Method for forming nano crystal double phase anisotropic neodymium iron boron binding magnet and apparatus thereof

An anisotropic, bonded magnet technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of low magnet density, multiple binders, poor magnetic properties of anisotropic bonded magnets, etc. , to achieve the effect of increasing density, reducing cost and improving magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

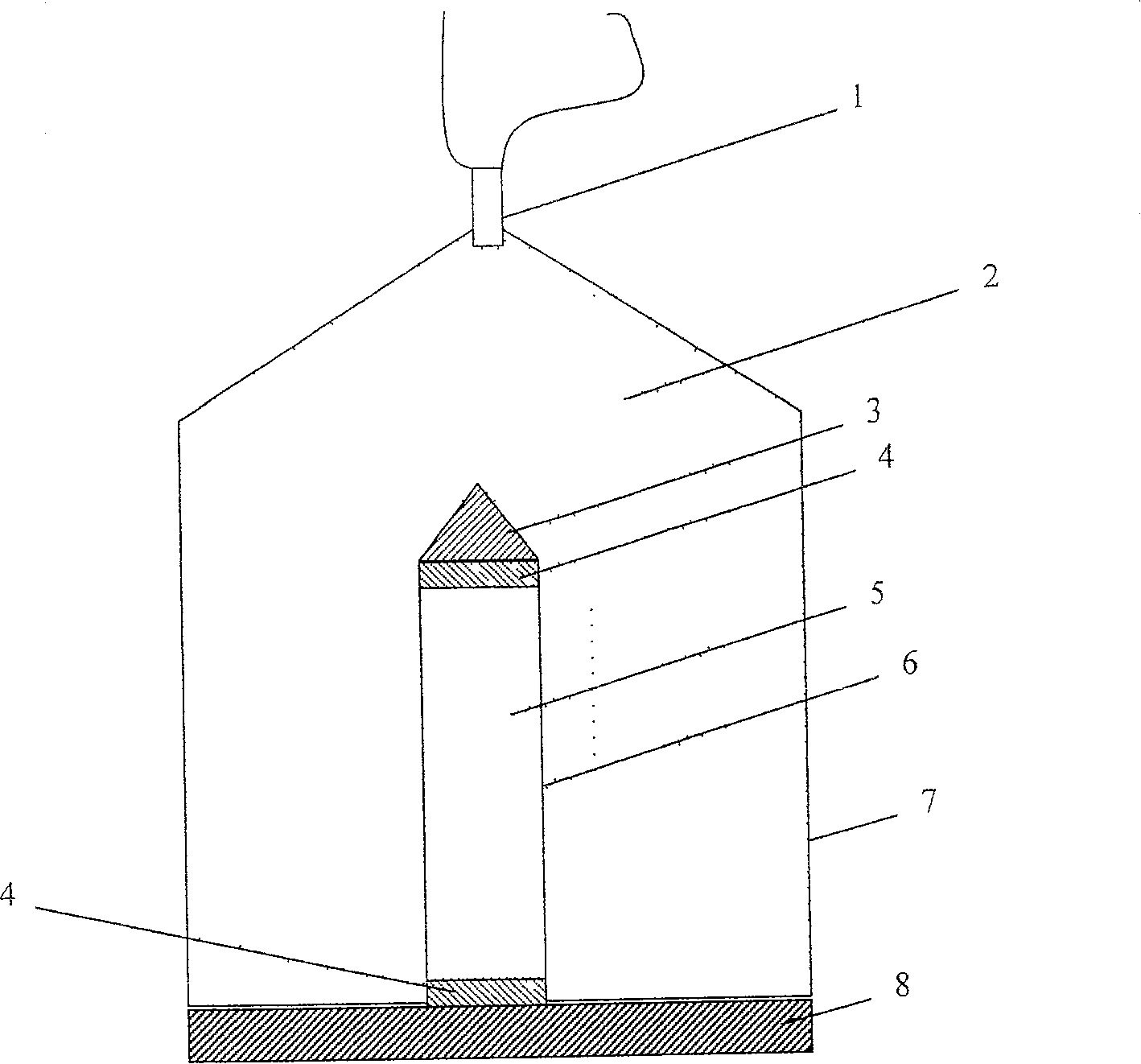

Embodiment 1

[0022] In the embodiment, the nanocrystalline isotropic NdFeB magnetic powder is prepared in this way. Firstly, the raw materials are prepared, and the Nd 8.5 (FeCoZr) 84.5 Cr 0.5 B 6.5 On the basis of the stoichiometric formula, the amorphous magnet is obtained by the melt rapid quenching method, and then the nanocrystalline dual-phase magnet powder is obtained through crystallization treatment; the nanocrystalline dual-phase isotropic NdFeB magnetic powder is bonded with 0.2wt% Mix the powder evenly, and then put it into the steel casing 6, the wall thickness of the steel casing 6 is 1.5mm, slowly carry out the powder filling, and vibrate while loading, and at the same time, it is treated under a 12T magnetic field, The upper and lower ends of the casing 6 are welded and sealed with steel plugs 4; the casing 6 is placed on a circular plastic plate fixed base 8, the thickness of which is 10 mm, the base is placed on a level ground, and a circular explosive is placed on the ...

Embodiment 2

[0024] Evenly mix the nanocrystalline dual-phase isotropic NdFeB magnetic powder with 0.3wt% binder, then put it into the steel casing 6, the wall thickness of the steel casing 6 is 1mm, and slowly carry out the powder loading .While loading and vibrating, and at the same time processed under a 10T magnetic field, the upper and lower ends of the casing 6 are welded and sealed with steel plugs 4; the casing 6 is placed on a circular plastic plate fixing base 8, the thickness of which is 10mm, the base is placed on the level ground, a round explosive cartridge is placed on the base, a removable compact 3 is placed on the plug at the upper end of the casing 6, and then explosives are evenly loaded in the explosive cartridge, and the explosive is ammonium nitrate Base explosives with a density of 0.90g / cm 3, the thickness of the loaded explosives is 60mm. The detonator is released by the detonating system 1 at the tip of the top of the explosive cartridge for detonation. The sho...

Embodiment 3

[0026] Evenly mix the nanocrystalline dual-phase isotropic NdFeB magnetic powder with 0.5wt% binder, then put it into the steel casing 6, the wall thickness of the steel casing 6 is 1mm, and slowly carry out the powder loading , and vibrate while loading, and at the same time through the treatment under the 13T magnetic field, the upper and lower ends of the casing 6 are welded and sealed with steel plugs 4; the casing 6 is placed on the circular plastic plate fixed base 8, the thickness 10mm, the base is placed on the level ground, a round explosive cartridge is placed on the base, a removable compact 3 is placed on the plug at the upper end of the casing 6, and then explosives are evenly loaded in the explosive cartridge, and the explosive is ammonium nitrate Base explosives with a density of 1.2g / cm 3 , the thickness of the loaded explosives is 65mm. The detonator is released by the detonating system 1 at the tip of the top of the explosive cartridge for detonation. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com