Patents

Literature

131results about How to "Close bite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vertical air shaft explosion protection door capable of quickly resetting

InactiveCN101943025AReduce labor intensityEliminate potential safety hazardsMining devicesTunnel/mines ventillationArray data structureExplosion protection

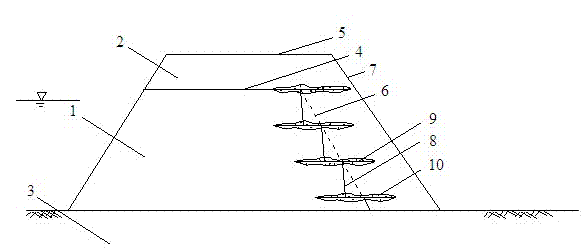

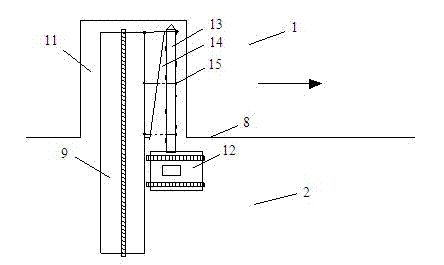

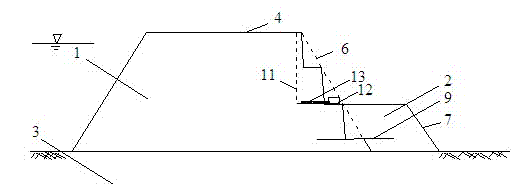

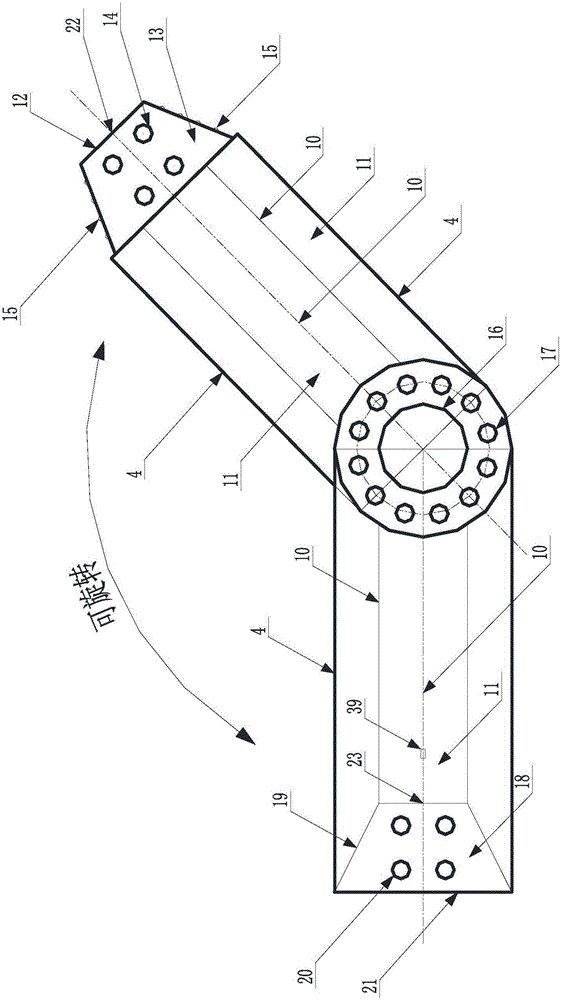

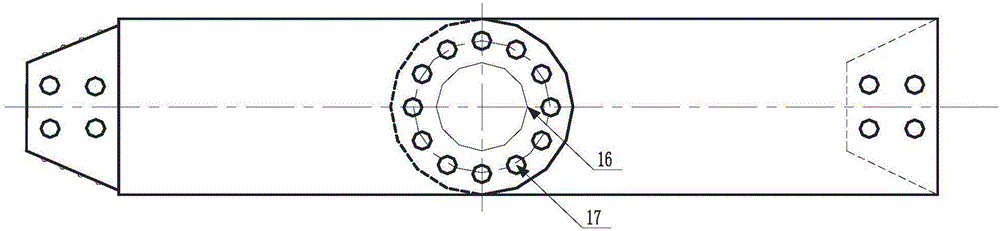

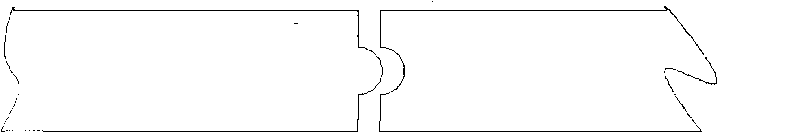

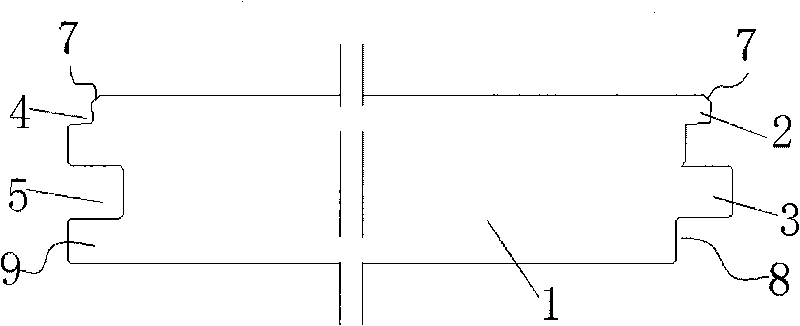

The invention discloses a vertical air shaft explosion protection door / cover capable of quickly resetting, belonging to a coal mine ventilation safety facility. The vertical air shaft explosion protection door is mainly composed of a door body 2, a heavy punch part, an inverted ventilation lock catch device and an oiling small shaft, wherein multiple groups of heavy punch assemblies of the heavy punch part are variable quality tank heavy punch assemblies 4 or variable quality tanks 19, and the variable quality tank heavy punch assemblies 4 or the variable quality tanks 19 are connected with the explosion protection door body 2 by a steel wire rope 7 and a pulley block 8; the variable quality tanks 19 are liquid storage tanks and are connected with a water supply by a water inlet and outlet pipe 13; and water reserve in the variable quality tanks is increased or reduced to replace the action of increasing or reducing the number of the weight, thus controlling the weight of the heavy punch assembly. The explosion protection door is also provided with the quick inverted ventilation lock catch device 1 and a stable synchronous elevator mechanism. The explosion protection door adopts mechanical operation to realize remote monitoring of the latch and the reset of the explosion protection door, changes outdoor operation into indoor operation, has the advantages of high resetting and latching speed, time and labour saving and safe operation, lightens physical work and improves the coal mine ventilation safety.

Owner:兖矿能源集团股份有限公司

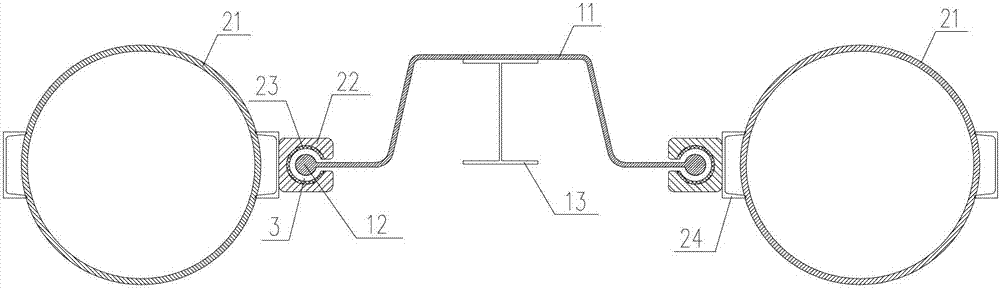

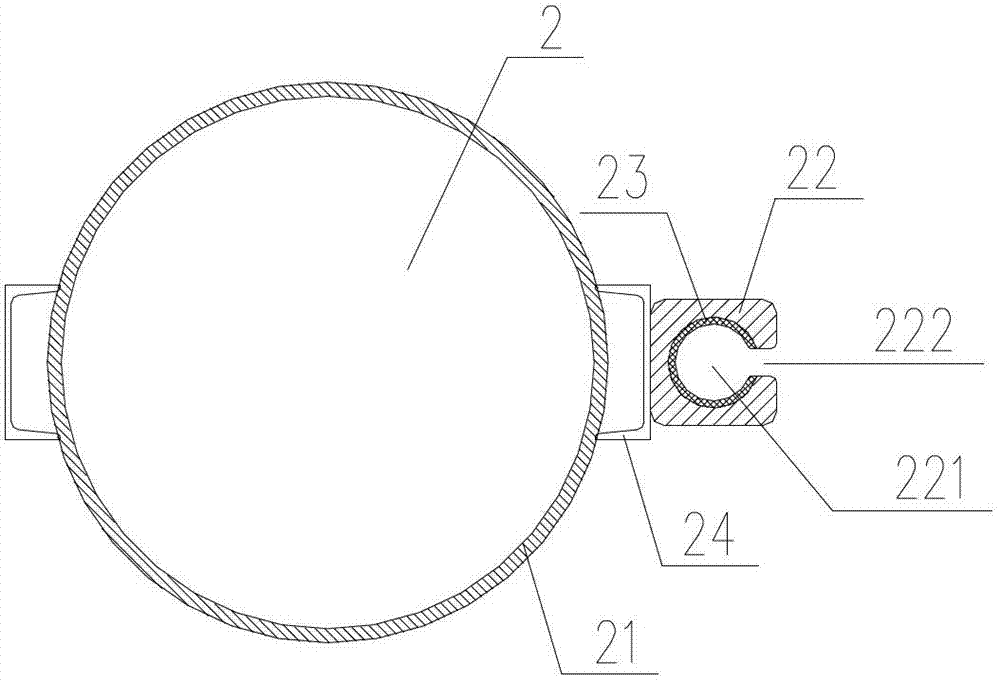

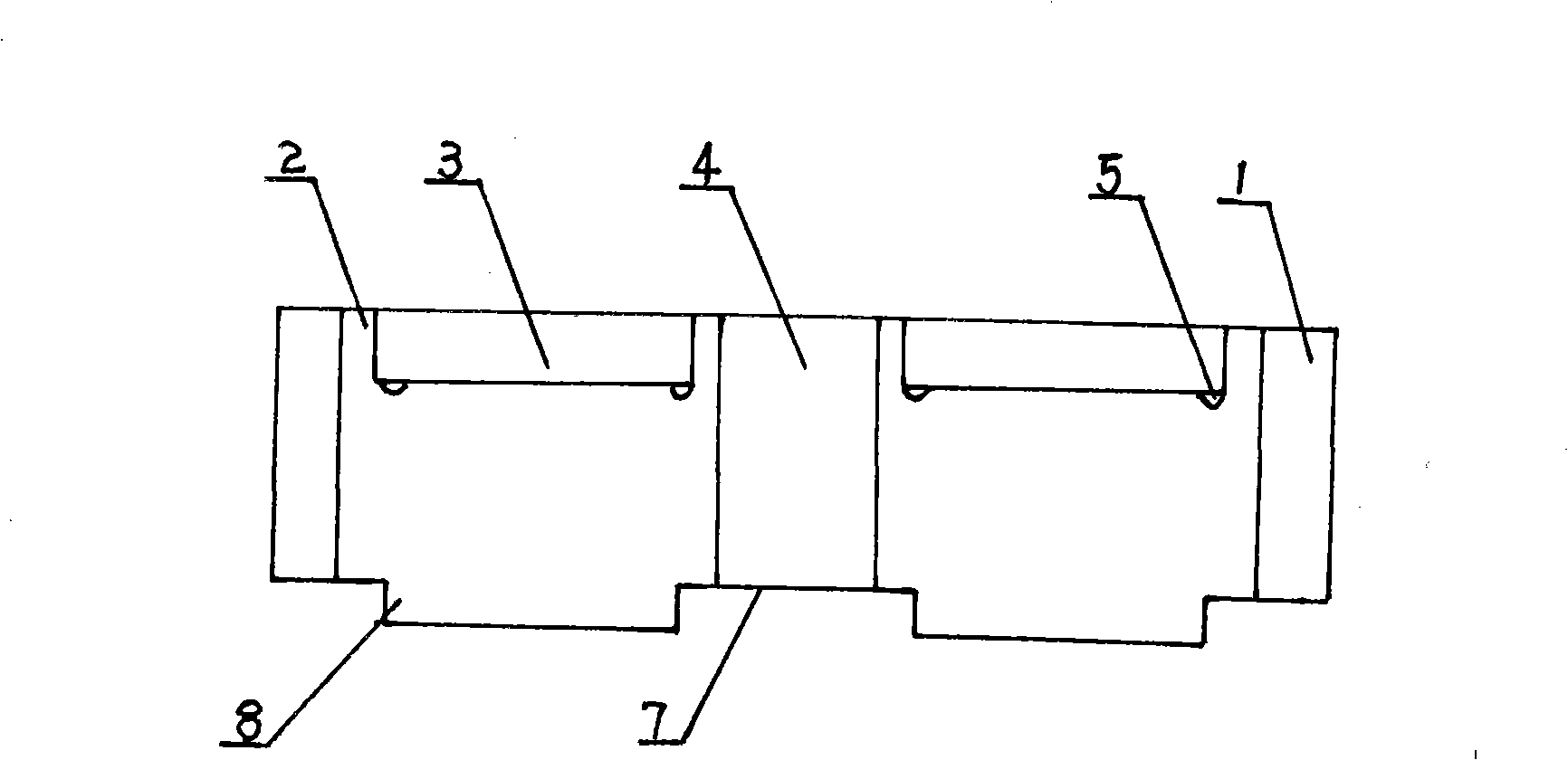

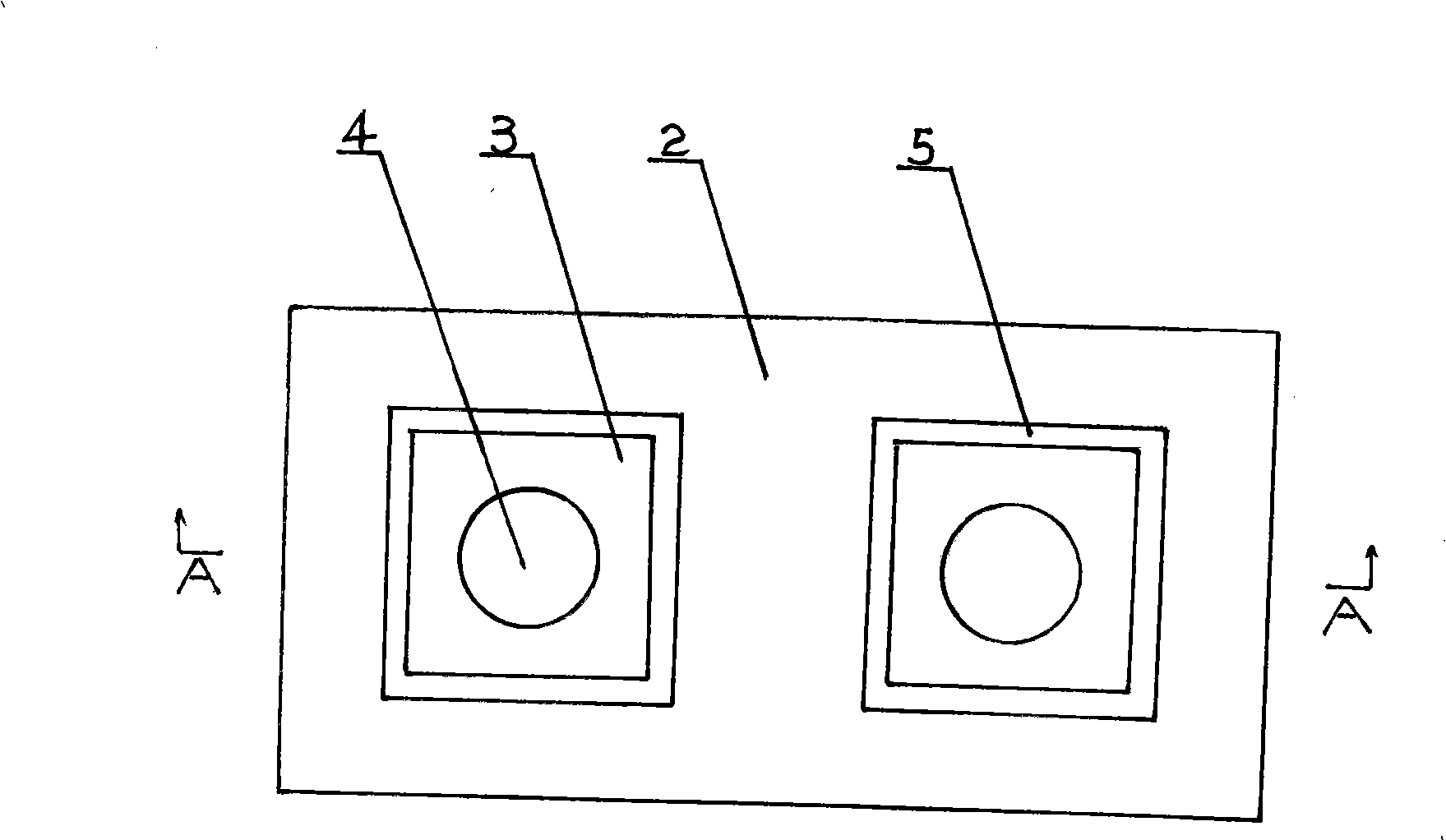

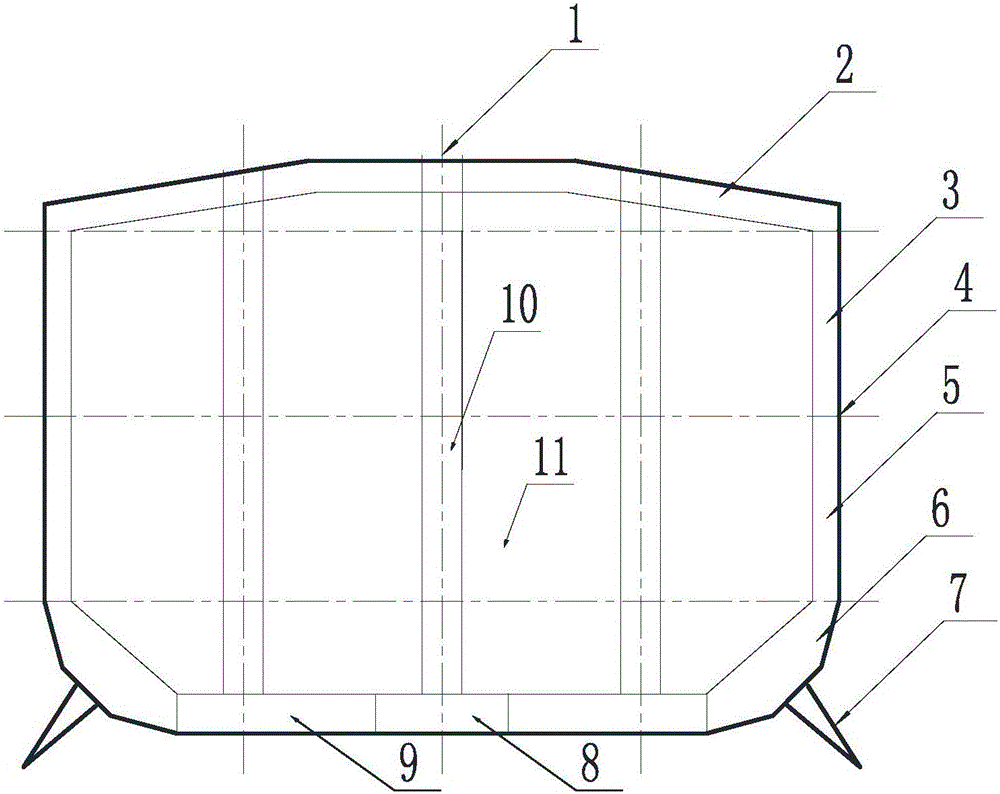

Combined steel pile cofferdam provided with water swellable waterproof rubber fore shaft

InactiveCN102900089AFast constructionGood waterproof performanceBulkheads/pilesStructural rigidityWater resistance

The invention discloses a combined steel pile cofferdam provided with a water swellable waterproof rubber fore shaft, which comprises cofferdam pegs and cofferdam long piles used for connecting two adjacent cofferdam pegs. Each cofferdam peg comprises a U-shaped steel sheet pile and a fore shaft sub-part, and the left and right ends of each U-shaped steel sheet pile are respectively and fixedly connected with one fore shaft sub-part. Each cofferdam long pile comprises a steel pipe pile, a fore shaft parent part arranged at the outer side of the steel pipe pile, and a water swellable rubber liner arranged in the fore shaft parent part; a tubular inner cylinder matched with each fore shaft sub-part and a notch connecting the interior of each tubular inner cylinder with the exterior of each tubular inner cylinder are arranged on the fore shaft parent part; each water swellable rubber liner is fixedly arranged on the inner wall of the corresponding tubular inner cylinder; each fore shaft sub-part is sleeved into the corresponding tubular inner cylinder; and bentonite compound filler is filled in a gap between each fore shaft sub-part and each water swellable rubber liner. By taking the combination of a rigid steel pile and a flexible steel pile to have complementary advantages, the combined steel pile cofferdam has good water resistance; the fore shaft is reliable in connection; the material of the combined steel pile cofferdam is easy to obtain; and the combined steel pile cofferdam is strong in integral structural rigidity and low in cost and is quick to construct.

Owner:SOUTHEAST UNIV

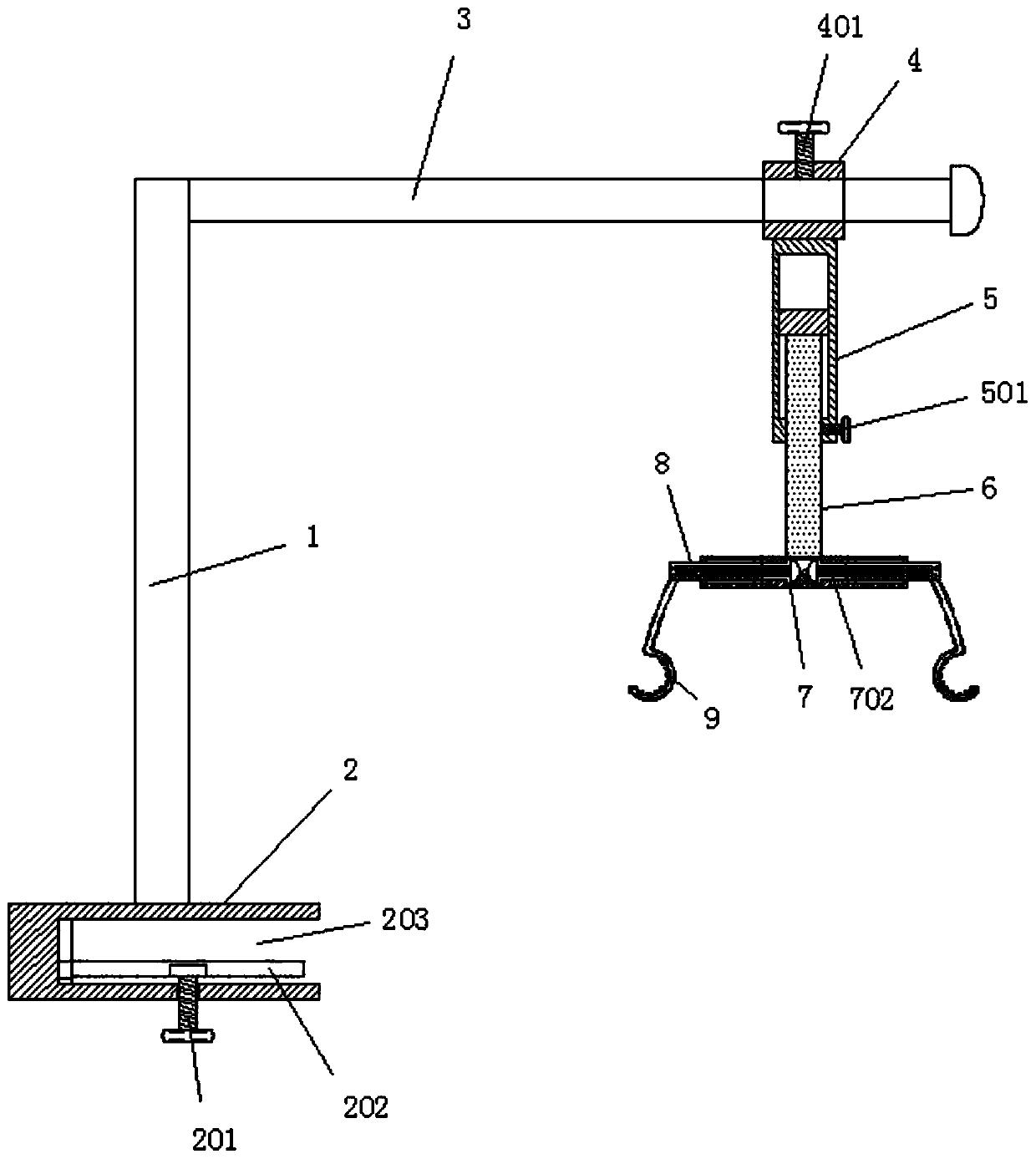

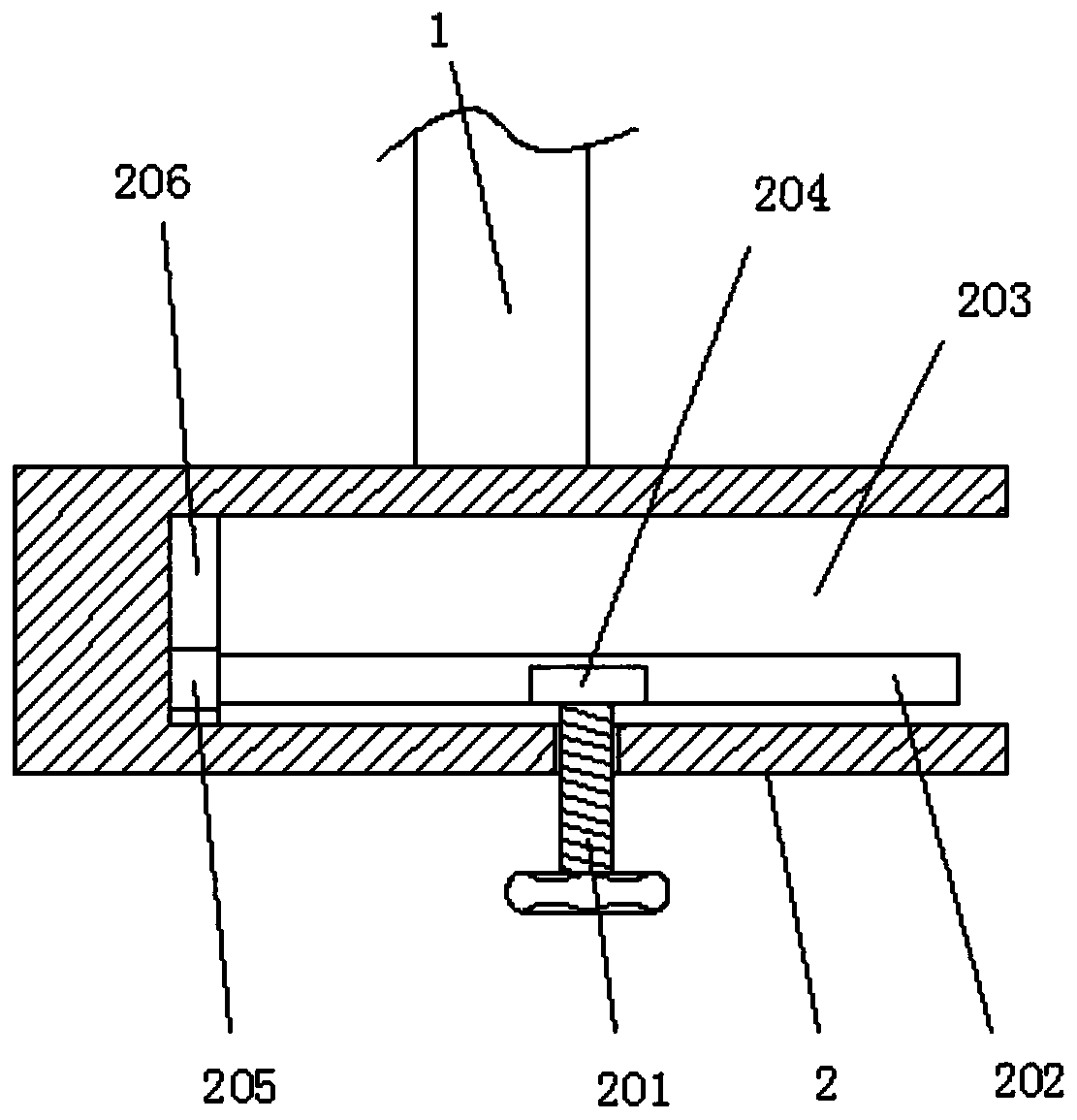

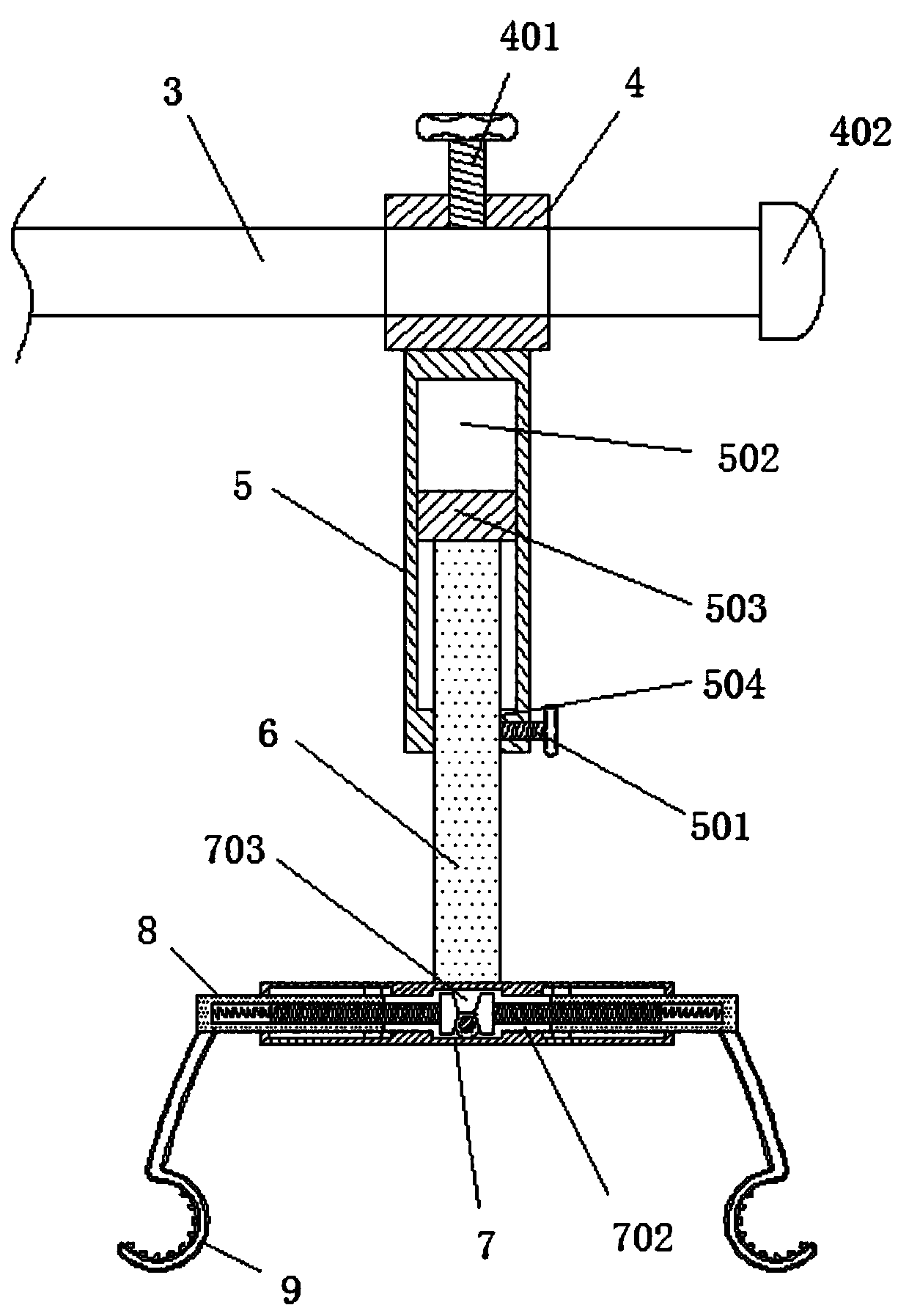

Sliding located draw hook for surgical operations of livers and gallbladders

InactiveCN110893110AEasy to adjustEasy to adjust up and down positionOperating tablesMedical practitionerStructural engineering

Owner:李捷

Matrix brick of greening protect slope and preparation method thereof

ActiveCN107816048AGood water permeabilityFull of nutritionCoastlines protectionGrowth substratesBrickHusk

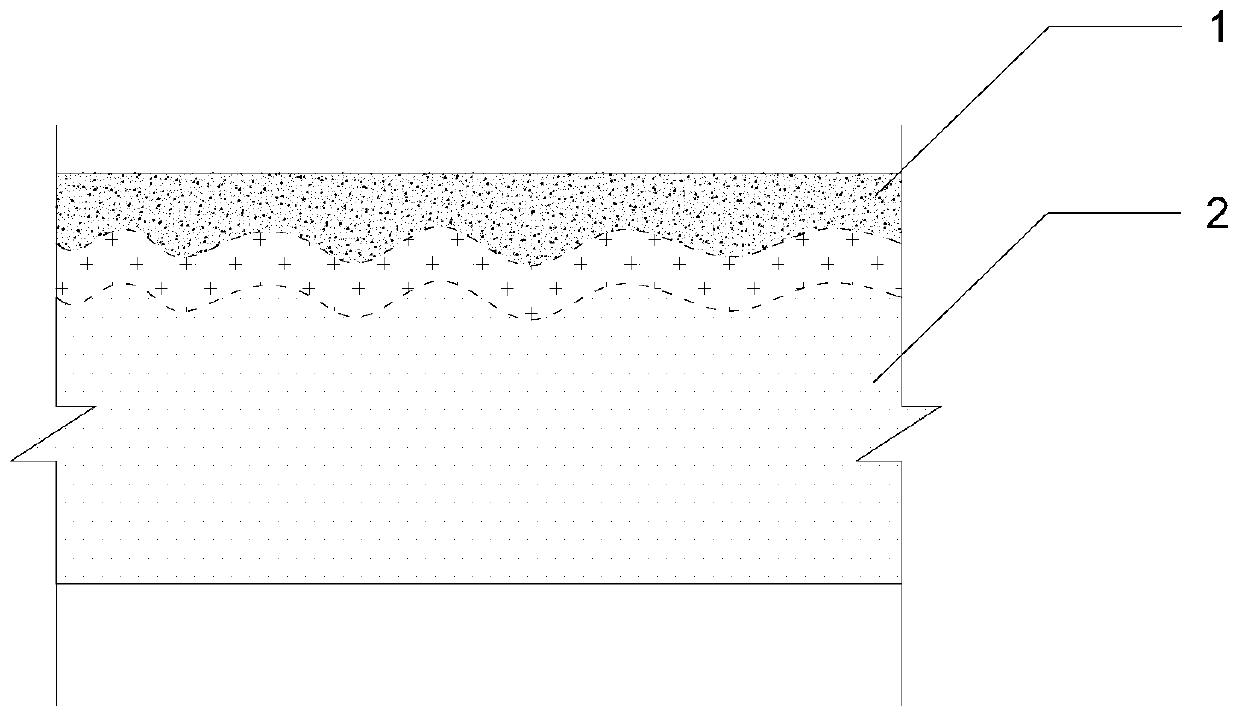

The invention relates to a matrix brick of a greening protect slope and a preparation method thereof. The material of a brick body adopts cement, aggregate, admixture, a porous material and fertilizerand comprises pervious concrete. A matrix block is embedded in the pervious concrete. The preparation method comprises the main steps of high temperature composting agricultural wastes, incineratingand crushing rubbing rice husk and straw, adjusting matrix moisture content and pH value, compressing the matrix block, making up the pervious concrete, preparing the matrix brick by moulding and laying, curing, demoulding and the like. The matrix brick is simple in production technology, low in cost, convenient for transportation and construction management and suited to scale production.

Owner:JIANGSU UNIV

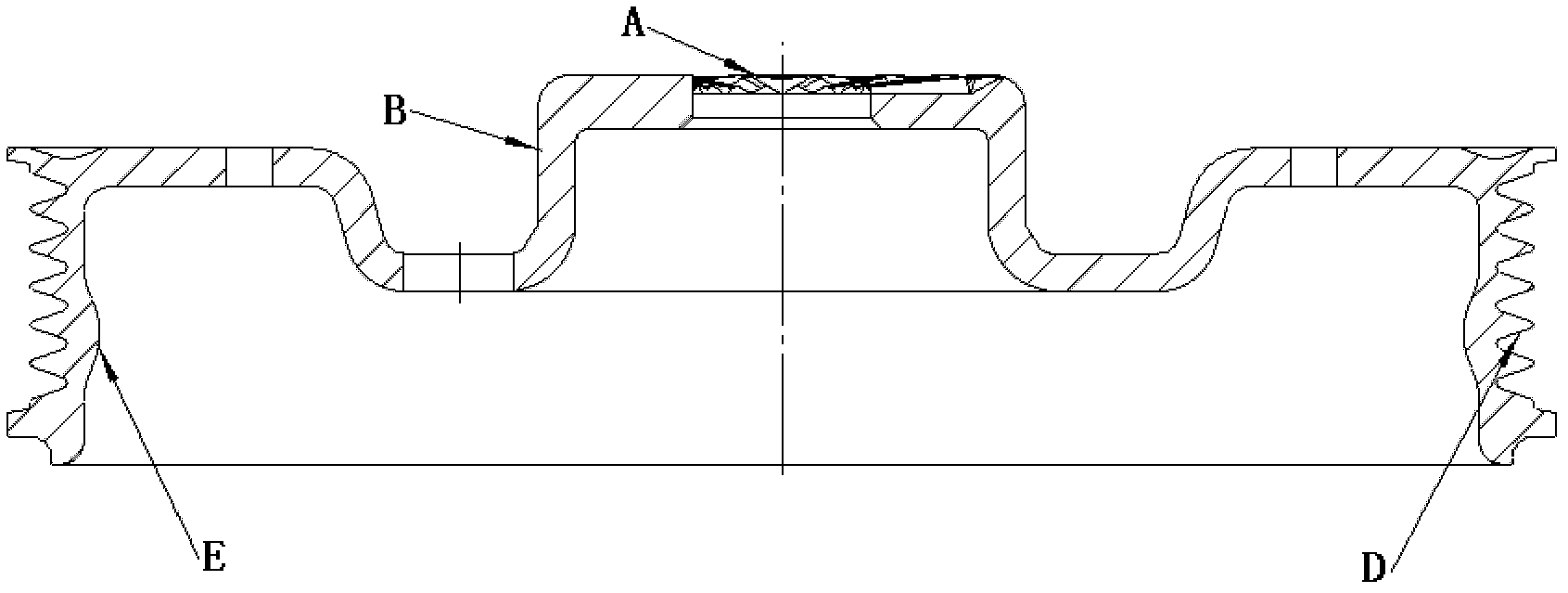

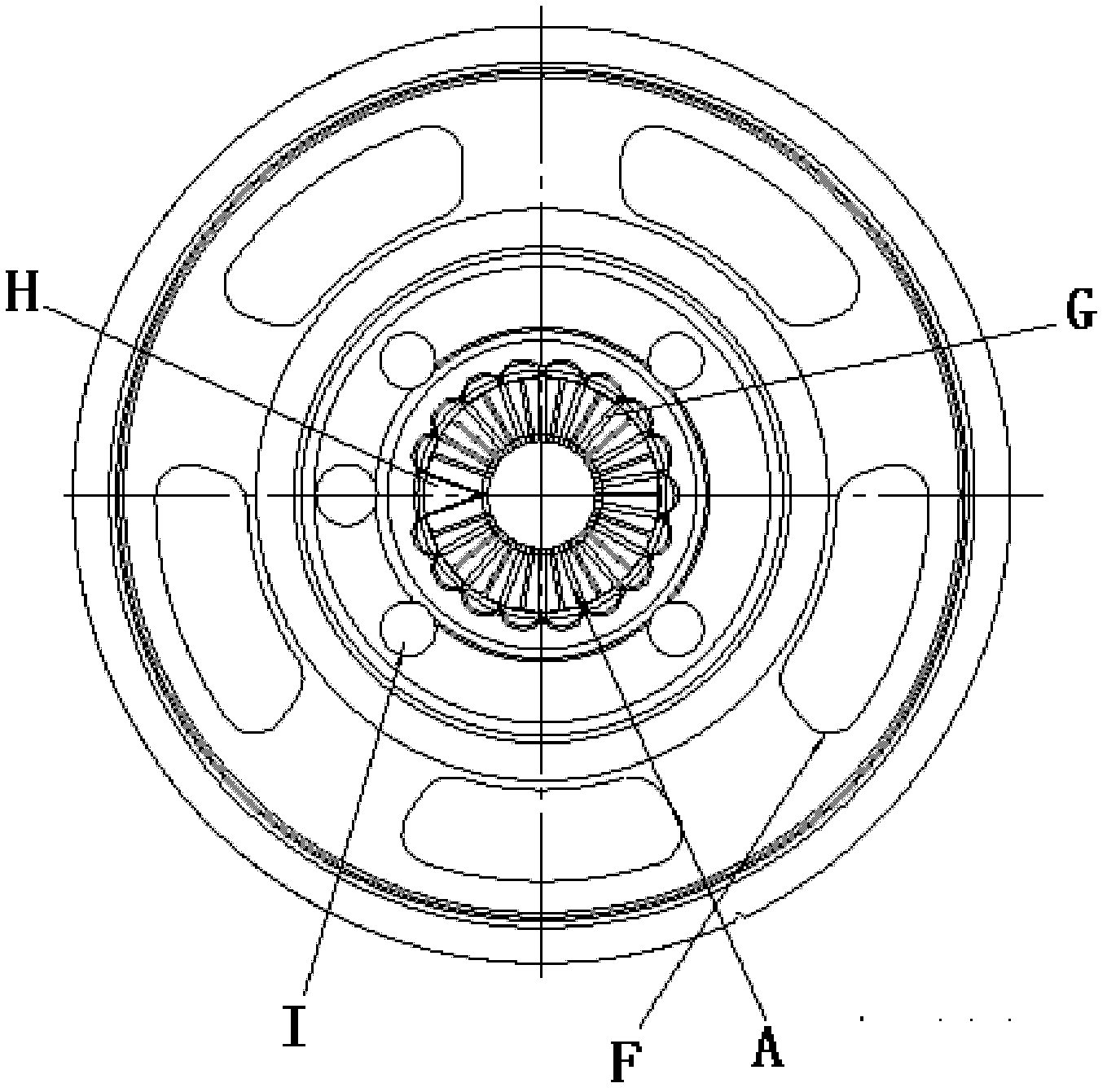

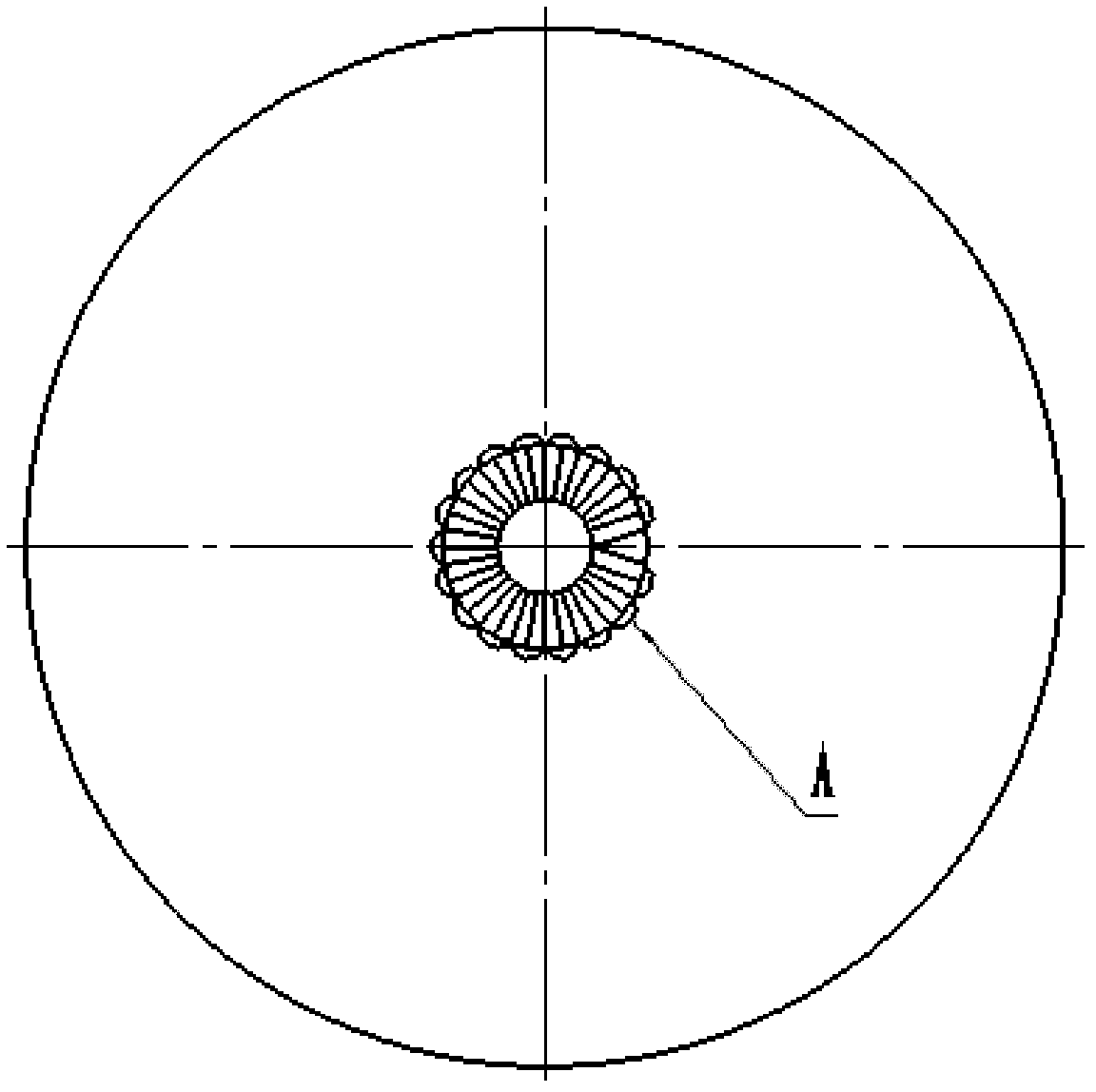

Processing method for engine crankshaft vibration damping pulley wheel hub with end surface rat fluted disc

The invention relates to a processing method for engine crankshaft vibration damping pulley wheel hub with end surface rat fluted disc. The specific steps are as follows: (1) processing an end surface rat fluted disc A on the metal circular sheet material by using end surface spinning technology; (2) processing a cylindrical assembling surface B at the outer side of the end surface rat fluted disc A by the spinning technology; (3) processing a curve C on the outer side radiation plate of the cylindrical assembling surface B by the spinning technology; (4) processing a multi-wedge tooth D on the blank excircle obtained in above procedures by the spinning technology; (5) processing an annular assembling surface E with an anti-slide bulge at the inner side of the multi-wedge tooth D by machining method; (6) punching a technological hole 1 and an installing hole F on the spoke. The processing method for engine crankshaft vibration damping pulley wheel hub with end surface rat fluted disc has the end surface rat tooth to be tightly engaged with the crankshaft tail, thus the transmission is precise and the transfer torque is larger; meanwhile, by fully using the spinning technology, the processing method is simple in manufacturing technique, convenient in installation and low in cost; at the same time, the processing method has small dynamic balance quantity, lowers noise of the engine and improves service life of the crankshaft.

Owner:WUHAN HONTRUST AUTO PULLEY IND

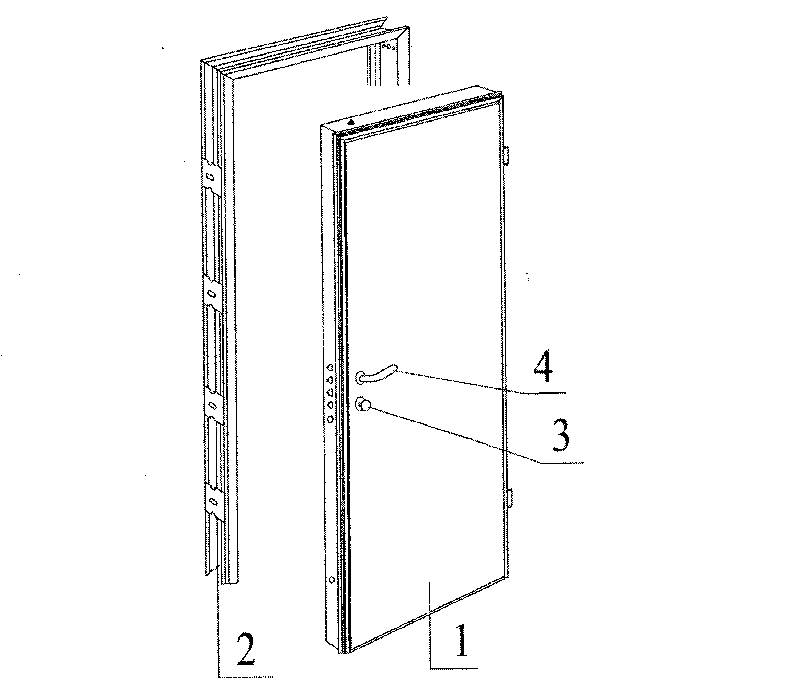

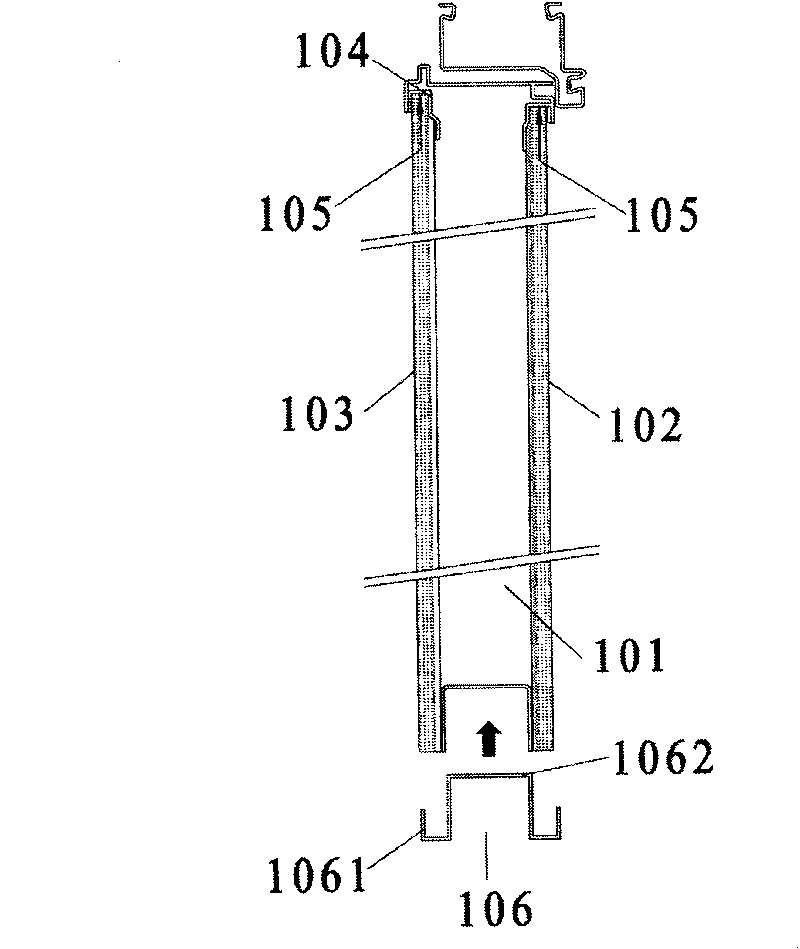

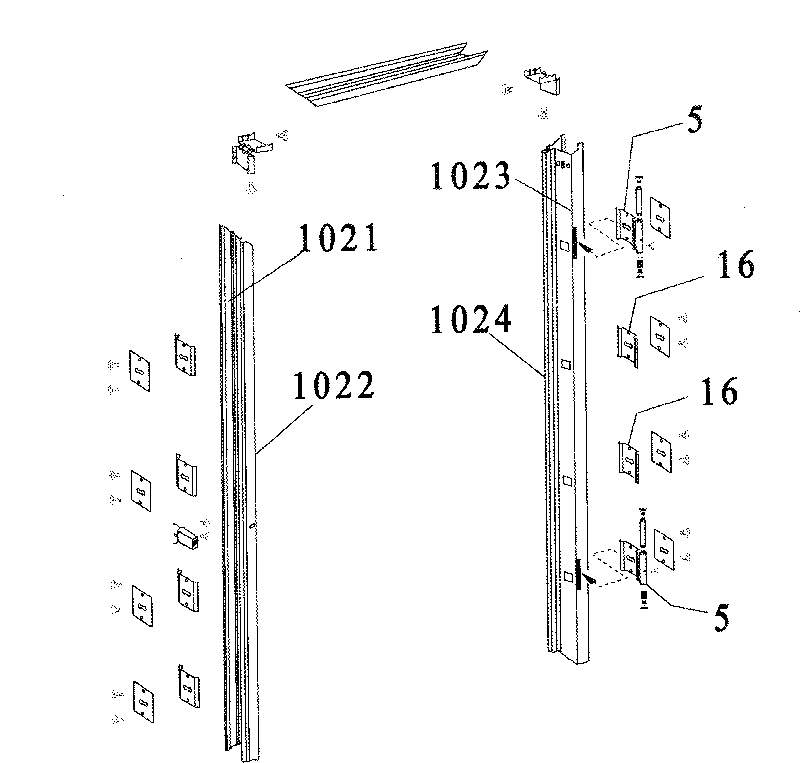

Armored door

InactiveCN101691828APlay fire resistancePlay the role of anti-theftBurglary protectionFireproof doorsEngineeringMechanical engineering

The invention discloses an armored door, comprising a door leaf and a door frame, wherein, the door leaf is composed of a door core made of steel, a front decorative plate and a rear decorative plate, wherein, the door core, the front decorative plate and the rear decorative plate are inserted into a sealed groove to be jammed; the bottom of the door leaf is provided with an omega shaped bayonet which jams the door core, the front decorative plate and the rear decorative plate; and the door leaf and the door frame adopt a double square rule to match. The armored door provided by the invention has the beneficial effects of good anti-theft effect, beauty, capability of replacing the front decorative plate and the rear decorative plate at any time and convenient installation; the door leaf and the door frame adopt a double square rule structure, and join tightly without seams; and the sound insulation and sealing effects are two times than those of the common flat opening doors.

Owner:北京贝格尼木业有限公司

Construction method for treating widened and heightened engineering joint surfaces of dikes on soft clay foundation

The invention relates to a construction method for treating widened and heightened engineering joint surfaces of dikes on a soft clay foundation. A waterproof laminated film with a grouting pipe is embedded when a horizontal drill stem is utilized to drill a horizontal hair crack along the direction of an old dike, and the joint surfaces of new and old dikes are grouted by the grouting pipe embedded in the waterproof laminated film, so that longitudinal cracks of the dikes, which are caused by differential settlement of the joint surfaces of the new and old dikes, are effectively controlled and the problem of seepage prevention of the joint surface of the new and old dikes is solved. The technical method disclosed by the invention solves the technical difficult problem of laying transverse reinforced materials in the old dike; and the grouting is carried out by the waterproof laminated film with the grouting pipe, so that the joint surfaces of the new and old dikes are compacted and the seepage of water on the joint surfaces of the new and old dikes is effectively prevented. Therefore, the problems of the longitudinal cracks of the dikes and seepage, which are caused by improper treatment on the widened and heightened engineering joint surfaces of the dikes on the soft clay foundation, are effectively controlled. The method has the advantages of simple construction process and strong operability, is convenient for quality control and has obvious economic benefits and obvious treatment effects.

Owner:HOHAI UNIV

Microorganism curing kit and calcareous sand in-site curing method

ActiveCN110438974APromote colonizationLow costBacteriaMicroorganism based processesCalcium in biologyMicroorganism

The invention discloses a microorganism curing kit and a calcareous sand in-site curing method, and belongs to the field of geological engineering and microorganism interdisciplines. The microorganismcuring kit is used for calcareous sand in-site curing and comprises a first component containing carboxylic acid, a second component containing microorganisms capable of generating urease, and a third component containing urea and a nutrient solution. The calcareous sand in-site curing method comprises the step that calcareous sand is partially dissolved by the first component. A calcium source can be efficiently obtained from sandy soil of an in-situ area or a nearby area of a calcareous sand soil body and then reacts with the microorganisms to deposit calcium carbonate, and the in-situ curing effect is realized.

Owner:NANJING UNIV

Transparent resin controlling auto repair color difference

The invention relates to transparent resin controlling auto repair color difference. The transparent resin controlling auto repair color difference is composed of the following components in parts by weight: 70-90 parts of balance control agent, 8-15 parts of roll line solvent and 20-30 parts of diluents. After the local defect part of the auto coating is processed on conventional treatment, the components are mixed and stirred evenly, the mixture is sprayed for two times in wet state, the film thickness is 20-30 microns around, the colored paint is sprayed according to the conventional coating technique method while the bottom varnish layer is not dry, and the varnish is sprayed. Compared with the prior art, the arrangement of the silver powder particles of the colored paint of the technology is regular, the adhesive force is good, the new and old paint films can be tightly combined without dark circle, the degree of finish is good and the color is perfect.

Owner:DONGLAI COATING TECH SHANGHAI

Stem block plant smashing device

The invention discloses a stem block plant smashing device. The stem block plant smashing device comprises a motor for providing power and a machine body, wherein the motor drives a main shaft to move through a belt transmission device, and one end of the main shaft is sleeved with a moving tooth disc; a hammer is sleeved on the moving tooth disc, a rotating screen drum is arranged outside the hammer, and a coarse screen drum is arranged between the rotating screen drum and the hammer; a fine screen drum with a taper is arranged outside the rotating drum; one end of the fine screen drum is fixed on the machine body, and the other end of the fine screen drum is fixed on a fixed tooth disc; the disc surface of the moving tooth disc is provided with spike teeth; spike teeth meshed with the moving tooth disc in a staggered way are arranged on the fixed tooth disc; the moving tooth disc is connected with a cutter bar through a clamp device; and the cutter bar is provided with a first tool and a second tool in the sequence from outside to inside. The stem block plant smashing device provided by the invention has the advantages that the smashing for a stem block plant is divided into four stages, the use ratio of the stem block plant is greatly improved through ultrafine processing in four stages, more amylum in the equal stem block is extracted, resources are saved, and the stem block plant smashing device has popularization and application values.

Owner:JIANGSU UNIV OF SCI & TECH

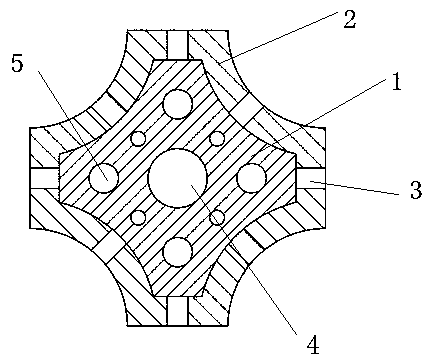

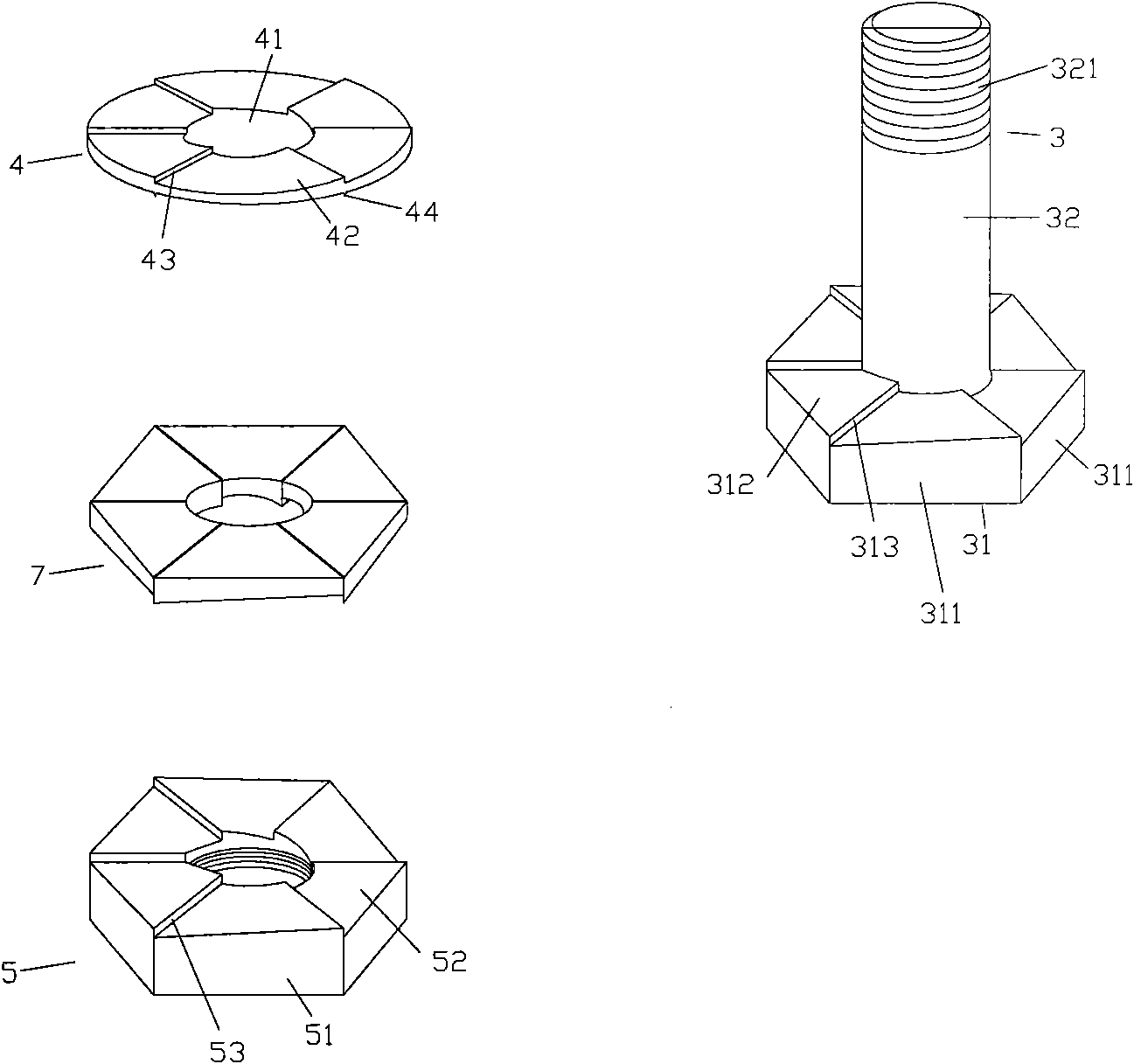

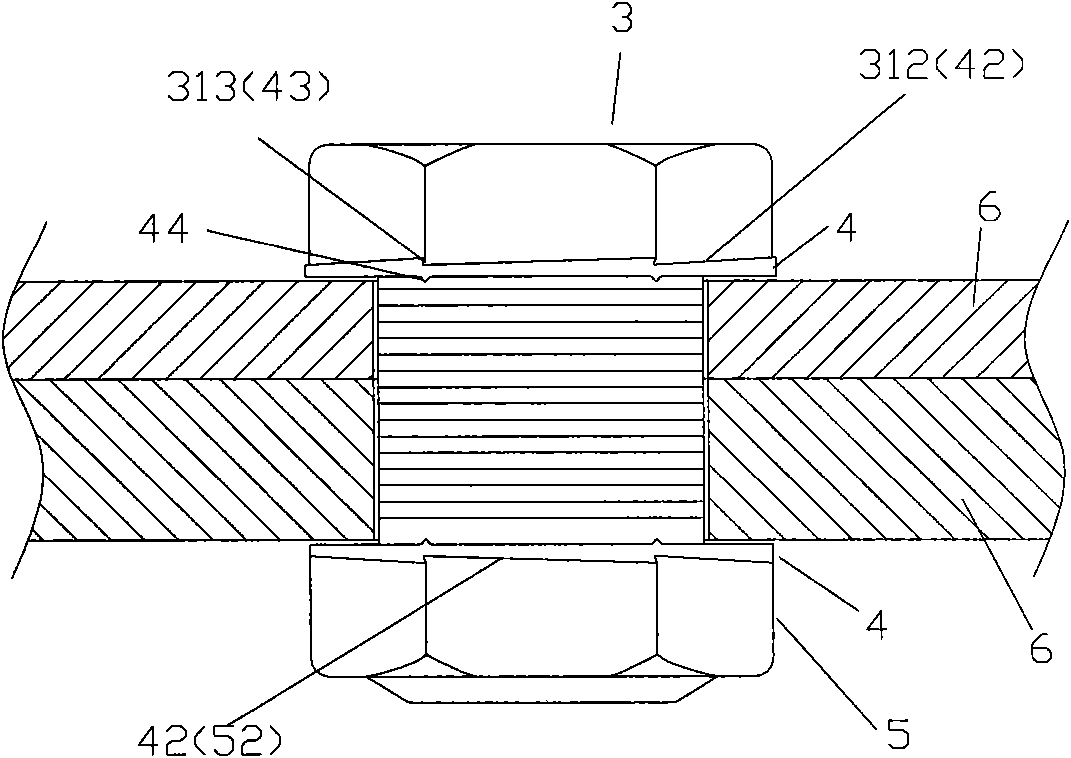

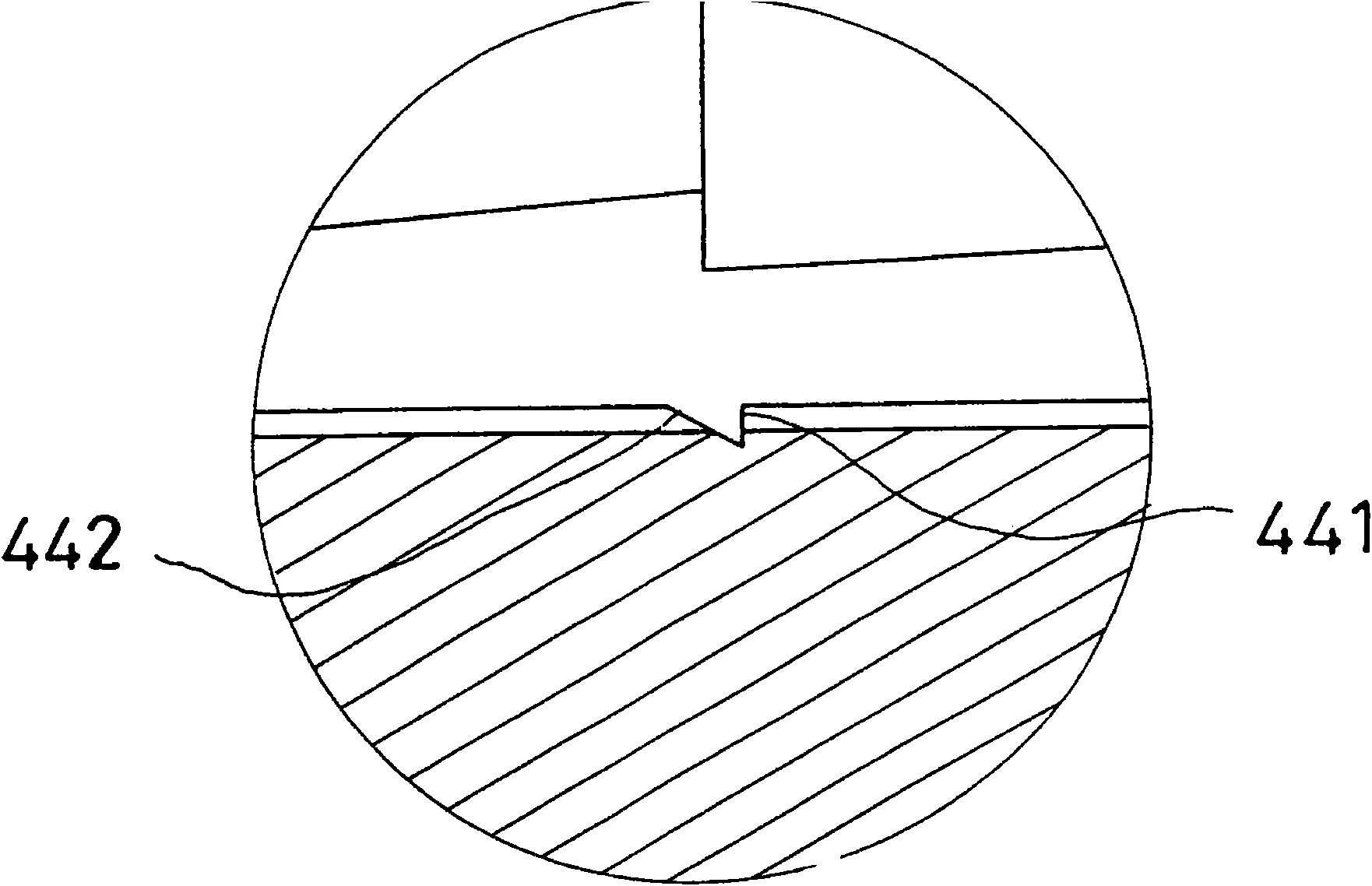

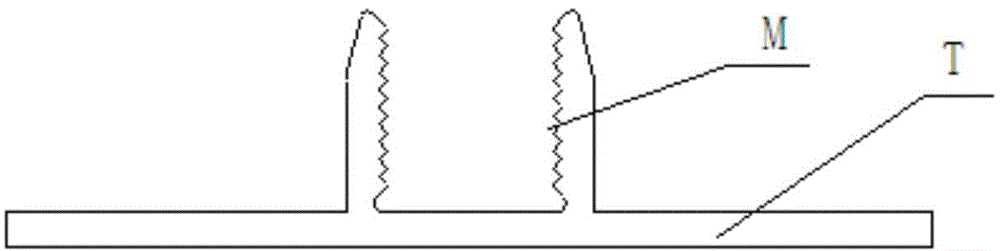

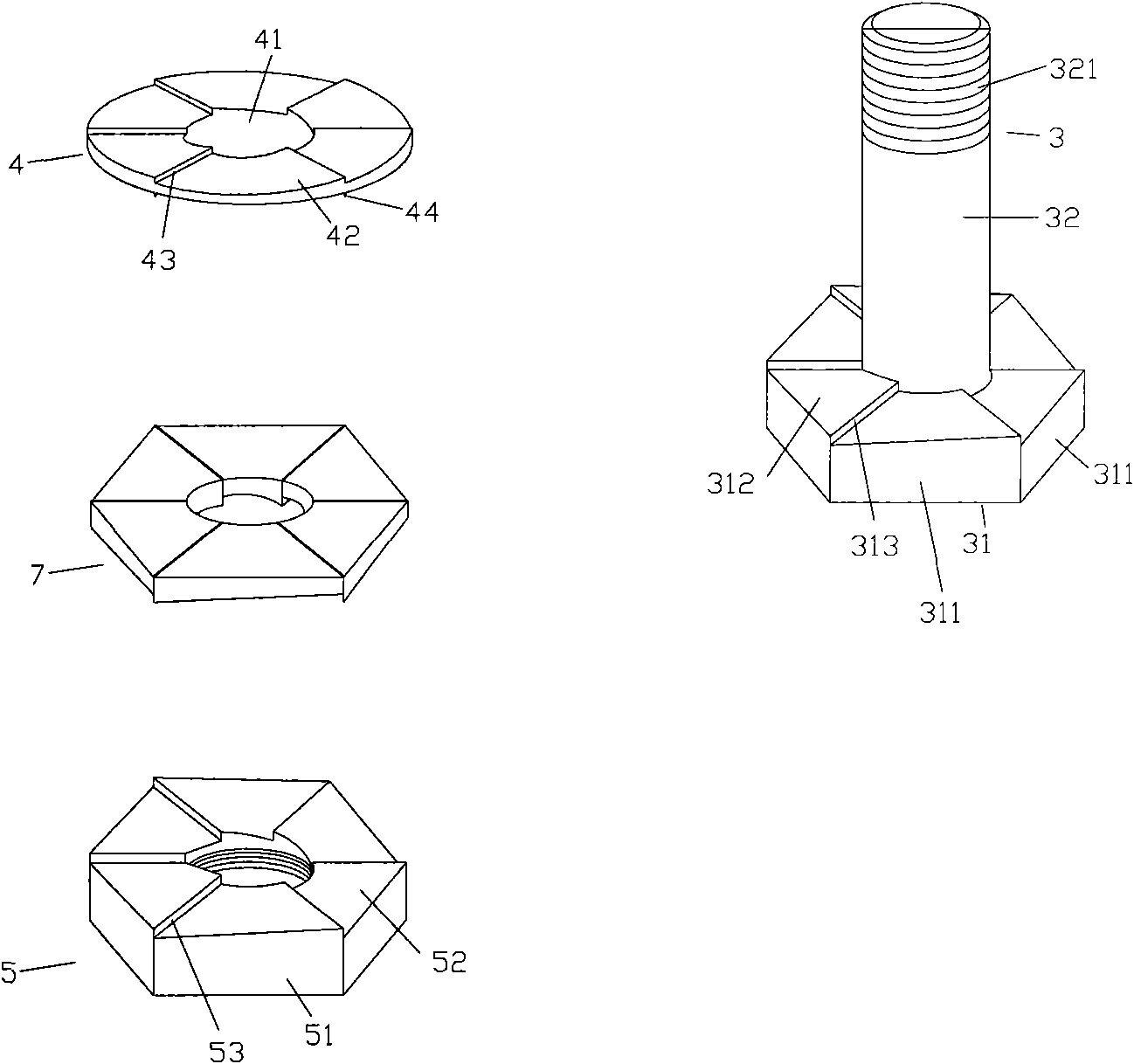

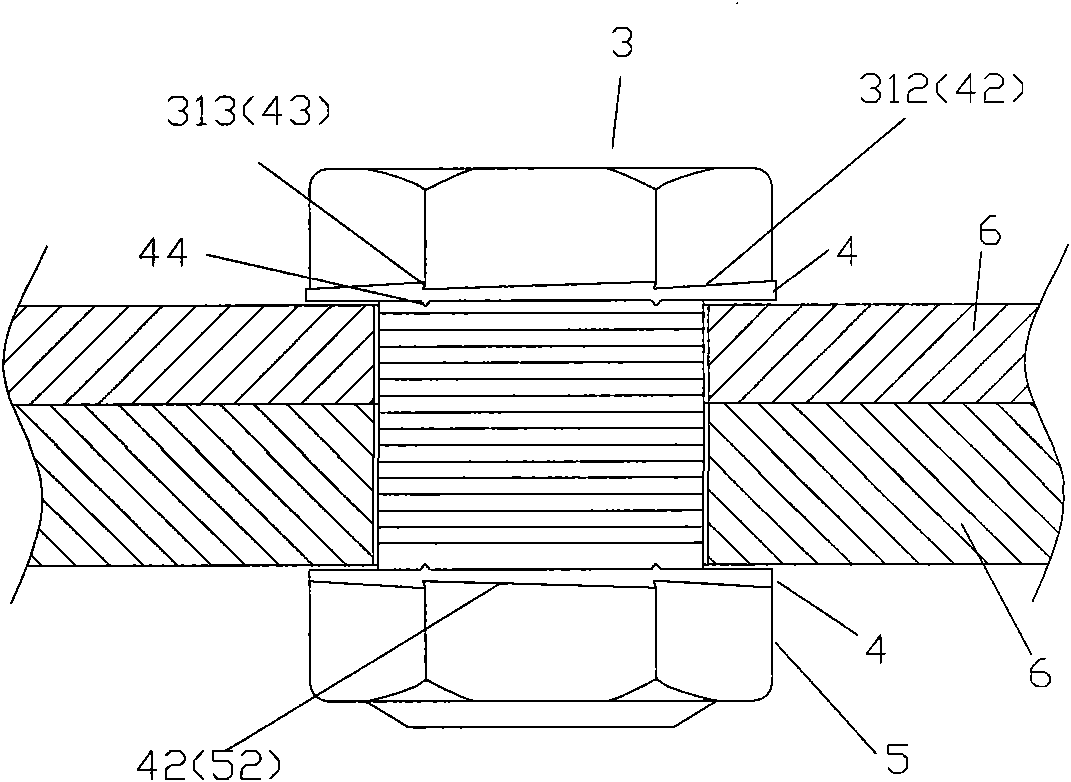

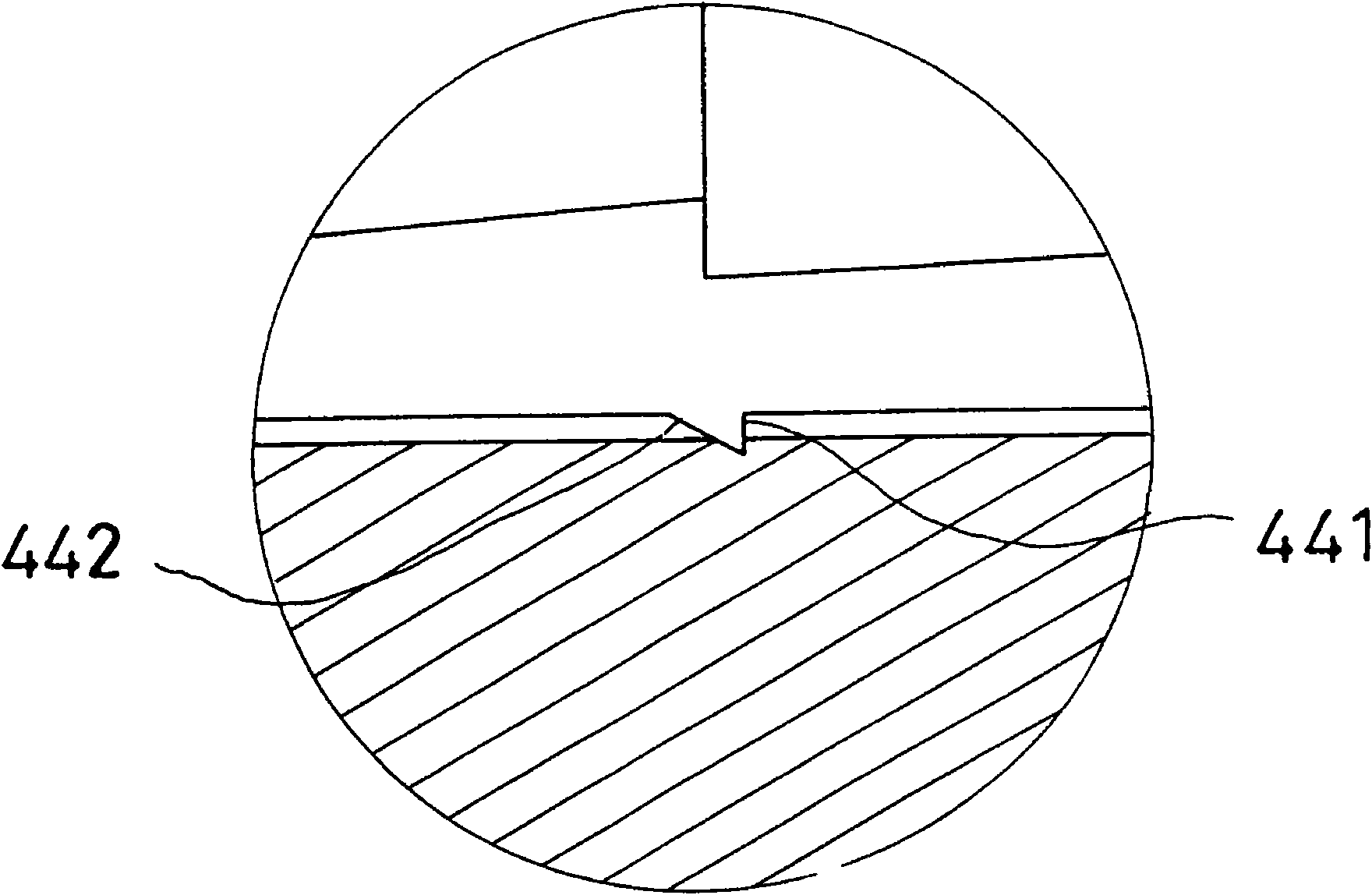

Loosing and theft preventing bolt structure body

InactiveCN101598168ALow construction requirementsGood anti-theft effectPinsWashersBearing surfaceAcute angle

The invention discloses a bolt structure body, which comprises a nut, two washers and a bolt, wherein the bottom rim of a bolt head and the upper rim of the nut are provided with a wedgy tooth-shaped inclined plane with one higher edge and one lower edge respectively, and the connecting parts of the wedgy tooth-shaped inclined planes form retaining surfaces; included angles alpha between the retaining surfaces and a plane of the bolt head and a plane of the nut are acute angles; one surface of each washer forms an inclined plane which corresponds to and is matched with the wedgy tooth-shaped inclined planes of the bolt head and the nut; the connecting parts of the inclined planes form bearing surfaces; included angles beta between the bearing surfaces and planes of the washers are acute angles; and the other surface of the washer is provided with an insertion strip or a bump, and the washers are irregular round. The bolt structure body does not fall off under the conditions of breeze vibration, spiral vibration and the like, the wedgy tooth-shaped inclined planes of the acute angles are meshed tightly, and the construction requirement is reduced simultaneously; the bolt structure body has better anti-theft function, a screw driver and other tools cannot find the position of force application, and only a special tool is used to take the bolt structure body down; the curve insertion strips or the bumps can increase frictional resistance and prevent rusting connection; and a manufacturing process of the bumps is simple.

Owner:北京驰神管理有限公司

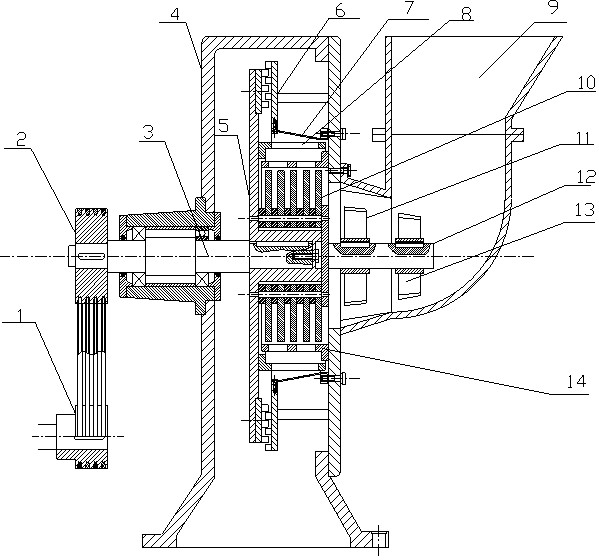

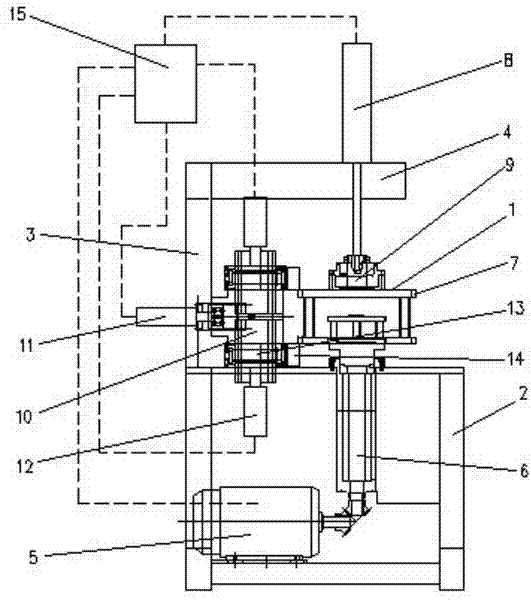

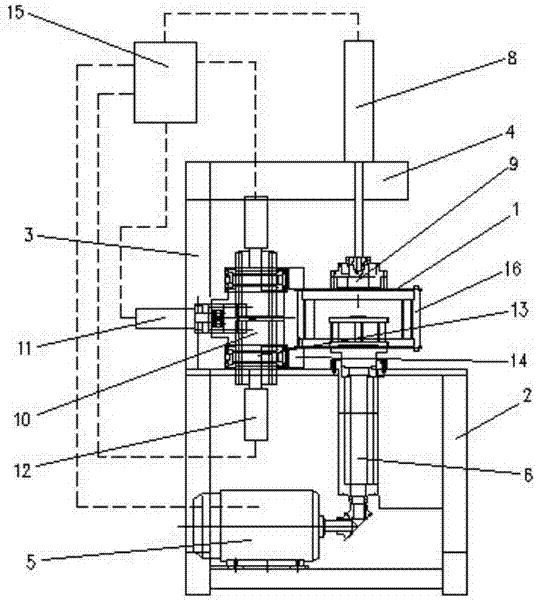

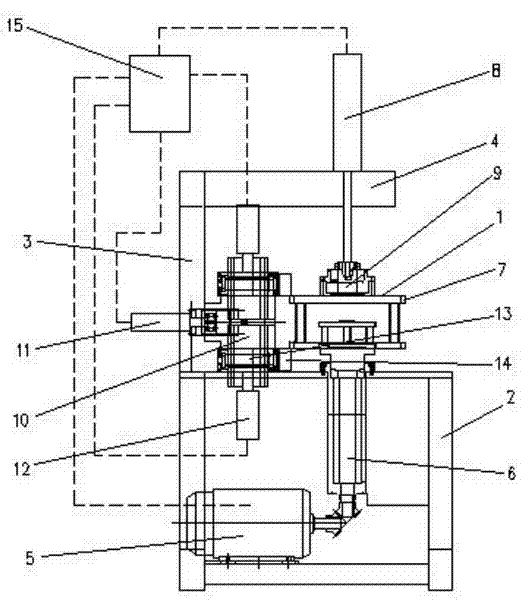

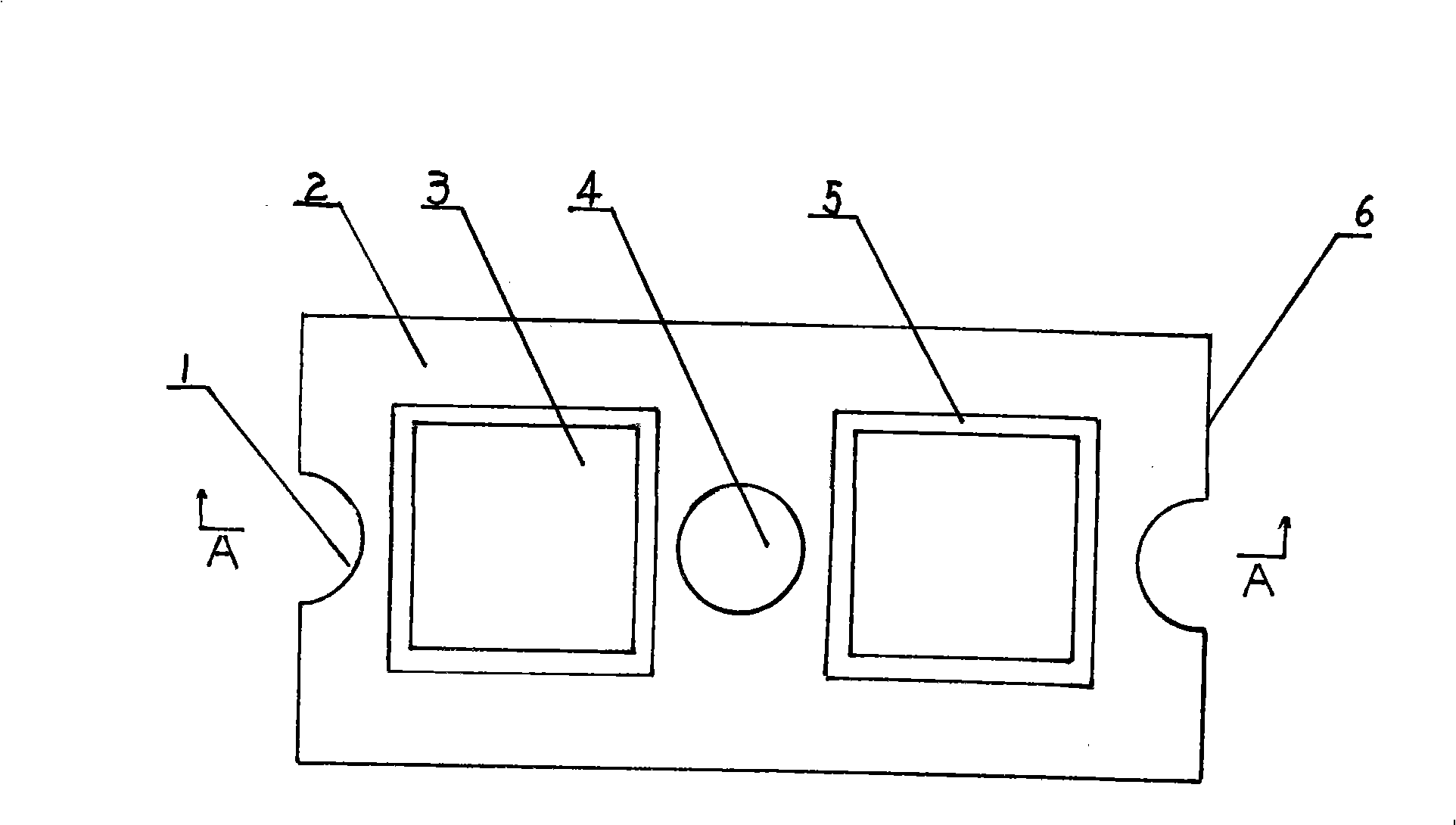

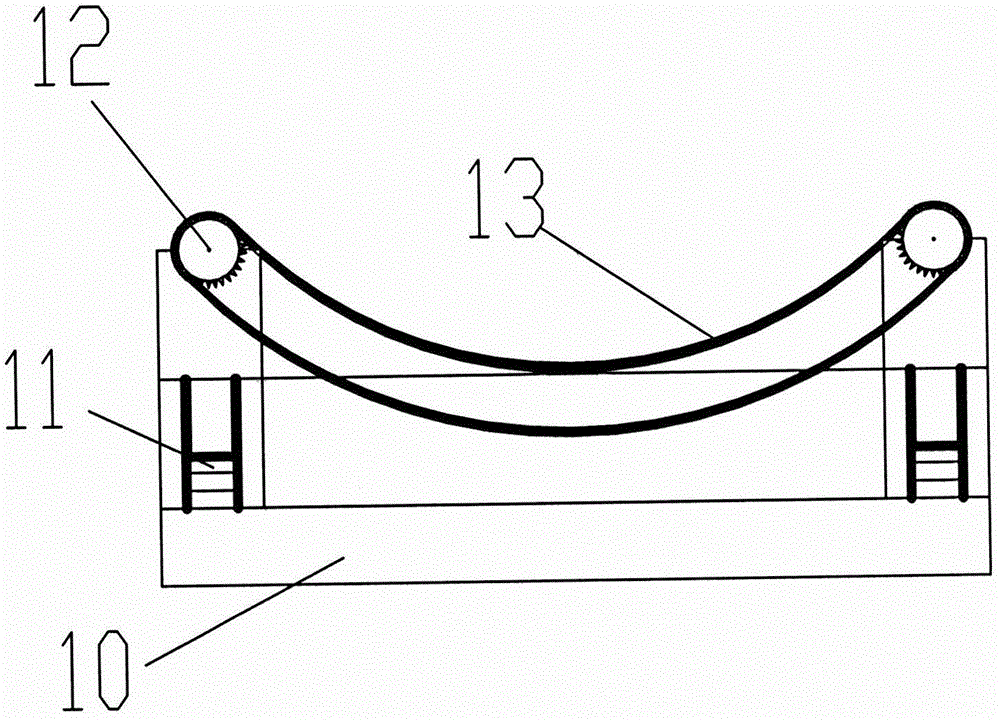

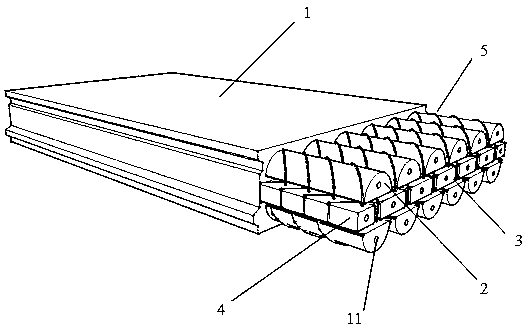

Impeller assembly machine for multi-blade centrifugal fan

InactiveCN102338127AImprove assembly qualityImprove work efficiencyPump componentsPumpsImpellerEngineering

The invention discloses an impeller assembly machine for a multi-blade centrifugal fan. The impeller assembly machine comprises a workbench, a vertical post and a beam, wherein a power device and a main shaft are arranged in the workbench; an impeller mold is connected to the main shaft; a feeding cylinder and a spinning frame fixed on a piston of the feeding cylinder are fixedly arranged on the vertical post; two spinning cylinders and spinning wheel components fixed on pistons of the spinning cylinders are fixedly arranged on the spinning frame; the positions of the two spinning wheel components are on the same vertical protection surface; each spinning wheel component is rotatably connected with a spinning wheel; a tightening cylinder and a tightening block fixed on a piston of the tightening cylinder are fixedly arranged on the beam; and the center of the tightening block and the center of the impeller mold are on the same axis. An initially-assembled impeller is fixed on the impeller mold and tightly clamped by the spinning wheels of the two spinning wheel components, and fixed end pieces at the two ends of the impeller are respectively bent at one time and fixed between a front disc and a rear disc, so the working efficiency is greatly improved, and the assembly quality of the impeller is improved.

Owner:ZHEJIANG SHUANGYANG FAN

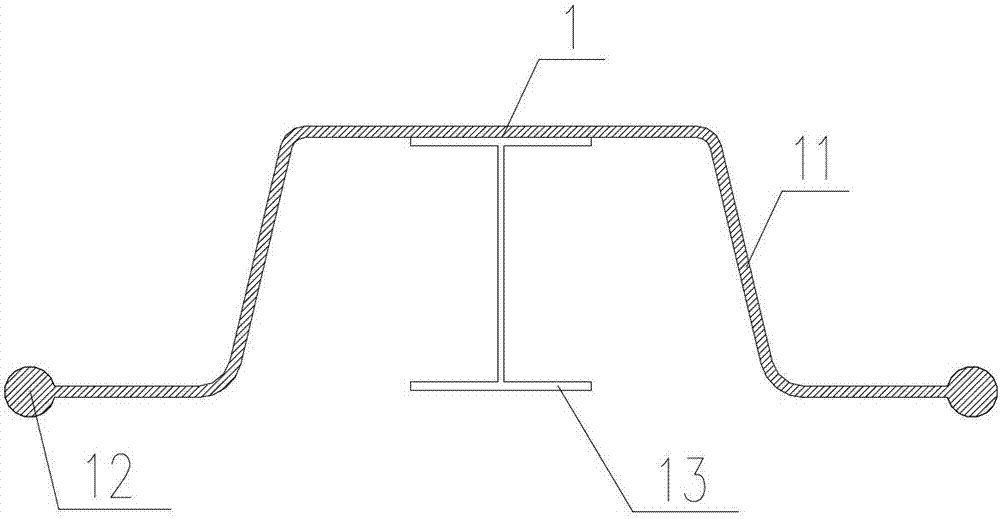

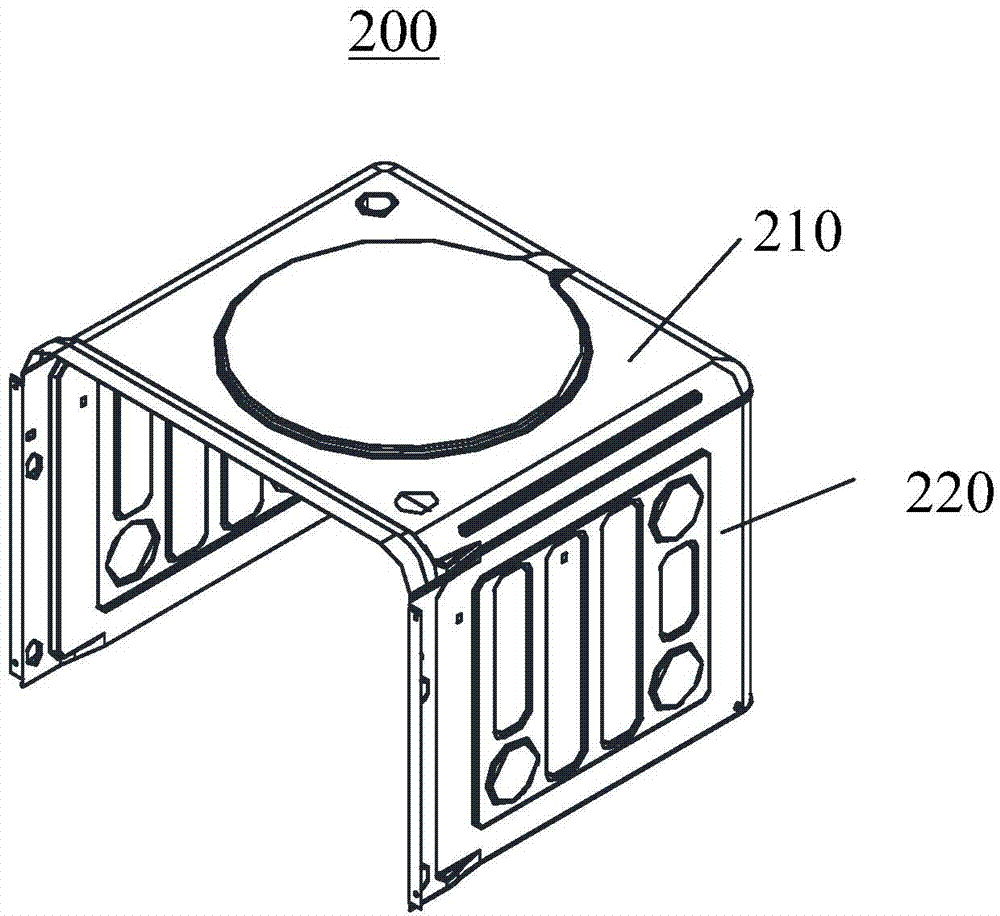

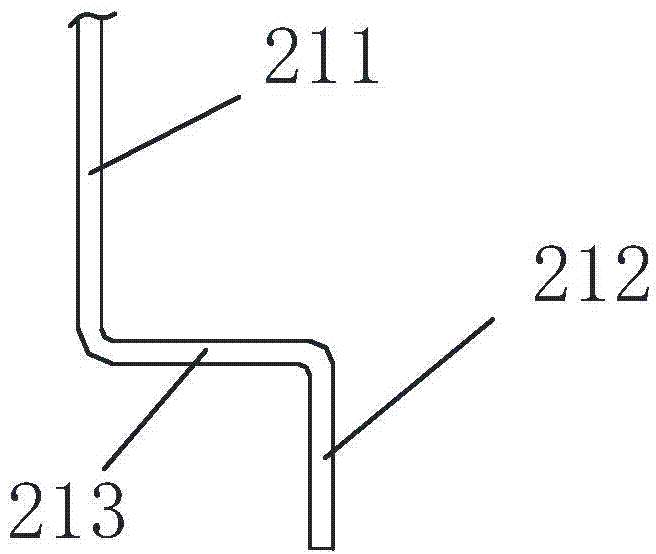

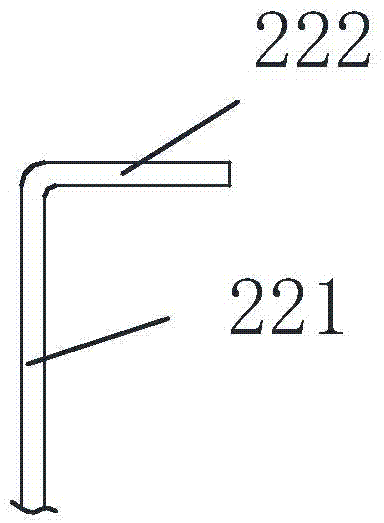

Edge meshing technology of inner container of dish-washing machine

The invention discloses an edge meshing technology of an inner container of a dish-washing machine. Firstly, the shape of the meshed edges of a top plate and a middle plate is uniquely designed, then the middle plate and the top plate are connected in a sleeving mode, pressing of a series of procedures is carried out on the sleeved top plate and middle plate through a material pressing machine and a forming insert, and the edge of the top plate and the edge of the middle plate are closely meshed. Through the technology, the good meshing effect can be achieved, meshing work can be completed by manufacturers only through several conventional oil presses, and no edge meshing machine needs to be additionally arranged only for the edge meshing work.

Owner:浙江安德电器有限公司

Rotator cuff balloon

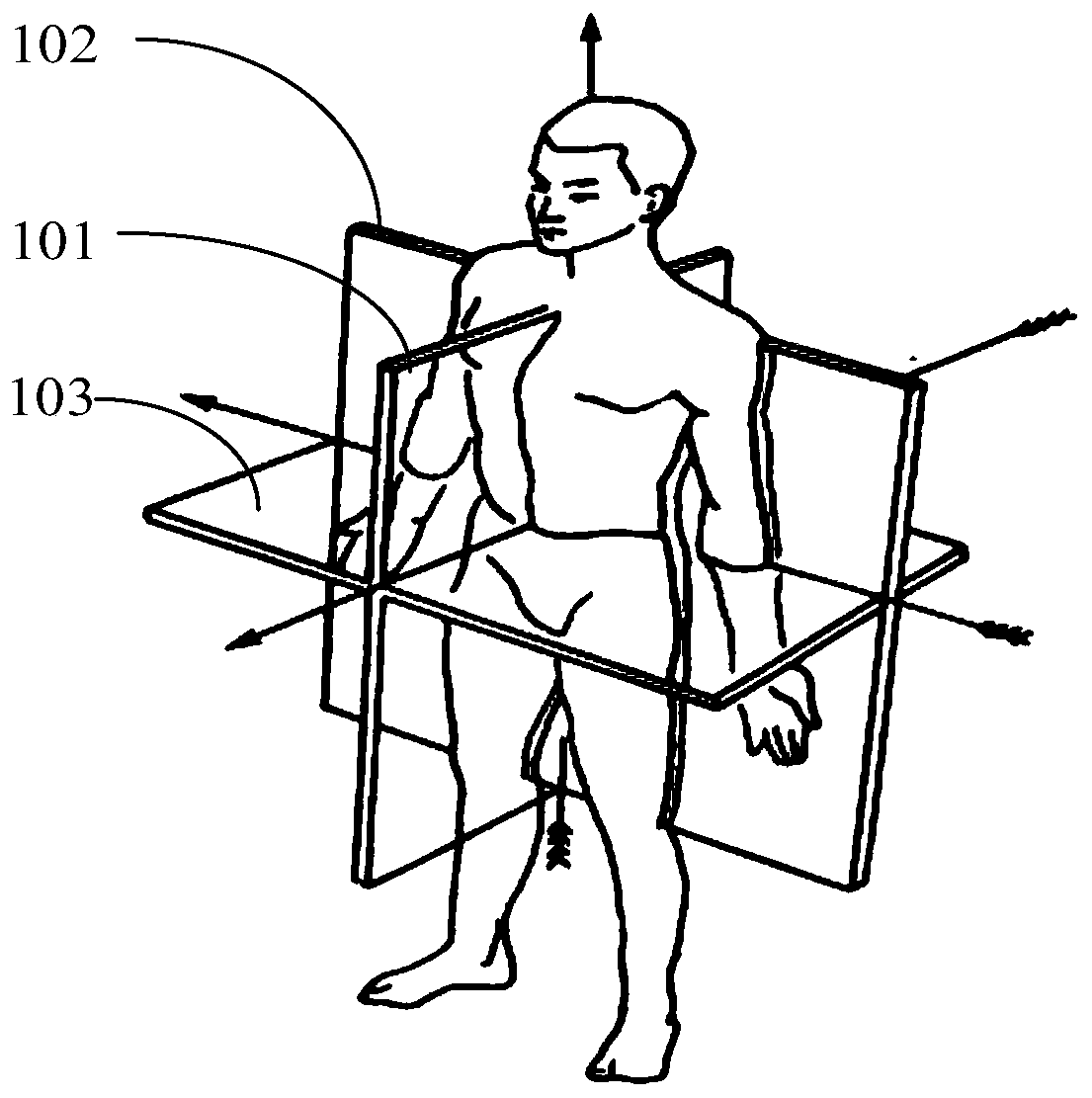

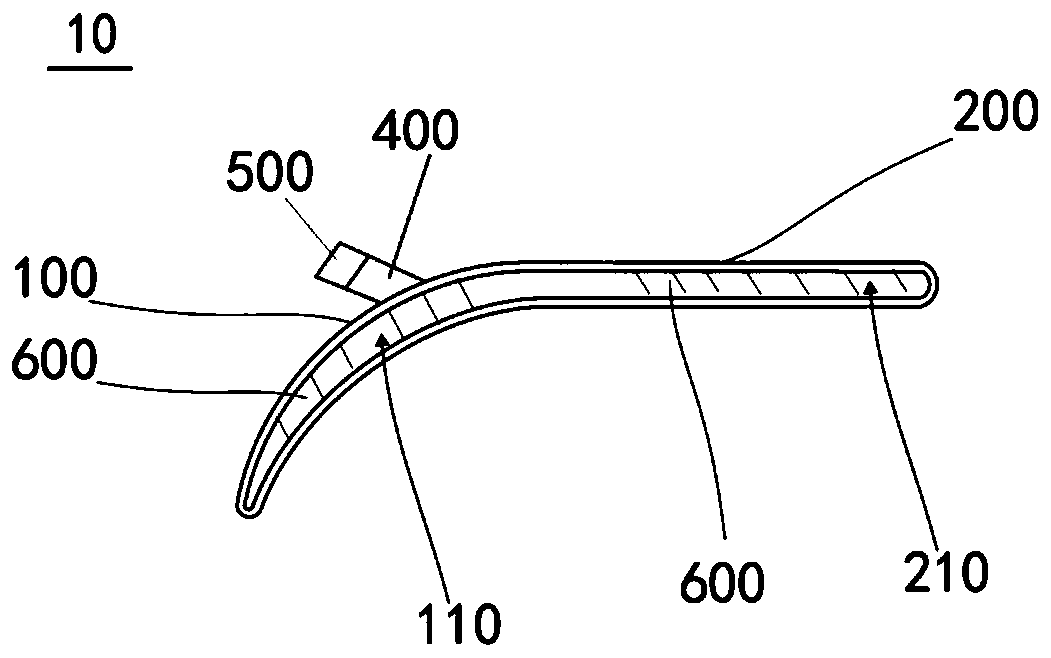

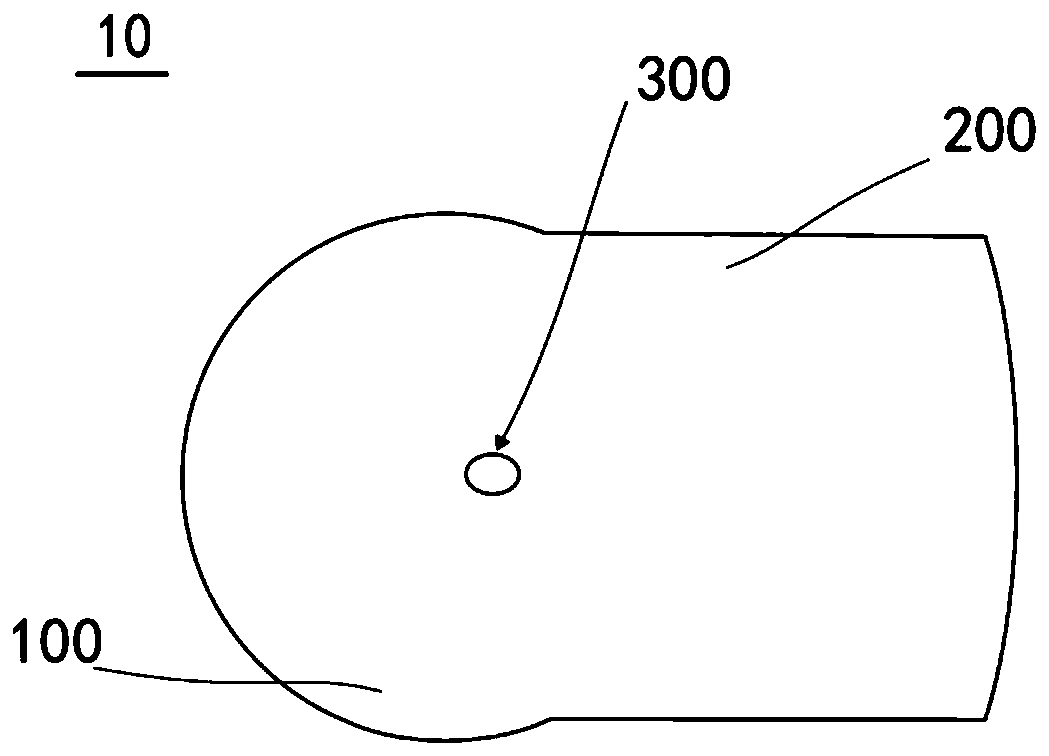

PendingCN111096824AReduce foreign body sensationReduce dislocationLigamentsJoint implantsCoronal planeProsthesis

The invention discloses a rotator cuff balloon. The rotator cuff balloon comprises a limiting structure and a protection structure connected to the limiting structure. The limiting structure has an arc along the coronal plane. The prosthesis conforms to the physiological structure of the shoulder joint of the human body, is limited to the subacromial space, and can reduce adverse events such as foreign body sensation, dislocation and functional failure of a patient. The prosthesis conforms to the physiological structure of the shoulder joint of the human body, is limited to the subacromial space, and can reduce adverse events such as foreign body sensation, dislocation and functional failure of a patient.

Owner:SHANGHAI ENDOPHIX CO LTD

Boring-tamping lime-soil compacting pile construction process

InactiveCN1676762AConstruction noise is smallReduce vibrationBulkheads/pilesSoil preservationUltimate tensile strengthPile driver

The invention refers to a construction technique, which has a good effect for the drilling ram enlarge the gray soil and the stake. The concrete process is that perching the drill, vertical revising, drilling, milling the material, perching the pile driver, empty ram, filling in material, covering the top and moving the pile driver. The technique has the merits that it having small noisy, light vibration, can avoid the damp sinking efficiently, has a strong stake, the base can bear more weight, has the low cost of the project, project can be constructed in the city and has a broader application among the damp and sink loess areas.

Owner:祁春伟

Environment protection buckling press through-combining type antiseismic wall structure

The invention belongs to an environmental protection buckled penetrating and assembling type antiseismic wall structure, which adopts a buckled penetrating and assembling type brick consisting of a brick top surface, a brick side surface and a brick bottom surface. Penetrating and assembling holes penetrating the brick top surface and the brick bottom surface are arranged on the buckled penetrating and assembling type brick, a groove is arranged on the brick top surface, and a clamping convex block inserted and fixed in the groove is arranged on the brick bottom surface; the lower end part of reinforced ribs are fixed and connected into an integrative structure with foundation reinforcement bars in the foundation, or directly fixed into a whole with the foundation, each reinforced rib spacing is arranged according to the spacing between the penetrating and assembling holes, the reinforced ribs penetrates and are assembled in each penetrating and assembling hole of the bricks, all the bricks are staggered and built to form the wall structure, and the reinforced ribs are caused to penetrate the penetrating and assembling holes and the penetrating and assembling holes with semicircular openings, at least one reinforced rib penetrates each brick, and the reinforced ribs are welded with each other and connected into a whole and integrated with the reinforcement bar on housetop, or integrated with a housetop support. The antiseismic wall structure leads the bricks to be compactly occlusive, penetrated and fixed into the integrative antiseismic wall structure, and the wall has the advantages of high strength and shockproof property, can effectively resist quake, simplify construction and save raw material, has simple installation and disassembly, and can be recycled after disassembly.

Owner:北京太极金圆新型材料技术有限公司

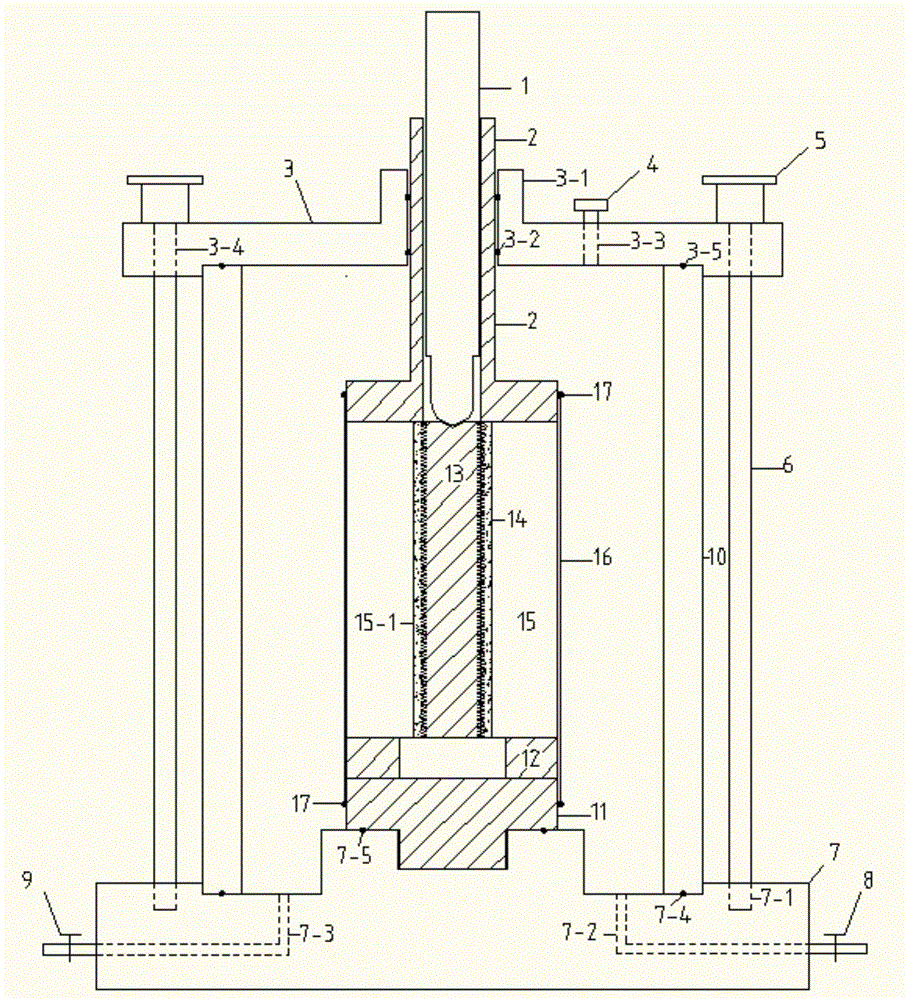

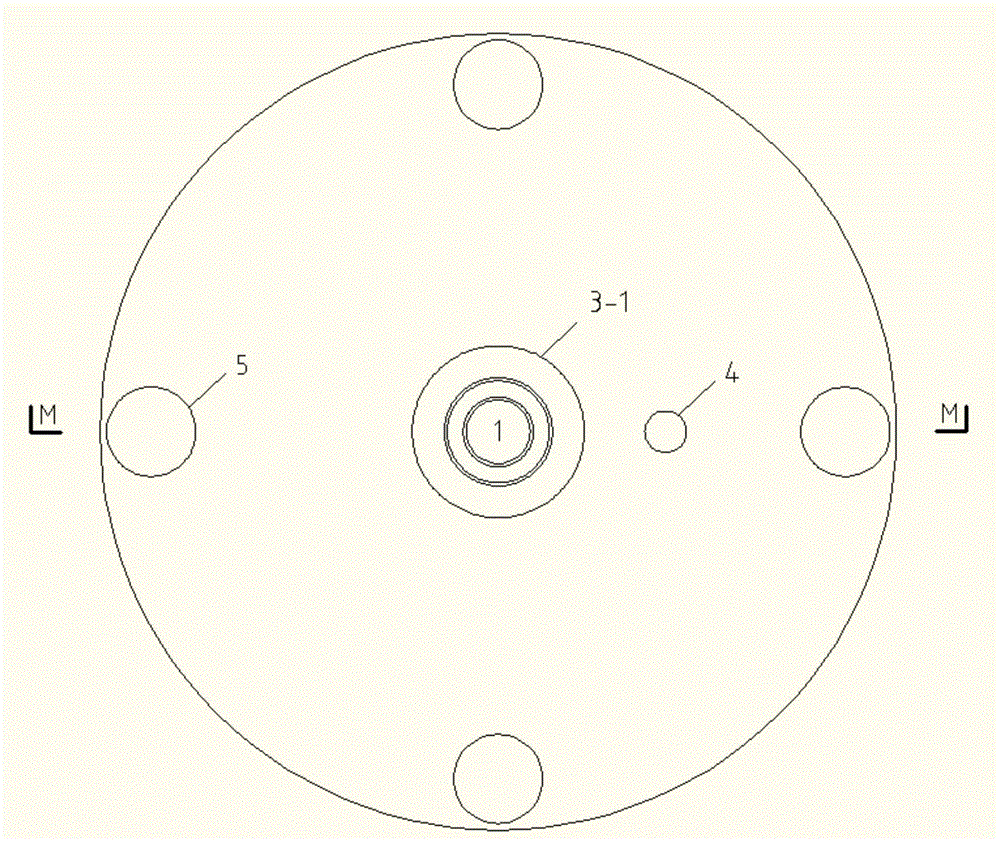

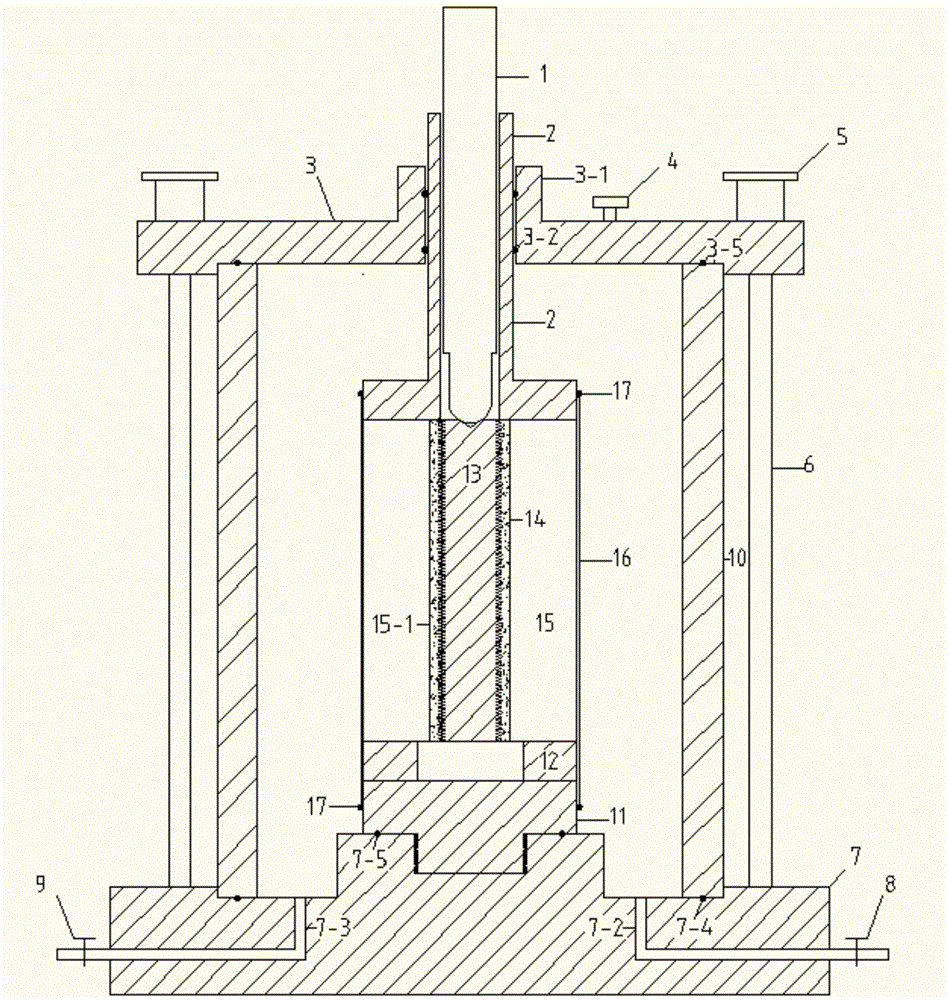

Confining pressure-controllable testing apparatus and testing method for lateral friction of rock

ActiveCN105547841ASuitable for side friction resistance testUnified standardMaterial strength using tensile/compressive forcesAxial forceRock sample

The invention discloses a confining pressure-controllable testing apparatus and testing method for the lateral friction of rock, belonging to the field of technology for embedding piles in rock in rock mass mechanics. The apparatus is such structured that a lower cover plate, a pressure chamber and an upper cover plate are successively connected from top to bottom to form an external structure; a base, a backing ring, a rock sample and a guide pipe are successively connected from bottom to top to form an internal structure, and a latex film is used to nest the above-mentioned internal members into an integral body; a through rock sample circular hole is longitudinally arranged at the center of the rock sample, threaded rods of a same length are arranged in the rock sample circular hole, gaps are left between the threaded rods and the inner wall of the rock sample circular hole and cement mortar with high fluidity is poured into the gaps; and a guide rod passes through the guide pipe and connected with the threaded rods in an up-and-down manner. The apparatus can simulate the failure characteristics of rock-socketed piles and a rock interface and hydraulic pressure action in a pressure chamber is employed to simulate confining pressure conditions of the piles in an actual rock stratum, so the law that axial force changes with displacement of the model piles is obtained and the lateral friction of rock is calculated; and the testing apparatus and testing method have unified standards, can be industrially replicated a plurality of times and are applicable to testing of lateral friction of a variety of rock masses.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

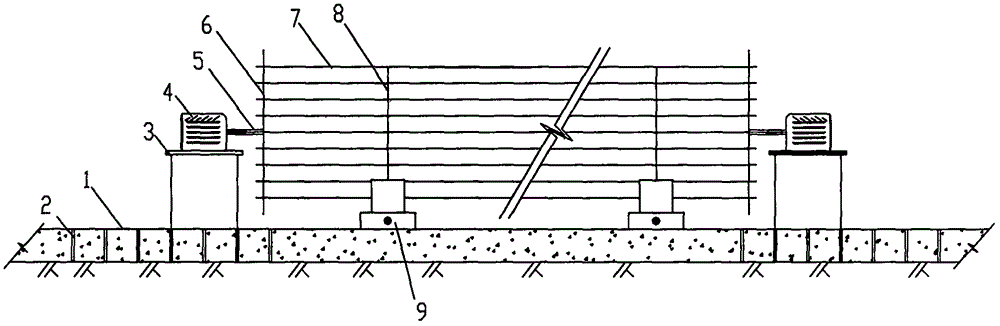

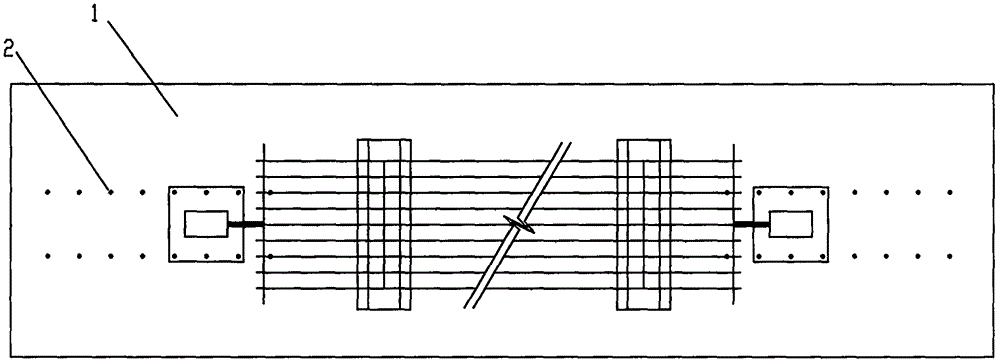

Pile foundation reinforcement cage spiral reinforcement machining and binding integrated construction method

InactiveCN106677167ATight biteConducive to the control of outer diameterBuilding material handlingBulkheads/pilesRebarFoundation engineering

The invention relates to a pile foundation reinforcement cage spiral reinforcement machining and binding integrated construction method. The pile foundation reinforcement cage spiral reinforcement machining and binding integrated construction method is characterized in that a rectangular hardened ground is firstly built; two lines of pre-buried steel casing pipes are arranged on the hardened ground; a reinforcement cage framework is manufactured; according to the length of the reinforcement cage framework, chain jack supporting systems are arranged on the center axis at equal intervals on a construction plant with the center line between the two lines of pre-buried steel casing pipes as the center axis; the reinforcement cage framework is hoisted to the chain jack supporting systems through a crane; the two ends of the reinforcement cage framework are each provided with a rotating power system; coiled reinforcements are straightened through reinforcement straightening equipment; the ends of the straightened reinforcements are locked at one end of the reinforcement cage framework; power devices are immediately started; spiral reinforcement binding personnel carry out distance control; and after all the spiral reinforcements are wound and bound, the spiral reinforcements are fixed in a binding or welding manner. The pile foundation reinforcement cage spiral reinforcement machining and binding integrated construction method has the beneficial effects that the spiral reinforcements and main reinforcements are meshed closely, and the pile foundation engineering quality is guaranteed.

Owner:CHINA MCC 2 GRP CO LTD

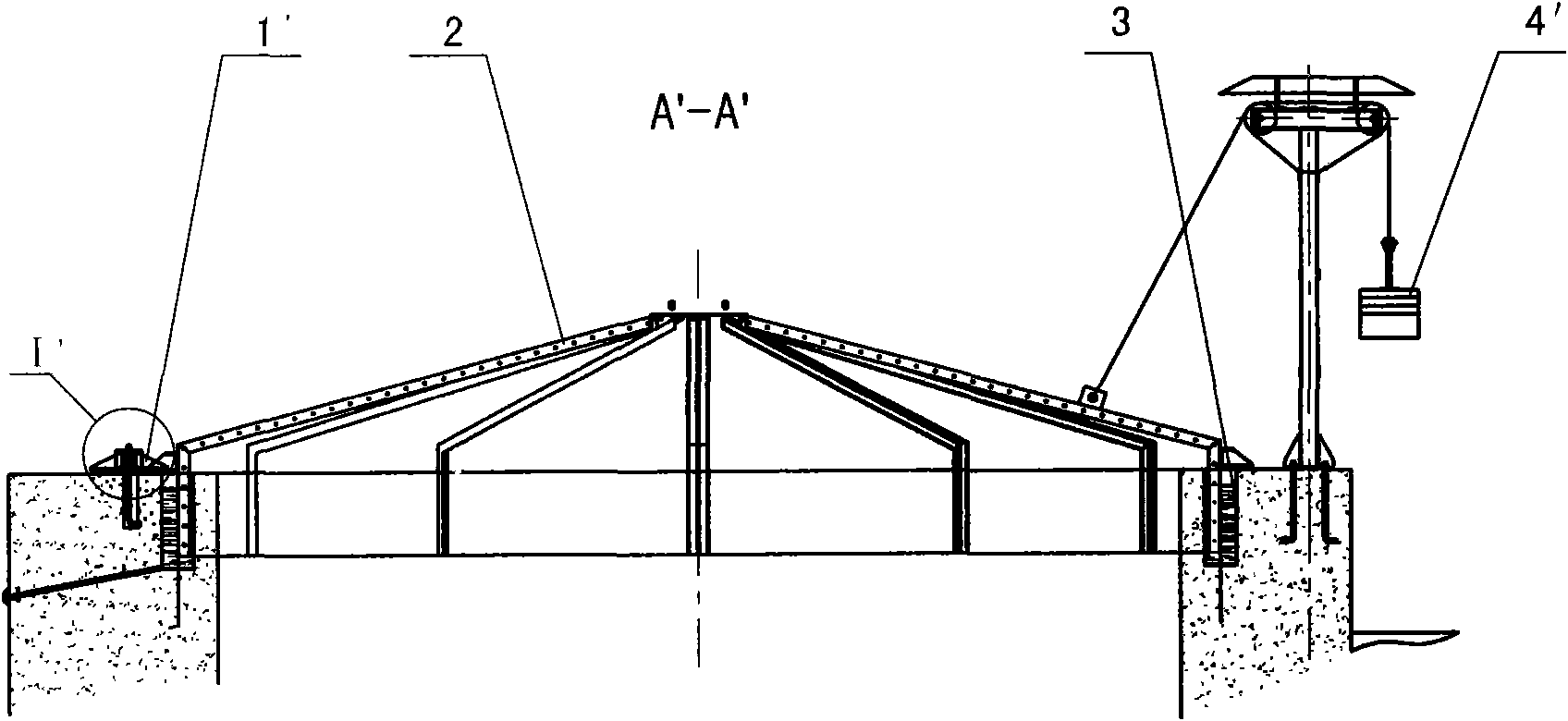

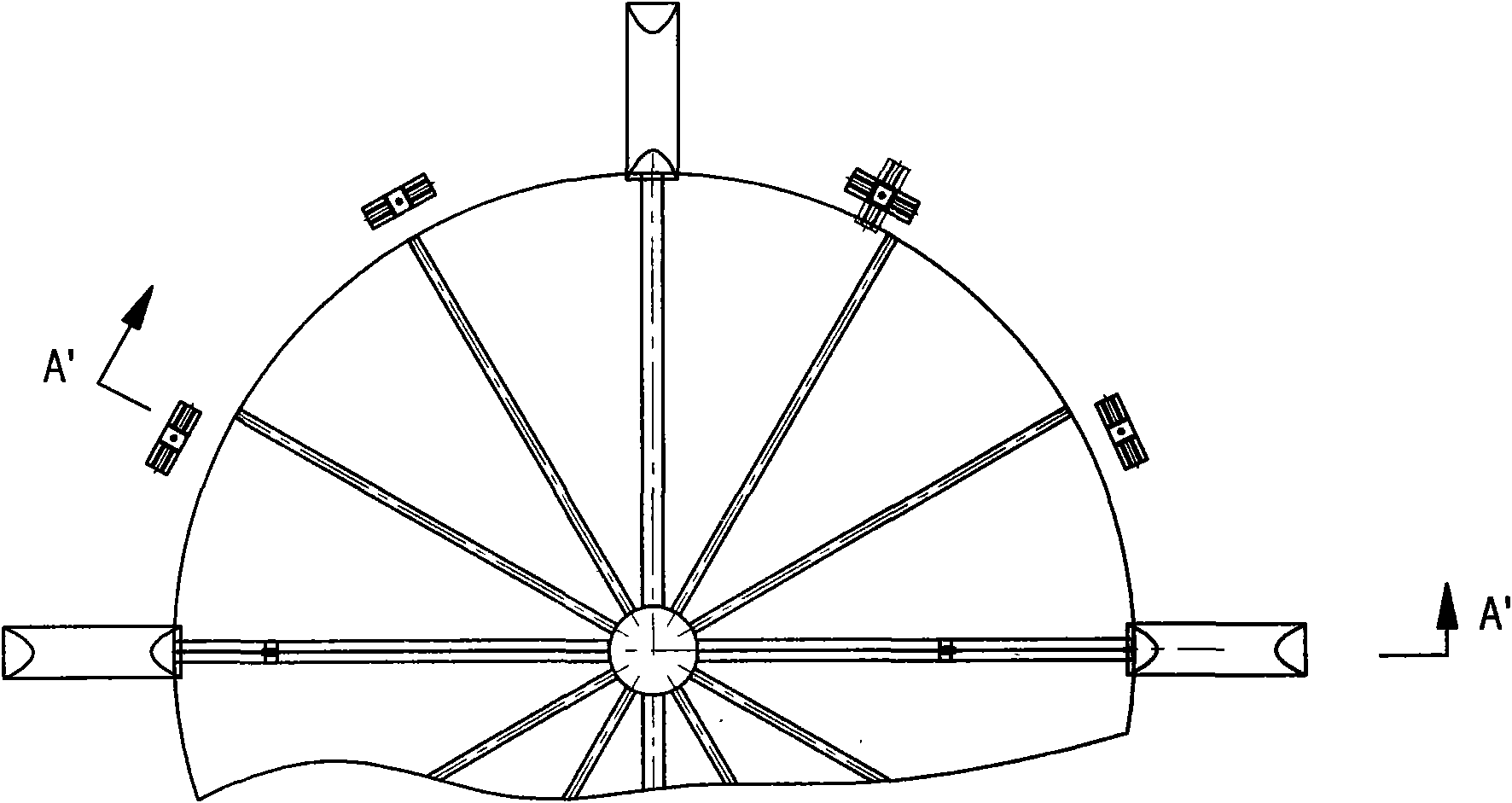

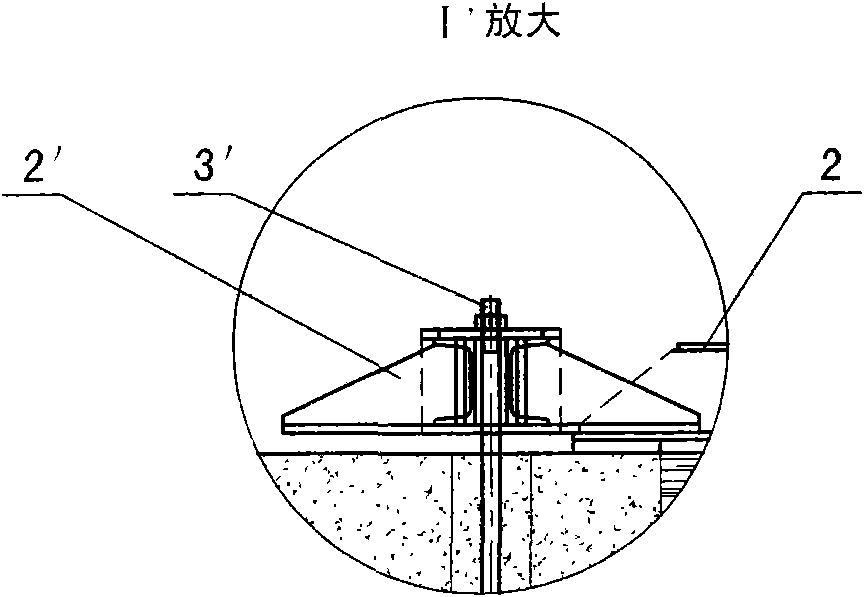

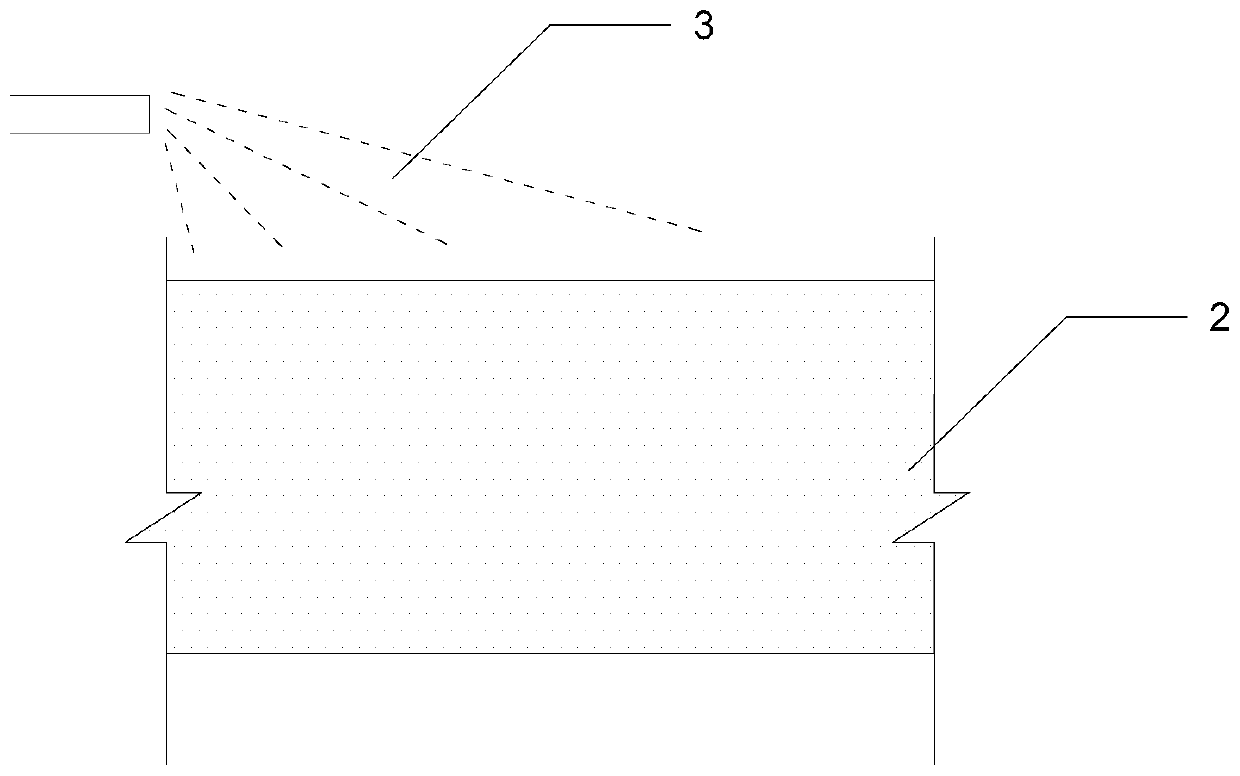

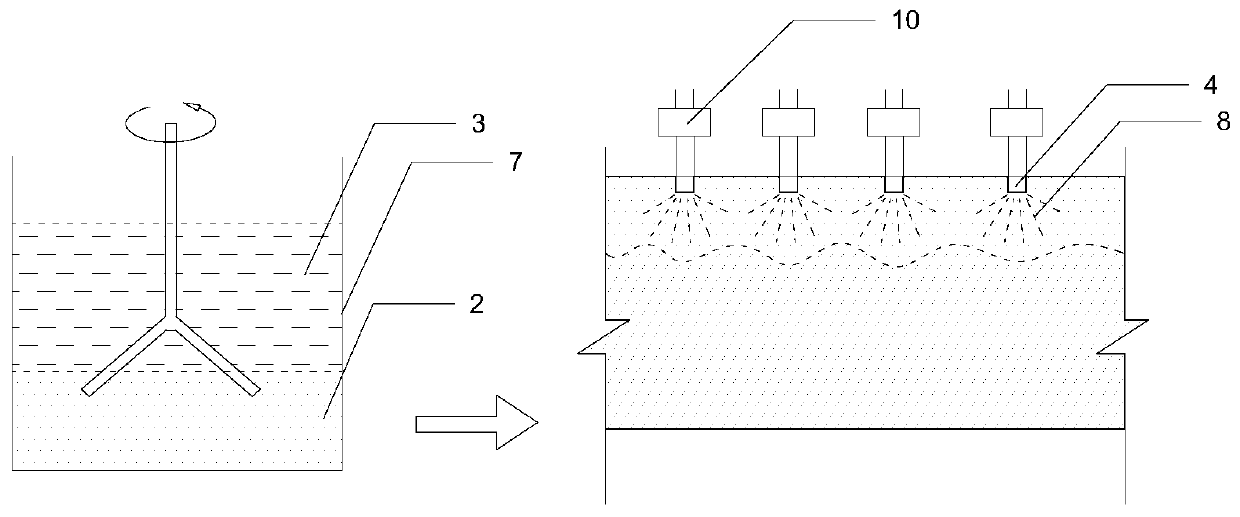

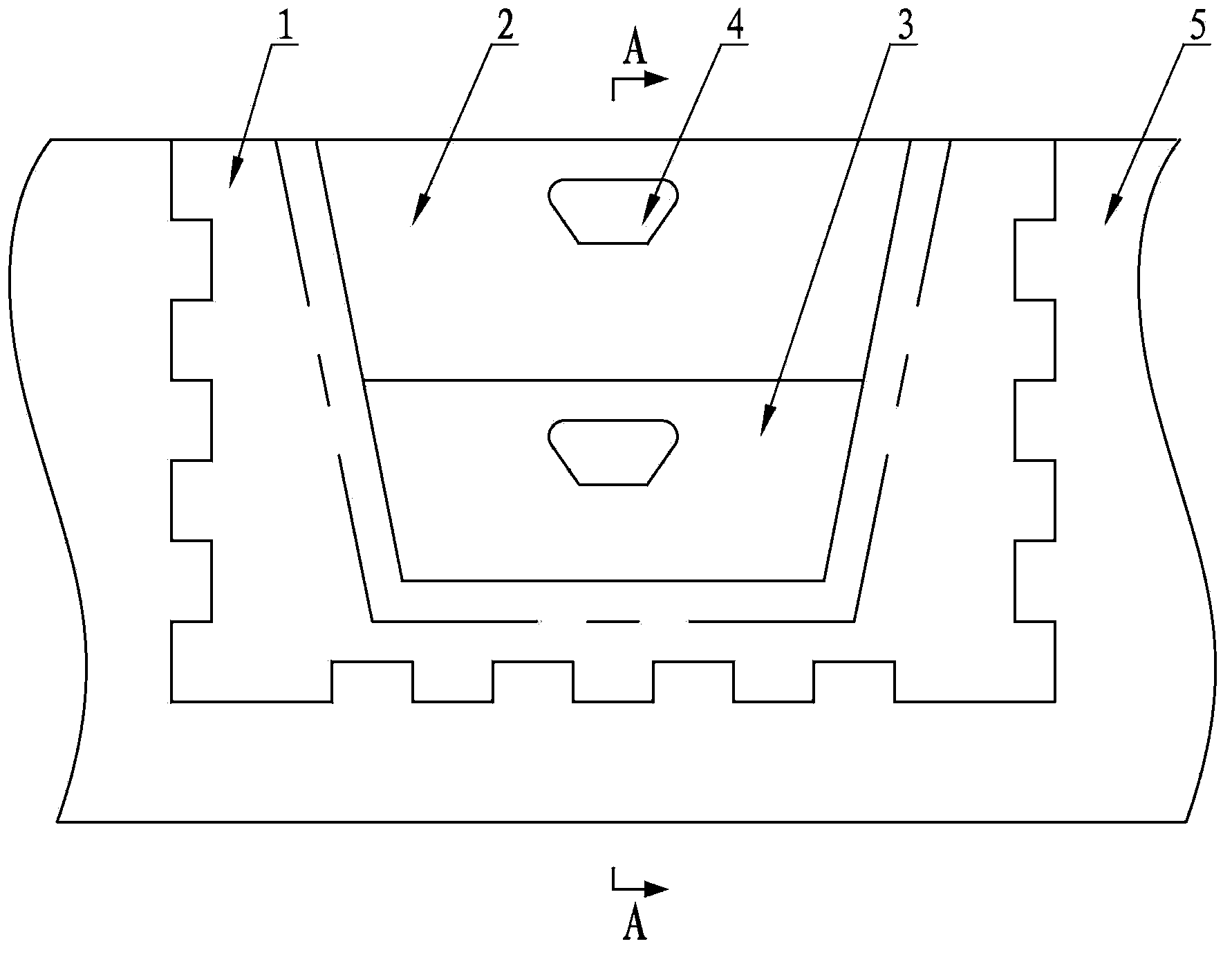

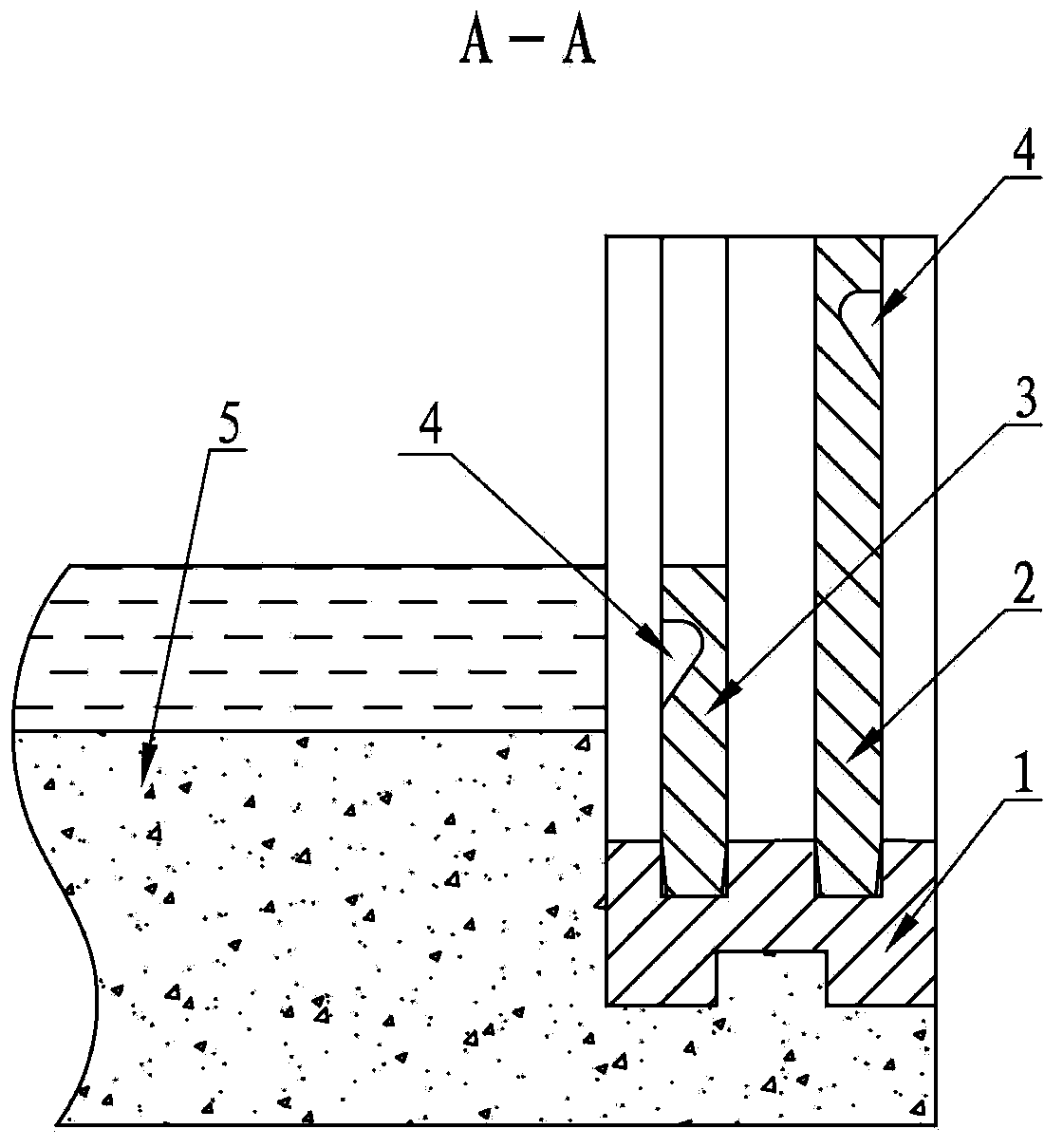

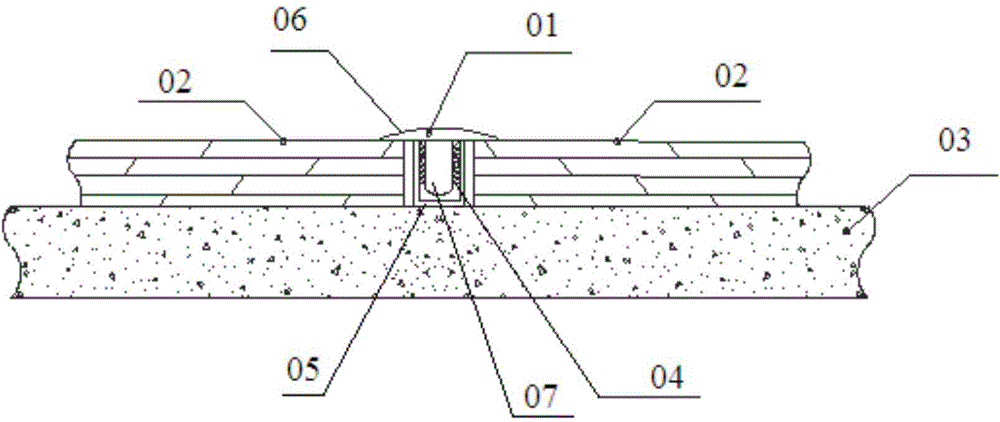

Prefabricated irrigation water intake and drainage control device for a paddy field

InactiveCN103348899AReduce labor intensityProtect water retentionWatering devicesCultivating equipmentsWater leakageWater resources

Owner:王卓民

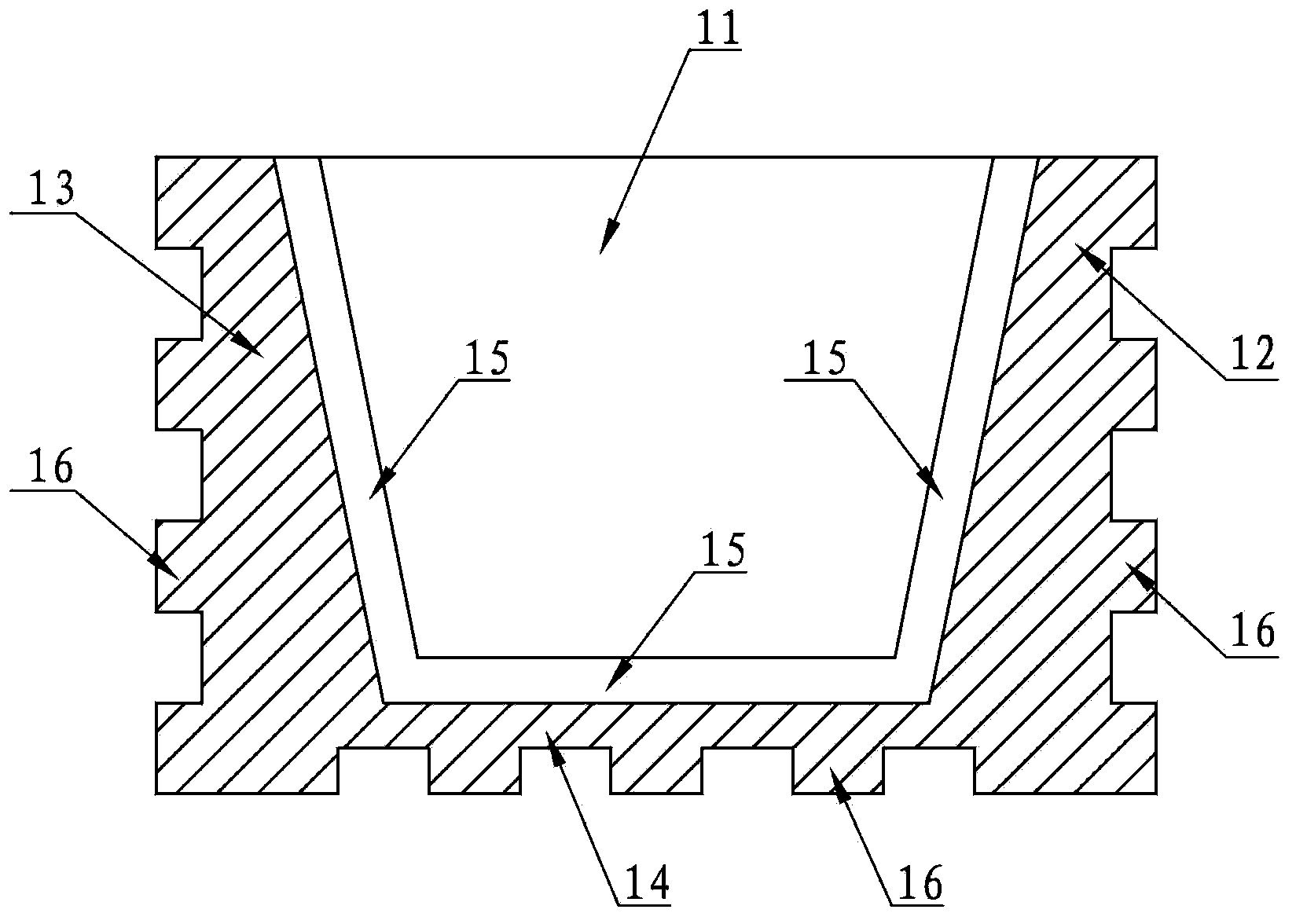

Combined-drawer-type floating breakwater

ActiveCN106759085AEliminate Wave Diffraction ProblemsImprove connection strengthBreakwatersQuaysEngineeringRebar

The invention discloses a combined-drawer-type floating breakwater. The combined-drawer-type floating breakwater comprises a plurality of single bodies of the same structure, wherein each single body comprises a male box body and a female box body and is formed in the way that one end of the male box body is hinged to one end of the female box body; a drawer-type male splicing opening in one end of each male box body is spliced with a drawer-type female splicing opening in one end of the adjacent female box body; a drawer-type female splicing opening in the other end of each female box body is spliced with a drawer-type male splicing opening in one end of the adjacent male box body; after end-to-end splicing of the box bodies of the single bodies, a strip-shaped floating breakwater is formed; the shape of the floating breakwater can be changed through changing the hinging included angles of hinges; the length of the floating breakwater can be changed through increasing or reducing the number of the single bodies; and the male box bodies and the female box bodies are manufactured in the way that concrete is poured outside rebars. As the single bodies are in close connection, wave diffraction of a traditional floating breakwater is prevented; as for different sea conditions, the overall length and shape of the breakwater can be randomly changed through increasing or reducing the number of the single bodies and changing the included angles of the hinges; and the combined-drawer-type floating breakwater has universal applicability and a wide application prospect.

Owner:ZHEJIANG UNIV

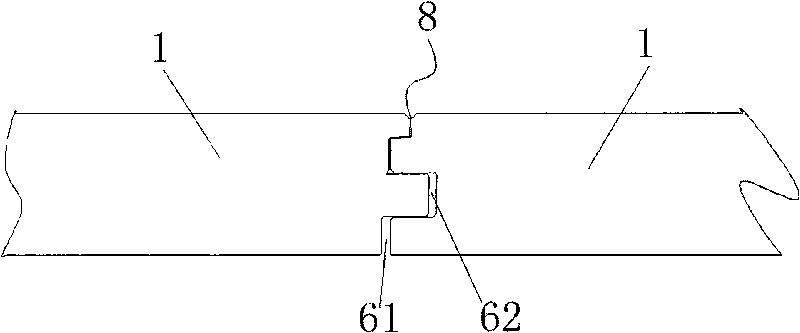

Decorative board

InactiveCN101713243AEasy to splice and installSimple structureCovering/liningsEngineeringUltimate tensile strength

Owner:GUANGDONG YINGRAN WOOD IND

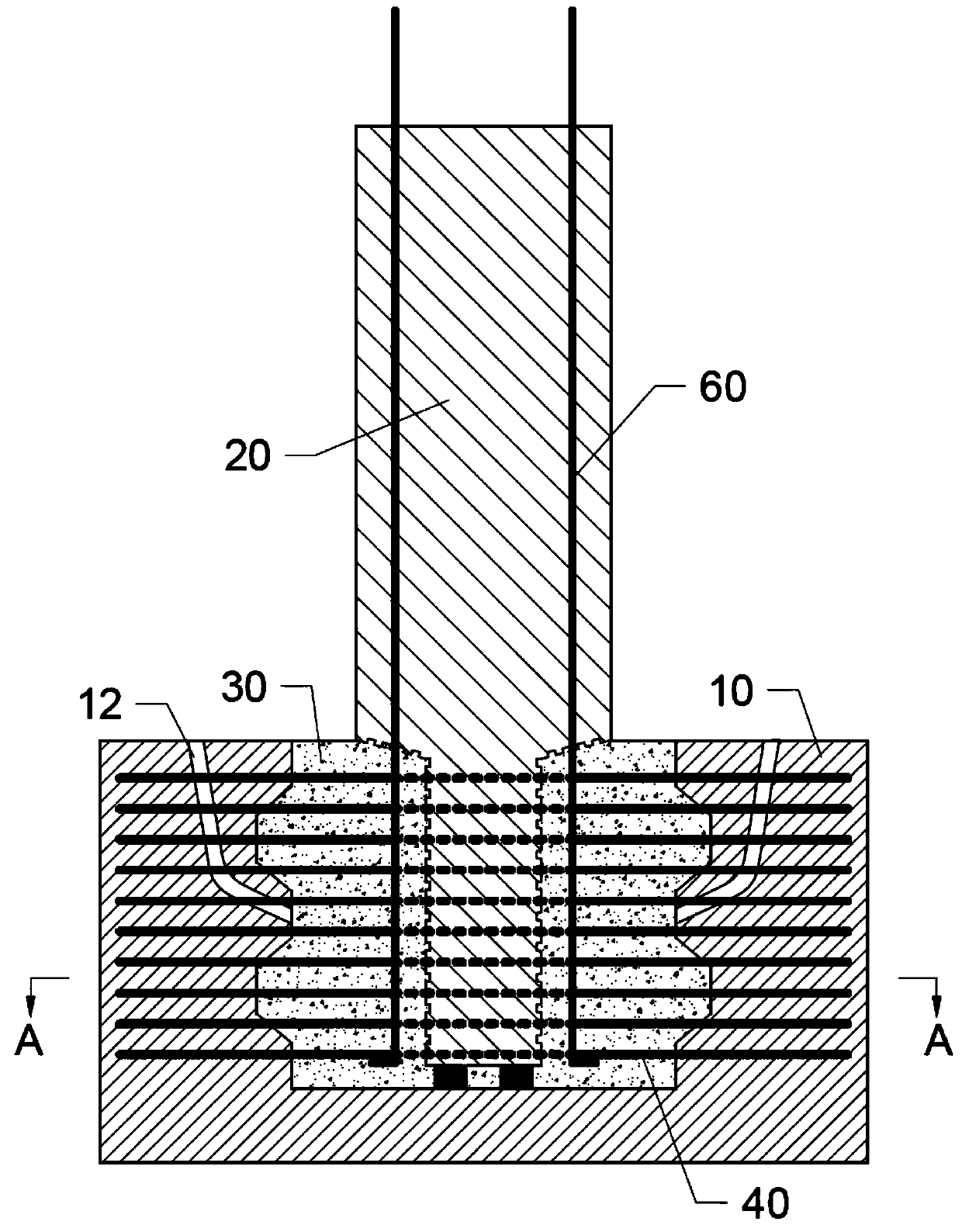

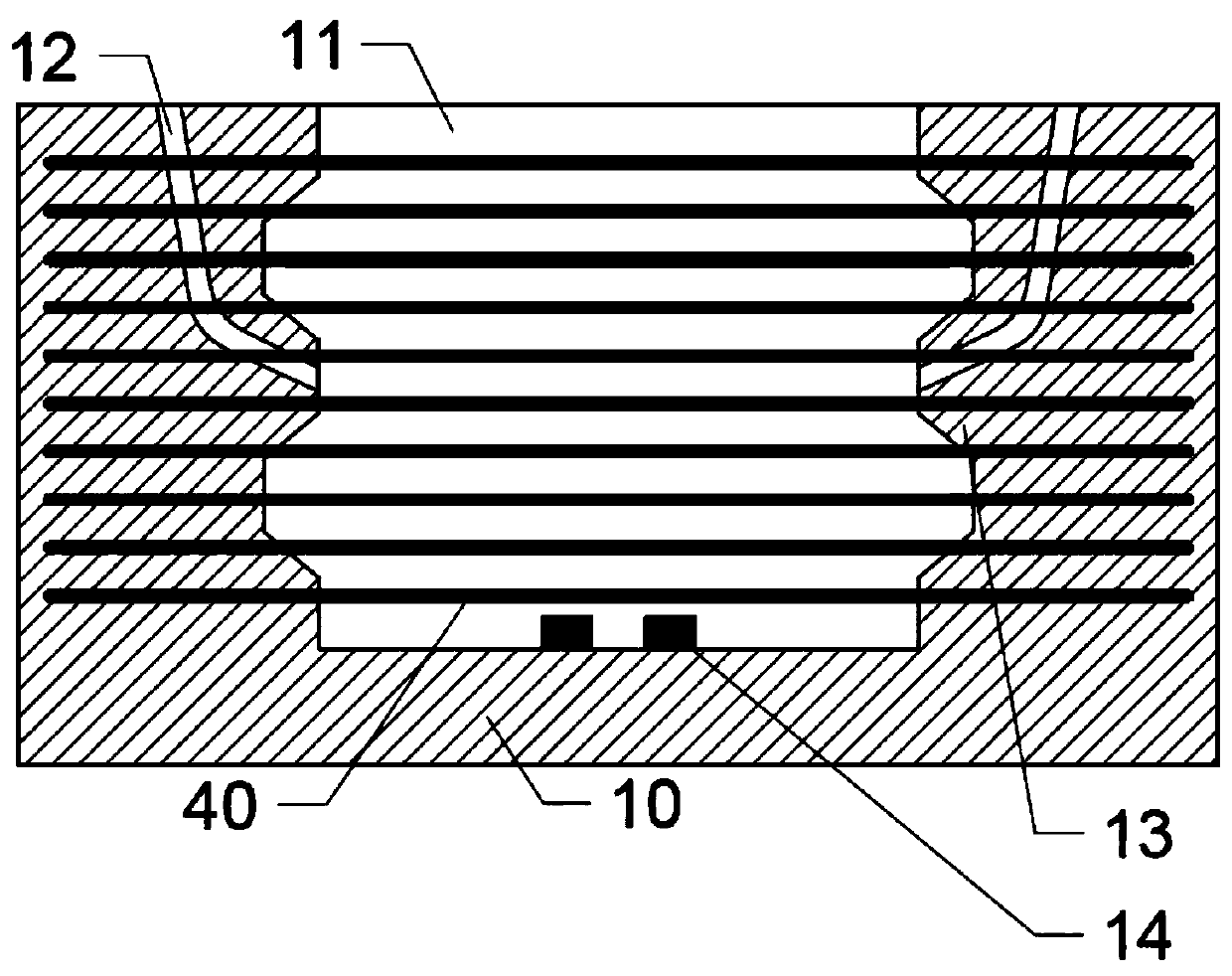

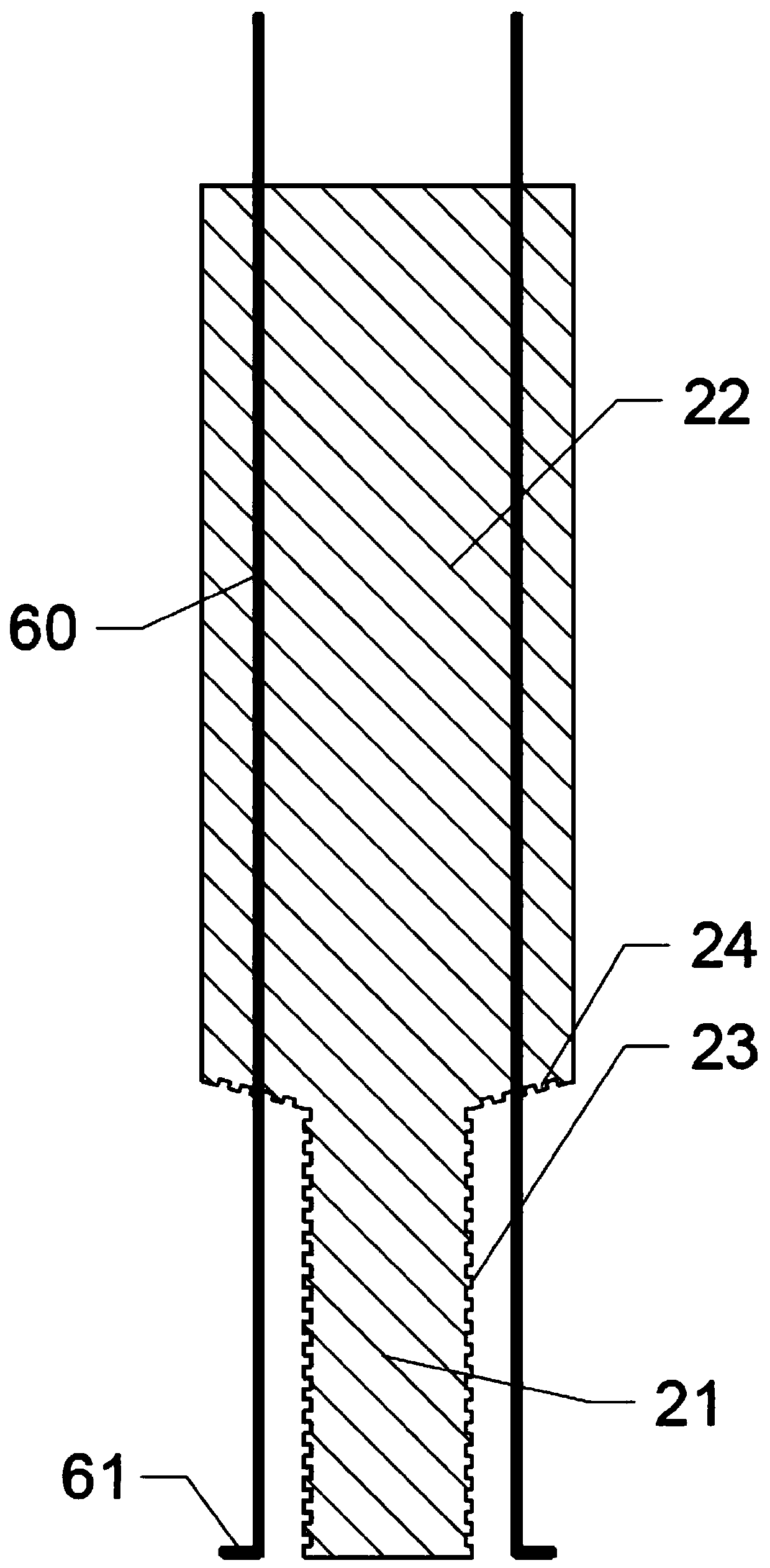

Connecting structure and construction method for assembly type bridge pier column and bearing platform

InactiveCN110863427AFirmly connectedEasy constructionBridge structural detailsFoundation engineeringArchitectural engineeringEngineering

The invention provides a construction method for an assembly type bridge pier column and a bearing platform, and relates to the technical field of assembly type bridge construction. The method comprises the steps: 1, prefabricating the pier column; 2, manufacturing the bearing platform with a bearing platform reserved slot hole on the upper end face; 3, installing the pier column into the bearingplatform reserved slot hole; 4, pressing grouting materials into the bearing platform reserved slot hole; wherein step 1 comprises the substeps of prefabricating a first part and a second part of thepier column, wherein the outer diameter of the first part is smaller than that of the second part, and connecting the first part to the lower end surface of the second part; the step 1 further comprises the substep of arranging a transverse anchoring head and a vertical anchoring head; and in the step 3, the first part of the pier column is installed into the bearing platform reserved slot hole until the lower end face of the second part is not higher than the opening depth of the bearing platform reserved slot hole. The construction method is convenient and fast to construct, can enable the connection of the pier column and the bearing platform to be stable, and is suitable for wide-range popularization.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

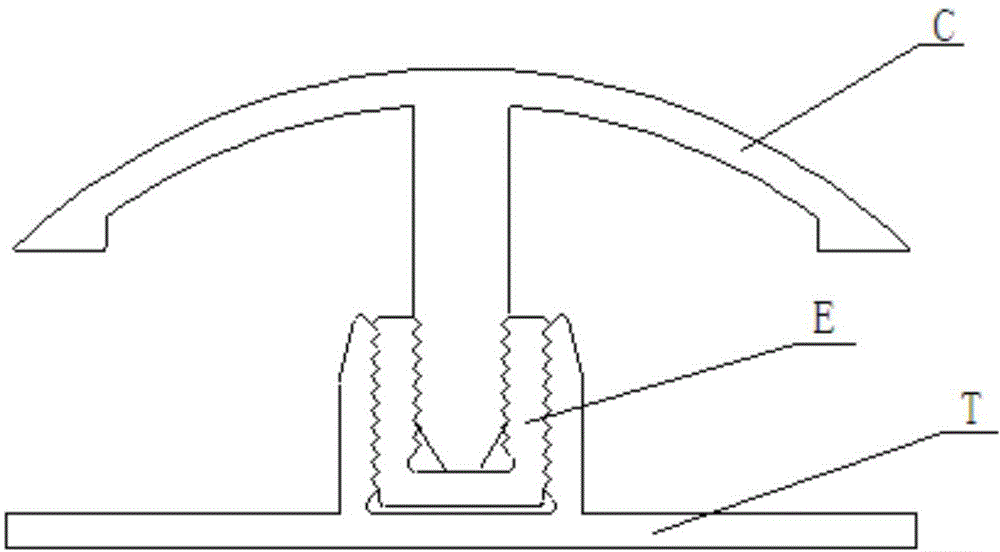

Spring type floor end cap assembly

InactiveCN104018649AWith adjustable rangeAvoid loose and upturned situationsBuilding constructionsEngineeringMechanical engineering

The invention provides a spring type floor end cap assembly which comprises a base, closing press bars with reverse teeth, a transitional piece and a spring, wherein the transitional piece is arranged in a groove of the base and matched with tooth shapes of the reverse teeth of the closing press bars, and the spring is used to fix the base and the transitional piece. The closing press bars are engaged with the transitional piece by the reverse teeth, the base is fixed with the transitional piece by the spring, the spring is of up and down adjustment amplitude so as to make the engagement tight, prevent an end cap from loosening and bending upwards, and always enable the closing press bars to be attached to the floor. Due to the fact that the spring type floor end cap assembly is dismantled in a lifting mode or mounted in a pressing mode only by overcoming the elastic force of the spring, and lateral dismantling or installation isn't needed, the spring type floor end cap assembly is convenient to dismantle, and practical and beautiful in appearance, and is free of destructive dismantling.

Owner:倪国梁

Self-heat-preservation outer wall board and outer wall for fabricated building

ActiveCN107605098ANot prone to crackingNot easy to crack and other quality problemsClimate change adaptationBuilding componentsEarthquake resistanceEngineering

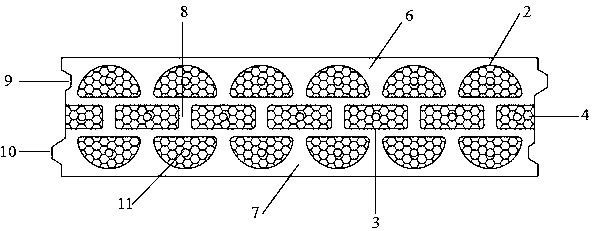

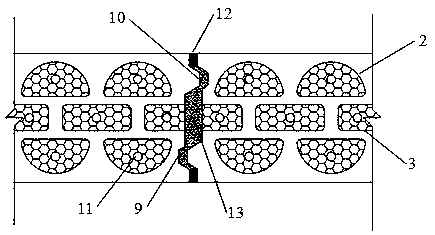

The invention discloses a self-heat-preservation outer wall board and outer wall for a fabricated building. The self-heat-preservation outer wall board comprises a wall board base body and a prefabricated heat-preservation piece embedded in the wall board base body; the wall board base body is composed of an upper transverse rib board, a lower transverse rib board and an intermediate rib board; arow of semicircular hole channels is formed in each of the upper transverse rib board and the lower transverse rib board at intervals, and a row of rectangular hole channels is formed in the intermediate rib board at intervals; a female mortise and a male mortise are formed in the transverse splicing face of the wall board base body; and during mounting, the two ends of a wall board splicing seamare filled with elastic waterproof sealant, and the middle of the wall board splicing seam is filled with heat-preservation anti-crack bonding mortar. The self-heat-preservation outer wall board has the advantages of good integrity, stable force bearing, lightness, earthquake resistance, heat preservation, sound insulation and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

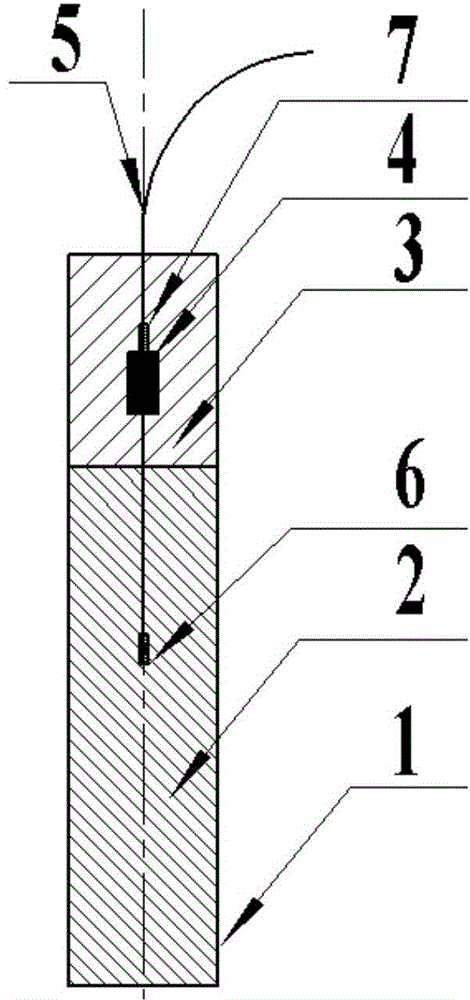

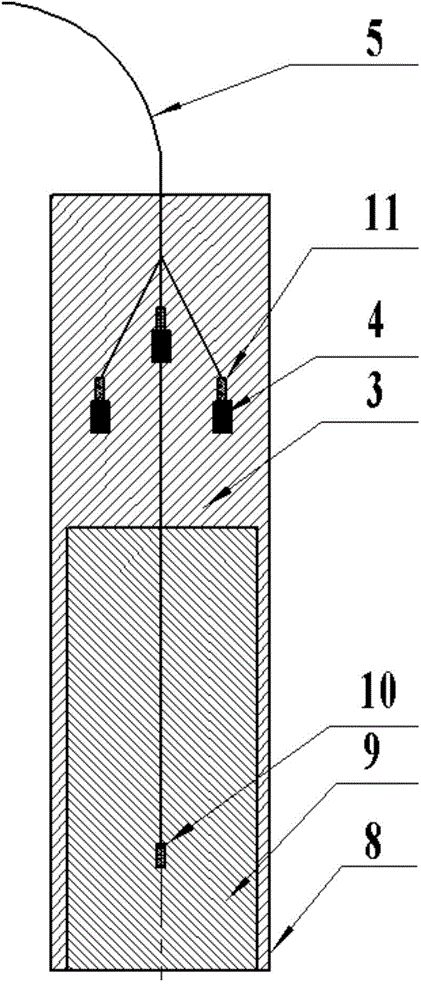

Hole filling method by blasting

The invention relates to a hole filling method by blasting. The materials used comprises two parts, i.e., a hole filling material and hole filling cartridge bags. A blast hole is sealed by using a common hole filling material; the hole filling cartridge bags are alternately arranged inside the hole filling material along the direction of the blast hole. A time-delayed detonating method is employed for allowing the cartridge bags to be detonated firstly inside the blast hole. The energy generated by the explosion of the explosive inside the hole filling cartridge bags allows the common hole filling material above and below the explosive to be compacted, thereby increasing the frictional force between the hole filling material and the wall surface of the blast hole. Meanwhile, the delayed time between a hole filling cartridge bag and a main charge of a charge section is designed, thereby achieving that the detonation gas generated by the hole filling cartridge bags inside the filling section is not escaped upon detonating the main charge, and accordingly generating a high pressure environment inside the filling section, and increasing the hole filling effect.

Owner:UNIV OF SCI & TECH OF CHINA +1

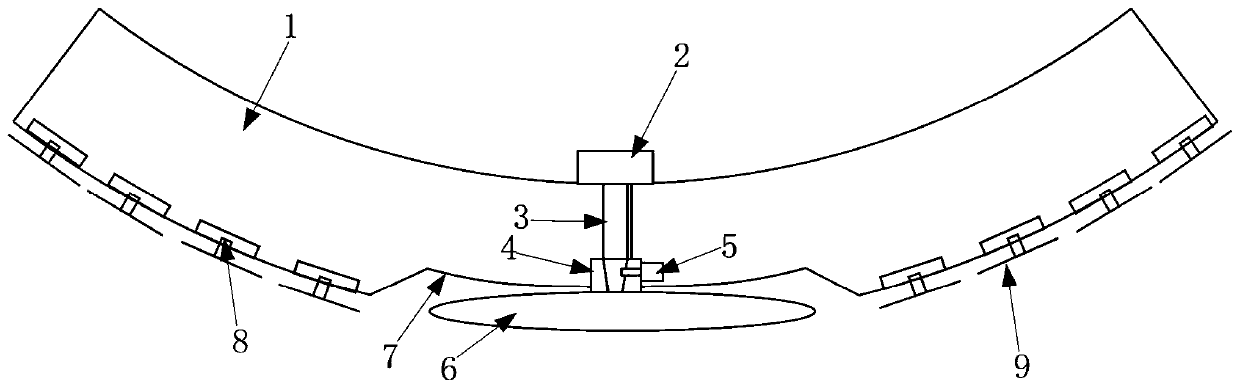

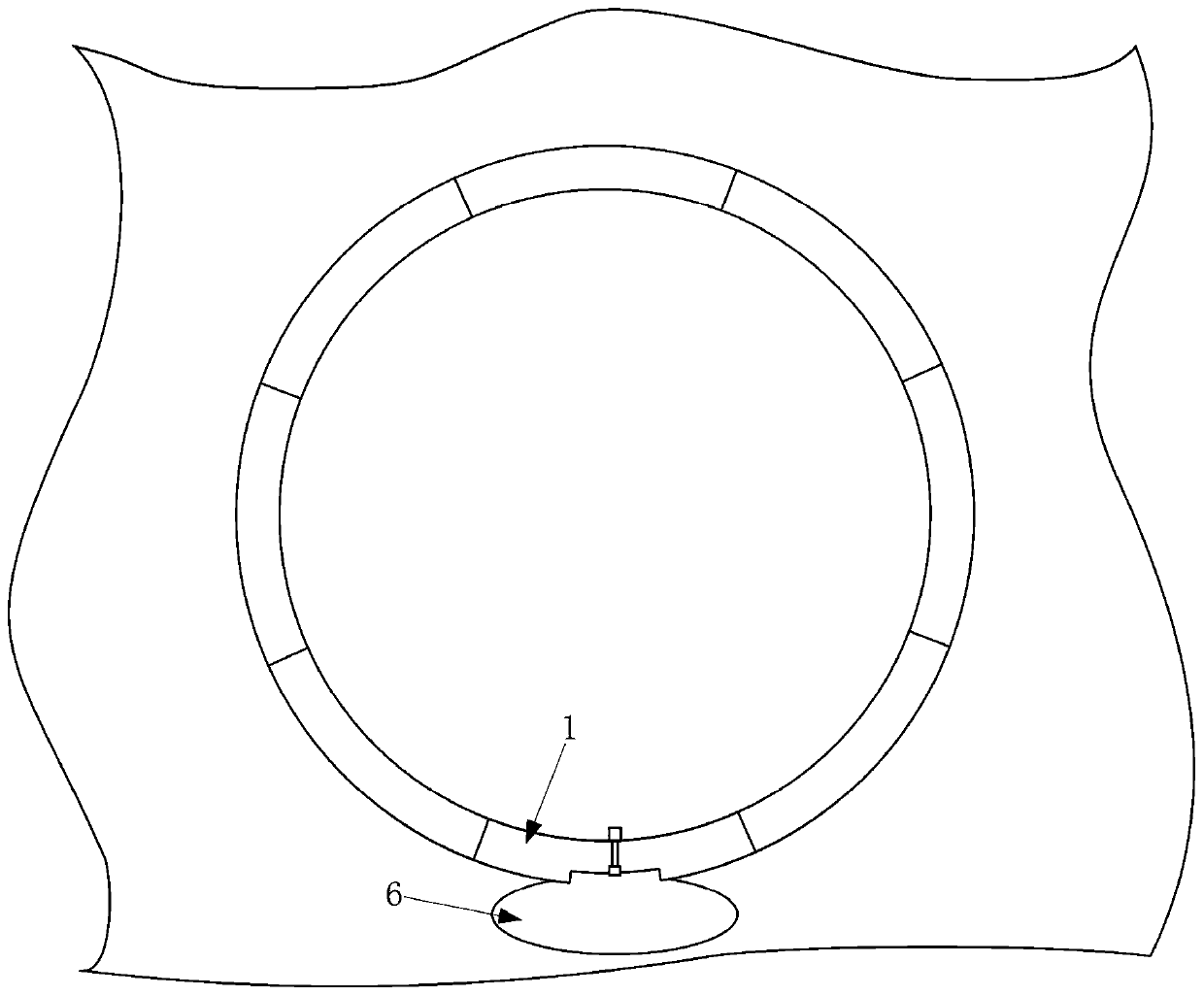

Structure for preventing differential settlement of shield tunnel and implementing method

ActiveCN110593896AAvoid uneven settlementGuaranteed stabilityMining devicesUnderground chambersSludgeEngineering

The invention discloses a structure for preventing differential settlement of a shield tunnel. The structure comprises an arc bottom supporting pipe sheet and a plurality of arc ordinary supporting pipe sheets, and the bottom supporting pipe sheet and the ordinary supporting pipe sheets are spliced into a tunnel. The outer side of the bottom supporting pipe sheet is provided with an air bag, the air bag is connected with an inflation pipeline through a connector, and the inflation pipeline is connected with an inflation device arranged on the inner side of the bottom supporting pipe sheet. Theconnector is provided with an air pressure detection device. An implementing method of the structure for preventing differential settlement of the shield tunnel comprises the steps from the first step to the seventh step, since mucky clay in a sludge stratum is not stable, differential settlement of the tunnel is caused in the long-term running process, the mucky clay is fluid-like, and the supporting and floating effect can be generated to the air bag; and the air bag is arranged in the tunnel bottom sludge stratum, the air bag at the bottom of the supporting pipe sheet supports the tunnel,and through air pressure adjustment of the air bag, differential settlement of the tunnel is relieved and even avoided.

Owner:SOUTHWEST JIAOTONG UNIV

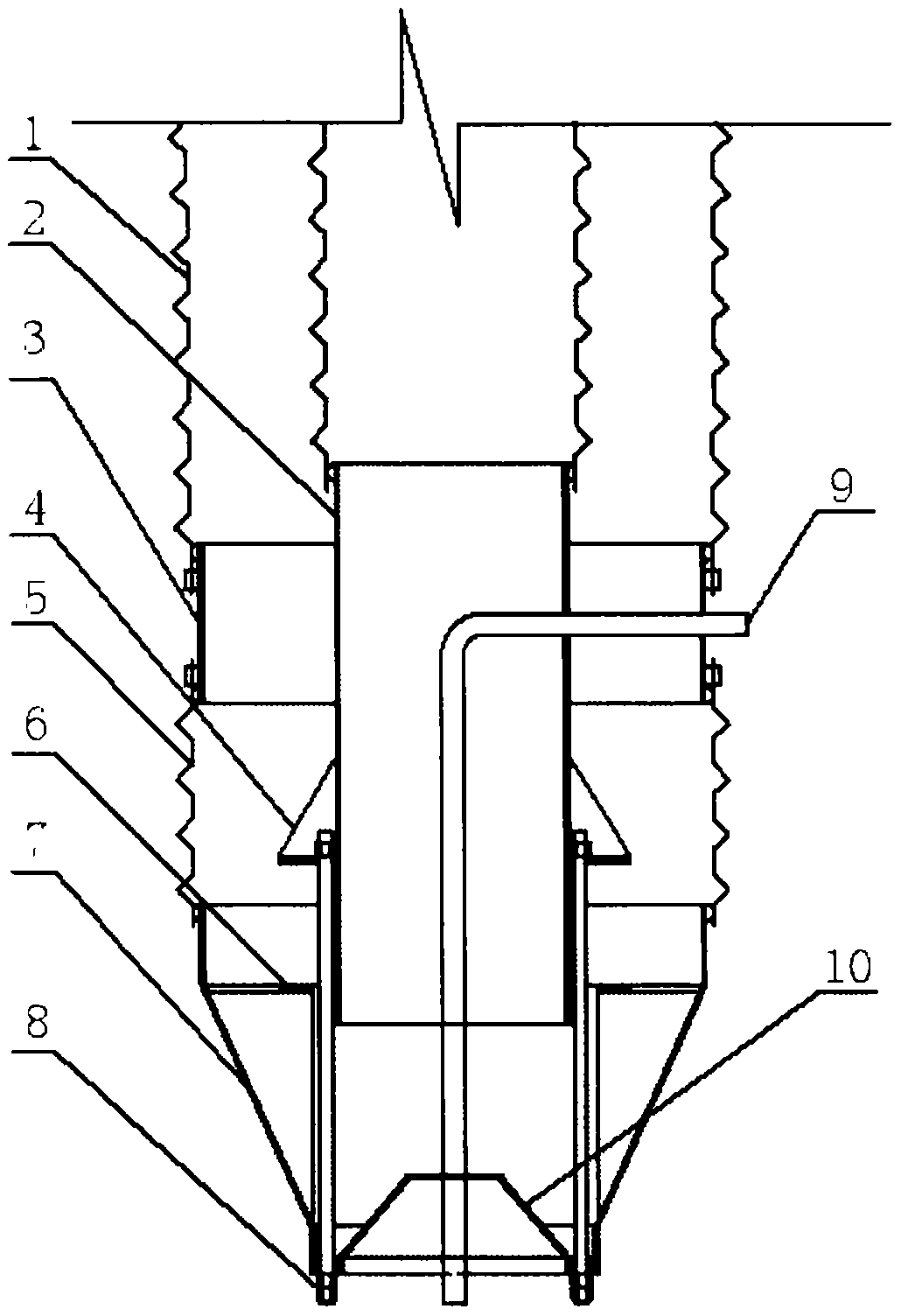

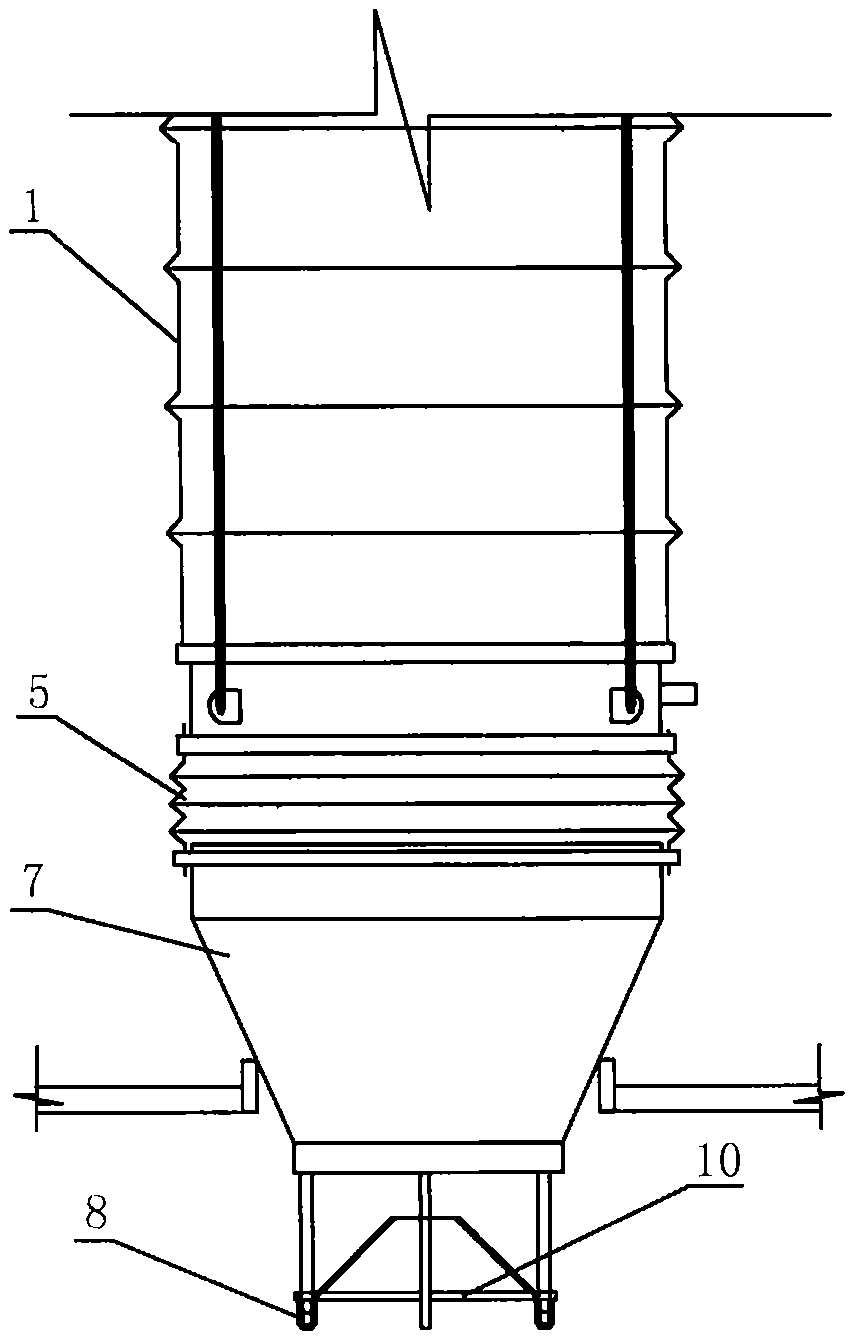

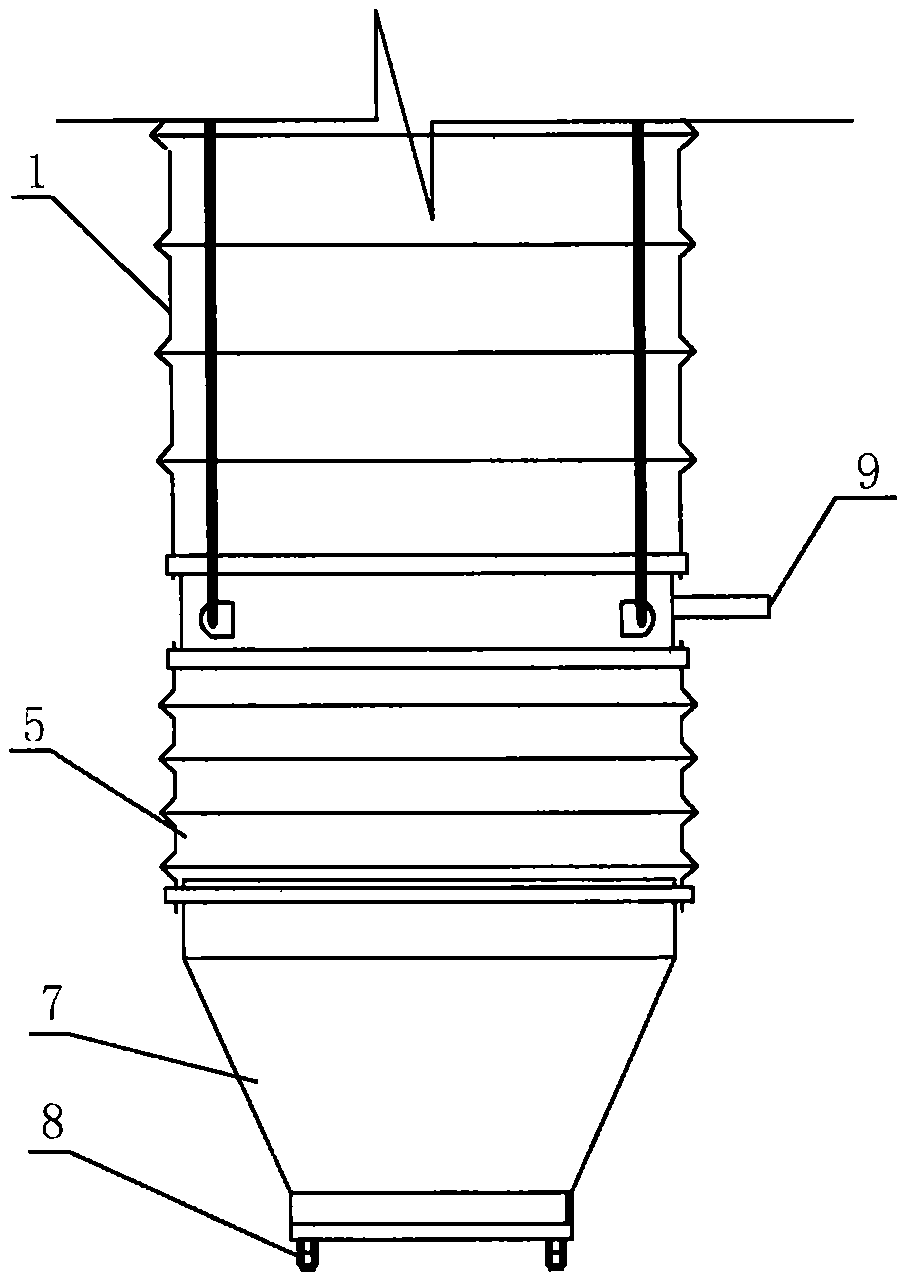

Dry powder material powder leakage preventing bulk machine head device

The invention discloses a dry powder material powder leakage preventing bulk machine head device. The dry powder material powder leakage preventing bulk machine head device comprises a soft connectionpart, a movable assembly and a non-movable assembly. The movable assembly comprises a material guiding barrel and a material guiding barrel base ring. The outer side of the material guiding barrel isconnected with the material guiding barrel base ring. The material guiding barrel base ring is connected with a lower inverted-cone-shaped sealing cover through two or more vertical bolt assemblies,and the big end of the inverted-cone-shaped sealing cover is arranged downwards. The non-movable assembly comprises a material guiding barrel limiting ring and a material receiving cone barrel. The material guiding barrel and the bolt assemblies in the movable assembly penetrate an outlet in the bottom of the material receiving cone barrel and the material guiding barrel limiting ring and move upand down. After unloading is finished in the structure, the inverted-cone-shaped sealing cover ascends and makes contact with the outlet in the bottom of the material receiving cone barrel for closing, automatic sealing is achieved, dust pollution and powder leakage waste are prevented, and the work efficiency is improved.

Owner:潞城市泰山石膏建材有限公司

Concrete exposed aggregate agent and preparation method thereof

The invention discloses a concrete exposed aggregate agent and a preparation method thereof and belongs to the field of buildings. The concrete exposed aggregate agent comprises the following components in parts by mass: 15-25 parts of white sugar, 5-8 parts of sodium citrate, 1-3 parts of a penetrating agent, 0.5-1 part of an anti-rust agent, 0.5-2 parts of a bactericide and 50-70 parts of deionized water. The concrete exposed aggregate agent disclosed by the invention is mainly applied to concrete aggregate exposed treatment, methods for milling, planing, chiseling, filing and the like are not need during treatment of buildings, concrete constructed joints, tail ends or continuous construction, the formed aggregate exposed rough and solid concrete surface can be connected with fresh concrete into a whole, and the joint interface is kept firm and crack-less.

Owner:石家庄筑佳节能产品科技有限责任公司

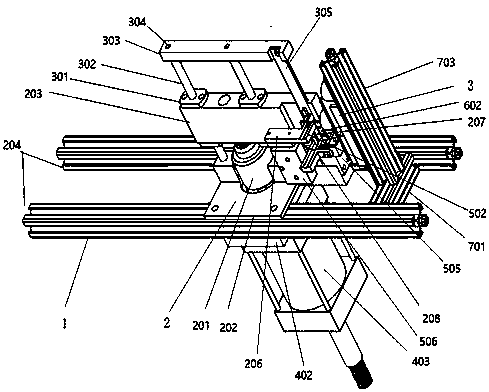

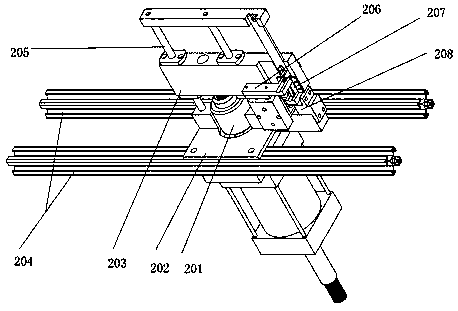

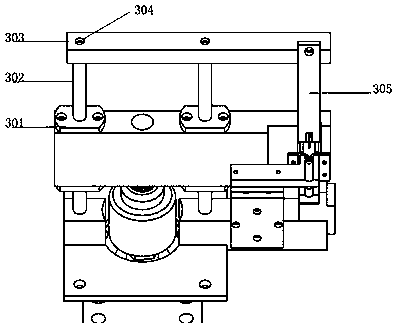

Cutting and jointing device for automatic grafting of seedlings

The invention discloses a rootstock and scion support mechanism for automatic grafting, which comprises a scion support assembly and a rootstock support assembly; the rootstock support assembly is provided with a scion front bearing and a scion rear bearing; the scion front bearing and the scion rear bearing are respectively arranged on two sides of a moving seat; the rootstock support assembly isprovided with a rootstock front bearing and a rootstock rear bearing, the rootstock front bearing and the rootstock rear bearing are respectively arranged at two sides below the moving seat; the scion front bearing and the rootstock front bearing are connected with a driving part, and the scion front bearing and the rootstock front bearing are driven to move in the vertical direction. The rootstock and scion support mechanism for automatic grafting is used for supporting and positioning a rootstock and a scion in the operating process of a grafting machine so as to assist in completing the grafting and cutting operation.

Owner:LIAOCHENG UNIV

Improved loosing and theft preventing bolt structure body

InactiveCN101598169ALow construction requirementsGood anti-theft effectPinsWashersBearing surfaceAcute angle

The invention discloses a bolt structure body, which comprises a nut, two washers and a bolt, wherein the bottom rim of a bolt head and the upper rim of the nut are provided with a wedgy tooth-shaped inclined plane with one higher edge and one lower edge respectively, and the connecting part of each wedgy tooth-shaped inclined plane forms a retaining surface; one surface of each washer forms an inclined plane which corresponds to and is matched with the wedgy tooth-shaped inclined planes of the bolt head and the nut; the connecting parts of the inclined planes form bearing surfaces; the other surface of the washer is provided with an insertion strip or a bump, and the washers are irregular round; included angles alpha between the retaining surfaces and a plane of the bolt head and a plane of the nut are acute angles; and included angles beta between the bearing surfaces and planes of the washers are acute angles. The bolt structure body does not fall off under the conditions of breeze vibration, spiral vibration and the like, the wedgy tooth-shaped inclined planes of the acute angles are meshed tightly, and the construction requirement is reduced simultaneously; the bolt structure body has better anti-theft function, a screw driver and other tools cannot find the position of force application, and only a special tool is used to take the bolt structure body down; the curve insertion strips or the bumps can increase frictional resistance and prevent rusting connection; and a manufacturing process of the bumps is simple.

Owner:北京驰神投资管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com