Method for increasing neodymium-iron-boron permanent magnetic performance and corrosion-resisting performance

A permanent magnet material, neodymium iron boron technology, applied in the direction of inorganic materials, magnetic materials, magnetic objects, etc., can solve the problems of magnetic phase order crystal structure destruction, magnetic performance decline, magnetic performance reduction, etc., to achieve increased magnet density , Improve the stability and improve the corrosion resistance of the magnet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

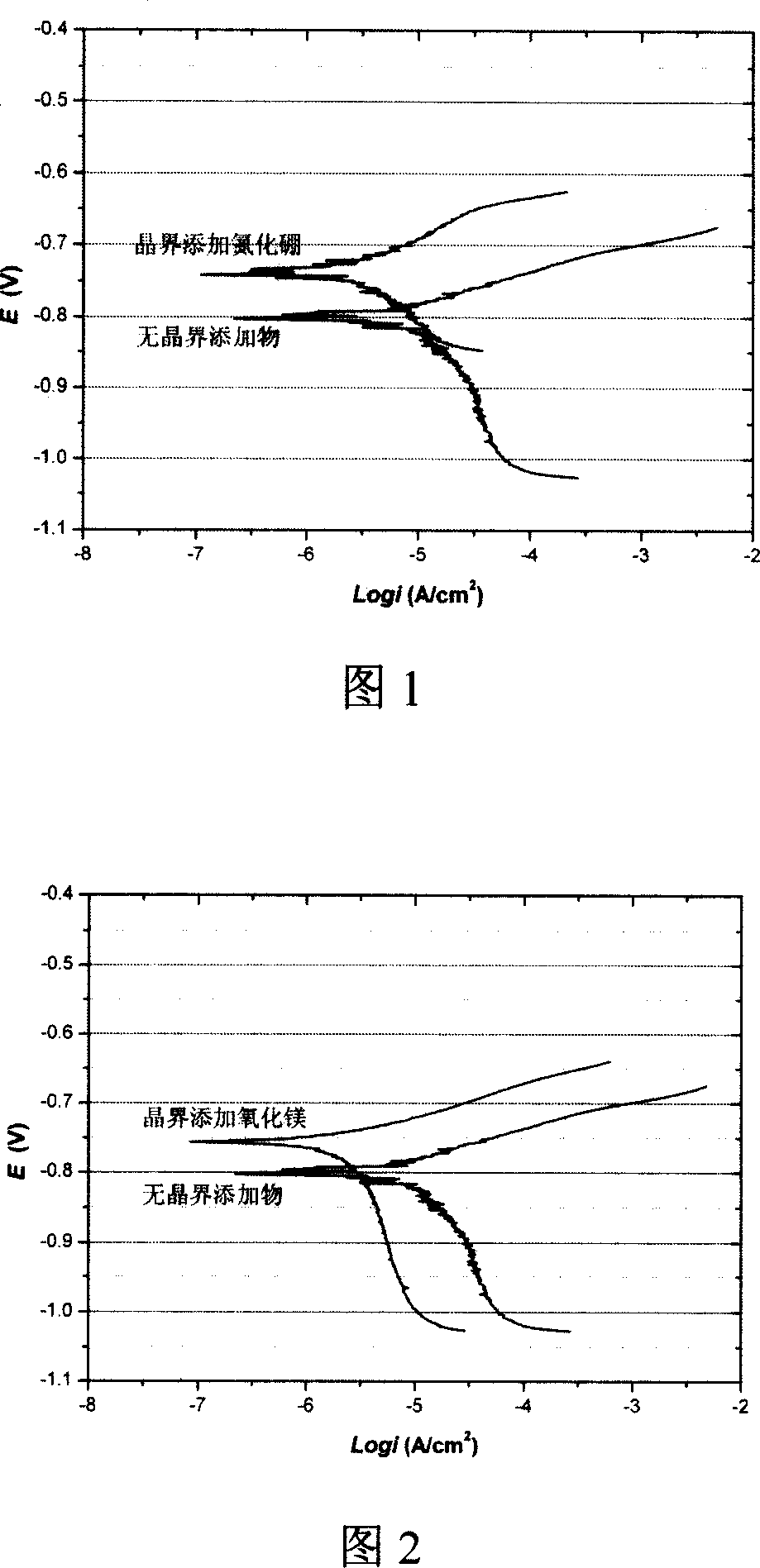

Embodiment 1

[0027] (1) NdFeB ingot alloy is made by ingot casting process, and its composition is Nd 15 Fe 余 B 6 (Dy 0.5 Al 0.4 Nb 0.2 ) (at%), the alloy is first coarsely crushed in a jaw crusher, then crushed to 80-100 mesh in a secondary crusher, and finally made into a powder with an average particle diameter of 4-5 μm by jet milling.

[0028] (2) Add boron nitride powder with a particle size of about 1 μm and dispersed treatment by ball milling and powder mixing, and its weight accounts for 0.5% of the NdFeB powder. The mixing time of the ball mill is 60 minutes, and the mixing medium is petroleum ether.

[0029] (3) The mixed powder is pressed and formed in a magnetic field orientation forming press, and the forming orientation magnetic field is 1.2T. After orientation pressing, the blank is subjected to cold isostatic pressing to increase the density of the blank, and the isostatic pressing pressure is 220 MPa.

[0030] (4) Put the blank into a high vacuum sintering furnace,...

Embodiment 2

[0036] (1) NdFeB ingot alloy is made by quick-setting sheet technology, the speed of copper roller is 2m / s, and its composition is Nd 18 Fe 余 B 5.5 Al 0.4 Dy 0.5 Ga 0.33 (at%). The alloy is first coarsely crushed in a jaw crusher, then crushed to 80-100 mesh in a secondary crusher, and finally made into a powder with an average particle diameter of 4-5 μm by jet milling.

[0037] (2) Adding dispersed magnesium oxide powder with a particle size of about 1 μm by ball milling, the weight of which accounts for 2% of the NdFeB powder. The mixing time of the ball mill is 20 minutes, and the mixing medium is petroleum ether.

[0038] (3) The mixed powder is pressed and formed in a magnetic field orientation forming press, and the forming orientation magnetic field is 1.8T. After orientation pressing, the blank is subjected to cold isostatic pressing to increase the density of the blank, and the isostatic pressing pressure is 180 MPa.

[0039] (4) Put the blank into a high vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com