Patents

Literature

98results about How to "Improve thermal cracking resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Impact-resistance double-roller roughing roll and manufacturing method thereof

InactiveCN101974723AQuality improvementExtended roll lifeFurnace typesRollsChemical compositionMetallurgy

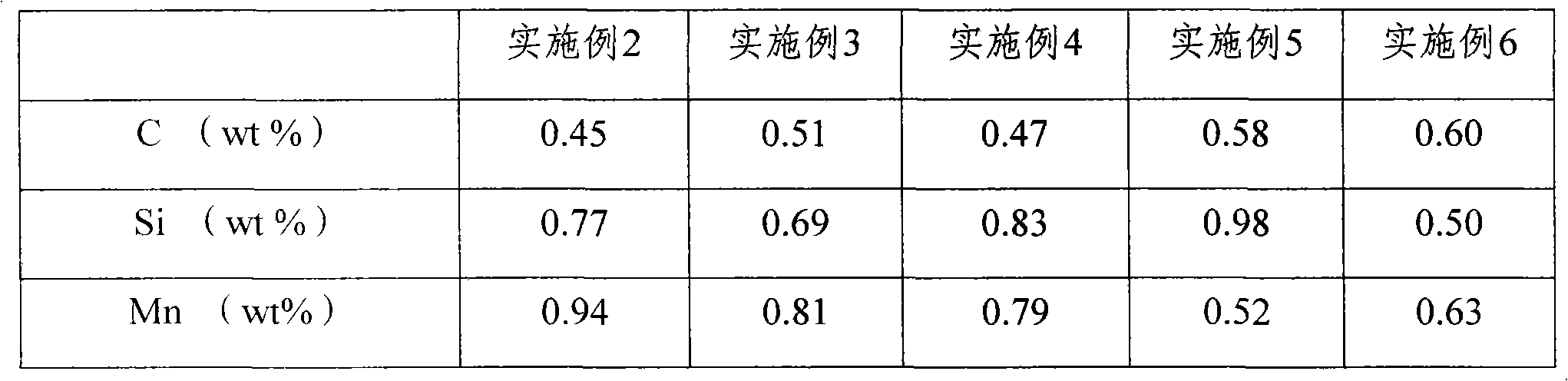

The invention discloses an impact-resistance double-roller roughing roll, comprising the following chemical compositions in percentage by weight: 0.30-0.65% of C, 0.35-1.20% of Si, 0.30-1.00% of Mn, 3.00-5.50% of Cr, 0.30-1.20% of Ni, 0.50-1.50% of Mo, 0.20-2.00% of V, less than or equal to 0.02% of S and less than or equal to 0.02% of P, and the balance of Fe and unavoidable impurities. The surface hardness of the double-roller roughing roll of the invention is 65-75HSD and the double-roller roughing roll has the characteristics of fine high temperature impact resistance property, thermal fatigability resistance and abrasive resistance.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

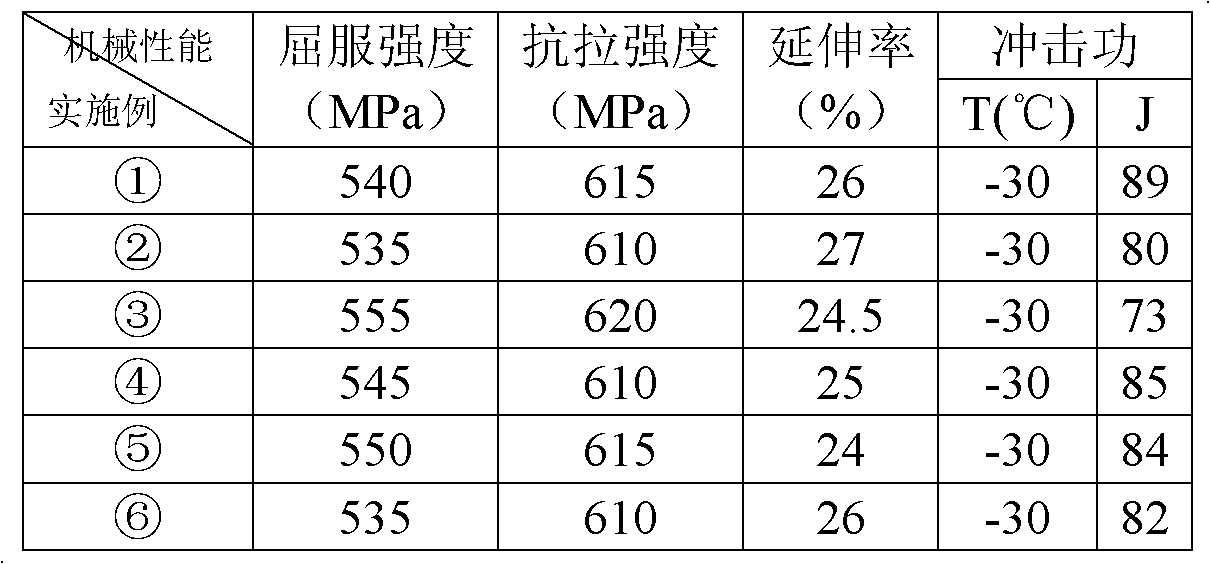

High-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire

ActiveCN102528332AIncrease coverageArc stabilizationWelding/cutting media/materialsSoldering mediaHydrogen contentMetal

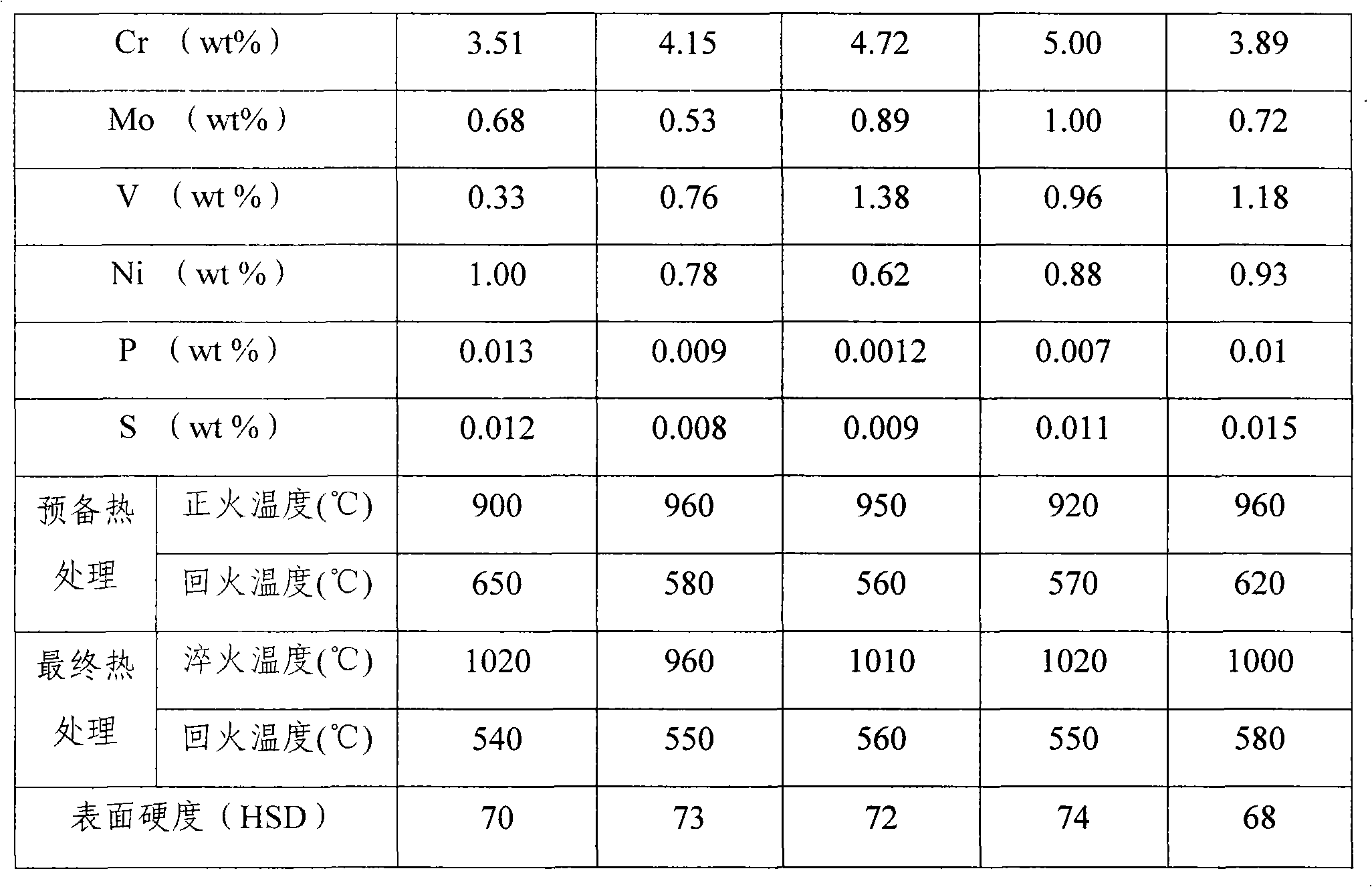

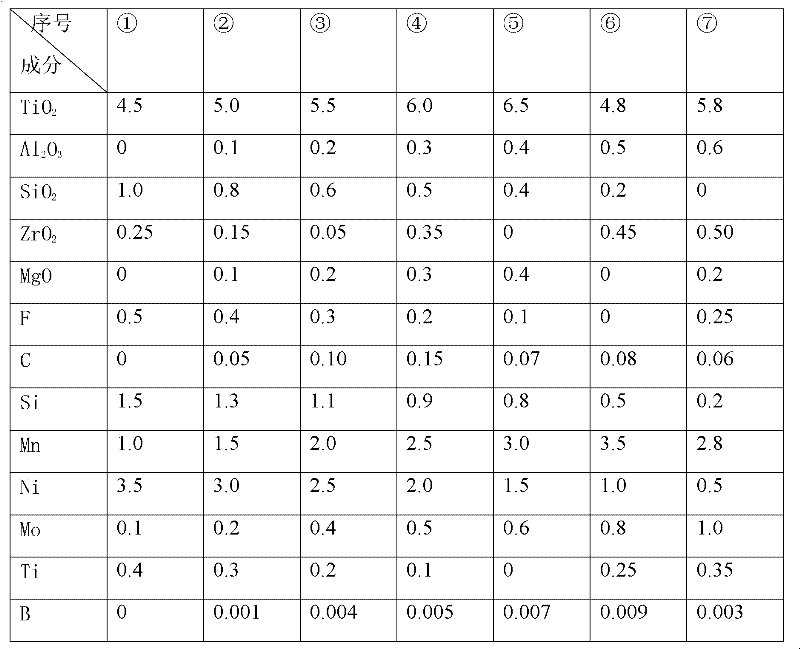

The invention discloses a high-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire, which comprises the following components in percentage by mass (based on total mass): 4.5-6.5% of TiO2, 0-0.6% of Al2O3, 0-1% of SiO2, 0-0.5% of ZrO2, 0-0.4% of MgO, 0-0.5% of F, 0-0.15% of C, 0.2-1.5% of Si, 1.0-3.5% of Mn, 0.5-3.5% of Ni, 0.1-1.0% of Mo, 0-0.4% of Ti and 0-0.009% of B. The cold-rolled steel strip for preparing the flux-cored wire comprises the following chemical ingredients by weight content: not more than 0.02% of C, not more than 0.010% of P, and not more than 0.008% of S. The tensile strength of the deposited metal can reach more than 760MPa, the low-temperature impact at -60 DEG C achieves more than 47J, and the diffusible hydrogen content is smaller than 4mL / 100g ( mercury method); and the flux-cored wire has excellent welding operational performance, and is suitable for port machines, ocean platforms, bridges and the like.

Owner:KUSN GINTUNE WELDING

High-strength heat-resistant aluminum alloy suitable for large-size complex structure castings and preparation process

ActiveCN108251724AImprove thermal cracking resistanceOvercoming the problem of insufficient thermal cracking resistanceHeat resistanceSolid solution

The invention relates to a high-strength heat-resistant cast aluminum alloy material and a preparation process thereof which are suitable for casting large-size castings. A high-strength heat-resistant cast aluminum alloy comprises, by mass, 6.0-7.7% of Cu, 0.6-1.7% of Ag, 0.10-0.38% of Mg, 0.2-0.5% of Mn, 0.10-0.35% of V, 0.05-0.15% of Ti, no less than 15% and no more than 60% of Cu / Mg ratio, nomore than 0.06% of Fe, no more than 0.06% of Si, and the balance Al and other unavoidable impurity elements. The preparation process includes smelting and casting of the alloy and solid solution agingheat treatment of the castings. According to the high-strength heat-resistant cast aluminum alloy material and the preparation process thereof, the large-size castings with good heat resistance, roomtemperature mechanical properties and cutting machining properties can be casted.

Owner:CENT SOUTH UNIV

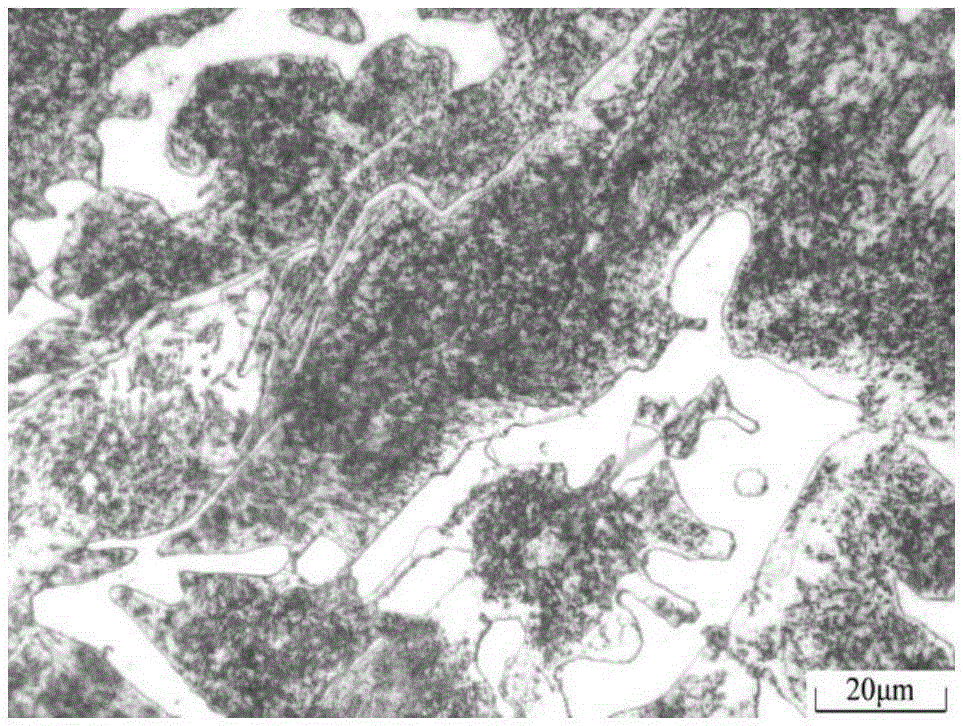

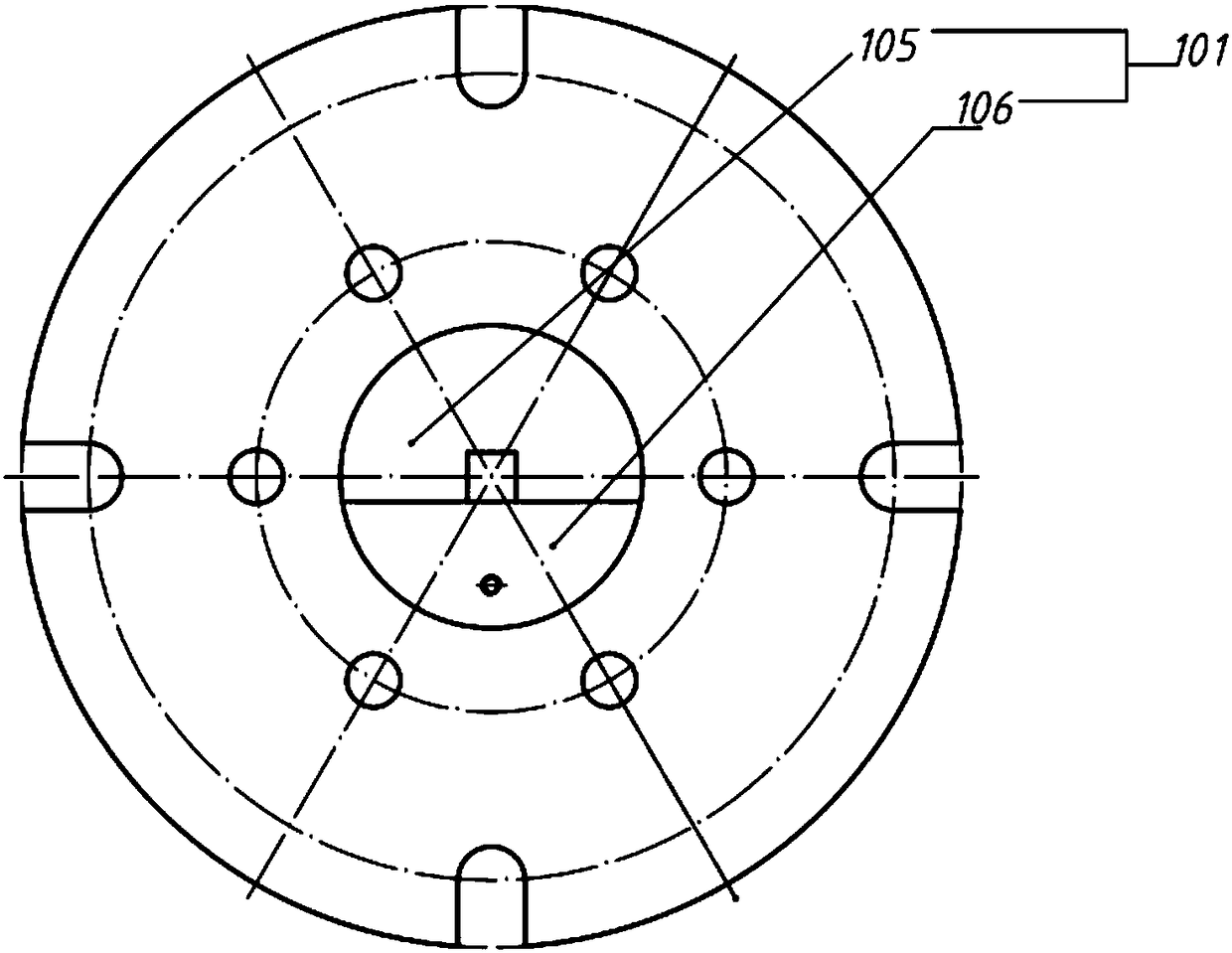

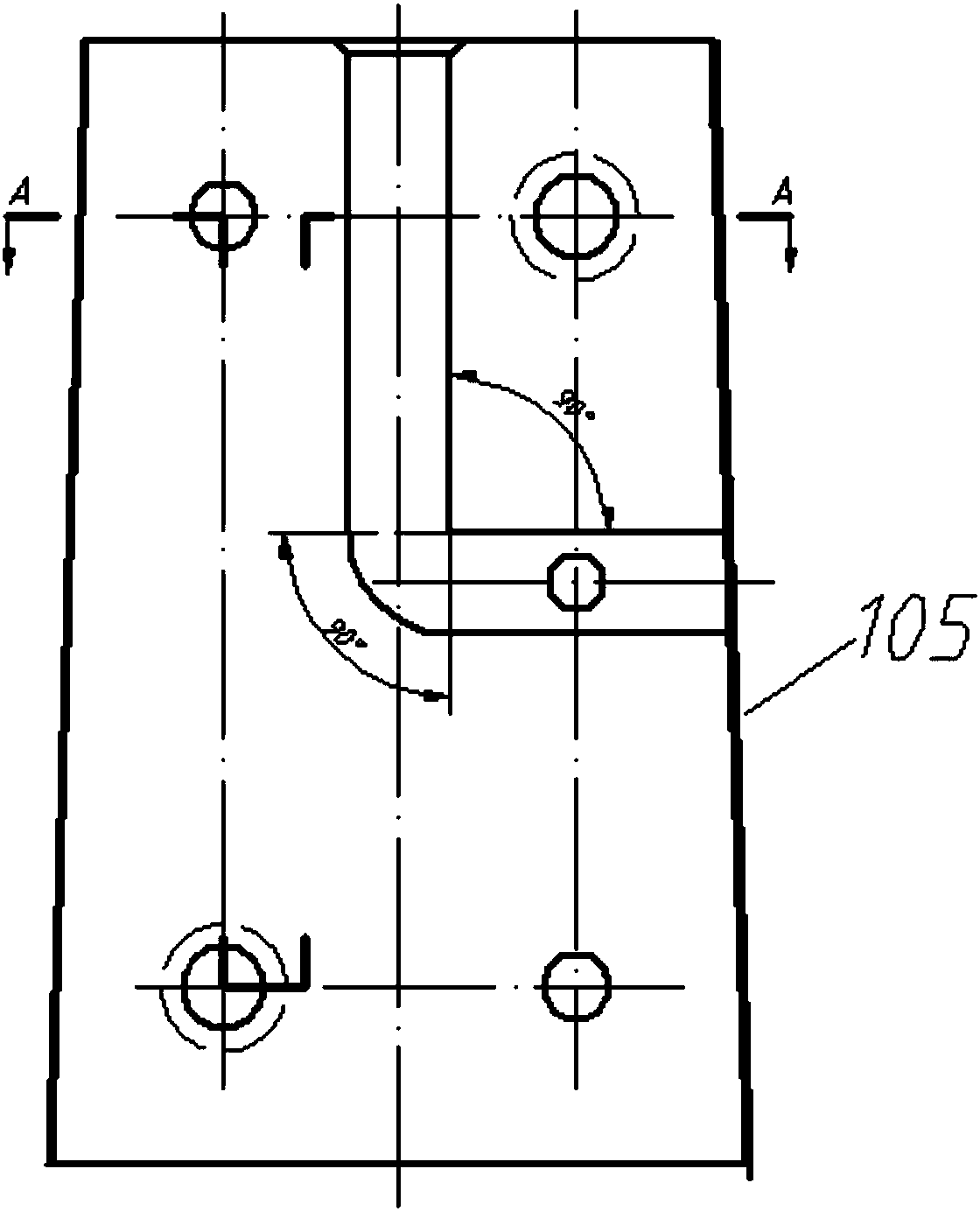

Universal type steel ball unthreaded ball iron roller ring and manufacturing method thereof

The invention discloses a universal type steel ball unthreaded ball iron roller ring which comprises an outer layer and an inner core. The proportion between the outer layer and the inner core is 2:1. The alloy component of the outer layer comprises, by weight, 3.0-3.5% of C, 1.2-2.0% of Si, 0.5-1.2% of Mn, 0.1% or less of P, 0.02% or less of S, 0.2-1.0% of Cr, 0.5-1.5% of Ni, 0.2-1.0% of Mo, and the balance Fe and inevitable impurities. The alloy component of the inner core comprises, by weight, 1.0-1.5% of C, 1.3-1.7% of Si, 0.5-1.0% of Mn, 0.08% or less of P, 0.03% or less of S, 0.5% or less of Cr, 0.3% or less of Ni, 0.13% or less of Mo, and the balance Fe and inevitable impurities. A manufacturing method comprises the steps of A, smelting, B, inoculation and spheroidizing, and C, casting. By means of the universal type steel ball unthreaded ball iron roller ring and the manufacturing method thereof, the hardness fall of rollers can become small, the steel adhesion tendency is relieved, and the comprehensive using performance of the roller ring is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Hot roll for rolling titanium plate and manufacturing method of hot roll

The invention discloses a hot roll for rolling a titanium plate, and a manufacturing method of the hot roll. The hot roll comprises the following chemical constituents in percentage by weight: 0.30-0.50% of C, 0.60-2.00% of Si, 0.20-1.00% of Mn, 4.50-6.00% of Cr, 0.05-0.65% of Ni, 1.00-2.00% of Mo, 0.50-1.50% of V, less than or equal to 0.025% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. The manufacturing method of the hot roll for rolling the titanium plate comprises the processing steps of steel ingot refining, roll blank forging, thermal refining, induction quenching treatment, tempering treatment and the like. Compared with the traditional hot roll made of a Cr3 material, the hot roll is good in abrasive resistance, corrosion resistance and thermal crack resistance, and the service life of the hot roll can be prolonged by above 70%.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

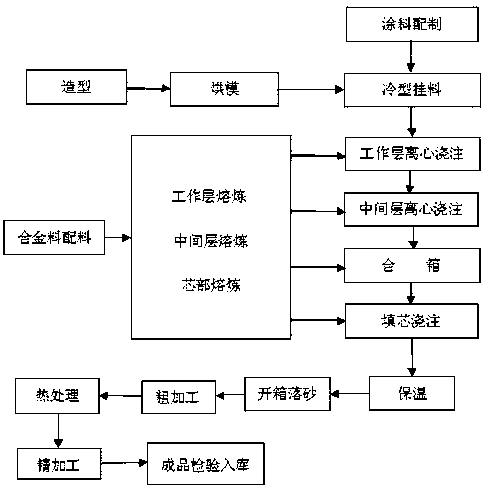

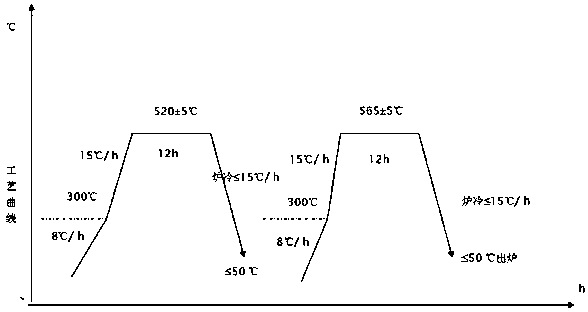

Wear-resistant high-chromium cast iron centrifugal composite roller for ribbon steel two-roller mill and production process

ActiveCN107779733AStress reliefImprove wear resistanceFurnace typesRollsSocial benefitsWear resistant

The invention discloses a wear-resistant high-chromium cast iron centrifugal composite roller for ribbon steel two-roller mill and a production process. The roller comprises a three-layer centrifugalcomposite structure, a working layer is made of high-chromium cast iron, a middle transition layer is made of graphitic steel, and a roller core portion is made of spheroidal cast iron. The productionprocess includes processes of molten iron modification, centrifugal casting and thermal treatment, wherein the thermal treatment process refers to adopting two sections of stress relief annealing thermal treatment processes. Through reasonable composition design, molten iron modification, special centrifugal casting and thermal treatment, wear resistance and thermostability of the roller are improved remarkably. The roller is safe and reliable to use; compared with common nickel chromium molybdenum infinitely chilled spheroidal cast iron centrifugal rollers, production cost of the roller is reduced by 10-20%, rolled total amount of steel can reach 2-3 times, and the roller has remarkable economic and social benefit when being popularized and applied and can completely replace the common nickel chromium molybdenum infinitely chilled spheroidal cast iron centrifugal rollers.

Owner:唐山钢铁集团重机装备有限公司 +2

Thermal cracking resistant hard sand

InactiveCN101941047AImprove adhesion and heat resistanceImprove thermal crack resistanceFoundry mouldsFoundry coresFuranOxide

The invention discloses thermal cracking resistant hard sand, which comprises raw sand, adhesive, curing agent, coupling agent and lubricating agent, wherein the using amount of the curing agent is 30 to 50 percent based on the using amount of the adhesive, the using amount of the coupling agent is 0.2 to 0.4 percent based on the using amount of the adhesive, the using amount of the adhesive is 2 to 5 percent based on the using amount of the raw sand, and the using amount of the lubricating agent is 1 to 3 percent based on the using amount of the raw sand; the adhesive consists of the following components in part by weight: 60 to 70 parts of furan resin, 20 to 30 parts of phenolic resin and 5 to 15 parts of tricresyl phosphate; and the raw sand comprises return sand, quartz sand, silica sand and ferric oxide powder. The thermal cracking resistant hard sand has the advantages of low brittleness, cracking resistance and low cost.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

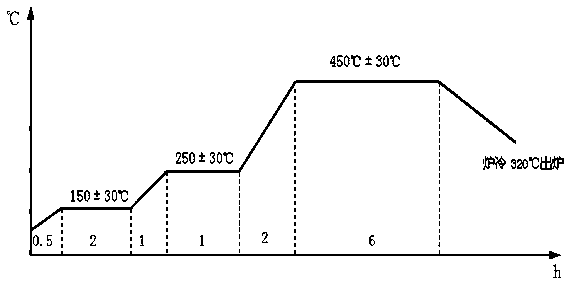

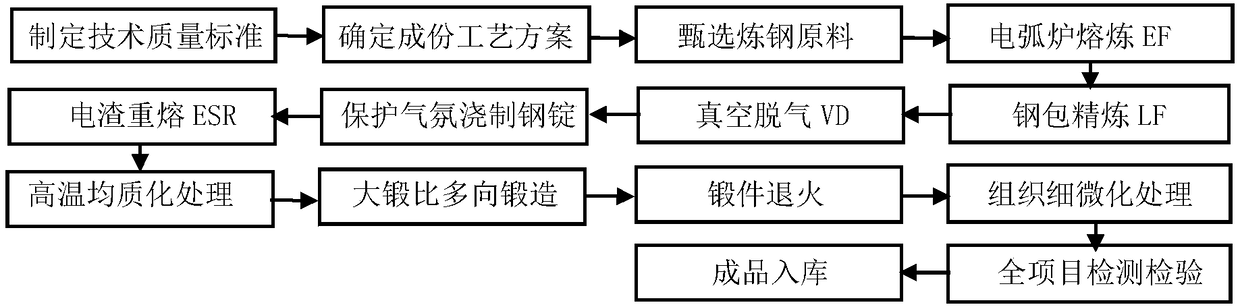

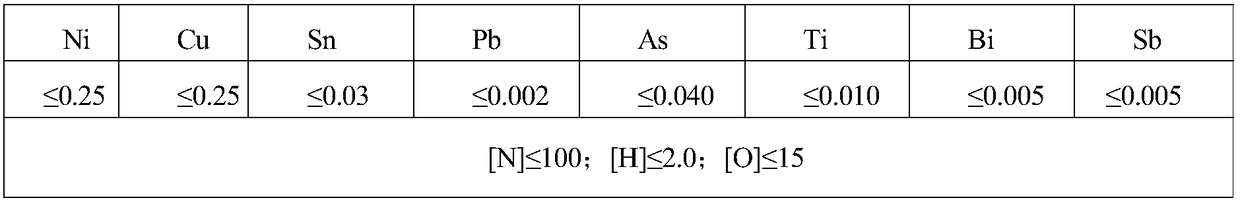

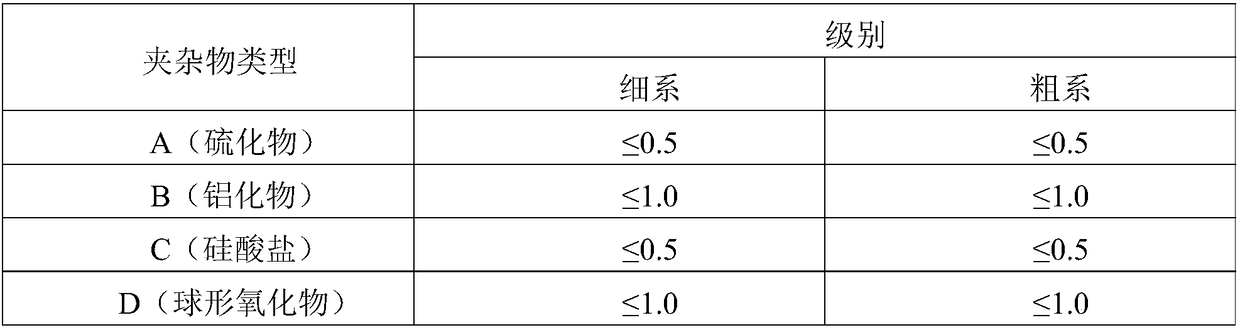

Special hot-stamping die steel HS7 and preparation method thereof

InactiveCN109402514AExcellent toughness and ductilityImprove performanceProcess efficiency improvementHot stampingCrack resistance

The invention discloses novel special hot-stamping die steel HS7 and relates to the technical field of die steel component formulas and manufacturing. The chemical components of the special hot-stamping die steel include, by weight, 0.41-0.45% of C, 0.45-0.55% of Si, 0.35-0.45% of Mn, 6.4-6.80% of Cr, 1.20-1.40% of Mo, 0.75-0.85% of V, 015% or below of P, 0.003% or below of S and the balance Fe and inevitable impurities and residual trace elements. The die steel adopts unique optimized alloy element proportion, the organization level of and purity degree of materials are greatly improved through refined smelting and multidirectional forging and combination with high temperature homogenizing, ultrafine processing and other processes, the key indicators of the hot-stamping die steel are obviously improved, including abrasion resistance, high temperature abrasion resistance, thermal fatigue cracking resistance, resistance to plastic deformation and the like. Therefore, improve the qualityof hot stamping dies can be obviously improved, the service life of the dies can be prolonged, and better economic benefits can be obtained.

Owner:上海合毓模具技术有限公司

Ultralow temperature steel nickel-based welding rod with core wire added with rare earth element and preparing method thereof

ActiveCN106363313APrevent oxidationAvoid consumptionWelding/cutting media/materialsSoldering mediaRare-earth elementNickel based

The invention relates to an ultralow temperature steel nickel-based welding rod with a core wire added with the rare earth element. The ultralow temperature steel nickel-based welding rod is formed by the core wire and a coating wrapping the surface of the core wire, the content of the rare earth element in the core wire ranges from 0.01% to 0.20% by weight, the rare earth element is at least one of Ce, Y and Nd, and the other components include, by weight, 55.0%-70.0% of Ni, 15.00%-19.00% of Cr, 4.50%-8.00% of Mo, 2.50%-4.50% of Mn, 1.50%-5.0% of Fe, 1.00%-3.00% of Nb, 0.50%-1.50% of W, 0.10%-0.30% of Cu, 0.20%-0.50% of Si and not larger than 0.05% of C. The invention further provides a preparing method of the above welding rod.

Owner:SICHUAN UNIV

High speed steel cold roller

InactiveCN104711486AImprove wear resistanceImprove red hardnessChemical compositionSurface roughness

The invention discloses a high speed steel cold roller. The high speed steel cold roller comprises, by mass, 0.6-1.0% of C, 0.5-1.0% of Si, 0.2-1.0% of Mn, 6.0-10.0% of Cr, 0.2-0.8% of Ni, 0.5-2.0% of Mo, 0.1-0.5% of W, 0.5-2.0% of V, 0.05-0.20% of Nb, and the balance of Fe and inevitable impurities. The surface hardness, the hardness uniformity, the neck tensile strength and the V notch impact work of the roller are 63-67HRC, 1.5HRC or less, 1200MPa or more and 20J or more respectively. The produced high speed steel cold roller has the advantages of strong surface roughness maintaining ability and good accident resistance when the high speed steel cold roller is used for rolling high strength steel plates, can be widely used in rough rolling and finish rolling frames of a cold rolled steel band rolling mill, and greatly improves working efficiency of the rolling mill.

Owner:YIXING YONGCHANG ROLL

Hot roll for rolling aluminium products and manufacturing method thereof

ActiveCN103436789AImprove wear resistanceGood thermal crack resistanceFurnace typesRollsAluminiumThermal treatment

The invention discloses a hot roll for rolling aluminium products and a manufacturing method thereof. The hot roll is prepared from the following chemical constituents in percentage by weight: 0.50-0.80% of C, 0.20-1.50% of Si, 0.20-1.00% of Mn, no more than 0.025% of P, no more than 0.025% of S, 4.50-6.00% of Cr, 0.50-2.00% of Mo, 0.10-1.00% of V and the balance of Fe and inevitable impurities. The manufacturing method for the hot roll for rolling aluminium products includes the technological steps of steel ingot refining, roll blank forging, hardening and tempering as well as machining, quenching thermal treatment, tempering and the like. The hot roll for rolling aluminium products, which is provided by the invention, has high wearing resistance, excellent hot cracking resistance and electrochemical corrosion resistance, and the service life of the hot roll is prolonged by 50% above in comparison with that of a common hot roll made of Cr3 material.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

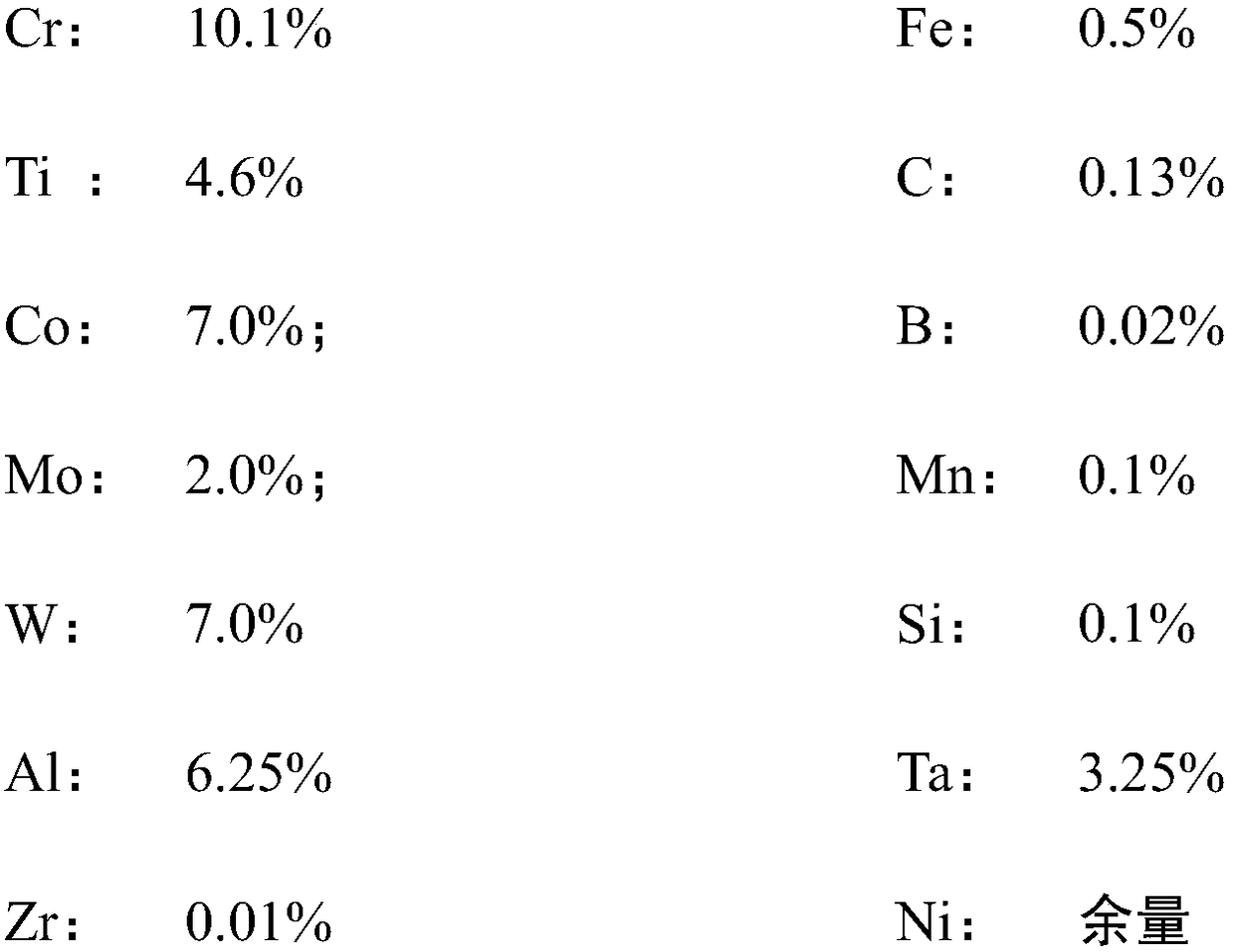

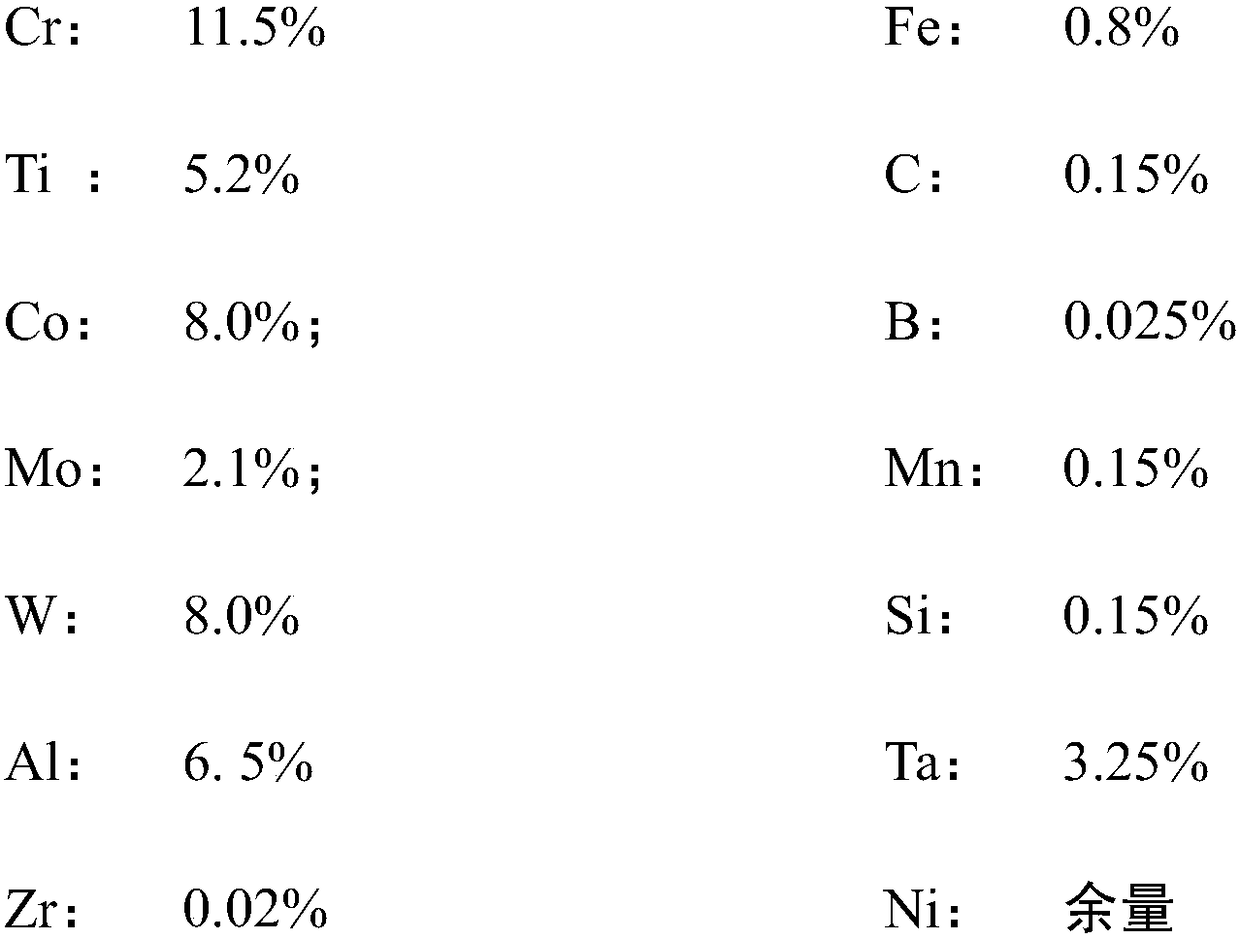

High-temperature alloy and preparation method thereof

The invention discloses a high-temperature alloy. The high-temperature alloy comprises the following raw materials of, by mass percent, 10.1-12.5% of Cr, 4.6-5.8% of Ti, 7.0-9.0% of Co, 2.0-2.25% of Mo, 7.0-9.0% of W, 6.25-6.75% of Al, less than or equal to 0.03% of Zr, less than or equal to 1.0% of Fe, 0.13-0.17% of C, 0.02-0.03% of B, less than or equal to 0.2% of Mn, less than or equal to 0.2%of Si, 3.25-3.75% of Ta, and the balance Ni. The invention further discloses a preparation method of the high-temperature alloy and belongs to the technical field of the high-temperature alloys. Compared with a similar formed material, the high-temperature alloy obtained by the preparation method has higher high-temperature endurance life and has the advantage of excellent resistance to thermal crack, and the thermal crack problem of the high-temperature alloy is solved greatly.

Owner:ANHUI TATSU PRECISION ALLOY

Method of processing surfaces of aluminium alloy pistons and precision friction pairs

ActiveCN103484849AHigh densityLow friction factorMaterial nanotechnologyMetallic material coating processesVolumetric Mass DensityMachining

The invention relates to a method of processing the surfaces of light alloy, in particular to a method of processing the surfaces of aluminium alloy pistons and precision friction pairs. The method comprises the steps that (1) washing is performed; (2) oxidization is performed; (3) hole plugging is performed. Nanoscale metal matrix ceramic oxidation film layers with the density up to the standard are respectively grown on the aluminium alloy pistons and precision friction pairs processed in the method, the density is increased, the diameters of blind holes are decreased obviously, nanometer penetrant blind holes are sealed, roughness is reduced, the friction coefficient is reduced, and the geometric dimensions are unchanged basically. The aluminium alloy pistons and precision friction pairs processed in the method can be installed for use in a matched mode without finish machining, industrial mass production can be achieved, and the method reduces production cost greatly compared with original technical methods.

Owner:邓才松 +1

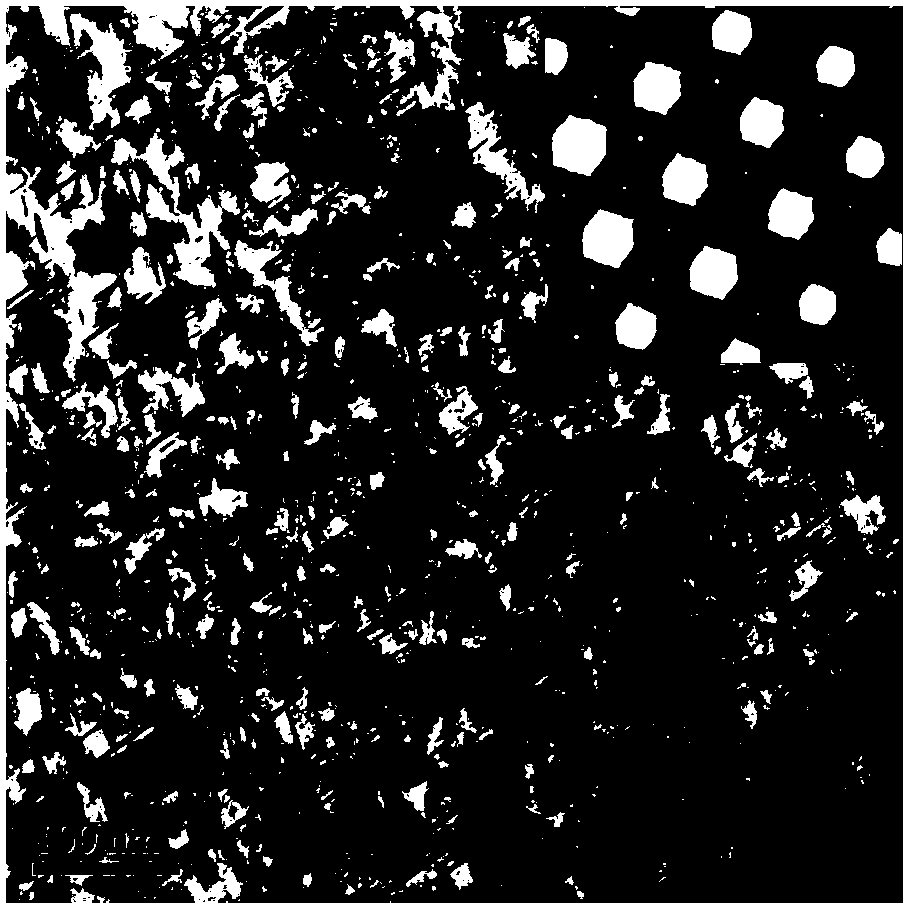

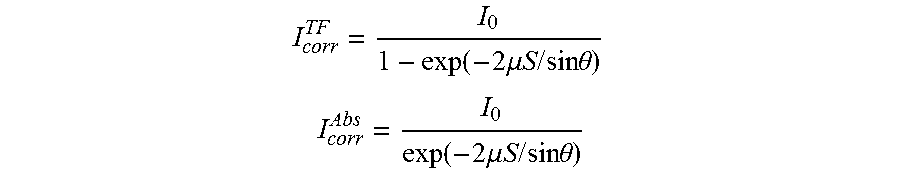

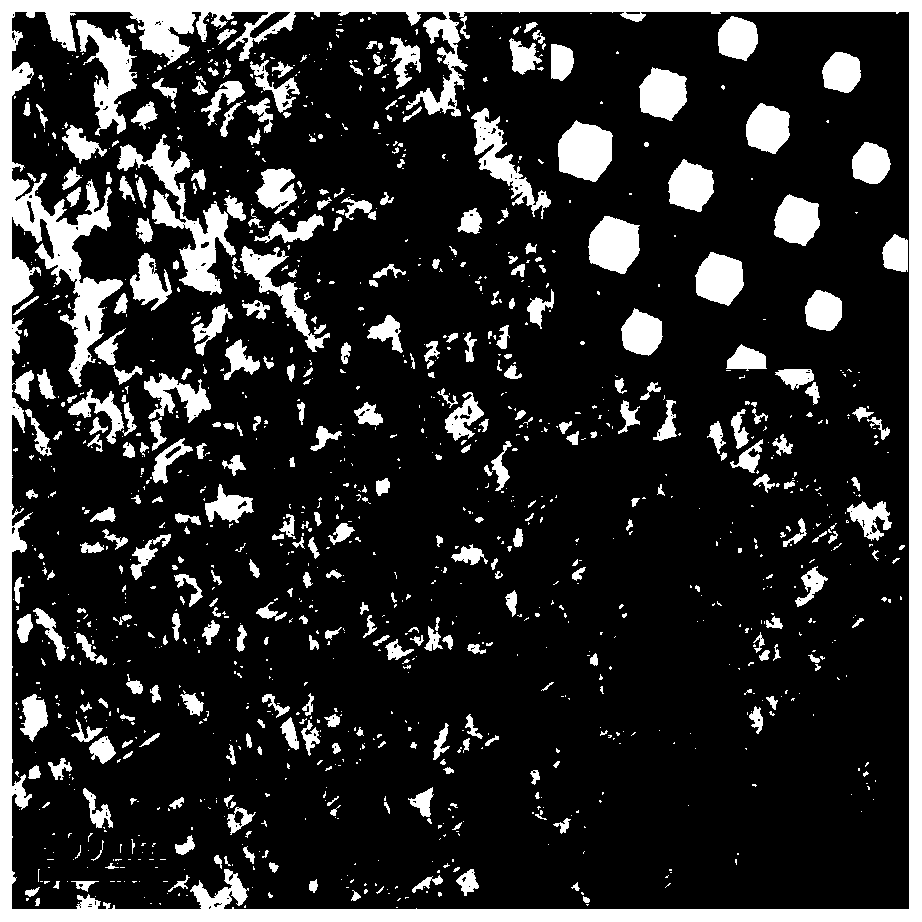

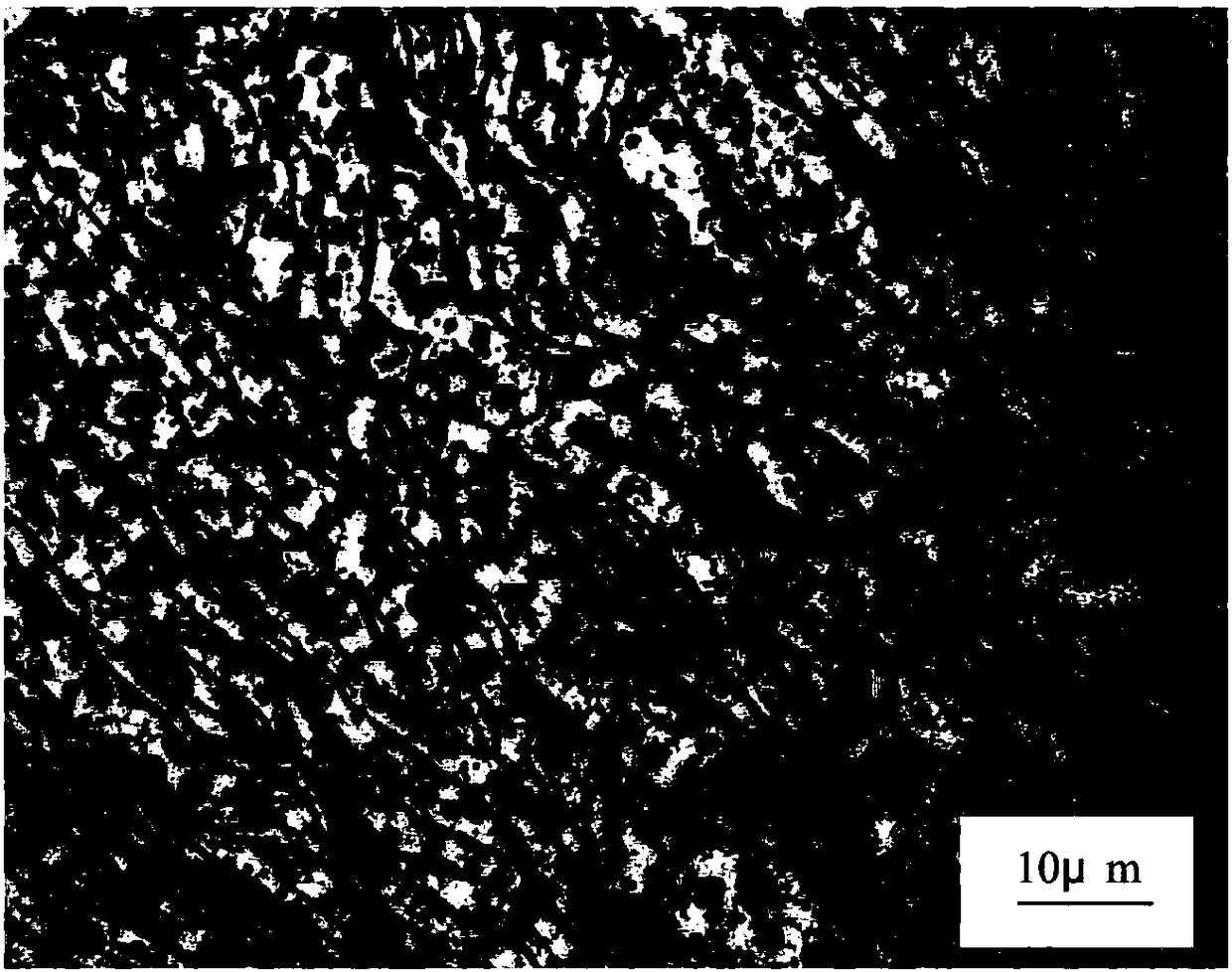

Coated Cutting Tool Insert with MT-CVD TiCN on TiAI(C,N)

ActiveUS20170275765A1Improve wear resistanceImprove thermal cracking resistanceWorkpiecesTurning toolsTitanium aluminium nitrideFiber

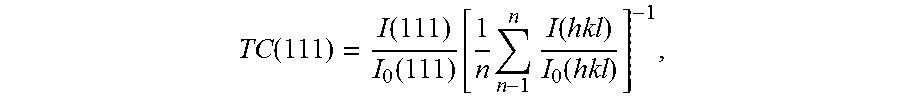

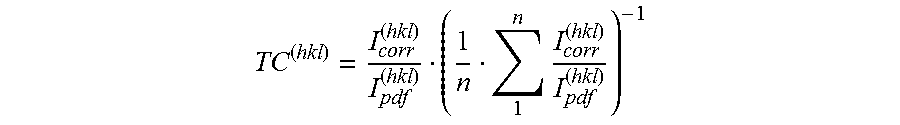

A coated cutting tool includes a substrate of cemented carbide, cermet, ceramics, steel or cubic boron nitride, a multi-layered wear resistant coating and at least two refractory coating layers deposited. The at least two refractory coating layers include a first coating layer and a second coating layer deposited on top of each other. The first coating layer is titanium aluminium nitride or carbonitride Ti1-uAluCvNw, with 0.2≦u≦1.0, 0≦v≦0.25 and 0.7≦w≦1.15 deposited by CVD. The second coating layer is titanium carbonitride TixCyN1-y, with 0.85≦x≦1.1 and 0.4≦y≦0.85, and is deposited on top of the first coating layer by MT-CVD. The second TixCyN1-y coating layer has a columnar grain morphology and the overall fiber texture of the TixCyN1-y coating layer is characterized by a texture coefficient TC (1 1 1)>2.

Owner:WALTER AG

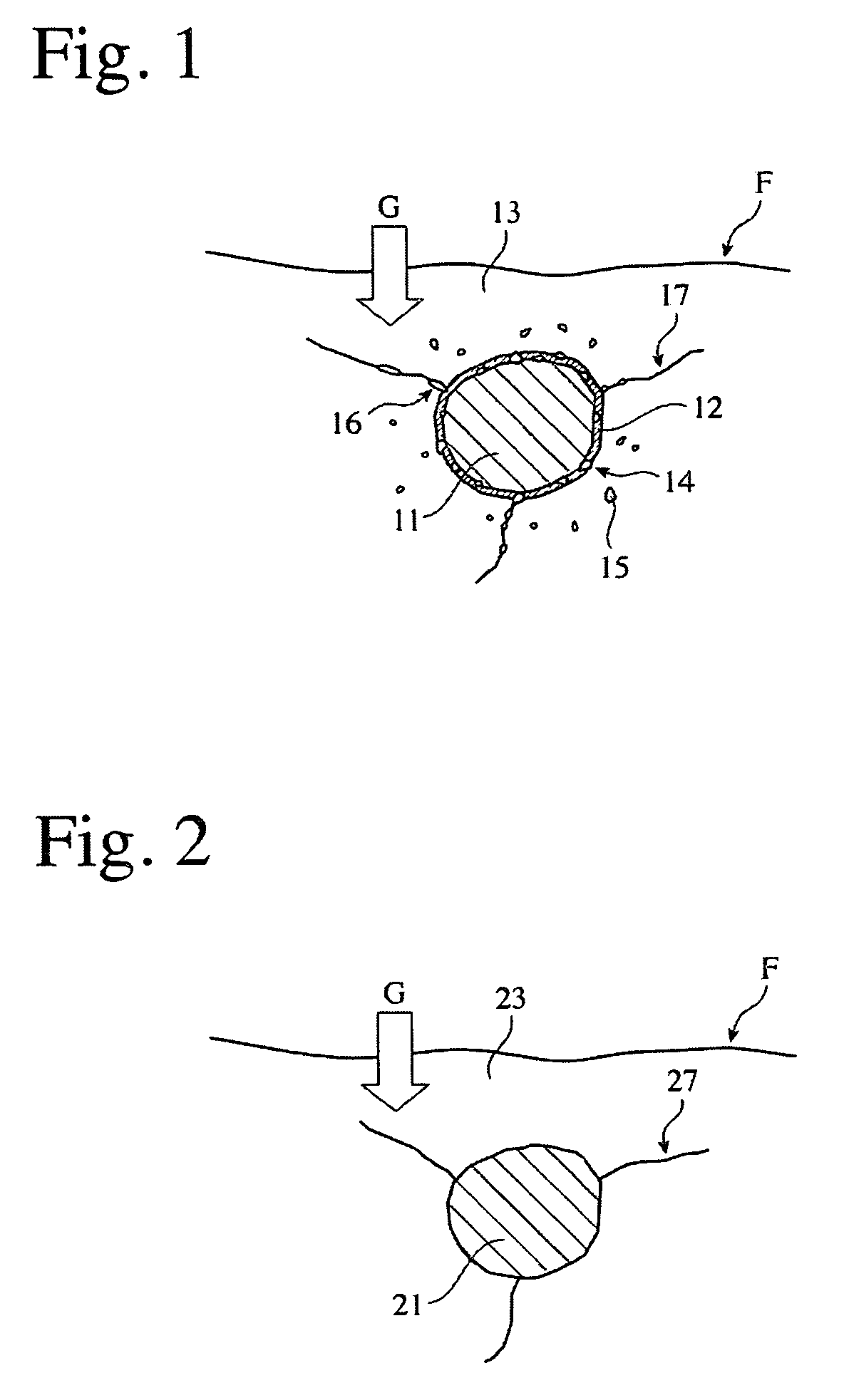

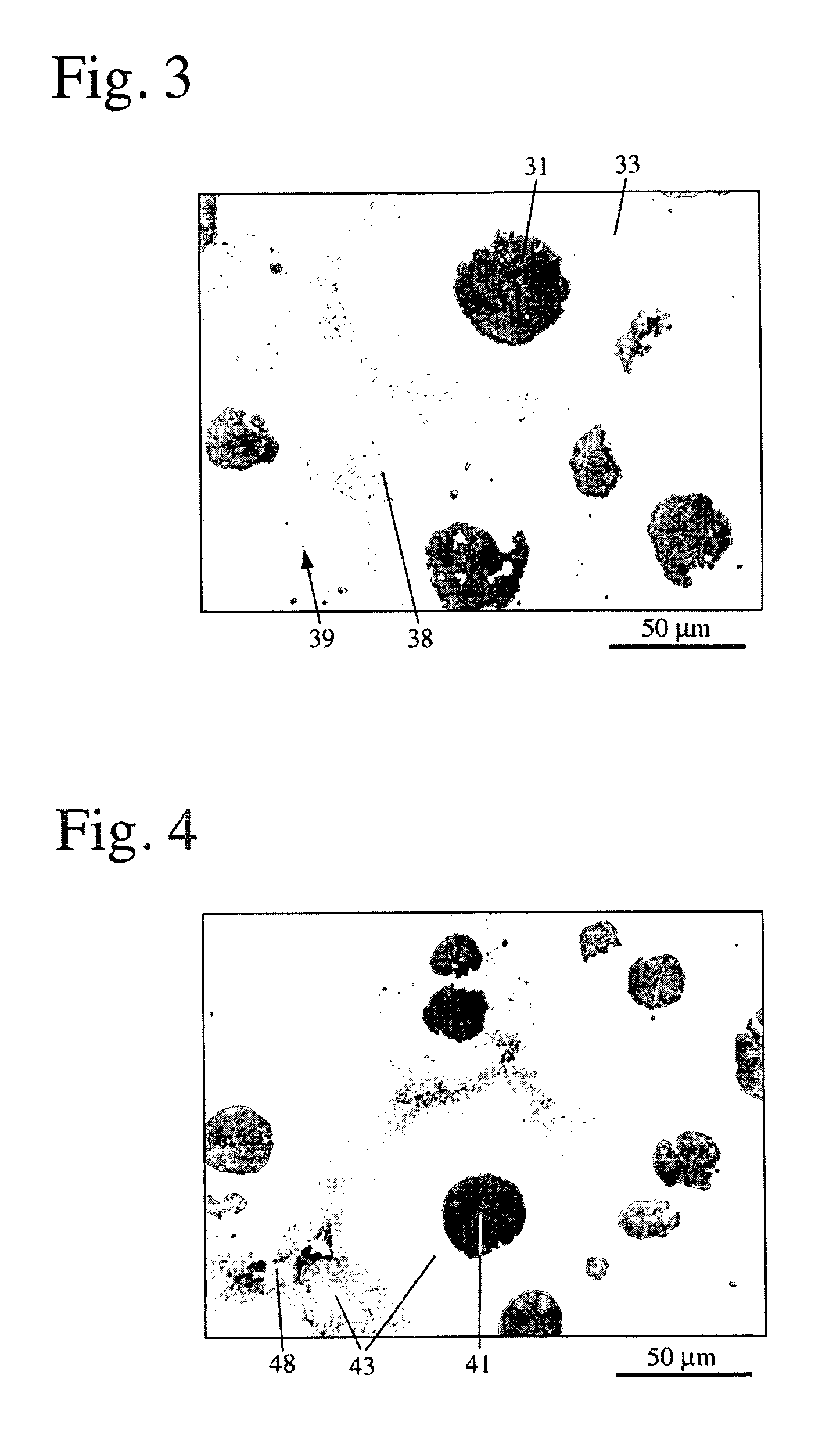

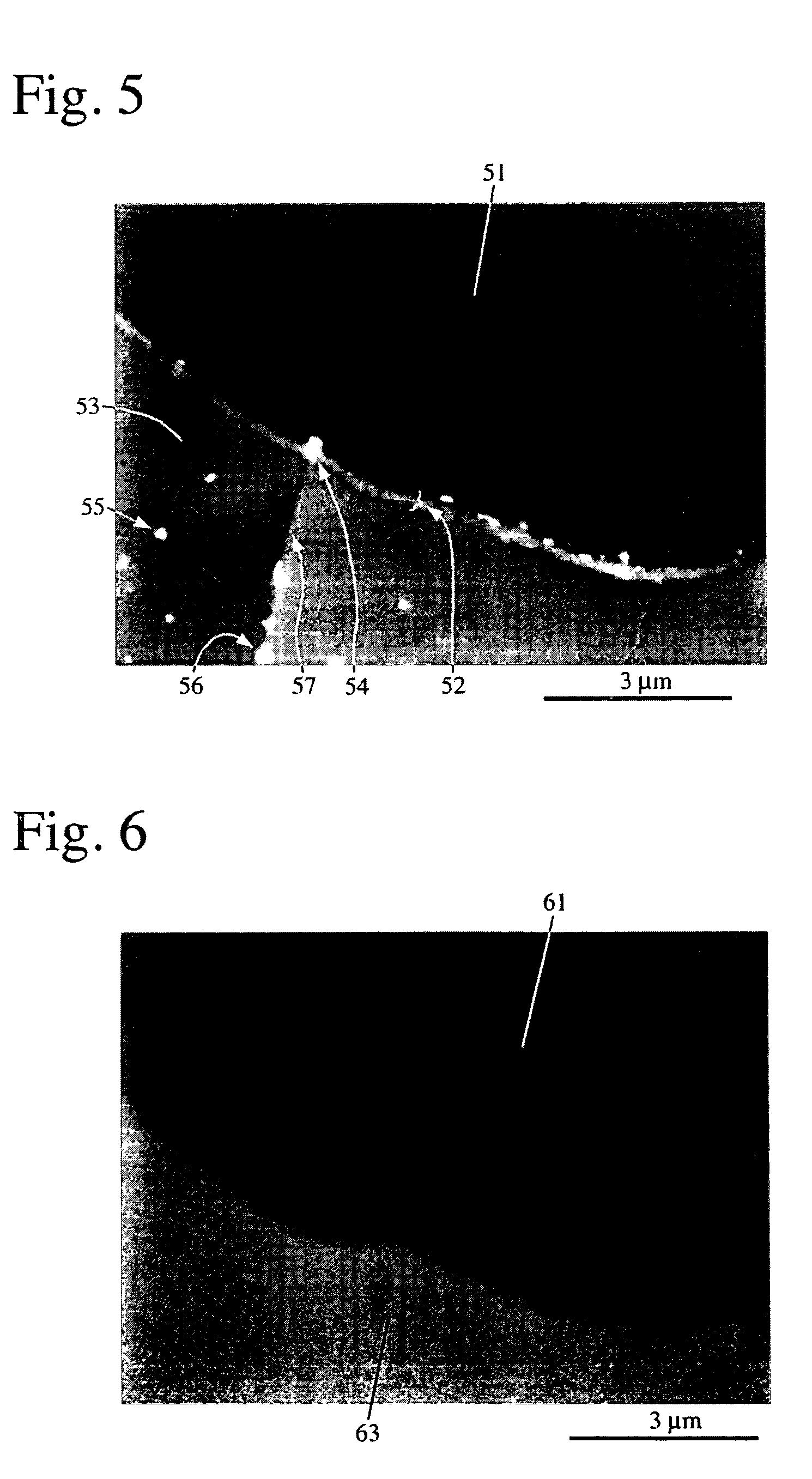

Heat-Resistant Cast Iron And Exhaust Equipment Member Formed Thereby

ActiveUS20080308193A1Low costGood thermal crack resistanceExhaust apparatusSilencing apparatusCast ironGraphite particle

A graphite-containing, heat-resistant cast iron for exhaust equipment members used at temperatures exceeding 800° C., comprising 3.5-5.6% of Si and 1.2-15% of W on a weight basis, and having intermediate layers, in which W and Si are concentrated, in the boundaries of graphite particles and a matrix. An exhaust equipment member formed by this heat-resistant cast iron has an AC transformation point is 840° C. or higher when measured from 30° C. at a temperature-elevating speed of 3° C. / minute, and a thermal cracking life of 780 cycles or more in a thermal fatigue test, in which heating and cooling are conducted under the conditions of an upper-limit temperature of 840° C., a temperature amplitude of 690° C. and a constraint ratio of 0.25.

Owner:HITACHI METALS LTD

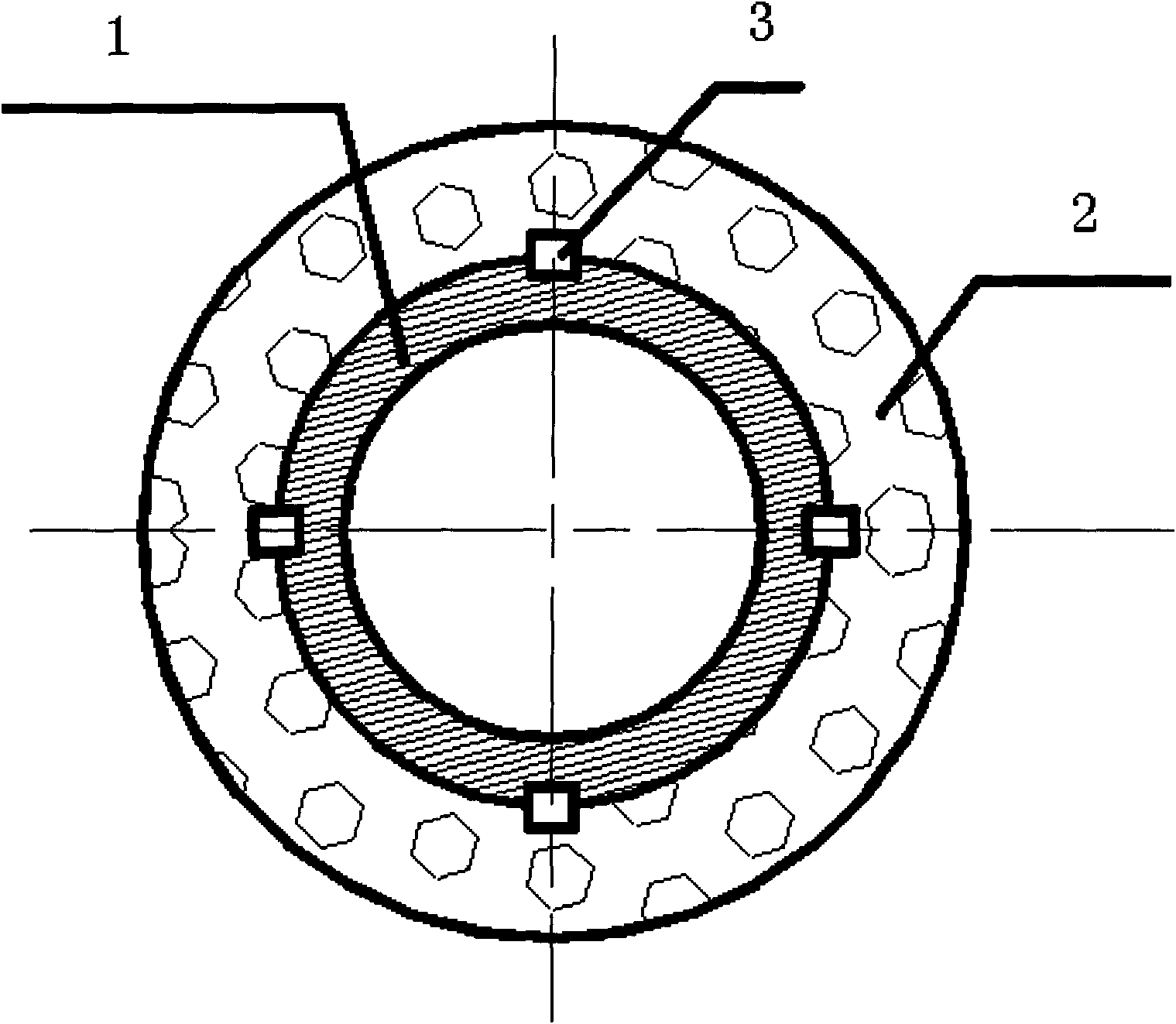

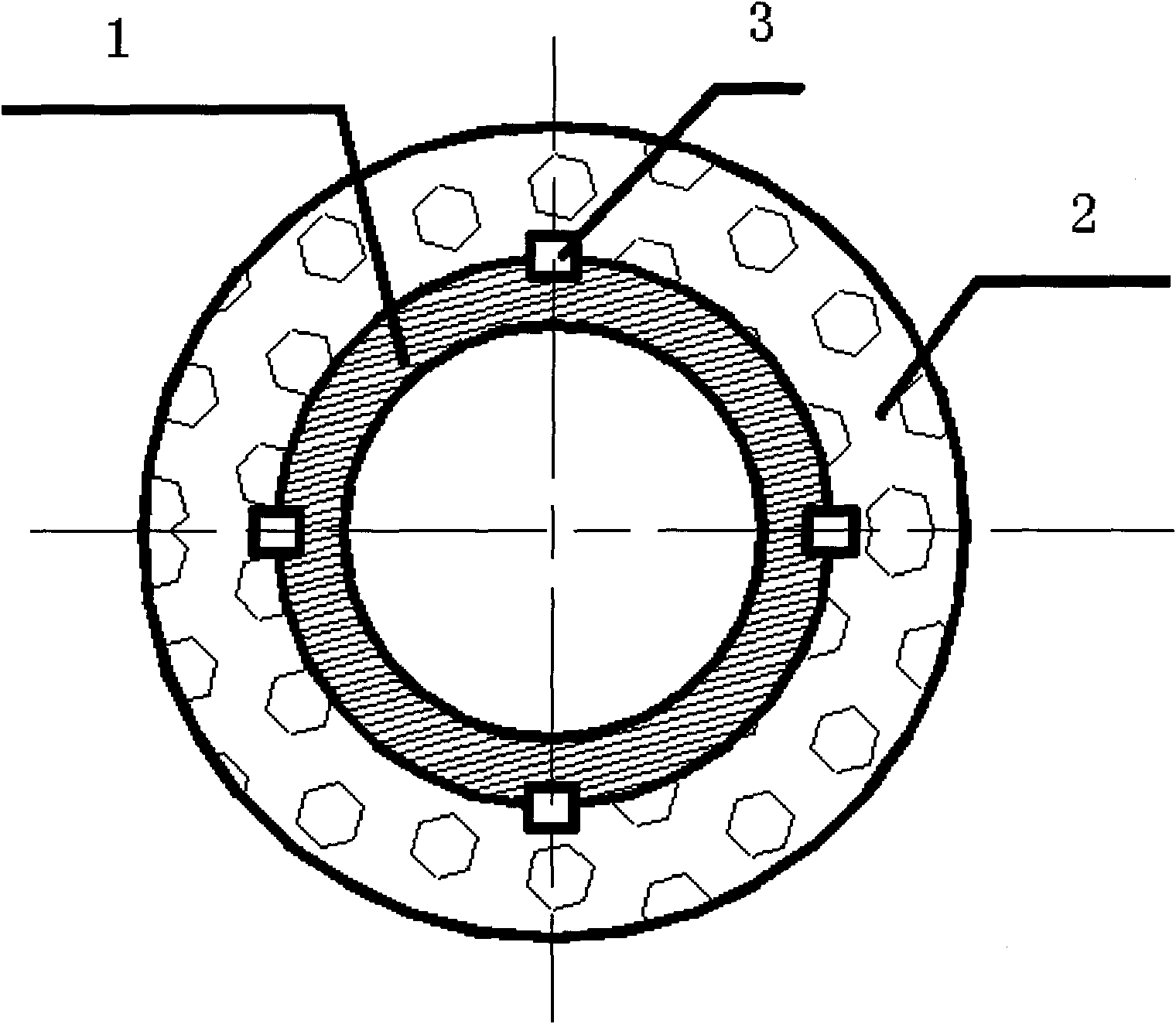

Roll collar of furnace roller of roller hearth heating furnace

ActiveCN101812580AGood thermal crack resistanceImprove wear resistanceFurnace typesHeat treatment furnacesCeramic compositeHeat resistance

The invention discloses a roll collar of a furnace roller of a roller hearth heating furnace, which is a ceramic-heat resistance steel composite roll collar. Compared with the prior art, the ceramic outer ring has good high-temperature strength, good thermal cracking resistance, high wear resistance, strong resistance to ferric oxide corrosion and no adhesion to the ferric oxide scale. The ceramic outer ring has high surface temperature, which is beneficial to eliminating the heating billet black mark and increasing the billet heating quality. Compared with the heat-resisting steel roll collar, the furnace roller provided with a ceramic composite roll collar has the advantages that the temperature difference between supply and return of cooling water is reduced by 20%, which shows that the thermal loss caused by the cooling water is reduced by 20%, and the energy-saving effect is evident; the ceramic composite roll collar has low manufacture cost, the cost of the CSP furnace roller manufactured by the metal-ceramic composite roll collar is reduced by 50% compared with the imported CSP(Cast Steel Plate) furnace roller.

Owner:MAANSHAN IRON & STEEL CO LTD

Heat-resistant cast iron and exhaust equipment member formed thereby

ActiveUS7794650B2Low costGood thermal crack resistanceExhaust apparatusSilencing apparatusThermal fatigueGraphite particle

A graphite-containing, heat-resistant cast iron for exhaust equipment members used at temperatures exceeding 800° C., comprising 3.5-5.6% of Si and 1.2-15% of W on a weight basis, and having intermediate layers, in which W and Si are concentrated, in the boundaries of graphite particles and a matrix. An exhaust equipment member formed by this heat-resistant cast iron has an AC1 transformation point is 840° C. or higher when measured from 30° C. at a temperature-elevating speed of 3° C. / minute, and a thermal cracking life of 780 cycles or more in a thermal fatigue test, in which heating and cooling are conducted under the conditions of an upper-limit temperature of 840° C., a temperature amplitude of 690° C. and a constraint ratio of 0.25.

Owner:HITACHI METALS LTD

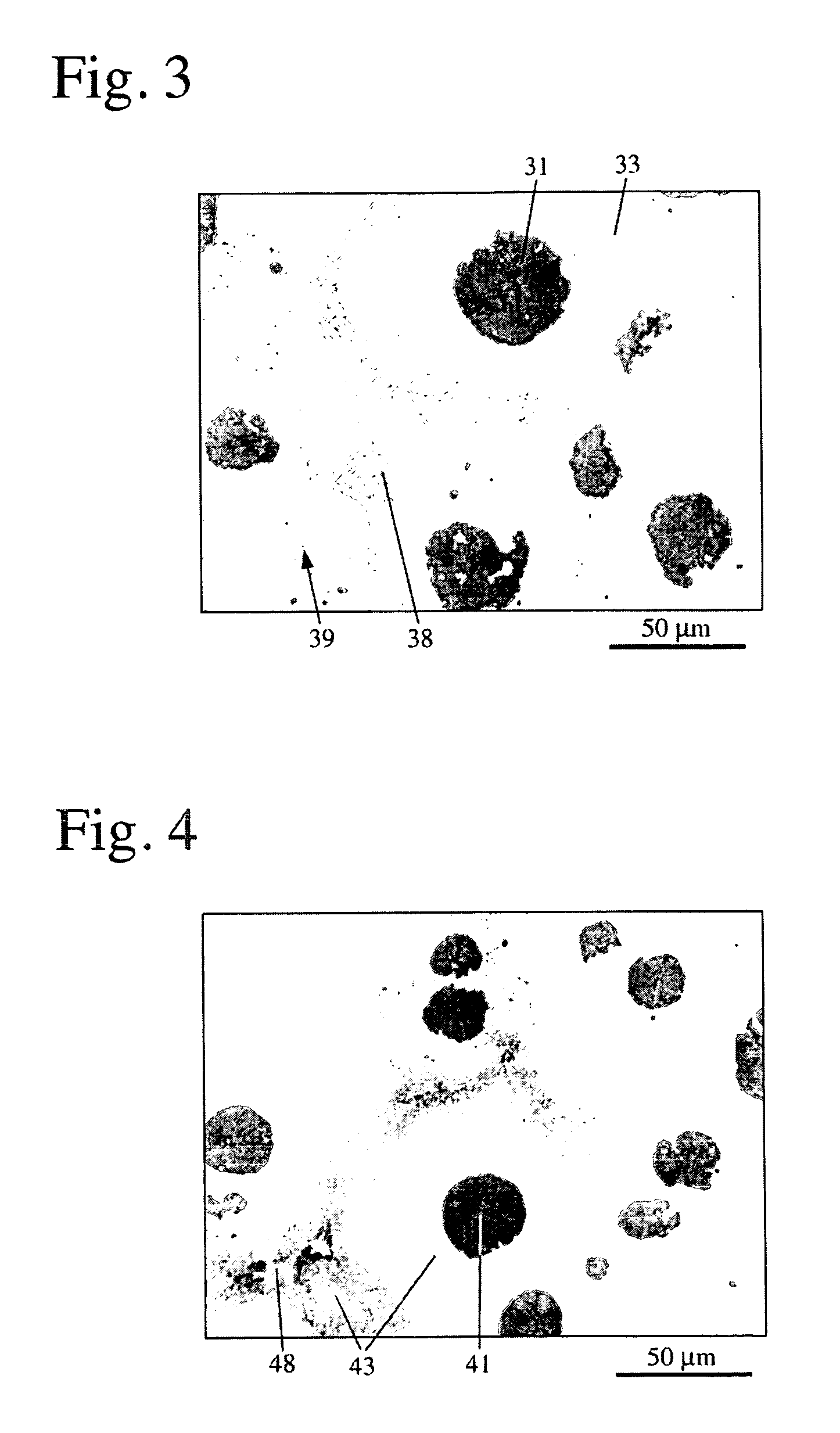

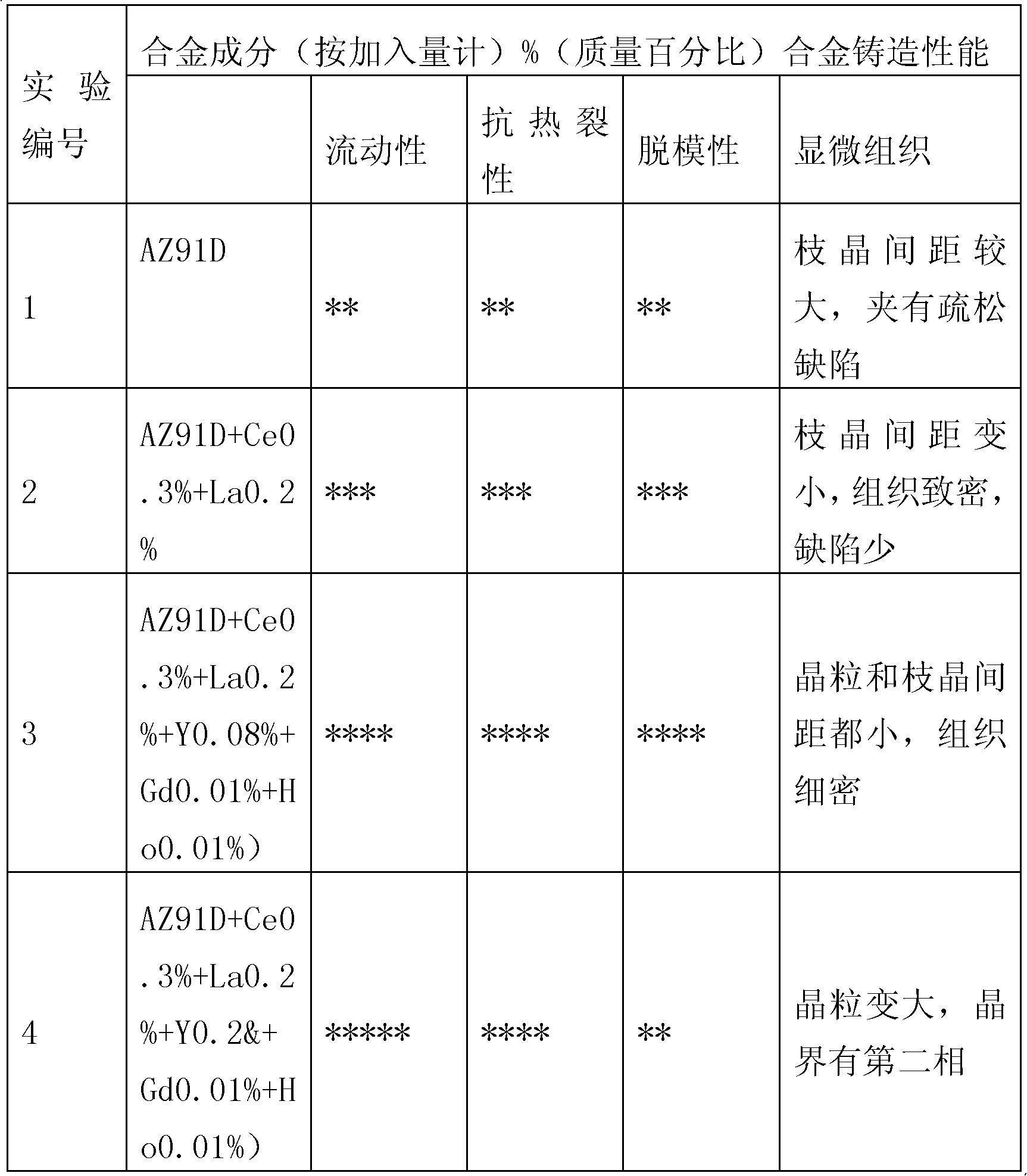

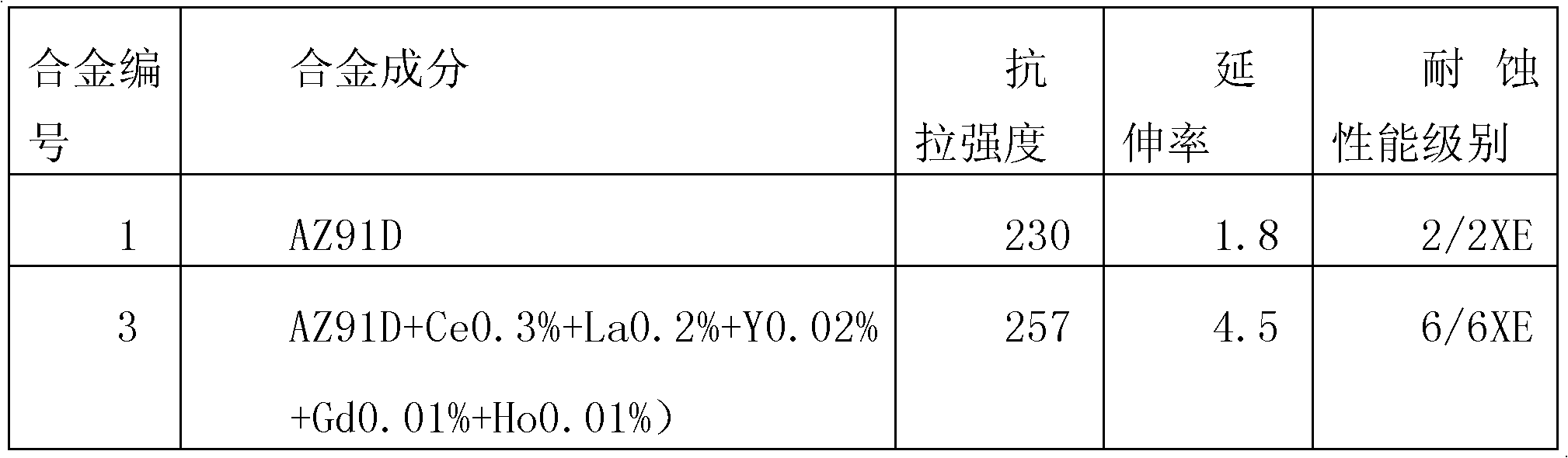

Die cast magnesium alloy with heat cracking resistance and high fluidity

Owner:KA SHUI TECH HUIZHOU CO LTD

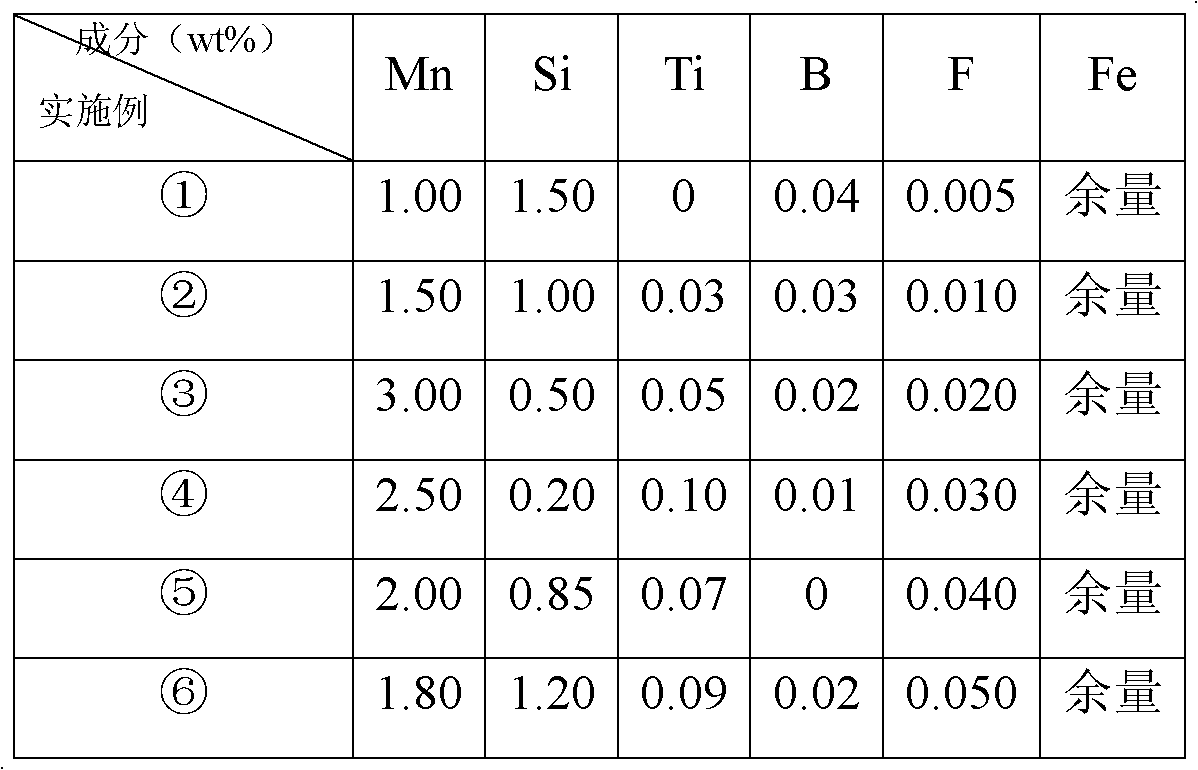

Metal powder flux-cored wire for high-strength steel

InactiveCN102554496AImprove purityImprove thermal cracking resistanceWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a metal powder flux-cored wire for high-strength steel, which comprises carbon steel sheath and a flux core with the filling ratio of 10-20%. The metal powder flux-cored wire is characterized in that in the overall weight percent of the wire, components in the flux core include 1.00-3.00% of Mn (manganese), 0.20-1.50% of Si (silicon), 0.005-0.050% of F (fluorine), 0-0.1% of Ti (titanium) and 0-0.004% of B (boron). The flux-cored wire is applicable to backing weld of the high-strength steel of an X80 pipeline, and when in welding, deposition efficiency is high, speed is high, arc is stable, splash is little, a welding bead is smooth and beautiful in appearance, and post-welding slag is little.

Owner:KUSN GINTUNE WELDING

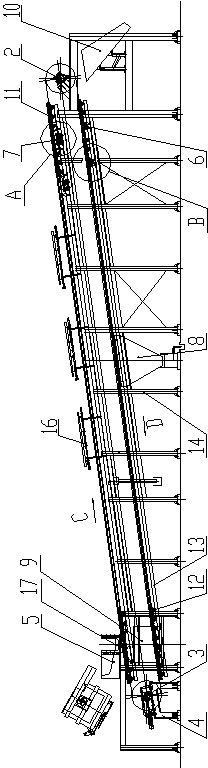

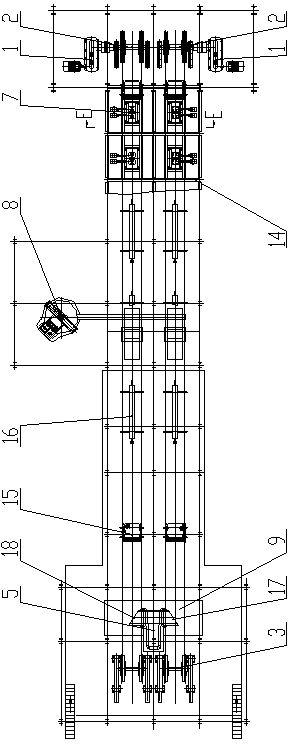

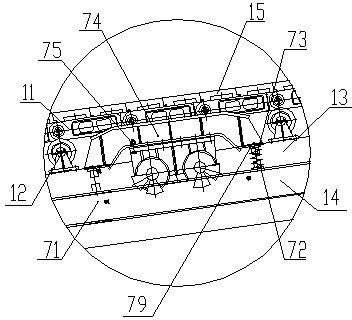

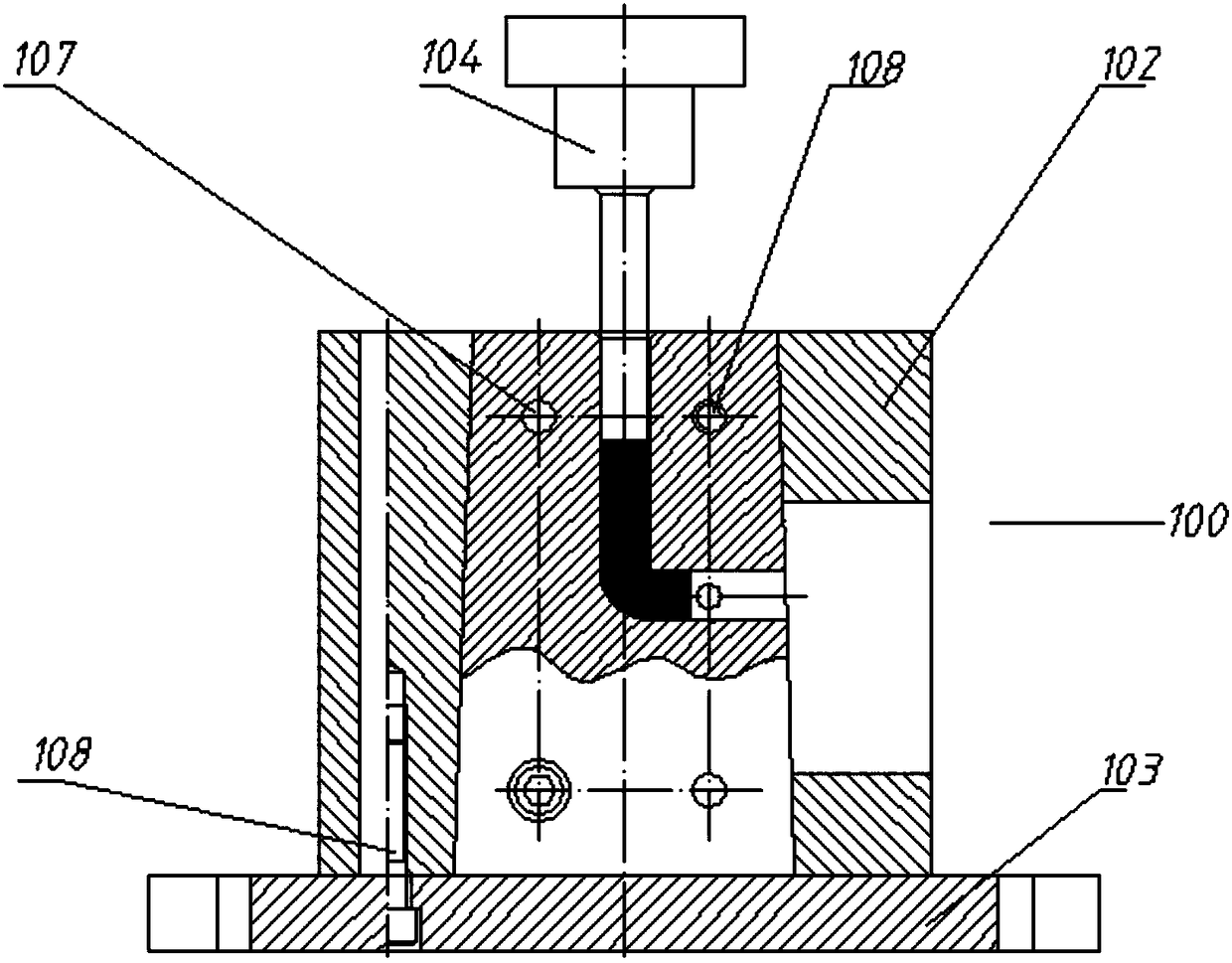

Casting machine used for casting special materials

ActiveCN103706768AReduce sizeReduce concentrated stressPig casting plantsDrive wheelMetallic materials

The invention discloses a casting machine used for casting special materials. The casting machine comprises a transmission device, a driving chain wheel device, a driven wheel device, a driven wheel support, a casting launder, an iron scrabbling wheel assembly, a vibrating and striking device, a remnant iron collecting device, a fixed chute, a chain belt device, an idler wheel device, an idler wheel base, a steel structure frame and a casting mold. The driven wheel support is installed on a ground foundation, the driven wheel device and the driven wheel support are assembled together, the transmission device, the driving chain wheel device, the casting launder, the vibrating and striking device, the remnant iron collecting device, the fixed chute and the idler wheel base are installed on the steel structure frame, the iron scrabbling wheel assembly and the idler wheel device are installed on the idler wheel base, the casting mold is in linkage with the chain belt device, and the chain belt is supported by the driving chain wheel device, the driven wheel device and the idler wheel device together. An existing casting molding production technology of alloy iron ingots and non-metallic materials is changed, in this way, technical problems, existing in use, of the existing production technology are solved, the casting machine is the equipment meeting the production technology of the small alloy iron ingots or the non-metallic materials, wherein the production technology is needed by markets, production capacity and service life of the casting machine are improved, and the finished product ratio is improved remarkably.

Owner:SHILIN LUOHE METALLURGY EQUIP

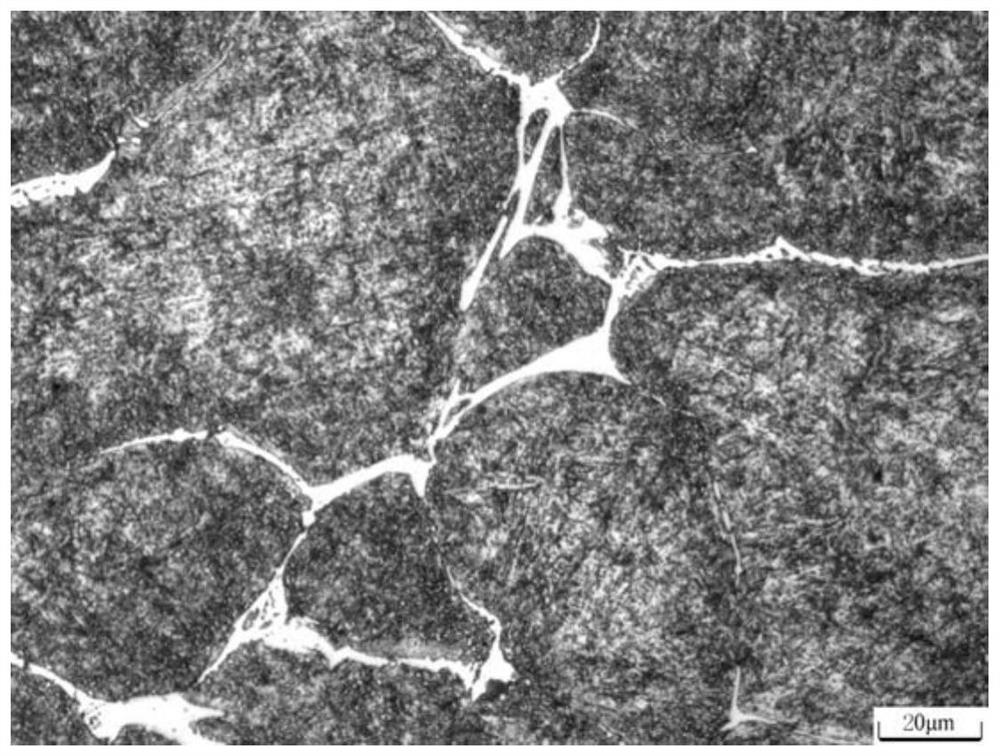

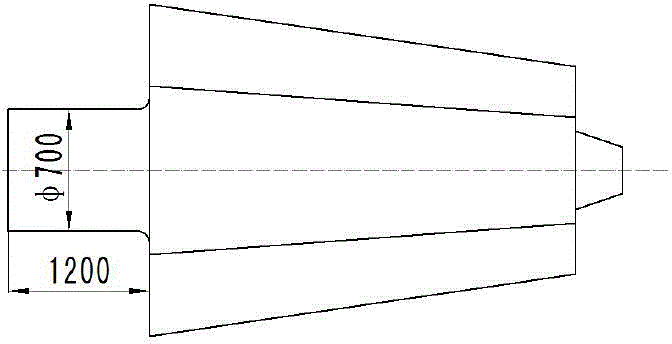

Working roller for wire and bar roughing mill stand and manufacturing method thereof

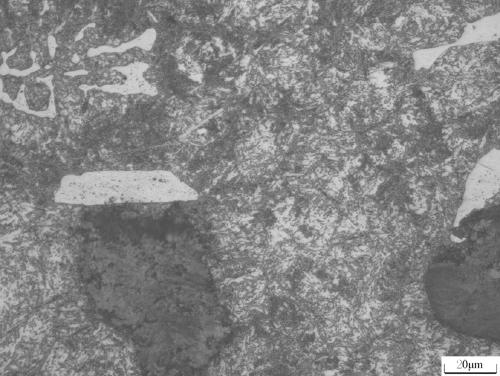

ActiveCN111101053AIncrease Ni contentImprove thermal cracking resistanceFurnace typesRollsCarbideDuctile iron

The invention discloses a working roller for a wire and bar roughing mill stand. The working roller comprises, by weight, 2.9-3.6% of C, 1.2-2.0% of Si, 0.3-0.8% of Mn, 0.2-1.0% of Cr, 1.0-2.0% of Ni,0.2-0.5% of Mo, less than or equal to 0.15% of P, less than or equal to 0.3% of S, and the balance being Fe and inevitable impurities. A manufacturing method is characterized in that a pearlitic ductile cast iron blank manufactured through integral casting is subjected to rough machining and then quenching heat treatment to obtain the working roller with the structure of bainite, tempered sorbiteand carbide for the roughing mill stand. The pearlitic ductile cast iron blank manufactured through integral casting is subjected to rough machining and then quenching heat treatment, so that not only is the hardness drop inside and outside a working layer reduced, but also the wear resistance is improved, and the probability of occurrence of hot cracks at the bottom of a roller groove is reduced.

Owner:邢台轧辊线棒辊有限责任公司

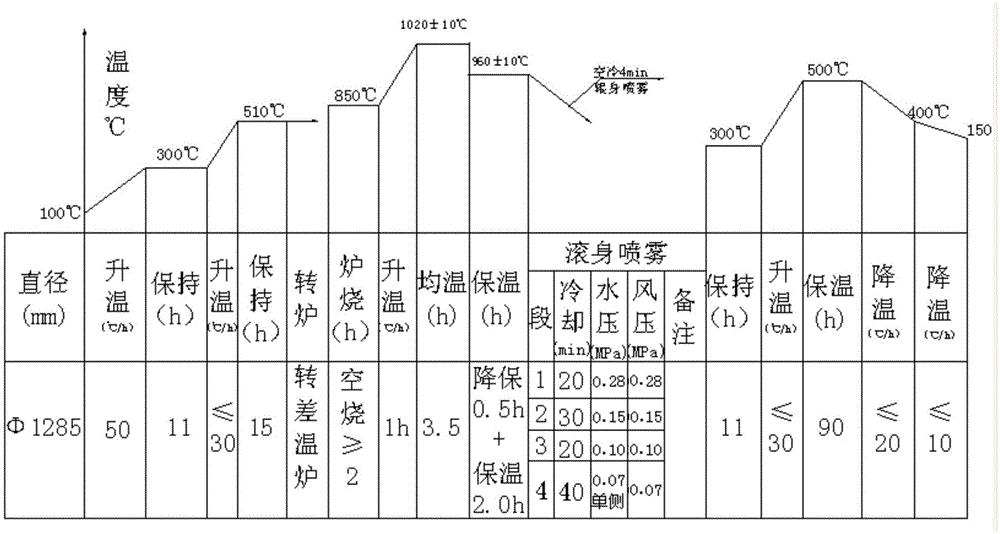

Forged steel rubber and plastic calendar roller and heat treatment method thereof

ActiveCN105568135AStrong thermal cracking resistanceGuaranteed processing effectHeating timeMedium frequency

The invention discloses a forged steel rubber and plastic calendar roller and a heat treatment method thereof. The roller comprises, by weight percentage, 0.50%-0.75% of C, 0.40%-0.80% of Si, 0.60%-0.90% of Mn, not larger than 0.025% of P, not larger than 0.025% of S, 2.50%-3.50% of Cr, 0.30%-0.50% of Mo, 0.05%-0.15% of V and the balance Fe and inevitable impurities. According to the forged steel rubber and plastic calendar roller and the heat treatment method, the medium-frequency induction quenching technology is adopted, the heating speed is high, the quenching temperature is high, and weer and more even textures are obtained on the surface of the roller; and meanwhile, in cooperation with the movement speed during roller quenching, the heating time is controlled to obtain the shallow quenching layer thickness, and the machining performance of an inner layer is guaranteed.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Method for manufacturing pipeline assembly from shape memory alloy

ActiveCN108723110AHigh material strengthIncreased strength and recoveryExtrusion diesShearing deformationCrystallite

The invention relates to a method for manufacturing a pipeline assembly from shape memory alloy. The method adopts an equal-diameter bending extrusion mould to form an equal-diameter bending extrusionmethod for processing the shape memory alloy; the method can realize large shearing deformation of a test sample under relatively low load and relatively load stress in case of not changing the crosssection area of the material; in a deforming process, crystalline grains are greatly refined by processing and hardening, dynamic recovery and re-crystallizing of block materials; and finally, a sub-microcrystal or nano structure is finally formed, so that the material strength is improved; and according to the research, the strength and the recovery rate of iron-based shape memory alloy can be remarkably improved by ECAP deformed refined crystalline grains. Therefore, the method belongs to the technical field of metal material refining.

Owner:江苏华晨气缸套股份有限公司

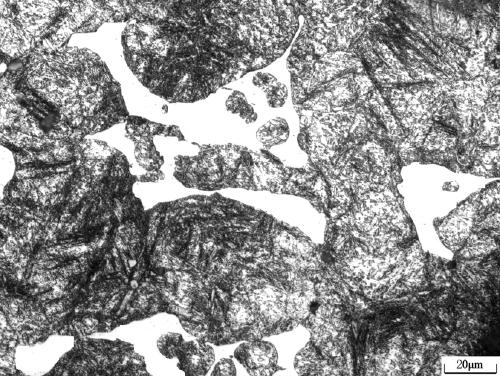

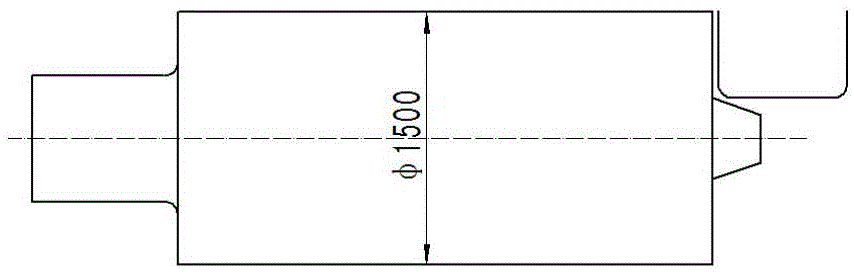

Preparation method of rough rolling high-speed steel working roll for full endless rolling of sheet billets

PendingCN113547099AExtend the machine cycleImprove wear resistanceFurnace typesProcess efficiency improvementTemperingFerrochrome

The invention discloses a preparation method of a rough rolling high-speed steel working roll for full endless rolling of sheet billets. The preparation method comprises the following steps that A, scrap steel, ferronickel, ferrovanadium, ferrochromium, ferromolybdenum, ferrotungsten and electrode powder are taken as raw materials, a line frequency furnace is adopted for smelting outer-layer molten iron and core molten iron; B, the product manufacturing mode is centrifugal composite manufacturing, and after smelting components reach the standard, outer-layer molten iron and core molten iron are heated, discharged out of a furnace and poured; C, after pouring is completed, a box is opened in a cold mode, and rough machining is conducted after the box is opened in the cold mode; D, after machining is completed, a roll body is subjected to quenching heating and overall tempering treatment; and E, after quenching heating is finished, finish machining is conducted, and detection is conducted till a finished product is obtained. According to the method, the requirements of short-process endless rolling technologies such as ESP are met, and the roll quality is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

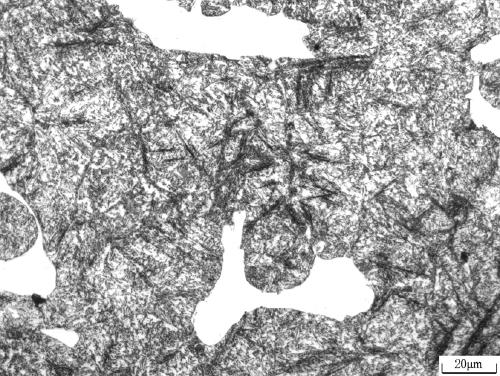

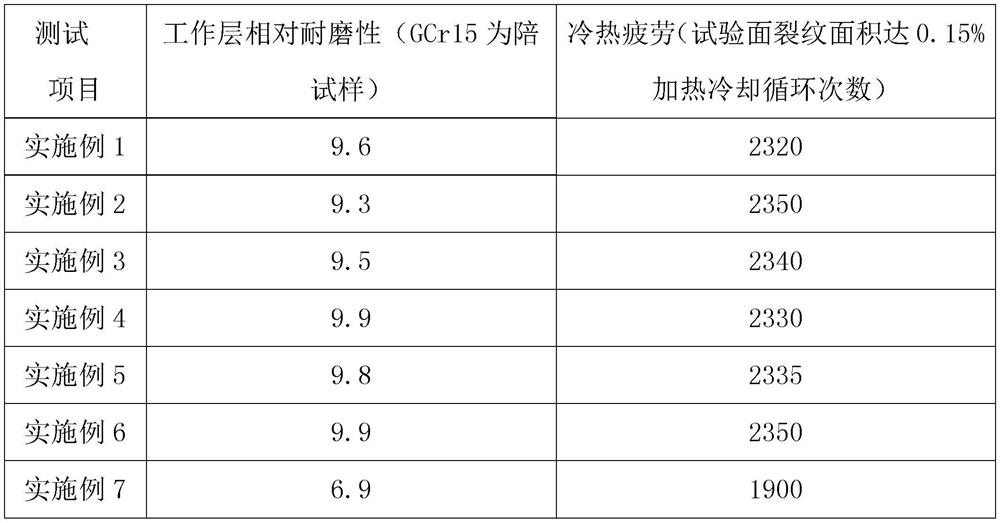

Forging rough-rolling tool steel roller and manufacturing method thereof

InactiveCN105861952AImprove thermal cracking resistanceImprove wear resistanceRollsMetal rolling arrangementsChemical compositionAlloy

The invention relates to a forged rough-rolled tool steel roll and a manufacturing method, comprising the following chemical components in weight percent: C 0.65-0.75; Si 0.2-0.55; Mn 0.20-0.30; Cr 1.00-5.50; Ni 1-5.5; Mo 0.30-0.40; V 0.10-0.20; S≤0.015; P≤0.015; the rest are Fe and unavoidable impurities. Manufacturing method: LF furnace refining, heat treatment, hydraulic forging, post-forging heat treatment, quenching and tempering treatment, differential temperature quenching, and finished products in sequence. The advantages are: new alloy compounds are obtained through smelting technology, and new alloy compounds can improve the heat resistance of rolls. Crack and wear resistance, increase the strength of the roll through a reasonable forging ratio, and obtain a good structure with advanced differential temperature heat treatment.

Owner:ANGANG STEEL CO LTD

High-strength heat-resistant aluminum alloy suitable for large-scale complex structure castings and its preparation process

ActiveCN108251724BImprove thermal cracking resistanceOvercoming the problem of insufficient thermal cracking resistanceHeat resistanceSolid solution

The invention relates to a high-strength heat-resistant cast aluminum alloy material and a preparation process thereof which are suitable for casting large-size castings. A high-strength heat-resistant cast aluminum alloy comprises, by mass, 6.0-7.7% of Cu, 0.6-1.7% of Ag, 0.10-0.38% of Mg, 0.2-0.5% of Mn, 0.10-0.35% of V, 0.05-0.15% of Ti, no less than 15% and no more than 60% of Cu / Mg ratio, nomore than 0.06% of Fe, no more than 0.06% of Si, and the balance Al and other unavoidable impurity elements. The preparation process includes smelting and casting of the alloy and solid solution agingheat treatment of the castings. According to the high-strength heat-resistant cast aluminum alloy material and the preparation process thereof, the large-size castings with good heat resistance, roomtemperature mechanical properties and cutting machining properties can be casted.

Owner:CENT SOUTH UNIV

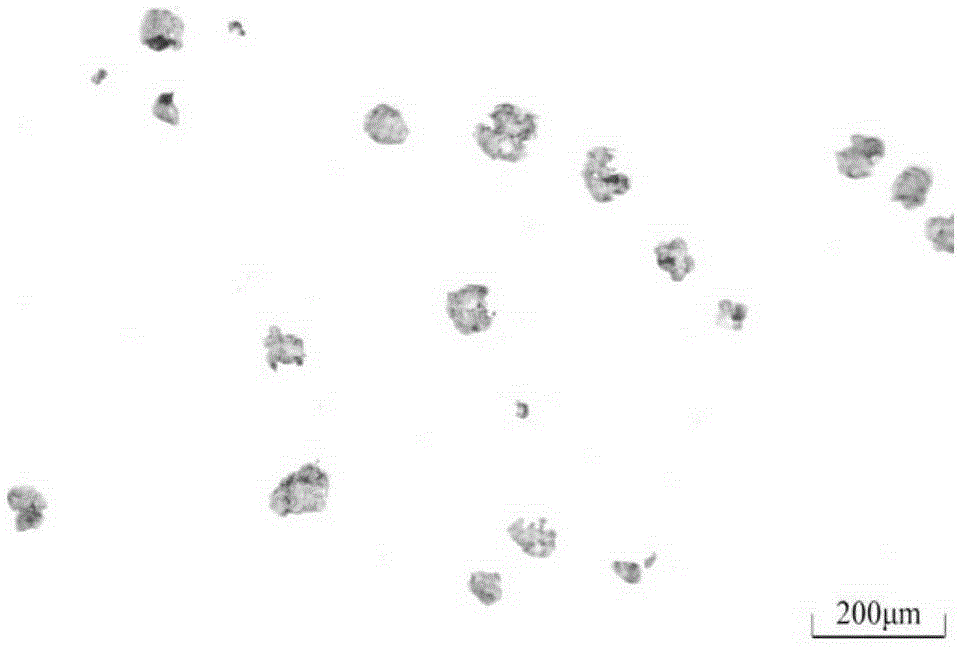

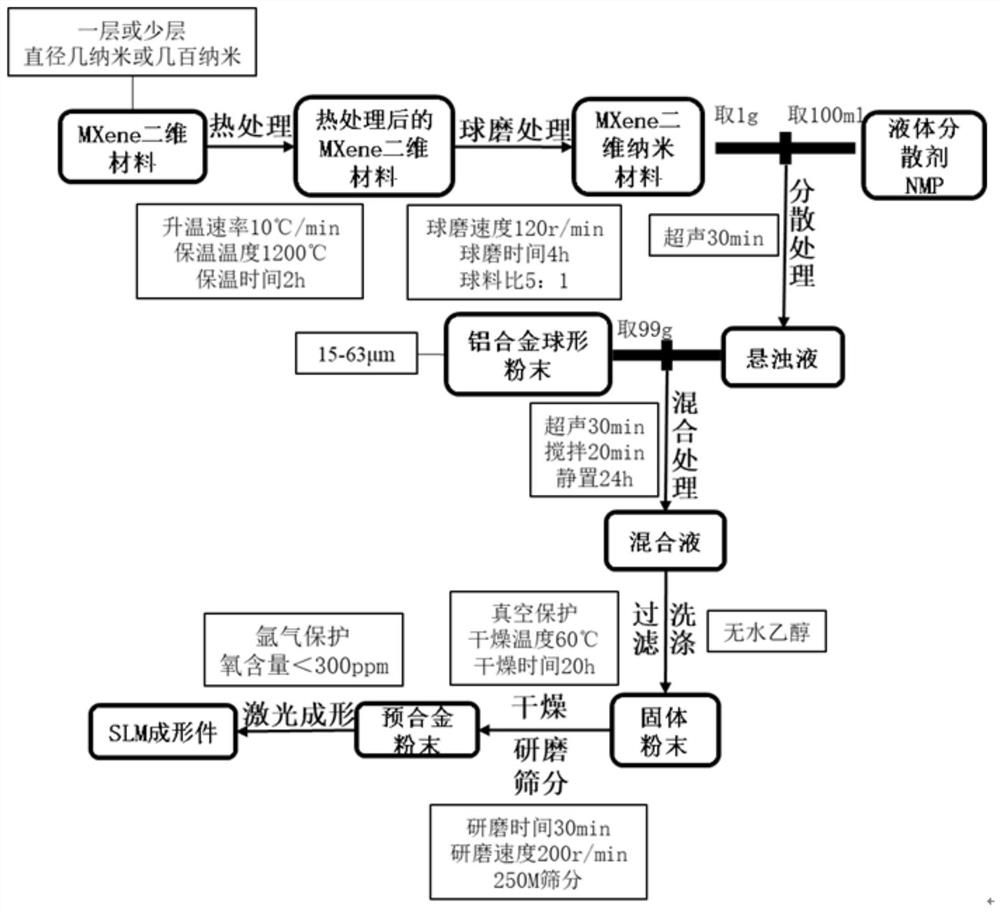

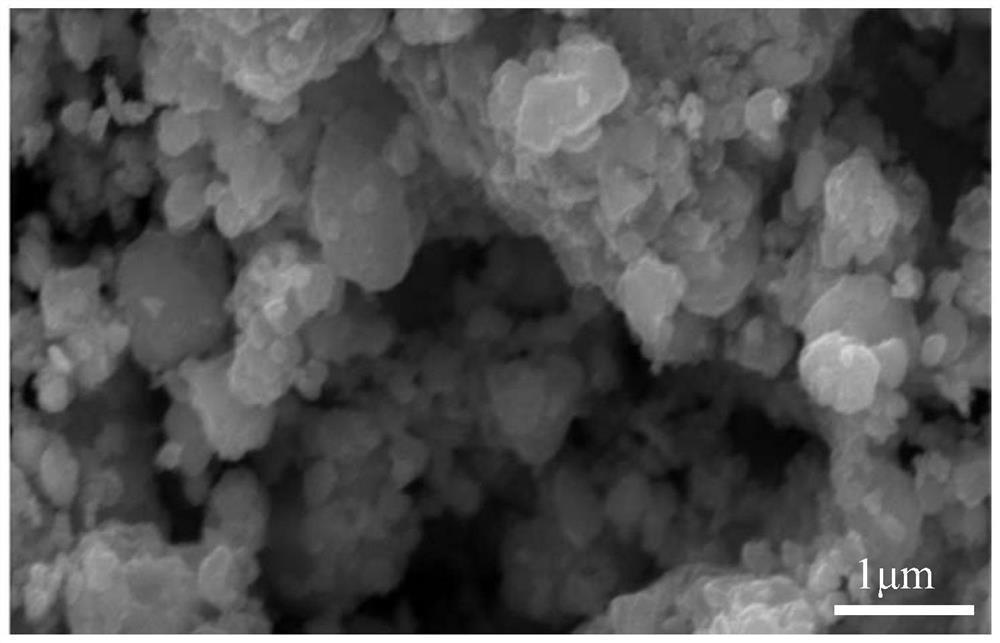

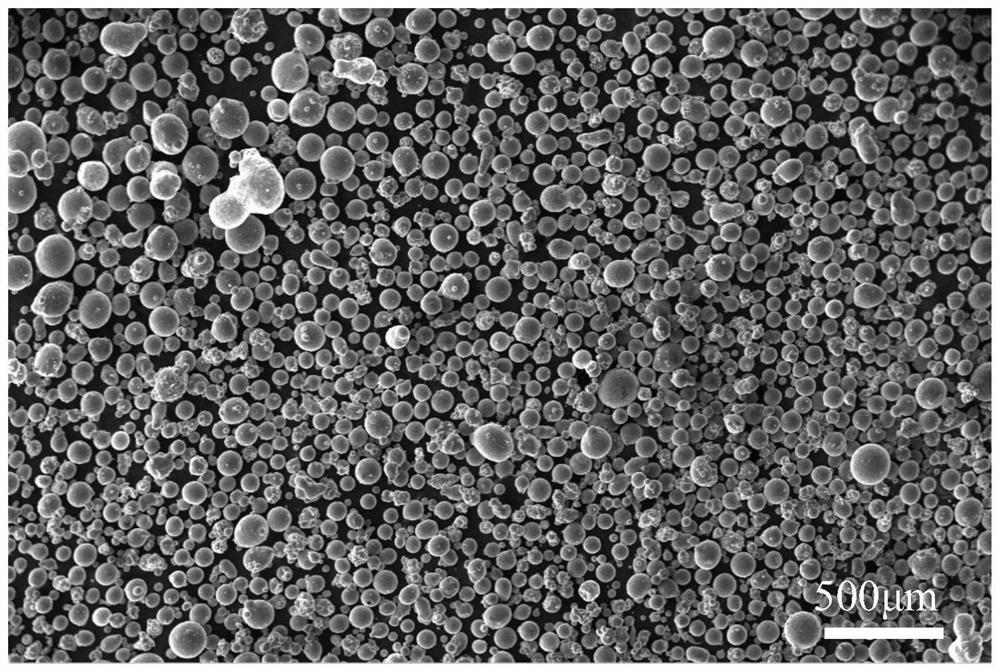

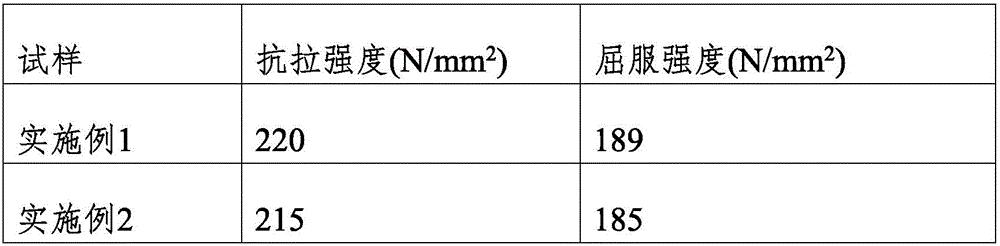

Method for refining 3D printing aluminum alloy grains and improving thermal conductivity of 3D printing aluminum alloy grains

ActiveCN112743092AGrain refinementImprove thermal cracking resistanceAdditive manufacturing apparatusTransportation and packagingSelective laser meltingHeat treated

The invention discloses a method for refining 3D printing aluminum alloy grains and improving the thermal conductivity of the 3D printing aluminum alloy grains. The method comprises the following steps: (1) carrying out high-temperature heat treatment on an MXene two-dimensional nano lamellar material; (2) carrying out ball milling treatment on the MXene subjected to heat treatment and a ball milling medium; (3) performing colloid mixing on the MXene subjected to ball milling treatment and the aluminum alloy spherical powder; (4) grinding and screening after drying treatment to obtain the composite powder for selective laser melting forming; and (5) conducting selective laser melting forming on the composite powder obtained in the step (4) to form the aluminum alloy, and after forming is finished, an aluminum alloy formed part is obtained after natural cooling. According to the method, the MXene two-dimensional nano lamellar material is used as a nano additive to promote grain refinement; and meanwhile, the thermal conductivity of the alloy is improved by utilizing the characteristics of high thermal conductivity and large adhesion area of the lamellar structure.

Owner:NANJING UNIV OF SCI & TECH +1

Aluminum magnesium alloy and surface modifying method thereof

ActiveCN105734362AHigh strengthImprove toughnessLiquid surface applicatorsMolten spray coatingRare earthManganese

The invention relates to the technical field of metal alloy, in particular to an aluminum magnesium alloy and a surface modifying method thereof. The aluminum magnesium alloy is prepared from aluminum, manganese, titanium, chromium, magnesium, iron and rare earth metals. The surface modifying method of the aluminum magnesium alloy comprises the steps that the aluminum magnesium alloy is polished and cleaned with acetone till the surface is clean; an electric arc spraying method is adopted to form a silicon substrate coating and a chromium-aluminum coating on a base body; a magnetron sputtering coating method is adopted to form a titanium metal layer, the electric arc spraying method is adopted to form an inorganic silicon layer, and finally the alloy is coated with a protective layer. The aluminum magnesium alloy obtained by adopting the surface modifying method has the good anti-explosion and electromagnetic shielding effects, and also has the advantages of being resistant to corrosion and high temperature and high in comprehensive chemical property.

Owner:贵州航天风华精密设备有限公司

Cantilevered roller and manufacturing method thereof

Owner:江苏长友特钢机械有限公司

Graphene-reinforced high-silicon aluminum-based composite material and preparation method thereof

The invention relates to a graphene-reinforced high-silicon aluminum-based composite material and a preparation method thereof. The composite material is prepared from the components in percentage bymass: 15.0 to 20.0 percent of silicon, 2.0 to 4.0 percent of copper, 0.5 to 1.0 percent of magnesium, 0.05 to 0.07 percent of titanium, 0.02 to 0.05 percent of boron, 0.3 to 0.6 percent of graphene, and the balance aluminum. The preparation method comprises the steps of (1) mixing the raw material components under gas protection to obtain alloy powder; (2) compacting the alloy powder into a massive sintered blank, and vacuum sintering to obtain a sintered blank; and (3) aiming at different silicon contents, quenching and tempering, or multi-directionally forging and annealing, and obtaining the graphene-reinforced high-silicon aluminum-based composite material. According to the method provided by the invention, reinforced-phase particles are distributed more uniformly, a large number of dislocations are produced in the material, dislocation cells are broken into sub grains or fine grains, and the fine grains are strengthened; the tensile strength is improved to be more than 400MPa; andmeanwhile, the yield strength of the material is improved to be more than 236MPa.

Owner:SHENYANG LIGONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com