Patents

Literature

132results about How to "Reduce product weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

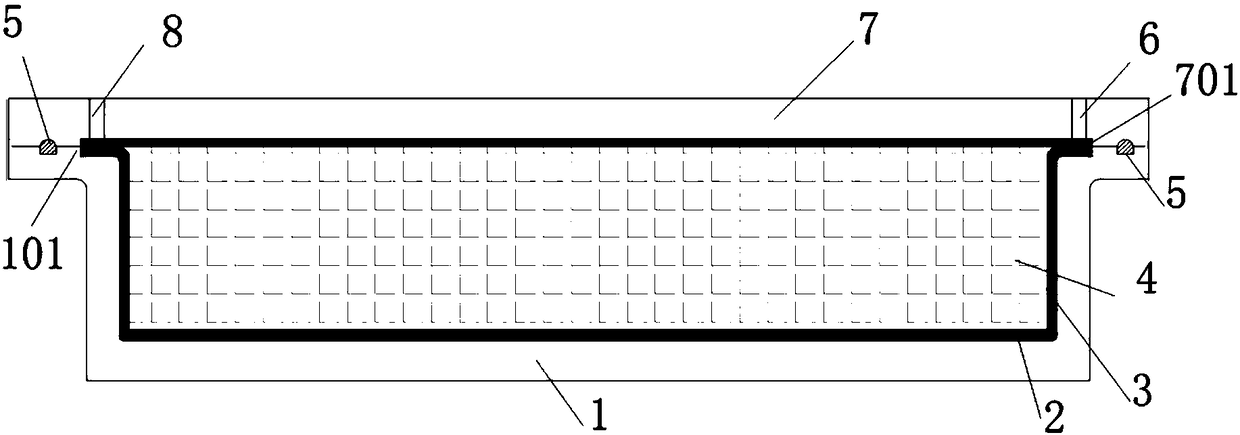

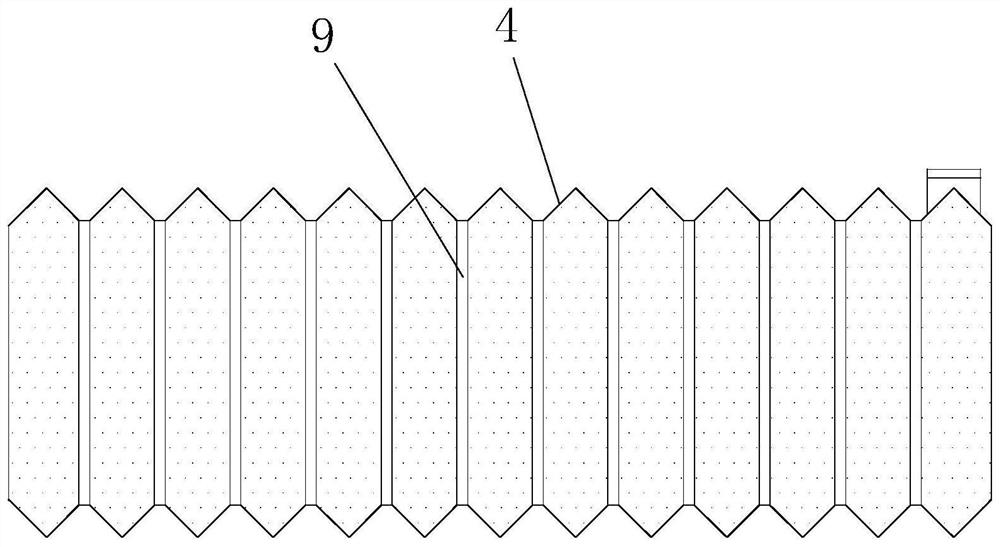

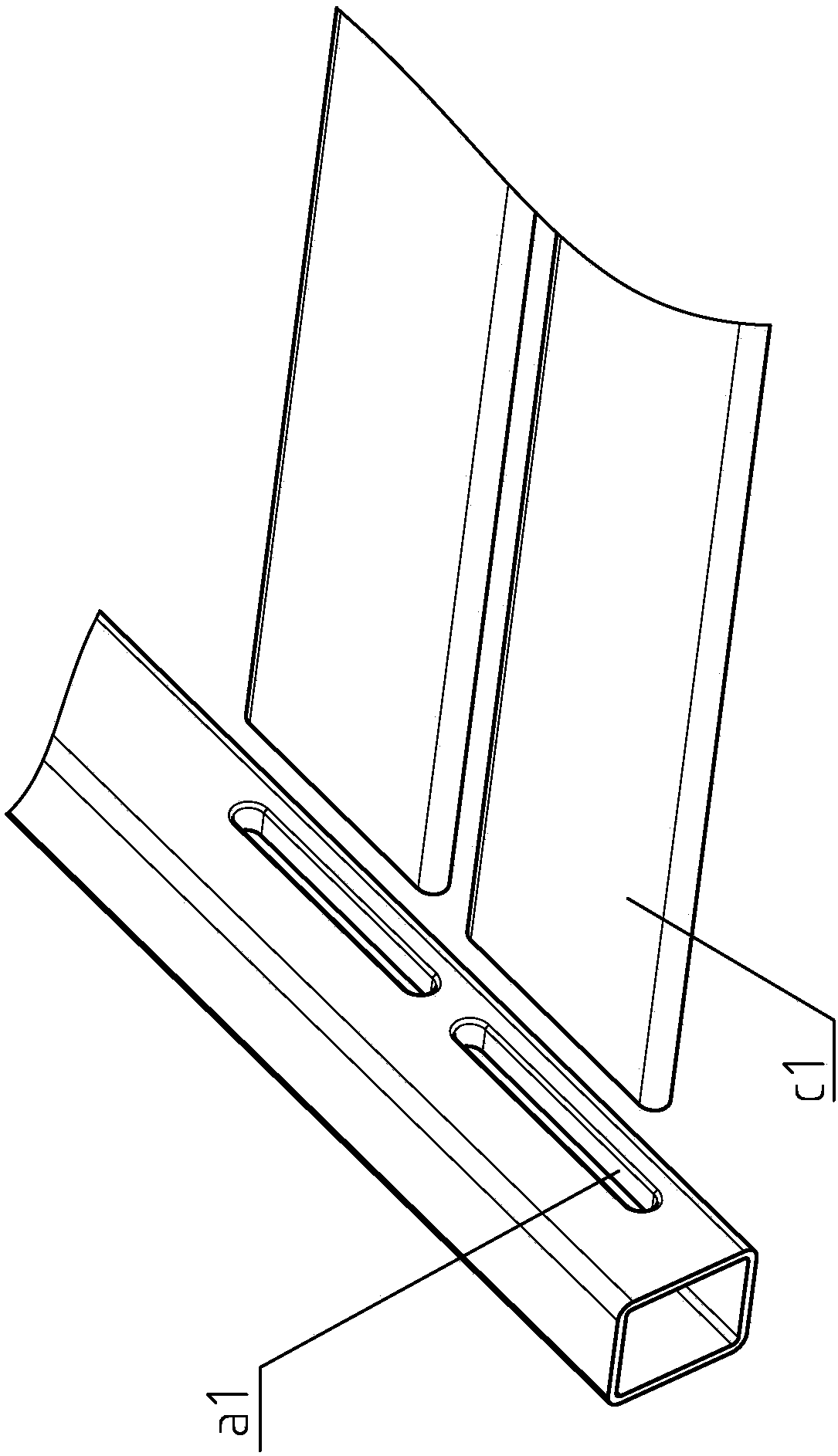

Self cleaning shield

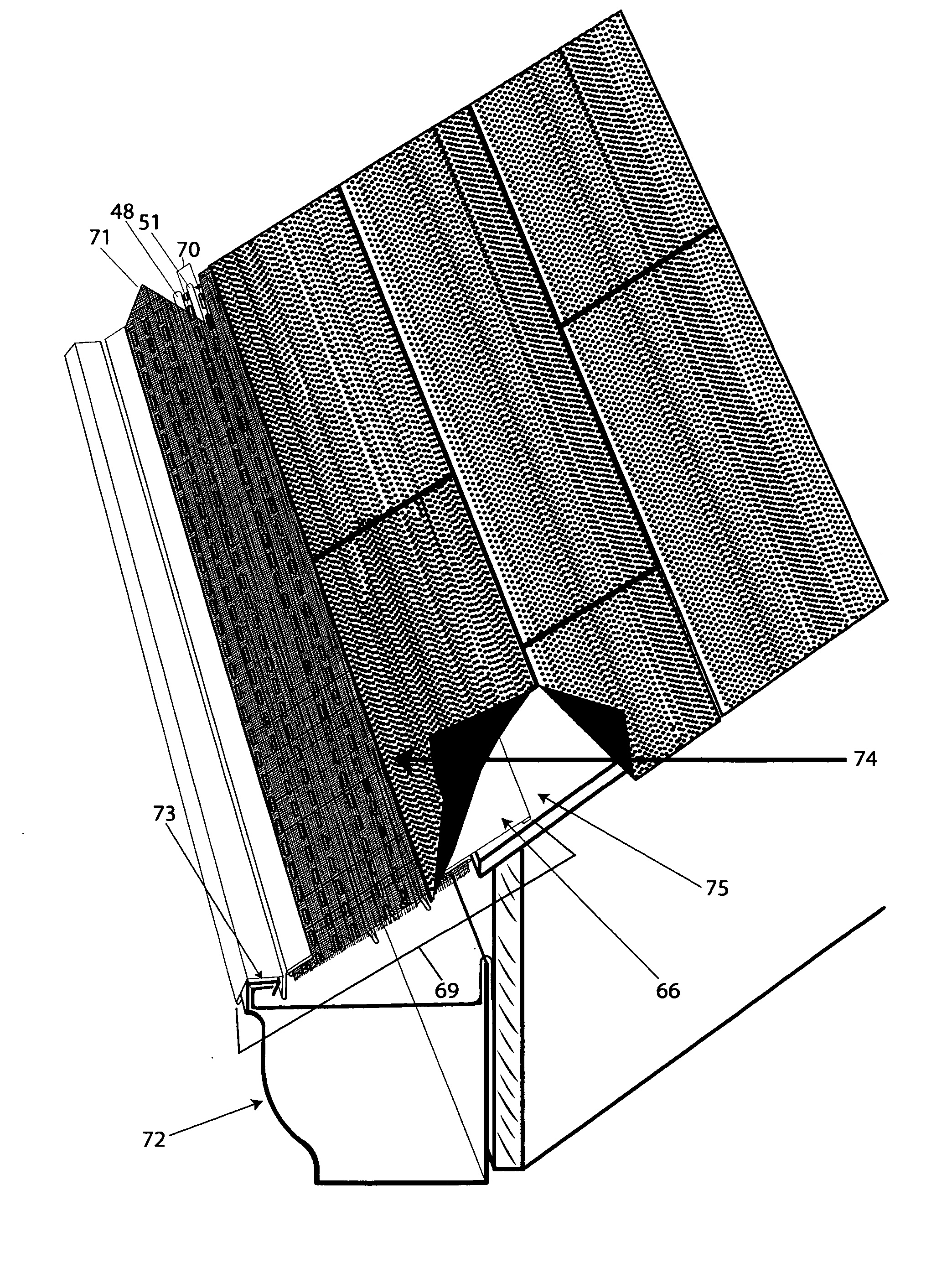

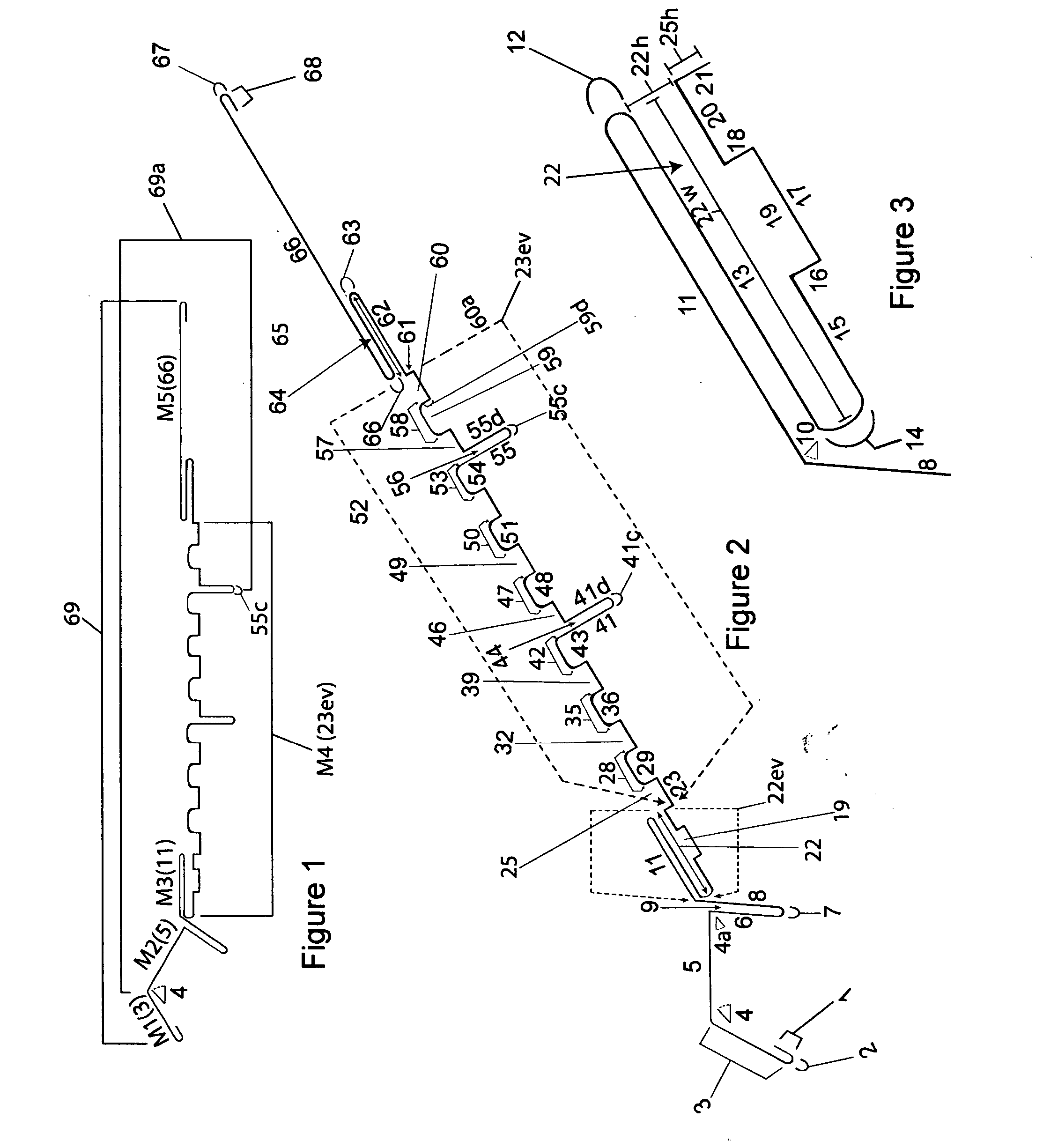

ActiveUS20050257432A1Reduce product weightReduce materialRoof coveringLoose filtering material filtersVertical planeFiltration membrane

An elongated strip of extruded plastic or roll formed metal material includes a rear securing fifth plane that inserts beneath a roofing membrane of a building structure. The rear plane integrally connects to a forward extending perforated fourth plane by means of a u shaped channel, one of two u shaped channels, which additionally serve to receive and secure a lateral edge of a filtration membrane. The perforated fourth plane contains intrinsic and intersecting vertical water directing planes that extend above and beneath the surface of the fourth plane and which serve to support and contact an overlying insertable filtration membrane. The fourth plane connects to a forward extending third plane by means of a u shaped channel that serves to receive and secure a lateral edge of a filtration membrane. The third plane connects to a second plane by means of a downward extending u shaped channel. The second plane rests on the top front lip of a k-style gutter and is adjoined by a downward angled first plane that serves to disallow roof water runoff from contacting the front face of a k-style gutter. A combination of a filtration membrane configured for water permeability and debris repellency resting on vertical planes serves to break the forward flow of water, at points of contact between the vertical planes and filtration membrane, and also serves to further channel water downward through an underlying perforated plane into an underlying rain gutter. The filtration membrane is readily inserted into the u-shaped channels existing on the forward and rear edges of a perforated fourth plane.

Owner:MGP MFG

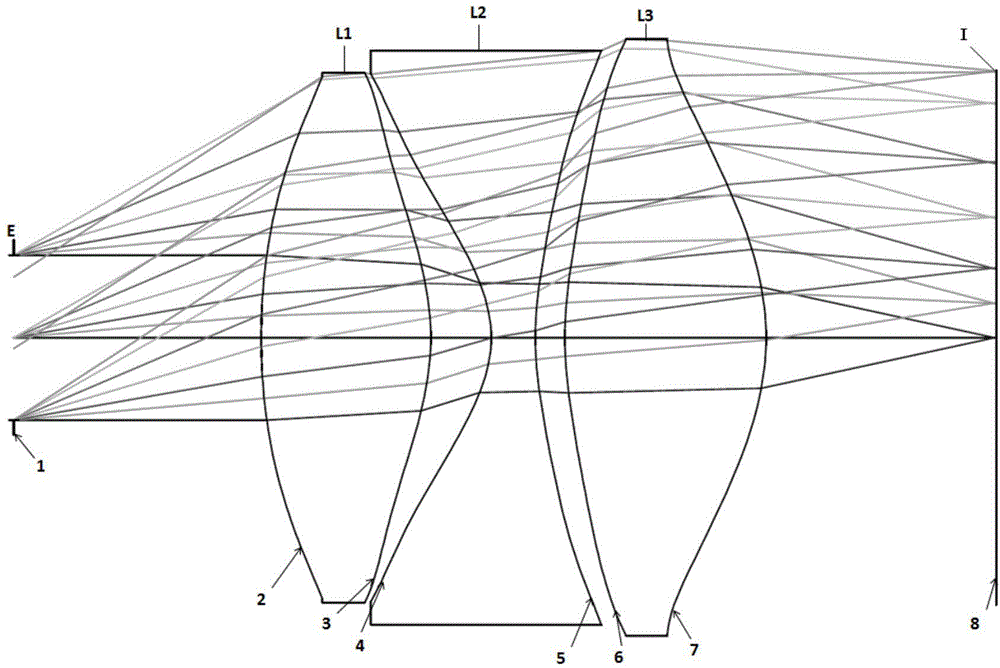

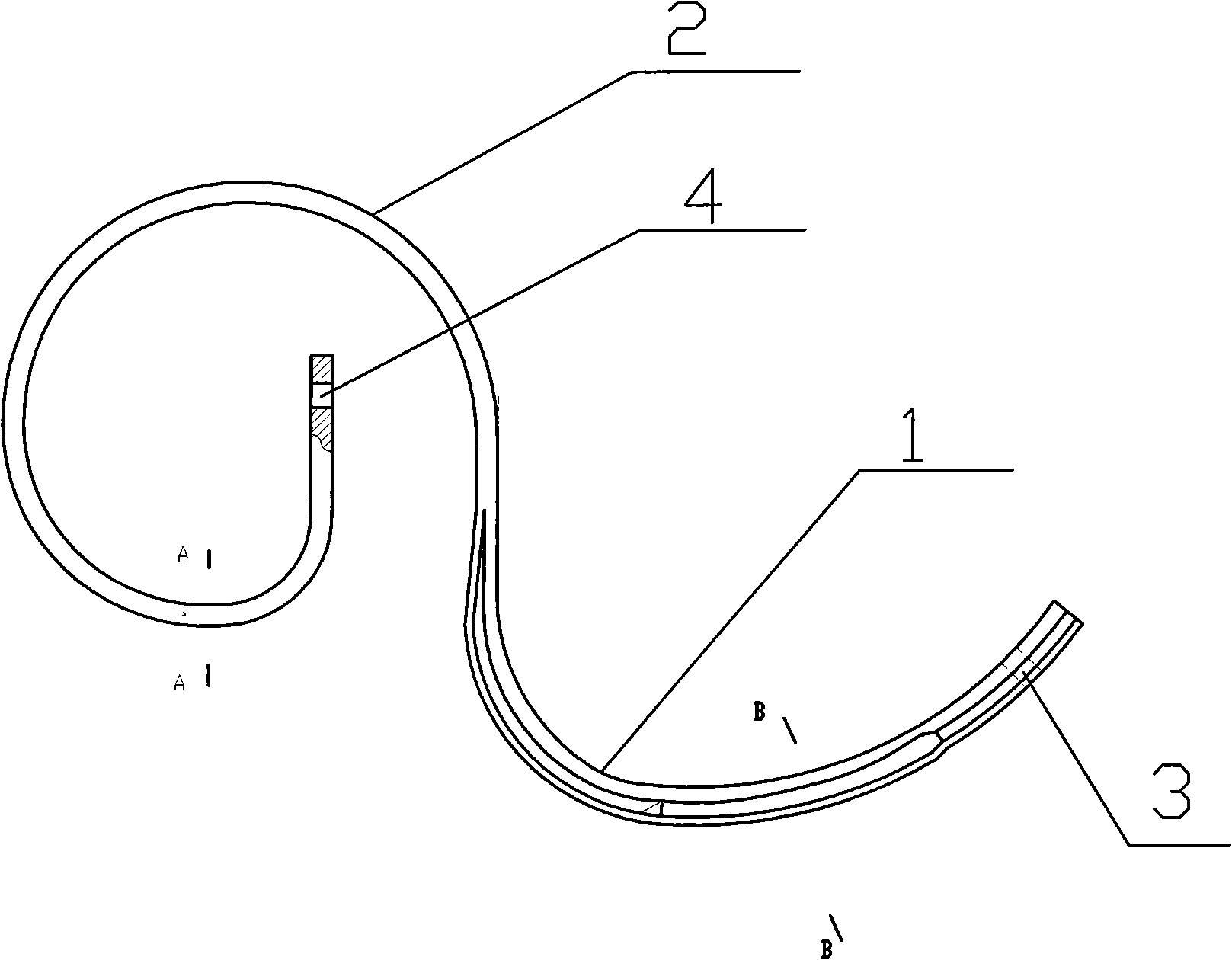

Large-field-angle eye lens optical system

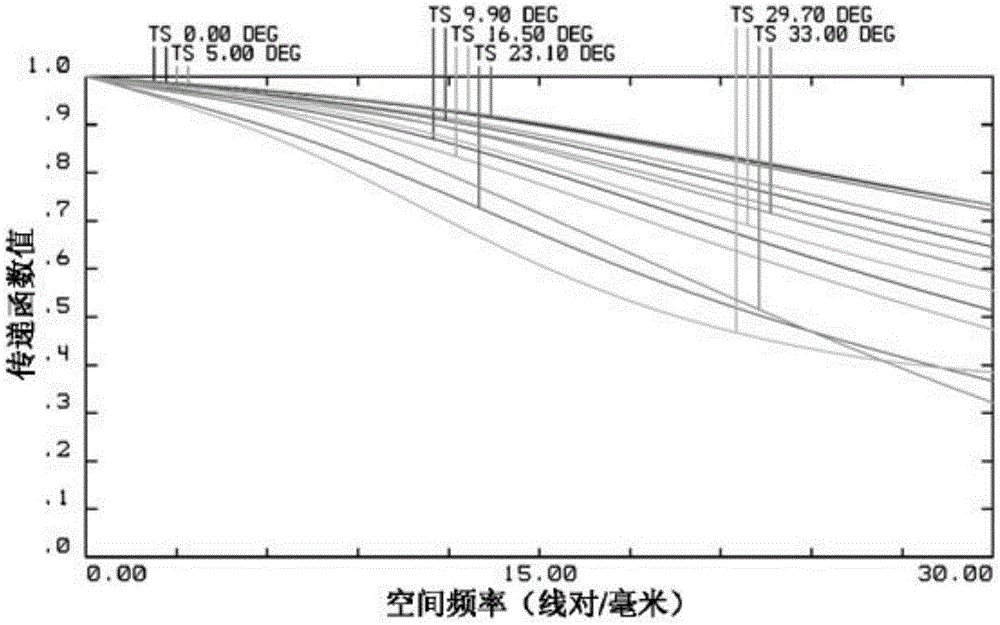

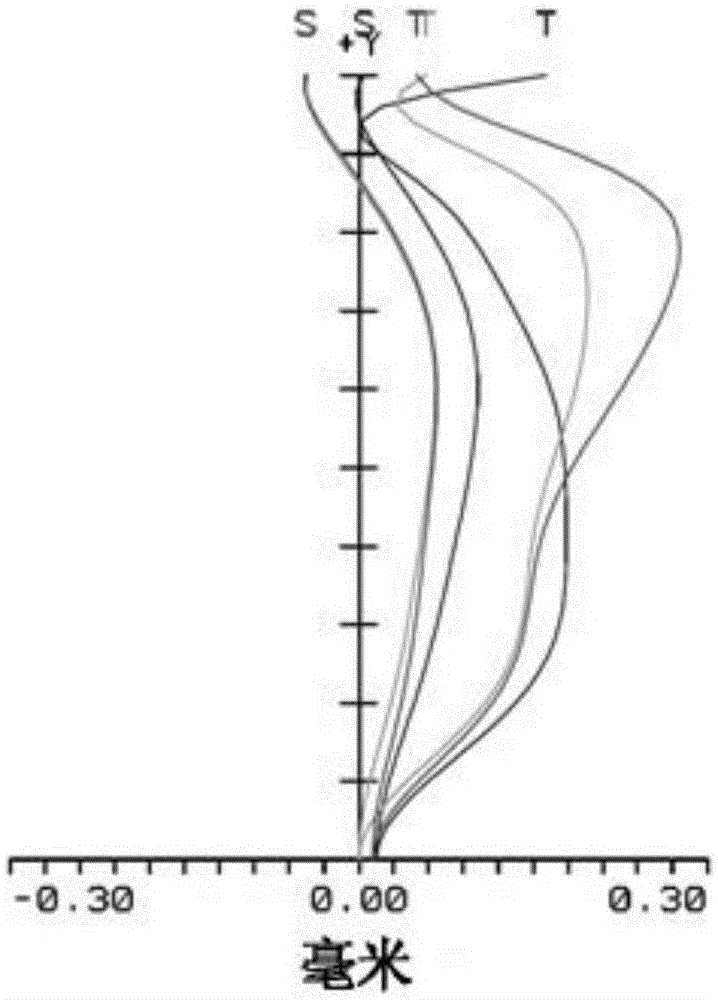

The invention provides a large-field-angle eye lens optical system used for a head worn displayer. The large-field-angle eye lens optical system comprises a first lens, a second lens and a third lens which are coaxially arranged from a human eye observation side to a displayer side in turn along an optical axis direction, and the first lens and the third lens are positive lenses and the second lens is a negative lens. The surface, which faces the human eye observation side, of the first lens convexly faces the human eye observation side, and the radius of curvature is a positive value. The surface, which faces a diaphragm, of the second lens concavely faces the human eye observation side, and the radius of curvature is a negative value. Meanwhile, the material, the focal length and the position of the first lens, the second lens and the third lens meet a certain relation so that an image displayed on a display device is enabled to be imaged in human eyes through amplification of an eye lens. The eye lens has advantages of large aperture, large field of view, high resolution, low distortion and small size so as to be suitable for the head worn displayer and similar devices.

Owner:SHENZHEN NED OPTICS CO LTD

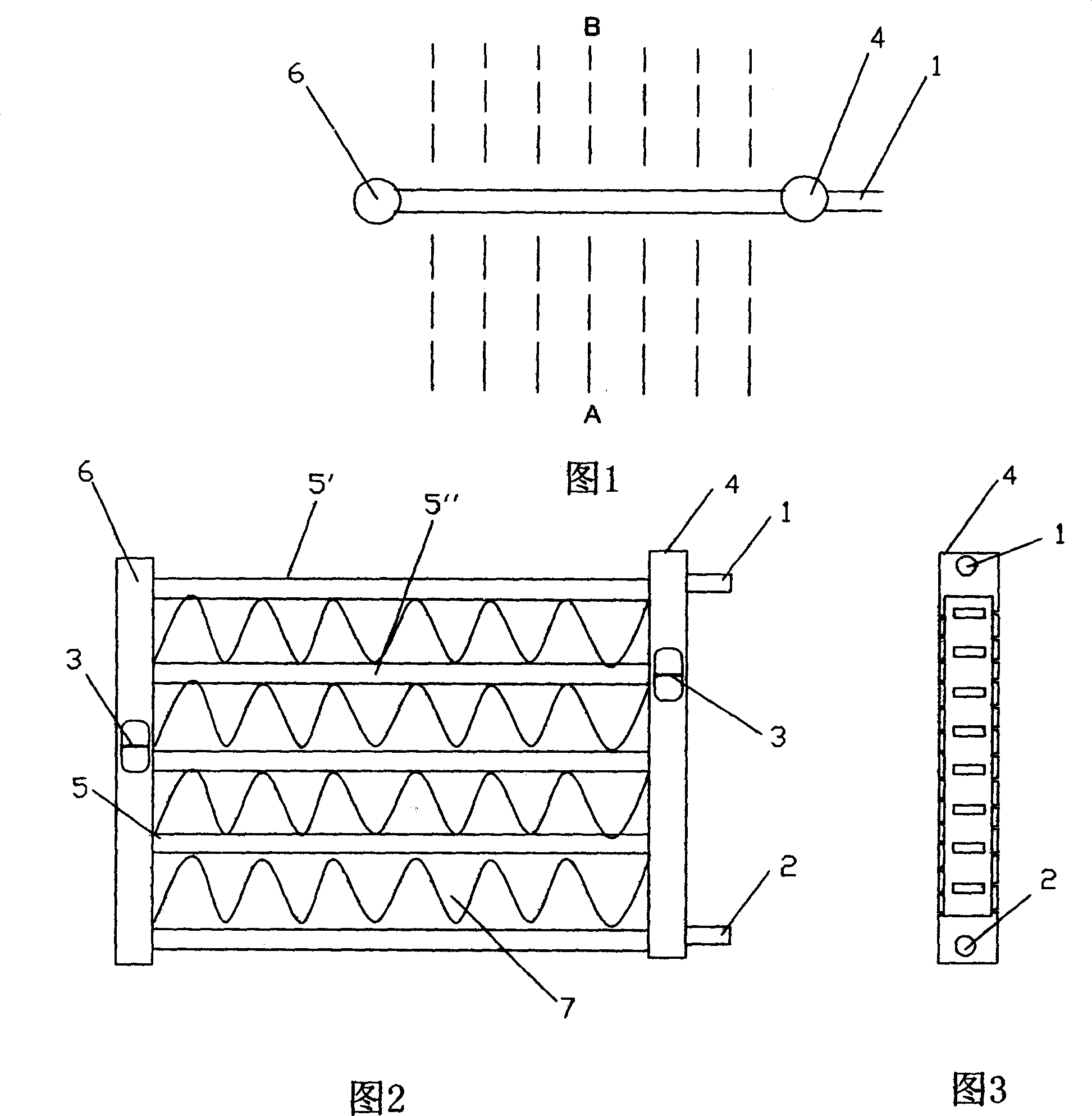

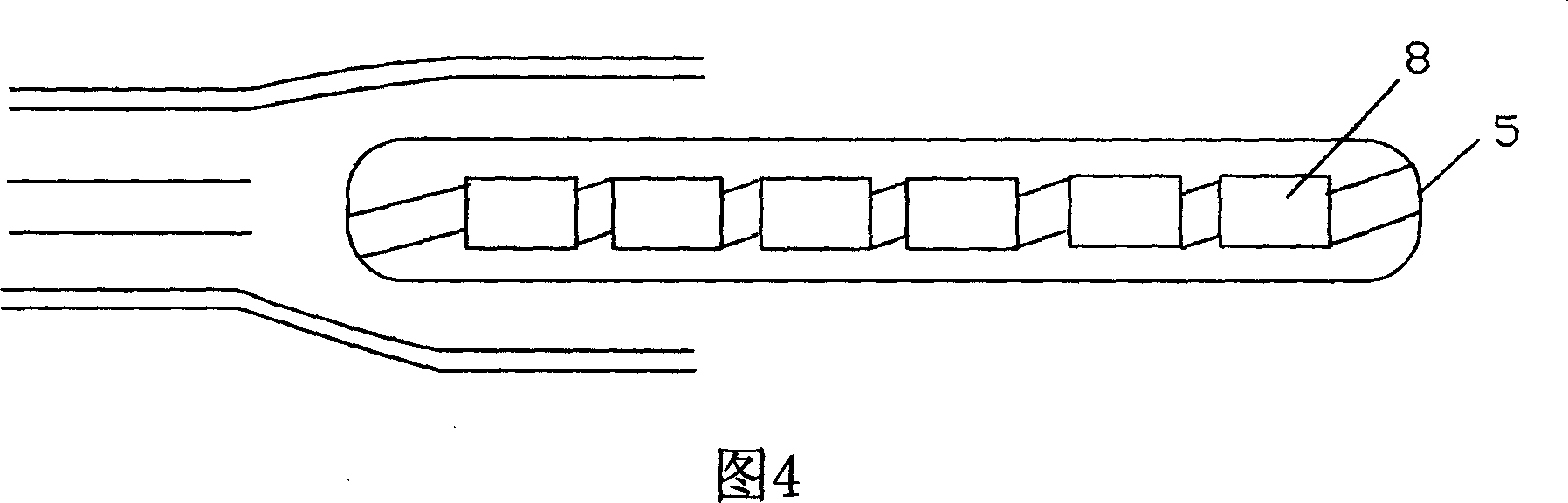

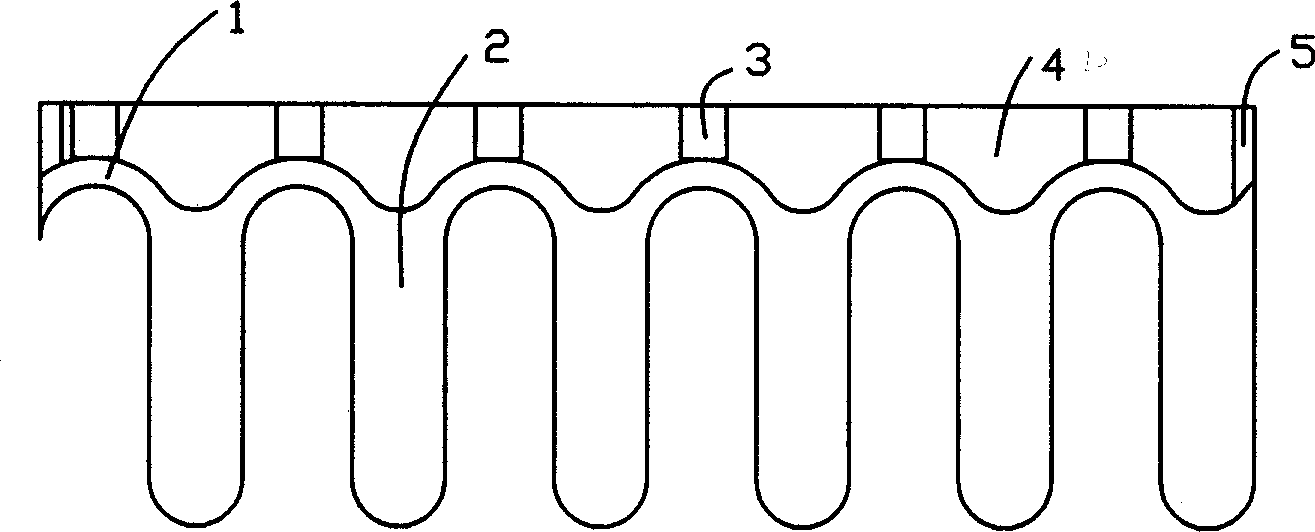

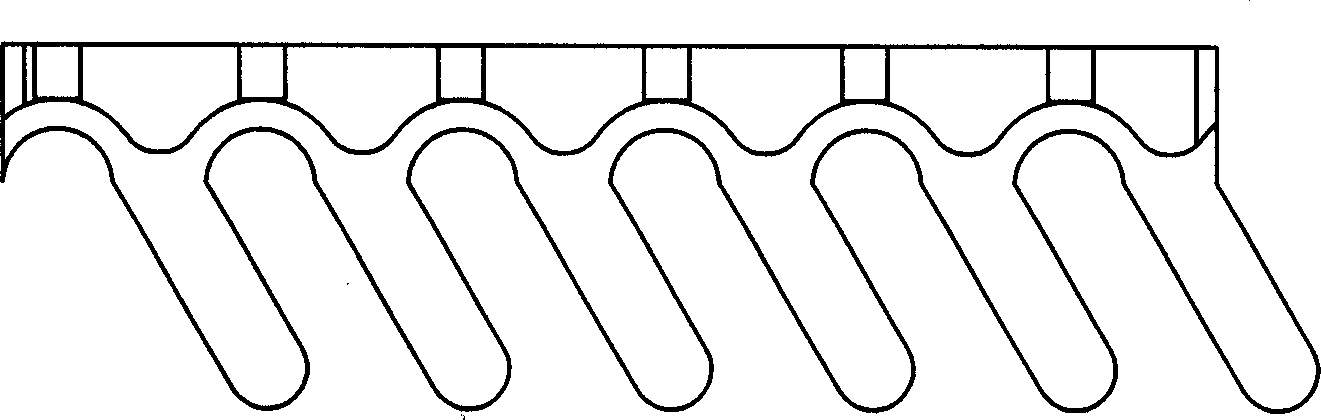

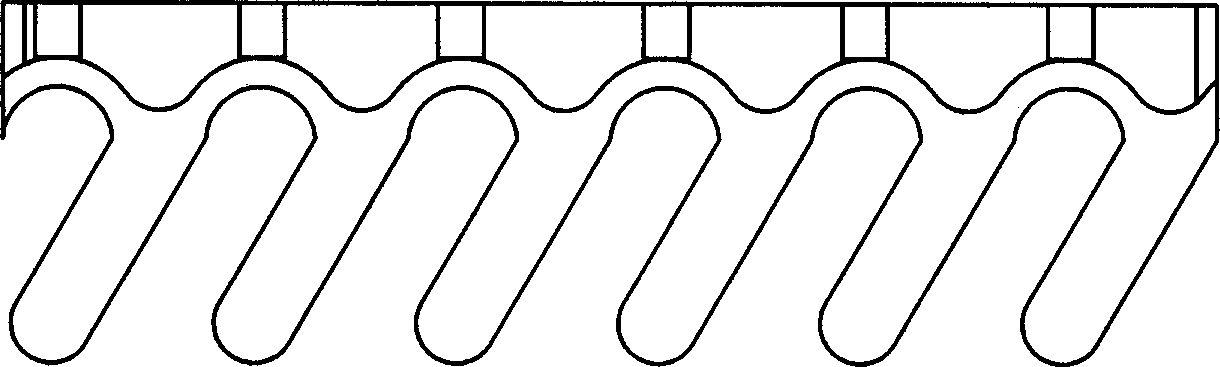

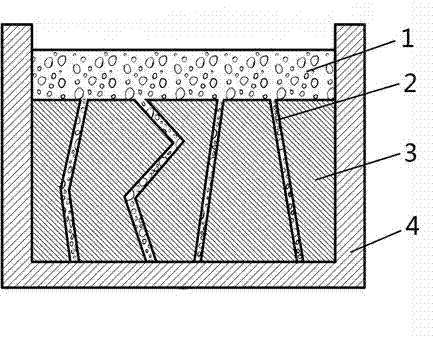

Cold heat exchanger

InactiveCN1967126AImprove corrosion resistanceIncrease contact areaStationary conduit assembliesAutomatic transmissionAutomobile air conditioning

A heat exchanger has No.1 and No.2 manifolds with joint holes, many parallel flat tubes connecting inserting into joint holes of No.1 and No.2 manifolds, outer fins between adjacent flat tubes, with each flat tube unit composed of at least one flat through channels. There is a parallel section between the flat tubes through channels. The said flat tube channel is made of aluminum extrusion of thin wall section bars, with over one coolant and heating flow channels. It applies to horizontal flow cooler of vehicle transmission and horizontal flow water tank of automobile engine coolant, and horizontal warm air core for warm air for auto air conditioner.

Owner:王磊

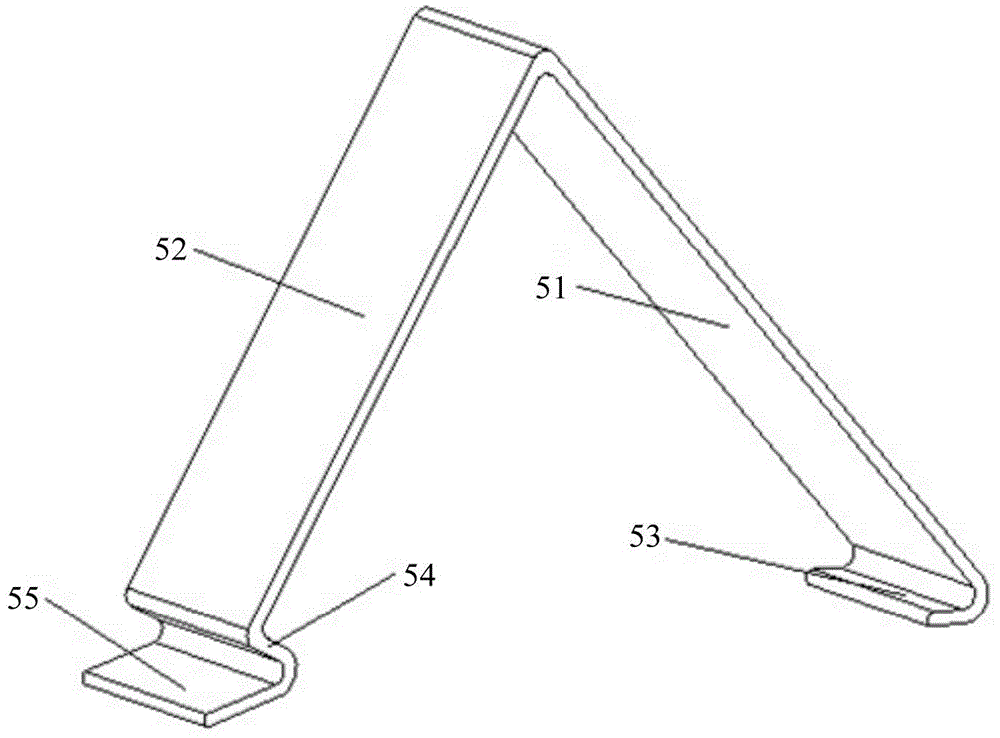

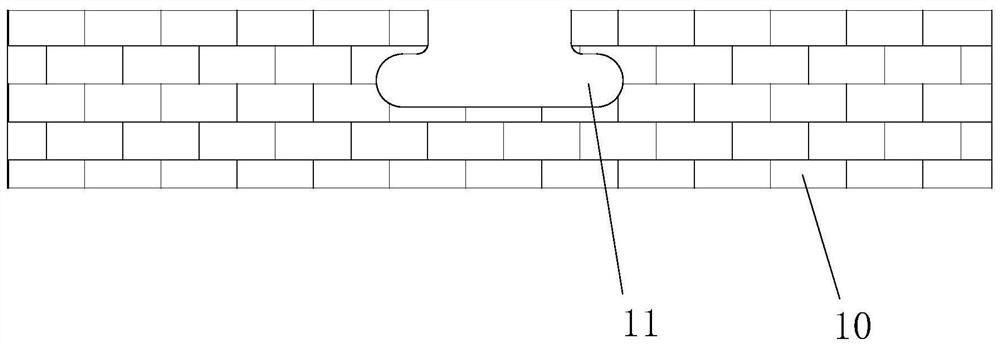

Expansion joint regulator element and expansion joint regulator made therefrom

InactiveCN1464141ASimple structureCompact structureBridge structural detailsResonanceExpansion joint

The expansion joint regulator member consists of expansion back and cast expansion beams on sides of the expansion back. The expansion beams are equal in length and parallel, and the expansion back has its top and bottom planes coinciding with the top and bottom planes of the expansion beams. The expansion joint regulator consists of two identical members inserted mutually. The member is formed through once casting. The expansion joint regulator with two identical members inserted mutually can avoid resonance caused by the impact of the running vehicles, and prolong the service life of bridge and other buildings.

Owner:李永政

Vacuum welding method for thick film substrate and power shell

ActiveCN103934534AReduce product weightReduce interface void rateSoldering apparatusSolder pasteReflow soldering

The invention belongs to the technical field of electronic installation and relates to a vacuum welding method for a thick film substrate and a power shell. Tin coating is conducted on the surface of a raw material according to the ratio of 1:1, and a high brazing rate with the voidage smaller than 5% is achieved. An SiC-Al composite material power shell is adopted to replace a 10# steel shell, and the product weight is reduced. Vacuum welding is adopted to replace reflow soldering, soldering lug Tin coating is adopted to replace soldering paste, it is favorable for removing residual bubbles caused by the fact that soldering flux is not discharged in time, the interface voidage is reduced, and the soldering flux does not need to be cleaned any more after vacuum welding. During vacuum welding, a soldering lug does not need to be added between the thick film substrate and the power shell, empty welding holes caused by surface oxidation of the soldering lug can be effectively removed, oxidation films on the surfaces of the thick film substrate and the power shell are removed by conducting Tin coating on the thick film substrate and the power shell, the clean welded surfaces are obtained, the wettability is improved, and an exhausting channel is smoother in the welding process.

Owner:BEIJING SATELLITE MFG FACTORY

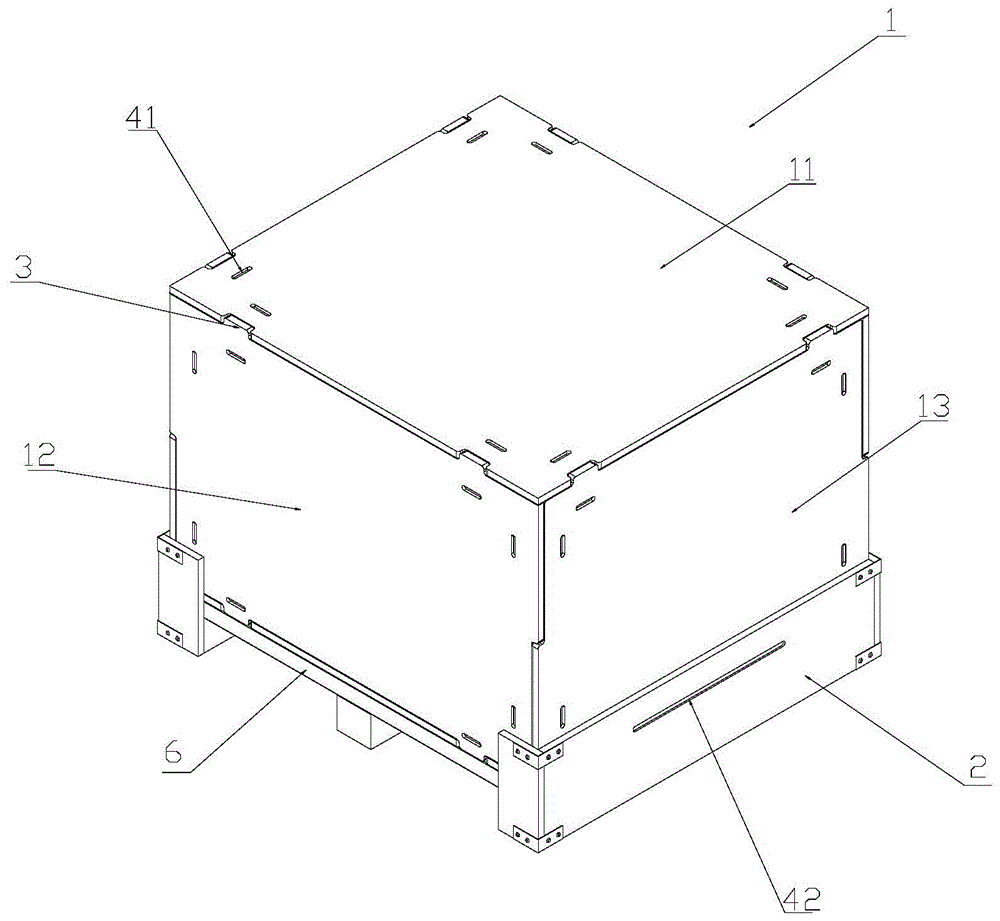

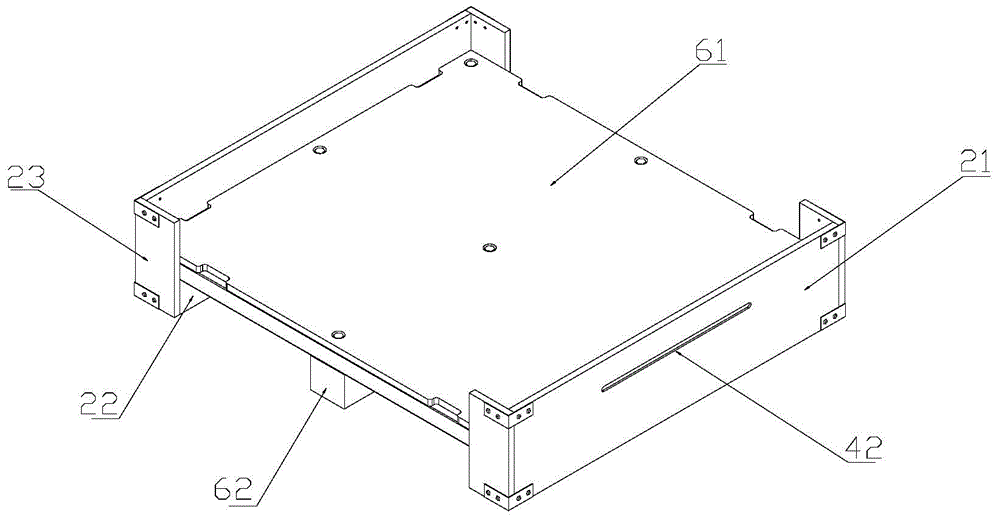

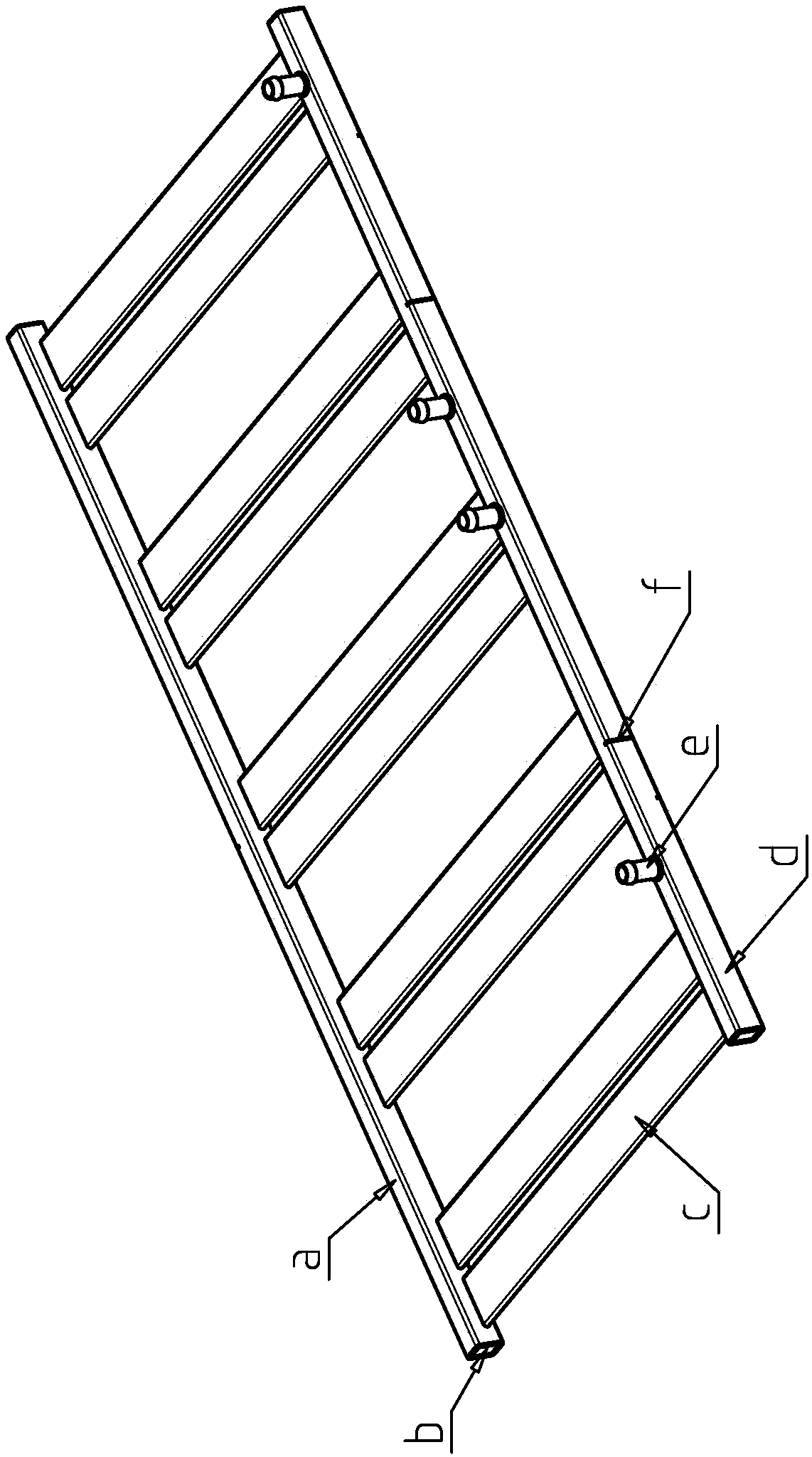

Combined packing case capable of being recovered and quickly dismantled

ActiveCN104787432ASolve the safety problem of slipping and falling for no reasonClose bitePackage recyclingRigid containersTongue and grooveEngineering

The invention provides a combined packing case capable of being recovered and quickly dismantled. All surrounding plates of a case body are connected in a meshed mode through at least one tongue-and-groove structure. Two bottom supports are arranged at the two ends of the case body. Each bottom support comprises two limiting plates arranged on the two sides of the case body respectively and a supporting plate connected with the two limiting plates. Each connecting buckle is of a bent structure composed of two clamping parts. In a combined state of the case body, each connecting buckle is buckled into two corresponding preformed holes of one tongue-and-groove structure. In a recovery state of the case body, the surrounding plates are stacked onto a bottom pallet, and the connecting buckles are buckled onto first preformed grooves and the surrounding plate stacked on the top layer. According to the combined packing case, all the surrounding plates are connected through the tongue-and-groove structures; in the dismantling process, the connecting buckles can be pried and then can disengage from the case body; during assembly and disassembly, no damage is caused to the case body, and the case body can be repeatedly used at high frequency. As for different packing cases, different surrounding plate stacking modes are adopted, the surrounding plates can be effectively prevented from moving in the stacking process, the occupied space is small, and warehousing and logistics recycling are facilitated.

Owner:上海亮立包装技术有限公司

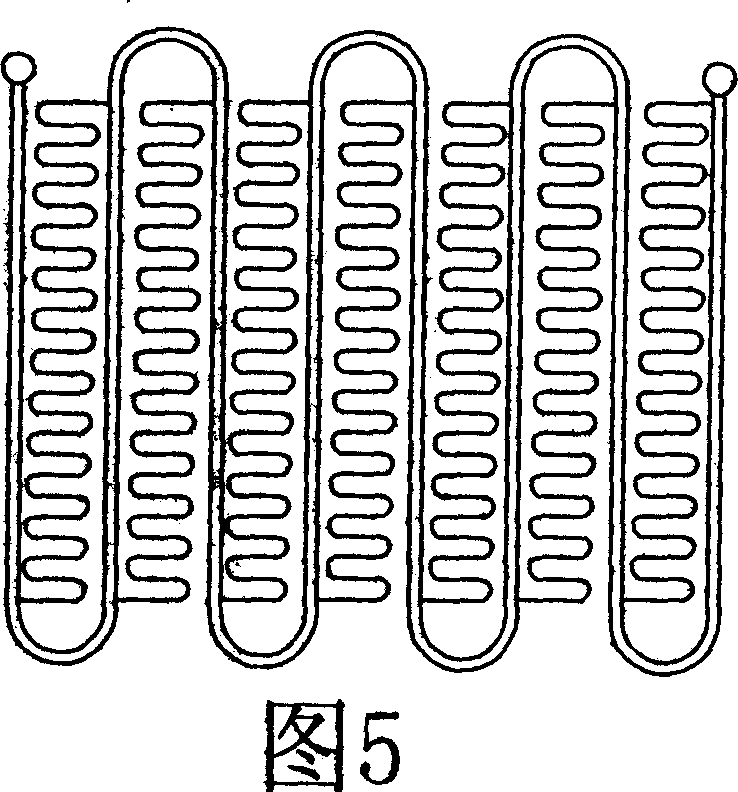

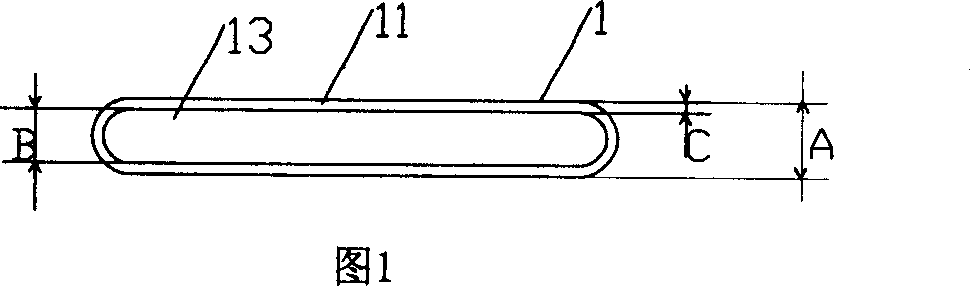

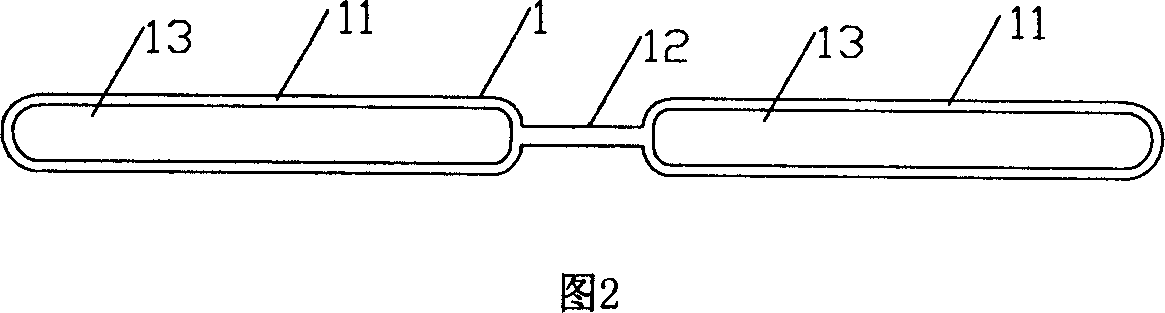

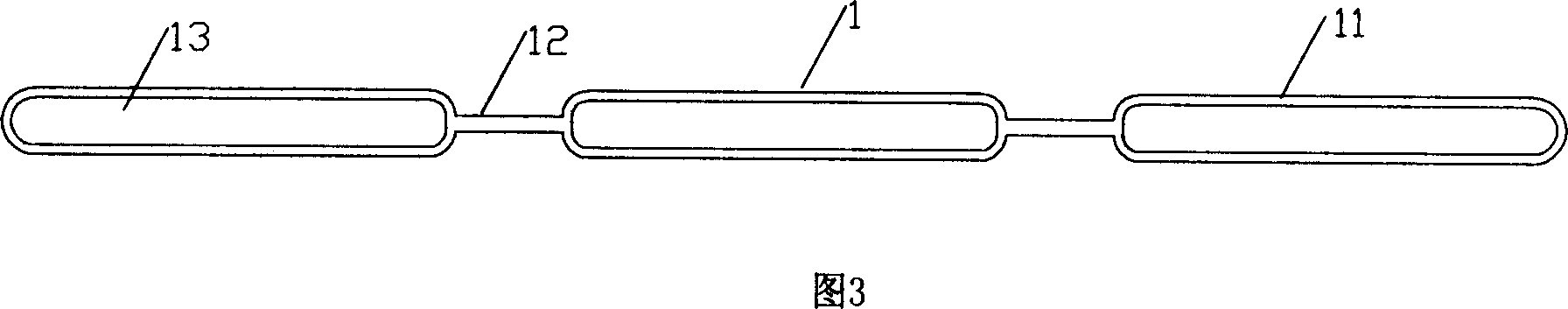

Aluminium-made extrusion slender section

An aluminum extrusion thin wall section bar is made of more than one flat though channels. The parallel through channels are independently connected through joint section horizontally, forming symmetrical or asymmetric multi through channels formed parallel flow channel. There are at least one coolant and heating agent flow channels with the cross section in any shape inside the through channel. At least part of the flow channels having the shape of round, elliptical, polygonal, wave or random combination of them to suit for varied requirements for coolants or heating agents. The parallel flow channels for coolants or heating agents form the dual flow channel aluminum extrusion thin wall section bar or multi channel aluminum extrusion thin wall section bar. Fins are used to separate the flow channels for coolants or heating agents. It can replace traditional electrolytic copper pipe, reduce energy consumption, environment pollution and improved utilization of resources. It has low recovery cost, with extensive applications.

Owner:王磊

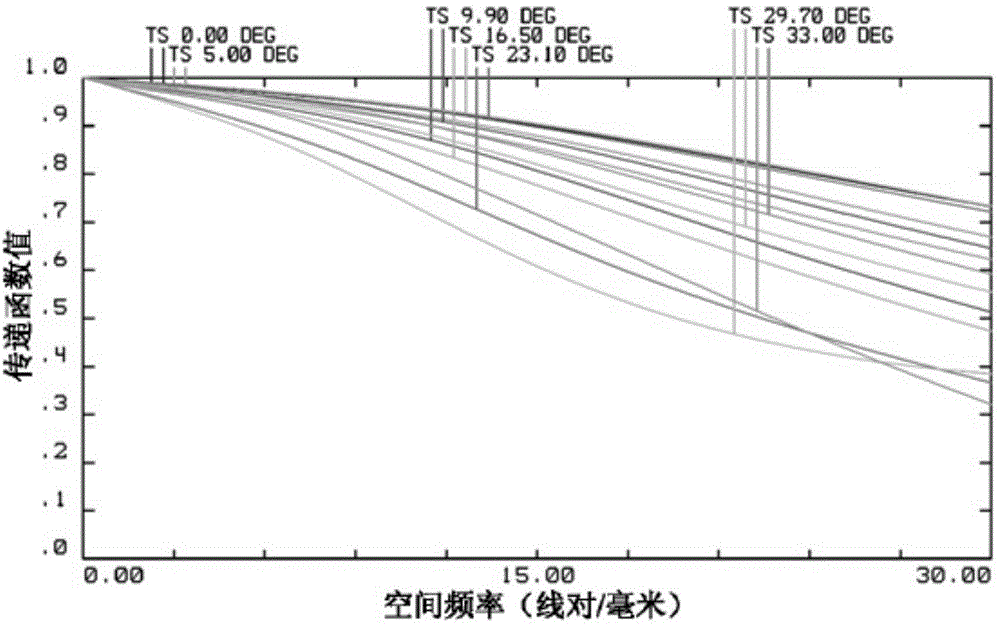

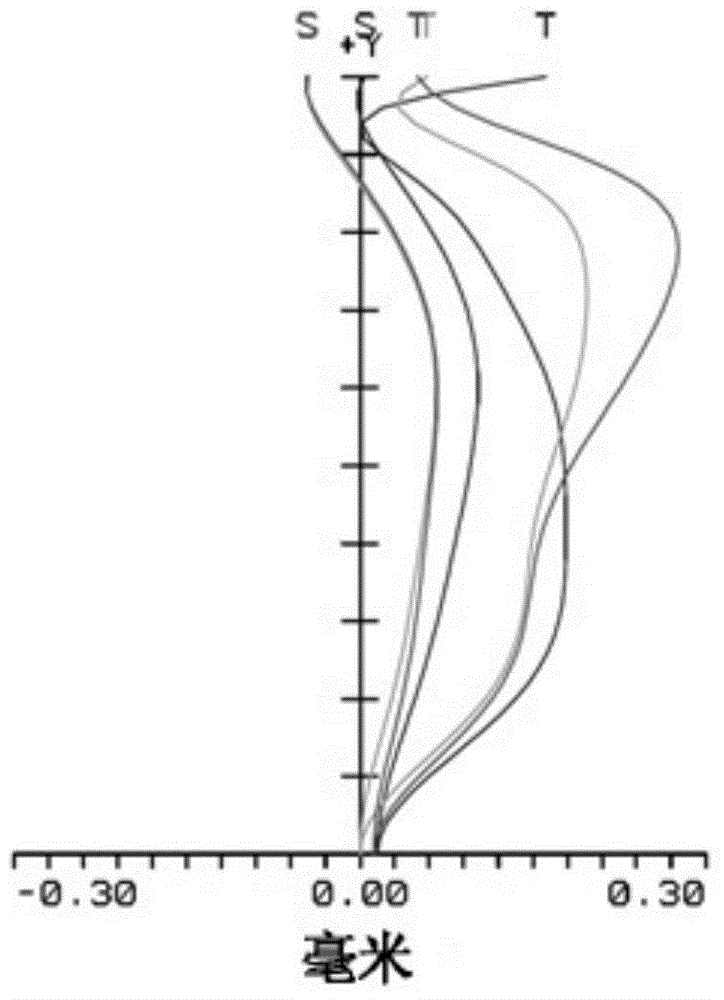

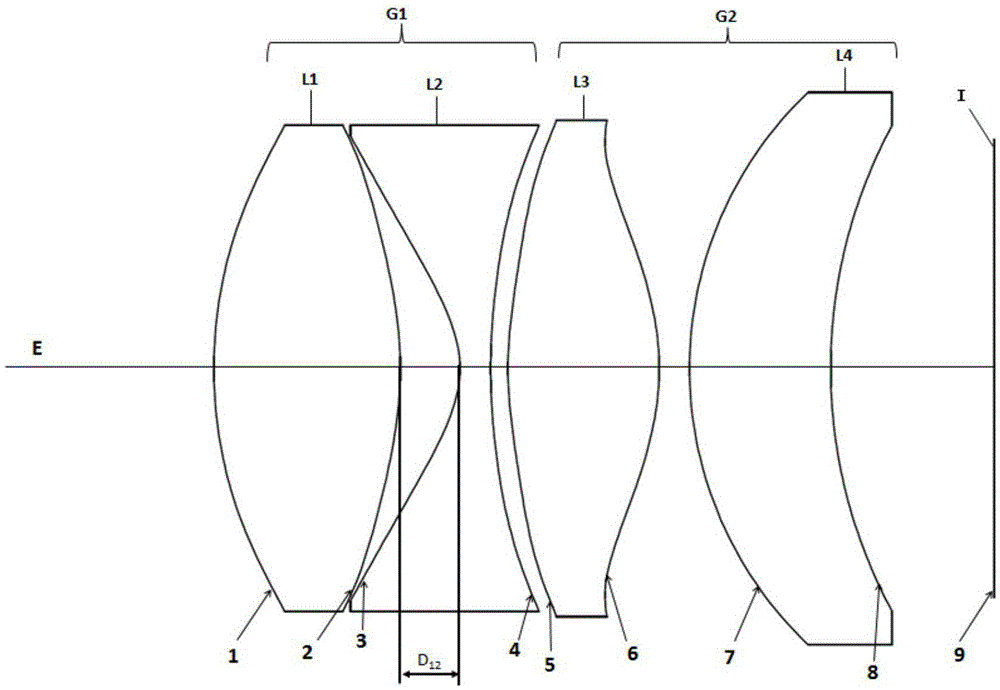

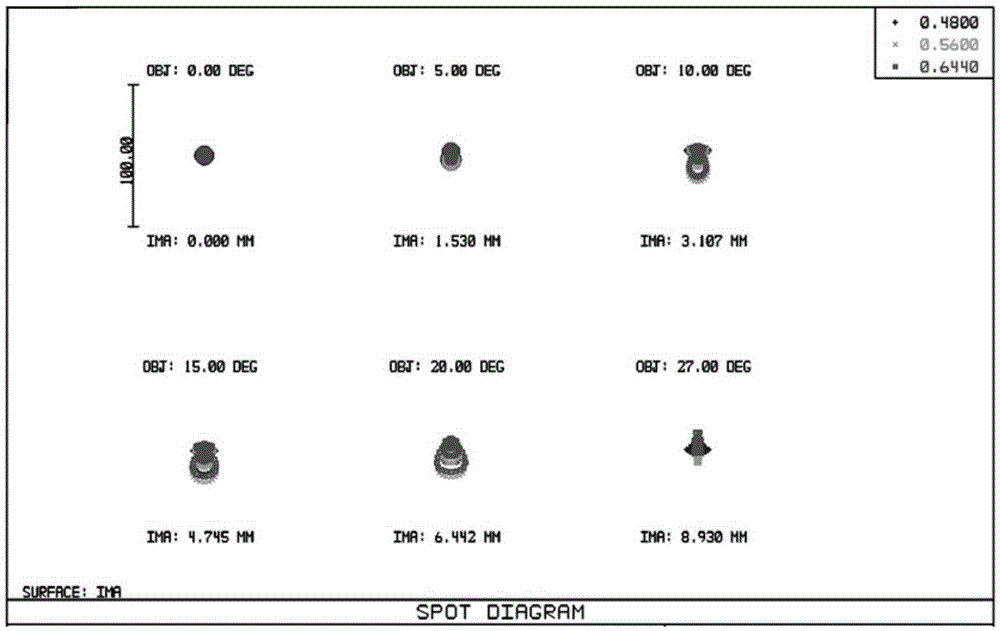

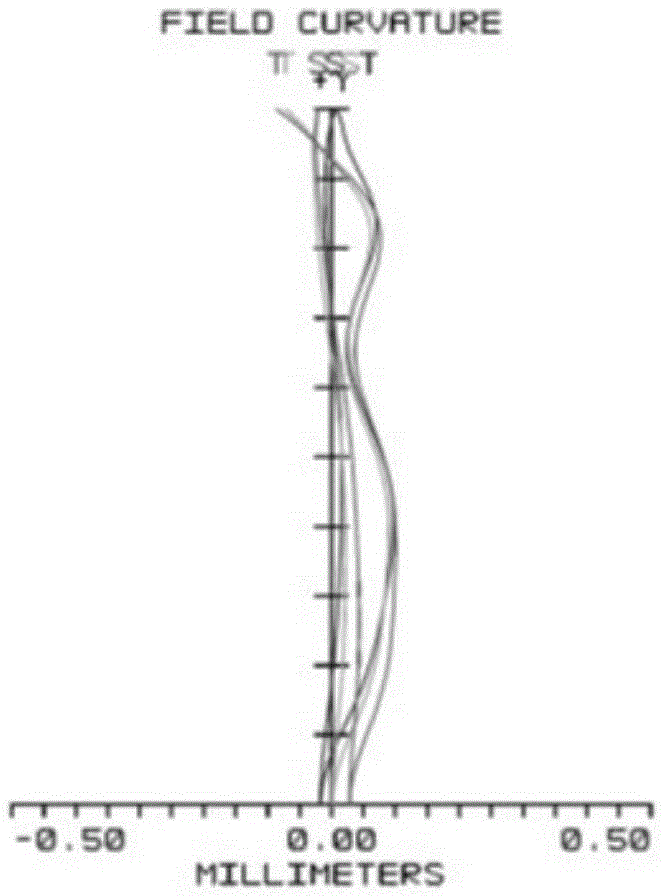

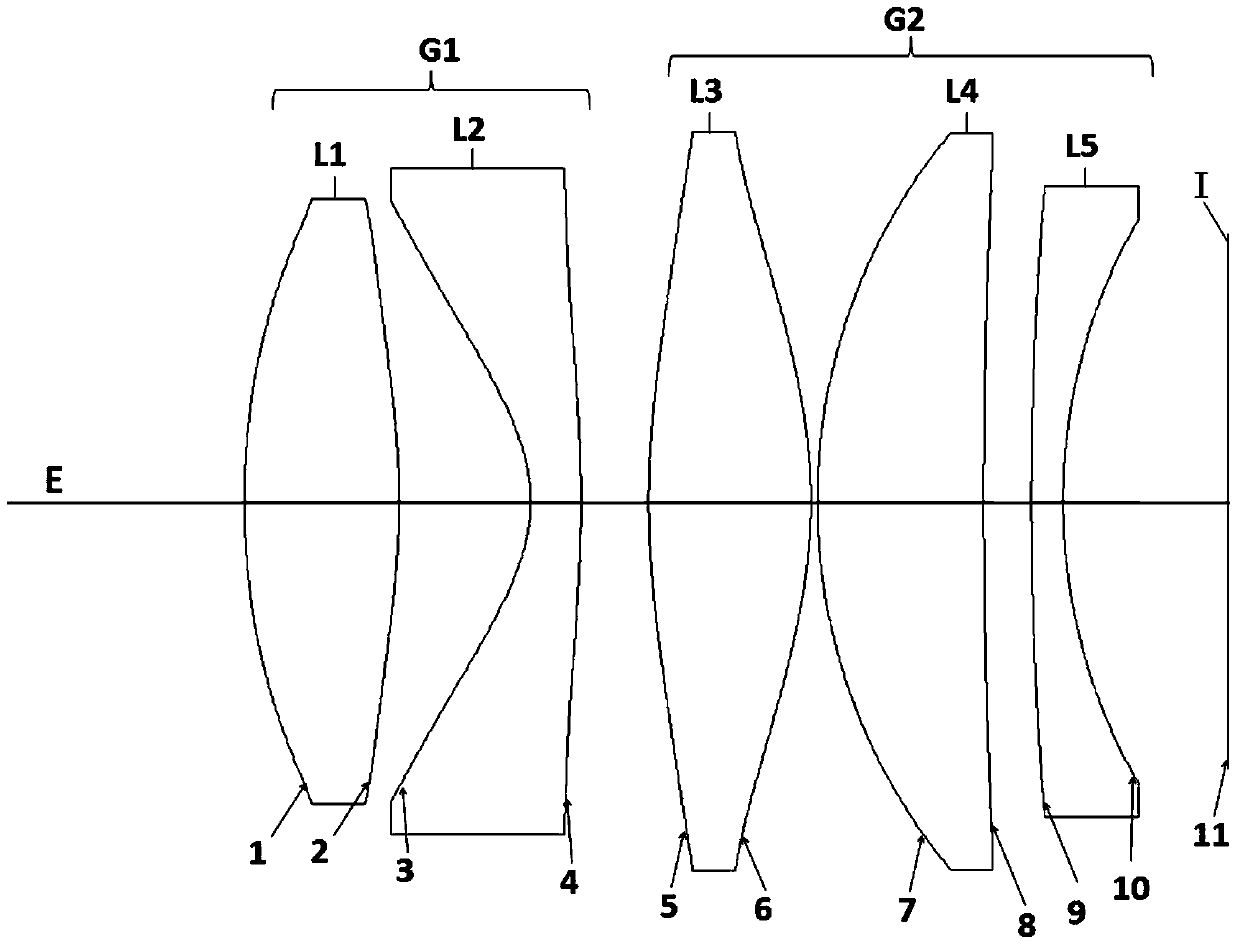

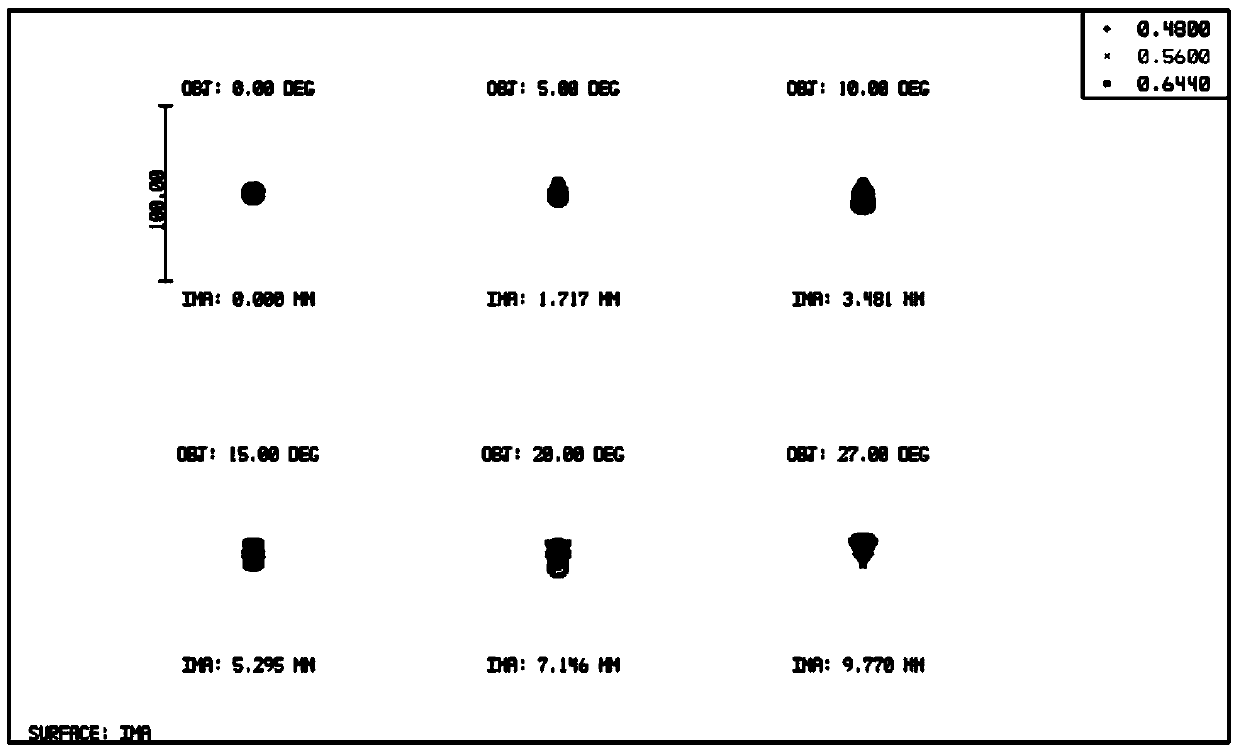

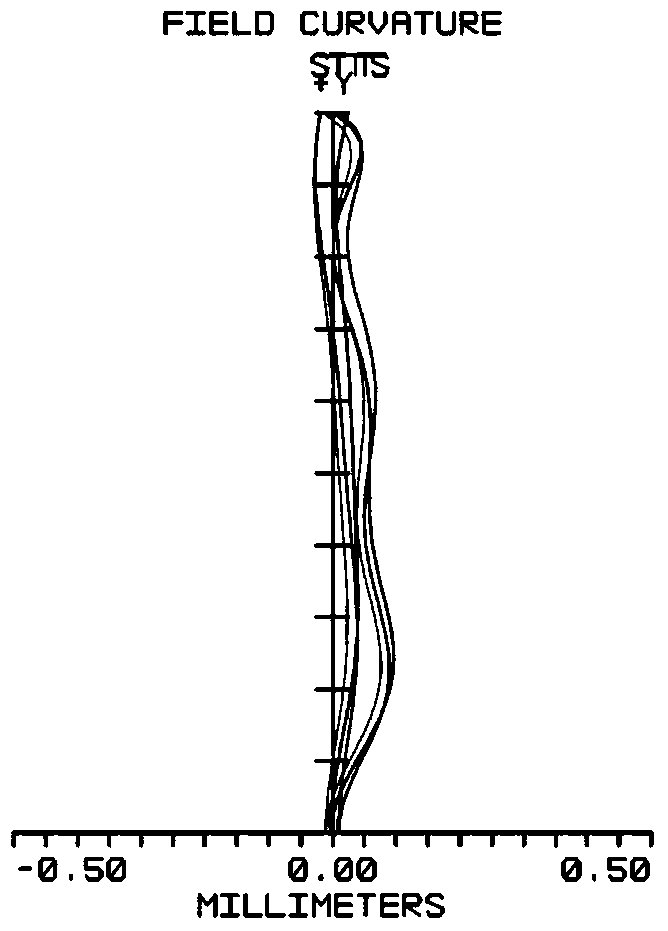

Large-visual-field-angle high-image-quality eyepiece optical system and head-mounted display device

The invention relates to a large-visual-field-angle high-image-quality eyepiece optical system and a head-mounted display device. The large-visual-field-angle high-image-quality eyepiece optical system comprises a first lens group and a second lens group which are coaxially and sequentially arranged from a human eye to an image source along an optical axis direction, wherein the first lens group and the second lens group satisfy a certain focal length relationship. The effective focal length of the first lens group is a negative value, and the first lens group is composed of a first lens close to the human eye and a second lens away from the human eye. The effective focal length of the second lens group is a positive value, and the second lens group is composed of one or two pieces of lenses. The first lens is in a biconvex shape, the optical surface, close to the human eye, of the second lens is recessed towards the human eye, and the first lens and the second lens are each of an aspheric surface type. The distance between the first lens and the second lens, a focal length relationship between lenses in the second lens group, and material characteristics of the lenses satisfy certain relationships, and the second lens group further comprises a fourth lens. The large-visual-field-angle high-image-quality eyepiece optical system has the advantages of large aperture, large field of view, high resolution, low distortion, small size and the like, and is suitable for the head-mounted display and similar devices.

Owner:SHENZHEN NED OPTICS CO LTD

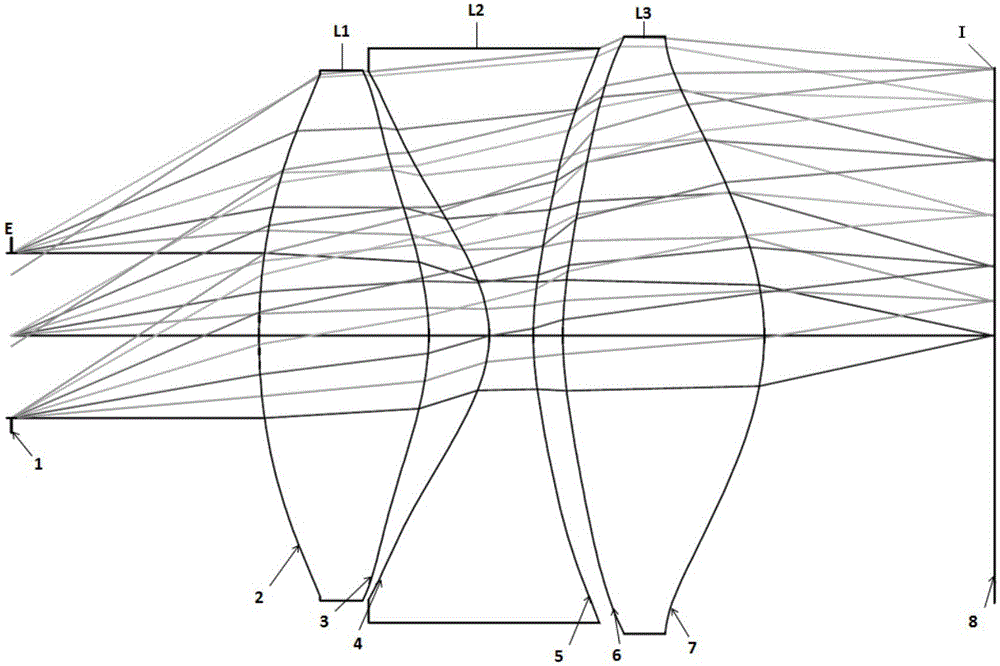

Large-field angle eyepiece optical system

The invention provides a large-field angle eyepiece optical system used for a head display. The optical system comprises a first lens, a second lens and a third lens, which are coaxially arranged from the eye observation side to the display side along the direction of the optical axis successively. The first lens and the third lens are positive lenses and the second lens is a negative lens. The first lens protrudes towards the eye observation side from the face of the eye observation side and the radius of curvature is the positive value. The second lens recessed towards the eye observation side from one side of a diaphragm and the radius of curvature is the negative value. When materials, focal lengths and positions of the first, second and third lenses satisfy certain relations, images displayed on a display device are formed in people's eyes after being amplified via the eyepieces. The eyepiece optical system is advantaged by large diameter, large field angle, high definition, low distortion and small size, and suitable for a head display and similar devices.

Owner:SHENZHEN NED OPTICS CO LTD

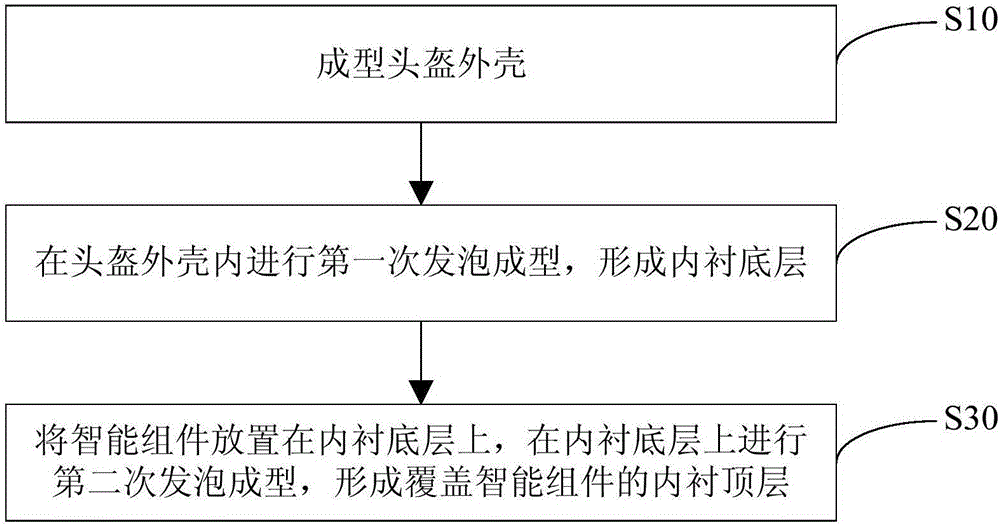

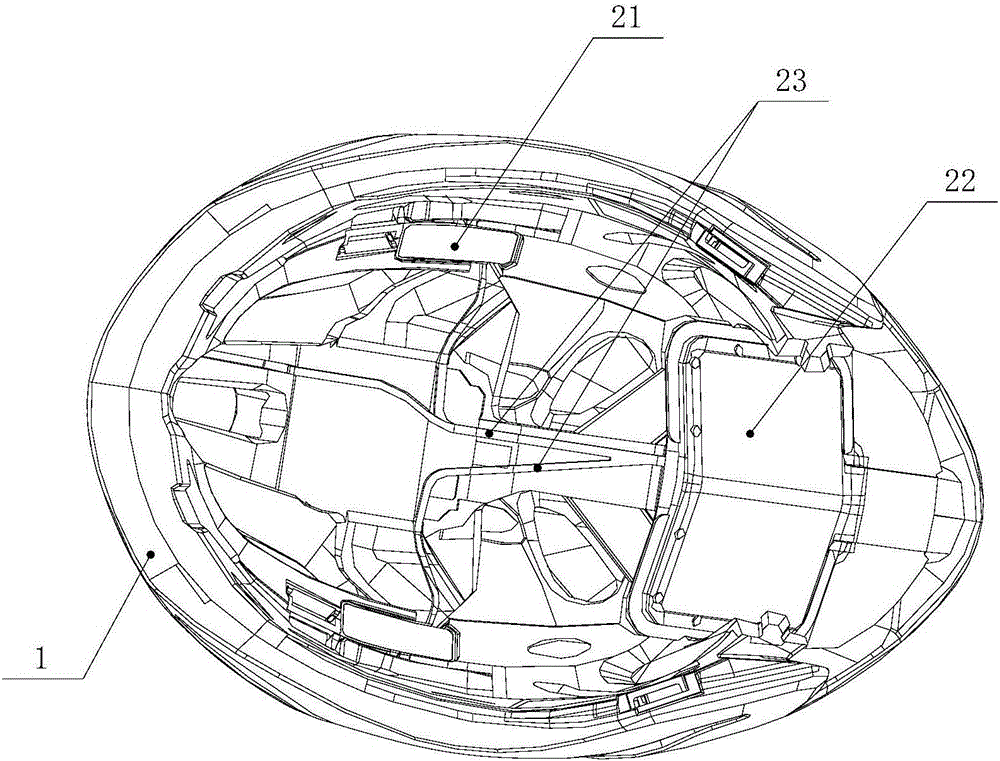

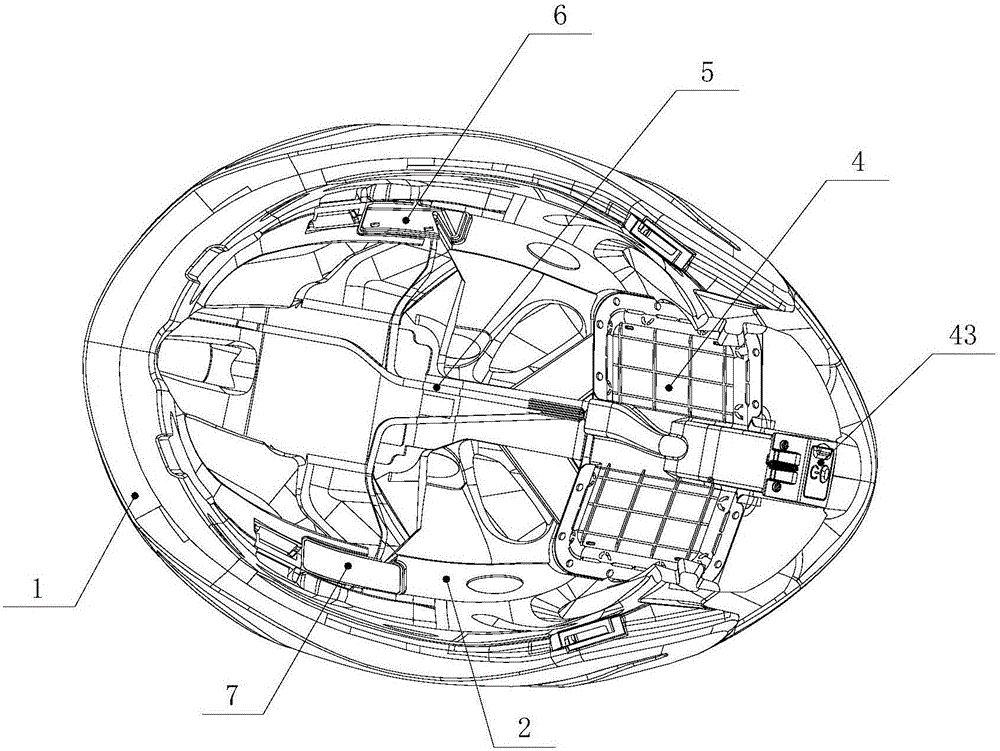

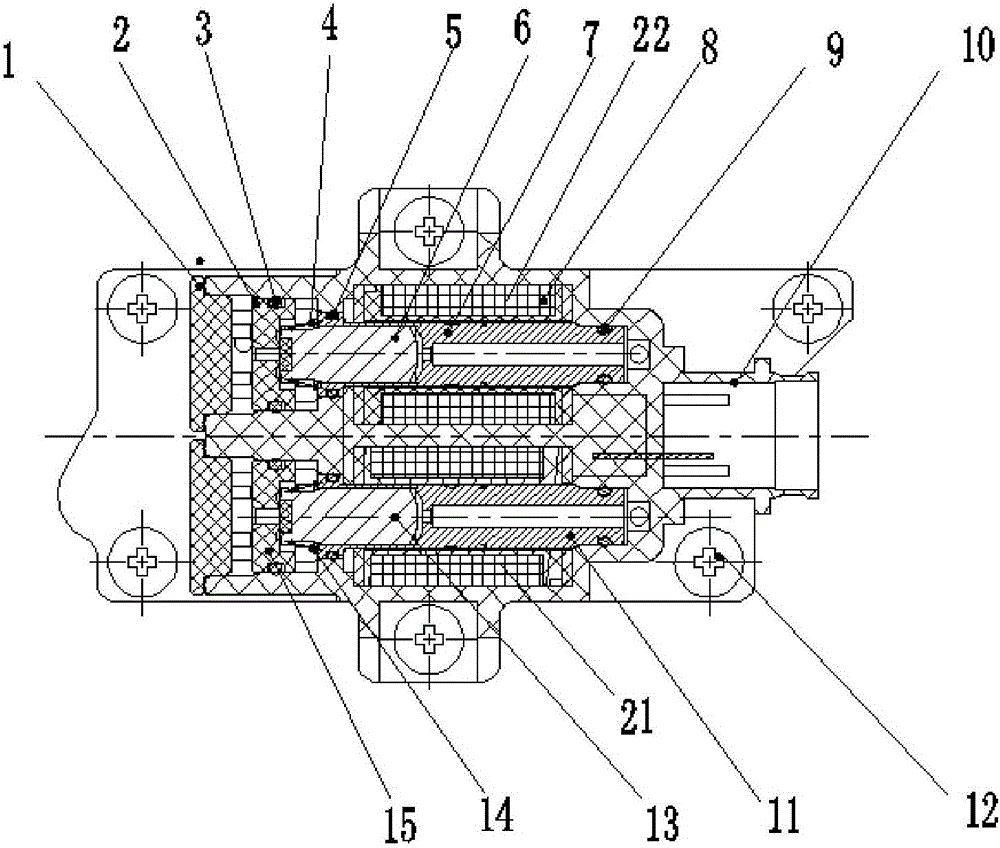

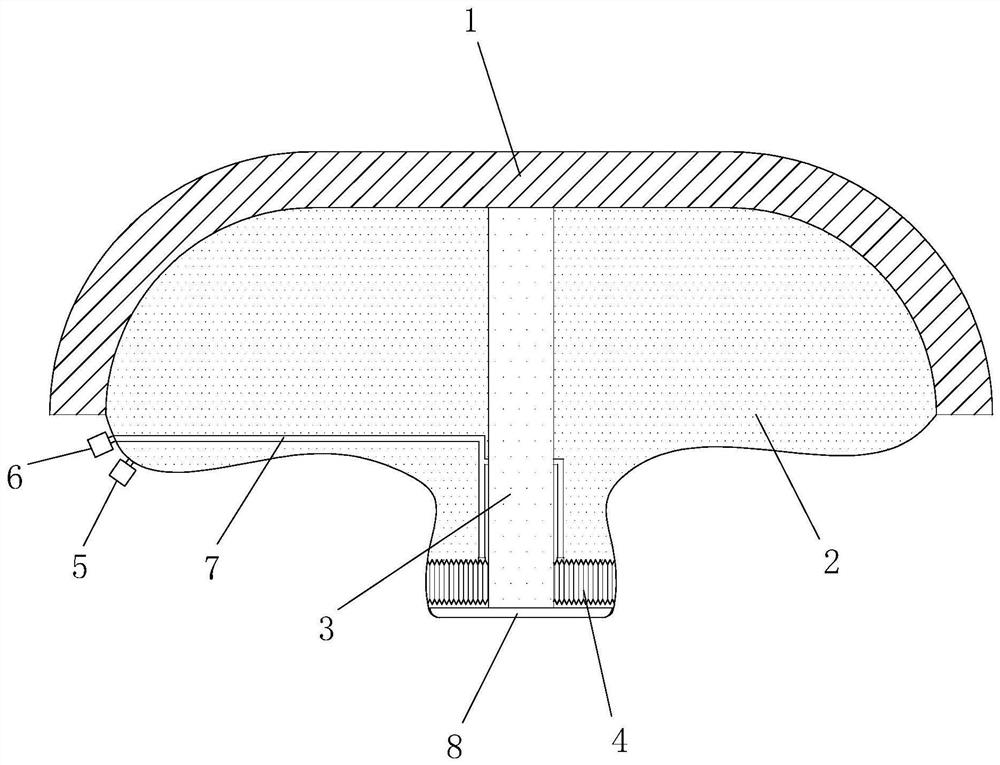

Intelligent helmet and manufacturing method thereof

PendingCN106213651AFunction increasePrevent disengagementHelmetsHelmet coversManufacturing engineering

The invention belongs to the technical field of production of helmets and discloses an intelligent helmet and a manufacturing method thereof. The manufacturing method of the intelligent helmet comprises the following steps: step 1: molding a helmet shell; step 2: carrying out first time of foaming and molding in the helmet shell to form a lining bottom layer; and step 3: putting an intelligent assembly on the lining bottom layer and carrying out second time of foaming and molding on the lining bottom layer to form a lining top player covering the intelligent assembly. The intelligent helmet comprises the helmet shell, and the lining bottom layer and the lining top player which are molded in the helmet shell and are arranged in sequence from inside to outside; and the intelligent assembly is integrally molded between the lining bottom layer and the lining top player. When the intelligent helmet disclosed by the invention is produced through the manufacturing method above, the intelligent assembly and the helmet shell are integrally foamed and molded; and compared with an existing technology of mounting the intelligent assembly through a lead wire framework, manufacturing and a mold of the lead wire framework are eliminated; and the weight of a product lightened and the manufacturing cost is effectively reduced.

Owner:GUANGDONG COROS SPORTS TECH JOINT CO

Fiberglass/PP composite fiber cloth assisting resin transfer molding (RTM) process method and molding mold

The invention relates to a fiberglass / PP composite fiber cloth assisting resin transfer molding (RTM) process method and a molding mold. The adopted mold comprises a lower mold, foam, a sealing rubberstrip, a glue injection opening, an upper mold and a vacuumizing opening. In a process, fiberglass and PP material are woven into composite fiber cloth according to required gram weight first, then needed carbon fibers or fiberglass cloth are / is laid on the surface of a mold cavity, then the fiberglass / PP composite fiber cloth is laid, the foam processed through computer numerical control (CNC) is put in, and then according to symmetrical laminates, fiberglass / PP composite fiber cloth, carbon fibers or fiberglass cloth are laid. Finally, mold assembly, vacuumizing and resin injection are conducted, after product solidification, the molding mold is opened, and a product is taken. According to the fiberglass / PP composite fiber cloth assisting resin transfer molding (RTM) process method andthe molding mold, the fiberglass / PP composite fiber cloth is adopted, PP felt and the foam are attached during material laying, the PP felt is fluffy, thus channels are provided for resin flowing, theproblem of uneven resin flowing on the surface of the foam is solved, the foam does not need slotting or punching, and machining cost of the foam is lowered greatly.

Owner:上海晋飞碳纤科技股份有限公司

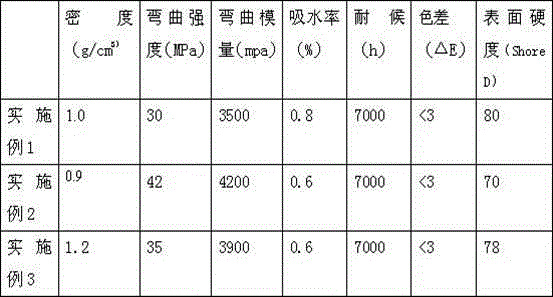

Production method for artificial stone composite boards

InactiveCN103240790ACuring shrinkage is smallHigh densityCeramic shaping apparatusEpoxyArchitectural engineering

The invention belongs to the field of building and ornament materials, and particularly relates to a production method for artificial stone composite boards. The method includes placing monoblock base boards or jointed boards in moulds, fully mixing with low-shrink unsaturated polyester resin or low-shrink epoxy resin and auxiliary materials to obtain mixtures after grading artificial stone packing, directly spreading the mixtures on the base boards, trowelling and vibrating the mixtures to enable material surfaces to be smooth, placing the base boards into vacuum equipment to remove bubbles, performing natural or heating solidification, and optionally polishing surfaces to obtain artificial stone composite board products. The production method is simple in process and low in cost, and composition is firm; abandoned defective products such as ceramic, stone and artificial stone can be effectively utilized, and one-time forming is realized without bonding; and the products are attractive in surface and not slippery when touching water, have high strength and wear-resisting properties, are easy and convenient to pave like floor tiles, and are widely applied to the field of the building and ornament materials.

Owner:成都汇玉科技产业有限公司

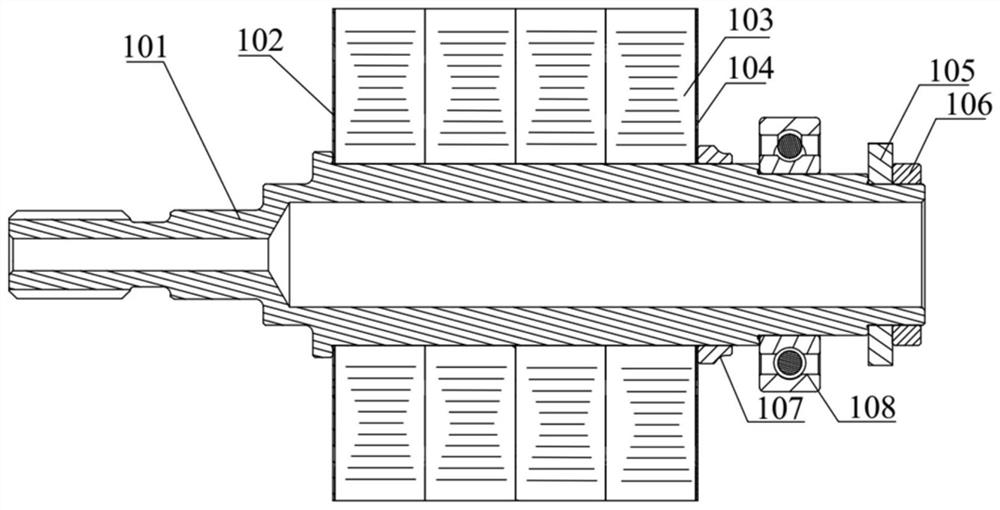

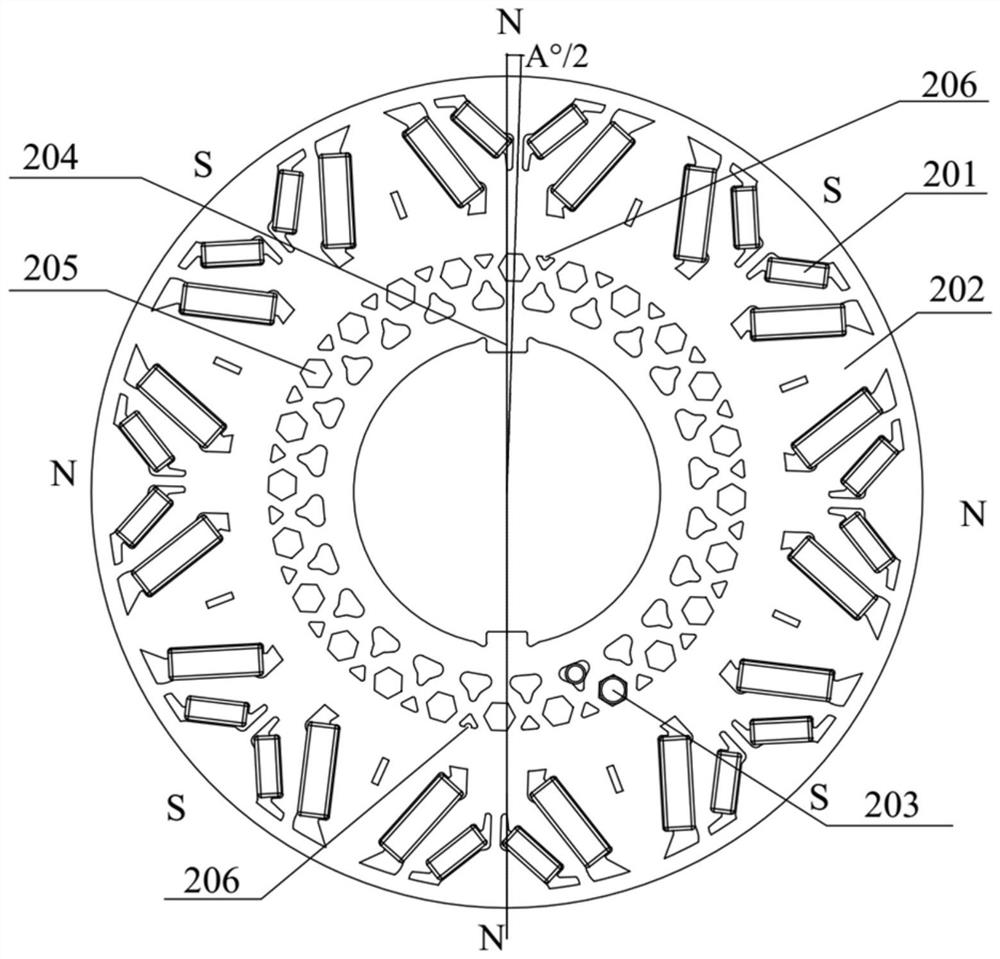

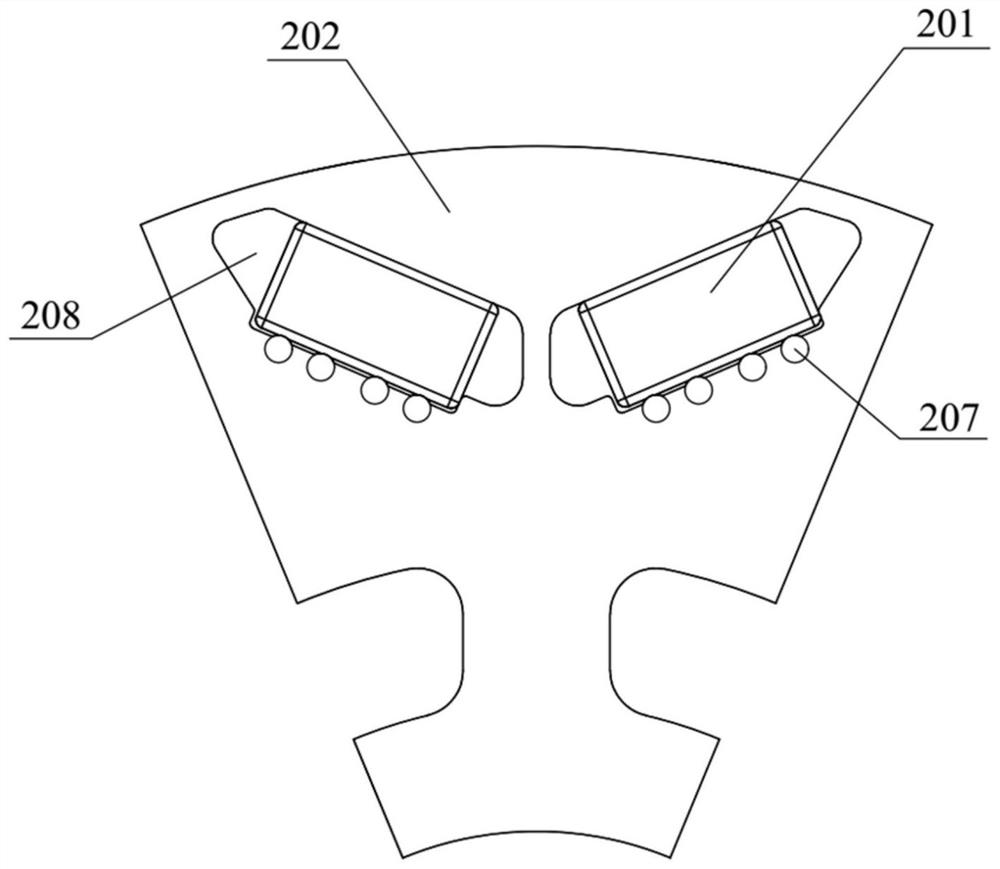

Permanent magnet synchronous motor rotor assembly for vehicle, and design method thereof and motor

ActiveCN112260434AShorten the axial lengthReduce weightMagnetic circuit rotating partsMechanical energy handlingPermanent magnet synchronous motorElectric machinery

The invention relates to the technical field of permanent magnet synchronous motors, particularly to a permanent magnet synchronous motor rotor assembly for a vehicle, and a design method thereof anda motor. The permanent magnet synchronous motor rotor assembly for the vehicle comprises a rotor shaft, a rotor iron core attached magnetic steel assembly and magnetism isolating fixing end plates, wherein the rotor iron core attached magnetic steel assembly comprises a permanent magnet, a rotor iron core and a counterweight pin, the rotor iron core is in key connection with the rotor shaft, a permanent magnet groove and a weight removing hole are formed in the rotor iron core, the permanent magnet is inserted into the permanent magnet groove, the counterweight pin is inserted into the weightremoving hole, the magnetism isolating fixing end plates are in key connection with the rotor shaft, and the two magnetism isolating fixing end plates are arranged at the two ends of the rotor iron core attached magnetic steel assembly respectively. According to the permanent magnet synchronous motor rotor assembly for the vehicle, the counterweight pin is arranged in the weight removing hole of the rotor core, so that a dynamic balance plate can be omitted, the weight of the magnetism isolating fixing end plate can be reduced, the thickness of the magnetism isolating fixing end plate can be reduced, the axial length of the rotor assembly can be shortened, and the weight and the cost of a product can be reduced.

Owner:CHINA FIRST AUTOMOBILE

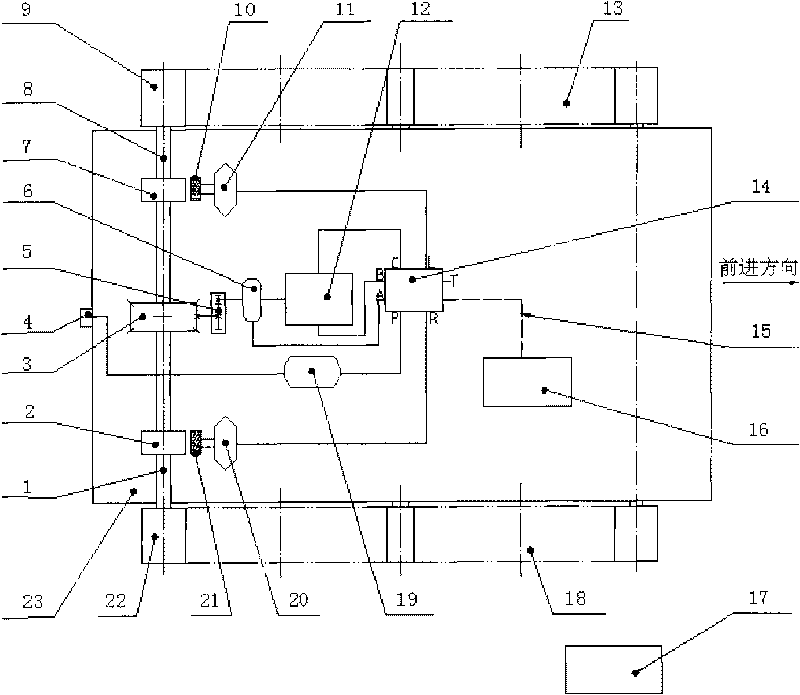

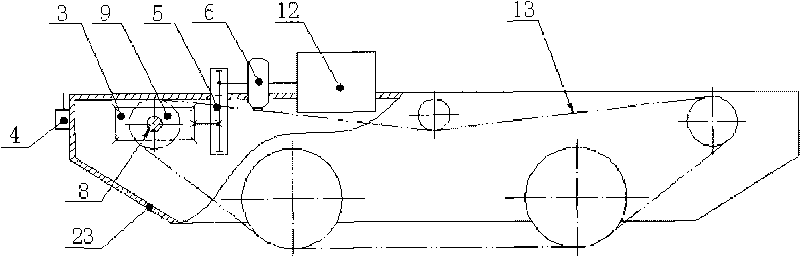

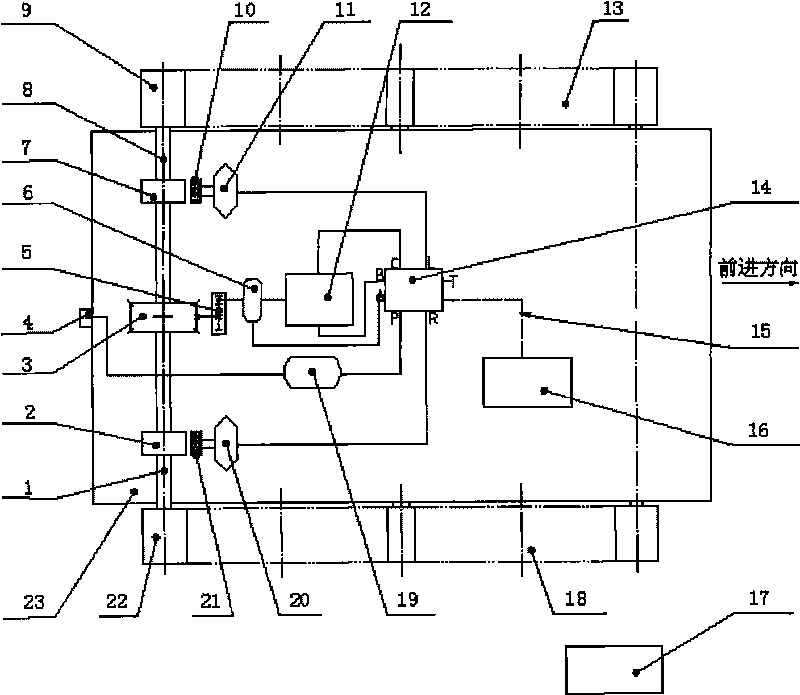

Small pneumatic vehicle used in fire scene

The invention relates to a small pneumatic vehicle used in a fire scene, which has the technical scheme that an air source joint [4] arranged at the tail part of a vehicle body [23] is connected with a valve opening P of an electromagnetic valve block [14] through a high-pressure air pipe via an energy accumulator [19], a valve opening B and a valve opening C of the electromagnetic valve block [14] are respectively connected with two air holes of a pneumatic motor [12] through high-pressure air pipes, the valve opening A of the electromagnetic valve block [14] is connected with a clutch [6] through a high-pressure air pipe, a valve opening L and a valve opening R of the electromagnetic valve block [14] are respectively connected with a left braking air cylinder [11] and a right braking air cylinder [20] through high-pressure gas pipes, the pneumatic motor [12] respectively drives a left side driving shaft [8] and a right side driving shaft [1] of the small vehicle through the clutch [6], a speed reducer [5] and a differential mechanism [3], a remote controller [17] is in wireless connection with a signal receiving and control module [16], and the signal receiving and control module [16] is connected with the electromagnetic valve block [14] through a cable [15]. The invention has the characteristics that the small pneumatic vehicle is applicable to the dangerous environment such as high-temperature environment, the explosive environment and the like, and the safety of firefighters can be ensured.

Owner:WUHAN UNIV OF SCI & TECH

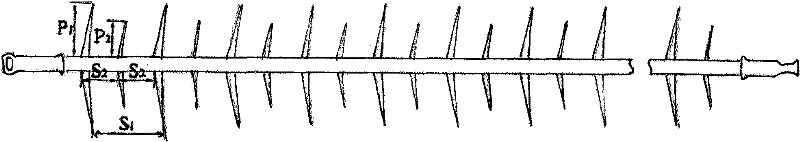

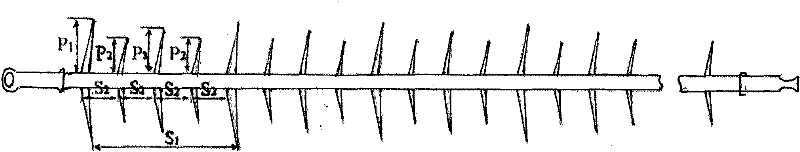

AC hanging-type composite insulator

ActiveCN101752042AExcellent anti-pollution flashover performanceIncrease profitSuspension/strain insulatorsComposite insulatorsEngineering

The invention discloses an AC hanging-type composite insulator, comprising a mandrel, hardware arranged at both ends of the mandrel, a sheath covered outside the mandrel, wherein, the outside of the mandrel is provided with large umbrellas which are coaxial with the mandrel and whose diameter is identical to that of the mandrel and small umbrellas or the combination of a medium umbrella and the small umbrella. Through adjusting the arranging sequence of the umbrellas with different diameters, the umbrella extension and the umbrella clearance of the umbrellas with different diameters are optimized, and umbrella-skirt structural parameter of AC composite insulator with the optimal pollution flashover characteristic is obtained. The umbrella-skirt structural parameter after optimization design leads the composite insulator to have excellent resistance to pollution flashover under the conditions of the same structural heights, meanwhile, the design of the structure is reasonable, accordingly, the umbrella-skirt material of the composite insulator is greatly saved, and the waste of the material is avoided.

Owner:HEBEI XINHUA HIGH VOLTAGE ELECTRICAL EQUIP +1

ASA plastic-wood material and preparation method thereof

The invention provided an ASA plastic-wood material. The ASA plastic-wood material comprises the following components in percentage by mass: 70-90% of ASA plastic particles, 0.3-1% of a foaming agent, 10-30% of wood flour, 2-5% of a compatilizer and 1-4% of a lubricant. Because the wood flour used for preparing the ASA plastic-wood material is treated by an additive, the combinability and interface compatibility of the wood four and the ASA can be enhanced, the quality of the product can be improved, and thus the ASA plastic-wood material has great popularization value.

Owner:DONGGUAN CHNV TECH CO LTD

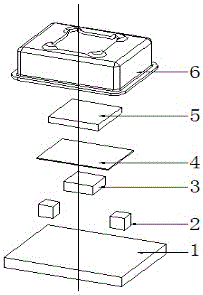

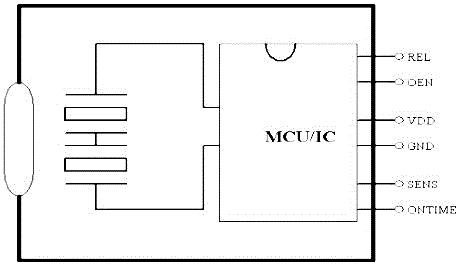

SMT intelligent pyroelectric infrared sensor

InactiveCN105698936AImprove anti-interference abilityStrong product weightSensing radiation from moving bodiesManufacturing cost reductionControl signal

The invention relates to a chip-type intelligent pyroelectric infrared sensor, which is a closed structure shell composed of a tube cap and a substrate. The upper surface of the tube cap has a window, and an infrared optical filter is embedded on the window; and the tube cap and the A receiving space is formed between the substrates, and the receiving space accommodates and encapsulates the infrared sensitive element, the supporting component and the signal processing module; the infrared sensitive element is fixed by the supporting component, and the supporting component and the signal processing module are directly fixed on the substrate. The pyroelectric infrared sensor of the present invention has the characteristics of miniaturization, intelligence, and the ability to output multiple control signals. This packaging structure is suitable for SMT automatic patch and reflow soldering processes, which is conducive to mass automatic production and improves manufacturing efficiency. Reduce manufacturing costs.

Owner:SENBA SENSING TECH CO LTD

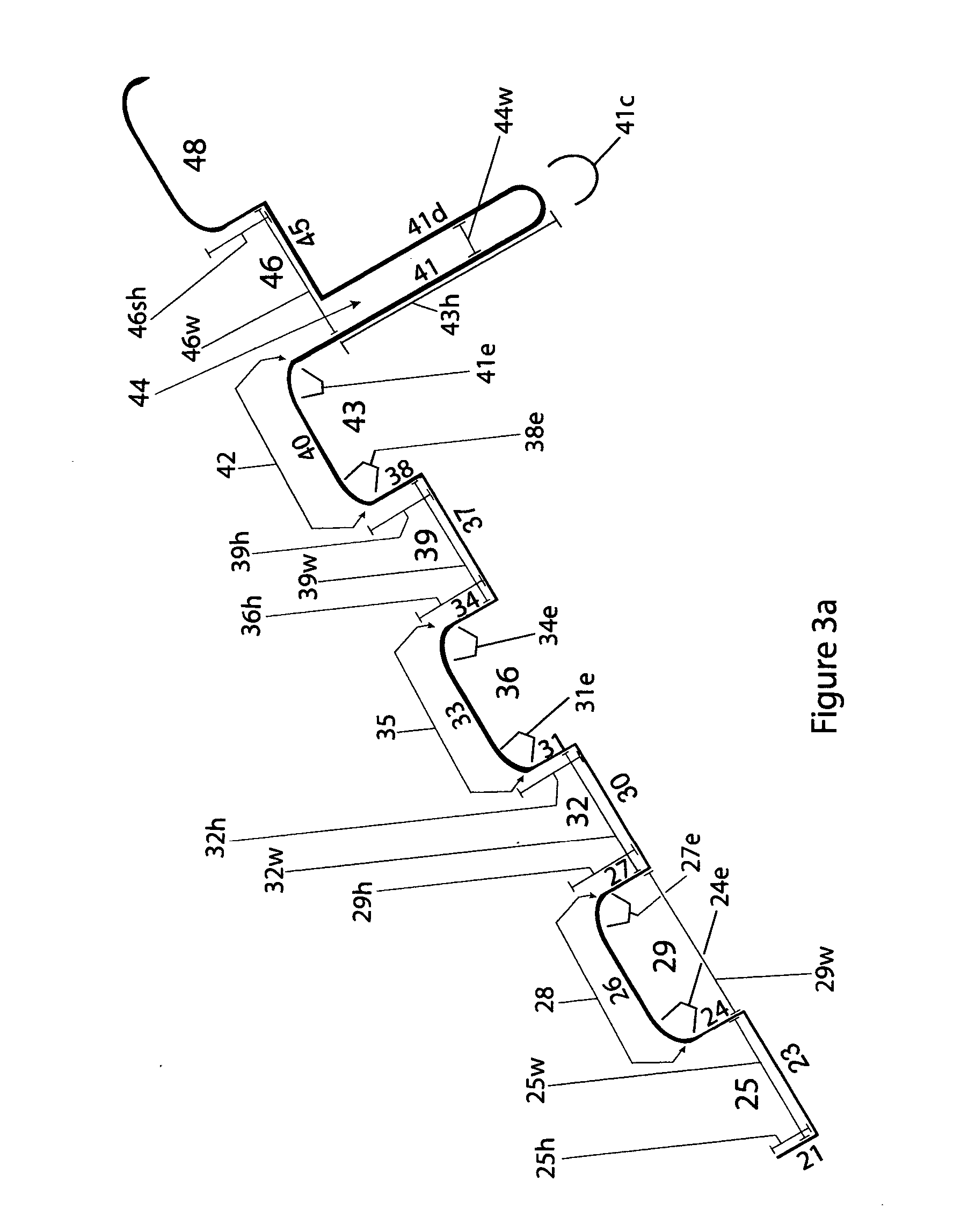

S-shaped section molding process equipment

ActiveCN102078893AReduce product weightImprove craftsmanshipProduction engineeringEngineering production

The invention belongs to a sheet metal part molding art and relates to S-shaped section molding process equipment. The molding process equipment comprises a bending mold and a bending clamp, wherein the bending mold comprises an upper mold, a base plate, a lower mold and an S-shaped block assembly; and the bending clamp comprises a left clamp and a right clamp. In the invention, the bending mold is adopted and is matched with the bending clamp to implement an S-shaped section integral bending and molding art, thereby providing a solution for optimizing the structure of a product, lightening the weight of the product, enhancing the manufacturability of the product, reducing the number of the process equipment in the production engineering of the product, shortening the manufacturing period of the product, simplifying the assembling flow of the product, enhancing the production efficiency of the product and lowering the production cost of the product.

Owner:SHAANXI AIRCRAFT CORPORATION

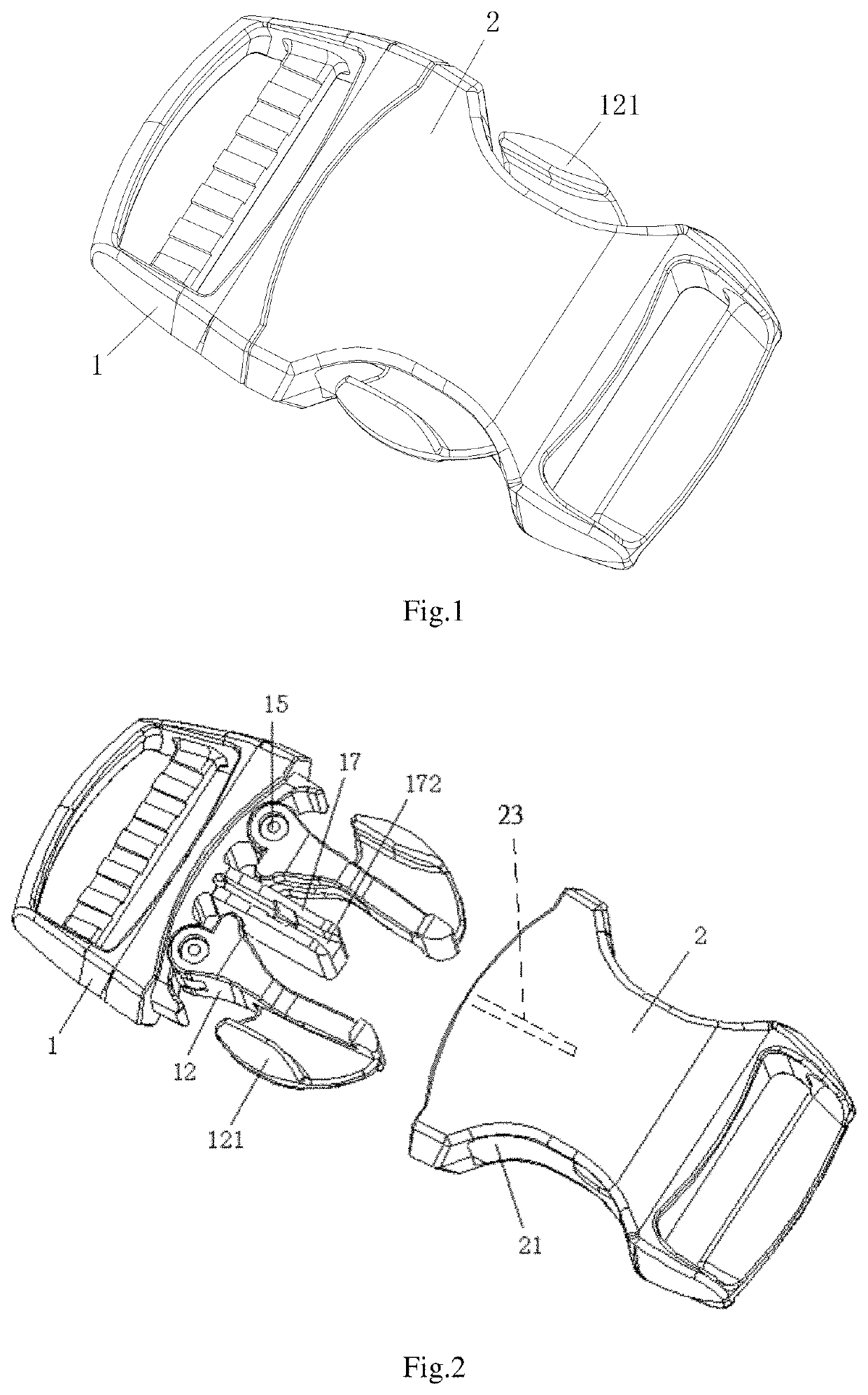

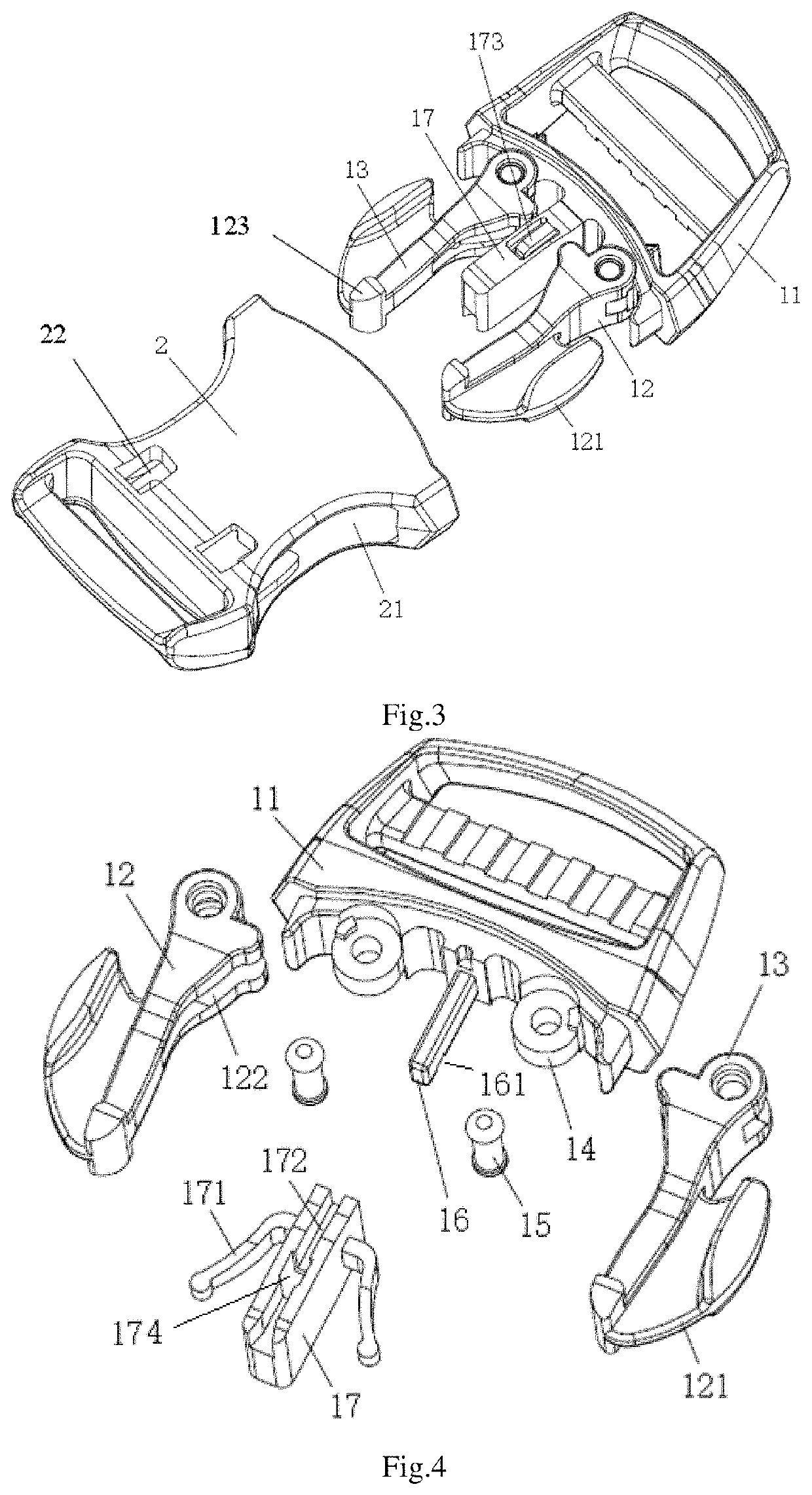

Metal body buckle

The present invention discloses an integrated buckle of metal and plastics, comprising a female buckle and a male buckle. The male buckle comprises a male buckle body and left and right pins connected to the male buckle body. The male buckle body is made of metal, the left and right pins are connected to the male buckle body by rotating shafts to form a side-to-side rotational structure. A plastic flick piece is located between two pins, the plastic flick piece is fixed to the male buckle body. An elastic arm is located on both sides of plastic flick piece respectively, the two elastic arms hold two pins respectively. The present invention uses metal material to make male buckle body and pins, and the elasticity of pins is derived from the elastic arms on both sides of plastic flick piece.

Owner:YEN YING CHUAN

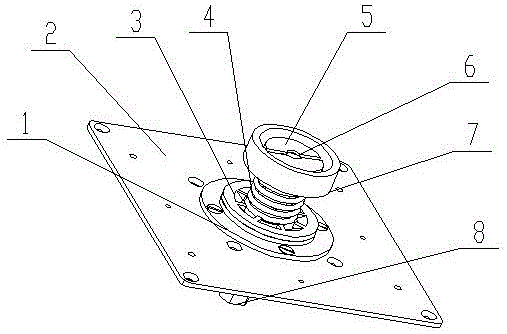

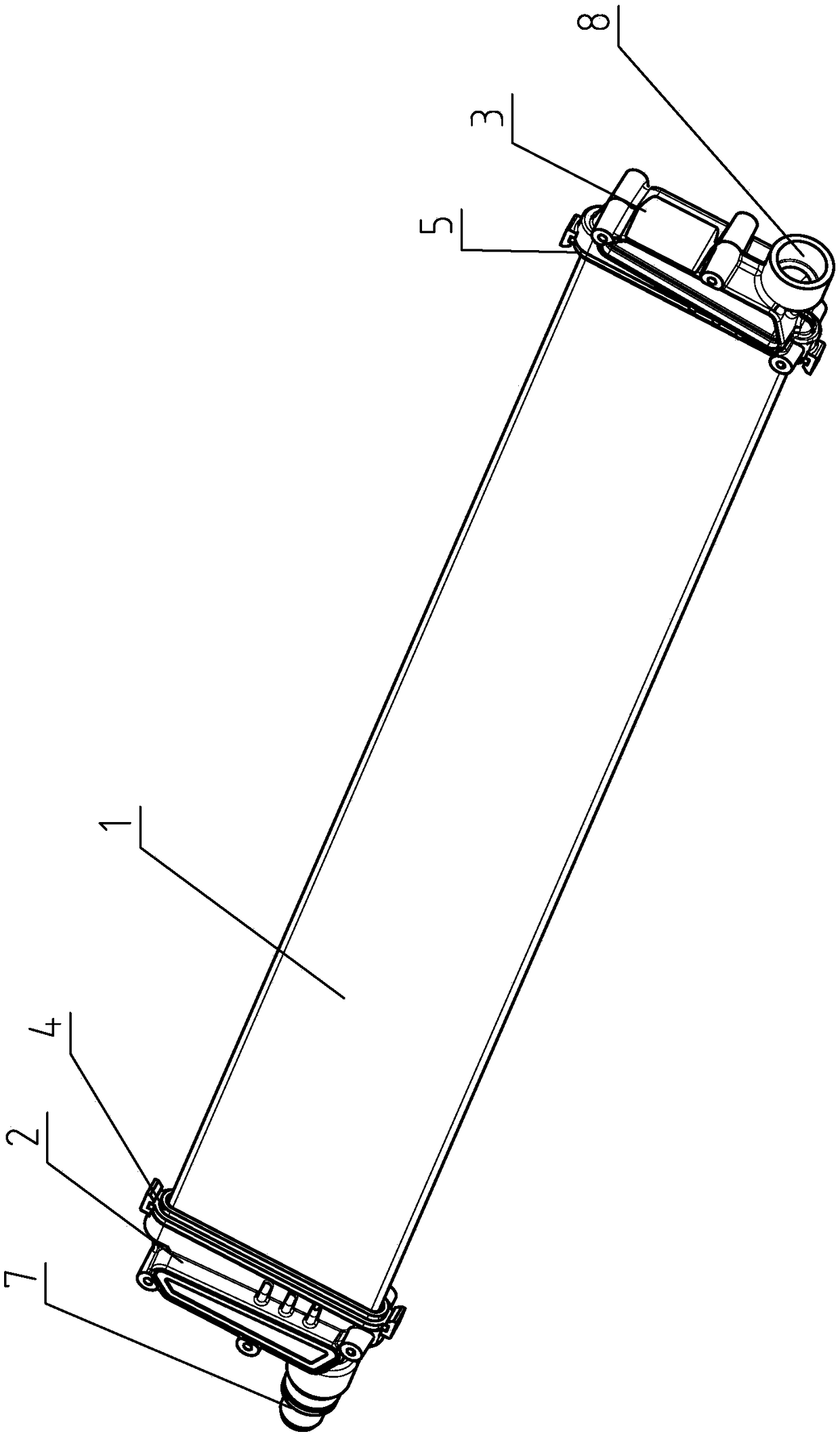

Automatic middle return mechanism

ActiveCN105936213AIncrease and decrease steering forceSmall control forceGearing controlControl devicesEngineeringGasket

The invention discloses an automatic middle return mechanism which comprises an installing panel (2), a locating bottom plate (1) and a center shaft (8). The automatic middle return mechanism is characterized in that the center shaft (8) is installed in the middle of the installing panel (2) in a penetrating mode, the locating bottom plate (1) is connected to the installing panel (2), a spring base (3) is connected to the upper portion of the locating bottom plate (1), a spring (4) is installed in the spring base (3), the center shaft (8) is sleeved with the spring (4), an adjusting nut (5) is installed on the upper portion of the spring (4), a fastening nut (7) is arranged outside the adjusting nut (5), the spring base (3) and the locating bottom plate (1) are matched in a spherical face mode, the locating bottom plate (1) is a concave spherical face, the spring base (3) is a convex spherical face, and an adjusting gasket (6) is installed on the adjusting nut (5). The automatic middle return mechanism is compact in structure, convenient to operate, reliable to carry, high in precision and suitable for use and popularization in automatic middle return.

Owner:GUIZHOU HUAYANG ELECTRICAL

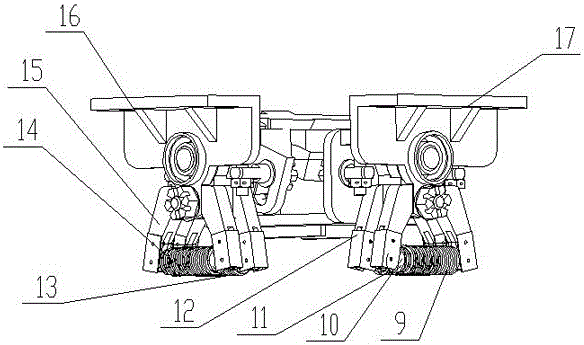

Universal integrated light ABS electromagnetic valve

ActiveCN105774789AReduce product weightShort response timeOperating means/releasing devices for valvesApplication and release valvesEngineeringElectromagnetic valve

The invention relates to a universal integrated light ABS electromagnetic valve. A blanking cap of the universal integrated light ABS electromagnetic valve is arranged outside a valve body, an air inlet valve is arranged between the blanking cap and a movable air inlet valve element, an air inlet spring is arranged between the air inlet valve and the movable air inlet valve element which is arranged between the air inlet valve and a static air inlet iron core, and the movable air inlet valve element and a movable exhaust iron core are of a symmetric structure on the two sides of a central line. A bottom plate assembly is arranged below the valve body, and a special-shaped sealing ring is arranged between the bottom plate assembly and the valve body. A static exhaust iron core and the bottom plate assembly are arranged to be of a parallel structure. An exhaust spring is arranged between an exhaust valve and a movable exhaust valve element. A coil winding is arranged outside the movable air inlet iron core and the static air inlet iron core, and a coil winding is arranged outside the movable exhaust iron core and the static exhaust iron core. An ABS electromagnetic valve body is provided with a control end, an air inlet, an outlet, an air outlet and an exhaust port.Linkage through middle pipelines is omitted, the product weight is reduced, the responding time of the system is shortened, and the system is safer and more reliable.

Owner:温州瑞立科密汽车电子有限公司

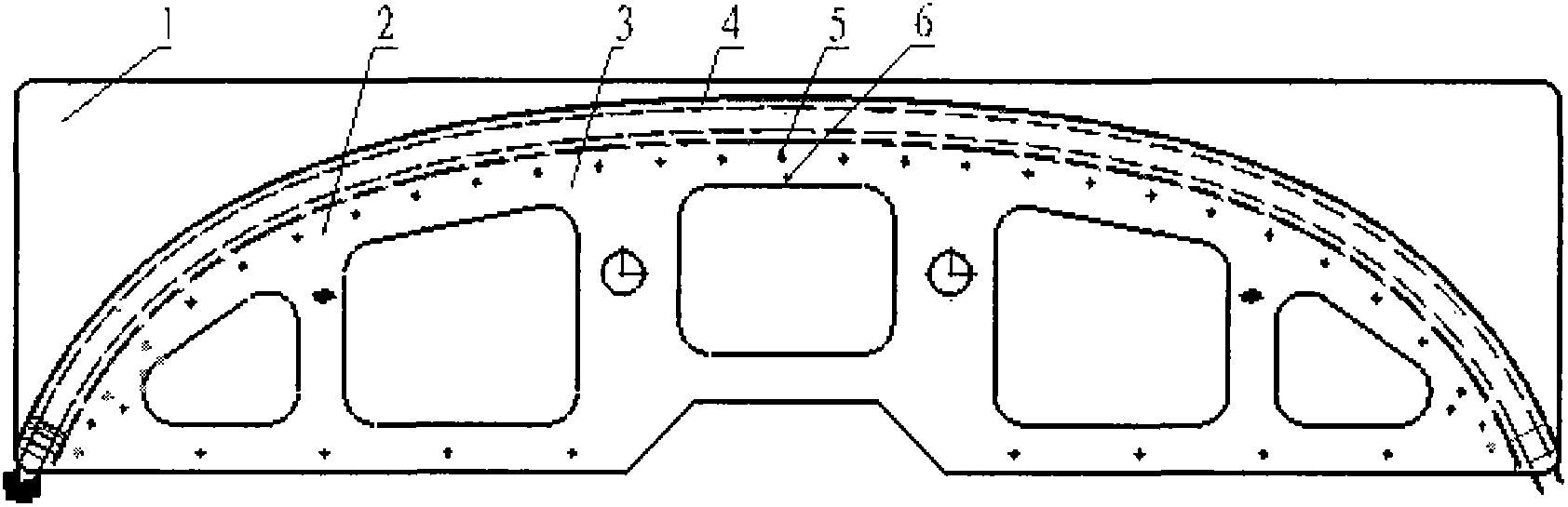

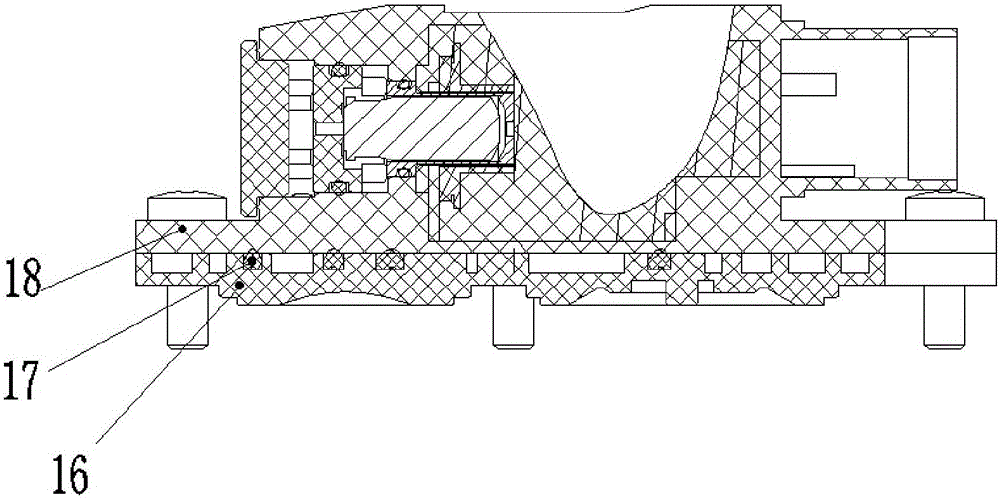

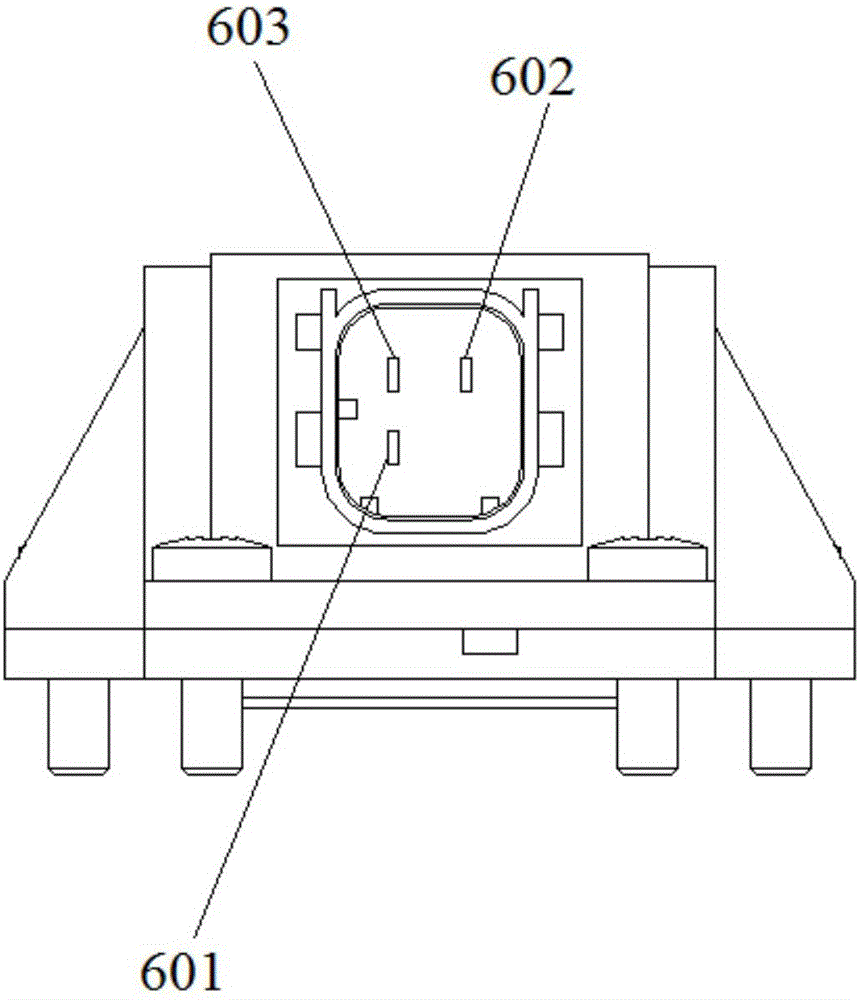

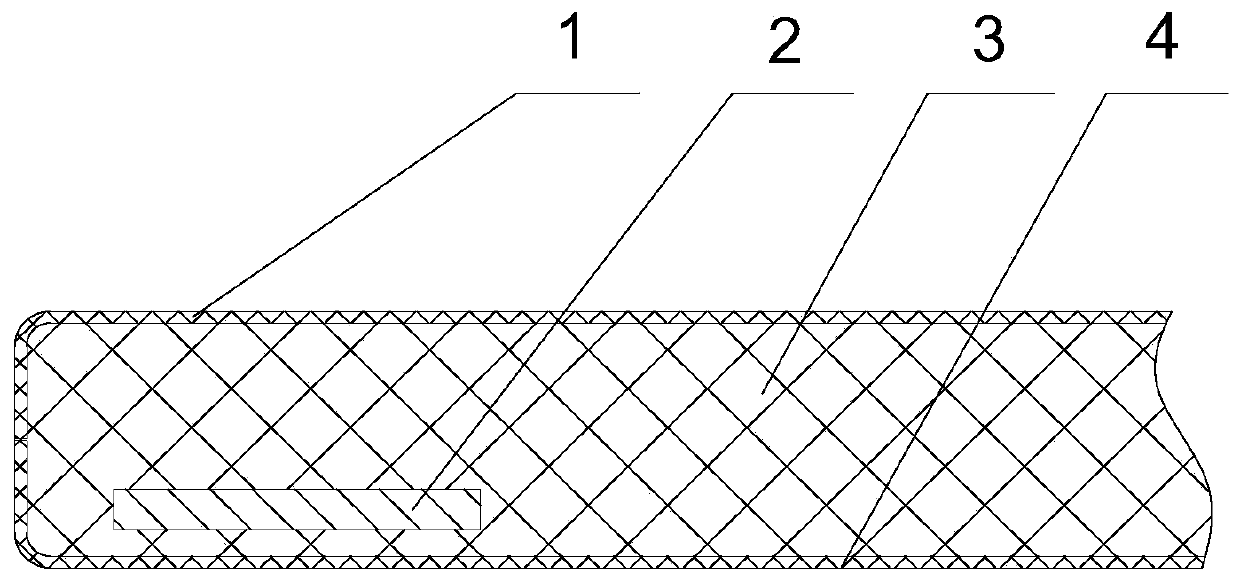

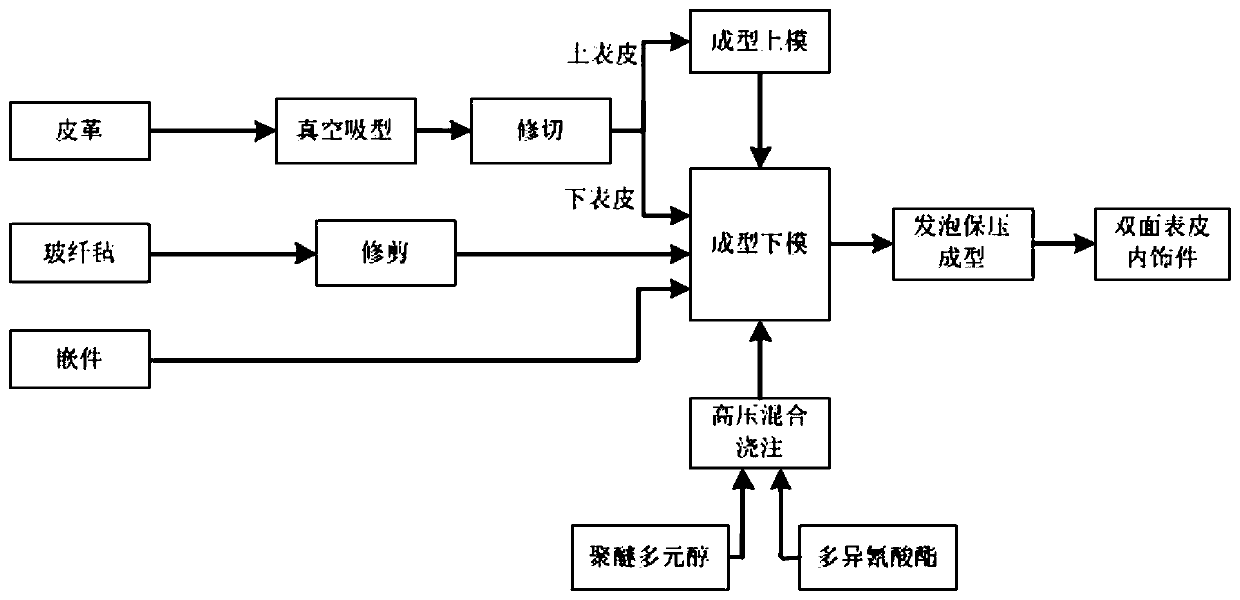

Dual-face surface foaming car interior trim part and forming process thereof

PendingCN110356335AEasy to implementImprove molding efficiencySuperstructure subunitsGlass fiberEngineering

The invention discloses a dual-face surface foaming car interior trim part. The part comprises an upper surface, a foaming layer, an insert and a lower surface. The foaming layer is a glass fiber reinforced polyurethane foaming layer, the insert is the insert embedded in the foaming layer during forming, the upper surface and the lower surface completely wrap the foaming layer and the insert, andthrough one-time forming of the glass fiber reinforced polyurethane, the integrated car interior trim part is subjected to composite molding. According to the dual-face surface foaming car interior trim part, one-time foaming molding is achieved, the aim is easily achieved, the forming efficiency is high, the cost is low, and the combination strength is high. According to the dual-face surface foaming car interior trim part, the raw material cost of the one-time molded product is small, and the weight is small. The invention further discloses a forming process of the dual-face surface foamingcar interior trim part. The product is attractive in appearance, small in weight, and capable of reducing product weight, and meeting the car lightweight needs, meanwhile, the labor efficiency is improved in a multiplied manner, and the cost is reduced.

Owner:扬州市邗江扬子汽车内饰件有限公司

Eyepiece optical system with large field of view and high image quality and head-mounted display device

The invention relates to an eyepiece optical system with large field angle and high image quality and a head-mounted display device. The eyepiece optical system with large field angle and high image quality comprises a first lens group and a second lens group, which are coaxially and sequentially arranged along an optical axis from a human eye to an image source and satisfy a certain focal length relationship. The first lens group is composed of a first lens near the human eye and a second lens far away from the human eye. The second lens group is composed of one or two lenses. The first lens is biconvex. The optical surface, near the human eye, of the second lens is concave towards the human eye, and is aspheric. The spacing between the first lens and the second lens, the focal length relationship between the lenses in the second lens group and the materials of the lenses satisfy a certain relationship. The second lens group further includes a fourth lens and a fifth lens arranged separately. The eyepiece optical system of the invention has the advantages of large aperture, large field of view, high resolution, low distortion, small size, and the like, and is suitable for head-mounted displays and similar devices.

Owner:SHENZHEN NED OPTICS CO LTD

Compression-resistant hyperbolic aluminum veneer

ActiveCN111622395AImprove stress resistanceAchieve installationWallsBuilding insulationsAirbagGas bladder inflation

The invention discloses a compression-resistant hyperbolic aluminum veneer. The compression-resistant hyperbolic aluminum veneer comprises an aluminum veneer body of which the inner side surface is concave; the inner side surface of the aluminum veneer body is bonded with a main airbag; a first airbag column is arranged inside the main airbag; the first airbag column is always in an inflated and expanded state; the top end of the first airbag column is bonded to the inner side surface of the aluminum veneer body; the bottom end of the first airbag column is used for supporting the main airbag;the side of the bottom end of the first airbag column is bonded with a plurality of second airbag columns; the main airbag is provided with a main inflation opening and a secondary inflation opening;the main inflation opening is used for directly inflating the main airbag; and the secondary inflation opening is used for inflating the second airbag column. The hyperbolic aluminum veneer completely realizes installation and bottom support through the airbags; when the exterior of the aluminum veneer receives impact and extrusion, the bottom airbag can provide a whole buffer effect, thereby significantly improving the compression resistance of the hyperbolic aluminum veneer; besides, by filling and discharging air, quite quick and convenient mounting and dismounting of the hyperbolic aluminum veneer are realized; moreover, the installation firmness can be guaranteed; and the product weight is also greatly reduced.

Owner:ANHUI CHENHANG ALUMINUM

Efficient and energy-saving magnet-collecting direction-control linear motor for compression refrigeration

InactiveCN106505820AThe structure of the whole machine is simpleUse energy efficientPiston pumpsDynamo-electric machinesElectricityElectric machine

The invention discloses an efficient and energy-saving magnet-collecting direction-control linear motor for compression refrigeration. The linear motor comprises an annular permanent magnet stator or a mover and an iron core coil mover or a stator; the linear motor is characterized in that N poles or S poles of permanent magnets for forming an annular magnetic field all face to interior of a ring to form inner ring homo-polar property so as to generate a strong annular inversion magnetic field with opposite ring opening magnetic field directions; the S poles or N poles of the permanent magnets for forming the annular magnetic field all face to exterior of the ring to form outer ring homo-polar property; and an iron core coil with certain length is placed in the inversion magnetic field ring. The efficient and energy-saving magnet-collecting direction-control linear motor has the advantages of simple structure, low production cost, energy-saving, electricity-saving, and high working efficiency; when a motor apparatus and a compression apparatus are directly combined into one body, a complex crank connecting rod structure can be omitted, intermediate consumption of electric energy can be reduced, and the operating efficiency of a mechanical system can be greatly improved by prolonging a piston travel of the inversion magnetic field, thereby enabling the piston pushing force to be higher.

Owner:李扬远

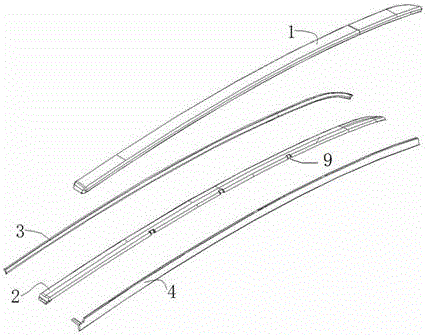

Three-color external decoration strip for automobile windshield and forming mold and method thereof

ActiveCN105965768AImprove appearance qualityImprove the level of environmental protectionEngine sealsVehicle sealing arrangementsEngineeringSpecular surface

The invention discloses a three-color external decoration strip for an automobile windshield and a forming mold and method of the three-color external decoration strip. The three-color external decoration strip for the automobile windshield comprises an ABS framework, a PMMA specular surface layer and TPU soft edges. The PMMA specular surface layer and the TPU soft edges are arranged on the ABS framework. The ABS framework 2 is provided with injection molding channels communicating with the front TPU soft edge 3 and the back TPU soft edge 4. According to the forming mold, the body framework is placed in a double-color injection mold as an insert, and then the three-color specular product, which is integrally formed from the three materials comprising the ABS body framework, the PMMA specular body surface layer and the TPU soft edges, is obtained; and besides, the technical breakthrough of front and back rubber coating is achieved through the combination of sliding blocks and sealing rubber cutters, and the problems caused when existing three-color injection molds are used are well solved. According to the three-color external decoration strip for the automobile windshield, under the condition of the same structure, the appearance quality and the environmental protection level of products are improved, and the product cost and the product weight are reduced.

Owner:湖南浩润汽车零部件有限公司

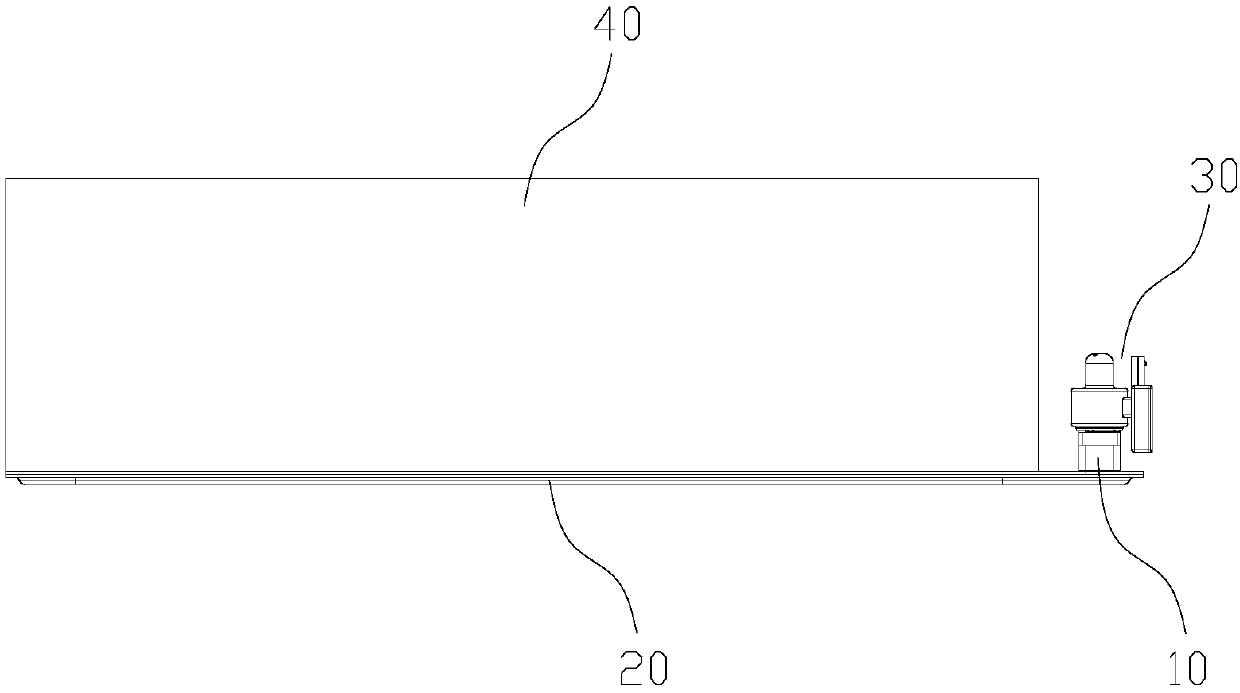

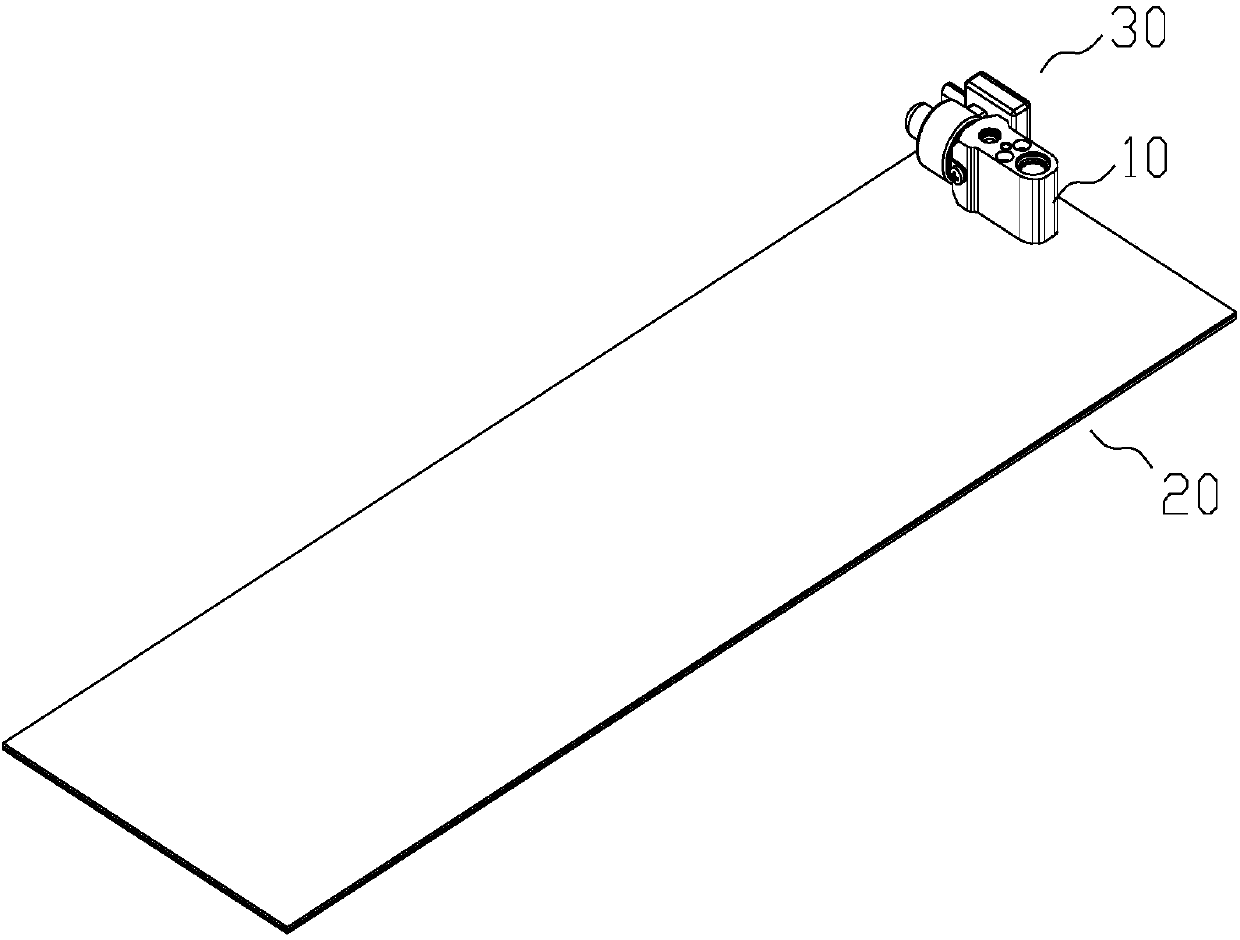

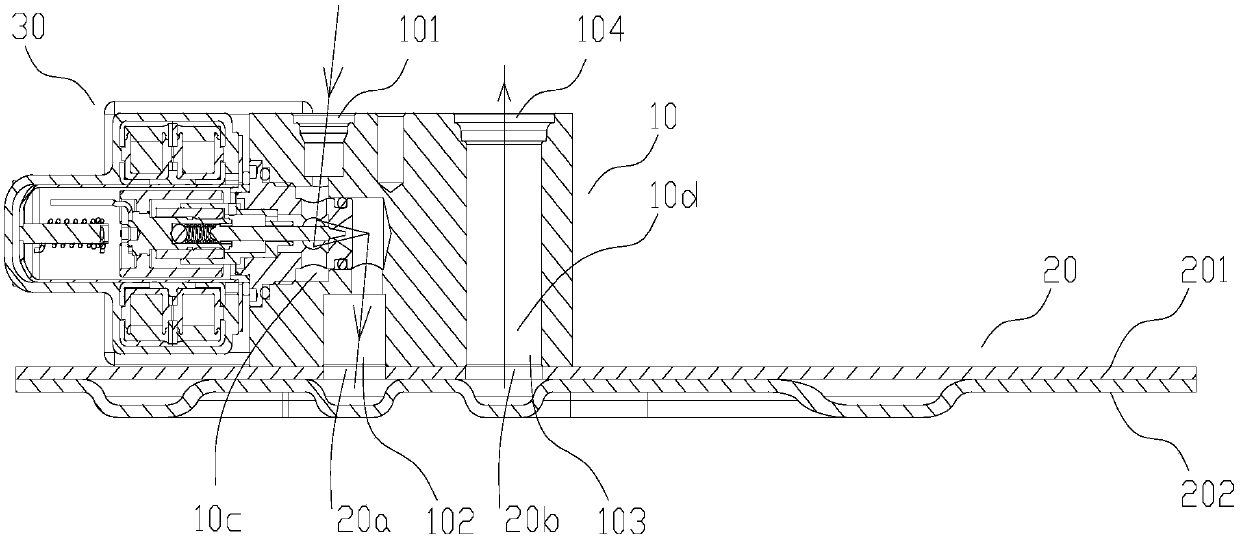

Cooling plate integrated module and battery module

InactiveCN109599621ASimple structureCompact structureSecondary cellsBatteriesEngineeringMechanical engineering

The invention discloses a cooling plate integrated module and a battery module. The cooling plate integrated module comprises a cooling plate and a valve assembly, wherein the cooling plate is provided with a first interface and a second interface, the valve assembly and the cooling plate are fixedly arranged to form a whole, the valve assembly comprises a connection block and a valve core assembly, the connection block is at least provided with an installation hole, a first port and a second port, the installation hole is used for installing the valve core assembly, the first port and the second port communicate with the installation hole, the second port is arranged at an inner end surface of the connection block, the inner end surface faces the cooling board, the first port communicateswith the second port, the valve assembly comprises a first fluid passage, one end of the passage is the first port of the connection block, the other end of the passage is the second port, the passage flowing area of the first fluid passage is zero or above, and the passage flowing area of the first fluid passage is changed between zero and the rated flowing area range of the first fluid passage.The cooling plate integrated module is simple and compact in structure, and the heat exchange efficiency is favorably improved.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

Fireproof paint formula

The invention discloses a fireproof paint formula and belongs to the technical field of buildings. The formula is prepared by mixing 45g of paint, 12g of zeolite powder, 25g of a mixture of chlorinated paraffin and antimony oxide, 16g of rosin resin and linseed oil, 5g of hydroxyethyl cellulose, 10g of fine asbestos, 2g of borax and 6g of mica powder. As the mixture of chlorinated paraffin and antimony oxide, asbestos and borax which have the main function of flame retardance are added into the paint, the safety coefficient in a paint using process is increased; the added mixture of rosin resin and linseed oil is safe and environmental-friendly.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

Quick-inserting type cooling device for power lithium battery

PendingCN108428966AReduce welding difficultyReduce product weightSecondary cellsEngineeringElectrical and Electronics engineering

The invention discloses a quick-inserting type cooling device for a power lithium battery. The device comprises current collectors at two ends and extrusion tubes, and tube joints are arranged on at least one current collector. The device is characterized in that at least one inserting port is formed in each current collector, and two ends of each extrusion tube are in inserted connection with theinserting port through a connector. According to the quick-inserting type cooling device for the power lithium battery, the extrusion tubes and the connectors are connected to form assemblies, and all that is required is that the extrusion tube and connector assemblies are in inserted connection with the current collectors during assembly. Due to the small processing area of the extrusion tubes and the connectors, the welding difficulty and product weight are greatly reduced, the manufacturing cost is saved, product flatness is improved, and product quality is guaranteed.

Owner:ZHEJIANG YINLUN MACHINERY

S-shaped harrow cutter

InactiveCN101589662AReduce product weightImprove fatigue strengthHarrowsPloughsEngineeringMechanical engineering

The invention discloses an S-shaped harrow cutter, which comprises a cutter body. The cutter body has an inverse S-shaped structure, the cutter body comprises a main blade and a secondary blade, and two side edges of the main blade are bent upwards along the axis; and the secondary blade has a structure of which spiral cross section is elliptic. By comparing the elliptic section adopted by the blank of the invention and the conventional oblong section, the product weight is lightened; and under the condition that the processing means and the thermal treatment mode are the same, the mechanical property index, namely the fatigue strength of the product is greatly improved, and the service life is improved by about 40 to 45 percent. The elliptic section of the main blade of the S-shaped harrow cutter is bent and folded to form a curved surface, and the defects that the prior harrow cutter is easy to generate cracks and the like are overcome.

Owner:青岛东陆科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com