Edge meshing technology of inner container of dish-washing machine

A technology of a dishwasher liner and a process is applied in the field of dishwasher manufacturing, which can solve the problems of high input cost and poor fixed connection effect, and achieve the effect of good occlusal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

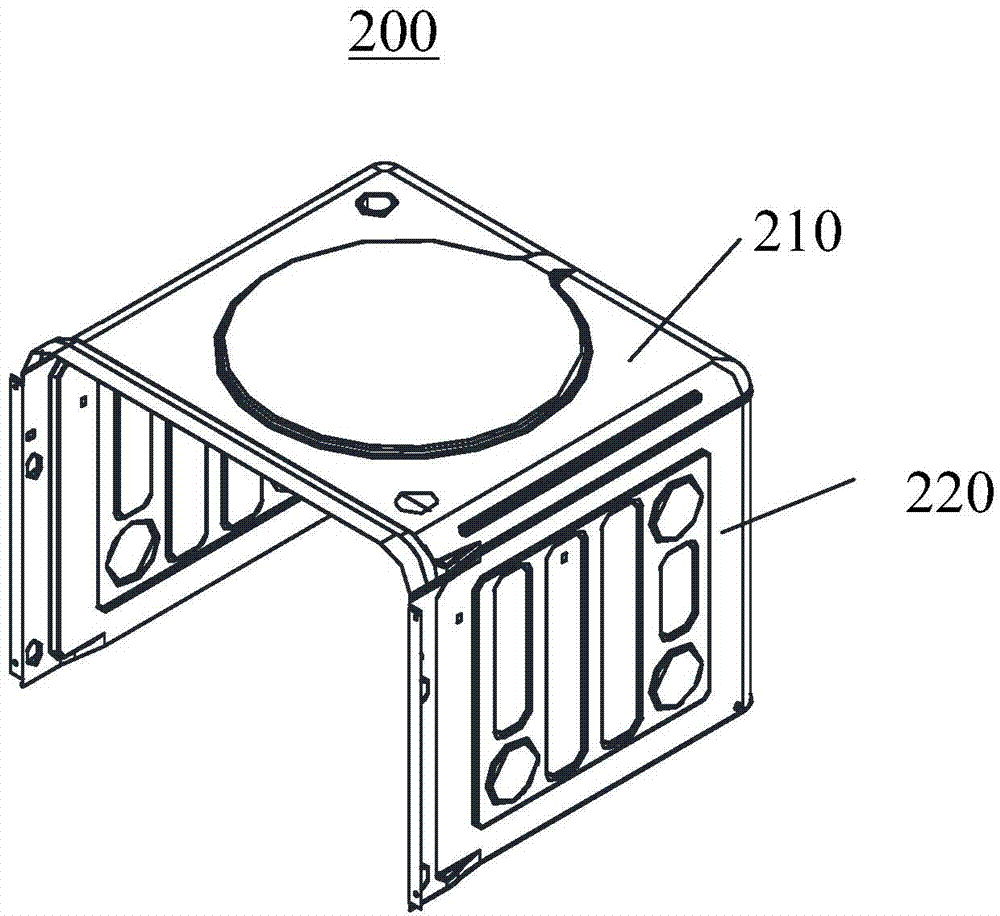

[0025] The present invention provides an undercutting process 100 of a dishwasher liner 200, the undercutting process 100 is used to engage the top plate 210 and the middle plate 220 of the dishwasher liner 200 (see figure 1 ), including the following steps:

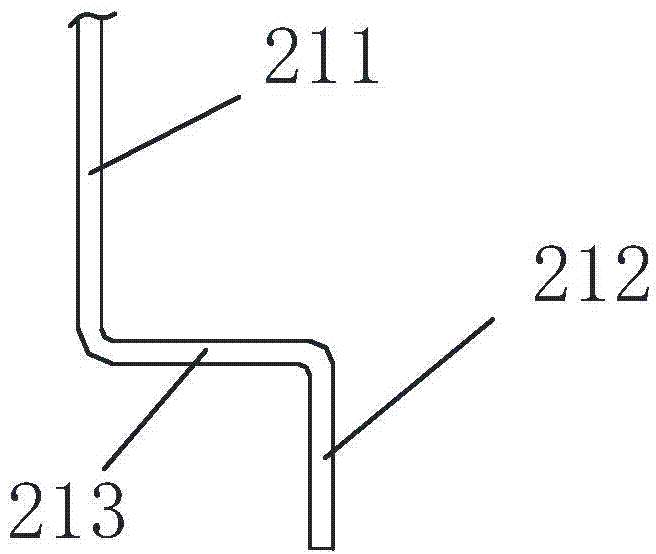

[0026] Step 101, preparing the top plate 210, see figure 2 The occlusal edge of the top plate 210 includes a vertically downward top plate base surface 211 connected to the main body of the top plate 210 on the inner side, a vertically arranged first right-angle bending surface 212 on the outer side, and a connecting surface located in the middle The top plate base surface 211 and the second right-angle bending surface 213 of the first right-angle bending surface 212 are arranged horizontally.

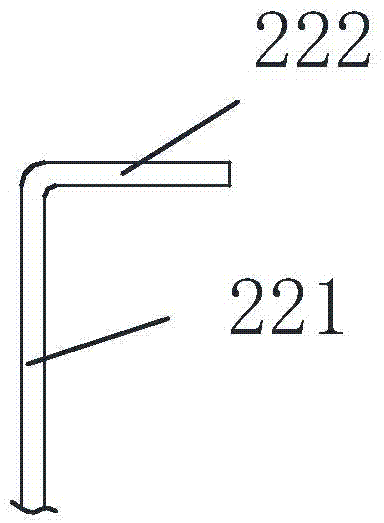

[0027] Prepare the middle plate 220, see image 3 The occlusal edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com