Automatic engaging device

A occlusal device and automatic technology, applied in the field of automatic occlusal devices, can solve problems such as laboriousness and low efficiency, and achieve the effect of improving work efficiency, slow solution speed, and good occlusal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present technology will be further described below through the embodiments in conjunction with the accompanying drawings.

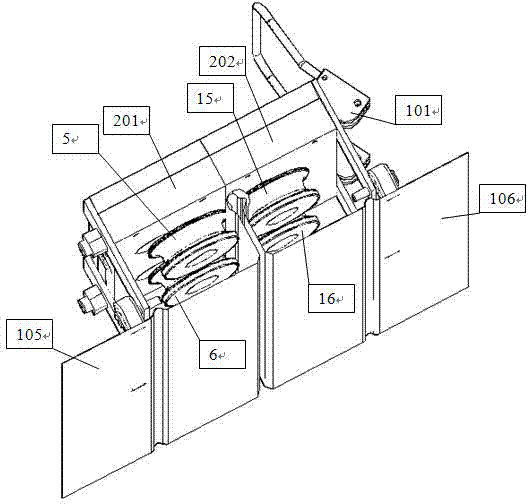

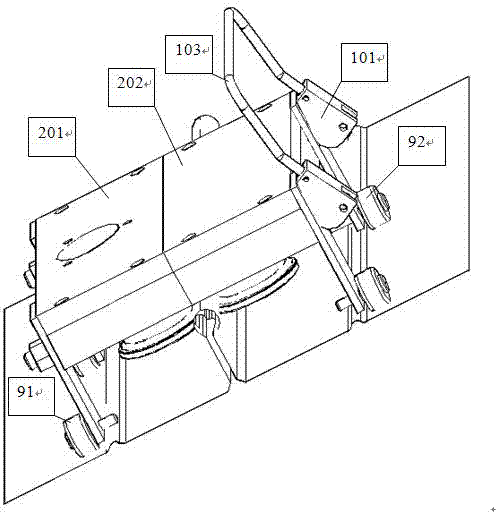

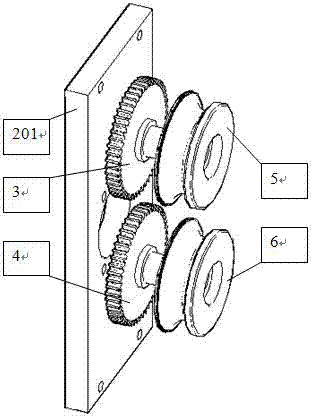

[0016] Such as Figure 1-4 In the shown automatic occlusal device, the frame includes a fixed frame 201 and a movable frame 202, and the fixed frame is provided with rollers 91 for supporting the fixed frame and driving the fixed frame to move. Rollers 92 for supporting the movable frame and driving the movable frame to move are provided. Two guide rods 100 are fixed on the fixed frame, and the axes of the guide rods are parallel to the axes of the rollers. The movable rack slides and is arranged on the guide rod. The cam (locking device) 101 is rotated and arranged at the end of the guide rod. When the cam is rotated, the cam edge can push the movable frame to move along the guide rod to contact the fixed frame, and this state can be locked. A handle 103 is fixed on the locking cam 101 to facilitate the rotation of the cam.

[0017] The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com