Combined steel pile cofferdam provided with water swellable waterproof rubber fore shaft

A water-swellable rubber and waterproof lock technology, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problem that the draw hooks on both sides are not easy to be centered and aligned straightly, the strength and stiffness of the draw hook lock are low, and the draw hook lock Problems such as easy deformation of the mouth by force, achieve the effect of repeated reuse, simplify the construction process of the lock, and reduce the workload of on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

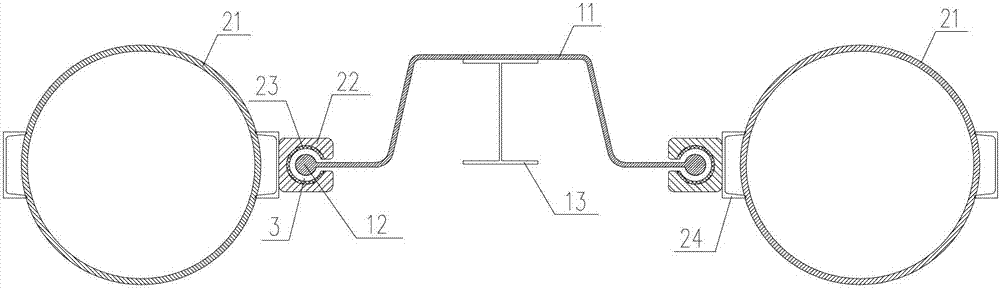

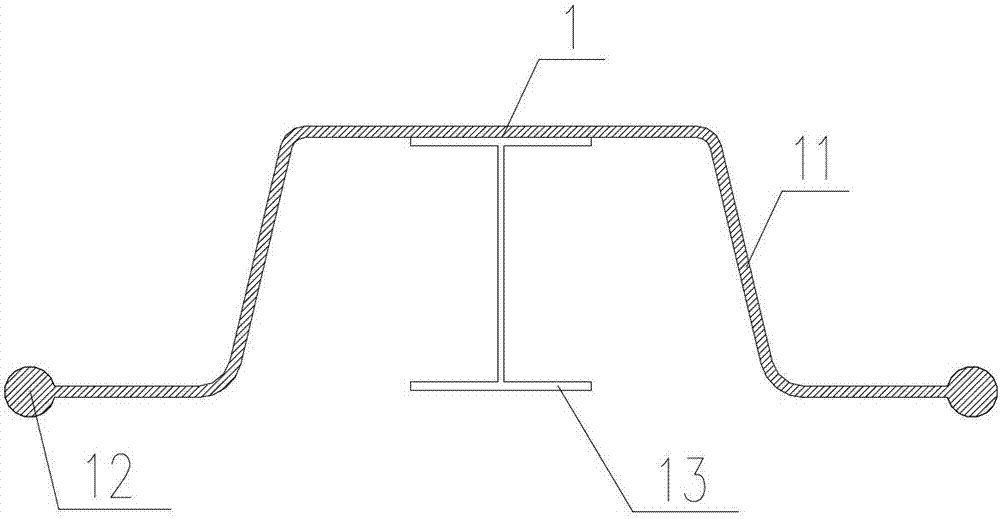

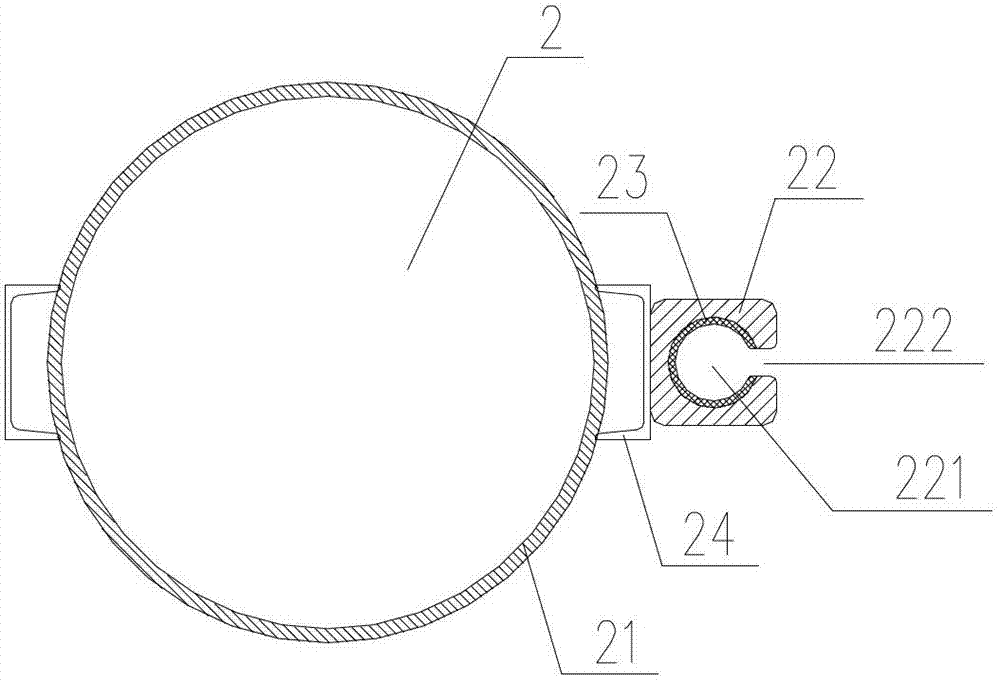

[0034] The combined steel pile cofferdam with water-swellable rubber waterproof lock of the present invention consists of steel pipe piles, U-shaped steel sheet piles, Ω-shaped steel lock female parts, Ω-shaped water-swellable rubber tubes, and locks. It consists of round steel rods, bentonite mixture filler, channel steel connectors and H-shaped steel piles. Steel pipe piles are used as long piles in the cofferdam structure, U-shaped steel sheet piles are used as short piles in the cofferdam structure, and Ω-shaped steel locks The Ω hole-shaped water-expandable rubber tube is embedded in the mouth parent part as the waterproof lock body part, the round steel rod of the lock part is inserted into the Ω-hole-shaped water-expandable rubber tube, and the Ω-hole-shaped water-expandable rubber tube and the lock part The cavities between the steel rods are filled and compacted with bentonite mixture filler.

[0035] The locking mother part is composed of a hot-rolled steel bar and a...

Embodiment 2

[0041] The construction method of the combined steel pile cofferdam with water-swellable rubber waterproof lock of the present invention comprises the following steps:

[0042] Step 1: Determine the plane size of the waterproof cofferdam according to the range of hydraulic structures or bridge piers, clean up the riverbed, avoid encountering obstacles at the position where the steel piles are inserted, take precise stakeout measurements, and install guide frames;

[0043] Step 2: At the construction site, the steel pipe piles are blanked, and the channel steel connectors are welded on the outside of the steel pipe piles. Then, the Ω hole-shaped steel lock female part and the strip embedded with the Ω hole-shaped water-swellable rubber tube The finished product is welded on the outside of the channel steel connector to form a long pile of waterproof cofferdam, and the long pile is driven into the design depth;

[0044] The weight ratio of step 3 preparation is: bentonite conten...

Embodiment 3

[0047] A cofferdam is rectangular in shape, 15 meters long and 10 meters wide, the water depth of the cofferdam is 10 meters, and the underwater excavation depth of the pier foundation is 5 meters. Steel pipe piles with a diameter of 800mm and a wall thickness of 16mm are selected as the long piles of the cofferdam, and the length of the steel pipe piles is designed to be 30 meters. Cold-formed U-shaped steel sheet piles with a width of 1200mm, a height of 300mm, and a wall thickness of 14mm are selected as the short piles of the cofferdam. The length of the U-shaped steel sheet piles is designed to be 24 meters. H350*250*10*14 shaped steel supports are used to reinforce U-shaped steel sheet piles, and the length of H-shaped steel piles is designed to be 26 meters. The hot-rolled forming process is used to produce the Ω-shaped steel lock female part. The shape of the lock female part is square on the outside and circle on the inside. The outer surface is a square with a width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com