Laser texturing processing method on surface of roller

A technology of laser texturing and processing method, applied in the direction of keeping the roll equipment in an effective state, laser welding equipment, metal rolling, etc., can solve problems such as affecting the appearance quality, improve appearance quality, prolong service life, and improve rolling quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

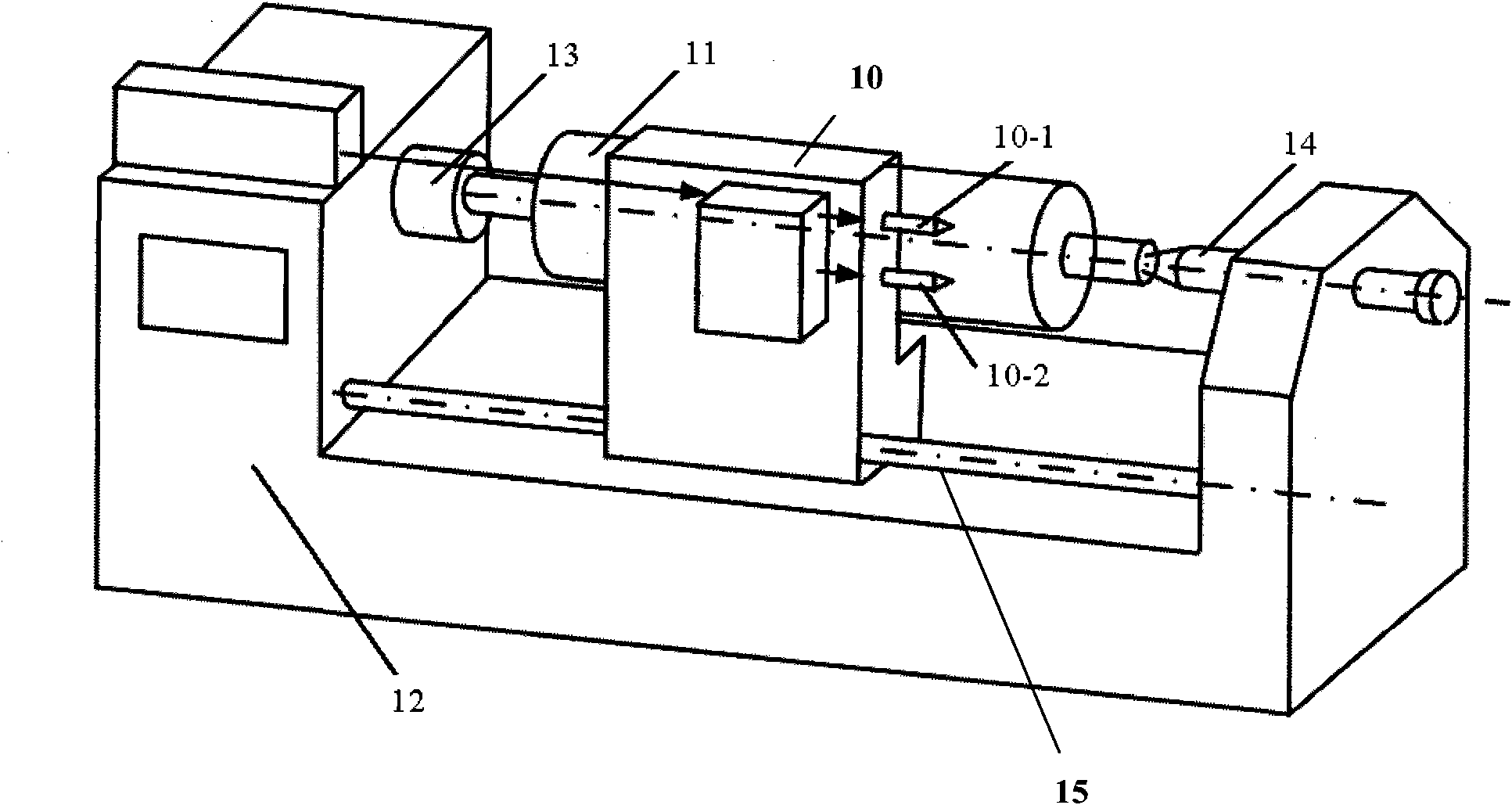

[0029] Embodiment 1: The laser roughening treatment method of this roll surface provided by the present embodiment still adopts such as figure 1 The existing laser texturing equipment shown is completed. The laser texturing equipment is composed of a laser and a numerically controlled machine tool 12. On the bed of the numerically controlled machine tool 12, a headstock and a tailstock are respectively installed oppositely. The rotating shaft 13 for the roll 11 to rotate, and the top 14 for pressing the roll 11 is arranged on the tailstock. Simultaneously, a translation guide rail 15 parallel to the rotation axis 13 is provided on the bed, a supporting plate is fixed on the translation guide rail 15, and a laser texturing head 10 is placed on the supporting plate; the laser texturing head 10 is provided with a first And the second two focusing heads 10-1, 10-2.

[0030] The specific texturing process is as follows: the roll 11 is placed on the rotating shaft 13 of the CNC mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com