High-performance magnetic ring with engineering plastic as carrier

An engineering plastic, high-performance technology, applied in the direction of coils, coil manufacturing, electrical components, etc., can solve problems such as corrosion and impact resistance, and achieve the effects of improving product life and reliability, reducing product weight, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

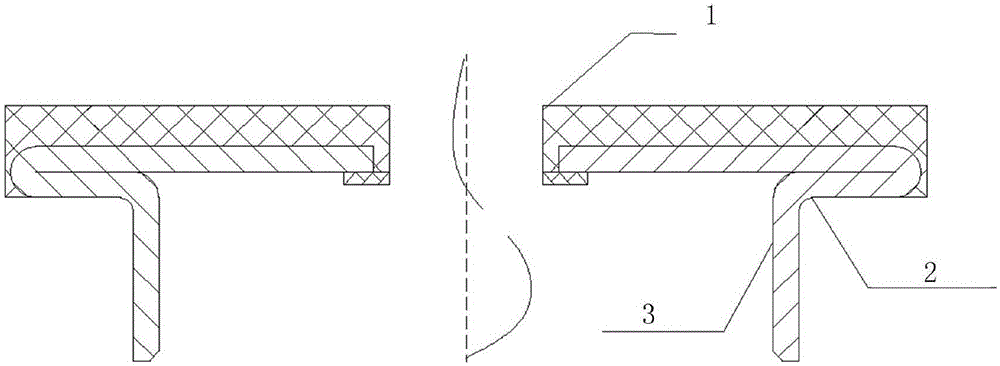

[0026] Such as figure 1 As shown, a high-performance magnetic ring based on engineering plastics as a carrier includes a ring-shaped engineering plastic layer 1 containing ferrite materials and a metal ring skeleton 2. The ring-shaped engineering plastic layer 1 is wrapped in an injection molding process by an injection molding machine. On the metal ring frame 2, the metal ring frame 2 is a "T" shaped metal ring frame, and the chamfer at the lower part is the assembly inner diameter 3; the ring-shaped engineering plastic layer containing ferrite material is injected by an injection molding machine Immediately after orientation, demagnetization, machining and re-magnetization of the magnetic powder, a continuous emission of signals perpendicular to the N / S pole phase of the engineering plastic layer can be produced.

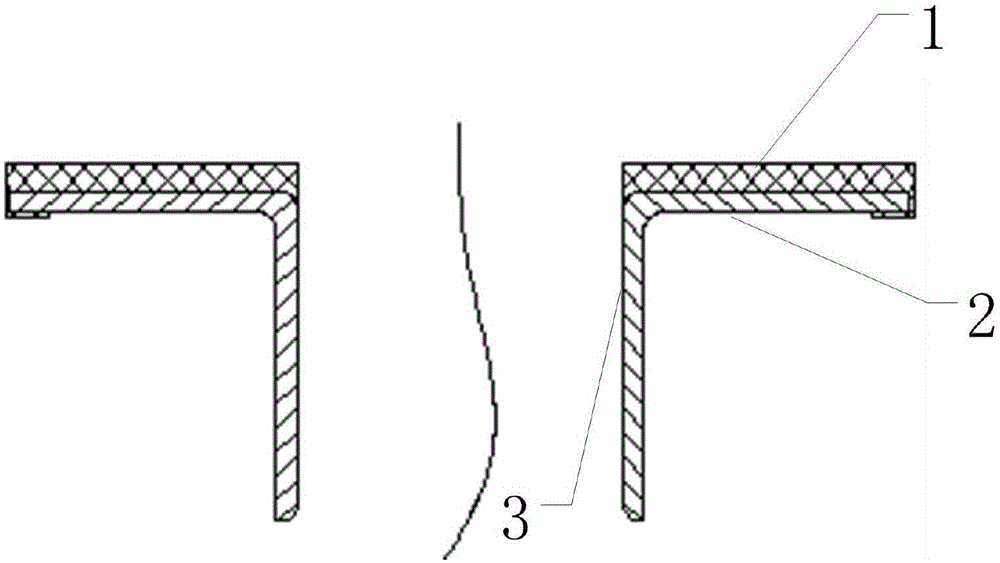

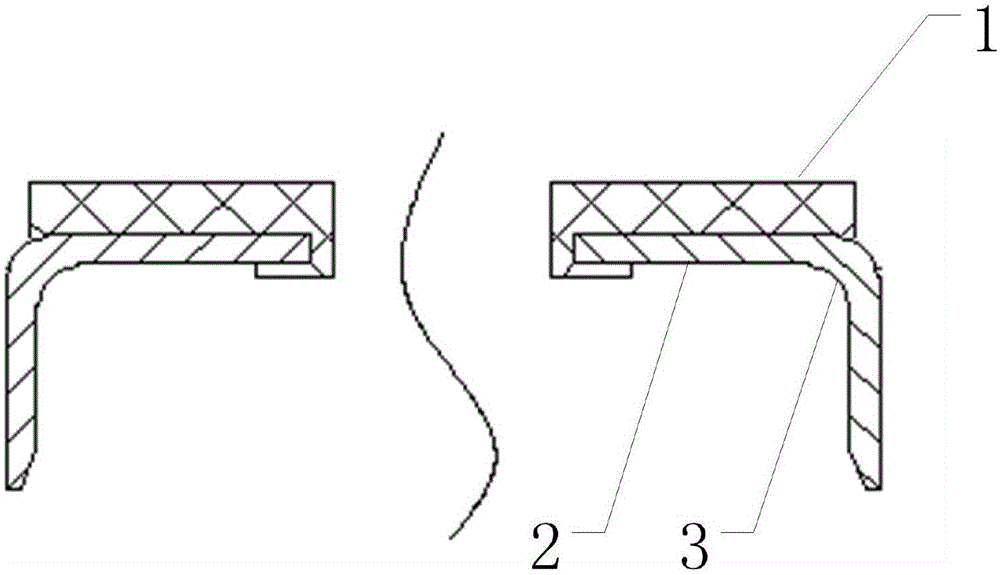

[0027] Such as figure 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com