Patents

Literature

36results about How to "Good bite performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

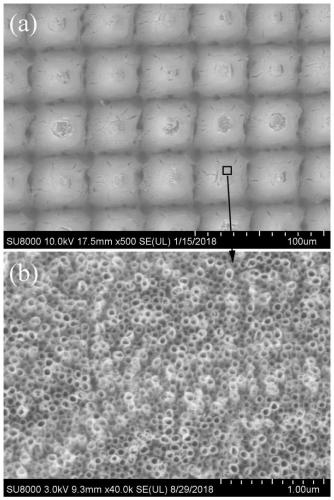

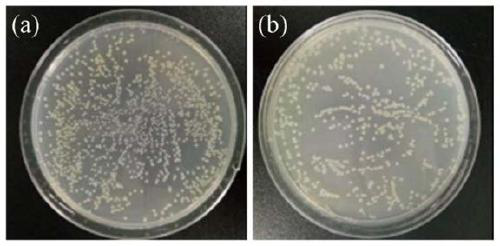

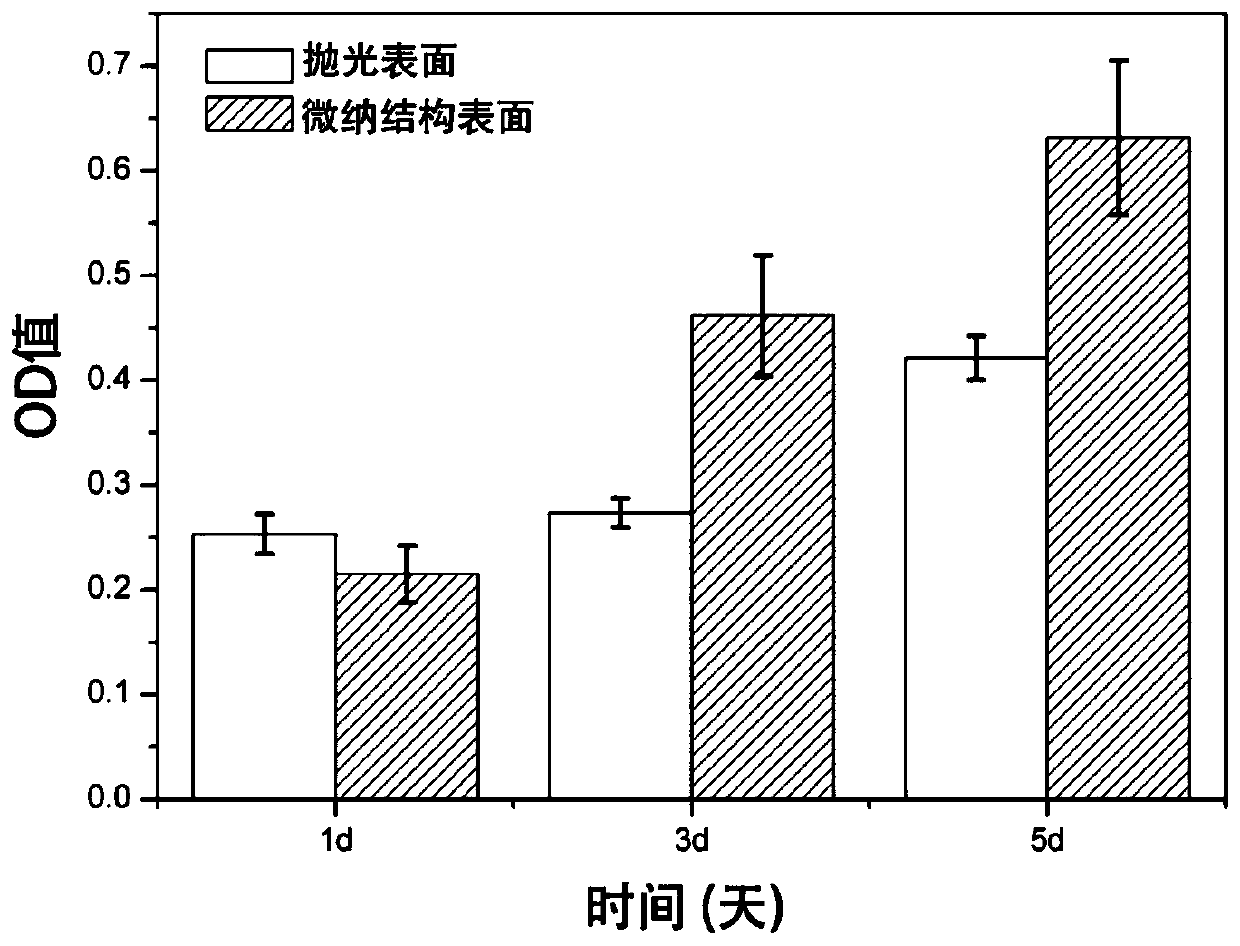

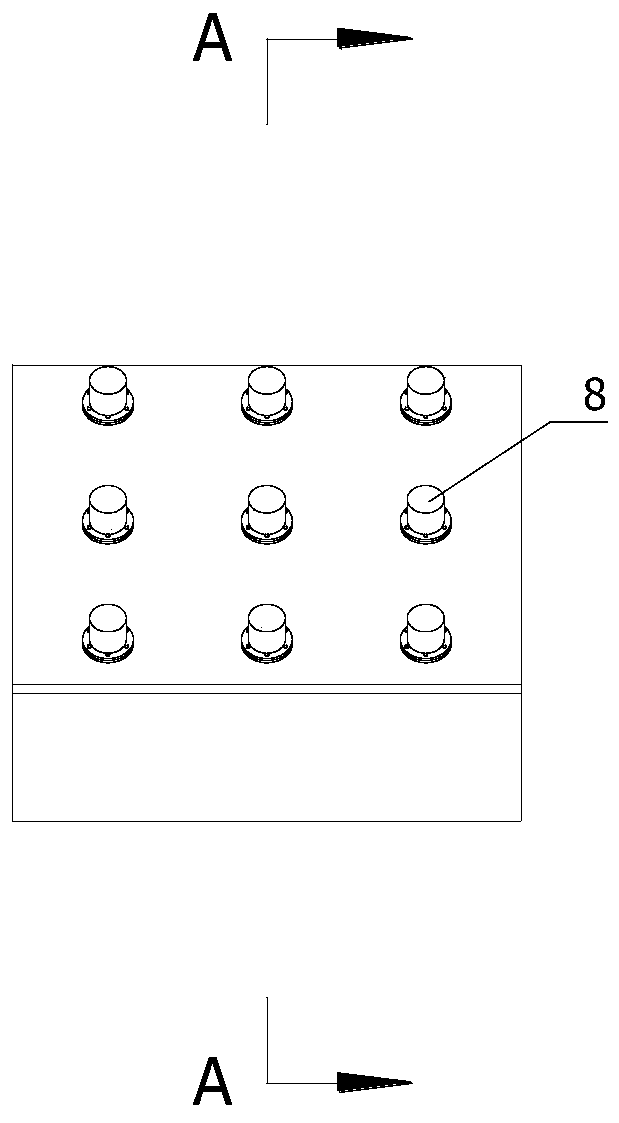

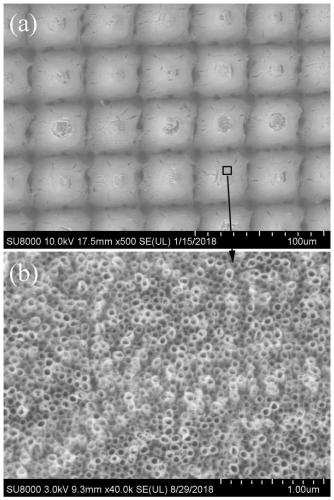

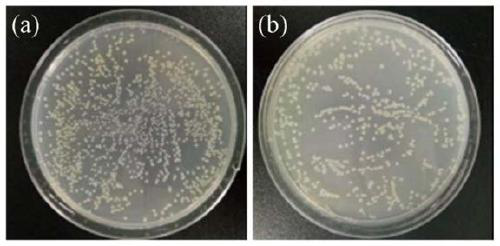

Titanium and titanium alloy surface micro-nano structure modification method

ActiveCN109848546AImprove antibacterial abilityImprove osseointegrationSurface reaction electrolytic coatingLaser beam welding apparatusAnodic oxidationPlastic surgery

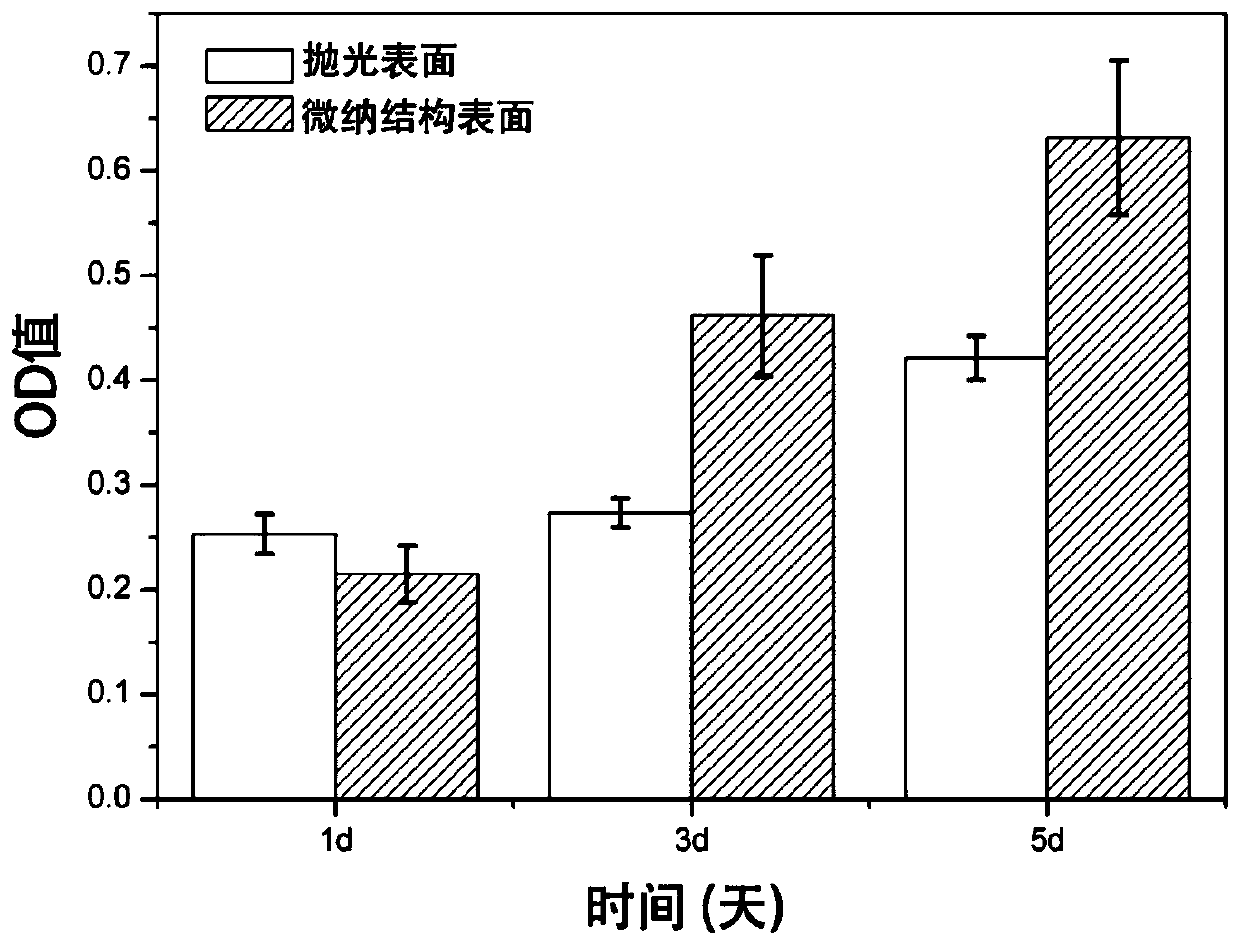

Metal titanium and titanium alloy are widely applied to implants of oral prosthodontics, orthopedic surgery and plastic surgery at present, but have the problems of having poor osseous integration capability and being prone to have bacterial infection after implantation. The invention discloses a titanium and titanium alloy surface micro-nano structure modification method, and aims to improve theosseous integration capability and antibacterial capability of titanium and titanium alloy surfaces. The micro-nano structure modification method is characterized in that a femtosecond laser processing technology is adopted, the polished titanium alloy surface is ablated to form a micropost periodic structure with the spacing and the depth not greater than 200 microns, nanotubes with the diameterssmaller than 200 nm are prepared on the micropost periodic structure in an anodic oxidation mode after further acid pickling, and then annealing heat treatment is carried out to obtain a final sample. According to the method, the surface with a micro-nano structure can be prepared on the titanium and titanium alloy surfaces, and the titanium and the titanium alloy with such surfaces have good biocompatibility and antibacterial capability.

Owner:UNIV OF SCI & TECH BEIJING

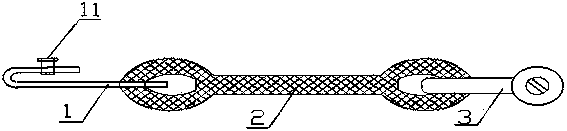

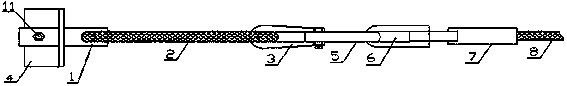

Special tool for dual protection of wire of strain tower

InactiveCN103795005AIncrease contact areaGood bite performanceApparatus for overhead lines/cablesYarnClosed loop

The invention relates to a special tool for dual protection of a wire of a strain tower. The special tool comprises a U-shaped fixture connected with a cross arm, wherein a bolt used for locking the cross arm is installed on a flange on one side of the U-shaped fixture, an insulating rope is connected to a flange on the other side of the U-shaped fixture, and a U-shaped retaining ring is connected to the other end of the insulating rope. The U-shaped fixture is formed by finish machining high-quality special steel. The insulating rope is made of insulating nylon yarn. The head portion and the tail portion of the insulating rope respectively form a closed loop, and the two closed loops are connected with the U-shaped retaining ring and the U-shaped fixture respectively. The special tool aims to overcome the defects that when a wire clamping device is used for dual protection of an original wire, a closed loop is not formed and the wire falls off easily when the wire clamping device is in the loose state, and improve the safety of people, equipment and lines when line repair personnel conduct replacement of a strain insulator string and other operation on the power transmission line strain tower with a 35 kV voltage or a higher voltage.

Owner:STATE GRID CORP OF CHINA +3

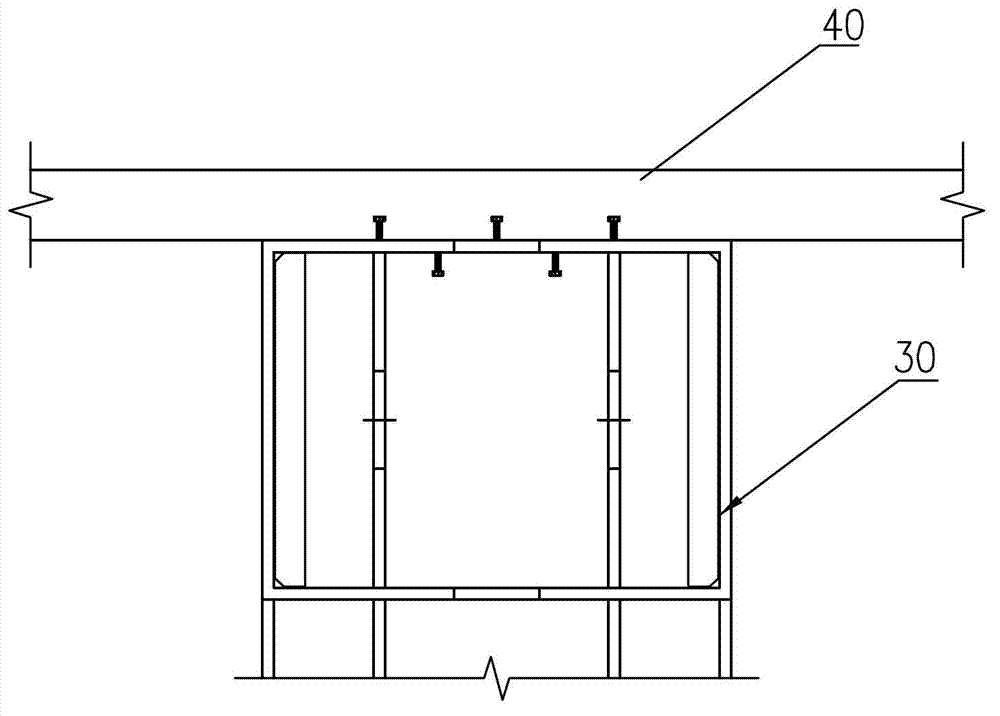

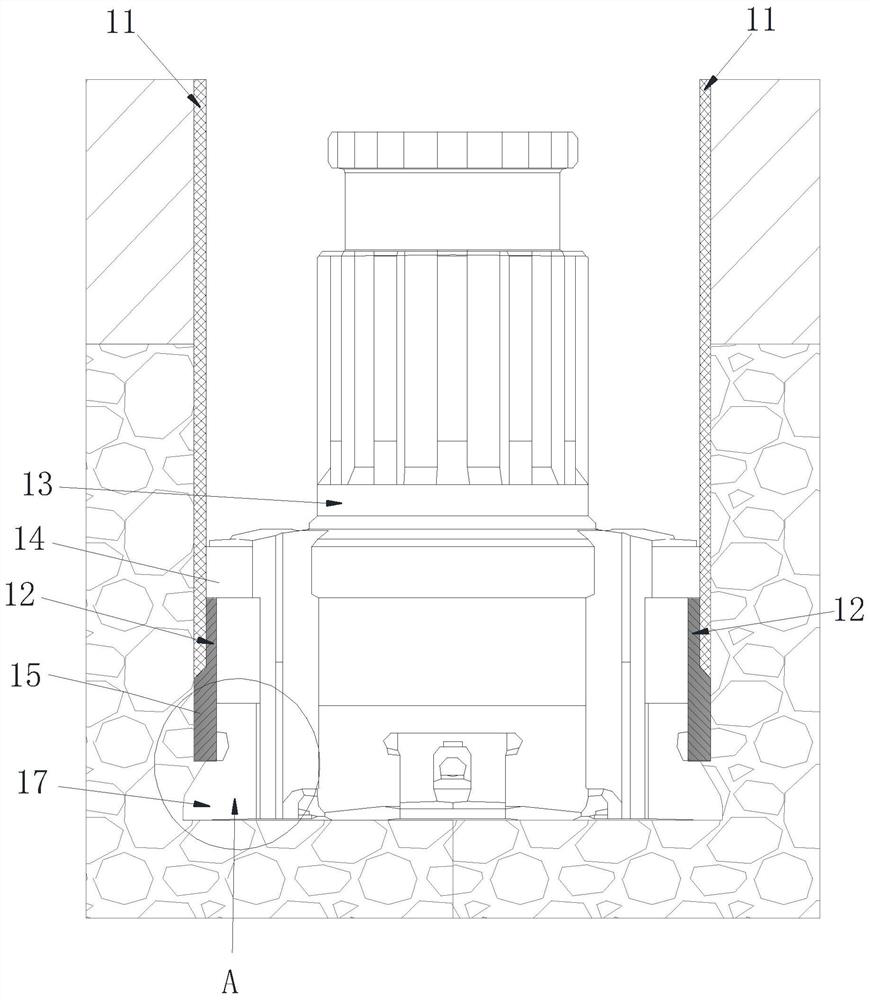

Occlusive pile construction method

InactiveCN103967002AFast crossingReduce processing difficultyBulkheads/pilesReinforced concreteRebar

An occlusive pipe construction method comprises the following steps: constructing reinforced concrete piles in advance; constructing full-plain concrete piles by using a manual construction mode among piles after the reinforced concrete piles are solidified to a certain strength, wherein the full-plain concrete piles and the reinforced concrete piles are mutually occluded. According to the method, the reinforced concrete piles are constructed in advance, then the full-plain concrete piles are constructed manually without cutting the bodies of the reinforced concrete piles, and the constructing processes of the reinforced concrete piles and the full-plain concrete piles are relatively independent of each other and do not interact; in addition, strict requirements on time can be avoided as the construction of the reinforced concrete piles can be carried out without judging the forming states of the full-plain concrete piles first; the technology difficulty is greatly reduced, and the construction of manual hole shaping is free of strict shape requirements; construction manners can be flexibly changed when a rocky stratum is encountered during construction, the rocky stratum can be rapidly penetrated, the hole shaping quality can be controlled conveniently, and the occlusive effect is better than that of the traditional construction manner.

Owner:SHENZHEN GEOTECHN INVESTIGATION & SURVEYING INST

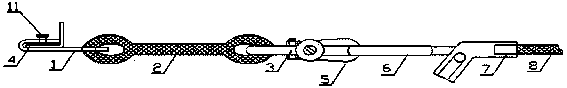

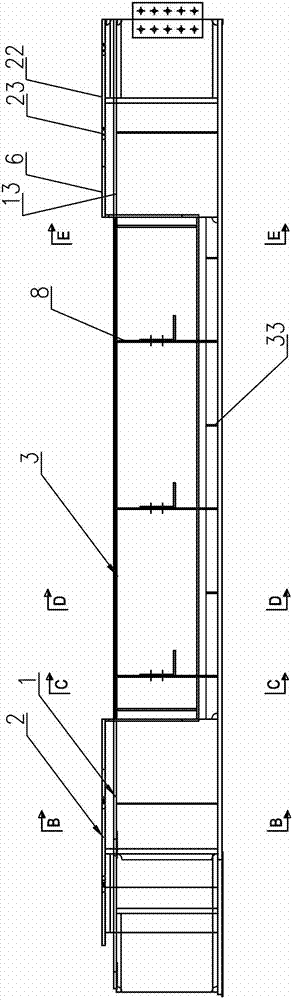

Steel box component and steel box-concrete combined U-shaped girder composed of same

ActiveCN103046462AImprove bearing capacityDense perfusionLoad-supporting elementsBridge structural detailsMaterials scienceSteel tube

The invention discloses a steel box component. The component is mainly composed of a U-shaped steel piece, n-shaped steel pieces and a steel tube which is arranged at a mid-span position of the U-shaped steel piece. The n-shaped steel pieces are arranged in U-shaped space at two ends of the U-shaped steel piece, the length directions of the n-shaped steel pieces are consistent with the longitudinal direction of the U-shaped steel piece, the lower ends of inner side plates of the n-shaped steel pieces are fixed on a bottom plate of the U-shaped steel piece and surround with the bottom plate of the U-shaped steel piece to form hollow pouring chambers with inner and outer ports, and pouring holes are opened on top plates of the n-shaped steel pieces. Vertical sealing plates are arranged at inner end openings of the pouring chambers, the steel tube is arranged in a suspension mode, steel openings at the two ends of the steel tube are connected onto the sealing plates respectively and blocked by the sealing plates; and gaps are arranged between the U-shaped steel piece and the n-shaped steel pieces and between the U-shaped steel piece and the steel tube. The invention further discloses a steel box-concrete combined U-shaped girder composed of the steel box component. By means of the steel box component and the steel box-concrete combined U-shaped girder composed of the same, the construction cost is saved, the construction period is shortened, the bearing capacity and the bending resistance at the girder support position are improved, and the reinforcement area and about 25% of dead-weight are reduced.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

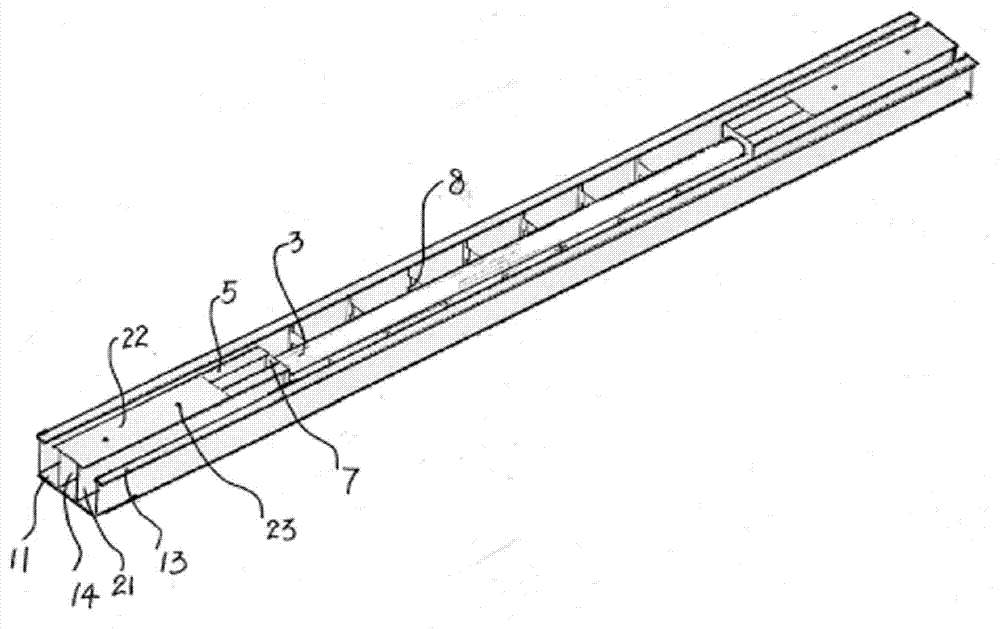

Combined paper cutter tool

InactiveCN102049794AGood bite performanceSimple structureMetal working apparatusProcessing accuracyKnife blades

The invention discloses a combined paper cutter tool characterized by comprising an upper cutter blade and a lower cutter blade which are respectively arranged on an upper cutter shaft and a lower cutter shaft, wherein the upper cutter blade is arranged on a cutter rest; a spring is arranged between the upper cutter blade and the cutter rest; the upper cutter blade is provided with a retainer ring; and the cutter rest, the spring and the upper cutter blade are limited and fixedly connected by the retainer ring. The invention has the advantages of simple structure, convenience of installation and removal, and high processing accuracy.

Owner:THE NORTHWEST MACHINE

Bright aluminum foil MYLAR conductive tape for electromagnetic wave shielding and preparation method

InactiveCN104789147AEasy to prepareThe preparation method is easy to realizeFilm/foil adhesivesCoatingsElectric propertiesSubstrate surface

The invention discloses a bright aluminum foil MYLAR conductive tape for electromagnetic wave shielding and a preparation method thereof. Bright aluminum foil MYLAR is processed and the substrate surface of a base material is coated with a functional coating; the preparation method is simple and easy to realize; the bright aluminum foil MYLAR conductive tape used for electromagnetic wave shielding and having characteristics of excellent flexing resistance, good occlusion property and superior compound property and conductivity is obtained; the conductive tape is very outstanding in electric property and physical property, thereby having a good market application prospect.

Owner:江苏伊诺尔新材料科技有限公司

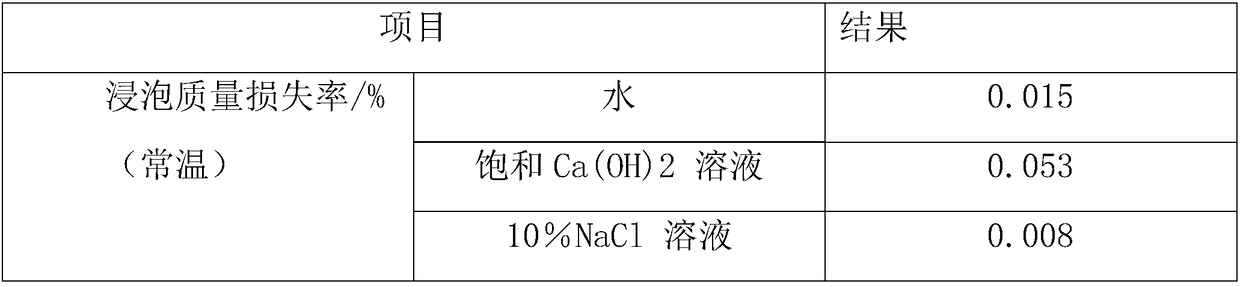

Expansion joint sealing material for waterproof layer of ballastless railway track subgrade surface

InactiveCN109401638AImprove water stabilityGood chemical resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyToluene diisocyanate

The invention discloses an expansion joint sealing material for a waterproof layer of a ballastless railway track subgrade surface. The expansion joint sealing material comprises raw materials as follows: epoxy resin, butyl cellosolve, n-butyl alcohol, methylacrylic acid, toluene diisocyanate, polyether diols, polyether triols, polyphenyl polyisocyanate, polydimethylsilane, 3,3'-dichloro-4,4'-diaminodiphenylmethane, dibutyltin dilaurate, tin maleate, modified packing and a tackifier. The expansion joint sealing material has good soaking stability, chemical stability, fatigue resistance and temperature stability, and can keep stable performance and good sealing effect in severe environments such as high temperature in summer, low temperature in winter, ozone and the like; the expansion joint sealing material has good adhesion and engagement effects with an expansion joint base material and has good displacement deformation resistance and anti-strip strength.

Owner:CHONGQING JIAOTONG UNIVERSITY

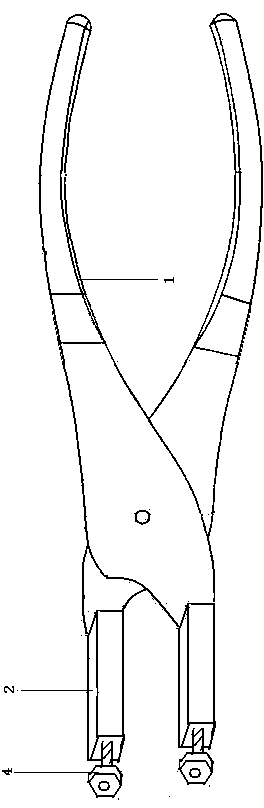

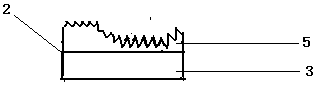

Slip-joint pliers with replaceable teeth

Owner:张家港市星星工具制造有限公司

Fabric comfortable to wear and dying process for fabric

InactiveCN105696376AGood bite performancePromote environmental protectionWeft knittingCarbon fibresAdhesiveEngineering

The invention relates to fabric comfortable to wear and a dying process for the fabric. The fabric is characterized by comprising a first fabric layer, a second fabric layer and a third fabric layer, wherein the second fabric layer is located between the first fabric layer and the third fabric layer, and bulges with sections in an equilateral triangle shape are arranged on two sides of the second fabric layer; a first groove with a section in the equilateral triangle shape is formed in the side, facing the second fabric layer, of the first fabric layer; a second groove with a section in the equilateral triangle shape is formed in the side, facing the second fabric layer, of the third fabric layer; the bulges of the second fabric layer are matched with the first groove of the first fabric layer and the second groove of the third fabric layer; lower-layer pores are formed in the first fabric layer; upper-layer pores are formed in the third fabric layer. According to the fabric comfortable to wear and the dying process for the fabric, the fabric has good mutual embedded performance and is highly environment-friendly, soft in texture and comfortable to wear, and no chemical adhesive is used.

Owner:JIANGYIN BEIYE TEXTILE

Anti-biting pet toy material and preparation method thereof

The invention relates to an anti-biting pet toy material and a preparation method thereof. The material comprises the following components in parts by weight: 70-85 parts of thermoplastic elastomer, 2-20 parts of a scent attractant, 5-15 parts of a biocompatible agent, 1-10 parts of an interface modifier, 0.5-6 parts of a nano modifier and 0.3-1 part of other auxiliary agents. The anti-biting pettoy material has the characteristics that the material resists biting of a pet, smells good, is non-toxic, and is high in safety, and the product does not shrink or deform; and meanwhile, with the aidof the synergistic effect of the nano modifying agent and the biocompatible agent, mixed dispersion of the components of the material is improved, the interface binding strength of the components isenhanced effectively, a toy which is uniform in inside and outside, has high tearing strength, can be bit by the pet, and can give out smell attracting the pet, the effect is stable, and migration hidden dangers are avoided.

Owner:NANJING JULONG SCI&TECH CO LTD

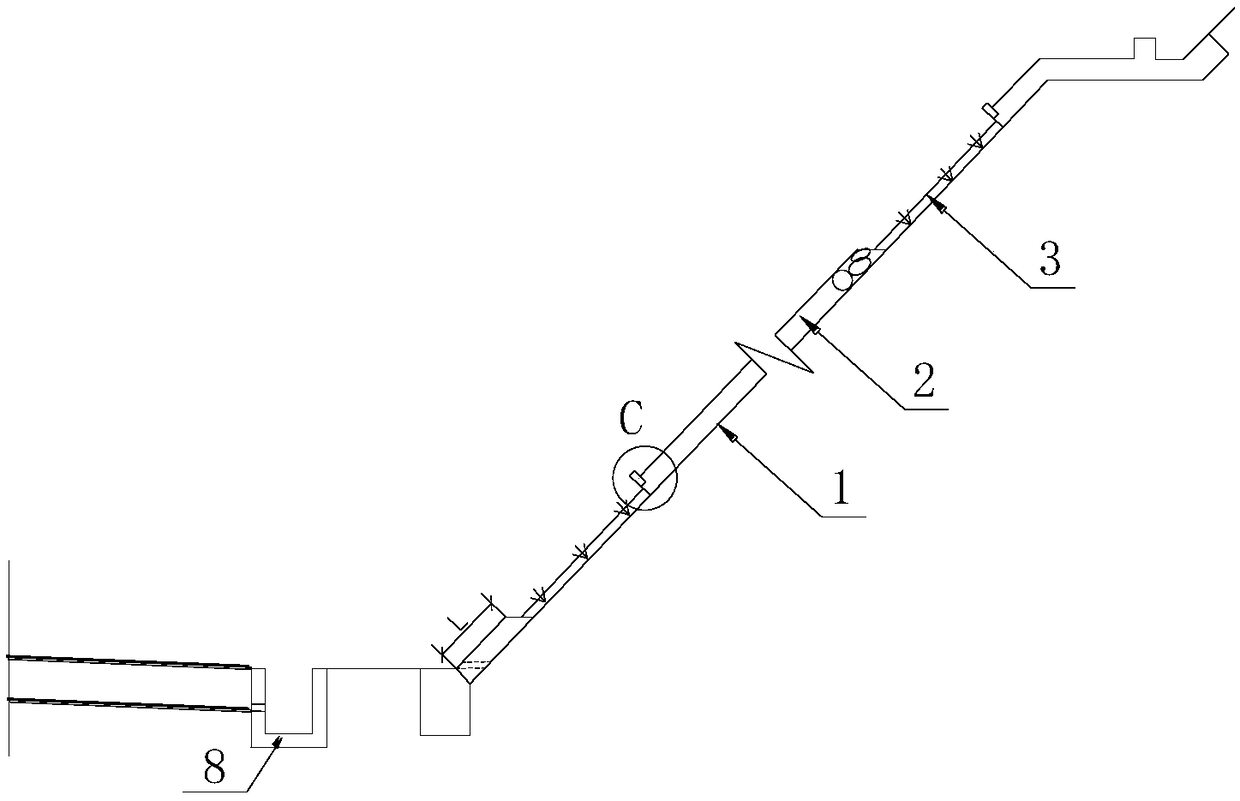

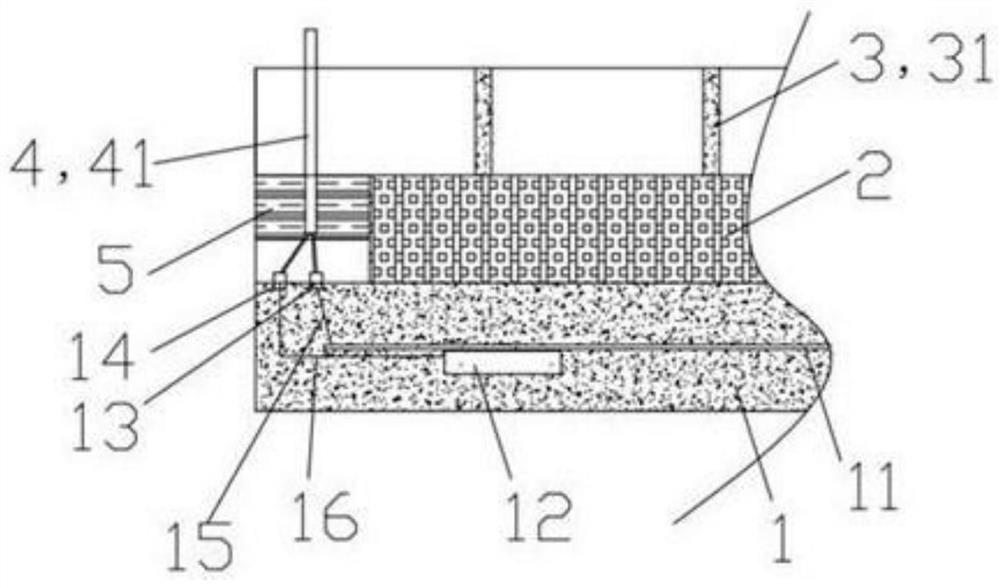

Anti-landslide device for deep foundation pit and using method of anti-landslide device

ActiveCN111576434AEasy to installLess prone to landslidesExcavationsBulkheads/pilesLandslideVibration absorption

The invention relates to the technical field of landslide construction, in particular to an anti-landslide device for a deep foundation pit and a using method of the anti-landslide device. The anti-landslide device is applied to fix a slope, the slope comprises an inclined plane, threaded deep holes are vertically formed in the inclined plane at equal intervals, and a channel is formed in the bottom end of the slope. The anti-landslide device comprises a base, a vibration absorption fastener and a covering plate, wherein the base is coaxially arranged in the channel; the vibration absorption fastener comprises fixing heads, fastening steel rods, concrete threaded columns, yielding buffer parts and fixing abutting parts, the fixing heads are arranged in the threaded deep holes, and in the working state, the concrete threaded columns are formed by pouring concrete into the threaded deep holes; the fixing abutting parts are coaxially arranged at outlets of the threaded deep holes, and theouter ends of the concrete threaded columns abut against the other abutting ends of the fixing abutting parts; and the covering plate is arranged on the slope face, the fastening steel rods penetratethrough the covering plate to be elastically connected with the covering plate through the fixing abutting parts in a fastened mode, and the bottom end of the covering plate abuts against the top endof the base. The device is stable in structure, sliding of landslide soil can be effectively prevented, and vibration force can be eliminated.

Owner:上海九城建设科技集团有限公司

Production method of nanocomposite surface piston ring

The invention discloses a production method of a nanocomposite surface piston ring. The method comprises the following steps: performing degreasing to a piston ring blank made of cast iron substrate before planting, cleaning the surface of the blank, performing sand blasting to the blank, adding the piston blank into electroplate liquid I to be subjected to reverse etching, adding the blank subjected to reverse etching into electroplate liquid II to be subjected to electrolytic deposition till the thickness of nano-coating formed on the outside circle surface of the blank is 0.06 to 0.12mm, and adding a semi-finished piston ring into a grinding cylinder to grind the semi-finished piston ring till the thickness of the nano-coating is 0.04 to 0.10mm to form a finished piston ring. According to the method, a nano wild phase with high wearing resistance, corrosion resistance, good tenacity and self-lubrication to replace micron-sized traditional solid particles to modify the surface of the piston ring, an electric pulse technology is adopted to realize the nanocrystallization of Ni-P crystal grain on the surface of the piston ring, and nano-coating with the nano-phase embedded uniformly further improves the tenacity and the wearing resistance of the surface of the piston ring.

Owner:江苏仪征金派内燃机配件有限公司

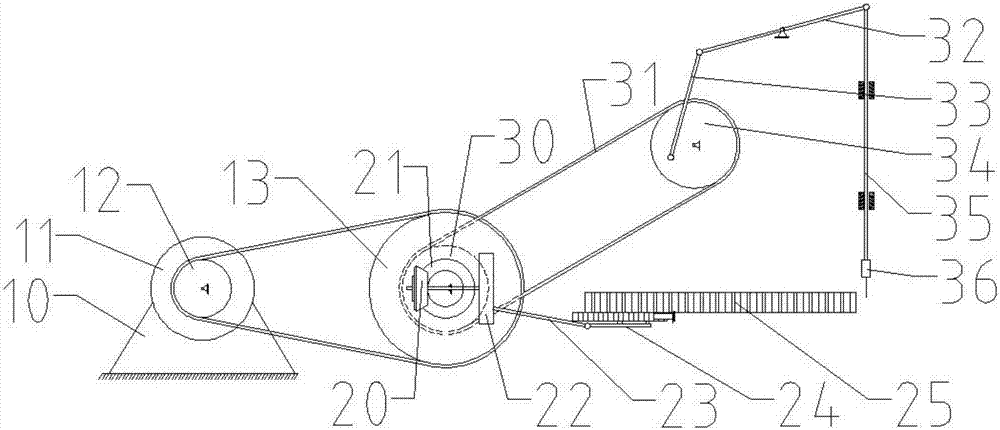

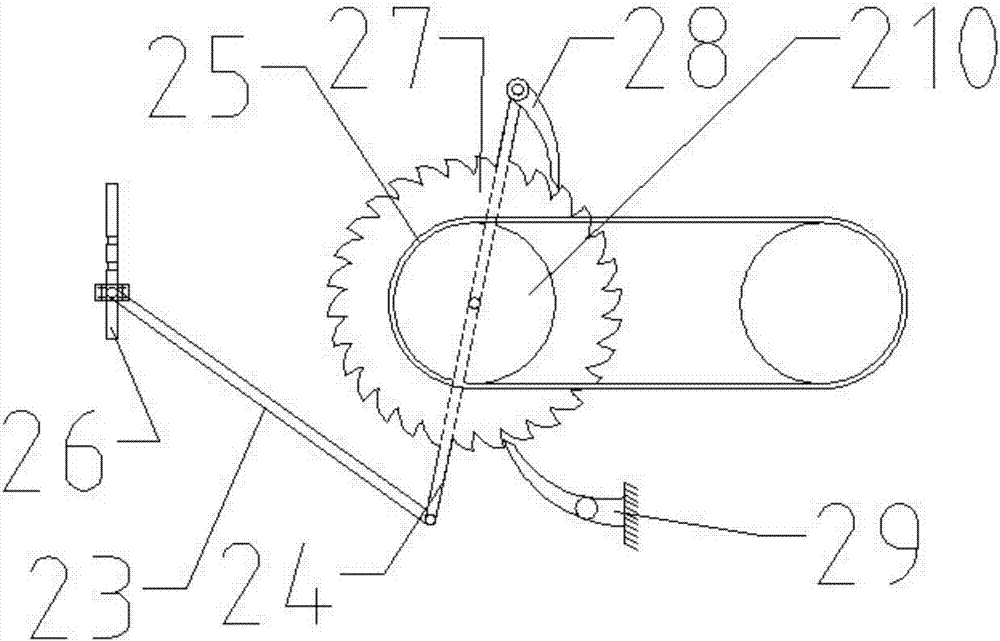

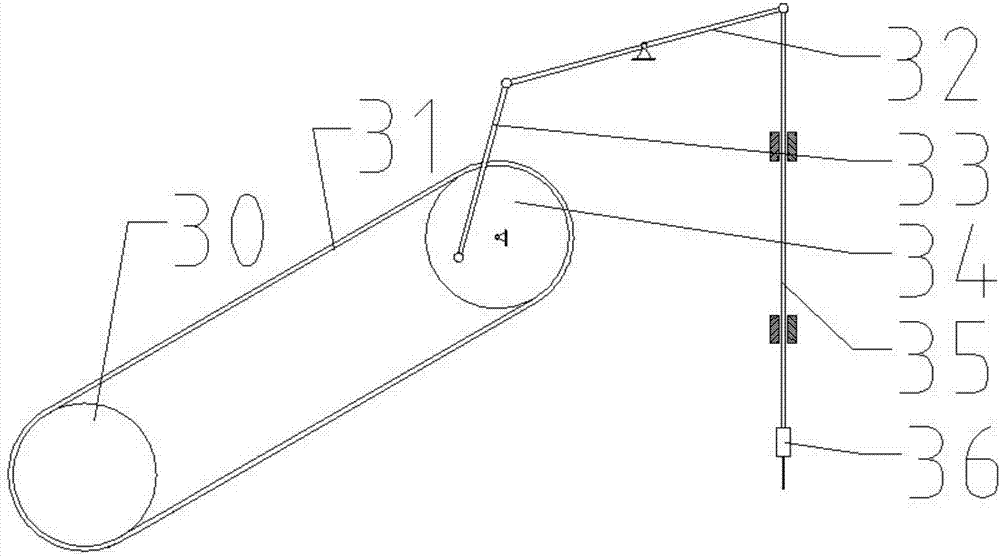

Rice seedling transplanter

InactiveCN107211634AGood bite performancePrevent slippingTransplantingAgricultural scienceRisk stroke

The invention relates to a rice seedling transplanter. The rice seedling transplanter comprises a traveling mechanism, a driving mechanism, a separate planting mechanism and a seedling conveying mechanism, wherein the traveling mechanism comprises a rubber caterpillar track, an anti-sinking plate and a chassis and is applicable to different pavements, the rice seedling transplanter is prevented from being get stuck in a rice seedling bed, and the steady advancing of the rice seedling transplanter in the seedling planting process is ensured; the driving mechanism adopts belt driving and has the advantages of steadiness in driving and low cost; the separate planting mechanism adopts a chain wheel to drive a group of crank and slide rod mechanism to move, a slide rod is provided with a seedling separating fork for realizing a seedling separation action, not only can quick-return characteristics be achieved, but also the seedling separating fork is enabled to have almost constant-speed movement in a working stroke, the seedling separating efficiency is high, and the empty rate is relatively low; and the seedling conveying mechanism is formed by connecting a linkage mechanism, a ratchet wheel mechanism and a group of rubber crawler-track conveyor belt wheel, the length of a crank can be adjusted to control a rotating angle of a ratchet wheel so as to control a feeding amount of the crawler belt wheel, and the rice seedling transplanter has the characteristics of high controllability, stability in feeding, applicability to seedlings with different soil amounts and the like.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

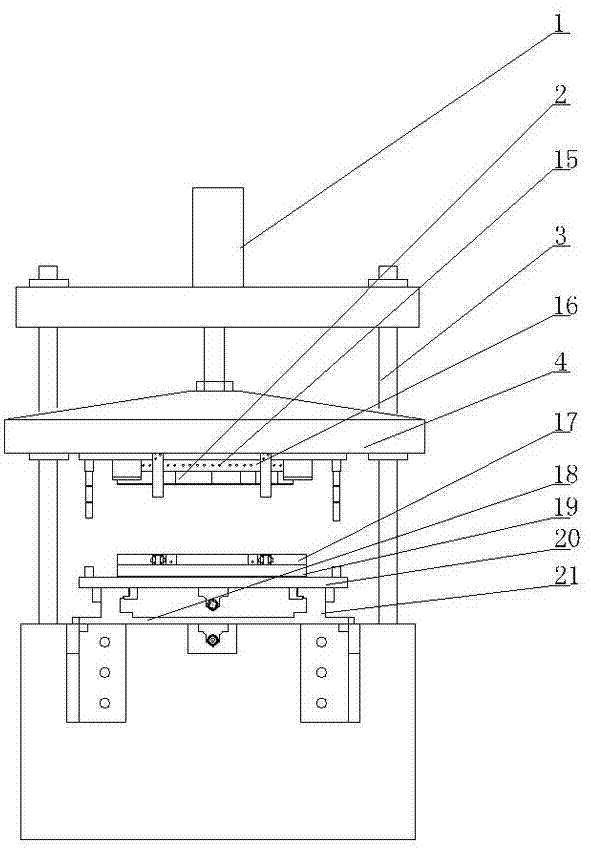

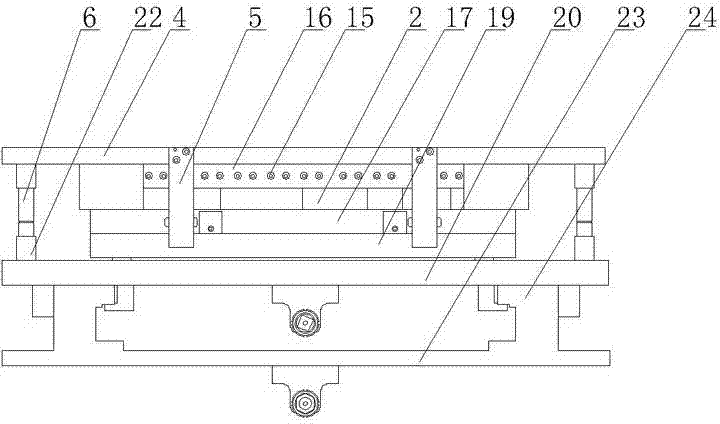

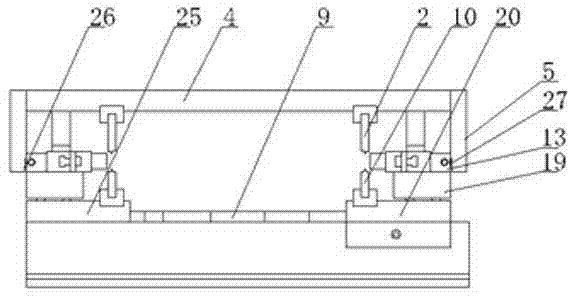

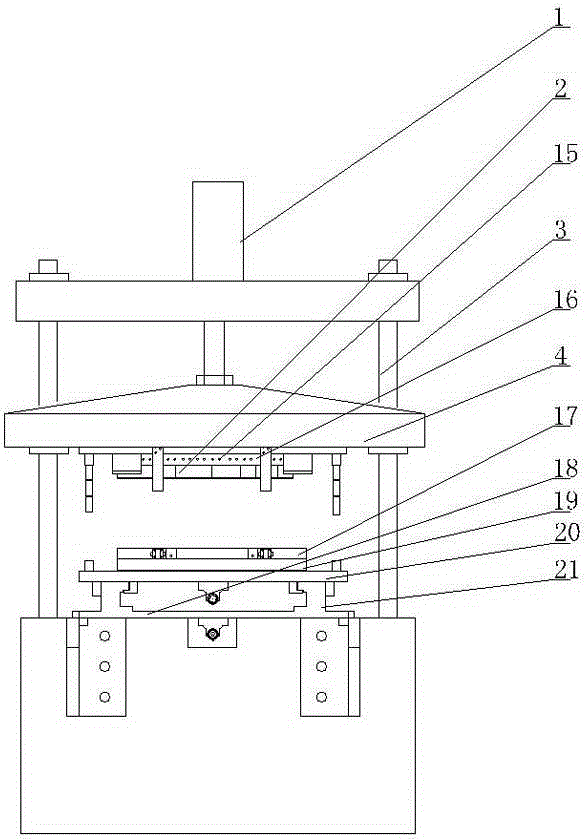

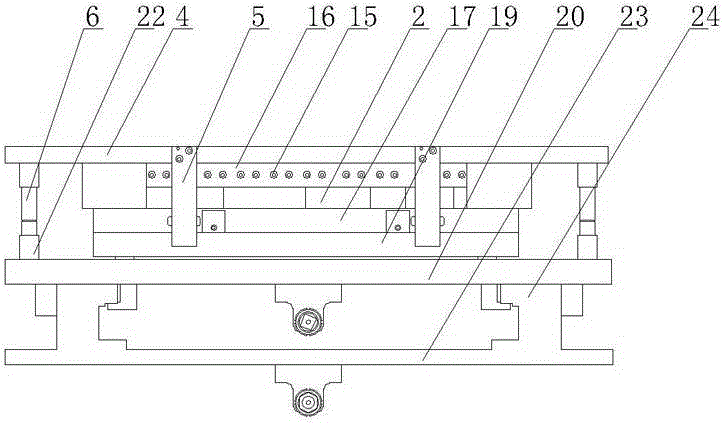

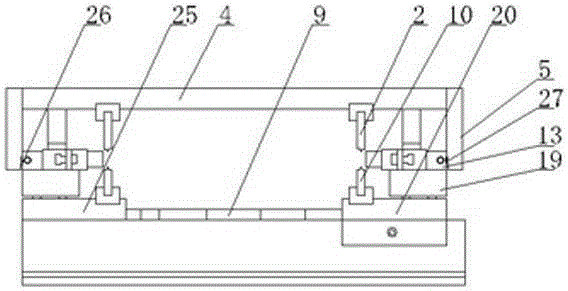

Side undercutting mechanism for side plate of automobile radiator

InactiveCN104325041AGood bite performanceImprove general performanceHeat exchange apparatusRear quarterBlock match

The invention discloses a side undercutting mechanism for a side plate of an automobile radiator. The side undercutting mechanism comprises a frame, an upper template, a lower template and a bedplate, wherein the upper template is connected with a piston rod of a first hydraulic oil cylinder; the lower template is arranged on the bedplate; the bedplate is movably arranged on the frame. The side undercutting mechanism is characterized in that an upper undercutting knife and a side push block are arranged on the upper template; the side push block is arranged on one side of the upper undercutting knife; the inner side of the end part of the side push block is provided with an inclined plane; a lower undercutting knife and a side propping plate are arranged on the lower template; the side propping plate is arranged on the lower template in a sliding way; a top block matched with the inclined plane is arranged on the side propping plate; the lower undercutting knife which corresponds to the upper undercutting knife is fixed on the lower template; the side push block is connected with a depression bar. According to the side undercutting mechanism, the side plate on the radiator can be meshed on the radiator, so that a good undercutting effect, high production efficiency and high generality are achieved; moreover, the side undercutting mechanism is convenient, safe and reliable to operate.

Owner:RUIAN XINHAI AUTO PARTS

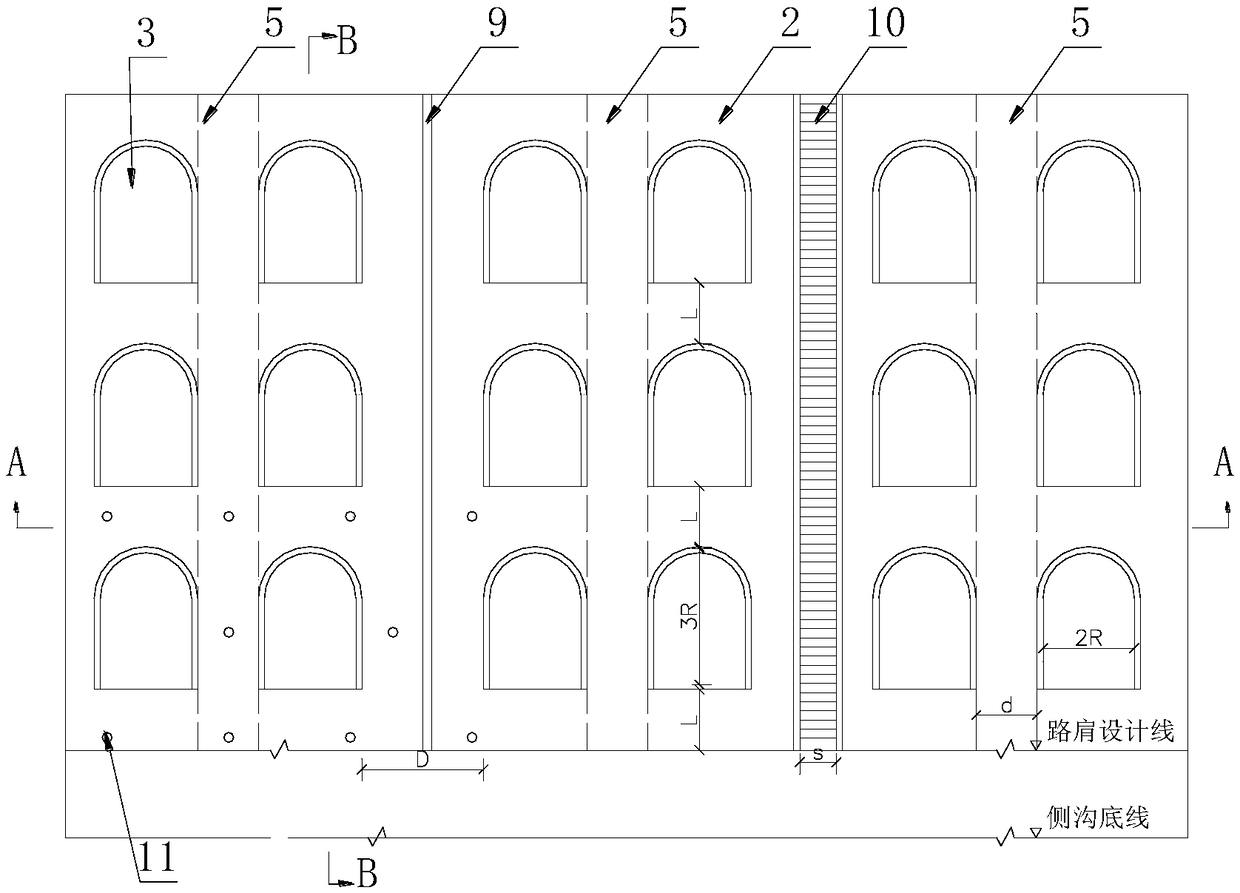

Slope protection structure for broken rock cutting side slope

The invention discloses a slope protection structure for a broken rock cutting side slope. The slope protection structure comprises an overall hole window type slope protection wall located on a slope. Hole windows are transversely and longitudinally formed in the hole window type slope protection wall at intervals. The slope protection structure is characterized in that longitudinal strip-shapedditches are longitudinally downwards indented in the slope and transversely arranged at intervals, a plurality of longitudinal strip-shaped bases are arranged on the bottom face of the hole window type slope protection wall, and each longitudinal strip-shaped base is correspondingly embedded in the corresponding longitudinal strip-shaped ditch. By organically combining the longitudinal strip-shaped bases and the hole window type slope protection wall, in the presence of the longitudinal strip-shaped bases, the meshing force of the protection slope and the slope is greatly improved; by formingan organic whole with the hole window type slope protection wall and the broken rock cutting side slope, the defect that an existing hole window type slope protection wall is prone to creeping along aslope and is prone to emptying and cracking damage is overcome.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A kind of surface micro-nano structure modification method of titanium and titanium alloy

ActiveCN109848546BEasy to integrateReduce usageSurface reaction electrolytic coatingLaser beam welding apparatusOrthopedics surgeryOsseointegration

Metal titanium and titanium alloy are widely applied to implants of oral prosthodontics, orthopedic surgery and plastic surgery at present, but have the problems of having poor osseous integration capability and being prone to have bacterial infection after implantation. The invention discloses a titanium and titanium alloy surface micro-nano structure modification method, and aims to improve theosseous integration capability and antibacterial capability of titanium and titanium alloy surfaces. The micro-nano structure modification method is characterized in that a femtosecond laser processing technology is adopted, the polished titanium alloy surface is ablated to form a micropost periodic structure with the spacing and the depth not greater than 200 microns, nanotubes with the diameterssmaller than 200 nm are prepared on the micropost periodic structure in an anodic oxidation mode after further acid pickling, and then annealing heat treatment is carried out to obtain a final sample. According to the method, the surface with a micro-nano structure can be prepared on the titanium and titanium alloy surfaces, and the titanium and the titanium alloy with such surfaces have good biocompatibility and antibacterial capability.

Owner:UNIV OF SCI & TECH BEIJING

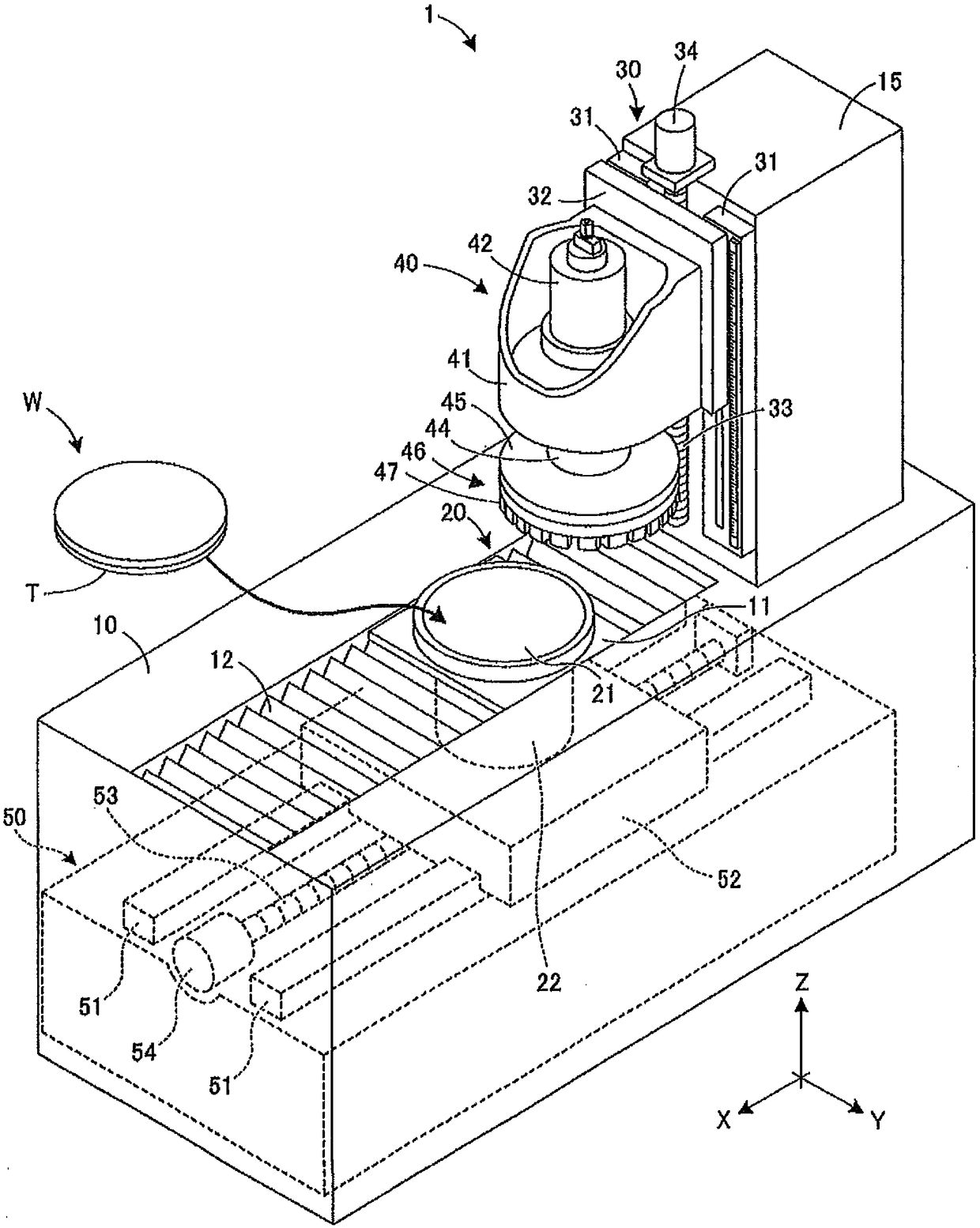

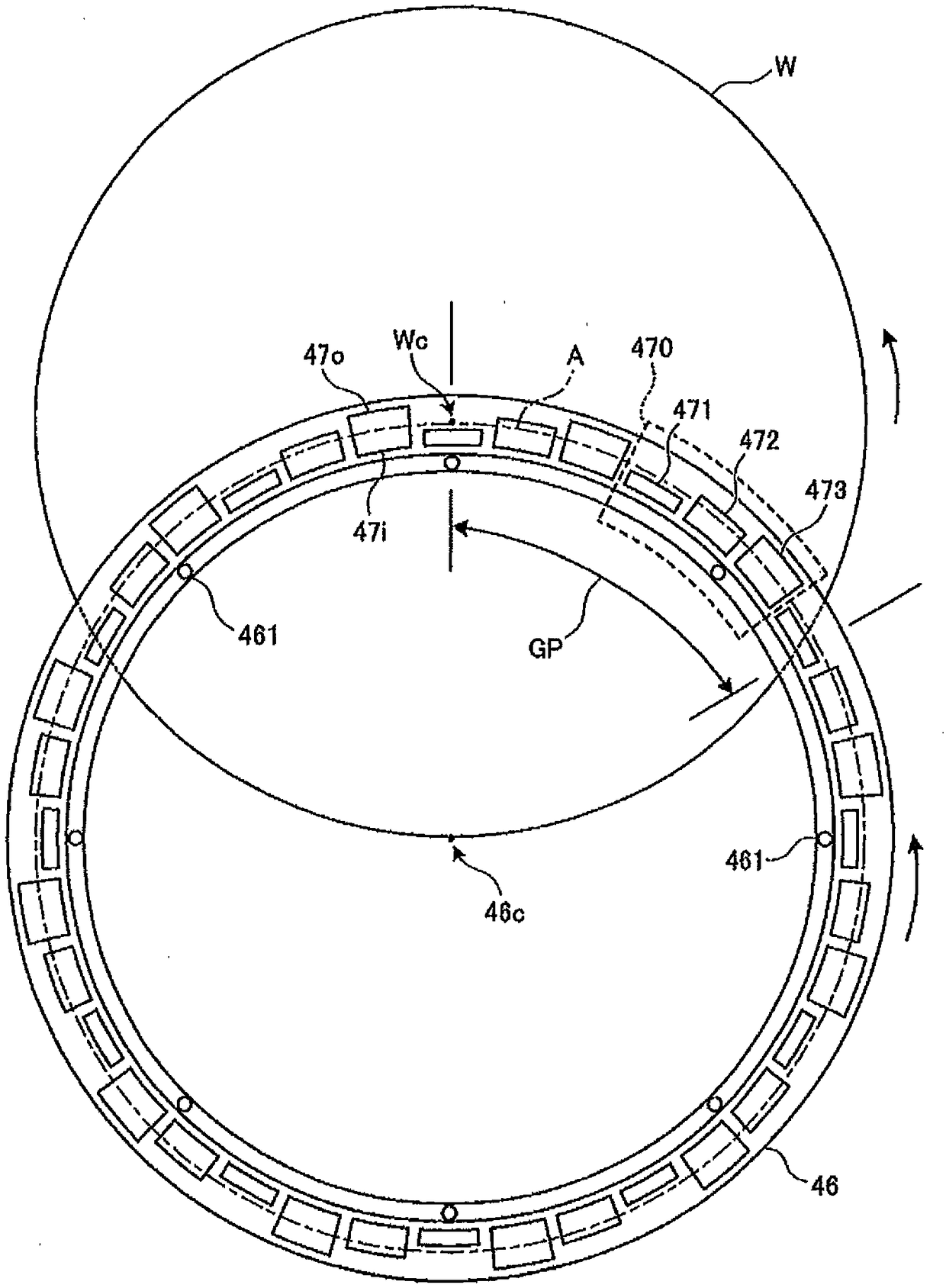

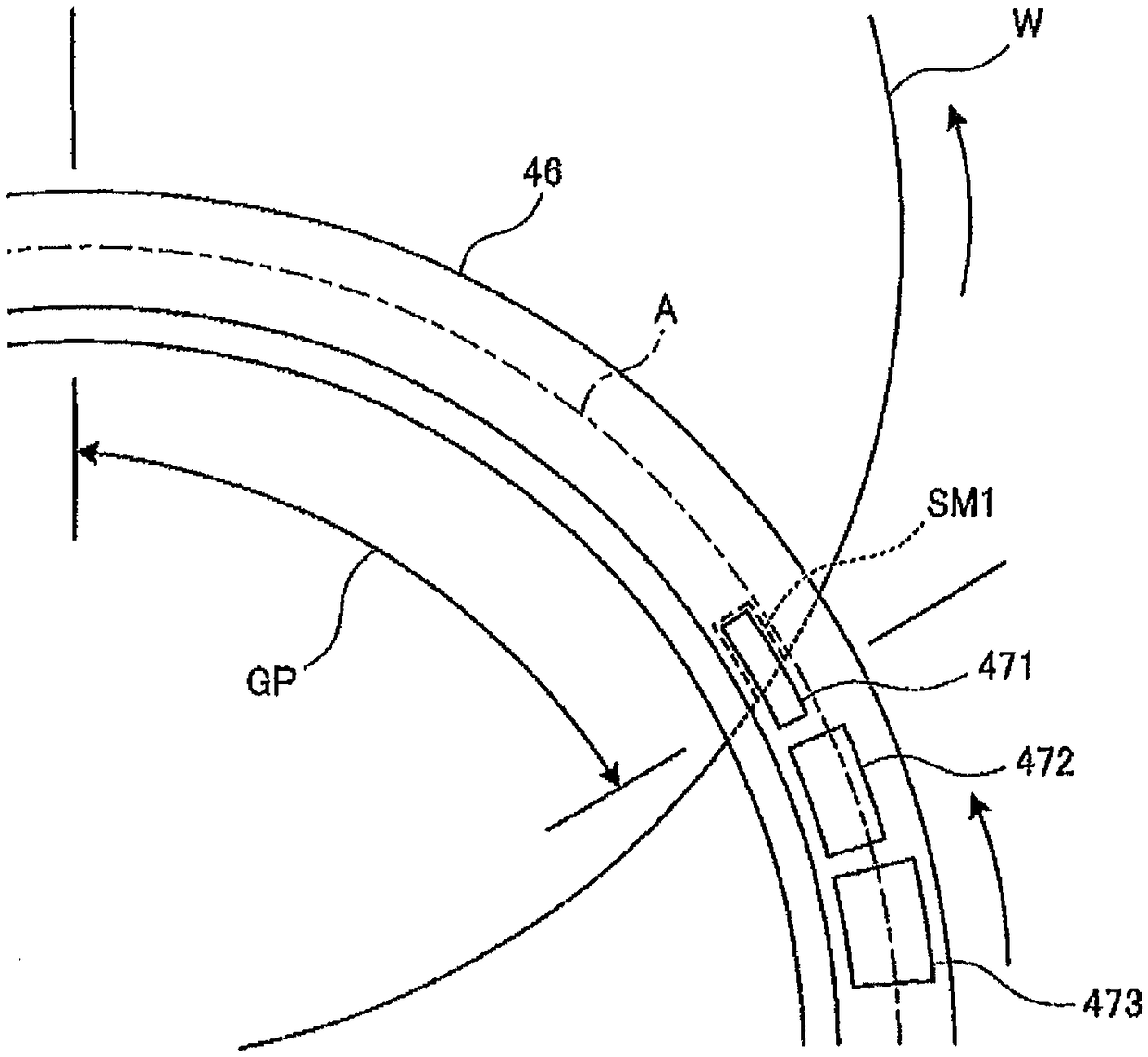

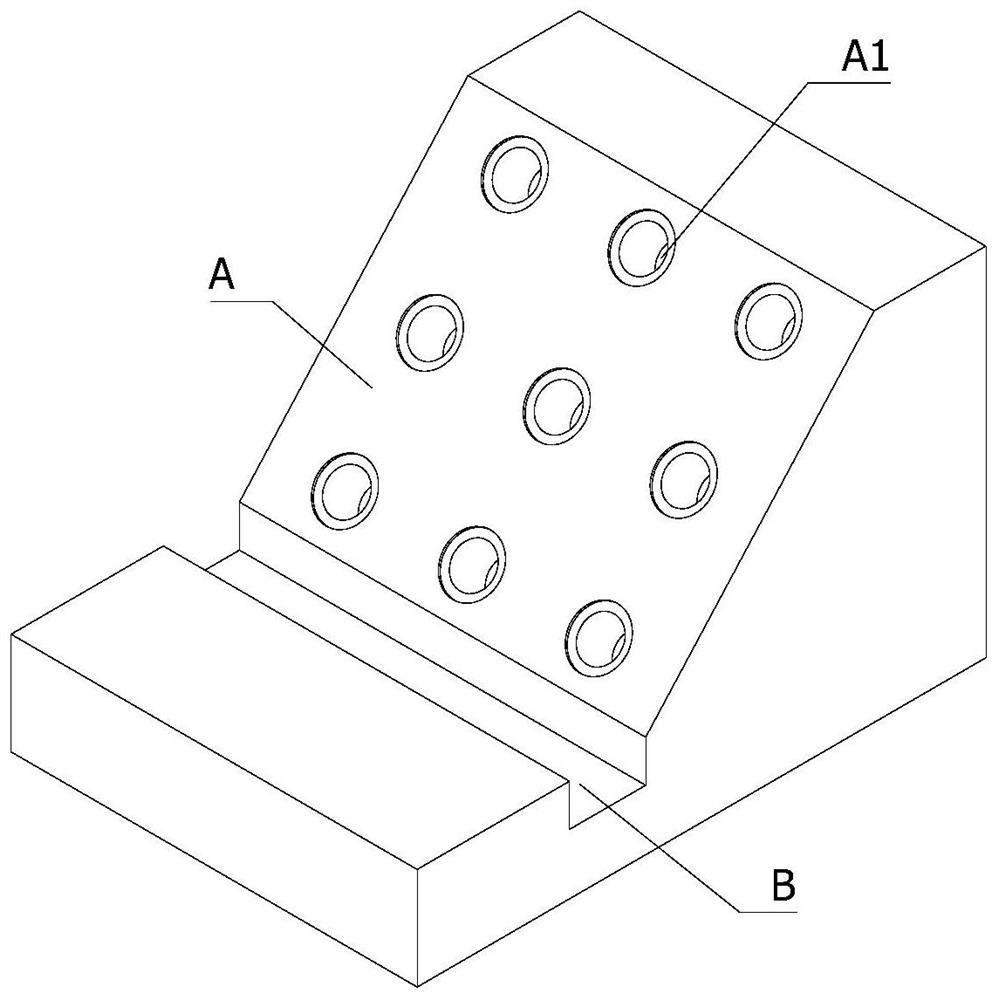

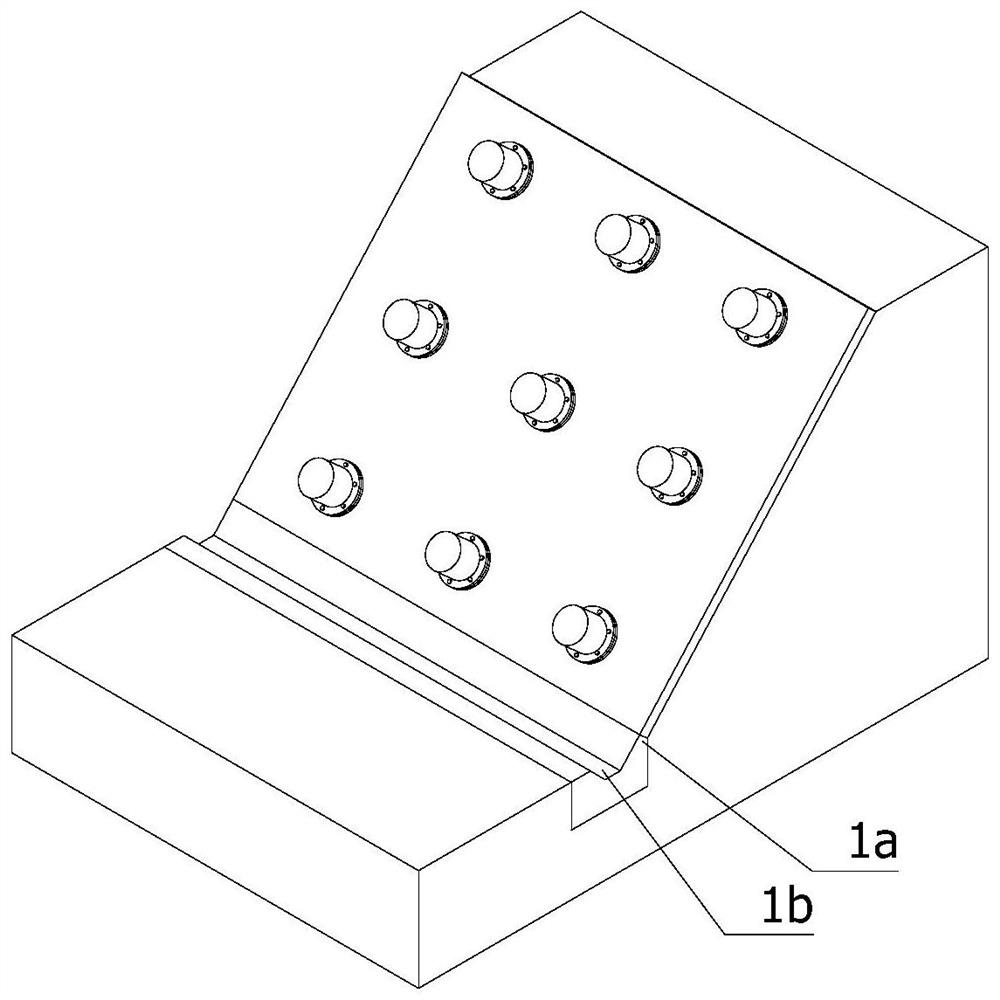

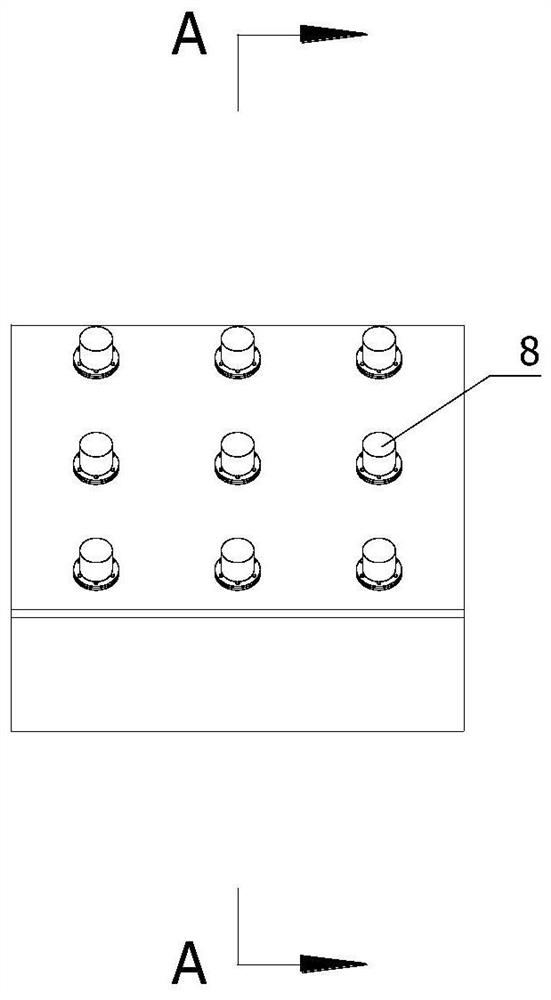

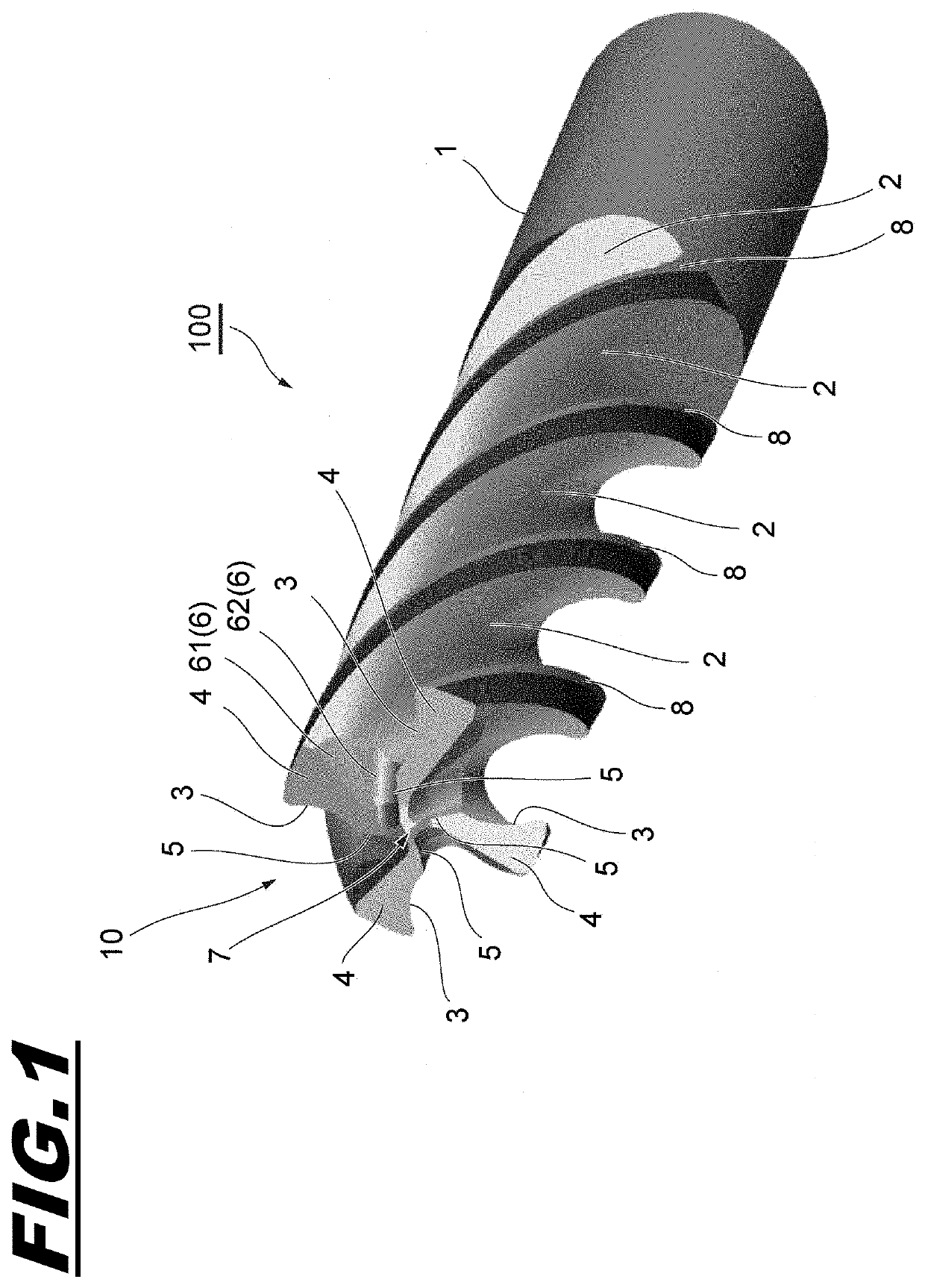

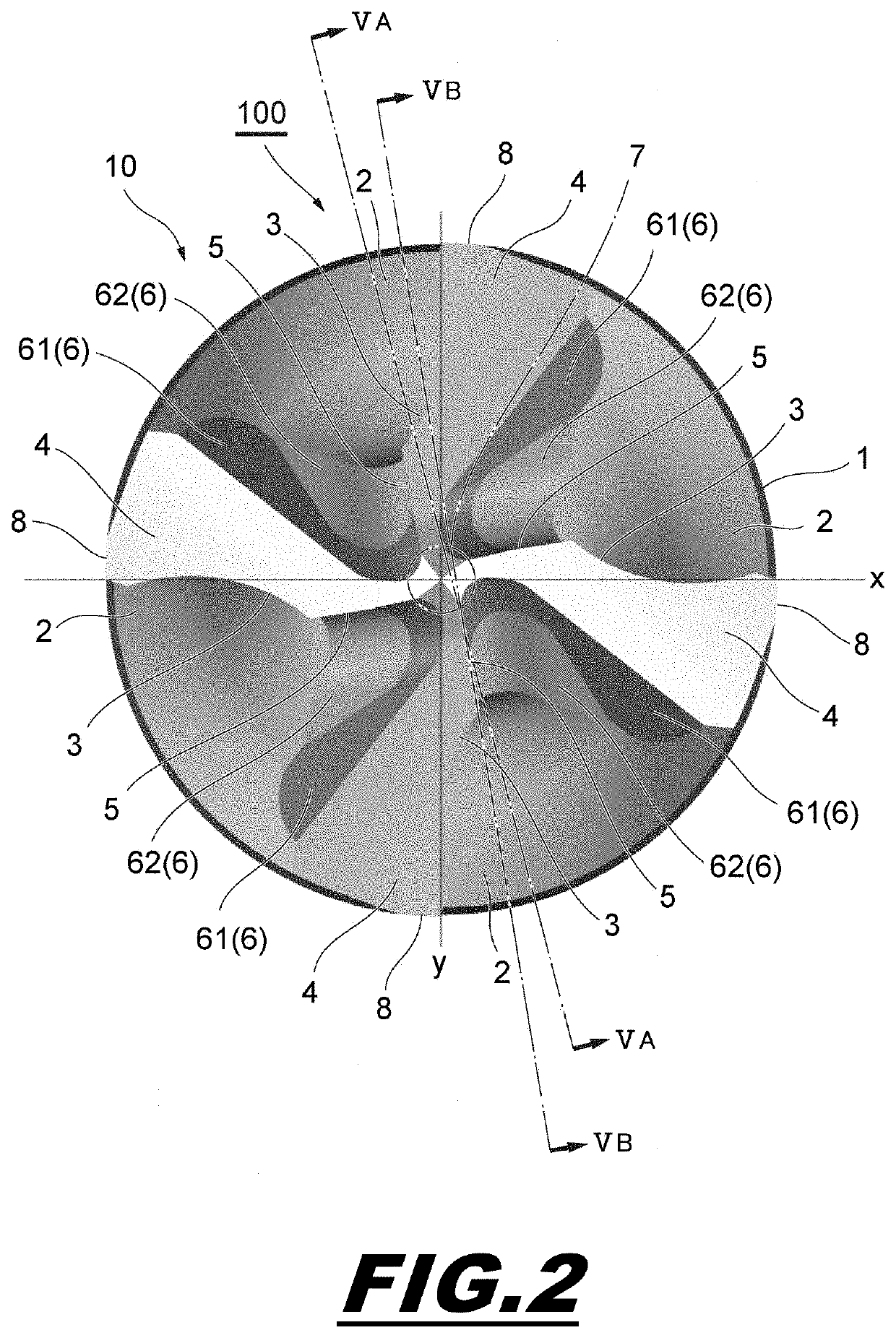

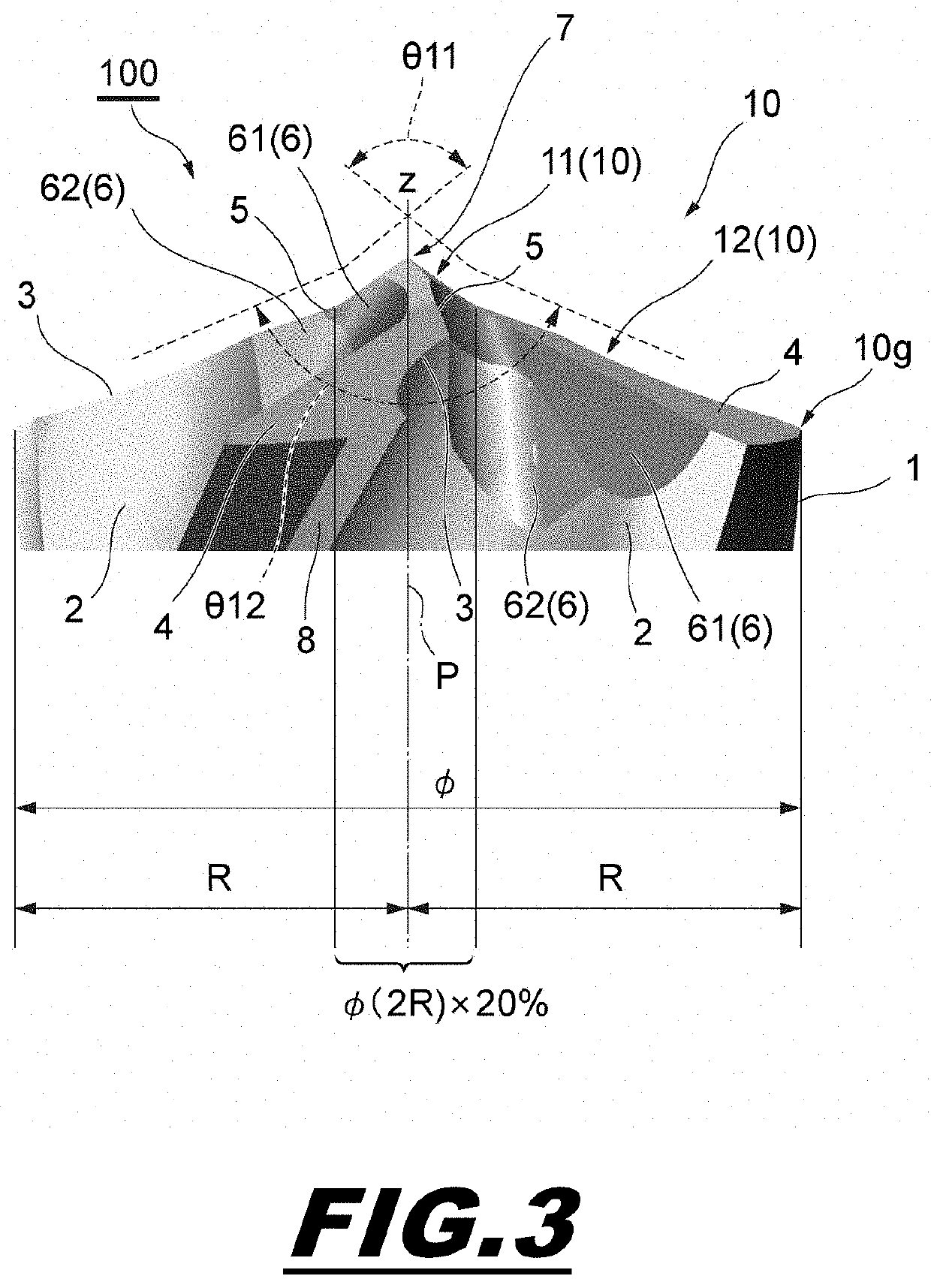

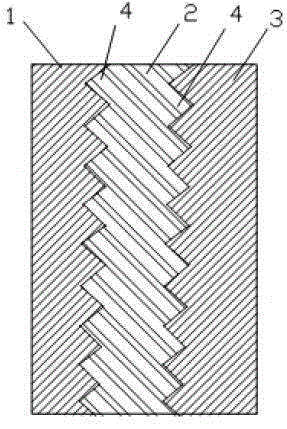

Grinding wheel and grinding apparatus

ActiveCN109483352AGood bite performanceGrinding drivesBonded abrasive wheelsGrinding wheelAnnular array

A grinding wheel and a grinding apparatus are provided to improve an ability to bite into the surface being ground. The grinding wheel (46) includes, in order to grind a wafer W, a plurality of grinding stone groups arranged in an annular array and each formed by a plurality of grinding stone segments (47), each of the grinding stone groups including at least three grinding stone segments (471-473) having different thicknesses. The grinding stone segments having different thicknesses are successively arranged in the order from the grinding stone segment (471) having the smallest thickness to the grinding stone segment (473) having the largest thickness and have respective radially inner edges aligned with each other in an annular shape, with uniform gaps left therebetween.

Owner:DISCO CORP

Soft fabric and spinning technology thereof

InactiveCN106364073AGood bite performancePromote environmental protectionSynthetic resin layered productsCellulosic plastic layered productsWeft yarnCompound (substance)

The invention relates to a soft fabric and a spinning technology thereof. The fabric is characterized in that fabric layers of the fabric are connected through spinning yarn, and each fabric layer is formed by interweaving and blending warp yarn and weft yarn; viscose is adopted as the warp yarn, the fineness is 126-185 dtex, and the warp density is 34.2-38.5 pieces per centimeter; copper ammonia fiber is adopted as the weft yarn, the fineness is 112-228 dtex, and the warp density is 29.8-43.8 pieces per centimeter; a fabric block is covered with a lace layer, a fluff layer is arranged on the bottom face of the fabric block, an anti-static layer is arranged on the bottom face of the fluff layer, and lower-layer air holes are formed in the anti-static layer. According to the soft fabric and the spinning technology thereof, the good meshing performance is achieved, and no chemical adhesive is used in the whole process, so that environmental friendliness of the fabric is improved, the texture is soft, and wearing is comfortable.

Owner:JIANGYIN DONGFA GARMENT MAKING

Anti-creeping electric heating plate for breeding industry

InactiveCN112351515AImprove waterproof performanceImprove leakage prevention performanceOhmic-resistance heating detailsInsulation layerThermal insulation

The invention discloses an anti-creeping electric heating plate for the breeding industry, which comprises a structure reinforcing layer, a heating layer, a thermal insulation layer and a power supplyconnecting structure, and is characterized in that a temperature sensor, a first copper nut, a second copper nut and the heating plate are integrally formed by die-casting an SMC composite material,so that the waterproof and anti-creeping performance of the anti-creeping electric heating plate for the breeding industry is improved, and meanwhile, the spring sleeve and the heat shrink tube are arranged, and the anti-creeping and animal biting-off prevention performance is further improved.

Owner:湖南平安三农科技有限公司

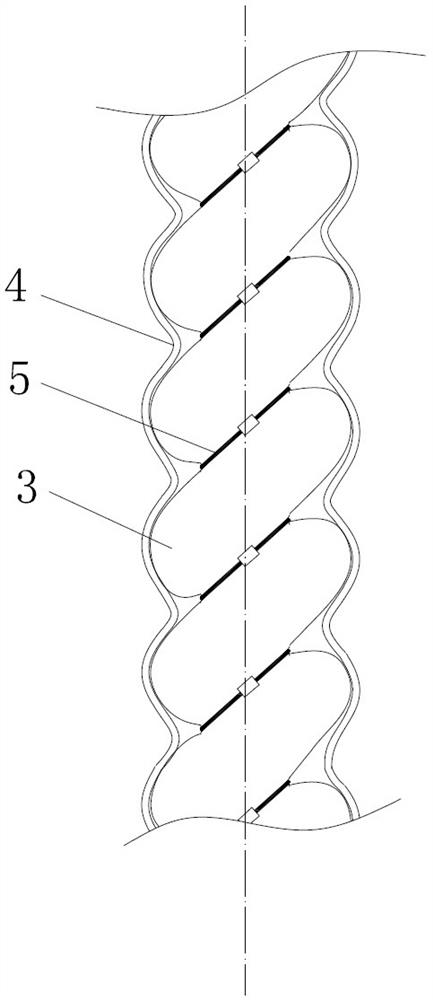

An expansion-resistant uplift anchor pile suitable for soft soil and loose rock and soil

The invention relates to an expansion anti-uplift anchor pile suitable for soft soil and loose rock and soil, which solves the problem of the foundation pit enclosure and slope support under the geological conditions of soft soil and loose rock and soil by the existing anti-uplift rod pile. , The effect of tunnel reinforcement is not obvious. The center of the bottom end of the anchor rod of this device is a grouting pipe, and the outer casing of the grouting pipe is provided with a cylindrical geotechnical bag. The upper or lower end of the stranded wire is fixed with the anchor rod, and the other end is a free end. The grouting hole is opened on the pipe wall of the grouting pipe along the helical line surrounding the pipe wall. The outer side of the geotechnical bag is helically bound with a spiral steel strand. The spiral steel strand has the same spiral direction and the same pitch as the spirally opened grouting hole, and the positions of the spiral wires are misaligned. The invention forms a helical segment type with alternating expansion degrees in the layer, and cooperates with a wave-shaped axial steel strand to provide a more reliable pull-out resistance effect.

Owner:GEOTECHN TECH

A kind of anti-landslide device for deep foundation pit and using method thereof

ActiveCN111576434BEasy to installLess prone to landslidesExcavationsBulkheads/pilesLandslideScrew thread

The present invention involves the field of landslides construction technology. It is specifically involved in a deep -founded pits and a non -slip slope device and its usage method. It is applied to a fixed slope. The slope includes a slope.The slot, the non -slip slope device includes the base, the tightness of the vibration, and the cover plate. The coaxial of the base is set in the slot.Caps and fixing the connection. The fixed head is set in the deep hole of the thread. In the working state, pour the concrete thread pillar into the deep hole of the thread;Delivery at another end -off end of the fixing connection, the covering plate is set on the slope surface and the tight steel rod runs through the overwriting plate through fixing the connection with the elasticity of the cover plate.At the top, the structure of the device is stable, which can effectively prevent the sliding soil sliding and eliminate vibration power.

Owner:上海九城建设科技集团有限公司

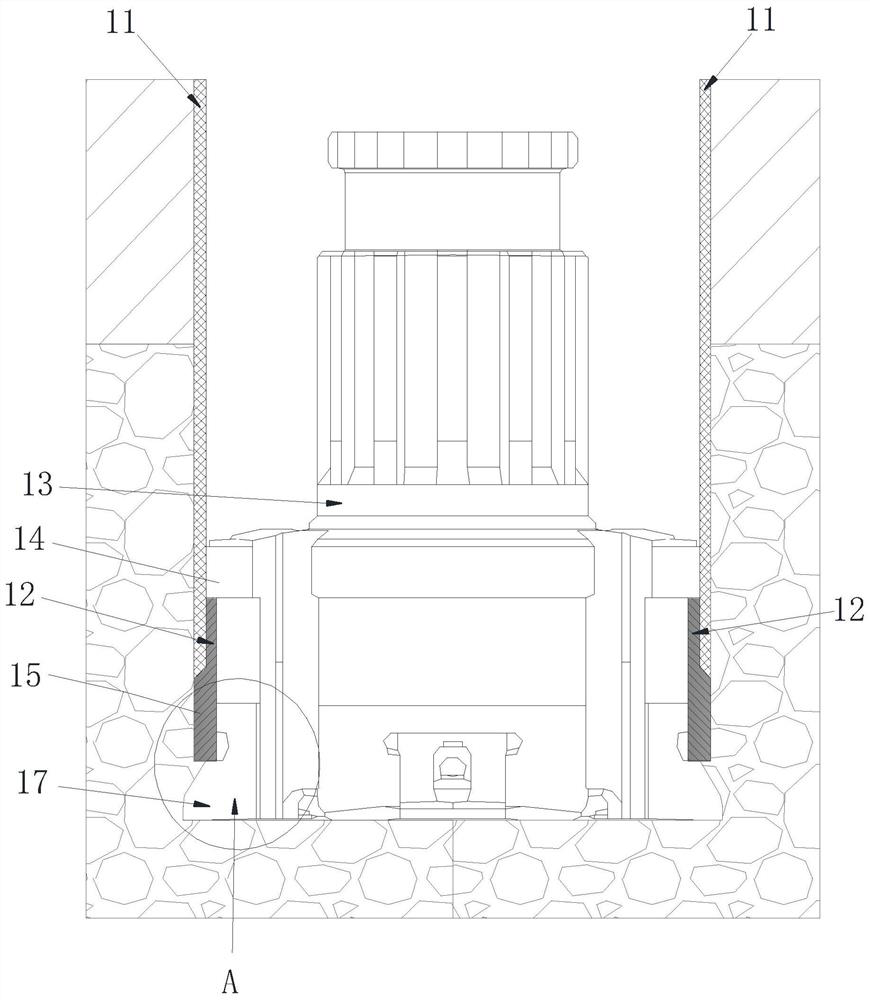

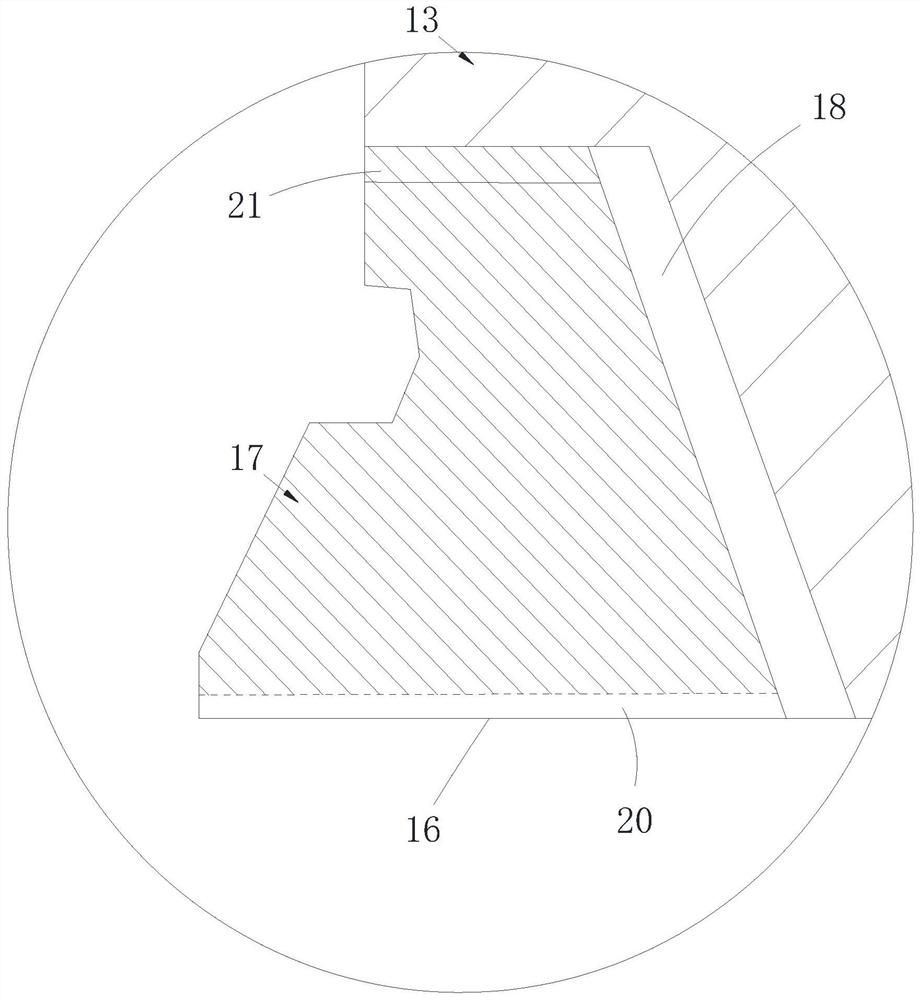

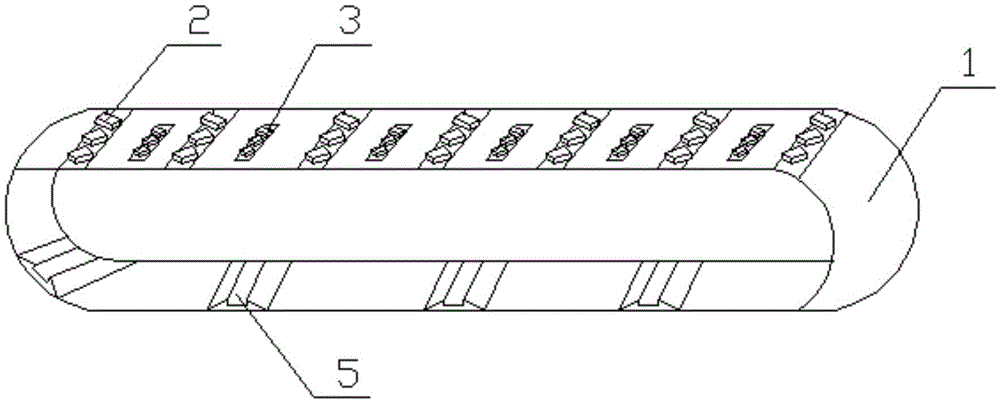

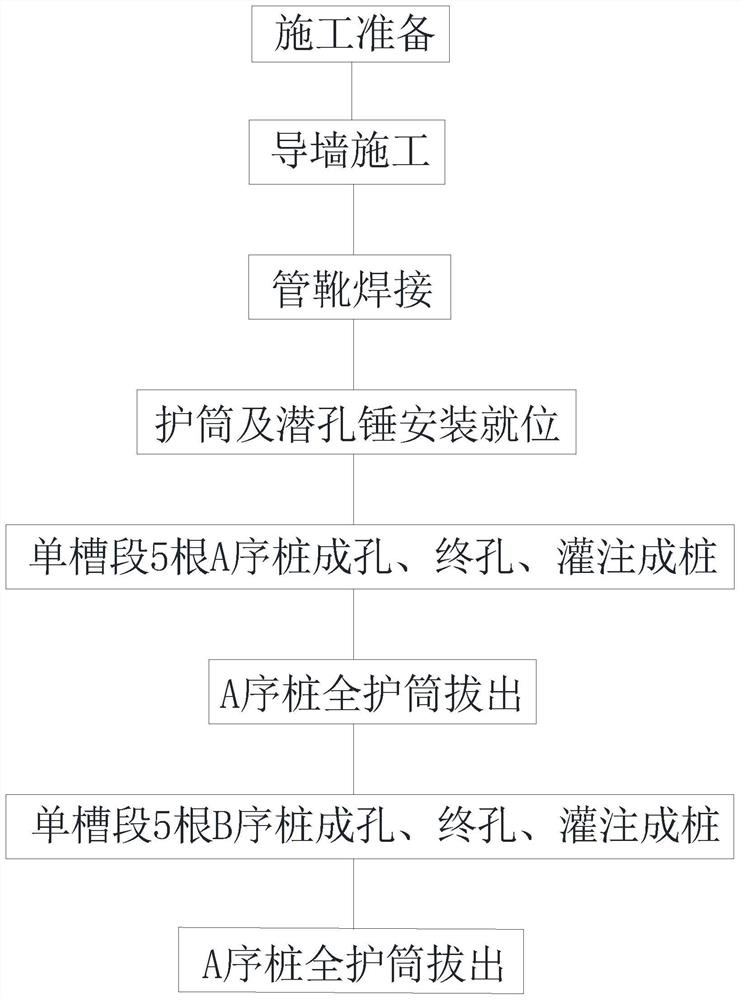

Comprehensive Construction Method of DTH Hammer and Pipe Engagement of Water-stop Curtain in Deep Rock Filling Layer

ActiveCN111663522BReduce repeated brokenImprove pore forming efficiencyBulkheads/pilesSlag (welding)Architectural engineering

Owner:SHENZHEN GONGKAN GEOTECHN GRP +1

Agricultural machine track

InactiveCN106809293ANon-slipWith wear resistanceEndless track vehiclesWear resistantAgricultural engineering

The invention provides a crawler belt for agricultural machinery, which comprises a ring-shaped crawler body, strip-shaped long pattern belts and short pattern belts are arranged on the outer surface of the track body, the length of the long pattern belt is longer than that of the short pattern belt, and the long pattern belt and the short pattern belt The belts are alternately spaced and arranged at equal intervals. Both the long pattern belt and the short pattern belt are provided with multiple diamond-shaped bumps that protrude outward and are of equal thickness. The drive grooves are equally spaced around the inner surface of the crawler body; the long pattern belts and short pattern belts of the present invention are alternately arranged at intervals, and the diamond-shaped bumps provided have anti-slip and wear-resistant properties, which prolongs the service life of the crawler belt.

Owner:CHONGQING CITY DAZU DISTRICT LIBANG MACHINE PARTS CO LTD

Cutting tool

PendingUS20220314341A1Improve discharge performanceGood bite performanceTransportation and packagingTwist drillsEngineeringDrill bit

Provided is a cutting tool capable of improving both the biting property to a work material and the chip discharge property. The cutting tool includes a drill body rotated about a central axis, four or more cutting edges formed on one end portion of the drill body to face a forward side of a rotation direction, and a flute groove that is formed between the cutting edges adjacent to each other in a circumferential direction and extends substantially spirally along the central axis. (1) The one end portion includes a first tip portion that includes the central axis and has a first tip angle, and a second tip portion that extends from the first tip portion to an outer peripheral edge of the drill body and has a second tip angle larger than the first tip angle, and (2) the drill body includes a first core thickness portion that is formed in such a manner that a core thickness thereof gradually decreases from the one end portion to the other end portion, and a second core thickness portion that is formed in such a manner that a core thickness thereof is constant from the first core thickness portion toward the other end portion.

Owner:TUNGALOY CORP

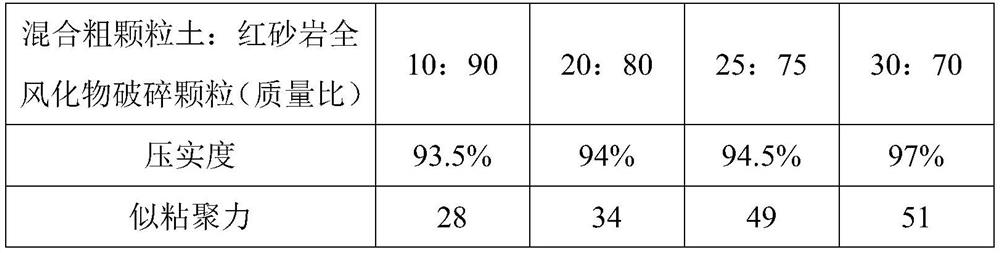

Red sandstone fully-weathered substance-based high-compactness filler and preparation method thereof

PendingCN114541203ALow investment costLow costSustainable biological treatmentRoads maintainencePhysical chemistryPellets

The invention discloses a red sandstone fully-weathered substance-based high-compactness filler and a preparation method thereof. The red sandstone fully-weathered substance-based high-compactness filler comprises mixed coarse-grained soil and red sandstone fully-weathered substance crushed particles, the mixed coarse particle soil comprises coarse sand with the particle size of 0.5 mm to 2 mm, fine gravel with the particle size of 2 mm to 5 mm and medium gravel with the particle size of 5 mm to 20 mm; the mass ratio of the coarse sand to the fine gravel to the medium gravel is 1: 2: 3. The mixed coarse-grained soil and red sandstone fully-weathered crushed particles are mixed according to a certain proportion, and the mixed filler which is good in occlusion effect and easy to compact is obtained. Compared with other improved schemes, the engineering investment cost can be effectively saved according to the blending proportion of the raw materials in the red sandstone fully-weathered substance-based high-compactness filler provided by the invention; and the scheme of remote transportation of high-quality filler can be replaced, so that the construction cost is saved, the construction efficiency is improved, and the environment is protected.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

Side undercut mechanism of car radiator side panel

InactiveCN104325041BGood bite performanceImprove general performanceHeat exchange apparatusRear quarterBlock match

The invention discloses a side undercutting mechanism for a side plate of an automobile radiator. The side undercutting mechanism comprises a frame, an upper template, a lower template and a bedplate, wherein the upper template is connected with a piston rod of a first hydraulic oil cylinder; the lower template is arranged on the bedplate; the bedplate is movably arranged on the frame. The side undercutting mechanism is characterized in that an upper undercutting knife and a side push block are arranged on the upper template; the side push block is arranged on one side of the upper undercutting knife; the inner side of the end part of the side push block is provided with an inclined plane; a lower undercutting knife and a side propping plate are arranged on the lower template; the side propping plate is arranged on the lower template in a sliding way; a top block matched with the inclined plane is arranged on the side propping plate; the lower undercutting knife which corresponds to the upper undercutting knife is fixed on the lower template; the side push block is connected with a depression bar. According to the side undercutting mechanism, the side plate on the radiator can be meshed on the radiator, so that a good undercutting effect, high production efficiency and high generality are achieved; moreover, the side undercutting mechanism is convenient, safe and reliable to operate.

Owner:RUIAN XINHAI AUTO PARTS

A kind of production method of nanocomposite surface piston ring

The invention discloses a production method of a nanocomposite surface piston ring. The method comprises the following steps: performing degreasing to a piston ring blank made of cast iron substrate before planting, cleaning the surface of the blank, performing sand blasting to the blank, adding the piston blank into electroplate liquid I to be subjected to reverse etching, adding the blank subjected to reverse etching into electroplate liquid II to be subjected to electrolytic deposition till the thickness of nano-coating formed on the outside circle surface of the blank is 0.06 to 0.12mm, and adding a semi-finished piston ring into a grinding cylinder to grind the semi-finished piston ring till the thickness of the nano-coating is 0.04 to 0.10mm to form a finished piston ring. According to the method, a nano wild phase with high wearing resistance, corrosion resistance, good tenacity and self-lubrication to replace micron-sized traditional solid particles to modify the surface of the piston ring, an electric pulse technology is adopted to realize the nanocrystallization of Ni-P crystal grain on the surface of the piston ring, and nano-coating with the nano-phase embedded uniformly further improves the tenacity and the wearing resistance of the surface of the piston ring.

Owner:江苏仪征金派内燃机配件有限公司

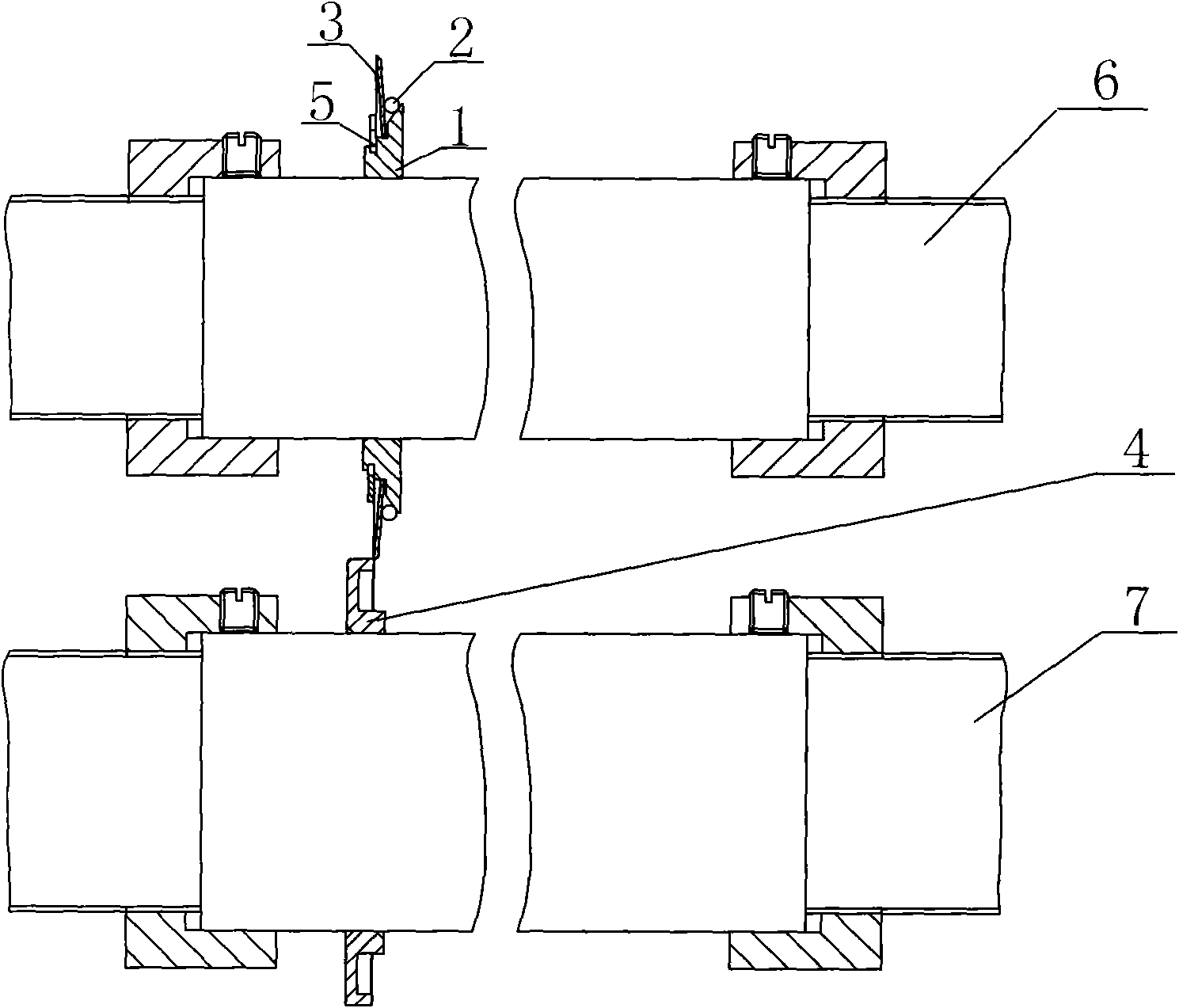

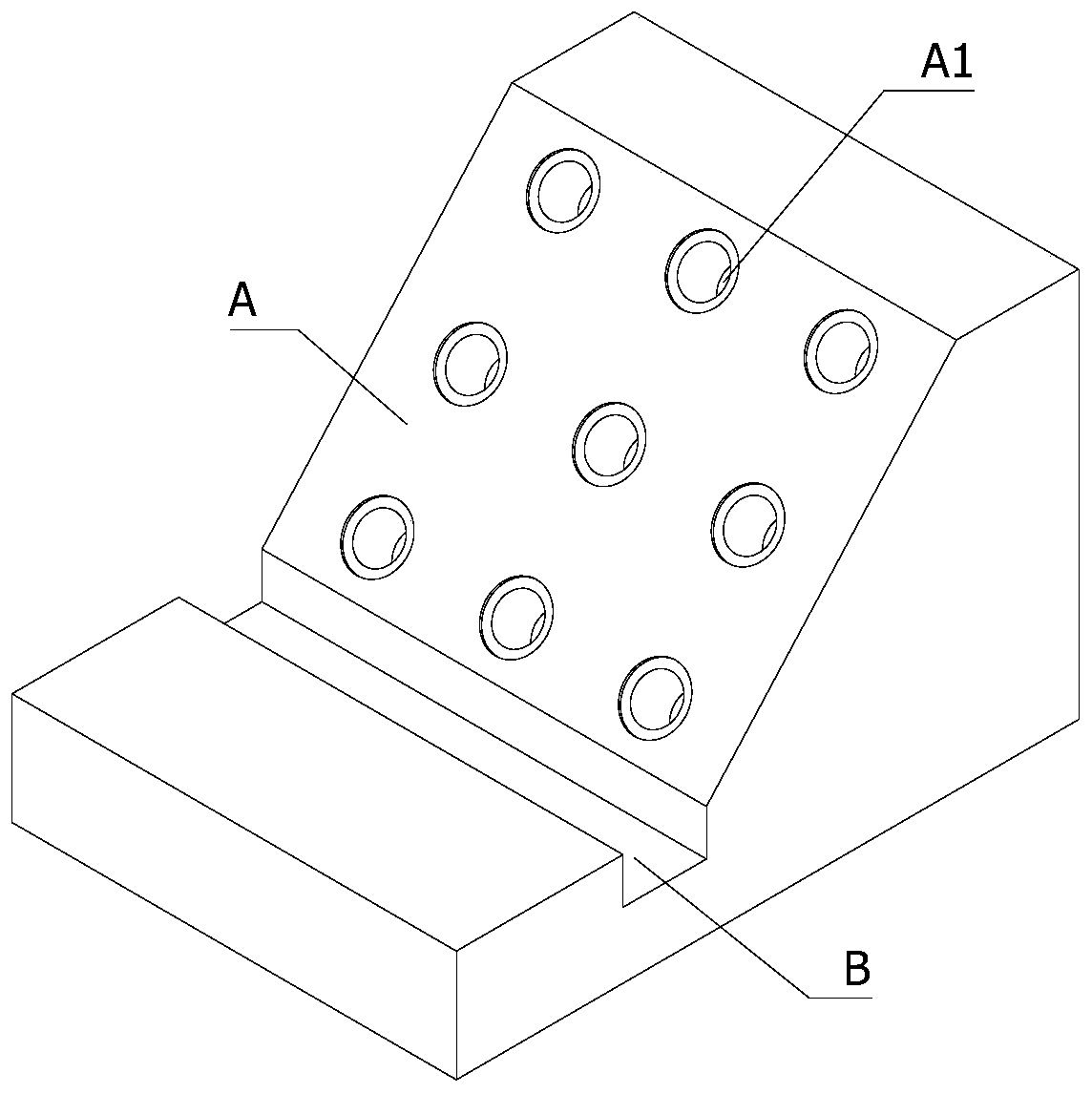

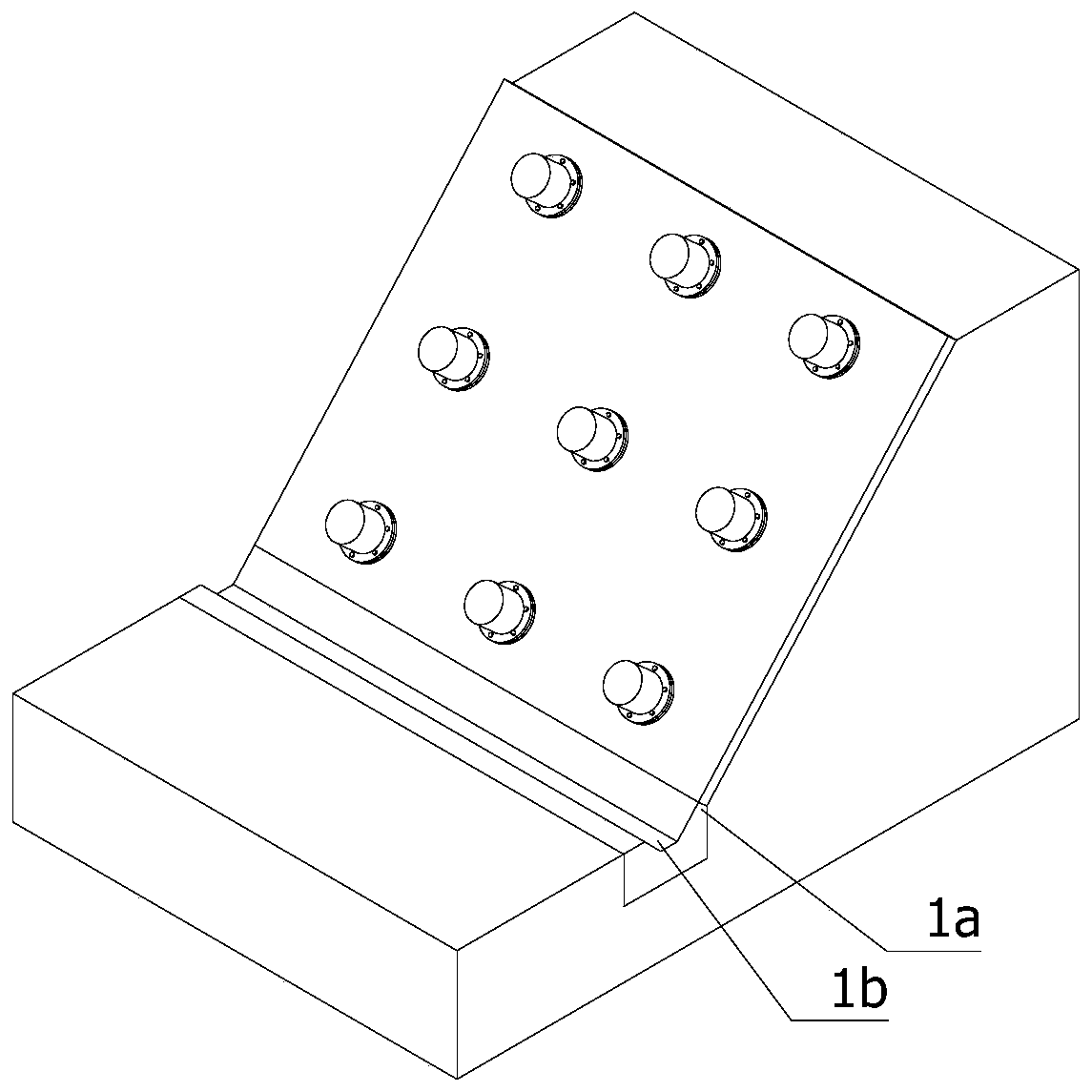

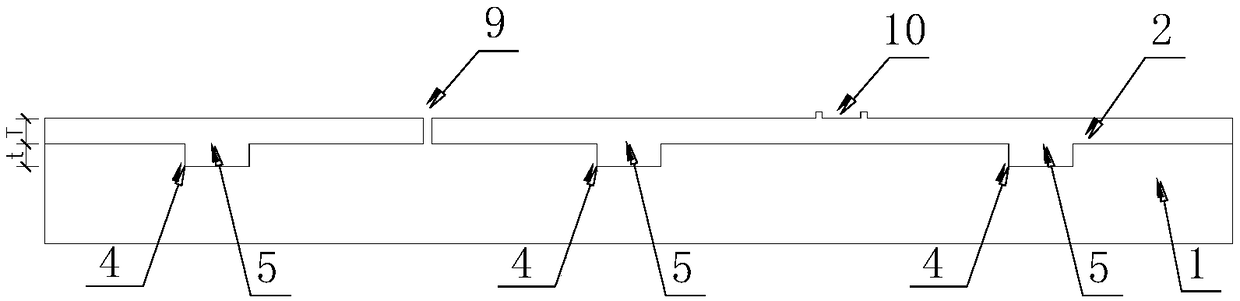

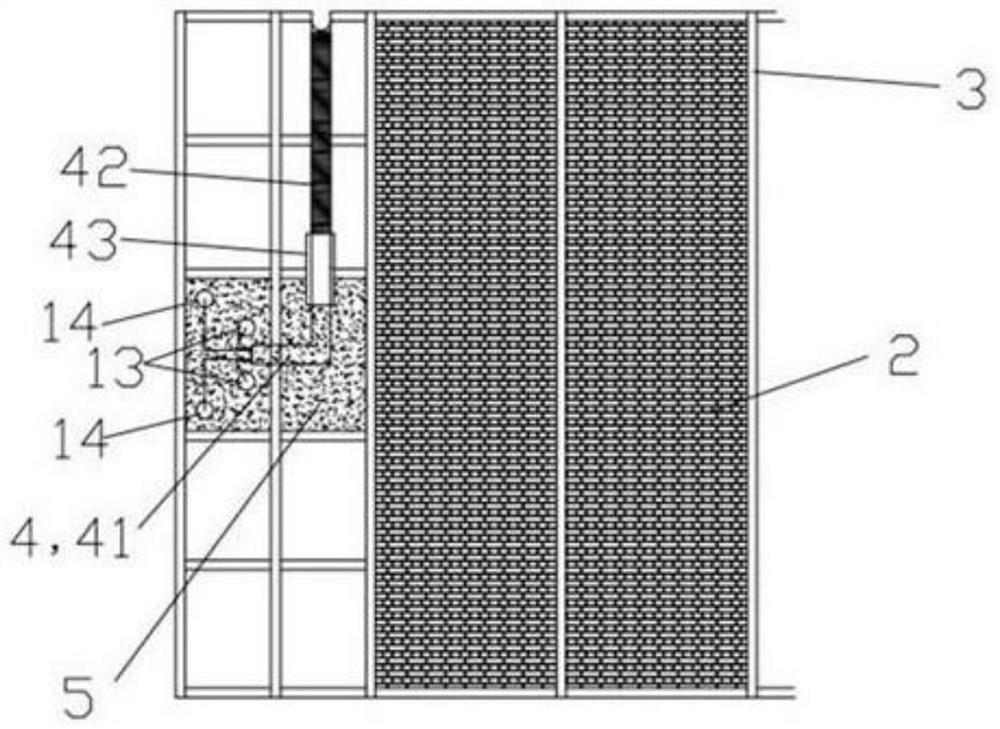

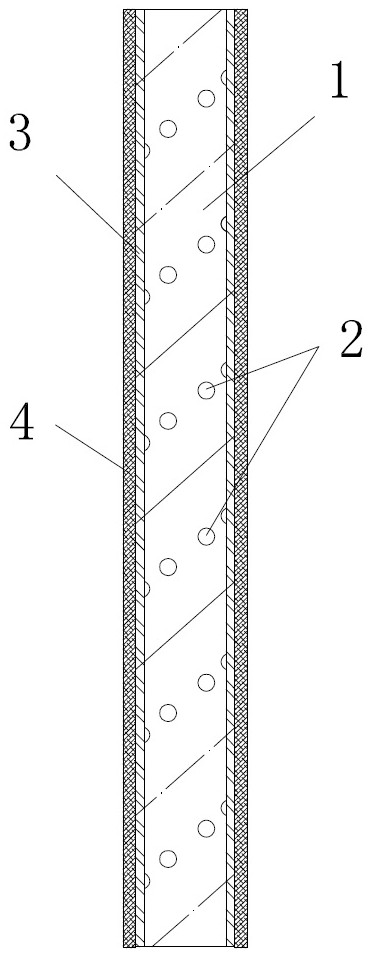

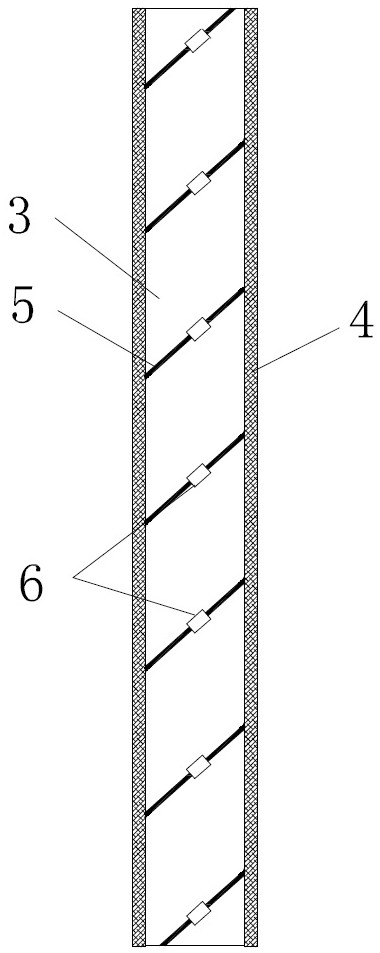

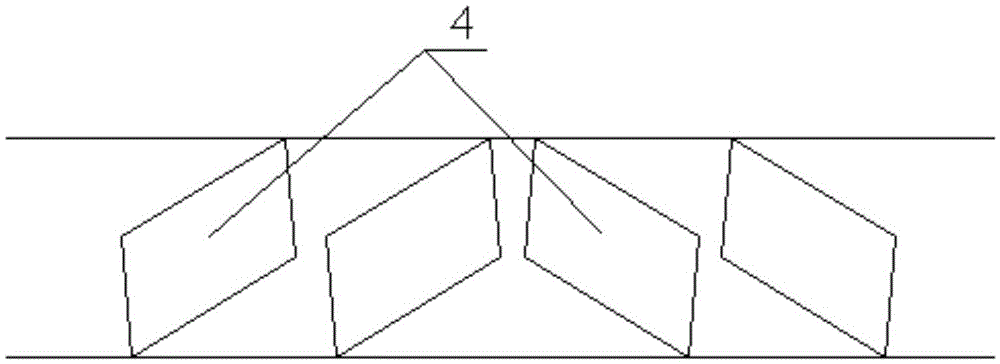

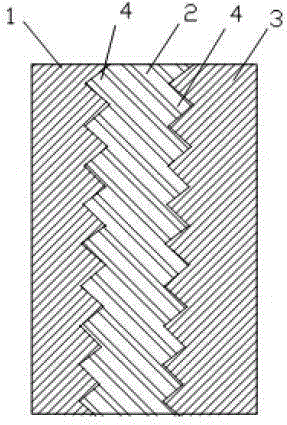

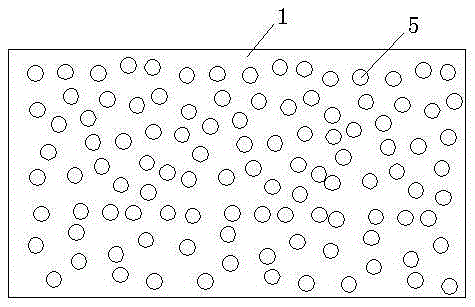

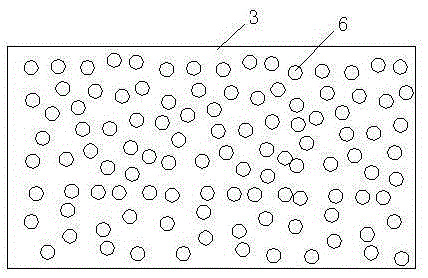

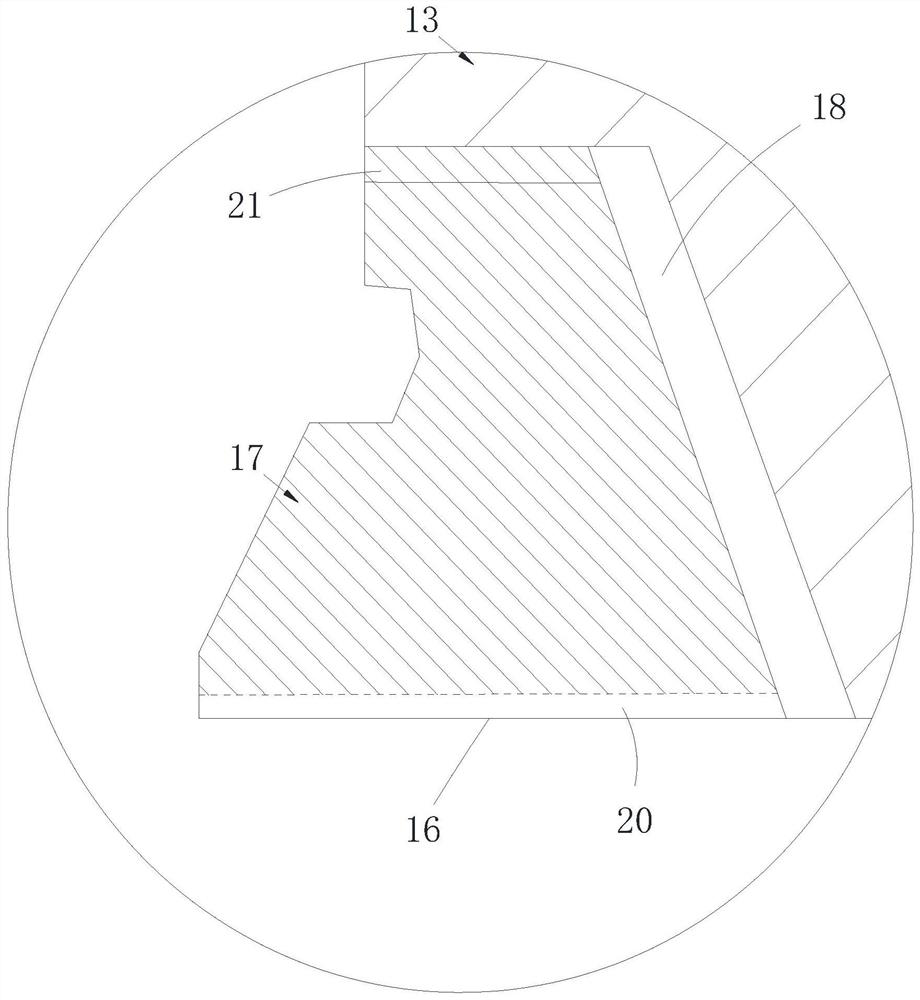

Fabric good in seizing performance

InactiveCN105411063AGood bite performanceImprove biteLayered productsWoven fabricsAdhesiveEngineering

The invention relates to a fabric good in seizing performance. The fabric is characterized by comprising a first fabric layer (1), a second fabric layer (2) and a third fabric layer (3), the second fabric layer (2) is located between the first fabric layer (1) and the third fabric layer (3), protrusions (4) with regular triangular sections are arranged on the two sides of the second fabric layer (2), first grooves with regular triangular sections are formed in the side, facing the second fabric layer (2), of the first fabric layer (1), second grooves with regular triangular sections are formed in the side, facing the second fabric layer (2), of the third fabric layer (3), and the protrusions (4) of the second fabric layer (2) are matched with the first grooves of the first fabric layer (1) and the second grooves of the third fabric layer (3). The fabric has good seizing performance, no chemical adhesives are used, and the fabric is high in environment protection performance, soft in texture and comfortable to wear.

Owner:JIANGSU WEILUOSAI KNITTING CLOTHING CO LTD

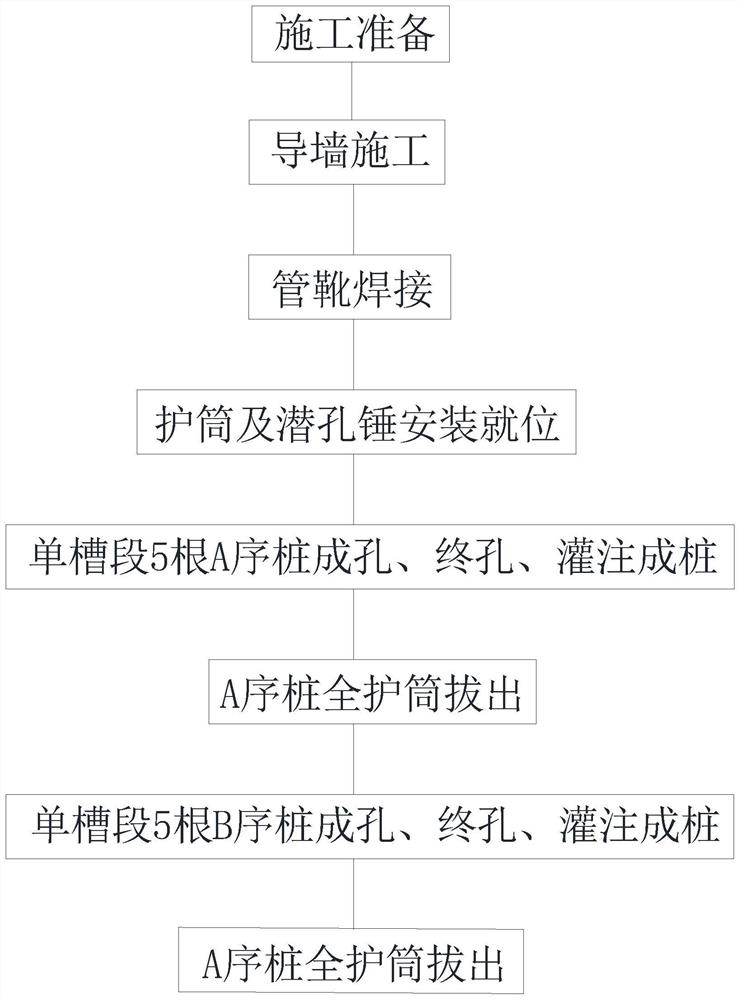

Deep backfilled stone layer waterproof curtain dth hammer and follow-pipe occlusion comprehensive construction method

ActiveCN111663522ASolve the problems of slow construction progress and difficult pile formation in traditional construction techniquesSolve the problem of slow construction progress and difficult pile formationBulkheads/pilesSlag (welding)Architectural engineering

The invention relates to the technical field of deep backfilled stone layer waterproof curtain construction and discloses a deep backfilled stone layer waterproof curtain dth hammer and follow-pipe occlusion comprehensive construction method which comprises the following steps: S1, construction preparation: carrying out ground leveling, positioning and paying off, and enabling construction equipment and machines and tools to enter the construction site; S2, guide wall construction; S3, shoe welding; S4, installation of a guard barrel and a dth hammer in position; S5, enable the dth hammer andthe follow-pipe to realize occlusion to drill a hole and a final hole; S6, mounting and placing a pouring guide pipe; S7, pouring underwater concrete to form a pile; and S8, adopting a vibratory hammer to pull the guard barrel. The construction method has the following benefits: the hole forming efficiency is high, when the waterproof curtain realizes occlusion to form a pile, the entire guard barrel follows to realize occlusion, the cutting perpendicularity is controlled well, the occlusion effect is excellent, the problems that the traditional construction technology of the deep backfilled stone layer is slow in construction progress and difficult in pile forming are effectively solved; and the ultra high wind pressure enables the broken rock slag to be blown out of the holes at one time, so that repeated crushing of the rock slag in the holes is reduced, and the hole forming speed is more than five times of that of rotary excavating drilling, so that the hole forming speed is greatly accelerated, the pile forming quality is high, and the comprehensive cost is low.

Owner:SHENZHEN GONGKAN GEOTECHN GRP +1

Fabric with good seizure property

InactiveCN105231562AGood bite performanceImprove biteBiochemical fibre treatmentWoven fabricsEngineeringChemical binding

The invention relates to a fabric with a good seizure property. The fabric is characterized by comprising a first fabric layer (1), a second fabric layer (2) and a third fabric layer (3), wherein the second fabric layer (2) is located between the first fabric layer (1) and the third fabric layer (3); bumps (4) with cross sections represented as regular triangles are arranged on two sides of the second fabric layer (2); on one side facing the second fabric layer (2), the first fabric layer (1) is provided with a first groove with cross section represented as a regular triangle; on one side facing the second fabric layer (2), the third fabric layer (3) is provided with a second groove with cross section represented as a regular triangle; and the bumps (4) of the second fabric layer (2) are respectively matched with the first groove of the first fabric layer (1) and the second groove of the third fabric layer (3). The fabric with the good seizure property has good seizure property and is free from use of any chemical binding agents, and the fabric is strongly environment-friendly, soft in texture and comfortable to wear.

Owner:JIANGYIN XIANGFEI APPAREL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com