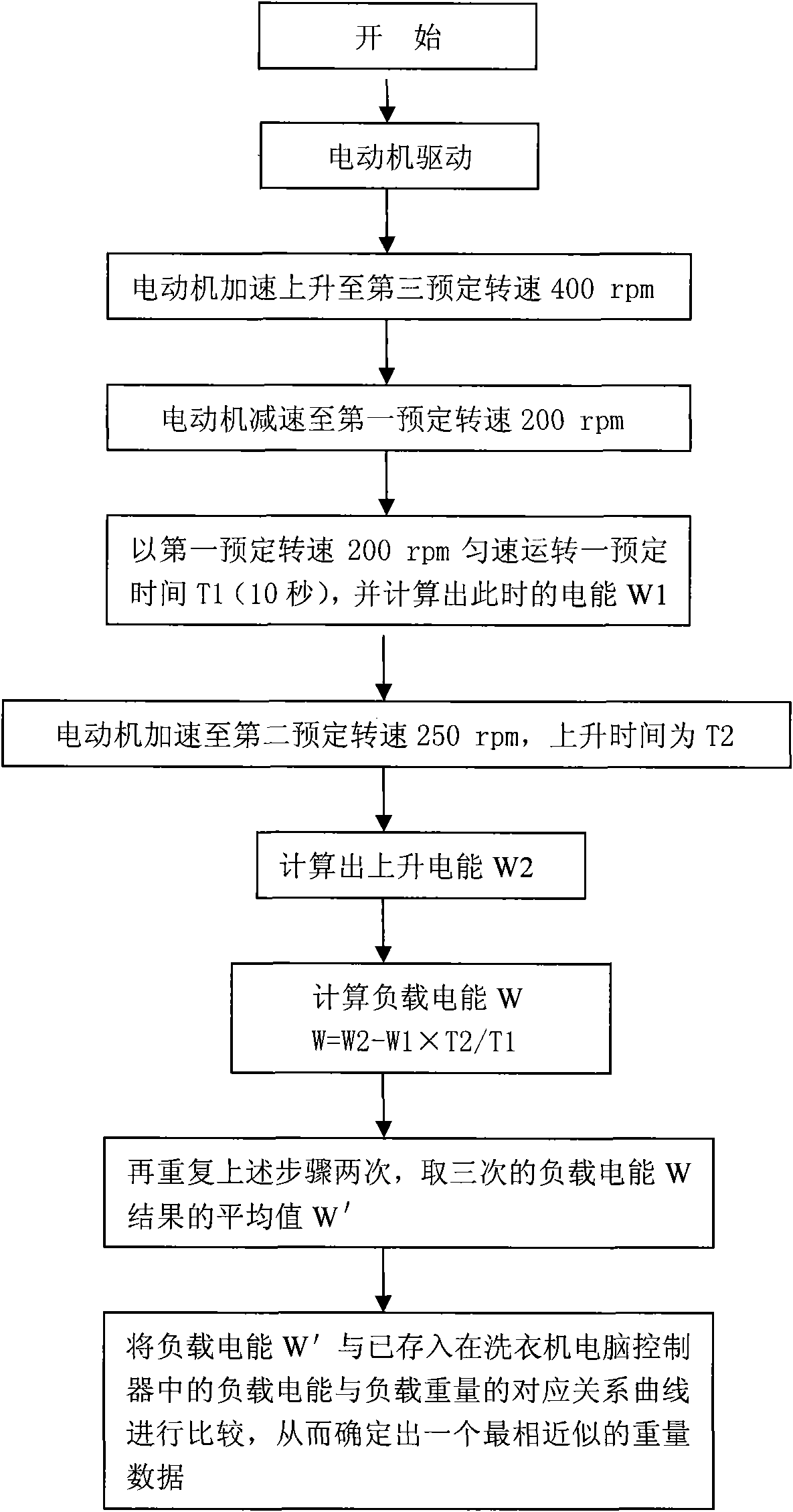

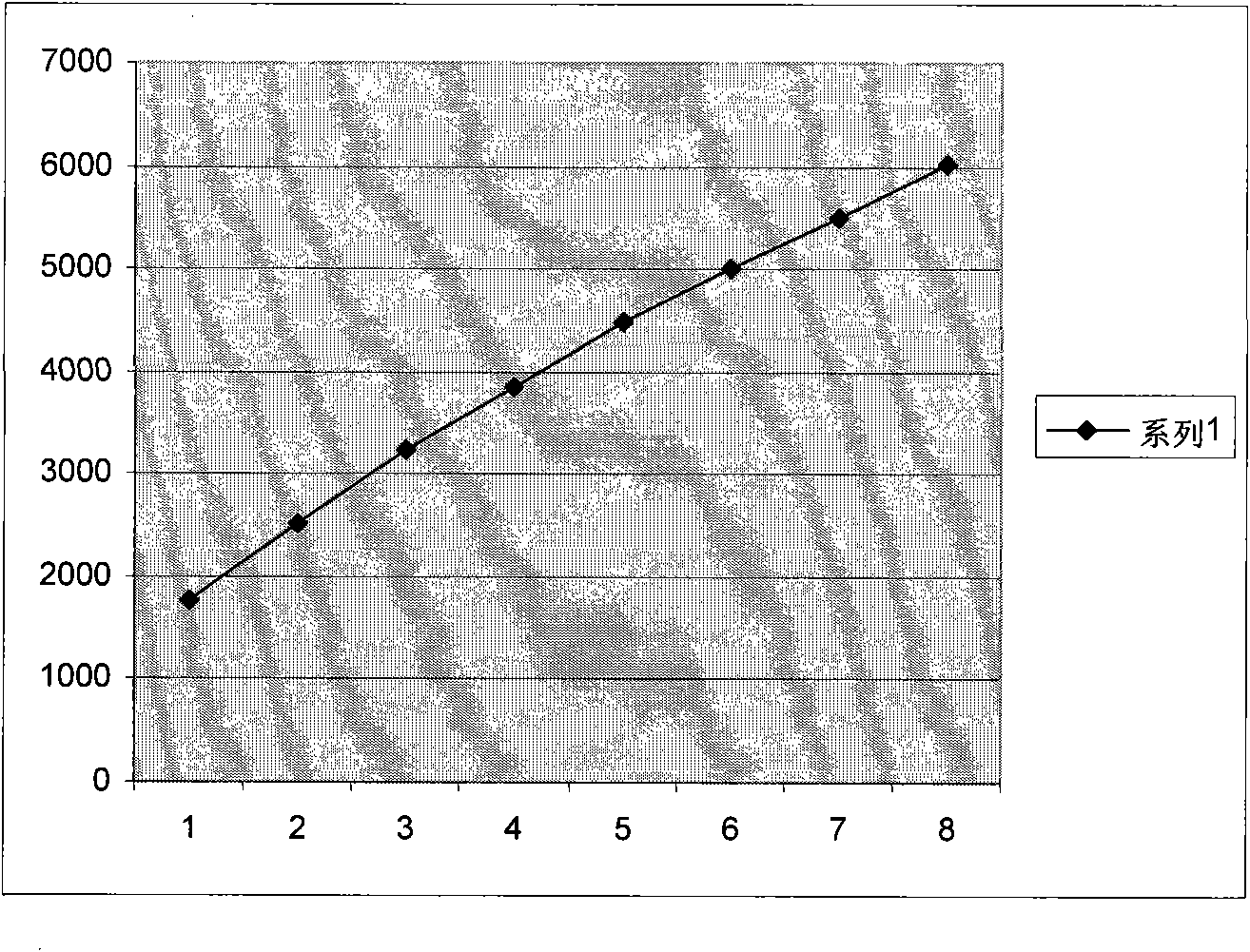

Automatic weighing method of barrel washing machine

ActiveCN101575793AAccurate measurementAutomatic weighing is accurateCurrent/voltage measurementOther washing machinesElectric machineUniform rotation

The invention relates to an automatic weighing method of a barrel washing machine. The method comprises the following steps: firstly, controlling a motor to reach a first preset rotating speed, enabling the motor to rotate at a uniform speed by the first preset rotating speed, and measuring the electrical energy of the drive load of the motor at the time; then, controlling the motor to be accelerated from the first preset rotating speed to a second preset rotating speed and measuring the ascending electrical energy of the motor when accelerated from the first preset rotating speed to the second preset rotating speed; finally, using the ascending electrical energy of the motor when accelerated from the first preset rotating speed to the second preset rotating speed to subtract a differencevalue obtained by multiplying the electrical energy of the motor rotating at the uniform speed by the first preset rotating speed by a time modification parameter according to the detection result, and calculating the corresponding load electrical energy; and comparing the corresponding relation curve of the obtained load electrical energy and the load weight with the corresponding relation curveof the load electrical energy stored in a computer controller of a washing machine and the load weight after the modification step so as to determine the most approximate weight data. The invention has high detection precision and short detection time.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

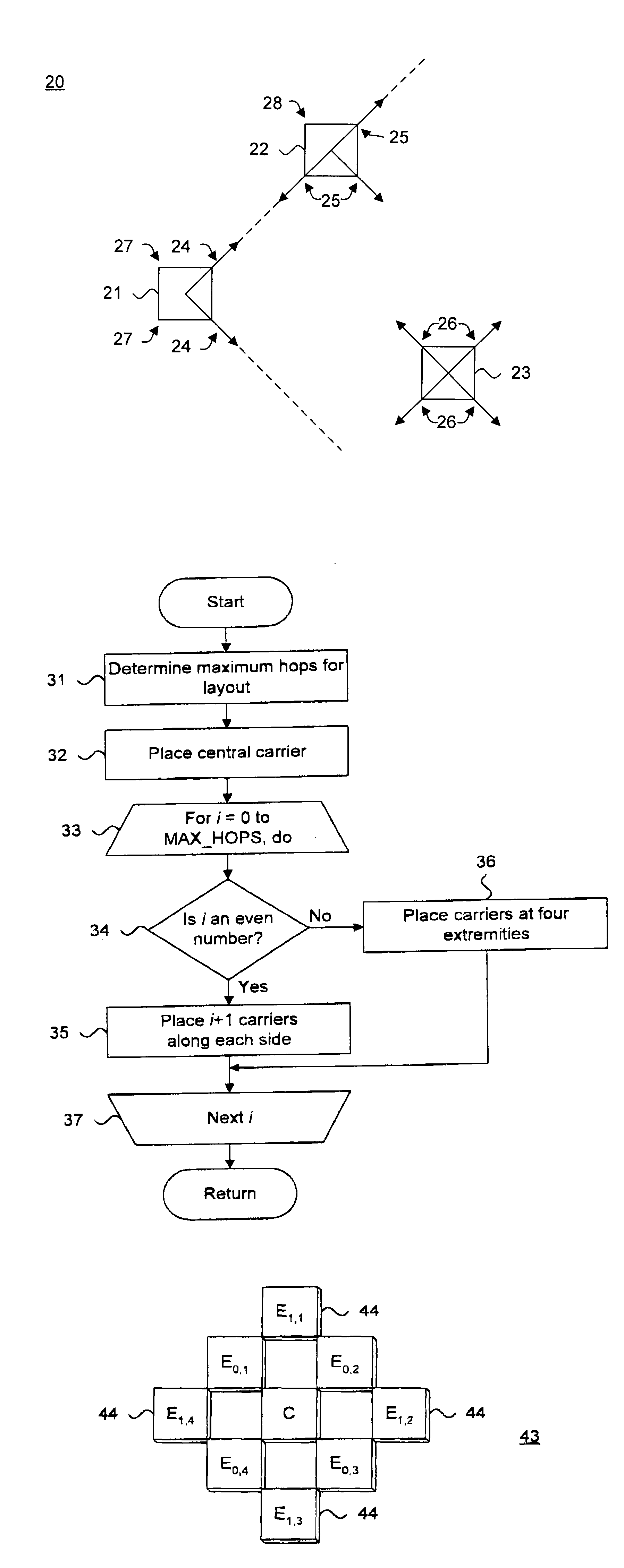

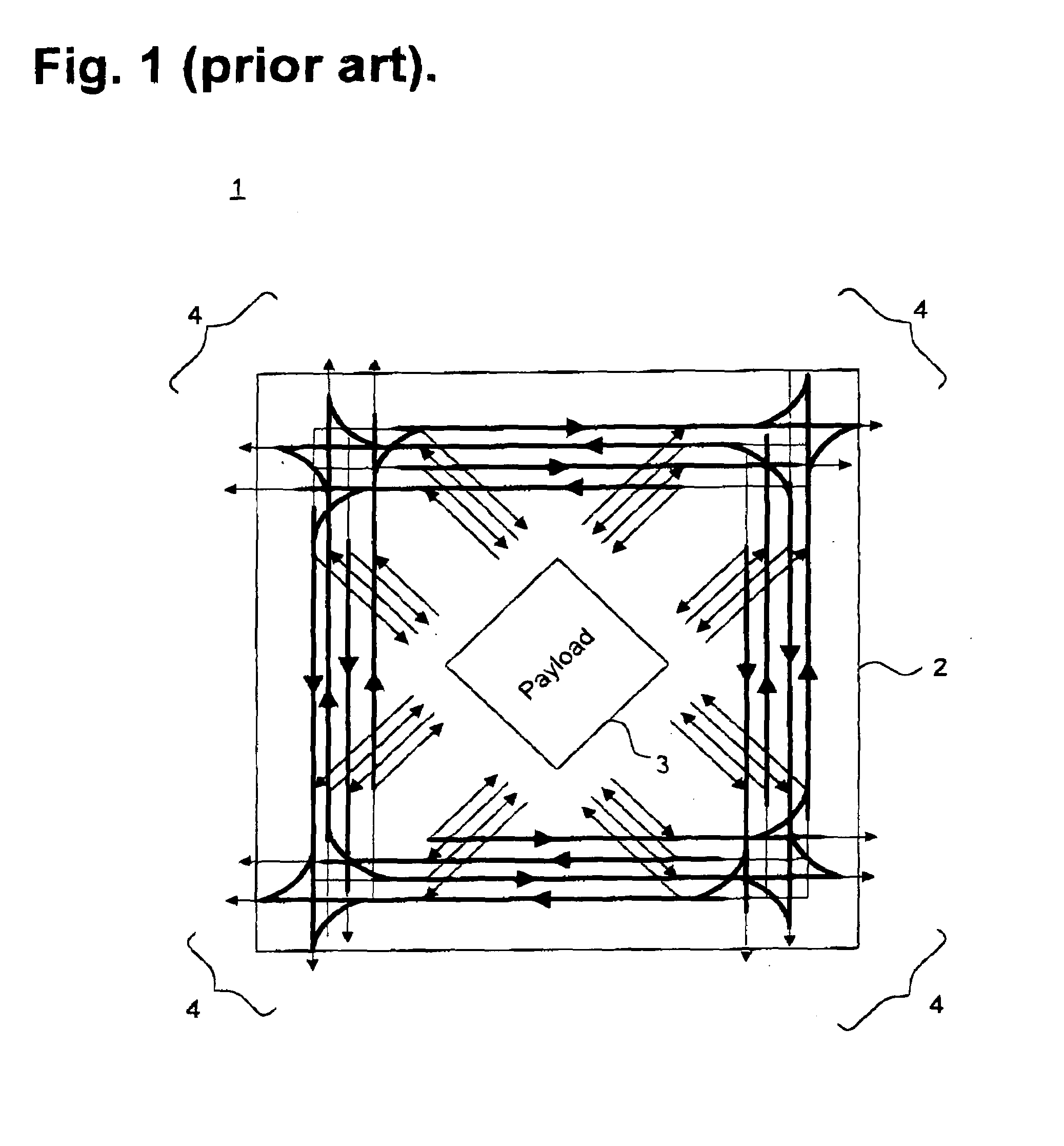

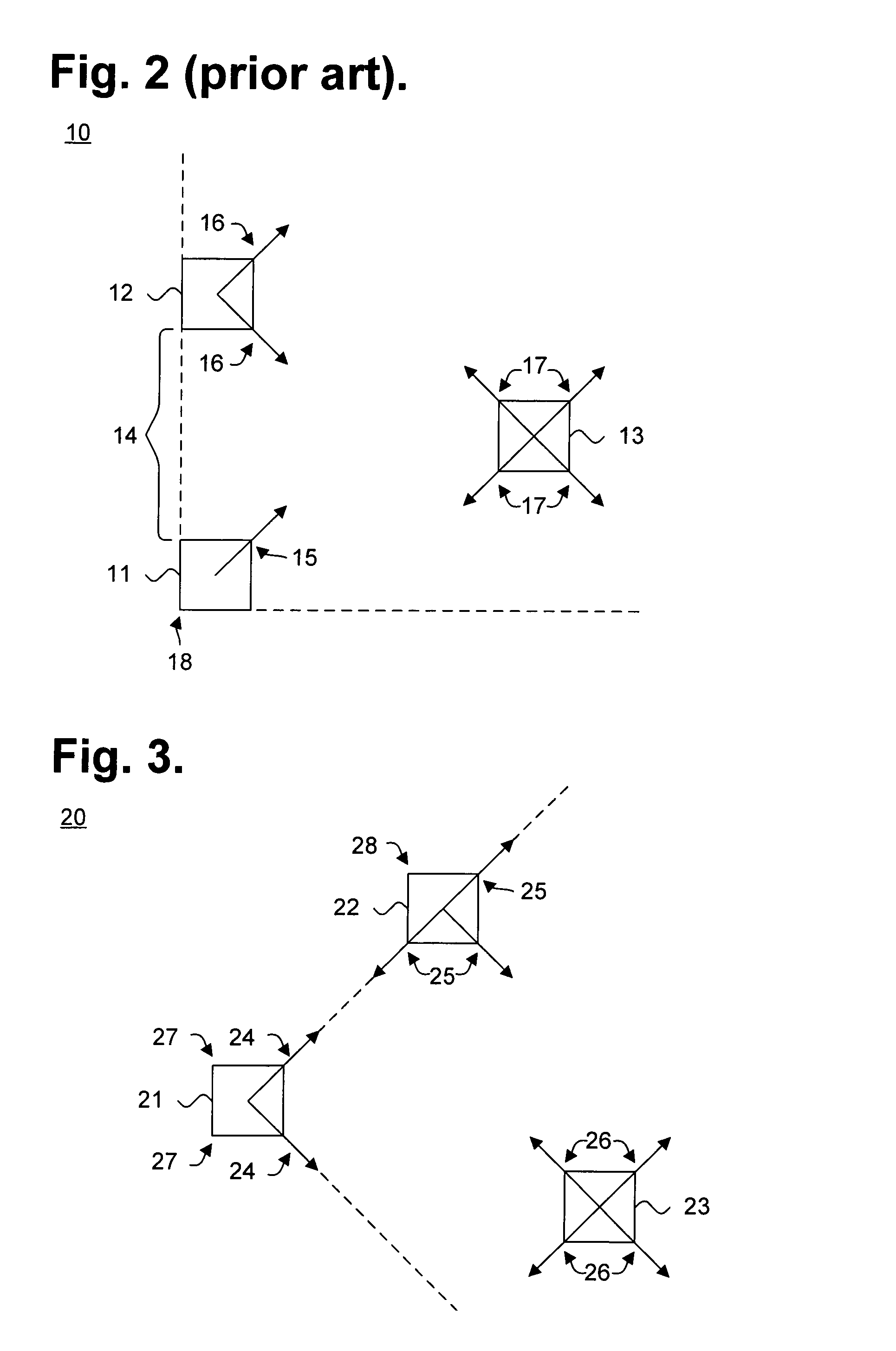

System and method for determining a carrier layout using cornered chip-to-chip input/output

ActiveUS7191422B1Minimize Hamming distanceDistance minimizationTransmissionSoftware simulation/interpretation/emulationCarrier signalUniform rotation

A system and method for determining a carrier layout using cornered chip-to-chip input / output is presented. Each of a plurality of individual integrated circuit carriers communicatively interfaceable through cornered input / output ports is oriented at a uniform rotation relative to an edge of a carrier layout. Each carrier defines a set of rectilinear edges. Each carrier is placed juxtaposed at an open corner to at least one other carrier within a rectilinear lattice topologically arranged in the carrier layout to substantially minimize Hamming distances between each of the carriers.

Owner:ORACLE INT CORP

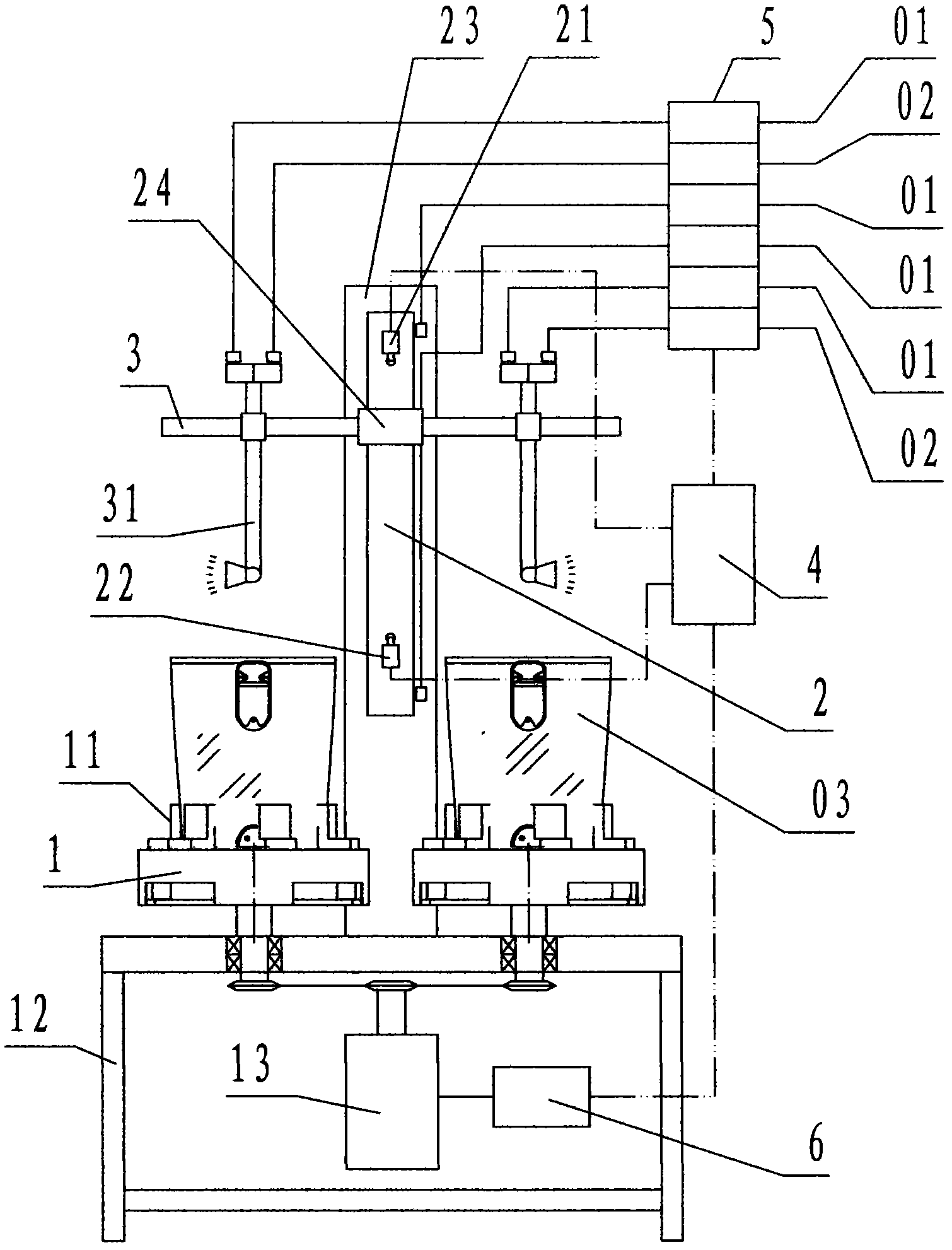

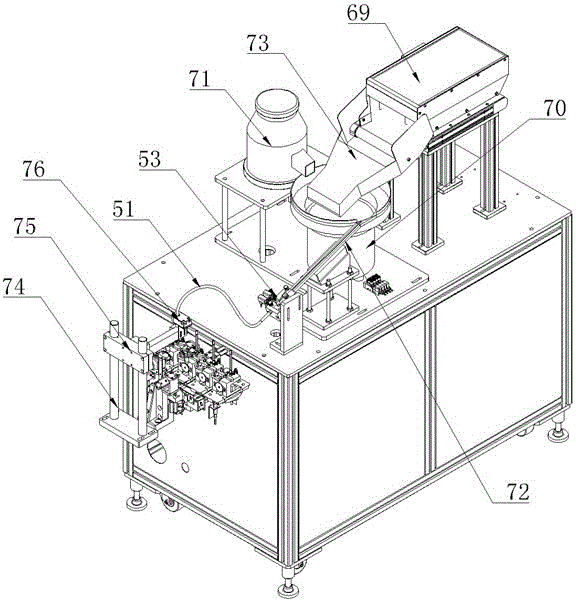

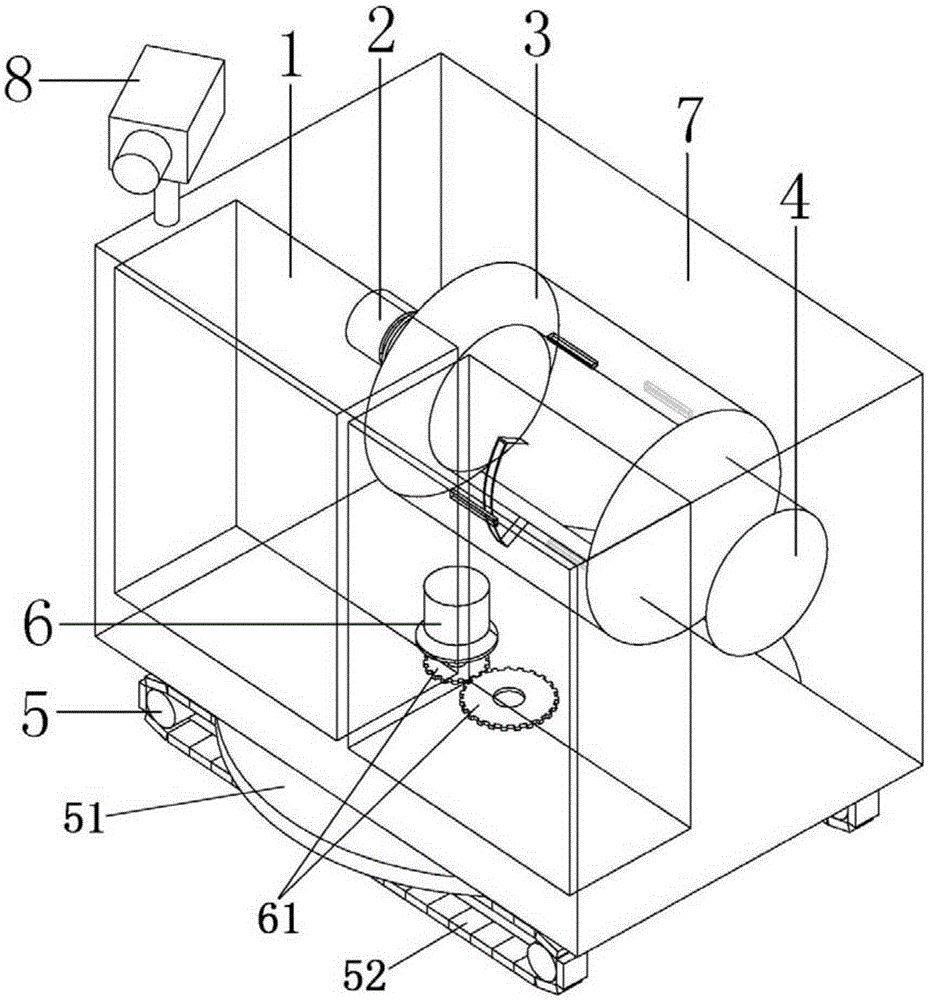

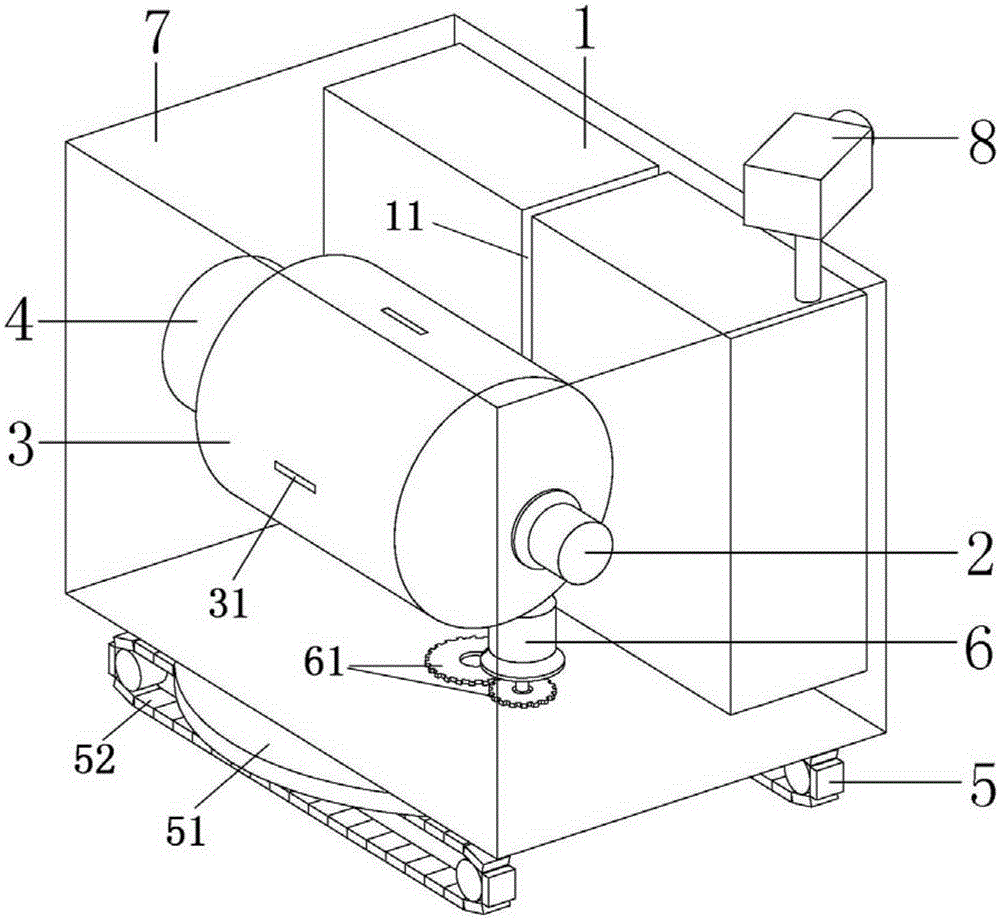

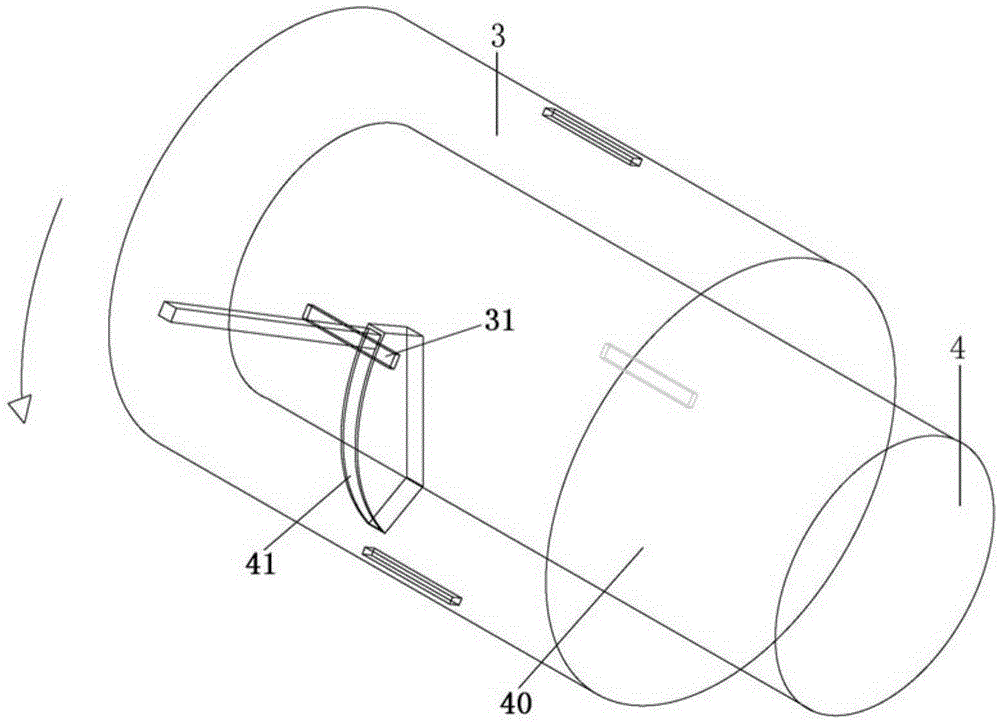

Automatic inner wall spraying device for round cup-shaped injection molding products

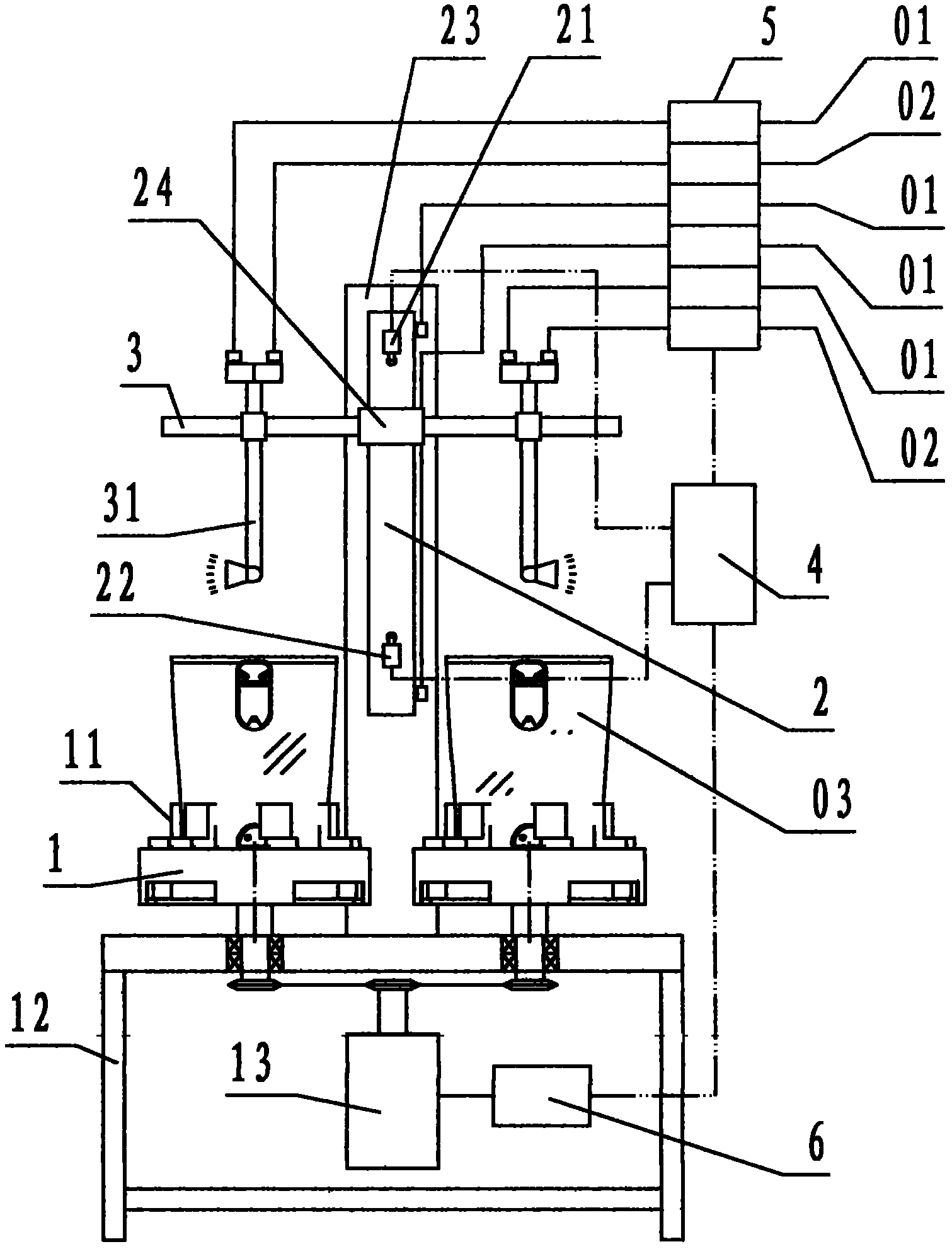

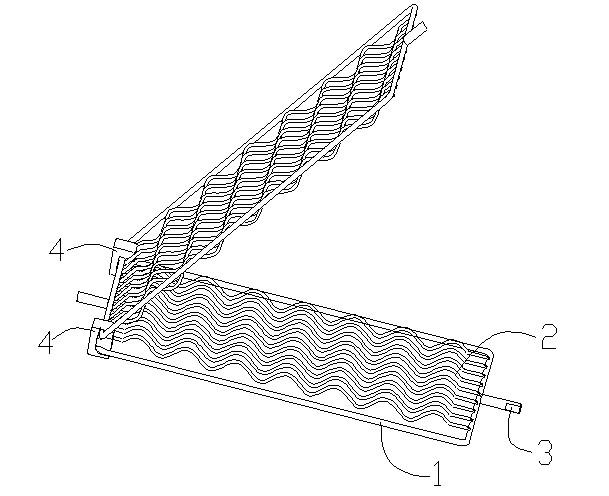

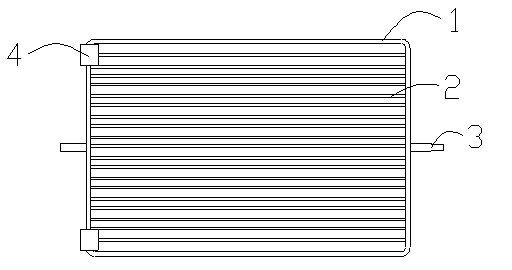

InactiveCN102626684AOvercome consistencyOvercome costsLiquid surface applicatorsSpraying apparatusFrequency conversionProgrammable logic controller

The invention discloses an automatic inner wall spraying device for round cup-shaped injection molding products. The automatic inner wall spraying device comprises a rotary workbench (1), a base (12), a motor (13), an air cylinder (2), a cantilever (3), a spray gun (31), a bracket (23), a PLC (Programmable Logic Controller) (4), an electromagnetic valve (5) and a frequency-conversion speed regulator (6). According to the invention, the device consisting of the rotary workbench, the motor, the air cylinder, the cantilever, the spray gun, the PLC, the electromagnetic valve and the frequency-conversion speed regulator is adopted; and when the automatic inner wall spraying device works, the round cup-shaped product is clamped on the rotary workbench and driven by the motor to rotate at a constant speed, the air cylinder drives the cantilever to carry the spray gun to be inserted into a cavity of the round cup-shaped product to spray up and down at a constant speed, and the PLC controls the spray gun to be started and stopped through the electromagnetic valve and controls the air cylinder to act up and down. Due to the technical scheme that the frequency-conversion speed regulator controls the rotating speed of the motor, the inner wall of the round cup-shaped injection molding product is sprayed to reach the purposes of keeping consistency of quality, reducing cost, improving efficiency and reducing waste.

Owner:NINGBO HUABAO PLASTICS & RUBBER MOLD

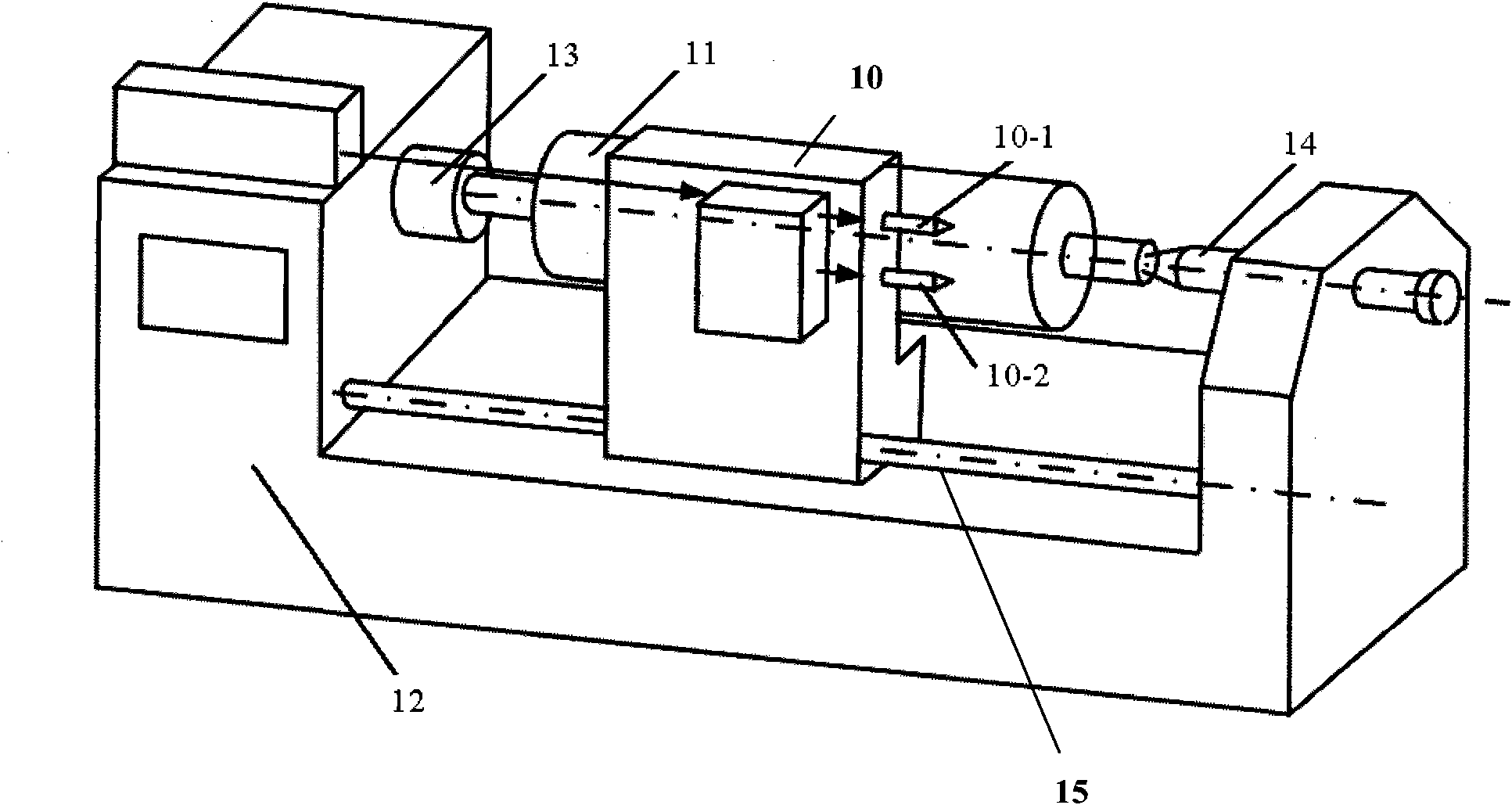

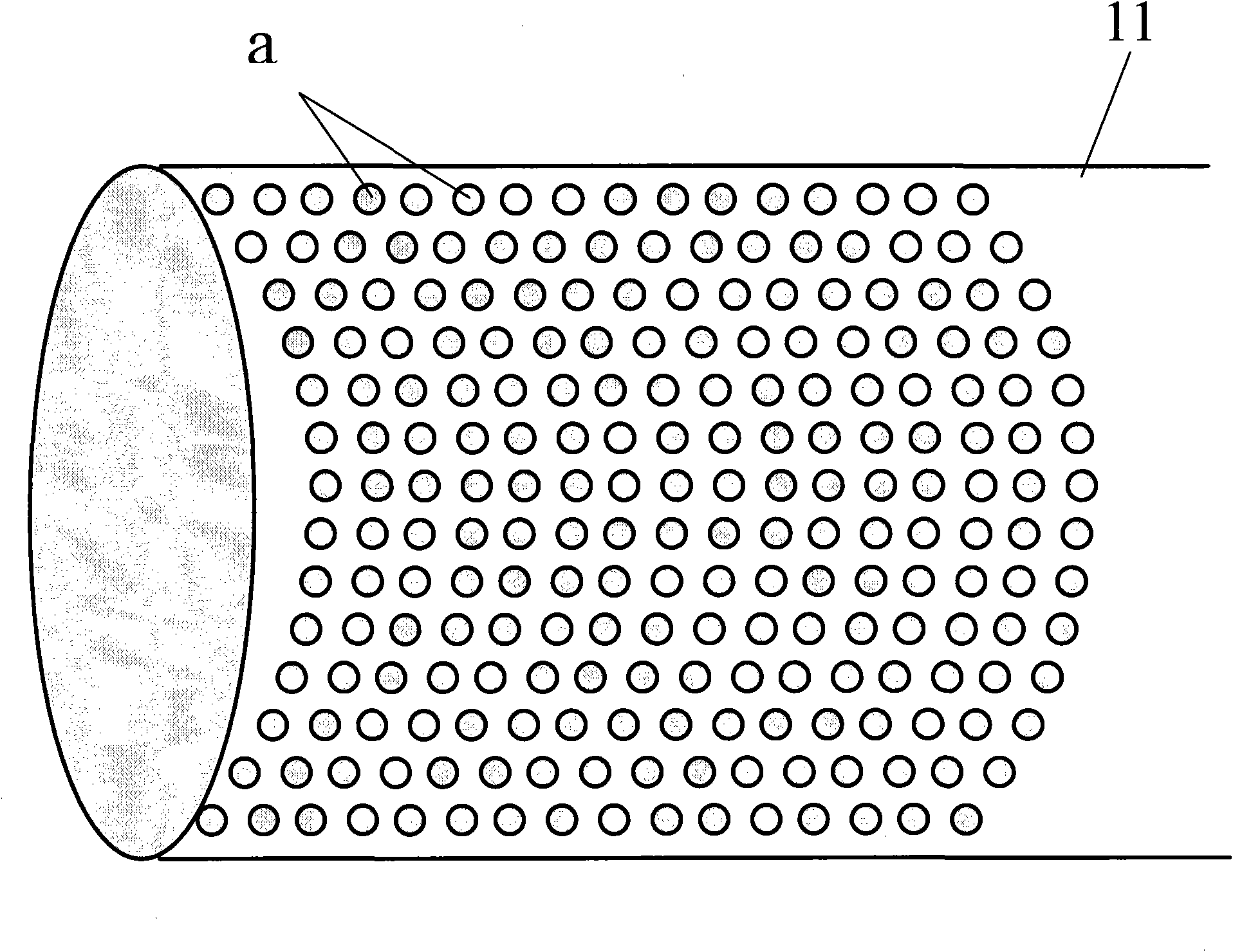

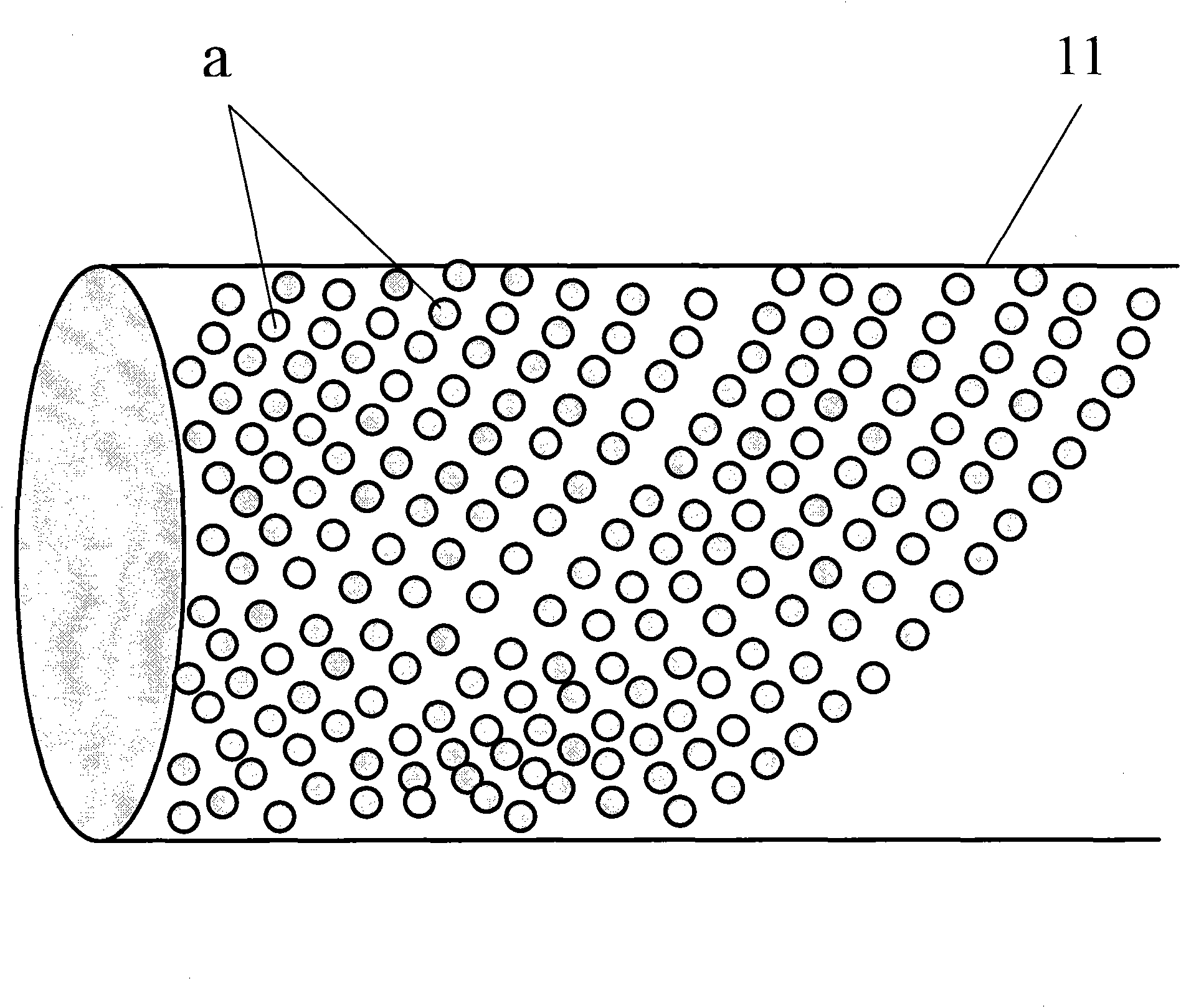

Laser texturing processing method on surface of roller

InactiveCN101642778AImprove rolling qualityImprove wear resistanceRolling equipment maintainenceLaser beam welding apparatusHelical lineSheet steel

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; simultaneously, leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized in that by accelerating the moving speed V of the laser texturing head along the axial direction of the roller, the texturing spots are distributed along the high inclination-angle helical line with the thread pitch of delta being equal to 2-200mm on the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbedby texturing concave holes crisscross distributed on the peripheral direction of the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

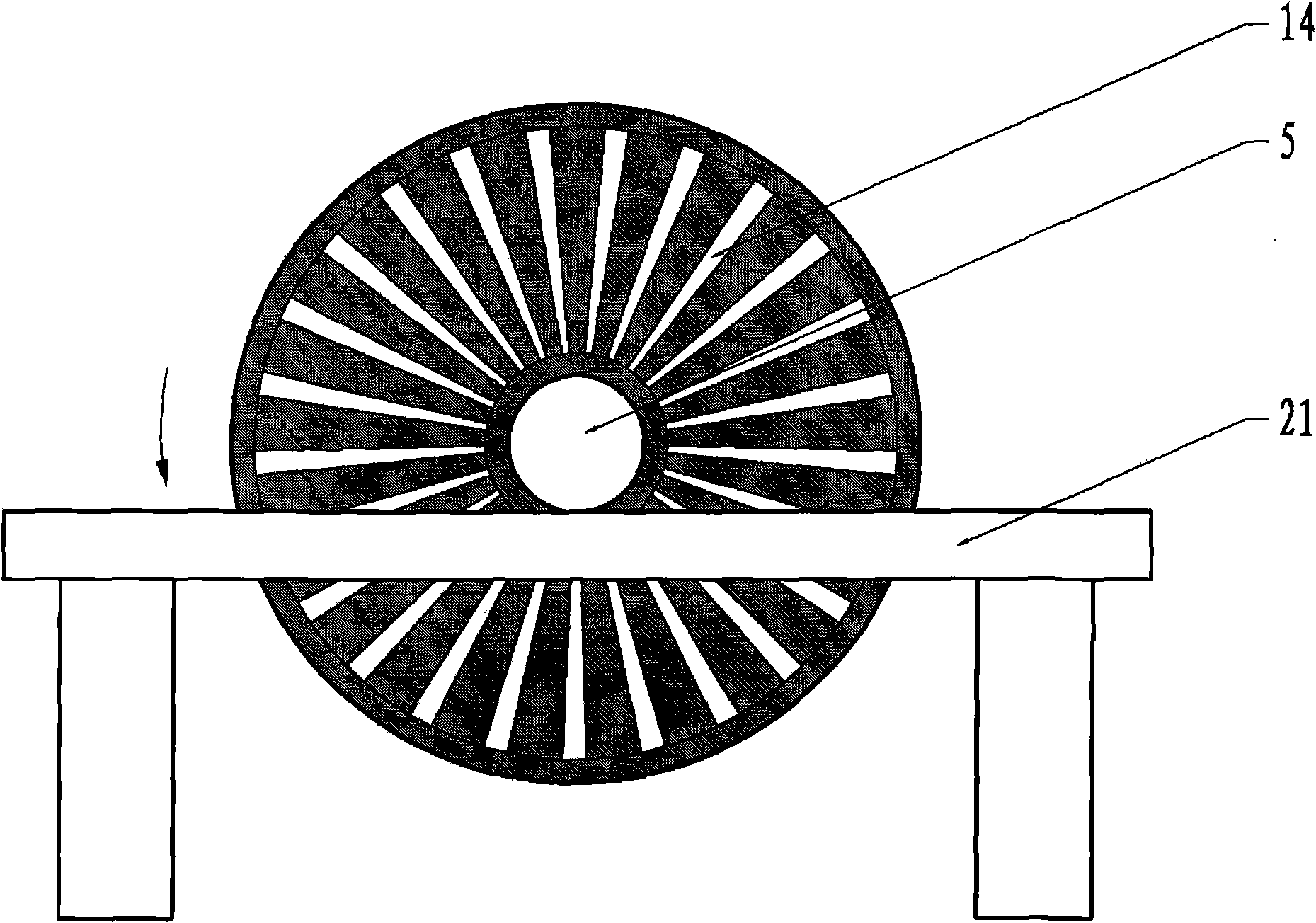

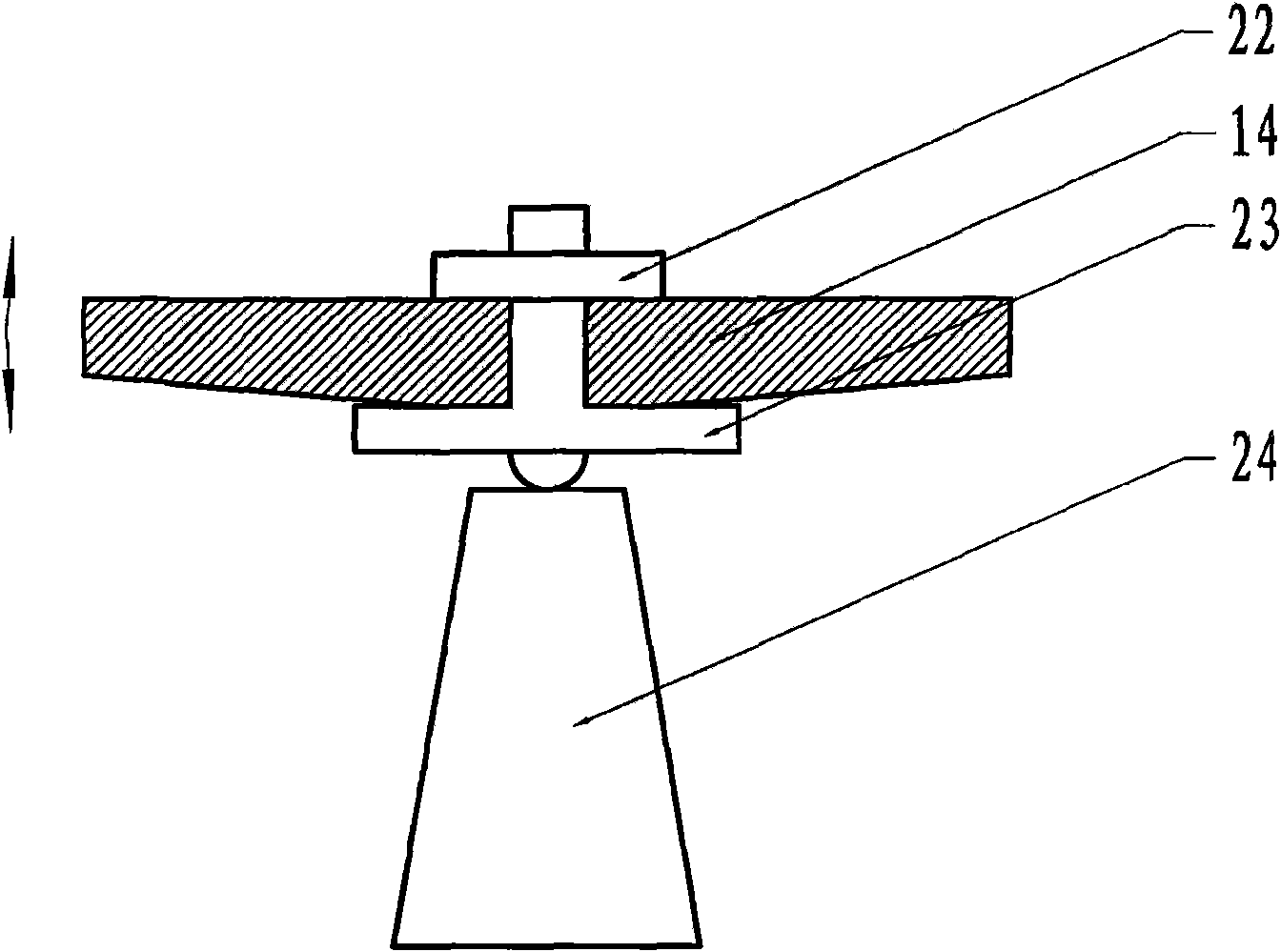

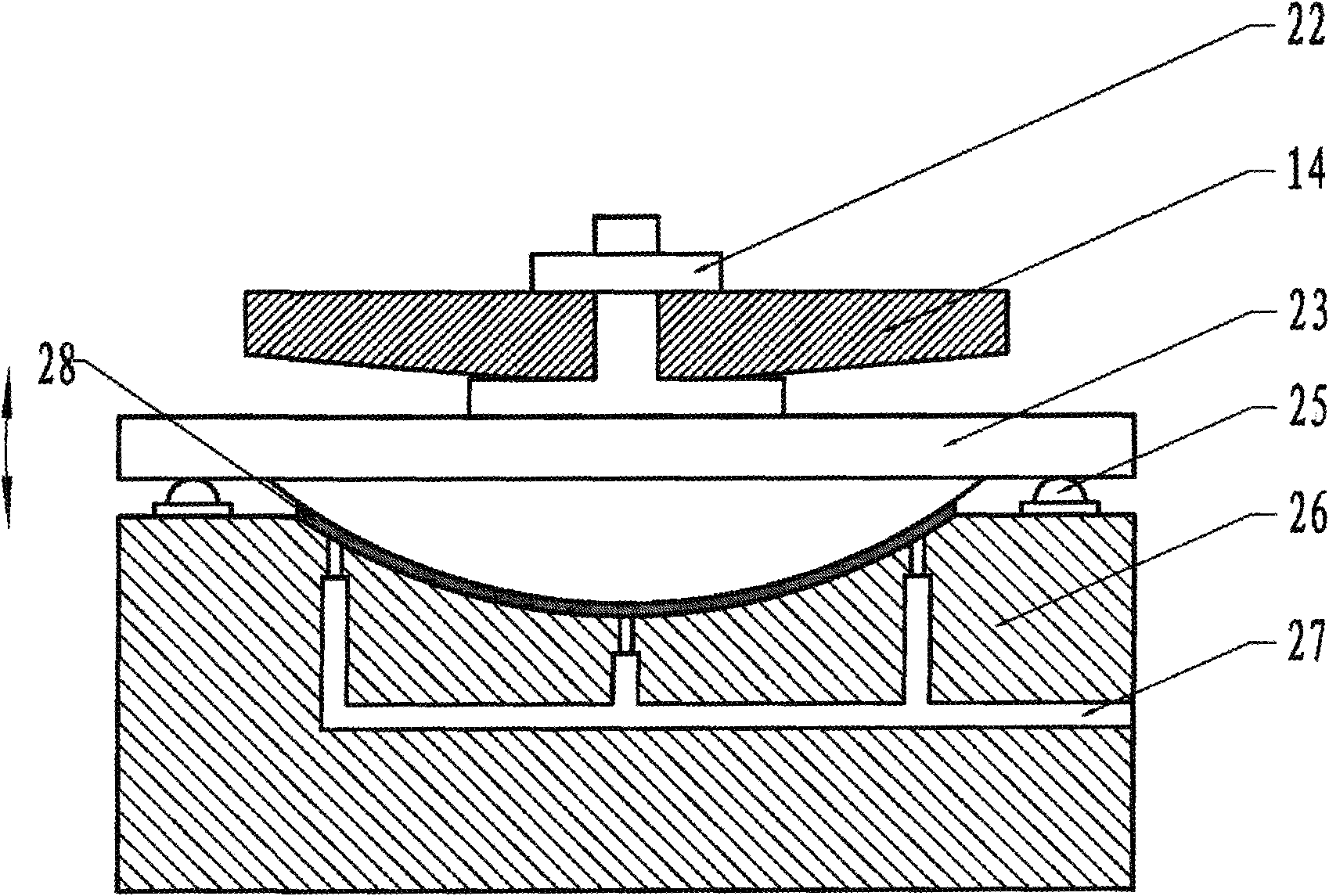

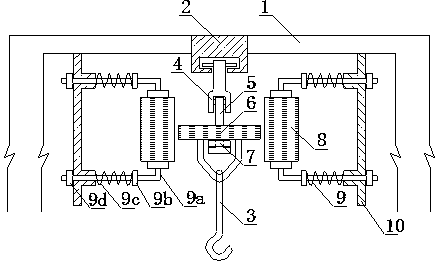

Measuring method for static balance of turbine vane wheel and device thereof

InactiveCN101576425AEliminate systematic errorsLink to reduce errorsStatic/dynamic balance measurementAir bearingDrive motor

The invention relates to a static balance measuring technique for a turbine vane wheel, which belongs to the technical field of precision finishing and measuring. The device comprises a vane wheel, a driving motor, a torque sensor, a data-processing system, an air journal bearing, an air journal bearing supporting mechanism, air-bearing guide ways, an air-bearing guide way supporting mechanism, a hydro bearing, a constant-force generator, and a hydro bearing supporting mechanism. The driving motor is used for driving the air journal bearing, driving the vane wheels for uniform rotation, measuring the output torque of the driving motor during one circle of rotation of the vane wheels, and calculating the amount of unbalance of the vane wheels so as to remove the amount of unbalance quantificationally. The invention has the advantages that the independent rotation of the vane wheels eliminates the system error caused by the amount of unbalance of other parts; fluid lubrication adopted in the main running gear of the measuring system greatly decreases kinetic friction force, reduces the minimum amount of unbalance of measurable vane wheel, improves measurement precision and sensitivity, realizes quantification of measuring results by transmission and measurement of toque, and raises working efficiency. The invention can be widely applied to the checkout gear of static balance for the turbine vane wheel.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

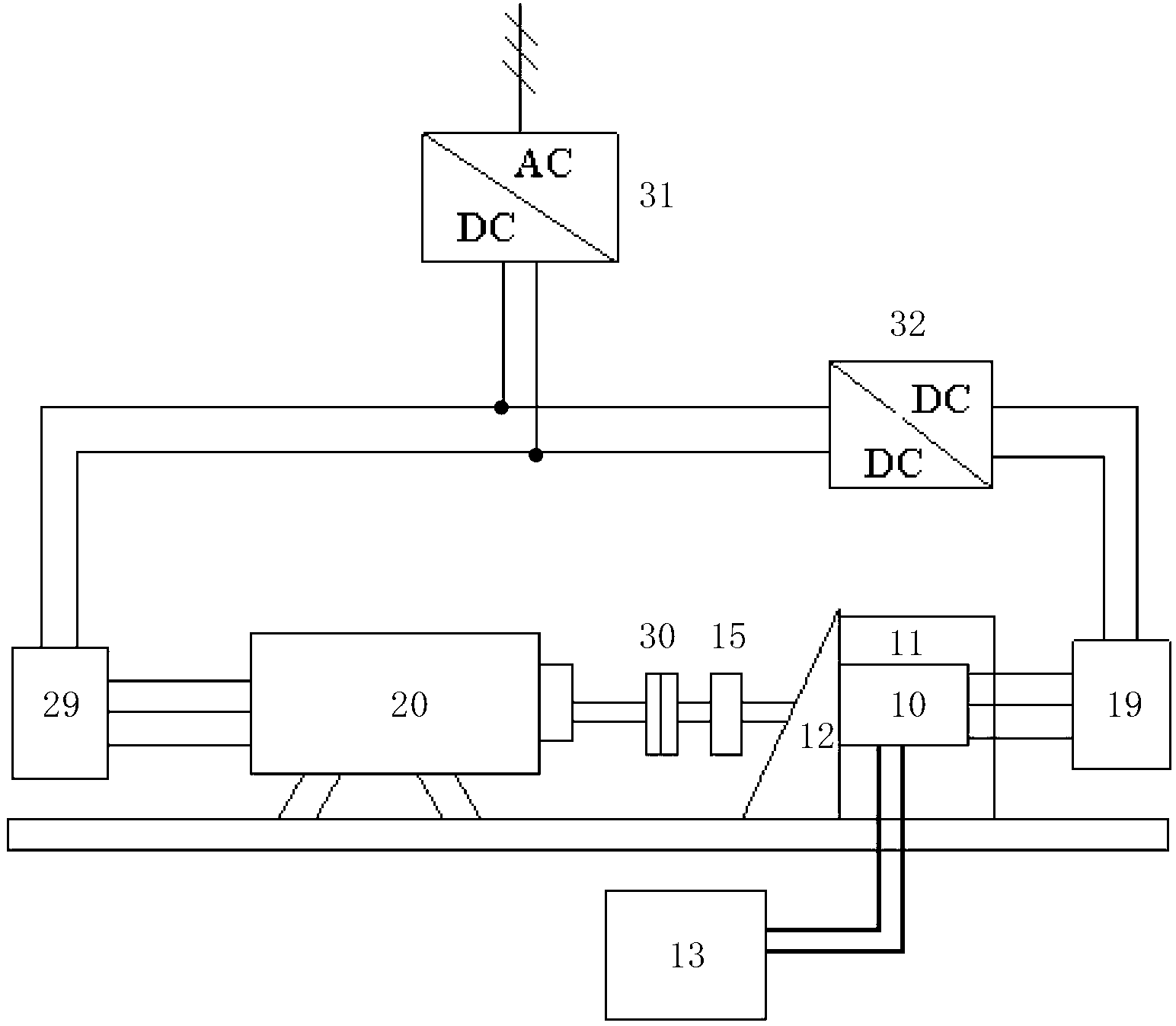

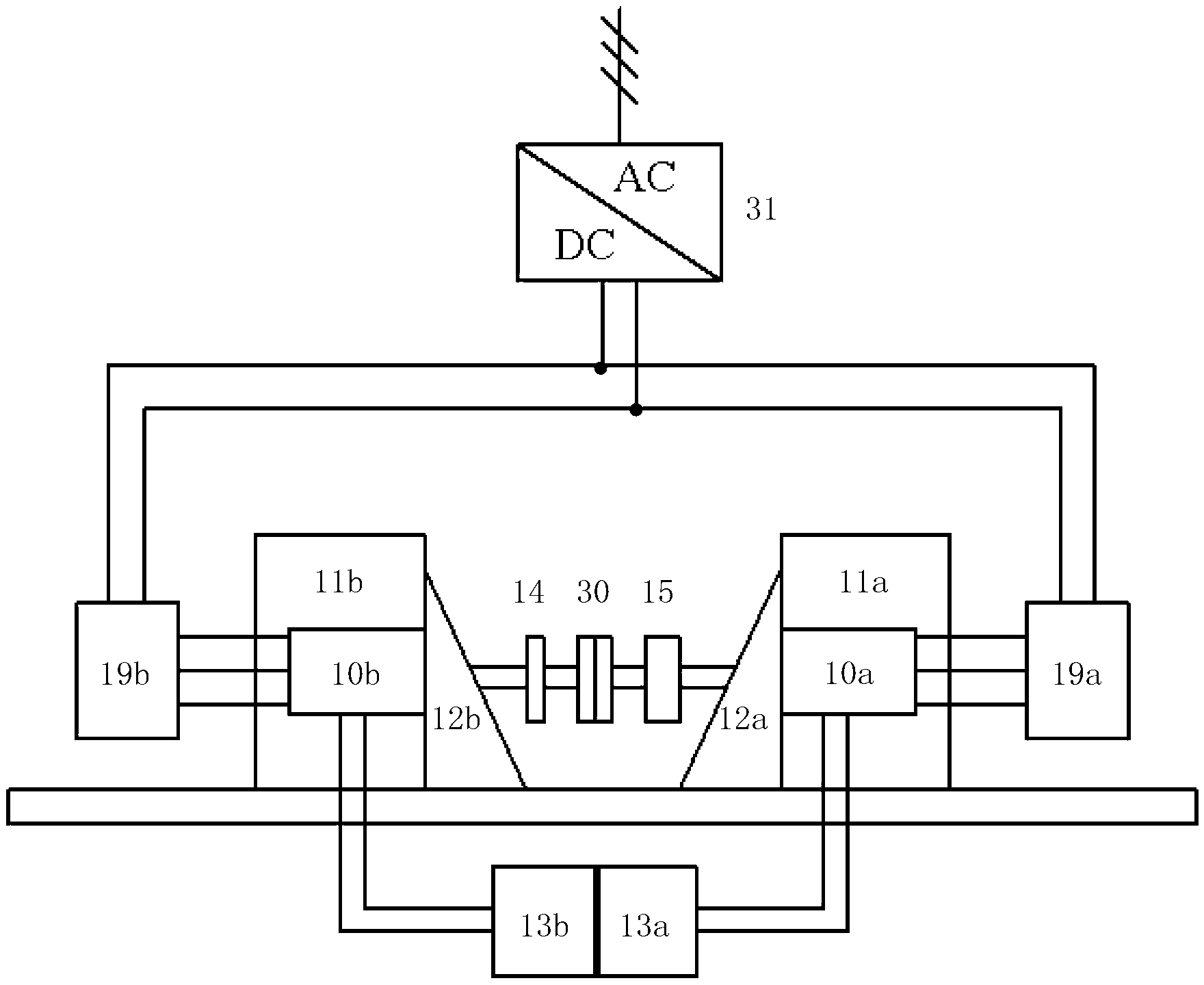

System and method thereof for testing endurance of symmetrical motor

InactiveCN103235261AEasy to testSimple structureDynamo-electric machine testingTest efficiencyElectric machine

The invention discloses a system for testing endurance of a symmetrical motor. The system comprises two to-be-tested motors, two environment compartments, two cooling machine units, a torque sensor, two motor controllers, a coupling and a rectifying unit, wherein the two to-be-tested motors are respectively a three-phase alternating current motor, the temperatures of the interiors of the environment compartments are adjustable, the environment compartments are used for respectively accommodating the two to-be-tested motors, the two cooling machine units are used for respectively radiating the heat of windings of the two to-be-tested motors, the torque sensor is arranged on a rotary shaft of any to-be-tested motor, the first motor controller is used for controlling the current of the direct shaft and the rotation speed of the rotary shaft of the first to-be-tested motor, the second motor controller is used for controlling the current of the direct shaft and the quadrature axis current of the second to-be-tested motor, the rotary shafts of the two to-be-tested motors are connected by the coupling to ensure the uniform rotation speeds of the two rotary shafts, and the rectifying unit is used for converting the alternating current into the constant direct current, and then is used for respectively supplying power to the two motors. The invention also discloses a test method. The test system has the advantages that the structure is simple, the test efficiency is higher, and the universality is higher.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

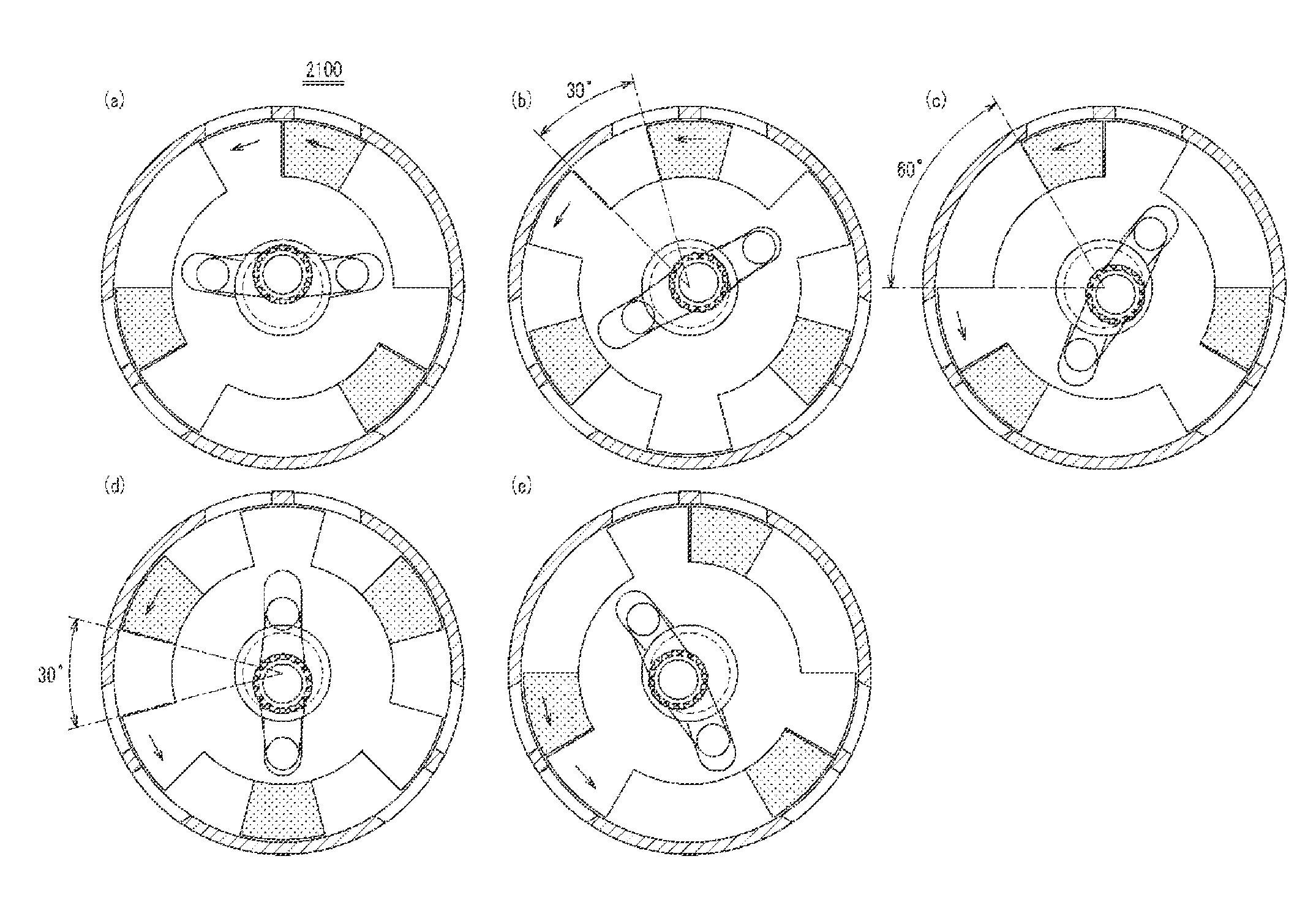

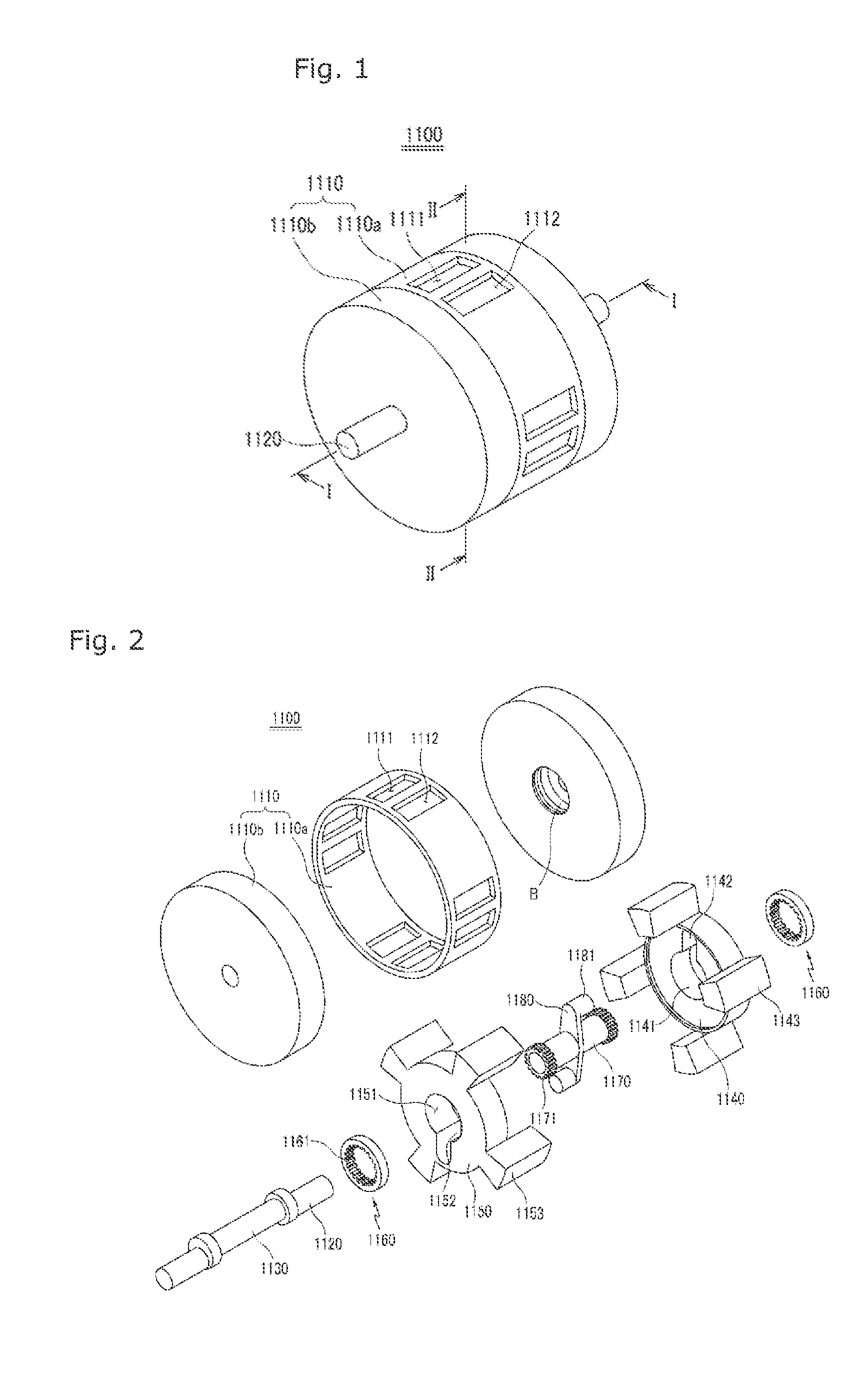

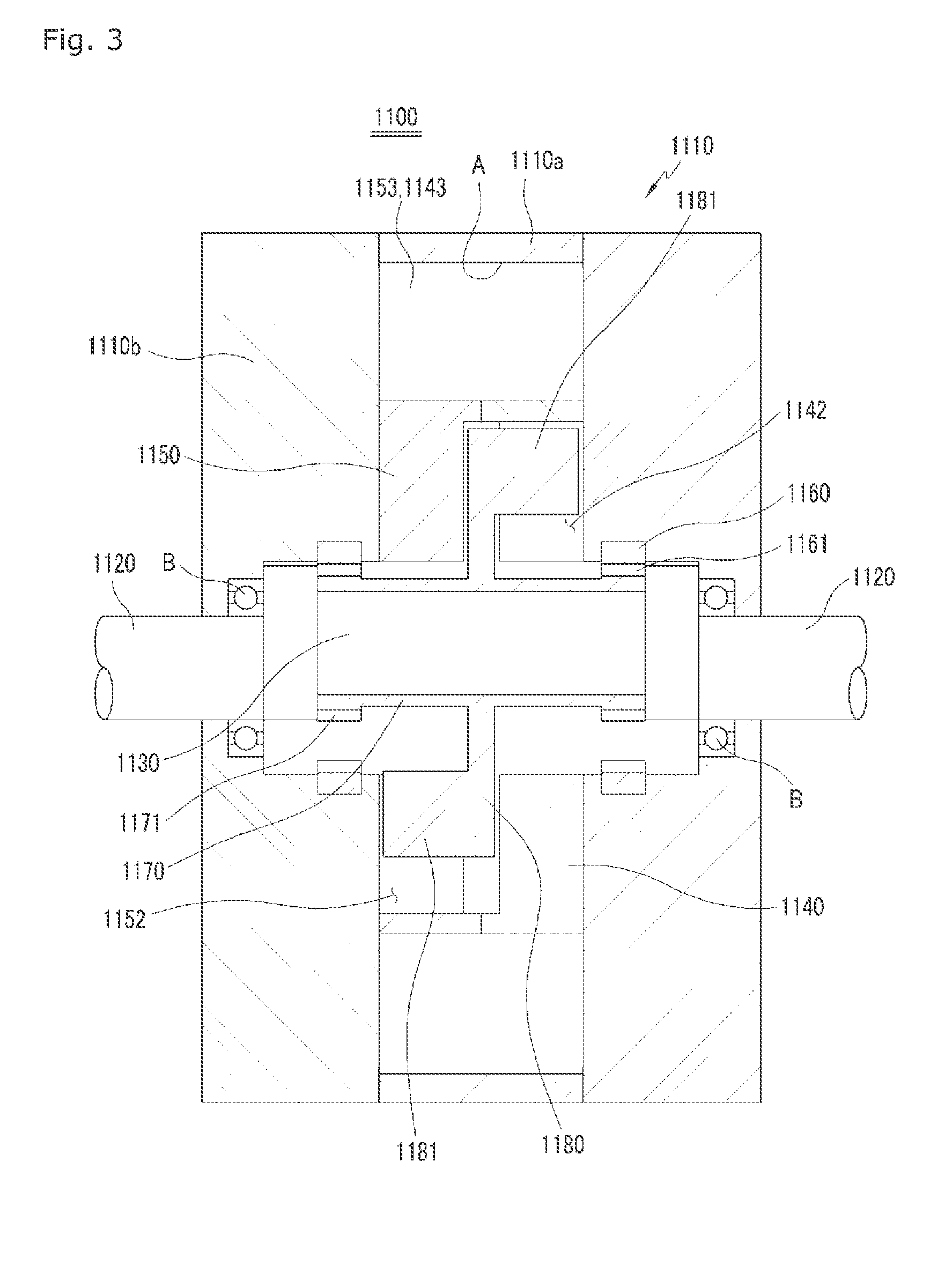

Rotational clap suction/pressure device

InactiveUS20140056747A1High mechanical strengthSuperiorly copeEngine of intermeshing engagement typeRotary piston pumpsCombustionExternal combustion engine

The present invention relates to a simple and straightforward positive displacement suction / pressure device (rotational clap suction / pressure device) for utilizing in general industrial flow machines, such as various positive displacement pumps, vacuum pumps, compressors, flow meters, and rotary internal combustion engines. The object of the present invention using a double non-uniform rotation is to provide a simple and durable mechanical device having improved efficiency, by replacing the existing linear contact between various types of rotors or between a rotor and a housing, which is a problem in existing positive displacement flow machines and rotary internal combustion engines, with a whole surface.

Owner:KIM JONG MUN

Optical detection and measurement radar with multiple sensors

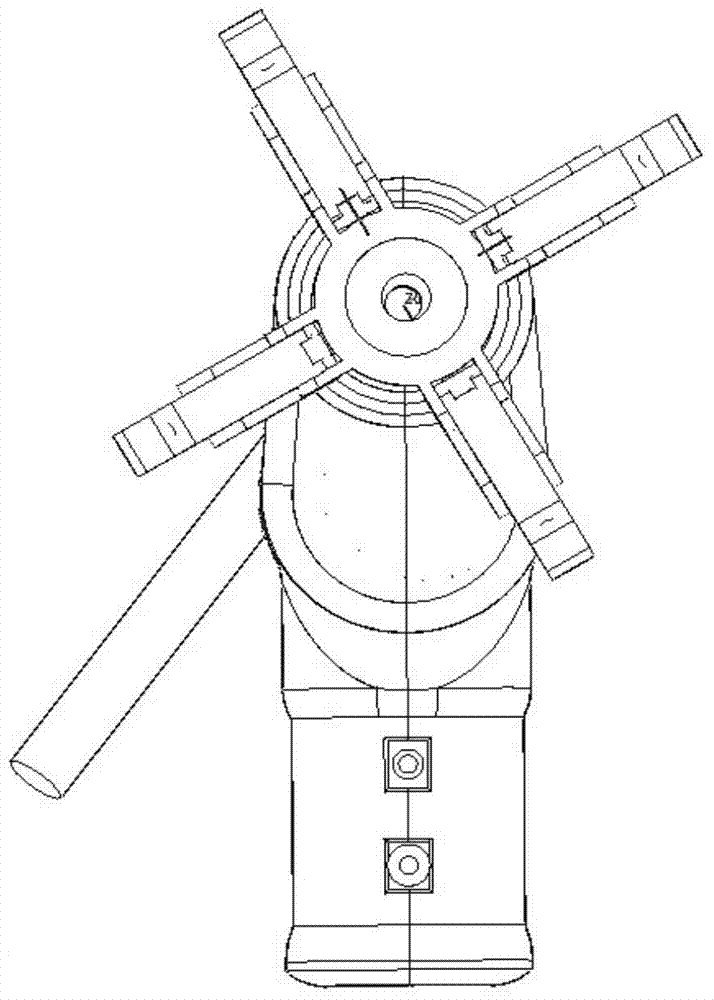

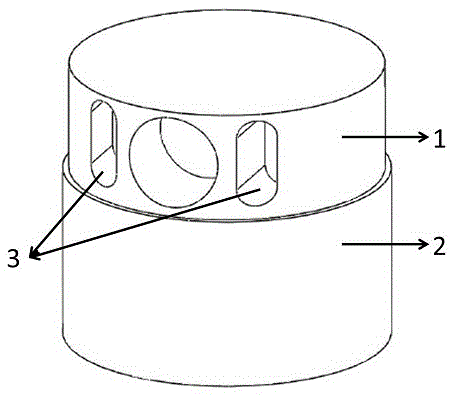

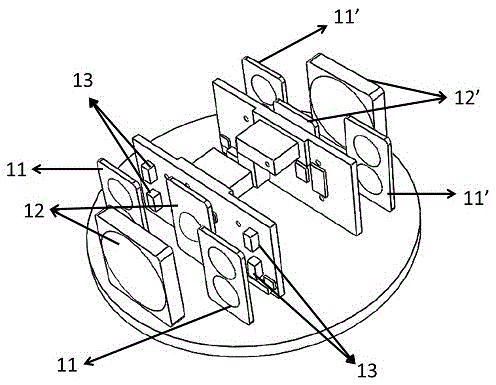

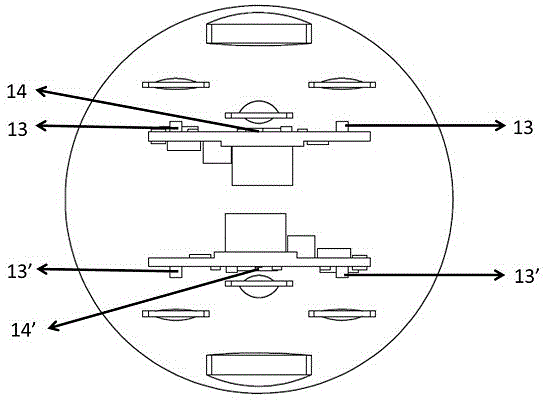

ActiveCN105548988AExtended service lifeIncrease the number of measurementsElectromagnetic wave reradiationMultiple sensorDrive motor

The invention provides an optical detection and measurement radar with multiple sensors in order to solve the problems that by means of an optical detection and measurement radar, the number of scanning times of measuring obstacles is not sufficient and the ranging accuracy is limited. The radar comprises a rotary shell, a base, two or more infrared light emission modules, two or more electro-optical ranging units, a rotary drive motor, a slide ring and a corresponding drive circuit, wherein the rotary shell rotates relative to the base, the infrared light emission modules are fixed into the rotary shell and emit infrared detection light, the electro-optical ranging units are fixed into the rotary shell, each electro-optical ranging unit comprises an electro-optical sensor for converting received infrared light signals into electric signals, and the rotary drive motor is used for driving the rotary shell to rotate at a constant speed. By designing the two or more sensors, compared with the optical detection and measurement radar with a single sensor, the number of measurement times within a single measurement cycle is increased, and the ranging accuracy is improved.

Owner:BENEWAKE BEIJING TECH CO LTD

Domestic intelligent electric oven

InactiveCN106943034AImprove the baking effectImprove job stabilityRoasters/grillsAutomatic controlEngineering

The invention discloses a household intelligent electric oven, which comprises a box body, an insulation layer is arranged on the outer wall of the box body, and a partition board is horizontally arranged on the lower side inside the box body, and the partition board divides the box body into a baking cavity on the upper side and a baking chamber on the upper side. In the installation cavity on the lower side, a turntable is horizontally arranged at the center of the lower side of the box body, and a circular groove is opened at the center of the upper surface of the turntable. The limiting protrusion of the household electric oven of the present invention can effectively eliminate oil fume and reduce pollution during the baking process, can automatically control the baking temperature, improve the baking effect, and drive the food to rotate at a uniform speed during baking, so that The food is baked more evenly. Infrared heating and hot air are used for baking, which improves the baking efficiency, effectively reduces shock, improves stability, and improves the efficiency of heat use, avoids heat loss, and saves energy.

Owner:湖南鸣腾智能科技有限公司

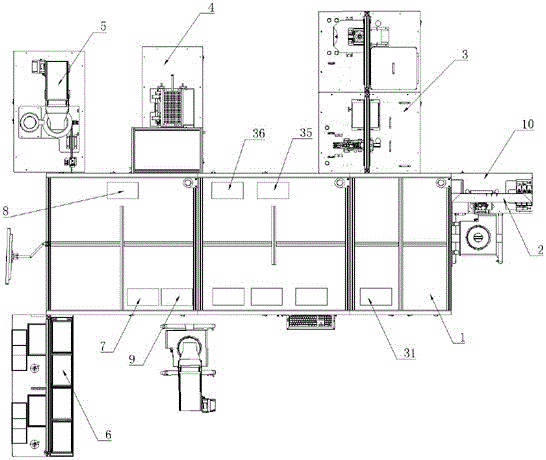

Automatic gas valve assembly line

ActiveCN105773132AImprove production and assembly efficiencyImprove detection accuracyMeasurement devicesAssembly machinesClosed loopEngineering

The invention discloses and provides an automatic gas valve assembly line. By the adoption of the automatic gas valve assembly line, automatic assembly and detection integration of gas valves can be achieved, and the production and assembly efficiency and the detection accuracy of the gas valves are effectively improved. The automatic gas valve assembly line comprises a frame body, an assembly part and a detection part, wherein the assembly part and the detection part are arranged on the frame body. A connection conveying belt is arranged between the assembly part and the detection part. A closed-loop conveying belt is arranged in the assembly part. The assembly part comprises an inner spray nozzle assembly station, a valve core feeding station, a spring feeding station, a valve deck installation station and a screwing station. A valve body blowing-off station, a grease filling station and a grease uniform-rotation station are arranged between the inner spray nozzle assembly station and the valve core feeding station as well as between the valve core feeding station and the spring feeding station correspondingly. A spring detection station and a screw detection station are further arranged beside the screwing station. An LP spray nozzle installation station is arranged in the position of the connection conveying belt. A comprehensive detection device is arranged on the detection part.

Owner:COPRECI COMPONENT ZHUHAI CO LTD

Automatic rotating paint-spraying suspension device

InactiveCN104209210ASmooth rotationHarm reductionSpraying apparatusClassical mechanicsStructural engineering

The invention discloses an automatic rotating paint-spraying suspension device and belongs to the field of paint spraying. The device comprises a bracket, a guide rail and a pothook, wherein the guide rail is connected with the pothook through a rotating mechanism; a driving belt, a spring adjusting rod and a lateral plate are arranged on each of two sides of the rotating mechanism; the driving belts are fixed on the lateral plates through the spring adjusting rods; the lateral plates are fixed on the bracket. The rotating mechanism is connected between the pothook and the guide rail and the driving belts are used for rubbing the rotating mechanism to rotate, so that the paint-spraying pothook is rotated at a uniform speed, the paint-spraying efficiency and the paint-spraying quality are increased, and the harm to a human body caused by near-distance paint-spraying is reduced.

Owner:ANQING TIANRUN ENG MACHINERY

Noncontact type automatic detection method and device for drum-shaped workpiece shape and position dimension

InactiveCN101078617ASimple structureEasy to installUsing subsonic/sonic/ultrasonic vibration meansUniform rotationMachining process

The invention relates to a non-contacting automatic measuring method for shape and position dimension of cylinder part and the device. The problem that because measuring accuracy for part pipe wall is influenced by human factor in process for cylinder part production qualification ratio is low. The method is that the measuring base point is determined and multiple measuring sections on the outer surface of measuring part are labeled; measuring part is fixed on the chuck of lathe and it is controlled to rotate in constant speed; ultrasonic coupling medium sprays to measured surface continuously and evenly; ultrasonic probe is adjusted to aim at multiple measuring sections so that ultrasonic emitted by said ultrasonic probe rips into measuring surface vertically; according information collected by encoder rotating angle of measuring section, corresponding surface information and wall thickness information is measured and recorded; outer surface information and wall thickness information of multiple measuring sections are stated and analyzed. The measuring method and the device in invention can be widely applied in measuring and machining process of prior cylinder part.

Owner:HARBIN INST OF TECH

Engineering machine and controlling method and controlling system for engineering machine

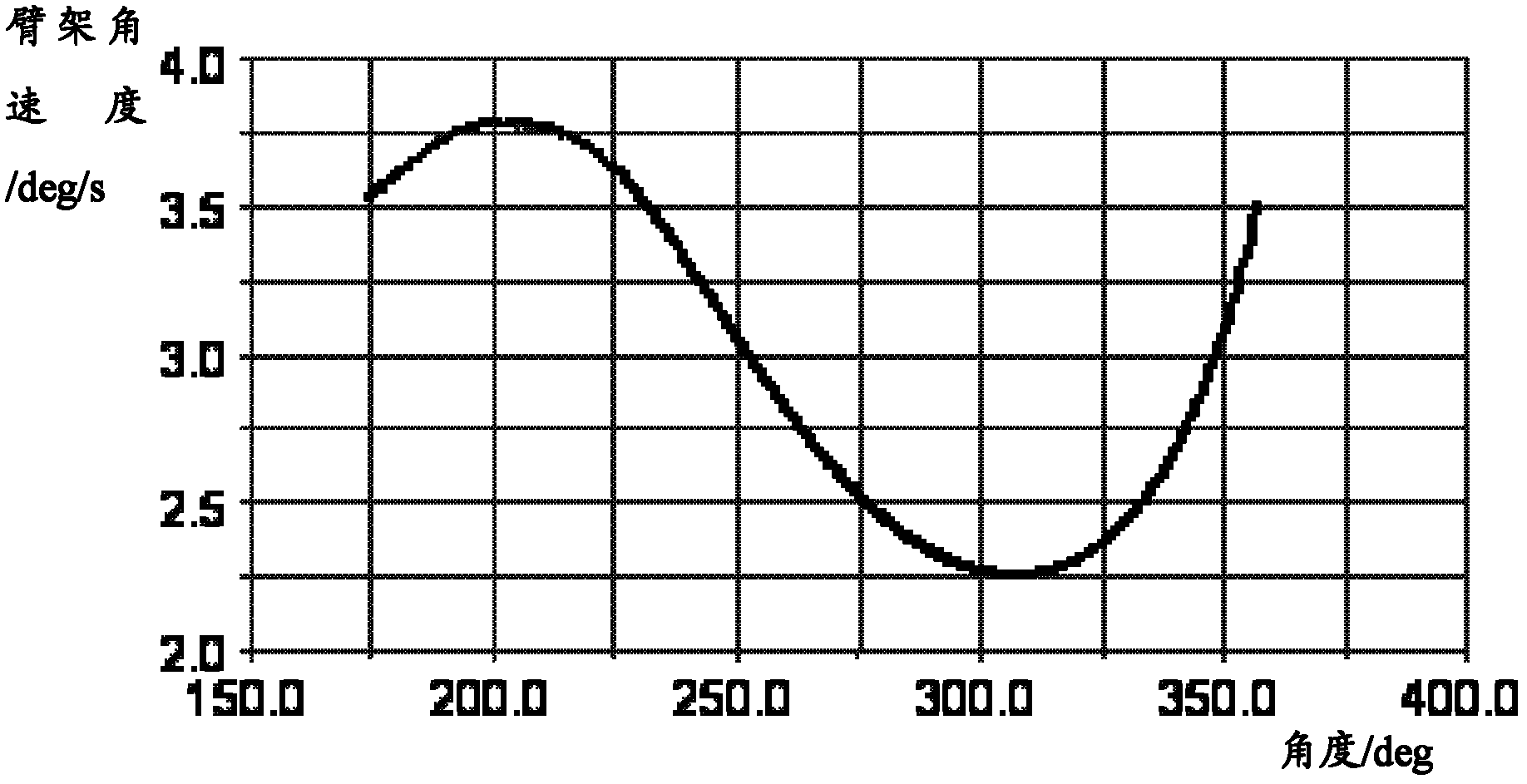

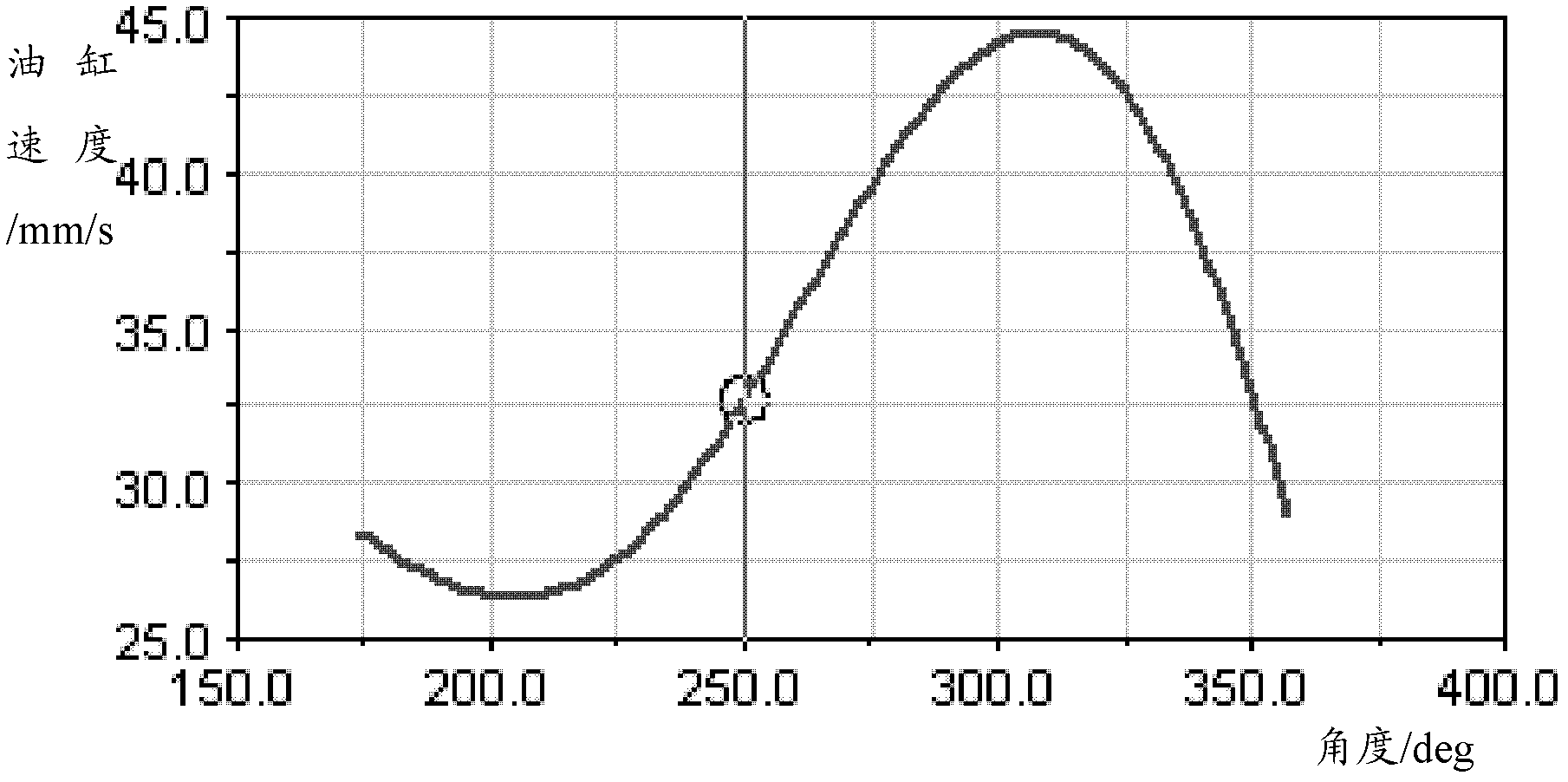

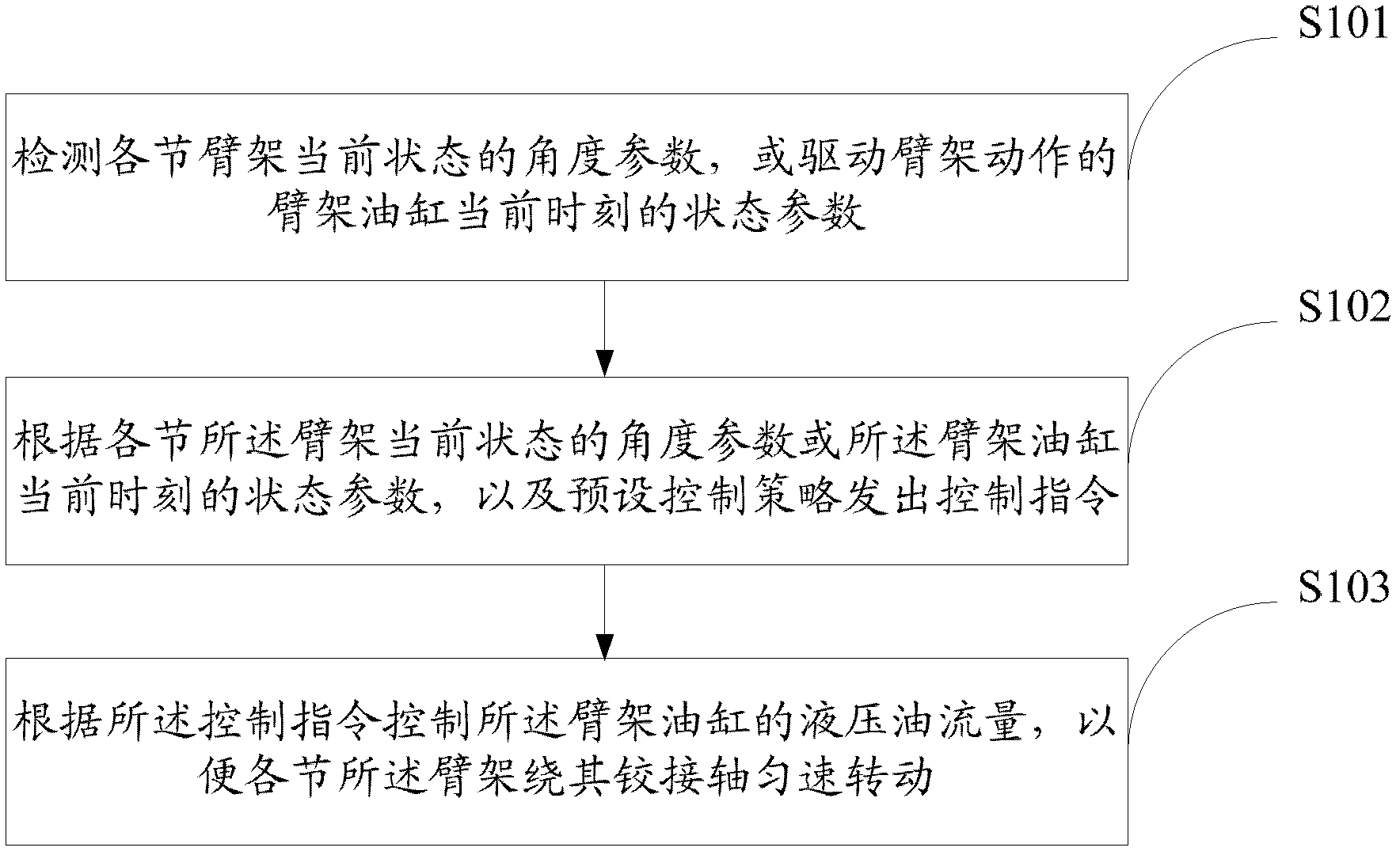

ActiveCN102566598AStretch at a constant speedUniform retractionControl using feedbackBuilding material handlingState parameterControl system

The invention discloses an engineering machine and a controlling method and a controlling system for the engineering machine. The engineering machine comprises n sections of arm supports sequentially hinged through hinged shafts. The controlling method comprises the following steps of: detecting the angle parameter of each arm support in the current state or the state parameter of an arm support cylinder for driving the arm supports to move at the current moment; sending a control instruction according to the angle parameters in the current state or the state parameter of the arm support cylinder at the current moment and a preset control strategy; and controlling hydraulic oil flow of the arm support cylinder according to the control instruction, so that each arm support uniformly rotates around the corresponding hinged shaft. By the controlling method, the hydraulic oil flow of the cylinder for driving the arm supports to move can be adjusted in real time, and uniform rotation of the arm supports is realized; the controlling method is relatively high in control precision and easy to implement; and a hydraulic element is not required to be added, and the control program can be directly improved in the conventional hydraulic system, so that the reformation cost is reduced.

Owner:SANY AUTOMOBILE MFG CO LTD

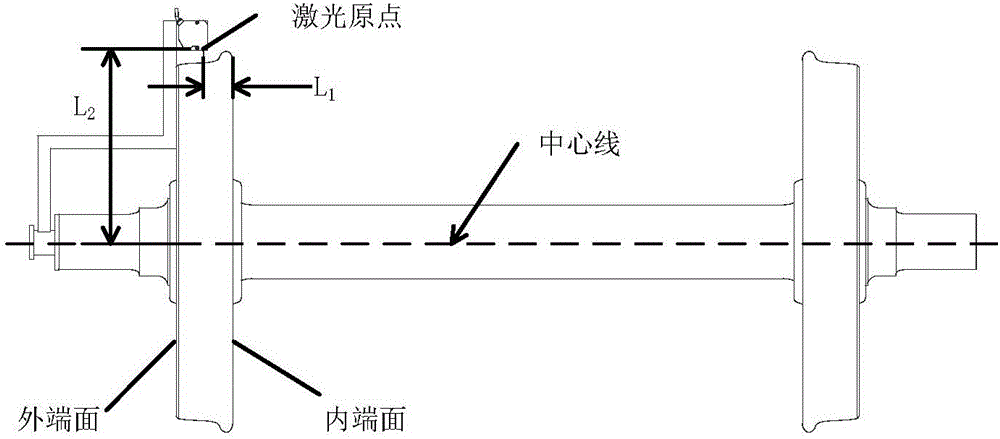

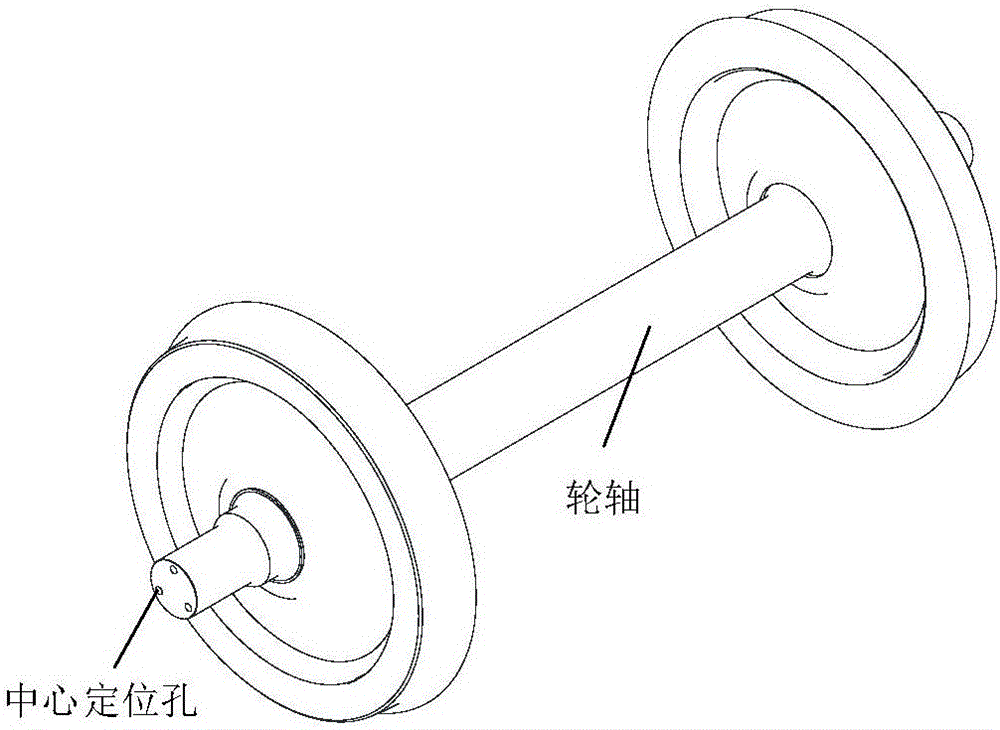

Dropping wheel type wheel out-of-roundness measurement device and method

InactiveCN106225716ASimple structureEasy to carryUsing optical meansRailway auxillary equipmentMeasurement deviceEngineering

The invention discloses a dropping wheel type wheel out-of-roundness measurement device and method. The device comprises a positioning device, an end cover, a sensor bracket and a laser displacement sensor, wherein the positioning device is provided with three locating pins to position the center of a circle of a wheel; the sensor bracket is of a step shape and comprises longitudinal beams of which two ends are in parallel, and a cross beam used for vertically connecting the longitudinal beams, wherein the tail end of one longitudinal beam is fixedly connected with the positioning device, the other longitudinal beam is tightly attached to the outer end surface of the wheel, and the tail end of the longitudinal beam is provided with a laser displacement sensor; the end cover and the positioning device are connected through a thread, and a distance between the laser original point of the laser displacement sensor and the inner end surface of the wheel is L1; the distance between the center axis of the positioning device and the laser original point is L2. The wheel rotates for one circle at a constant speed under the driving of external force, and a rolling circle on a wheel tread is subjected to polynomial fitting so as to determine the wheel out-of-roundness situation. The device is simple, convenient in carrying and low in cost, the out-of-roundness measurement can be carried out on the wheel under a dropping wheel situation, and a technical basis is provided for the spinning repair of the wheel.

Owner:NANJING UNIV OF SCI & TECH

Preparation of polyvinyl fluoride thin film by solution casting method

InactiveCN101168296AImproving the method of cast film productionHigh film forming rateFlat articlesCoatingsEvaporationPolyvinyl chloride

The invention relates to a formula and technique for preparing polyvinyl fluoride thin film by using liquor flowing and extending method, wherein the technique comprises dissolving the polyvinyl fluoride in a strong polar solvent to be a dilute solution which is used as primary liquid for preparing films, then flowing and extending the primary liquid for preparing films from the machine gap after filtering and de-aerating, or coating the primary liquid on a dry roller which is continuously heated and rotates in uniform speed or on a steel belt via a roll-type coater, to form film, or using the roller which is continuously heated and rotates in uniform speed, to dip in the liquor for forming film, finally releasing film rapidly after evaporation of the solvent. The forming, drying and shaping are simultaneously carried through in the process of film preparation, the rate of filming is high, and the efficiency is high, the filming apparatuses which are fit for filming are many, the filming technique is simple and flexible, the thin film has good setting-out level and flat degree, homogeneous thickness and high extending degree.

Owner:BEIJING UNIV OF CHEM TECH

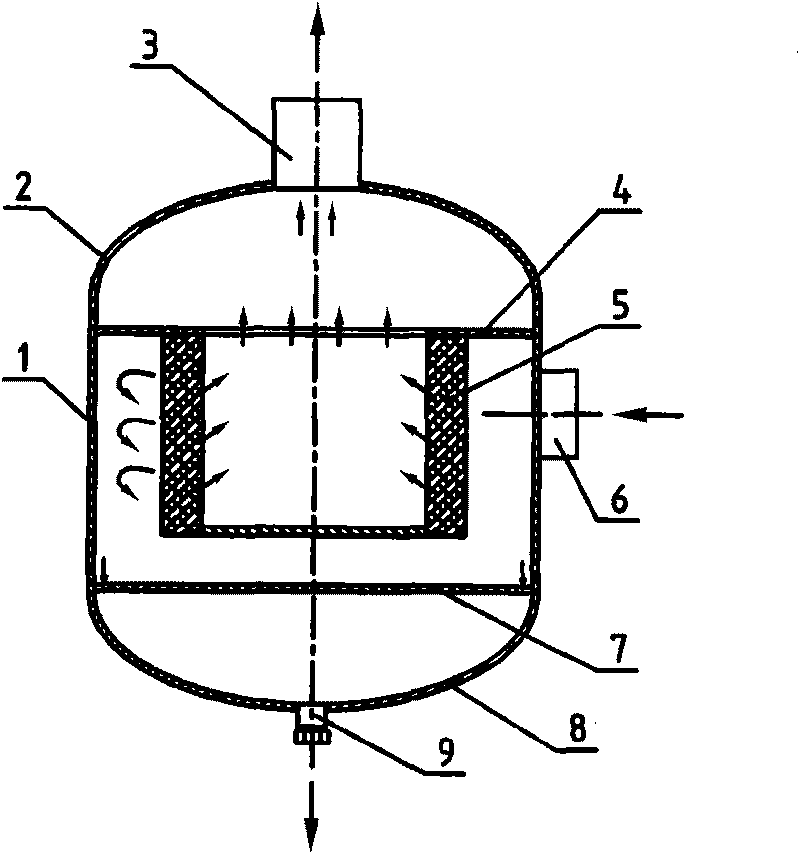

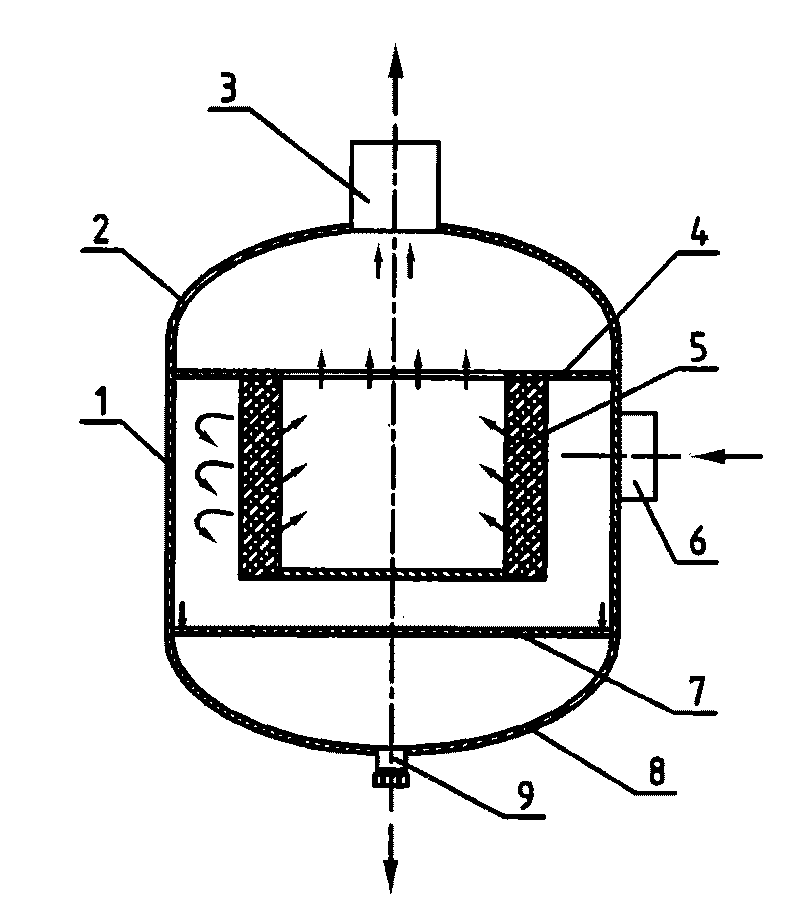

High-efficiency vertical oil separator device and using method

ActiveCN101738034AEasy to separateImprove energy efficiencyRefrigeration componentsUniform rotationCentrifugal force

The invention relates to a high-efficiency vertical oil separator device and a using method. Oil separators commonly adopted at present have large volume and poor oil and gas separation effect. The invention has the technical scheme that oil and gas are totally separated by rotating centrifugal force and fine filtering action; the high-efficiency vertical oil separator device is composed of a cylinder, an upper end socket, an escape pipe, a fixing plate, a fine filtering body, an intake pipe, an oil seal plate, a lower end socket and a return opening, wherein the intake pipe is welded on the outer side surface in the middle of the cylinder along the tangential direction to ensure that gaseous phase mixture of refrigerant and refrigeration oil can rotate at a constant speed along the radial tangential direction of the inner wall of the cylinder; centrifugal force causes oil and gas to be totally separated. The invention has the beneficial effect that the technical scheme of rotary centrifugal force and fine filtering stepping separation is used for secondary total separation of the gaseous phase mixture of refrigerant and refrigeration oil so as to ensure full oil and gas separation process. The high-efficiency vertical oil separator device has simple integral structure, reduces volume, improves oil and gas separation effect for 10-15% if compared with the existing oil and gas separator and lowers energy consumption.

Owner:SHANGHAI HUANQIU REFRIGERATION EQUIP

Walking track base backscattering imager

ActiveCN105403926AImprove the protective effectAvoid harmNuclear radiation detectionX-rayRoad surface

The invention discloses a walking track base backscattering imager, which comprises a shielding shell, a detector, an X ray machine, a drum, a drum driving device, and a driving control device, wherein the bottom part of the shielding shell is provided with a turntable track base, and the turntable track base is internally provided with a base driving device driving the turntable track base to drive the shielding shell to rotate and move and a driving part; the detector is arranged at one side inside the shielding shell for acquiring an image and processing the image into a complete image; the X ray machine is arranged inside the shielding shell and located beside the detector, and the light-emitting face of the X ray machine faces the detector; the drum covers the light-emitting face of the X ray machine and rotates around the light-emitting face of the X ray machine, a light outgoing port is arranged on the drum, and the light outgoing port is corresponding to the detector; the drum driving device is connected with the drum for driving the drum to rotate at a constant speed; and the driving control device respectively controls the base driving device and the drum driving device. The imager has the advantages that the detection area is large; a wall can be detected; operation on a wild rugged road surface can be realized; the detector can be rotated to image a fan-shaped area; and X rays can be well protected.

Owner:PURPLE SQUARE TECH

Rotatable roasting supporter

The invention discloses a rotatable roasting supporter. The roasting supporter comprises roasting boards formed by arranging a grill frame and multiple roasting anvil bars in the roasting frame, wherein the roasting boards are provided with an upper layer and a lower layer, and the two layers of roasting boards are movably connected with each other, so that the two layers of roasting boards can be unfolded and folded; and two opposite sides of the grill frame are provided with rotating shafts. When the roasting frame is used, food is fixed between the two layers of the roasting frame, the rotating shaft can be connected with a rotating motor, and the roasting frame is driven to rotate for roasting by the motor, so that the food can rotate at a constant speed on the roasting frame and be heated completely and uniformly at the angle of 360 degrees, the roasting function can be improved comprehensively, the roasting effect can be strengthened, and the operation can be simplified; simultaneously, the roasting frame can ensure that the relative position between the two layers of roasting boards is stable, is difficult to deform, is safely used, can be used independently, can be used in all types of roasting equipment, and has a wide application range.

Owner:WHIRLPOOL CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com