Roll collar of furnace roller of roller hearth heating furnace

A technology of heating furnace and roll ring, which is applied in the field of roll ring of roller bottom heating furnace roller, which can solve the problems of unfavorable energy saving and elimination of heating billets, affecting the surface quality of coils, and high thermal conductivity of heat-resistant steel, so as to achieve energy saving effect Remarkable, strong anti-oxidation iron corrosion performance, good thermal cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

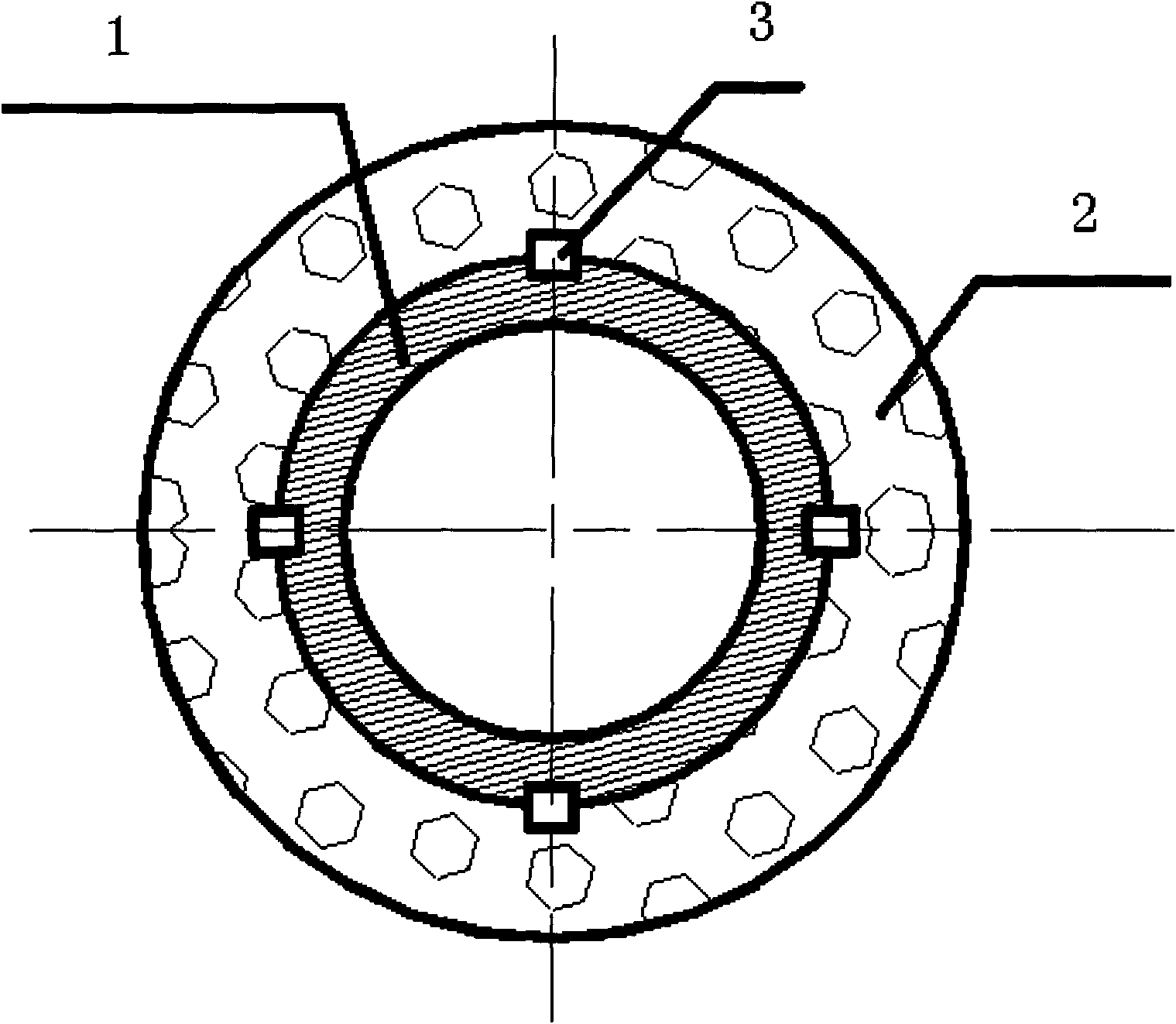

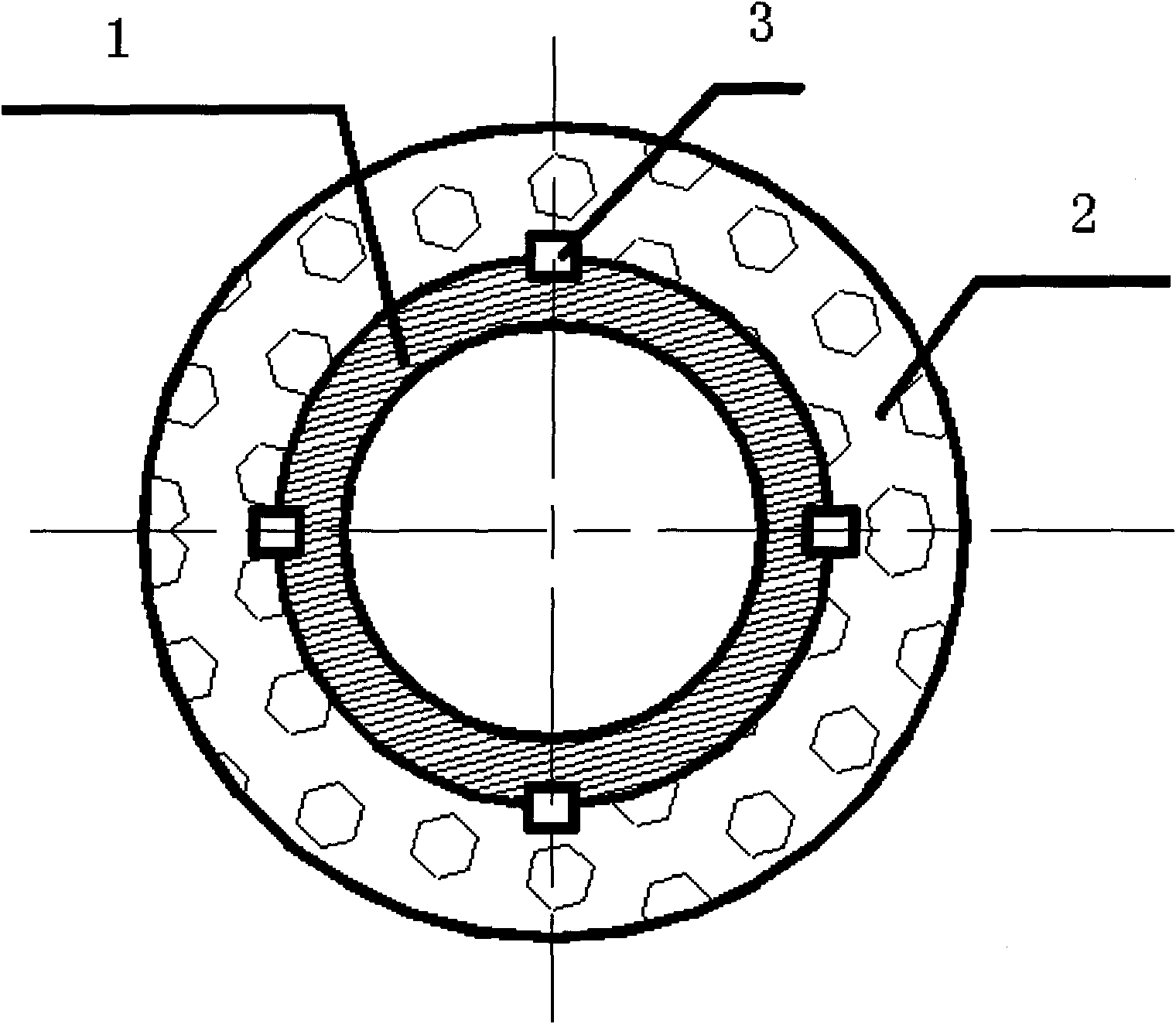

[0031] Ceramic-heat-resistant steel composite roller ring, including outer ring 2 and inner ring 1, the material of outer ring 2 is high-temperature ceramic material, the material of inner ring 1 is 1Gr18Ni9Ti heat-resistant steel, and the passage between stainless steel inner ring 1 and outer ring 2 Key 3 is connected. .

[0032] The high-temperature ceramic material contains 45% alumina (by weight), 1% chromium oxide, 36% zirconia, 17% silicon dioxide, and 1% calcium oxide. It is formed by vibration casting and fired at 1200 ° C. .

Embodiment 2

[0034] Except that the high-temperature ceramic material contains 37% alumina (weight), 1.2% chromium oxide, 39% zirconium oxide, 21.5% silicon dioxide, and 0.8% calcium oxide; the rest is the same as Example 1.

[0035] The high-temperature ceramic technical index of embodiment 1,2 is as follows:

[0036]

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com