Polyethylene-based injection-molded magnetic composite material for inductor and preparation method thereof

A magnetic composite material, polyethylene-based technology, applied in the manufacture of inductors/transformers/magnets, the magnetism of organic materials/organic magnetic materials, circuits, etc., can solve the problems of low magnetic inorganic filler filling and low maximum magnetic energy product , to achieve the effect of increasing the filling amount, ensuring the mechanical strength and improving the compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

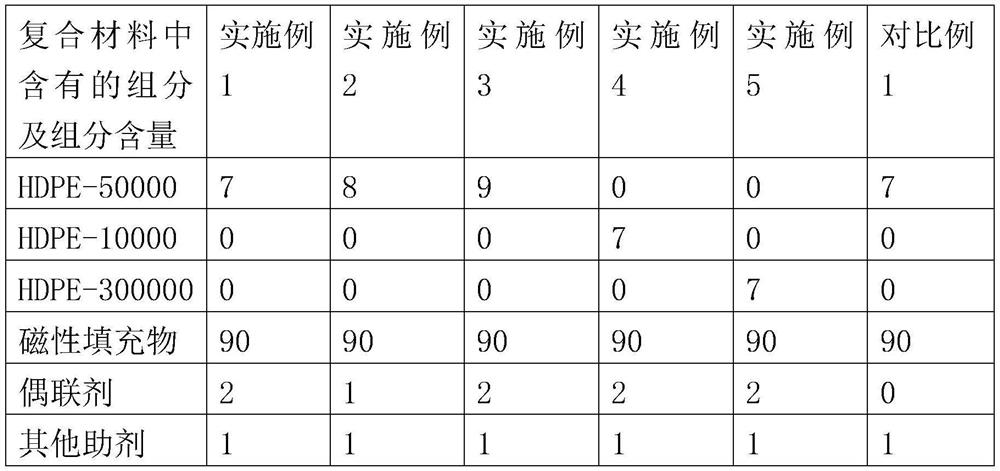

[0040] According to the following method, according to the feed ratio of each raw material in Table 1, the polyethylene-based injection-molded magnetic composite material of the present invention is prepared by feeding:

[0041] Step A: crushing the polyethylene substrate to 100 mesh to obtain polyethylene micropowder;

[0042] Step B: Hydrolyze the measured polymer with 30% distilled water relative to its mass for 2 hours in advance to obtain a coupling agent hydrolyzate, then add the magnetic filler to a high-speed batch mixer with temperature control, and then add the above coupling For the hydrolyzate of the agent, first mix at high speed for 10 minutes, after mixing evenly, adjust the speed of the mixer to 5r / min, raise the temperature to 100°C, pre-react for 2 hours, and stop the temperature control.

[0043] Step C: Continue to put polyethylene micropowder and other additives into the high-speed batching mixer described in step B, and mix at high speed for 10 minutes to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com