High-precision evanescent mode cast steel coating

A Lost Foam, High Precision Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

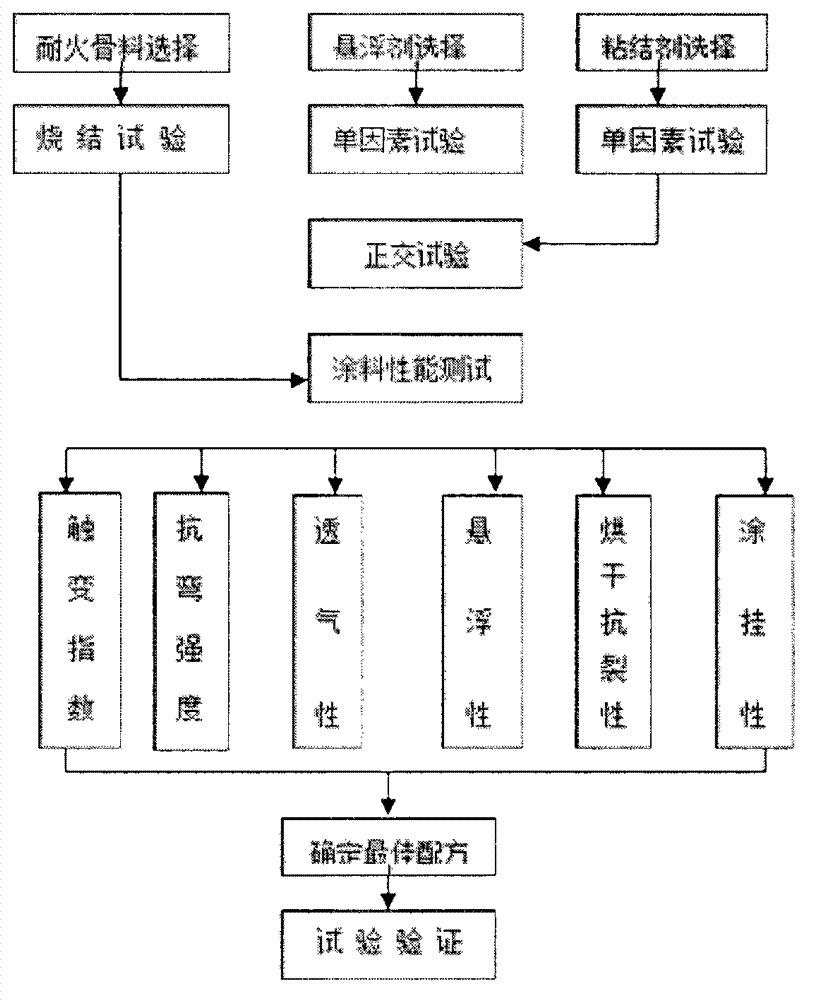

Method used

Image

Examples

Embodiment 1

[0027] Aluminum silicon powder coating formula:

[0028] Refractory aggregate: 100kg of aluminum silicate powder + 10kg of additives + 3kg of silica sol + 10-50kg of water as the carrier.

[0029] Among them, the internal components of the auxiliary agent include, by mass percentage, binder: potato modified starch 15%, suspending agent: Ca-based bentonite 30%, mineral adjustment powder: heavy calcium carbonate 50%, surfactant: FC -4430 Fluorosurfactant 5%.

Embodiment 2

[0031] Refractory aggregate: 100kg of quartz powder + 10kg of additives + 3kg of silica sol + 10-50kg of water as a carrier.

[0032] Among them, the internal components of the auxiliary agent include, by mass percentage, binder: potato modified starch 15%, suspending agent: Ca-based bentonite 30%, mineral adjustment powder: heavy calcium carbonate 50%, surfactant: FC -4430 Fluorosurfactant 5%.

Embodiment 3

[0034] Refractory aggregate: Bauxite clinker 100kg + additive 10kg + silica sol 3kg + 10-50kg water as carrier.

[0035] Among them, the internal components of the auxiliary agent include, by mass percentage, binder: potato modified starch 15%, suspending agent: Ca-based bentonite 30%, mineral adjustment powder: heavy calcium carbonate 50%, surfactant: FC -4430 Fluorosurfactant 5%.

[0036] Compared with ordinary paints, the advantages of this high-precision lost foam cast steel water-based paint are as follows:

[0037] (1) Reduce the surface roughness value of castings. After using this coating, the surface roughness of castings can be reduced by two or three grades, reaching Ra=3.2-6.3um, thereby improving the surface quality and performance of castings;

[0038] (2) It helps to prevent castings or reduce casting defects such as sand sticking and sand holes in castings, because the coating establishes a barrier with high fire resistance, chemical properties and high stabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com