Sensing fiber used in reflective all-fiber current sensor

A technology of current sensor and sensing fiber, applied in the direction of cladding fiber, optical waveguide light guide, voltage/current isolation, etc., can solve the problems of low utilization rate of equipment, waste of resources, reduced rotation speed, etc., to improve the yield, manufacture The effect of cost reduction and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below according to the drawings:

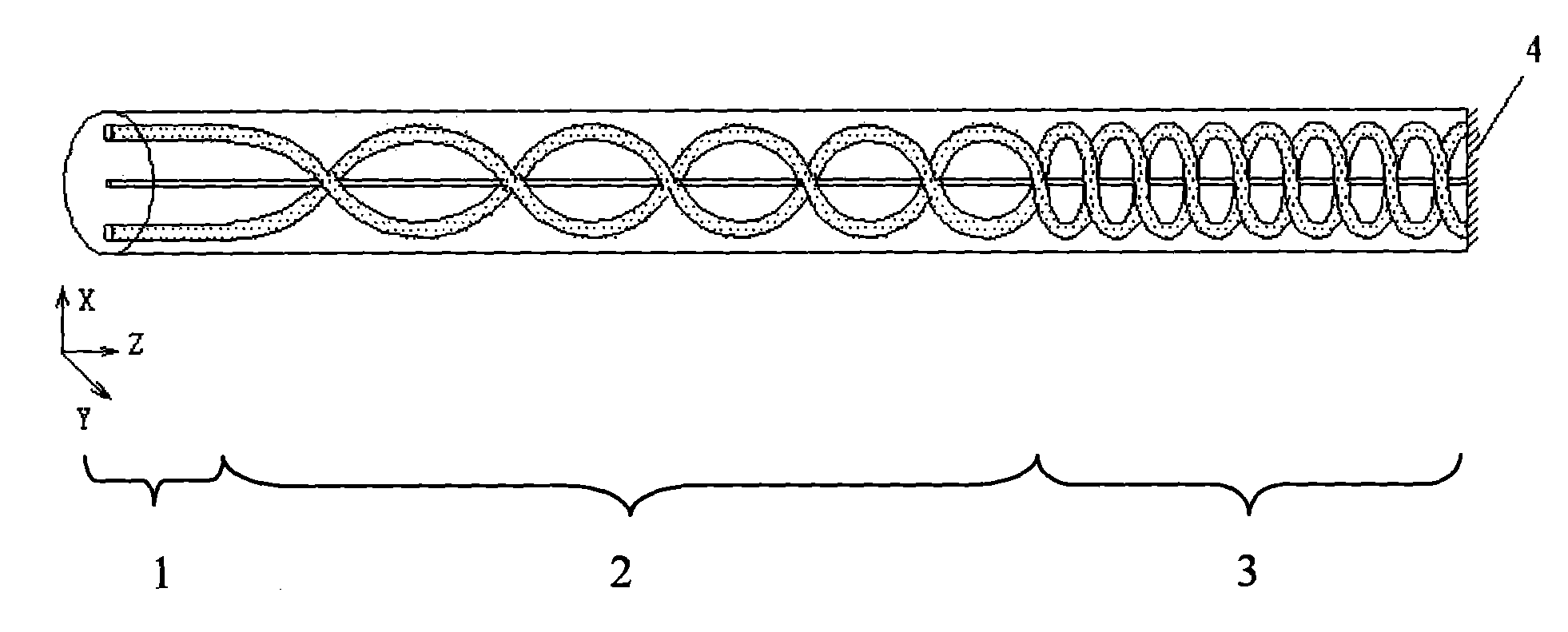

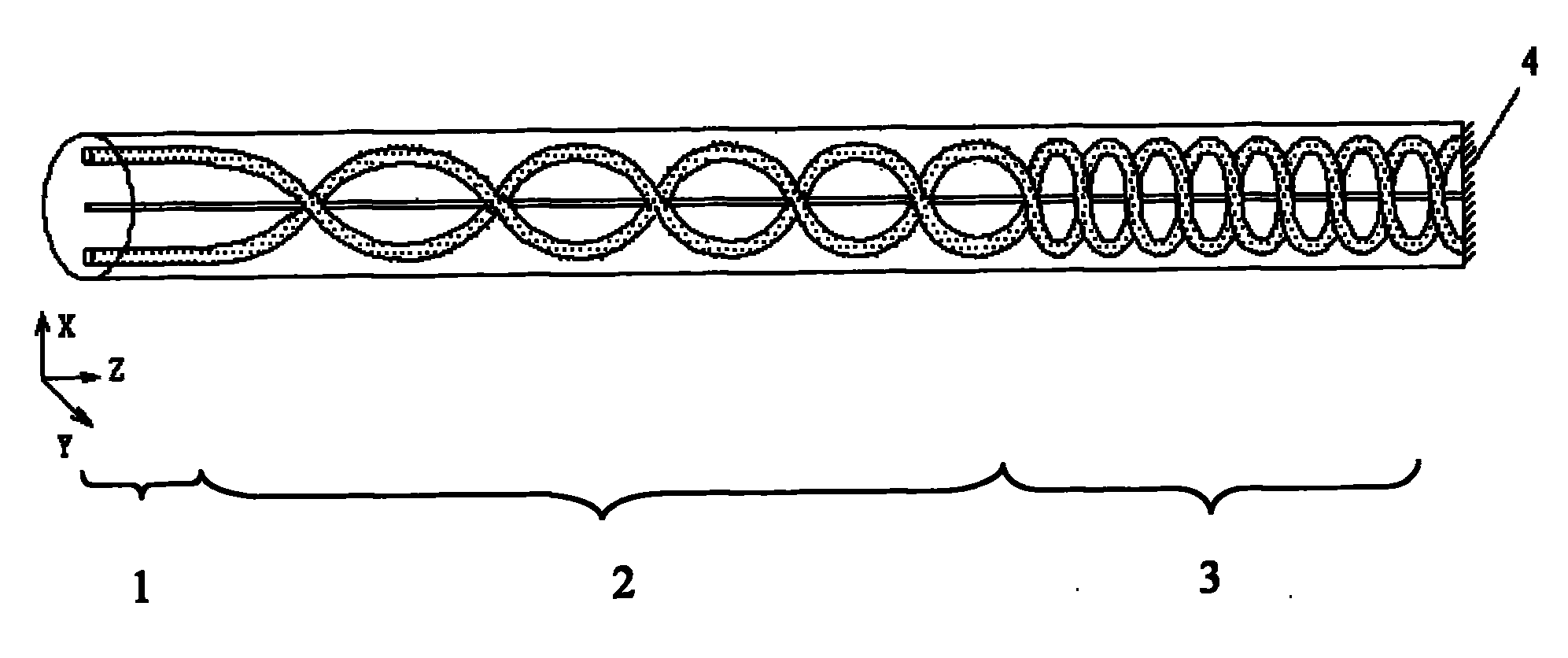

[0025] Such as figure 1 As shown, the sensing fiber used in the reflective all-fiber current sensor includes the non-rotating section 1, the spinning section 2 and the uniform rotating section 3 in the online polarization maintaining fiber. The end surface of the uniform rotating section 3 is plated with reflection 膜4。 Film 4.

[0026] The non-rotating section 1 of the linear polarization-maintaining optical fiber is used for butt-welding with the transmission line polarization-maintaining optical cable. Its length is arbitrary, as long as it can be welded. The spin-off section 2 is the optical fiber that starts to rotate at a constant speed when it is melted. The length of this section of optical fiber is usually a few centimeters to ten centimeters. The uniform-speed rotating section of the optical fiber 3 basically maintains a uniform rotation, and its length is generally 1-3 meters; the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com