Patents

Literature

55results about How to "Increase the maximum energy product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

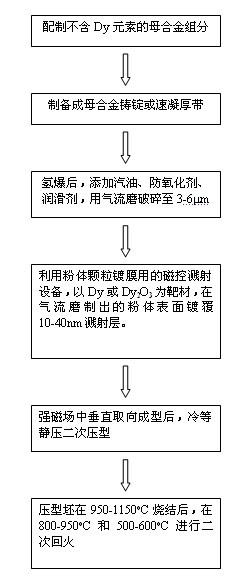

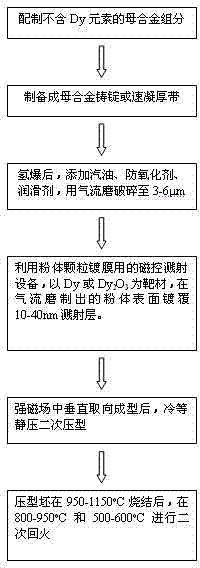

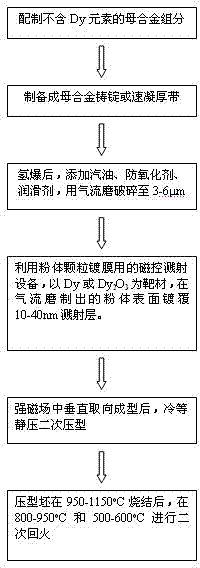

A preparation method of high-performance sintered NdFeB with low dysprosium content

The invention discloses a method for preparing sintered NdFeB with low dysprosium (Dy) content and high performance; the method comprises the following steps of: sputtering and plating the Dy element on the surface of jet mill powder by using the powder plate technology based on magnetron sputtering on the basis of preparing NdFeB powder, and then sufficiently dispersing the Dy element to micron-sized NdFeB crystal particles by dispersing the Dy element at high temperature in the sintering and tempering process, thereby achieving the effect of improving magnetic performance of the sintered NdFeB. Compared with the introduction of the Dy element in the proportioning process of the prior art, the method disclosed by the invention has the advantages: the low dysprosium content and high performance is limited in the nano-size by adopting the physical gas-phase deposition, the consumption quantity of the Dy element during the production process is controlled effectively and the preparationof sintered NdFeB with low dysprosium content and high performance is realized. Compared with the sintered NdFeB of the same components prepared by the traditional casting and powder metallurgy process, both the intrinsic coercivity and the maximum magnetic energy product of the sintered NdFeB rare-earth permanent magnetic material obtained according to the invention are improved obviously; compared with the sintered NdFeB with the same performance prepared by the traditional casting and powder metallurgy process, the dosage of the dysprosium element is reduced remarkably. The method can be widely applicable to producing and manufacturing sintered NdFeB with high performance.

Owner:NANJING UNIV OF SCI & TECH +1

Sintered neodymium-iron-boron magnet and preparation method thereof

ActiveCN102903472AImprove remanenceImprove coercive forcePermanent magnetsInorganic material magnetismMetallurgyMagnetic energy

The invention discloses a sintered neodymium-iron-boron magnet, comprising the following components in percent by weight: 29.5%-32.5% of R, 62.85%-67.54% of Fe, 0.96%-1.15% of B and 2.0%-3.5% of TM, wherein R consists of Nd, Pr and Gd or consists of Nd, Pr and Ho; B represents boron, Fe represents iron, and Tm is one or more in Al, Nb, Cu, Co, Ga and Zr. In addition, the invention also discloses a preparation method of the sintered neodymium-iron-boron magnet, and the sintered neodymium-iron-boron magnet is prepared by adopting a quick-curing piece technology and a forming and pre-pressing process. The invention has the advantages that the largest magnetic energy product and intrinsic coercive force of the sintered neodymium-iron-boron magnet can be furthest improved, and the produced sintered neodymium-iron-boron magnet has high residual magnetism and high coercive force and is lower in cost.

Owner:NINGBO YUNSHENG +4

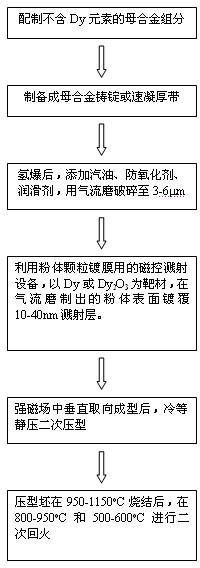

Method for increasing neodymium-iron-boron permanent magnetic performance and corrosion-resisting performance

The method includes steps: (1) using ingot-casting technique to manufacture Nd-Fe-B ingot-casting alloy, or using technique of rapid hardening sheet to produce rapid hardening sheet of Nd-Fe-B alloy; (2) first carrying out coarse crushing for alloy, then producing powder through airflow grinding; (3) adding powder of boron nitride or magnesia, and mixing them evenly; (4) pressure molding oriented mixed powders under magnetic field, and then carrying out cold isopressing process for blanks; (5) sintering and tempering blanks in high vacuum sintering furnace. Nd-Fe-B magnet produced according to the invention possesses better magnetic performance and corrosion resistance than magnetic performance and corrosion resistance of magnet without adding powder of boron nitride or magnesia.

Owner:SHANGHAI JIAO TONG UNIV

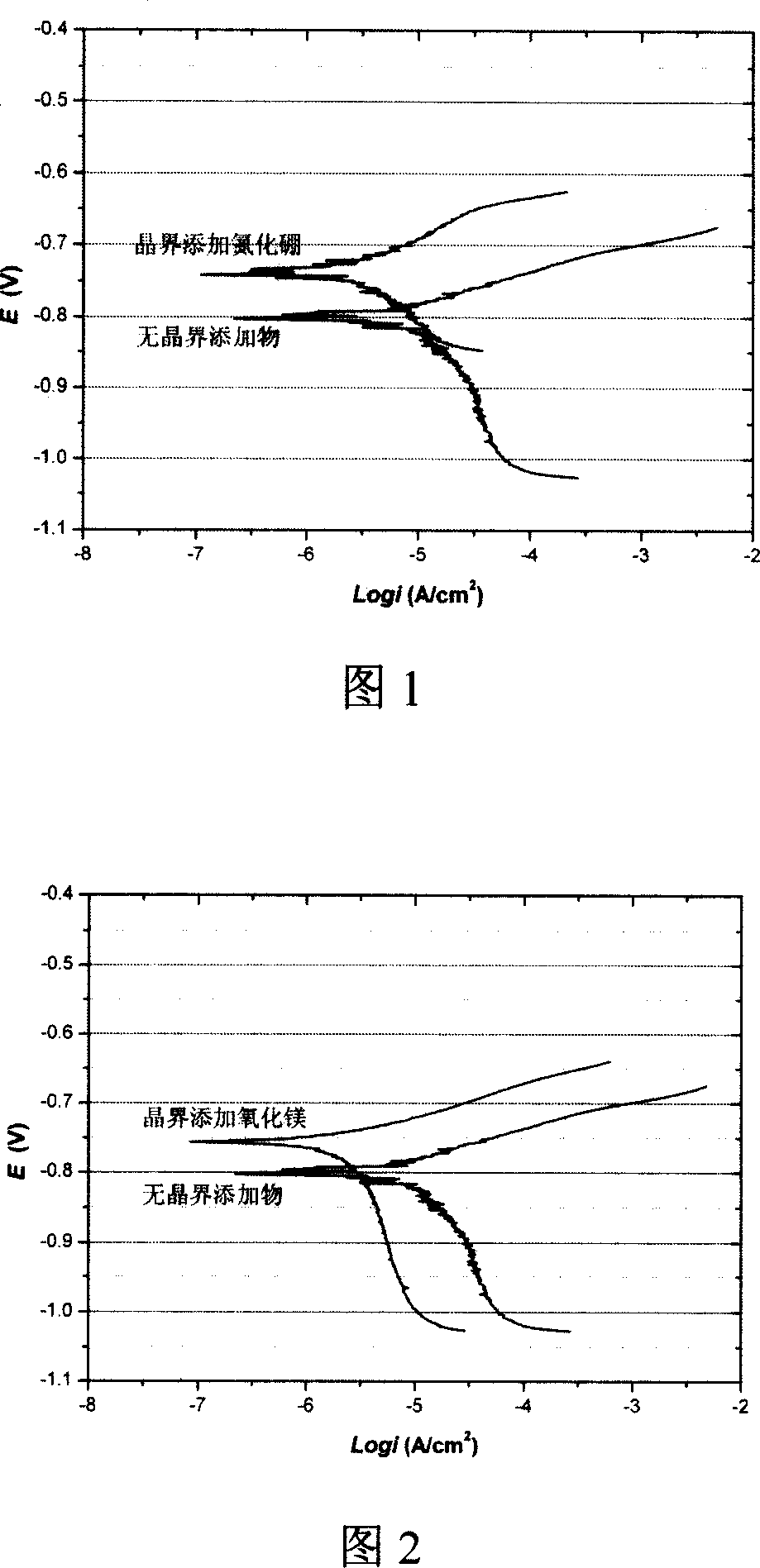

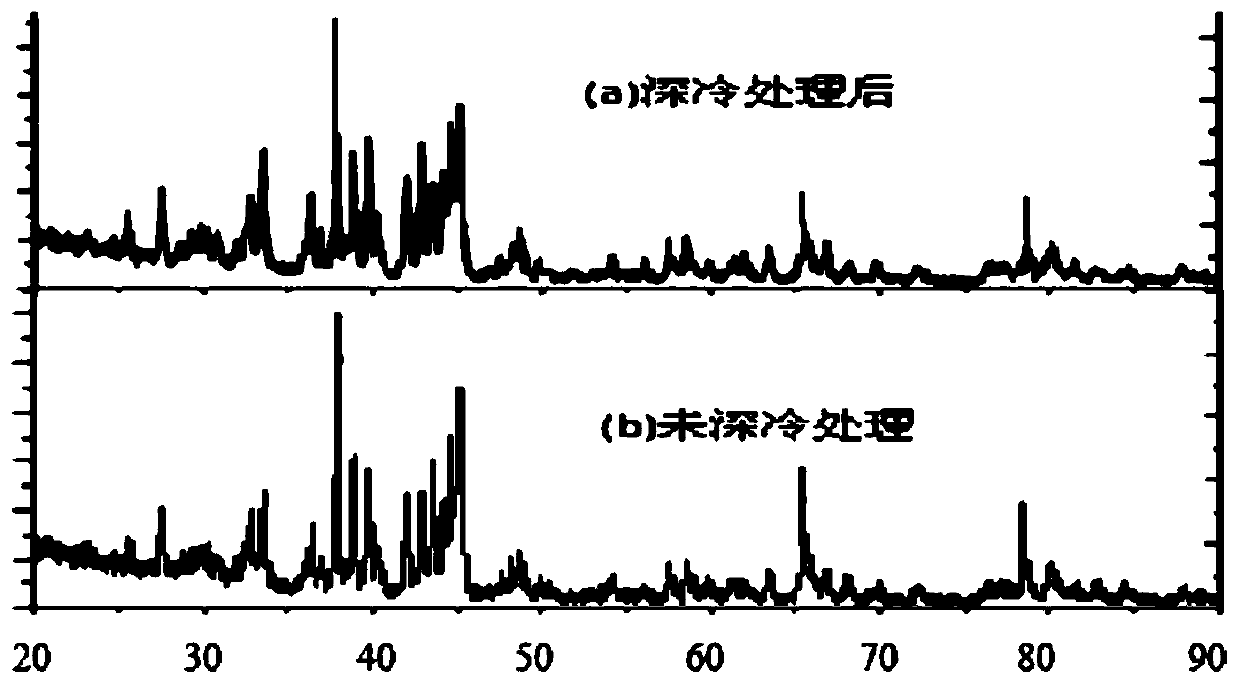

High-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and preparation method thereof

ActiveCN110523997AHigh strengthEvenly distributedTransportation and packagingMetal-working apparatusCompression moldingMaterials preparation

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and a preparation method thereof. High-entropy alloy components are optimally designed, then vacuum ball milling is conducted to prepare high-entropy alloy, and high-entropy alloy powder and microalloyed aluminum matrix powder are evenly mixed in proportion and dried to obtain mixed powder; compression molding is performed by utilizing isostatic cool pressing to obtain a composite billet; a microwave sintering process is adopted to obtain a high-entropy alloy particle reinforced aluminum-based composite material; and finally, cryogenic treatment is performed on the aluminum-based compositematerial. According to the high-entropy alloy particle reinforced aluminum-based composite material, the strength and plasticity of the aluminum-based composite material are improved, and meanwhile the aluminum-based composite material can have good magnetic performance.

Owner:JIANGSU UNIV

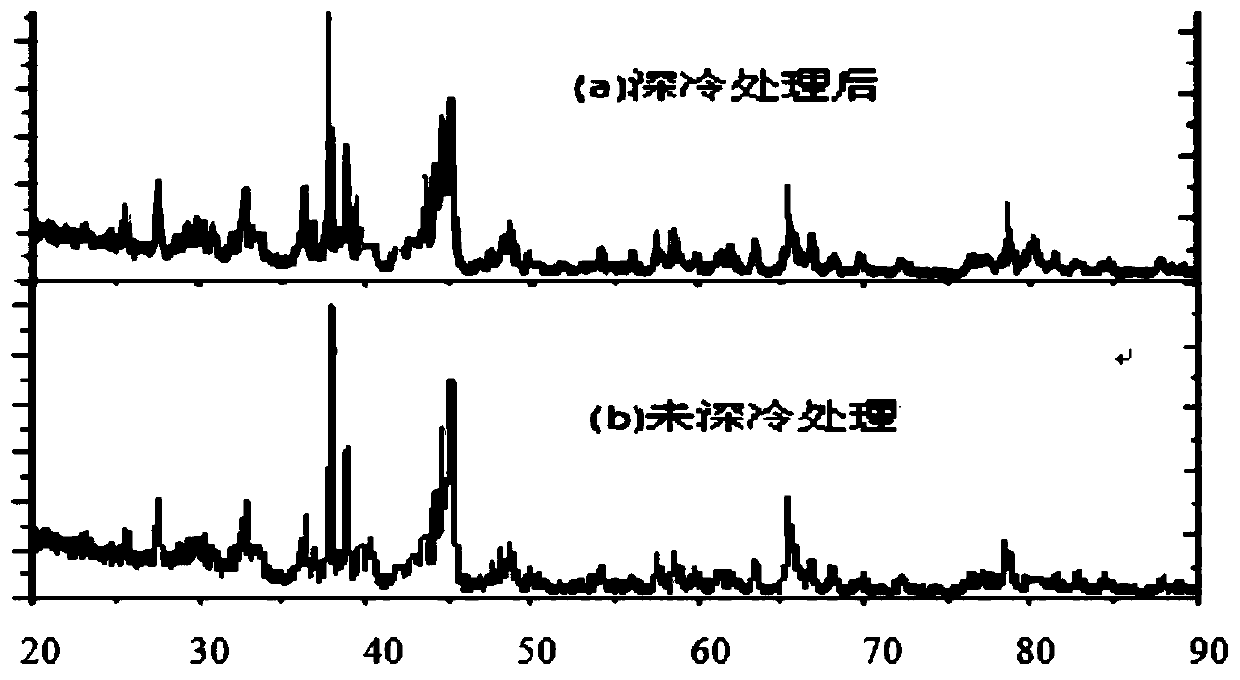

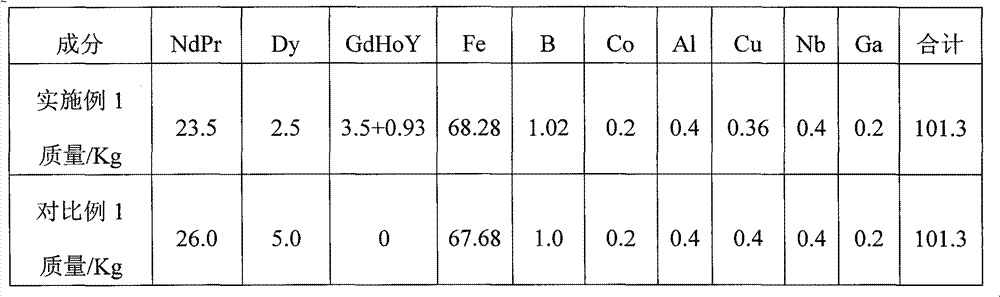

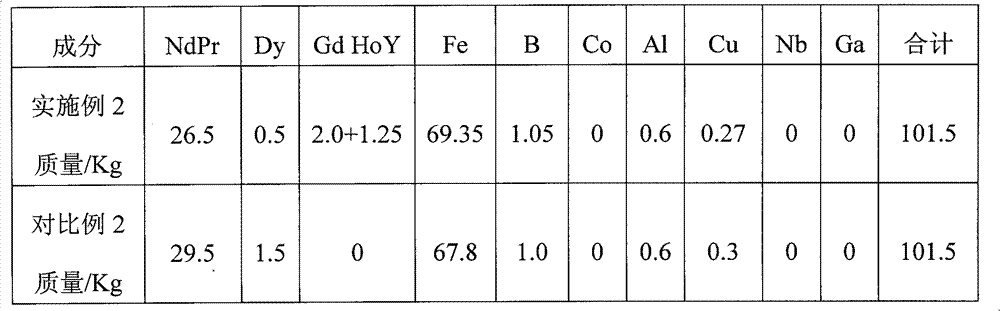

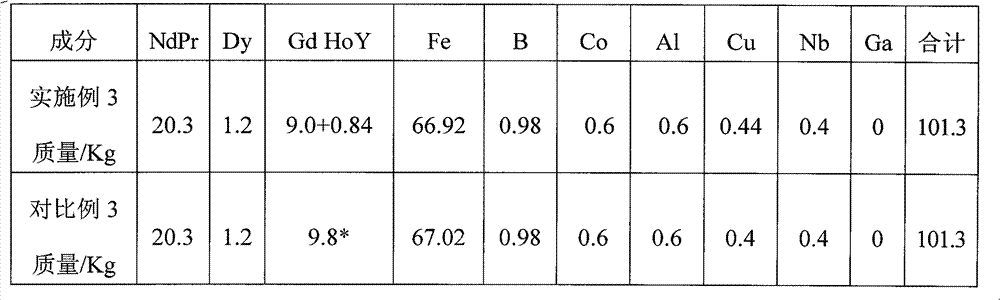

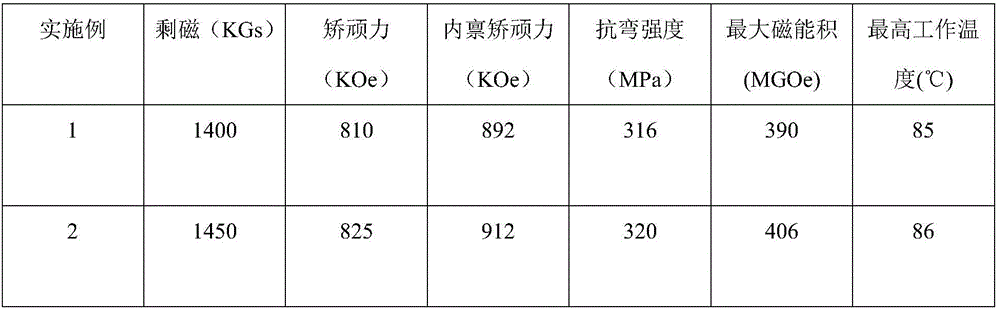

Method for preparing composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium

ActiveCN102956336AImprove remanenceIncrease the maximum energy productInorganic material magnetismRare-earth elementCurie temperature

The invention provides a method for preparing a composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium. The method includes the steps of primary batching, fusion casting, milling, secondary batching, powder mixing, forming, sintering and heat treatment, wherein in the primary batching step, iron alloy added with three rare earth elements of the gadolinium, the holmium and the yttrium is composited, and in the secondary batching step, oxide added with the three rare earth elements of ultrafine gadolinium, holmium and yttrium and cuprous oxide powder are composited. By the method, the relative surplus and cheap gadolinium, holmium and yttrium can be used for partially substituting for rare earth elements of neodymium, praseodymium or dysprosium, and accordingly neodymium, praseodymium or dysprosium consumption can be decreased by 10-30wt.%. Besides, Curie temperature and coercivity force of the prepared neodymium-iron-boron permanent magnet material are increased, corrosion resistance is enhanced, operating temperature and toughness are increased, and processability is improved.

Owner:GANZHOU JIATON ADVANCED MATERIALS

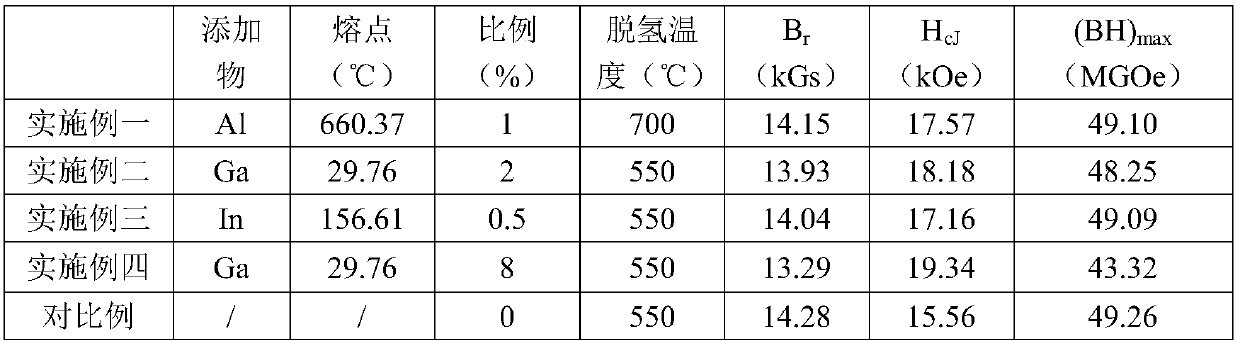

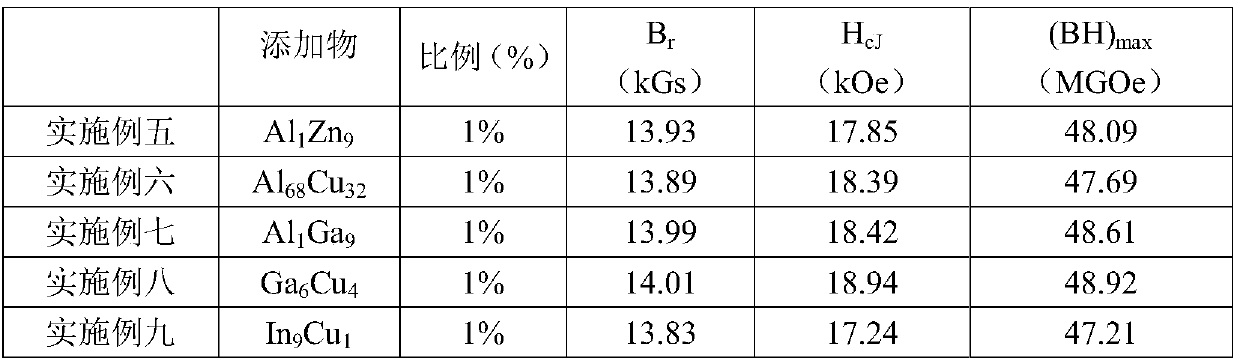

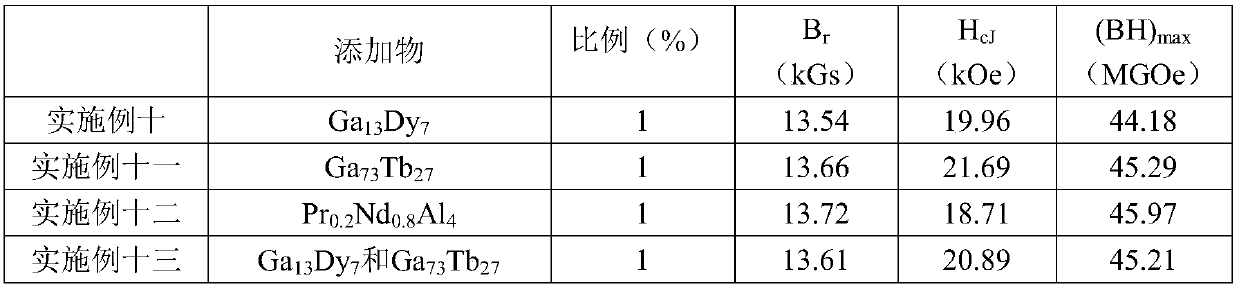

Preparation method of a sintered NdFeB magnet

InactiveCN109585113ALow heavy rare earth contentLess heavy rare earth contentInductances/transformers/magnets manufactureMagnetic materialsHydrogenRare earth

The invention discloses a preparation method of sintered NdFeB magnet. The method comprises the steps of: mixing a NdFeB alloy with a low melting point metal material to perform hydrogen crushing, andobtaining a sintered NdFeB magnet by powdering, forming, sintering and low temperature heat treatment. The sintered NdFeB magnet prepared by employing the method is high in coercive force and high inthe maximum magnetic energy product and excellent in the comprehensive magnetic properties, can save the amount of heavy rare earth and can reduce the cost.

Owner:NINGBO YUNSHENG +2

Permanent magnet for loudspeaker and processing technology thereof

InactiveCN103700463AIncrease the maximum energy productImprove coercive forceElectrical transducersPermanent magnetsAlloySound quality

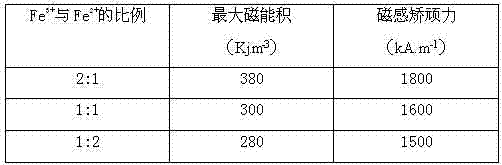

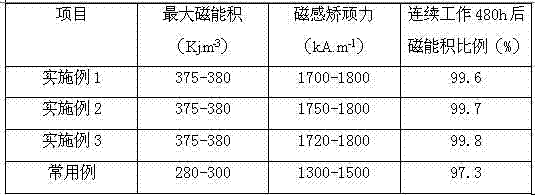

The invention discloses a permanent magnet for a loudspeaker and a processing technology thereof. The permanent magnet comprises the following components by weight percentage: 10-14.5 percent of neodymium, 1.5-2.4 percent of calcium carbonate, 2.2-2.6 percent of titanium, 8-12.5 percent of zinc oxide, 2-4.5 percent of boron, 3-4.5 percent of aluminum oxide, 0.2-0.8 percent of gallium and balance of iron oxide. The raw materials are treated through oxidization, air-stream milling, molding, isostatic pressing, oil peeling, sintering and post-processing to obtain products. By using the iron oxide as the foundation bed of the permanent magnet, when the molar ratio of ferric iron to ferrous iron in the iron oxide is 2:1, the maximum magnetic energy product of the permanent magnet is the highest, the magnetic induction coercivity is high, the connection of grains in the permanent magnet is stable after long-time use, the sound quality of the loudspeaker is guaranteed, the long-time use of the loudspeaker is facilitated, different alloy metals can be added according to loudspeakers at different frequencies, the application scope is wide and the overall performance of the loudspeaker is improved.

Owner:NINGBO STAR MATERIALS HI TECH

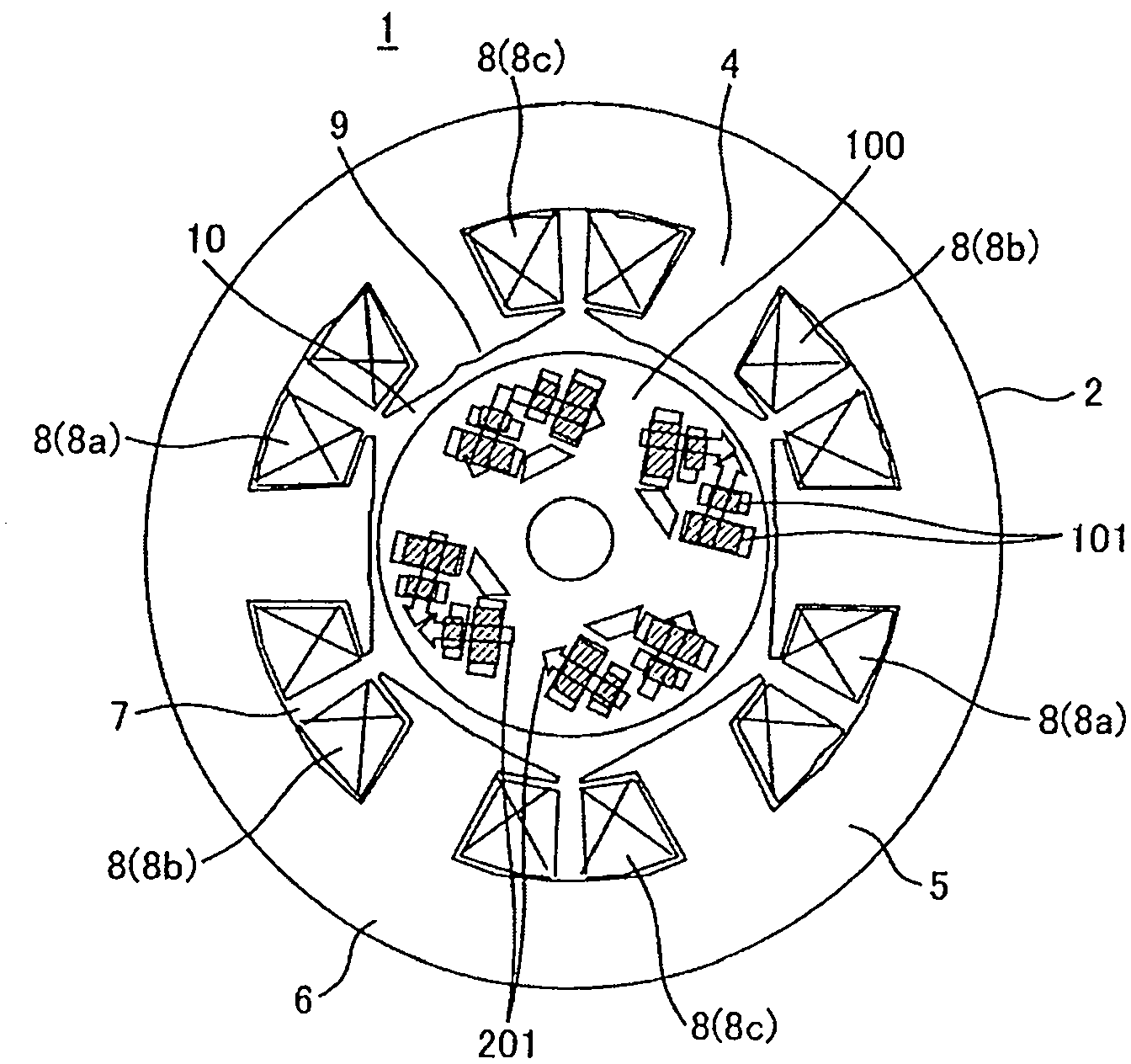

Sintered magnet motor

InactiveCN103187811AReduce usageImprove coercive forceMagnetic circuit rotating partsInorganic material magnetismEnergy productsMetallurgy

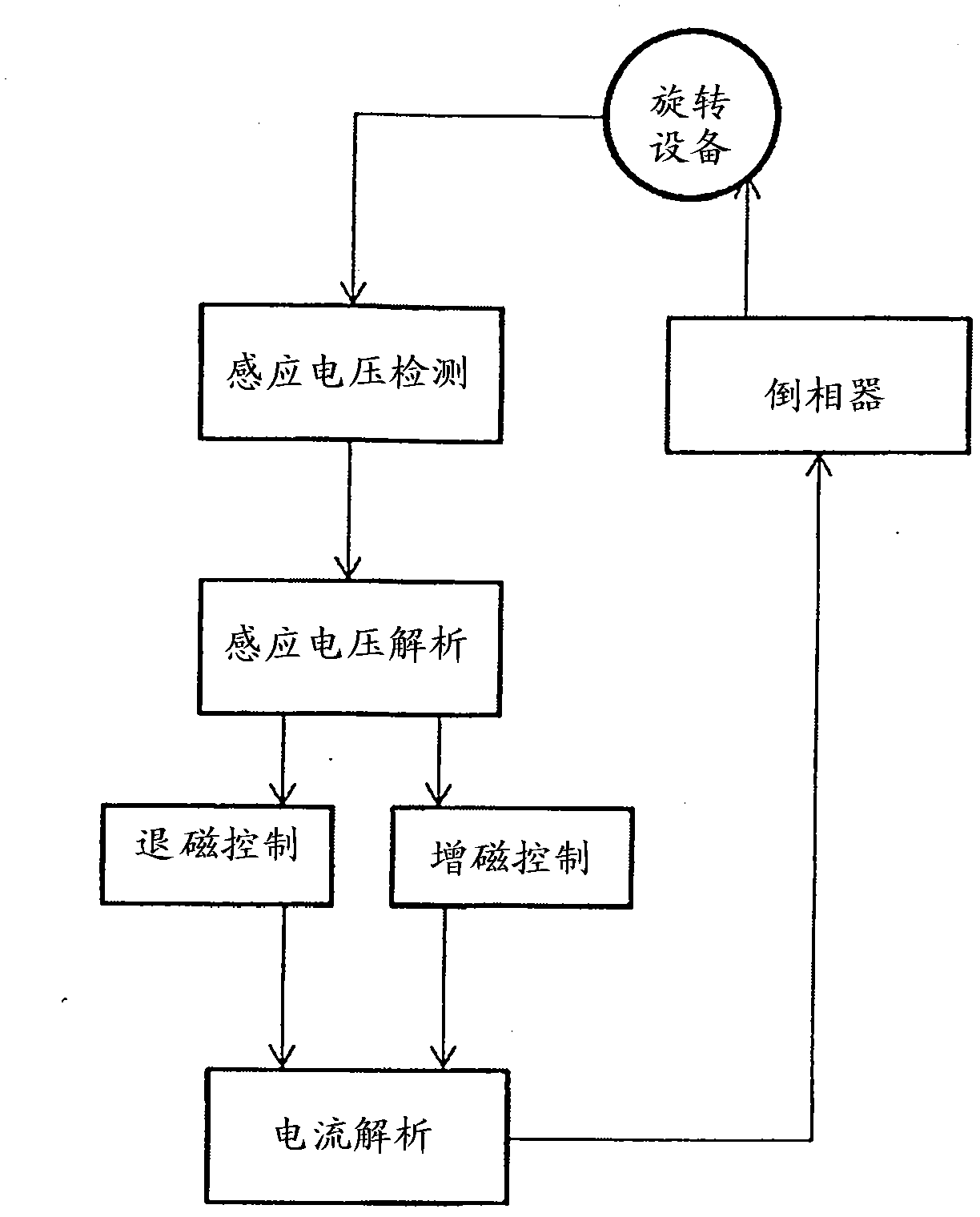

The invention relates to a sintered magnet motor. In conventional technology, there is no example in which the maximum energy product of a Nd2Fe14B sintered magnet is increased and the remanent magnetic flux density is made variable, and it is difficult to provide a variable magnetic flux motor using a sintered magnet of one kind. The sintered magnet motor includes a rotor, a stator, and coils. Sintered magnets are disposed on the rotor. In the sintered magnet motor, a residual magnetic flux density of each of the sintered magnets is controlled by a magnetic field generated by a coil current.

Owner:HITACHI LTD

Ferromagnetic particle powder, method for producing same, anisotropic magnet, and bonded magnet

ActiveCN103119664AIncrease the maximum energy productMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsMetalFerric

The present invention is a ferromagnetic particle powder constituted of 70% or more Fe16N2compound phase according to the Mossbauer spectrum. Specifically, the present invention relates to a ferromagnetic particle powder characterized by containing one or more metal elements (X) selected from Mn, Ni, Ti, Ga, Al, Ge, Zn, Pt, and Si in a molar ratio to Fe of 0.04 - 25% and having BHmax for the ferromagnetic particle powder of 5 MGOe. The present invention further relates to a method for producing the same and an anisotropic magnet and bonded magnet in which this ferromagnetic particle powder is magnetically oriented. This ferromagnetic particle powder can be produced industrially and is a Fe16N2 particle powder that contains a different metal element having a large BHmax.

Owner:TOHOKU UNIV

Method for forming nano crystal neodymium iron boron binding magnet

InactiveCN1792510AUniform densityHigh densityInductances/transformers/magnets manufactureHigh densityMetallurgy

An isostatic pressing method for shaping the adhered nano-crystalline NdFeB magnet includes such steps as proportionally mixing the nano-crystalline NdFeB magnet powder with adhesive, loading the mixture in sleeve rubber pipe, isostatic pressing under 500-800 MPa, and solidifying at 130-200 deg.C. Its advantages are high density, high magnetic performance and less consumption of adhesive.

Owner:SHANGHAI UNIV

High-performance Nd-Fe-B permanent magnet material and preparation method thereof

ActiveCN106128671AImprove plasticityImprove toughnessInductances/transformers/magnets manufactureMagnetic materialsMetallurgyRare earth

The invention relates to a high-performance Nd-Fe-B permanent magnet material. The permanent magnet material is characterized by comprising the following constituents by weight percent: 31-35% of PrNd, 0.5-1% of Gd, 0.05-0.15% of Ga, 0.05-0.15% of Zr, 0.8-1.6% of B, 0.2-0.5% of Co, 0.1-0.4% of Al, 0.05-0.2% of Cu, 0.05-0.3% of Mo, 0.05-0.3% of Ti and 0.1-0.5% of LaCe with the balance being Fe. In the permanent magnet material, the PrNd content and the Nd content are reasonably controlled, meanwhile, elements such as rear earth and Zr are added, thus, the integral maximum magnetic energy product of a magnet is improved, the usage amount of the magnet is reduced, and the permanent magnet material is lighter and is lower in cost.

Owner:宁波雄海稀土速凝技术有限公司

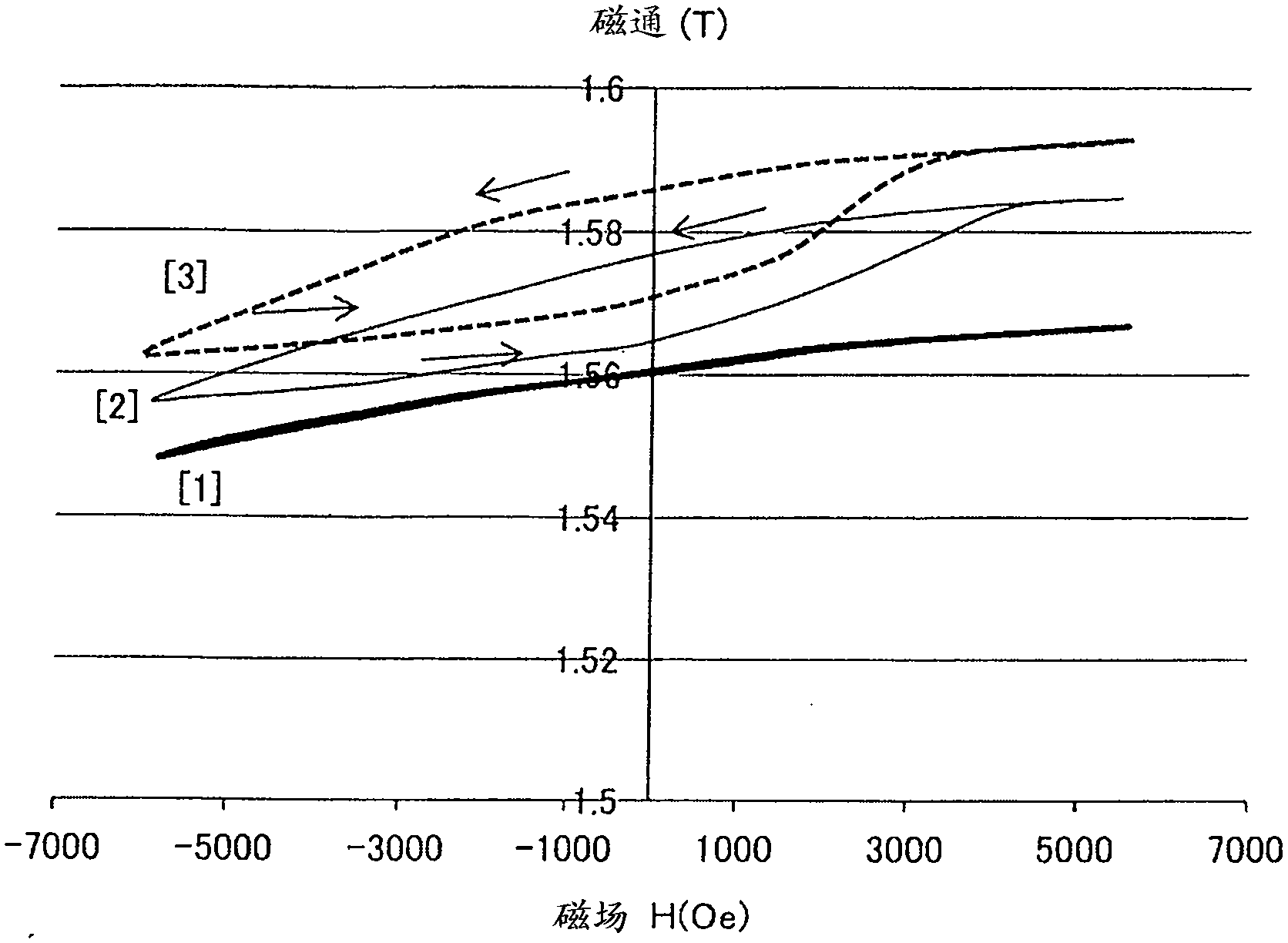

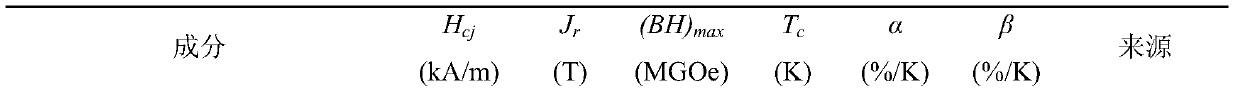

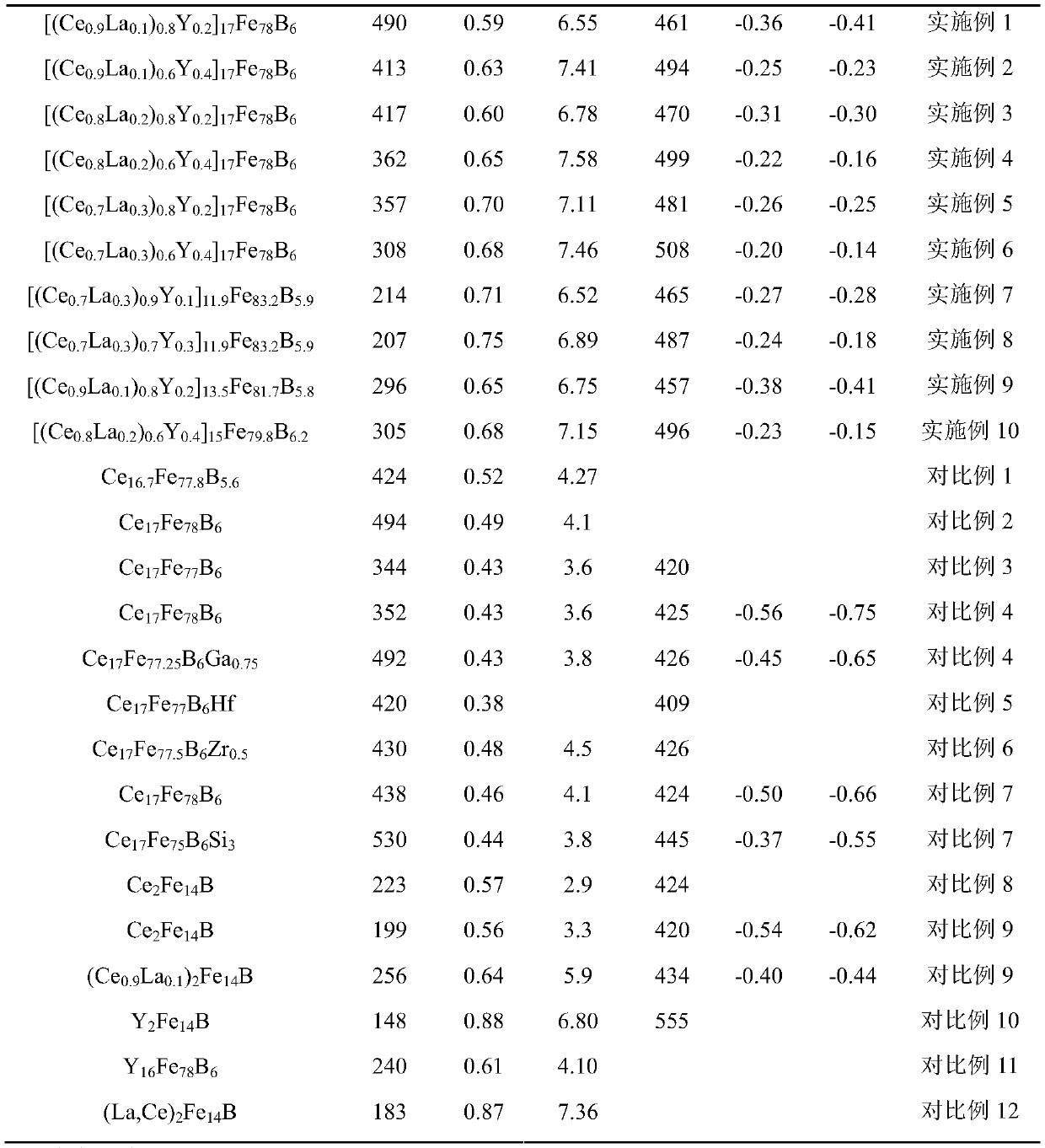

Pure high-abundance rare earth Ce, La and Y-based multi-element nanocrystalline permanent magnet alloy and preparation

InactiveCN110534279AAlleviate the problem of unbalanced utilizationIncrease the application ratioInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementAlloy

The invention belongs to the field of rare earth permanent magnet materials, and discloses a pure high-abundance rare earth Ce, La and Y-based multi-element nanocrystalline permanent magnet alloy andpreparation. The pure high-abundance rare earth Ce, La and Y-based multi-element nanocrystalline permanent magnet alloy has a composition of RE<x>Fe<101-x-y>B<y> according to an atomic ratio, x is greater than 11.5 and less than 17.5, y is greater than 5.7 and less than 6.3, and RE is [(Ce<1-a>La)<1-b>Y] composed of three rare earth elements Ce, La and Y according to a certain ratio, a is greater than 0 and less than 0.5 and b is greater than 0 and less than 0.5. The nanocrystalline permanent magnet alloy with high coercive force, high maximum magnetic energy product and excellent thermal stability is prepared by adjusting the mutual synergistic effect among high-abundance rare earth Ce, La and Y. The alloy does not contain Nd / Pr / Dy / Tb and other low-abundance rare earth, the cost performance of the magnet can be improved, and the problem of unbalanced utilization of the rare earth can be effectively solved.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of anisotropic neodymium iron boron magnetic body

InactiveCN1794387AGood orientationImprove magnetismInductances/transformers/magnets manufactureIngotMaterials science

This invention relates to a preparation method for anisotropy bond NdFeB magnet including: mixing the anisotropy bond NdFeB powder, a binder and other additives to be pressed to an ingot then putting it into a curing furnace to be cured, in which, the magnetic field is a constant or a pulse magnetic field, the magnetic density is 1-100 Tesla, the frequency of the pulse magnetic field is 0.03-0.1Hz, the cured temperature is 100-250deg.C and the time is 10 minutes to 2 hours.

Owner:SHANGHAI UNIV

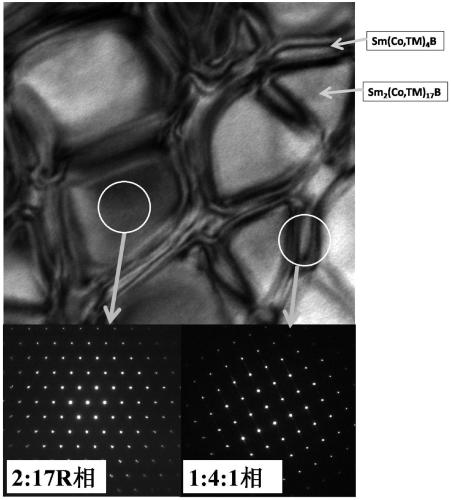

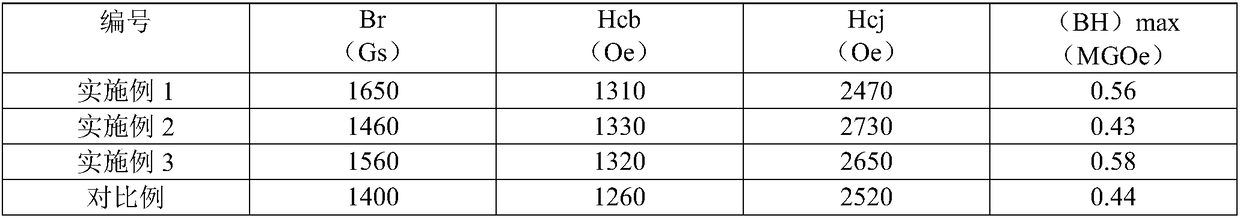

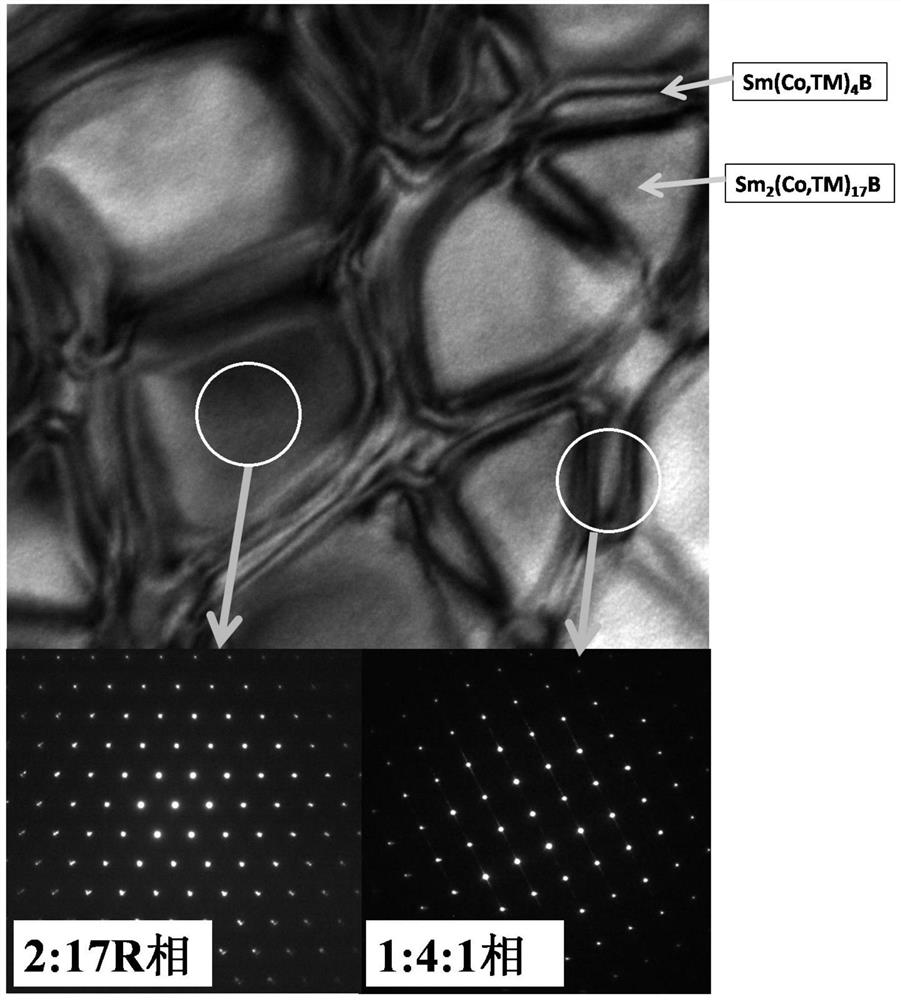

(2:17)-type SmCoCuFeZrB sintered permanent magnet and preparation method thereof

ActiveCN111180157AImprove magnetic propertiesOptimize high temperature comprehensive magnetic propertiesIncreasing energy efficiencyInductances/transformers/magnets manufactureCrystal structureSamarium

The invention discloses a (2:17)-type SmCoCuFeZrB sintered permanent magnet. The element composition formula of the sintered permanent magnet is Smx(Co1-a-b-c-dFeaCubZrcBd)z, wherein the symbols x, a,b, c, d and z in the formula represent composition ranges of limited elements, and the atomic number ratio of x to a to b to c to d to z is 1:(0.01-0.4):(0-0.03):(0.01-0.05):(0.01-0.04):(6.8-8.4); the magnet has a cellular structure, a cell wall phase is an Sm(CoFeCu)4B phase with a 1:4:1 type crystal structure, and an intracellular main phase is an Sm2(CoFe)17B phase. The invention also discloses a preparation method of the sintered permanent magnet, and the density and orientation degree of the sintered permanent magnet prepared by adoption of the method are incomparable to those of nanocrystalline and amorphous magnets; a heat treatment process, an oxygen control process and the like are matched, uncontrolled decomposition of the phase of the magnet in the heat treatment process is effectively inhibited, effective regulation and control of the microstructure and phase composition are achieved, the adding amount of the Fe element in the sintered (2:17)-type samarium-cobalt magnet isincreased, the intrinsic coercive force of the magnet under the high Fe content is improved, and then the maximum magnetic energy product of the sintered (2:17)-type samarium-cobalt magnet is increased.

Owner:CHINA JILIANG UNIV +1

Method for preparing sintered NdFeB with low dysprosium content and high performance

Owner:NANJING UNIV OF SCI & TECH +1

Dry pressing isotropic ferrite preparation method

The invention relates to the technical field of magnetic materials, particularly to a dry pressing isotropic ferrite preparation method, which comprises: (1) fine grinding of raw materials; (2) mixing: adding a primary additive to the grinded raw materials, and uniformly mixing in a powerful mixer to obtain a mixture; (3) pelletizing: carrying out pelletizing molding on the mixture and water to obtain raw ball; (4) pre-burning: making the raw ball pass through a chain fence machine, and pre-burning in a rotary kiln to obtain a pre-burning material; and (5) crushing: carrying out dry crushing on the pre-burning material to obtain the dry pressing isotropic ferrite product. According to the present invention, the method has characteristics of relatively simple preparation process and relatively low cost, and is suitable for industrial production; and the dry pressing isotropic ferrite prepared through the method can simultaneously have high remanence, high intrinsic coercive force and maximum magnetic energy product.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

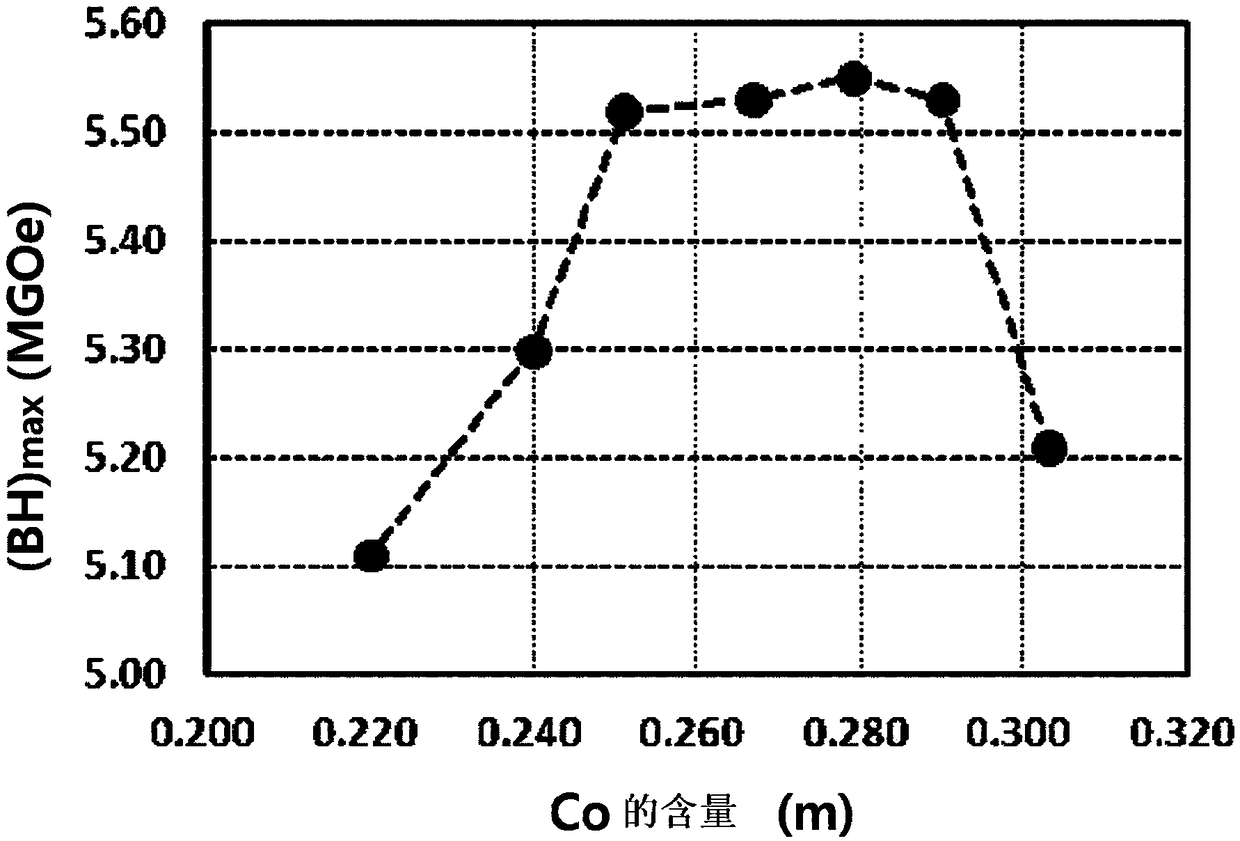

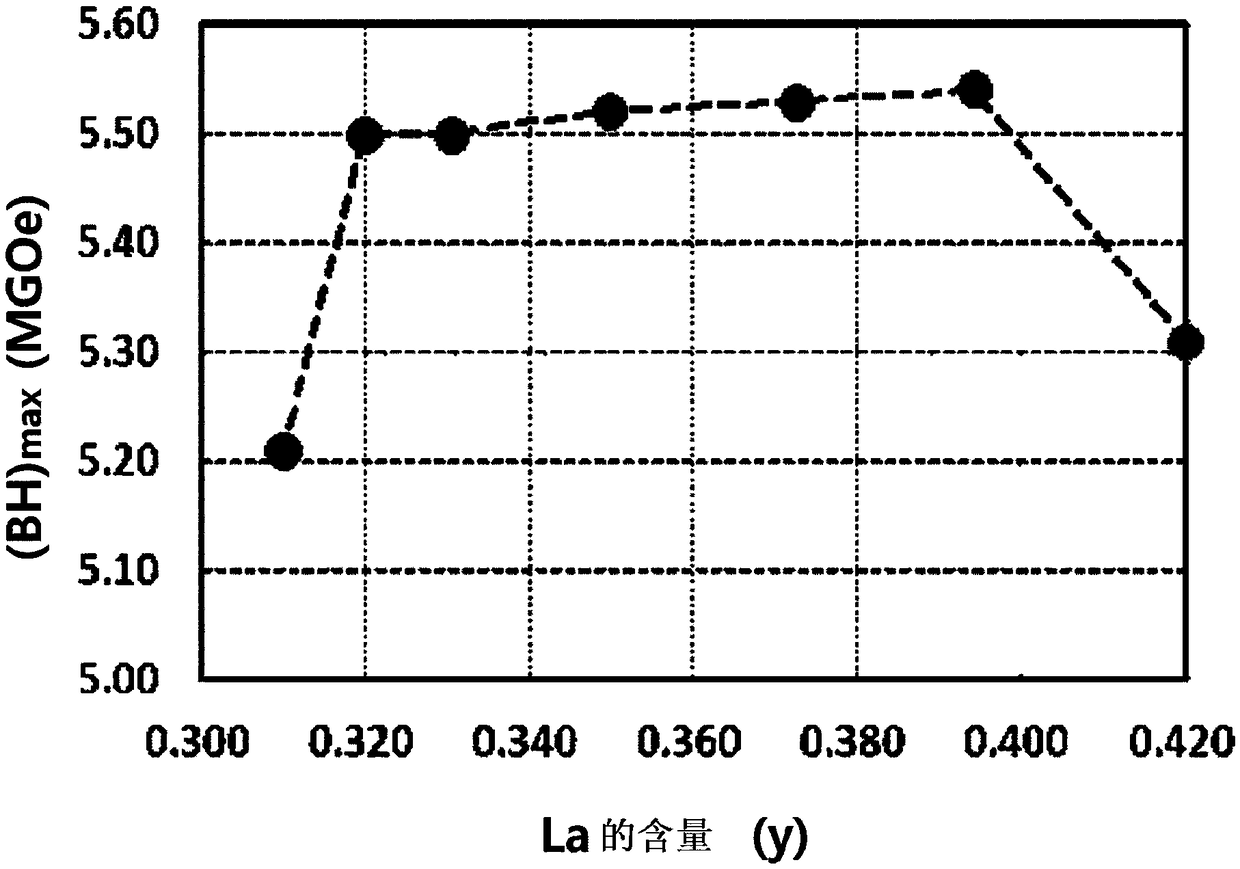

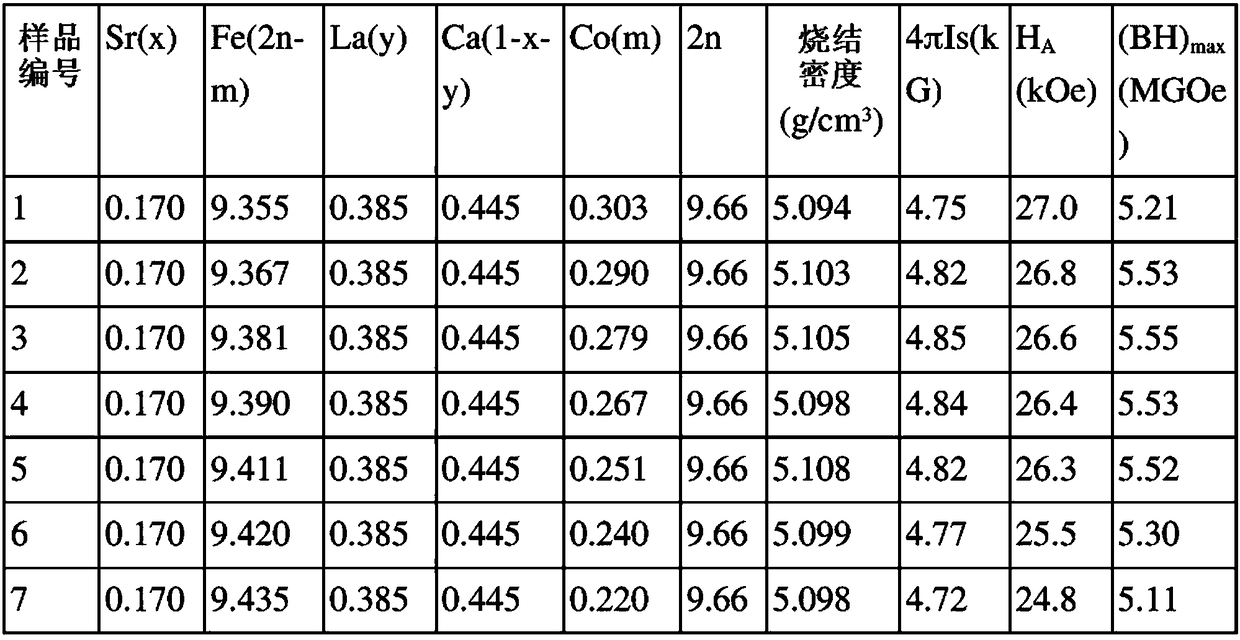

Ferrite magnetic material and ferrite sintered magnet

InactiveCN109311762AIncrease the maximum energy productEfficient processElectric machinesInorganic material magnetismSintered magnetsFerrite (magnet)

The present invention provides a ferrite magnetic material capable of inducing inexpensive high saturation magnetization and a high anisotropic magnetic field by adding a low amount of La and Co, thereby providing a maximum magnetic energy product ((BH)max) remarkably higher than that of a conventional ferrite magnetic material.

Owner:UNION MATERIALS CORP

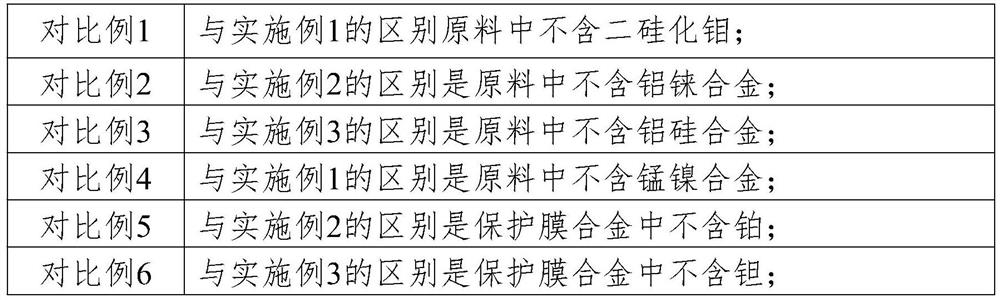

Sintered neodymium-iron-boron permanent magnet material and preparation method thereof

PendingCN111933374AIncreased uniformityGood magnetic stabilityInductances/transformers/magnets manufactureMagnetic materialsRheniumSilicon alloy

The invention relates to the technical field of permanent magnet materials, in particular to a sintered neodymium-iron-boron permanent magnet material and a preparation method thereof. The permanent magnet material is prepared from the following raw materials in parts by mass: 5-10 parts of a zinc-neodymium alloy, 8-10 parts of a praseodymium-iron alloy, 0.3-0.8 part of molybdenum disilicide, 0.1-0.5 part of silicon hexaboride, 0.01-0.1 part of an aluminum-rhenium alloy, 0.2-0.9 part of an aluminum-silicon alloy, 1-3 parts of a manganese-nickel alloy, 1-5 parts of a boron-magnesium alloy, 50-65 parts of iron powder and 5-7 parts of a protective film alloy. The residual magnetism and the maximum magnetic energy product of the magnetic material are improved; an efficient stable film is formed on the surface of the magnet in a magnetic material surface coating mode, and the cost is effectively reduced on the premise that the performance and corrosion resistance of the magnet are both considered.

Owner:宁波元辰新材料有限公司

High coercive force and high stability NdFeB magnet based on grain boundary reconstruction and its preparation method

ActiveCN103106991BImprove organizationImprove distributionPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementReconstruction method

Owner:ZHEJIANG UNIV

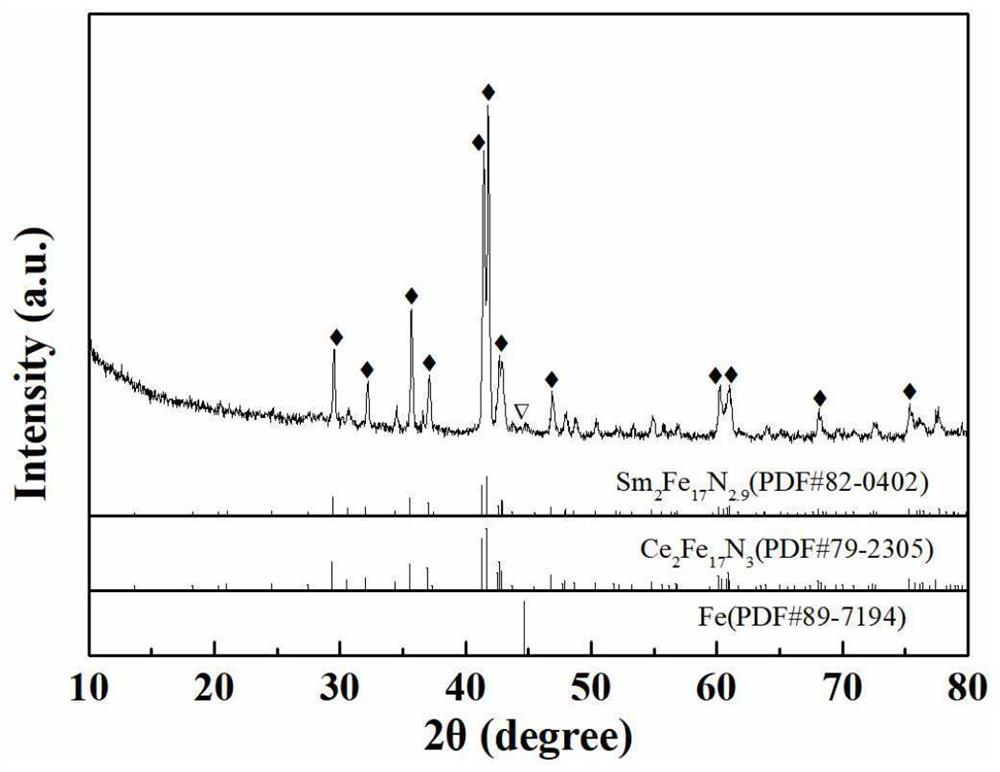

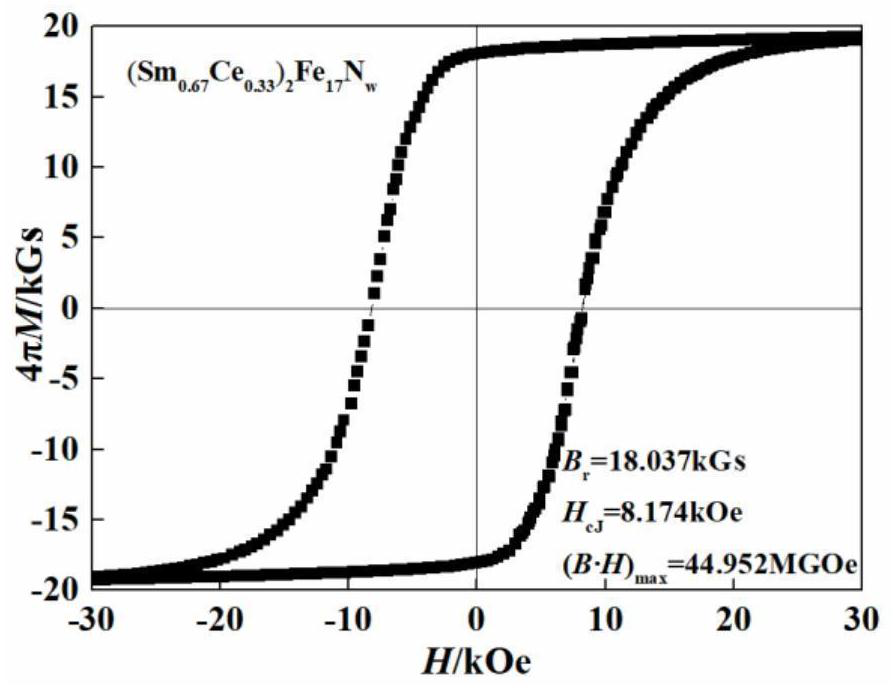

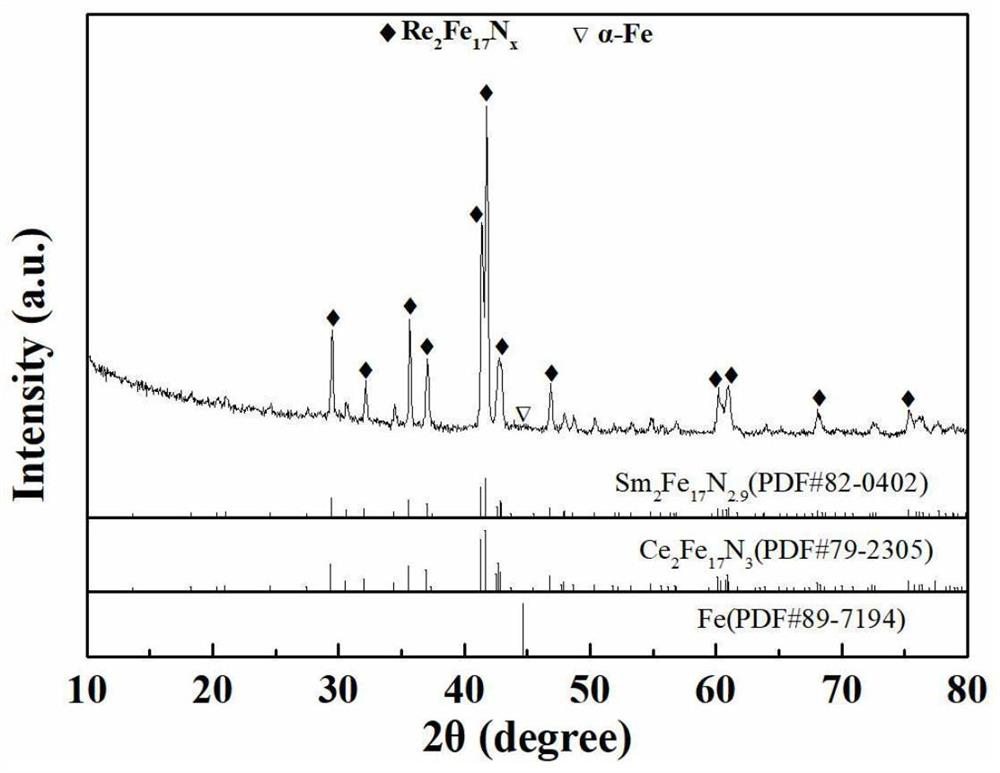

High-abundance rare earth Ce/Y/Nd/La substituted samarium-iron-nitrogen-based magnetic powder with high maximum magnetic energy product

InactiveCN111755191ACoercivity retentionSmall residual magnetismMagnetic materialsRare-earth elementCurie temperature

The invention discloses high-abundance rare earth Ce / Y / Nd / La substituted samarium-iron-nitrogen-based magnetic powder with high maximum magnetic energy product. The samarium-iron-nitrogen magnetic powder comprises the following components as shown in a molecular formula: (Sm<1-x>, REx)u(Fe<1-y-z>, Ty, Mz)vNw, wherein RE is a rare earth element Ce / Y / Nd / La or a combination of Ce / Y / Nd / La and other rare earth elements, and x is greater than or equal to 0.33 and less than or equal to 0.95. The samarium-iron-nitrogen-based magnetic powder has high maximum magnetic energy product, coercive force, residual magnetic induction intensity and high-temperature use performance. The addition of RE leads to improvement of saturation magnetization of the magnetic powder, the anisotropy is slightly reduced,and the addition of T and M can inhibit or counteract reduction of anisotropy of the magnetic powder caused by the addition of RE. RE, T and M are used for improving the saturation magnetization intensity of the magnetic powder and slightly weakening, keeping and even improving the anisotropy of the magnetic powder, and the magnetic powder still keeps a high Curie temperature.

Owner:ZHEJIANG UNIV OF TECH

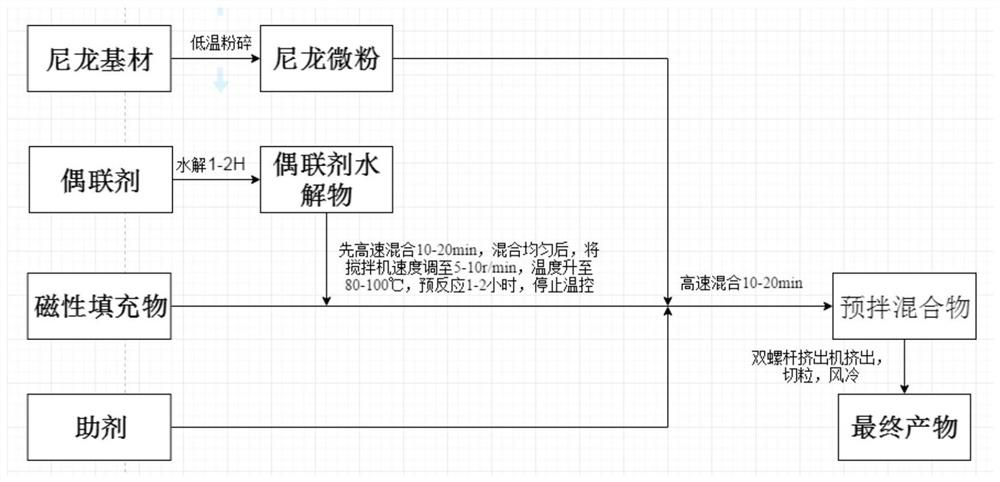

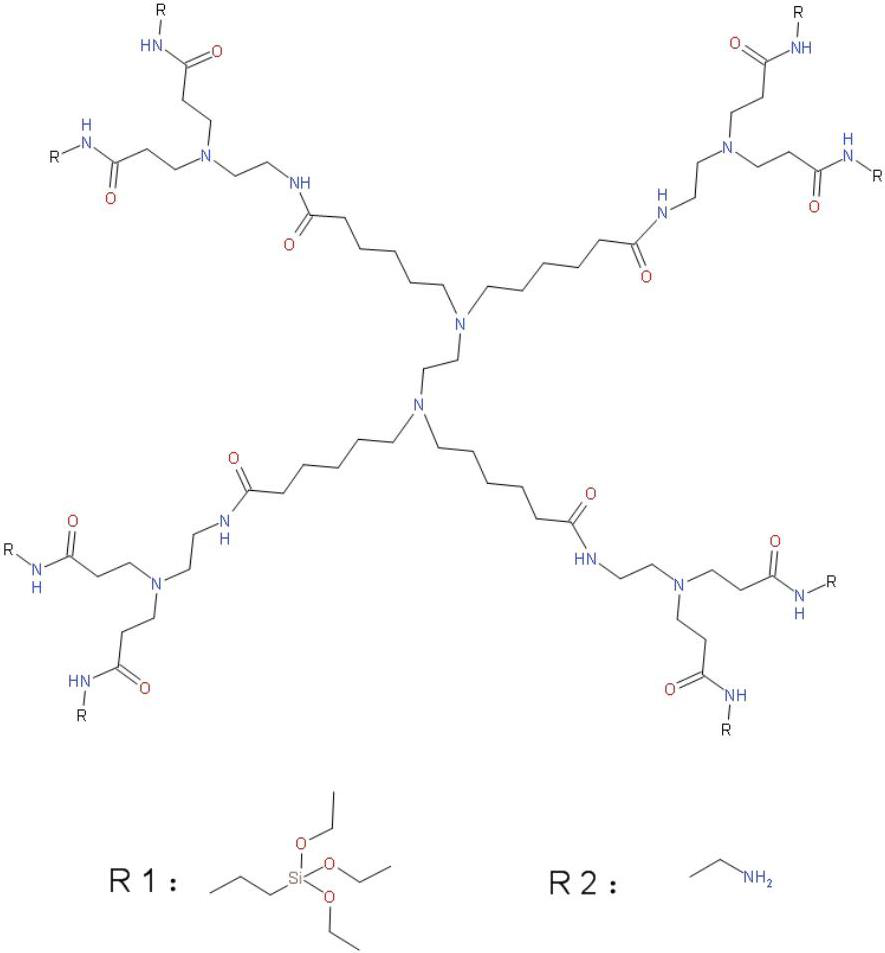

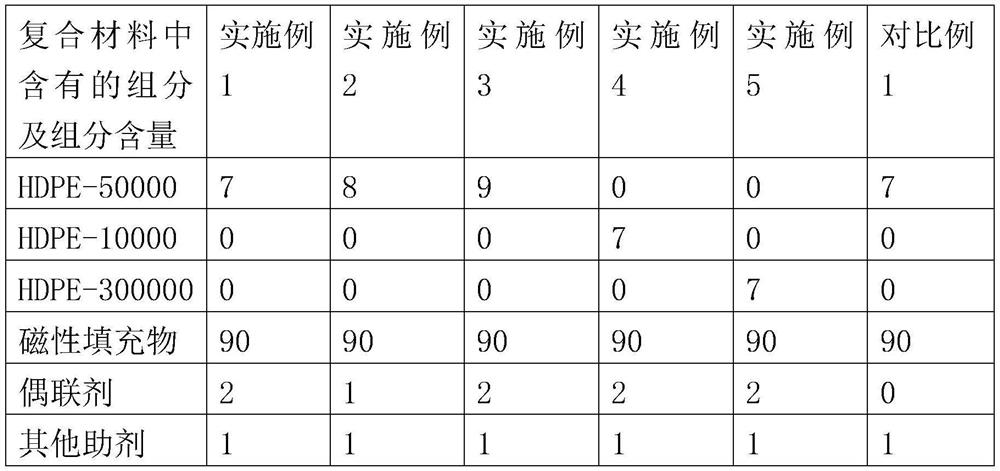

Nylon-based injection molding magnetic composite material and preparation method thereof

ActiveCN111995294AFully contactedImprove cohesive energyOrganic/organic-metallic materials magnetismUltimate tensile strengthCompatibilization

The invention belongs to the field of high polymer materials, and particularly relates to a nylon-based injection molding magnetic composite material and a preparation method thereof. The nylon-basedinjection molding magnetic composite material is prepared from the following raw materials in percentage by mass: 5%-30% of a nylon base material, 70%-95% of a magnetic filler, 1%-4% of a coupling agent and 1%-4% of an auxiliary agent. The invention discloses the nylon-based injection molding magnetic composite material. The nylon base material can be in more sufficient contact with the interfaceof the magnetic filler; the compatibility is improved, so that the filling amount is increased, the maximum magnetic energy product is increased, meanwhile, the cohesive energy of the nylon-based injection molding magnetic composite material is greatly improved due to the improvement of the interface adhesion, and the mechanical strength of the nylon-based injection molding magnetic composite material is guaranteed while the high-magnetism filler is filled.

Owner:GUANGZHOU CHENDONG NEW MATERIALS

High-speed press forming method for anisotropic binder-free neodymium iron boron magnet

ActiveCN101937769BAvoid the effects of densityNo pollution in the processInorganic material magnetismInductances/transformers/magnets manufactureRemanenceMagnetic energy

Owner:GUANGDONG YUEHAI HUAJIN TECH CO LTD

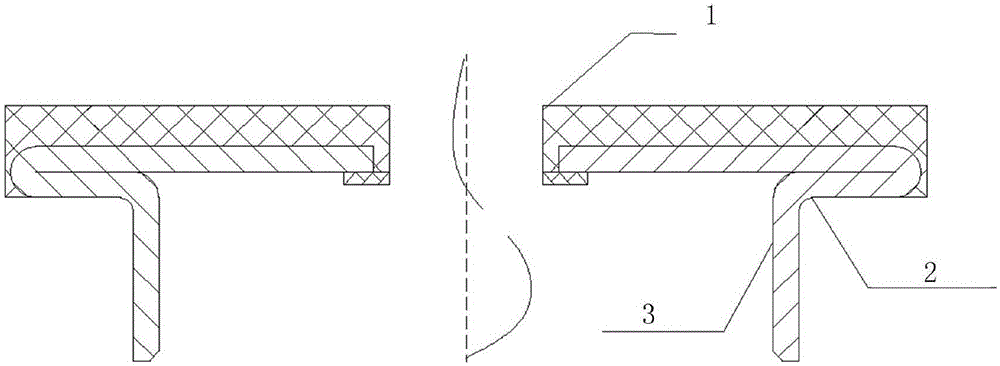

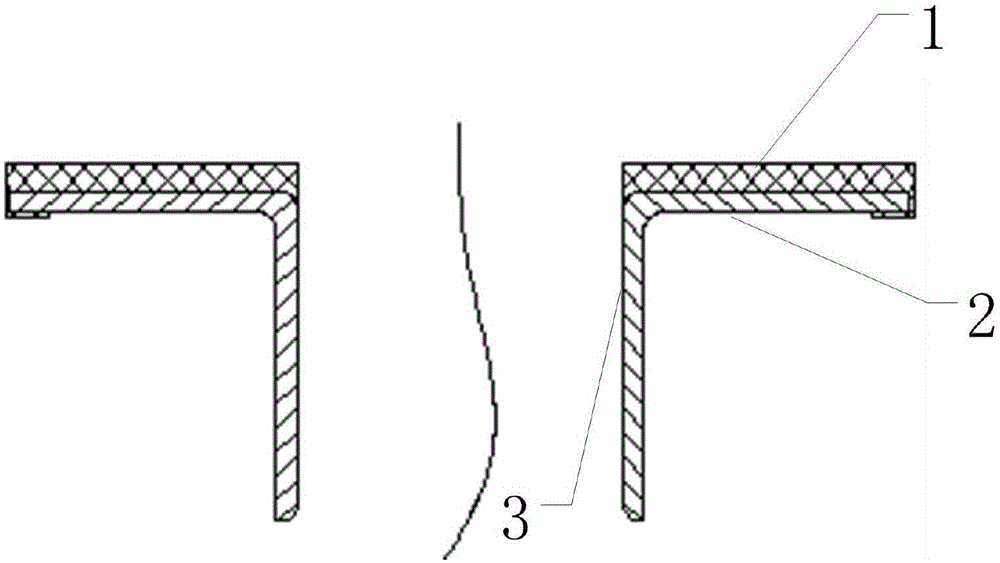

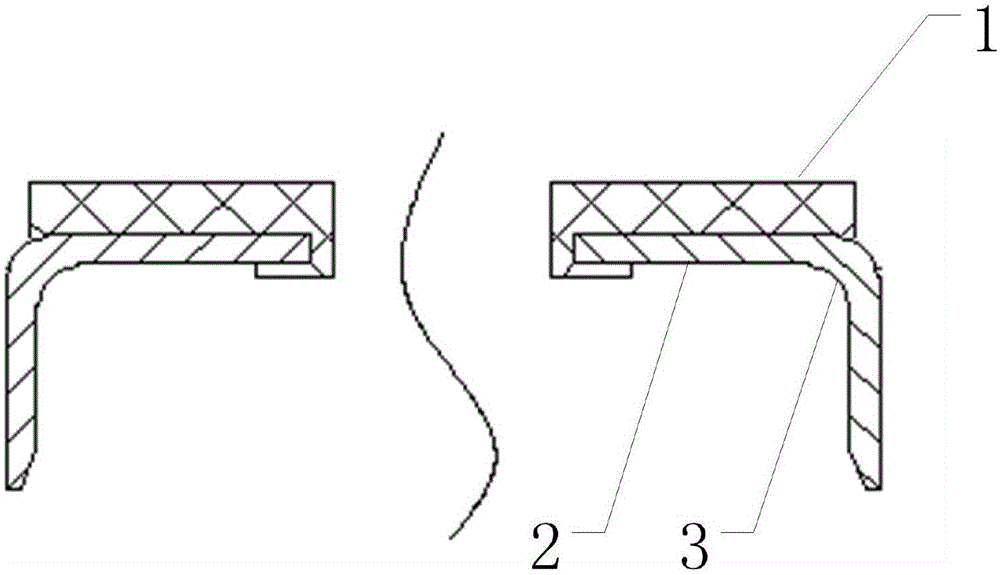

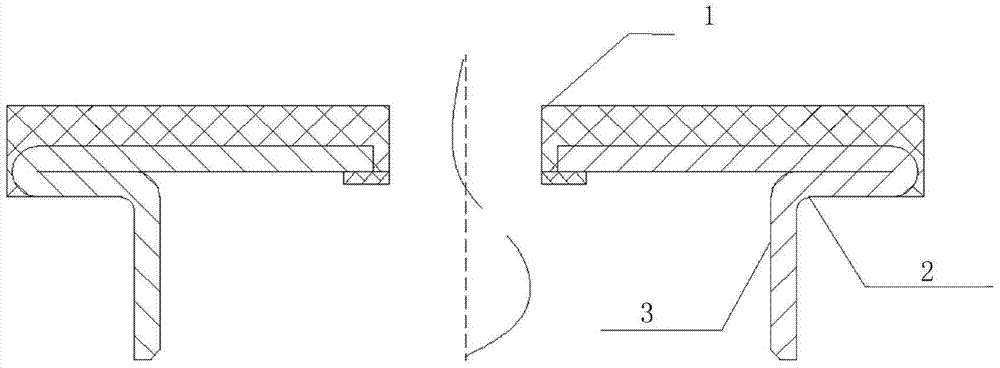

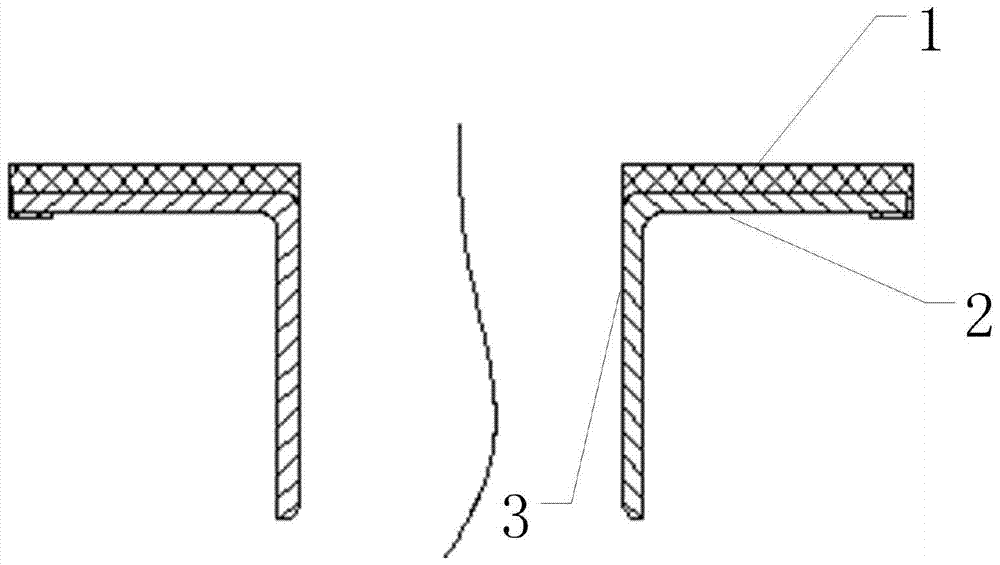

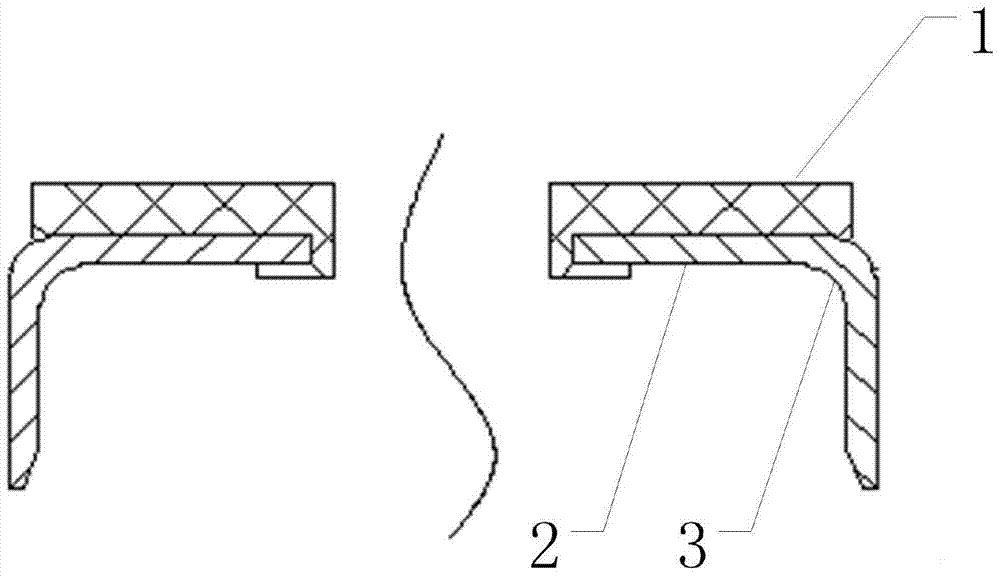

High-performance magnetic ring with engineering plastic as carrier

ActiveCN105070456AGood weather resistanceExtend your lifeCoils manufactureCoilsEngineering plasticEngineering

The invention discloses a high-performance magnetic ring with engineering plastic as a carrier. The high-performance magnetic ring comprises an annular engineering plastic layer containing ferrite materials and a metal ring skeleton. The annular engineering plastic layer is arranged on the metal ring skeleton through an injection molding technology of an injection molding machine in a wrapping mode. The metal ring skeleton is in a T or semi-T shape, and the chamfering position of the lower portion of the metal ring skeleton serves as an assembling inner diameter. The annular engineering plastic layer containing the ferrite materials conducts orientation, demagnetization, machining and remagnetization on magnetic powder in four directions immediately after injection molding is conducted on the annular engineering plastic layer through the injection molding machine and then can continuously transmit signals perpendicular to phases of N / S electrodes of the engineering plastic layer. The high-performance magnetic ring mainly solves the problems that a magnetic ring with NBR-based rubber and plastic materials serving as base materials is poor in ozone resistance, aging resistance, oil and chemical medicine corrosion resistance, impact resistance and the like; besides, residual magnetism, the maximum magnetic energy product, the intrinsic coercive field and other magnetic performance are greatly improved.

Owner:HANGZHOU WOGUAN AUTO PARTS

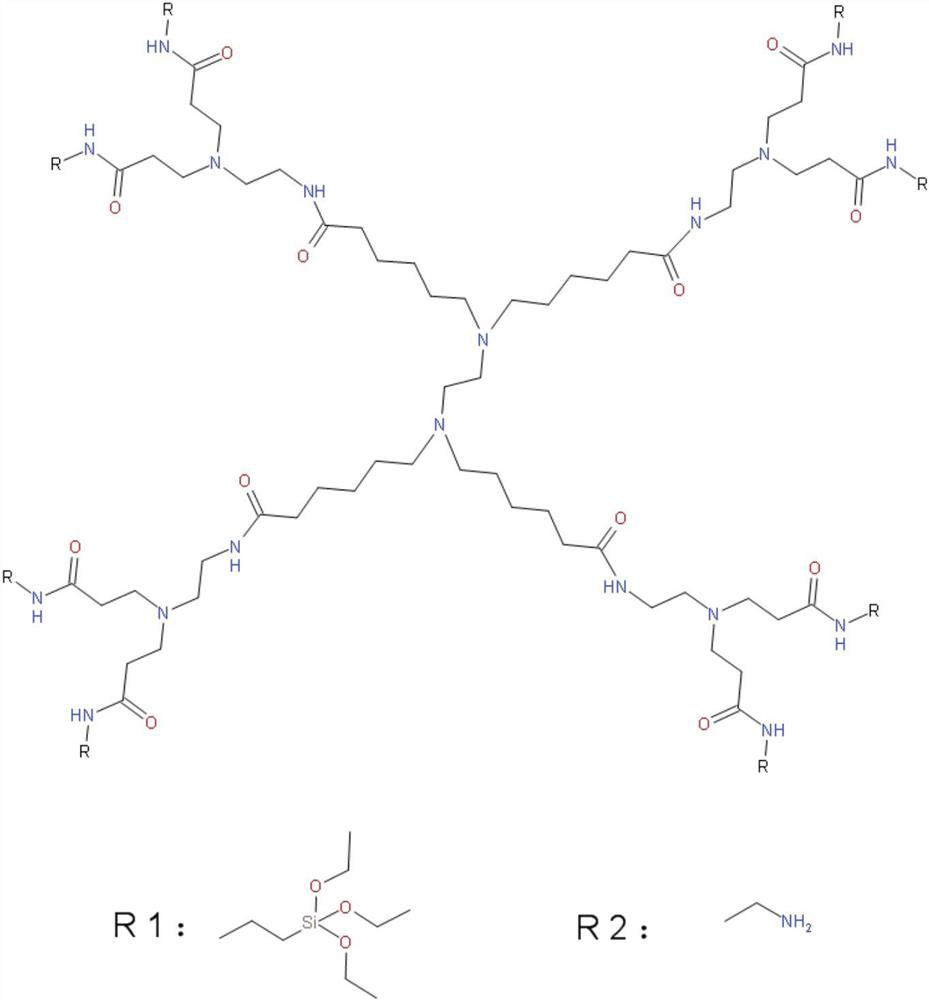

Polyethylene-based injection-molded magnetic composite material for inductor and preparation method thereof

PendingCN112679820AImprove compatibilityIncrease filling volumeOrganic/organic-metallic materials magnetismInductances/transformers/magnets manufactureInductorMagnetic composite

The invention belongs to the technical field of inductance components, and particularly relates to a polyethylene-based injection-molded magnetic composite material for a inductor and a preparation method thereof. The polyethylene-based injection-molded magnetic composite material is prepared from the following raw materials in percentage by mass: 5%-30% of a polyethylene base material, 70%-95% of a magnetic filler, 1%-4% of a coupling agent and 1%-4% of an auxiliary agent. According to the polyethylene-based injection-molded magnetic composite material disclosed by the invention, the nylon base material can be in more sufficient contact with the interface of the magnetic filler, and compatibility is improved, so a filling amount can be increased, and the maximum magnetic energy product is improved; meanwhile, the cohesive energy of the polyethylene-based injection-molded magnetic composite material is greatly improved due to the improvement of interface adhesion; and therefore, the mechanical strength of the polyethylene-based injection-molded magnetic composite material is ensured while filling of the high-magnetism filler is conducted.

Owner:慧迈材料科技(广东)有限公司

A magnetic ring based on engineering plastics as a carrier

ActiveCN105070456BEvenly dispersedGood weather resistanceCoils manufactureCoilsRubber materialEngineering plastic

The invention discloses a high-performance magnetic ring based on engineering plastics as a carrier, which includes a ring-shaped engineering plastic layer containing ferrite materials and a metal ring skeleton, and the ring-shaped engineering plastic layer is wrapped in the metal ring through an injection molding process of an injection molding machine On the skeleton, the metal ring skeleton is a "T" or "half T" shaped metal ring skeleton, and the chamfer at the lower part is the inner diameter of the assembly; the ring-shaped engineering plastic layer containing ferrite material is injected by an injection molding machine Immediately after orientation, demagnetization, machining and re-magnetization of the magnetic powder in all directions, it can continuously emit signals perpendicular to the N / S pole phase of the engineering plastic layer. The patent of this invention mainly solves the problems of ozone resistance, aging resistance, oil resistance, chemical corrosion resistance, and poor impact resistance of the magnetic ring with NBR as the main rubber and plastic material as the base material. In addition, the residual magnetism, maximum magnetic energy product, The magnetic properties such as intrinsic coercive force have been greatly improved.

Owner:HANGZHOU WOGUAN AUTO PARTS

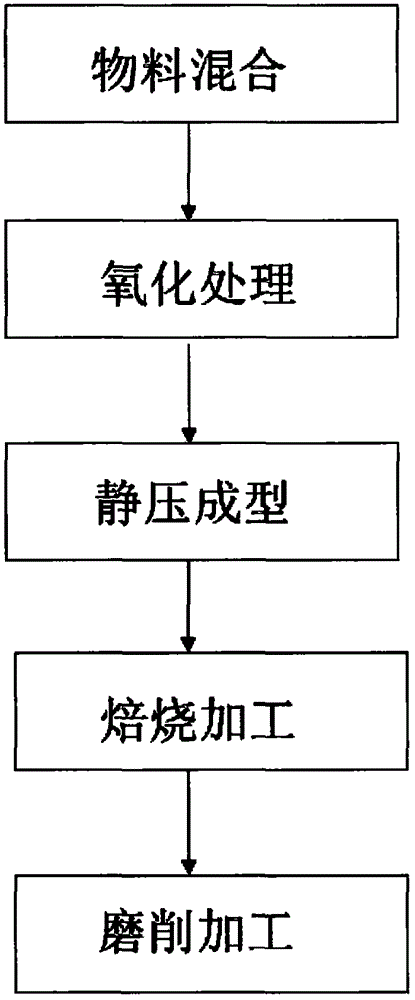

Permanent magnet for loudspeaker and preparation method thereof

InactiveCN105957685ALow costFlexible and efficient production preparationPermanent magnetsInductances/transformers/magnets manufactureLoudspeakerYttrium

The invention provides a permanent magnet for a loudspeaker. The permanent magnet is prepared from the following components in percentages by weight: 1.5%-2.5% of neodymium, 2.1%-3.5% of titanium, 3%-7% of boron, 0-3% of yttrium-iron alloy, 1%-8% of kaolin and the balance of ferric oxide. A preparation method thereof comprises the five steps of material mixing, oxidation treatment, static pressure molding, roasting processing and abrasive machining. The permanent magnet is simple in technology, low in production condition requirement and relatively low in raw material cost compared with a traditional magnet, so that the preparation for magnet production can be developed flexibly and efficiently, and the production cost of the magnet is reduced; meanwhile, the density and structural strength of the magnet are effectively improved, the crystallite stability inside the magnet is good, the maximum magnetic energy product is high, and the coercive force of magnetic induction is high, so that the service life of the loudspeaker can be effectively prolonged, the sound quality effect of the loudspeaker is improved, and the quality of the loudspeaker is improved.

Owner:NANTONG WANBAO IND

Preparation method of 2:17 type SmCoCuFeZrB sintered permanent magnet

ActiveCN113020595AImprove magnetic propertiesOptimize high temperature comprehensive magnetic propertiesIncreasing energy efficiencyInductances/transformers/magnets manufactureSamariumMagnet

The invention discloses a preparation method of a 2:17 type SmCoCuFeZrB sintered permanent magnet. The preparation method is used for preparing the sintered permanent magnet Smx (Co1-a-b-c-dFeaCubZrcBd)z, the symbols x, a, b, c, d and z in the formula represent the composition range of limited elements, and the atomic number ratio of x to a to b to c to d to z is 1: (0.01-0.4): (0-0.03): (0.01-0.05): (0.01-0.04): (6.8-8.4); and the magnet has a cellular organization structure, and an intracellular main phase is an Sm2 (CoFe) 17B phase. The density and orientation degree of the sintered permanent magnet prepared by the method are incomparable to those of a nanocrystalline magnet and an amorphous magnet; and through cooperation of a heat treatment process, an oxygen control process and the like, uncontrolled phase decomposition of the magnet in the heat treatment process is effectively inhibited, effective regulation and control of a microstructure and phase composition are achieved, the addition amount of Fe elements in the sintered 2:17 type samarium-cobalt magnet is increased, the intrinsic coercive force of the magnet under the high Fe content is improved, and the maximum magnetic energy product of the sintered 2:17 type samarium-cobalt magnet is further improved.

Owner:CHINA JILIANG UNIV +1

Durable magnetic ceramic material

The invention discloses a durable magnetic ceramic material. The durable magnetic ceramic material is prepared from 30-45 parts by weight of zirconium dioxide, 0.8-1.4 parts by weight of cobaltous sulfide, 1-4 parts by weight of ferriferrous oxide, 12-18 parts by weight of magnesium oxide, 10-20 parts by weight of titanium dioxide, 8-14 parts by weight of tin oxide, 2-4 parts by weight of polyethylene, 12-16 parts by weight of a curing agent, 10-15 parts by weight of carbonyl iron powder, 6-8 parts by weight of aliphatic polyurethane acrylate, 3-5 parts by weight of a coupling agent, 2-4 parts by weight of ferroboron, 1-2 parts by weight of holmium iron oxide, 1-2-2.3 parts by weight of cobalt and 2-4 parts by weight of iron oxide. The durable magnetic ceramic material has the advantages of high maximum magnetic energy product, high hardness, wear resistance, durability, excellent corrosion resistance, simple preparation processes and long service life.

Owner:QINGDAO YUXING INTELLIGENT TECH DEV CO LTD

A kind of preparation method of high performance permanent magnet ferrite

ActiveCN112209707BReduce churnReduce processing costsInorganic material magnetismInductances/transformers/magnets manufactureGrogDry mixing

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

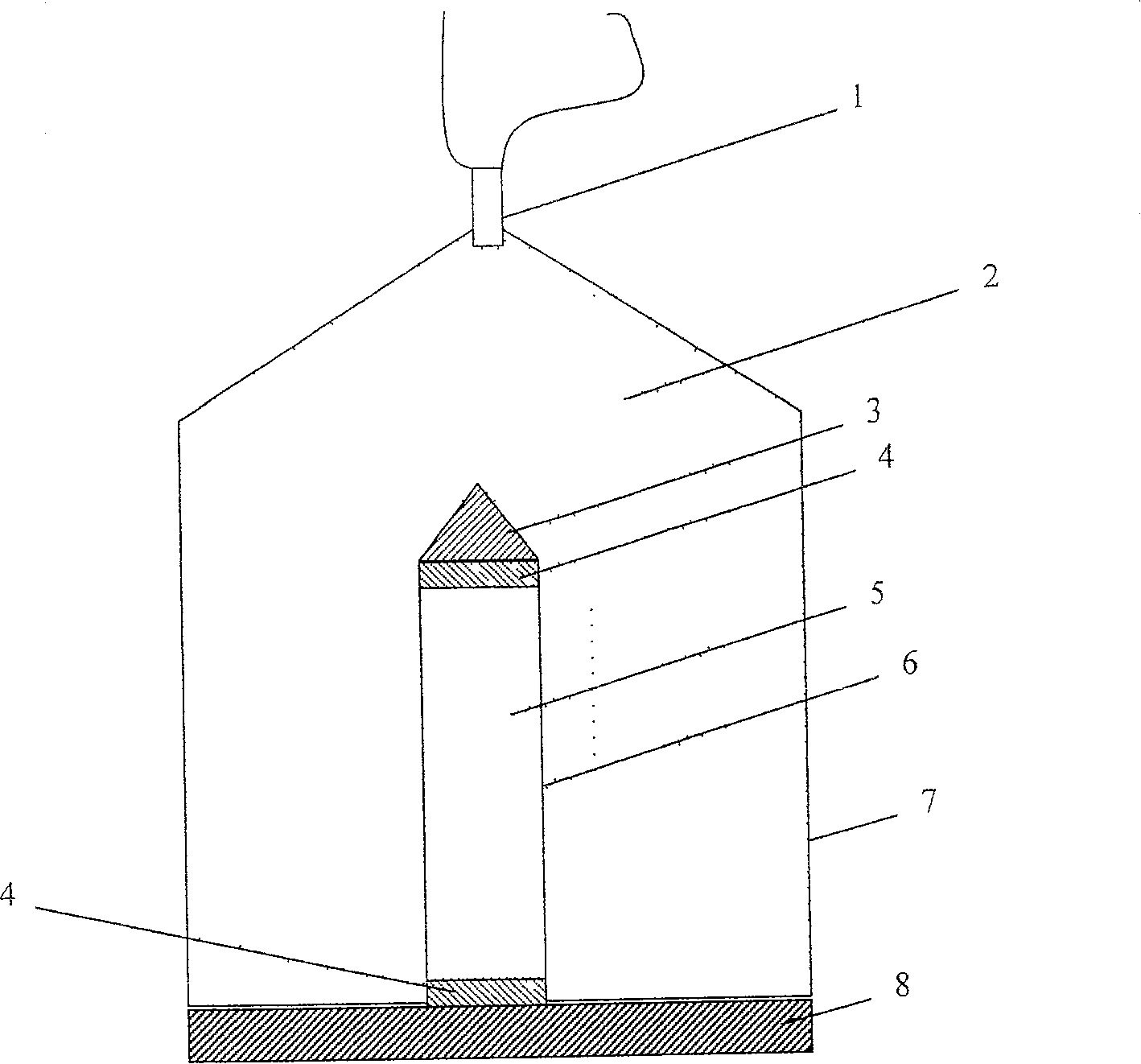

Method for forming nano crystal double phase anisotropic neodymium iron boron binding magnet and apparatus thereof

InactiveCN100400205CHigh densityImprove magnetic propertiesInductances/transformers/magnets manufactureHigh densityDouble phase

An explosion method for shaping the adhered dual-phase nano-crystalline anisotropic NdFeB magnet includes such steps as loading the isotropic NdFeB magnet powder in sleeve steel cylinder, treating by magnetic field, fixing the sleeve steel cylinder onto base with an explosive tube on it, filling explosive in the tube, and exploding. Its advantages are high density and high magnetic performance.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com